Page 1

LiftHoseKit

TX1000CompactToolCarrier

ModelNo.133-8590

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Installation

FormNo.3413-815RevA

InstallationInstructions

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Nopartsrequired

Longtrimseal2

Shorttrimseal

Righthoses2

Hosesleeve1

Cabletie

Lefthose

Hosenut2

Hosesleeve1

Cabletie

Nopartsrequired

Qty.

Use

–

–

2

2

2

2

–

Preparethemachine.

Removethehoses.

Installthetrimseals.

Replacingtherighthoses.

Installthelefthoses.

Completetheinstallation.

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3413-815*A

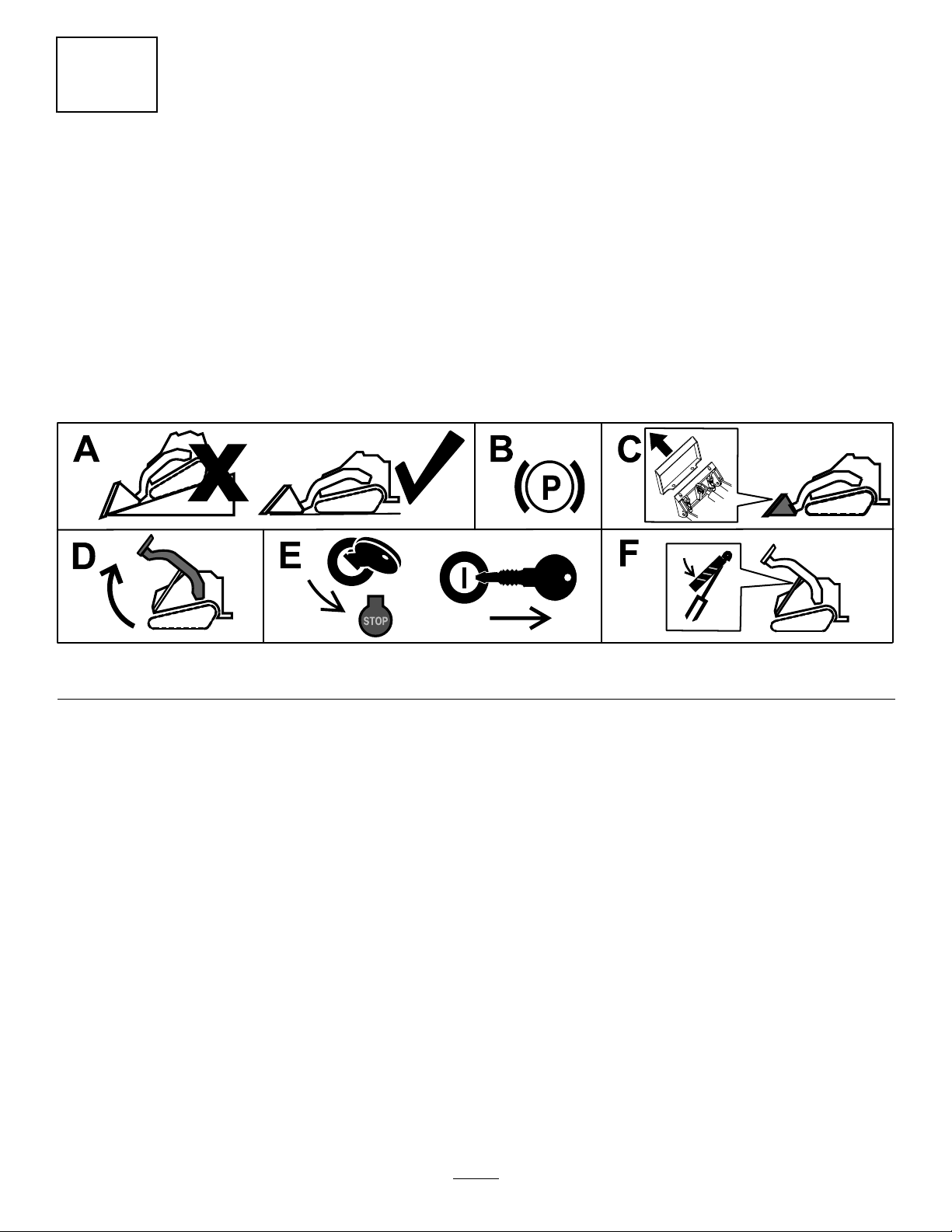

Page 2

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Removeanyattachments.

4.Raisetheloaderarms.

5.Shutofftheengineandremovethekey .

6.Installthecylinderlocks.

Figure1

g203664

2

Page 3

2

RemovingtheHoses

NoPartsRequired

Procedure

1.Cycletheloader-valvehandleforwardandbackto

relievepressureinthehydraulic-cylinderhoses.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Ifhydraulicuidisinjectedintotheskin,

itmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththistype

ofinjury.Gangrenemayresultifthisis

notdone.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Makesurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsare

tightbeforeapplyingpressuretohydraulic

system.

