Page 1

Installation

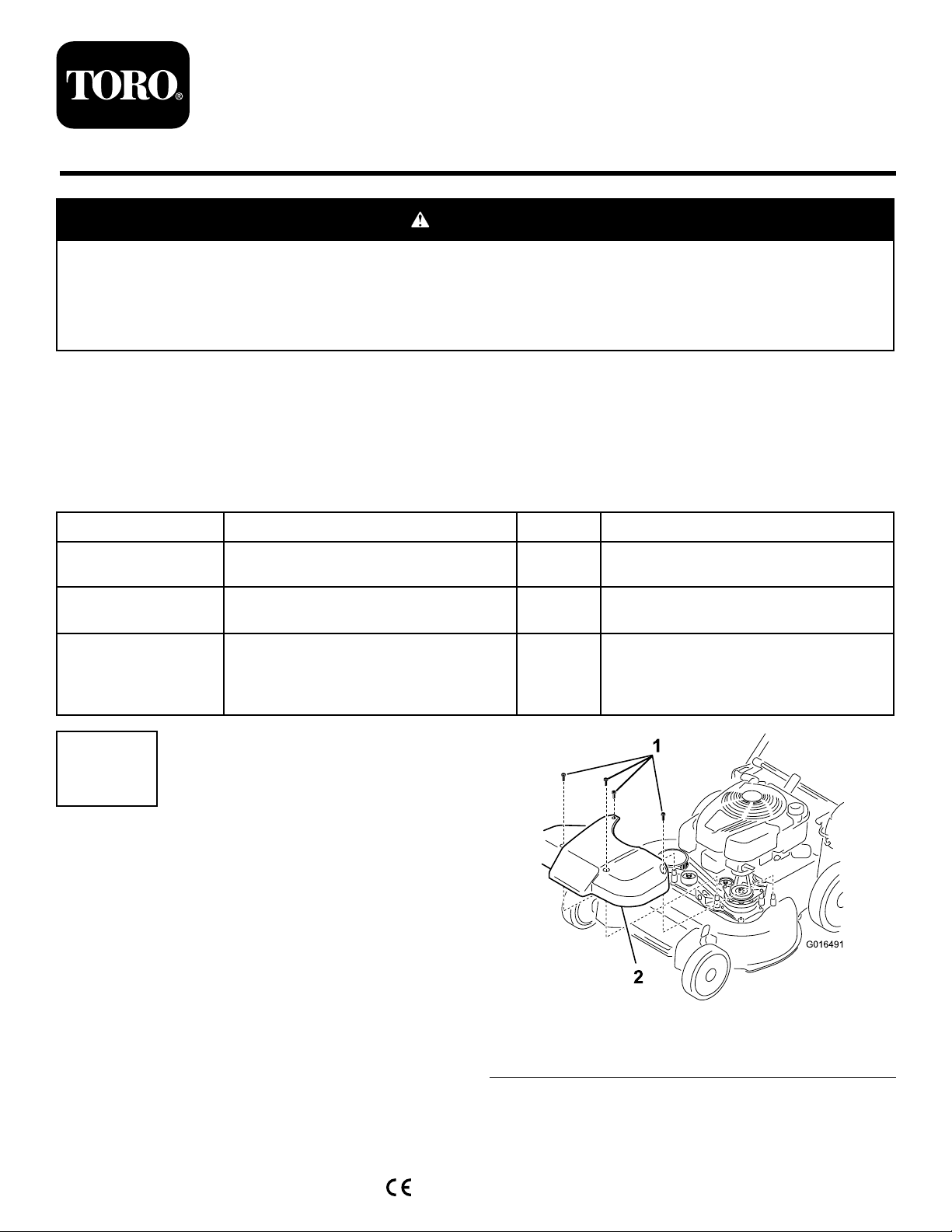

G016491

1

2

LooseParts

FormNo.3411-616RevA

BBCArmServiceKit

TimeMaster30inor76cmLawnMower

ModelNo.133-8158

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

Nopartsrequired

Nopartsrequired

Brakearm1

Brakecable1

Rubberspacer1

Cabletie

1

PreparingtheMachinefor

Installation

NoPartsRequired

Qty.

Use

–

–

2

Preparethemachineforinstallation.

Removetheexistingbrakearmand

brakecable.

Installthebrakearmandbrakecable.

