Page 1

Toastmaster

A Middleby Company

OWNER'S OPERATING

& INSTALLATION

MANUAL

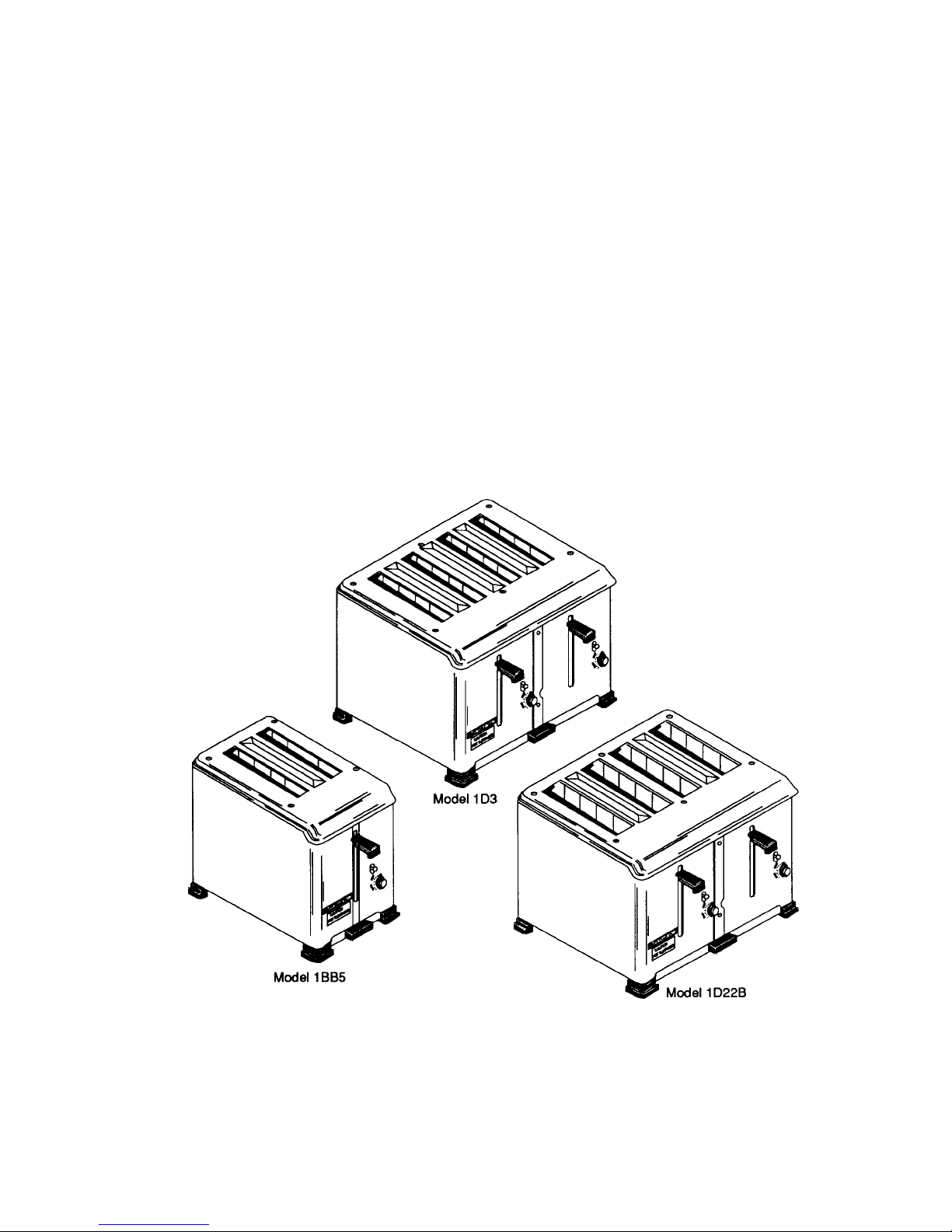

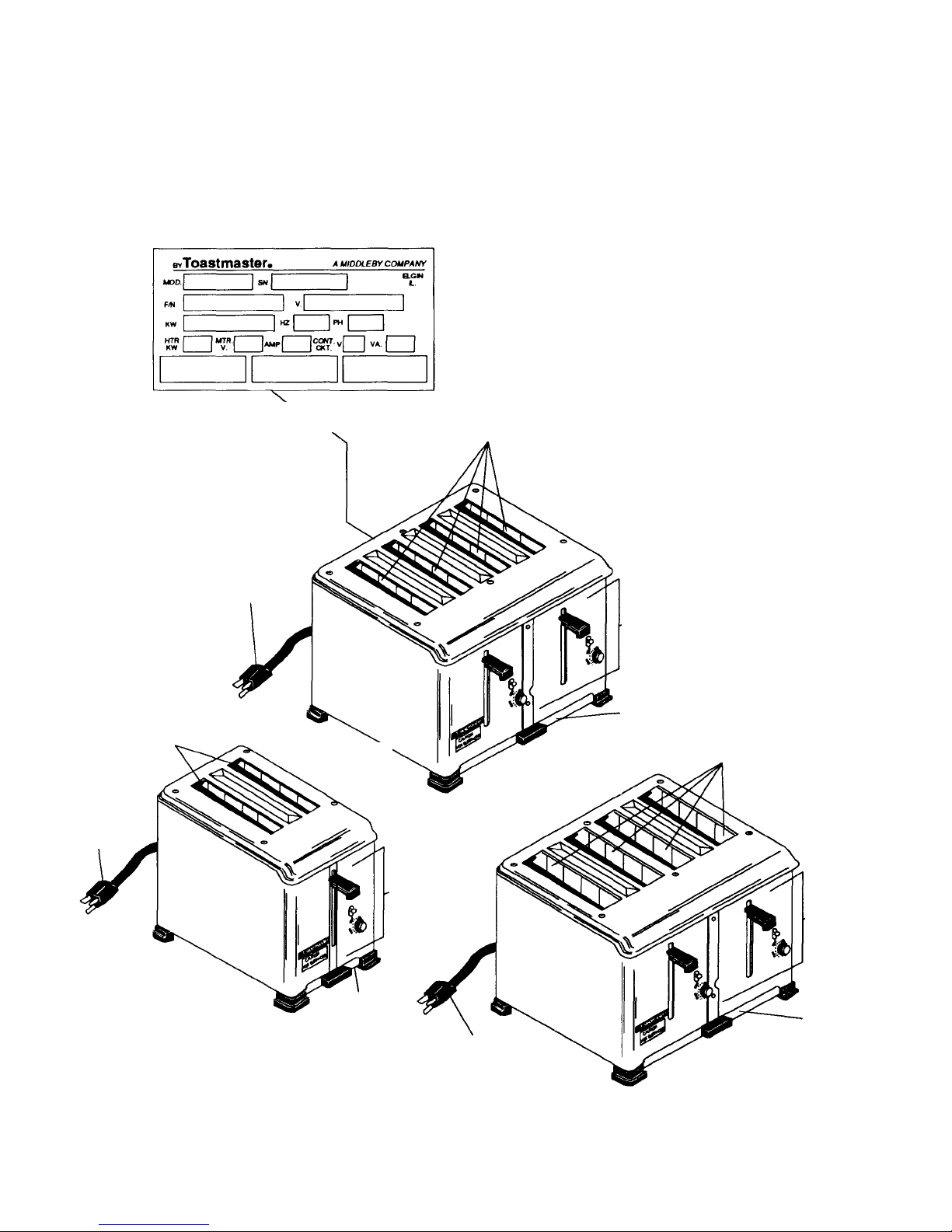

MECHANICAL SLOT TOASTERS

Models 1D3,1D22B & 1BB5

®

Toastmaster® • 1400 Toastmaster Drive • Elgin, IL 60120 • (708)741-3300

A Middleby Company

Middleby Corp 24 Hour Service Hotline 1-800-238-8444

Part No. 3102564

P3/93

Page 2

Toastmaster

The warranty period for Accu

-

Miser griddles shall be

24

months from the date of installation or

30 months from the date of purchase, whichever is earlier.

authorized service personnel. Authorized service agencies are located in principal cities througho

ut the

contiguous United States, Alaska and Hawaii. This no quibble warranty is only valid in the

50

United

States. Outside of the United States, warranty labor will only be performed during normal working hours.

any action including breach of contract or negligence. In no event shall Seller be liable for a sum in

®

TOASTMASTER, HEREINAFTER REFERRED TO AS THE SELLER, WARRANTS EQUIPMENT

MANUFACTURED BY IT TO BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIP

WHICH IT IS RESPONSIBLE. THE SELLER'S OBLIGATION UNDER THIS WARRANTY SHALL BE

LIMITED TO REPLACING OR REPAIRING AT SELLER'S OPTION, WITHOUT CHARGE, ANY

FOUND TO BE DEFECTIVE AND ANY LABOR AND MATERIAL EXPENSE INCURRED BY

IN REPLACING OR REPAIRING SUCH PART. SUCH WARRANTY SHALL BE LIMITED TO THE

ORIGINAL PURCHASER ONLY AND SHALL BE EFFECTIVE FOR A PERIOD OF ONE YEAR

DATE OF ORIGINAL INSTALLATION, OR 18 MONTHS FROM DATE OF PURCHASE,

IS EARLIER; PROVIDED THAT TERMS OF PAYMENT HAVE BEEN FULLY MET.

Normal maintenance functions and customer abuse are not covered by this no quibble warranty.

Seller shall be responsible only for repairs or replacements of defective parts performed by Seller's

Overtime and/or premium labor charges are the responsibility of the Buyer.

