Page 1

FieldKit

2024DirectionalDrill

ModelNo.133-9467

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Safety

SafetyandInstructionalDecals

FormNo.3408-241RevA

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

117–2718

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3408-241*A

Page 2

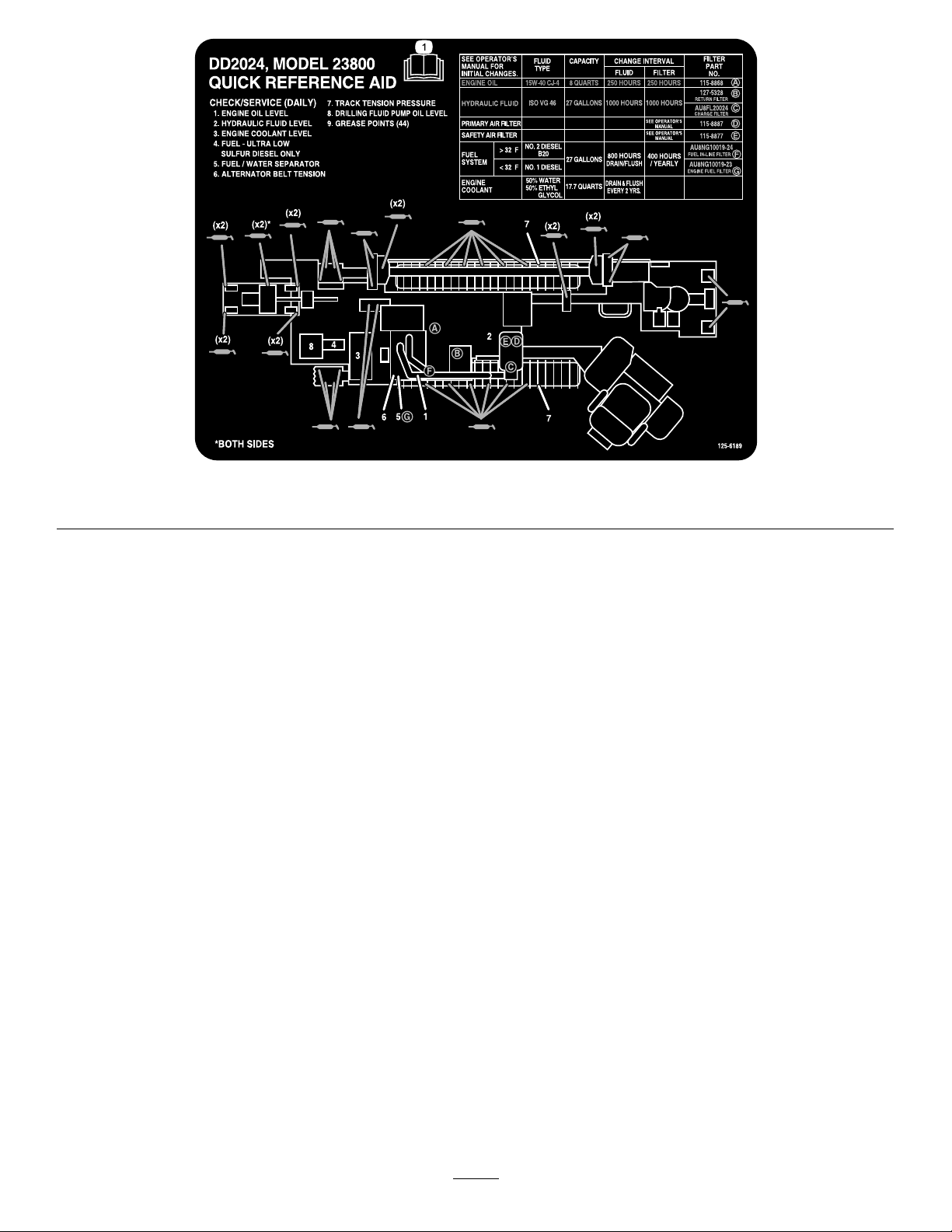

1.ReadtheOperator'sManualformoreinformationonservicingthemachine.

