Page 1

INSTRUCTION MANUAL

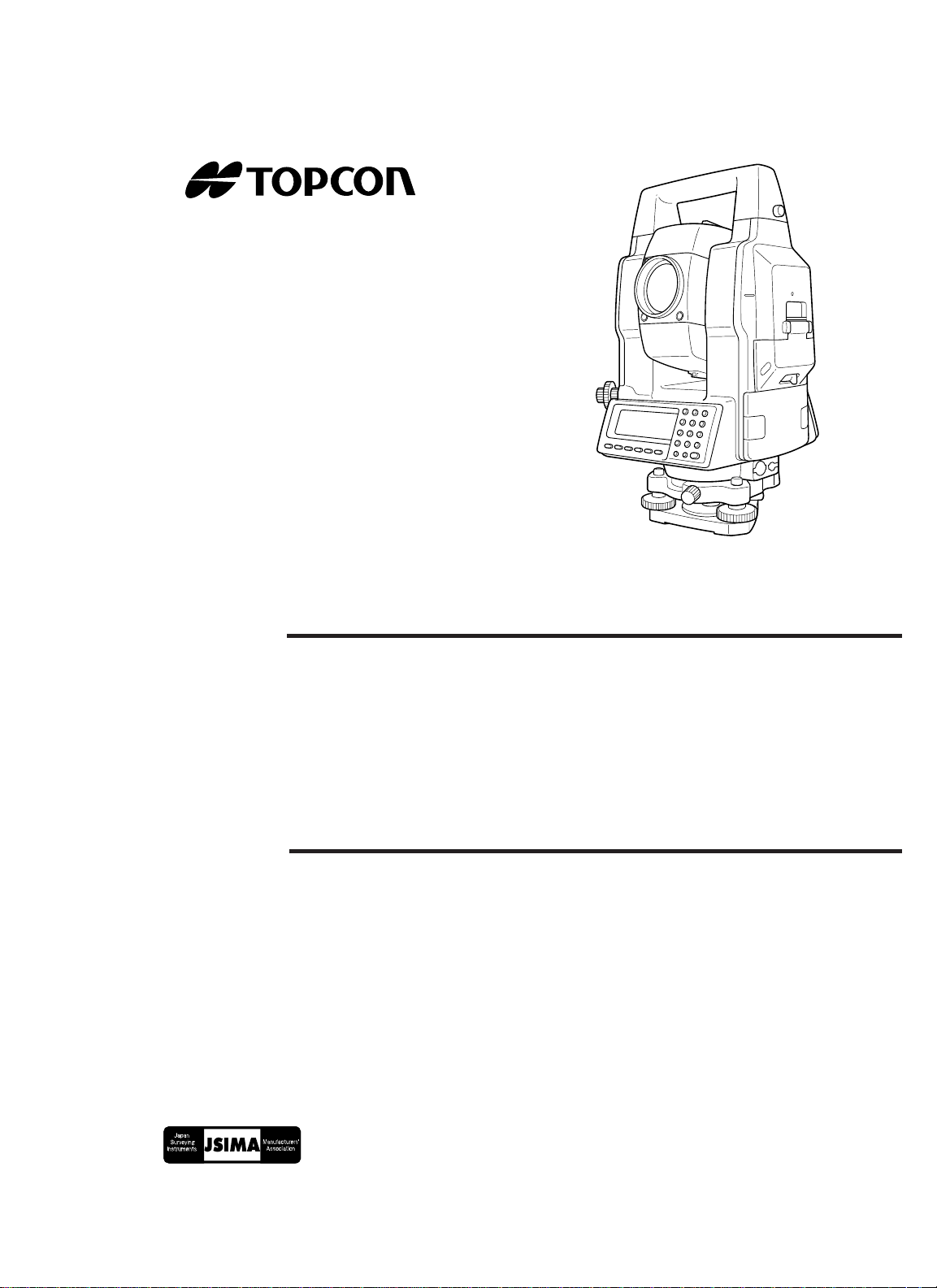

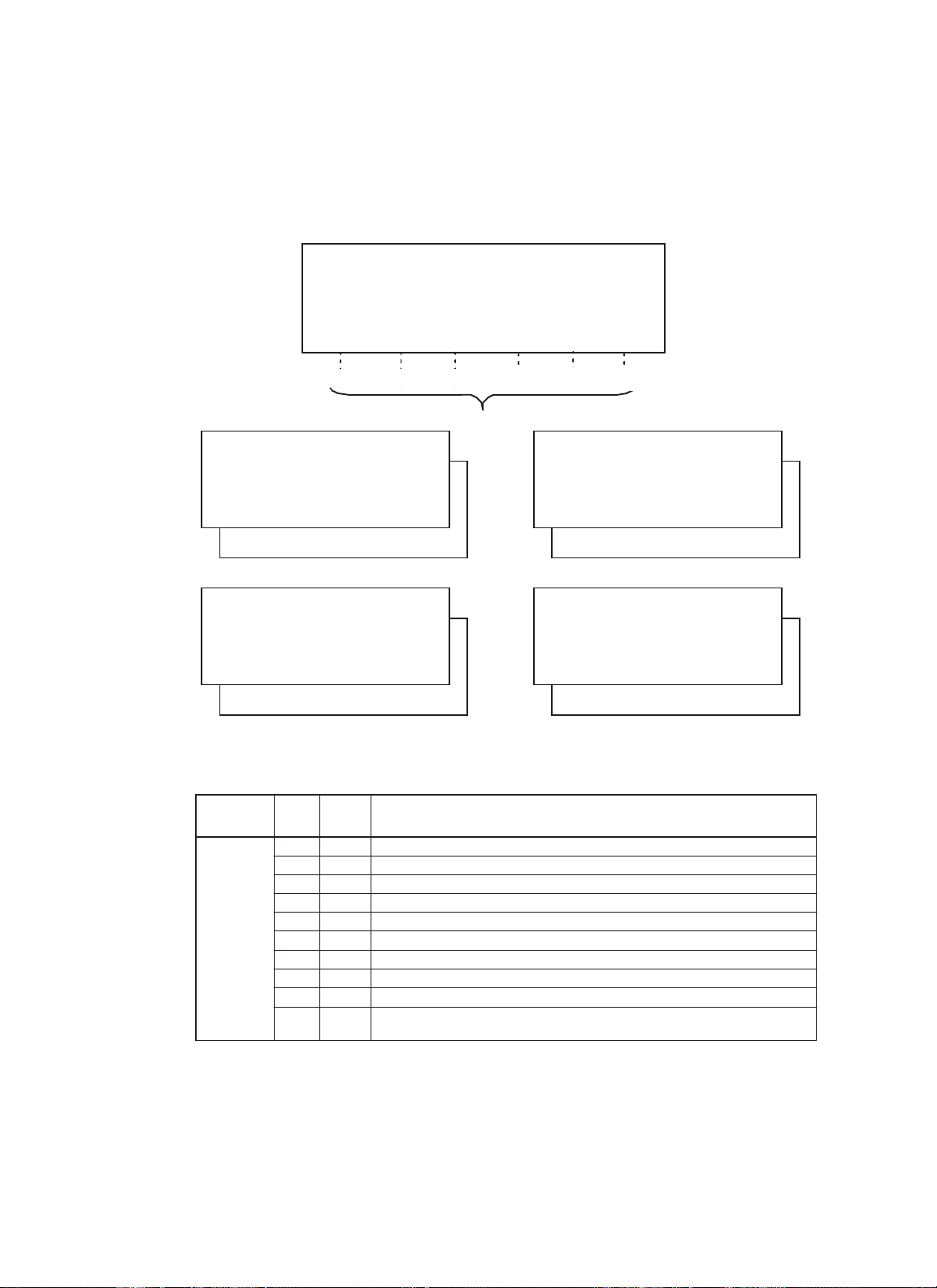

AUTOMATIC TRACKING PULSE TOTAL STATION

GPT-8000A

SERVO PULSE TOTAL STATION

SERIES

GPT-8001A

GPT-8002A

GPT-8003A

GPT-8005A

GPT-8000

SERIES

GPT-8001

GPT-8002

GPT-8003

GPT-8005

Page 2

.

AUTO TRACKING TOTAL STATION

GPT-8000A series

SERVO TOTAL STATION

GPT-8000 series

TOPCON POSITIONING SYSTEMS, INC.

5758 West Las Positas Blvd., Pleasanton, CA 94588, U.S.A.

Phone: 925-460-1300 Fax: 925-460-1315 www.topcon.com

TOPCON CALIFORNIA

3380 Industrial Blvd, Suite 105, West Sacramento, CA 95691,

Phone: 916-374-8575 Fax: 916-374-8329

TOPCON MIDWEST

891 Busse Road, Elk Grove Village, IL 60007, U.S.A.

Phone: 847-734-1700 Fax: 847-734-1712

TOPCON EUROPE B.V .

Essebaan 11, 2908 LJ Capelle a/d IJssel, The Netherlands.

Phone: 010-4585077 Fax: 010-4585045 www.topconeurope.com

TOPCON BELGIUM

Preenakker 8, 1785 Merchtem, Belgium

Phone: 052-37.45.48 Fax: 052-37.45.79

TOPCON DEUTSCHLAND G.m.b.H.

Weidkamp 180, 45356 Essen, GERMANY

Phone: 0201-8619-100 Fax: 0201-8619-111 ps@topcon.de

www.topcon.de

TOPCON S.A.R.L.

89, Rue de Paris, 92585 Clichy, Cedex, France.

Phone: 33-1-41069490 Fax: 33-1-47390251 topcon@topcon.fr

U.S.A.

TOPCON ESPAÑA S.A.

HEAD OFFICE

Frederic Mompou 5, ED. Euro 3, 08960, Sant Just Desvern Barcelona, Spain.

Phone: 93-473-4057 Fax: 93-473-3932 www.topconesp.com

MADRID OFFICE

Avenida Burgos, 16E, 1 28036, Madrid, Spain.

Phone: 91-302-4129 Fax: 91-383-3890

TOPCON SCANDINAVIA A. B.

Neongatan 2 S-43151 Mölndal, SWEDEN

Phone: 031-7109200 Fax: 031-7109249

TOPCON CORPORA TION

75-1 Hasunuma-cho, Itabashi-ku, Tokyo 174-8580, Japan

Phone: 3-3558-2520 Fax: 3-3960-4214 www.topcon.co.jp

TOPCON (GREA T

HEAD OFFICE

Topcon House Kennet Side, Bone Lane, Newbury, Berkshire RG14 5PX U.K.

Phone: 44-1635-551120 Fax: 44-1635-551170

survey.sales@topcon.co.uk laser.sales@topcon.co.uk

TOPCON SOUTH ASIA PTE. LTD.

Blk 192 Pandan Loop, Pantech Industrial Complex, #07-01, Singapore 128381

Phone: 62780222 Fax: 62733540 www.topcon.com.sg

TOPCON AUSTRALIA PTY . L TD .

408 Victoria Road, Gladesville, NSW 2111, Australia

Phone: 02-9817-4666 Fax: 02-9817-4654 www.topcon.com.au

TOPCON INSTRUMENTS (THAILAND) CO., LTD.

77/162 Sinn Sathorn T ower, 37th Fl.,

Krungdhonburi Rd., Klongtonsai, Klongsarn, Bangkok 10600 Thailand.

Phone: 662-440-1152~7 Fax: 662-440-1158

TOPCON INSTRUMENTS (MALA YSIA) SDN. BHD .

Lot 226 Jalan Negara 2, Pusat Bandar Taman Melawati,

Taman Melawati, 53100, Kuala Lumpur, Malaysia.

Phone: 03-41079801 Fax: 03-41079796

TOPCON KOREA CORPORA TION

2F Yooseoung Bldg., 1595-3, Seocho-Dong, Seocho-gu, Seoul, 137-876, Korea

Phone: 82-2-2055-0321 Fax: 82-2-2055-0319 www.topcon.co.kr

TOPCON OPTICAL (H.K.) LIMITED

2/F., Meeco Industrial Bldg., No. 53-55 A u Pui W an Street, Fo Tan Road,

Shatin, N.T ., Hong Kong

Phone: 2690-1328 Fax: 2690-2221 www.topcon.com.hk

TOPCON CORPORATION BEIJING OFFICE

Room No. 962 Poly Plaza Building, 14 Dongzhimen Nandajie,

Dongcheng District, Beijing, 100027, China

Phone: 10-6501-4191~2 Fax: 10-6501-4190

TOPCON CORPORATION BEIRUT OFFICE

P. O. BOX 70-1002 Antelias, BEIRUT-LEBANON.

Phone: 961-4-523525/961-4-523526 Fax: 961-4-521119

TOPCON CORPORATION DUBAI OFFICE

P.O.Box 28595, 102, Al Naily Bldg., 245 Abu Hail Road, Deira,Dubai,UAE

Phone: 971-4-2696511 Fax: 971-4-2695272

BRIT AIN) LTD.

64538 90020 GPT- 8000/8000A Series A 0207 (2B)

Page 3

FOREWORD

1

FOREWORD

Thank you for purchasing the TOPCON Auto Tracking Pulse Total Station / Servo Pulse Total

Station, GPT-8000A/8000 series. For the best performance of the instruments, please carefully

read these instructions and keep them in a conve-nient location for future reference.

General Ha nd ling P rec aut i on s

Before starting work or operation, be sure to check that the instrument is functioning

correctly with normal performance.

Do not submerge the instrument into water.

The instrument can not be submerged underwater.

The instrument is designed based on the International Standard IP54, therefore it is protected from

the normal rainfall.

Setting the instrument on a tripod

When mounting the instrument on a tripod, use a wooden tripod when possible. The vibrations that

may occur when using a metallic tripod can effect the measuring precision.

Installing the tribrach

If the tribrach is installed incorrectly, the measuring precision could be effected. Occasionally check

the adjusting screws on the tribrach. Make sure the base fixing lever is locked and the base fixing

screws are tightened.

Guarding the instrument against shocks

When transporting the instrument, provide some protection to minimize risk of shocks. Heavy

shocks may cause the measurement to be faulty.

Carrying the instrument

Always carry the instrument by its handgrip.

Exposing the instrument to extreme heat.

Do not leave the instrument in extreme heat for longer than necessary. It could adversely affect its

performance.

Sudden changes of temperature

Any sudden change of temperature to the instrument or prism may result in a reduction of

measuring distance range, i.e when taking the instrument out from a heated vehicle. Let instrument

acclimate itself to ambient temperature.

Battery level check

Confirm battery level remaining before operating.

Memory back up

The instrument has a built in battery for memory back up. If the battery power is low, “Back up

battery empty” will display. Contact your dealer, to replace the battery.

Taking the battery out

It is recommended not to take the battery out during the power is on. All the data stored is possible

gone at that time. So please do your assembling or taking the battery out after the power is off.

No responsibility

TOPCON Corporation has no responsibility for loss of data stored in the memory in case

unexpected accidents.

Page 4

FOREWORD

2

Rotating the instrument and telescope

Rotation of the instrument or telescope is driven electronically in normal operation.

Do not disturb the rotation.

Storage in the case

Keep the telescope horizontally and turn the instrument to align its mark with the lower base mark

(Storage mark). Keep its objective lens side downward. Storing it in the case in any other way may

cause damage. Hold the hand grips and base with both hands, when taking the instrument out of the

case, or putting the equipment in the case.

Maintenance for driving parts.

Every 4,000~5,000 hours operation in total, change grease of driving parts.

Contact your dealer or TOPCON Head Office for the maintenance.

Page 5

FOREWORD

3

Display for Safe Use

In order to encourage the safe use of products and prevent any danger to the operator and

others or damage to properties, important warnings are put on the products and inserted in

the instruction manuals.

We suggest that everyone understand the meaning of the following displays and icons before

reading the “Safety Cautions” and text.