The foregoing warranty is exclusive and in lieu of all other warranties, expressed or implied.

There are no implied warranties of merchantability or of fitness for a particular purpose.

NO QUIBBLE LIMITED WARRANTY

The foregoing shall be Seller's sole and exclusive obligation and Buyer's sole and exclusive remedy for

excess of the purchase price of the item. Seller shall not be liable for any prospective or lost profits of

Buyer.

This warranty is effective on Toastmaster equipment sold on, or after August 1,1995.

© 1993 Toastmaster

Toastmaster • 1400 Toastmaster Dr. • Elgin, IL 60120-9272 • (708) 741 -3300 • FAX (708) 741 -0015

Middleby Corp 24 Hour Service Hotline 1-800-238-8444

i

Page 3

IN CASE OF FIRE

De-energize toaster at disconnect switch. This will cut off power to the heating elements allowing

toaster to cool. This reduces the flash point temperature making it easier to stop the fire.

CAUTION:

Do not attempt to fight a grease fire by playing the nozzle of the fire extinguisher directly on the

burning grease. The force will cause the burning grease to be sprayed to adjoining equipment

making it difficult to contain the fire. Only use a fire extinguisher filled with CO;, which is for liquids

and oils and suitable for electric powered equipment.

WARNING

DO NOT pick up the toaster by sticking fingers into toaster slots and grasping the heating elements.

Damage to the heating elements and electrical shock can result.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

This manual provides detailed information for installation and operation of your new Simplicity Toaster.

It also contains some information to assist the operator in diagnosing problems in the event of a

malfunction. This manual is an important tool for the operator and should be kept readily available.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE

NOTICE

Using any parts other than

genuine Toastmaster factory

supplied parts relieves the

manufacturer of all liability.

