Page 1

Toastmaster, 10 Sunnen Drive, St. Louis, MO 63143, (314) 781-2777

2M-32345

Page 2

1. De-energize

griddle

to

griddle

cool. This reduces

IN

at disconnect

the flash

switch. This will cut off

CASE OF FIRE

power

point

temperature

making it

to the heating

easier to stop the fire.

elements allowing

2. Cover

blanket

Do not

buming

making it

RETAIN

manual

This

contains

malfunction.

the

affected area

or

cover

to seal

attempt

to

grease.

difficult to contain the fire.

THIS

provides

information

manual

This

with

off

air thus smotherino

grease

fight

a

The

force will

and

oils and suitable

MANUAL FOR

detailed

to assist the

is

an important

DO

OR

OTHER FLAMMABLE

IN THE

VICINITY

a heavy blanket

the fire.

CAUTION:

playing

fire

by

cause the

information

technician

readilY

FOR

NOT

buming

Only

use a

for electric

for

tool for the

available.

YOt.IR SAFETY

STORE

OF

TH|S OR ANY

canvas. Play the fire

or

the

nozzle of the fire extinguisher

grease

fire

extinguisher

be

to

powered

FUTUHE

servicing the

in diagnosing

authorized

OR USE

VAPORS

problems in

GASOLINE

OTHER

extinguisher

sprayed to

filled with

equipment.

REFERENCE

Accu-Miser

technician

OR LIQUIDS

APPLIANCE

nozzle over the

directly on the

adjoining

which

CO.

griddle.

event

the

should be

and

equipment

is for liquids

lt

also

of a

kept

Using

genuine

parts

manufacturer

Toastmaster

to change

without

the

provements,

specifications

notice.

buyer

to

previously

NCTICE

parts

any

Toastmaster

relieves

NOTICE

(Manufacturer)

Such revisions

corresponding

additions or

purchased

other

of

all liability.

reserues

and

replacements

equipment.