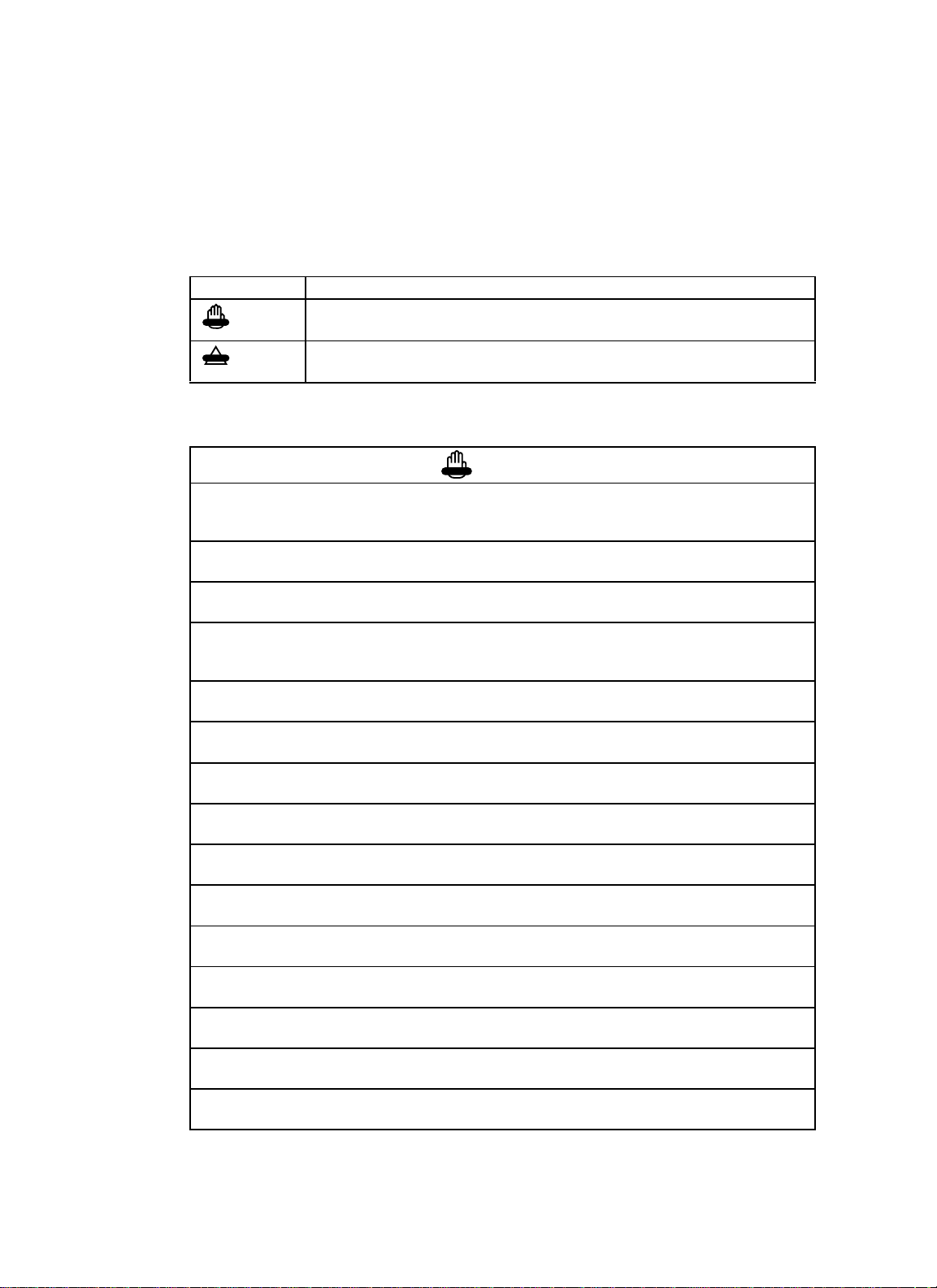

Display Meaning

WARNING

WARNING

CAUTION

CAUTION

• Injury refers to hurt, burn, electric shock, etc.

• Physical damage refers to extensive damage to buildings or equipment and furniture.

Safety Cautions

•There is a risk of fire, electric shock or physical harm if you attempt to disassemble or

r epair the instrument yourself.

This is only to be carried out by TOPCON or an authorized dealer, only!

•Cause eye injury or blindness.

Do not look at the sun through a telescope.

•Laser beams can be dangerous, and can cause eye injury's if used incorrectly.

Never attempt to repair the instrument yourself. (GPT-8000A series and laser plummet model)

•Cause eye injury or blindness.

Do not stare into beam.

(GPT-8000A series and laser plummet model)

•High temperature may cause fire.

Do not cover the charger while it is charging.

•High temperature may cause fire.

Do not connect the battery to an instrument while it is charging.

•Risk of fire or electric shock.

Do not use damaged power cable, plug and socket.

•Risk of fire or electric shock.

Do not use a wet battery or charger.

•May ignite explosively.

Never use an instrument near flammable gas, liquid matter, and do not use in a coal mine.

•Battery can cause explosion or injury.

Do not dispose in fire or heat.

•Risk of fire or electric shock.

Do not use any power voltage except the one given on manufacturers instructions.

•Battery can cause outbreak of fire.

Do not use any other type of charger other than the one specified.

•Risk of fire.

Do not use any other power cable other than the one specified.

•Battery can cause outbreak of fire.

Do not block up the vent of the battery.

•The short circuit of a battery can cause a fire.

Do not short circuit battery when storing it.

Ignoring or disregard of this display may lead to the danger of death or

serious injury.

Ignoring or disregard of this display may lead to personal injury or phys

-ical damage.

WARNING

WARNING

Page 6

FOREWORD

4

User

1) This product is for professional use only!

The user is required to be a qualified surveyor or have a good knowledge of surveying, in

order to understand the user and safety instructions, before operating, inspecting or adjusting.

2) Wear the required protectors (safety shoes, helmet, etc.) when operating.

Exceptions from Responsibility

Exceptions from Responsibility

1) The user of this product is expected to follow all operating instructions and make periodic

checks of the product’s performance.

2) The manufacturer, or its representatives, assumes no responsibility for results of a faulty or

intentional usage or misuse including any direct, indirect, consequential damage, and loss

of profits.

3) The manufacturer, or its representatives, assumes no responsibility for consequential

damage, and loss of profits by any disaster, (an earthquake, storms, floods etc.).

A fire, accident, or an act of a third party and/or a usage any other usual conditions.

4) The manufacturer, or its representatives, assumes no responsibility for any damage, and

loss of profits due to a change of data, loss of data, an interruption of business etc., caused

by using the product or an unusable product.

5) The manufacturer, or its representatives, assumes no responsibility for any damage, and loss

of profits caused by usage except for explained in the user manual.

6) The manufacturer, or its representatives, assumes no responsibility for damage caused by

wrong movement, or action due to connecting with other products.

CAUTION

CAUTION

Use of controls or adjustment or performance of procedures other than those specified herein

may result in hazardous radiation exposure.(GPT-8000A series and laser plummet model)

Let the laser beam reach the aimed object or the target without anybody else in the laser beam

path. In case you operate laser beam open, avoid radiating laser beam to the height of man's

head. It is quite possible for the beam to enter into one's eyes, and it is possible to lose visual

sight temporarily, and lose one's caution and awareness of other dangers - avoid glaring beam.

(GPT-8000A series and laser plummet model)

Do not connect or disconnect equipment with wet hands, you are at risk of electric shocks if you

do!

Risk of injury by overturn the carrying case.

Do not stand or sit on the carrying cases.

Please note that the tips of tripod can be hazardous, be aware of this when setting up or

carrying the tripod.

Risk of injury by falling down the instrument or case.

Do not use a carrying case with a damaged which belts, grips or latches.

Do not allow skin or clothing to come into contact with acid from the batteries, if this does occur

then wash off with copious amounts of water and seek medical advice.

A plumb bob can cause an injury to a person if used incorrectly.

It could be dangerous if the instrument falls over, please ensure you attach a handle battery to

the instrument securely.

Ensure that you mount the Tribrach correctly, failing to do so may result in injury if the tribrach

were to fall over.

It could be dangerous if the instrument falls over, please check that you fix the instrument to the

tripod correctly.

Risk of injury by falling down a tripod and an instrument.

Always check that the screws of tripod are tightened.

Page 7

FOREWORD

5

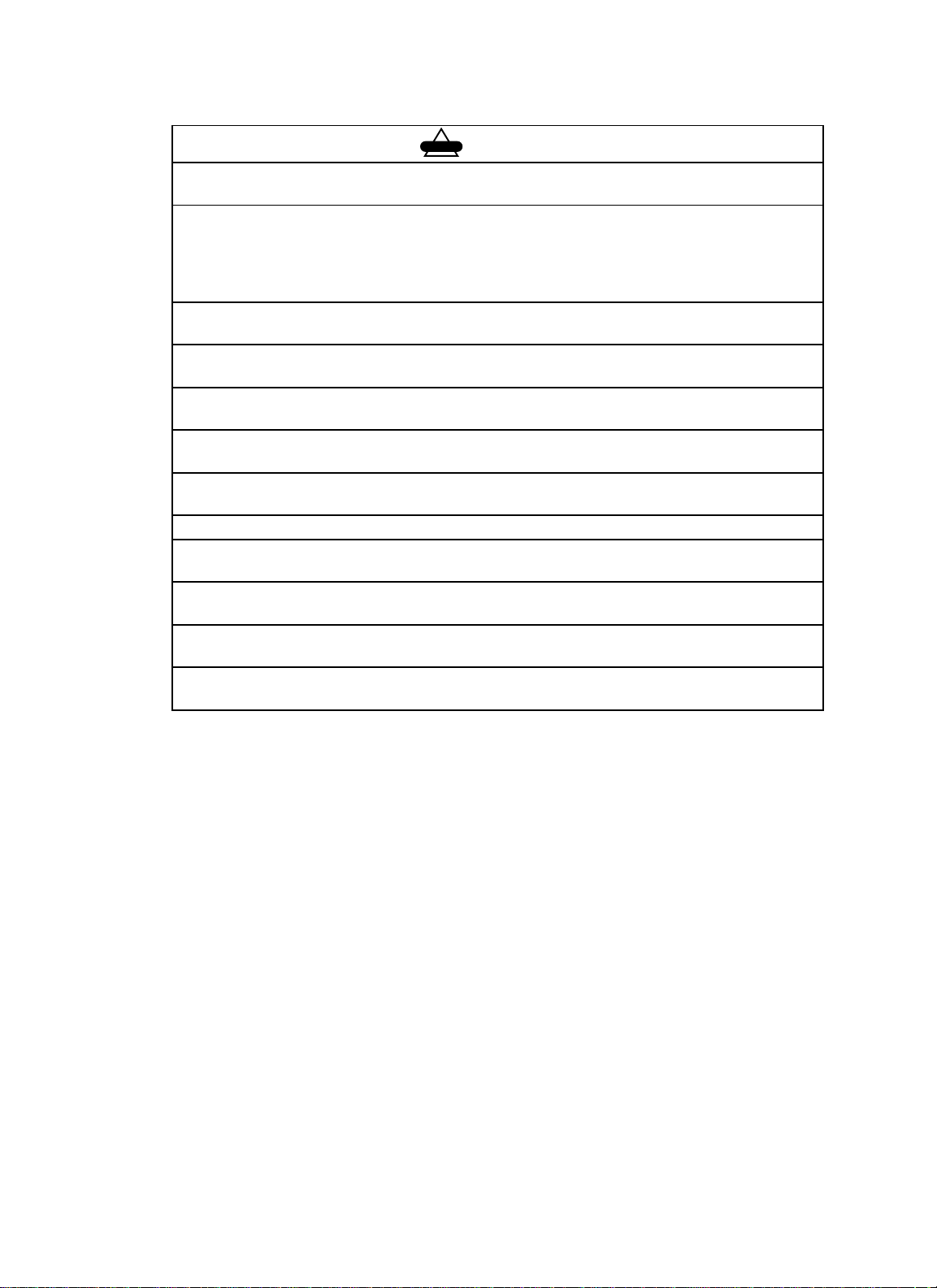

Laser Safety

•

Distance measurement

GPT-8000A/8000 series uses the invisible laser beam to measure the distance. The GPT-8000A/8000

series are manufactured and sold in accordance with "Performance Standards for Light-Emitting

Products" (FDA/BRH 21 CFR 1040) or "Radiation Safety of Laser Products, Equipment Classification,

Requirements and User`s Guide" (IEC Publication 60825-1) provided on the safety standard for laser

beam.

As per the said standard, the GPT-8000 series is classified as "Class 1 (l) Laser Products".

In case of any failure, do not disassemble the instrument. Contact TOPCON or your

TOPCON dealer.

•

GPT-8000A series

GPT-8000Aseries uses the visible laser beam for auto tracking and optical communication. The

GPT-8000Aseries products are manufactured and sold in accordance with “Radiation Safety of Laser

Products, Equipment Classification, Requirements and User‘s Guide” (IEC Publication 60825-1) or

“Performance Standards for Light-Emitting Products” (FDA/BRH 21 CFR 1040) provided on the safety

standards for laser beam.

As per the said standards, GPT-8000Aseries is classified as “Class 2 (CLASS II) Laser Products”.

The laser beam belongs not very dangerous type but we request you to keep and understand “Safety

standard for users” as mentioned in the manual instruction.

In case of any failure, do not disassemble the instrument. Contact TOPCON or your

TOPCON dealer.

Labels

Find the labels which describes the caution and safety about the laser beam as follows in GPT-8000A

series. We request you to replace it one anytime the caution labels are damaged or lost and paste a

new one at the same place. You can get the labels from Topcon or

your dealer.

Beam aperture

ent

Beam aperture

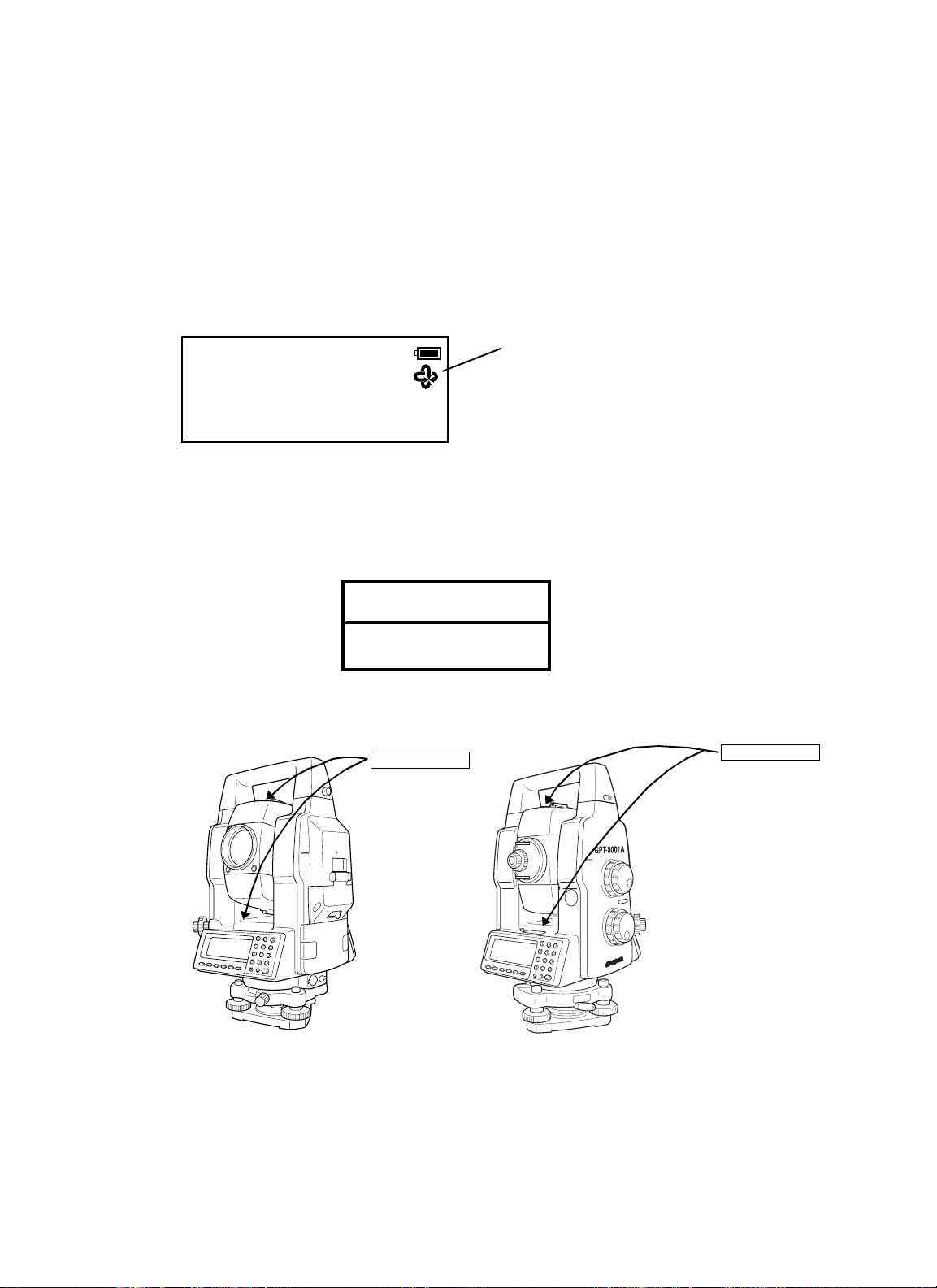

GPT-8000A series

Symbol marks while the laser is emitting.

The following symbol marks of instrument status will indicate that the laser is emitting.

Marks Status of instrum

V : 87°55'45"

HR: 180°44'12"

SD HD NEZ 0SET HOLD P1↓

The symbol mark

Warning Label

Explanatory Label

CAUTION

LASER RADIA TION

DO NOT STARE INTO BEAM

Maximum output 1mW Wave length 690nm CW

CLASS 2 LASER PRODUCT

Each label is differed by the market.