Procedure

Important:Refertoyourmachine

formaintenancesafetyinformation.

©2016—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

1.Movethemachinetoalevelsurface.

2.Releasetheblade-controlbar.

3.Disconnectthespark-plugwirefromthesparkplug.

4.Removetheblade-drivesystemcoverfromthemachine

(Figure1).

Operator’ s Man ual

Registeratwww.T oro.com.

Figure1

1.Bolt(4)

5.Tipthemachineontoitsside,withtheairlterfacing

upward,untiltheupperhandlerestsontheground.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

2.Blade-drivesystemcover

*3411-616*A

g016491

Page 2

Important:Tippingthemachinemaycausethe

fueltoleak.Fuelisammableandexplosive,and

cancausepersonalinjury.Runtheenginedryto

removethefuelwithahandpump;neversiphon

thefuel.

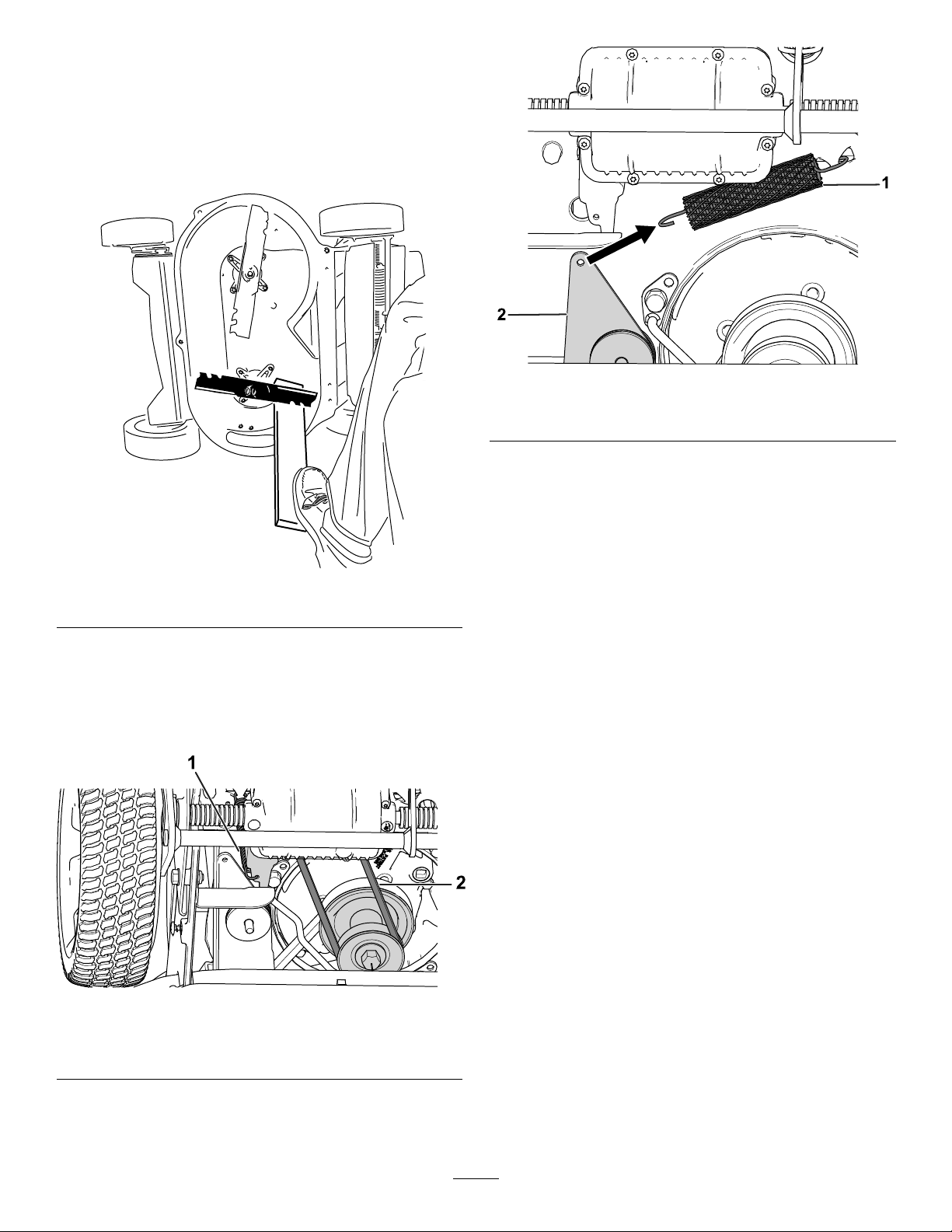

6.Useablockofwoodtoholdeachbladesteady(Figure

2).

g194726

Figure4

1.Brake-extensionspring2.Brakearm

Figure2

7.Removethetransmissionbeltandthetransmission

tensionspringfromthemachine(Figure3).