than

factory

the

the

product

not

do

changes,

right

design

entifle

im-

for

Page 3

TABLE OF

CONTENTS

Description

Sequence

Specifications

Accessing

Temperature

Calibration

Heating

Removal

Thermocouples

Critical

Or/Off

----------------

of Operation

Griddle

the

Control

of Temperature

Elemqnts

and

---------

Replactment-

Switch

for Service

--

Replacement

Control

7

3

5

8

l0

t2

13

14

-------

LED

Wiring Schematics

t4

15

2l

Page 4

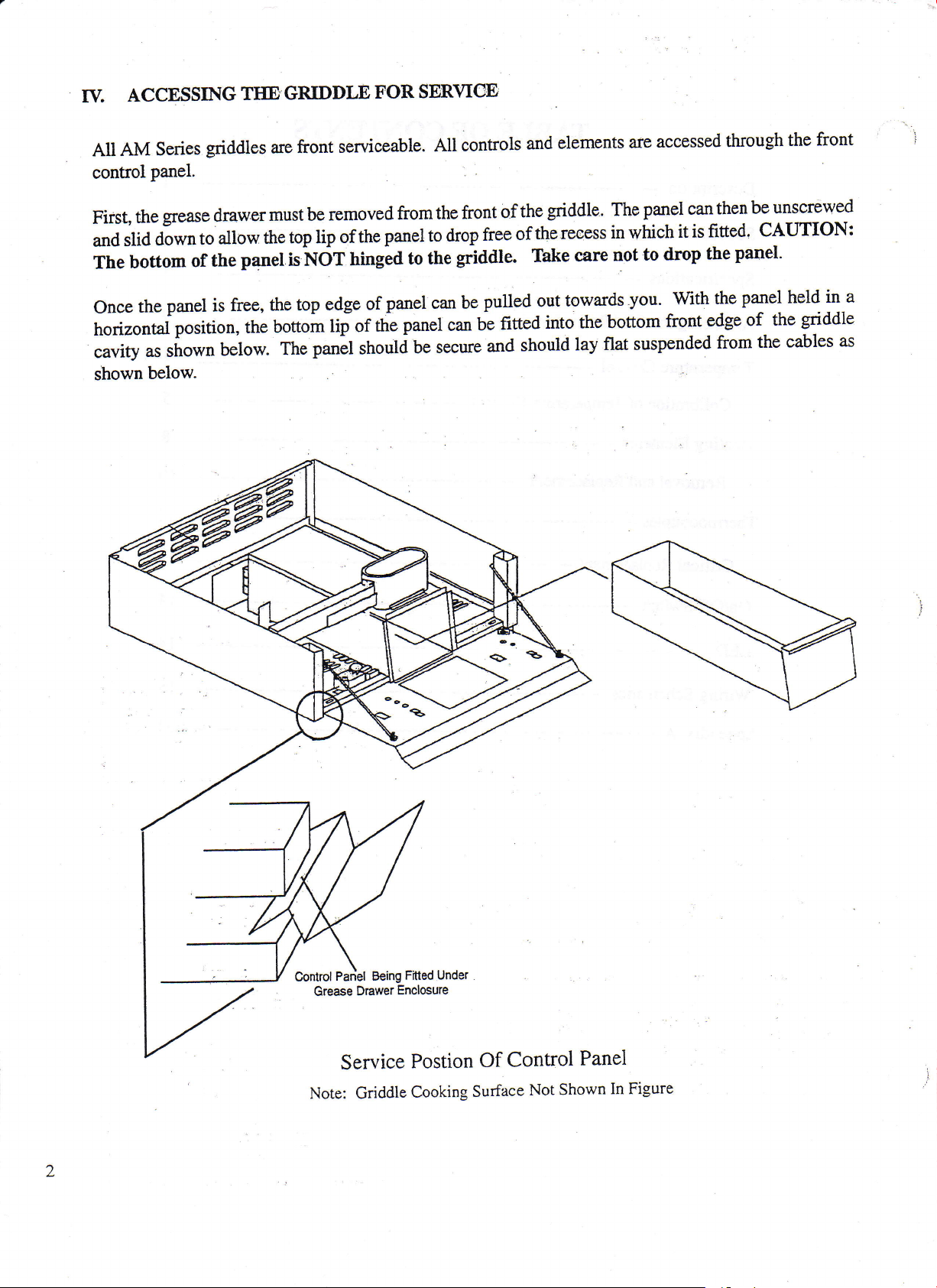

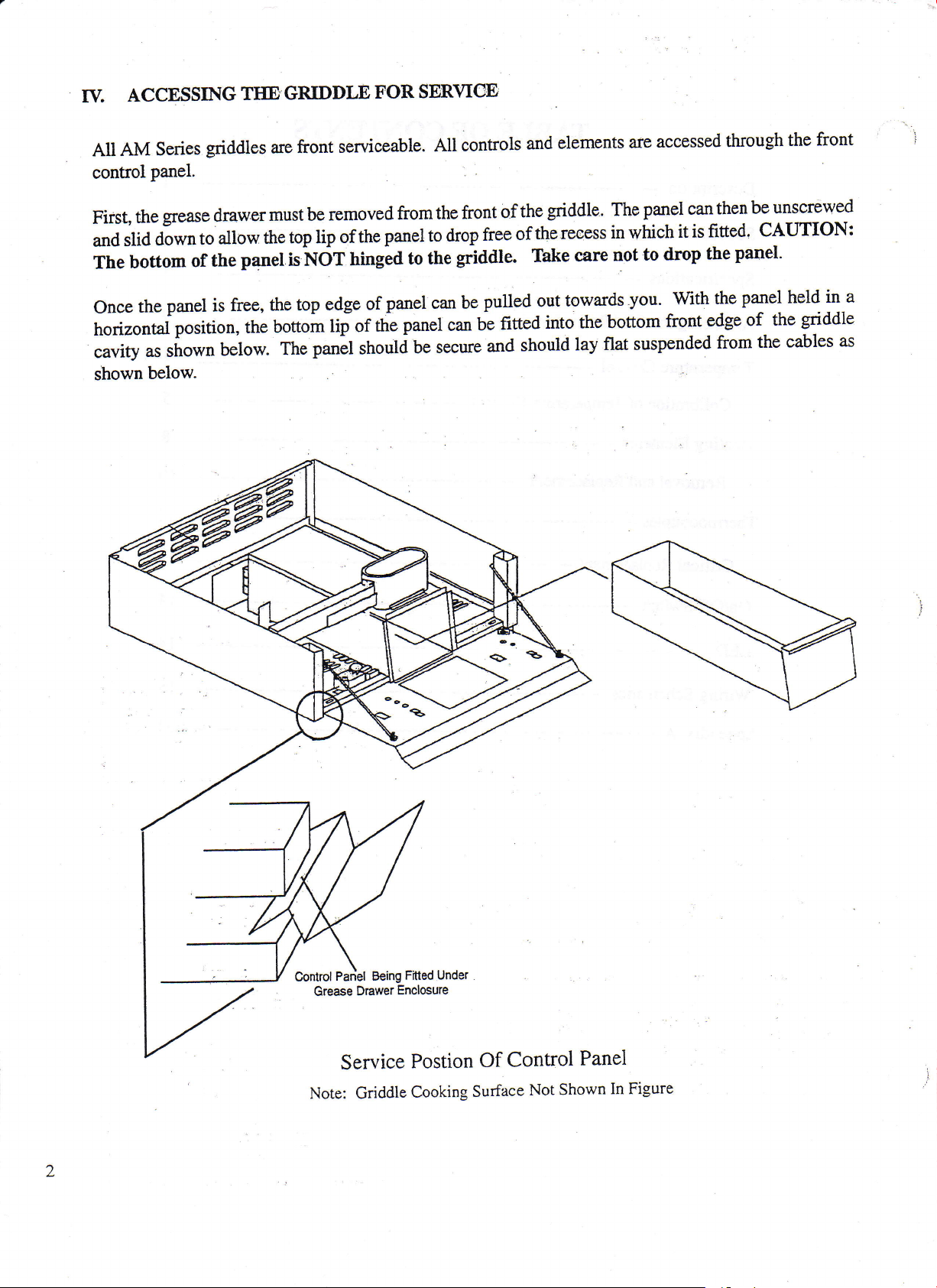

W.

AM

All

control

First,

and

The

ACCESSING

Series

griddles

panel.

grease

the

down

slid

bottom

drawer

to

the

of

allow

TIIE.GRIDDLE

serviceable.

front

are

must be

the

panet

removed

top lip

is NdT

of

ningla

FOR

the

SBRVICO

from

panel

to

All controls

the front

drop

to

the

of

free

griddle.

elements

and

griddle. The

the

recess

the

of

Thke

care

accessed

are

panel

in which

not to

drop

can

it is

through

be unscrewed

then

fitted.

the

CAUTION:

panel'

the

front

the

Once

horizontal

cavity

shown

u, ,ho*n

below.

panel

is

position,

free,

the

below.

