Page 1

TC2000 (CE)

English

Middleby Cooking Systems Group 1400 Toastmaster Drive Elgin, IL 60120 (847)741-3300 FAX (847)741-4406

Conveyor Oven

Model TC2000

OWNER'S OPERATING AND

INSTALLATION MANUAL

P/N 42513

Price $5.00

Rev. B V1 11/99

© 1999 Toastmaster, A Middleby Company.

is a registered trademark of Toastmaster, A Middleby Company. All rights reserved.

WARNING: IN CASE OF FIRE

Disconnect the oven from its power source

IMMEDIATELY. This allows the unit to cool,

making it easier to put out the fire.

WARNING

FOR YOUR SAFETY DO NOT STORE OR

USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION AND OPERATING INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

WARNING

DISCONNECT THE OVEN FROM ITS ELECTRICAL POWER SUPPLY BEFORE CLEANING OR SERVICING.

CAUTION

Using any parts other than genuine Toastmaster

factory parts relieves the manufacturer of all

liability.

IMPORTANT

Contact your authorized service agent to perform

maintenance and repairs. A service agency

directory is supplied with your oven.

IMPORTANT

Toastmaster (manufacturer) reserves the right to

change specifications and product design without notice. Such revisions do not entitle the buyer

to corresponding changes, improvements, additions or replacements for previously purchased

equipment.

RETAIN THIS MANUAL FOR FUTURE

REFERENCE

This manual provides detailed information for the

installation and operation of your oven. It also

contains information to assist the operator in

diagnosing problems in the event of a malfunction. This manual is an important tool for the

operator and should be kept readily available.

