Page 1

ToshibaGlobalCommerceSolutions

SureMark 4610 Printers

Hardw are Service Guide f o r

Models 1NR, 1NA, and 1ND

G362-0565-05

Page 2

Page 3

ToshibaGlobalCommerceSolutions

SureMark 4610 Printers

Hardw are Service Guide for

Models 1NR, 1NA, and 1ND

G362-0565-05

Page 4

Note

Before using this information and the product it supports, be sure to read Safety Information- Read This First, Warranty

|

Information, Uninterruptible Power Supply Information, and the information under Appendix B, “Notices,” on page 75.

|

November 2013

This edition applies to Toshiba SureMark Printer Models 1NR, 1NA, and 1ND.

|

If you send information to Toshiba Global Commerce Solutions (Toshiba), you grant Toshiba a nonexclusive right to

|

use or distribute whatever information you supply in any way it believes appropriate without incurring any obligation

|

to you.

|

© Copyright Toshiba Global Commerce Solutions, Inc. 2013

© Copyright IBM Corporation 2009, 2011

Page 5

Contents

||

||

||

||

||

||

||

||

||

||

||

||

||

||

||

||

||

Figures ...........................vii

Tables ............................ix

Safety ............................xi

About this guide .......................xiii

Who should read this guide ....................xiii

Where to find more information ...................xiii

Notice statements ........................xiii

Summary of changes ......................xv

November 2013.........................xv

September 2013 ........................xv

May 2013 ...........................xv

October 2011 .........................xv

June 2010...........................xv

January 2010 .........................xv

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND .......1

Features and specifications.....................1

Communication and power .....................3

Ethernet Configuration .....................6

Addressing ..........................7

DHCP ...........................7

Auto IP ...........................7

Systems management support with Ethernet - SNMP ..........8

HTTP Server ........................10

Login and Overview ......................11

Web Pages .........................11

Web API for printer configuration management ............12

Retrieving Printer’s configuration using HTTP Server Get ........12

HTTP Server POST ......................15

Configuration file format ....................17

Printer sharing ........................21

Locating the power button ....................21

Operating system requirements ...................22

RS-232 Printer ........................22

RS-485 Printer ........................23

USB Printer .........................25

Ethernet Printer........................25

Hardware requirements ......................26

Calling for service ........................26

Printer information label ....................26

Chapter 2. Product specifications .................29

Physical dimensions .......................29

Temperature and humidity limits ..................29

Connector pin assignments ....................30

Power supply ........................30

USB............................30

Powered USB ........................30

RS-232...........................30

iii

Page 6

RS-485...........................31

Cash drawer .........................32

Printing width, speed, and acoustics .................32

Bar codes ...........................33

Resident code pages ......................33

Chapter 3. Adjusting and maintaining the 4610 ............35

Using and maintaining the 4610 ..................35

Replenishing consumable supplies ................35

Cleaning recommendations ...................37

Chapter 4. Running tests and diagnostics ..............39

||

||

||

||

||

Toshiba Diagnostics for POS Systems and Peripherals ..........39

Toshiba Diagnostics for the Ethernet Printer ..............39

Situations of Importance for the Ethernet Printer ...........40

Toshiba Diagnostics for the RS-232 Printer ..............42

Toshiba Diagnostics for the USB or RS-485 Printer ...........42

Testing the 4610 ........................43

Low paper sensing and calibration.................43

Firmware offline tests .....................45

Troubleshooting ........................49

Chapter 5. Removing and replacing FRUs ..............51

Handling static-sensitive devices ..................51

Removing the interface card ....................52

Removing the covers ......................53

Removing the top cover ....................53

Removing the main cover ....................55

Removing the paper-out sensor...................56

Removing the thermal printhead ..................58

Removing the logic card .....................60

Removing the thermal printhead flat cable ...............61

Removing the cutter motor and paper door assembly ...........62

Removing the rollers .......................64

Removing the low-paper sensor ..................66

Removing the paper transport frame from the main frame .........68

Appendix A. Parts listing ....................71

How to use the FRU catalog ....................71

Assembly 1: Models 1NR, 1NA, and 1ND ...............72

Appendix B. Notices ......................75

Telecommunication regulatory statement ...............77

Electronic Emission Notices ....................77

Federal Communications Commission (FCC) Statement .........77

Industry Canada Class A Emission Compliance statement ........77

Avis de conformité à la réglementation d'Industrie Canada ........77

Australia and New Zealand Class A Statement ............77

European Union Electromagnetic Compatibility (EMC) Directive Conformance

Germany Class A Statement ...................78

Japan Voluntary Control Council for Interference Class A statement ....79

Japan Electronics and Information Technology Industries Association (JEITA)