the top

bottom

panel

The

edge

lip of

should

panel can be

of

panet

the

be secure

.*

pulled

fitted

br

and

towards

out

into the

should

you. With

bottom

flat suspended

lay

front

the

edge

from

panel

of

held

the

griddle

the cables

in a

as

Pariel Being

Control

Grease

Drawer

Service

Note: Griddle

Under

Fitted

Enclosure

Postion

Cooking

Control

Of

Surface

Not

Panel

Shown

In Figure

Page 5

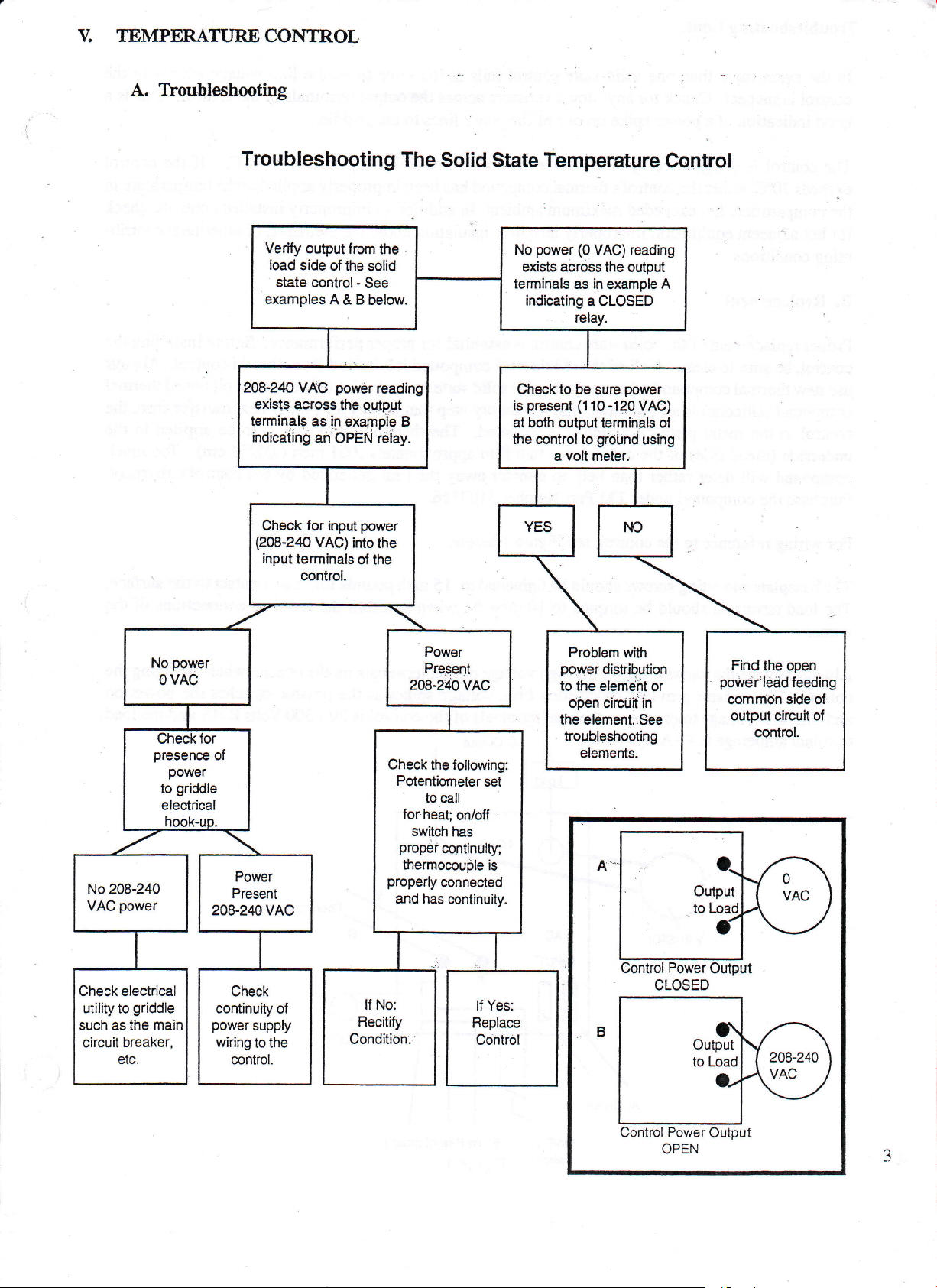

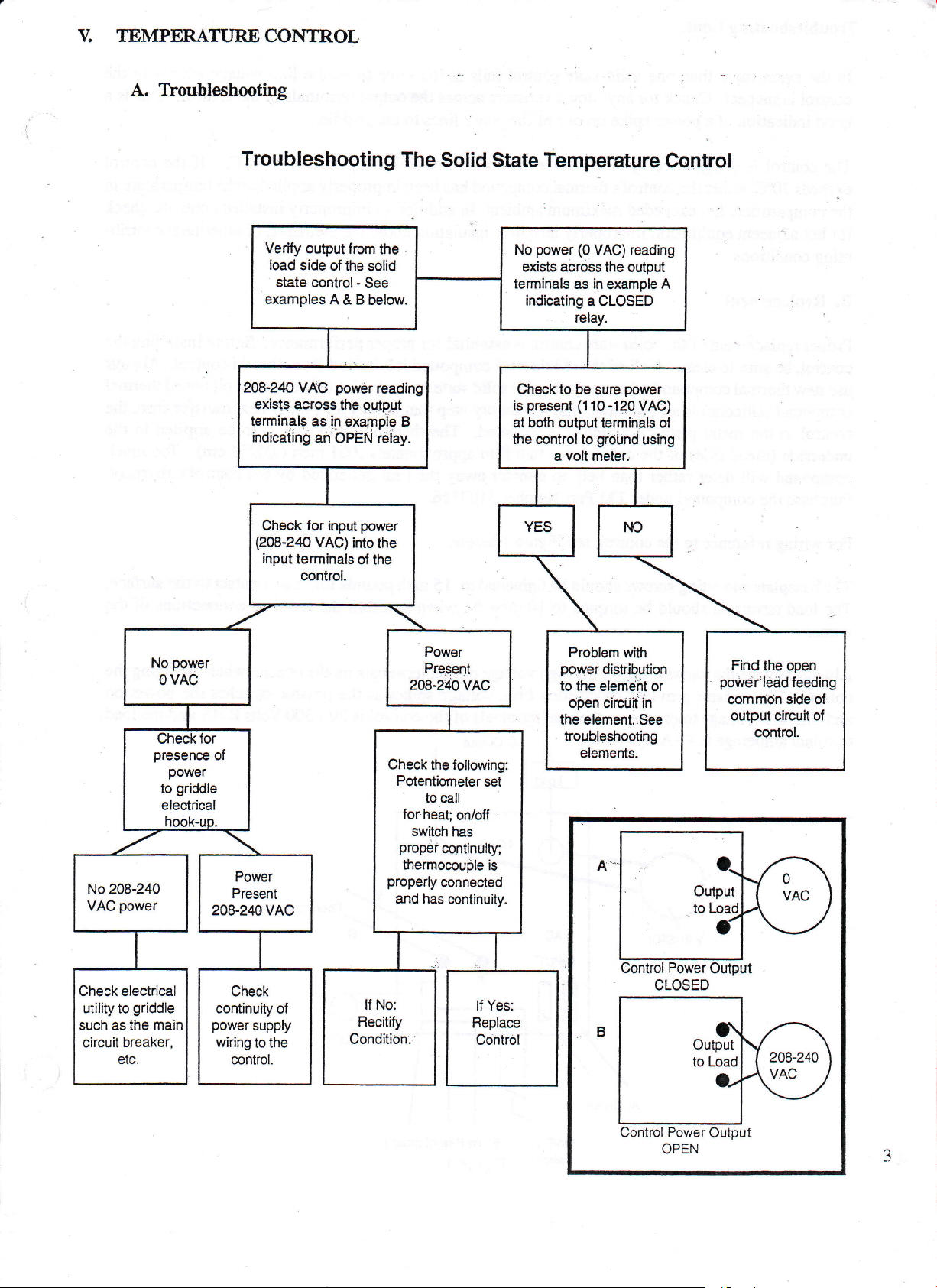

V. TEMPERATTJRECONTROL

A. Tboubleshooting

Troubleshooting

Verify output

load

side

state control-

examplesA&Bbelow

208-24o VAC

exists across

terminals

indicating

Check

(208-240

input

terminals

control.

from

the

of

power

the output

as in

exampie B

an OPEN

for

input

VAC)

inro

The

the

solid

See

reading

relay.

power

the

of the

Solid

State Temperature

power

a

(0

as in

relay.

(110

volt

a CLOSED

VAC) reading

the output

example

sure

-120

terminals of

ground

meter.

No

exists across

terminals

indicating

Check to be

present

is

at both output

the control to

Centrol

A

powel

VAC)

using

No

208-240

power

VAC

Check electrical

utility to

such as the

circuit

griddle

main

breaker,

ofF

Check

continuity

power

supply

wiring

to the

control.

of

Check

Potentiorneter

for

switch

proper

therrnocouple

properly

and has

lf No:

Recitify

Condition.

the following:

set

to call

heat;

onloll

has

continuity;

is

connected

continuity.

lf Yes:

Replace

Control

Problem

power

to the element

open

the element..See

troubleshooting

with

distribution

or

cilcUit in

elements.

CLOSED

Find

the open

power'ledd

common

output

feeding

side of

circuit

control.

o{

OPEN

Page 6

Tfoubleshooting

Cont.

than one solid

In the event

control is suspect.

good

indication

The control

exceeds

compartment

the

for hot adjacent

more

of

is designed

eitherthe

70oC,

equipment, improperty installed insulation

Check

a

has exceeded

uting conditions.

B.