Page 2

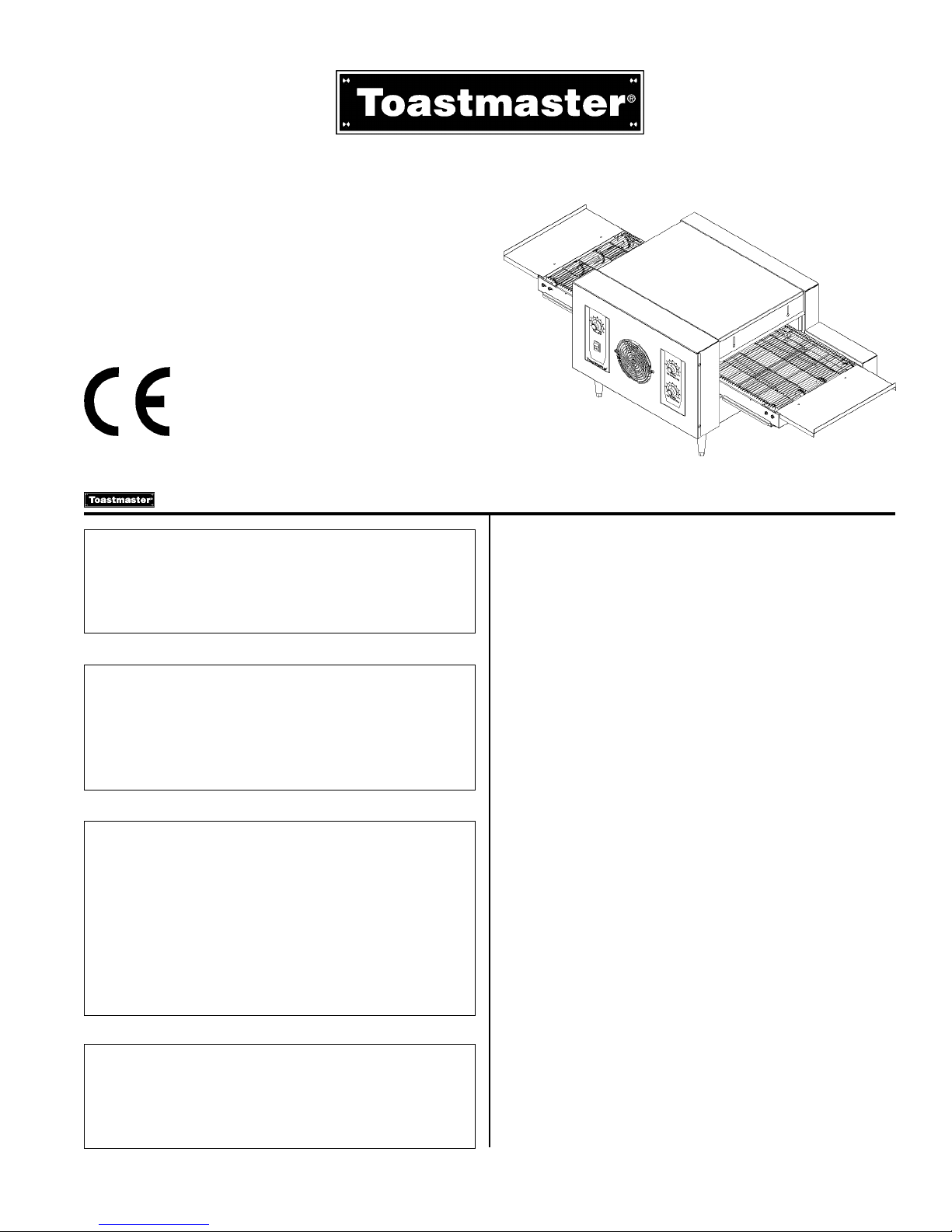

I. DESCRIPTION AND SPECIFICATIONS

A. Component Location

The major components of the oven are shown in Figure 1 below.

Figure 1

8. Fan

7. Adjustable draft

curtain (2)

Figure 2

6. Conveyor

1.

Conveyor

speed

control

knob

2. Power On/Off

(I/O) switch

3. Upper and Lower

temperature

adjustment knobs

B. Component Function (see Figure 1)

1-3. Oven controls - see Section III, Operation.

4. Crumb trays - Collect crumbs from the food product. One

tray is centered under the conveyor, while another is located

under each end of the conveyor. All three trays can be

removed for cleaning.

5. Conveyor end trays - Provide additional loading/exit space at

the ends of the conveyor.

6. Conveyor - Transports the food product through the oven,

between the top and bottom heating elements.

7. Adjustable draft curtains - Reduce draft into the oven and

prevent heat loss into the environment.

8. Fan - Cools the interior components of the oven.

C. Oven Information

Pre-Heat Time: 10 minutes

NOTE: Electrical specifications are provided on the wiring

diagrams at the back of this Manual.

4. Crumb trays (3)

5. Conveyor

end trays (2)

A. INSTALLATION OPTIONS & KIT AVAILABILITY

IMPORTANT

IT IS THE CUSTOMERS RESPONSIBILITY TO REPORT ANY

CONCEALED OR NON-CONCEALED DAMAGE TO THE FREIGHT

COMPANY.

If the installation will require two or three ovens to be stacked, you

must use the separately-available Stacking Kit (P/N T2114STACK).

One Kit is required for a two-stack, while two kits are required for a

three-stack. Stacking more than three ovens is not permitted.

Wherever the Stacking Kits instructions are different from those listed

below, follow the instructions provided with the Kit.

