Page 1

Installation

LooseParts

FormNo.3407-721RevA

BrakeReplacementKit

Twister

ModelNo.136-1199

®

orWorkman

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

®

UtilityVehicle

InstallationInstructions

WARNING

CALIFORNIA

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Nopartsrequired

Nopartsrequired

Rightspindle1

Leftspindle

Brake-caliperassembly2

Flange-headbolt(3/8x1inch)

Rotor2

Hex-socketbolt(5/16x3/4inch)

Frontbrake-lineassembly1

Banjowasher4

Banjobolt2

Clip

Bleedscrew2

Nopartsrequired

Nopartsrequired

Qty.

Use

–

–

1

4

8

2

–

–

Preparethemachine.

Removetheexistingbrakeassembly.

Installthenewbrakeassembly.

Bleedthebrakecalipers.

Installthewheels.

6

7

©2016—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Nopartsrequired

Nopartsrequired

Registeratwww.T oro.com.

–

–

Adjustthefrontwheeltoe-in.

Burnish(break-in)thebrakes.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3407-721*A

Page 2

1

PreparingtheMachine

NoPartsRequired

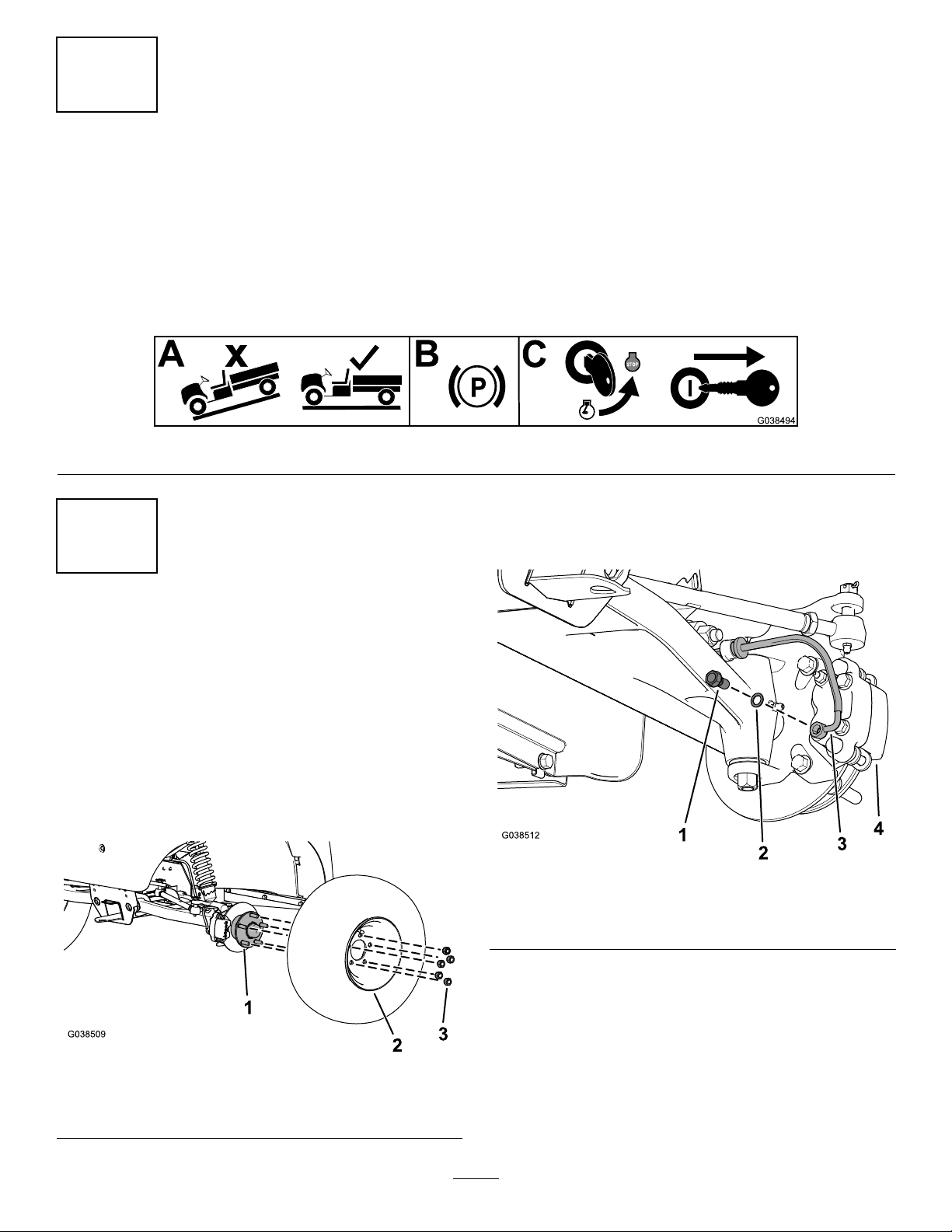

Procedure

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekeyfromthekeyswitch.

2

Figure1

3.Removethebanjoboltandwasherfromthe

brake-caliperassembly ,andremovethefrontbrakeline

fromthebrake-caliperassembly(Figure3).

RemovingtheExistingBrake

Assembly

NoPartsRequired

Procedure

1.Liftthefrontofthemachineandsupportitwithjack

stands.

2.Removethelugnutsthatsecurethewheeltothehub

(Figure2).