125-6189

2

Page 3

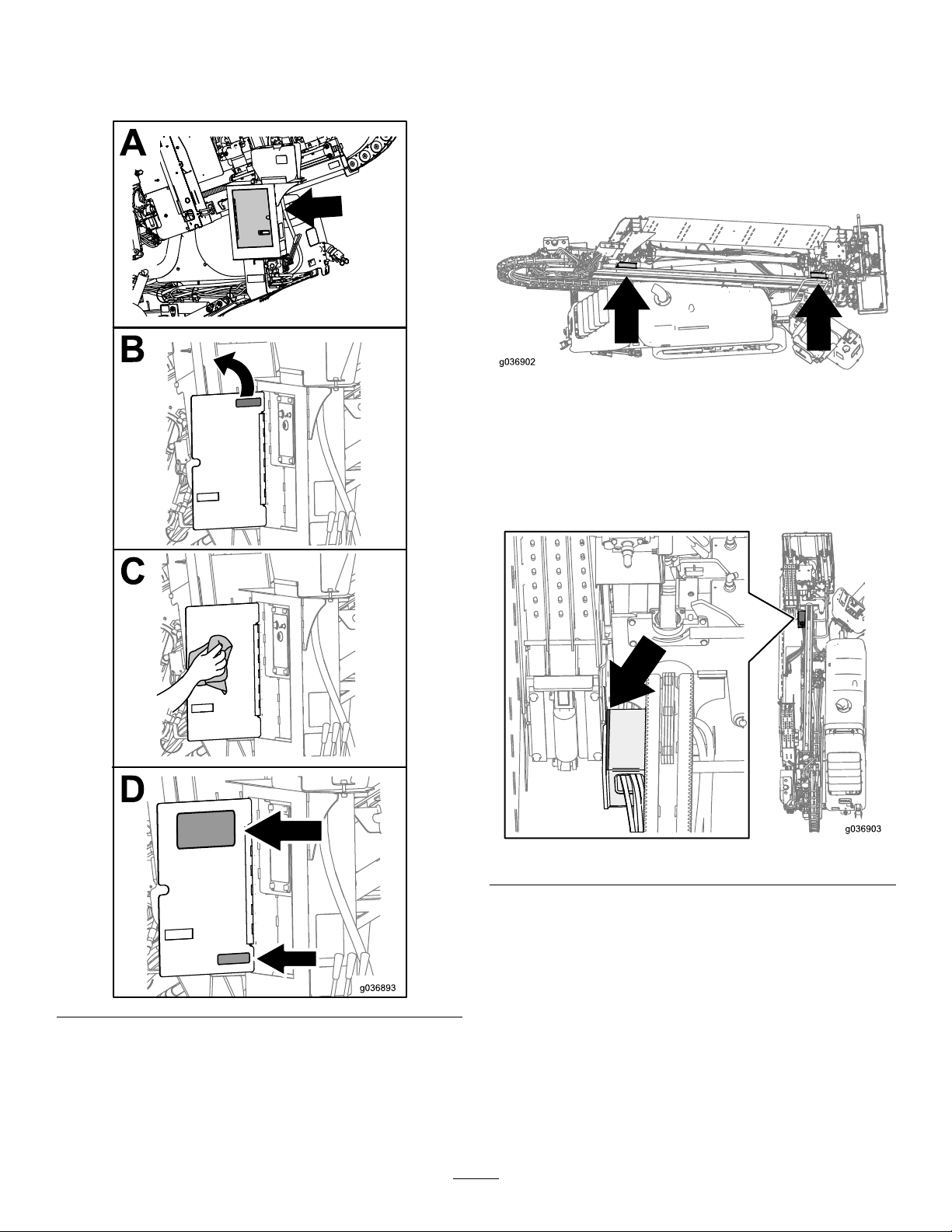

InstallingtheDecals

WeldingtheRod-Box

Removethecurrentdecal,cleanthesurface,andinstallthe

newdecals.

