TORO

Advantage

Issue No. 12, June 2006 Information From Toro to Help YOU and YOUR Course

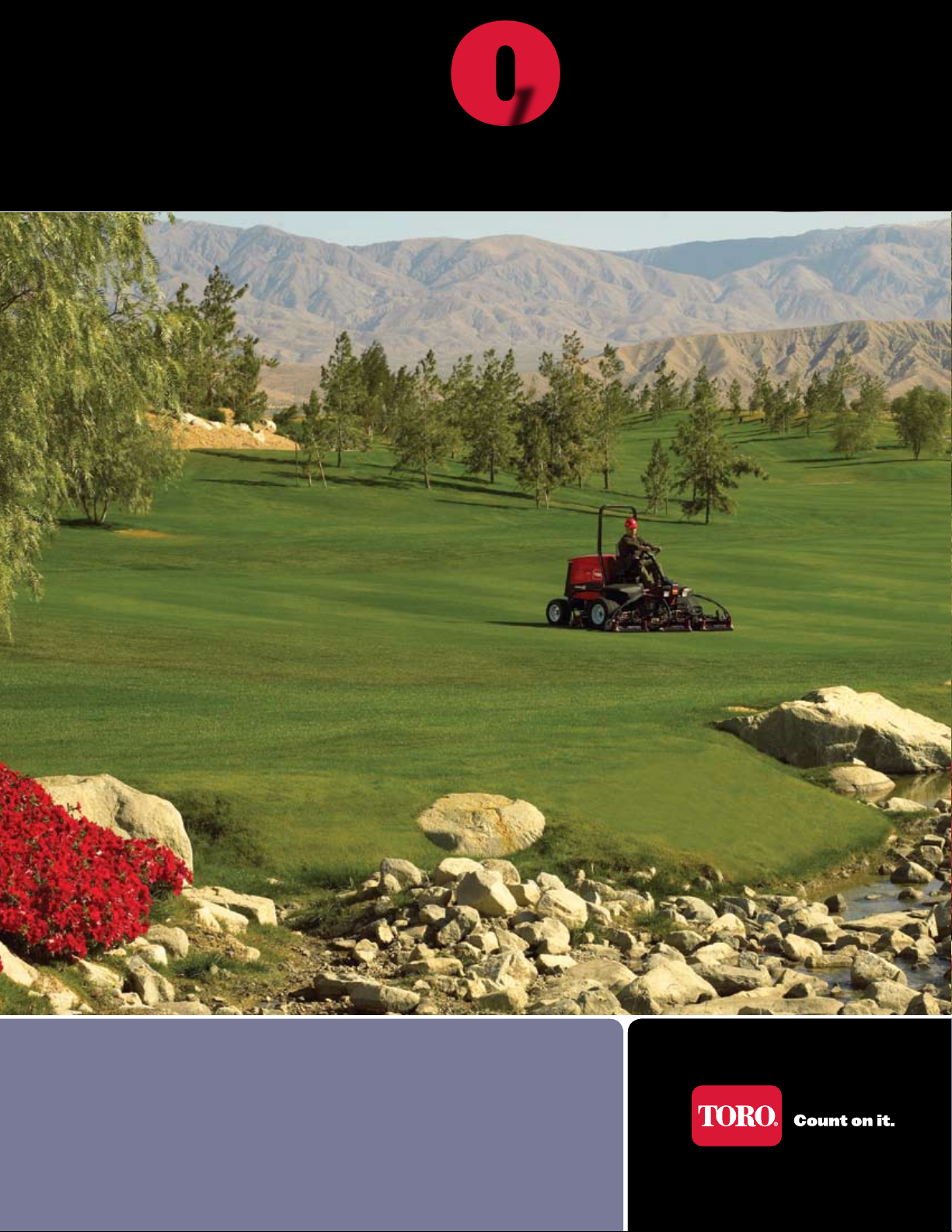

New Reelmaster® Fairway Mowers

A Better Cut, From Start To Finish

(See page 2)