Figure3

1.Banjobolt3.Frontbrakeline

2.Banjowasher4.Brake-caliperassembly

Figure2

1.Hub3.Lugnut

2.Wheel

2

Page 3

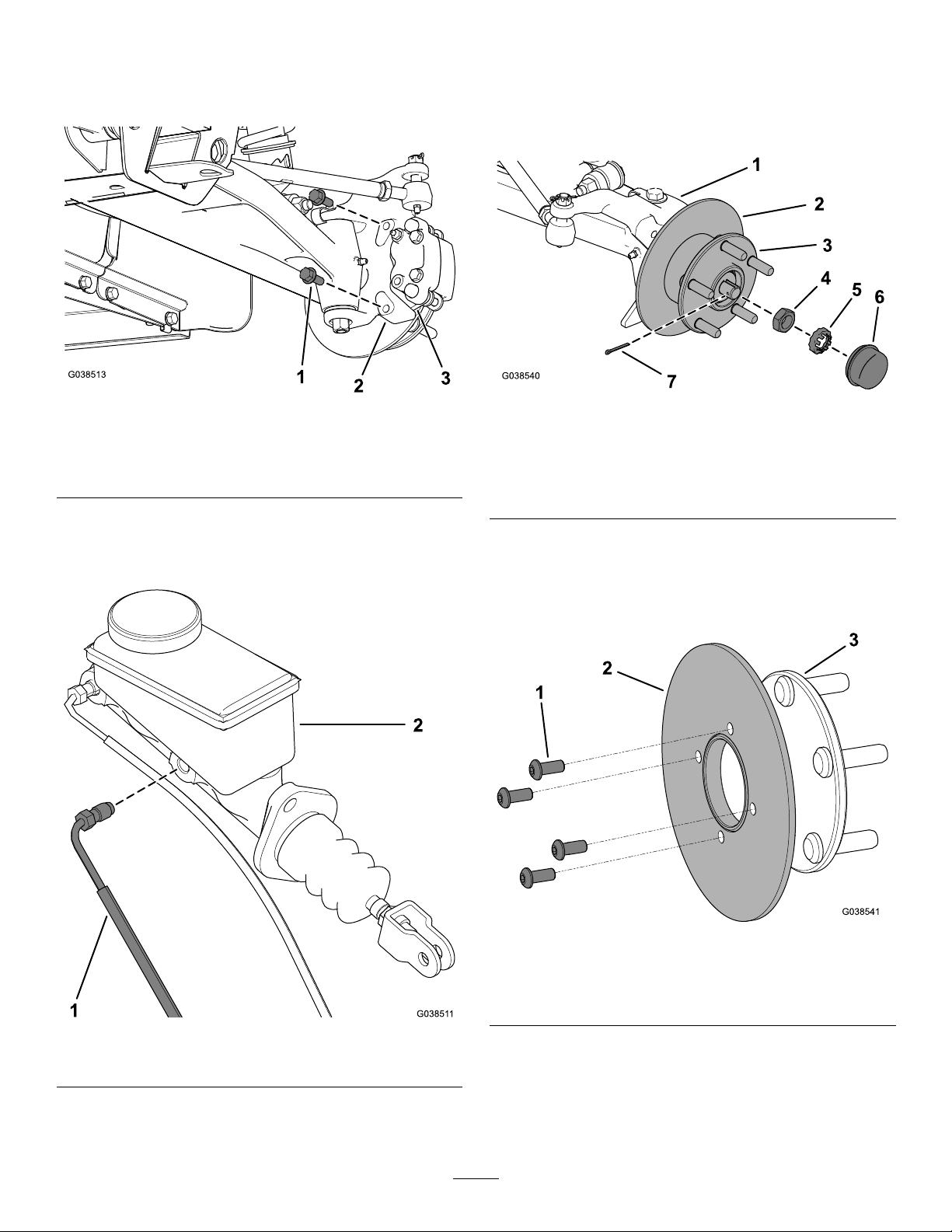

4.Removetheange-headbolts(3/8x1inch)that

securethebracketforthebrake-caliperassemblytothe

spindleandremovethebrake-caliperassemblyfrom

thespindle(Figure4).

6.Removethedustcap,hairpincotter,nutretainer,and

jamnut,andremovethehubandrotorfromthe

spindle(Figure6).

Note:Retainthehub,dustcap,jamnut,nutretainer,

andhairpincotter.

Figure4

1.Flange-headbolt(3/8x1

inch)

2.Spindle

3.Caliperbracket

(brake-caliperassembly)

5.Removethefrontbrakelinefromthemastercylinder

(Figure5).

Note:Discardthefrontbrakeline.

Figure6

1.Spindle

2.Rotor6.Dustcap

3.Hub7.Hairpincotter

4.Jamnut

5.Nutretainer

7.Removethe4hex-socketbolts(5/16x3/4inch),and

removetherotorfromthehub(Figure7).

Note:Discardtherotorand4hex-socketbolts(5/16

x3/4inch).

Figure5

1.Frontbrakeline2.Mastercylinder

1.Hex-socketbolt(5/16x3/4

inch)

2.Rotor

3

Figure7

3.Hub

Page 4

8.Removethehairpincotterandslottedhexnutfrom

thetierodballjoint,anddisconnectthetierodfrom

thespindle(Figure8).

Note:Retainthehairpincotterandslottedhexnut.

Figure8

1.Tierod

2.Hairpincotter

3.Balljoint

9.Removethehex-headbolt(1/2x6inches),clip,and