NOTICE

Toastmaster (Manufacturer) reserves the

right to change specifications and product

design without notice. Such revisions do

not entitle the buyer to corresponding

changes, Im provements, additions or

replacements for previously purchased

equipment.

ii

Page 4

TABLE OF CONTENTS

A Inspect For Shipping Damage

SECTION 1

DESCRIPTION

A Component Location

B Component Function

C Toaster Specifications

D Toaster Dimension Drawings

1

2

3

4

5-6

SECTION 2

INSTALLATION

B Unpacking Toaster

C Electrical Connection

D Checking the Installation

SECTION 3

OPERATION 9

A Location and Function of Controls

B Operating Procedure

C Operating Hints and Cautions

D Operating Capacity

E Cleaning

SECTION 4

PARTS LIST

Model 1D3 & 1 D2-2 Exploded Drawing

Model 1D22B& 1D3B Exploded Drawing

Model 1BB5 Exploded Drawing

SECTION 5

ELECTRICAL SCHEMATIC

Model 1D3 Schematic

Model 1D22B Schematic

Model 1BB5 Schematic

7

7

7

7

7

9

10

11

11

11

13

14-15

16-17

18-19

21

21

22

23

iii

Page 5

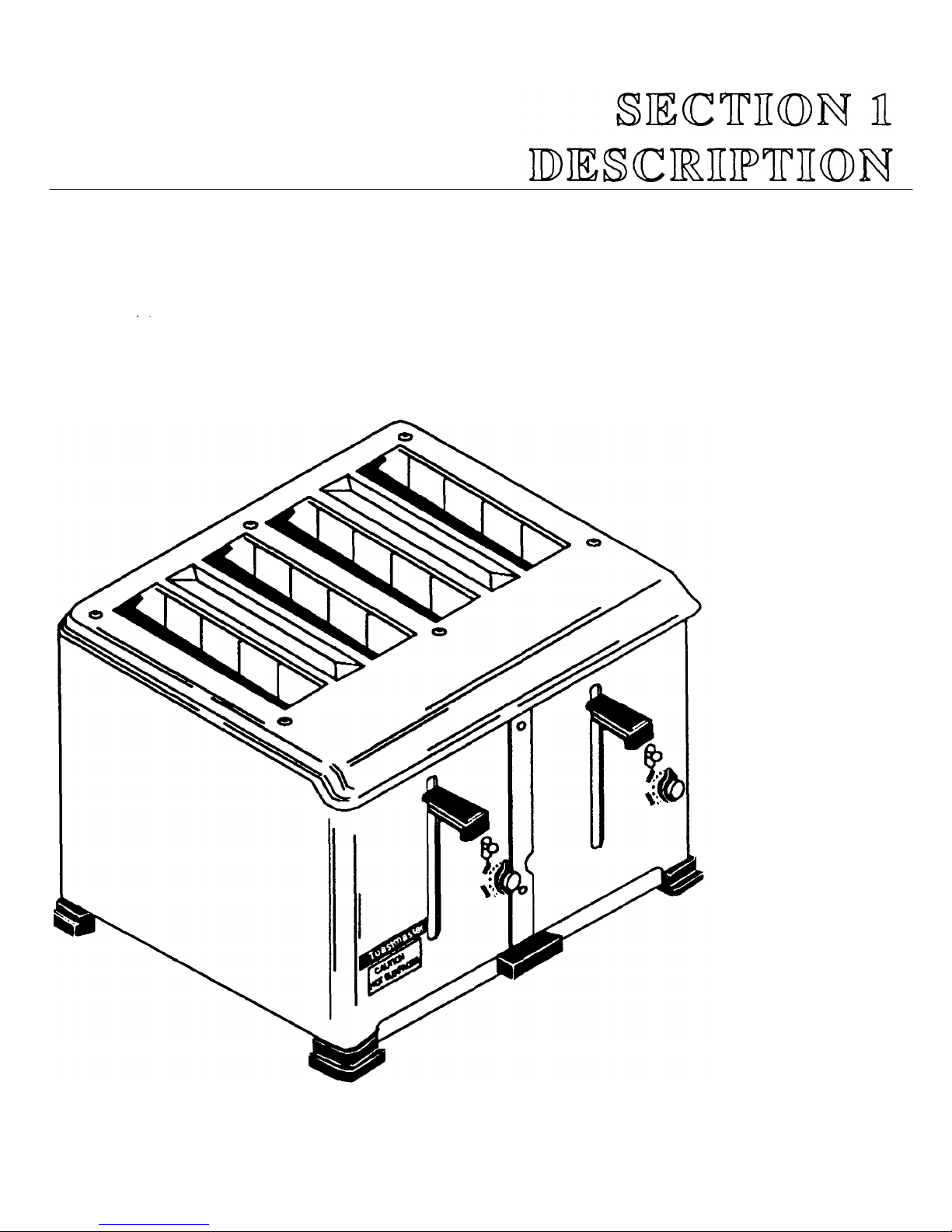

1

Toastmaster Model 1D3, 1D22B and 1BB5 Toasters are:

• Equipped with heating elements to provide uniform heat for even toasting.

• Automatic pop-up type toasters

• Equipped with an operating lever, color selection knob and manual release lever for each pair of toaster

• Equipped with wide slots. The Model 1 D22B bun toaster is equipped with extra wide slots.

• Timer controlled.

• Equipped with a crumb tray.

Figure 1-1

Page 6

SECTION 1 - DESCRIPTION

Data Plate Located At

Slots

- Model 1D3 Has A Heating

Operating Controls (See

Crumb

36 "

Cord & Plug

36"

Cord

Crumb

Operating

Slots -

Model

1

BBS

Slots

-

Model 1D22B

Operating

36 " Cord

&

Plug

Figure 1

-2

A. Component Location

Has A Heating

Element on Both

Sides of Each Slot

&Plug

Rear Of Toasters

Element on Both Sides of Each Slot.

Model 1D3

Controls

(See

Operation

Section 3)

Operation Section 3)

Tray

Has A Heating Element

On Only One Side Of

Each Slot.

Controls

(See

Operation

Section 3)

2

Tray

Component Location

Crumb

Tray

Page 7

SECTION 1 - DESCRIPTION

B. Component Function

1. Slots

a. Model 1D3 Toaster has four slots for toasting one to four slices of bread. The width of the toasting

slots will accommodate "Texas Size" bread, frozen waffles, English muffins and many other food

items. A heating element is located on both sides of each slot for a total of 8 elements.

b. Model 1 BBS Toaster has two slots for toasting one or two slices of bread. The width of the toasting

slots will accommodate "Texas Size" bread, frozen waffles, English muffins and many other food

items. A heating element is located on both sides of each slot for a total of 4 elements.

c. Model 1 D22B is a bun toaster which has four extra wide slots for toasting one to four buns. The

toaster is equipped with an element on only one side of each of four slots for a total of four elements.