Replacement

Proper replacement

to clean off all of the old thermal compound

control, be

use new

compound

control to the

underside

compound

Purchase

sure

therrnal

compound when replacingthe solid

(silicone)

metal

(metal

will

side)

deter rather than help to transfer away

the compound

control fails

state

for

any blown

power

spike

on one

to

operate,with a

control's

thermal compound has

maximum

of the solid state

is an important and

plate

of

which it is mounted. The.thermal

orl

the

control as a

varistors

phase

of the

maximum heatsink

ambient.

control is essential for

mandatory

thin film

under TM Part Number 3103116.

same time, the

the

at

ouput

across

the

lines

to the

temperature of 7fC.

been improperly

In addition

to

under the

proper performance.

left behind

control. Use

state

that allows

step

approximately

heat

the

line voltage suppty to the

terminals

griddle

applied orthe temperature

improperly

elentents,

from the old

of'the special

proper

for

compound

inch

.001

generated

by the

Control. This is a

of the

If the control

in

installed controls, check

other heat contrib-

or

Before

installing the

control. Always

heat

is to be

(0A254

oil

based

transfer from the

applied to the

cm).

thermal

Too

much

control's thyristor.

For wiring reference

The baseplate

The load

mounting

terminals should

wires.

Always

replaqp the

control. The

and

off.

The

terminal amperage

varistor across the high

varistor

voltage

is

to the

control,

Figure 1

see

screws should be

be torqued

to

provides proctoction

tolprarice on the load

40 Amps

RMS.

below.

tightened

10

voltage

inch

to

lbs

oiitput

from voltage

terminals

AC Output

of

pounds

inch

.15

whe:r securing

terminals on the

spikes as the

control is 20 - 300

the

for exact

contact to

the terminal

control. when

tyristor

switches

Volts

Thermocouole

the

surface.

connections of the

the

on

load

RMS

changing

power

the

and the

A

On/Off

Switch

Potentiometer

From

Figure I.