locknut(1/2inch)fromthecontrolarm,andremove

thespindle(Figure9).

4.Spindle

5.Slottedhexnut

3

InstallingtheNewBrake

Assembly

Partsneededforthisprocedure:

1Rightspindle

1

Leftspindle

2Brake-caliperassembly

4

Flange-headbolt(3/8x1inch)

2Rotor

8

Hex-socketbolt(5/16x3/4inch)

1Frontbrake-lineassembly

4Banjowasher

2Banjobolt

2

Clip

2Bleedscrew

Note:Retainthehex-headbolt(1/2x6inches)and

locknut(1/2inch).

Note:Discardthespindle.

Figure9

1.Hex-headbolt(1/2x6

inches)

2.Clip4.Locknut(1/2inch)

3.Spindle

Procedure

1.Installthefrontbrakelinetothemastercylinder

(Figure5).

2.Installthespindleassemblytothecontrolarmusing

thehex-headbolt(1/2x6inches),clip,andlocknut

(1/2inch)asshowninFigure9.

3.Torquethelocknut(1/2inch)to102to136N∙m(75

to100ft-lb).

4.Installthetierodtothespindleassemblyusingthe

slottedhexnutandhairpincotter(Figure8).

Note:Iftheholedoesnotaligntoinstallthecotter

key,tightenonlytoaligntheslottednuttoensurethat

theholeforthehairpincotterisvisible,theninstall

thehairpincotter.

5.Torquetheslottedhexnutto27to34N∙m(20to25

ft-lb).

6.Installtherotortothehubusing4hex-socketbolts

(5/16x3/4inch)asshowninFigure7.

7.Torquethe4hex-socketbolts(5/16x3/4inch)to12

to15N∙m(9to11ft-lb).

10.Repeatsteps2through9ontheothersideofthe

machine.