INSIDE THIS ISSUE

2

New Reelmaster® Fairway Mowers

Better Quality Of Cut Is Just The Start

4

Sand Pro® Bunker Rakes

From Good…To Better…To Best

6

Operator Training

Sand Pro Quick Attach System

8

DL2000 Subsurface Irrigation

Saves Time, Solves Problems

10

Options & Attachments

New Multi Pro® Sprayer Attachments

11

Technician Tips

835S/855S Flexible Features

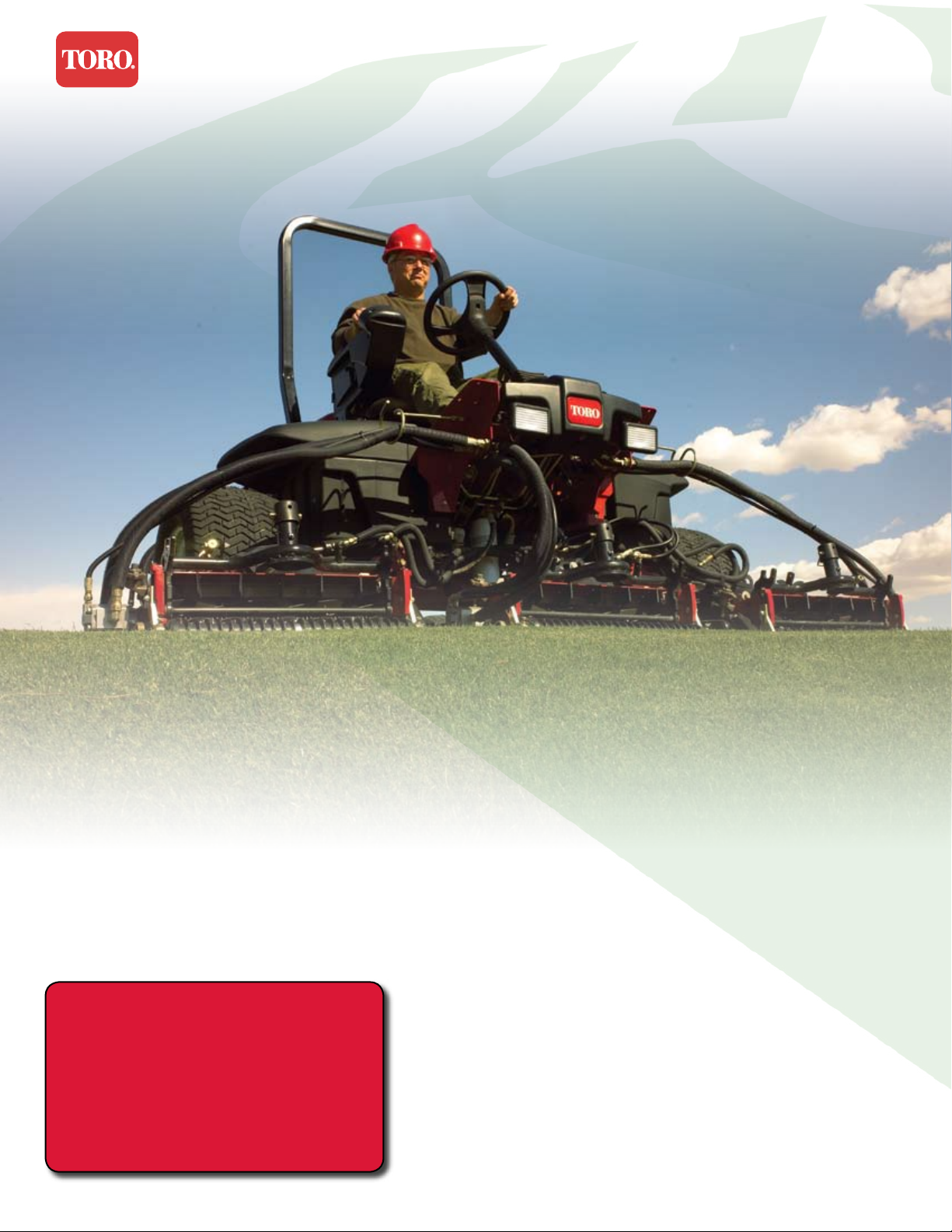

New Reelmaster Fairway Mowers

Better Quality Of Cut Is Just The Start

t the Toro Company, we’re

grateful to have a reputation

A

continually striving to improve our products and create new ones.

In this spirit, Toro recently

introduced four new mowers in our

popular Reelmaster line, each built for

exceptional performance and improved

after-cut appearance on fairways.

Drawing a great deal of attention at

the 2006 Golf Industry Show, the four

new Reelmaster mowers—models 5210,

5410, 5510 and 5610—feature Toro’s

innovative Dual “Precision” Adjustment

for being innovative and for

(DPA) cutting units, an all-wheel drive

system and numerous other advanced

capabilities.

Customer-Inspired Design

and feedback we received from golf

course superintendents, operators and

technicians,” says Tony Ferguson,

marketing manager for Toro’s Reelmaster

mowers. “They wanted a better fairway

mower that provided improved quality of

cut and after-cut appearance along with

reduced maintenance, easier adjustments

and improvements in operator comfort.

“The adjustments on the reels

themselves were really easy.

With this, it’s just 1-2-3.”

— Craig Currier, Golf Course Superintendent

Bethpage State Park, Long Island, New York

“The new units are based on research

Based on the feedback we’ve

received from many customer

visits, the new Reelmasters

have succeeded in all of

those areas.”

Ferguson and his crew tested

the new machines at about 100

courses around the country.

Superintendents at these test

sites were impressed.

“Simply put, it did a great

job,” says Jeff Eldridge, golf

course superintendent at the Nicklaus

Golf Club, a newer, high-end, private

facility in Overland Park, Kansas.

Located in a warm-season/cool-season

grass transition zone, the Nicklaus Club

has zoysiagrass fairways, which have

always been a challenge for mowing and

grooming.

“Zoysiagrass is ornery,” Eldridge

explains. “But Toro’s new units are a vast

improvement on zoysiagrass. Right off

the truck it did a great job of mowing.”

DPA Earns Praise

Many superintendents were most

impressed with the mowers’ new

DPA cutting units—an exclusive

Toro innovation that makes reel blade

adjusting much faster and easier.

“The DPA—that’s huge because it’s

so much simpler than other machines in

terms of adjusting it,” says Craig Currier,

golf course superintendent at Bethpage

State Park in Long Island, New York, site

of the 2002 and 2009 U.S. Opens. “The

adjustments on the reels themselves were

really easy. With this, it’s just 1-2-3.”

2

Eldridge agrees, viewing the new

DPA cutting units as the product’s most

important feature.

“The biggest thing is the new

cutting unit, the DPA” he says. “That’s

something we’ve been requesting for

years, and I think that’s going to really

help us to do our jobs better.”

“With the DPA, I think you get a

better reel-to-bedknife adjustment,”

Eldridge explains. “Out in the field, we’re

able to do a better job of adjusting one

side instead of having to adjust the entire

bedknife.”