Page 7

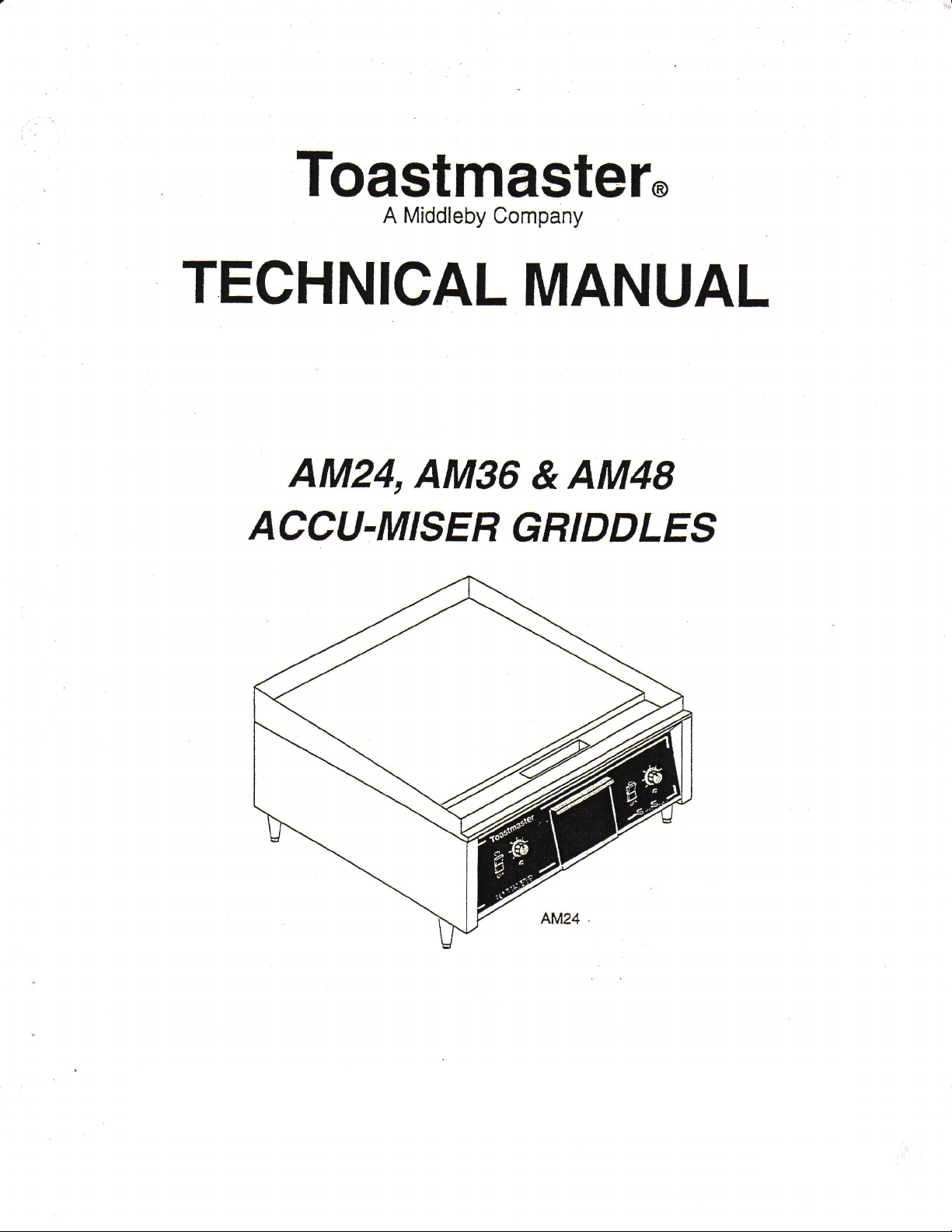

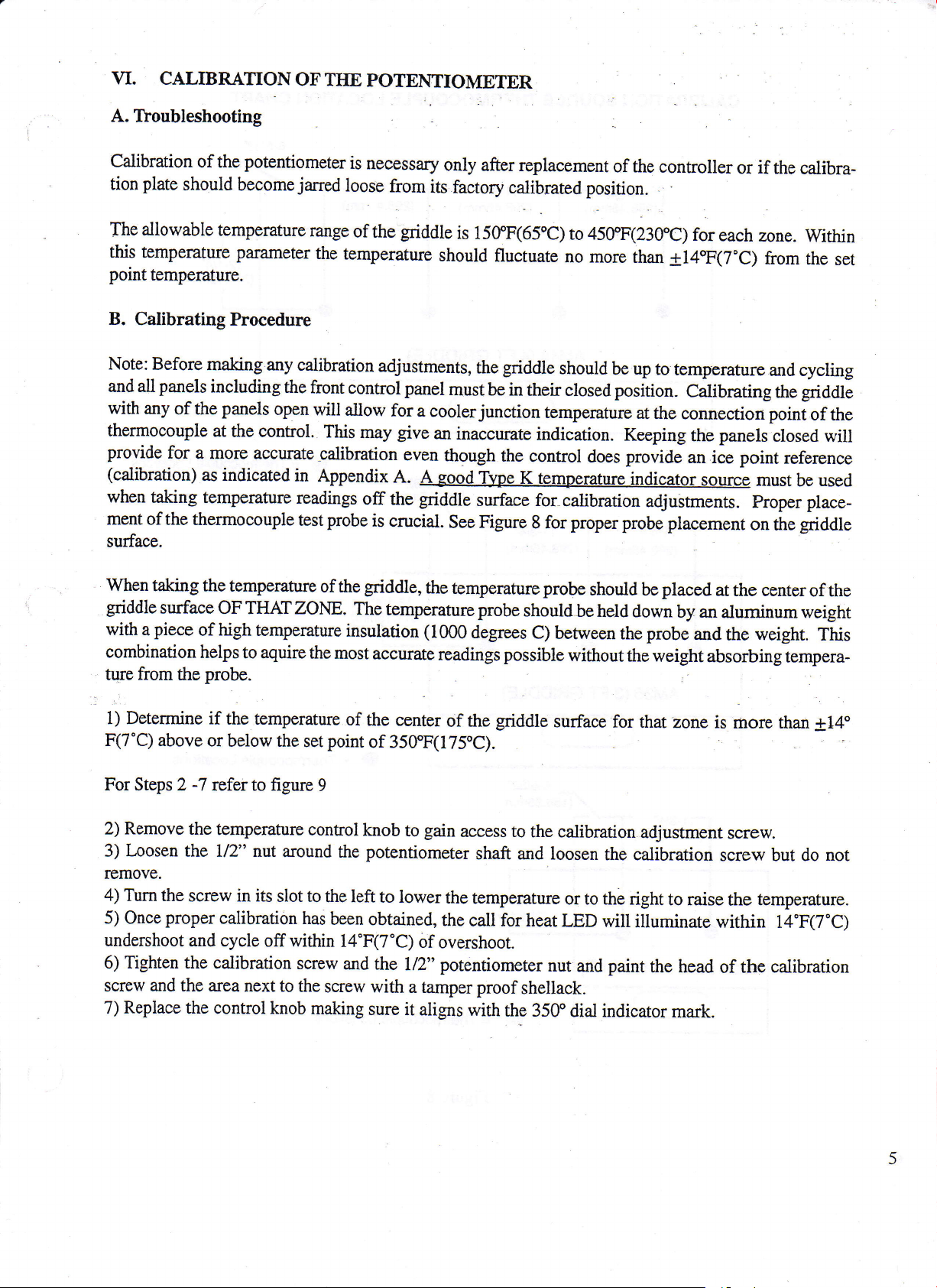

VI.