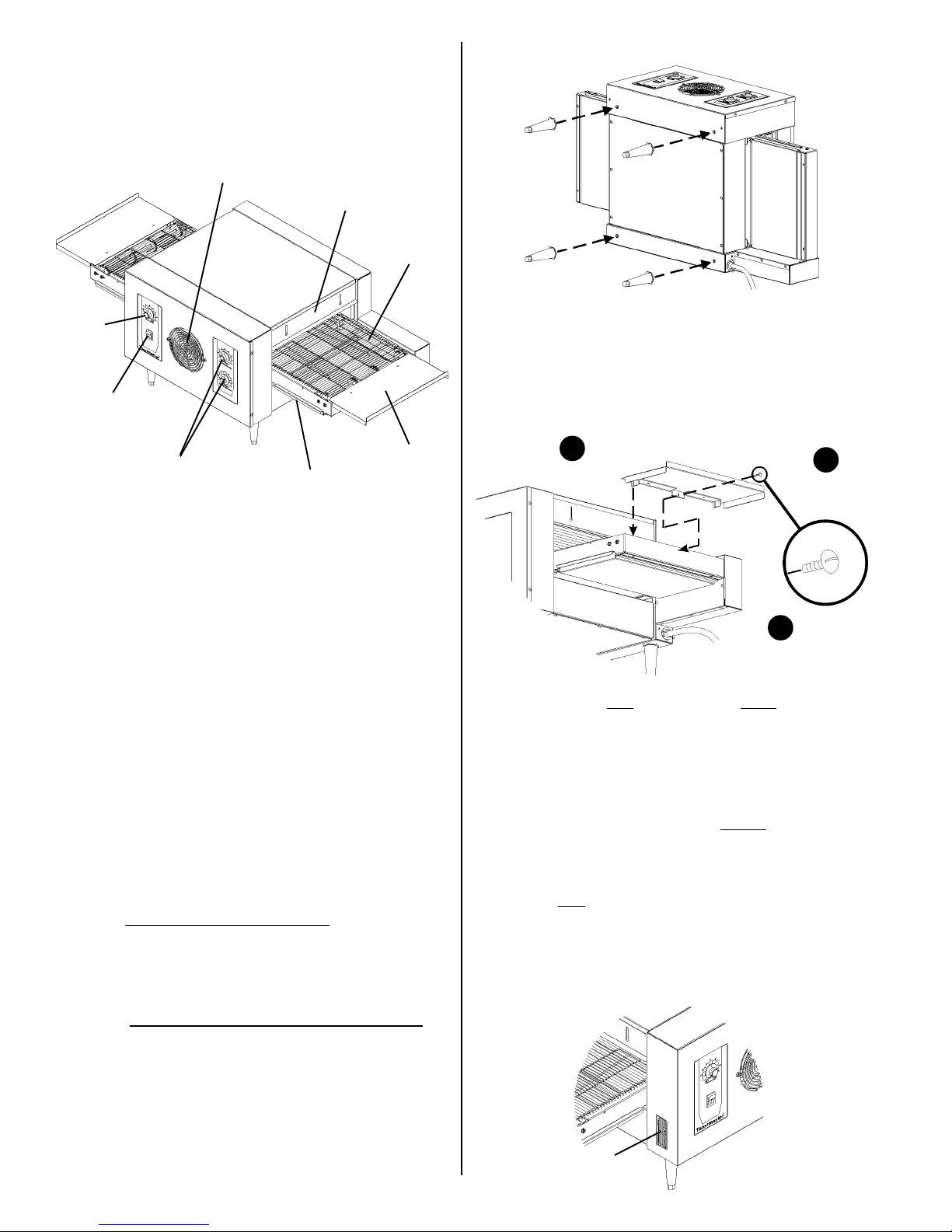

2. Installing the Conveyor End Trays - see Figure 3.

a. Press one of the conveyor end trays down over the end plate

of the conveyor frame.

b. Fasten the end tray in place with one of the supplied 8-32x3/

8 screws.

c. Repeat the above steps to install the second end tray at the

opposite end of the conveyor frame.

1

Position tray

Figure 3

2

Fasten in place

with screw

3

Repeat for

second tray

CAUTION

THE SUPPLIED LEGS AND THE END TRAYS MUST BE FASTENED

IN PLACE BEFORE OPERATING THE OVEN.

C. ELECTRICAL CONNECTION

IMPORTANT

Wiring diagrams for the oven are provided at the back of this

Manual.

The electrical connection to the oven requires a circuit breaker/

fused disconnect. Consult applicable IEC/CEE and local code

requirements to determine the rating of the breaker/disconnect.

