Part No. 08164SL (Rev. A)

Service Manual

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing

and repair of major systems and components on the

Workman MDE.

REFER TO THE OPERATOR’S MANUAL FOR OPERATING, MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. For reference, insert a copy of the

Operator’s Manual and Parts Catalog for your machine

into Chapter 2 of this service manual. Additional copies

of the Operator’s Manual and Parts Catalog are available on the internet at www.Toro.com.

The Toro Company reserves the right to change product

specifications or this publication without notice.

Workman

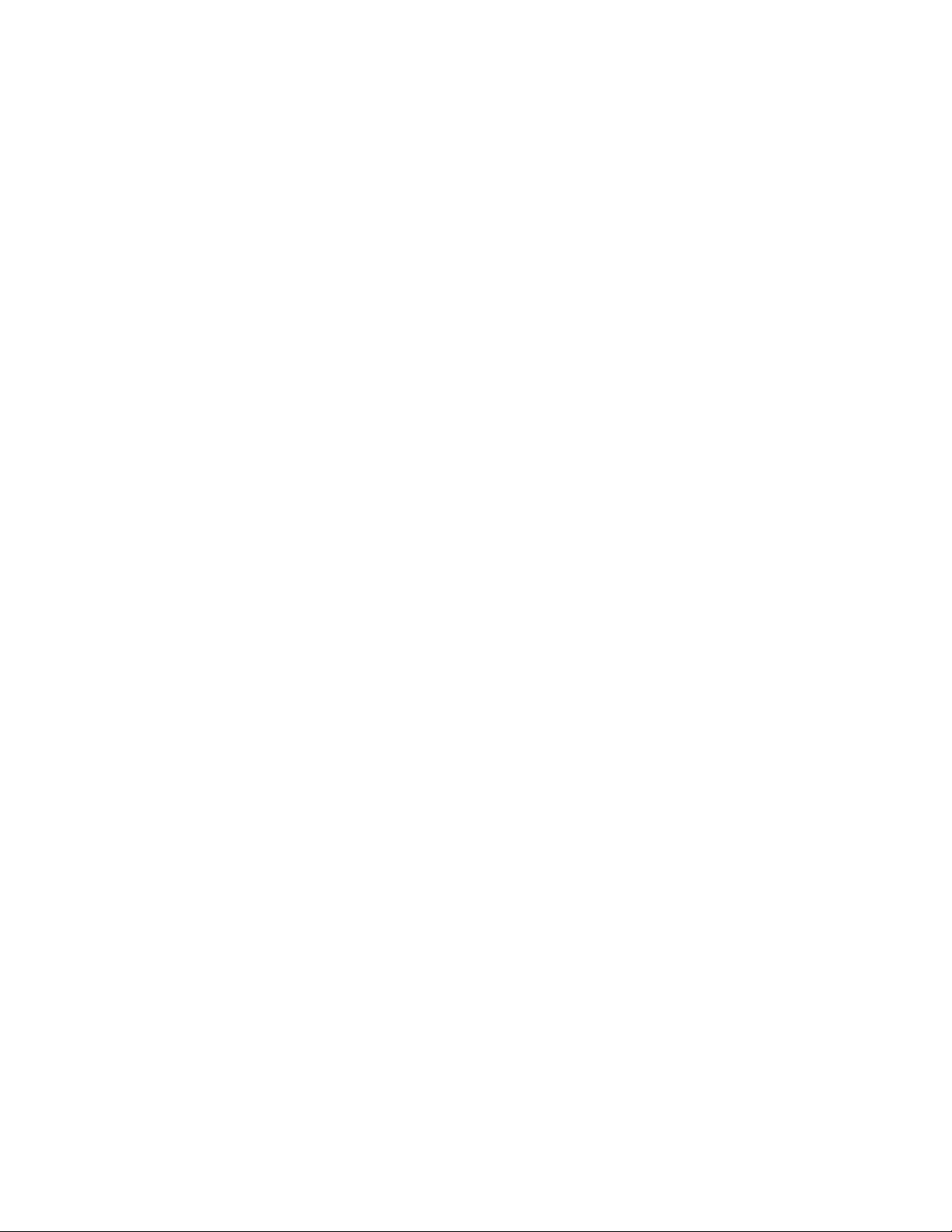

This safety symbol means DANGER, WARNING

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give im portant instructions which must be followed to prevent damage to systems or components on the

machine.

MDE

R

E The Toro Company -- 2008, 2011

This page is intentionally blank.

Workman MDE

Table Of Contents

Chapter 1 -- Safety

Safety Instructions 1 -- 2..........................

Jacking and Other Instructions 1 -- 4...............

Safety and Instruction Decals 1 -- 5................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Electrical System

General Information 3 -- 2........................

Electrical Diagrams 3 -- 3.........................

Vehicle Operation 3 -- 4..........................

Special Tools 3 -- 5..............................

Troubleshooting 3 -- 8............................

Adjustments 3 -- 11..............................

Component Testing 3 -- 14........................

Service and Repairs 3 -- 28.......................

LESTER ELECTRICAL TECHNICIAN

SERVICE GUIDE

Chapter 4 -- Transaxle and Brakes

SafetyProduct Records

and Maintenance

SystemBrakes

ElectricalChassisElectrical

Transaxle and

General Information 4 -- 2........................

Specifications 4 -- 3..............................

Troubleshooting 4 -- 4............................

Service and Repairs 4 -- 6........................

SPICER OFF--HIGHWAY COMPONENTS MODEL

12 (ELECTRIC) MAINTENANCE MANUAL

Chapter 5 -- Chassis

General Information 5 -- 1........................

Specifications 5 -- 2..............................

Troubleshooting 5 -- 3............................

Service and Repairs 5 -- 5........................

Chapter 6 -- Electrical Diagrams

Electrical Schematic 6 -- 3........................

Electrical Circuit Drawings 6 -- 4...................

Electrical Harness Drawings 6 -- 8.................

Diagrams

Workman MDE

Rev. A

This page is intentionally blank.

Workman MDE

Table of Contents

SAFETY INSTRUCTIONS 2......................

Before Operating 2............................

While Operating 2.............................

Maintenance and Service 3....................

JACKING AND OTHER INSTRUCTIONS 4.........

Jacking Vehicle 4.............................

Towing Vehicle 4..............................

Transporting Vehicle 4.........................

SAFETY AND INSTRUCTION DECALS 5..........

Chapter 1

Safety

Safety

Workman MDE Page 1 -- 1 Safety

Safety Instructions

The Workman MDE is designed and tested to offer safe

service when operated and maintained properly. Although hazard control and accident prevention are partially dependent upon the design and configuration of

the machine, these factors are also dependent upon the

awareness, concern and proper training of the personnel involved in the operation, transport, maintenance

and storage of the machine. Improper use or maintenance of the machine can result in injury or death. To reduce the potential for injury or death, comply with the

following safety instructions.

Before Operating

WARNING

To reduce the potential for injury or death,

comply with the following safety instructions.

1. Review and understand the contents of the Operator’s Manual and Operator’s DVD before starting and

operating the vehicle. Become familiar with the controls

and know how to stop the vehicle and engine quickly.

Additional copies of the Operator’s Manual are available

on the internet at www.Toro.com.

While Operating

WARNING

The Workman MDE is an off-- highway vehicle

only. It is not designed, equipped or manufactured for use on public streets, roads or highways.

1. Sit on the operator seat when starting and operating

the vehicle.

2. Before starting the vehicle:

A. Make sure that the battery charger is disconnected from the vehicle charger receptacle.

2. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective, illegible or

damaged, repair or replace it before operating the machine. Also tighten any loose nuts, bolts or screws to ensure machine is in safe operating condition.

3. Before getting off the operator seat:

A. Stop vehicle, turn on/off switch OFF and remove

key from switch.

B. Apply the parking brake.

4. If vehicle is parked on incline, chock or block the

wheels after getting off the vehicle.

B. Engage the parking brake.

C. Make sure accelerator pedal is not depressed.

D. Check position of forward/reverse switch and Hi/

Low speed switch.

Workman MDEPage 1 -- 2Safety

Maintenance and Service

1. Before servicing or making adjustments to the vehicle, stop vehicle, turn on/off switch to OFF, engage

parking brake and remove key from the on/off switch.

2. Make sure machine is in safe operating condition by

keeping all nuts, bolts and screws tight.

3. Do not use open pans of flammable cleaning fluids

for cleaning parts.

4. Keep battery area free of excessive grease, grass,

leaves and dirt.

5. Disconnect batteries before servicing the machine.

Carefully remove one of the battery cables from the battery pack as the first step in any repair. Once a battery

cable has been removed, the electrical system on the

vehicle can be safely worked on. Take care during repairs, however, to not allow tools or vehicle components

to complete the battery circuit that was opened with the

cable removal. Reattach the removed cable to the battery pack as the last step in any repair.

6. When using metal, uninsulated tools around batteries, do not allow tools to contact both positive and negative battery terminals simultaneously.

7. Remove jewelry and watches before servicing electrical components of the vehicle.

8. Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes and clothing. Protect your

face, eyes and clothing when working with batteries.

10.Never use an open flame to check level or leakage

of battery electrolyte.

11. When connecting the battery charger to the vehicle,

connect the charger cord to the vehicle charger receptacle before plugging the charger power cord into an

outlet. After charging the vehicle batteries, unplug the

charger power cord from theoutlet before disconnecting

the charger cord from the vehicle charger receptacle.

12.If major repairs are ever needed or assistance is desired, contact an Authorized Toro Distributor.

13.To assure optimum performance and continued

safety of the machine, use genuine Toro replacement

parts and accessories. Replacement parts and accessories made by other manufacturers may result in nonconformance with safety standards and the warranty

may be voided.

14.When raising the machine to change tires or to perform other service, use correct blocks, hoists and jacks.

Make sure machine is parked on a solid level surface

such as a concrete floor.Prior to raising the machine, remove any attachments that may interfere with the safe

and proper raising of the machine. Always chock or

block wheels. Use jack stands to support the raised machine. If the machine is not properly supported b y jack

stands, the machine may move or fall, which may result

in personalinjury (see Jacking Instructions inthe Operator’s Manual and in this Chapter).

Safety

9. Battery gases can explode. Keep cigarettes, sparks

and flames away from the batteries. Always service,

store and charge thevehicle batteries in a wellventilated

area.

Workman MDE Page 1 -- 3 Safety

Jacking and Other Instructions

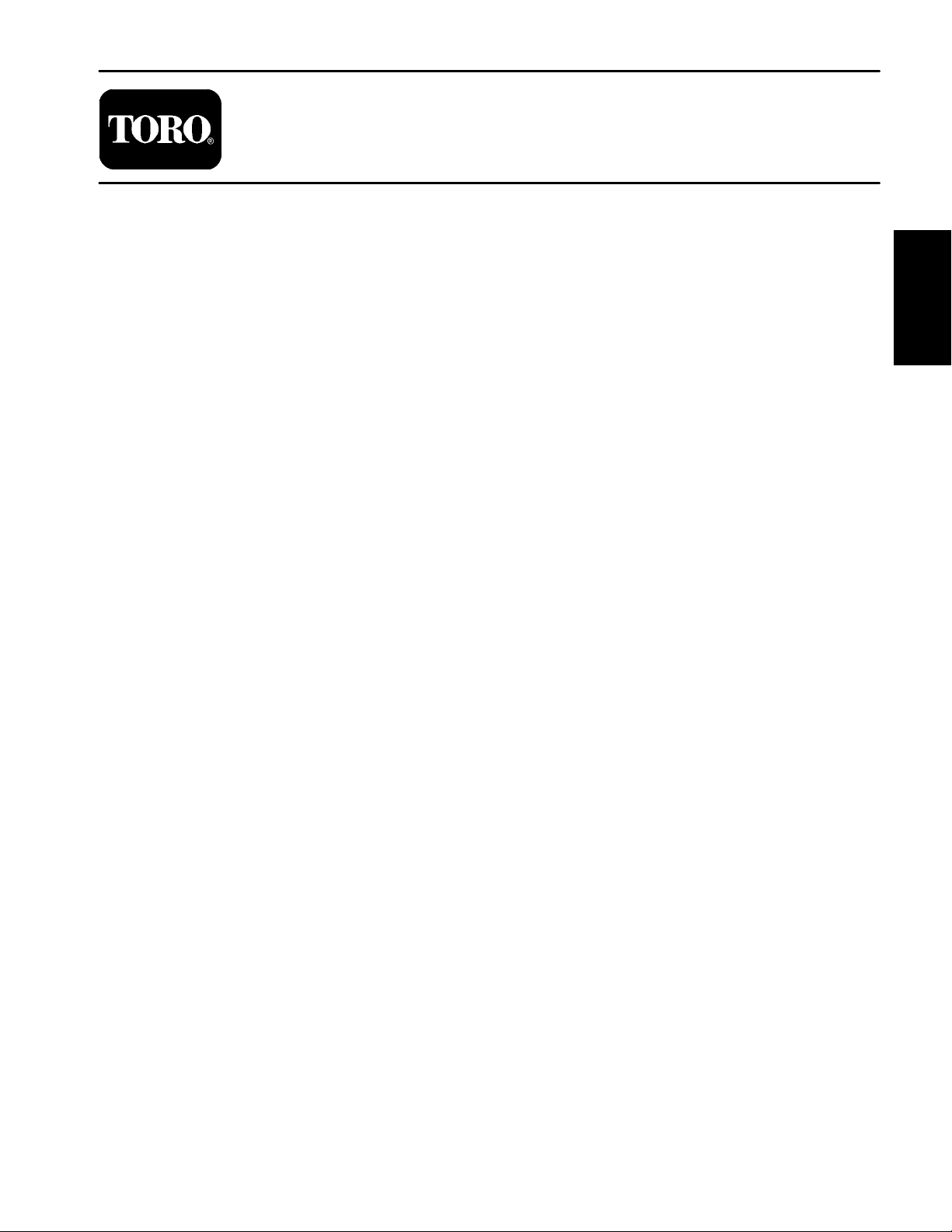

Jacking Vehicle

DANGER

POTENTIAL HAZARD

• A vehicle that is not properly supported

may become unstable.

WHAT CAN HAPPEN

• The vehicle may move or fall. Personal

injury or damage to the machine may result.

HOW TO AVOID THE HAZARD

• Make sure vehicle is parked on a solid level

surface, such as a concrete floor.

• Make sure on/off switch is OFF and key is

removed from the switch before getting off

the vehicle.

• Before raising the vehicle, remove any

attachments that may interfere with the safe

and proper raising of the vehicle.

• Always chock or block wheels to prevent

the vehicle from rolling.

• Make sure proper hoists and jack stands

are used to raise and support the vehicle.

1

Figure 1

1. Front frame 2. Towing tongue

2

Jacking Locations

1. Jack front of the vehicle on the front of the frame behind the towing tongue (Fig. 1).

2. Jack rear of the vehicle under each rear axle tube. Do

not jack vehicle below the transaxle case (Fig. 2).

Towing Vehicle

IMPORTANT: Frequent or long distance towing of

the Workman MDE is not recommended.

In case of emergency, the vehicle can be towed for a

short distance. See Operator ’s Manual for towing information.

Transporting Vehicle

When moving the vehicle long distances, use a trailer or

flatbed truck. Make sure vehicle is secured to the trailer

properly. See Operator’s Manual for transport information.

1

1. Rear axle tube 2. Transaxle case

IMPORTANT: If vehicle is towed, make sure that on/

off switch is in the OFF position and key is removed

from switch.

2

Figure 2

1

Workman MDEPage 1 -- 4Safety

Safety and Instruction Decals

There are several safety and instruction decals attached

to your Workman vehicle. If any decal becomes illegible

or damaged, install a new decal. Part numbers are listed

in the Parts Catalog. Order replacement decals from

your Authorized Toro Distributor.

Safety

Workman MDE Page 1 -- 5 Safety

This page is intentionally blank.

Workman MDEPage 1 -- 6Safety

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1...............................

