Toro 41188, Multi Pro 1750 Operator's Manual

FormNo.3393-823RevC

MultiPro

ModelNo.41188—SerialNo.315000001andUp

®

1750TurfSprayer

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3393-823*C

TheMultiProturfsprayerisadedicatedturfsprayapplication

vehicleandisintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Itisprimarilydesigned

forsprayingonwell-maintainedlawnsinparks,golfcourses,

sportselds,andoncommercialgrounds.

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

Introduction

Readthismanualcarefullytolearnhowtooperateand

maintainyourproductproperly.Theinformationinthis

manualcanhelpyouandothersavoidinjuryandproduct

damage.AlthoughTorodesignsandproducessafeproducts,

youareresponsibleforoperatingtheproductproperlyand

safely.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.

Figure1

1.Locationofthemodelandserialnumbers

ThissparkignitionsystemcomplieswithCanadianICES-002.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ChemicalSafety.......................................................5

WhileOperating......................................................5

Maintenance...........................................................7

SoundPower..........................................................7

SoundPressure.......................................................7

Hand-ArmVibration...............................................7

WholeBodyVibration.............................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................14

1InstallingtheAnti-siphonFillReceptacle.................14

2CheckingtheBoomHingeSprings.........................14

3LearningMoreaboutYourProduct........................15

ProductOverview.........................................................16

Controls...............................................................18

Specications........................................................21

Attachments/Accessories........................................21

Operation....................................................................22

SafetyFirst............................................................22

PreparingtoDrivetheSprayerfortheFirst

Time.................................................................22

PerformingthePre-StartingChecks..........................23

DrivingtheSprayer.................................................23

BreakinginaNewSprayer.......................................24

AdjustingtheBoomstoLevel..................................24

OperatingtheSprayer.............................................25

FillingtheFreshWaterTank....................................26

FillingtheSprayTank..............................................26

OperatingtheBooms..............................................26

Spraying................................................................26

SprayingTips.........................................................27

CleaningtheSprayer...............................................27

UsingtheInfoCenterLCDDisplay...........................28

CalibratingtheSprayerFlow....................................30

CalibratingtheSprayerSpeed...................................31

CalibratingtheBoom-SectionBypassValves..............32

AgitationBypassValveKnobPosition.......................32

CalibratingtheAgitationBypassValve.......................33

AdjustingtheMasterBoomBypassValve...................33

LocatingthePump.................................................33

TransportingtheSprayer.........................................34

TowingtheSprayer.................................................34

Maintenance.................................................................35

RecommendedMaintenanceSchedule(s)......................35

DailyMaintenanceChecklist....................................36

NotationforAreasofConcern.................................37

PremaintenanceProcedures........................................38

JackingUptheSprayer............................................38

Lubrication...............................................................38

GreasingtheSprayer...............................................38

GreasingtheBoomHinges......................................38

EngineMaintenance..................................................39

CheckingtheAirIntakeScreen.................................39

ServicingtheAirCleaner.........................................39

ServicingtheEngineOil..........................................40

ChangingtheSparkPlugs........................................41

FuelSystemMaintenance...........................................42

ReplacingtheFuelFilter..........................................42

DrainingtheFuelTank...........................................42

ElectricalSystemMaintenance....................................43

LocatingtheFuses..................................................43

ServicingtheBattery...............................................43

DriveSystemMaintenance.........................................45

InspectingtheWheelsandTires...............................45

AdjustingtheFrontWheelToe-in.............................45

BrakeMaintenance....................................................46

CheckingtheBrakeFluid.........................................46

InspectingtheBrakes..............................................46

AdjustingtheParkingBrake.....................................46

HydraulicSystemMaintenance....................................47

CheckingtheTransaxle/HydraulicFluid....................47

ChangingTransaxle/HydraulicFluid.........................47

ReplacingtheHydraulicFilter..................................48

SpraySystemMaintenance..........................................48

InspectingtheHoses..............................................48

ChangingthePressureFilter....................................49

InspectingthePump...............................................49

InspectingtheNylonPivotBushings.........................49

SprayerFlowDiagram.............................................51

Cleaning...................................................................52

CleaningtheFlowmeter..........................................52

CleaningtheSuctionStrainer...................................52

CleaningtheSprayerValves.....................................53

Storage........................................................................62

Troubleshooting...........................................................64

3

Safety

•Neverallowuntrainedpeopletooperateorservicethe

equipment.

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

ThemachinemeetstherequirementsofSAEJ2258.

SafeOperatingPractices

Important:Themachineisdesignedprimarilyasan

off-roadvehicleandisnotintendedforextensiveuseon

publicroads.Whenusingthemachineonpublicroads,

followalltrafcregulationsanduseanyadditional

accessoriesthatmayberequiredbylaw,suchaslights,

turnsignals,slowmovingvehicle(SMV)sign,and

othersasrequired.

TheMulti-Pro1750TurfSprayerwasdesignedandtestedto

offersafeservicewhenoperatedandmaintainedproperly.

Althoughhazardcontrolandaccidentpreventionpartiallyare

dependentuponthedesignandcongurationofthemachine,

thesefactorsarealsodependentupontheawareness,concern,

andpropertrainingofthepersonnelinvolvedintheoperation,

maintenanceandstorageofthemachine.Improperuseor

maintenanceofthemachinecanresultininjuryordeath.

NotalloftheattachmentsthatadapttotheMulti-Pro1750

TurfSprayerarecoveredinthismanual.Seethespecic

Operator’sManualprovidedwitheachattachmentfor

additionalsafetyinstructions.Readthesemanuals.

Toreducethepotentialforinjuryordeath,complywiththe

followingsafetyinstructions:

Note:Localregulationsmayrestricttheageofthe

operator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,ordamagetoproperty.

BeforeOperating

•Operatethemachineonlyafterreadingandunderstanding

thecontentsofthismanual.

•Neverallowchildrentooperatethesprayer.

•Neverallowotheradultstooperatethesprayerwithout

rstreadingandunderstandingtheOperator'sManual.

Onlytrainedandauthorizedpersonsshouldoperatethis

sprayer.Makesurethatalloperatorsarephysicallyand

mentallycapableofoperatingthesprayer.

•Thissprayerisdesignedtocarryonlyyou,theoperator.

Nevercarryanypassengersonthesprayer.

•Neveroperatethesprayerwhenundertheinuence

ofdrugsoralcohol.Evenprescriptiondrugsandcold

medicinescancausedrowsiness.

•Donotdrivethesprayerwhenyouaretired.Besureto

takeoccasionalbreaks.Itisveryimportantthatyoustay

alertatalltimes.

•Becomefamiliarwiththecontrolsandknowhowtostop

theenginequickly.

•Keepallshields,safetydevices,anddecalsinplace.Ifa

shield,safetydevice,ordecalismalfunctioning,illegible,

ordamaged,repairorreplaceitbeforeoperatingthe

machine.

Supervisor'sResponsibilities

•Makesurethatoperatorsarethoroughlytrainedand

familiarwiththeOperator'sManual,EngineManual,andall

labelsonthesprayer.

•Establishyourownspecialproceduresandworkrules

forunusualoperatingconditions(e.g.slopestoosteep

forsprayeroperation).

Training

•ReadtheOperator'sManualandothertrainingmaterial

beforeoperatingthemachine.

Note:Iftheoperator(s)ormechanic(s)cannotreadthe

manuallanguage,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Wearappropriateclothing;includingahardhat,safety

glasses,longpants,safetyshoes,rubberboots,gloves,and

hearingprotection.Donotwearloosettingclothingor

jewelrywhichcouldgetcaughtinmovingpartsandcause

personalinjury.

Note:Wearingsafetyglasses,safetyshoes,longpants,

andahelmetisadvisableandrequiredbysomelocal

safetyandinsuranceregulations.

CAUTION

Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besuretodrive

4

cautiously,usetheheadlights,andevenconsideradding

additionallights.

•Beextremelycarefulwhenoperatingaroundpeople.

Alwaysbeawareofwherebystandersmightbeandkeep

themawayfromtheworkarea.

•Beforeoperatingthesprayer,alwayscheckthedesignated

areasofthesprayerthatarestatedinthePre-Starting

ChecksintheOperationsection.Ifthemachinedoes

notfunctioncorrectlyorisdamagedinanyway ,donot

usethesprayer.Makesurethattheproblemiscorrected

beforethesprayerorattachmentisoperated.

•Makesuretheoperator’sareaiscleanandfreefrom

chemicalresidueanddebrisbuildup.

•Ensurethatalluidlineconnectorsaretightandallhoses

areingoodconditionbeforeapplyingpressuretothe

system.

•Sincefuelishighlyammable,handleitcarefully.

–Useanapprovedfuelcontainer.

–Donotremovethecapfromthefueltankwhenthe

engineishotorrunning.Allowtheenginetocool

beforefuelingthemachine.

–Donotsmokewhilehandlinggasoline.

–Fillthefueltankofthemachineoutdoors.

–Fillthefueltankofthemachinetoabout25mm(1

inch)belowthetopofthetank(thebottomofthe

llerneck).Donotoverllthefueltank.

–Wipeupanyspilledfuel.

ChemicalSafety

WARNING

•Chemicalsubstancesusedinthesprayersystem

maybehazardousandtoxictoyou,bystanders,

animals,plants,soilsorotherproperty.

•Carefullyreadandfollowthechemicalwarning

labelsandMaterialSafetyDataSheets(MSDS)

forallchemicalsusedandprotectyourself

accordingtothechemicalmanufacturer's

recommendations.Ensurethataslittleskin

aspossibleisexposedwhileusingchemicals.

UseappropriatePersonalProtectiveEquipment

(PPE)toguardagainstpersonalcontactwith

chemicals,suchas:

–safetyglasses,goggles,and/orfaceshield

–respiratororltermask

–chemicalresistantgloves

–rubberbootsorothersubstantialfootwear

–hearingprotection

–cleanchangeofclothes,soap,anddisposable

towels,tobekepton-hand,intheeventof

achemicalspill.

Important:Keepinmindthattheremaybemorethan

onechemicalused,andinformationoneachchemical

shouldbeassessed.