Auto-collimating

Auto-tracking

Waiting

Searching

Page 8

FOREWORD

6

•

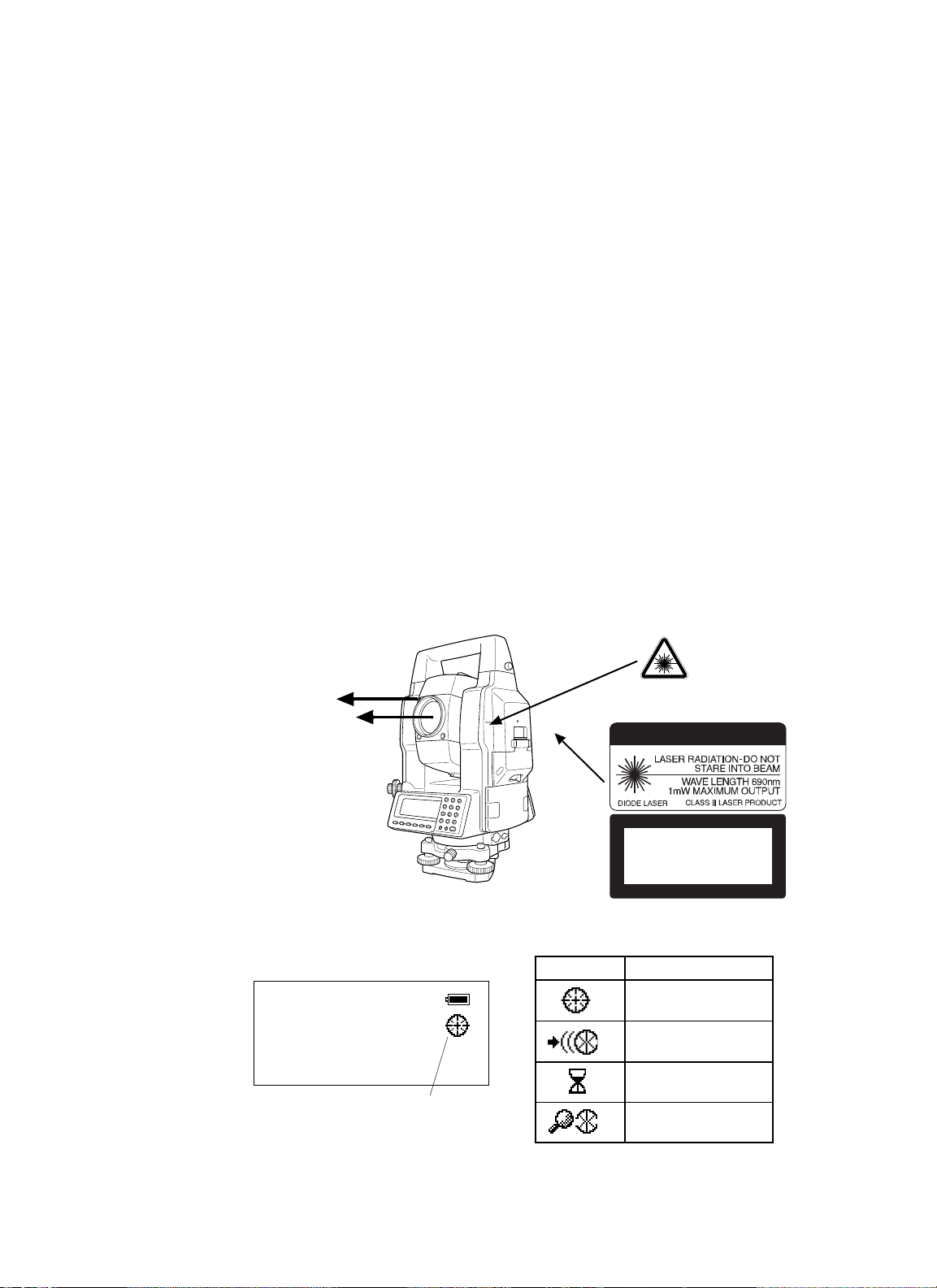

Laser Plummet Model

GPT-8000A/8000 series Laser plummet model use a visible laser beam to perform the plumb laser

function. The GPT-8000A/8000 series Laser plummet type products are manufactured and sold in

accordance with "Radiation Safety of Laser Products, Equipment Classification, Requirements and

User`s Guide" (IEC Publication 60825-1) or "Performance Standards for Light-Emitting Products"

(FDA/BRH 21 CFR 1040) regarding the safety standard for laser products.

As per these standards, the GPT-8000A/8000 series Laser plummet type is classified as "Class II (2)

Laser Products".

Since Laser radiation is emitted from the GPT-8000A/8000 series Laser plummet type instruments,

please refer to the "Laser Safety" bulletin which accompanies the instrument in the United States as

well as the "Safety Standard for Users" that is mentioned in the instruction manual.

In the case of any technical failure, do not disassemble the instrument. Contact either TOPCON or

your authorized TOPCON dealer.

Labels

The following labels are found on the instruments which describe the GPT-8000A/8000 series

Laser plummet type: Precautions and safety information about the laser beam.

If, at any time, any of these labels are damaged and become illegible, please replace these

important labels. Please the new labels in exactly the same position as the original labels.

Replacement labels can be obtained from Topcon or your authorized Topcon dealer.

Depending on the country where the instrumetn is sold, either of these labels may be

found on the GPT-8000A/8000 series laser plummet type.

Symbol mark while the laser is emitting.

The following symbol mark willappear at the right side of the second line.

The symbol mark will blink while the laser

plummet is working.

Warning Label

GPT-8000A/8000 series

Laser Plummet type

P1

Ap

erture Label

AVOID EXPOSURE

LASER LIGHT IS EMITTED

FROM THIS APERTURE

Beam aperture

V : 87°55'45"5

HR: 180°44'12"5

SD HD NEZ 0SET HOLD

P1

↓

Explanatory Label

CAUTION

LASER RADIA TION-DO NOT

STARE INTO BEAM

WAVE LENGTH 633n m

1mW MAXIMUM OUTPUT

CLASS II LASER PRODUCT

LASER RADIATION

DO NOT STARE INTO BEAM

Maximum output 1mW Wave length 633nm

CLASS 2

LASER PRODUCT

Page 9

FOREWORD

7

Contents

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Display for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Exceptions from Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Standard Set Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 NOMENCLATURE AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 Operating Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4 Function Key (Soft Key) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.5 Star key mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.6 Auto Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.7 Data Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.8 Rotating Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.8.1 Rotating by H/V Shuttle and H/V Jog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.8.2 Auto Inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.8.3 Rotating automatically to a required Horizontal and Vertical angle . . . . . . . . . 1-13

1.9 Using together with RC-2II Remote Control System

(GPT-8000Aseries) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.10 Using connecting with Personal Computer (PC) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

2 PREPARATION FOR MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Setting Instrument Up For Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Power Switch Key ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 Battery Level Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5 Main Menu Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6 Vertical and Horizontal Angle Tilt Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.7 Compensation of Systematic Error of Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.8 Resume Mode ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.9 How to Enter Numerals and Alphabet Letters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.10 Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.11 Inclination of Prism and Measuring Error (GPT-8000A series) . . . . . . . . . . . . . . . . . 2-10

3 AUTOMATIC TRACKING / AUTOMATIC COLLIMATION

(GPT-8000A series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Automatic Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Automatic Collimation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Range of Laser for Auto-tracking and Auto-collimating . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Setting Parameters for Auto-Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.1 Setting Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.2 How to set the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

4 STANDARD MEASUREMENT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Angle Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Measuring Horizontal Angle Right and Vertical Angle . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Switching Horizontal Angle Right/Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.3 Measuring from the Required Horizontal Angle . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.4 Vertical Angle Percent Grade(%) Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.5 Automatic Rotation to a Required Horizontal and Vertical Absolute Angle . . . . 4-4

4.2 Distance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.1 Setting of the Atmospheric Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.2 Setting of the Correction for Prism Constant / Non-prism Constant . . . . . . . . . 4-5

4.2.3 Distance Measurement (Continuous Measurement) . . . . . . . . . . . . . . . . . . . . 4-6

4.2.4 Distance Measurement (Single/N-times Measurement) . . . . . . . . . . . . . . . . . 4-7

4.2.5 Fine / Coarse Measuring Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.2.6 Stake Out (S-O) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.3 COORDINATE MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Page 10

FOREWORD

8

4.3.1 Setting Coordinate Values of Occupied Point . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.3.2 Setting of the Instrument Height / Prism Height . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.3.3 Execution of Coordinate Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.4 DATA OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

5 PROGRAM MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Setting a Direction Angle for Backsight Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Retaining a Coordinate (STORE- NEZ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3 Remote Elevation measurement (REM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4 Missing Line Measurement (MLM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.5 Line Measurement (LINE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.6 Offset measurement (OFFSET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.6.1 Angle Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.6.2 Distance Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.6.3 Plane Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.6.4 Column Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.7 External Link (GPT-8000Aseries) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.7.1 Starting compatible communication program of AP-L1A . . . . . . . . . . . . . . . . 5-23

5.7.2 Setting for the communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.7.3 Carrying out Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

6 MEMORY MANAGE MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 View Internal Memory and Card Memory Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Protect a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 Rename a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.4 Deleting a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.5 Copy a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.6 Initializing Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

7 COMMUNICATION MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Setting of PROTOCOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Data File In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.3 Data File Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

8 PARAMETERS SETTING MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 Parameter Setting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.1 Parameters for Measurement and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.2 Parameters for communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2 Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.2.1 Parameters for Measurement and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.2.2 Parameters for Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.2.3 Password Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

9 CHECK AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Checking and Adjusting of Instrument Constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1.1 Checking of the accuracy of the non-prism mode . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Checking the Optical Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.3 Checking/Adjusting the Theodolite Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.3.1 Checking /Adjusting the Plate Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.3.2 Checking /Adjusting the Circular Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.3.3 Adjustment of the Vertical Cross-hair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.3.4 Collimation of the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

9.3.5 Checking / Adjusting the Optical Plummet Telescope . . . . . . . . . . . . . . . . . . . 9-8

9.3.6 Checking / Adjusting the Laser Plummet (For Laser Plummet type) . . . . . . . . 9-9

9.4 Adjustment of Compensation Systematic Error of Instrument . . . . . . . . . . . . . . . . . . 9-10

9.5 Showing Constant List and Switch ON/OFF

Compensation Systematic Error of Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.6 How to adjust the date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

9.7 How to Set the Instrument Constant Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

9.8 Inspection and Adjustment of Optic Axis for Auto -Tracking

(GPT-8000ASeries) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

10 SETTING THE PRISM / NON-PRISM CONSTANT VALUE . . . . . . . . . . . 10-1

11 SETTING ATMOSPHERIC CORRECTION . . . . . . . . . . . . . . . . . . . . . . . 11-1

11.1 Calculation of Atmospheric Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

11.2 Setting of Atmospheric Correction Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Page 11

FOREWORD

9

12 CORRECTION FOR REFRACTION AND EARTH CURVATURE . . . . . . . 12-1

12.1 Distance Calculation Formula. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

13 POWER SOURCE AND CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

13.1 Rechargeable Battery BT-56Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

14 DETACH/ATTACH OF TRIBRACH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

15 BATTERY SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

16 PRISM SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

17 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-1

18 ERROR DISPLAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

19 SPECIAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-1

20 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . APPENDIX-1

Dual Axis Compensation ............................................................................................ APPENDIX-1

Precaution when Charging or Storing Batteries.......................................................... APPENDIX-3

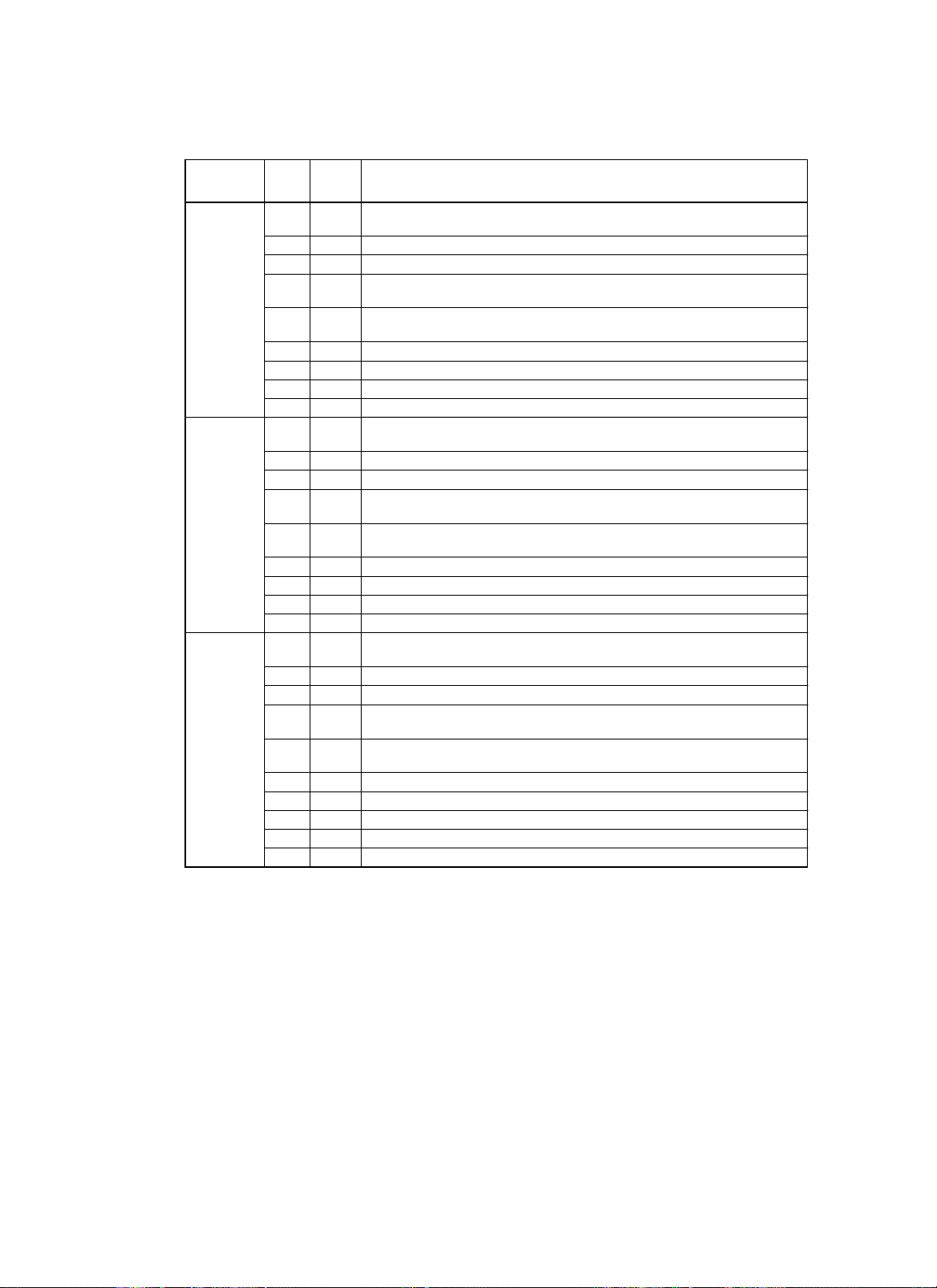

Standard Set Composition

1) GPT-8000A/8000 series (with lens cap) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

2) Battery BT-56Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

3) Battery charger BC-27BR or BC-27CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

4) Tool kit with case [ rod pins, screwdriver, cleaning brush ] . . . . . . . . . . . . . . . . . . . 1 set

5) Plastic carrying case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

6) Silicon cloth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

7) Plastic rain cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

8) Instruction manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

(Make sure that all of the above items are with the instrument when purchased.)

Remarks:

1) Battery charger BC-27CR is for AC 230V use and BC-27BR is for AC 120V use.