Electrical specifications are listed on the ovens serial plate (shown

in Figure 4) and on the wiring diagrams at the back of this Manual.

The oven must be electrically grounded in accordance with current

IEC/CEE and local code requirements. The location of the

equipotential ground lug is shown in Figure 5.

Consult all applicable IEC/CEE and local codes for further electrical

connection requirements.

Figure 4

B. ASSEMBLY

1. Installing the Legs - see Figure 2.

a. Carefully tilt the oven onto its rear side. The front (controller)

side should be facing directly upwards.

b. Thread the four legs into the four holes provided on the bottom

of the oven. Tighten them until they are secure.

Serial plate

2

Page 3

1. Before proceeding with the electrical connection, check that the

electrical supply matches the ovens requirements. Refer to the

serial plate (Figure 4) and to the electrical specifications shown

on the wiring diagrams at the back of this Manual.

WARNING

ENSURE THAT BOTH THE CIRCUIT BREAKER/FUSED DISCONNECT AND THE POWER ON/OFF (I/O) SWITCH ARE IN

THE O (OFF) POSITION BEFORE PROCEEDING.

WARNING

ENSURE THAT ANY PACKING MATERIAL RESIDUE HAS

BEEN REMOVED FROM INSIDE THE OVENS COOKING

CHAMBER.

2. Single-phase ovens only:

Check that the appropriate receptacle is available for the

power cord plug.

Insert the power cord plug into its receptacle.

3. Three-phase ovens only:

Remove the two screws that hold the rear cover panel in

place; then, remove the cover panel.

Insert the end of the electrical supply through the connector

shown in Figure 5.

Attach the electrical supply wires to their terminal block

connections, as shown in Figure 5.

Secure the supply wires to the floor of the electrical

compartment using the supplied cable clamp. The wires must

not interfere with the drive chain and sprocket. See Figure 5.

Secure the supply as it passes through the connector on the

outside wall of the oven.

Replace the rear wall of the oven and fasten it in place.

4. All ovens:

Connect an equipotential ground wire to the lug shown in Figure

5. The equipotential ground connection must meet current IEC/

CEE and local code requirements.

Figure 5

Wiring connections

(3-phase ovens

only)

Equipotential ground lug

and symbol (all ovens)

Connector

(3-phase ovens only)

Terminal

block

Cable clamp

III. OPERATION

A. Location and Function of Controls

This section provides a basic description of the oven controls, their

location, and the functions they perform. The operator MUST be familiar

with the controls. Refer to Figure 6.

2. Conveyor

speed control

knob

1. Power On/Off

(I/O) switch

1. Power On/Off (I/O) switch

Switches the oven ON and OFF.

2. Conveyor speed control knob

Adjusts the speed of the conveyor. This controls the bake time.

1 is the minimum speed setting, which produces the longest

available bake time.

9 is the maximum speed setting, which produces the shortest

available bake time.

3-4. Upper and Lower temperature adjustment knobs

Adjust the temperature settings of the upper and lower heating

zones.

1 is the minimum temperature setting, which sets the heating

zone to the lowest available temperature.

9 is the maximum temperature setting, which sets the

heating zone to the highest available temperature.

B. Operation Procedure

1. Adjust the position of the draft curtains at the ends of the cooking

chamber (if necessary). This procedure is described in detail in

Part D, Draft Curtain Adjustment, in this section.

IMPORTANT

When cooking at very high temperatures (a setting of 8 or higher

on either temperature adjustment knob), the oven should be preheated for at least 10 minutes WITH THE DRAFT CURTAINS IN

THE FULLY-LOWERED POSITION. After pre-heating, the curtains

may be repositioned as required.

2. Restore electrical power to the oven at the circuit breaker/fused

disconnect.

3. Switch the Power On/Off (I/O) Switch to the ON (I) position.

4. Adjust the bake time (if necessary) by turning the conveyor speed

control knob. Adjust the upper and lower temperature settings (if

necessary) by turning the temperature adjustment knobs.

