Page 1

Copyright © 2003, Tjernlund Products, Inc. All rights reserved. P/N 8504106

REV. B 05/03

OWNER INSTRUCTIONS, DO NOT DESTROY

Recognize this symbol as an indication of important Safety Information!

NOTE: FLUE GAS TEMPERATURES MUST NOT EXCEED 600OF

AT VENT SYSTEM INLET FOR U.S. INSTALLATIONS

AND 285

O

C (550OF) AT VENT SYSTEM INLET FOR

CANADIAN INSTALLATIONS.

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR PROPER INSTALLATION, ADJUSTMENT AND OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY BEFORE

ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK,

CARBON MONOXIDE POISONING, EXPLOSION, OR PERSONAL INJURY OR

PROPERTY DAMAGE.

!

DO NOT DESTROY. PLEASE READ CAREFULLY AND KEEP IN

A SAFE PLACE ON JOB SITE FOR FUTURE REFERENCE.

MODELS

HSJ HS1 HS2

FOR NATURAL GAS, LP OR OIL

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

INCLUDES NEW UC1

UNIVERSAL CONTROL

VERSION

X.04

Page 2

Address all correspondence to:

Customer Service • Tjernlund Products, Inc. • 1601 Ninth Street • White Bear Lake, MN 55110-6794

Call us toll free at 800-255-4208, visit our web site @ www.tjernlund.com or email us at fanmail@tjfans.com.

TABLE OF CONTENTS

PAGE(S)

SIZING TABLES AND SPECIFICATIONS ..................................................................................................................................... 1 - 2

INSTALLATION RESTRICTIONS .......................................................................................................................................................... 2

CAUTIONS ....................................................................................................................................................................................... 2 - 3

GENERAL INFORMATION .................................................................................................................................................................... 3

SAFETY INSPECTION OF PREVIOUSLY USED APPLIANCE............................................................................................................ 3

UC1 UNIVERSAL CONTROL BOARD FEATURES ..............................................................................................................................4

LED STATUS / FAULT INDICATORS AND FAULT RETRIEVAL FROM MEMORY ...........................................................................4, 5

PRE / POST-PURGE & PROVER STATUS CHECK SETTINGS ......................................................................................................5, 6

INSTALLATION ..................................................................................................................................................................................... 6

VENT SYSTEM TERMINATION U.S. INSTALLATIONS ....................................................................................................... 6

VENT SYSTEM TERMINATION CANADIAN INSTALLATIONS ........................................................................................... 7

POWER VENTER INSTALLATION ...................................................................................................................................................... 7

CODE REQUIREMENTS .......................................................................................................................................................7

INSTALLATION RESTRICTIONS .......................................................................................................................................... 8

POWER VENTER MOUNTING............................................................................................................................................. 9

DRAFT CONTROL INSTALLATION ON AN INDUCED DRAFT GAS APPLIANCE ...................................................... 9 - 10

UC1 UNIVERSAL CONTROL INSTALLATION ................................................................................................................................... 10

ELECTRICAL WIRING .........................................................................................................................................................................10

WARNINGS, SEQUENCE OF OPERATION & INTERNAL SCHEMATIC ...................................................................10 - 11

UC1 WIRING CONNECTIONS TO VENTER GROUND, MOTOR AND PROVER LEADS ................................................11

MULTIPLE OR MILLIVOLT APPLIANCE INTERLOCKS .....................................................................................................11

UC1 WIRING TO GAS FIRED APPLIANCE ................................................................................................................12 - 14

UC1 WIRING TO OIL FIRED EQUIPMENT .................................................................................................................14 -16

UC1 OPERATION CHECK, DRAFT CHECK, SAFETY INTERLOCK / COMBUSTION AIR TEST..............................................16 - 17

MAINTENANCE .................................................................................................................................................................................. 18

TROUBLESHOOTING ..................................................................................................................................................................18 - 19

WARRANTY & REPLACEMENT PARTS .............................................................................................................................................19