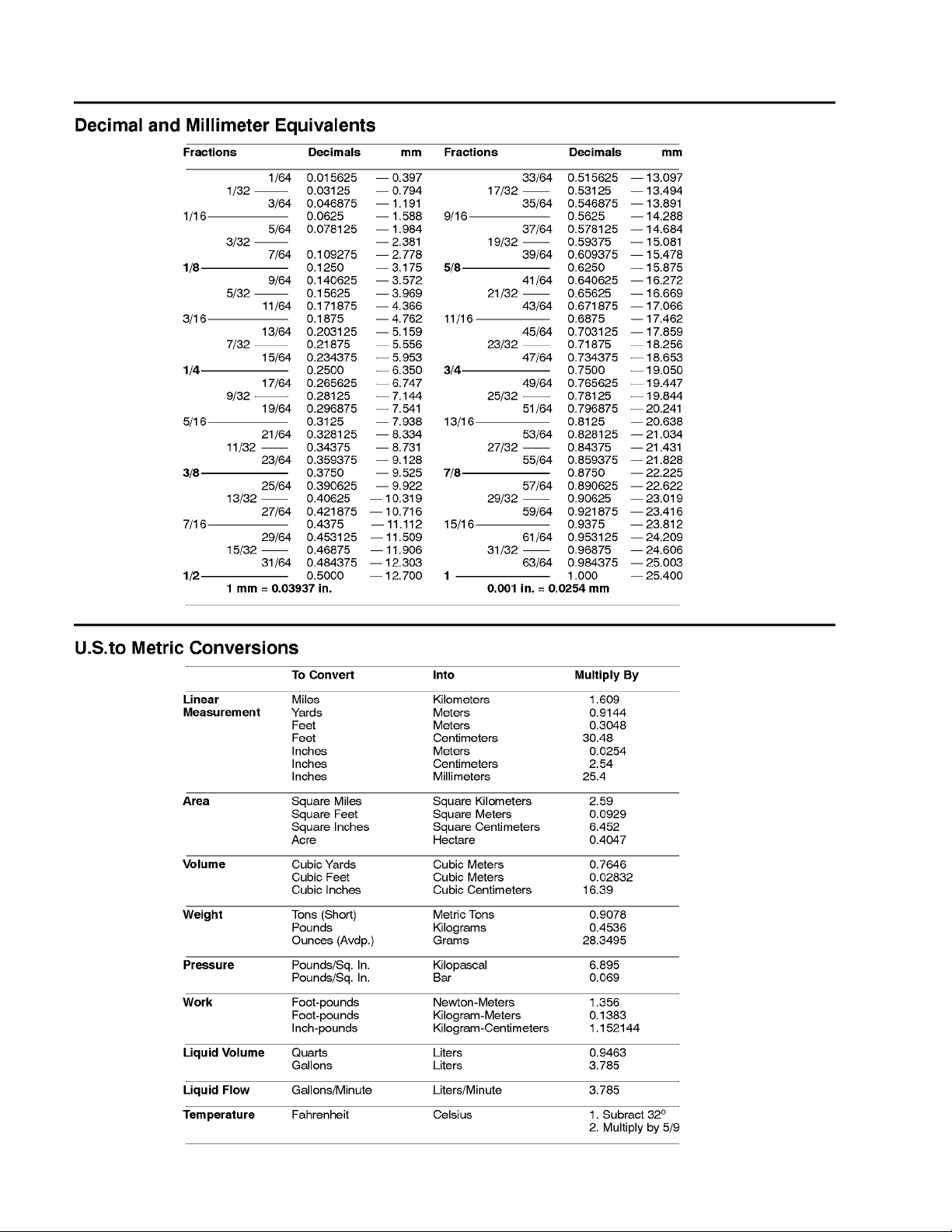

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3....................

Fastener Identification 3.......................

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series) 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Fasteners) 5...........

Other Torque Specifications 6..................

Conversion Factors 6..........................

Product Records

Chapter 2

Product Records

and Maintenance

Insert Operator’s Manual and Parts Catalog for your

Workman vehicle at the end of this chapter. Additionally,

if any optional equipment or accessories have been

installed to your Workman, insert the Installation Instructions, Operator’s Manuals and Parts Catalogs for

those options at the end of this chapter.

Maintenance

Maintenance procedures and recommended service intervals for the Workman MDE are covered in the Operator’s Manual. Refer to that publication when performing

regular vehicle maintenance.

Workman MDE Page 2 -- 1 Product Records and Maintenance

Equivalents and Conversions

0.09375

Workman MDEPage 2 -- 2Product Records and Maintenance

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque that

is unique to the application is clearly identified and specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners s hall apply to all fasteners which

do not have a specific requirement identified in this Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence of a prevailing torque feature

(e.g. Nylock nut), hardness of the surface underneath

the fastener’s head or similar condition which affects the

installation.

Fastener Identification

As noted in the following tables, torque values should be

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measure the torque required to tighten the fastener until

the lines match up.

Product Records

and Maintenance

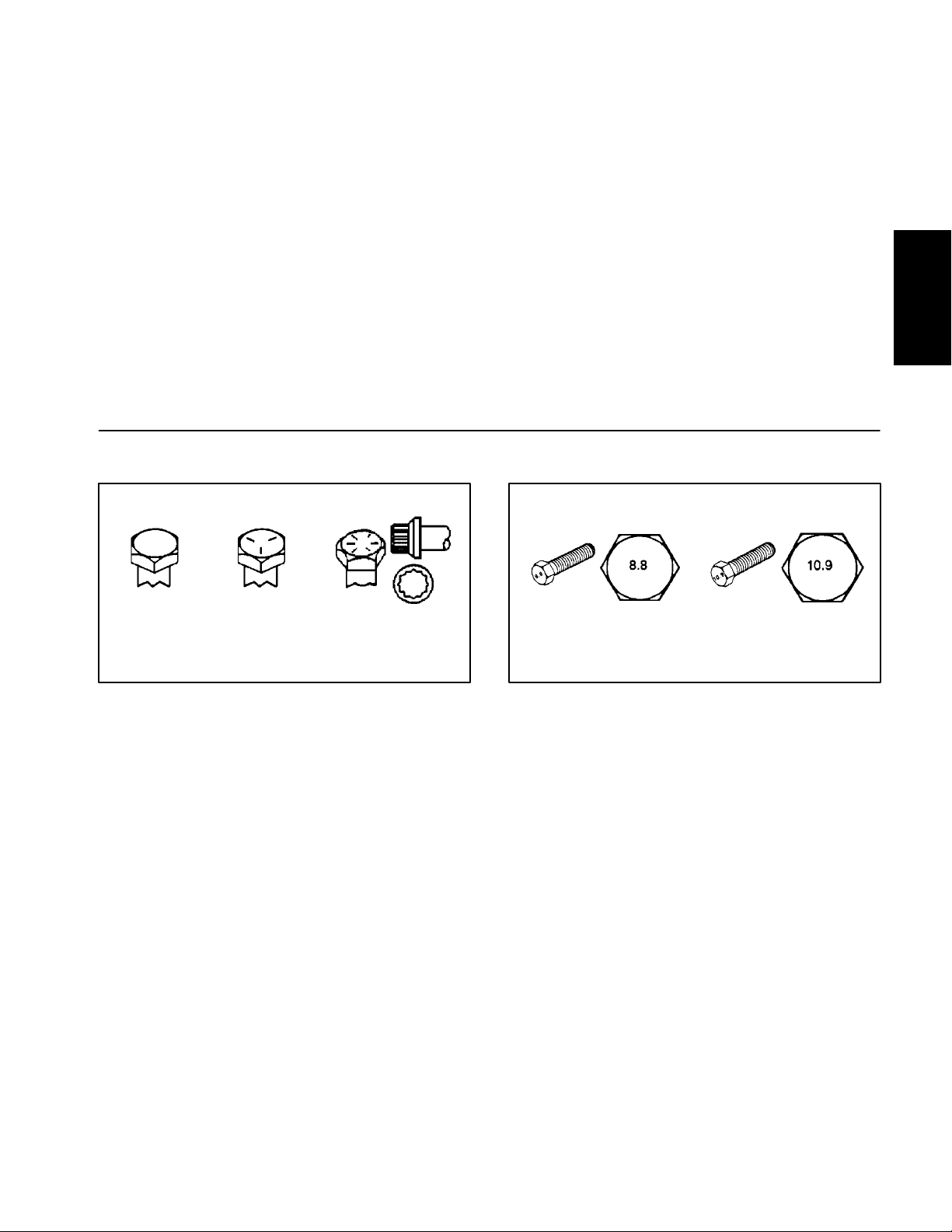

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

Workman MDE Page 2 -- 3 Product Records and Maintenance

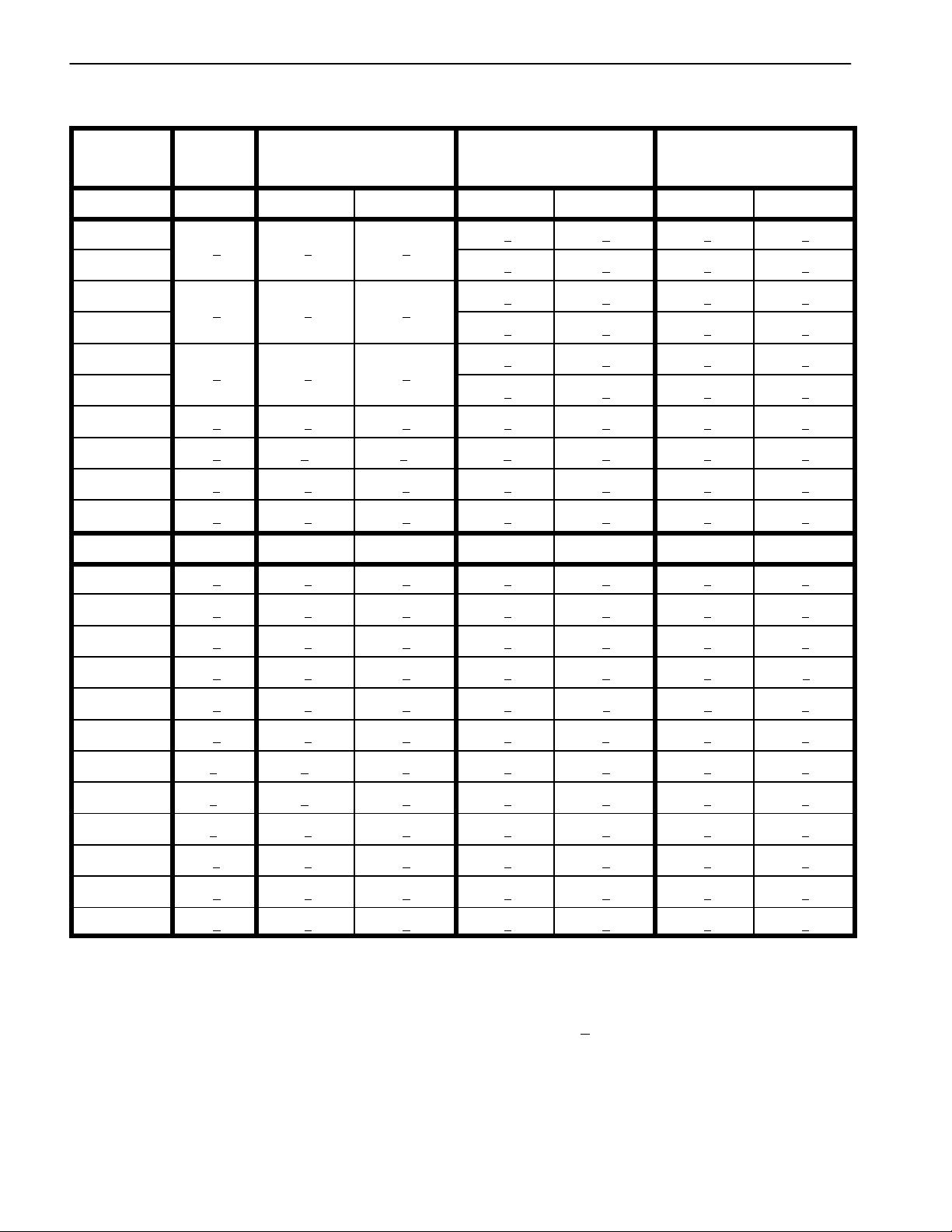

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

# 6 -- 32 UNC

# 6 -- 40 UNF

# 8 -- 32 UNC

# 8 -- 36 UNF

#10--24UNC

#10--32UNF

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130 + 113 140 + 15 1582 + 169

1/4 -- 28 UNF 53 + 7 65 + 10 734 + 11 3 11 5 + 12 1299 + 136 160 + 17 1808 + 192

5/16 -- 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672 + 373

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

Grade 1, 5 &

8withThin

Height Nuts

in--lb in--lb N--cm in-- lb N--cm in-- lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

17 + 2 192 + 23 25 + 3 282 + 34

29 + 3 328 + 34 41 + 5 463 + 56

31 + 4 350 + 45 43 + 5 486 + 56

42 + 5 475 + 56 60 + 6 678 + 68

48 + 5 542 + 56 68 + 7 768 + 79

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 -- 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 21 285 + 28

5/8 -- 18 UNF 75 + 10 95 + 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508 + 52

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 + 43 569 + 58

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimum proof load specified in SAE J429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Rev. A

Workman MDEPage 2 -- 4Product Records and Maintenance

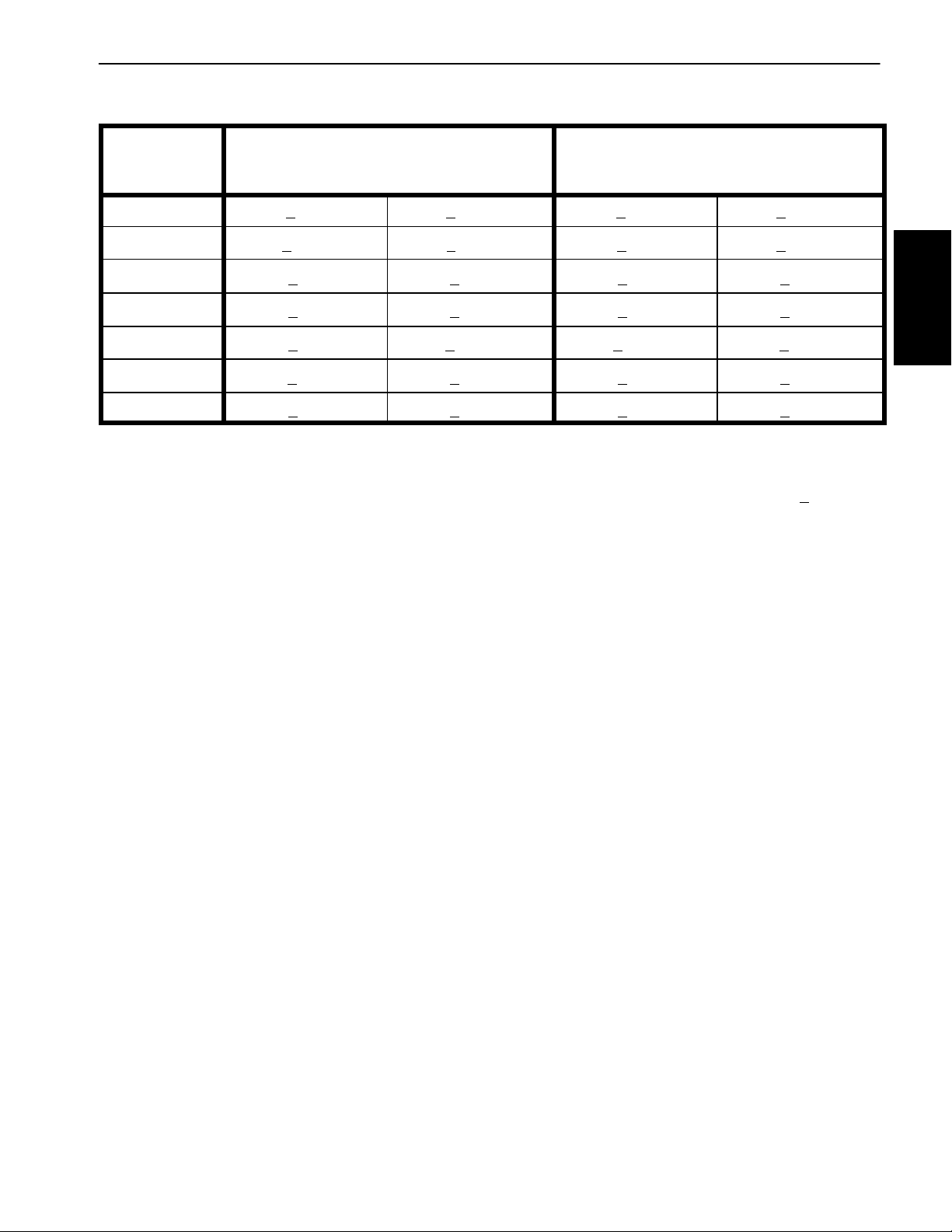

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

Class 8.8 Bolts, Screws and Studs with

Thread Size Regular Height Nuts

(Class 8 or Stronger Nuts)