2) Plumb bob set and plumb bob hook are supplied for certain markets.Remarks:

Page 12

1 NOMENCLATURE AND FUNCTIONS

1-1

1 NOMENCLATURE AND FUNCTIONS

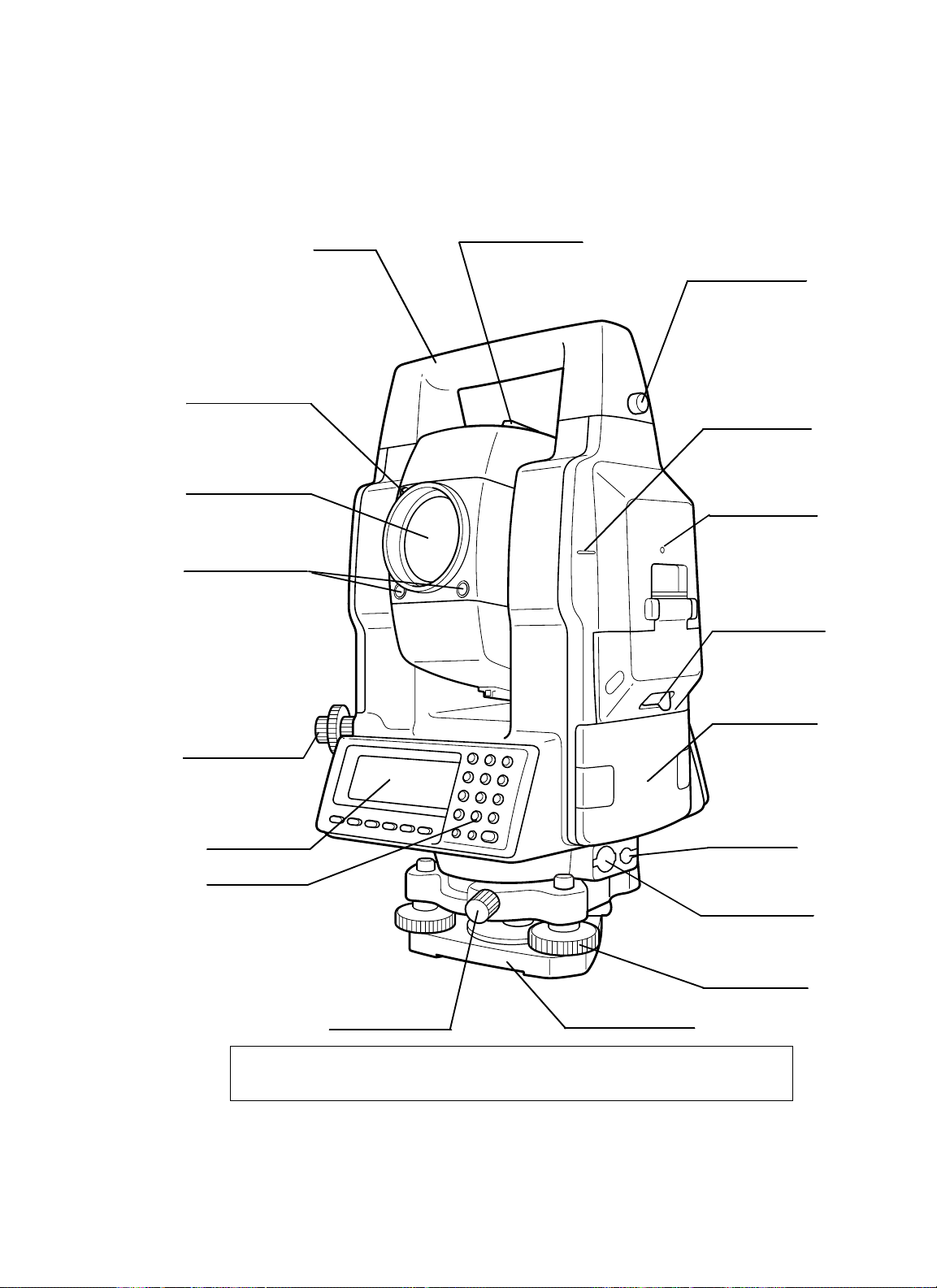

1.1 Nomenclature

Laser aperture

(for optical

communication)

(GPT-8000A series)

Objective lens

Laser aperture

(for auto-tracking)

(GPT-8000A series)

Tracking indicator

(GPT-8000A series)

Point guide

(GPT-8000 series)

Handle

Sighting collimator

Handle fi xing knob

Instrument height

mark

Instrument center

mark

Card cover lever

.

Optical plummet

telescope

Display window

Operation keys

The caution l abels are past ed up GPT-8000A series and Laser plummet mo del which describe

the warning of laser beam.

Refer to " Lase r Safety" and "Laser plum me t model" about l abe l posi ti o ns and their shapes

Base fixing screw

Battery BT-56Q

Power suppl y

connector

Serial Signal

Connector-1(6pin)

Leveling screw

Base (Model 5)

Page 13

1 NOMENCLATURE AND FUNCTIONS

1-2

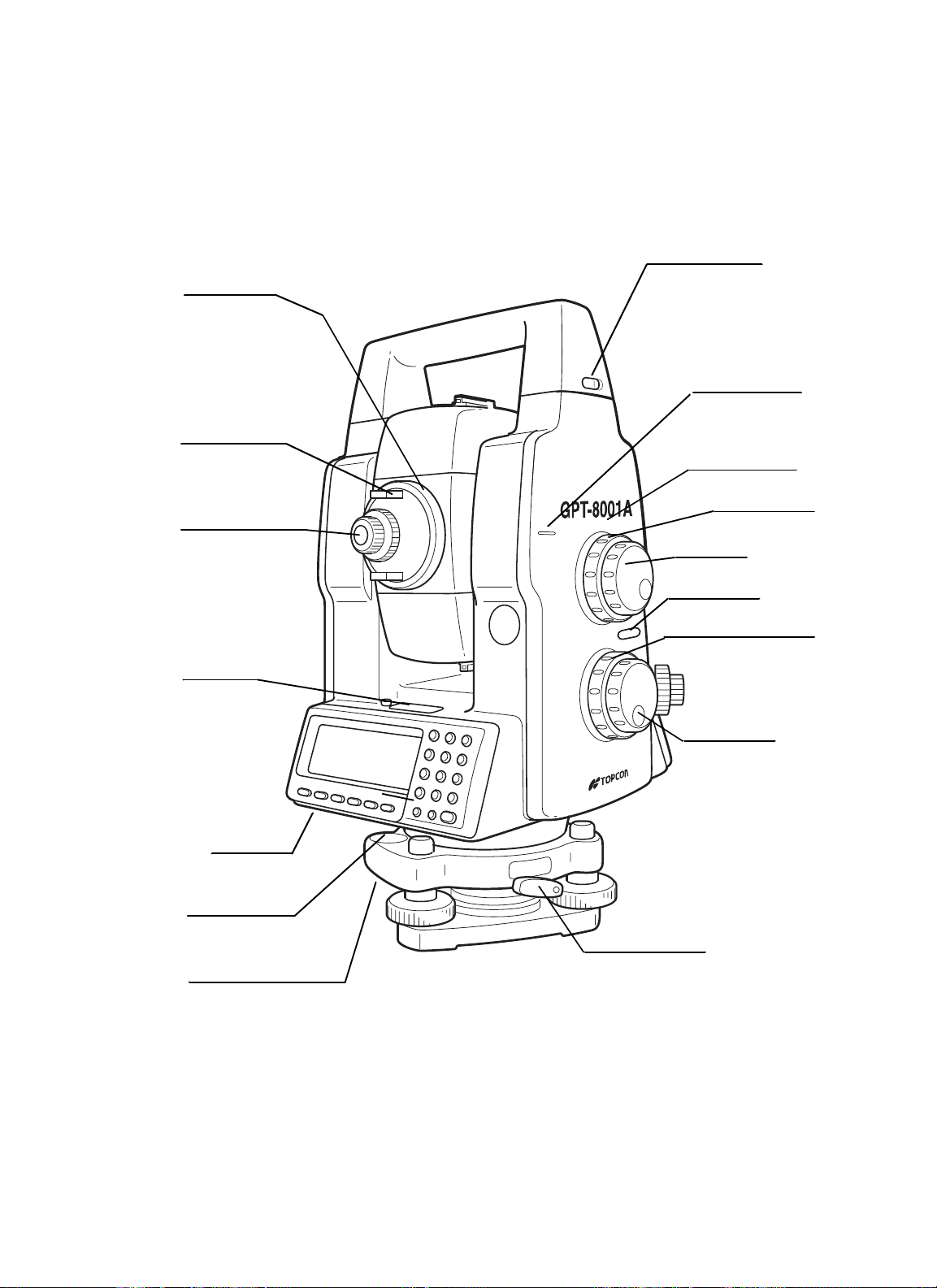

Telescope

focusing knob

Battery fixing knob

Instrument height

mark

Telesco pe gri p

Telescope eyepi ece

Plate level

Centronics

connector

Circular level

Instrument center

mark

Vertical shuttle

Vertical jog

Power switc

Horizontal shuttle

h

Horizontal jog

Adjusting screws for

circul ar level

Tribrach fixing lever

Page 14

1 NOMENCLATURE AND FUNCTIONS

1-3

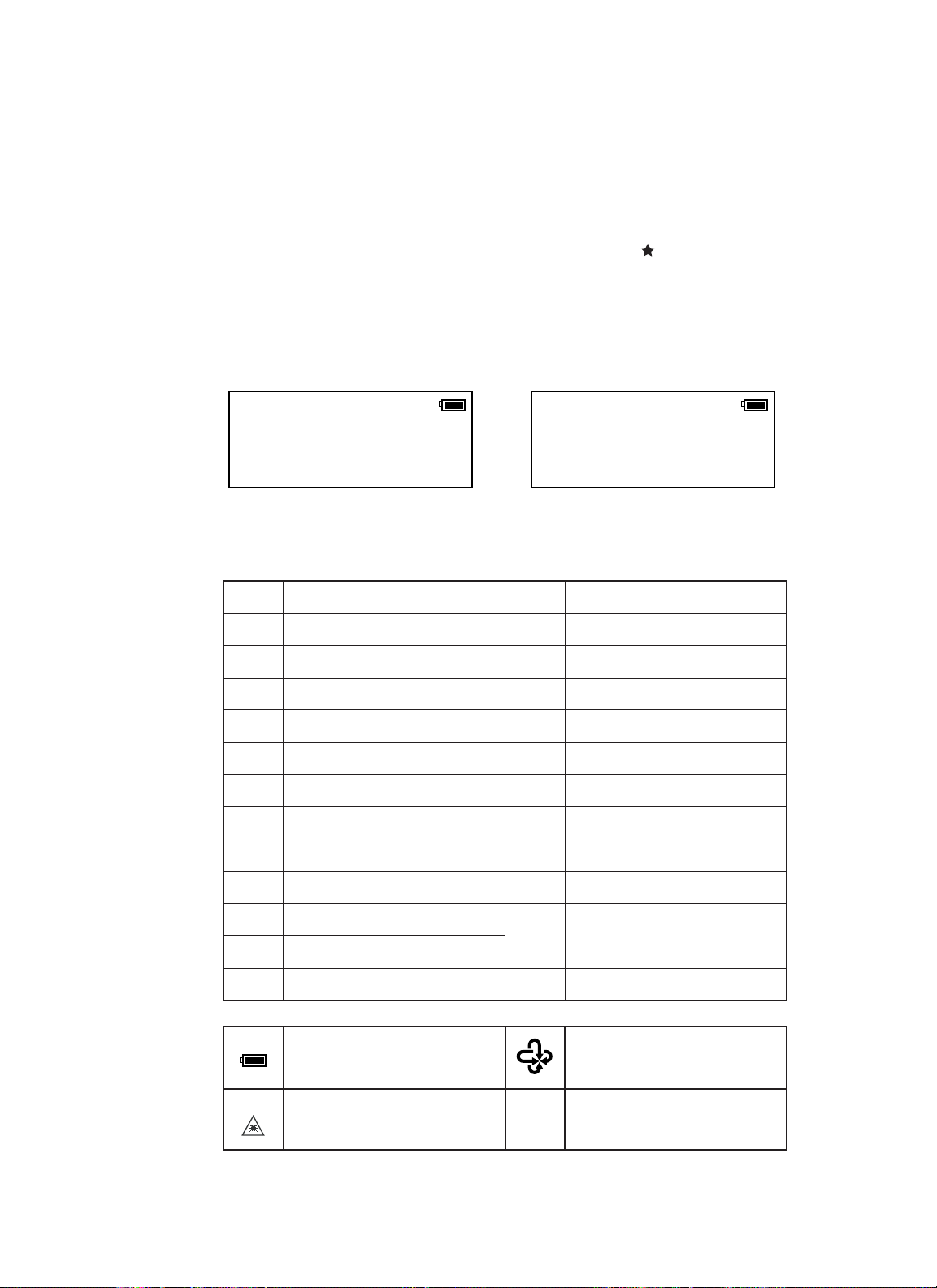

1.2 Display

• Display

In general upper four lines display the measuring data, and the bottom line displays the soft key

function which is changed by the measuring mode.

• Contrast

The contrast and illumination of display window are adjusted by star ( ) key.

• Heater (Automatic)

The built-in heater keeps the display functional when the temperature goes below 0°C (32 °F). To

switch the heater ON or OFF, refer to Chapter 8 "PARAMETERS SETTING MODE". When the

heater is ON and the temperature goes below 0°C (32 °F), the heater automatically

adjust the temperature to the display to keep it operating.

• Example

Angle measurement mode

V-angle: 87º55’45”

H-angle: 180º44’12”

Distance measurement mode

Horizontal-angle: 87º55’45”

Horizontal distance: 180º44’12”

Relative elevation: 12.345m

V : 87°55'45"

HR: 180°44'12"

SD HD NEZ 0SET HOLD P1

Display Contents Display Content

VV-angle(m)Meter unit

V% Percent grade ( f) Feet unit

HR H-angle right F Fine mode

HL H-angle left C Coarse mode (1m m)

HD Horizontal distance c Coarse mode (10mm)

VD Relative elevation R Repeat measurement

SD Slope distance S Single measurement

NN coordinate N N-times measurement

↓

V : 87°55'40"

HR: 180 °44'12" PSM 0.0

SD: 12.345 PPM 0.0

(m) *F.R

MEAS MODE VH HD NEZ

↓

EE coordinate ppm Atmosphe ric correction value

ZZ coordinate PSM Prism constant value

*EDM workingNPM Non-Prism constant value

NP Non-prism mode

Battery Level Indicator

Refer to Section 2.4 “Battery Lev e l

Indicator” for further information.

Laser plum me t is work ing.

(Only for lase r pl ummet model)

Rotation Indicator

Refer to Section 1.8 “Rotating

Method” for further information.

Page 15

1 NOMENCLATURE AND FUNCTIONS

1-4

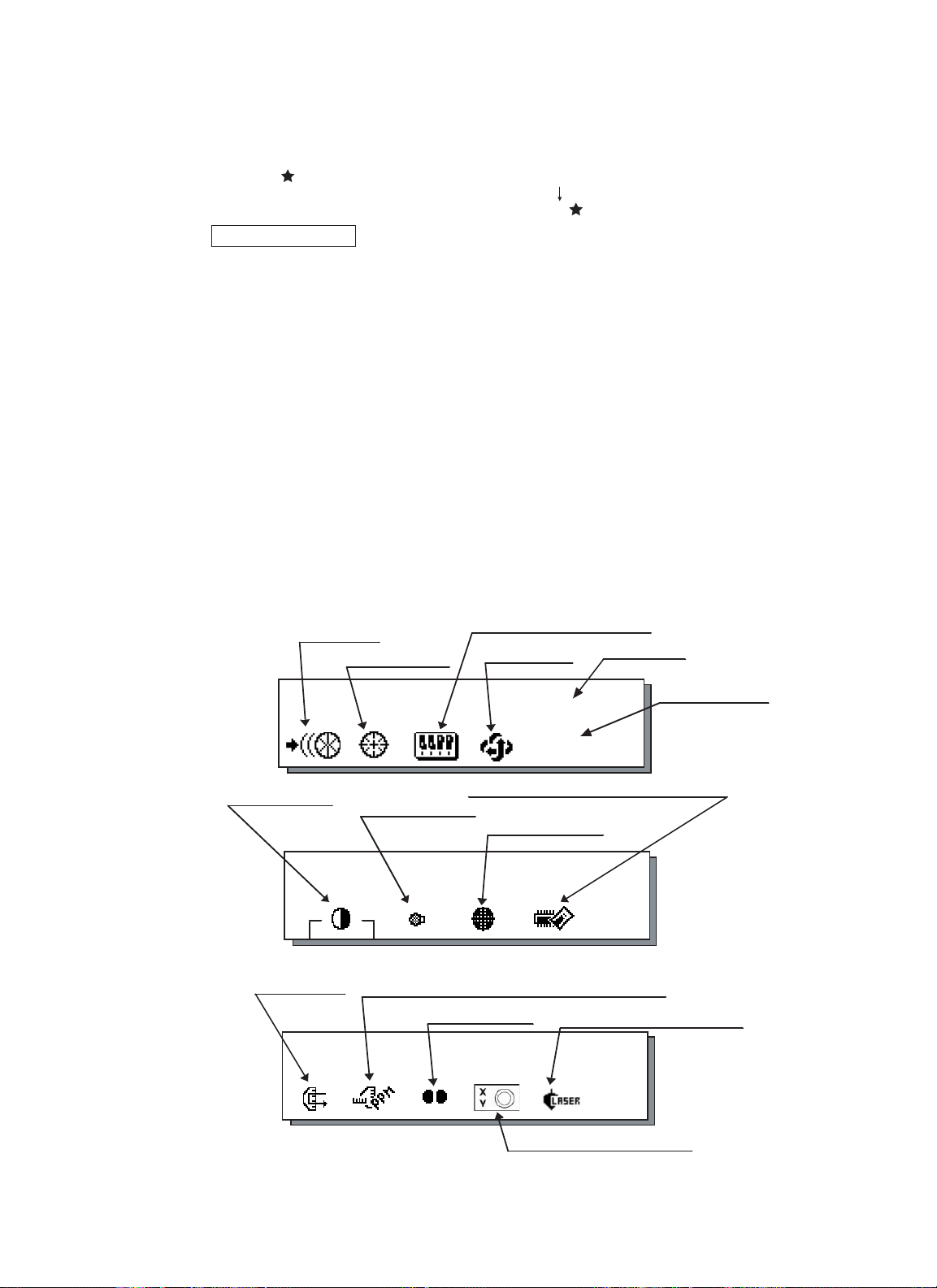

• The symbol marks for Auto-tracking and Auto-collimating (GPT-8000A series)

1.3 Operating Key

Auto-collimating

(

Laser is emitting

GPT-8000A s eries is in autocollimating status.

Waiting (Laser is emitting)

GPT-8000A series is in waiting

status.

Failure in auto-collimating.

(

Laser is off

GPT-8000A series could not find

the target prism during autocollimating.

)

Auto-tracking

)

(

Laser is emitting

GPT-8000A series is in au totracking status.