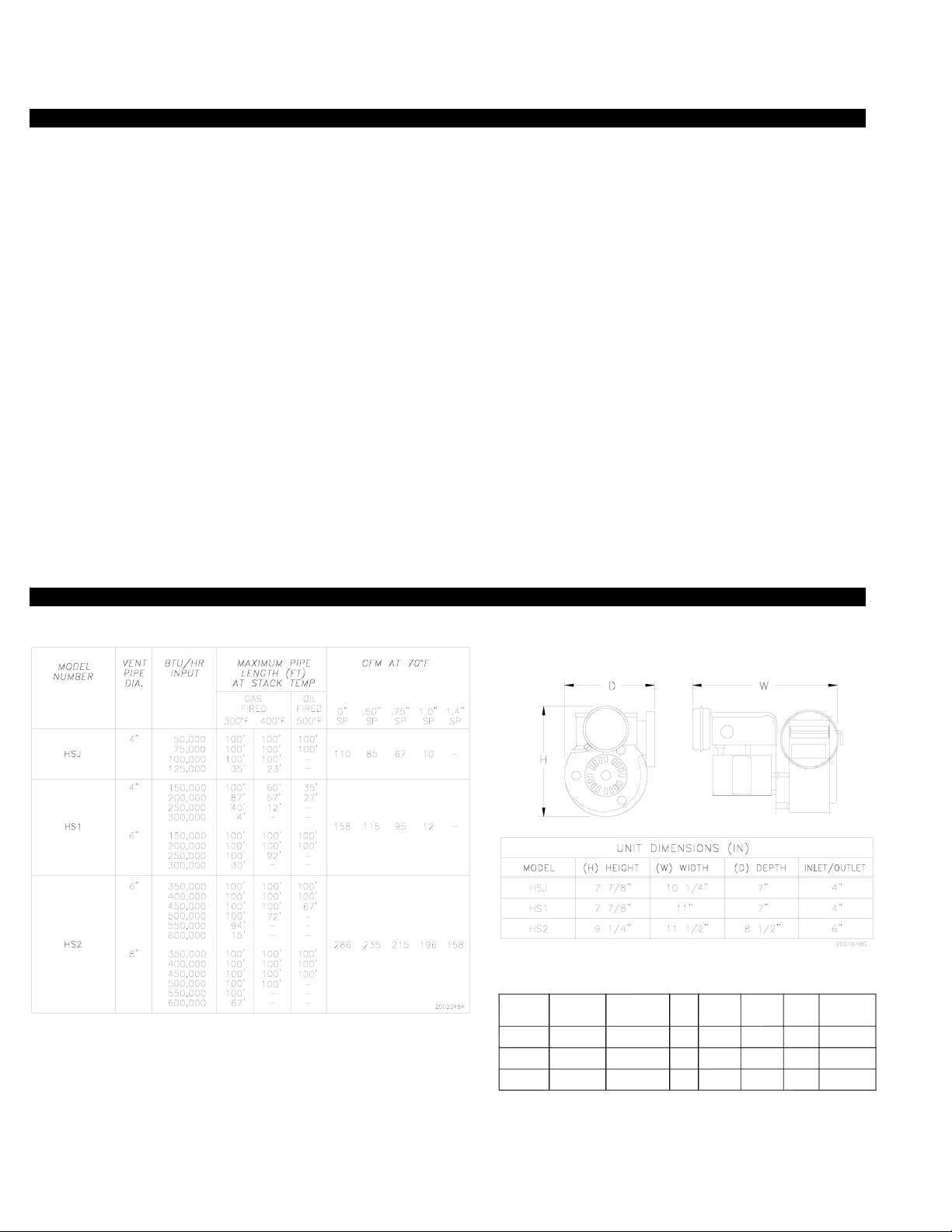

VENTER SPECIFICATIONS

1

HS-SERIES MODEL SELECTION TABLE

POWER VENTER DIMENSIONS

IMPORTANT

Table footage is based on equivalent vent pipe length. To calculate

equivalent vent pipe length, add the straight vent pipe plus 10’ for

every 90

O

elbow and 5’ for every 45Oelbow.

If venting multiple appliances with one Power Venter, the total combined BTU/hr. input of all appliances must be added together to size

the Power Venter.

60

60

60

3000 95 1.26

YES

953000 YES1.26

2243000 YES1.51

MODEL

CONTROLMOTOR

Hz R.P.M. WATTS AMPS

THERMAL

115

24/115/DRYHSJ

24/115/DRY115

24/115/DRY115

HS1

HS2

VOLTAGEVOLTAGE PROTEC.

2001018H

The UC1 Universal Control may be interlocked with Dry

Contact, 24 VAC or 115 VAC heater control circuits.

Page 3

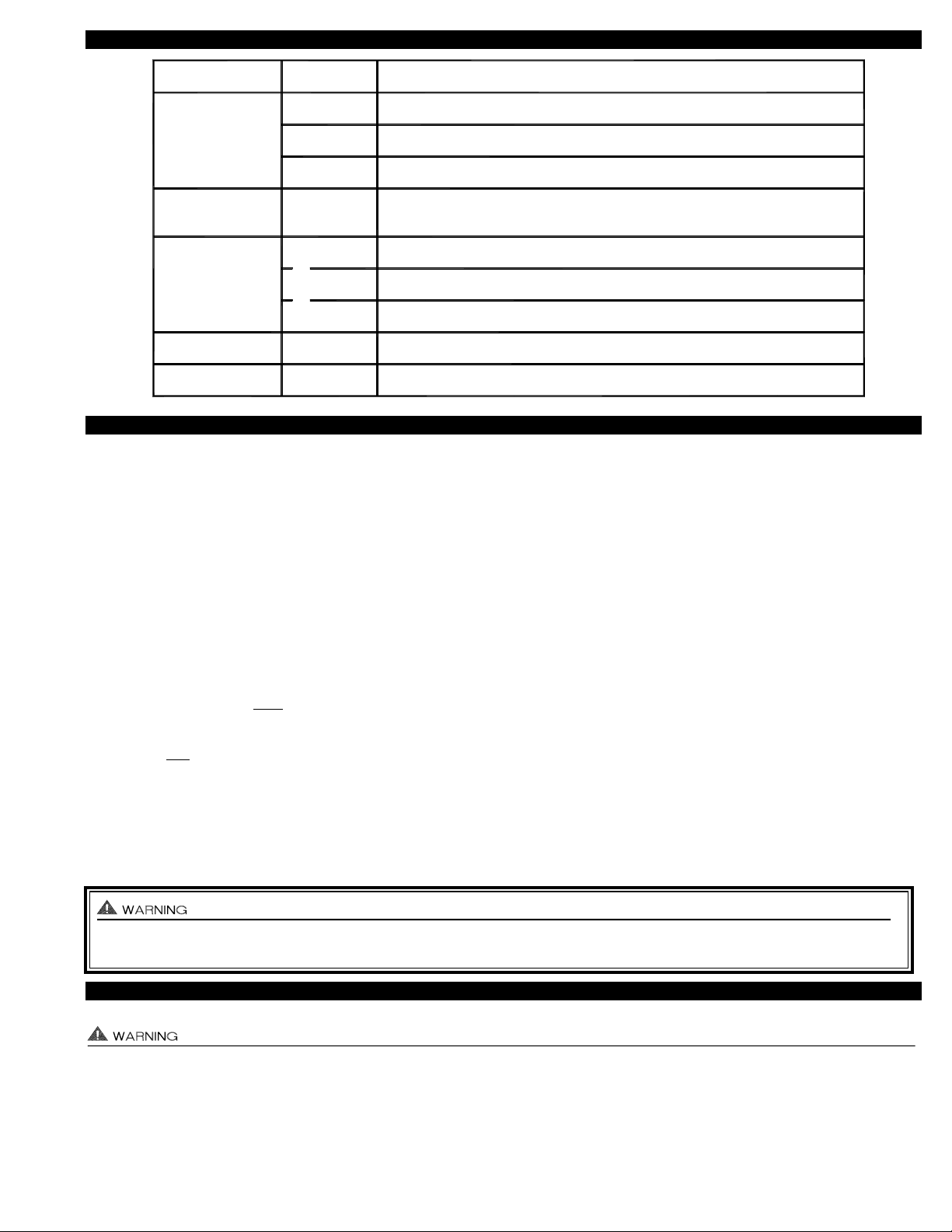

UC1 UNIVERSAL CONTROL SPECIFICATIONS

INSTALLATION RESTRICTIONS

1. This device must be installed by a qualified professional installer in accordance with these instructions. If improperly installed, a

hazardous condition such as explosion or carbon monoxide poisoning could result.

2. Do not install the Power Venter on incinerators, incinerating toilets, condensing type appliances or solid-fuel burning appliances.

3. The Power Venter shall only be installed on Natural Gas, LP or Oil-fired appliances.

4. Do not install the Power Venter on an appliance with an automatic valve having a manual opener unless the manual opener has

been rendered inoperative or the automatic valve has been replaced with a valve not equipped with a manual opener.