Better Quality Of Cut

The DPA cutting units are brandnew and leverage many innovative and

proprietary features that together elevate

the overall quality of the Reelmaster

mowers. With special suspension and

weight balance, the cutting units’

innovative design optimizes groundfollowing and mowing performance to

deliver unbelievable quality of cut on a

variety of terrains.

The cutting units are also made with a

proprietary reel blade material—another

innovation exclusive to Toro.

“By using a harder base metal and

an advanced tempering process, the

blades hold an edge much longer,”

says Ferguson. “The result is reduced

adjustments and less frequent

backlapping and grinding. That helps

to ensure a consistently higher quality

of cut because the sharper edge shears

the grass blade off cleanly, so grasses stay

green and healthy. We even scalloped the

reel blades for a built-in relief, which also

helps keep the blade sharp.”

A related improvement on the cutting

units is a heavy-duty bedknife called

EdgeMax™—used exclusively by Toro,

which incorporates a harder, leadingedge tool steel to retain its sharp edge

up to three times longer than standard

bedknives. You can choose from among

three cutting units: a 5-inch diameter 8

blade; a 7-inch diameter 8 blade; and a

7-inch diameter 11 blade.

More reliable mowing is further

enhanced by the Reelmasters’ specially

designed all-wheel drive system—another

innovation that’s new to the industry.

The CrossTrax™ drive system is based on

Toro’s patented Series/Parallel traction

system. This drive system provides

superior traction on wet slopes by

transferring power from the front tires to

the opposite rear tires. That way, if the

upslope tire starts to lose traction, the

opposing rear tire absorbs more weight

to help propel the unit forward and up

the hill.

“I think the quality of the cut is great,

and it was really quick,” Currier says.

With five courses and nearly 300,000

rounds played every year at Bethpage, a

high level of productivity is essential for

him and his crew. “With all the play we

have here at our facility, we need to get

in and out as quick as we can without

sacrificing quality.”

Lighter Frame, Less

Compaction

With the new Reelmaster machines,

Toro also offers another important

benefit: a product that’s not only better,

but lighter. The mowers weigh up to

280 pounds less than Toro’s older units,

and that’s even with the more powerful

engines.

“We trimmed unnecessary weight

so the mower would have a lighter

footprint, but without sacrificing any

durability or functionality,” Ferguson

says. “That means the new Reelmasters

provide the finest fairway cutting with

less compaction or turf abrasion.”

Eldridge and Currier viewed this

feature as an important benefit.

“Lighter frames are a benefit because

any time you get a lighter footprint

on the turfgrass surface, you’re doing

yourself a big favor,” Eldridge says.

“The lighter the mower is, the less

compaction,” Currier says. “For what

we’re looking for, the weight is good.”

Many Other Advantages

To provide better after-cut appearance,

the Reelmasters accommodate a series

of built-in features and optional

attachments, including platform

groomers, powered rear roller brushes,

collection baskets, cutting-unit combs

and more. The mowers can even be

configured with Toro’s TurfDefender

Leak Detector, a device that identifies

hydraulic leaks and then shuts down the

cutting system to prevent turf damage.

The new mowers also offer increased

operator comfort, providing a deluxe seat

suspension, a control panel within closer

reach, easier step-entry and exit, tilt

steering wheel and reduced noise.

“Comfort-wise, it was great, too,”

Currier says. “It’s such a comfortable and

smooth machine. When you’re riding

around on a golf course all day it’s pretty

rough, so the operators are definitely

going to enjoy not bouncing up and

down all over the place.”

Currier adds: “There’s plenty of room

on the machine and it’s easy to use,” said

Currier. “It’s also big enough to make

sure you have plenty of power.”

“They did a nice job,” concludes

Eldridge. “I think Toro has made great

strides with these machines.”