This allows toasting of buns on one side only.

2. Operating Controls

(Refer to Operation Section 3)

3. Crumb Tray

The crumb tray is located in the bottom of the toaster under all slots. The crumb tray is removed for

cleaning by pulling straight out from the front of the toaster.

3

Page 8

SECTION 1 - DESCRIPTION

Overall Dimensions

NOTICE

C. Toaster Specifications:

4

Toastmaster (Manufacturer) reserves the right to change specifications and product design

without notice. Such revisions do not entitle the buyer to corresponding changes, improve-

ments, additions or replacements for previously purchased equipment.

SPECIFICATION CHART

Model1D3 Model 1BB5 Model 1D22B

Width 11-5/8" (292mm) 6-1/2" (165mm) 11-5/8" (292mm)

x X x

Depth 13" (330mm) 12-9/16" (319mm) 13" (330mm)

x X x

Height 8-3/4" (222mm) 8-3/4" (222mm) 8-3/4" (222mm)

Toasting Slot Dimensions

Width 1-1/8" (29mm) wide 1-1/8" (29mm) wide 1-9/16" (40mm) wide

x x x

Length 5-1/4" (133mm) long 5-1/4" (133mm) long 5-1/4" (133mm) long

Approximate Net Weight 20 Ibs (9.1 kg) 13 Ibs (5.9 kg) 20 Ibs (9.1 kg)

Approximate Shipping Weight 25 IDS (11.3 kg) 15 Ibs (6.8 kg) 25 Ibs (11.3 kg)

Construction Formed & Welded Sheet Steel

Finish Chrome Steel

Capacity 4 slices/load, 2 slices/ load 4 bun halves/load

250 slices/hour 125 slices/hour 250/hour

Cord 36" (914mm) 36" (914mm) 36" (914mm)

Plug: Current NEMA6-15P NEMA5-15P NEMA5-20P

(208V & 240V) (120V) (120V)

Non-Current

NEMA14-20P NEMA6-15P NEMA6-15P

(120/208 V, 115/230 V (208V,230V & 240V) (208V,230V & 240V)

& 120/240V)

NEMA 14-20P

(120V, 120/208V,

115/230 V&120/240V)

Electrical: Current 208V(12.5Amp) 120V, 10.83 Amp 120V, 16.0 Amp,

240V (10.83 Amp), 2 Pole, 3 Wire 2 Pole, 3 Wire

2 Pole, 3 Wire

Non-Current 120/208 V, 120/240V, 208V (6.25 Amp), 120/208V, 120/240V,

10.83Amp/line, 240V (5.42 Amp), 8.0 Amp/line

3 Pole, 4 Wire 2 Pole, 3 Wire

208V, 4.62 Amp

240V, 4.0 Amp

2 Pole, 3 Wire

Page 9

D. Model 1D3 and 1D22B Toaster Dimension Drawings

1D22B

Top View

SECTION 1 - DESCRIPTION

1D3 and/or 1D22B mounted on 1D3CS Stand

1D3 TOD View

1D3 or 1D22B Front View

1D3 or 1D22B Side View

1D3 and/or 1D22B Dimension Drawings

Page 10

SECTION 1 - DESCRIPTION

6

D (continued). Model 1BB5 Toaster Dimension Drawing

Top View

Front View Side View

1BB5 Dimension Drawing

Page 11

A. Inspect for Shipping Damage

All shipping containers should be examined for damage before and during unloading. This equipment

was carefully inspected and packaged at the factory.

The freight carrier has assumed responsibility for its

safe transit and delivery. If equipment is received in

damaged condition, either apparent or concealed, a

claim must be made with the delivering carrier.

1. Apparent Damage or Loss - If damage or loss is

apparent it must be noted on the freight bill or

express receipt at the time of delivery, and it must

be signed by the earner's agent (driver). If this is not

done, the carrier may refuse the claim. The carrier

will supply the necessary claim forms.

CAUTION:

Before making any electrical connection be sure

the main electrical supply source Is turned "OFF".

C. Electrical Connection

All 1D3, 1BB5 and 1D22B toasters are factory

equipped with cord and plug. Do not change cord

and plug to fit existing receptacle. Proper receptacle

must be in place in accordance with local electrical

codes.

Refer to Specification Chart in Section 1 for plug

numbers.

2. Concealed Damage or Loss - If damage or loss is

NOT apparent until after equipment is unpacked, a

request for inspection of concealed damage must

be made with carrier within 15 days. The carrier will

make an inspection and will supply necessary claim

forms. Be certain to retain all contents plus external

and internal packaging materials for inspection.

B. Unpacking Toaster

1. Remove staples from carton.

2. Lift out foam packing and poly bag from around

toaster.

WARNING:

When handling toaster DO NOT stick your fingers

into slots as damage to heating

elements may result.

3. Lift toaster out of carton and set in place on

counter.

D. Checking the Installation

1. Turn main electrical supply source "ON".

2. Move Color Selector Knob to 9 o'clock position.

3. Lower operating lever.

4. Check if all toaster slots are heating. Check that

all heating elements are heating.

5. Lift manual release lever.

6. Check that all heating elements are no longer

heating.

7

Page 12

A. Location and Function of Controls

36 "

Cord & Plug

Operating

Manua

l Release

Color

Crumb Tray

The following information provides a basic description of the toaster controls, their location and the function they

perform. The operator must be familiar with the controls.

Lever

Lever

Selection

Knob

Figure 3-1

Operation Controls

(Model 1D3 shown. Models 1 BBS and 1 D22B operation control are basically the same as the Model 1 D3)

1. Operating Lever

Lowering the operating lever lowers the bread into the toasting chambers. When the toast has reached its

set darkness the operating lever and the toast will automatically be raised.

2. Color Selection Knob

Color selection knob is used to set the desired darkness of the toast.

3. Manual Release Lever

Manual release lever is used to manually raise the toast during the toasting cycle.

9

Page 13

SECTION 3 - OPERATION

B.