5. The Power Venter may only be installed on appliances equipped with a draft hood, draft diverter or barometric draft control.

6. The Power Venter shall not be installed where flue gas temperatures exceed 600

0

F. at Power Venter inlet for U.S. or 2850C

(550

0

F) for Canadian installations.

FLUE GAS TEMPERATURE VERIFICATION:

A) Consult appliance manufacturer for temperature of gases at the appliance outlet after dilution by draft hood, draft diverter or baro-

metric draft control.

AND

B) Measure temperature of flue gases at the Power Venter inlet at time of installation. Temperature should be measured after

appliance and Power Venter have operated for at least 15 minutes, allowing flue gas temperature to stabilize.

Flue gas temperature at Power Venter inlet must not exceed 600

0

F. for U.S. or 2850C (5500F) for Canadian installations.

7. The appliance(s) may only be installed on the suction side of Power Venter.

8. The UC1 is intended for indoor installation only. Do not mount the UC1 junction box on a heat source that exceeds 140oF.

Examples of improper mounting surfaces include vent pipe, top of heater casing or any place where radiant or convective heat

would cause the junction box temperature to exceed 140oF (60oC).

CAUTIONS

The Power Venter must be installed by a qualified installer in accordance with these instructions and all local codes or in their

absence in accordance with the latest edition of The National Fuel Gas Code (ANSI Z223.1/NFPA #54), NFPA # 31 Oil Burning

Equipment, the latest edition of the National Electrical Code (NFPA#70) and the Occupational Safety and Health Act (OSHA) when

applicable. Canadian installations must comply with The Natural Gas Installation Code (CAN/CGA-B149.1); Propane Installation

Code (CAN/CGA-B149.2); Installation Code For Oil Burning Equipment (CAN/CSA-B139). Improper installation can create a hazardous condition such as an explosion, fire, electrical shock or carbon monoxide poisoning resulting in property damage, personal

injury or death. “Qualified Installer” shall mean an individual properly trained and licensed in accordance with local codes.

2

Improper installation, adjustment, alterations, service or maintenance can cause injury or property damage. Refer to this manual.

For assistance or additional information consult a qualified installer, service agency, gas or oil supplier.

POWER

REQUIREMENTS

EXTERNAL

POWER SWITCHING

CAPACITY

J1 / J2

JUMPER

SAFETY

CIRCUIT

ADD VENTER MOTOR

LOAD PLUS 1/2 AMP

FOR UC1 LOAD

EXTERNAL

CALL TRIGGER

METHODS

J1 / J2

P1 / P2

L / N

3 TO 4

T-BLOCK

T-BLOCK

(RELAY K1)

XL / XN

UC1 CONTROL

M & MTR

(RELAY K2)

T-BLOCK

A / B

24V

1 / 2

115V

1 / 2

OR

OR

USED TO JUMP CALL HOT (24 VAC) OR CALL LINE (115 VAC) FROM TERMINAL 1 TO TERMINAL 3.

CONNECTED TO FAN PROVER.

1 mA @ 5 VDC. DO NOT SUPPLY POWER HERE.

REMOVE J1-J2 JUMPER IF A DIFFERENT VOLTAGE SOURCE IS PROVIDED TO TERMINAL 3.

120 VAC ±10 %, 50/60 Hz

MOTOR - 1 H.P. MAX. @ 120 VAC, 50/60 Hz

USER-PROVIDED 24 VAC AT TERMINALS 1 & 2. 1 = CALL HOT, 2 = COMMON. CONTROL

REQUIRES 5 mA @ 24 VAC TO TRIGGER. MOVE RED VOLTAGE JUMPER TO "24V" LOCATION.

3 mA @ 5 VDC. MOVE RED VOLTAGE JUMPER TO "DRY" LOCATION. DO NOT SUPPLY POWER.

USER-PROVIDED CONTACT CLOSURE FROM A TO B. SIZE CONTACT CLOSURE TO HANDLE

GENERAL PURPOSE - 15A @ 120 VAC, 50/60 Hz

DURING OPERATION THE CONTROL USES 50 mA MAX @ 120 VAC

MOTOR - 1 H.P. MAX. @ 120 VAC, 50/60 Hz

150 mA MAX @ 120 VAC, 50/60 Hz

CAN ONLY BE CONNECTED TO TJERNLUND-SPECIFIED AUXILIARY DEVICE

CIRCUIT PROTECTION PROVIDED BY INSTALLER

GENERAL PURPOSE - 15A @ 120 VAC, 50/60 Hz

RESISTIVE - 10A @ 28 VDC PILOT DUTY - 470 VA

USER-PROVIDED 115 VAC AT TERMINALS 1 & 2. 1 = CALL LINE, 2 = NEUTRAL. CONTROL

REQUIRES 1 mA @ 115 VAC TO TRIGGER. MOVE RED VOLTAGE JUMPER TO "115V" LOCATION.

D/N 9183006H

Page 4

Failure to install, maintain and/or operate the Power Venter in accordance with manufacturer's instructions may result in conditions

which can produce bodily injury and property damage.

Disconnect power supply from the UC1 and heating equipment when making wiring connections and servicing the Venter. Failure to

do so may result in personal injury and/or equipment damage. LED #5 (RED) should be off with power removed.

1. In order to comply with the ETL Listing of the Power Venters the Fan Prover must be wired with the appliance so as to prevent the

main burner(s) from firing if the Power Venter malfunctions or the flue is blocked. It is not safe to use the Power Venter as is on

millivolt appliances, such as water heaters which employ a combination gas valve/temperature controller, since the Fan Prover can

not be wired as described in this manual. Millivolt appliances require additional interlock controls such as our WHKE kit. See

millivolt wiring diagram in this manual for more details.

2. Plan the vent system so that Code required distances are maintained from plumbing and wiring.

3. The Power Venter motor shaft must be mounted horizontally to ensure proper operation of the Fan Proving Switch and prevent

motor bearing wear.

4. Make certain the power supply is adequate for the fan motor and UC1 requirements. Do not add the Power Venter to a circuit

where the total load is unknown.

5. The installer must verify that the BTU/hr. input of the appliance does not exceed the recommended input of the Power Venter. See

selection table on page 1 of these instructions for sizing information.

6. Flue gas temperatures must not exceed 600

0

F. at the Power Venter inlet for U.S. installations and 2850C (5500F) for Canadian

installations. Ambient temperatures surrounding Power Venter must not exceed 400C (1040F). See “Flue Gas Temperature

Verification”, on page 2.

7. “Safety Inspection Of a Previously Used Appliance”, below, must be performed before installation on previously used equipment.