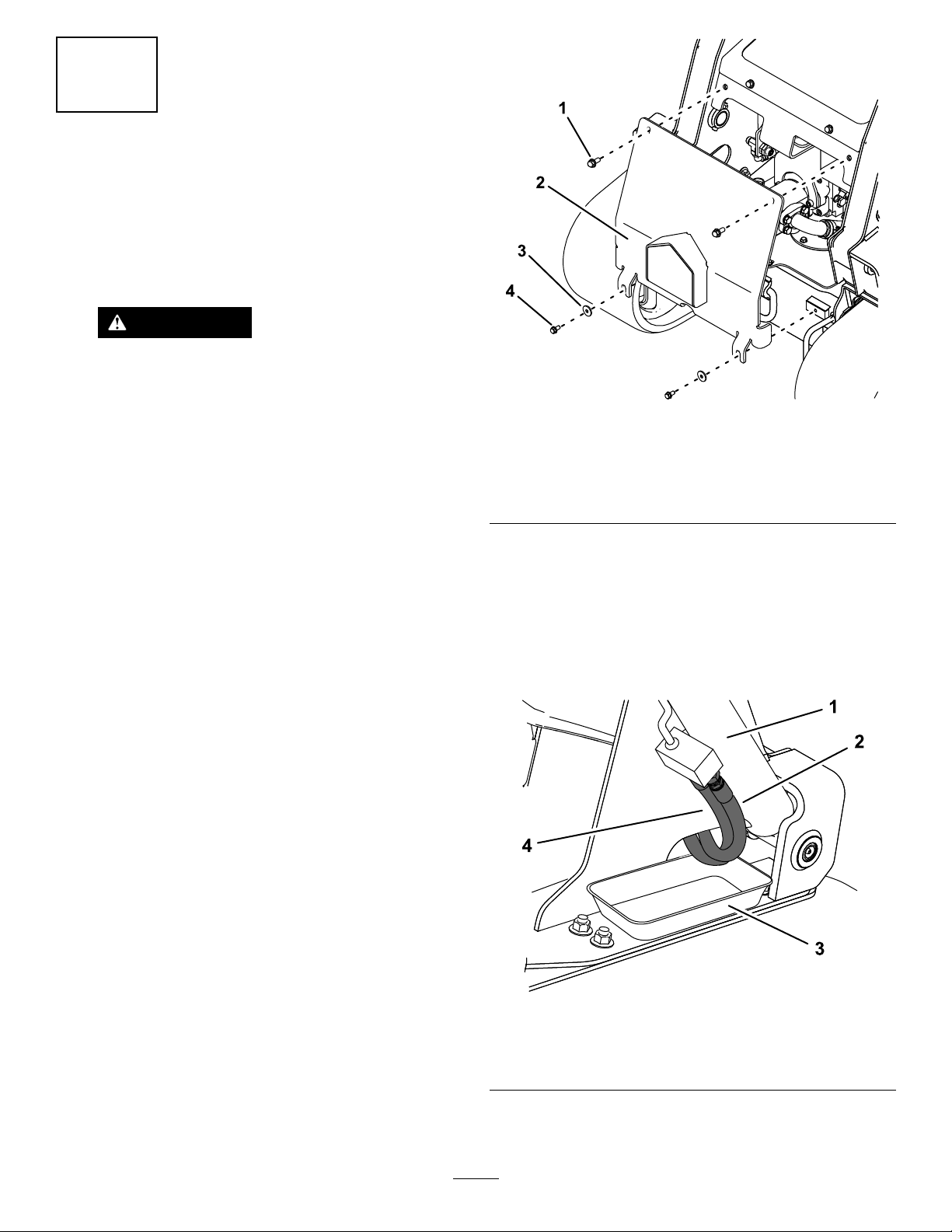

2.Usinga9/16-inchsocket,removethe2upperbolts

(3/8x1inch)fromthefrontcover(Figure2).

Figure2

1.Upperbolt(2)—3/8x1

inch

2.Frontcover

3.Usinga1/2-inchsocket,removethe2lowerbolts

(5/16x5/8inch),2washers,andfrontcover(Figure2).

4.Placeanoilcontainerorabsorbenttowelsunder

thehydrauliccylinderhosesontherightsideofthe

machine(Figure3).

5.Removetheouterandinnerhosesusinga13/16-inch

open-endwrench(Figure3).

3.Washer(2)

4.Lowerbolt(2)—5/16x5/8

inch

g204032

Figure3

1.Hydrauliccylinder

2.Outerhydraulichose

6.Drainanyexcessuidfromthehoses.

3

3.Container

4.Innerhydraulichose

g203988

Page 4

7.Usinga13/16-inchwrench,removetherightouterand

innerhydraulichosesfromtheteettings(Figure4).