Searching (Laser is emitting)

GPT-8000A series is searc hing

a prism.

)

KEY NAME FUNCTION

F1~F6 Soft key Functions are ac cording to the displayed message.

0~9 . - Numeric key Numeric Character Entry for Preset Data

A ~/ Alp ha key Alpha Characte r Entry

ESC Escape key Escape to Previous Display or Menu

Star key Optional instrument functions

ENTEnter key End operat i on of data input and accept s data

POWER Power key

ON/OFF of power sou rce.

(Power key is locate d on the side of the instrument.

Page 16

1 NOMENCLATURE AND FUNCTIONS

1-5

1.4 Function Key (Soft Key)

The Soft Key Functions are labeled on teh bottom of display. Soft Key functions are different for

each measurement).

V : 87°55'45"5

HR: 180°44'12"5

SD HD NEZ 0SET HOLD

P1

↓

[F1] [F2] [F3] [F4]

V : 87°55'45"5

HR: 180°44'12"5

SD HD NEZ 0SET HOLD P1

TURN HSET R/L V/% TILT P2

Angle measuring

V : 90 10'20"5

HR: 120 30'40"5 PSM 0.0

HD: PPM 0.0

VD: (m) F.R

MEAS MODE VH SD NEZ P1

REC SO MEAN P2

Horizontal distance measuring

Page D isplay

Angle

measuring

NEZ F3 Coordinate distanc

0SET F4 Set horizontal angle to 0¡00’00".

HOLD F5 Horizontal angle hold.

TURN F1 Turns the instrument to required angle automatically.

HSET F2 Preset a horizonta l angle .

V/% F4 Changes the display to vertical angle or percent of grade.

TILT F5

Soft

key

SD F1 Slope dista nce measuring mode.

HD F2 Horizontal distance measuring mode.

R/L F3 Changes horizontal angle right or left.

Sets the tilt function, ON/OFF.

If ON, the display shows tilt correction value.

Soft keys

↓

↓

P1

↓

↓

e measuring mode.

[F5]

[F6]

V : 90°10'20"5

HR: 120°30'40"5 PSM 0.0

SD: PPM 0.0

(m) F.R

MEAS MODE VH HD NEZ

TURN SO MEAN m/ft P2

Slope distance measuring

N : 12345.6789

E : -12345.6789 PSM 0.0

Z : 10.1234 PPM 0.0

(m) F.R

MEAS MODE VH SD HD P1

↓

TURN HT MEAN P2

Coordinate measuring

Function

↓

↓

↓

Page 17

1 NOMENCLATURE AND FUNCTIONS

1-6

Page Display

Slope

distance

measuring

Horizontal

distance

measuring

Coordinate

measuring

Soft

key

MEAS F1

MODE F2 Changes Fine / Coarse(1mm) /Coarse(10mm) mode.

VH F3 Angle measurement mode.

HD F4

NEZ F5

TURN F1 Turns the instrument to required angle automatically.

SO F2 Stake out measurem ent mode .

MEAN F3 Sets the number of N-time measur ement.

m/ft F4 Changes distance measurement unit to meter or feet.

MEAS F1

MODE F2 Changes Fine / Coarse(1mm) /Coarse(10mm) mode.

VH F3 Angle measurement mode.

SD F4

NEZ F5

TURN F1 Turns the instrument to required angle automatically.

SO F2 Stake out measurem ent mode .

MEAN F3 Sets the number of N-time measur ement.

m/ft F4 Switches meter or feet unit.

MEAS F1

MODE F2 Changes Fine / Coarse(1mm) /Coarse(10mm) mode.

VH F3 Angle measurement mode.

SD F4

HD F5

TURN F1 Turns the instrument to required angle automatically.

HT F2 Input Instrument / prism height values.

MEAN F3 Sets the number of N-t i me meas u rement.

m/ft F4 Switches meter or feet unit.

SET F5 Pre-set instrument coordi nate v alues

Starts slope distan ce measurement mode.

Changes Continuous/ N-times (single) measurement mode.

Horizontal distance measurement mode. Displays the horizontal distance

data after N-times or single measurement.

Coordinate measurement mode.

Displays the coordinate after N-times or single measurement.

Starts horizont al d ist ance measurement mode .

Changes continuous/ N-times (single) measurement mode.

Slope distance measuring mode.

Display the slope distance after N-time

Coordinate measurement mode.

Displays the coordinate after N-times or single measurement.

.

Starts coordinate measurement mode.

Changes continuous/ N-times (single) measurement mode.

Slope distance measuring mode.

Display the slope distance after N-t imes or single measurement.

Horizontal distance measurement mode. Displays the horizontal distance

data after N-times or single measurement.

Function

s or single measurement.

Page 18

1.5 Star Key Mode

Press the ( ) key to view the instrument options. Since there are three screens (GPT-8000Aseries)

or two screens (GPT-8000 series) of options, press [F6](1 ) soft key to view the next screen.

The following instrument options can be selected from the ( ):

GPT-8000A Series

• Screen One

1) View Date & Time

2) Auto-tracking [F1]

3) Auto-collimating [F2]

4) Set the parameters for Auto-tracking. [F3]

5) Auto- inversion [F4]

6) Non-prism mode / Prism mode selection [F5]

• Screen Two

7) Adjustment the contrast of the display [F1 & F2]

8) Turn the back light of the display ON/OFF [F3]

9) Reticle illumination---Off / Low / Medium / High [F4]

10) View free memory for internal and card memory [F5]

• Screen Three

11) The light acceptance quantity level (signal level) is displayed.[F1]

12) Set the Temperature, Pressure, Atmospheric Correction Value (PPM), and Prism

Constant Value (PSM) [F2]

13) Turn the Tracking Indicator option ON/OFF [F3]

14) Electric circular graphic display [F5]

15) Turn the Laser plummet option ON/OFF [F5] (only for Laser plummet model)

1 NOMENCLATURE AND FUNCTIONS

1-7

2002-07-07 14:30:40

1

↓

2002-07-07 14:30:40

2

↓

Back Light of Display

Auto- inversion

Date & Time

Set para meter for Au to-tr ack ing

Auto-collimating

Auto-tracking

2002-07-07 14:30:40

3

↓

Contrast adjustment

T

racking in dicator

Set the Temperature, Pressure, Atmospheric Correction

Value (PPM), and Prism Constant Value (PSM)

Displaying

Signal Level

Screen 1

Screen 2

Screen 3

View free memory for Card/Internal Memory

Reticle illumination

Laser Plummet

(Only for Laser Plummet type)

Electric circular graphic display

NP/P

Non-prism/ Prism

mode

Page 19

1 NOMENCLATURE AND FUNCTIONS

1-8

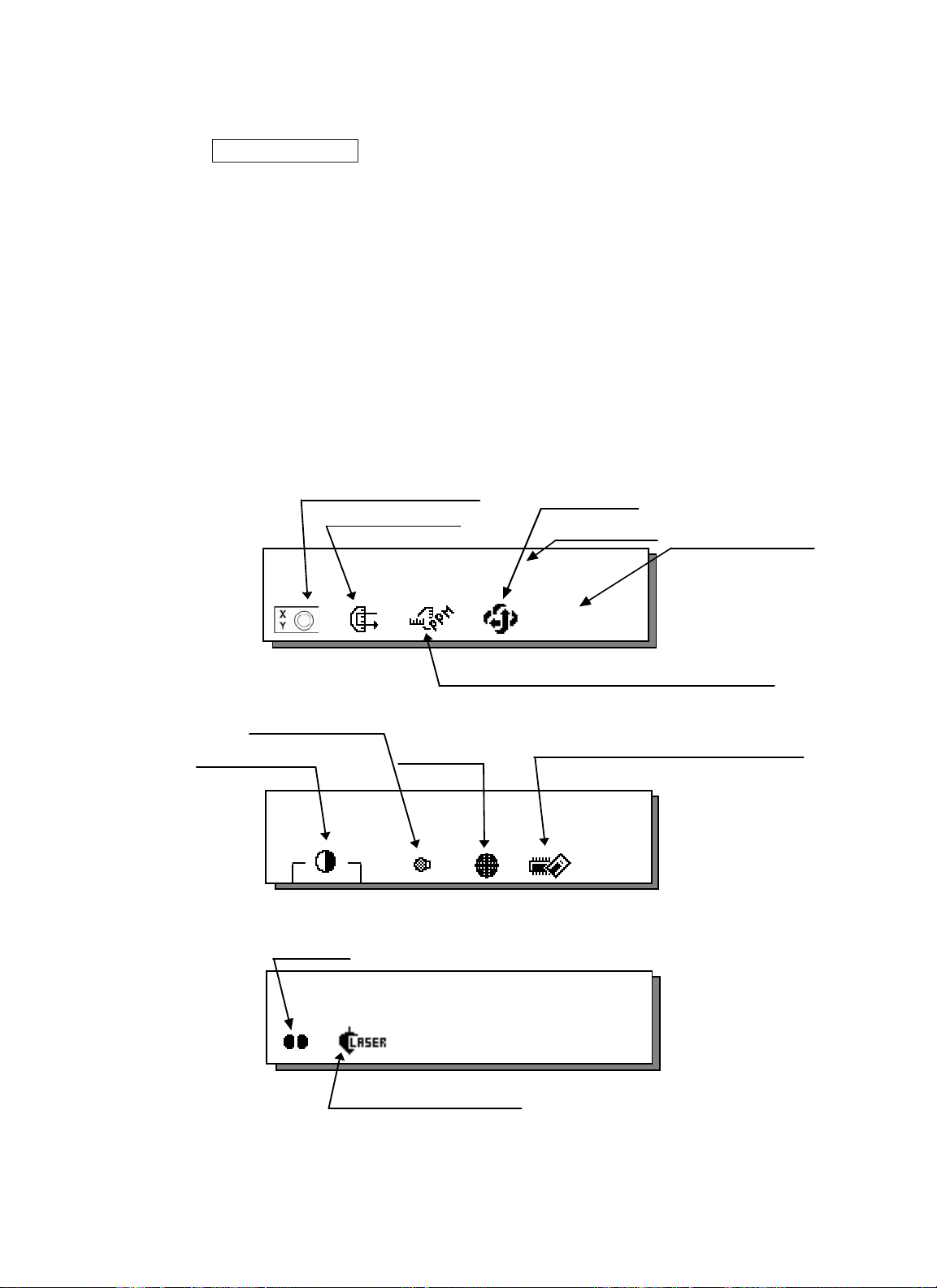

GPT-8000A Series

• Screen One

1) View Date & Time

2) Electric circular graphic display [F1]

3) The light acceptance quantity level (signal level) is displayed [F2]

4) Set the Temperature, Pressure, Atmospheric Correction Value (PPM), and Prism

Constant Value (PSM)[F3]

5) Auto- inversion [F4]

6) Non-prism mode / Prism mode selection [F5]

• Screen Two

7) Adjustment the contrast of the display [F1 & F2]

8) Turn the back light of the display ON/OFF [F3]

9) Reticle illumination---Off / Low / Medium / High [F4]

10) View free memory for internal and card memory [F5]

• Screen Three

11)Turn the Point Guide option ON/OFF.[F1]

12) Turn the Laser plummet option ON/OFF [F1] (only for Laser plummet model)

Electric circular graphic display

Displaying Signal Level

Back Light of Display

Contrast adjustment

● Only for Laser Plummet type

Point guide

2002-07-07 14:30:40

2002-07-07 14:30:40

Auto- inversion

Date & Time

↓

e

Set the Temperature, Pressure, Atmospheric Correction

Value (PPM), and Prism Constant Val ue (PSM)

Reticle

illumination

NP/P

View free memory for the Card/Internal Memory

1

↓

2

Non-prism/ Pri sm mod

Screen 1

Screen 2

2001-07-10 14:30:40

Laser Plummet

(Only for Laser Plummet type)

Screen 3

3

↓

Page 20

1 NOMENCLATURE AND FUNCTIONS

1-9

1) View Date & Time

The date and time can be viewed on both screens. To change the displayed order of the date,

(Date/Month/Year), (Month / Date / Year) or (Year/Month/Date), see Chapter 8 “PARAMETERS SETTING MODE” .

To set the date and time, see Chapter 9 “CHECK AND ADJUSTMENT”.

2) Turn the auto-tracking ON/OFF (GPT-8000A series)

Press the [F1] key to start auto-tracking. See Section 3.1 “Automatic Tracking” .

3) Turn the auto-collimating ON/OFF (GPT-8000A series)

Press the [F2] key to start auto-collimating. See Section 3.2 “ Automatic Collimation” .

4) Set the parameters for the auto-tracking (GPT-8000A series)

A proper setting for each parameter such as tracking pattern, tracking range, waiting time, trackingspeed and tracking sensitivity. See Section 3.4 “Setting Parameters for

Auto-Tracking” .

5) Auto Inversion

Pressing the [F4] key causes the instrument to reverse and turn the telescope and

instrument automatically.

•To stop auto rotating in case of emergency, press any keys except POWER key.

• During auto rotation, do not disturb the instrument.(Stopping the rotation with a touch of the hand).

Such action may cause trouble or harm to instrument or operator.

6) Adjustment the contrast of the display

This enable you to adjust the contrast of the display.

Press the [F6] key to get to Screen 2 on the display.

Press the [F1] or [F2] key to brighten or dim the display.

7) Turn the display back light ON/OFF

When the back light is OFF, the light bulb icon is dark.

Press the [F6] key to get to Screen 2 on the display.

To turn the back light ON, press the [F3] key. Press [F3] again to turn the back light OFF.

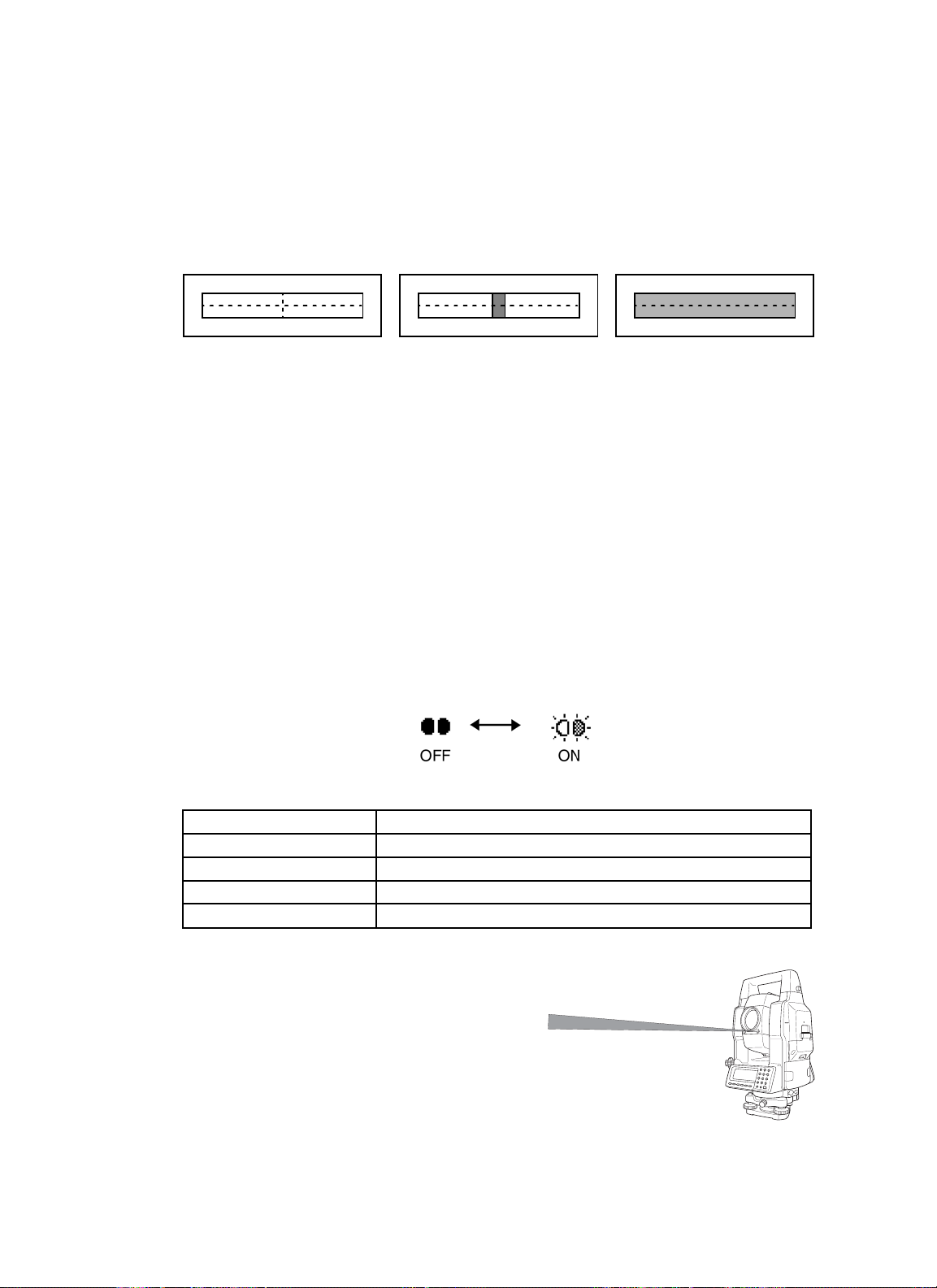

8) Reticle illumination (OFF/Low/Middle/High)

Press the [F6] key to get to Screen 2 on the display. Press the [F4] key to turn the reticle illumination

ON. Continuing to press [F4] will change the intensity options.