Korean communications statement ................80

Russian Electromagnetic Interference (EMI) Class A statement ......80

iv SureMark Hardware Service

Statement .........................77

statement .........................79

Page 7

People's Republic of China Class A electronic emission Statement .....80

Taiwan Class A compliance statement ...............80

European Community (EC) Mark of Conformity Statement ........81

Electrostatic Discharge (ESD) ..................81

Japanese Electrical Appliance and Material Safety Law statement .....81

Japanese power line harmonics compliance statement .........81

Cable ferrite requirement .....................82

Product recycling and disposal ...................82

Battery return program ......................83

For Taiwan: .........................83

For the European Union: ....................83

For California: ........................84

Flat panel displays .......................84

Monitors and workstations.....................85

Trademarks ..........................86

Index ............................87

Contents v

Page 8

vi SureMark Hardware Service

Page 9

Figures

1. SureMark 4610 printer .............................1

2. USB interface card ..............................3

3. RS-232 interface card .............................3

4. RS-485 interface card .............................4

||

5. Ethernet interface card .............................4

||

6. Get Configuration header example ........................13

||

7. The configuration file open in a hex editor .....................20

||

8. The configuration file open in a hex editor .....................21

9. Power button ................................22

10. Location of label with machine type, model number and serial number ...........27

11. SureMark 4610 Models 1NR, 1NA, and 1ND dimensions ................29

12. Offline tests activation .............................45

13. Example of the offline selection main menu .....................46

14. Removing the interface card ..........................52

15. Opening the top cover .............................53

16. Removing the top cover ............................54

17. Main cover tab ...............................55

18. Paper-out sensor...............................56

19. Paper door release lever ............................58

20. Paper door release lever ............................59

21. Removing the logic card ............................60

22. Grounding the logic card ............................61

23. Cutter motor screws..............................63

24. Clearing the door brake ............................63

25. Removing the topmost roller ..........................65

26. Place Holder for Future Artwork .........................66

27. Low-paper sensor removal ...........................67

28. Removing the grounding strap from the main frame ..................68

vii

Page 10

viii SureMark Hardware Service

Page 11

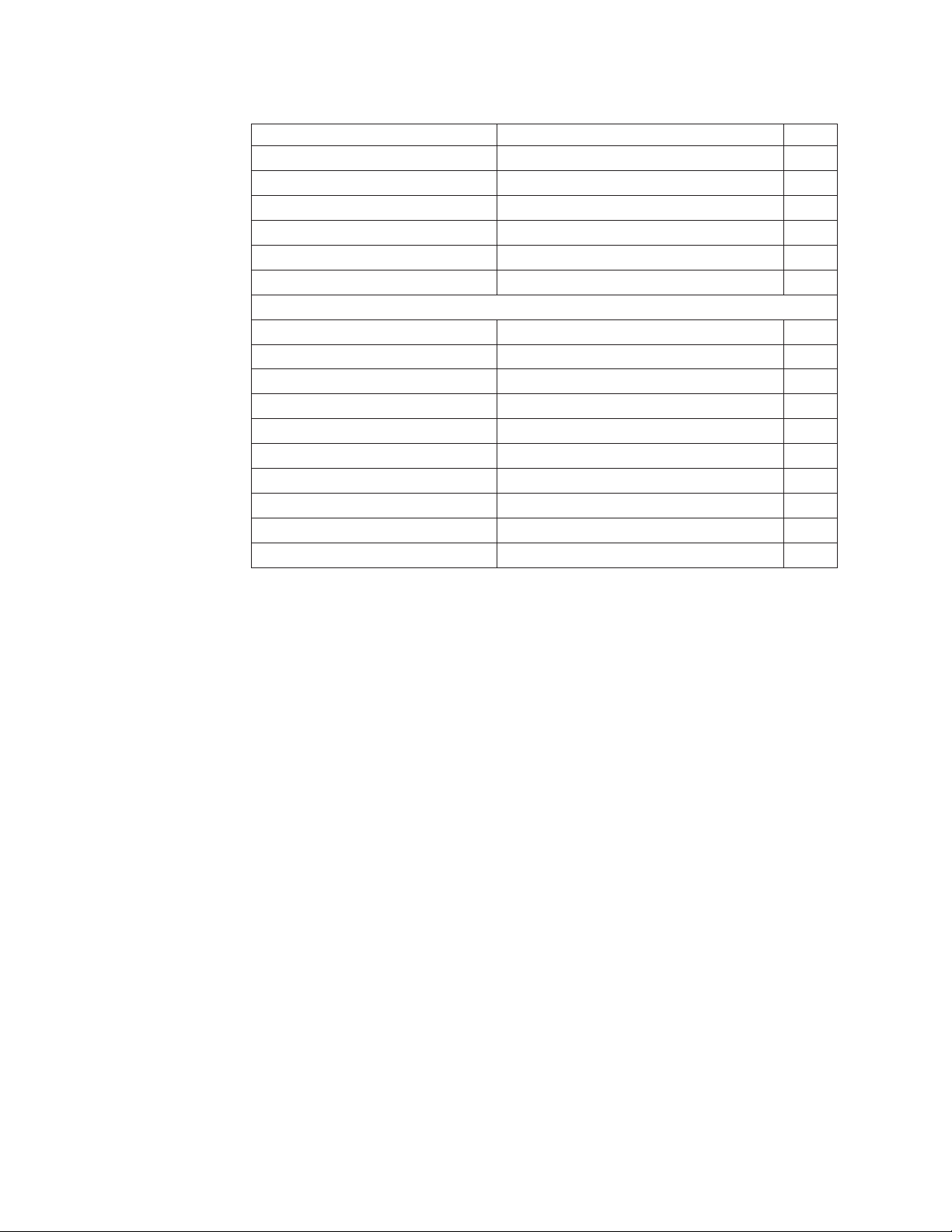

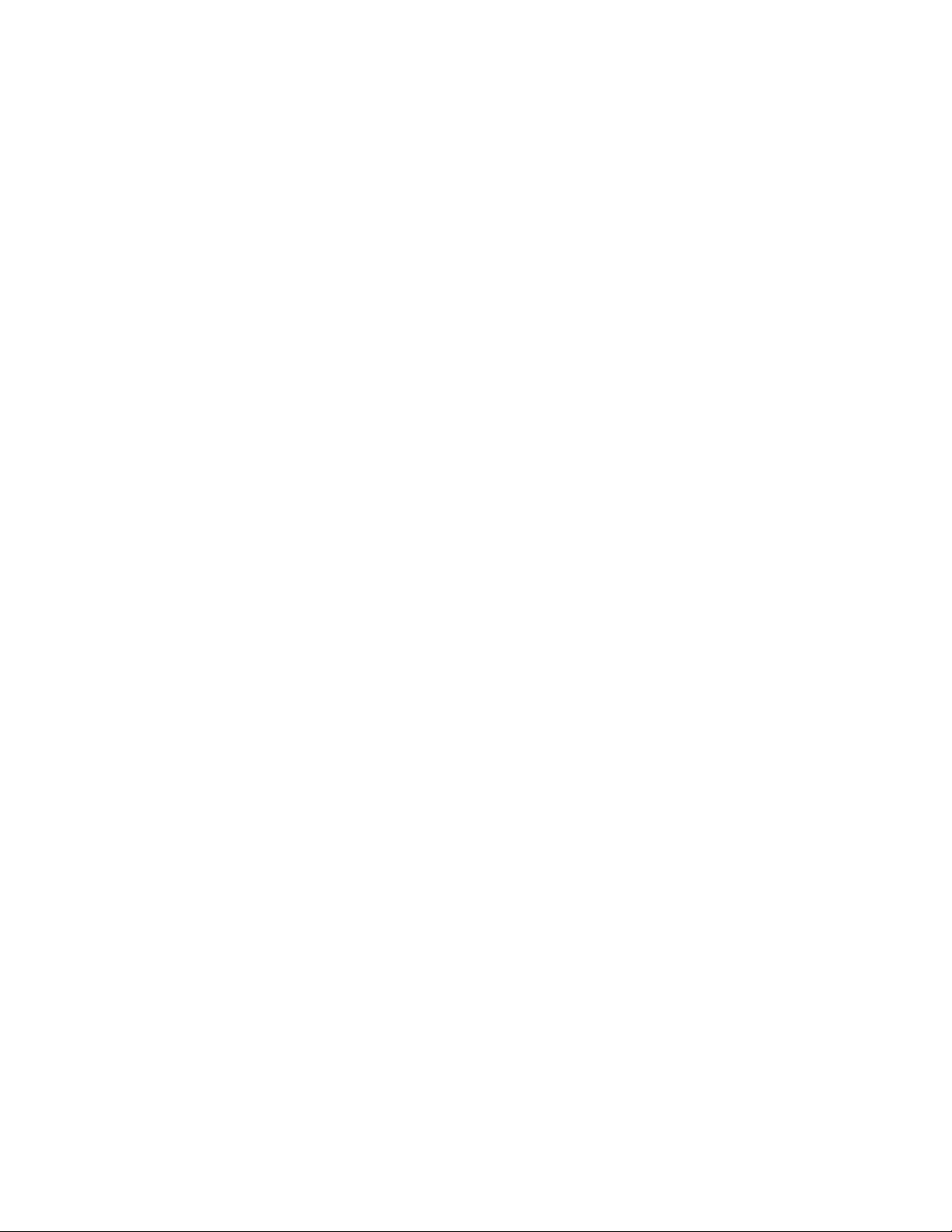

Tables

1. Printer specifications ..............................2

2. Communication interface, rate, and power source ...................4

||

3. Provided ports ................................7

||

4. Supported DHCP options ............................7

||

5. Printer state changes..............................8

||

6. 4610 Private Enterprise MIB ...........................9

7. Native Mode Support - RS-232 Printer .......................22

8. Native Mode Support - RS-485 Printer .......................24

9. Native Mode Support - USB Printer ........................25

||

10. Native Mode Support - Ethernet Printer ......................25

11. Summary of dimensions ............................29

12. Power supply pin designations ..........................30

13. USB pin designations .............................30

14. Powered USB pin designations .........................30

15. RS-232 pin designations ............................30

16. RS-485 pin designations ............................31

17. Cash drawer connector pin designations ......................32

18. Station characteristics .............................32

19. Sound characteristics .............................32

20. MCT load command settings for low-paper and critically low-paper amounts .........44

||

21. Summary of the offline test menu items ......................46

22. Troubleshooting ...............................49

ix

Page 12

x SureMark Hardware Service

Page 13

Safety

Before installing this product, read the Safety Information- Read This First.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d'installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

xi

Page 14

Antes de instalar este producto, lea la informacion de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

xii SureMark Hardware Service

Page 15

About this guide

This guide contains information about installing, using, and maintaining the Toshiba

SureMark™Models 1NR, 1NA, and 1ND printers.

Who should read this guide

This manual is intended for use by trained service representatives.

Where to find more information

|

|

|

|

|

Current versions of Toshiba publications are available on the Toshiba Global

Commerce Solutions support website: www.toshibagcs.com/support.

1. On the right side of the web page under Popular Links, select Publications.

2. Click on the publication related to your product.

Notice statements

Notices in this guide are defined as follows:

Notes These notices provide important tips, guidance, or advice.

Important These notices provide information or advice that might help you

avoid inconvenient or problem situations.

Attention These notices indicate potential damage to programs, devices, or

data. An attention notice is placed just before the instruction or

situation in which damage could occur.

®

CAUTION These statements indicate situations that can be potentially

hazardous to you. A caution statement is placed just before the

description of a potentially hazardous procedure step or situation.

DANGER These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just

before the description of a potentially lethal or extremely hazardous

procedure step or situation.

xiii

Page 16

xiv SureMark Hardware Service

Page 17

Summary of changes

This section documents the updates made to each revision of this guide.

November 2013

|

|

|

|

September 2013

|

|

|

|

May 2013

|

|

|

|

October 2011

June 2010

This edition of the SureMark 4610 Models 1NR, 1NA, and 1ND Service Guide

includes the following updates:

v Minor content updates and the addition of a third-party software notice.

This edition of the SureMark 4610 Models 1NR, 1NA, and 1ND Service Guide

includes the following updates:

v Ethernet support and related information added.

This edition of the SureMark 4610 Models 1NR, 1NA, and 1ND Service Guide

includes the following updates:

v Transition to Toshiba branding updates.

This edition of the SureMark 4610 Models 1NR, 1NA, and 1ND Service Guide

(G362-0565-04) highlights table changes for operating system requirements.

This edition of the SureMark 4610 Models 1NR, 1NA, and 1ND Service Guide

(G362-0565-02) includes the following updates:

v Additional details on how to calibrate the low paper sensor.

v Enhanced offline test menu descriptions.

v Additional troubleshooting scenarios.

v Revised or new part numbers.

v Enhanced the index.

January 2010

This edition of the SureMark 4610 Models 1NR, 1NA, and 1ND User's Guide

(G362-0565-01) includes the following updates:

v Miscellaneous updates and corrections on the Model 1NR, 1NA, and 1ND

specifications.

v Corrections to the illustrations and procedures to service the Models 1NR, 1NA,

and 1ND prnters.

xv

Page 18

xvi SureMark Hardware Service

Page 19

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND

|

|

|

|

|

This manual provides problem determination and testing information, and includes a

parts listing of field-replaceable units (FRUs) for the SureMark printers.

The SureMark 4610 Models 1NR, 1NA, and 1ND are single-station printers with a

high-speed thermal station and an improved cutter. The Models 1NR, 1NA, and

1ND printers are designed for ease of service.

Figure 1. SureMark 4610 printer

In addition to increased printing speed and an improved cutter, enhanced system

management sensors and serviceability features have been added. The 1NR, 1NA,

and 1ND printers also include a paper-out sensor, low-paper sensor, and print head

"health" sensor. For easy paper loading, there is a cover open button to enable

one-handed paper loading.

Features and specifications

The SureMark 4610 Models 1NR, 1NA, and 1ND provides:

v Easy paper loading

v Fast, quiet receipt printing

v High-speed thermal station printing

v Enhanced system management sensors

– Paper present

– Low-paper sensing

1

Page 20

– Printhead status

– Characters printed

v Beeper

v Quieter paper cutter

|

v USB, RS-232, RS-485, and Ethernet interfaces

v 3 MB flash memory for storing messages, logos, code pages, and electronic

journal data

v DBCS thermal font - 24 x 24 matrix

v Bar code generation

v Downloadable fonts and code pages

v Downloadable microcode

v Small footprint

v Wall mount

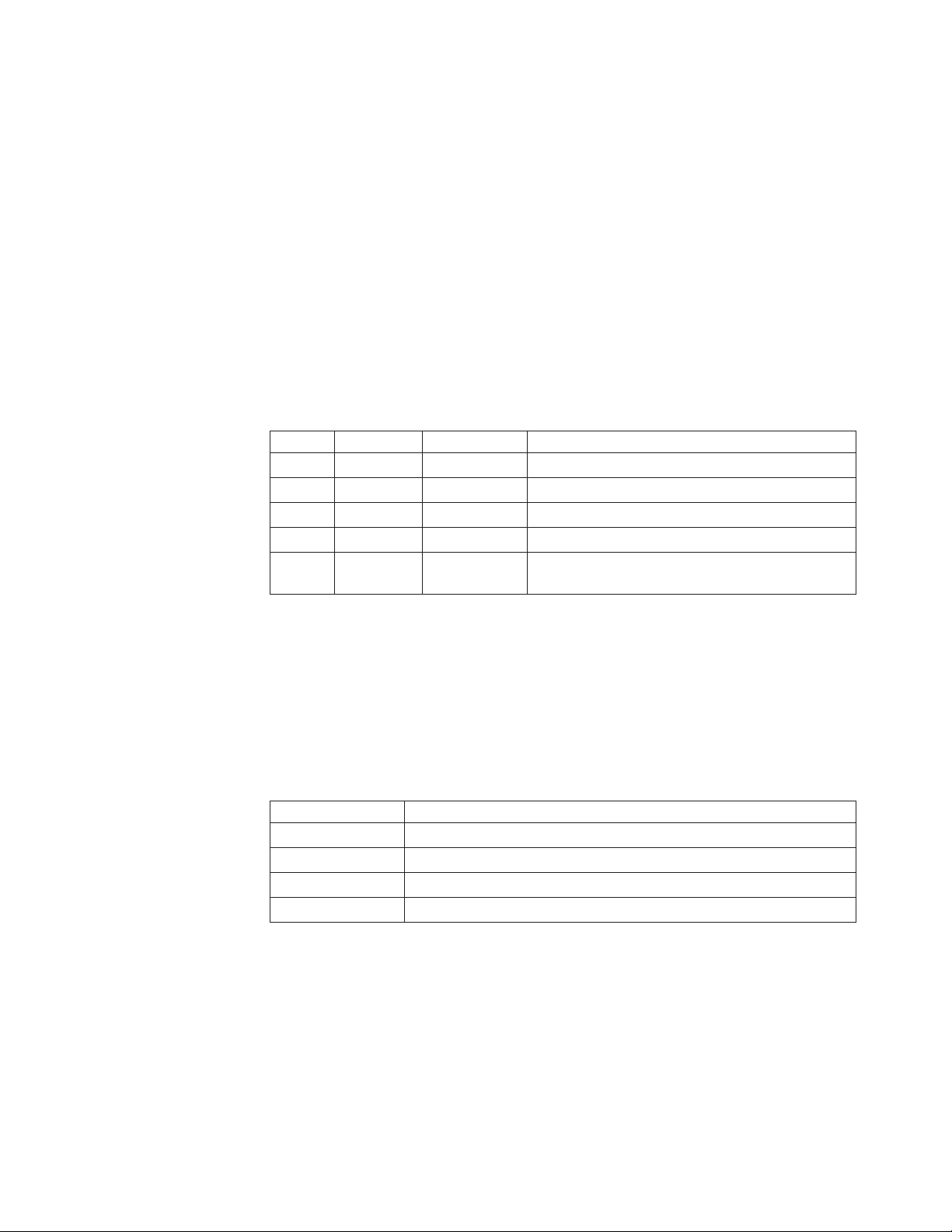

Table 1. Printer specifications

Printer:

v Print speed - up to 80 lps (thermal

single color printing)

v Dots per inch (dpi)- 203

v Print method - Thermal

v Tear bar - Standard (Need additional

information)

v Rotate printing supported (line by

line)

v Beeper

v Paper:

|

|

|

|

|

|

|

|

– Size:

- 58 mm or 80 mm single- or

two-color

- 102 mm (4 in) maximum outer

diameter internal roll

– Loading - Drop and load

– Cutter - standard

v Color

– Iron gray

– Pearl white

v Mounting

– Integrated (tray or filler panel)

– Distributive (free standing)

Communication:

v Ports and connectors:

– RS-232 (9-pin D-shell) for POS

Terminal Communications

– Powered USB port

– Power input connector

– Cash Drawer (RJ-11)

– RS-485 for POS Terminal

Communications

– Standard USB port

– Ethernet port

v Drivers:

– Windows

– UPOS (OPOS and JavaPOS

– 4690 OS

™

Physical dimensions:

v Size

– Height:

- Cover closed - 159 mm (6.26 in)

- Cover open - 260 mm (10.24 in)

– Depth -177 mm (6.97 in)

– Width - 145 mm (5.71 in)

– Weight:

- Without interface card - 1.4 kg (3.09 lb)

- With interface card - 2.5 kg (5.51 lb)

Power supply:

v Standard 4610 power supply (P/N 40N5050, or

later):

– 110/220 VAC Input

– +24 VDC Output

–75W

v Terminal supplied power option (Powered

USB):

– 24 V powered USB connection using the

Toshiba supplied cable (P/N 40N4790 =

0.75 m, 40N4789=2m,42J2477 = 1.55 m)

Controls and indicators:

v Cover Open

v Paper feed

v Beeper

v Status LED

v Paper status LED

v Power switch

)

2 SureMark Hardware Service

Page 21

Communication and power

|

|

|

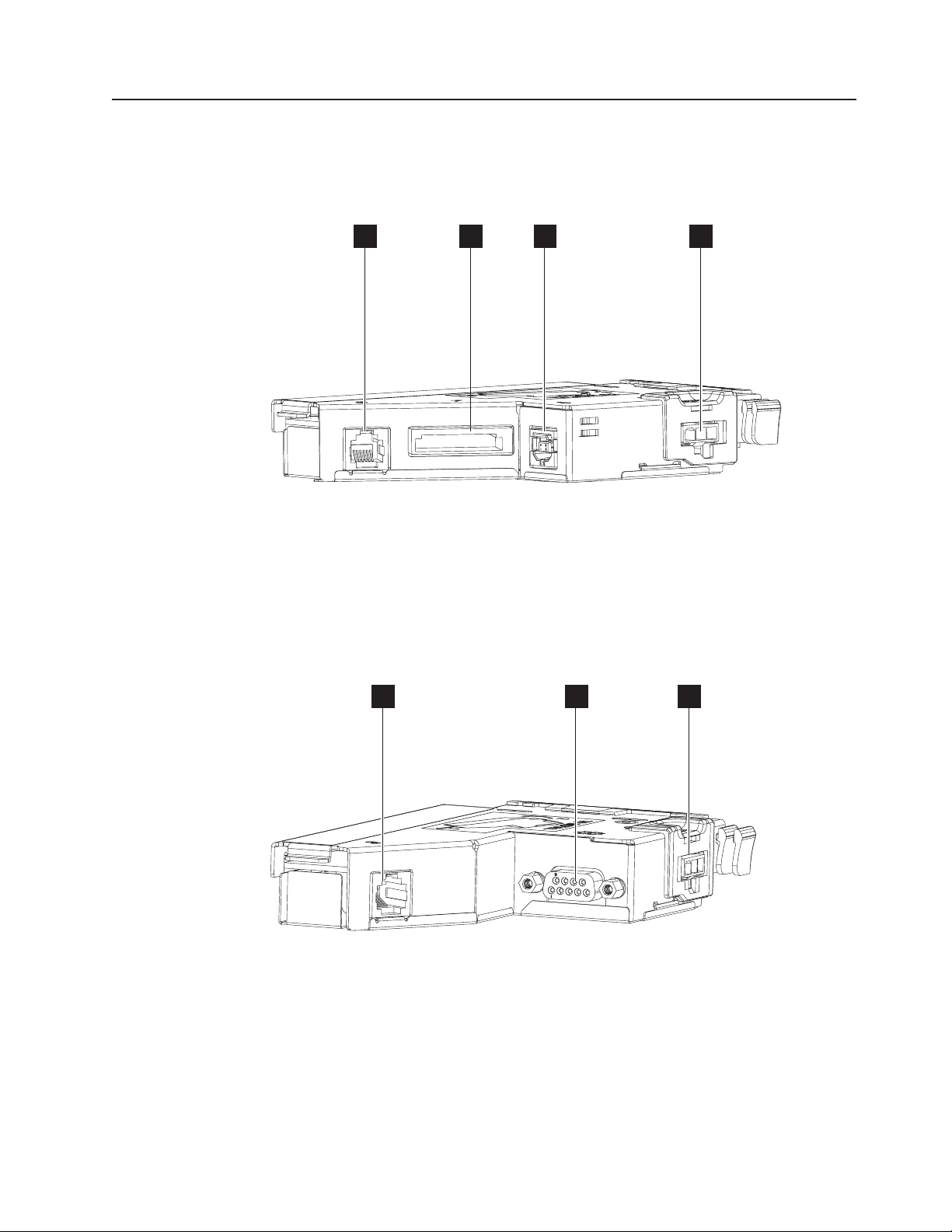

An interface card provides communication with the SureMark Models 1NR, 1NA,

and 1ND to the system unit. Select the card for your type of communication: the

RS-485, RS-232, USB, or Ethernet.

BA C D

Figure 2. USB interface card

A Cash drawer

B Powered USB

C Standard USB

D Power supply

E F G

Figure 3. RS-232 interface card

E Cash drawer

F RS-232

G Power supply

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 3

Page 22

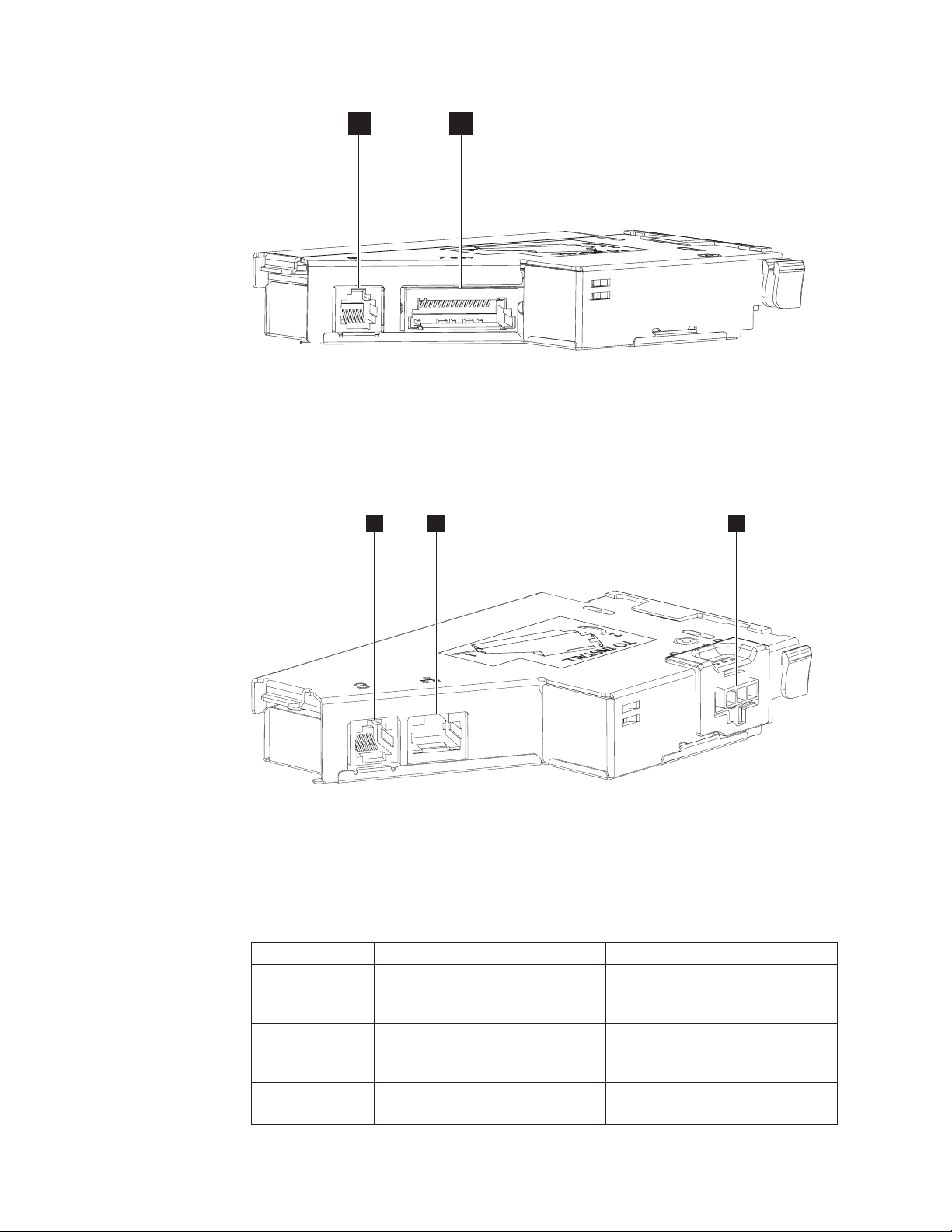

H

Figure 4. RS-485 interface card

I

H Cash drawer

I RS-485

Figure 5 illustrates the communications connections on the Ethernet interface card.

|

J

|

|

Figure 5. Ethernet interface card

K

L

|

||

||

||

|

|

J Ethernet

K Power supply

L Cash drawer

Table 2. Communication interface, rate, and power source

Device Description Power

Ethernet 10/100 Ethernet port for connection

to an industry standard Ethernet

LAN

RS-232 9.6K-115.2 K (selectable using

offline or online configuration) baud

rate

RS-485 Toshiba proprietary System unit input voltage +38 V or

Requires separate power supply

Requires separate power supply

+24 V (Japan only)

4 SureMark Hardware Service

Page 23

Table 2. Communication interface, rate, and power source (continued)

Device Description Power

USB USB is 2.0-Compliant Full-Speed

HID; bulk transfers at 12 Mbps

(megabits per second)

System unit input voltage (+24 V);

power supply if standard USB

cable is used

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 5

Page 24

Ethernet Configuration

|

|

|

|

Ethernet communications are supported on printers manufactured after June 10,

2013, with firmware EC level 14.00 and above. The date of manufacture can be

found on the bottom of the printer.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Older levels of the main logic cards (MLC) for these printers manufactured prior to

June 10, 2013 will not support Ethernet. MLCs that have the circuitry to support

Ethernet will be identified internal to the card.