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

M5 X 0.8 57 + 6in--lb 644 + 68 N--cm 78 + 8in--lb 881 + 90 N--cm

M6 X 1.0 96 + 10 in--lb 1085 + 113 N - -c m 133 + 14 in--lb 1503 + 158 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 28 + 3ft--lb 38 + 4N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 54 + 6ft--lb 73 + 8N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 93 + 10 ft--lb 126 + 14 N--m

M16 X 2.0 166 + 17 ft--lb 225 + 23 N--m 229 + 23 ft--lb 310 + 31 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 46 ft--lb 610 + 62 N--m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately +

nominal torque value.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

10% ofthe

Product Records

and Maintenance

Workman MDE Page 2 -- 5 Product Records and Maintenance

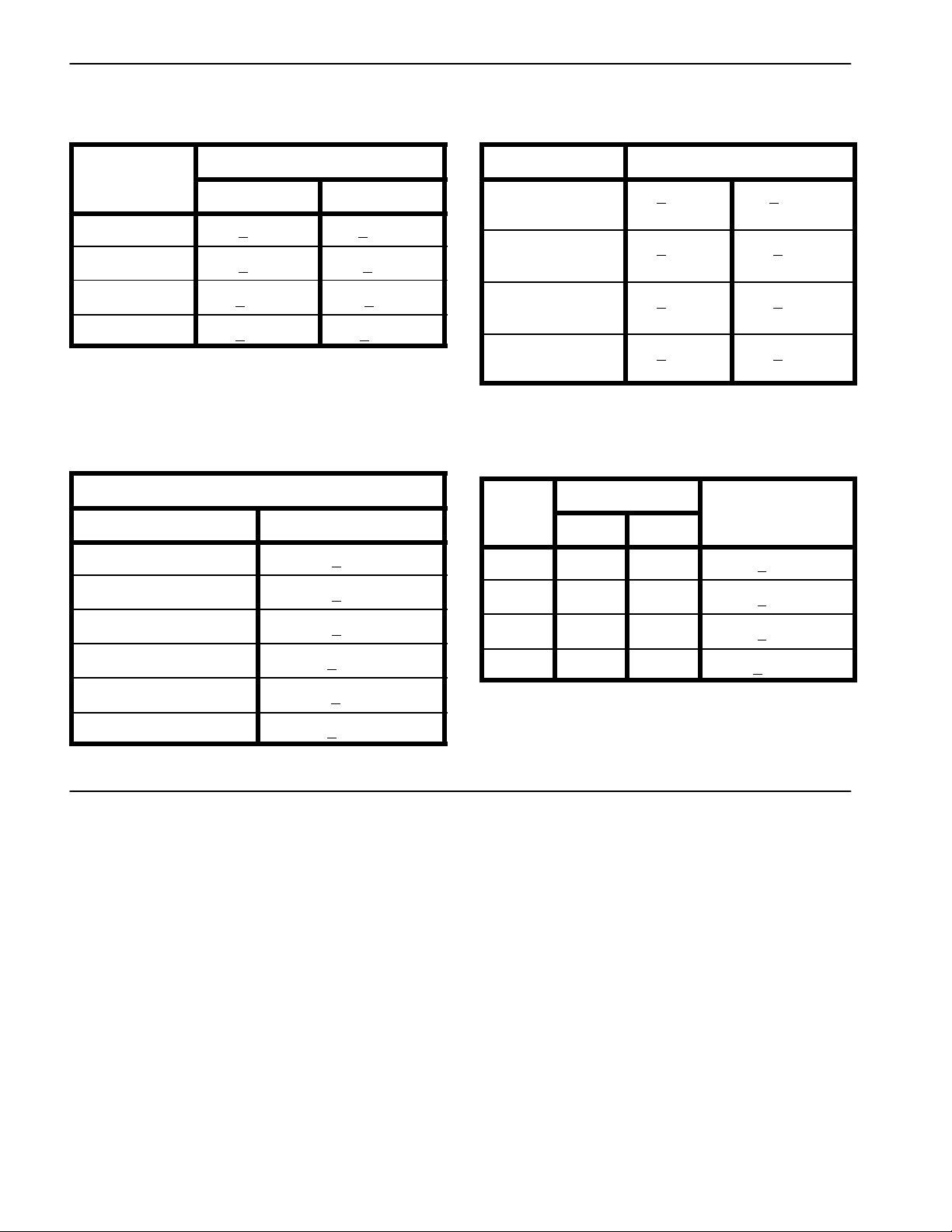

Other Torque Specifications

*

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Typ e B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N --m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

* Holesize, material strength, material thickness and fin-

ish must be considered when determining specific

torque values. All torque values are based on non--lubri-

cated fasteners.

Workman MDEPage 2 -- 6Product Records and Maintenance

Table of Contents

Chapter 3

Electrical System

GENERAL INFORMATION 2.....................

Operator’s Manual 2..........................

Opening Battery Circuit 2......................

ELECTRICAL DIAGRAMS 3......................

VEHICLE OPERATION 4........................

SPECIAL TOOLS 5.............................

TROUBLESHOOTING 8.........................

General Run Problems 8.......................

Battery Charger Operation 9....................

Battery Charger Problems 10...................

ADJUSTMENTS 11.............................

Accelerator Switch Adjustment 11...............

Accelerator Potentiometer Adjustment

(Potentiometer with Short Lever) 12............

Accelerator Potentiometer Adjustment

(Potentiometer with Long Lever) 12.1..........

Accelerator System Calibration 13...............

COMPONENT TESTING 14......................

On/Off Switch 14..............................

Battery Discharge Indicator and Hour

Meter Gauge 15.............................

Vehicle Direction (Forward/Reverse) and

Headlight Switches 16.......................

Vehicle Status Light 17........................

Supervisor Speed Limit Switch 18...............

Audio Alarm (Reverse) 18......................

Charger Interlock Switch 19....................

Main and Accessories Contactors 20............

Fuses 22....................................

Fusible Links 23..............................

Accelerator Switch 24.........................

Accelerator Potentiometer 25...................

Controller 26.................................

SERVICE AND REPAIRS 28.....................

Battery Service 28............................

Battery Specifications 28.....................

Battery Removal 29..........................

Battery Installation 29........................

Battery Charging 30..........................

Battery Inspection and Maintenance 30.........

Battery Testing 31...........................

Battery Storage 32...........................

Traction Motor Brushes 33.....................

Traction Motor 34.............................

Traction Motor Service 38......................

Battery Charger 42............................

LESTER ELECTRICAL TECHNICIAN

SERVICE GUIDE

System

Electrical

Workman MDE

Page 3 -- 1

Rev. A

Electrical System

General Information

The Workman MDE uses a 48 volt DC electrical system

that is an isolated circuit. The vehicle frame is not used

for any ground connections.

The vehicle controller monitors operator and vehicle inputs to determine voltage to the traction motor. If a problem exists that will prevent normal vehicle operation, an

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Workman vehicle. Refer to the Operator’s Manual for additional information when servicing

the machine.

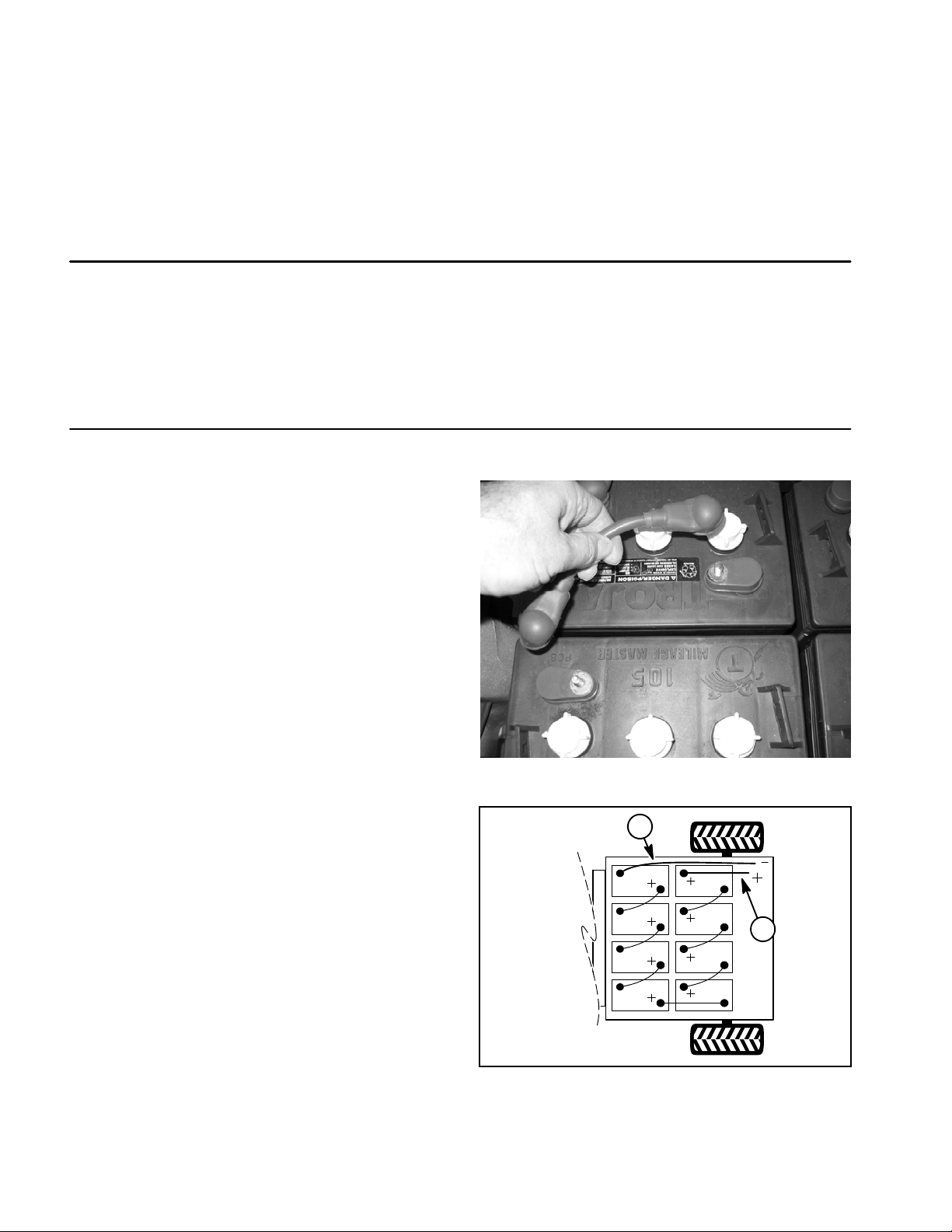

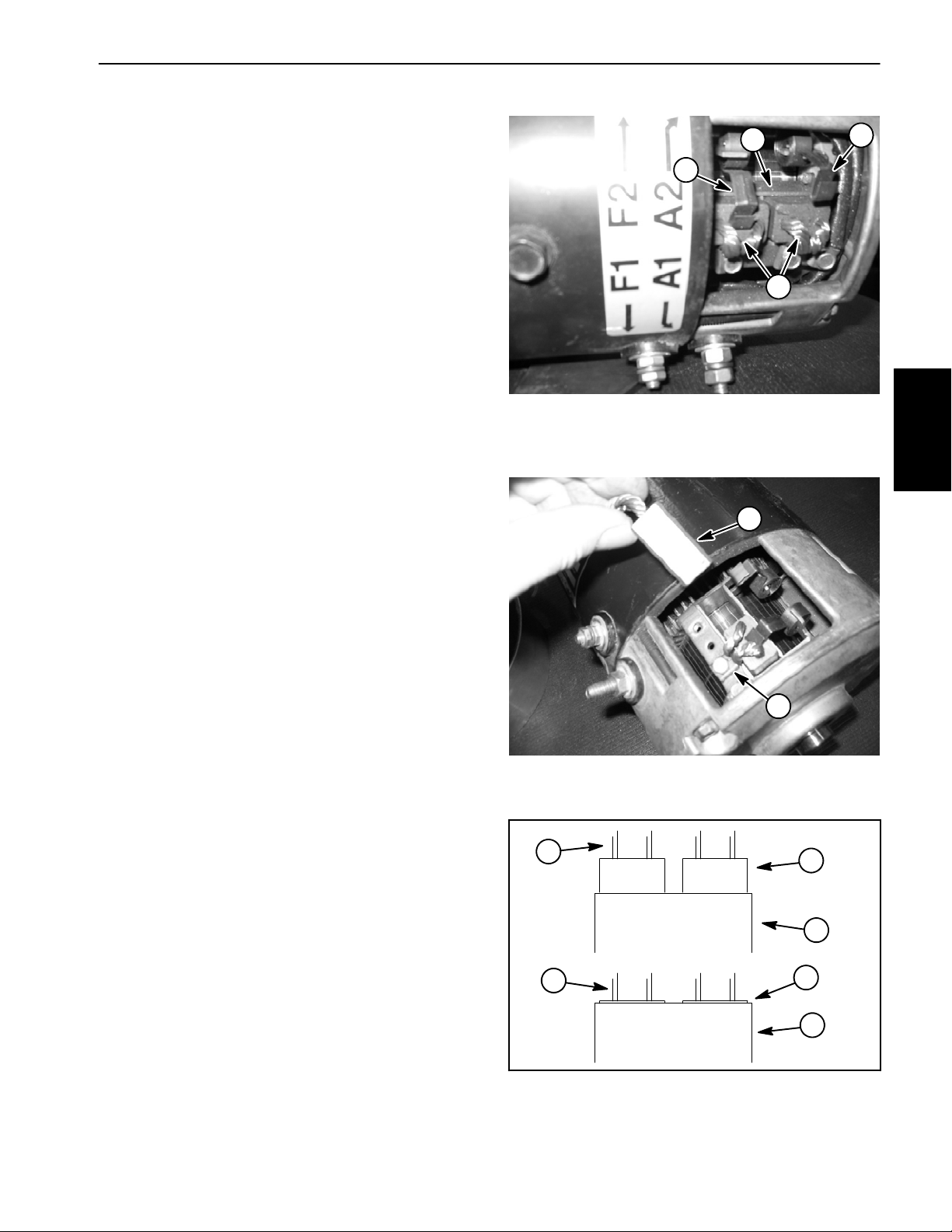

Opening Battery Circuit

To prevent allowing a current path through tools used

during vehicle electrical circuit repairs, remove one of

the battery cables from the battery pack as the first step

in any repair (Fig. 1). Once a cable has been removed,

the electrical system on the vehicle can be safely

worked on. Take care during repairs, however, to not allow tools or vehicle components to complete the battery

circuit that was opened with the cable r emoval.

LED on the controller and the vehicle status light on the

dash panel will flash a fault code to assist in identifying

the problem.

After performing any repair on electrical components on

the vehicle, make sure that wiring is routed and secured

so as to prevent abrasion or contact with moving parts.