A. Ttoubleshooting

CALIBRATION

OF TIIE

POTENTIOMETER

Calibration

plate

tion

The allowable

this temperature

point

temperature.

B.

Calibrating

Note:Before

and all

with any

thermocouple

provide

(calibration)

when

taking

ment of

surface.

When taking

griddle

with

a

combination

from

ture

of the

should become

temperature

Procedure

making

panels

surface

piece

including

of the

for

the thermocouple

panels

at

a more

indicated

as

temperature

the temperature

OF THAI ZONE.

high

of

helps

probe.

the

potentiometer

jarred

range

paftrmeterthe

any calibration

the front

open

will

the control.

accurate

temperature

to aquire

This

calibration

in

Appendix

readings

probe

test

of the

the most

is

necessary

loose

from

its

of the

temperature

control

allow

The

insulation

gdddle

should

adjustments,

panel

for a

cooler

give

may

off

is

griddle,

temperature

accurate

an

even

A. A good

griddle

the

cmcial.

the

(1000

readings

only

after replacement

factory

is

must

inaccurate

though

See Figure

temperature

calibrated position.

15CPF(65'C)

fluctuate

griddle

the

be in

their closed position-

junction

indication.

the

control

K temperature

tvpe

surface for

8 for

probe

should

degrees

C) between

possible

of the

450'F(230.C)

to

no

more than

should

temperature

calibration

proper probe

probe

be

without the

up

be

at

Keeping

provide

does

indicator

should be

held down

the

controller

for

+14"F(j'C)

to

temperature

Calibrating

the connectiorrpoiniof

the

an ice

source

adjustrnents.

placement

placed

by an aluminum weight

probe

and

weight

absorbing

if

or

the

calibra-

each zone.

panelsrclosed

point

must

Proper

on thr

at the center

weight.

the

Within

from the

and cycling

griddle

the

reference

be

place-

griddle

of the

tempera-

set

the

will

used

This

1) Determine if

F(7"C) above

For Steps 2

2) Remove

Loosen

3)

remove.

4)

Turn the

5) Once

undershoot

6)

screw and the

7)

proper

Tighten the calibration

Replace

the temperature

or

below the

-7

refer

to figure

the temperature

the L/2" nut

screw in its

calibration

and cycle

area next to

the control

of

point

set

9

control

around

slot to

within

off

knob making

the

the left

has

been

14"F(7'C)

screw

the

screw with

and the

the center

of 350"F(175"C).

knob

to

potentiometer

to lower

obtained,

of

l/2"

a tamper

sure

it aligns

the

of

gain

access to

shaft and loosen

the

temperature

the

call for heat

overshoot.

potentiometer

proof

with

griddle

the 350'dial

surface

the calibration

or to the

LED will

nut

shellack.

for

that zone

adjustment

the calibration

right

illuminate

paint

and

indicaror

the head

is more than

screw but do not

to raise

within 14'F(7'C)

of the

mark.

screw.

temperature.

the

calibration

+14.

Page 8

CALIBRATION

SOURCE

11-3t4"

(298.4Smm) (298.45mm)

THERMOCOUPLE

11-3t4j

LOCATION CHART

11-3t4'

(298.45mm)

6-5/32"

(ls,,/r']'ml

12-114',

(311.1Smm)

1-314"

(298.45mm)

AM36

1-314i

(3

11-314"

(298.45mm)

FT GRTDDLE)

6-5133

12.Uq

(311.15mm)

12-1/4J

(311.1

=Thermocouple

|

=

Thermocouple Locations

O

Locations

(24FT

4

GRIDDLE)

=

Thermocouple

Figure

8

Locations

6

Page 9

Potentiometer

Calibration

Figure

9

$ss

r$s

Note: The

figure 10

below represents

Griddle.

Two waves

numbered | &2

a common temPerature

of l4"F(7"C)

as

the

graph

arc

setting

reveals.

Location

a temperature

the individual

of

350"F( I

75'C).

Behird

zones

of

I /2a

Knob

of the

properly

A

Nut

graph

taken

during

griddle.

2 ft

calibrated

the calibration

gdddle

The

griddle

will

have

of an

ANI24

was calibrated

a

Stolerance

at

Temperature

Swing

Figure

At 350eF

10

Page 10

VII. IIEMING

A. Tloubleshooting

Start Here

ELEMENTS

Using an amprobe

check for

proper

amp draw at

leads to element.

if

to

the

the amps

griddle

Qualify

are

specifications.

See Chart

Fig.3.

Calibibtion

with

See calibration

seclion for'guidance.

p_rotlern

the control.

...=...jj

Check for

voltage

of

presence

to the

element and for

open circuits.

Track down

probable

cause.

Check for open

ciicUit

i6

element.

Check

voltage;

resistance of

8

incoming

check

element.

Charts

Figs.,2& 3.

cold

Prob-lem:..208- VAG

applied

griddfe

to 240

or wrong or

ddfeetive

VAC

el6ment,

Page 11

common

most

The

circuits

short

circumstances,

The only

element.

element.

current.

placing the

when

grounded

Once

ture.

disconnecting

after

tion. Check

to

lead

or

the

to

way

Check

With an

this

If so,

or shorted

element

the

continuity

ground

for short

problems

ground

grounded

determine

across

amp

good

is a

volt meter from one

element

power

through

with

faults.

the leads

clip

is up

circuits.