GENERAL INFORMATION

These units have been factory tested and rated in accordance with AMCA standard 210, Test Code for Air Moving Devices.

Each Power Venter and UC1 is electrically factory line tested before shipment.

After opening carton, inspect thoroughly for hidden damage. Wheel should rotate freely. If any damage is found notify freight carrier

and your distributor immediately and file a concealed damage claim.

IMPORTANT

We do not recommend using the model HSJ for oil fired equipment since the small blower wheel is more susceptible to soot buildup.

We recommend using the SideShot Series for oil inputs under 1 GPH (142,000 BTU/hr.) firing rates.

*SAFETY INSPECTION OF A PREVIOUSLY USED APPLIANCE

(Perform prior to Power Venter installation)

The following procedure is intended as a guide to aid in determining that an appliance is properly installed and is in safe condition for

continuing use. This procedure is based on central furnace and boiler installations and it should be recognized that generalized procedures cannot anticipate all situations. Accordingly, in some cases deviation from this procedure may be necessary to determine

safe operation of the equipment.

a. This procedure should be performed prior to any attempt at modifications of the appliance or installation of the Venter.

b. If it is determined there is a condition which could result in an unsafe operation, the appliance should be shut off and the owner

advised of the unsafe condition.

The following steps should be followed in making the safety inspection:

1. Visually inspect the venting system and determine there is no blockage or restriction, leakage, corrosion or other deficiencies

which could cause an unsafe condition.

2a. Oil Inst

allations: Inspect burner and primary control for proper operation.

2b. Gas Inst

allations: Conduct a gas leakage test of the appliance piping and control system downstream of the shutoff valve

in the supply line to the appliance.

Inspect burners and cross overs for blockage and corrosion.

3. Applicable only to furnaces:

Inspect heat exchanger for cracks, openings or excessive corrosion. Check both the limit control

and fan control for proper operation.

4. Applicable only to boilers:

Inspect for evidence of water or combustion product leaks. Determine that the water pumps are in

operating condition. Test low water cutoffs, automatic feed controls, pressure and temperature limit controls and relief valves in

accordance with the manufacturer's recommendations to determine that they are in operating order.

* Excerpts from the National Fuel Gas Code (ANSI Z223.1/NFPA #54), Appendix H.