5. Allow the oven to pre-heat for at least 10 minutes.

6. Load the entrance end of the conveyor with the food product. The

motion of the conveyor will move the food product into the cooking

chamber.

C. Shutdown Procedure

1. Switch the Power On/Off (I/O) switch to the OFF (O) position.

2. Wait for the ovens cooling fan to turn off.

3. Disconnect electrical power to the oven at the circuit breaker/fused

disconnect.

3

Figure 6

3. Upper and Lower

temperature adjustment

knobs

Page 4

D. Draft Curtain Adjustment

The draft curtains may need to be repositioned to provide adequate

clearance for some food products. The curtains should be positioned

to prevent drafts into the oven, and heat loss into the environment.

The draft curtains can be removed from the oven to permit the maximum

vertical clearance above the conveyor.

WARNING

BEFORE ADJUSTING THE DRAFT CURTAINS, SWITCH THE

POWER ON/OFF SWITCH TO THE OFF (O) POSITION.

WHEN REPOSITIONING THE CURTAINS:

WEAR A HEAVY OVEN MITT.

DO NOT REACH INTO THE OVENS COOKING CHAMBER!

See Figure 7.

1. To reposition the draft curtains:

a. Loosen the two screws that hold the draft curtain in place.

b. Slide the curtain to the desired clearance above the conveyor.

c. Tighten the two screws to hold the curtain in place.

d. Repeat these steps for the curtain at the opposite end of the

oven.

2. To remove the curtains from the oven:

a. Remove the two screws that hold the draft curtain in place.

b. Remove the draft curtain.

c. Repeat these steps for the curtain at the opposite end of the

oven.

Figure 7

Screws

E. Daily Cleaning

WARNING

WHEN CLEANING THE OVEN:

NEVER USE PRESSURIZED WATER.

NEVER USE A CLEANING SOLUTION OTHER THAN SOAP

AND WATER ON PORTIONS OF THE OVEN THAT COME

INTO CONTACT WITH FOOD PRODUCTS. THESE AREAS

INCLUDE THE CONVEYOR BELT AND END TRAYS.

NEVER APPLY ENOUGH LIQUID TO STAND IN PLACE ON

THE OVEN. LIQUID INSIDE THE OVEN WILL CAUSE A

SEVERE ELECTRICAL HAZARD AND MAY OTHERWISE

DAMAGE THE OVEN.

CAUTION

DO NOT clean your oven using abrasive cleaners or pads. Both will

scratch and dull the finish.

1. With the conveyor running, use a brush to clean any crumbs off

the conveyor into the crumb trays.

2. Switch the Power On/Off (I/O) switch to the OFF (O) position,

and wait for the cooling fan to turn off.

3. Disconnect electrical power to the oven at the circuit breaker/fused

disconnect.

4. Allow the oven to cool.

CAUTION - HOT SURFACES

DO NOT TOUCH HOT SURFACES ON THE OVEN, OR REACH

INTO THE COOKING CHAMBER, UNTIL THE UNIT HAS

COOLED THOROUGHLY.

5. Clean the fan grill on the front of the oven using a stiff nylon brush.

6. Clean the end trays USING SOAP AND WATER ONLY and towel

them dry. If necessary, the end trays can be removed for cleaning

by removing the screws that hold them in place. See Figure 3 (in

Section II).

IMPORTANT

If the end trays are removed for cleaning, they must be replaced

prior to operating the oven.

7. Slide the end crumb trays out from underneath the entrance and

exit ends of the conveyor. See Figure 8.

Draft curtain

CAUTION - HOT

DO NOT

REACH INSIDE

COOKING CHAMBER!

Figure 8

Conveyor

Support

tab

Center tray fits BE-

End crumb

trays slide

straight out

TWEEN conveyor

and support tab.

DO NOT insert

tray on floor of

oven!

8. Lift BOTH ends of the center crumb tray; then, slide the tray out of

either end of the oven.