Reattach the removed cable to the battery pack as the

last step in any repair. Secure cable on each battery terminal with lock washer and nut. Torque nuts from 115 to

125 in--lb (13.0 to 14.1 N--m).

Battery pack cable routing is shown in Figure 2.

Figure 1

1

A

Figure 2

1. Negative cable to vehicle 2. Positive cable to vehicle

2

4

Electrical System

Page 3 -- 2

Workman MDE

Electrical Diagrams

The electrical schematic, circuit drawings and wire harness drawings for the Workman MDE are located in

Chapter 6 -- Electrical Diagrams.

System

Electrical

Workman MDE

Page 3 -- 3

Electrical System

Vehicle Operation

The Workman MDE electrical system uses a 48 volt battery pack, an electric traction motor, a vehicle controller

and numerous other electrical components to allow vehicle operation.

Eight, 6 volt, deep cycle batteries that are connected in

series provide current for a 48 volt DC, high torque traction motor, the vehicle controller and vehicle accessories (headlights, horn, various optional accessories).

The batteries are discharged as the vehicle is used so

charging the batteries after using the vehicle is necessary. A battery discharge indicator gauge on the dash

provides the operator with information on battery charge

level. Demands on the vehicle during use (speed, payload, incline use), battery condition (age, charge level),

ambient temperature and vehicle condition will all put

constraints onhow long a vehicle can be used beforethe

batteries are discharged.

An automatic, 115 VAC (230 VAC on international models) batterycharger is included with the vehicle. An interlock switch on the vehicle charger receptacle prevents

the vehicle from operating when the charger cord is

plugged into the vehicle.

The electric traction motor directly drives a double reduction transaxle with differential. Operator inputs for

forward/reverse, supervisor switch position (high or low

speed) and accelerator pedal position are used by the

controller to determine voltage to the traction motor.

The vehicle controller is a sealed electronic logic device

that uses inputs from several vehicle components to

control motor speed and direction. These inputs include

several switches (on/off, forward/reverse, accelerator,

supervisor, charger), a motor temperature sensor, an

accelerator pedal potentiometer and the vehicle contactor (solenoid). The controller also provides regenerative

braking to assist in slowing the vehicle. The controller

has fault detection capabilities to help identify system

problems. Battery current is available to the controller

whenever the on/off switch is ON which energizes the

main contactor. A high current fuse protects this high

current circuit.

The Workman controller also provides a roll off warning

in instances when the vehicle begins to move (roll away)

after being stopped. On an incline and with the on/off

switch in the ON position, if the vehicle starts moving,

the alarm will sound warning the operator that the vehicle is moving. When the vehicle goes into this roll--off

mode, regenerative braking will limit vehicle speed.

Vehicle accessories include headlights, horn and optional electrical equipment. The accessories contactor

(solenoid) on the vehicle provides battery current to

these components when the on/off switch is ON. Fuses

provide circuit protection for these accessories.

The traction motor is cooled with an external fan. Additionally, the motor is protected from overheating by a

thermal switch in the motor housing. If unsafe motor

temperature is sensed by the switch, the controller is

signaled to limit vehicle speed and torqueuntil the motor

temperature reduces to a normal level.

Electrical System

Page 3 -- 4

Workman MDE

Special Tools

Order special tools from your Toro Distributor. Some

tools may also be available from a local supplier.

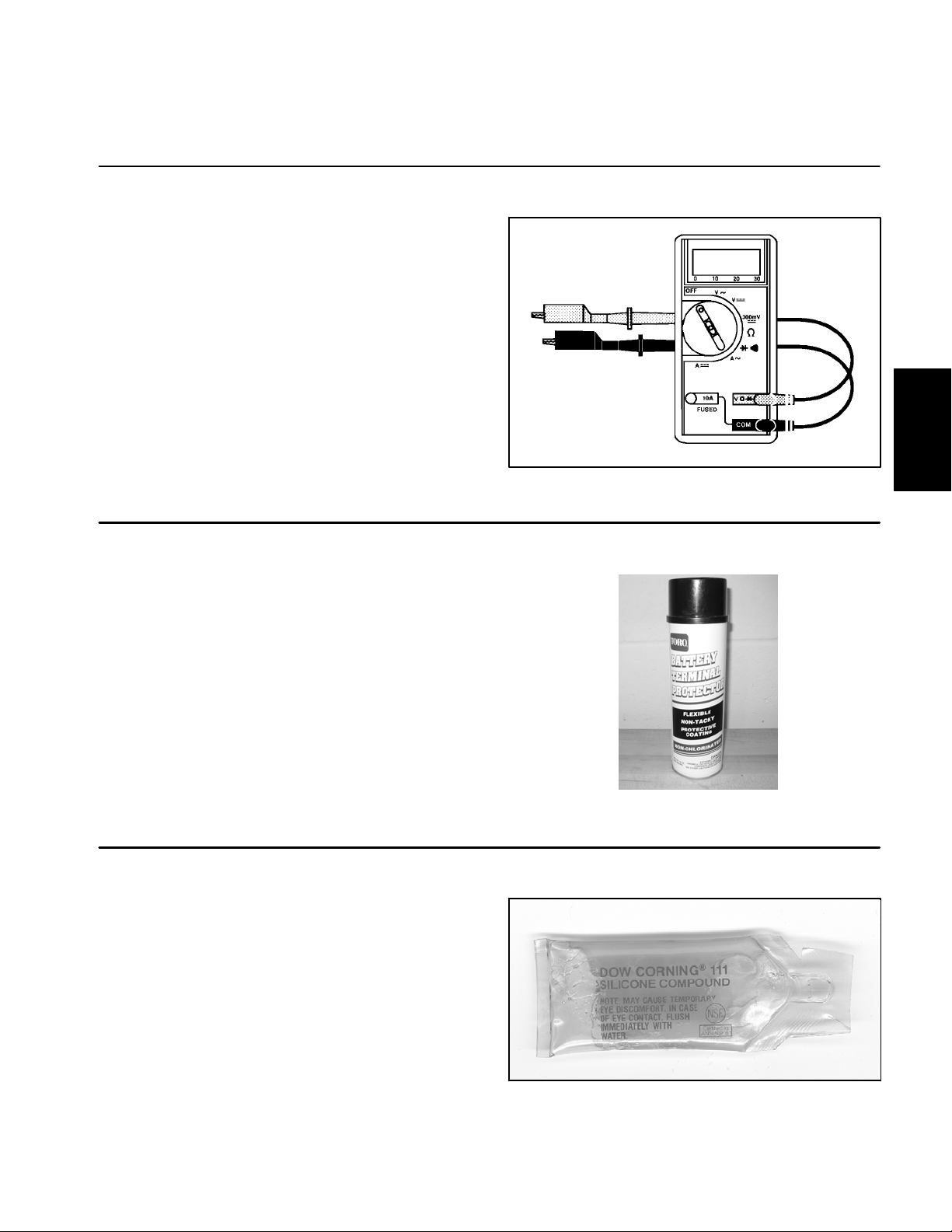

Multimeter

The multimeter can test electrical components and circuits for current, resistance or voltage.

NOTE: Toro recommends the use of a DIGITAL Volt-Ohm--Amp multimeter when testing e lectrical circuits.

The highimpedance (internal resistance) of a digital meter in the voltage mode will make sure that excess current is not allowed through the meter. This excess

current can cause damage to circuits not designed to

carry it.

NOTE: Workman MDE vehicles use a 48 volt, DC electrical system. If multimeter is not of the auto--range type,

make sure to properly set multimeter range before performing any voltage test.

Figure 3

System

Electrical

Battery Terminal Protector

Battery Terminal Protector is an aerosol spray that

should be used on all battery and controller terminals to

reduce corrosion problems. Apply terminal protector after cable has been secured to terminal.

Toro Part Number: 107--0392

Dielectric Gel

Dielectric gel should be used to prevent corrosion of

connection terminals.To ensurecomplete coating of terminals, liberally apply gel to both component and wire

harness connector, plug connector to component, unplug connector, reapply gel to both surfaces and reconnect harness connector to c omponent. Connectors

should be thoroughly packed with gel for effective results.

Figure 4

Toro Part Number: 107--0342

Workman MDE

Page 3 -- 5

Figure 5

Electrical System

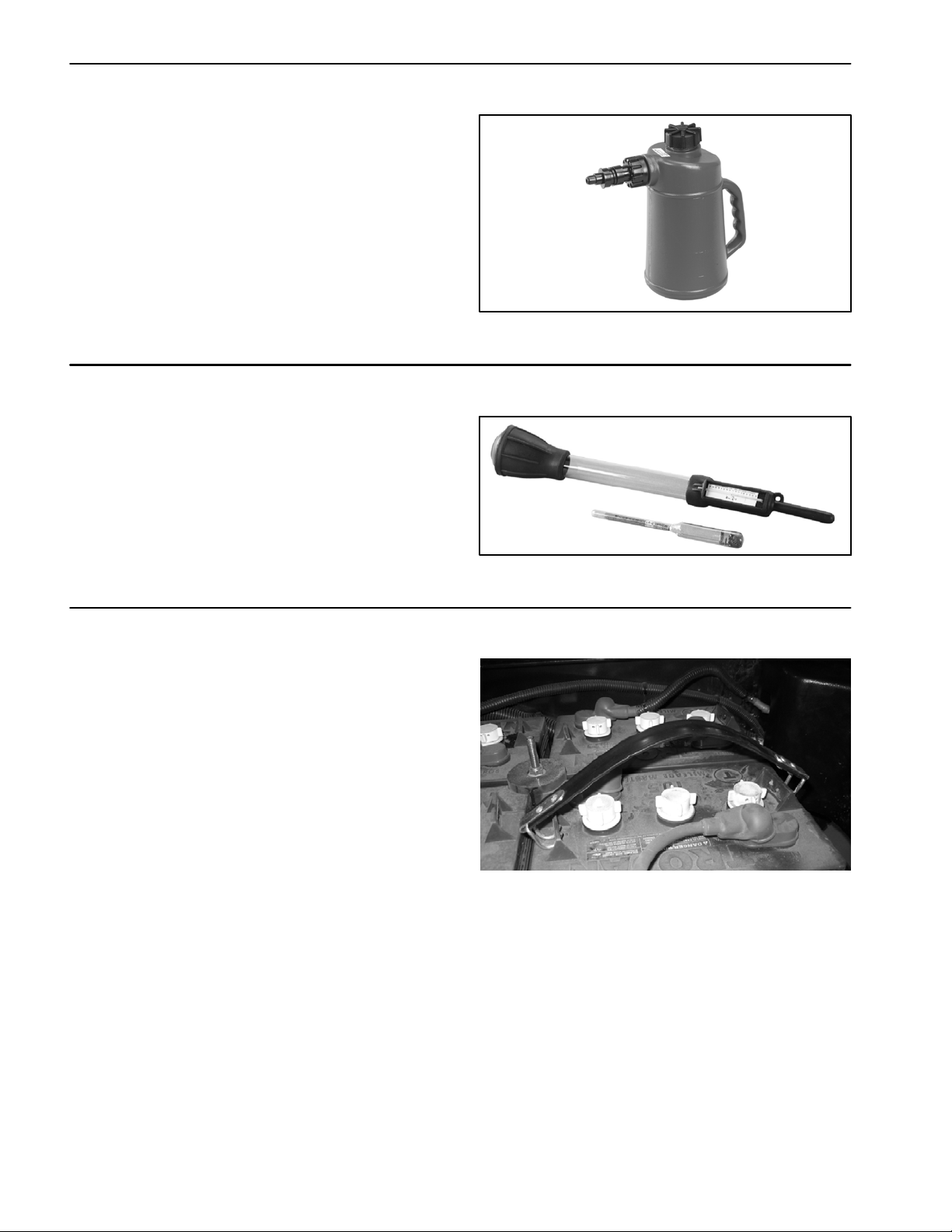

Battery Watering Dispenser

Use the battery watering dispenser when adding distilled water to vehicle batteries.

Toro Part Number: TOR4102

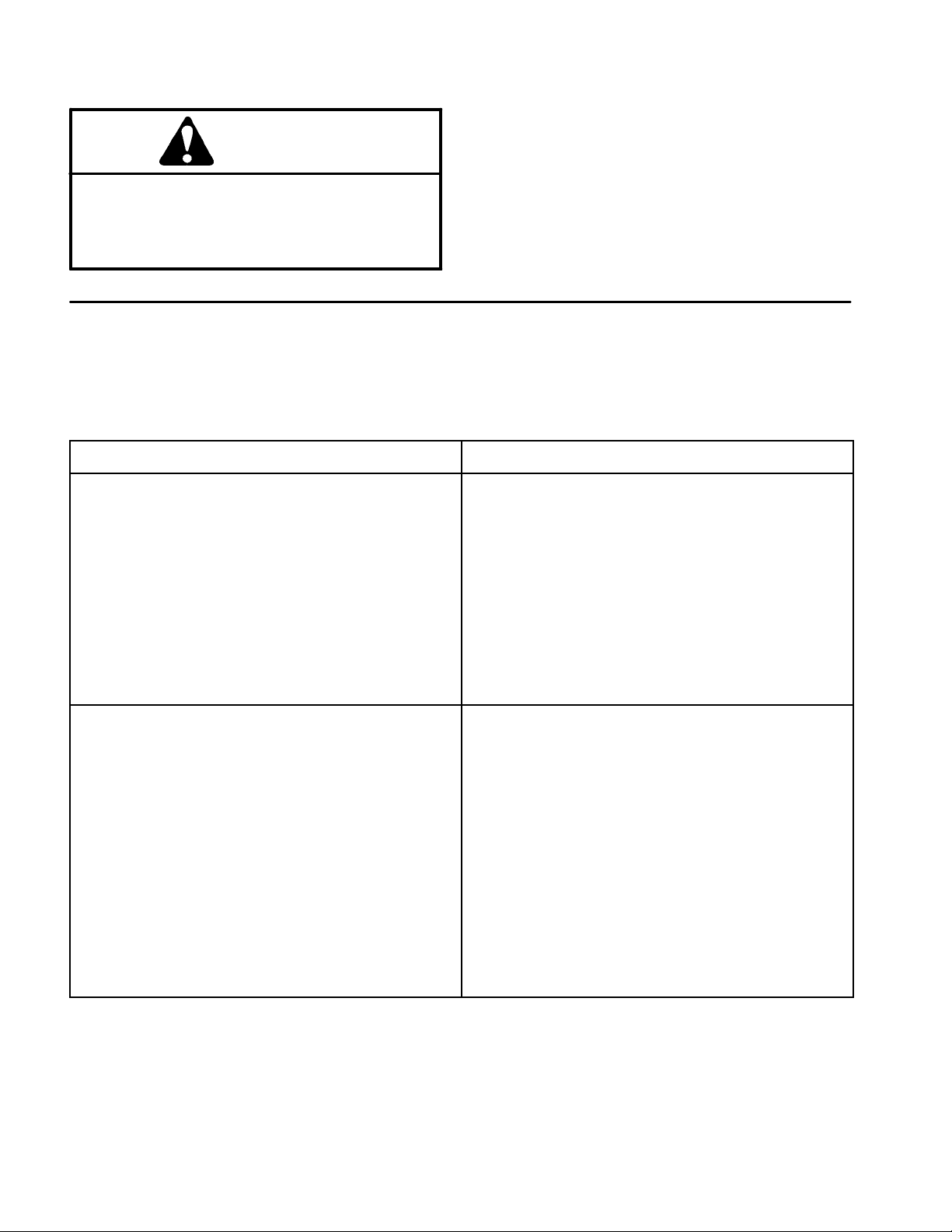

Battery Hydrometer

Use the battery hydrometer when measuring s pecific

gravity of battery electrolyte. Obtain hydrometer locally.