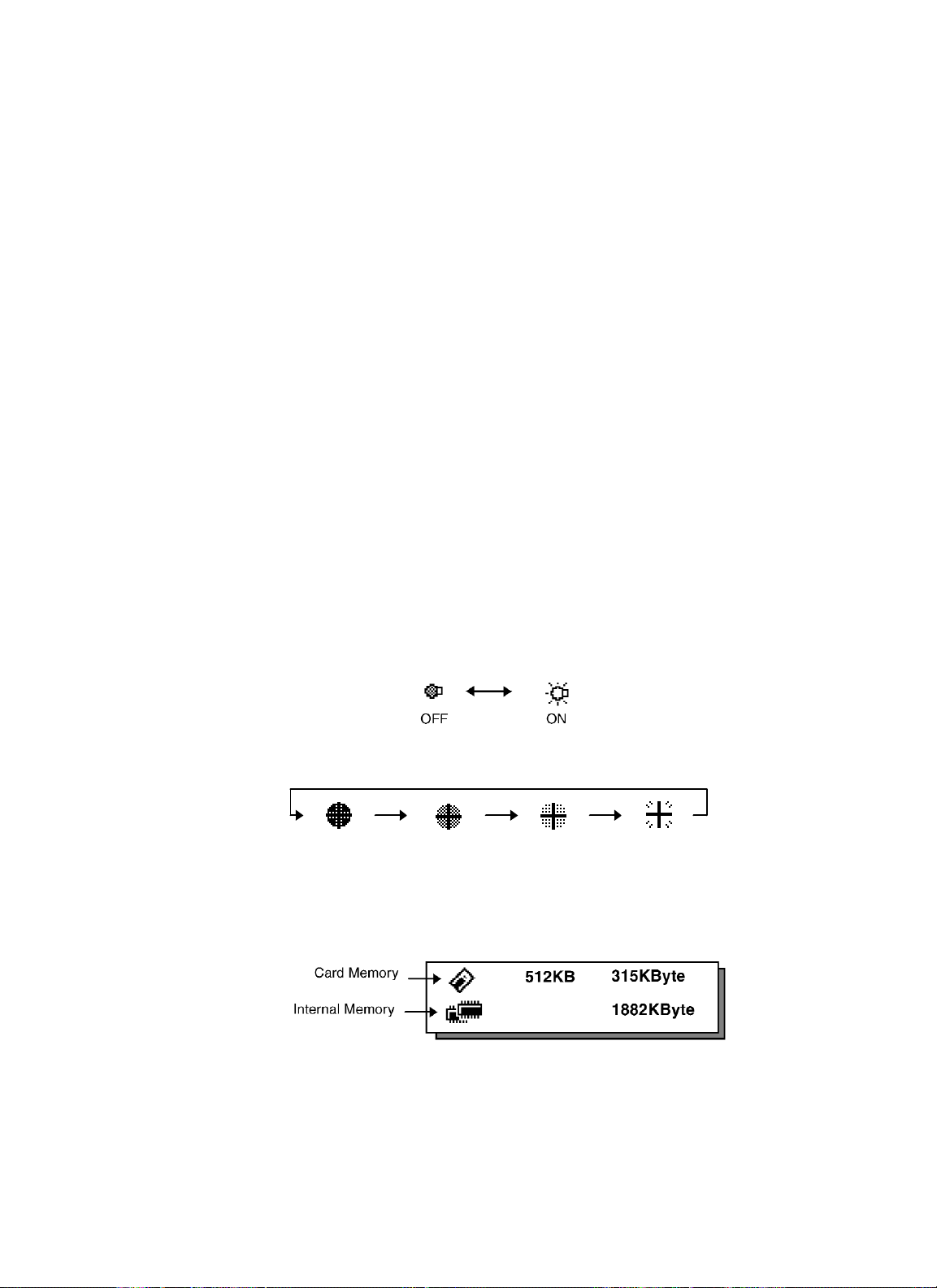

9) View free memory

The amount of free memory for the card or internal memory can be displayed.

Press the [F6] key to get to Screen 2 on the display.

Press the [F5] key to view free memory.

The card memory icon (top left side of the display) shows the size of the card and the amount of free

memory. The second icon shows the amount of free internal memory.

See Chapter 6 “MEMORY MANAGE MODES”, for further options and instructions.

Low

OFF

Middle

High

Page 21

1 NOMENCLATURE AND FUNCTIONS

1-10

10) Set audio mode

The light acceptance quantity level (Signal level) is displayed in this mode.

When reflected light from the prism is received, a buzzer sounds. This function is good for easy

collimation when the target is difficult to find.

Press the [F1] key on screen 3 (GPT-8000Aseries) or [F2] key on screen 1 (GPT-8000 series).

The received return signal level is displayed with bar graph as follows.

(1) To stop the buzzer, see Chapter 8 “PARAMETERS SETTING MODE”.

(2) Also, it is possible to display the signal level in Distance Measuring Mode.

11) Setting Temperature, Pressure, Atmospheric correction value (PPM), Prism

constant value (PSM)

The temperature, pressure, PPM, and PSM can be viewed by pressing the [F2] key on screen 3

(GPT-8000Aseries) or [F3] key on screen 1 (GPT-8000 series).

The received return signal level is displayed with bar graph as follows.

Refer to Chapter 10 “SETTING THE PRISM / NON-PRISM CONSTANT VALUE” and Chapter 11

“SETTING ATMOSPHERIC CORRECTION”, for further instructions.

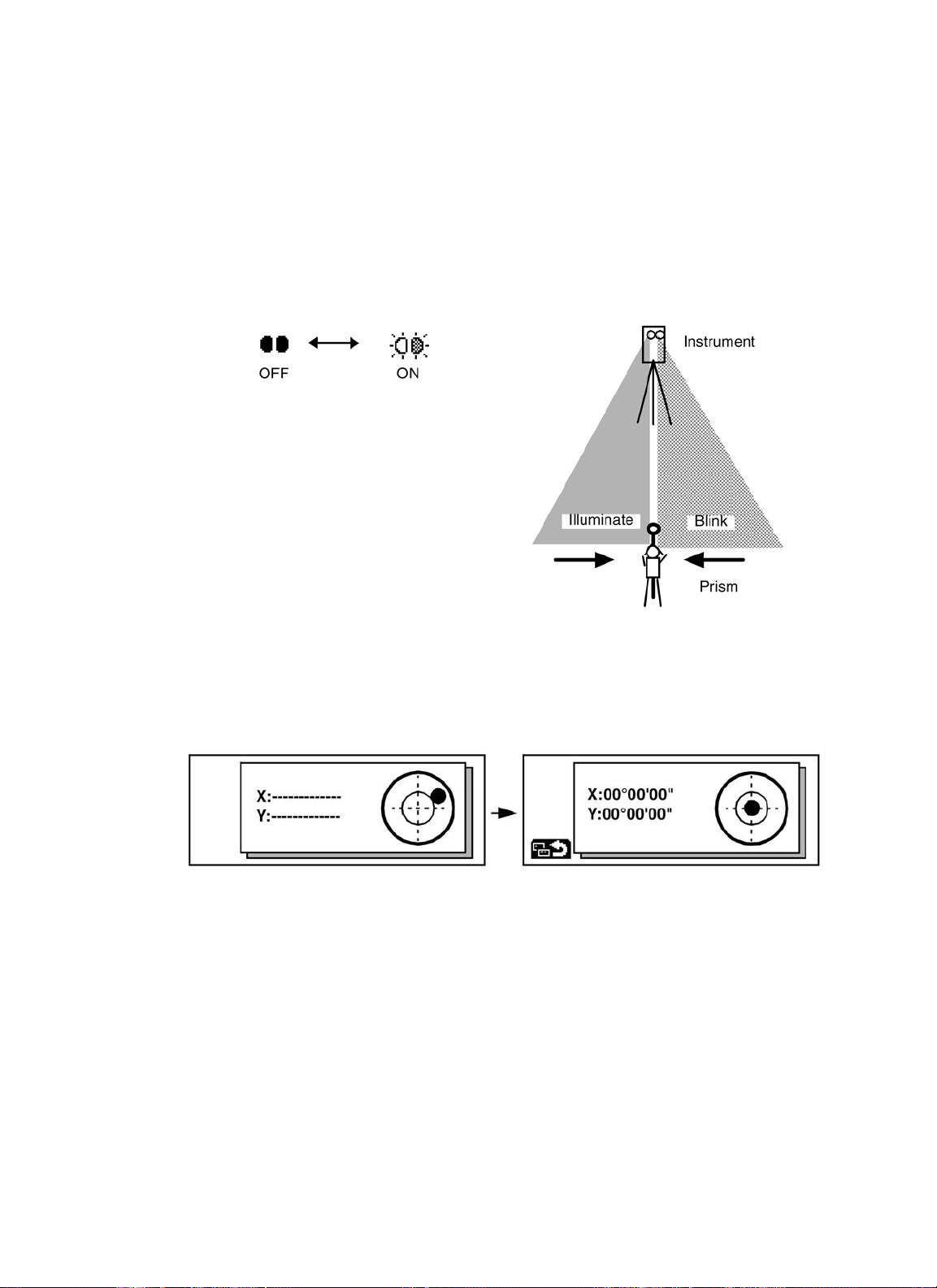

12) Tracking Indicator (GPT-8000A series)

A man who is staying on line with the direction of GPT-8000Aseries or automatic tracking status

by emitted LED light (orange color) from GPT-8000Aseries.

• Operation

Pressing [F3] key on the screen three functions Tracking Indicator. The tracking indicator status

will be changed according to the type of auto tracking mode and its conditions. Aman from the

prism side can recognize the status of instrument.

When angle measuring value turns stable during tracking still object, the tracking indicator

changes from quick continuous flashing to quick intermittent flashing. So you can decide from the

sign of flashing for recording data timing at one person surveying.

Meaning of Tracking Indicator ON or Flashing

• The function of the Tracking Indicator will be

used as a guide to know the status of GPT8000A series from the prism side. This is not a

function to determine precise collimating for

measuring.

• The quality of its results will depend on the

weather conditions and the use's eyesight.

• Sometimes happens difficulty of seeing the

tracking indicator because too much bright of

the beam for tracking.

• Using Tracking Indicator mode will result shorter

in reduced time out of the battery.

No light acceptance

Minimum quantity level

Maximum quantity leve

Tracking Indicator Status of instrume nt

Continuous ON Wait status

Slow flash ing Manual mode

Quick continuous flashing In case angle measuring value is instable during auto tracking mode.

Quick intermittent flashing In case angle measuring value is stable during auto tracking mode.

Page 22

1 NOMENCLATURE AND FUNCTIONS

1-11

13) Point-guide (Point guide type of GPT-8000 series only)

This feature is most useful when doing stake out work. The Point Guide's red LEDs on the

GPT-8000 Series telescope assist the rod person in getting on-line. The Point Guide feature is fast

and simple to use.

•Operating Instructions

Press the [F1] key on the screen three to turn ON the Point Guide LEDs. The Point guide icon on the

display will become bright when turned ON. Looking the objective lens of the telescope, the right LED

will blink and the left LED will stay lit.

The Point Guide should be used within a distance of 100 meters (328 ft.). The quality of its

results will depend on the weather conditions

and the use's eyesight.

The goal of the rod person is to look at both

LEDs on the instrument and move the prism

on-line until both LEDs become equally bright .

If the solid LED is brighter, move to the right. If

the blinking LED is brighter, move to the left.

14) Electric circular level graphic display

Electric circular level can be displayed by graphic. This function is good for level the instrument

when the circular level is difficult to see directly.

Press the [F4](GPT-8000Aseries) on the screen three or [F1] (GPT-8000 series) on the screen one

key to display the graphic.

In the displays of reverse side, the graphic bubble moves in reverse.

Rotate the leveling screws while observing the display.

After leveling, press [F1]. The display changes to the previous mode.

Page 23

1 NOMENCLATURE AND FUNCTIONS

1-12

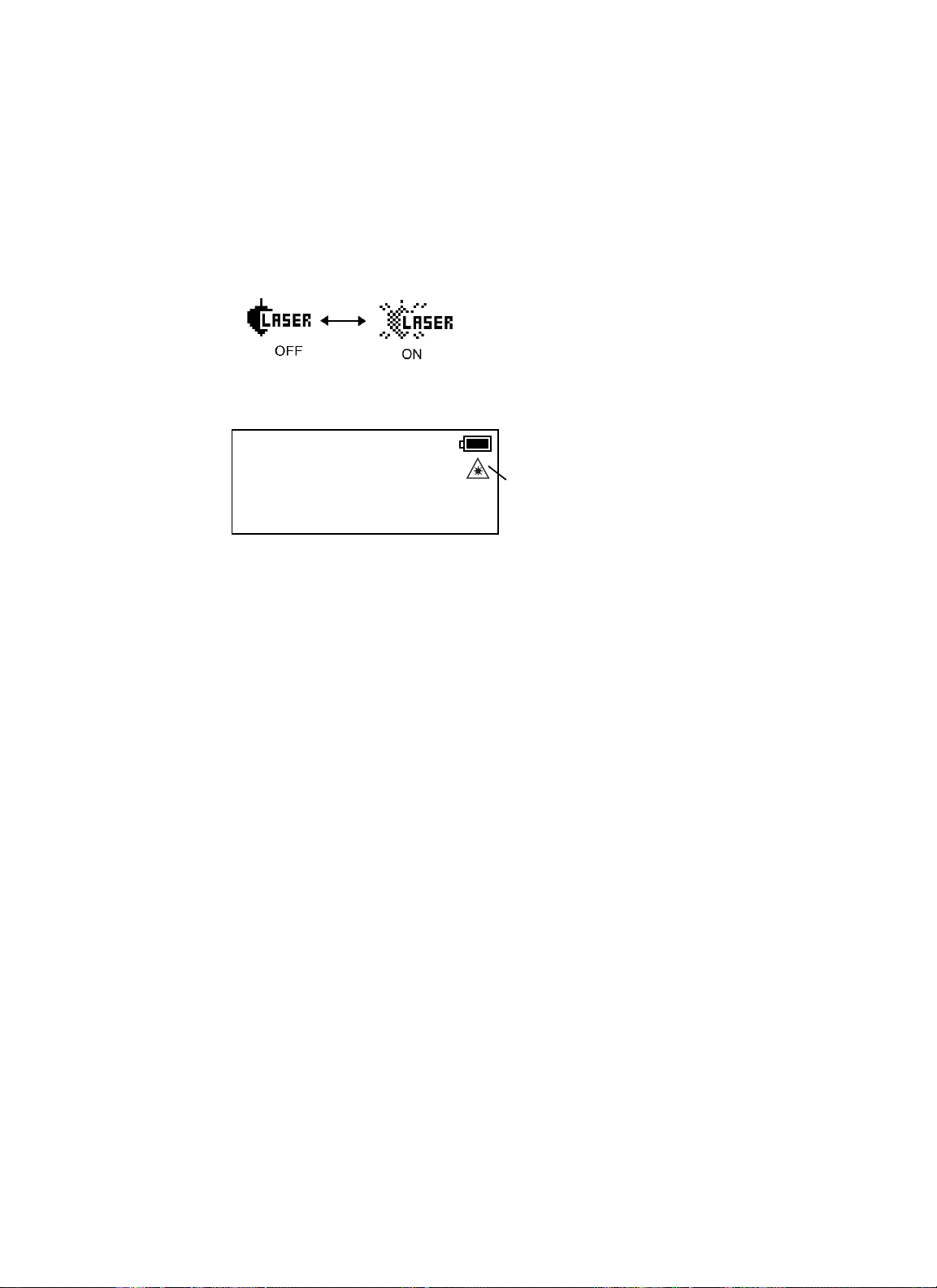

15) Laser Plummet (Only for Laser Plummet type)

Laser plummet option will help you to center the instrument easily onto the measurement point.

Press the star key to view the instrument options. Since there are three screens of options, press

[F6](•) soft key twice to view the screen 3.

Press the [F1] key (GPT-8000 series) or [F5] key (GPT-8000A series) to turn on/off of laser plummet option.

Laser plummet icon will change as follows.

Symbol mark while the laser is emitting.

The following symbol mark will indicate that the laser is emitting.

Laser Plummet auto-cut off function

The laser plummet will be turned off automatically after 1 to 99 minutes (Default:3 minutes). It is

also possible to stop the auto-cut off function.

Refer to Chapter 8 “PARAMETERS SETTING MODE” to change the time or to invalidate the

function.

1.6 Auto Power Off

The Auto Power OFF feature can be set from 1 to 99 minutes. If no keys are pressed within the set

time, the Auto Power OFF will automatically turn the instrument OFF in order to save the

battery time.

See Chapter 8 “PARAMETERS SETTING MODE”, for further instructions.