3

Page 5

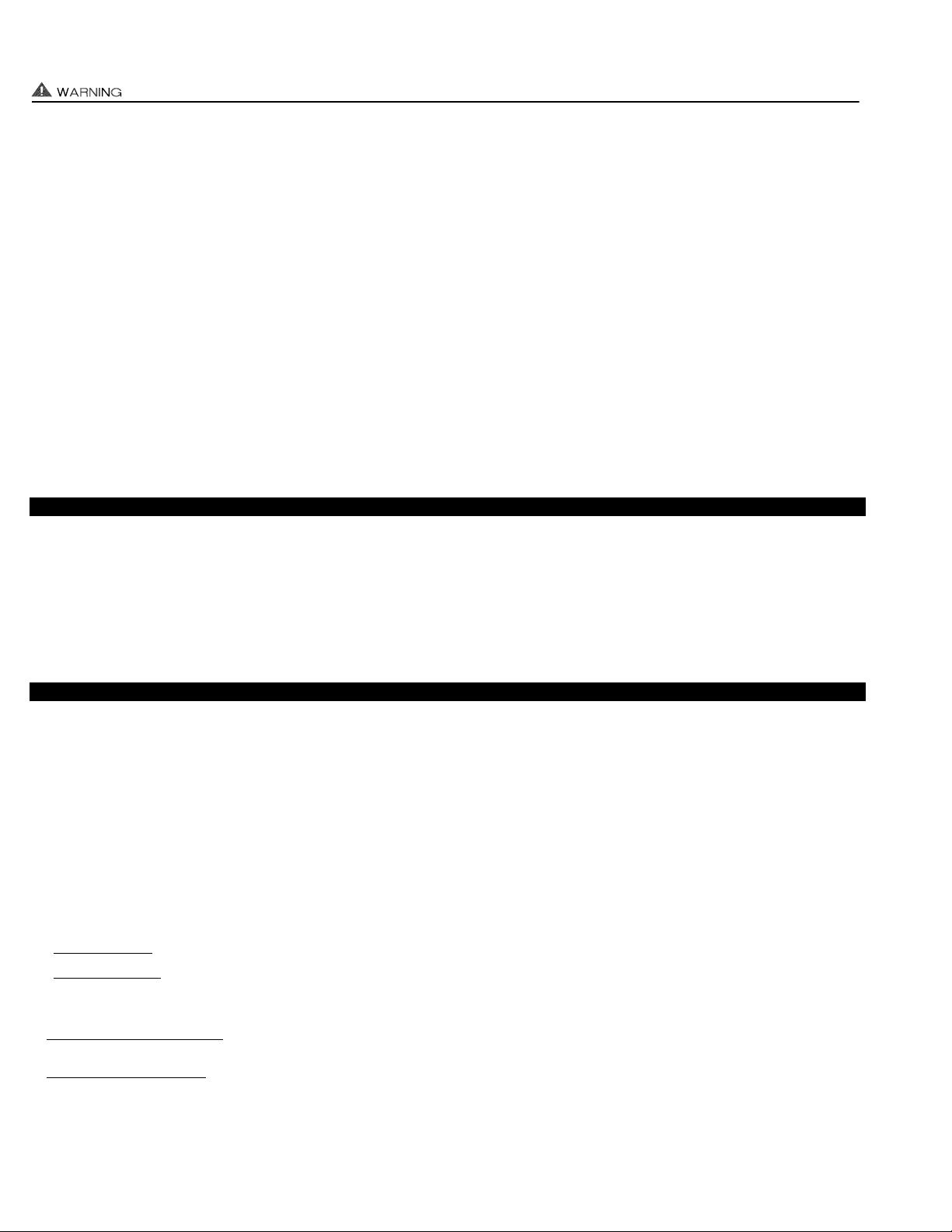

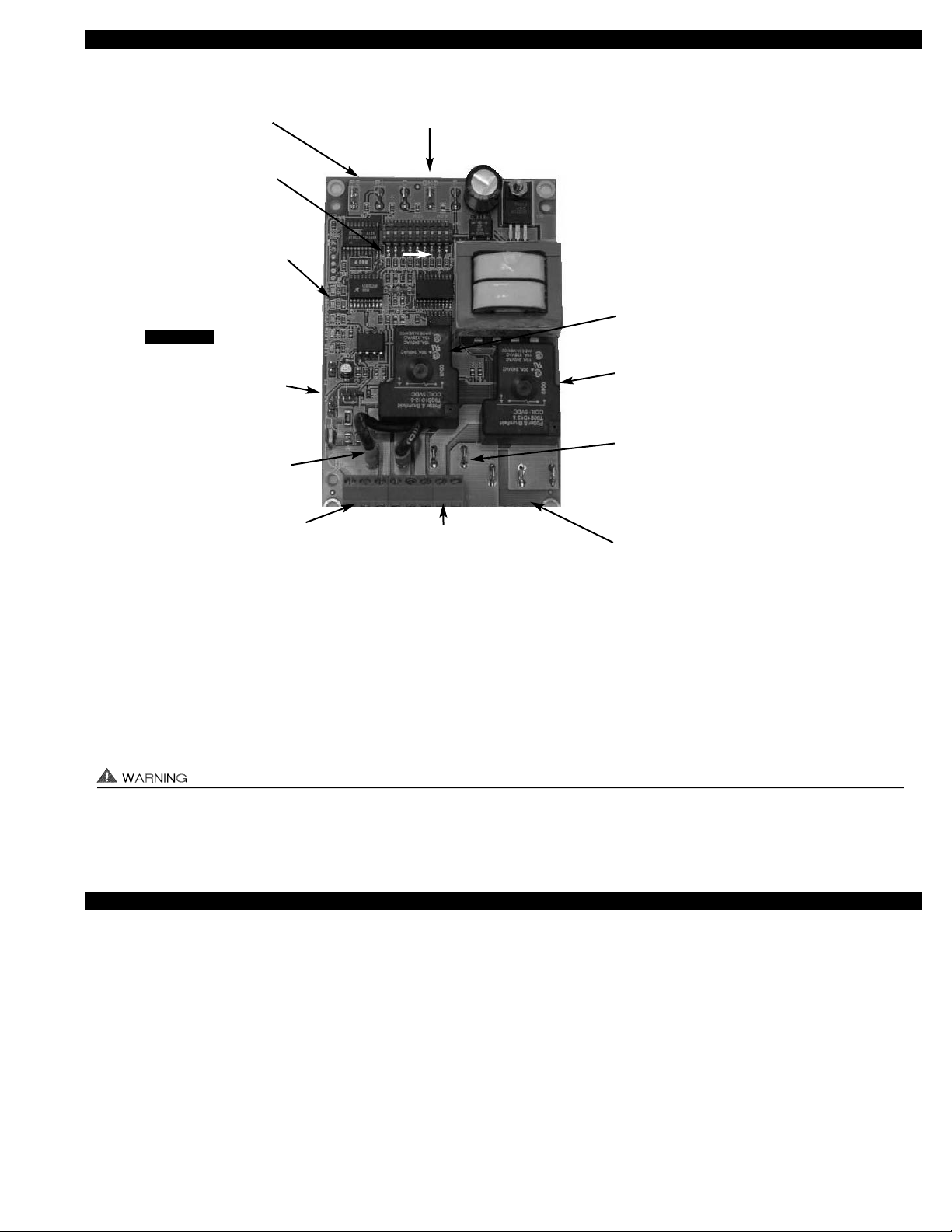

UC1 UNIVERSAL CONTROL BOARD FEATURES

# 1. Power supplied by board. Do not supply power to this area or control damage may result.

# 2. Do not supply power to the appliance interlock block with the call selector in the “DRY” position.

Control damage may result if power is supplied.

# 3. Circuit protection must be provided by the installer. 16 Amps is the maximum current allowed for this device at terminal L.

A 15 Amp circuit breaker is recommended.

VETI

I

LED STATUS & FAULT INDICATORS

LED INDICATOR LIGHTS

LED #1 (Amber) Appliance call for heat.

LED #2 (Green) Safety circuit through P1 & P2 (Venter Fan Prover) is verified “Open” upon start-up. Indicates Venter prover is

closed during run cycle. Burner circuit is energized with contact closure from terminal 3 to 4.

LED #3 (Green) Power switched to Venter motor from L to MTR & M.

LED #4 (Red) Status / Fault indicator.

LED #5 (Red) 115 VAC power supplied to board. Also used as a status indicator.

LED STATUS INDICATORS

LED #4 & #5 (Red) Flashing Alternately = Venter in Pre-purge. (Pre-Purge options 0, 5, 20, 35 seconds)

LED #4 & #5 (Red) Flashing in Unison = Venter in Post-Purge. (Post-Purge options 0, 30 seconds or 1, 2, 4, 8, 16 minutes)

LED #4 Flashes Continuously* = Fan Prover opened for more than 10 seconds during burner cycle.

(Venter will run for 10 minutes, attempting to make Fan Prover)

4

APPLIANCE CALL

VOLTAGE SELECTION

Place RED voltage jumper in

proper location based on

appliance call interlock voltage. SEE WARNING # 2.

IMPORTANT

LED 1 (AMBER)

LED 2 (GREEN)

LED 3 (GREEN)

LED 4 (RED)

LED 5 (RED)

DRY

24 V

115 V

APPLIANCE

INTERLOCK

RELAY

VENTER

MOTOR

RELAY

A B 1 2 3 4 L N

J1 J2 XL XN

P1 P2 C GND F

(1 9)

N M MTR

J1- J2 CALL

JUMPER

Used when the call signal is

used as the “proven” return

signal to the appliance. See

wiring section for details.

L / N - 115 VAC POWER

SUPPLY BLOCK

115 VAC / 50-60 Hz

Circuit protection provided by installer.

SEE WARNING # 3.

MTR & M / N LOAD TERMINALS

FROM VENTER MOTOR RELAY

Used to drive Venter Motor.

1 HP MAX LOAD across terminals MTR & M / N.

XL / XN AUXILIARY DEVICE

POWER TERMINALS

115 VAC - Maximum of 0.15 Amps.

Only connect to Tjernlund auxiliary devices.

SEE WARNING # 1.

APPLIANCE INTERLOCK

RELAY

1 HP MAX LOAD across

terminals 3 & 4.

P1 - P2 SAFETY CIRCUIT

TERMINALS

1 mA @ 5VDC.

SEE WARNING # 1.

C, GND, F AUXILIARY DEVICE

COMMUNICATION TERMINALS

2 mA @ 5VDC. For Tjernlund MAC1E or

MAC4E auxiliary devices. SEE WARNING # 1.