Refusetooperateorworkonthesprayerifthis

informationisnotavailable!

Beforeworkingonasprayersystem,makesurethatthe

systemhasbeentriplerinsedandneutralizedaccording

totherecommendationsofthechemicalmanufacturer(s)

andallofthevalveshavebeencycled3times.

Verifythereisanadequatesupplyofcleanwaterand

soapnearby ,andimmediatelywashoffanychemicals

thatcontactyou.

•Obtainpropertrainingbeforeusingorhandling

chemicals.

•Usethecorrectchemicalforthejob.

•Followthechemicalmanufacturer'sinstructionsfor

thesafeapplicationofthechemical.Donotexceed

recommendedsystemapplicationpressure.

•Donotll,calibrate,orcleantheunitwhenpeople,

especiallychildren,orpetsareinthearea.

•Handlechemicalsinawellventilatedarea.

•Havecleanwateravailableespeciallywhenllingthe

spraytank.

•Donoteat,drink,orsmokewhileworkingwithchemicals.

•Donotcleanspraynozzlesbyblowingthroughthemor

placinginmouth.

•Alwayswashyourhandsandotherexposedareasassoon

aspossibleafteryounishworkingwithchemicals.

•Keepchemicalsintheiroriginalpackagesandstoredin

asafelocation.

•Properlydisposeofunusedchemicalsandchemical

containersasinstructedbythechemicalmanufacturer

andyourlocalcodes.

•Chemicalsandfumesaredangerous;neverenterthetank

orplaceyourheadoverorintheopeningofatank.

•Followalllocal,state,andfederalregulationsfor

spreadingorsprayingchemicals.

WhileOperating

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Theoperatorshouldremainseatedwheneverthesprayer

isinmotion.Theoperatorshouldkeepbothhandson

thesteeringwheelwheneverpossible.Keepyourarms

andlegswithinthesprayerbodyatalltimes.

•Alwayswatchoutforandavoidlowoverhangssuchas

treelimbs,doorjambs,andoverheadwalkways.Make

surethereisenoughroomoverheadtoeasilyclearthe

sprayerandyourhead.

5

•Failuretooperatethesprayersafelymayresultinan

accident,tipoverofthesprayer,andseriousinjuryor

death.Drivecarefully .Topreventtippingorlossof

control:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,unfamiliarareas,oranyareasthathaveabrupt

changesingroundconditionsorelevation.

–Watchforholesorotherhiddenhazards.

Braking

•Slowdownbeforeyouapproachanobstacle.Thisgives

youextratimetostoporturnaway.Hittinganobstacle

candamagethesprayeranditscontents.Moreimportant,

itcaninjureyou.

•GrossVehicleWeight(GVW)hasamajorimpactonyour

abilitytostopand/orturn.Heavyloadsandattachments

makeasprayerhardertostoporturn.Theheavierthe

load,thelongerittakestostop.

–Useextracautionwhenoperatingthesprayeronwet

surfaces,inadverseweatherconditions,athigher

speeds,orwithafullload.Stoppingtimeanddistance

willincreasewithafullload.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithoutrst

comingtoacompletestop.

–Slowdownbeforeturning.Donotattemptsharp

turnsorabruptmaneuversorotherunsafedriving

actionsthatmaycausealossofsprayercontrol.

–Beforebackingup,looktotherearandensurethat

nooneisbehindyou.Backupslowly.

–Watchoutfortrafcwhenyouarenearorcrossing

roads.Alwaysyieldtherightofwaytopedestrians

andothervehicles.Thissprayerisnotdesignedfor

useonstreetsorhighways.Alwayssignalyourturns

orstopearlyenoughsothatotherpeopleknowwhat

youplantodo.Obeyalltrafcrulesandregulations.

–Theelectricalandexhaustsystemsofthesprayercan

producesparkscapableofignitingexplosivematerials.

Neveroperatethesprayerinornearanareawhere

thereisdustorfumesintheairwhichareexplosive.

–Ifyouareeverunsureaboutsafeoperation,stop

workandaskyoursupervisor.

•Donottouchtheengineormuferwhiletheengineis

runningorsoonafterithasstopped.Theseareasmaybe

hotenoughtocauseburns.

•Ifthemachineevervibratesabnormally,stopimmediately ,

waitforallmotiontostop,andinspectthesprayerfor

damage.Repairalldamagebeforeresumingoperation.

•Beforegettingoffoftheseat:

1.Stopthemovementofthemachine.

2.PlacetherangeselectorinNeutralandsetthe

parkingbrake.

3.TurntheignitionkeytoOff.

4.Removetheignitionkey .

•Turfandpavementaremuchmoreslipperywhenthey

arewet.Itcantake2to4timesaslongtostoponwet

surfacesasondrysurfaces.Ifyoudrivethroughstanding

waterdeepenoughtogetthebrakeswet,theywillnot

workwelluntiltheyaredry.Afterdrivingthroughwater,

youshouldtestthebrakestomakesuretheywork

properly.Iftheydonot,driveslowlywhileputtinglight

pressureonthebrakepedal.Thiswilldrythebrakesout.

OperatingonHillsandRoughTerrain

Operatingthesprayeronahillmaycausetippingorrolling

ofthesprayer,ortheenginemaystallandyoucouldlose

headwayonthehill.Thiscouldresultinpersonalinjury.

•Donotacceleratequicklyorslamonthebrakeswhen

backingdownahill,especiallywithaload.

•Neverdriveacrossasteephill;alwaysdrivestraightupor

downorgoaroundthehill.

•Iftheenginestallsoryoubegintoloseheadwaywhile

climbingahill,graduallyapplythebrakesandslowlyback

straightdownthehill.

•Turningwhiletravelingupordownhillscanbedangerous.

Ifyouhavetoturnwhileonahill,doitslowlyand

cautiously.Nevermakesharporfastturns.

•Heavyloadsaffectstability.Reducetheweightoftheload

andyourspeedwhenoperatingonhills.

•Avoidstoppingonhills,especiallywithaload.Stopping

whilegoingdownahillwilltakelongerthanstopping

onlevelground.Ifthesprayermustbestopped,avoid

suddenspeedchanges,whichmayinitiatetippingor

rollingofthesprayer.Donotslamonthebrakes

whenrollingbackward,asthismaycausethesprayerto

overturn.

•Usetheseatbeltwhenoperatingthemachineandbe

certainthatitcanbereleasedquicklyintheeventofan

emergency.

•Donotremoveoraltertherolloverprotectionsystem

(ROPS).

Important:Donotparkthemachineonan

incline.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Reducespeedandloadwhenoperatingonroughterrain,

unevenground,andnearcurbs,holes,andothersudden

changesinterrain.Loadsmayshift,causingthesprayer

tobecomeunstable.

6

WARNING

Suddenchangesinterrainmaycauseabrupt

steeringwheelmovement,possiblyresultingin

handandarminjuries.

•Reduceyourspeedwhenoperatingonroughterrainand

nearcurbs.

•Gripthesteeringwheellooselyaroundtheperimeter.

Keepyourhandsclearofthesteeringwheelspokes.

Loading

Theweightofthecargocanchangethesprayercenterof

gravityandsprayerhandling.Toavoidlossofcontroland

personalinjury,followtheseguidelines:

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthighpressureuid.Usecardboardor

papertondleaks.Fluidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithin

afewhoursbyaqualiedsurgeon;otherwise,gangrene

mayresult.

•Ifmajorrepairsareeverneededorassistanceisrequired,

contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety,

alwayspurchasegenuineTororeplacementpartsand

accessories.Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous.Alteringthis

sprayerinanymannerthatmayaffectsprayeroperation,

performance,durability ,oritsuse,mayresultininjuryor

death.Suchusecouldvoidtheproductwarranty.

•Reducetheweightoftheloadwhenoperatingonhills

androughterraintoavoidtippingoroverturningofthe

sprayer.

•Liquidloadscanshift.Thisshiftinghappensmostoften

whileturning,goingupordownhills,suddenlychanging

speeds,orwhiledrivingoverroughsurfaces.Shifting

loadscancausethesprayertotipover.

•Whenoperatingwithaheavyload,reduceyourspeedand

allowforsufcientbrakingdistance.Donotsuddenly

applythebrakes.Useextracautiononslopes.

•Beawarethatheavyloadsincreaseyourstoppingdistance

andreduceyourabilitytoturnquicklywithouttipping

over.

Maintenance

•Onlypermitqualiedandauthorizedpersonnelto

maintain,repair,adjust,orinspectthesprayer.

•Beforeservicingormakingadjustmentstothemachine,

stoptheengine,settheparkingbrake,andremovethekey

fromtheignitiontopreventsomeonefromaccidentally

startingtheengine.

•Tomakesurethattheentiremachineisingoodcondition,

keepallnuts,bolts,andscrewsproperlytightened.

SoundPower

Thisunithasaguaranteedsoundpowerlevelofof98dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof86

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Hand-ArmVibration

Measuredvibrationlevelforrighthand=3.00m/s

Measuredvibrationlevelforlefthand=3.20m/s

UncertaintyValue(K)=1.6m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO20643.

2

2

2

•Toreducethepotentialforre,keeptheengineareafree

ofexcessivegrease,grass,leaves,andaccumulationofdirt.

•Neveruseanopenametocheckthelevelorleakageof

fuelorbatteryelectrolyte.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keepyourhands,feet,clothing,andanyparts

ofyourbodyawayfromtheengineandanymovingparts.

Keepeveryoneaway.

•Donotuseopenpansoffuelorammablecleaning

uidswhencleaningparts.

•Donotadjustthegroundspeedgovernor.Toensure

safetyandaccuracy ,haveanAuthorizedToroDistributor

checkthegroundspeed.