Operation Procedure

1. Insert bread into toaster slots.

IMPORTANT: On Model 1D22B bun toasters the buns must be inserted

so the side to be toasted faces the heating elements. The heating

elements are located as shown in Figure 3-2.

2. Positon color selection knob at desired darkness. A medium color

setting is 9 o'clock. Turn left for lighter toast and right for darker toast.

NOTE: It will be necessary to determine the color setting for each different

product you toast. Test a single piece at a 9 o'clock setting and then

increase or decrease as necessary.

3. Lower the operating lever to lower the bread into the toasting

chambers.

4. Wait for the completion of the cycle, and toast will automatically be

raised.

Side of bun to be toast ed must

face the heating element.

Heating elements are on the side

of the slots as shown.

10

1D22B Top View

Figure 3-2

Page 14

SECTION 3 - OPERATION

C. Operating Hints and Cautions

1. Toast Color

Experiment with the color selection knob so you can find the proper setting for the color you desire in your

toasted product.

2. Moisture In Bread

When toasting bread it is advisable to use one or two day old bread. Fresh bread contains more moisture

and is apt to toast unevenly.

3. Products to Toast

Use your Models 1 D3 and 1 BBS toasters for bread, texas toast, frozen waffles, English muffins and

similar items.

Use your Model 1 D22B toaster to toast buns (Toasts on one side only).

4. Clearing Jams

CAUTION! Disconnect electric power or unplug toaster before attempting to remove a toast jam.

CAUTION! DO NOT stick knives and forks Into the toasting chambers as you may damage the

heating elements, and cause electrical shock.

Use extreme caution to remove a toast jam. It is always better to wait for toaster to cool, if time permits,

before removing jammed toast. Unplug toaster before removing a toast jam.

5. Lifting Toaster

WARNING! DO NOT pick up the toaster by sticking fingers into toaster slots and grasping the

heating elements. Damage to the heating elements and electrical shock can result.

CAUTION! Always disconnect electrical power or unplug toaster before cleaning or performing any

service.

6. Service

Service MUST BE performed only by an authorized Toastmaster Service Agent.

D. Operation Capacity

The Model 1D3 will toast up to 250 slices/hour.

The Model 1BB5 will toast up to 125 slices/hour.

The Model 1D22B will toast up to 250 buns/hour.

E. Cleaning

CAUTION! Always disconnect electrical power or unplug toaster before cleaning or performing any

service.

1. Exterior

The exterior of your toaster may be kept clean by wiping with a sponge or cloth squeezed from hot or

warm detergent water. Wipe with clean, damp cloth to remove detergent and then wipe dry. DO NOT use

an abrasive cleaner or abrasive pads as it will scratch and dull the finish.

2. Crumb tray

The crumb tray should be removed and emptied daily. Wash crumb tray with warm detergent water and

rinse with clear water.

11

Page 15

SECTION 4 - PARTS LIST

ITEM#

QTY PART#

DESCRIPTION

9 4 1B6S61

MACHINE SCREW,

#8-32 x 1/4",

TRUSS HEAD

MODEL

1

D3 with cord

& 1

D2-2 without cord

14

Four Slice Bread Toasters

Figure 4-1

Overall Exploded Drawing

1 6 K1DS136 MACHINE SCREW, #10-32 x 1/4", TRUSS HEAD

2 1 K1DC42 CASE TOP

3 1 K1D85A CASE ASSEMBLY, COMPLETE

5 1 K1DC10 FRONT CASE BINDER

6 1 K1DC11 REAR CASE BINDER

7 4 K1 DS201 RIVET, 0.141x1/4"

8 1 2400075 TOASTMASTER NAME PLATE

Page 16

1

11 1

12 8

1

14 1

14

15 6

16 6

17 2

19 2 K1DS101

CUP BUSHING

2

21 1

22 2

23 4

24 4

25 4

26 1

27 1

28 1

29 1

2

31 2

32 4

33 2

34 2

35 2

36 2

37 2

38 2

39 2

40 2

41 2

42 4

43 2

44 4

45 4

46 16

47 12

48 8

49 16

50 16

51 16

8

52 8

53 8

54 8

* 2

55 2

56 2

57 2

58 8

59 2

60 2

61 4

62 2

63 2

* 2

* 2

64 2

65 2

66 2

67 2

68 2

* 2

69 2

70 2

71 1

72 4

SECTION 4 - PARTS LIST

10

13 1 3882D8735 1/2" CABLE CONNECTOR

14

18 1 K1DC40 JUMPER WIRE (208V, 230V & 240V TOASTERS ONLY)

20

30 2 K1DF20 OVEN RETAINER ASSEMBLY, FRONT OR REAR

•

52 8 K1D3917 ELEMENT ASSEMBLY 104V/325W FOR 208V TOASTERS (CURRENT)

52

K1DC32

K1DC39

1DS6

1D3S5

1D3S4

3001059

1DS29

K1DF140

141108821 MACHINE SCREW, #8-32 x 1", ROUND HEAD

3B82D8755 BRASS CUP WASHER, #8

K1D43

K1DF143

K1DS185

K1DS198

K1DS268

K1D92A

K1DS182

K1DS186

K1DF202

K1D47

K1DB46

K1AS20

K1D42

K1D40A1

K1D41

3B82D8809 SMALL HORSESHOE WASHER

K1 D46A

K1DS27

K1DF121

K1D52

B102851

1429A8817 MACHINE SCREW, #8-32 x 3/8", ROUNDHEAD

K1D48

K1D18010 OVEN & GUARD WIRE ASSEMBLY, RIGHT OR LEFT

K1DF102

E336A8803 STEEL HEX NUT, #5-40 x 1/4"

K1DS48

K1D116

K1DS111

K1DF165

K1DS47

K1D3922

K1D3922

K1D159

K1D158

K1D77B

K1C42B

1D3F25

K1DS209

K1DS195

K1D14610 VERTICAL ROLLER ASSEMBLY

K1DF116

K1DF175

K1DS213

K1D147

K1DF114

K1DS114

3562A15

8140804

K1DS181

K1DM4

K1DC30

K1DS206

K1D201

K1DF88

1D5B15

7002192

TERMINAL BOX COVER

TERMINAL BOX

MACHINE SCREW, #8-32 x 1/4", ROUND HEAD

CORD & PLUG, 250V (CURRENT)

CORD & PLUG, 125V/250V (4 WIRE, NON -CURRENT)

CORD & PLUG, 125V (3 WIRE, NON -CURRENT)

HEX NUT, BRASS, #8-32 x 11/32"

BRASS WASHER, 1/2" O.D. x 0.195 I.D.