9. Clean all three of the crumb trays using a commercial oven cleaner.

If necessary, towel them dry.

10. Replace the center crumb tray in the oven as shown in Figure 8.

IMPORTANT

Proper positioning of the center crumb tray is REQUIRED for proper

cooking. Ensure that the tray is replaced inside the conveyor frame,

as shown in Figure 8, and NOT on the floor of the cooking chamber!

11. Replace the two end crumb trays.

12. Clean the outside of the oven using a damp cloth with EITHER

soap and water OR a stainless steel cleaner. Use caution to ensure

that liquids do not enter the oven during cleaning.

4

Page 5

POT 1

100KΩ

NLE

TERMINAL

BLOCK

UPR

TEMP

CTRL

Wiring Diagram - Model TC2000, 230V, 1-Phase

CONTACTOR

RFI

FILTER

UPPER

HEATING ELEMENT

CONVEYOR

SPEED

CONTROLLER

POWER

ON/OFF

(I/O)

SWITCH

TSTAT

N.C.

TSTAT

N.O.

FAN

POT 2

100KΩ

LWR

TEMP

CTRL

LOWER

HEATING ELEMENT

POT

1MΩ

FUSE

0.25 A

MOTOR

Electrical Schematic - Model TC2000, 230V, 1-Phase Electrical

Specifications:

(L1)

TSTAT

N.O.

TSTAT

N.C.

C2

POWER ON/OFF (I/O) SWITCH

2 POLE

POT

100KΩ

UPPER TEMP

CONTROL

FAN

C

RFI FILTER

POT

1MΩ

CONVEYOR

SPEED

CONTROLLER

FUSE 0.25 A

MOTOR

(L2)

230V, 50Hz, 1 Ph,

5.0kW, 21.7A

C1

Cord and Plug

Information:

Kabelmetal-type

HO7RN-F cord with

3 x 4,0mm conductors and

moulded-on IEC 309 plug.

Plug is rated 230VAC/32A.

UPPER HEATING ELEMENT

LOWER TEMP

CONTROL

LOWER HEATING ELEMENT

5

POT

100KΩ

Page 6

E

L1 L2 L3 N

Wiring Diagram - Model TC2000, 380-400V, 3-Phase

(N)

C1

POT 1

100KΩ

TERMINAL BLOCK

UPR

TEMP

CTRL

TSTAT

N.C.

LINE FILTER

UPPER

HEATING ELEMENT

POT 2

100KΩ

LWR

TEMP

CTRL

LOWER

HEATING ELEMENT

Electrical Schematic -

Model TC2000, 380-400V, 3-Phase

LINE FILTER

TSTAT

N.O.

POWER ON/OFF (I/O) SWITCH

2 POLE

FAN

C

RFI

FILTER

CONVEYOR

SPEED

CONTROLLER

POT

1MΩ

CONTACTOR

POWER

ON/OFF

SWITCH

FUSE

0.25 A

(L1)C2(L2) (L3) E

(I/O)

MOTOR

C3 C4

TSTAT

N.C.

TSTAT

N.O.

FAN

Electrical

Specifications:

380-400V, 50Hz,

3 Ph, 5.0kW

Current draw:

N 11.0A

L1 0.6A

L2 11.0A

L3 11.0A

CONVEYOR

SPEED

CONTROLLER

LOWER HEATING ELEMENT

UPPER TEMP

CONTROL

UPPER HEATING ELEMENT

POT

100KΩ

Toastmaster 1400 Toastmaster Drive Elgin, IL 60120 USA (847)741-3300 FAX (847)741-4406

Middleby Corp 24-Hour Service Hotline 1-800-238-8444

RFI FILTER

POT

1MΩ

FUSE 0.25 A

MOTOR

POT

100KΩ

LOWER TEMP

CONTROL

A Middleby Company

www.middleby.com

6

Cord and Plug

Information: N/A

Loading...

Loading...