WholeBodyVibration

Measuredvibrationlevel=0.58m/s

UncertaintyValue(K)=0.29m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

7

2

2

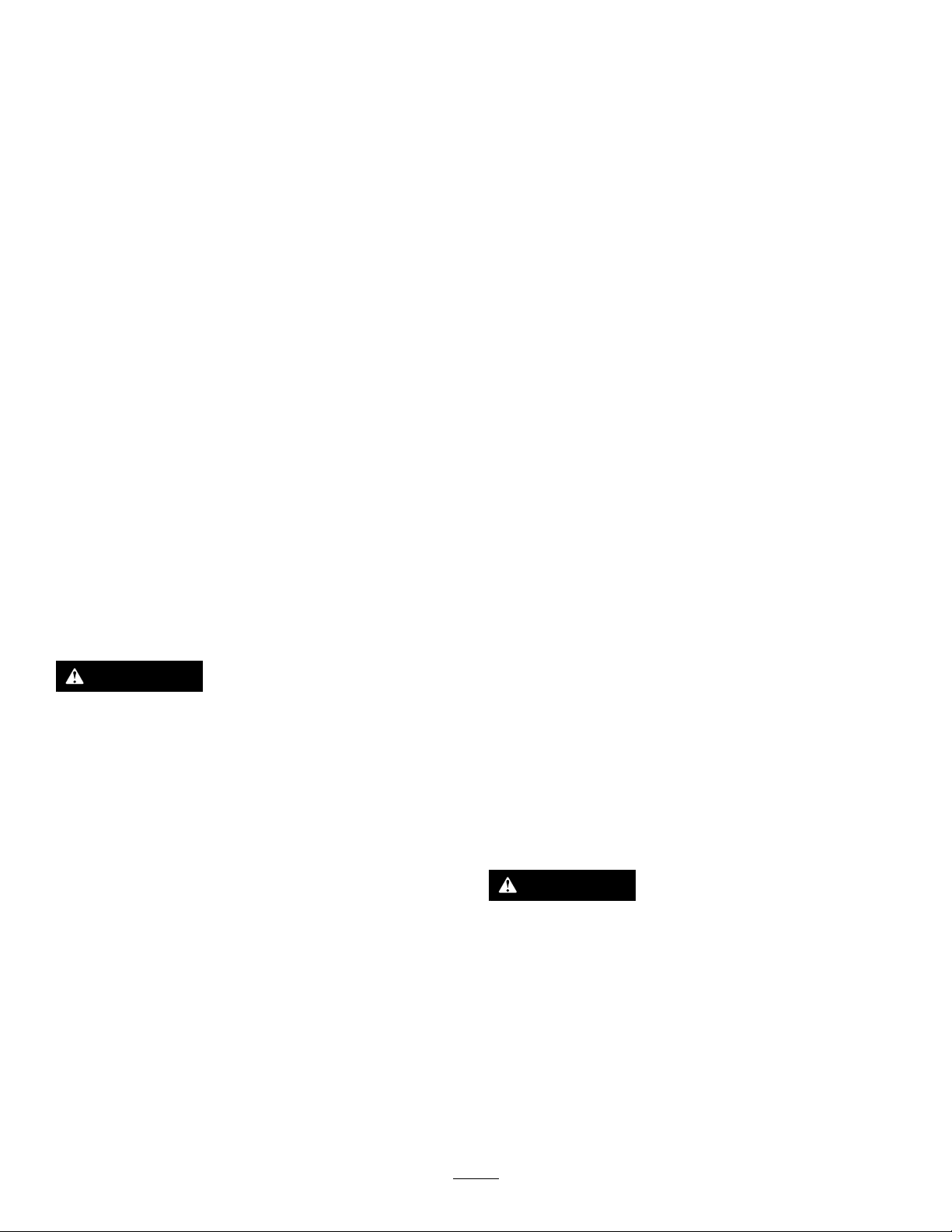

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117–2718

120–0622

106-9206

1.Wheeltorquespecications

2.ReadtheOperator'sManual.

120–0616

1.Warning—readtheOperator’sManual;usefresh,clean

waterforrst-aidwashing.

1.Warning—readthe

Operator’sManual.

2.Warning—donotenterthe

sprayertank.

3.Chemicalburnhazard;

toxicgasinhalation

hazard—wearhandand

skinprotection;weareye

andrespiratoryprotection.

1.Severinghazardofhand,

pinchingpoint—keep

awayfromactuatedjoints.

120–0617

2.Crushinghazard—keep

bystandersawayfromthe

machine.

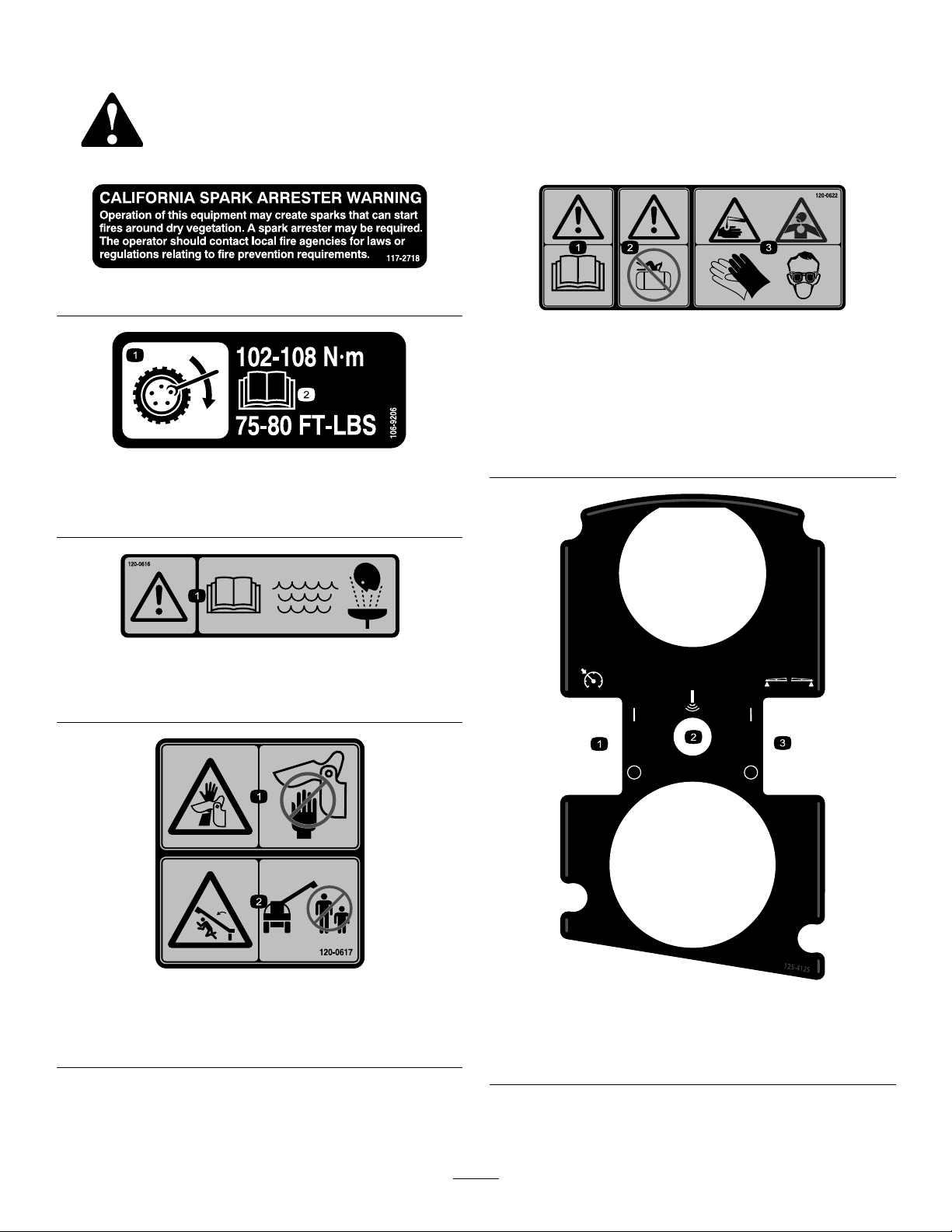

1.Turnthethrottle

lock/speedlockon/off

2.Sonicboom(optional)

125–4125

3.Turnthefoammakers

on/off(optional)