4

Page 5

8.Installtherotorandhubassemblytothespindleby

performingthefollowing:

A.Tightenthejamnutwhileturningthehubtoseat

thebearings,andtorquethejamnutto16to20

N∙m(12to15ft-lb)asshowninFigure6.

B.Loosenthejamnutuntilitisawayfromthetab

washerandhub,andtorquethejamnutto169to

226N∙cm(15to20in-lb)whilerotatingthehub

(Figure6).

C.Installthenutretaineroverthejamnut,ensure

thattheholeforthehairpincotterisvisible,and

installthehairpincotter(Figure6).

D.Installthedustcap(Figure6).

9.Installthenewbrake-caliperassemblytothespindle

using2ange-headbolts(3/8x1inch)asshownin

Figure4.

10.Torquethe2ange-headbolts(3/8x1inch)to47to

54N∙m(35to40ft-lb).

11.Installthebleedscrewintothetopholeofthe

brake-caliperassembly(Figure10).

4

BleedingtheBrakeCalipers

NoPartsRequired

Procedure

Important:Y ouwillneed2peopletoperformthis

procedure.

1.Pushdownthebrakepedalfully.

2.Withbrakepedalpusheddownfully,loosenthebleed

screw1/4turn(Figure11).

3.Withbrakepedalpusheddownfully,tightenthebleed

screw1/4turn(Figure11).

Figure10

1.Bleedscrew

12.Torquethebleedscrewto6to7.5N∙m(4.5to5.5ft-lb).

13.Installthefrontbrakelinetothebrake-caliperassembly

usingabanjoboltand2banjowashers(Figure3).

14.Torquethebanjoboltto12to15N∙m(9to11ft-lb).

2.Topholeofthe

brake-caliperassembly

Figure11

4.Repeatthisprocessuntilairnolongerreleasesfrom

thecalipers.

Note:Whenairnolongerreleases,youshouldnotsee

anymoreairbubblesinthebrakeuid.

5.Fillthemastercylinderwithbrakeuid;refertoyour

Operator’sManual.

5

Page 6

5

G009235

1

2

3

InstallingtheWheels

NoPartsRequired

Procedure

1.Installthewheelontothehubusingthepreviously

removedlugnuts(Figure2).

1.Measurethedistancebetweenbothofthefronttiresat

theaxleheightatboththefrontandrearofthefront

tires(Figure12).

2.Torquethelugnutsinastarpatternto102to129N∙m

(75to95ft-lb).

6

AdjustingtheFrontWheel

Toe-in

NoPartsRequired

Procedure

Thetoe-inshouldbe0to6mm(0to1/4inch).

•Checkthetirepressuretoensurethatthefronttiresare

inatedto82kPa(12psi).

•Either,addweighttothedriver'sseatequaltotheaverage

operatorwhowillrunthemachine,orhaveanoperator

sitontheseat.Theweightoroperatormustremainon

theseatforthedurationoftheprocedure.

Figure12

1.Tirecenterline—back3.Axlecenterline

2.Tirecenterline—front

2.Ifthemeasurementdoesnotfallwithin0to6mm(0

to1/4inch),loosenthejamnutsattheouterendof

thetierods(Figure13).

Figure13

1.Tierod2.Jamnut

•Onalevelsurface,rollthemachinestraightback2to3

m(6to10ft)andthenstraightforwardtotheoriginal

startingposition.Thisallowsthesuspensiontosettleinto

theoperatingposition.

•Measurethetoe-inwiththewheelsfacingstraightahead.

3.Rotatebothtierodstomovethefrontofthetire

inwardoroutward.

4.Tightenthetierodjamnutswhentheadjustmentis

correct.

5.Ensurethatthereisfulltravelofthesteeringwheelin

bothdirections.

6

Page 7

7

BurnishingtheBrakes

NoPartsRequired

Procedure

Toensureoptimumperformanceofthebrakesystem,burnish

(break-in)thebrakesbeforeuse.

1.Bringthemachineuptofullspeed,applythebrakesto

rapidlystopthemachinewithoutlockingupthetires.

2.Repeatthisprocedure10times,waiting1minute

betweenstops,toavoidoverheatingthebrakes.

Important:Thisprocedureismosteffectiveifthe

machineisloadedwith227kg(500lb).

7

Page 8

Loading...

Loading...