3

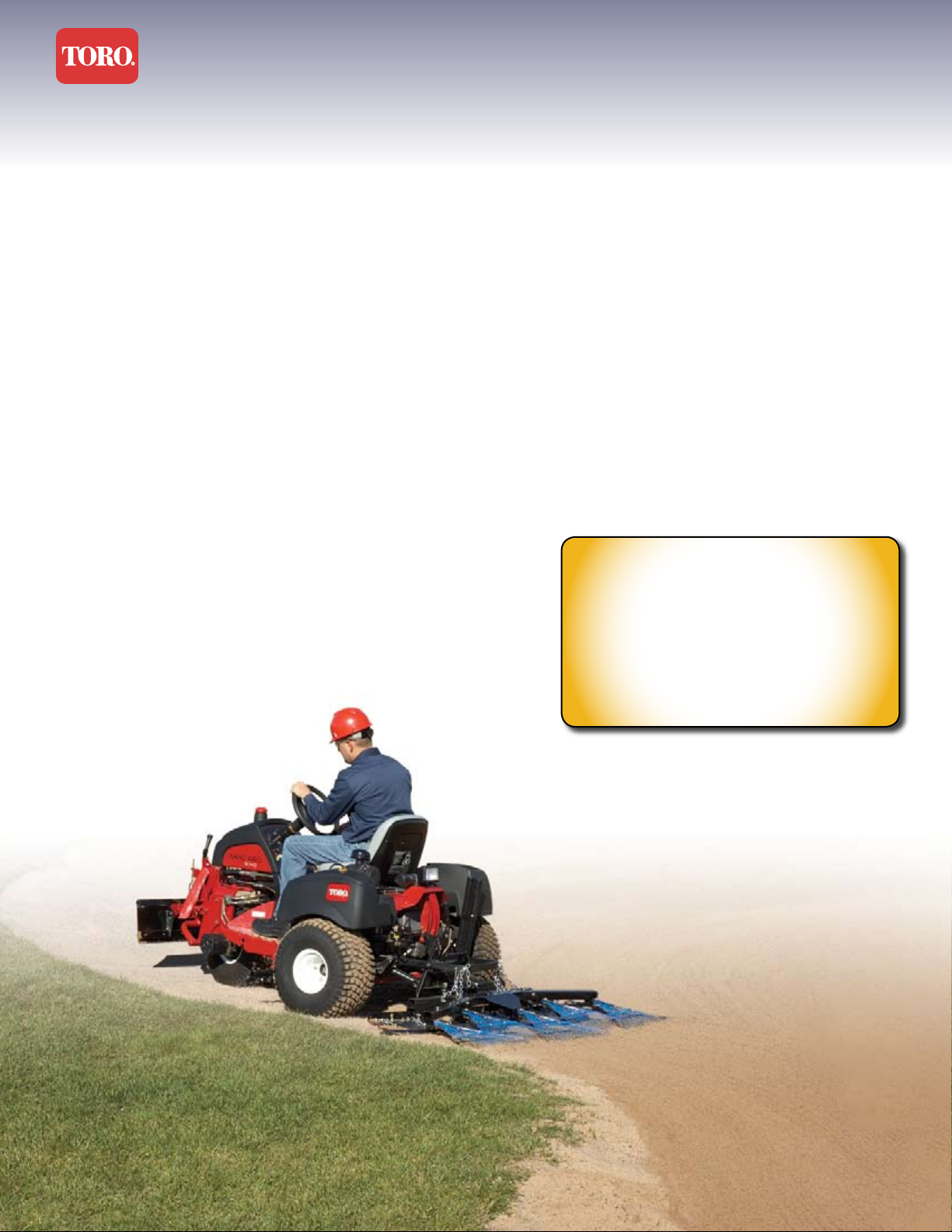

New, Improved Sand Pro® Bunker Rakes

From Good…To Better…To Best

t one point in the not-sodistant past, the Toro Sand

A

game, may have spent a little more time

resting in the shop than working on the

course. But all this has changed. The

Sand Pro 3020 and 5020 models recently

underwent some major modifications

and upgrades. Now with improved

hydraulic capabilities, more ground clearance, steerable front-end attachments

and under-a-minute attachment changes,

the new and improved Sand Pro 3040

and 5040 are ready to hit the market.

Pro®, while at the top of its

From Good To Better

To make changes to these reliable

bunker-management machines, Toro

went straight to its customers. With

hands-on test sites set up across the

nation, golf course superintendents,

assistants, technicians and operators had

the opportunity to spend a few hours

examining—and trying out—the new

features and changes.

“Since we are replacing a product

that is number one in its field for

quality, we wanted to make sure

that we understood what our

clients did and did not like,”

explains Greg Janey,

marketing manager

for the Toro Sand Pro. “First, we decided

that this product could improve overall

with a Quick Attach System that allows

anyone to change attachments in under

a minute without any tools. This is

compared to over an hour with the

older models.”

“Also, we decided that the chain design

on the 3020 for the steering wasn’t as

reliable as we would like, especially in

these harsh sand and dirt environments.

So we completely got rid of it. The new

3040 has a gear design that is completely

sealed from the environment and its

harmful elements. Even better, the

5040 has new hydraulic power

steering.”

Taking into consideration

customers’ varied needs, comments

and concerns, Toro took the

under-utilized Sand Pro and made

it more functional and easier to

use. This way, customers can be

more productive—

accomplishing more

with less.

Scott Cochran,

golf course

superintendent at

Ballantyne Country

Club, a 130-acre

Rees Jones-

designed

course in Charlotte, North Carolina,

is already making plans for a more

productive day with the new Sand Pro

models.

“We constantly strive to exceed the

expectations of our members and have

spent probably 40 percent of our time

on bunkers this year,” Cochran describes.

“We currently use the older Sand Pro

models, and we operate them 5 to 6

times a week from 2 to 5 hours a day on

our daily maintenance.”

The golf course is characterized by

rolling hills, beautiful lakes, magnificent

“Toro really listened to what

we asked for and delivered the

improvements. I feel lucky that

they asked for my input.”

– Scott Cochran, Golf Course Superintendent,

Ballantyne Country Club, Charlotte,

North Carolina

views—and 95 well-manicured bunkers;

however, the hilly terrain occasionally

causes bunkers to wash out during

heavy rainstorms.

“Our bunkers tend to catch some

run-off during big rain events, but with

our Sand Pros we’re able to put them

together again fairly quickly,” Cochran

says. “It will be even easier with the new

Sand Pro.”

Cochran adds: “I feel like the best

machine on the market was the 5020,

and I didn’t think Toro could improve

on it. But they have.”

4

Cochran admits that he and his

staff are usually a bit skeptical when

companies decide to make changes to

existing products and machinery, but

they were more than pleased with the

new Sand Pro 5040, especially with its

17 attachments that can be switched out

easily in less a minute.

“I think the new Sand Pro is going to

be a very useful tool from our standpoint

Sand Pro 5040

because it’s going to give

us the ability to do more than just one

particular job,” Cochran explains. “We

have limited floor space in our shop,

and if we can purchase attachments to

make a machine more versatile, then it’s

definitely something we’ll consider. Toro

really listened to what we asked for and

delivered the improvements. They have

been extremely helpful. I feel lucky that

they asked for my input.”