If an Ethernet Interface adapter is installed and the MLC indicates that Ethernet is

not supported, an error message is printed. On the 1xR printers, the ready light will

blink amber.

A media access control (MAC) address is necessary for Ethernet function and will

be stored in the Ethernet interface adapter at the factory. The printer will print out

an error message if the MAC address is invalid or is not stored in the Interface

card. There is no capability of changing or cloning a MAC address in the field.

Every interface card (IFC) has a unique MAC address. See “Toshiba Diagnostics for

the Ethernet Printer” on page 39 for more information.

If an Ethernet adapter is detected, the firmware will not back-level to a pre-Ethernet

supported level.

Ethernet addressing options can be changed via:

1. Offline menus: See “Firmware offline tests” on page 45 for more information.

Reset Network Configuration will reset the user-modifiable network configuration

items to factory default. MAC is not affected.

2. Web interface.

3. Configuration utility.

4. Web API configuration download.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When these options are changed, they are stored in the MLC (main logic card) and

backed up in the IFC (interface card). If the printer's IFC is replaced, the values will

be updated with the following logic:

v When an IFC does not have a valid serial number (a card from FRU stock), all

Ethernet options will be copied automatically from the MLC to the IFC.

v If an IFC has a valid serial number, but it is different from the printer's serial

number, a menu will print with the options of updating MLC or updating IFC.

Remarks:

v The MAC address in the IFC will never change.

v On the 1NR printer, the serial number of the printer will not be overwritten by the

serial number in the IFC.

v On the 2xR printer, the menu will ask which serial number is correct. The

Ethernet options will be updated along with the serial number and other stored

data.

Note: The exception to the logic above occurs when the IFC is setup as a slave

card. When the IFC is a slave card, the Ethernet options used will be those

pulled from the IFC.

Slave cards may be used by a depot or integrators to setup configurations or flash

the printer's firmware without changing any settings on the MLC before it is shipped.

6 SureMark Hardware Service

Page 25

|

|

Addressing

|

|

|

|

|

|

|

|

|

To make an IFC slave card:

v Store a serial number of 55-55555.

The printer supports standard Internet Protocol version 4 (IPv4) addressing. The IP

address and other IP network parameters are assigned using the following list of

priorities:

1. Fixed, if enabled and defined for the fixed IP selected.

2. Dynamic Host Configuration Protocol (DHCP), if the previous assignment

method does not apply and a DHCP server is available.

3. Auto IP, if neither of the previous assignment methods apply and Auto IP is

enabled.

|

|

|

|

||||

||||

||||

||||

||||

|||||

|

DHCP

|

|

|

|

|

|

|

|

|

||

||

||

||

||

|

When Fixed IP and Auto IP are disabled, the printer will wait for a valid DHCP

server.

Table 3. Provided ports

Port Protocol Service Comments

80 TCP HTTP

161 UDP SNMP Version 1 and 2 are supported.

162 TCP/UDP SNMP Trap

9100 UDP Printer Control Used for reservation and other control function.

TCP PDL Data

Stream

Used to send RAW printer data to a printer.

Dynamic Host Configuration Protocol (DHCP) is the default IP configuration method

(see “Addressing” on page 7 for more information). DHCP will be implemented

according to Request for Comments (RFC) 2131, Dynamic Host Configuration

Protocol, RFC 2132, DHCP Options and BOOTP Vendor Extensions, and applicable

updates. These specifications and applicable updates may be found at

http://datatracker.ietf.org/.

Table 4. Supported DHCP options

Tag Name

1 Subnet Mask

3 Router

6 Domain Name Server

12 Hostname

Auto IP

|

|

|

|

|

|

|

Auto IP is a method for a host to assign itself a Local Link IP address, described in

RFC 3927. The printer will randomly select an address from the range 169.254.1.0

to 169.254.254.255 and verify that it is not in use.

Auto IP can be disabled when the user determines that the printer should always

have a valid server. This will keep the printer from setting up an auto IP when the

server is temporarily unavailable.

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 7

Page 26

|

|

|

Systems management support with Ethernet - SNMP

|

Note: A printer may take two minutes or more to obtain an IP address via Auto IP

due to the DHCP server time-out and other required delays. Auto IP is

intended for initial printer setup when a DHCP server is not available.

Ethernet printers support Read Only Simple Network Management Protocol (SNMP)

for systems management. The printers support management information base II

(MIB II) for management of the Ethernet configuration (RFC 1213) and a private,

enterprise MIB for the 4610 printers. Any client can retrieve the MIB data from the

printer. The printer will also support up to two SNMP managers to receive SNMP

Traps on state changes in the printer and attached cash drawers.

SNMP is used to manage the printer, not the printing process. SNMP gathers

information about the state of the printer:

v Status: Information regarding the current operating state of the printer (offline / on

line / error conditions).

v Alert: The representation of a reportable event in the printer. An event is a

change in the state of the printer; sent as an SNMP trap.

SNMP contains support for retrieving data (Get and GetNext requests) and

receiving notification of change of state and error conditions via Alerts (or Traps) as

unsolicited messages to listening managers. Setting or changing a condition in the

printer (Set requests) is not supported via SNMP.

|

|

|

|

|||

||||

||||

||||

||||

|||

|||

|||

|||

|||

|||

Alerts

Clients can register to receive Traps on the following state changes in the printer:

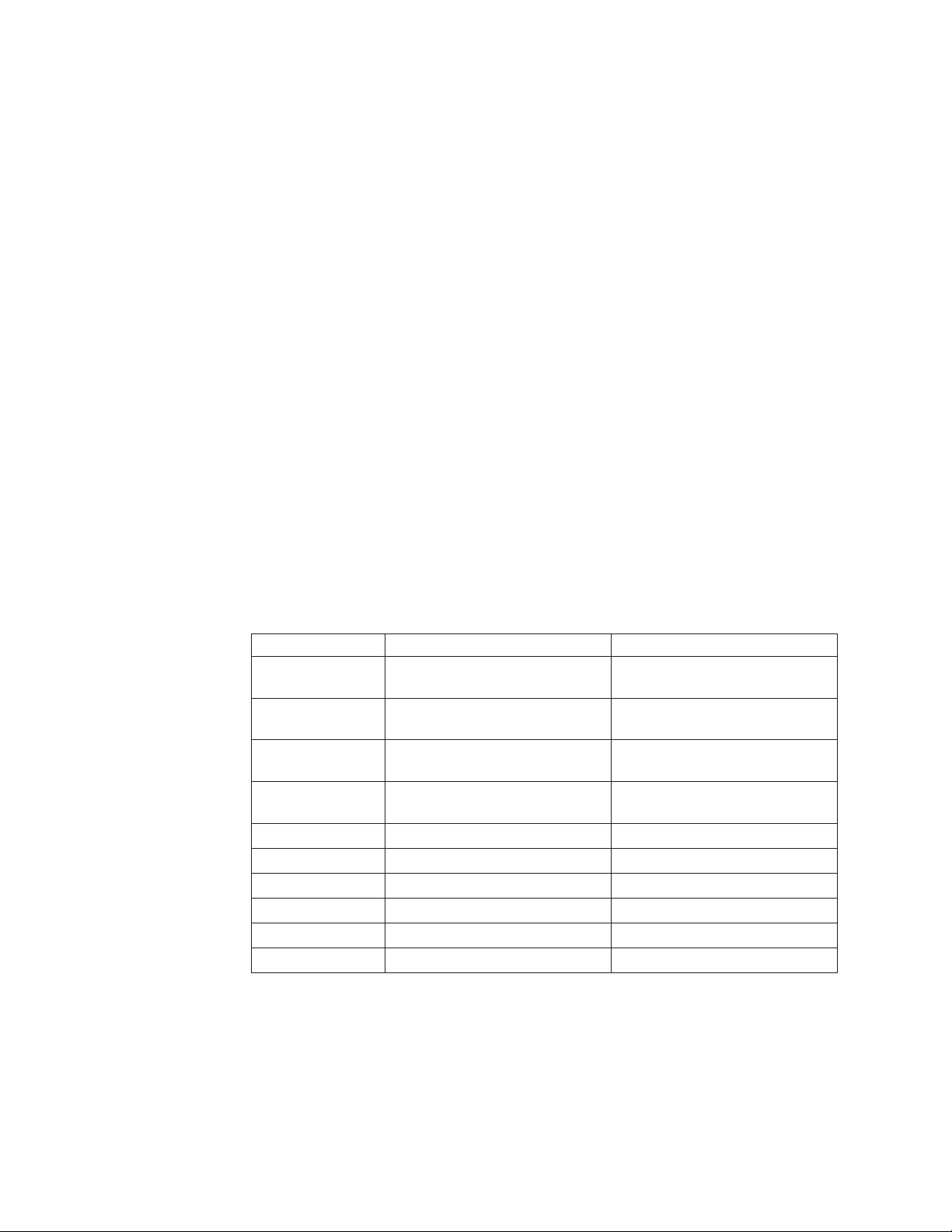

Table 5. Printer state changes

Function Name Object Identifier (OID)

Cash Draw Open /

Closed

Magnetic

Interference MICR

CR cover Open /

Closed

DI Cover Open /

Closed

Paper Out receiptEmpty 1.3.6.1.4.1.1129.2.500.1.1.2.2

Paper Low NA 1.3.6.1.4.1.1129.2.500.1.3.2.2

Home Error NA 1.3.6.1.4.1.1129.2.500.1.3.2.3

Offline / Online NA 1.3.6.1.4.1.1129.2.500.1.3.2.6

Paper Jam NA 1.3.6.1.4.1.1129.2.500.1.3.2.5

Cutter Jam NA 1.3.6.1.4.1.1129.2.500.1.3.2.1

DrawerOpened 1.3.6.1.4.1.1129.2.500.1.1.3.1

MICR_CurrentMICRNoiseValue 1.3.6.1.4.1.1129.2.500.1.1.3.6

receiptCoverOpen 1.3.6.1.4.1.1129.2.500.1.1.2.1

NA 1.3.6.1.4.1.1129.2.500.1.3.2.4

|

|

|

Up to two SNMP managers can be enabled to receive these alerts. See Statistics

table entries for details on enabling these traps.

|

|

|

|

8 SureMark Hardware Service

4610 Private Enterprise MIB

The 4610 Private Enterprise management information base (MIB) is shown in

Table 6 on page 9. Get request to the printer will retrieve this data.

Note: The access type for all entries is Read Only.