1.7 Data Output

When GPT-8000A/8000 series receives data output command from an external

connected device, the measured data will be output by GPT-8000A/8000 series. Select

from the following 2 ways for the output. (For setting, see Chapter 8 “PARAMETERS

SETTING MODE” .)

REC-A : The measurement is started and new data is output.

REC-B : The data being displayed is output.

1.8 Rotating Method

1.8.1 Rotating by H/V Shuttle and H/V Jog

H/V shuttle or H/V jog can be used to rotate the instrument manually. The shuttle movement or

displacement is proportional in speed and size of angle desired. Asmall, slow turn of the shuttle will

result in a slow small angle displaced. Likewise, a larger abrupt turn of the shuttle will result in a

coarse angle displacement. H/V jog can be used for accurate collimating of the target much like a

standard tangent screw.

1.8.2 Auto Inversion

Pressing the [F4] key in Star Key mode causes the instrument to reverse and turn the telescope and

instrument automatically.

•To stop auto rotating by auto inversion key in case of emergency, press any keys except

POWER key.

V : 87°55'45"5

HR: 180°44'12"5

SD HD NEZ

The symbol mark will blink while the laser

plummet is working

↓

Page 24

1 NOMENCLATURE AND FUNCTIONS

1-13

• During auto rotation, don't disturb the instrument.(Stopping the rotation with a touch of the

hand). Such action may cause trouble or harm to instrument or operator.

See Section 1.5 “Star key mode” for further instructions.

1.8.3 Rotating automatically to a required Horizontal and Vertical angle

In Standard Measurement Modes, the instrument can be rotated automatically by input a required

horizontal and/or vertical angle.

For further instructions, see Section 4.1.5 “Automatic Rotation to a Required Horizontal and Vertical

Absolute Angle” .

• Attaching Precaution Label

Attach 4 precaution labels to the instrument in specified places to avoid the unexpected

accident such as pinching fingers between telescope and body of instrument or telescope

and hand grip during automatic rotation.

• Attach upper side of telescope and near the plate level.

V : 87°55'45"5

This mark will appear while the

instrument is rotating automat ically.

HR: 180°44'12"5

SD HD NEZ 0SET HOLD P1

Caution label

↓

CAUTION

Do not place fingers near

telescope during rotation.

● Attach upper side of telescope and nea r the pla t e le vel

Caution label

Caution l abel

Page 25

1 NOMENCLATURE AND FUNCTIONS

1-14

1.9 Using together with RC-2II Remote Control System

(GPT-8000A series)

Using together with RC-2II Remote Control System makes it possible to optical communicate

between the instrument and remote controller RC-2II, the prism side. This gives easy operation by

one man surveying in applying programs.

Also connecting data collector to remote controller, you can manage communication reciprocally

between the instrument and direct to data collector.

Turn-round function

You can turn the GPT-8000A series round to the remote controller RC-2II side easily by [Turn-round]

key of the remote controller RC-2II. This function helps to increase one man surveying efficiency.

See to Section 5.7 “External Link (GPT-8000Aseries)” and Chapter 8 “PARAMETERS SETTING

MODE” for further information.

• Set the transmit path to " RC".

• Set the transmit channel same as RC-2II side.

•To execute transmission, set the remote in Programs mode to [Remote].

Page 26

1 NOMENCLATURE AND FUNCTIONS

1-15

1.10 Using connecting with Personal Computer (PC)

Commands for tracking mode correspond only to GPT-8000A series.

The auto-tracking function or auto collimating function makes easy remote control of the instrument

from PC. The followings are the main communication commands and explanations. How to communicate or more informations of communication command, you can see the interface manual which provided optionally.Commands for tracking mode correspond only to GPT-8000A series. The auto-tracking function or auto collimating function makes easy remote control of the instrument from PC. The followings are the main communication commands and explanations. How to communicate or more

informations of communication command, you can see the interface manual which provided optionally.

Commands Action of GPT-8000A series

Transmit

command

Mode setting

Trans m i t command for measured data

Trans m i t command for tracking mode

Trans m i t command for battery level The ba ttery level will be out put.

Trans m i t command for coordinate of

instrument point

Trans m i t command for tracking

parameter

Setting of angle measurement

Setting of distance measurement

Setting coordinate of instrument point Setting the coordinate of instrument point.

Setting the tracking parameter

Each measured data will be out put

according to the com man d ty pe.

The status of Automatic Tracking mode

will be out put.

Setting coordinate of instrument point will

be out pu t .

Each setting trac king parameter of

instrument will be out put acc or d ing to the

command type.

Each selecting mode in horizontal angle

or angle measurement can be decided

according to the purpose of comm and.

Setting the measurement mode for

distance measurement.

Setti ng each tracki ng parameter

according to the com man d.

Action

T.I. ON / OFF ON / OFF of Tracking indicator.

Rotating command Rotating of s ett ing angle.

Inversion Inversion movement.

Setting tracki ng mode

Setting from automatic tracking mode to

each command mode.

Page 27

2 PREPARATION FOR MEASUREMENT

2-1

2 PREPARATION FOR MEASUREMENT

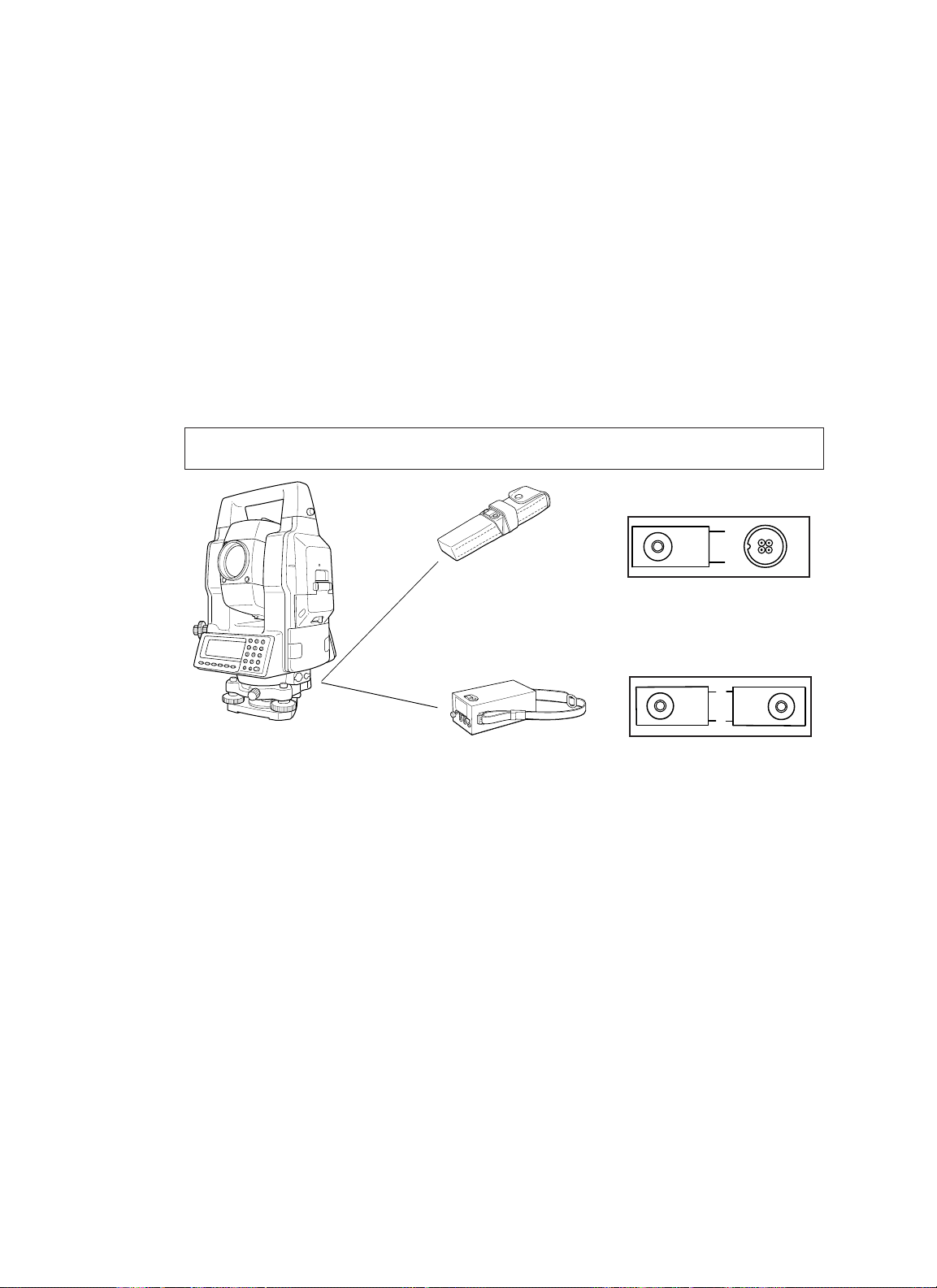

2.1 Power Connection

(unnecessary if on-board Ni-MH battery BT-56Q is used)

See below for connecting the external battery pack.

• Battery pack BT-3Q

Power cord , PC-5 is used.

• Large capacity battery pack BT-3L

Power cord PC-6 is used.

• When using a external battery, the rechargeable battery BT-56Q should be attached

(The instrument will lack in balance if the internal battery BT-56Q is removed.)

The external battery and the internal battery can be used at the same time. The GPT-8000A/8000

series will select a battery due to the battery remaining automatically.

Connector ends

PC-5

PC-6

BT-3Q

BT

-3L

PC-5

PC-6

Page 28

2 PREPARATION FOR MEASUREMENT

2-2

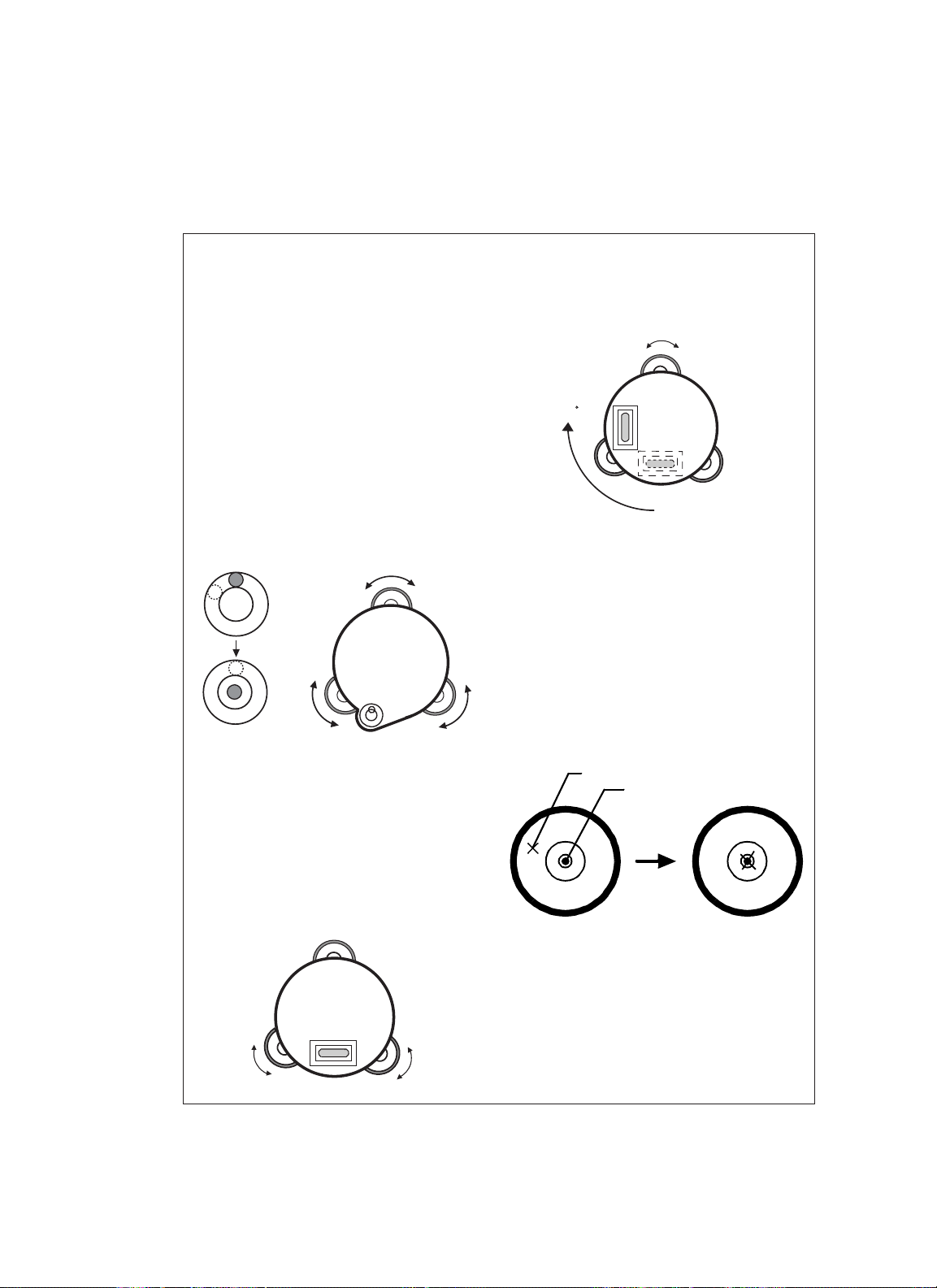

2.2 Setting Instrument Up For Measurement

Mount the instrument to the tripod. Level and center the instrument precisely to insure the best performance. Use tripods with a tripod screw of 5/8 in. diameter and 11 threads per inch, such as the

Type E TOPCON wide- frame wooden tripod.

Reference: Leveling and Centering the Instrumen

1. Setting up the T r ipod

First, e xtend the e xtension legs to suitable lengths

and tighten the screws on their mid sections.

2. Attaching the Instrument on the Tripod

Head

Place the instrument carefully on the tripod head

and slide the instrument by loosening the tripod

screw . If the plumb bob is positioned right over the

center of th e point, slightly ti gh ten t he tripod

screw.

3. Roughly Le veling the Instru men t by Using

the Circular Level

1Turn the leveling screws A and B to move the

bubble in the circular level. The bubble is now

located on a line per pendicular to a line

running throug h the centers o f the tw o le ve ling

screws being adjusted.

Leveling screw C

Leveling

screw A

2Turn the leveling screw C to bring the bubble

to the center of the circul ar l e vel.

4. Centering by Using the Plate Level

1Rotate the instrument horizon tally by using

the Horizontal motion/clamp screw and place

the plate level par allel with the line connecting

leveling screws A and B, and then bring the

bubble to the center of the plate level by

turning leveling screws A and B.

Leveling screw B

2Rotate the instrument 90

ver tical axis and turn the remaining leveling

screw or C to center the bubble once more.

90

3Repeat the procedures 1 and 2 for each 90

(100g) rotation of the instrument and check

whethe r t he bubble i s correctly cente red f o r all

four points.

5. Centering b y Usin g the Optical Plummet

Telescope

Adjust t he e y epiece of the optical plumm et

telescope to your ey esight.

Slide the instrument by loosening the tripod

t

screw, place the point on the cent er mark, and

then tighten the tripod screw. Sliding the

instrument carefully not to rotate that allows you

to get the least dislocation of the bubbl e.

Point

°

(100g) around its

Leveling screw C

Center mark

°

Leveling

screw A

6. Completely Leveling the Instrument

Lev el i ng the instrum ent precisely in a simila r way

to 4. Rotate the instrument and check to see that

the bub ble is in the center of t he plate level

regardless o f telescope dir ecti on, then tighten th e

tripod screw hard.