From Better To Best

To better meet the needs of customers,

the improved Sand Pro 3040, which

will eventually replace the 3020 model,

is equipped with a fuel-efficient, 16horsepower Vanguard® engine. It features

improved gear-drive assisted steering and

a Quick Attach System on the back as

well as the standard hydraulic lift,

3-wheel drive traction.

The 18-horsepower Sand Pro 5040

will take the place of the 5020. In

addition to the standard series features,

this premium model offers new hydraulic

power steering, a front and back

Quick Attach System and the comfort,

efficiency and dependability that Toro

customers have come to expect for

keeping bunkers conditioned and ready

for play.

The new improvements and innovative

features of the 3040 and 5040 make

these bunker rakes unsurpassed for

grooming, construction activities and

specialty maintenance across your

entire course. But one of the favorite

additions to the upgraded designs is

the Hydraulic Flex Blade, which

is an ideal attachment for golf

courses that get more than their

fair share of inclement

weather. The Sand

Pro has always had

a blade, but it was

operated manually.

Until now, this

manual blade was a

cause for lost time and

spent energy. With the new models,

however, the hydraulic capabilities make

reconstructing bunker faces much less

problematic.

With about 170 bunkers on 400 acres

at Carmel Country Club in Charlotte,

North Carolina, Bill Anderson, greens

and grounds director, appreciates this

new improvement. Anderson, who has

more than 32 years of experience, says,

“Overall, the Sand Pro

is a good machine that

they made even better.

I’d give it an A+.”

– Bill Anderson, Greens and Grounds

Director, Carmel Country Club,

Charlotte, North Carolina

Toro's new Sand Pro models offer superior productivity and result in beautifully groomed bunkers.

“we average 50-plus inches of rain a

year, so pushing the sand back after a

heavy rain is a big part of our bunker

maintenance. The Sand Pro’s new

Hydraulic Flex Blade will make that an

easier and faster job. The thing that I like

the most is not so much the flex but the

fact that you don’t have to manually lift

the blade up or down. Overall, the Sand

Pro is a good machine that they made

even better. I’d give it an A+.”

With increased versatility, capability,

and ease of use, the new and improved

3040 and 5040 models are more

competitive, performance-driven,

operator- and technicianfriendly. Undoubtedly,

the Toro Sand Pro will be

spending less time in the

shop. From now on, it looks

like the Sand Pro will be

spending a lot more time in

the bunkers and out on the

course.

5

Operator

Training

Toro Sand Pro 3040/5040 Bunker Rakes

Quick Attach System Provides Ultimate Versatility In Three Easy Steps

Step 1A Step 2A Step 1B

his Changes

Everything is the

T

ated with Toro’s new Sand

Pro 3040 and 5040 bunker

rakes—and it couldn’t be a

more appropriate statement.

Thanks to superintendent

and operator feedback, Toro

designers created completely

revamped machines

featuring power steering

and/or gear-drive manual

steering, Reduced Simplified

Maintenance (RSM),

improved ground clearance

and 3WD series/parallel

traction.

But the Sand Pro’s most

significant innovation—the

revolutionary Quick Attach

System (QAS)—is the feature

that will drastically change

how you do your job.

The Quick Attach System

allows you to switch out the

machine’s 17 attachments in

less than a minute, no tools

required! This capability,

which makes the Sand Pro the

most versatile power groomer

on the market today, is designed to

maximize your time and skyrocket your

productivity.

With no tools required, this hands-on

tagline associ-

The new Sand Pro models

can be outfitted with 17

attachments, including:

n Hydraulic Flex Blade

n Steerable Front Attachments

n Spring-Loaded Manual Blade

n Rear Segmented Grooming Broom

n Coco Drag Mat Carrier System

n Mid-Mount Cultivator

n Mid-Mount Leveling Blade

n Utility Box

n Blower

n Spiker

n Box Blade

n And many more

system allows a single operator to quickly

change out the machine’s attachments.

Even more good news is the Quick

Attach System is as easy to learn as it is

to use.

In three easy steps, here’s

how it works:

Step 1A: Position the attachment onto

the QAS latching A-frame,

making sure it is properly

aligned. All attachments connect in the same way.

Step 2A: Once the attachment is in

place, pull the QAS lever

firmly into the ‘up’ position.

This locks the system, ensuring that the attachment stays

in place during use.

Step 1B: To remove the attachment,

release the QAS lever into the

‘down’ position and lower the

lift. This unlocks the QAS,

allowing you to take attachments off and/or put attachments on in a minute or less.

Toro’s QAS is the easiest, quickest

attachment-changing system in the

industry. With the old system, it could

take up to an hour to switch among

attachments. But now, this new Sand

Pro innovation ensures that you spend

less time changing attachments and more

time doing the tasks your job requires.

6

Capacitación

de Operadores

Rastrillos de búnker Toro Sand Pro 3040/5040

El sistema de acoplamiento rápido ofrece una versatilidad total en tres sencillos pasos

sto lo cambia todo es el eslogan asociado con los nuevos

E

Pro 3040 y 5040 de Toro, y sería difícil

encontrar una definición mejor. Gracias a

los comentarios que recibimos de supervisores y operadores, los diseñadores de

Toro han creado máquinas totalmente

renovadas, con dirección asistida y/o

dirección manual con transmisión por

engranajes, Mantenimiento Rutinario

Simplificado (MRS), mayor altura sobre

el suelo y tracción a 3 ruedas Series/

Parallel.