Page 27

|

|

|||

|||

|||

|||

|||

|||

|||

Table 6. 4610 Private Enterprise MIB

Name Object Identifier (OID) Type

receiptStationPresent 1.3.6.1.4.1.1129.2.500.1.1.1.1 Integer

paperCutter 1.3.6.1.4.1.1129.2.500.1.1.1.2 Integer

coverSensor 1.3.6.1.4.1.1129.2.500.1.1.1.3 Integer

receiptEmptySensor 1.3.6.1.4.1.1129.2.500.1.1.1.4 Integer

nearEndSensor 1.3.6.1.4.1.1129.2.500.1.1.1.5 Integer

receiptPageMode 1.3.6.1.4.1.1129.2.500.1.1.1.6 Integer

|

|||

|||

|||

|||

|||

|||

|||

|||

|||

|||

|||

|||

|||

|||

|||

|||

|||

receiptCoverOpen 1.3.6.1.4.1.1129.2.500.1.1.2.1 Integer

receiptEmpty 1.3.6.1.4.1.1129.2.500.1.1.2.2 Integer

ThermalPrintHeadElementFailure 1.3.6.1.4.1.1129.2.500.1.1.2.3 Integer

receiptNearEnd 1.3.6.1.4.1.1129.2.500.1.1.2.4 Integer

receiptPaperRemaining 1.3.6.1.4.1.1129.2.500.1.1.2.5 Integer

receiptPaperJamCount 1.3.6.1.4.1.1129.2.500.1.1.2.6 Integer

receiptUnexpectedCoverOpenCount 1.3.6.1.4.1.1129.2.500.1.1.2.7 Integer

receiptPaperCutCount 1.3.6.1.4.1.1129.2.500.1.1.2.8 Integer

receiptCharactersPrintedCount 1.3.6.1.4.1.1129.2.500.1.1.2.9 Integer

receiptCoverOpenCount 1.3.6.1.4.1.1129.2.500.1.1.2.10 Integer

receiptLineFeedCount 1.3.6.1.4.1.1129.2.500.1.1.2.11 Integer

receiptFailedPaperCutCount 1.3.6.1.4.1.1129.2.500.1.1.2.12 Integer

writeCountNVRAM 1.3.6.1.4.1.1129.2.500.1.1.2.13 Integer

maximumTemperatureReachedCount 1.3.6.1.4.1.1129.2.500.1.1.2.14 Integer

receiptPrintHeadFailureCount 1.3.6.1.4.1.1129.2.500.1.1.2.15 Integer

flashWriteFailedCount 1.3.6.1.4.1.1129.2.500.1.1.2.16 Integer

barcodePrintedCount 1.3.6.1.4.1.1129.2.500.1.1.2.17 Integer

|

|||

|||

|||

|||

|||

|||

DrawerOpened 1.3.6.1.4.1.1129.2.500.1.1.3.1 Integer

DrawerGoodOpenCount 1.3.6.1.4.1.1129.2.500.1.1.3.2 Integer

DrawerFailedOpenCount 1.3.6.1.4.1.1129.2.500.1.1.3.3 Integer

MICR_GoodReadCount 1.3.6.1.4.1.1129.2.500.1.1.3.4 Integer

MICR_FailedReadCount 1.3.6.1.4.1.1129.2.500.1.1.3.5 Integer

MICR_CurrentMICRNoiseValue 1.3.6.1.4.1.1129.2.500.1.1.3.6 Integer

|

|||

|||

|||

slipStationPresent 1.3.6.1.4.1.1129.2.500.1.2.1.1 Integer

fullSlip 1.3.6.1.4.1.1129.2.500.1.2.1.2 Integer

bothSidesPrint 1.3.6.1.4.1.1129.2.500.1.2.1.3 Integer

|

|||

|||

|||

|||

ImpactHeadFailedCount 1.3.6.1.4.1.1129.2.500.1.2.2.1 Integer

PrintSideChangeCount 1.3.6.1.4.1.1129.2.500.1.2.2.2 Integer

FailedPrintSideChangeCount 1.3.6.1.4.1.1129.2.500.1.2.2.3 Integer

slipCharactersPrintedCount 1.3.6.1.4.1.1129.2.500.1.2.2.4 Integer

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 9

Page 28

|

|||

|||

|||

|||

|||

|||

|||

Table 6. 4610 Private Enterprise MIB (continued)

Name Object Identifier (OID) Type

slipCoverOpenCount 1.3.6.1.4.1.1129.2.500.1.2.2.5 Integer

slipLineFeedCount 1.3.6.1.4.1.1129.2.500.1.2.2.6 Integer

slipUnexpectedCoverOpenCount 1.3.6.1.4.1.1129.2.500.1.2.2.7 Integer

slipFeedErrorCount 1.3.6.1.4.1.1129.2.500.1.2.2.8 Integer

HomeErrorCount 1.3.6.1.4.1.1129.2.500.1.2.2.9 Integer

FormInsertionCount 1.3.6.1.4.1.1129.2.500.1.2.2.10 Integer

|

|||

|||

|||

|||

|||

|||

|||

|||

|||

|||

DeviceID 1.3.6.1.4.1.1129.2.500.1.3.1.1 String

PhysicalDeviceDescription 1.3.6.1.4.1.1129.2.500.1.3.1.2 String

PhysicalDeviceName 1.3.6.1.4.1.1129.2.500.1.3.1.3 String

Bus 1.3.6.1.4.1.1129.2.500.1.3.1.4 String

DeviceCategory 1.3.6.1.4.1.1129.2.500.1.3.1.5 String

FirmwareRevision 1.3.6.1.4.1.1129.2.500.1.3.1.6 String

ManufactureDate 1.3.6.1.4.1.1129.2.500.1.3.1.7 String

ManufacturerName 1.3.6.1.4.1.1129.2.500.1.3.1.8 String

ModelName 1.3.6.1.4.1.1129.2.500.1.3.1.9 String

SerialNumber 1.3.6.1.4.1.1129.2.500.1.3.1.10 String

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HTTP Server

|

|

|

MIB II

Management information base II (MIB II) is used to convey information about the

TCP/IP configuration. The majority of the data that is recorded as part of MIB II will

not be useful in supporting the printer. For details, see the following information on

RFC 1213:

v Tree view of the RFC: http://www.snmplink.org/OnLineMIB/Standards/

v Full text: http://tools.ietf.org/html/rfc1213

The objects in MIB II are arranged in the following groups:

v System

v Interfaces

v Address Translation (deprecated)

v IP

v ICMP

v TCP

v UDP

v EGP

v Transmission

v SNMP

The printer provides an HTTP server for configuration, management, and diagnostic

functions.

10 SureMark Hardware Service

Page 29

Login and Overview

|

|

|

|

|

When a new HTTP connection is made, the printer prompts for a User Name and

Password. Completion of login establishes an active session which enables the

functionality as defined in the following sections. The logon screen varies depending

on the browser.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Web Pages

|

|

|

The default Username and Password are “Admin” and “Admin” respectively. These

may be redefined with the Web Interface in the HTTP Server, the Configuration

Utility, or the Web API configuration (see “Web API for printer configuration

management” on page 12).

The User Name and Password are limited to eight alphanumeric characters and are

case sensitive.

Data Display/Entry Fields

User Name:

Admin

v If an alternate login name is defined, the data entry field is blank;

otherwise, the default login name is displayed.

Password:

Admin

v The password is not displayed. A dummy character “*” is displayed for

each character entered.

The HTTP session remains active until the user logs off.

Once logged on, there are several pages in the printer that can be used for printer

management.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overview:

Reports the printer’s serial number, model, firmware level, and the current

Ethernet setting.

Diagnostic:

Supports printing of an offline receipt, reports the user statistics of the

printer, and shows the current status of the printer.

Network:

Allows the user to change the current Network configuration.

SNMP:

Allows the user to set up the SNMP managers.

Admin Access:

Allows the user to change the Login and Password used for the HTTP

server.

System Update:

Allows the user to configure the printer and to download firmware, font, and

configuration files.

Reset:

Allows the user to reset the printer.

Logout:

Allows the user to log out of the printer.

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 11

Page 30

Web API for printer configuration management

|

|

|

|

|

|

|

|

|

|

|

The Managing Client can retrieve the printer’s configuration via an HTTP “Get”. The

printer will respond with a configuration file (see “Retrieving Printer’s configuration

using HTTP Server Get” on page 12). This file will include all necessary information

to determine the current printer configuration or setup:

v Firmware version

v Checksums of the various flash memory sectors:

– Fonts

– Character sets

– Messages

v Network settings

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Knowledge of the printer specification and the locations of the given parameters are

required to interpret the output.

Once the manager determines that a printer requires updating, there are three file

types the printer will accept. These will come to the printer via HTTP POST:

1. Firmware file: The same firmware file that is supported by the drivers. *.hex

file.

The printer will verify the file format, validity (correct CRC), and version before

beginning the update process. Once verification is complete, it will program the

new firmware and reset. Following the reset, the printer will run at the new

firmware level.

2. Configuration file: Contains all the data the printer would need for

configuration in a given environment. This includes the network configuration.

3. Font file: The *.fon file that is supported by the UPOS drivers. See the UPOS

font support for creating this file with a configuration tool 4610cvnt.exe.

This file contains all the required data for setting up the font file in the printer. If

necessary, the printer will erase and then store all the font files and MCT values

associated with the font file. Example: If one of the DBCS font files is

downloaded, the printer will store the DBCS Impact, DBCS Thermal, SBCS

Impact User defined set 1, and SBCS Thermal User defined set 1, as well as

the MCTs needed to use these files by the printer and the UPOS drivers. If

required when downloading DBCS character sets, the printer will reset when the

font is done storing.

|

|

Retrieving Printer’s configuration using HTTP Server Get

|

|

|

|

|

Upon completion of setup, the printer will respond by sending a response to the

HTTP file.

The HTTP server Get is used for retrieving the configuration of the printer.

The HTTP header starts with get_Config:

GET /get_Config HTTP

12 SureMark Hardware Service

Page 31

|

|

Figure 6. Get Configuration header example

|

|

|

|

The format of the file sent back is the following:

<Configuration>

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<serial_number>SSSSSSSS</serial_number>

<mac_address>MMMMMMMMMMMM</mac_address>

<ip4>xx.xx.xx.xx</ip4>

<firmware>xx.xx</firmware>

<devinfo>Printer ID</devinfo>

<mct><length><512></length><data>data</data></mct>

<stat>><length><512></length><data>data</data></stat>

<snmptrap1>databytes</snmpttrap1>

<snmptrap2>databytes</snmpttrap2>

<snmpmanager1>xx.xx.xx</snmpmanager1>

<snmpmanager2>xx.xx.xx</snmpmanager2>

<hostname>name</snmpmanager2>

<autoipenable>xxx</autoipenable>

<fixedipenable>xxx</fixedipenable>

<fixedipselected>fixedipselected</fixedipselected>

<ipv4fixedip>xx.xx.xx</ipv4fixedip>

<subnet>xx.xx.xx</subnet>

<gateway>xx.xx.xx</gateway>

|

|

</Configuration>

|

|

|

|

|

||

|

|

|

|

||

||

Where:

SSSSSSSS

Printer Serial Number; ASCII alphanumeric string.

MMMMMMMMMMMM

Printer’s MAC address; ASCII encoded HEX.

name ASCII String; max 12 characters.

xx.xx.xx Valid IP address

v snmpmanager1: IP address of the 1st client receiving SNMP alerts

v snmpmanager2: IP address of the 2nd client receiving SNMP alerts

v ipv4fixedip: User Defined Fixed IP

xx.xx ASCII encoded Hex number representing the EC level of the firmware.

xxx YES or NO.