8

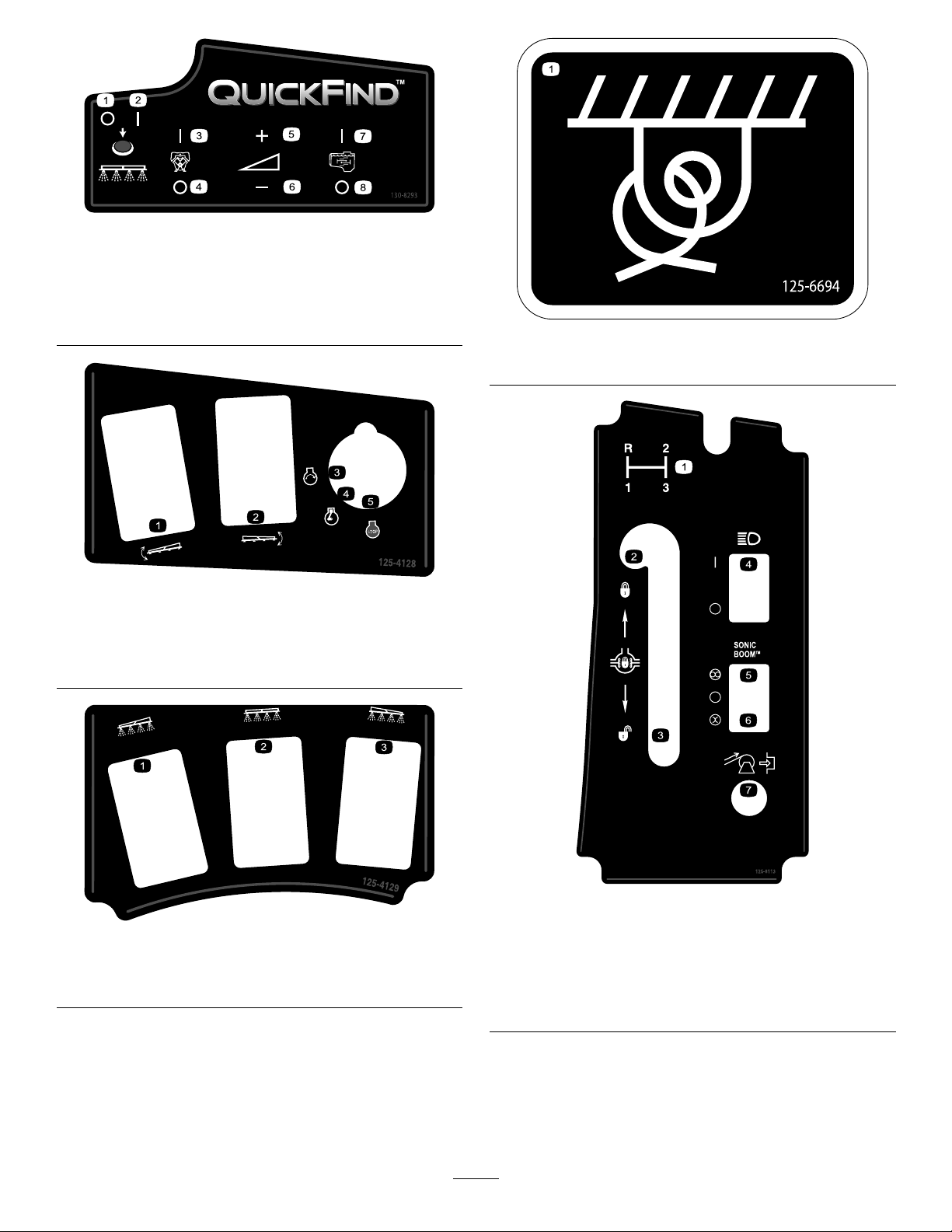

130-8293

1.Sprayeroff

2.Sprayeron

3.Engineon7.Agitationon

4.Engineoff8.Agitationoff

5.Increasespeed

6.Decreasespeed

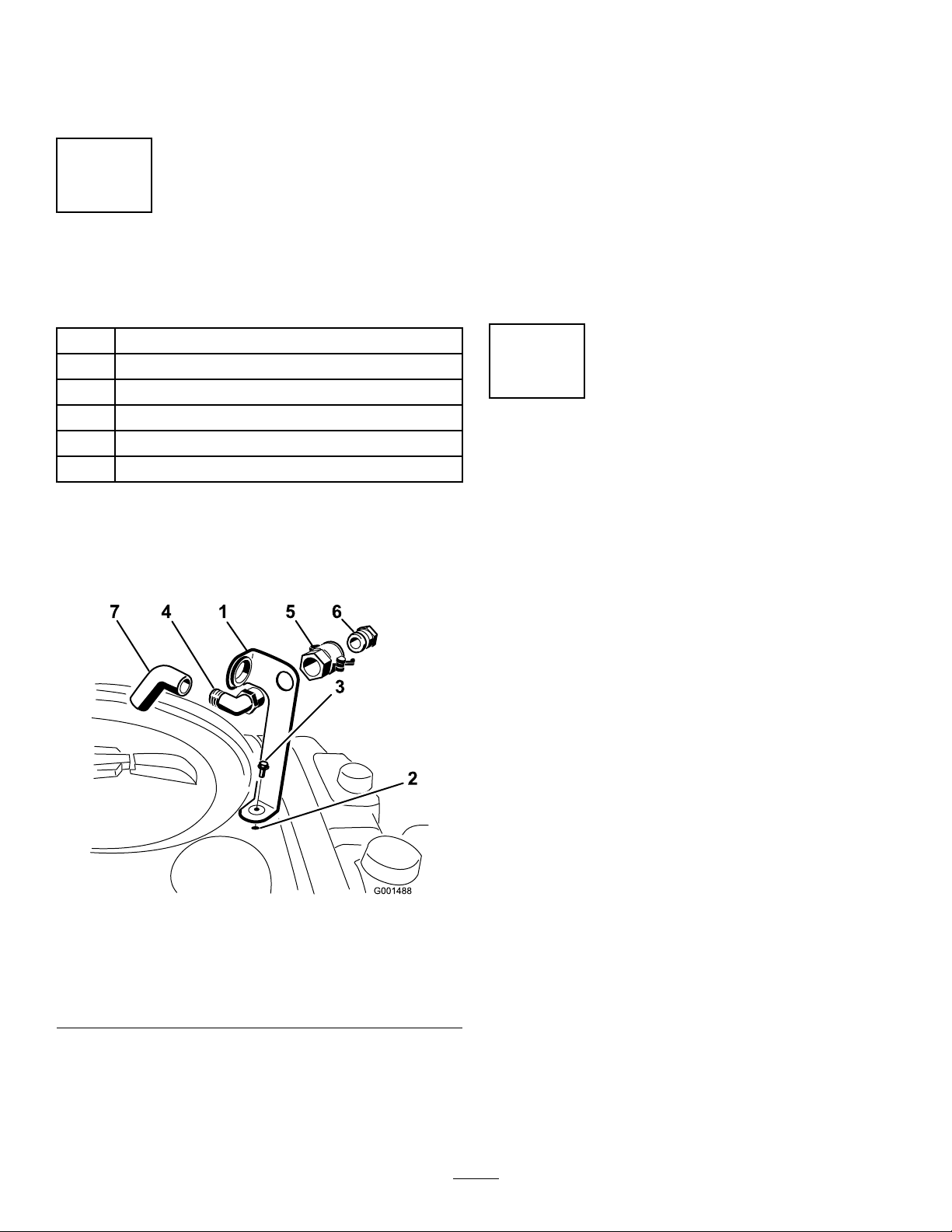

125–4128

1.Raise/lowerleftboom

2.Raise/lowerrightboom

3.Engine—start

4.Engine—run

5.Engine—stop

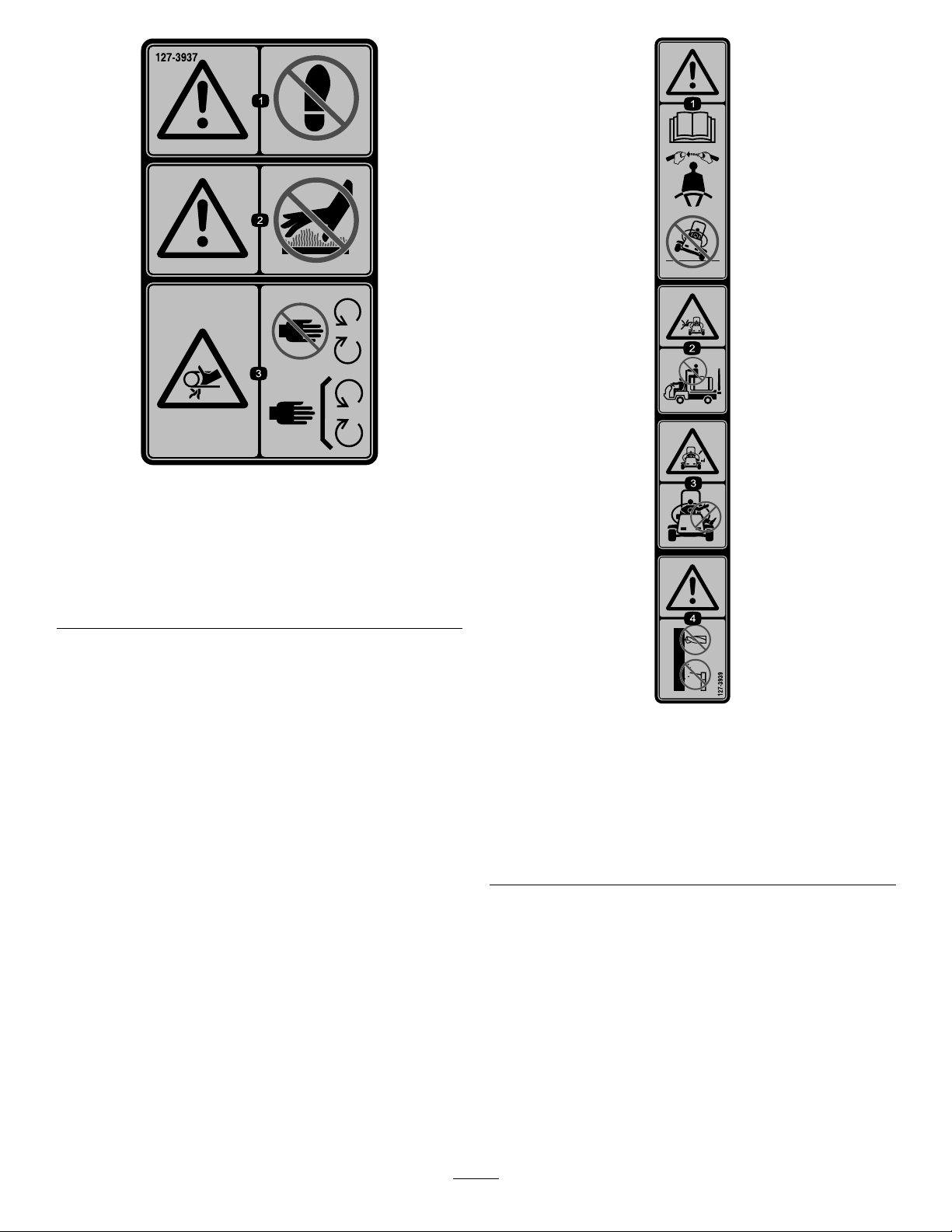

125–6694

1.Tiedownlocation

1.Leftboom

2.Centerboom

125–8113

125–4129

3.Rightboom

1.Gearselection5.Automatic(optional)

2.Lockdifferentiallock6.Manual(optional)

3.Unlockdifferentiallock

4.Toggleheadlightson/off

7.Rewindhosereel

(optional)

9

125–8114

1.Ratelockout

locked/unlocked

2.Togglerinsepumpon/off

127–3942

1.ReadtheOperator’s

Manualforinformationon

fuses.

2.10A—Ignition7.7.5A

3.15A—Sprayerboom8.2A—TEC

4.15A—Headlights9.30A—Rinsetank

5.7.5A

6.7.5A

1.Parkingbrake

2.Forinformationonstarting

theengine,readthe

Operator’sManual—1)

Engagetheparkingbrake;

2)Insertthekeyintothe

ignition;3)Turnthekeyto

theenginerunposition.