Pero la innovación más significativa

del Sand Pro—el revolucionario

Sistema de Acoplamiento Rápido (SAR)

— cambiará para siempre la forma

en que usted trabaja. El Sistema de

Acoplamiento Rápido le permite cambiar

cualquiera de los 17 accesorios de la

máquina en menos de un minuto - ¡sin

herramientas! Este sistema, que hace del

Sand Pro el acondicionador motorizado

más versátil que se encuentra hoy en el

mercado, está diseñado para ayudarle a

aprovechar mejor su tiempo y maximizar

su productividad.

rastrillos de búnker Sand

Sin necesidad de herramientas, este

práctico sistema permite que un único

operador cambie rápidamente los

accesorios de la máquina. Y mejor aún, el

Sistema de Acoplamiento Rápido es tan

fácil de aprender como de usar.

Funciona así, en tres

sencillos pasos:

Paso 1A: Coloque el accesorio en la

pletina triangular del SAR,

asegurándose de que

quede correctamente

alineado. Todos los

accesorios se conectan

de la misma manera.

Paso 2A: Una vez posicionado el

accesorio, jale firmemente de la palanca

SAR hasta la posición

“elevado”. Esto bloquea

el sistema, garantizando

que el accesorio quede

acoplado durante el

uso.

Paso 1B: Para retirar el accesorio,

ponga la palanca SAR

en posición “bajado” y

baje el accesorio. Esto

desbloquea el SAR y

permite acoplar o desmontar accesorios en

un minuto o menos.

El SAR de Toro es el sistema de

cambio de accesorios más sencillo

y rápido del sector. Con el sistema

antiguo, el cambio de accesorios podría

necesitar hasta una hora. Pero ahora, esta

innovación del Sand Pro asegura que

usted dedique menos tiempo a cambiar

de accesorio y más tiempo haciendo las

tareas que su trabajo exige.

Los nuevos modelos de

Sand Pro pueden llevar 17

accesorios, tales como:

n Pala flexible hidráulica

n Accesorios delanteros dirigibles

n Pala manual tensada con muelles

n Cepillo acondicionador segmentado

trasero

n Sistema portador de estera de coco

n Cultivadora de montaje intermedio

n Grada de montaje intermedio

n Caja de transporte

n Soplador

n Perforador

n Traílla

n Y muchos más

7

Introducing DL2000 System Golf Kit

New Subsurface Irrigation Saves Time, Solves Problems

very now and then somebody comes up with a different and better way to use popular technology to

E

Toro Irrigation.

For years, Toro has offered subsurface “drip” irrigation

systems for specialized applications in landscape and agriculture.

Drip irrigation — named for its slow, consistent delivery of

small amounts of moisture — provides water-savings and other

benefits through its efficient distribution process, and when

installed below ground, it’s invisible.

Recently, Toro engineers were inspired to try subsurface

drip systems on golf courses. Although the industry already

had a tremendous range of versatile, adjustable sprinklers and

DL2000 System Golf Kit

in bunkers. It’s also not a good use of time. So we’re hoping

when they see this, the light bulb will go on.”

solve an old problem. That’s just what happened at

controllers, superintendents still had

hard-to-water areas, such as tee

boxes and bunker surrounds.

“There really isn’t a golf

course out there that hasn’t

struggled with that at some

time,” says Michele Baird,

Product Marketing

Manager for Toro, one

of the people behind the

idea. “They’re usually

hand-watering those areas,

and that may cause problems

Early Successes

Two years ago, Toro began installing its existing DL2000®

Series Subsurface Irrigation System on selected golf courses.

Those applications have proven so successful, the company is

now introducing DL2000 to the golf industry.

“For us, it’s been a home run,” says Dan Hawkins, golf

course superintendent at The Club at Flying Horse in Colorado

Springs, Colorado. Hawkins installed DL2000 drip systems on

three fairway bunkers at the upscale course in 2004.

“One of our biggest labor costs was hand-watering bunker

fingers,” he explains. “They tend to dry out during the day, so

you either spend labor dollars or put in supplemental irrigation.

DL2000 has really cut down our costs. I’d rather do the drip

because I know it works.”

How Subsurface Irrigation Works

The DL2000 uses underground polyethylene tubing with

regularly spaced inline emitters. The subsurface network hooks

into your existing control system and operates with its own

separate control valve.

DL2000 provides many valuable advantages. Agronomically,

subsurface drip irrigation enables you to apply precise amounts

of water directly to the root zones of your turfgrass and

8

maintain optimum soil moisture all the

time. It also reduces water lost to wind

and evaporation, and avoids problems

of erosion or collapse around bunkers.

Bunker sand stays dry as well.

But better yet, underground DL2000

drip systems on a golf course eliminate

the problem of interfering with golfers’

play, and as Hawkins says, they greatly

reduce the time and expense of handwatering.

“With the drip, you can schedule your

irrigation to apply water at the rate you

need to meet your turf demands and

The new DL2000 system provides ideal watering

for bunker surrounds.

soil conditions,” says Bill Carroll, Drip

Irrigation District Manager for Toro.

“You can even irrigate while people are

teeing off, and they don’t know what’s

going on because the water is applied

subsurface.”

“It’s worked out fantastically. If I had

the opportunity, I’d put it around all of

my bunkers,” says David Emmons, golf

course superintendent at the private, 27hole Longboat Key Club in Longboat

Key, Florida. “With the ability to supply

water to stressed turf at any time of the

day, the convenience is outstanding.”

Located on a barrier island in the

Gulf of Mexico, Longboat Key faces

environmental stresses such as salt air

and water-quality issues. Certain areas of

the course that are harder to irrigate can

visibly react to the stress.