TERMINAL PLATE ASSEMBLY

SPACER

THREAD CUTTING SCREW, #8-18 x 1/2", FLAT HEAD

ZYTEL FOOT

RUBBER FOOT INSERT

CRUMB PAN ASSEMBLY

DRAWER PULL CRUMB PAN HANDLE, ZYTEL

THREAD CUTTING SCREW, #5-40 x 3/8", PAN HEAD

GUIDE SHAFT RETAINER

SHOCK ABSORBER BRACKET & PISTON ASSEMBLY

BAFFLE PLATE

MACHINE SCREW, #5-40 x 1/8", ROUND HEAD

SHOCK ABSORBER CYLINDER & BRACKET ASSEMBLY

TRIP RELEASE BRACKET ASSEMBLY

TRIP RELEASE LEVER & SPRING ASSEMBLY

SHOCK ABSORBER PISTON & LINK ASSEMBLY

OPERATING SPRING LEVER

OPERATING LEVER ROLLER STUD

OPERATING LEVER ASSEMBLY

"E" RETAINING RING, 0.126"

THERMOSTAT, HOOK & BRACKET ASSEMBLY

CHANGE-OVER LINK, SHORT

ELEMENT POST INSU LATOR

TERMINAL POST & STRAP ASSEMBLY

BINDING POST SCREW, #5-40 x 7/16", PAN HEAD

BINDING POST NUT

ELEMENT CLIP INSULATOR

ELEMENT ASSEMBLY 120V/325W FOR 240V TOASTERS (CURRENT)

ELEMENT ASSEMBLY 120V/325W FOR 120/208V and 120/240V TOASTERS (NON-CURRENT)

REAR BINDING POST, UNKEYED

REAR BINDING POST, KEYED

SWITCH ASSEMBLY, COMPLETE, TWO POLE

STATIONARY SWITCH ASSEMBLY, TWO POLE

MOVEABLE SWITCH ASSEMBLY, TWO POLE

MACHINE SCREW, #5-40 x 5/16", S.S., ROUND HEAD, PRE-ASSEMBLED

MACHINE SCREW, #5-40 x 3/16", ROUND HEAD

HANDLE BRACKET STUD,SHORT

VERTICAL SHAFT

FRONT HANDLE SCREW, #6-32 x 1/4", PAN HEAD

HANDLE BRACKET ASSEMBLY

HANDLE BRACKET RELEASE CLIP

HANDLE BRACKET RELEASE CLIP STUD

OPERATING HANDLE, ZYTEL

TIMING BUTTON INSERT

TIMING BUTTON, ZYTEL

TIMER UNDERCOVER GUARD

MANUAL RELEASE STUD

TRIP RELEASE LEVER SPRING

TIMER ASSEMBLY

TIMER RETAINER BRACKET

TERMINAL BAFFLE

BREAD RACK, RIGHT OR LEFT (BREAD)

*PARTS NOT IDENTIFIED BY KEY NUMBERS

15

Page 17

SECTION 4 - PARTS LIST

2 1 K1DC34

CASE TOP, BUN

3 1 K1D85A

CAS

E ASSEMBLY, COMPLETE

5 1

K1DC10

FRONT CASE BINDER

6 1

K1DC11

REAR CASE BINDER

7 4

K1DS201

RIVET,

0.141

x

1/4" 8 1 2400075

TOASTMASTER NAMEPLATE

9 4 1B6S61

MACHINE SCREW,

#8-32 x 1/4",

TRUSS HEAD

MODEL 1D22B&1D3B

16

Bun Toaster

Parts List for Figure 4-2

Overall Exploded Drawing

ITEM QTY PART NO. DESCRIPTION

1 6 K1DS136 MACHINE SCREW, #10-32 x 1/4", TRUSS HEAD

Page 18

SECTION 4 - PARTS LIST

10 1 K1 DC32

TERMINAL BOX COVER

11 1

K1DC39

TERMINAL BOX

12 8

1DS6 MACHINE SCREW,

#8-32 x 1/4",

ROUND HEAD

13 1

3882D8735

1/2"

CABLE CONNECTOR

14 1 1D3S5

CORD

&

PLUG, 250V (CURRENT)

14 1 1D3S4

CORD

&

PLUG, 125V/250V

(4

WIRE, NO

N-CURRENT)

14 1 3001059

CORD

&

PLUG, 125V

(3

WIRE (NON

-

CURRENT)

15 6 1DS29

HEX NUT, BRASS,

#8-32 x 11/32"

16 6 K1DF140

BRASS WASH ER,

1/2"

O.D. x

0.195

I.D. 17 2 1411D8821

MACHINE SCREW,

#8-32

x 1", ROUND HEAD

18 1 K1DC40

JUMPER WIRE (208V, 230V

&

240

V TOASTERS ONLY)