127–3935

3.Forinformationon

stoppingtheengine,read

theOperator’sManual—1)

Pressdownonthebrake

pedal;2)Setthegearto

neutral;3)Engagethe

parkingbrake;4)Release

thebrakepedal;5)Turn

theignitionkeytothe

enginestopposition;6)

Removethekeyfromthe

ignition.

4.Entanglementhazard,

belt—keepawayfrom

movingparts;keepall

guardsandshieldsin

place.

10

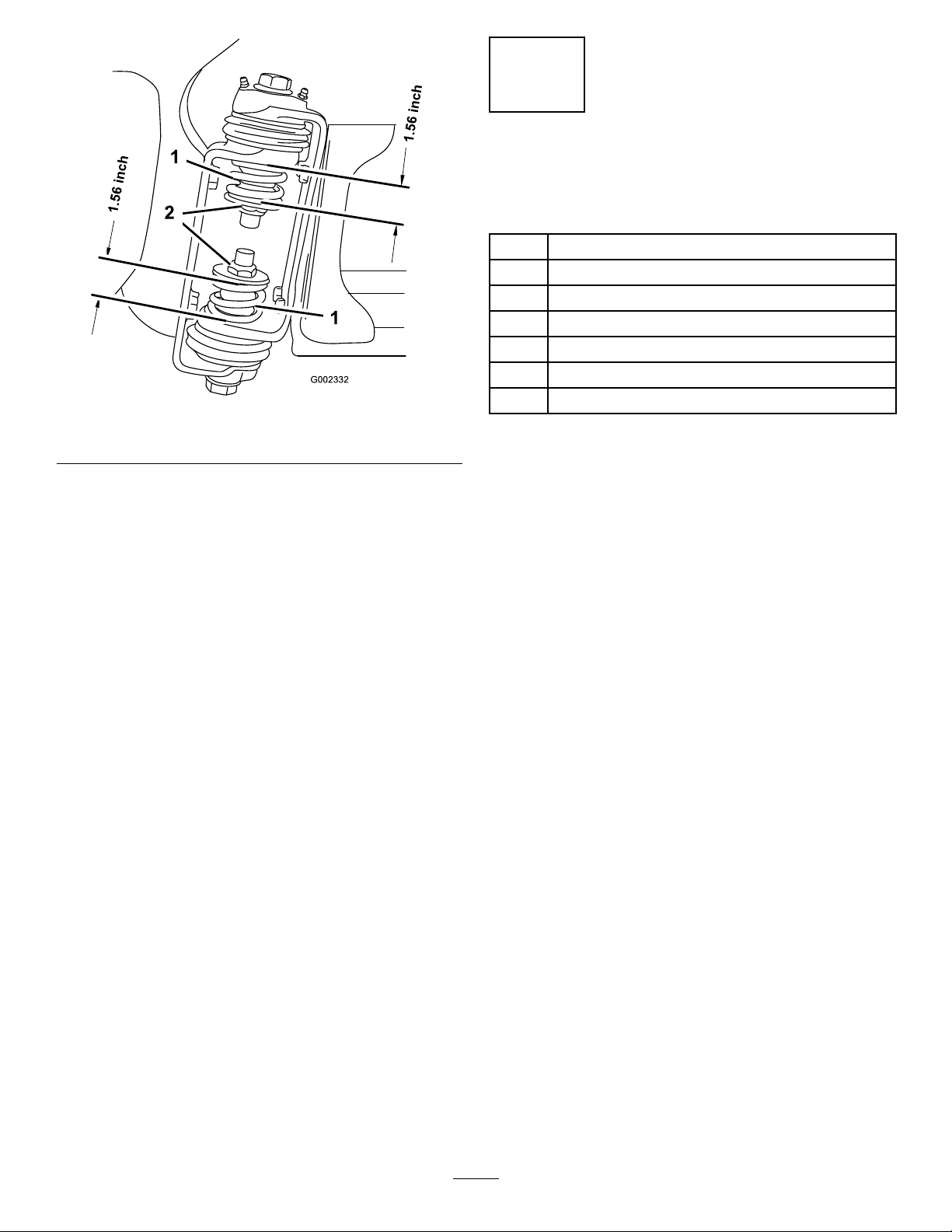

127–3937

1.Warning—donotstep.3.Entanglementhazard,

belt—keepawayfrom

movingparts;keepall

guardsandshieldsin

place.

2.Warning—keepawayfrom

hotsurfaces.

1.Warning—readthe

Operator’sManual;always

wearaseatbeltwhen

operatingthemachine;do

nottipthemachine.

2.Fallinghazard—donot

carrypassengersonthe

sprayertank.

127–3939

3.Cutting/dismemberment

hazard—keeparmsand

legsinsidethevehicleat

alltimes.

4.Warning—donotdrill,

weld,oraltertheROPS

system.

11

1.ReadtheOperator’sManual.

127–3938

127–3941

1.Warning—donotoperatethemachinewithoutpropertraining;

readtheOperator’sManual.

2.Warning—keepbystandersawaywhenoperatingthe

machine.

3.Warning—keepawayfrommovingparts;keepallguardsand

shieldsinplace.

4.Electricalshockhazard,overheadpowerlines—checkthe

areaforoverheadpowerlinesbeforeoperatingthemachine

inthearea.

5.Warning—Engagetheparkingbrake,stoptheengine,and

removethekeyfromtheignitionbeforeleavingthemachine.

6.Tippinghazard—Moveslowlywhenthesprayertankisfull;

moveslowlywhendrivingoverroughterrain;donotturnat

highspeed;turnslowly;driveslowlywhendrivingacrossor

upslopes.

12

127-6976

1.Decrease2.Increase

127-6982

127-6979

1.Pump-returnow3.Agitationow

2.Flow

1.Bypass-returnow

1.Flow

2.Boomspray

127-6984

2.Tank-returnow

1.Bypass-returnow

2.Flow

127-6981

3.Boomspray

13

Setup

tankopeningsothewaterwillarcintothetankwhen

youllit.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

InstallingtheAnti-siphonFill Receptacle

Partsneededforthisprocedure:

1

90°tting

1

Quickcoupler

1Hoseadapter

1Fillreceptaclebracket

1

Flange-headbolt,5/16x3/4inch

1Anti-siphonhose

Procedure

1.Placethellreceptaclebracketoverthethreaded

holeinthetankandsecureitwithaange-headbolt

(5/16x3/4inch)(Figure3).

3.Installthehoseadapterintothequickcoupler(Figure

3).

4.Locktheadapterintoplacebyswingingthelevers

towardtheadapterandthensecurethemwiththe

hairpincotters(Figure3).

5.Installtheanti-siphonhosethroughthelargeopening

onthebracketandontothebarbedendofthe90°

elbowtting(Figure3).

Important:Donotlengthenthehosetoallow

contactwiththetankuids.

2

CheckingtheBoomHinge Springs

NoPartsRequired

Procedure

Important:Operatingthespraysystemwiththeboom

hingespringsundertheincorrectcompressioncould

damagetheboomassembly.Measurethespringsand

usethejamnuttocompressthespringsto4cm(1–1/2

inches)ifnecessary.

Figure3

1.Fillreceptaclebracket

2.Threadedholeinthetank6.Hoseadapter

3.Flangebolt,5/16x3/4inch

4.90°elbowtting

2.Placethethreadedendofthe90°elbowttingthrough

thebracketandthreadthequickcouplerontoit,

securingittothebracket(Figure3).

Note:Installthettingwiththeopenendpointing

towardthelargeopeninginthebracketandtowardthe

5.Quickcoupler

7.Anti-siphonhose

Thesprayerisshippedwiththeboomextensionsswung

forwardtofacilitatepackagingofthemachine.Thesprings

arenotfullytightenedatthetimeofmanufacturetoallowthe

boomstobeinthispositionfortransit.Beforeoperating

themachine,thespringsmustbeadjustedtothecorrect

compression.

1.Ifnecessary,removethepackingcomponentsthat

securetherightandleftextensionboomsduring

shipping.

2.Supporttheboomswhiletheyareextendedtothe

sprayposition.

3.Attheboomhinge,measurethecompressionofthe

upperandlowerspringswhiletheboomsareintheir

extendedposition(Figure4).

A.Allspringsmustbecompresseduntiltheymeasure

4cm(1–1/2inches).

B.Usethejamnuttocompressanyspringthat

measuregreaterthan4cm(1–1/2inches).

14

Figure4

1.Boomhingespring2.Jamnut

3

LearningMoreaboutYour Product

Partsneededforthisprocedure:

1Ignitionkey

1

Operator'sManual

1

EngineOperator'sManual

1

PartsCatalog

1

Operatortrainingmaterial

1Registrationcard

1

Pre-deliveryInspectionSheet

Procedure

4.Repeattheprocedureforeachspringonbothboom

hinges.

5.Movetheboomsintothetransport“X”position.See

UsingtheBoomTransportCradle(page26)formore

information.

1.Readthemanuals.

2.Viewtheoperatortrainingmaterial.

3.CompletetheregistrationcardandreturnittoToro.

4.Storethedocumentationinasafeplace.