A

element

if an element

meter,

indication

problems

to operating

griddle

to the

the element

grounded

for the

electric

check

heating

or

shorted

continue to

can

grounded

is

resistance

griddle

the

grounded

a

of

element

may

power

NOT

temperature

and disconnecting

for

open

elements

element

heat

or shorted

reading

ground

element.

lead to

unless

occur

the

circiuts

arc open

normally trip

will

without

and frorn

the element

element

one

and/or

tripping

is to

wire to

Check to see

element is

the

can be

element

ground

connections,;bad

a breaker.

a breaker.

disconnect

one lead

if there

see

case.

checked

lead

faults

all

ground

to

is any

power

if full

in mind that

Keep

up to operating

with an ohm

from the

power

and frorn

connections,

In some

wires from the

for a shorted

indication

can be

tempera-

distribu-

the

of

read

many

meter

element

referenced

As

griddle

perforrnance

Figure

ofthese

geatly

can

reveals

3

ratings

depending

below

in figure Z,the Accumiser

reduce

208 Volt

Maximum

Minumum

important

are+

the life

on the element

of

Element

Allowable

21 5 VAC

Allowable

1 92 VAC

Element

amperage

I07o.

voltage specific

is a

the element and/or

vs.

the electrical

240 Vott

Maximum

Minumum

Voltage Tolerances

Figure 2

and resistance

ratings

destroy the

service,

Element

Allowable

2s3 VAC

Allowable

VAC

21 6

the specific

of

griddle.

element

voltage elements.

wrong

The

immediatel!

voltage

or cause

l

Tolerances

to the

poor

Accumiser

Voltage

248

Voltage

240

lndividual

Element

Watts

31 20

Watts

3120

Ratings:

Resistance

Cold

Cold Resistance

Figure

Models

(Ohms)

13.87

(Ohms)

18.46

3

AM24,36

48

&

Draw

Amp

Element

Amp Draw

Element

Lgads

15.0

Leads

13.0

At

At

Page 12

B.

Element Removal

elernents

The

heating

sf the

are

griddle

box assembly and

and the elimination

element'assembly

An

lower'the

front control

&

to,,be

surface,

ttre top heater

air

of

can

support bracket, itemA,

the Left and

the frame

tion cover

element assembly can

fonvard

Right side of the

supporf with the heater

and insulatiqn

be

out

position.

of

Alignment

Replacement

replaced

entrapment

as an

The

elements

plate.

assembly

This

between

be removed'through

panel

and

gain

to

then

the insulation

heater

assembly

access

assembly will pivot

mounted.below

pivoted

all

the

the

way down

ALWAYS!

are

specially

provides

the

the

to

frame

even heat

element and heater

front

of

elements.

the

item B. Thixl

strip,

support.

down. It

frame

support. Fourth.

and the element

.Failure

compressed

transfer

plate.

.'

griddle.

the

Seeond,

loosen

As

the nuts are

noj

is

necessary

once

assembly

to

do

between the

to the

Refer

remove

will

so

result in uneven

element

griddle

cooking

to Figure 4 belsw.

the front insulation

evenly, the'l/16" nuts

loosened,

front end

the

to remove the insula-

the nut$ arc removed, the

can be unwired and

package

surface

ErsL

on

of

slid

See figure 4

Proper

a) crush the

below for the following

alignment

of the top heater

thermocouple

b) cause improper

The heater

thermocouple

griddle

sure to tighten

tightly in

plate

tube

surface.

the

place.

has. a long

As the new element

Insutation

After replacing

the element

below the element

and

support bracke-t) are

abnormal

ing

compartment

performance

and

mounting

surface contact

slot

centered

as the element

package'box

retaining

assembly,

frame

support

ptit

with

back'in pl6ee.

temperatures

control

b)

component

explantions.

plate

and

therrnocouple

tube

of the element

at

the front,

assembly

in

bg

is

package

the

nuts

qure

lifted

evenly

that

the insulation

Failure

and

heat losS

failure

tube is

assembly with

is important

It

and secured

pivoted

is

box

until the

the 1.5" thic-k

cover.

from the

due

properly

to

element.

to heat.

Make

essential in

the bottom

that the

into

back

up into

order not to:

of the

slot

its flush

its installed

whole element

l,nsulation

sure items

install

This

sheet is

A & B

all inSulation will

can result in:

griddle

surface

certers around

position

under

position,

assembly

is level

:

properly installed

(front

insulation

result

poor

a)

the

the

be

and

in

cook-

10

Page 13

eater

Assemb[y

lnsulation

Stand-Off

Package

Stand- O

Cotter Pih

The

Ng{ei

and the

as an

not need

pivoting

down.

insulation

exploded

to be

the

irrsulation

are

view

removed

element

lnsCorila

ver

cover

shown

do

and

while

assemblY

Frame

7/16" Nuts

Support

Frame

Support

Under

Element Assembly RemovaliReplacement

Figure

4

II

Page 14

\rIII.

THERMOCOT]PLES

,

A.

Troubleshooting

Control Circuit

a) an open

b) a shorted

c) a reversed

thermocouple

thermocouple

wired

will inhibit

will

cause

thermocouple

will

the conirol

the control

cause

the

from operating

to

run

away

since it defaults

confiol to read

backwards

to

room tempemture

and runaway

Shorting the thermocouple

troubleshooting.

temperature

ing this very

naturally

and

brief

Since

TEST,

shorting

call for

be

service.

The

followingchartlists

the

Junction

Temp

90eF(32rC)

85eF(29e

SorF(zFC)

7seF(24eC)

good

is

a

way

the thermocouple

heat

if the

sure to

remove

Type

Kthermocouple

200eF

(93rC)

2.s2

2.U

2.75

2.86

to

see if

potentiometer

ttrre

the control

is the

same as

is

short from the circuit

millivoltreadingfrom200"F(93"C)

Griddle

Temperature

300eF

(149sC)

4.80

4.91

5.02

5.14 7.36

400eF

204ec)

7.02

7.13

725

quickly

bridging

responds

the circuit,

set at a higher

before

500eF

(260ec)

9.27

o?a

9.49

9.60

by coming

it will

temperature.

placing

When

griddle

the

to

500"F(26trC).

on

default

perform-

back into

during

to room

t2

Example:

should

At room

Cold resistance

The

thermocouple

be 4.91

mV.

temperature a good

reading:

70eF(24eC)

65e(18eC)

60eF(16eC)

millivolt

thermocouple

6.5

OHMS

average.