Thrust-FrameSupports

1.Parkthemachineonahardlevelsurface.Shutoffthe

engine,removethekey,andsetthebatterydisconnect

switchtoOFF.

2.Locatethethrust-framesupportsnearthecam

assemblies.

3.Removeallofthepaintanddirtonthefrontandrear

thrust-framesupports.

Note:Protectthehosesandwiringharnessnearthe

thrust-framesupports.

4.Weldahorizontalweldalongthefrontandrear

thrust-framesupports.

Frontthrust-framesupport(horizontalweld)

3

Page 4

Rearthrust-framesupport(horizontalweld)

Rearthrust-framesupport(verticalweld)

5.Inspecttheverticalweldonthefrontandrear

thrust-framesupports.Iftheweldshowssignsof

fatigue,repeatstep3andweldthisarea.

Frontthrust-framesupport(verticalweld)

6.Aftertheweldscool,primeandpainttheweldedareas

withsemi-glossblackpaint.

4

Page 5

InstallingtheExhaust

InstallingandModifyingthe

InsulationRetainerRing

Removetheinsulation,foldtheretainerringontheinsulation

piece,andinstalltheassembly.

FrontHoodLatches

1.Removethecurrenthoodlatchandinstallthenew

hoodlatch.

2.Openthefronthoodanddisconnecttheinternalfront

hoodlatch.

3.Grinddownthetipoftheinternalfronthoodlatch.

Note:Ensurethatyouleavethehooklength1.6cm

(0.63inch)long.

5

Page 6

4.Installtheinternalfronthoodlatch.

4.Shutofftheengine,removethekey,andsetthe

battery-disconnectswitchtoOFF.

5.Supportthethrustframewithaliftingstrapconnected

toanoverheadcrane.

6.Loosenthelefttracktension;refertotheOperator’s

Manualforthemachine.

InstallingtheThrustFrame

PivotPin

1.Parkthemachineonahardlevelsurface.

2.Removethedrillpipesfromthepipebox.

3.Lowerthestake-downplatetotheground,raisethe

footstabilizers,andpositionthecarriageintheforward

position.

7.Locatethethrustframepivotpin.

8.Insertblocksbetweentheupperpartofthetrackand

thetrackframe.

9.Removethepivotpinkeeperboltandpin.

10.Begintoslideoutthecurrentpivotpin.

Note:Tackweldalargeslidehammertotheretainer

endofthepinandusetheslidehammertopullthepin

orusealongbarorpipeasadriveanddrivethepin

outfrombetweentherighttrackandthemainframe

ofthedrill.

11.Installthetemporarypinontheothersideofthethrust

frameandcontinuetoslideoutthecurrentpivotpin.

6

Page 7

12.Replacethebushing.

Note:Ifthebushingisweldedinplace,grindtheweld

smoothbeforeinstallingthenewpin.

14.Removethetemporarypinandreplacethebushing.

Note:Ifthebushingisweldedinplace,grindtheweld

smoothbeforeinstallingthenewpin.

15.Pushthenewpinallthewayin.

13.Addgreasetothenewpivotpinandpushitinalmost

allthewayin.

16.Usingthepivotagpinasaguide,drillaholeintothe

thrustframe.

17.Installthebolt,washer,andnut.

18.Installtheretainerringontheotherendofthenew

pivotpin.

7

Page 8

19.Cleanthegreasettingsandpumpgreaseintothe

ttingsuntilgreasebeignstooozeoutofthebearings.

20.Wipeupanyexcessgrease.

21.Removetheblocksfromthetrack.

22.Tightenthelefttracktension;refertotheOperator’s

Manualforthemachine.

23.Removethestrapfromthethrustframeandlowerthe

thrustframebackintothestowedposition.

24.SetthebatterydisconnectswitchtoON.

8

Loading...

Loading...