DIP SWITCH SETTINGS

Pre-Purge (1-2)

Post-Purge (3-8)

Prover status check (9)

See “Pre / Post Purge &

Prover Status Check Dip

Switch Settings”.

LED STATUS LIGHTS

See “LED Status & Fault

Indicator Section” for details.

APPLIANCE INTERLOCK

TERMINAL BLOCK (A-B, 1-4)

A- B- Dry Contact call. 3 mA @ 5VDC.

SEE WARNING # 1.

1 - 24 or 115 VAC intercepted call.

IMPORTANT: RED voltage jumper must

match intercepted call voltage.

2 - 24V common or 115V Neutral.

3 - Common terminal to appliance relay con-

tacts. IMPORTANT: J1-J2 jumper routes

call voltage at terminal 1 to 3. Remove

J1-J2 jumper if a different voltage source is

provided to terminal 3.

4 - Normally open terminal of appliance relay.

Will be energized from terminal 3 if safety

circuit is “proven”.

VENTER MOTOR RELAY

1 HP MAX LOAD from

terminals L to MTR & M.

Page 6

LED FAULT INDICATORS

Fault conditions are indicated by counting the number of times LED #4 (Red) flashes.

LED #4 Flashes 2 Times Fan Prover was in electrically closed position prior to venter operation.

LED #4 Flashes 3 Times* Fan Prover does not close within 60 seconds after call for heat.

LED #4 Flashes 4 Times* Fan Prover did not re-close after 10 minutes of Venter operation.

LED #4 Flashes 5 Times* Fan Prover opened for more than 10 seconds during burner cycle but closed within 10 minutes.

* Investigate causes of Fan Prover not making, i.e; Firing burner at capacities or temperatures exceeding Venter limits, excessive

vent pipe runs, elbows directly on venter discharge, high winds, plugged / kinked Fan Prover sensing tube or a faulty Fan Prover.

CHECKING MEMORY FOR LAST FAULT CODE

IMPORTANT: Prior to accessing the fault code memory, note the settings of the dip switches so that they can be returned to their

original Pre / Post-Purge positions. When power is supplied to the UC1 use caution when moving dip switches.

The last fault code can be retrieved at any time by setting all dip switches 1-8 to the up, or “on” position. The last fault code, or lack

there of, will be indicated by counting the number of times LED 4 flashes. By moving any of the dip switches back to their original

position, the fault code will be cleared. NOTE: The UC1 board must have its 115 VAC power supply present when any of the (1-8) dip

switches are moved back to their original position for the fault code to clear.

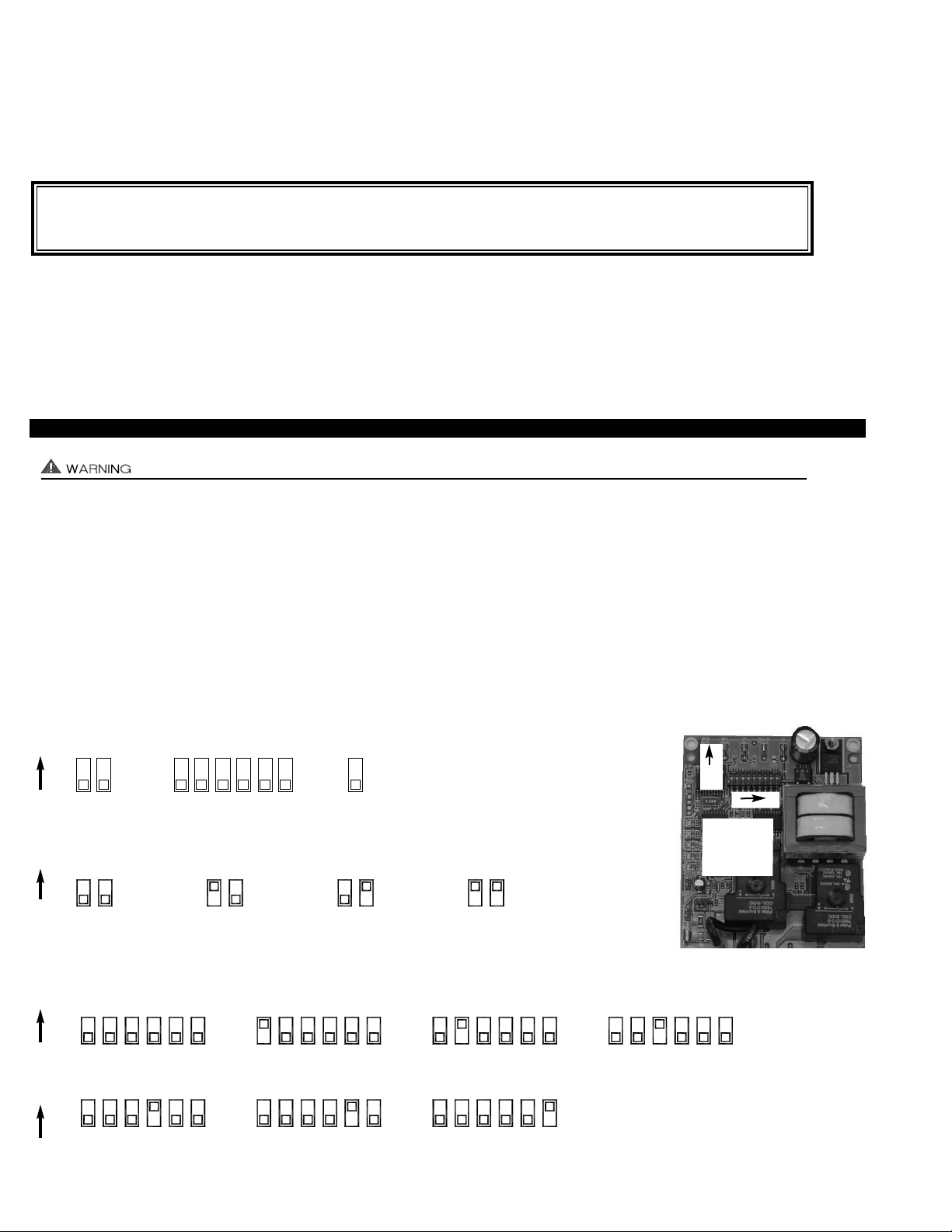

PRE / POST PURGE AND PROVER STATUS CHECK DIP SWITCH SETTINGS

Remove power to UC1 and heating equipment when installing, servicing or changing dip switch settings. Failure to do so may result in

personal injury and/or equipment damage. LED #5 (RED) should not be on if 115 VAC supply power is removed from the control.