2.98

3.09

3.2A

reading

will

5.25

5.36 t.c6

5.47 7.69

at

300'F( 149"C) with

read

between 5-8

7.47

junction

a

ohms.

9.72

9.83

9.94

temperature

of 85.F(29.C)

Page 15

B. Replacement

When

until

upward

of

rate

replacing

transition

the

iirto a channel

the surface.

temperature

the thermocouple;

crimp

Failufe

control of

toucheSthe

the bottom

at

position

to

gdddle

the

Thermocouple

it is imperative

tube'inlet.

Refef to

of thegriddle

the thetmocouple

adverse

and

imbedded

tube

into

bottom of

it

that

figure 5. Note

surface.

the

all

cooking

griddle

Thermocouple Placement

Figure 5

slides

way

into

enables accurate

This

into the support

results.

the

support

that the

tubsand is'inser'ted

thermocouple swings

temperature sensing

will cause inaccu-

tube

The thermocouples

couples

teristics

Terminal

nected

may also

the

of

connections

follows:

as

used

cause cooking

factory

YELLOW

are Type K.

No other

problems

since the control

installed thermocouple.

of the thermocouple

WIRE +

to

(POSITIVE)

thermcouple

typ"t

is

the control

RED

and

are to be used. Other

calibrated to the

are

WIRE

polarity

sensitive

(NEGATIVE)

length

and

K thermo-

type

and value

should

-.

charac-

con-

be

t3

Page 16

IX.

The

through the

important

resistance

ON/OTF SWITCHES

On/Off switch is designed

switch are very

to set the

reading of 1.0

ohm meter

to

handle

small at 12 VAC.

on the

ohms or

R x 100

greater

currents

will

as

Therefore when

scale,to

drop the 12

higfr as 20 Amps.

checking

possible

read

VAC

resistances

and- cause

The

cunent values

the

switch for

to

up

the control not

running

continuity, it

Any

ohm.

1.0

to operate.

is

When

shown

replacing the rocker

in

figure 6. This

boot keeps

switch,

Added

Rubber

Boot

be sure that

grease

out

Switch

Figure

the switctr

and moisture,

Boot

6

has a

protective

preventing

boot

surrounding its

short circuits.

body as

l4

X. LIGIIT

The LED

heat.

light emitting

incorrectly

the black terminal.

If the

1.5 to 2.0 VDC

EMITTING

below each temperature

gdddle

to

the

diode is

rnay damage it.

DIODE

is heating

LED.

If the LED

If

polarity

See ftgare

(LED)

control

and maintaining

voltage

the

sensitive and

still does

knob

present,

is

The

7.

not illuminate,

.#

.".11,,-

+

LED

Figure

illuminates

temperature

the wires should

red LED

Polarity

7

when

yet

check

to

goes

wire

then it can

the

be sure the LED

that zone

LED is

not be reversed. Wiring

to the red

be

not

determined

griddle

of the

illuminating, check for

wired

is

terminal and

properly.

inoperative.

is

calling for

The

of the LED

the

black to

Page 17

SCHEiVffiTICS

XI.

$$s

=

z

s.E9

6=5

Q€.v

542

i6 Fq

o xo

or

==

r'FE

I

I

x

N

EEH

$aB

€tg

=E

?

V-F

E;i

P

N

ll

t.

a

uF-

==

g

Eo

.F

-Ez

.

-#sE

€*-

+5t

=b

lv

t5

Page 18

XL

SCHEWIATICS

i'i

-ltl

B

g.

C'

F

95

6g)

',:

o

o.

E+

of

F

-

F--ii

_Jt'

t

E+=

i

g

o !E O-'

.^.E

VEEx

H

EEffi;

lss

e[T

l6

Page 19

XI. SCITEMATICS

-9

@J

EFE

lrJ

-x

u

I

I N

tH

\

vl

FE'<9

6 =:5

tl

t

N

z

o

E

H-

o

g

o

F

O9o

E;E

E FOI

o xo

=Jz

i

E6P

r+.=

<

-s.lo

tn c

E;

E$E

E

J

og?Ed

ooz

€o

GF

?:

z

17

Page 20

_.1t,

e

X'I.

SCI{EMATICS

l1

?

6,1

Fnr

:=

d(J)

N

o-.

jlr

E+.

n€

\./=

*r--!*

xrA i

E N8=

|

st4

H

fT1

"r

PPls*

'a:

or

5 Y6E

*

F

A.E

tlJ

*

?'

g*-

c?

E

o-

g

-f,1

",

€,uo;

t!.

(D

in5

.9

-ty

P

= =?

s

i=-

Vs

-

?E

E=

tr.

E*;

'o

-1

Enl I

E

3

o

g!

E=

oo)

z,=

i4s=

6rH I

>r

- a=

E<

o<

F5

uIa

a_

i

,a\E

tlJ

Y€

L_

I

i

I

I

I

I

I

I

I

j

\-,

I8

Page 21

XI. SCIIEMATICS

i$3

$$!

(el

Q€q

E!

682

l-i

t!

o

r!

-l

NI

$$!

-ct

=z

oo

ae

.b,Q

6Fa

f!:

6l

;Xf,

E;

t9

Page 22

o lr,

-1ll

6

I

a,

x3

E'

F* E

-

a-

i nE_

q

V=- 9g

-s--.1

EKa=

E

stl

€

=

! F

d'

o-

::

o

lTl

xrll ;

Ey18=

6tY I

)L-io

;n5

9V6

ti=

I - ?-

t ;<

s

H3

rJJ

XL SCITEMATICS

3

</

=f

t-

Y=

6o

ql

(

Ei

a

Ex;

al,

___Jtr

E

9,

;iN

Y}

r

rit

NI

JI

Y=

..':

Flt

E' :

5*

-a-

nE X;

rvE

J:A

=l+

l

-o

! ltn

tlJ

-r-l-

;\lx- d

'g

t\v-

ott

>rr

+.

Fq

F

q

-g:

l*9

oi x=

$+.

n5

Y5

:

1,.

Fo

"F'

-

20

Loading...

Loading...