“There was a particular bunker that

always looked weak around the edges,”

says Emmons. “We just couldn’t get

enough water on it without handwatering, and we don’t have the

manpower for that.”

After agreeing to try the DL2000,

that bunker was one of the first places

Emmons installed it.

“Within weeks it was greener than it

had ever been,” he says. “That really gave

it the help it needed.”

Pre-packaged Solution Makes

Installation Simple

Subsurface drip irrigation may

seem like a radical step for some. To

minimize concerns about such a different

approach, Toro made the choice easier

by creating a complete, ready-to-go

installation kit. All the parts needed

to implement DL2000 literally come

in one box, and are labeled for easy

identification.

“We knew that people might

be unfamiliar with these parts and

fittings, so we had the idea to put all

the components in a kit with easyto-follow instructions,” says Carroll.

“The components needed to install

most systems are included, and it’s

dramatically simplified with one hose

diameter, emitter spacing and flowrate.

You don’t need to worry about acquiring

fittings or anything. It all goes together

quite easily.”

There are four separate DL2000

System kits for different uses.

n A Low-Flow/Single Bunker System

with flow range from .1 to 8 gpm,

and system capacity up to 1000 lin-

ear feet.

n A High-Flow/Multi-Bunker System

Kit with flow range from of 2 to 20

gpm, and system capacity up to 2500

linear feet.

n A Tee Box System Kit that includes

Airjection® with flow range of 2 to

20 gpm and system capacity up to

2500 linear feet.

n An Additional Zone Kit containing a

500’ roll of DL2000 with fittings is

available for applications where extra

dripline is required.

The Tee Box Kit also includes

Toro’s unique, built-in Airjection®

system, which provides underground

aeration during the irrigation process.

This exclusive feature aerates the soil

by injecting micro-bubbles into the

water using existing system pressure.

The Airjection System reduces soil

compaction and improves turf quality.

Adding a DL2000 System—at depths

ranging from 1 to 6 inches—is quick

and easy.

“You just peel back the existing turf,

do the installation, put the turf back

over, then water it down and you’re good

to go,” explains Baird. “Usually you can

do it in about a day.”

“They basically just opened the turf

and tucked it in,” says Emmons about

his DL2000 installation. “Soon you

couldn’t even tell they’d been there.”

Protection Against Roots

Years of experience with subsurface

irrigation in landscapes has taught Toro

a lot about improving it. For example,

a common problem for years was root

intrusion, as aggressive roots would grow

toward the water and clog the emitters.

Toro solved this problem with its

exclusive, patented ROOTGUARD®

technology that impregnates the DL2000

emitters with Treflan® herbicide. It forms

a non-toxic chemical barrier which keeps

the system root-free, but won’t harm

turfgrass.

In addition to bunkers and tees, the

flexible and adaptable DL2000 System

kits can be used around lakes, hardscapes

and any areas that are hard to target with

conventional above-ground irrigation.

“DL2000 is a great solution that’s

remarkably simple,” Carroll concludes.

“It’s a win-win,” says Hawkins. “I

told a guy yesterday that if we were to

do another golf course, I’d do all the

bunkers with drip.”

Treflan® is a registered trademark of

Dow AgroSciences.

Airjection® is a registered trademark of

Mazzei Injector Corporation.

9

Options

Attachments

New Multi Pro® Sprayer Attachments

Effective, Driver-Friendly Options Offer More Choices

&

prayers ensure that pesticides and fertilizers are

S

golf course landscapes green, healthy

and beautiful. To make this process even

simpler, Toro offers several new spray

options and attachments, including a

redesigned spray boom and a sprayer

attachment that transforms a Workman®

utility vehicle into a 200-gallon sprayer.

applied evenly, helping keep

Newly Designed Spray Boom

Combining strength and durability,

Toro’s revamped spray boom is a more

robust model designed for use with

Multi Pro® spray vehicles and Heavy

Duty Workman 200 Gallon Sprayers.

The boom offers new, improved

features that make it more driverfriendly and resistant to damage.

Featuring a triangle-shaped truss

structure, the system’s wings offer a

strong yet lightweight design. The

system allows the operator to easily

switch the boom from spray mode to

transport mode and back again without

leaving the driver’s seat.

The system also features an innovative

“Whip-Spring” cradle that holds

the boom in place during machine

transport. In case of accidental contact

with low overhead objects, the cradle

mechanism allows the booms to break

free and avoid damage. Likewise, the

double-lobed hinge cams allow the

boom, while it is spraying, to break

away 90 degrees to the front and rear

in case of contact with trees or other

objects. The boom tips are even rounded

to be more tree-friendly!

In addition, the unit’s spray nozzles are

strategically mounted inside the boom

enclosure, helping protect them from

being damaged and/or rotated, which can

adversely affect the vehicle’s spray pattern.

The system also comes with a heavy-duty

boom actuator.

“This is a big advancement that

absorbs a bit of the shock load, thereby

increasing boom life,” says Toro Engineer

Tim Sosnowski.

Workman 200 Spray

System Attachment

Making Toro’s premium utility vehicle

even more versatile, the Workman 200

Spray System Attachment transforms the

Heavy Duty Workman 3000/4000 series

into a spray vehicle as effective as Toro’s

popular Multi Pro units.

The attachment comes with the

newly redesigned spray boom (discussed

above), a 200-gallon tank and electric

boom and rate control valves. The

required PTO kit allows the Workman

to power the sprayer. Best of all, the

system is easy to attach, converting

the Workman into a sprayer in less

than 30 minutes after initial

installation.

The new Multi Pro Spray Boom is more operator

friendly and damage resistant.