Pre-purge

Used for a Venter with longer vent runs to get draft fully established throughout the vent system prior to burner ignition. Also beneficial for negative pressure prone environments. IMPORTANT: Nuisance equipment lockouts may occur if Venter pre-purge is running

in conjunction with and is longer than any equipment timing circuit. Pre-purge settings must be shorter than burner control lockout

time unless wired prior to burner control timing circuit (i.e. aquastat / thermostat).

Post-purge

A Venter post-purge has been factory set at 2 minutes. Confirm that dip switch #5 is in the up or "on" position. Oil fired equipment

requires that the post-purge be long enough to eliminate post cycle nozzle drip odor. A longer post-purge may be necessary for longer

vent runs or high heat retention, refractory lined combustion chambers. A shorter post-purge may be desired for gas installations.

IMPORTANT: Fault codes will automatically be displayed after a fault condition occurs. If the call for heat interlock signal

or 115 VAC power is removed, the UC1 board will reset and the fault will be stored in memory instead of displayed. Any

new fault will replace any previous fault.

5

Pre-Purge

Post-Purge

Pre-Cycle

Prover Status

Check Activated

DIP SWITCH NUMBERING

1

ON

ON

POST-PURGE SETTINGS (SEE “POST-PURGE” ABOVE PRIOR TO SETTING)

ON

2

3

4

5

6

7

8 9

4348657 35678 345678 3 75468

4348657 35678 345678

4 Minutes 8 Minutes 16 Minutes

1 Minute0 Seconds 30 Seconds 2 Minutes

ON

PRE-PURGE SETTINGS (SEE “PRE-PURGE” ABOVE PRIOR TO SETTING)

12 12 12 12

0 Seconds 5 Seconds 20 Seconds 35 Seconds

1 9

LED 1 AMBER

LED 2 GREEN

LED 3 GREEN

LED 4 RED

LED 5 RED

ON

Page 7

INSTALLATION

VENT SYSTEM TERMINATION

Before installing Power Venter determine location of vent system termination.

TOOLS REQUIRED

• Saber Saw or Cement Drill • Drill • 1/8” and 1/4” Drill Bits

• Wood or Masonry Chisel • Blade Screwdriver or 1/4” Nut Driver • Wire Cutter/Stripper

NOTE: Termination of a Side Wall Vent System with a device other than the Tjernlund VH1 Series Vent Hood could affect system

performance and result in a possible safety hazard. Consult V

ent Hood instructions for complete installation details.

VENT HOOD TERMINATION CODE REQUIREMENTS FOR U.S. INSTALLATIONS

If possible, locate the Vent Hood on a wall that does not face the direction of prevailing winds. This will diminish the possibility of appliance interruption during periods of extreme winds and prevent oil odors caused by backdrafts.

If possible, locate the Vent Hood no closer than 3 feet from an inside corner of an L-shaped structure.

Terminate the vent system so that proper minimum clearances are maintained as cited in the latest edition of the National Fuel Gas

Code (NFPA # 54) and the latest edition of NFPA #211, or as follows:

• Not be less than 7 feet above grade when located adjacent to public walk ways.

• At least 3 feet above any forced air inlet located within 10 feet.

• At least 4 feet below, 4 feet horizontally from or 1 foot above any door, window or gravity air inlet into any building.

• At least 12 inches above grade.

• So that the flue gases are not directed so as to jeopardize people, overheat combustible structures or enter buildings, and

• Not less than 2 feet from an adjacent building.

6

For oil installations do not terminate HS-Series Power Venters on vinyl siding because temperatures can easily exceed 1500F.

The SideShot® is the only Tjernlund Power Venter recommended for termination on vinyl siding when using oil.

P1 & P2 PRE-CYCLE FAN PROVER STATUS CHECK

The Pre-Cycle Prover Status Check is activated from the factory. When activated the UC1

Universal Control checks across P1 & P2 safety circuit (Venter Fan Prover) to verify that the Fan

Prover switch is “Open” upon a call for heat and not stuck “Closed”. IMPORTANT: This must

always be in the down “Activated” position when sidewall venting.

Pre-Cycle

Prover Status

Check Activated

9

Page 8

VENT HOOD TERMINATION CODE REQUIREMENTS FOR CANADIAN INSTALLATIONS

If possible, locate the Vent Hood on a wall that does not face the direction of prevailing winds. This will diminish the

possibility of appliance interruption during periods of extreme winds and prevent oil odors caused by backdrafts.

N

TER

• A venting system shall not terminate underneath a veranda, porch, or deck, or above a paved sidewalk or a paved driveway that is

located between two buildings, and that serves both buildings.

• The exit terminals of mechanical draft systems shall not be less than 2.13m (7ft) above grade when located adjacent to a paved

sidewalk or driveway.

• A venting system shall not direct flue gases towards brickwork, siding, or other construction, in such a manner that may cause

damage from heat or condensate from the flue gases.

• A vent system shall not direct flue gases so as to jeopardize people, overheat combustible structures, or enter buildings.

A

venting system shall not terminate within 1.8 m (6f

t) of the following:

• A window, door or mechanical air supply inlet of any building, including soffit openings

• A gas service regulator vent outlet

• A combustion air inlet

• A property line

• A direction facing combustible materials or openings of surrounding buildings

A

venting system shall not terminate within 1m (3f

t) of the following:

• Above a gas meter/regulator assembly within 1m (3ft) horizontally of the vertical centreline of the regulator

• A oil tank or an oil tankfill inlet

• The inside corner of an L-shaped structure

A

venting system shall not terminate within .3m (1ft) of the following:

• Above grade level or any surface that may support snow, ice, or debris

POWER VENTER INSTALLATION

VERIFY POWER VENTER MODEL SELECTION USING TABLES ON PAGE 1.

CODE REQUIREMENTS

All Power Venter installations must follow the appropriate U.S. or Canadian requirements listed under the Installation Restrictions and

Cautions of this manual.

• All portions of the vent system under positive pressure during operation (on the outlet side of Power Venter) shall be designed and

installed so as to prevent leakage of flue or vent gases into the building.

• All appliances must enter the vent system on the inlet side of the Power Venter.

• Provision shall be made to interlock the appliance(s) to prevent the flow of gas to the main burners when the draft system is not

performing so as to satisfy the operating requirements of the equipment for safe performance. See “Electrical Wiring” section of

this manual for details.

7

Page 9

INSTALLATION RESTRICTIONS

1. Power Venter must be installed as close as possible to the termination of the vent system to obtain

optimal appliance efficiency and to prevent flue gas leakage, (See Diagram A).