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 13

Page 32

||

|

n Hex number for the slot number, MCT number or statistic number being

changed.

||

|

|

|

|

|

|

|

||

||

||

||

||

||

||

||

||

||

|

|

data Hex bytes.

v MCT: Two bytes for each location in the MCT table. The table is 256

locations of two bytes each. MCTs that are not defined are set as 0xffff.

v Stat: Two bytes for each location in the statistics table. The table is 256

locations of two bytes each. Statistics that are not defined are set as

0xffff.

databytes

Two hex bytes associated with the traps being set:

Bit 15 Cash Drawer Open / Closed

Bit 14 Magnetic Noise present (MICR read)

Bit 13 Paper Out

Bit 12 Paper Low

Bit 11 Home Error

Bit 10 Paper Jam

Bit 9 Cutter Jam

Bit 8 CR Cover Open / Closed

Bit 7 DI Cover Open / Closed

Bit 6 Hard Error at the printer (printer offline). MLC error / IFC error /

Firmware can not initialized motion sensor and/or thermal print

head.

|

|

|

|

||

||

||

|

|

||

||

||

||

||

||

||

||

Details:

snmptrap1:

Bits2-5

Reserved - should remain high

Bit 0, 1

Version option for returning Trap messages – SNMP manager 1:

11 Version 1

10 Version 2

01 Version 3 (Currently not supported)

Bit 15 Cash Drawer Open / Closed

Bit 14 Magnetic Noise present (MICR read)

Bit 13 Paper Out

Bit 12 Paper Low

Bit 11 Home Error

Bit 10 Paper Jam

Bit 9 Cutter Jam

Bit 8 CR Cover Open / Closed

||

14 SureMark Hardware Service

Bit 7 DI Cover Open / Closed

Page 33

||

|

|

Bit 6 Hard Error at the printer (printer offline). MLC error / IFC error /

Firmware can not initialized motion sensor and/or thermal print

head.

|

|

|

|

||

||

|

|

|

|

|

|

||

||

|

|

||

|

|

|

|

|

snmptrap2:

fip: fip: Hex byte

Bits2-5

Reserved - should remain high

Bit 0, 1

Version option for returning Trap messages – SNMP manager 1:

11 Version 1

10 Version 2

Default: 0xFF

Bits2-15

Reserved - should remain high

Bit 0, 1

Version option for returning Trap messages – SNMP manager 2:

11 Version 1

10 Version 2

Default:

0xFF

0x03 = User Configured Fixed IP Enabled (default) when there is a

fixed IP defined.

0x02 = Fixed IP Config 1 Enabled

0x01 = Fixed IP Config 2 Enabled

0x00 = Fixed IP Config 3 Enabled

|

|

|

|

|

HTTP Server POST

|

|

|

|

|

|

|

|

|

|

|

|

|

Default:

0xFF

ipv4fixedip

Valid IP address encoded as ASCII encoded Decimal that will return only

when User Configured Fixed IP is enabled and defined.

The HTTP server power-on self-test (POST) is used for updating firmware, sending

the font file, and sending the configuration file.

Firmware Upload:

v The HTTP header starts with upload after POST: POST /upload HTTP/.

v Content type is "multipart/form-data".

v Content-type: String needs to be at the end of header, beginning of data section.

v Response:

– On successful storing: Firmware file download complete.

– On any error with receiving or storing file: Invalid Firmware File.

Configuration Upload:

v The HTTP header starts /upload_Config after POST: POST /upload_Config

HTTP/.

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 15

Page 34

|

|

|

|

v Content type is "multipart/form-data".

v Response:

– On successful storing: Configuration Update completed.

– On any error with receiving or storing file: Invalid Configuration File.

|

|

|

|

|

|

|

|

Font Upload:

v The HTTP header starts /upload_Font after POST: POST /upload_Font HTTP/.

v Content type is "multipart/form-data".

v Response:

– On successful storing: Fonts download completed.

– On any error with receiving or storing file: Invalid Font File.

Example of Java Program for posting a file:

16 SureMark Hardware Service

Page 35

public static void main(String[] args) throws IOException {

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

uploadFile.getName() + "\";filename=\"" + "textFile" + "\"" + crlf).getBytes("UTF8"));

|

|

getBytes("UTF8"));

|

|

|

|

|

|

|

|

|

|

|

|

}

|

|

// takes file path from first program’s argument

String filePath = "C:\\ec12_0a.hex";

File uploadFile = new File(filePath);

System.out.println("File to upload: " + filePath);

// creates a HTTP connection

URL url = new URL(UPLOAD_URL);

HttpURLConnection httpConn = (HttpURLConnection) url.openConnection();

httpConn.setUseCaches(false);

httpConn.setDoOutput(true);

httpConn.setRequestMethod("POST");

httpConn.setRequestProperty("Content-type","multipart/form-data; boundary=" + boundary);

// sets file name as a HTTP header

httpConn.setRequestProperty("fileName", uploadFile.getName());

httpConn.connect(); // new.

// opens output stream of the HTTP connection for writing data

OutputStream outputStream = httpConn.getOutputStream();

// Opens input stream of the file for reading data

FileInputStream inputStream = new FileInputStream(uploadFile);

byte[] buffer = new byte[BUFFER_SIZE];

int bytesRead = -1;

System.out.println("Start writing data...");

outputStream.write((twoHyphens + boundary + crlf).getBytes("UTF8"));

outputStream.write(new String("Content-Disposition: form-data; name=\"" +

outputStream.write(new String("Content-Type: application/octet-stream\r\n\r\n").

while ((bytesRead = inputStream.read(buffer)) != -1) {

outputStream.write(buffer, 0, bytesRead);

}

outputStream.write(crlf.getBytes());

outputStream.write((twoHyphens + boundary + twoHyphens).getBytes());

System.out.println("Data was written.");

outputStream.close();

inputStream.close();

Configuration file format

|

|

|

|

|

|

<configuration>

<logo>

<erase>xxx</erase>

<slot><number>n</number><width>WW</width><height>HH</height><data>

databytes</data></slot>

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 17

Page 36

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<slot><number>n</number><width>WW</width><height>HH</height><data>

databytes</data></slot>

.......

</logo>

<message>

<erase>xxx</erase>

<slot><number>n</number><length>LLLL</length>

<data>databytes</data></slot>

<slot><number>n</number><length>LLLL</length>

<data>databytes</data></slot>

.......

</message>

<mct>

<slot><number>n</number><data>databytes</data></slot>

<slot><number>n</number><data>databytes</data></slot>

.......

</mct>

<statistics>

<slot><number>n</number><data>databytes</data></slot>

<slot><number>n</number><data>databytes</data></slot>

.......

</statistics>

<network>

<snmptrap1>databytes</snmpttrap1>

<snmptrap2>databytes</snmpttrap2>

<snmpmanager1>xx.xx.xx</snmpmanager1>

<snmpmanager2>xx.xx.xx</snmpmanager2>

<httpuserid>name</httpuserid>

<httppw>password</httppw>

<hostname>name</hostname>

<autoipenable>xxx</autoipenable>

<fixedipenable>xxx</fixedipenable>

<fixedipselected>fip</fixedipselected>

<ipv4fixedip>xx.xx.xx</ipv4fixedip>

<subnet>xx.xx.xx</subnet>

<gateway>xx.xx.xx</gateway>

</network>

</configuration>

|

||

||

|

||

||

||

|

|

||

|

|

18 SureMark Hardware Service

Where:

xxx YES or NO

n Hex number for the slot number, MCT number, or Statistic number being

changed.

LLLL Length of the message data (ASCII representation of hex value).

WW Width of the logo (ASCII representation of hex value).

HH Height of the logo (ASCII representation of hex value).

xx.xx.xx

Valid IP address encoded as ASCII encoded Decimal.

name ASCII String, Max 12 characters.

databytes

Hex number for data associated with this change.

Page 37

|

|

|

|

|

||

|

|

|

||

||

||

||

||

||

||

||

||

||

|

|

Details:

MCTs and Statistics:

2 bytes for each MCT number or Statistics number. There are 256 values

for each: MCT and Statistic. Values not defined are set as 0xffff.

Logo: Logo data in hex, of length WW x HH x 8.

Message:

Hex data of message length is defined by LLLL.

snmptrap1:

Bit 15 Cash Drawer Open / Closed

Bit 14 Magnetic Noise present (MICR read)

Bit 13 Paper Out

Bit 12 Paper Low

Bit 11 Home Error

Bit 10 Paper Jam

Bit 9 Cutter Jam

Bit 8 CR Cover Open / Closed

Bit 7 DI Cover Open / Closed

Bit 6 Hard Error at the printer (printer offline). MLC error / IFC error /

Firmware can not initialized motion sensor and/or thermal print

head.

|

|

|

|

||

||

|

|

snmptrap2:

|

|

|

|

||

||

|

|

|

fixedipselected:

|

|

|

Bits2-5

Reserved - should remain high

Bit 0, 1

Version option for returning Trap messages – SNMP manager 1:

11 Version 1

10 Version 2

Default: 0xFF

Bits2-15

Reserved - should remain high

Bit 0, 1

Version option for returning Trap messages – SNMP manager 2:

11 Version 1

10 Version 2

Default:

0xFF

fip: Hex byte

0x03 = User Configured Fixed IP Enabled (default) when there is a

fixed IP defined. See on page 20.

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 19

Page 38

|

|

|

0x02 = Fixed IP Config 1 Enabled

0x01 = Fixed IP Config 2 Enabled

0x00 = Fixed IP Config 3 Enabled

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ipv4fixedip

Configuration file examples

Example 1:

Default:

0xFF

Valid IP address encoded as ASCII encoded Decimal that will return only

when User Configured Fixed IP is enabled and defined.

fip: Hex byte

0x03 = User Configured Fixed IP Enabled (default) when there is a

fixed IP defined.

0x02 = Fixed IP Config 1 Enabled

0x01 = Fixed IP Config 2 Enabled

0x00 = Fixed IP Config 3 Enabled

To download these Predefined Messages:

v To Slot 16: abcdefghijklmnopqrstuvwxyz<linefeed>

v To Slot 02: <X'1B;2D;01'>

abcdefghijklmnopqrstuvwxyz<linefeed><X'1B;2d;00'>

|

Figure 7. The configuration file open in a hex editor

|

|

|

|

|

Example 2:

To downloada2x4logo to Slot 1:

20 SureMark Hardware Service

Page 39

|

|

Figure 8. The configuration file open in a hex editor

|

|

Printer sharing

|

|

|

|

|

The printer sharing protocol provides a means for multiple clients to share a printer,

with each being granted exclusive access during the time of usage. The protocol is

established with Toshiba supported drivers, which can be found on the Toshiba

Global Commerce Solutions support website at www.toshibagcs.com/support.

Locating the power button

The power button for the 4610 Models 1NR, 1NA, and 1ND is located under the

paper door (as shown in Figure 9 on page 22).

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 21

Page 40

A

Figure 9. Power button

Operating system requirements

|

|

|

This section describes the operating system requirements for your 4610 Model

1NR, 1NA or 1ND printer. You can download drivers from the Toshiba Global

Commerce Solutions support website at www.toshibagcs.com/support.

