TJERNLUND 950-0486 WHEEL KIT 8504085 REV. 0100, 950-0487 WHEEL KIT 8504085 REV. 0100, 950-1015 WHEEL KIT 8504085 REV. 0100, IN-FORCER, HS-5 User Manual

Page 1

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

IN-FORCER OR HS-5 WHEEL REPLACEMENT KIT

WARNING: Disconnect power from IN-FORCERTMand equipment before installing new wheel.

OPTION 1 FOR IN-FORCER WHEEL REMOVAL (PREFERRED)

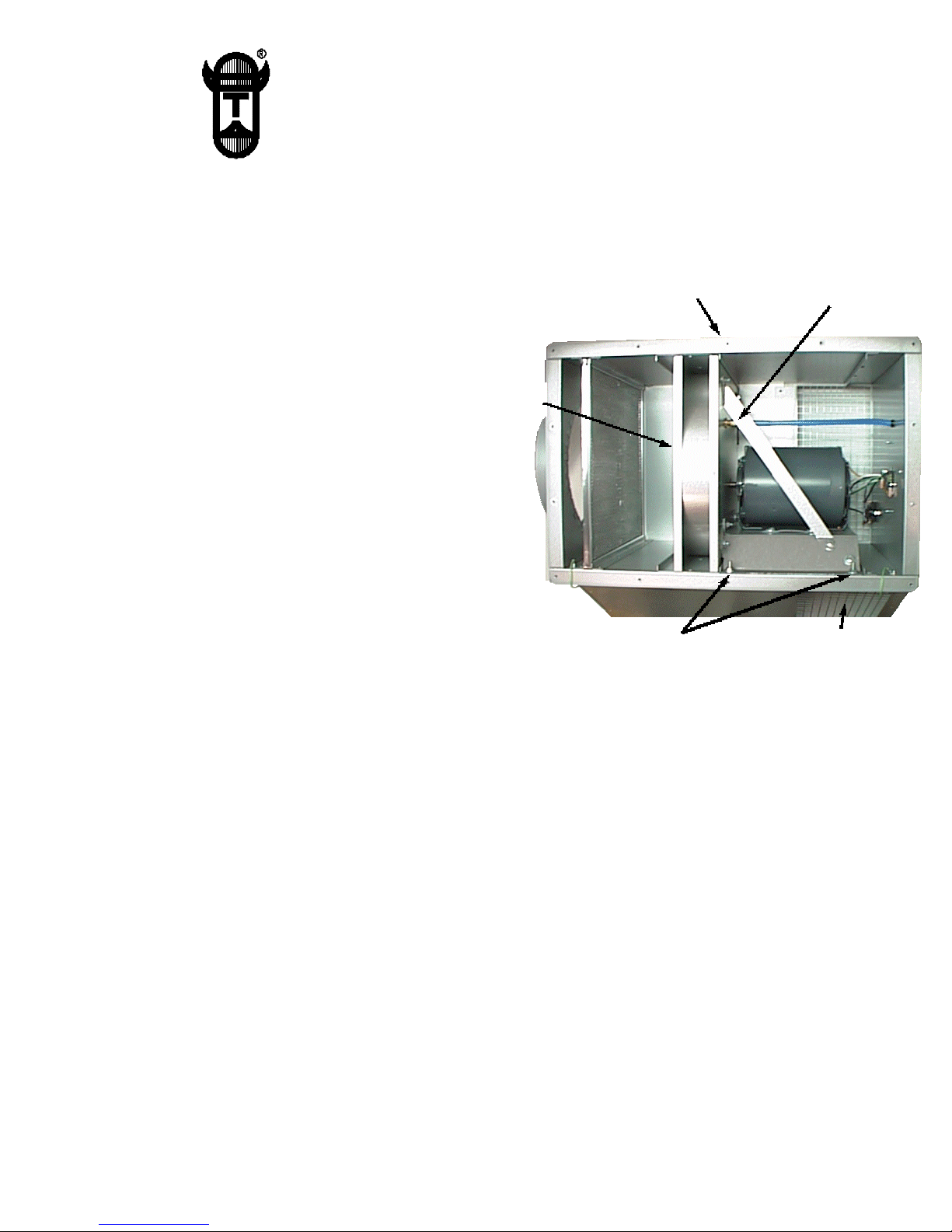

Motor assembly panel

screws (2) in front

Fan prover sensing

tube fitting

1. Remove access door screws on rear of IN-FORCER,

(See Diagram A).

DIAGRAM A

2. Remove screws from wheel housing inlet collar

and remove inlet collar.

Wheel housing

inlet collar

3. Loosen set screw(s) on wheel with allen wrench. If

set screw(s) can not be loosened this way, remove

pipe on discharge side of IN-FORCER if necessary

and loosen set screw(s) through neck of blower housing. Install new wheel making sure it is centered in

blower housing. Tighten set screw(s) on flat of motor

shaft. On model PAI-7 make sure key-way is in wheel

hub. Rotate wheel by hand to make sure it is not

rubbing.

4. Replace inlet collar on housing with tapered end towards

wheel and secure access door.

Blower assembly

bolts (4)

Access door

5. Reconnect power supply. Run IN-FORCER and heating equipment through several heating cycles to verify

proper operation.

OPTION 2 FOR IN-FORCER WHEEL REMOVAL

1. Blower assembly may also be removed from IN-FORCER cabinet if preferred. Remove Access door screws. Remove

(2) motor assembly panel screws on front of IN-FORCER, (See Diagram A).

2. Disconnect motor leads.

3. Remove Fan Prover sensing tube from motor assembly panel by loosening brass compression fitting.

4. Remove (4) bolts which hold blower assembly to IN-FORCER cabinet.

5. Carefully slide out blower assembly from IN-FORCER cabinet.

6. Remove screws from wheel housing inlet collar and remove inlet collar.

7. Loosen set screw(s) on wheel with allen wrench. Install new wheel making sure it is centered in blower housing. Tighten

set screw(s) on flat of motor shaft. On model PAI-7 make sure key-way is in wheel hub. Rotate wheel by hand to make

sure it is not rubbing.

8. Reassemble IN-FORCER following reverse of procedures in steps 6 through 1. Make sure tapered end of inlet collar faces

towards wheel.

9. Reconnect motor leads and power supply. Run IN-FORCER and heating equipment through several heating cycles to

verify proper operation.

For technical assistance contact Tjernlund’s Technical Customer Service at 1-800-255-4208; M-F 7:30 - 4:30 CST.

P/N 8504085 Copyright © 2000 Tjernlund Products, Inc. All rights reserved. REV. 01/00

Loading...

Loading...