15

ProductOverview

G028 639

1

2

3

4

5

6

7

8

10

11

12

9

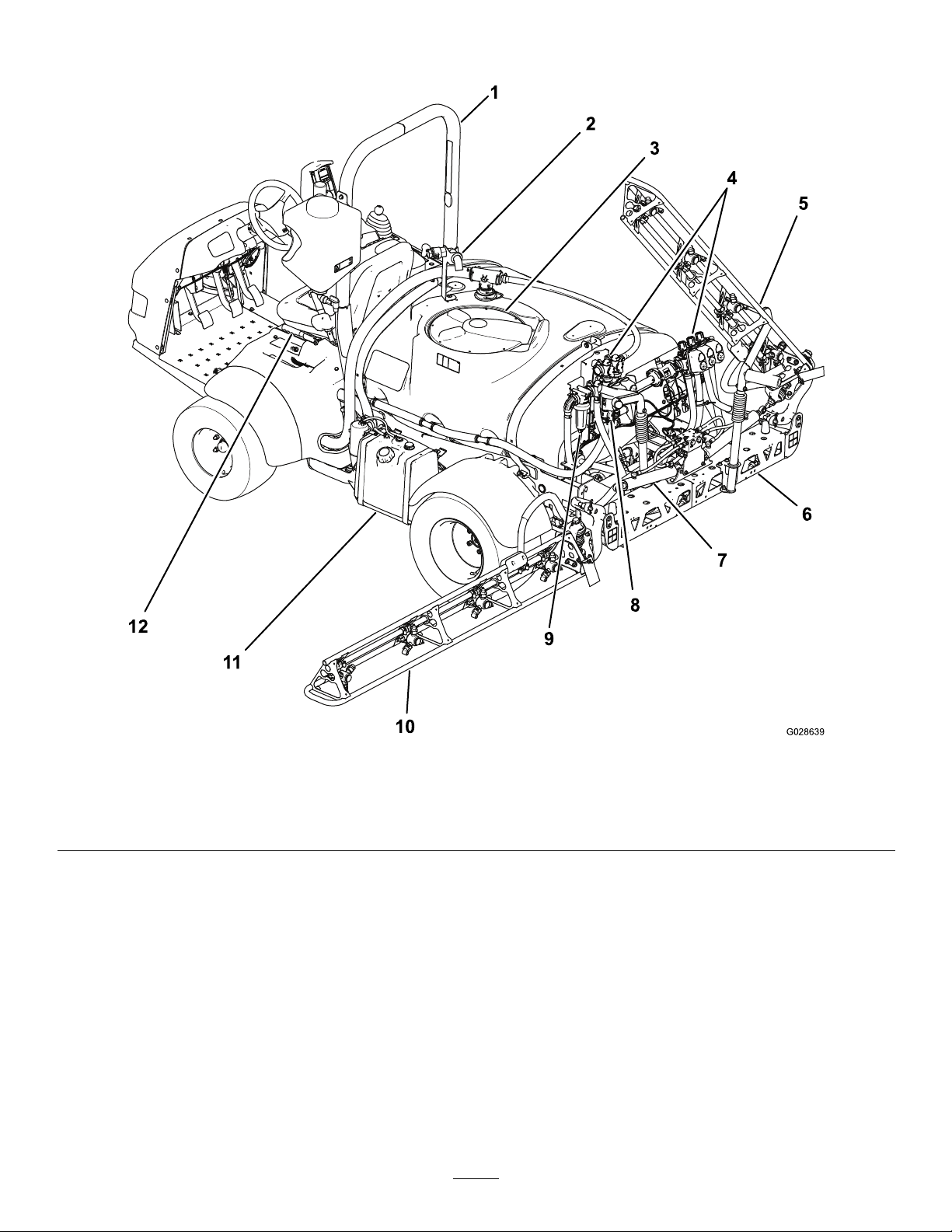

Figure5

1.ROPSbar4.Valvemanifolds

2.Anti-siphonreceptacle5.Rightboom8.Agitationthrottlevalve11.Fueltank

3.Chemicaltanklid6.Centerboom9.Pressurelter

7.Boomcontrolcylinder

10.Leftboom

12.Parkingbrake

16

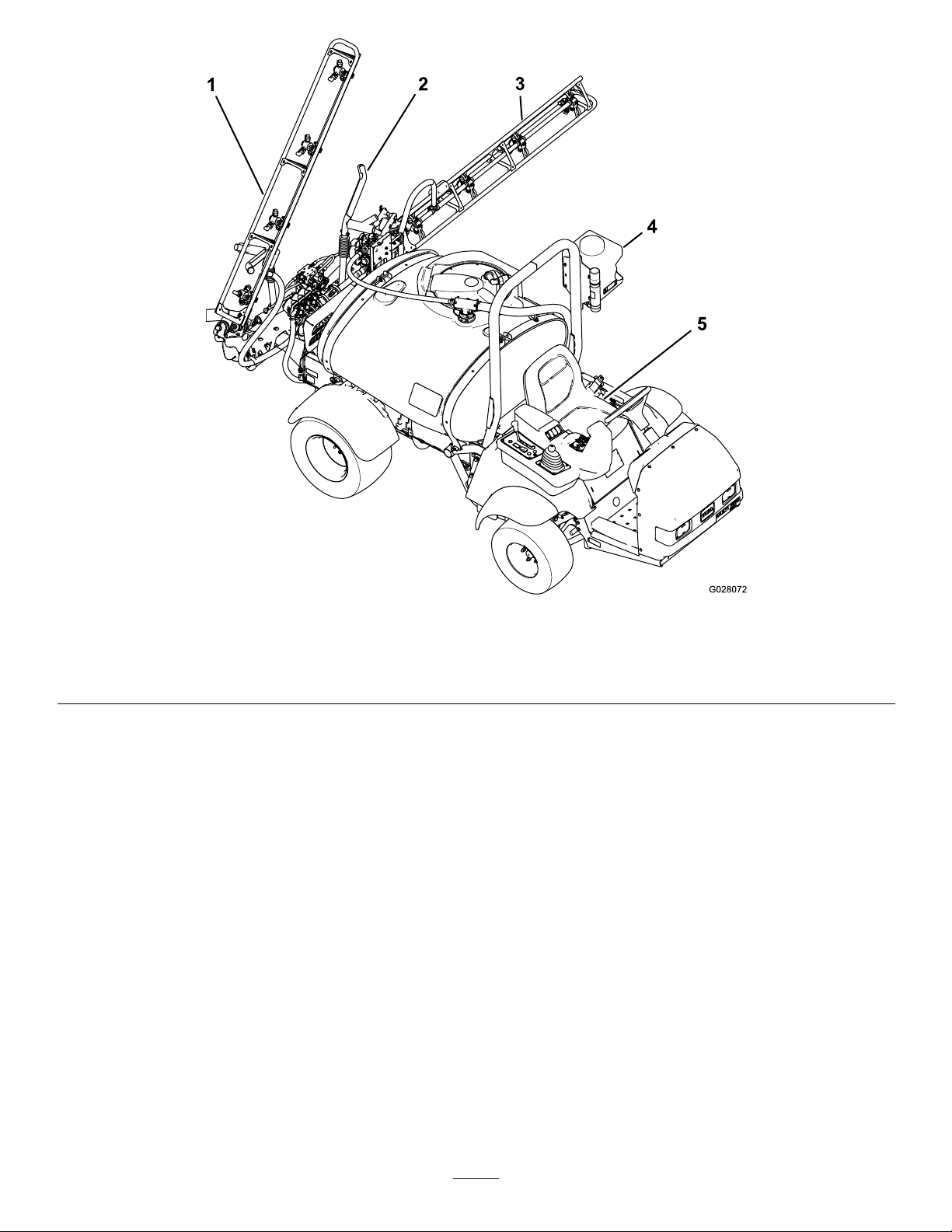

Figure6

1.Rightboom4.Freshwatertank

2.Boomtransportcradle

3.Leftboom

5.Operator’sseat

17

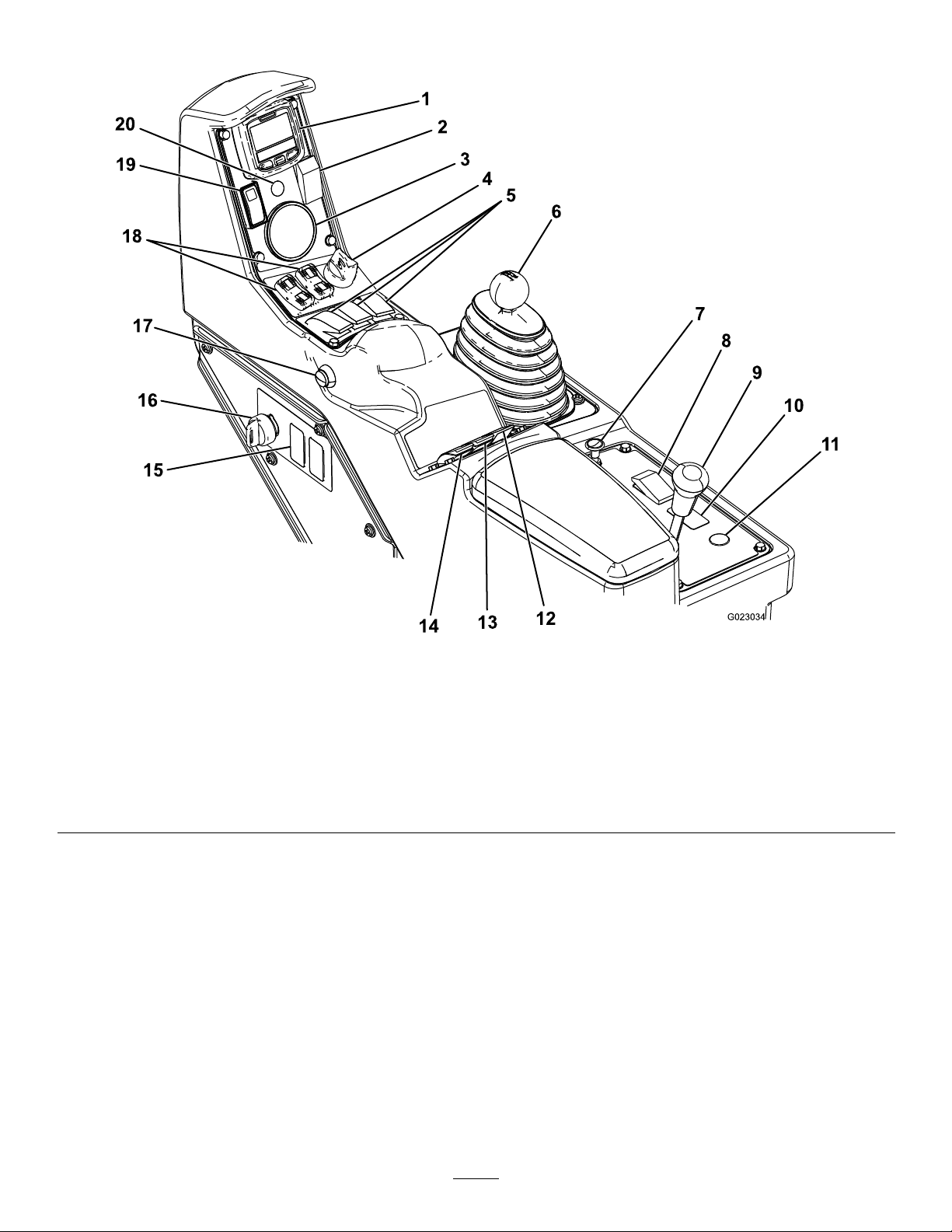

Controls

1.InfoCenter

2.Foammarkerswitch

(optional)