19 2 K1DS101

CUP BUSHING

20 2

3B82D8755

BRASS CUP WASHER,

#8 21 1 K1D43

TERMINAL PLATE ASSEMBLY

22 2

K1DF143

SPACER

23 4

K1DS185

THREAD CUTTING SCREW,

#8-18 x 1/2",

FLAT HEAD

24 4

K1DS198

ZYTEL FOOT

25 4 K1DS268

RUBBER FOOT INSERT

26 1 K1D92A CRUMB PAN ASSEMBLY

27 1

K1DS182

DRAWER PULL CRUMB PAN HANDLE, ZYTEL

28 1

K1DS186

THREAD CUTTING SCREW,

#5-40 x 3/8",

PAN HEAD

29 1

K1DF202

GUIDE SHAFT RETAINER

30 2

K1DF20

OVEN RETAINER ASSEMBLY, FRONT OR REAR

• 2

K1D47

SHOCK ABSORBER BRAC

KET & PISTON ASSEMBLY

31 2 K1 DB46

BAFFLE PLATE

32 4

K1AS20

MACHINE SCREW,

#5-40 x 1/8",

ROUND HEAD

33 2

K1D42

SHOCK ABSORBER CYLINDER

&

BRACKET ASSEMBLY

34 2

K1D40A1

TRIP RELEASE BRACKET ASSEMBLY

35 2

K1D41

TRIP RELEASE LEVER

&

SPRING ASSEMBLY

36 2

3B82D8809

SMALL HORSESHOE WASHER

37 2 K1 D46A

SHOCK ABSORBER PISTON

&

LINK ASSEMBLY

38 2

K1DS27

OPERATING SPRING LEVER

39 2

K1DF121

OPERATING LEVER ROLLER STUD

40 2

K1D52

OPERATING LEVER ASSEMBLY

41 2 B102851

"E" RETAINING RING,

0.126"

42 4

1429A8817

MACHINE SCREW,

#8-32 x 3/8",

ROUND HEAD

43 2

K1D48

THERMOSTAT, HOOK

&

BRACKET ASSEMBLY

44 2 K1D180

OVEN

&

GUARD WIRE ASSEMBLY (RIGHT)

44 2 K1D181

OVEN

&

GUARD WIRE ASSEMBLY (LEFT)

45 4

K1DF102

CHANGE

-

OVER LINK, SHORT

46 8

E336A8803

STEEL HEX NUT,

#5-40 x 1/4" 47 4 K1

DS48

ELEMENT POST INSULATOR

49 8

K1DS111

BINDING POST SCREW,

#5-40 x 7/16",

PAN HEAD

50 8

K1DF165

BINDING POST NUT

51 8

K1DS47

ELEMENT CLIP INSULATOR

52 4 K1

D3923

ELEMENT ASSEMBLY 120V, 480W FOR 120V TOASTERS (CURRENT)

52 4 K1D3918

ELEMENT ASSEMBLY 104V,

480W

FOR 208V TOASTERS (NON

-

CURRENT)

52 4

K1D3923

ELEMENT ASSEMBLY 120V,

480W

FOR 240V, 120/208V and 120/240V TOASTERS (NON

-

CURRENT)

53 4 K1D159

REAR BINDING POST, UNKEYED

54 4 K1D158

REAR BINDING POST, KEYED

* 2 K1D77B

SWITCH AS

SEMBLY, COMPLETE, TWO POLE

55 2

K1C42B

STATIONARY SWITCH ASSEMBLY, TWO POLE

56 2

1D3F25

MOVEABLE SWITCH ASSEMBLY, TWO POLE

57 2 K1

DS209

MACHINE SCREW,

#5-40 x 5/16",

S.S., ROUND HEAD PRE

-

ASSEMBLED

58 8 K1DS195

MACHINE SCREW,

#5-40 x 3/16",

ROUND HEAD

59 2

1D3B146

VERTICAL ROLLER ASSEMBLY

60 2

K1DF116

HANDLE BRACKET STUD, SHORT

61 4

K1DF175

VERTICAL SHAFT

62 2

K1DS213

FRONT HANDLE SCREW,

#6-32 x 1/4",

PAN HEAD

63 2

1D3B147

HANDLE BRACKET ASSEMBLY

* 2

K1DF114

HANDLE BRACKET RELEASE CLIP

* 2 K1DS114

HANDLE BRACKET RELEASE CLIP STUD

64 2 3562A15

OPERATING HANDLE, ZYTEL

65 2 B 140804

TIMING BUTTON INSERT

66 2 K1DS181

TIMING BUTTON, ZYTEL

67 2

K1DM4

TIMER UNDERCOVER GUARD

68 2

K1DC30

MANUAL RELEASE STUD

* 2 K1DS206

TRIP RELEASE LEVER SPRING

69 2

K1D201

TIMER ASSEMBLY

70 2

K1DF88

TIMER RETAINER BRACKET

71 1 1D5B15

TERMINAL BAFFLE

72 2

K1D170

BREAD RACK, RIGHT (BUN)

73 2

K1D171

BREAD RACK, LEFT (BUN)

*PARTS NOT IDENTIFIED BY KEY NUMBERS

17

Page 19

SECTION 4 - PARTS LIST

18

Figure

4-3

1 6 K1DS136

MACHINE SCREW,

#10-32 x 1/4",

TRUSS HEAD

2 1 S1BC2

CASE TOP, BREAD

3 1 1BB510

CASE ASSEMBLY

4 1 1523B3029

TOASTM

ASTER NAMEPLATE

5 1 1BB5B3

TERMINAL BAFFLE

6 1

1BB526

CORD TERMINAL

&

INSULATOR ASSEMBLY

7 2 1B12S60

TUBULAR STEEL RIVET, .118/.123 x

5/32

- 8 2 K1DS195

SCREW,

#5-40 x 1/4",

PAN HEAD, STAINLESS STEEL

MODEL1BB5

Two Slice Bread Toaster

Overall Exploded Drawing

ITEM

QTY

PART NO. DESCRIPTION

Page 20

1

1

1

1

1

1

1

1

1

9 2 K1AF17 BRASS WASHER. .128 I.D. x .308 O.D. x 1/32"

10 1 K1DS111 SEMS SCREW, PRE-ASSEMBLED, #5-40 x 1/2-, PAN HEAD

11 2 S1BC8 CABLE STRAIN RELIEF

12 1 1BB5C4 STRAIN RELIEF BOX

13 1 1511E8705 CORD & PLUG, 125V (CURRENT)

13 1 1BB5S4 CORD & PLUG, 250V (NON-CURRENT)