Note:Removingthetransmissionbeltandthe

transmissiontensionspringallowsaccesstothebrake

arm.

Figure3

g196361

g193793

1.Transmissiontension

spring

2.Transmissionbelt

8.Removethebrake-extensionspringfromthebrake

arm(Figure4).

2

Page 3

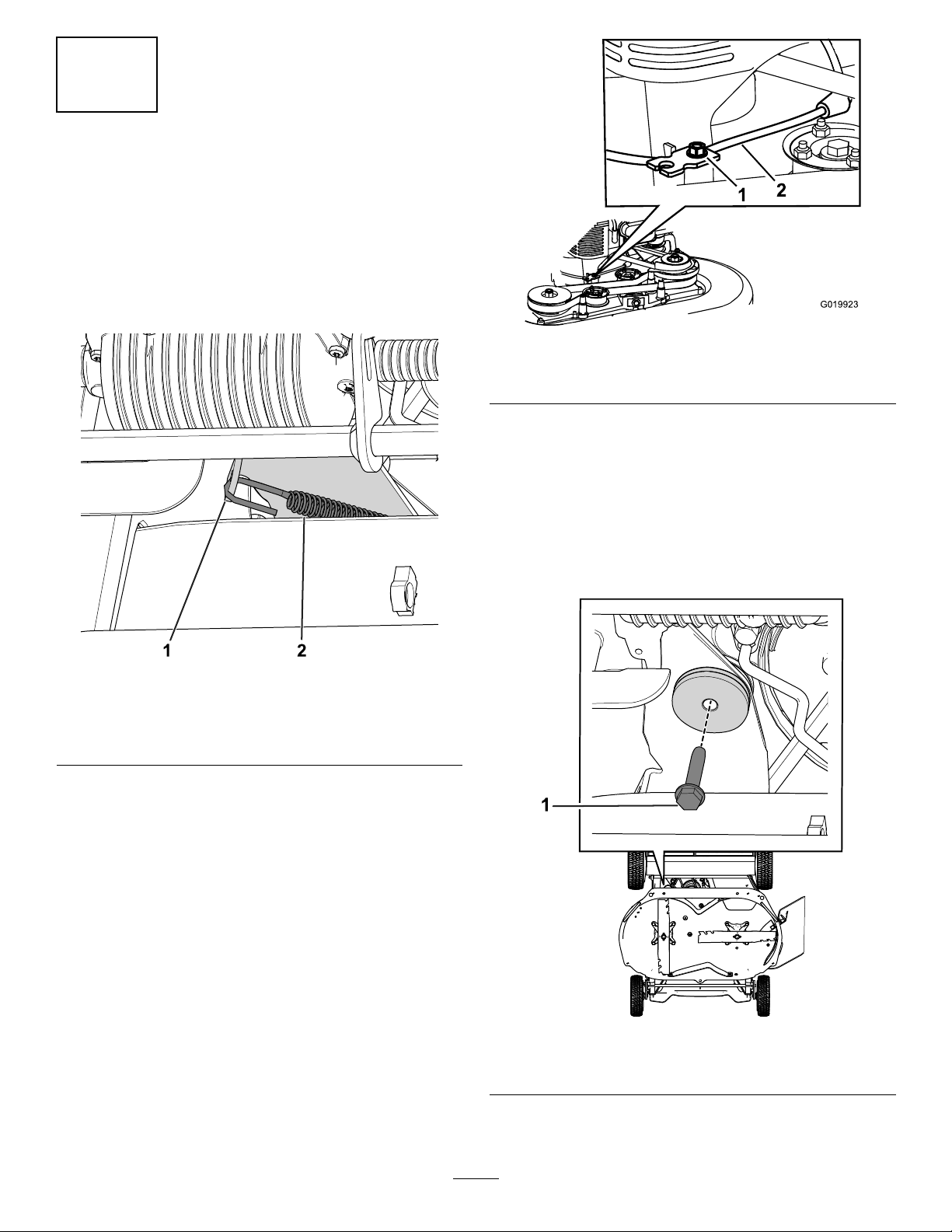

2

1

2

G019923

RemovingtheExistingBrake

ArmandBrakeCable

NoPartsRequired

Procedure

1.Removethebrakecablefromthebrake-armhook

(Figure5).

g019923

Figure6

Figure5

1.Brake-armhook2.Brakecable

2.Loosenthecable-clampscrewandslidethecableout

fromundertheengine(Figure6).