Figure 6

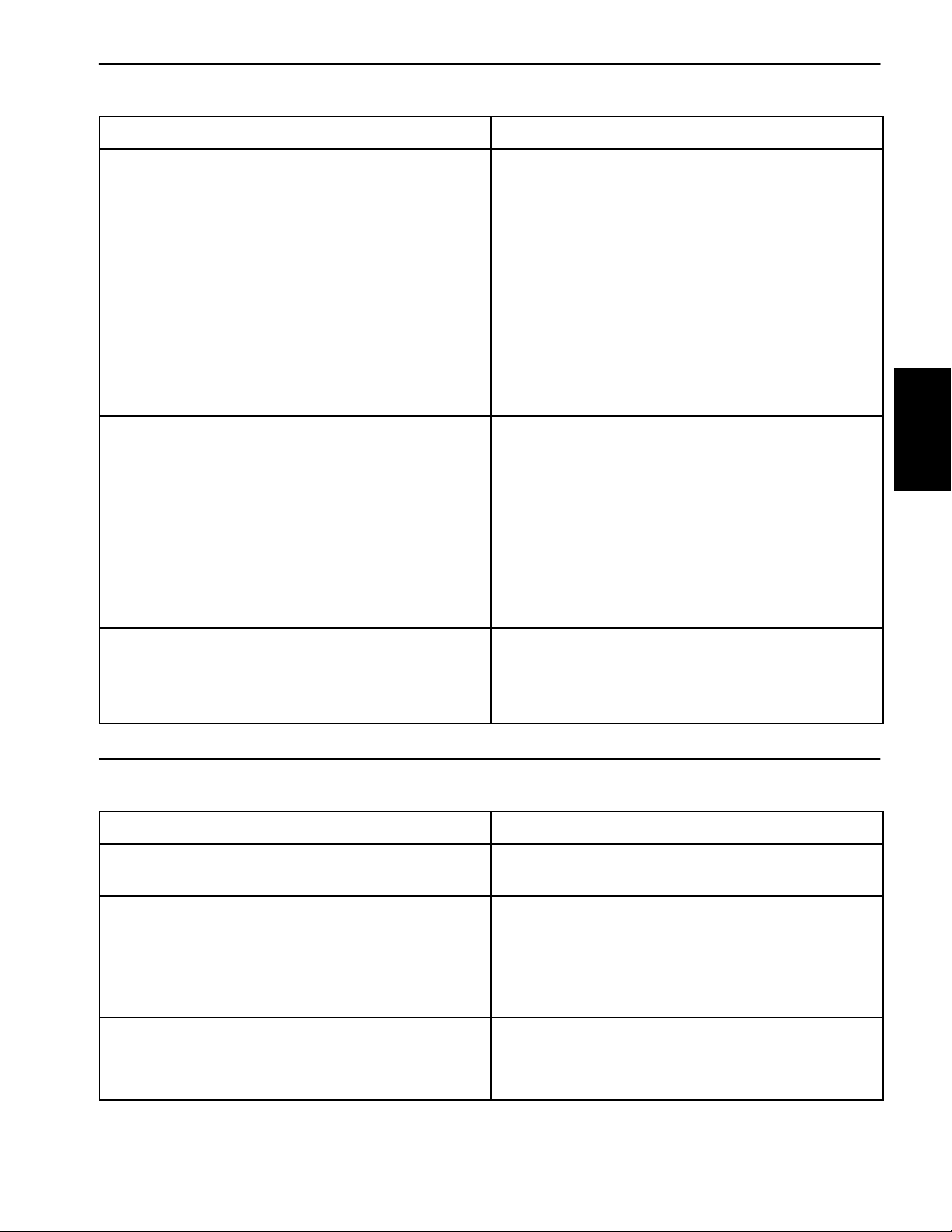

Battery Lift Strap

Use the battery lift strap to remove and install batteries

from the vehicle. Lift strap allows use of case loops on

battery tops as safe battery lifting points. Obtain battery

lift strap locally.

Figure 7

Figure 8

Electrical System

Page 3 -- 6

Workman MDE

36/48 Volt Battery Discharge Unit

The 36/48 Volt Battery Discharge Unit is recommended

for quick and accurate load testing for the batteries on

the Workman MDE. This tool is used to determine the

capacity of the Workman battery pack and also for finding a faulty battery (or batteries) in the battery pack.

Toro Part Number: TOR4106

Figure 9

System

Electrical

Workman MDE

Page 3 -- 7

Electrical System

Troubleshooting

CAUTION

Remove all jewelry, especially rings and

watches, before doing any electrical troubleshooting or testing. Disconnect a battery cable

from the battery pack to open the battery circuit

unless a test procedure requires battery voltage.

General Run Problems

NOTE: Check vehicle status light on dash panel and

controller LED for possible faults whenever diagnosing

vehicle problems (see Controller in the Component

Testing section of this chapter).

For effective troubleshooting and repairs, there must be

a good understanding of the electrical c ircuits and components used on this vehicle (see Electrical Schematic

in Chapter 6).

If the vehicle has any switches by--passed, they must be

reconnected for proper vehicle operation, troubleshooting and safety.

Problem

Main contactor clicks, but vehicle will not operate. Battery charge is low.

Nothing happens when on/off switch is turned to ON. Battery charge is extremely low.

Possible Causes

Battery cables are loose, corroded or damaged.

Cable connection(s) at controller is/are loose or

corroded.

Cable connection(s) at traction motor is/are loose or

corroded.

Traction motor is faulty.

Controller is faulty.

Battery cables are loose, corroded or damaged.

Cable connection(s) at controller is/are loose or

corroded.

10 ampere fuse (F2) to the on/off switch is loose or

blown.

Fusible link FL2 is faulty.

Electrical System

Main fuse (F1) is loose or blown.

The on/off switch or circuit wiring is faulty.

Controller is faulty.

Page 3 -- 8

Workman MDE

General Run Problems (Continued)

Problem Possible Causes

Traction motor stops during operation. Wiring to the traction motor components (e.g. main

contactor, controller, traction motor) loose, corroded or

damaged (see Electrical Schematic in Chapter 6 -Electrical Diagrams).

Battery cables are loose, corroded or damaged.

Controller is overheated.

Traction motor is overheated.

Traction motor is faulty.

Brake or transaxle problem (see Chapter 4 -- Transaxle

and Brakes).

Vehicle runs slowly. Supervisor speed limit switch in slow position.

Tire pressure is low (see Chapter 5 -- Chassis).

Brakes improperly adjusted (see Chapter 4 -Transaxle and Brakes).

System

Electrical

Battery charge is extremely low.

Controller is overheated.

Traction motor is overheated.

Vehicle movement is erratic or jerky. Collar on throttle is loose.

Accelerator potentiometer is improperly adjusted.

Accelerator system is out of adjustment.

Battery Charger Operation

Light Status Indicates

Green light on battery charger illuminated (not

flashing).

Green light on battery charger flashing. Slow flash (once per second): Batteries being charged

Batteries is fully charged. Vehicle ready to operate.

(batteries less than 80% charged). Continue charging.

Rapid flash (four times per second): Batteries being

charged (batteries more than 80% charged). Continue

charging.

Red light on battery charger flashing. Rapid flash: Charger timer shutoff has occurred after

20 hours of charging.

Slow flash: No current to charger. Check AC outlet.

Workman MDE

Page 3 -- 9

Electrical System

Battery Charger Problems

Problem Possible Causes

Battery charger does not turn on. AC outlet fuse/circuit breaker blown.

AC outlet is faulty.

Vehicle wiring is loose or damaged (see electrical

schematic in Chapter 6 -- Electrical Diagrams).

Fusible link FL1 is faulty.

Vehicle charger interlock switch or circuit wiring faulty.

Vehicle charger receptacle or circuit wiring damaged.

Battery charger is faulty.

Battery charger does not turn off. Battery charger is faulty.

NOTE: Charging new batteries or charging batteries in

cold temperatures may require extended charge time

to achieve full charge.

Battery charger fuse blows. Vehicle battery polarity is reversed (vehicle battery

cables incorrectly attached).

The AC outlet circuit breaker or fuse blows when using

the battery charger.

Vehicle charger receptacle polarity is reversed.

Battery charger is faulty.

Overloaded AC circuit.

Battery charger is faulty.

Electrical System

Page 3 -- 10

Workman MDE

Adjustments

Accelerator Switch Adjustment

1. Position vehicle on a level surface, turn on/off switch

OFF and remove key.

2. With the accelerator pedal released, check that the

distance between the head of the accelerator switch

stop cap screw and the body of the switch is 5/8 inch

(15.9 mm) (Fig. 12).

3. If distance is incorrect, loosen lock nut and adjust accelerator switch stop cap screw position (Fig. 11).

4. After adjustment, make sure that switch plunger is

not bottomed out when accelerator pedal is released.

5. Calibrate accelerator system after adjusting accelerator switch (see Accelerator System Calibration in this

section).

2

3

4

1. Accelerator pedal

2. Accelerator switch

3. Plate

Figure 10

2

1

6

5

4. Screw (2 used)

5. Switch stop cap screw

6. Lock nut

3

System

Electrical

1

Figure 11

1. Accelerator switch

2. Switch stop cap screw

3. Accelerator stop cap screw

5/8 inch

(15.9 mm)

1

2

Workman MDE

Page 3 -- 11

Figure 12

1. Switch stop cap screw 2. Accelerator switch

Electrical System

Accelerator Potentiometer Adjustment (Potentiometer with Short Lever)

NOTE: The following adjustment procedure should be

used onvehicles that have a potentiometer that includes

a short lever (Figure 14). If potentiometer has a long lever, use the procedure on the following page.

The accelerator potentiometer is used as one of the inputs for the vehicle controller and is attached to the pedal frame under the dash (Fig. 13). A collar with roll pin on

the accelerator pedal shaft positions the accelerator potentiometer lever. Potentiometers with a short lever use

a roll pin that extends approximately 1 1/2 inches (38

mm) out of the collar.

If the accelerator potentiometer is out of adjustment, the

diagnostic light on the dash will flash six (6) times. Additionally, if vehicle movement is erratic and jerky, potentiometer adjustment and calibration of the accelerator

system should be performed.

Adjustment

1. Position vehicle on a level surface, turn on/off switch

OFF and remove key.Make sure that acceleratorpotentiometer is securely attached to the pedal frame of the

machine.

5. Calibrate accelerator system after any accelerator

potentiometer adjustment(see Accelerator SystemCalibration in this section).

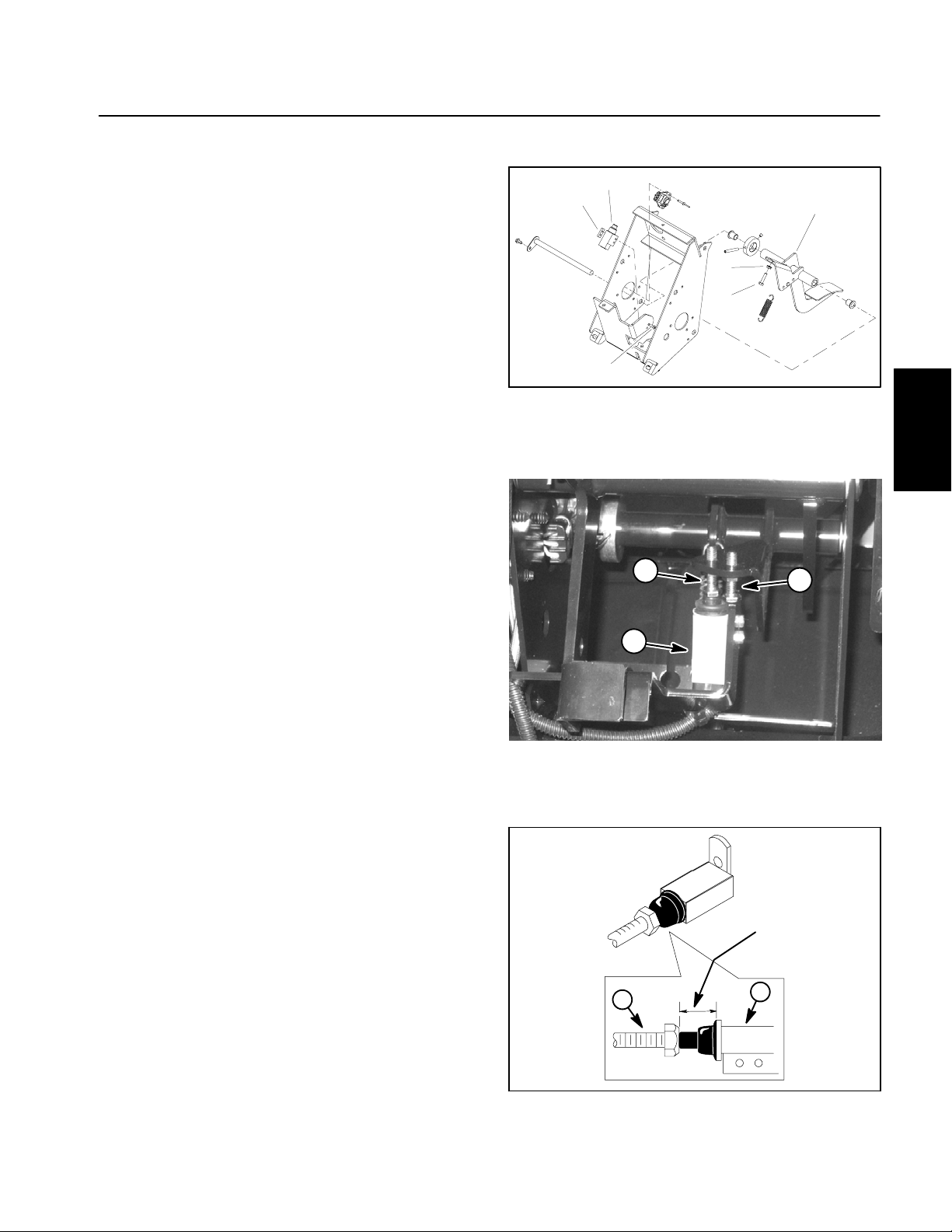

4

1

5

3

2

Figure 13

1. Potentiometer

2. Accelerator pedal

3. Throttle position collar

4. Roll pin

5. Set screw (2 used)

2. Check accelerator switch adjustment and adjust if

necessary (see Accelerator Switch Adjustment in this

section).

3. Check movement of the potentiometer lever:

A. With the accelerator pedal released, the roll pin

on the throttle position collar should keep the potentiometer lever from 0.050” to 0.100” (1.3 to 2.5 mm)

from the lower stop on the potentiometer body (Figure 14).

B. With the accelerator pedal fully depressed, theinput lever of the potentiometer should not contact the

upper stop on the potentiometer body (Figure 15).

4. If potentiometer lever movement is incorrect, adjust

location of collar on accelerator pedal shaft:

A. Loosen two (2) set screws that secure throttle

position collar to throttle pedal shaft and reposition

collar to allow correct potentiometer movement.

Make sure that there is clearance between roll pin

and side of potentiometer lever to prevent binding.

B. Remove set screws one at a time from collar and

apply Loctite #242 (or equivalent) to set screw

threads. Install and tighten set screws to secure collar to accelerator pedal shaft.