14 4 K1AS20 SCREW. #5-40 x 1/8-, ROUND HEAD

15 1 S1BF22 GUIDE SHAFT BRACKET

16 2 K1DS185 THREAD CUTTING SCREW, #8-18 x 1/2". FLAT HEAD

17 4 K1DS198 ZYTEL FOOT

18 1 K1DS186 THREAD CUTTING SCREW, #5-40 x 3/8", PAN HEAD

19 1 S1B3A CRUMB PAN

20 1 K1DS182 DRAWER PULL HANDLE, ZYTEL

21 4 K1DS228 RUBBER FOOT INSERT

22 1 K1DS12 #8 LOCKWASHER

23 1 K1D52 OPERATING LEVER ASSEMBLY

24 1 K1D48 THERMOSTAT HOOK & BRACKET ASSEMBLY

25 1 B102851 "E" RETAINING RING, #5144-9

26 1 1429A8827 HEX STEEL NUT, #8-32

27 1 K1DS115 PISTON RING

28 1 K1 DS27 OPERATING LEVER SPRING

29 1 K1DF121 OPERATING LEVER ROLLER STUD

30 1 K1D46A SHOCK ABSORBER PISTON & LINK ASSEMBLY

31 1 K1 DB54 BAFFLE PLATE

32 1 K1D42 SHOCK ABSORBER CYLINDER & BRACKET ASSEMBLY

33 1 K1D40A1 TRIP RELEASE BRACKET ASSEMBLY

34 1 K1D41 TRIP RELEASE LEVER & SPRING ASSEMBLY

35 2 1429A8817 SCREW, #8-32 x 3/8", ROUND HEAD

36 1 B112811 •E" RETAINING RING, #5144-18

• 1 K1D77B SWITCH ASSEMBLY, TWO POLE

37 1 K1C42B STATIONARY SWITCH ASSEMBLY, TWO POLE

38 1 1D3F25 MOVEABLE SWITCH ASSEMBLY, TWO POLE

39 1 K1DS209 MACHINE SCREW, PRE-ASSEMBLED, #5-40 x 5/16", ROUND HEAD, S.S.

40 2 7002192 BREAD RACK, RIGHT OR LEFT

41 1 K1D146A VERTICAL ROLLER ASSEMBLY WITH BREAD RACKS

42 1 K1DF116 HANDLE BRACKET STUD,SHORT

43 1 K1D147 HANDLE BRACKET ASSEMBLY (Refer to Item 47 for RELEASE CLIP)

44 1 K1DS206 SWITCH TENSION SPRING

45

46

47

*

48

49

50

51

52

53 2 K1DF175 VERTICAL SHAFT

54 2 K1D18010 OVEN & GUARD WIRE ASSEMBLY (RIGHT OR LEFT)

55 4 K1D3922 ELEMENT ASSEMBLY 120V, 325W FOR 120V TOASTERS (CURRENT)

55 4 K1D3922 ELEMENT ASSEMBLY 120V, 325W FOR 240V TOASTERS (NON-CURRENT)

55 4 K1D3917 ELEMENT ASSEMBLY 104V, 325W FOR 208V TOASTERS (NON-CURRENT)

56 4 K1D158 REAR BINDING POST, UNKEYED

57 4 K1D159 REAR BINDING POST, KEYED

58 2 K1DF102 CHANGEOVER LINK, SHORT

59 8 K1DS47 ELEMENT CLIP INSULATOR

60 1 K1DS206 TRIP RELEASE LEVER SPRING

61 8 K1DF165 BINDING POST NUT

62 4 K1D116 TERMINAL POST & STRAP ASSEMBLY

63 8 E336A8803 STEEL HEX NUT, #5-40x1/4"

64 4 K1DS48 ELEMENT POST INSULATOR

* 2 K1DF200 OVEN RETAINER, FRONT OR REAR

*PARTS NOT IDENTIFIED BY KEY NUMBERS

K1DS213 SCREW, #6-32 x 1/4", PAN HEAD

3562A15 ZYTEL HANDLE

K1DF114 HANDLE BRACKET RELEASE CLIP

K1DS114 HANDLE BRACKET RELEASE CLIP STUD

K1DM4 TIMER UNDERCOVER GUARD

K1DF88 TIMER RETAINER BRACKET

K1D201 TIMER ASSEMBLY

K1DC30 MANUAL RELEASE STUD

K1DS181 TIMING BUTTON, ZYTEL

SECTION 4 - PARTS LIST

19

Page 21

Current

Cord w/NEMA

6-1

5P Plug used with

6

-

Heating

Cord w/NEMA 14

-

20P Plug used

Neutral

Heating

208V and 240V

2 Pole, 3 Wire

Heat Switch Heat Switch

15R Receptacle, #16-3 AWG at least

90°C (194°F)

Elements

Non-Current 1

20/208V, 115/230V and 120/240V

3 Pole, 4 Wire

.

Heat Switch Heat Switch

with 14-20R Receptacle, #14-4

AWG at least 90°C (194°F)

Elements

Model 1D3 Schematics

21

Page 22

SECTION 5 - SCHEMATICS

Cord w/NEMA 5

-

20P Plug used

Heating

Cord w/NEMA

6-1

5P Plug used

Heating

Non-Current 120/208V, 115/230V

and 120/240V 3 Pole, 4 Wire

Cord w/NEMA 14-20P Plug used

with 14-20R Receptacle, #14-4

AWG at least 90°C (194°F)

Neutral

Current

120V

2 Pole, 3 Wire

Neutral

Heat Switch Heat Switch

Non-Current

208V and 240V

2 Pole, 3 Wire

Heat Switch Heat Switch

with 6-15R Receptacle, #16-3 AWG

with 5-20R Recept acle, #14-3

AWG at least 90°C (194°F)

Elements

at least 90°C (194°F)

Elements

22

Model 1D22B Schematics

Page 23

Current

Cord w/NEMA

5-1

5P Plug used

Heating

23

120V

2 Pole, 3 Wire

Heat Switch

SECTION 5 - SCHEMATICS

with 5-15R Receptacle, #16-3

AWG at least 90°C (194°F)

Elements

Non-Current

208V and 240V

2 Pole, 3 Wire

Cord w/NEMA 6-15P Plug used

with 6-15R Receptacle, #16-3

AWG at least 90°C (194°F)

Heat Switch

Model 1BB5 Schematics

Heating

Elements

Loading...

Loading...