3.Pressuregauge8.Headlightswitch

4.Engineswitch

5.Boom-Sectionswitches10.Sonicboomswitch

6.Rangeselector11.Hosereelrewindbutton

7.Choke

9.Differentiallock

(optional)

Figure7

(optional)

12.Agitationswitch17.Masterboomswitch

13.Spraypressureswitch18.Boomliftswitches

14.Pumpswitch

15.Rinsetankswitch(optional)20.Sonicboomindicator

16.Supervisor(ratelockout)

19.Throttle/speedlockswitch

switch

(optional)

18

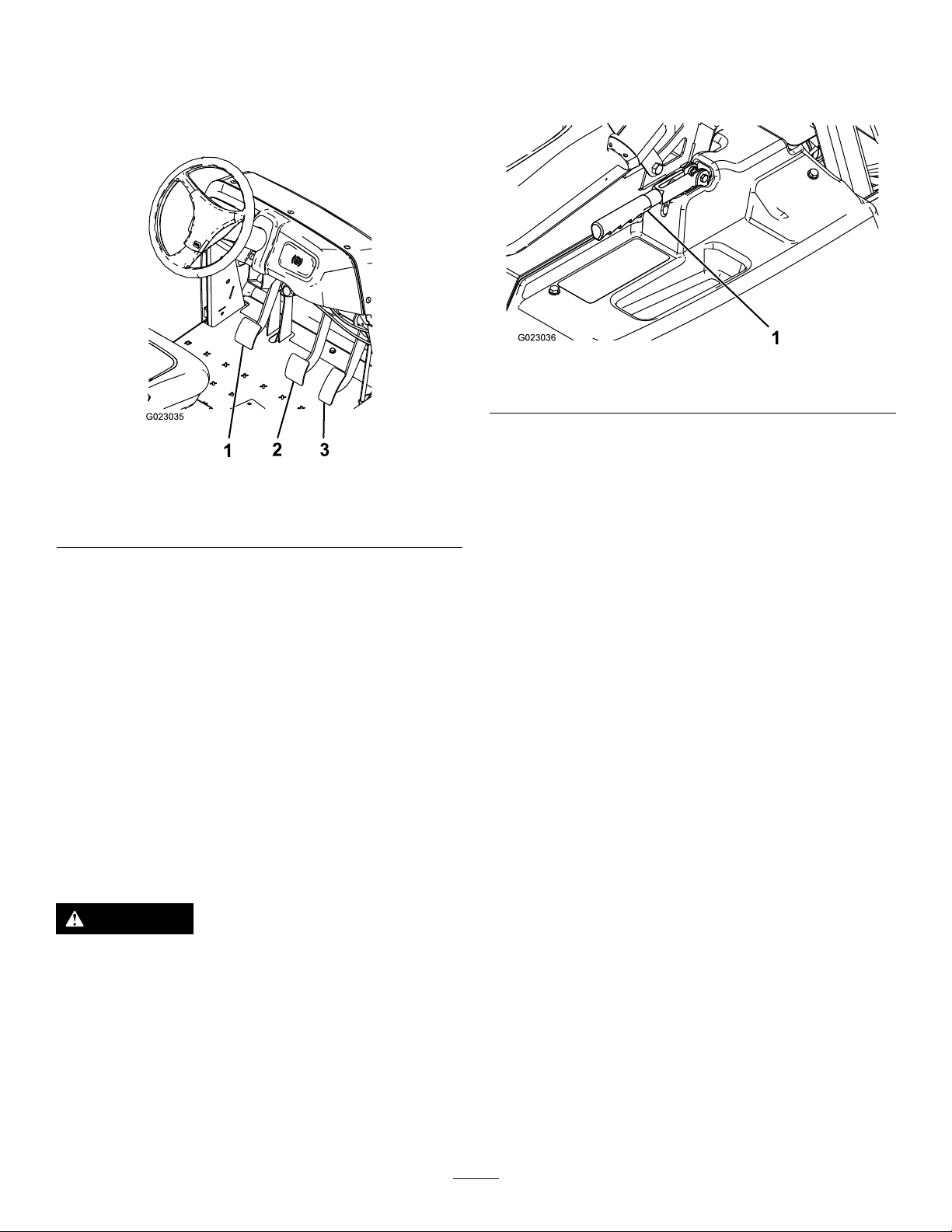

AcceleratorPedal

Theacceleratorpedal(Figure8)givesyoutheabilitytovary

thegroundspeedofthesprayer.Pressingthepedalincreases

groundspeed.Releasingthepedalwillslowthesprayerand

theenginewillidle.

engagetheparkingbrake,pullupandbackonthelever.To

disengage,pushitforwardanddown.Ifthesprayerisparked

onasteepgrade,applytheparkingbrakeandplaceblocksat

thedownhillsideofthewheels.

Figure9

1.Parkingbrakelever

Figure8

1.Clutchpedal

2.Brakepedal

3.Acceleratorpedal

ClutchPedal

Theclutchpedal(Figure8)mustbefullypressedtodisengage

clutchwhenstartingtheengineorshiftingtransmissiongears.

Releasethepedalsmoothlywhenthetransmissionisingear

topreventunnecessarywearonthetransmissionandother

relatedparts.

Important:Donotridetheclutchpedalduring

operation.Theclutchpedalmustbefullyoutorthe

clutchwillslipcausingheatandwear.Neverholdthe

vehiclestoppedonahillusingtheclutchpedal.Damage

totheclutchmayoccur.

BrakePedal

Usethebrakepedaltostoporslowthesprayer(Figure8).

CAUTION

Brakescanbecomewornorcanbeadjusted

incorrectlyresultinginpersonalinjury.

ChokeControl

Thechokecontrolisasmallknobbehindtherangeselector

(Figure7).Tostartacoldengine,pullthechokecontrolup.

Aftertheenginestarts,regulatethechoketokeeptheengine

runningsmoothly.Assoonaspossible,pushthecontrol

downtotheOffposition.Awarmenginerequireslittleor

nochoking.

RangeSelector

Therangeselector(Figure7)has5positions:3forward

speeds,Neutral,andReverse.Theenginewillstartonlywhen

therangeselectorisintheNeutralposition.

IgnitionSwitch

Theignitionswitch(Figure7),usedtostartandstopthe

engine,has3positions:Stop,Run,andStart.Rotatethekey

clockwisetotheStartpositiontostarttheengineandrelease

ittotheRunpositionwhenstarted.Rotatethekeytothe

Stoppositiontostoptheengine.

HeadlightSwitch

Toggletheswitchtooperatetheheadlights(Figure7).Pushit

forwardtoturnthelightsonandrearwardtoturnthemoff.

Ifbrakepedaltravelstowithin2.5cm(1inch)ofthe

sprayeroorboard,adjustorrepairthebrakes.

ParkingBrake

Theparkingbrakeisalargelevertotheleftoftheseat(Figure

9).Engagetheparkingbrakewheneveryouplanonleaving

theseattopreventaccidentalmovementofthesprayer.To

Throttle/SpeedLockSwitch

WhentherangeselectorisintheNeutralposition,youcan

usetheacceleratorpedaltospeeduptheengine,thenpush

theswitchbelowtheInfoCenterforwardtosettheengineat

thatspeed.Thisisnecessarytorunthechemicalagitation

whilestationaryoroperatingattachmentssuchasthehand

sprayer(Figure7).

19

Important:TherangeselectormustbeintheNeutral

positionandtheparkingbrakemustbesetfortheswitch

towork.

FuelGauge

Thefuelgaugeislocatedontopofthefueltank,ontheleft

sideofthemachine,andshowstheamountoffuelinthetank.

theInfoCenter.Thehourmeterstartstofunctionwhenever

thekeyisturnedtotheRunposition.

SonicBoom(Optional)

TheSonicBoomswitchisarockerswitchusedtooperate

theSonicBoom.T oggletheswitchforwardforautomatic,

rearwardformanualandcenterforOff.

MasterBoomSwitch

Themasterboomswitch(Figure7)islocatedonthesideof

theconsoleandtotherightoftheoperator.Itallowsyouto

startorstopthesprayoperation.Presstheswitchtoenable

ordisablethespraysystem.

Boom-SectionSwitches

Theboomswitchesarelocatedonthecontrolpanel(Figure

7).Toggleeachswitchforwardtoturnthecorresponding

boomsectiononandrearwardtoturnthemoff.Whenthe

switchisturnedon,alightontheswitchilluminates.These

switcheswillonlyaffectthespraysystemwhenthemaster

boomswitchison.

PumpSwitch

Thepumpswitchislocatedonthecontrolpaneltotheright

oftheseat(Figure7).T ogglethisswitchforwardtorunthe

pumporrearwardtostopthepump.

Important:Thepumpswitchwillonlyengagewhenthe

engineisatlowidletoavoiddamagingthepumpdrive.

FoamMarkerSwitchLocations

(Optional)

IfyouinstalltheFoamMarkerkit,youwilladdswitchesto

thecontrolpanelforcontrollingtheiroperation.Thesprayer

comeswithplasticplugsintheselocations.

Regulating(RateControl)Valve

Thisvalve,locatedbehindthetank(Figure9),controlsthe

amountofuidthatisroutedtotheboomsortheratereturn

tothetank.

ApplicationRateSwitch

Theapplicationrateswitchislocatedonthecontrolpanelto

therightoftheseat(Figure7).Pressandholdtheswitch

forwardtoincreasethespraysystempressure,orpressand

holditrearwardtodecreasethepressure.

Supervisor(RateLockout)Switch

Thesupervisorswitchislocatedonthecontrolpaneltothe

rightoftheseat(Figure7).Turnthekeycounterclockwise

tothelockedpositiontodisabletheapplicationrateswitch,

therebykeepinganyonefromaccidentallychangingthe

applicationrate.Turnthekeyclockwisetotheunlocked

positiontoenabletheapplicationrateswitch.