C. Recheck potentiometer lever movement.

1

3

2

Figure 14

1. Potentiometer lever (accelerator pedal released)

2. Potentiometer lower stop

3. Gap of 0.050” to 0.100” (1.3 to 2.5 mm)

1

3

2

Figure 15

1. Potentiometer lever (accelerator pedal fully depressed)

2. Potentiometer upper stop

3. No lever contact with stop

Electrical System

Page 3 -- 12

Rev. A

Workman MDE

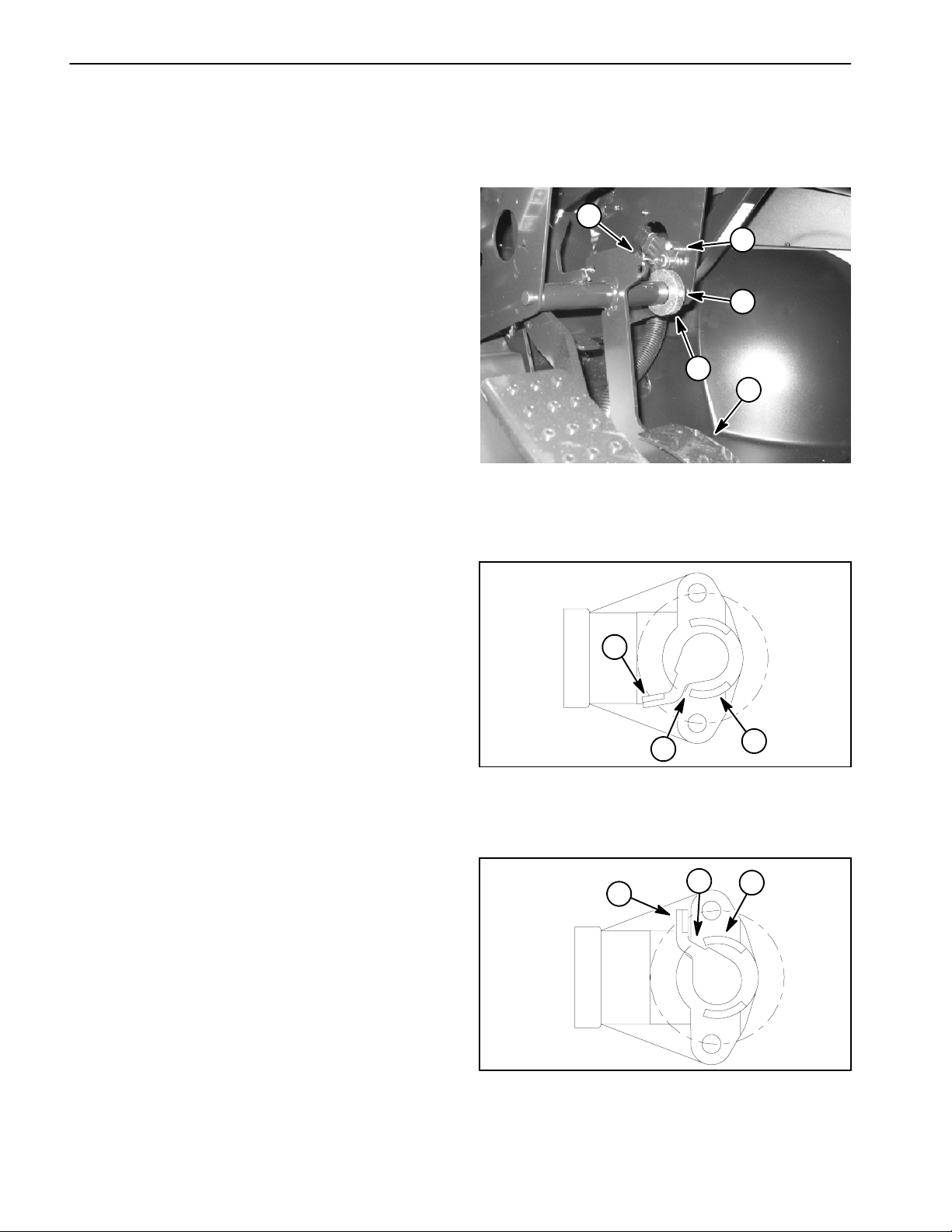

Accelerator Potentiometer Adjustment (Potentiometer with Long Lever)

NOTE: The following adjustment procedure should be

used on vehicles that have a potentiometer with a long

lever (Figure 15.1). If potentiometer has a short lever,

use the procedure on the preceding page.

1

The accelerator potentiometer is used as one of the inputs for the vehicle controller and is attached to the pedal frame under the dash (Fig. 15.2). A collar with roll p in

attached to the accelerator pedal shaft positions the accelerator potentiometer lever. Potentiometers with a

long lever use a roll pin that extends approximately 3

inches (76 mm) out of the collar.

If the accelerator potentiometer is out of adjustment, the

diagnostic light on the dash will flash six (6) times. Additionally, if vehicle movement is erratic and jerky, potentiometer adjustment and calibration of the accelerator

system should be performed.

Adjustment

1. Position vehicle on a level surface, turn on/off switch

OFF and remove key. Make sure that accelerator potentiometer assembly is securely attached to the pedal

frame of the machine.

2. Check accelerator switch adjustment and adjust if

necessary (see Accelerator Switch Adjustment in this

section).

1. Potentiometer

2. Lever

Figure 15.1

3. Retainer

4

2

3

System

Electrical

3

3. With the accelerator pedal released, inspect location

of roll pin on throttle position collar and potentiometer lever. The roll pin should just contact the potentiometer lever without rotating the lever (Figure 15.2).

4. If necessary, adjust location of collar on accelerator

pedal shaft so that roll pin is properly positioned:

A. Loosen two (2) set screws that secure throttle

position collar to throttle pedal shaft and reposition

collar so that roll pin on the throttle position collar just

contacts the potentiometer lever without rotating the

lever. Make sure that there is clearance between roll

pin and side of potentiometer lever to prevent binding.

B. Remove set screws one at a time from collar and

apply Loctite #242 (or equivalent) to set screw

threads. Install and tighten set screws to secure collar to accelerator pedal shaft.

C. Recheck potentiometer lever movement.

5. Calibrate accelerator system after any accelerator

potentiometer adjustment(see Accelerator SystemCalibration in this section).

1. Potentiometer

2. Collar

3. Lever

1

2

5

Figure 15.2

4. Roll pin

5. Accelerator pedal

Workman MDE Electrical System

Page 3 --

Rev. A12.1

This page is intentionally blank.

Rev. A12.2

Workman MDEElectrical System Page 3 --

Accelerator System Calibration

The accelerator system on the Workman MDE includes

the accelerator pedal assembly, the accelerator potentiometer, the accelerator switch and the controller. If any

of these components are adjusted, removed or replaced, the following calibration procedure should be

performed. Additionally, if vehicle movement is erratic,

jerky or if the diagnostic light on the dash is flashing six

(6) times, calibration of the accelerator system should

be performed.

1. Position vehicle on a level surface, turn on/off switch

OFF and remove key. Raise box and secure with prop

rod. Remove controller cover.

2. Check accelerator switch adjustment and adjust if

necessary (see Accelerator Switch Adjustment in this

section).

3. Check accelerator potentiometer adjustment and

adjust if necessary (see Accelerator Potentiometer Adjustment in this section).

4. Using a jumper wire, connect gray controller lead to

ground post (B--) on controller (Fig. 16).

4

1. Controller

2. Gray controller lead

3

Figure 16

3. Ground post (B-- )

4. Controller LED

1

2

System

Electrical

NOTE: During calibration, the vehiclestatus light onthe

dash should flash the same as the controller LED.

5. Turn on/off switch ON. The alarm should sound and

the controller LED should flash six (6) times.

6. Slowly depress accelerator pedal until the alarm momentarily stops and hold pedal in position. This should

take avery small movement of the pedal.Once alarm resumes, release accelerator pedal completely.

7. Depress and hold accelerator pedal fully. Alarm will

momentarily stop while controller calibration occurs.

Hold pedalfully depressed until alarm resumes and then

release pedal.

8. If calibration process was successful, alarm will chirp

and diagnosticlight on the dash willbe lit continuous (not

flashing). If alarm continues to sound or if diagnostic

light is flashing, turn on/off switch OFF and repeat steps

5, 6 and 7.

9. Turn on/off switch OFF and remove key. Disconnect

jumper wire from gray controller lead and controller

ground post (B --).

10.Install controller cover and lower box.

11. If vehicle operation continues to be erratic after completing the accelerator system calibration procedure,

evaluate the components in the accelerator system: accelerator switch, accelerator potentiometer, accelerator

pedal, circuit wiring and controller.

Workman MDE

Page 3 -- 13

Electrical System

Component Testing

For accurate resistance and/or continuity checks, electrically disconnect the component being tested from the

circuit (e.g. disconnect the harness wire connectors

from the vehicle on/off switch before doing a continuity

check on the on/off switch).

On/Off Switch

The Workman on/offswitch is located on the dash panel

(Fig. 17).The switch has two (2) positions (OFF and ON)

and three (3) switch terminals. Only two of the terminals

are used on the Workman MDE. The switch terminals

are positioned as shown in Figure 18.

CAUTION

When testing electrical components for continuity with a multimeter (ohms setting), make sure

that power to the circuit has been disconnected.

Testing

CAUTION

When testing the on/off switch for continuity

with a multimeter (ohms setting), make sure that

power to the circuit has been disconnected.

When the on/off switch is in the OFF position, no continuity should exist between the common (center) switch

terminal and the switched (side) terminal. In the ON

position, continuity should exist between the common

(center) switch terminal and the switched (side) terminal.

1

COMMON

TERMINAL

BACK OF

SWITCH

Figure 17

1. On/Off switch

SWITCHED

TERMINAL

NOT USED

Figure 18

Electrical System

Page 3 -- 14

Workman MDE

Battery Discharge Indicator and Hour Meter Gauge

The combination battery discharge indicator and hour

meter gauge is located on the dash panel (Fig. 19).

The battery indicator identifies state ofcharge of the battery pack.The battery indicator reads full (10 bars) when

the battery pack is fully charged (approximately 51

volts). As battery pack voltage decreases with vehicle

use, fewer battery indicator bars are shown.

When the battery indicator reaches 2 bars, a warning

light illuminates and a battery icon flashes on the gauge

face to identify that battery charge level is extremelylow.

At this point, the batteries should be charged.

If the battery indicator reaches 1 bar, the warning light

begins flashing and the vehicle will go into an energy

saving mode: vehicle speed will be reduced to 3 MPH.

At this point, the batteries should be charged to prevent

serious battery damage.

The hour meter registers operating time of the vehicle.

Whenever the vehicle is in motion, the hour meter

should increase one tenth every six (6) minutes of operation. If the vehicle remains stationary for thirty (30)

seconds (even if the on/off switch is ON), the hour meter

quits increasing.

The back of the gauge is shown in Figure 20. A wire harness connector plugs into the gauge. Terminals 1, 2 and

5 are not used on the Workman MDE. See Chapter 6 -Electrical Diagrams for schematic and wire harness information.

BACK OF

1

Figure 19

1. Battery discharge indicator and hour meter

85

14

GAUGE

Figure 20

System

Electrical

If the battery discharge indicator or the hour meter prove

to be inaccurate, the gauge should be replaced.

Workman MDE

Page 3 -- 15

Electrical System

Vehicle Direction (Forward/Reverse) and Headlight Switches

The vehicle direction (forward/reverse) switch (Fig. 21)

and headlight switch (Fig. 22) are located on the control

panel. These two switches have identical logic.

The vehicle direction switch is one of several inputs for

the vehicle controller and allows the direction (forward/

reverse) of the vehicle to be changed by the operator.

The headlight switch allows the headlights to be turned

on and off.

NOTE: The headlight system on the Workman MDE

consists of two (2) 24 volt lamps connected in series. If

one lamp is burned out or disconnected, neither lamp

will illuminate.

Testing

The s witch terminals for these switches are marked as

shown in Figure 23. The circuitry of the switch is s hown

in the chart below. With the use of a multimeter (ohms

setting), theswitch functions may be tested to determine

whether continuity exists between the various terminals

for each switch position. Verify continuity between

switch terminals.

SWITCH

POSITION

NORMAL

CIRCUITS

OTHER

CIRCUITS

OFF / FORWARD 1+2 4+5

ON / REVERSE 2+3 5+6

1

Figure 21

1. Direction switch

1

Figure 22

1. Headlight switch

56

Electrical System

Page 3 -- 16

1243

Figure 23

Workman MDE

Vehicle Status Light

The vehicle status light is located on the control panel

(Fig. 24). During normal operation, the status light

should be continuously illuminated. A vehicle electrical

problem will be identified by a flashing status light.

The vehicle status light and LED on the vehicle controller should have the same condition (off, illuminated or

flashing). If the vehicle status light does not illuminate

when the on/off switch is turned ON, check the LED on

the vehicle controller to make sure it is illuminated. If the

controller LED is illuminated and the vehicle status light

is not illuminated, check the vehicle status light and circuit wiring.

1

See Controller (in this section) and your Operator’s

Manual for information on a flashing vehicle status light.

Testing

1. Make sure on/off switch is turned OFF. Remove key

from switch.

2. Disconnect wire harness from vehicle status light.

IMPORTANT: The vehicle status light is a 12 volt DC

component. Do not test the light using jumper wires

from the vehicle battery pack (48 VDC).

3. The terminals for the light are marked as shown in

Figure 25. Correctly connect 12 VDC source to the light

terminals.

4. Light should illuminate. Remove voltage source from

the light and reconnect wire harness. Replace status

light if needed.

Figure 24

1. Vehicle status light

1B (--)

1A (+)

Figure 25

System

Electrical

Workman MDE

Page 3 -- 17

Electrical System

Supervisor Speed Limit Switch

The supervisor speed limit switch is open in OFF position (key vertical) and closed in ON position (key rotated

clockwise). The speed limit switch is one of several inputs forthe vehicle controller and allows the speed ofthe

vehicle to be limited.

Test the switch by disconnecting the wiring and connecting a continuity tester across switch terminals A and D

(Fig. 26). Rotate key to ON position: there should be an

indication of continuity. R otate key to OFF position:

there should be no continuity.

Audio Alarm (Reverse)

The audio alarm sounds when the direction (forward/reverse) switch is placed in the reverse position. The

alarm is located under the controller cover beneath the

cargo box.

Testing

IMPORTANT: Make sure to observe polarity on the

alarm terminals when testing. Damage to the alarm

may result from an improper connection.

OFF

B&C

45

o

ON

A&D

B&C

Figure 26

2

IMPORTANT: The audio alarm is a 12 volt DC component. Do not test the alarm using jumper wires

from the vehicle battery pack (48 VDC).

1. Make sure on/off switch is turned OFF. Remove key

from switch.Raise cargo box and removecontroller cover.

2. Disconnect wire harness connectors from alarm

(Fig. 27). Using jumper wires, correctly connect 12VDC

source to the alarm terminals noting polarity shown on

alarm decal.

3. Alarm should sound. Remove voltage source from

the alarm. Reconnect alarm to the circuit or replace

alarm if needed.