1.Cable-clampscrew

3.Removethebrakearmfromthemachine.

Note:Thebrakearmcanbemountedontothe

machinewithathread-formingscreworaboltanda

nut.

2.Brakecable

•Formachineswithathread-formingscrewthat

securesthebrakearmontothemachine:

Removethethread-formingscrew;retainandset

itaside(Figure7)

g194452

g195872

Figure7

1.Thread-formingscrew

•Formachineswithaboltandanutthatsecuresthe

brakearmontothemachine:

3

Page 4

Removetheboltandthenut;retainandsetthem

aside(Figure8andFigure9).

Important:Retainallhardwareforusein3

InstallingtheBrakeArmandBrakeCable(page

4).

g193781

Figure10

g194201

Figure8

6.Disconnectthebrakecablefromtheblade-controlbar;

retainandsetthepushnutaside(Figure11).

1.Bolt

g193932

Figure11

5.Cutandremovetheexistingcableties.

Figure9

1.Nut

4.Removethehardwarefromthebrakearm(Figure10).

1.Pushnut2.Brakecable

g194514

4

Page 5

Usethethread-formingscrewtosecurethebrake

armontothemachine(Figure7).

3

InstallingtheBrakeArmand

BrakeCable

Partsneededforthisprocedure:

1Brakearm

1Brakecable

1Rubberspacer

2

Cabletie

Procedure

1.Installtherubberspacerandthehardwarefromtheold

brakearmontothenewbrakearm(Figure12).

Important:Inspecttherubberfrictionwashersfor

excessivewear.Replacethewashersifnecessary.

Note:T orquethescrewto16to20N∙m(144to

176in-lb).

•Formachineswithaboltandanutthatsecuresthe

brakearmontothemachine:

Usetheboltandthenuttosecurethebrakearm

ontothemachine(Figure8andFigure9).

Note:T orquethenutto10to13N∙m(85to115

in-lb).

Note:Afterinstallation,thebrakearmshouldhavea

fullrangeofmotionwithaslightresistancecreatedby

thefrictionwashers.

5.Usethepushnuttoinstallthebrakecableontothe

blade-controlbar(Figure11).

6.Routethebrakecablethroughtheinsertbelowthe

cableclamp(Figure6).

7.Attachthebrakecabletothebrake-armhook(Figure

13).

Figure12

1.Rubberspacer

2.Guidetherubberspaceralongthehookuntilitisush

withtheplate.

3.Torquetheboltthatyoupreviouslyremovedinstep4

to10to13N∙m(85to115in-lb).

4.Attachthebrakearmtothemachine.

•Formachineswithathread-formingscrewthat

securesthebrakearmontothemachine:

g195893

g193739

1.Brake-armhook2.Brakecable

8.Pullthecablejackettoremoveslack(Figure14).

Note:Donotputtensiononthespring.

5

Figure13

Page 6

Figure14

1.Cableclamp2.Cablejacket

9.Markthebrakecable(Figure15),thenadjustthejacket

untilthereisapproximately3mm(1/8inch)ofslack

(Figure16).

10.Torquethecable-clampscrewto11to14N∙m(99to

121in-lb)tolocktheadjustmentinplace.

11.Attach2cabletiesattheindicatedlocationsshownin

Figure17.

g195540

g194372

Figure17

1.Markthecablehere

1.Cabletielocations

12.Attachthebrake-extensionspringtothebrakearm.

13.Installthetransmissionbeltandthetransmission

tensionspring(Figure3).

14.Installtheblade-drivesystemcover(Figure1).

15.Connectthespark-plugwiretothesparkplug.

g195615

Figure15

1.Slack—3mm(1/8inch)

g195616

Figure16

6

Page 7

Notes:

Page 8

Loading...

Loading...