A compatibility mode is provided in the printers to enable use of existing drivers and

applications with only minor modifications. For native mode support, see the

following tables:

RS-232 Printer

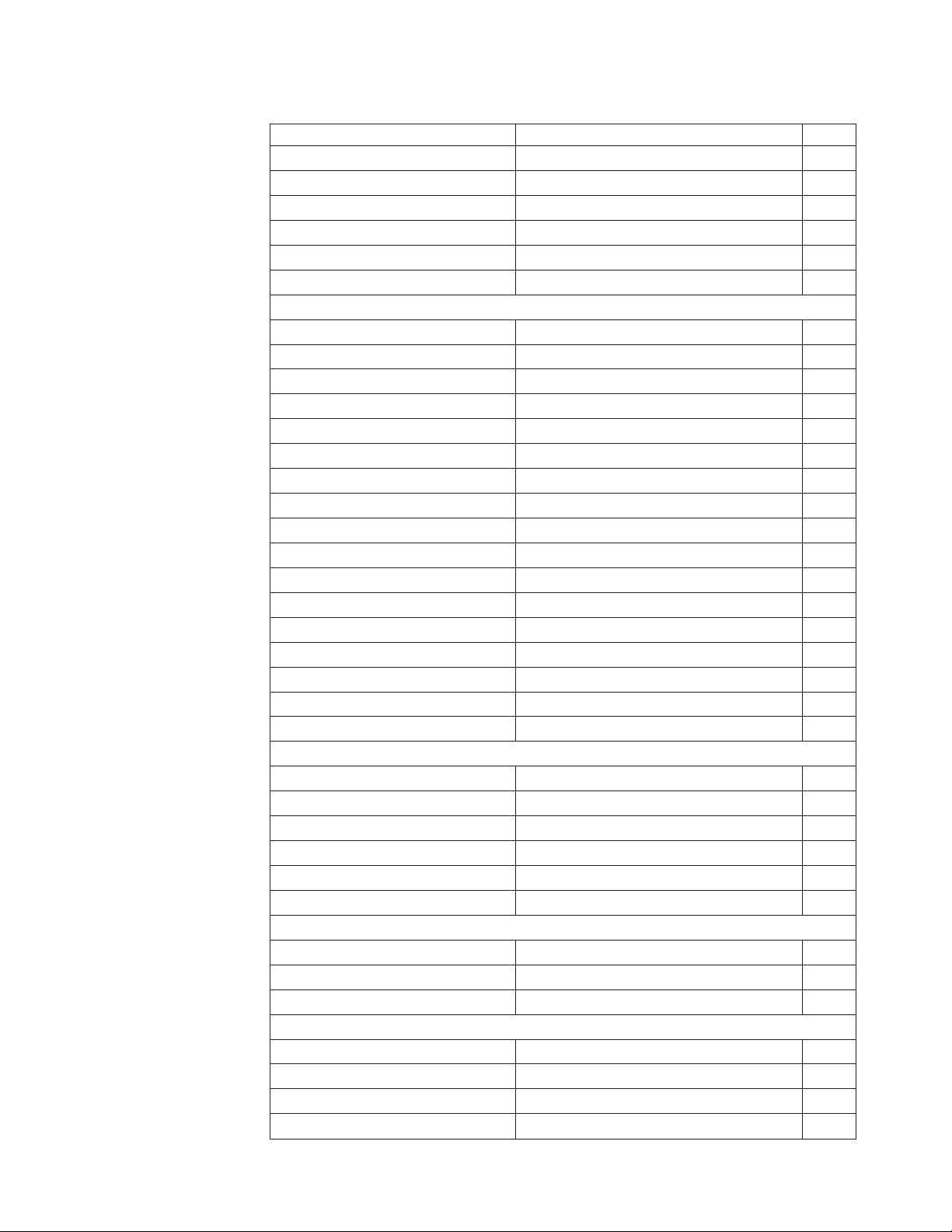

Table 7 includes a description of native mode support for the RS-232 Printer.

Table 7. Native Mode Support - RS-232 Printer

JavaPOS

Operating

System

4690 Yes V5R2 and

|

Microsoft

Windows®XP

®

Drivers 1.9.6

or later

Yes Yes Yes

OPOS Drivers

1.9.6 or later

POS

Subsystem

1.9.6 or later

Windows

Native Drivers

(NWD) Direct IO Comments

V6R2*

22 SureMark Hardware Service

Page 41

Table 7. Native Mode Support - RS-232 Printer (continued)

JavaPOS

Operating

System

Microsoft

Windows

Embedded for

Point of

Service

(WEPOS) 1.11

Microsoft

Windows

Embedded

POSReady

2009

|

Microsoft

|

Windows

|

Embedded

|

POSReady 7

Microsoft

Windows 7

(Professional/

Ultimate)

SUSE Linux

Enterprise

Desktop

(SLED) 11

SUSE Linux

Enterprise

Server (SLES)

11

SUSE Linux

Enterprise

Point of

Service

(SLEPOS) 11

PC DOS 2000 Yes

Drivers 1.9.6

or later

Yes Yes Yes Yes

Yes Yes Yes Yes

Yes Yes Yes Yes

Yes Yes Yes Yes

®

Yes Yes

Yes Yes

Yes Yes

OPOS Drivers

1.9.6 or later

POS

Subsystem

1.9.6 or later

Windows

Native Drivers

(NWD) Direct IO Comments

RS-485 Printer

Note: *The 2NR/2CR printers are supported in compatibility mode in V5R2 but

4690 OS can only update the firmware starting with the 0820 maintenance

package. The 1NR is supported in compatibility mode in V5R2 but requires

package 0900 for firmware update. All of these models are supported in

compatibility or native mode in V6R2.

Table 8 on page 24 includes a description of native mode support for the RS-485

Printer.

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 23

Page 42

Table 8. Native Mode Support - RS-485 Printer

Windows

JavaPOS

Drivers 1.9.6

Operating System

|

4690 V5R2 and

Microsoft Windows XP Yes Yes

Microsoft Windows

Embedded for Point of

Service (WEPOS) 1.11

Microsoft Windows

Embedded POSReady

2009

|

Microsoft Windows

|

Embedded POSReady

|

7

Microsoft Windows 7

(Professional/Ultimate)

SUSE Linux Enterprise

Desktop (SLED) 11

SUSE Linux Enterprise

Server (SLES) 11

SUSE Linux Enterprise

Point of Service

(SLEPOS) 11

PC DOS 2000 Not

or later

Yes Yes

Yes Yes

Yes Yes

Yes Yes

Yes Yes

Yes Yes

Yes Yes

OPOS

Drivers 1.9.6

or later

POS

Subsystem

1.9.6 or later

Native

Drivers

(NWD) Direct IO Comments

V6R2*

supported

Note: *The 2NR/2CR printers are supported in compatibility mode in V5R2 but

4690 OS can only update the firmware starting with the 0820 maintenance

package. The 1NR is supported in compatibility mode in V5R2 but requires

package 0900 for firmware update. All of these models are supported in

compatibility or native mode in V6R2.

24 SureMark Hardware Service

Page 43

USB Printer

Table 9 includes a description of native mode support for the USB Printer.

Table 9. Native Mode Support - USB Printer

Windows

JavaPOS

Drivers 1.9.6

Operating System

|

4690 V5R2 and

Microsoft Windows XP Yes Yes Yes

Microsoft Windows

Embedded for Point of

Service (WEPOS) 1.11

Microsoft Windows

Embedded POSReady

2009

|

Microsoft Windows

|

Embedded POSReady

|

7

Microsoft Windows 7

(Professional/Ultimate)

SUSE Linux Enterprise

Desktop (SLED) 11

SUSE Linux Enterprise

Server (SLES) 11

SUSE Linux Enterprise

Point of Service

(SLEPOS) 11

PC DOS 2000 Not

or later

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Yes Yes

Yes Yes

Yes Yes

OPOS

Drivers 1.9.6

or later

POS

Subsystem

1.9.6 or later

Native

Drivers

(NWD) Direct IO Comments

V6R2*

supported

Ethernet Printer

|

|

|

Table 10. Native Mode Support - Ethernet Printer

|

|

|

Operating System

|||||

||

4690 Not supported

|||||

Microsoft Windows XP Yes Yes

|||||

Microsoft Windows Embedded for

||||||

Point of Service (WEPOS) 1.11

Microsoft Windows Embedded

||||||

POSReady 2009

||||||

Microsoft Windows Embedded

POSReady 7

||||||

Microsoft Windows 7

(Professional/Ultimate)

Table 10 includes a description of native mode support for the Ethernet Printer.

Windows Native

JavaPOS Drivers

1.13.5 or later

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

Yes Ye s Yes

OPOS Drivers

1.13.5 or later

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 25

Drivers (NWD)

3.1.0 or later Comments

Page 44

Table 10. Native Mode Support - Ethernet Printer (continued)

|

|

|

|||||

||

Operating System

||||||

SUSE Linux Enterprise Desktop

(SLED) 11 Service Pack 3

||||||

SUSE Linux Enterprise Server

(SLES) 11 Service Pack 3

|

||||

SUSE Linux Enterprise Point of

|

Service (SLEPOS) 11 Service

|

Pack 3

|||||

PC DOS 2000 Not supported

JavaPOS Drivers

1.13.5 or later

Yes

Yes

Yes

OPOS Drivers

1.13.5 or later

Windows Native

Drivers (NWD)

3.1.0 or later Comments

|

|

Hardware requirements

SureMark printers work with the following systems:

|

|

|

|

|

|

v 4694 systems

v 4695 systems (RS-232 connection only and with power supply)

v PC or other store controller with an RS-232, USB, or Ethernet port

v SurePOS

™

100 Series systems

v SurePOS 300 Series systems

v SurePOS 500 Series systems

v SurePOS 700 Series systems

v Self Checkout solution

v AnyPlace

v TCx

™

™

Wave

Kiosk

Calling for service

Before calling for service, you will need the machine type, model number, and serial

number of the printer This information can be found on the two printer information

labels. See “Printer information label” for the location of the two printer information

labels.

Printer information label

The printer information labels are located beside the power button on the inside of

the printer and on the front right edge of the main cover (see Figure 10 on page

27).

26 SureMark Hardware Service

Page 45

Printer

Information

Label

Figure 10. Location of label with machine type, model number and serial number

Chapter 1. Introducing the 4610 Models 1NR, 1NA, and 1ND 27

Page 46

28 SureMark Hardware Service

Page 47

Chapter 2. Product specifications

This section describes the physical specifications for models 1NR, 1NA, and 1ND.

Physical dimensions

Figure 11 describes the physical dimensions.

159 mm

(6.26 in)

177 mm

(6.97 in)

Figure 11. SureMark 4610 Models 1NR, 1NA, and 1ND dimensions

Table 11. Summary of dimensions

Width: 145 mm (5.71 in.) footprint

Height: Cover closed: 159 mm (6.26 in.)

Cover open: 260 mm (10.24 in.)

Depth: 177 mm (6.97 in.)