1

Figure 27

1. Controller 2. Audio alarm

Electrical System

Page 3 -- 18

Workman MDE

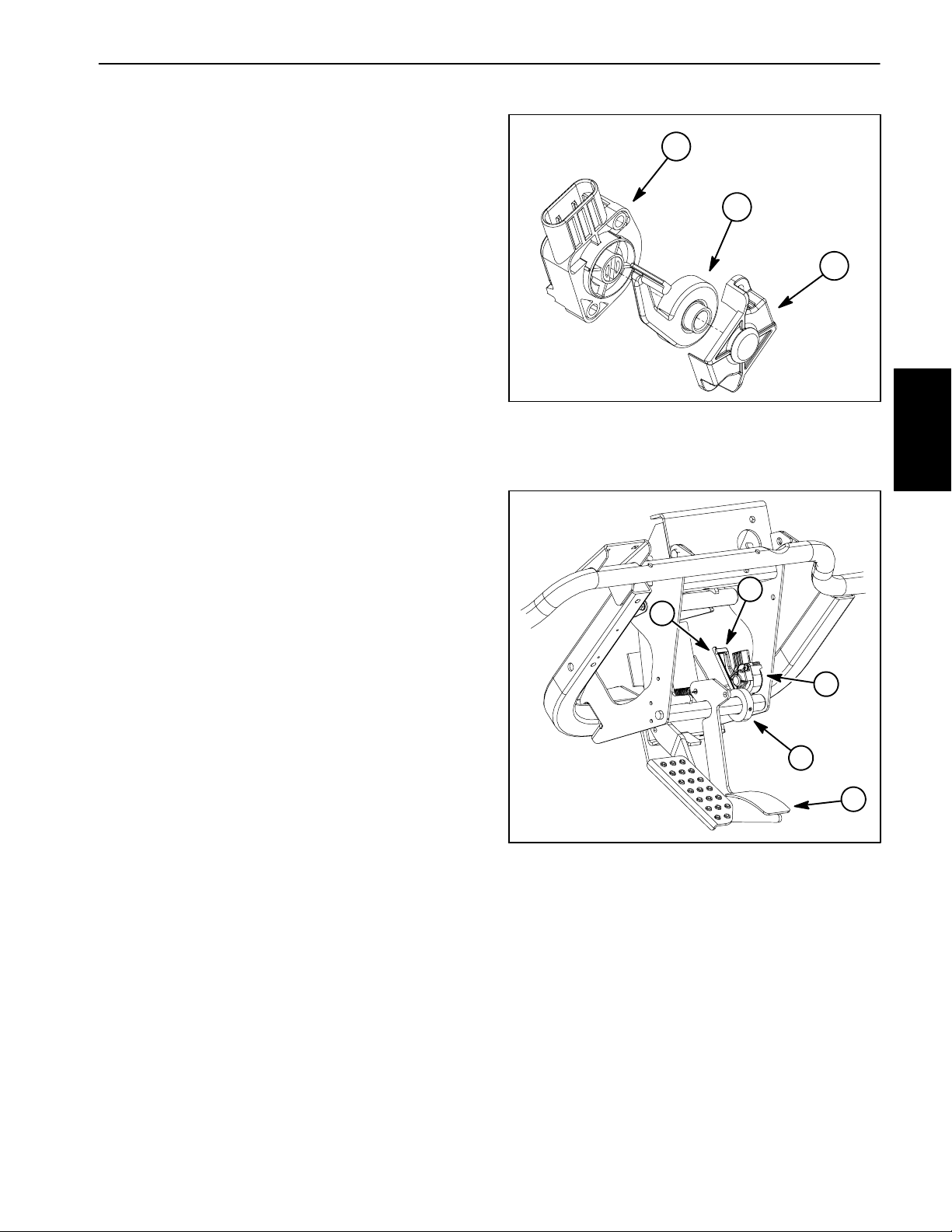

Charger Interlock Switch

The charger interlock switch is located behind the charger receptacle plate on the front of the seat base (Fig.

28). When the battery charger is plugged into the charger receptacle, the interlock switch closes and provides

an input to the vehicle controller to inhibit vehicle operation.

NOTE: The vehicle should not operate if the charger

plug is connected to the charger receptacle.

1. Make sure vehicle on/off switch is OFF. Remove k ey

from switch.

2. Remove receptacle plate from front of seat base.

3. Locate charger interlock switch on rear of receptacle

plate. Disconnect harness connector from the switch.

1

4

4. Check the continuity of the switch by connecting a

multimeter (ohms setting) across the connector terminals.

5. When the switch plunger is extended there should

not be continuity between the switch terminals.

6. When the switch plunger is depressed, there should

be continuity between the switch terminals.

7. Replace switch if needed.

8. Reconnect harness connector to switch. Install receptacle plate to front of seat base.

3

2

Figure 28

1. Receptacle plate

2. Screw (4 used)

2

3

6

Figure 29

1. Charger interlock switch

2. Switch plate

3. Charger receptacle

4. Rivet (2 used)

3. Charger receptacle

4. Charger interlock switch

1

7

5

5. Lock nut (2 used)

6. Socket head screw

7. Mount bracket

System

Electrical

4

Workman MDE

Page 3 -- 19

Electrical System

Main and Accessories Contactors

Two c ontactors (solenoids) are used on the Workman

MDE for circuit control.

The main contactor provides current to the vehicle controller and is energized when the on/off switch is ON.

The main contactor is located under the controller cover

beneath the cargo box (Fig. 30).

The accessories contactor provides current tothe headlights, horn and optional electrical accessories. The accessories contactor is energized when the on/off switch

is ON. The accessories contactor is located beneath the

dash panel.

Testing

NOTE: Prior to taking small resistance readings with a

digital multimeter, short the meter test leads together.

The meter will display a small resistance value (usually

0.5 ohms or less) that is due to the internal resistance of

the meter and test leads. Subtract this value from the

measured value of the component you are testing.

1. Make sure on/off switch is turned OFF. Open the battery circuit by r emoving one of the battery cables (see

Opening Battery Circuit in the General Information section of this chapter and Fig. 31).

2. Locate contactor that is to be tested. Disconnect all

vehicle harness electrical connections from contactor.

Note wire connector locations on contactor for reassembly purposes.

5

3

6

Figure 30

1. Main contactor

2. Cable to controller B+

3. Wire harness connector

1

A

4

4. Fuse (F1)

5. Positive battery cable

6. Isolator

1

2

4

2

3. Using jumperwires, apply 48 VDC directly across the

contactor coilposts (Fig. 32). The contactor should click.

With the contactor coil energized, resistance across the

main contact posts should be less than 1 ohm.

4. Remove voltage from contactor coil posts. The contactor shouldclick. With the contactor coil not energized,

resistance across the main contact posts should be infi-

nite ohms.

5. Measure resistance across the contactor coil posts

(Fig. 32):

A. For the main contactor, the resistance should be

approximately 126 ohms.

B. For the accessories contactor, the resistance

should be approximately 200 ohms.

Figure 31

1. Negative cable to vehicle 2. Positive cable to vehicle

4

4

3

3

2

3

4

4

1

3

Figure 32

1. Main contactor

2. Accessories contactor

3. Main contact posts

4. Contactor coil posts

Electrical System

Page 3 -- 20

Workman MDE

6. Replace contactor if necessary.

7. Connect electrical connections to contactor. If main

contactor connections were removed, use Figure 33 as

a guide for reattaching cable and wire harness connections.

8. Connect battery cable that was removed from battery pack.

3

4

6

7

8

1. Main contactor

2. Cable to controller B+

3. Lock nut

4. Flat washer

Figure 33

5. Wire harness connector

6. Fuse (F1)

7. Positive battery cable

8. Isolator

45 to 50 in-- lb

(5.1 to 5.6 N-- m)

5

4

3

2

1

System

Electrical

Workman MDE

Page 3 -- 21

Electrical System

Fuses

There are three (3) fuses in the Workman electrical system.

Two (2) of the fuses are located beneath the steering

column (Fig. 34). These fuses supply power to the following:

The upper10 ampere fuse (F2) supplies power to the

on/off switch and switched circuits.

The lower 10 ampere fuse (F3) supplies power to optional accessories.

The third fuse (F1) is located under the controller cover

beneath the cargo box (Fig. 35). This fuse is rated at 355

amperes continuous and allows current flow between

the batteries and the vehicle. If this fuse has failed, vehicle operation will not occur.

Testing

CAUTION

When testing fuses for continuity with a multimeter (ohms setting), make sure that fuse is removed from circuit.

1. Fuse (F2)

2

1

2

Figure 34

2. Fuse (F3)

1

IMPORTANT: Before removing fuse F1 (355 Amp)

for testing, open the battery circuit by removing one

of the battery cables (see Opening Battery Circuit in

the General Information section of this chapter).

Make sure on/off switch is turned OFF. Remove fuse to

check continuity. The test meter should read less than

1 ohm.

If fuse F1 was removed, torque the nuts that secure the

fuse from 45 to 50 in--lb (5.1 to 5.6 N--m).

3

1. Controller

2. Fuse (F1)

Figure 35

3. Main contactor

Electrical System

Page 3 -- 22

Workman MDE

Fusible Links

The w iring harness for the Workman includes three (3)

fusible links for circuit protection (Fig. 36).

Two (2) fusible links attach to the same main contactor

post as the main fuse. One of these fusible links (FL2)

is used for the switched power circuit. The other fusible

link (FL1) protects the charger circuit.

The third fusible link (FL3) is attached to the controller

B+ terminal. This link provides protection for the charge

indicator/hour meter gauge.

If anyof these fusiblelinks should fail,the affected circuit

will not function. See Chapter 6 -- Electrical Diagrams for

schematic and wire harness information.

3

1

2

4

Figure 36

1. Main contactor

2. Main fuse contactor post

3. Switched contactor post

5

4. Fusible links FL1 & FL2

5. Fusible link FL3

System

Electrical

Workman MDE

Page 3 -- 23

Electrical System

Accelerator Switch

The accelerator switch is a four terminal, two circuit

switch that is located on the control pedal frame (Fig.

37). The Workman MDE uses only one of the switch circuits (terminals 3 and 4). When the accelerator pedal is

depressed, the switch allows a closed circuit (input) for

the controller to allow traction motor operation. When

the accelerator pedal is released, the switch provides an

open circuit (no input) for the controller to prevent traction motor operation.

Testing

2

3

1

6

5

1. Park vehicle on a level surface, turn on/off switch

OFF and remove key from switch.

2. Locate accelerator switch on pedal frame under

dashboard of vehicle.

3. Unplug wiring harness connector from accelerator

switch.

4. With the use of a multimeter (ohms setting), the

switch functions may be tested to determine whether

continuity exists between the switch terminals for both

switch positions. Verify continuity between switch terminals using the following table:

PLUNGER

POSITION

CONTINUITY

NO

CONTINUITY

IN 1 and 2 3 and 4

OUT 3 and 4 1 and 2

5. When reconnecting wiring harness connector to

switch after testing, harness connector and switch terminal area should be filled with dielectric gel (see Special Tools) to prevent corrosion of connection terminals.

Apply gel fully to both harness connector and switch terminal area,plug harness connector into switch to distribute gel, unplug harness connector, reapply gel to both

surfaces and replug harness connector into switch.

4

1. Accelerator pedal

2. Accelerator switch

3. Plate

6

5

SIDE VIEW

1. Terminal 1

2. Terminal 2

3. Terminal 3

Figure 37

1

4

6

Figure 38

4. Screw (2 used)

5. Stop cap screw

6. Lock nut

2

END VIEW

3

4. Terminal 4

5. Switch plunger

6. Mounting tab

6. If switch replacement is needed, see Accelerator

Switch Adjustment procedure in the Adjustments section of this chapter.

Electrical System

Page 3 -- 24

Workman MDE

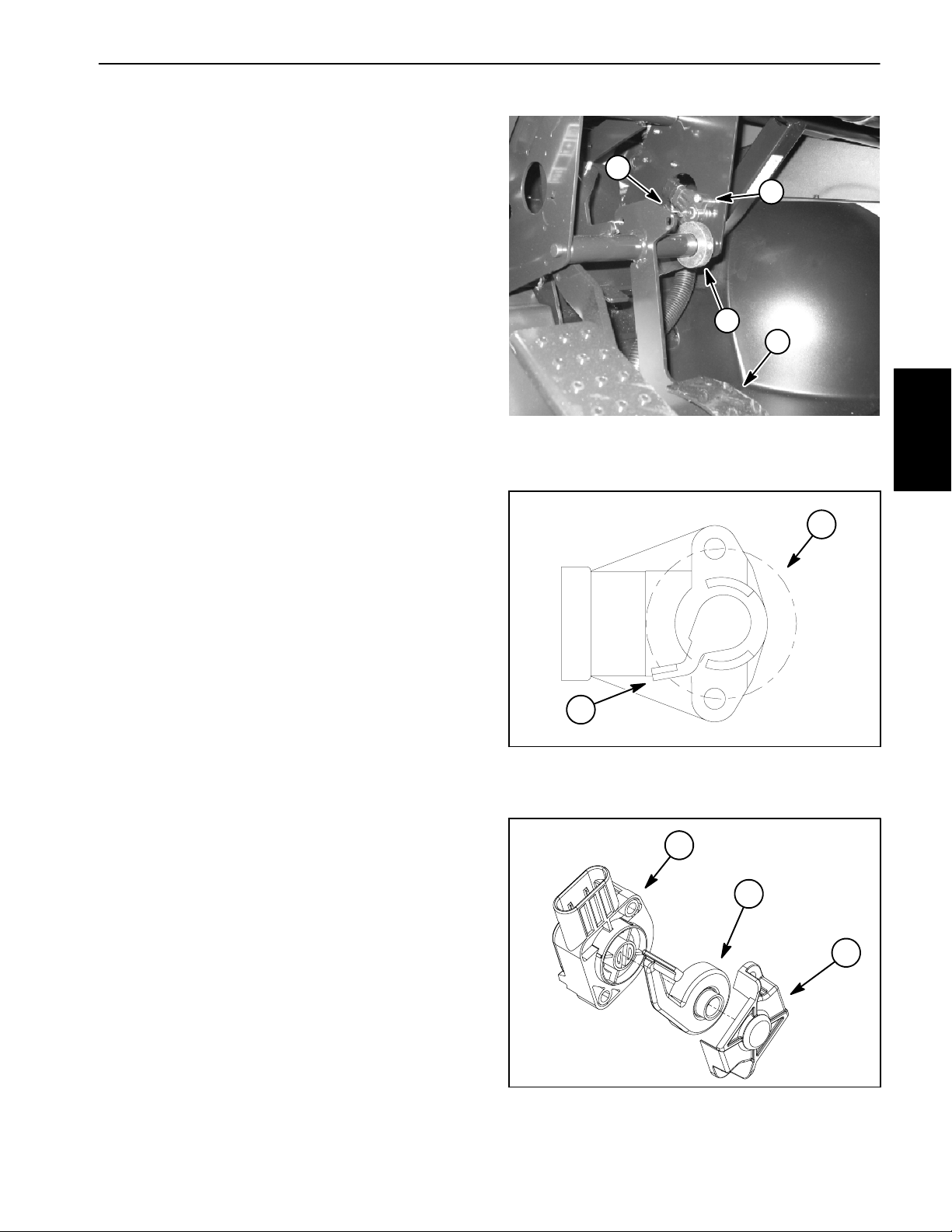

Accelerator Potentiometer

The accelerator potentiometer is attached to the pedal

frame under the dash (Fig. 39). This potentiometer is

used as one of the inputs for the vehicle controller to

command vehicle speed. The accelerator pedal positions the accelerator potentiometer lever. When the operator presses or releases the accelerator pedal, the

potentiometer resistance changes. This r esistance

change is used by the controller to determine current

flow to the traction motor.

Two styles of potentiometer have been used on Workman MDE vehicles. Vehicles with serial numbers below

310000000 have a potentiometer with a short lever (Fig.

40). This potentiometer is rotated by a roll pin that extends approximately 1 1/2 inches (38 mm) out of the collar. Vehicles with serial numbers above 310000000

have a potentiometer with a long lever (Fig. 41). This potentiometer is rotated by a roll pin that extends approximately 3 inches (76 mm) out of the collar. If a

potentiometer on an earlier vehicle has been replaced,

it may have a potentiometer with a long lever.

4

1. Potentiometer

2. Accelerator pedal

Figure 39

3. Collar

4. Roll pin

1

3

2

System

Electrical

If the accelerator potentiometer is out of adjustment, the

diagnostic light on the dash will flash six (6) times. Additionally, if vehicle movement is erratic or jerky, calibration of the accelerator system should be performed. See

Accelerator Potentiometer Adjustment and Accelerator

System Calibration in the Adjustments section of this

chapter.

Before suspecting a faulty potentiometer, follow adjustment procedures for the accelerator switch, accelerator

potentiometer and acceleration system calibration

found in the Adjustments section of this chapter.

1

2

Figure 40

1. Potentiometer 2. Lever (short)

1

2

3

Workman MDE

1. Potentiometer

2. Lever (long)

Page 3 -- 25

Rev. A

Figure 41

3. Retainer

Electrical System

Controller

The Workman controller is secured to the rear frame under the controller cover beneath the cargo box (Fig. 40).

The controller uses inputs from several vehicle switches

(on/off, forward/reverse, accelerator pedal, supervisor,

charger interlock, motor temperature, accelerator potentiometer) to accurately control vehicle speed, vehicle

direction (forward and reverse) and regenerative braking. An internal thermal sensor prevents overheating of

the controller.