Leveling

screw B

Page 29

2 PREPARATION FOR MEASUREMENT

2-3

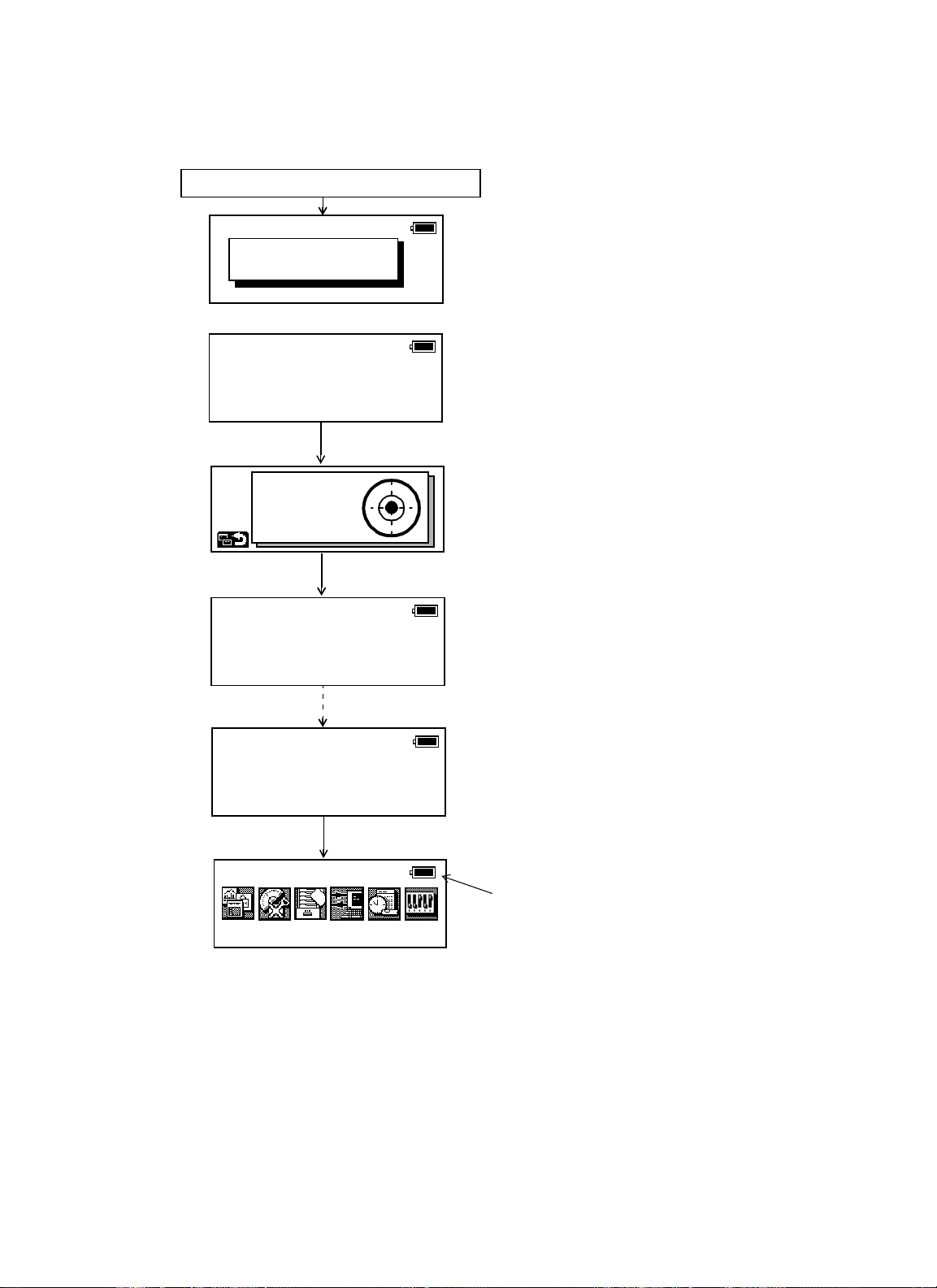

2.3 Power Switch Key ON

1) Confirm the instrument is leveled.

2) Turn the power switch ON.

3) Type your password.

Self checking mode will display.

To skip the self checking, press [F1](ESC)

key.

Level the instrument by turning the leveling

screws.

When the leveling is within ±30" and stable,

the self checking will start.

The instrument will turn automatically and

the tilt sensor offset value will be measured

and memorized.

After checking, the main menu icons will be

shown.

Battery Power Remaining Display

• Self checking option

The self checking function is to check internal communication and tilt sensor offset value. When

ambient temperature is changed or the instrument is not balanced by its internal battery is attached

or detached, the self checking is recommended.

• Password option

Setting a password (Maximum 10 digits number) and activating ON of password option can be helpful to avoid miss operation by unauthorized operator. Setting password option is necessary to use

this function. To set password option, see Chapter 8 “PARAMETERS SETTING MODE”.

• Confirm the battery power remaining on the display. Replace with charged battery or charge

when battery level is low. Refer to Section 2.4 “Battery Level Indicator”.

Power O N

Input a password

[ ]

Self check mode

ESC

X:00°00'00"

Y:00°00'00"

Self checking ...

[ 1/6 ]

ng

Self checki

2002-07-07 14:30

Prog Std Mem Com

...

[ 6/6 ]

Main menu icons

Adj

Para

Page 30

2 PREPARATION FOR MEASUREMENT

2-4

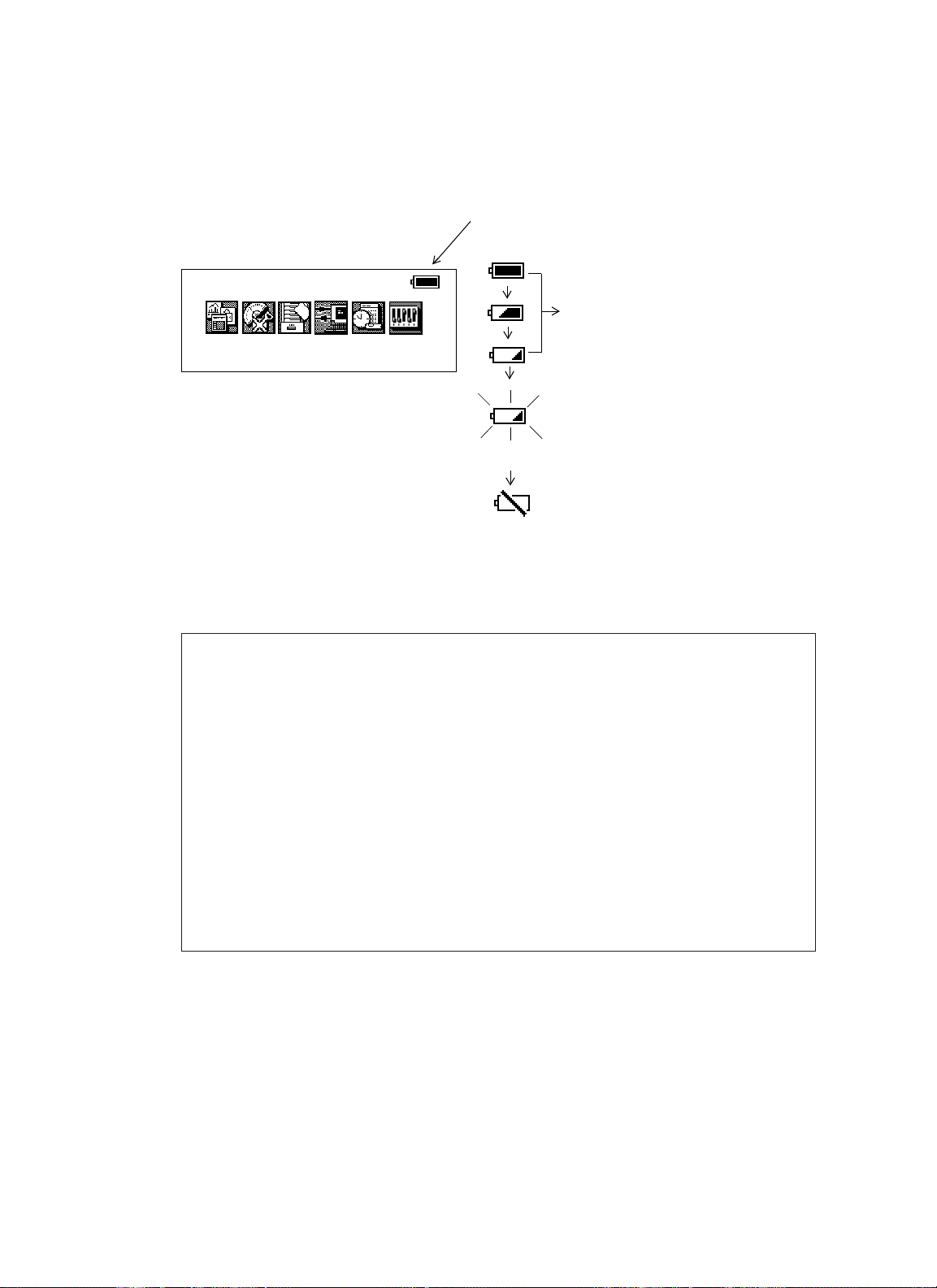

2.4 Battery Level Indicator

The battery power indicator shows the level of battery strength.

Indicates Battery Power Remaining

Measurement is possible.

The power is poor. The battery should

be recharged or replace

the battery.

(Angle measurement can only be possible, the auto-collimating and distance

measurement can not be possible.)

Measurement is impossible. Need to

recharge or replace the battery.

* Battery power remaining display is omitted in this manual.

Note:

1) The battery operating time will vary depending on the environmental conditions, such as

ambient temperature, charging time, and the number of times charging and discharging

the battery.

2)In low temperature (especially while the heater of display is working), the battery operating

time will shorten to one-half of normal temperature use.

3)The indicator for battery power remaining shows the power level during each measurement

mode. The condition indicated for the battery power remaining in the angle measurement mode

may not be adequate to measure a distance. Changing from angle mode to distance mode

during a poor battery condition may cause the EDM not to measure a distance. We recommend

that you check the battery condition before going into the field.

4)Also note, when changing from one measurement mode to another, the battery indicator

may not show a decrease or an increase immediately. The battery indicator system was

designed to show the general condition for the battery strength. It does not respond

instantly.

5)For more information on battery usage, refer to Chapter 13

“POWER SOURCE AND CHARGING”.

2002-07-10 15:30:40

Prog Std Mem Com

Adj

Para

Blinking

Page 31

2 PREPARATION FOR MEASUREMENT

2-5

2.5 Main Menu Icons

The main menu icons are as follows.

Select the menu by pressing soft keys ([F1]~[F6]).

PARAMETERS SETTING MODES

The PARAMETERS SETTING MODES are

stored in memory once the instrument is OFF.

(See Chapter 8 “PARAMETERS SETTING

MODE”.)

ADJUSTMENT MODES

Used for checking and adjustment.

• Systematic errors adjustment for compensation.

• Show compensation values of systematic errors of

instrument

• Set Date & Time

• Set instrument constant value

• Optic Axis for Auto-tracking (GPT-8000Aseries)

(See Chapter 9 “CHECK AND ADJUSTMENT”.)

COMMUNICATION MODES

• Set communication with external instrument

•Input/Output a data file

(See Chapter 7 “COMMUNICATION MODES”.)

MEMORY MANAGE MODES

• Display memory status

• Protect/Eras/Rename/Copy Files,

• Initialize a card or internal memory.

(See Chapter 6 “MEMORY MANAGE MODES” .)•2-6

STANDARD MEASUREMENT MODES

• Angle measurement

• Distance measurement

• Coordinate measurement

(See Chapter 4 “STANDARD MEASUREMENT MODE” .)

PROGRAM MODES (APPLICATION MEASUREMENT)

• Set a direction angle for horizontal orientation

• Retain Coordinate (STORE-NEZ)

• Remote elevation measurement

• Missing line measurement

• Line measurement

• External link for GPT-8000Aseries

• Off set measurement

(See Chapter 5 “PROGRAM MODES” .)

Page 32

2 PREPARATION FOR MEASUREMENT

2-6

2.6 Vertical and Horizontal Angle Tilt Correction

When the tilt sensors are activated, automatic correction of vertical and horizontal angle for mislevelment is displayed.

To ensure a precise angle measurement, tilt sensors must be turned on. The display can also be

used to fine level the instrument. If the (TILT OVER) display appears the instrument is out of automatic compensation range and must be leveled manually.

• GPT-8000A/8000 series compensates both the vertical angle and the horizontal angle

readings due to inclination of the standing axis in the X and Y directions.

• For more information about dual axis compensation, see Chapter “APPENDIX” “Dual Axis

Compensation”.

• The display of Vertical or Horizontal angle is unstable when instrument is on an unstable

stage or a windy day. You can turn off the auto tilt correction function of V/H angle in this case. To

set TILT correction mode ON/OFF, refer to next page or Chapter 8 “PARAMETERS SETTING

MODE”.

Rotate the leveling screws and level the

instrument.

After leveling (when each axis is within ±1'30"),

the display returns to the previous mode

automatically.

X,Y tilt correction range : within ±4'

Zenith

Zenith

Standing axis

Standing axis

Inclination of the stan di ng

axis in the Y dir ecti on

Inclination of the standing

axis in the X direction

Horizontal

W X

V

T

S

Q

P

D

O

When the instrument ti lted over correction

range.

U

R

|

Tru n nion axis

X:

Y:

X:00°00'00"

Y:00°00'00"

Page 33

2 PREPARATION FOR MEASUREMENT

2-7

• Setting Tilt Correction by Soft Key

Enable you to select tilt ON/OFF function on page 2.

The setting performed here will be memorized after powering OFF.

[Example] Setting X,Y Tilt ON

2.7 Compensation of Systematic Error of Instrument

1)Error of vertical axis (X,Y tilt sensor offset)

2) Collimation error

3) Error of vertical angle 0 datum

4) Error of horizontal axis

The above mentioned errors can be compensated by software, which calculated internally

according to each compensation value. Also these errors can be compensated by software collimating one side of the telescope that is carried out to delete the error by turning in normal and reverse

both sides of telescope so far.

•To adjust or reset the above compensation value, see Chapter 9 “CHECK AND ADJUSTMENT”.

• Enable you to stop this function, see Chapter 8 “PARAMETERS SETTING MODE” or

Chapter 9 “CHECK AND ADJUSTMENT”.

Operating procedure Option Display

1

Press [F6] key to get the function page 2.

V : 87°55'45"

HR: 180°44'12"

[F6]

2

Press [F5](TILT) key.

Current setting is displayed. *1

3

Press [F2](ON-2) key.

The displa y shows tilt correction valu e.

4

Press [F1] key.

The display returns previous mode.

*1) Pressing [F6](ESC) key, the display returns previous mode.

The tilt sensor setting will be stored in memory when the inst rument is turned OFF.

●

The tilt sensor option can also be changed in the Parameter Setting Modes. When you change the tilt

sensor option in the angle measurement mode, it will change in the Parameter Setting Modes and visa

verse.

[F5]

[F2]

[F1]

SD HD NEZ 0SET HOLD P1

REC HSET R/L V/% TILT P2

TILT ON (V)

ON-1 ON-2 OFF ESC

X:00° 00'00"

Y:00° 00'00"

↓

↓

Page 34

2 PREPARATION FOR MEASUREMENT

2-8

2.8 Resume Mode ON/OFF

The Resume mode will memorize the last display or mode when the power is turned OFF. When

the power is turned back ON, the last display or mode will be shown.

The Resume mode option only appears when the power is OFF.

2.9 How to Enter Numerals and Alphabet Letters

Alpha and numeric character key entry is simple and quick from the key board.

[Example] Renaming a file in the Memory Manager Modes.

Po wer sw it ch key OFF

Power off

Resume mode

OFF ON ESC

[F1] [F2]

Pressing [F1](OFF) key or [F2](ON) key, select the resume mode.

Operating procedure Option Display

Rename

Old name [TOPCON .DAT]

1

Press [F1](Alpha) key to be entering alphabet

letter mode.

2

Enter Alphabets. *1)

3

Press [F1](Num) key to be entering numeric

mode.

Type “H ”

Move cursor

Type “I”

Type “L”

Type “

”

Input “104”

[F1]

[9][9]

[F4]

[9][9][9]

[4][4][4]

[3][3][3]

[F1]

[1][0][4]

New name [

Alpha SPC ← →

Rename

Old name [TOPCON .DA

New name [HIL

Num SPC ← →

Rename

Old name [TOPCON .DAT]

New name [HIL

]

]

104 ]

T]

Alpha SPC ← →

4

Press [ENT] when complete.

*1) When the same alpha key is to be typed two or more times consecutively, press [F4](→) key between

characters. This moves the cursor to the right .

*2) Ext ens i ons can not be changed .

[ENT]

Page 35

2 PREPARATION FOR MEASUREMENT

2-9

2.10 Memory Card

How to insert a memory card

1) Pull the card cover lever to open the

card cover.

2) Insert a memory card until the card

guide is up.

3) Close the card cover.

How to extract a memory card

1) Pull the card cover lever to open the

card cover.

2) Pull down the card guide.

3) Extract the memory card.

Card cover lever

Card guide

Memory card

Card guide

Page 36

2 PREPARATION FOR MEASUREMENT

2-10

2.11 Inclination of Prism and Measuring Error

(GPT-8000A series)

For the best results, aim or point prisms in the direction of the GPT-8000Aseries so that maximum

signal can be returned to the instrument. Sighting prism obliquely because of inclined settings, may

result in measuring errors. These errors will be proportional to the misalignment as showing in following graphs. The more misalignment of the prism, the more error in measurement. Measured data

can be different according to the prism constant value. This can occur when a prism is moving. Pinpole prism set L1 (for one-person surveying) and pin-pole prism holder L1 (for fixed point observation) are designed to minimize measuring error in such case. Make the best use of them. In case

you are forced to use the normal prism in inclined state because there is no other way possible, we

recommend to use switching holder, prism constant value (0 or 30mm), and set to 30mm

(Compensation value of -30mm).

Prism constant value : 0mm

Prism

Inclined angle

Measuring

point

Instrument

point

Prism constant value : 30mm

Inclined angle

Page 37

2 PREPARATION FOR MEASUREMENT

2-11

● Prism type-2 (Normal prism)

(Example)

In case Prism constant value (C) = 0mm, Prism inclination = 20°, Measuring distance = 100m by

Prism type-2 :

• Distance error is :

From the graph prism type-2, the distance error shows in increasing range quantity 2.5mm along

curved line of C=0 when prism inclination is 20°.

• Angle error is :

From the graph prism type-2, along curved line of C=0 with prism inclination of 20°, find angle error

quantity (14.2mm) and calculate angle error by the following formula.

Distance Measuring error

6

5

4

Increasing

distance

3