Weight: 1.4 kg (3.09 lb)

Temperature and humidity limits

Shipping -40° to 60° C (-40° to 140° F) with 5% to 100% relative humidity

including condensation, but excluding rain

Storage 0° to 60° C (32° to 140° F) with 5% to 80% relative humidity

145 mm

(5.71 in)

Operating 5° to 40° C (42.8° to 104° F) with 8% to 80% relative humidity

29

Page 48

Connector pin assignments

The following sections describe the connector pin assignments for the external

connectors

Power supply

Table 12. Power supply pin designations

Pin Signal

1 +24Vdc

2 Not connected

3 Ground

USB

Table 13. USB pin designations

Pin Signal

1 Vbus (+5 V dc)

2 Minus data

3 Plus data

4 Ground

Powered USB

RS-232

Table 14. Powered USB pin designations

Pin Signal

1 Ground (+24 V dc)

2 (+24 V dc)

3 Ground (Vbus)

4 Plus data

5 Minus data

6 Vbus +5 V dc

7 +24Vdc

8 Ground (+24 V dc)

Table 15. RS-232 pin designations

Pin Signal

1 Not connected

2 Transmit

3 Receive

4 DTR

5 Signal ground

6 DSR

30 SureMark Hardware Service

Page 49

RS-485

Table 15. RS-232 pin designations (continued)

Pin Signal

7 Not connected

8RTS

9 Not connected

Table 16. RS-485 pin designations. Note: The 24 V version is available in Japan; all 38 V

DC's change to 24 V DC for that card.

Pin Signal

1 +5Vdc

2 Ground (5 V dc)

3 +5Vdc

4 Ground (5 V dc)

5 +5Vdc

6 Ground (5 V dc)

7 Data "B"

8 Data "A"

9 Ground (38 V dc)

10 +38 V dc

11 Ground (38 V dc)

12 +38 V dc

13 Ground (38 V dc)

14 +38 V dc

15 Ground (38 V dc)

16 +38 V dc

Chapter 2. Product specifications 31

Page 50

Cash drawer

A single connector can drive either a single cash drawer or two cash drawers using

a special cable. The connector provides a status line if one of the cash drawers is

open. The cash drawer cannot be activated while the printer is operating.

Table 17. Cash drawer connector pin designations

Pin Signal

1 Not connected

2 Solenoid 1 drawer

3 Cash drawer status

4 +24Vdc

5 Solenoid 2 drawer

6 Ground

Printing width, speed, and acoustics

Table 18. Station characteristics

Characteristic Customer receipt station

Speed (see note

following table)

Paper Width 58 mm or 80 mm

Print Width 34 characters at 12 cpi

Pitch 12, 15, 17, 20 cpi

Up to 80 lps thermal (one-color)

44 characters at 15 cpi

48 characters at 17 cpi

57 characters at 20 cpi

Note: To ensure reliable operation, the printer reduces throughput when printing

higher densities or continuous (no pause) paper feeding. This might affect

overall throughput. Optimize print density to maximum throughput.

The reduced print speed is based on the number of print dots that are turned

on for a given print line, which is defined as dot utilization. Dot utilization

typically is low for normal character printing and up to 100% for full black line

printing. The SureMark printer operates at 80 lps at low dot utilization, and at

slower speeds as the dot utilization increases. It is also controlled by receipt

motor use.

Table 19. Sound characteristics

Type Description LwAd LpAm <LpA>m

Operating

(bels)

SureMark Printer 5.7 N/A 61.5 N/A 47 N/A

Idling (bels) Operating

(dB)

Idling (dB) Operating

(dB)

Idling (dB)

Notes:

LwAd The declared upper limit of the sound power level for a random

sample of machines.

32 SureMark Hardware Service

Page 51

Bar codes

LpAm The mean value of the A-weighted sound pressure levels at the

operator position (if any) for a random sample of machines.

<LpA>m

The mean value of the A-weighted sound pressure levels at the

one-meter (bystander) positions for a random sample of machines.

N/A Indicates not applicable.

All measurements were made in accordance with ISO 7779 and reported in

conformance with ISO 9296.

SureMark printers can generate these bar codes:

v QR

v UPC A/E

v JAN 8 (EAN)

v Code 39

v ITF

v Code 93

v Code 128 A, B, C

v Codabar

v PDF417

Resident code pages

These code pages are resident in the printer:

v 437-US

v 858 - International

v 860 - Portuguese

v 863 - Canadian French

v 865 - Norwegian

v 869 - Greek

v 857 - Turkish

v 864 - Arabic

v 867 - Hebrew (Israel)

v 852 - Hungarian, Polish, Czech, Romanian, Slovak, Slovenian, Croatian

v 848 - Ukranian

v 866 - Russian (Cyrillic)

v 872 - Bulgarian, Serbian

v 775 - Lithuanian, Latvian, Estonia

v 861 - Icelandic

v 1250 - Windows Latin 2

v 1251 - Windows Cyrillic

v 1252 - Windows Latin 1

v 1253 - Windows Greek

v 1254 - Windows Turkish

v 1255 - Windows Hebrew

v 1256 - Windows Arabic

v 1257 - Windows Baltic Rim

These code pages may be downloaded to the printer:

v 932 - Japan

v 949 - Korea

v 950 - Traditional Chinese

v 1381 - Simplified Chinese

Chapter 2. Product specifications 33

Page 52

The firmware supports the following in the thermal station:

v Proportional fonts

v Scalable fonts

v Color printing: black plus one accent on two-color thermal paper (thermal station

only)

v Upside-down printing

v Watermark printing

34 SureMark Hardware Service

Page 53

Chapter 3. Adjusting and maintaining the 4610

To keep your 4610 Models 1NR, 1NA, and 1ND printers working properly, you

should periodically make printer adjustments and follow recommended maintenance

procedures. This section provides instructions on using, adjusting, and maintaining

your printer, and includes the following topics:

v Replenishing printer supplies

v Cleaning recommendations

For detailed technical information on the 4610 Models 1NR, 1NA, and 1ND printers,

see Chapter 2, “Product specifications,” on page 29.

|

|

Attention: All covers must be installed on the SureMark 4610 Models 1NR, 1NA,

and 1ND printer before and during operation.

Using and maintaining the 4610

Replenishing consumable supplies

You are responsible for replenishing the supply roll paper.

Loading and replacing the paper roll

Ensure that you have the correct paper for the 4610. See “Supported thermal

paper” on page 36.

1. Press and release the blue release button to release the paper door. In a

wall-mount configuration, you must also pull the door fully open, because of the

brake feature that decelerates it from the full force of gravity.

2. If necessary, remove any unused paper or the empty paper roll core before

inserting a new paper roll.

Note: Refer to the label inside the printer for a diagram of how to load paper.

3. Place the paper roll into the paper roll bucket as shown on the diagram. The

leading edge of the paper should come from the bottom of the roll as shown in

the diagram.

Note: The thermal printhead will not print on paper with glue on it. If the new

paper roll was sealed by glue, tear off the 6 to 8 inches of paper with

glue on it before loading it.

4. Close the paper cover.

5. Press the customer receipt feed button to advance the paper, to verify that the

paper is feeding correctly. Feed 30 cm (about 1 ft) of paper through to test for

correct alignment.

Attention: Do not pull the receipt paper out of the printer with the paper access

cover closed. This disengages the paper feed. The paper feed motor must then

catch up before the printer can feed the paper, which causes missing lines or partial

lines of print. Use the customer receipt feed button to advance the receipt and all

lines will print.

35

Page 54

Supported thermal paper

Attention: Using an inferior grade of paper can affect print quality as well as the

life of printheads and the printer mechanism.

Note: When selecting a paper, ensure that the paper's archive life meets the

requirements of the tax authorities of your country for archiving tax-related

data.

The paper used in the thermal receipt station must meet the following requirements:

Width 79.5 ± 0.5 mm (3.13 ± 0.02 in.) or 57.5 ± 0.5 mm (2.26 ± 0.02 in.)

Outside Diameter

102 mm (4.0 in.) maximum

Thickness

60 µm (0.00225 in.) optimal. Range: 41 µm minimum to 99 µm maximum.

Important

Paper has a significant manufacturing tolerance, and nominal paper

designations do not reflect actual measurements. The manufacturing

tolerance must fall within the published operating thickness range.

Customers should test paper in their specific configuration before use.

The intent of this specification is that if any spot measurement of the

paper is outside the specified range, the paper is deemed not to meet

the specification and the customer is responsible for any problems

caused by paper jams.

The paper must be wound with the printing side facing out. The paper should not

be attached to the core in any manner.

Important

Printer reliability and performance are directly related to the quality of the

supplies used by the customer. The published parameters for printer

performance are established using supplies that meet the specifications listed

above.

|

|

|

|

|

|

|

|

|

Thermal paper with watermarks, coupons, or advertisements printed on the

front or back of the paper is not covered by Toshiba specifications. Some

inks and printing processes work acceptably, but others do not. Printer

problems that are caused by supplies that do not meet Toshiba specifications

might result in a billable service call, regardless of the existence of a service

contract.

For supported papers, refer to the OEM Thermal Paper Testing table found under

SureMark Printers on the Toshiba Global Commerce Solutions support website:

www.toshibagcs.com/support.

Installing large paper rolls

|

|

|

The 4610 can accommodate extra-large rolls (up to 15 in.) of paper below the

printer. Mounting hardware is necessary to avoid placing undue strain on the paper

feed motor. See your Toshiba representative for additional information.

36 SureMark Hardware Service

Page 55

Cleaning recommendations

You should inspect your 4610 unit periodically and clean the cover as required. Use

a soft, clean cloth with warm, soapy water to clean the plastic parts. Do not use

abrasives or any alkaline, ammonia, or chloride-based cleaner.

Note: Do not apply cleaning solution directly to the cover. Always apply the cleaner

to a clean cloth and then wipe the cover with the damp cloth. Be certain that

the cloth is only damp and not dripping wet.

Cleaning the thermal printhead

|

|

|

|

|

The thermal printhead should be cleaned at regular intervals or when the print

quality has noticeably deteriorated. There are many factors that affect cleaning

frequency. Poor paper quality, high printer usage, or a dirty environment are all

reasons to clean the thermal printhead more often. Complete the following steps to

clean the thermal printhead:

1. Open the paper cover.

2. Using a cotton swab soaked in isopropyl alcohol, gently wipe the printhead

several times on its print line and on the surrounding area.

3. Wipe off any residual alcohol with a dry swab.

If print quality does not improve after cleaning the thermal printhead, run the

Thermal Printhead Health Test. If print quality still does not improve, call for service.

Chapter 3. Adjusting and maintaining the 4610 37

Page 56

38 SureMark Hardware Service

Page 57

Chapter 4. Running tests and diagnostics

|

|

|

|

Toshiba Diagnostics for POS Systems and Peripherals

|

|

|

|

|

|

|

|

|

|

Toshiba Diagnostics for the Ethernet Printer

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This chapter describes the diagnostics tools, offline tests, and troubleshooting

procedures for the SureMark 4610 Models 1NR, 1NA, and 1ND printers.

Attention: For firmware and driver updates, refer to SureMark 4610 Printers:

Programming Guide for Models 1xR and 2xR, GA27-5005.

The Toshiba Diagnostics for POS Systems and Peripherals package, available from

the Toshiba Global Commerce Solutions support website, can be used for

diagnosing problems with the printer and for configuring and maintaining the printer

using included utilities. The website contains information on downloading and

installing the package.

The diagnostic package provides tests for the various components and functions of

the printer. It also provides utilities to load printer firmware, logos, messages, and

fonts as well as utilities for configuring the printer. These are found by clicking the