This attachment enables the

Workman to function like a Multi Pro

sprayer in a number of ways. One key

feature is the attachment’s Spray Pro®

proportional drive control system, which

ensures that the Workman will provide

consistent spray application regardless of

the vehicle’s speed.

“In a similar manner to the Multi Pro

1200/1250 sprayers, the pump output

is mechanically linked to the ground

speed,” says Toro Marketing Manager

Greg Janey. “This means the faster

the Workman’s wheels turn, the faster

the sprayer pump turns, keeping your

application rate consistent even while

your vehicle speed changes.”

Equipped with the Workman

200 Spray System Attachment, the

traditional Workman utility vehicle is

transformed into a new product—

the Heavy Duty Workman 200

Gallon Sprayer.

“The attachment elevates the multipurpose nature of the Workman utility

vehicle even further,” Janey explains.

“If customers do not have a need for

a dedicated sprayer, they can convert

their Workman into a part-time sprayer

using the Workman 200 Spray System

Attachment, and it will cover their spray

application needs. This attachment is

simply designed to make the Workman

more versatile, offering customers more

options.”

10

Technician

Customer Care Available at toro.com/golf and toronsn.com

835S/855S Sprinklers

Offering Flexible Features

oro’s 800 Series sprinklers provide many features designed

T

dents and technicians.

to benefit both superinten-

True TruJectory

This feature allows the sprinklers to

be adjusted easily to direct water exactly

where you want it to go. The result is a lot

less water wasted.

n Experiment with all 24 settings simply

by adjusting the main nozzle trajectory

from the top of the sprinkler

n Fine-tune the radius and spray height

from 7 to 30 degrees

n Use this feature to get under trees or

up bunker faces

n Try adjusting the trajectory to com-

pensate for windy conditions

Part-Circle/Full-Circle

Coverage

With the same head, these sprinklers

also have the unique ability to spray either

part-circle patterns or true full circles.

n Make adjustments to the head without

changing out the rotor drives

n Try using the part-circle feature in

drought-sensitive areas when you need

to temporarily cut back on watering

roughs

n Experiment with full-circle coverage

during grow-in when adjacent native

vegetation needs consistent moisture

to get established

Nozzles

Part #

89-4785 650 25' 1.7 25' 1.9

102-2135 860S/880S 25' 4.1 26' 4.5

102-2136 860S/880S 24' 3.8 25' 4.1

89-3942 760/780 23' 2.4 24' 2.5

89-4652 760/780 30' 3.1 30' 3.5

89-3942 650 36' 3.4 36' 3.7

89-4738 650 29' 3.5 31' 3.8

89-4651 760/780 34' 2.6 36' 2.9

89-3942 760/780 36' 3.4 36' 3.7

89-4652 760/780 34' 3.8 34' 4.4

89-3729 760/780 33' 4.0 34' 4.5

89-4653 760/780 32' 4.1 32' 4.8

89-1879 760/780 35' 4.8 36' 5.0

89-4654 760/780 32' 4.7 32' 5.1

89-1878 780 36' 4.7 36' 5.2

102-2925 835S/855S 40' 2.9 40' 3.1

102-2926 835S/855S 43' 4.2 43' 4.4

102-2927 835S/855S 46' 4.6 47' 4.9

102-2928 835S/855S 50' 5.7 52' 6.3

102-2929 835S/855S 48' 7.2 53' 8.1

n Try this when your irrigation needs

require a different throw range or

water output

n Use a back nozzle in windy con-

ditions to help gain better trajectory behind the head and to get

better overall coverage

Model

65 PSI

Radius

tips

Popular Toro Nozzles

GPM

80 PSI

Radius

GPM

Back Nozzle Capabilities

A little-known but powerful capability,

Toro’s 800 Series sprinklers can be fitted

with 50 different back nozzles—providing

irrigation flexibility when a consistent fullcircle pattern won’t do.

n Experiment with this capability when

you need to water native plants and/or

ornamentals near the edge of a golf

course

Toro’s back nozzle selection

is expansive, providing a

solution for every application

need. The chart above

outlines a few of the most

popular nozzles, along with

information about radius and

water output.

835S/855S Sprinklers

11

www.toro.com

We Appreciate Your Feedback

If you have any questions, comments or suggestions, contact toroadvantage@toro.com or

fax 952.887.8693. Send us your ideas for future topics or tell us what you think about this

issue. We hope to hear from you soon.

Send Address Changes to:

Canyon Communications, 1630 S. Stapley Dr., Suite 117, Mesa, AZ 85204

or toroadvantage@toro.com

©2006 The Toro Company, 8111 Lyndale Ave. S., Bloomington, MN 55420-1196

Part No. 05-023-T

Toro Protection Plus Has You Covered

Plans Combine Strong Protection with Great Value

Stuff happens. Mowers break down. Sprinklers stop working. Aerators go on the fritz.

Even the best equipment needs to be repaired on occasion. And that’s where Toro

Protection Plus (TPP) steps in—providing golf course managers with a fool-proof way to

safeguard precious Toro equipment long after their warranty expires.

Offering the equipment industry’s most comprehensive protection against unexpected

and unwanted repair bills, Toro Protection Plus is available in two plans: drivetrain and

comprehensive protection.

Easily and affordably, Toro Protection Plus helps you:

n Protect your investments

n Save money by avoiding costly mechanical repairs

n Get the service you need when and where you need it

For detailed information about Toro Protection Plus, contact your Toro distributor at

800.803.8676 or visit www.toro.com.

Loading...

Loading...