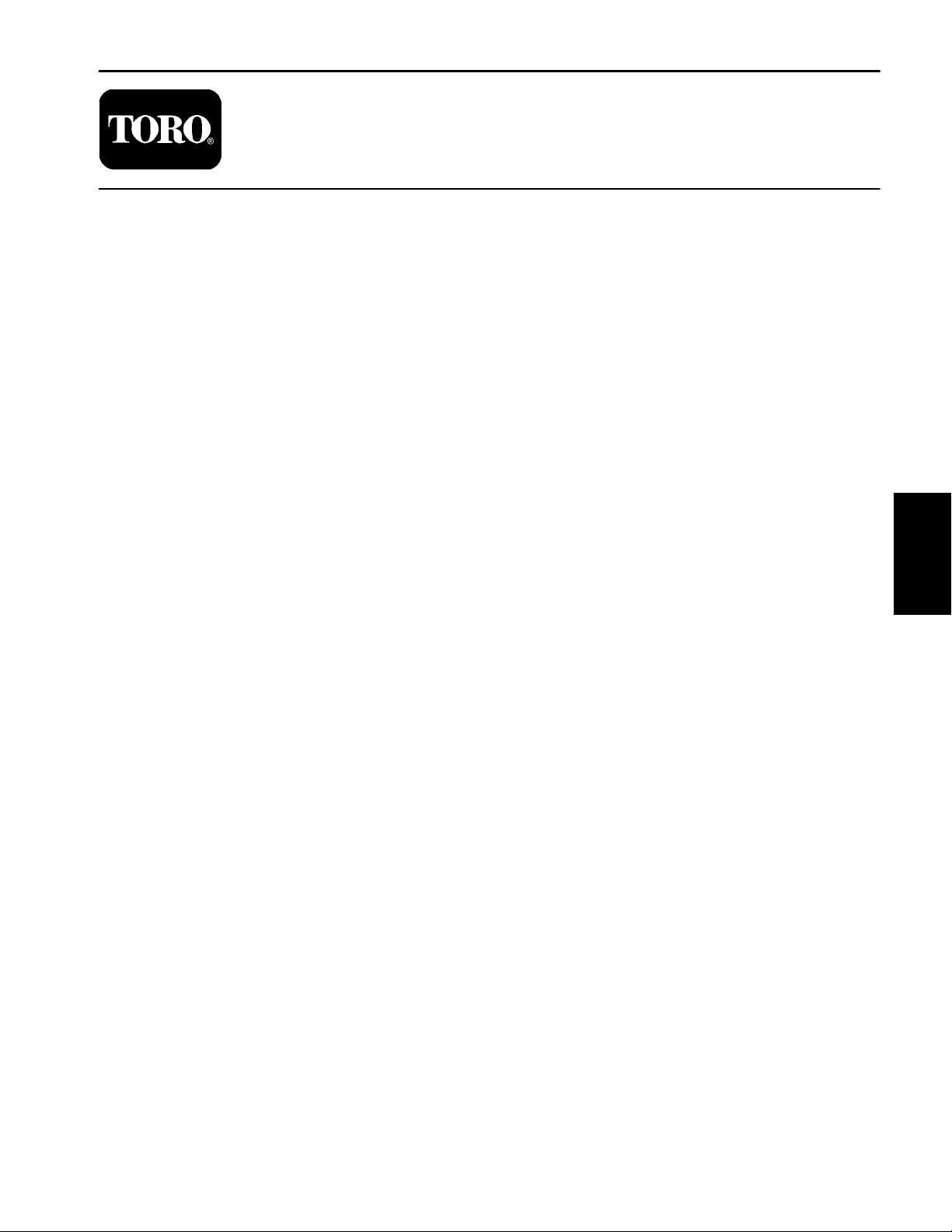

Cable connections for the controller are as follows:

Terminal B--: Negative (--) battery cable and wire

harness ground.

Terminal B+: Positive (+) cable from main contac-

tor post and wire harness fusible link (FL3).

Terminal M1: Cable to traction motor armature A2

post.

Terminal M2: Cable to traction motor armature A1

post.

Terminal F1: Cable to traction motor field F1 post.

Terminal F2: Cable to traction motor field F2 post.

When installing cables to controller, torque screws at

terminals B--, B+, M1 and M2 from 85 to 90 in--lb (9.6

to 10.2 N--m) and torque screws at terminals F1 and F2

from 55 to 60 in--lb (6.2 to 6.8 N-- m) (Fig. 41). Apply

Toro battery terminal protector (see Special Tools) to

controller connections after tightening terminal screws.

NOTE: If the controller LED and vehicle status light are

flashing, attempt to reset the controller by turning the on/

off switch to OFF, waiting a few seconds and then turning the switch to ON. If LED and status light continue

flashing, proceed with fault code identification and necessary action.

1

3

2

Figure 40

1. Controller

2. Controller LED

M2

3. Wire harness connector

UP

If wire harness connector is removed from controller,

both harness connector and controller socket should be

filled with dielectric gel to prevent corrosion of connection terminals and potential controller damage. Apply

gel fully to both harness connector and controller socket, plug harness connector into controller to distribute

gel, unplug harness connector, reapply gel to both surfaces and plug harness connector into controller.

M1

85 to 90 in-- lb

(9.6 to 10.2 N-- m)

B+

F1 F2

B--

A LED exists on the controller to identify normal operation or faults that will prevent the vehicle from operating

correctly. The vehicle status light on the dash panel displays the same information as the LED on the controller.

See chart below for light pattern fault codes identified by

55 to 60 in-- lb

(6.2 to 6.8 N-- m)

Figure 41

the controller LED and vehicle status light.

Light Pattern Cause Necessary Action

Always on (not

System functioning correctly. None

flashing)

Always off System inoperable. Check for low battery voltage, faulty fuse(s), loose

battery cable connections, damaged battery cables

and/or faulty main contactor.

If batteries, cables and other electrical components are

in good condition, controller replacement may be

necessary.

Electrical System

Page 3 -- 26

Workman MDE

1Flash

System inoperable. Turn on/off switch OFF, wait several seconds and turn

on/off switch ON. If controller does not reset correctly,

controller replacement may be necessary.

2 Flashes The accelerator pedal was

depressed when on/off

Turn on/off switch OFF, release accelerator pedal and

turn on/off switch to ON.

switch was turned ON.

If controller does not reset correctly, accelerator switch

adjustment may be necessary or switch may be faulty.

3 Flashes System inoperable. Turn on/off switch OFF, wait several seconds and turn

on/off switch ON. If controller does not reset, check

battery pack voltage and all battery cable connections.

Also check main contactor wire and cable connections

and main contactor. NOTE: If main contactor audibly

clicks when on/off switch is turned ON, problem is most

likely a faulty wire or cable connection.

Controller replacement may be necessary.

4 Flashes Main contactor malfunction. Turn on/off switch OFF, wait several seconds and turn

on/off switch ON. If controller does not reset, inspect

main contactor (see Main and Accessories Contactors in

this section). Check main contactor wire and cable

connections.

If problem continues, contactor replacement may be

necessary.

System

Electrical

5 Flashes The charger cord is plugged

into the vehicle charger

Turn on/off switch OFF, unplug charger cord from vehicle

and turn on/off switch ON.

receptacle.

If controller does not reset correctly, check charger

interlock switch.

6 Flashes Accelerator control

(accelerator switch and

potentiometer) is out of

adjustment.

7 Flashes Battery voltage is out of

range.

Adjust accelerator switch and potentiometer (see

Accelerator Switch and Accelerator Potentiometer

adjustment/calibration in the Adjustments section of this

chapter).

Inspect and test vehicle batteries and battery cable

connections (see Battery Service in the Service and

Repairs section of this chapter).

8 Flashes The controller is overheated. The vehicle will continue to operate but at reduced

power until the controller temperature lowers.

9 Flashes Thetractionmotoris

overheated (battery

discharge indicator displays

Stop vehicle and allow motor to cool before continuing

operation. Traction motor high temperature switch may

be faulty.

more than 1 bar).

The battery is nearly

discharged and the vehicle

Charge the batteries immediately to prevent battery

damage.

is in the energy saving mode

(reduced speed and battery

discharge indicator displays

1 bar with red light

illuminated).

Workman MDE

Page 3 -- 27

Electrical System

Service and Repairs

Battery Service

115 to 125 in lb

(13.0 to 14.1 N-- m)

6

5

4

5

4

8

7

115 to 125 in-- lb

(13.0 to 14.1 N-- m)

9

11

12

10

1

3

RIGHT

FRONT

1. Battery (8 used)

2. Battery rod (2 used)

3. Negative cable to vehicle

4. Lock washer (2 used per battery)

2

Figure 42

5. Hex nut (2 used per battery)

6. Cable terminal boot

7. Battery cable (6 used)

8. Positive cable to vehicle

9. Cable terminal boot

10. Battery retainer (2 used)

11. Flange nut (2 used)

12. Battery cable

The batteries are the heart of the Workman electrical

system. With regular and proper service, battery life can

be extended. Additionally, battery and electrical component failure can be prevented.

Electrical System

Page 3 -- 28

Battery Specifications:

Trojan model T--145 Battery (6 Volt Deep Cycle)

Weight: 72 lbs (33 kg)

Capacity: 210minutes @ 56.25 amps discharge

Workman MDE

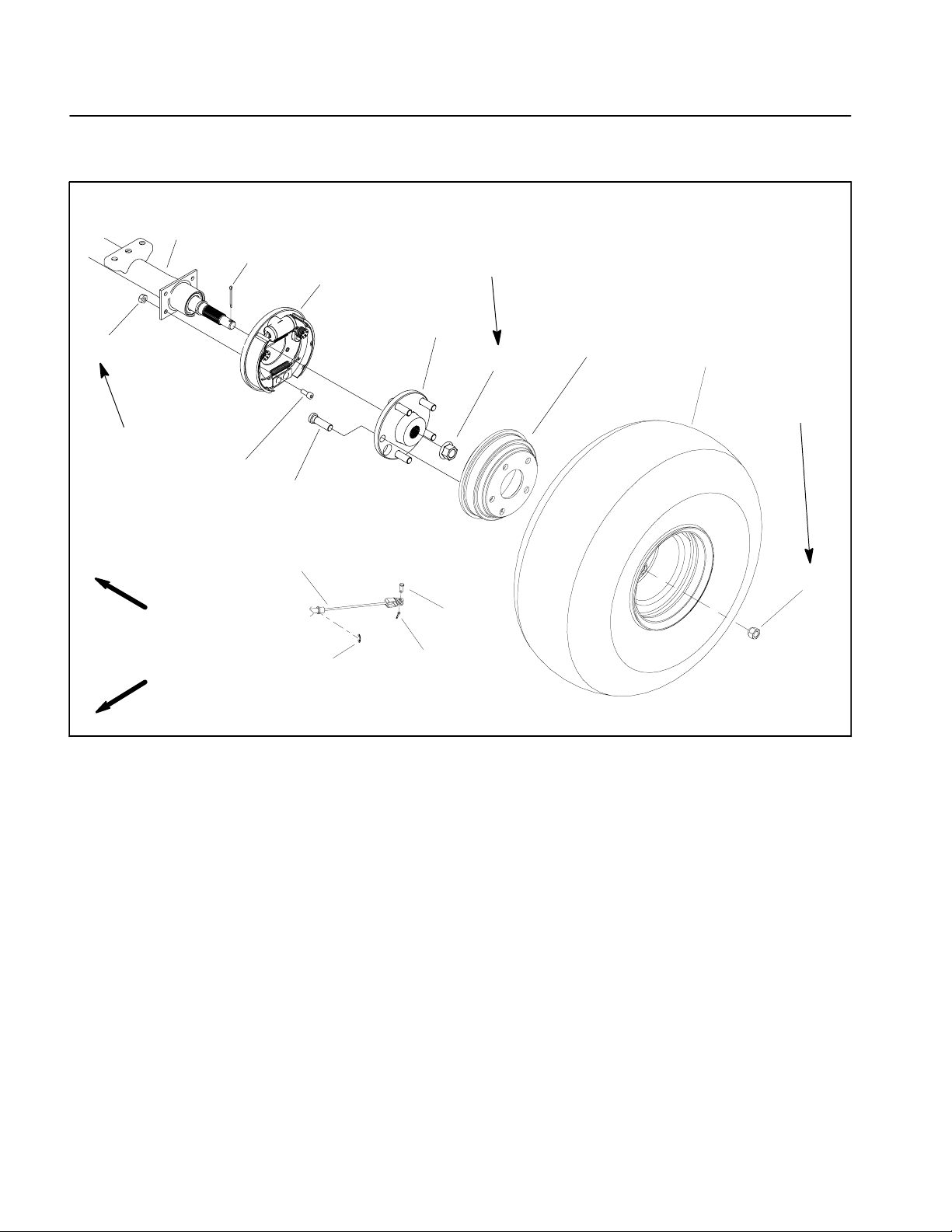

Battery Removal (Fig. 42)

2. Make sure the battery supports are clean and repainted if necessary. Make sure cables, terminals, rods

and hold down retainers are in good condition.

WARNING

POTENTIAL HAZARD:

The battery terminals, metal tools and metal ve-

hicle parts could short together.

WHAT CAN HAPPEN:

Sparks can cause battery gasses to explode.

Damaged cables could short against metal ve-

hicle parts and cause sparks.

HOW TO AVOID THE HAZARD:

When removing or installing the batteries, do

not allow the battery terminalsto short against

metal parts of the vehicle.

Do not allow metal tools or metal vehicle parts to

short between the battery terminals or battery

cables.

Always keep the battery retainers in place to

protect and secure the batteries.

IMPORTANT: Be careful to not damage terminal

posts or cable connectors when removing the battery cables.

1. Position vehicle on a level surface, set parking

brake, turn on/off switch OFF and remove key.

2. Raise cargo box and secure with prop rod.

3. Open the battery circuit by carefully removing one of

the battery cables (see Opening Battery Circuit in the

General Information section of this chapter).

IMPORTANT: When installing batteries into vehicle,

do not lift batteries using battery terminals as lift

points: battery damage may occur.

3. Using case loops on battery tops as lifting points, set

batteries on the battery supports with battery posts

properly orientated (Fig. 44). Make sure that battery

rods are positioned to allow installation of retainers.

4. Install two (2) battery retainers and nuts to secure

batteries to vehicle (Fig. 43). Torque nuts from 115 to

125 in--lb (13.0 to 14.1 N--m).

5. Install all but one of the battery cables used to connect battery pack including the positive (red) cable and

negative (black) cable from vehicle (Figures 42 and 44).

Make sure that cables are connected to correct battery

terminal noting battery polarity. Install lock washer and

nut on each battery terminal. Torque nuts from 115 to

125 in--lb (13.0 to 14.1 N--m) to secure cables.

6. Connect final battery cable to battery terminals.

Install lock washer and nut on battery terminals. Torque

nuts from 115 to 125 in--lb (13.0 to 14.1 N-- m).

7. Apply Toro battery terminal protector (see Special

Tools) to all battery posts and cable connectors to reduce corrosion after connections are made. Make sure

that terminal boots are positioned over all connections.

8. Lower and secure cargo box.

System

Electrical

4. Once initial cable has been removed from vehicle,

disconnect and remove remaining battery cables from

all battery terminals.

5. Remove flange nuts (item 11) and battery retainers

(item 10) used to secure batteries to vehicle (Fig. 43).

6. Make sure that all battery filler caps are on tightly.

IMPORTANT: When removing batteries from vehicle, do not lift batteries using battery terminals as

lift points: battery damage may occur.

7. Using case loops on battery tops as lifting points, remove batteries from vehicle.

Battery Installation (Fig. 42)

IMPORTANT: To prevent possible electrical problems, install only fully charged batteries.

1. Make sure vehicle on/off switch and all accessories

are OFF. Raise cargo box and secure with prop rod.

Workman MDE

Page 3 -- 29

1

3

Figure 43

1. Negative cable to vehicle

2. Positive cable to vehicle

A

Figure 44

2

4

3. Flange nut

4. Battery retainer

4

Electrical System

Battery Charging

When the vehicle is not in use, it is recommended to

keep the batteries charged by connecting the battery

charger that is included with the vehicle. The Workman

MDE charger is designed to automatically charge the