BoomLift

Theboomliftswitchesarelocatedonthecontrolpaneland

areusedtoraisetheleftandrightboomrespectively.

HourMeter

Thehourmeterindicatesthetotalnumberofhoursthe

enginehasrun.Thisnumberisdisplayedontherstscreenof

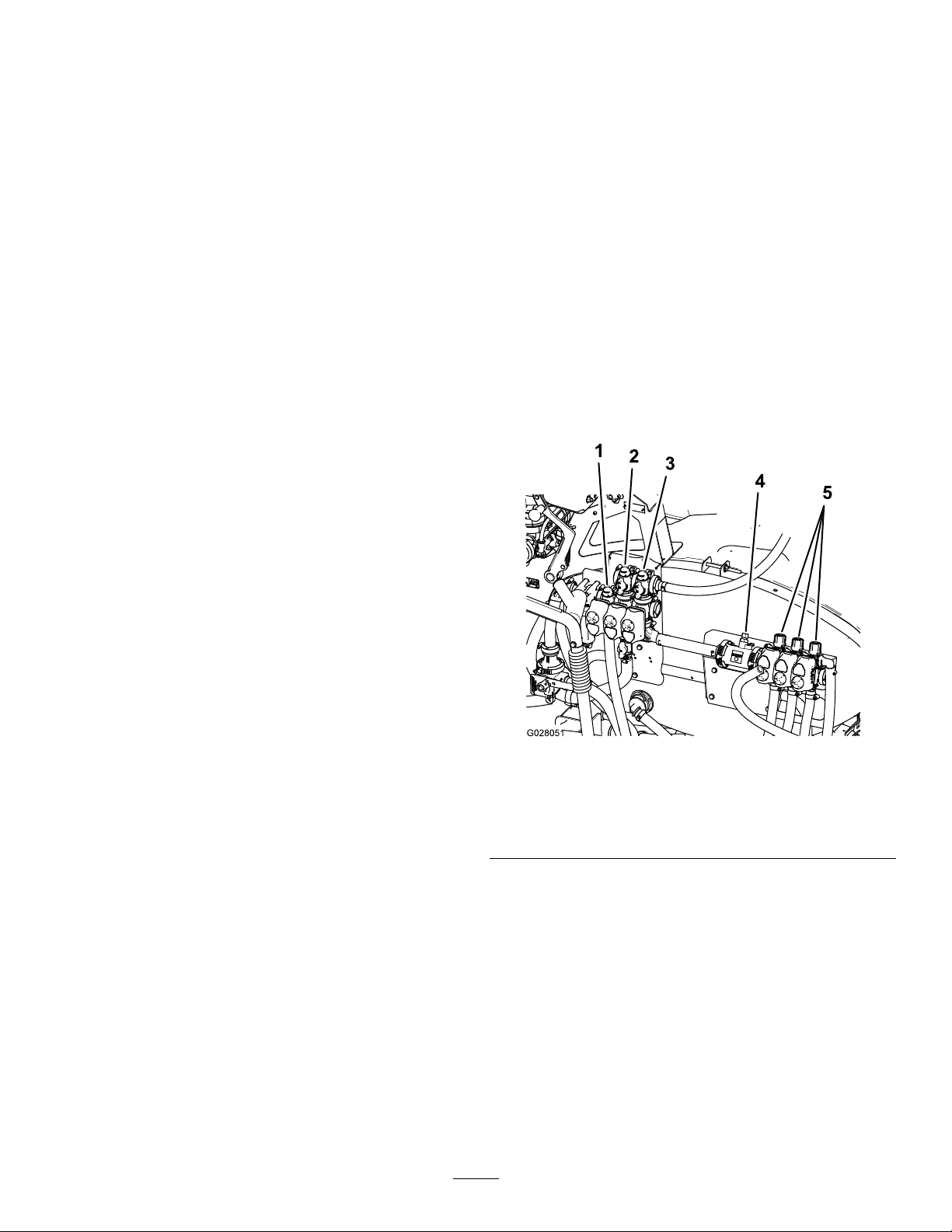

Figure10

1.Regulating(ratecontrol)

valve

2.Agitationvalve5.Boom-sectionvalves

3.Masterboomvalve

4.Flowmeter

MasterBoomValve

Themasterboomvalve(Figure10)isusedtostoptheowto

theowmeterandboomvalves.

Flowmeter

Theowmetermeasurestheowrateoftheuidforuseby

theInfoCentersystem(Figure10).

Boom-SectionValves

Thesevalvesturnthethreeboomsectionsonoroff(Figure

10).

20

Boom-SectionBypassValve

Specications

Theboombypassredirectstheuidowforaboomsection

tothetankwhenyouturnofftheboomsection.Y oucan

adjusttheboombypasstoensurethattheboompressure

remainsconstantnomatterhowmanyboomssectionsare

on.RefertoCalibratingtheBoom-SectionBypassValves

(page32).

AgitationValve

Thisvalveislocatedontherearofthetank(Figure10).When

agitationison,theowisdirectedthroughtheagitation

nozzlesinthetank.Whenagitationisoff,theowisdirected

throughthepumpsuction.

PressureGauge

Thepressuregaugeislocatedonthecontrolpanel(Figure7).

Thisgaugeshowsthepressureoftheuidinthesystemin

psiandkPa.

InfoCenterLCDDisplay

TheInfoCenterLCDdisplayshowsinformationaboutyour

machineandbatterypack,suchasthecurrentbatterycharge,

thespeed,diagnosticsinformation,andmore(Figure7).

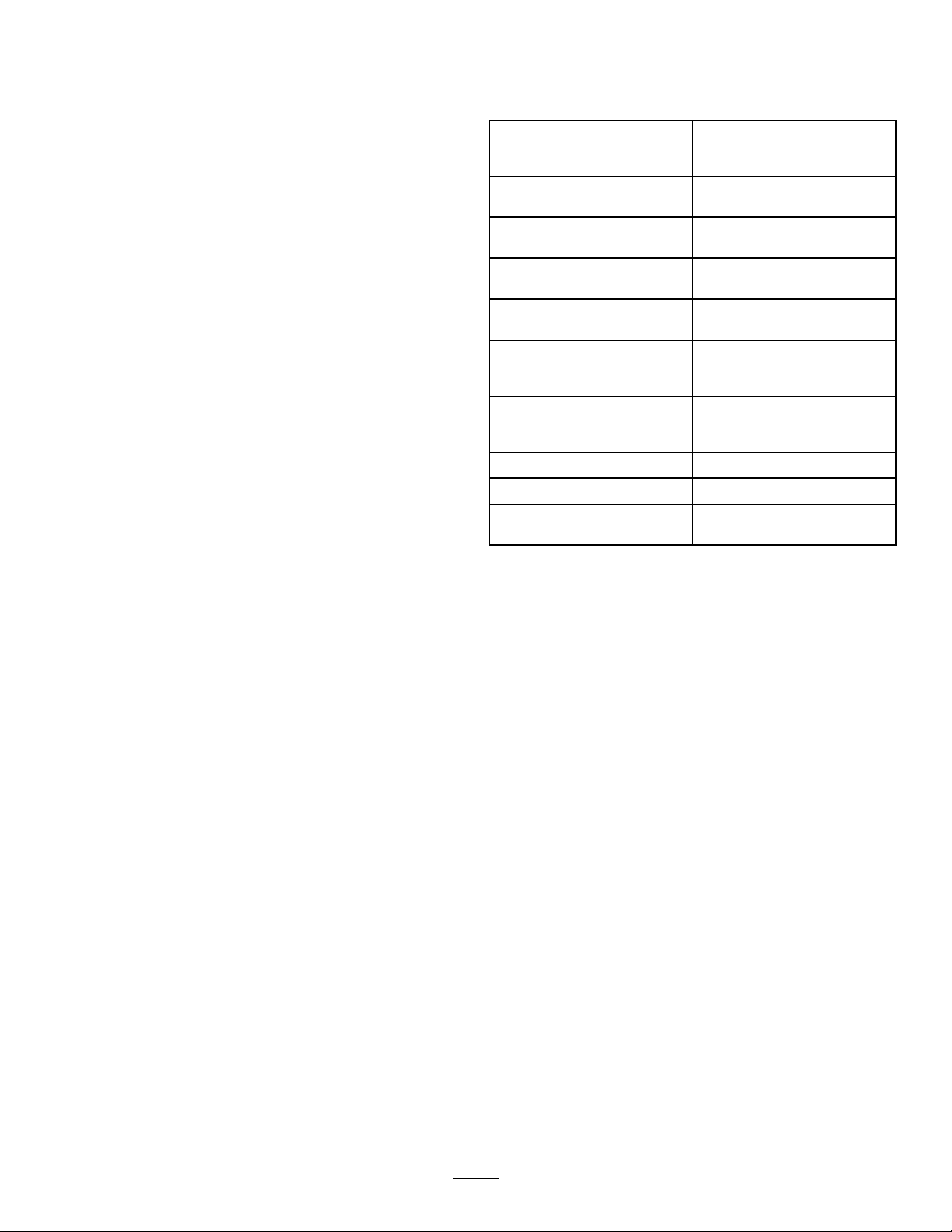

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Weightwithstandardspray

system,empty ,without

operator

Weightwithstandardspray

system,full,withoutoperator

Maximumgrossvehicleweight

(GVW)(onlevelground)

Overalllengthwithstandard

spraysystem

Overallheightwithstandard

spraysystem

Overallheightwithstandard

spraysystemtothetopofthe

boomsstoredintheXposition

Overallwidthwithstandard

spraysystemboomsstoredin

theXposition

Groundclearance14cm(5.5inches)

Wheelbase

Tankcapacity(includesthe

CE5%overow)

953kg(2,100lb)

1,678kg(3,700lb)

1,814kg(4,000lb)

343cm(135inches)

191cm(75inches)

246cm(97inches)

178cm(70inches)

155cm(61inches)

662L(175USgallons)

Formoreinformation,refertoUsingtheInfoCenterLCD

Display(page28).

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

21

Loading...

Loading...