Figure4

g204068

Figure5

1.Longtrimseal

3.Presstheshorttrimsealovertheouterframe(Figure

6).

g203989

1.Right,innerhydraulichose

2.Innerteetting5.Left,outerhydraulichose

3.Outerteetting

8.Removethehosesthroughtheframeopeningand

discardthem.

9.Repeatsteps4through8fortheothersideofthe

machine.

4.Left,innerhydraulichose

6.Right,outerhydraulichose

3

InstallingtheTrimSeals

Partsneededforthisprocedure:

2Longtrimseal

2

Shorttrimseal

Procedure

Note:Youmayuseanadhesivetoadherethetrimsealsto

themachineframe.

Figure6

1.Shorttrimseal

4.Repeattheprocedurefortheothersideofthemachine.

4

InstallingtheRightHoses

Partsneededforthisprocedure:

2Righthoses

1Hosesleeve

2

Cabletie

g204069

1.Cleantheinnerandouterframeopeningsofanydirt

andoil.

2.Startingatthetopoftheright,innerframeopening,

pressthelongtrimsealaroundtheopening(Figure5).

Cutthetrimsealsothatitdoesnotoverlap.

Procedure

Note:Therighthoseshave90-degreettingson1end.

1.InspecttheO-ringsintheteettings.Replaceanythat

havecuts/abrasionsoraredamaged.

4

Page 5

2.Removeanyprotectivecoveringfromtheendsofthe

hydraulichoses.

3.Installahosesleeveoverthestraightendsofthehoses,

leavingapproximately15.2cm(6inches)oftheend

exposed(Figure7).

Figure7

1.Hosesleeve

4.Insertthe90-degreehosettingsthroughtheouter

andinnerframeopening.Ensurethatthehosesleeve

liesinsidebothframeopeningsandthatthehosesare

atinsidetheopenings.

5.LooselyconnectbothhosestotheteettingsinFigure

4.

6.Positionthehosesconnectedtotheteettingsothat

theyverticalorslightlyturnedforward.Tightenthe

hosenutsusinga13/16-inchwrench.Torqueto36

to44N∙m(27to33ft-lb).

7.Connectthehosefromtheinnerteettingtotheinner

cylindertting;connectthehosefromtheoutertee

ttingtotheoutercylindertting(Figure8).

2.Approximately15.2cm(6

inches)

5

InstallingtheLeftHoses

Partsneededforthisprocedure:

2

Lefthose

2Hosenut

g204094

1Hosesleeve

2

Cabletie

Procedure

Note:Thelefthoseshaveastraightttingonbothends.

1.InspecttheO-ringsintheteettings.Replaceanythat

havecutsorabrasionsoraredamaged.

2.Removeanyprotectivecoveringfromtheendsofthe

hydraulichoses.

3.Installahosesleeveoverthehoses,leaving

approximately15.2cm(6inches)oftheendexposed

(Figure7).

4.Insertthehosesthroughtheouterandinnerframe

opening.Ensurethatthehosesleeveliesinsideboth

frameopeningsandthatthehosesareatinsidethe

openings.

Figure8

1.Hydrauliccylinder3.Hosesleeve

2.Outerhydraulichose

8.Usea13/16-inchoffsetwrenchtotightenthenuts

whileusinga11/16-inchopen-endwrenchtoholdthe

hosepositions.Torqueto36to44N∙m(27to33ft-lb).

4.Innerhydraulichose

5.Connectthehosestotheinnerandoutercylinder

ttings(Figure8).

Note:Usea13/16-inchoffsetwrenchtotightenthe

nutswhileusinga11/16-inchopen-endwrenchto

holdthehosepositions.

6.Installahosenutontobothteettingssothatthereare

enoughthreadstoseatthehoseends(Figure9).

Note:Youmayalsousehosenutsthatwerepreviously

installedonthetting.

7.Connectthehosefromtheinnercylinderttingto

therearteetting;connectthehosefromtheouter

cylinderttingtothefrontteetting(Figure9).

g204093

Note:Usea13/16-inchwrenchtotightenthehose

nutswhileusinga11/16-inchopen-endwrenchto

holdthehosepositions.

9.Usethecabletiestosecurethehosesleevetothe

hydraulichoses.

5

Page 6

Figure9

g204177

1.Existingandkithosenuts

2.Left,innerhydraulichose

8.Ensurethattheinnerhydraulichosedoesnotcontact

thebatterytray.

9.Usea1-inchwrenchtotightenthehosenutsonthetee

ttingsagainstthehydraulichosenuts.

10.Usethecabletiestosecurethehosesleevetothe

hydraulichoses.

3.Left,outerhydraulichose

6

CompletingtheInstallation

NoPartsRequired

Procedure

1.Starttheengine.

2.Raisetheloaderarmsandremovethecylinderlocks.

3.Raiseandlowertheloaderarms;checkthehose

connectionsforleaks.

4.Checkthehydraulic-uidlevel;refertotheOperator’s

Manualforthemachine.

5.Installthefrontcover.

6

Page 7

Notes:

Page 8

Loading...

Loading...