2. The Power Venter may be mounted in any position as long as the shaft of the motor remains

horizontal, to prevent motor bearing wear and to ensure proper Fan Proving Switch operation,

(See Diagram B).

3. The Power Venter housing is single wall. A 6” (15.2 CM) clearance

to combustibles must be maintained for gas and 18” (45.7 CM) clearance for oil applications, (See Diagram C). If the appliance name

plate specifies a vent connector clearance greater than 6 inches, the

greater clearance must be used. Verify these clearances are in

compliance with all local codes.

NOTE: Clearance to combustibles may be reduced. Please refer to

Clearance Table VI in NFPA #54 or your local code authority.

4. Vent pipe transitions, where necessary, must be

gradually tapered,

(See Diagram D).

5. Power Venter to vent pipe connections and all joints on the outlet side of the Power Venter must be

sealed with high-temperature silicone

sealant or aluminum vent pipe tape to prevent flue gas leakage, (See Diagram E).

6. Oil installations require

the use of a barometric draft control. Draft control must be installed between the appliance outlet and the Power

Venter inlet, (See Diagram E). Oil installations should use the same diameter pipe on the inlet and discharge side of the Power Venter.

7. Allow for a minimum straight section of pipe equal to 3 times the diameter of the vent pipe being used when installing elbows on the

discharge side of the Power Venter. For example, if using 4” pipe, allow for 12” of straight pipe before using an elbow, (See Diagram F).

8

DIAGRAM A

DIAGRAM B

DIAGRAM D

DIAGRAM E

ELBOW

PIPE

BEFORE ELBOW

SECTION OF PIPE

ADD A STRAIGHT

VENT PIPE

DIAMETER

3 TIMES

2201018D

DIAGRAM F

DIAGRAM C

Page 10

9

POWER VENTER MOUNTING

1. Slide the outlet of the Power Venter over the inner sleeve of the Vent Hood and connect them together using a tapered transition

fitting if necessary, (See Diagram G). If you are unable to make a direct connection to the Vent Hood, vent pipe may be installed

between the Power Venter and Vent Hood. However, all vent pipe connections after the Power Venter must be sealed with high

temperature silicone caulk or aluminum vent pipe tape to prevent flue gas leakage, (See Diagram E).

2. To facilitate installation and reduce vibration we have included 2 mounting brackets, 2 rubber isolaters and 2 rubber grommets. One

of the brackets may be used temporarily as a “third hand” while positioning it for permanent installation.

3. When installing the Power Venter for horizontal mount, install one of the brackets to the electrical box using the nut/screw

provided. Install the other to the damper rod as shown below. When installing the Power Venter for vertical mount, only one

bracket is needed. This bracket should be mounted to the motor as shown below. Temporarily support the Power Venter

using wire or a ladder and assemble the mounting brackets, (See Diagram H).

4. Verify required vent pipe diameter from “HS-Series Model Selection” on page 1. Verify that a full sized barometric control has been

installed on appliances not equipped with a draft hood or draft diverter.

5. Install properly sized vent pipe sections from Power Venter inlet to appliance outlet avoiding elbows wherever possible, using

only tapered transitions. In most cases a reduction in vent pipe diameter from that of the appliance flue outlet will be necessary.

6. Using four holes as guides, attach vent pipe to Power Venter inlet collar using sheet metal screws.

7. Support vent pipe in accordance with vent pipe manufacturer’s instructions.

8. All necessary vent pipe connections after the Power Venter will be under positive pressure during operation. These connections

must be sealed with high-temperature silicone sealant or aluminum vent pipe tape supplied by the installer, (See Diagram E).

FURNACE

POWER VENTER ON INDUCED DRAFT GAS APPLIANCES

When installing the Power Venter on induced draft gas appliances, a barometric draft control must be added. The draft control provides pressure relief to neutralize over-drafting and allows a means of draft adjustment for optimum burner efficiency. By adjusting

the draft control and Power Venter damper the installer can obtain the appliance manufacturer’s recommended draft setting.

Install the vent pipe and draft control as shown in the diagrams below. The draft control should connect to a tee off of the appliance

flue outlet. The Power Venter may only be used with appliances capable of being chimney vented. It is not suitable for use on highefficiency, condensing models.

DIAGRAM H

DIAGRAM G

(DOWNFLOW APPLIANCE)

Page 11

UC1 UNIVERSAL CONTROL INSTALLATION AND MOUNTING

The UC1 has a 2 foot whip that contains a ground lead and the leads to power the Venter motor and connect to the Fan Prover. If it

is desirable to mount the UC1 more than 2 feet from the Venter an additional electrical junction box and appropriate length of conduit

will be necessary. Any added wire should be 14 gauge and a pig tail should be added to each ground wire connection so that each

electrical junction box is grounded.

Do not mount the UC1 junction box on a heat source that exceeds 140oF (60oC). Examples of improper mounting surfaces include

vent pipe, top of heater casing or any place where radiant or convective heat would cause the junction box temperature to exceed 140oF.

The UC1 is intended for indoor installation only.

Using the key hole slots on the back of the UC1 junction box as a template, mark 4 holes on the mounting surface, drill pilot holes if

necessary, and secure junction box using provided screws.

ELECTRICAL WIRING

All wiring from the UC1 to the appliance must be appropriate Class 1 wiring as follows: installed in rigid metal conduit, intermediate metal

conduit, rigid non-metallic conduit, electrical metallic tubing, Type MI Cable, Type MC Cable, or be otherwise suitably protected

from physical damage.

SEQUENCE OF OPERATION WITH UC1 UNIVERSAL CONTROL AND 24 VAC OR 115 VAC HEATER CONTROL CIRCUIT:

Control signal from thermostat, aquastat, primary control or gas valve is intercepted and routed to terminal “1” on UC1 terminal strip.

When terminal “1” is energized with either 24 VAC or 115 VAC, the Venter motor is energized. After draft is established, the Fan

Proving Switch closes within 5 to 10 seconds energizing terminal “4”, which completes the circuit allowing burner to fire. NOTE: If a

Venter pre-purge is selected, the burner will not fire until the pre-purge time is finished. The Venter will continue to run after the burner has finished firing for the set post-purge time cycle. The UC1 is set for a 2 minute post-purge time period from the factory. See

“Pre / Post-Purge Settings” on page 5 for details.

The "1" input terminal on the UC1 can accept either a 24 VAC or 115 VAC control signal. IMPORTANT: The RED voltage

jumper must be positioned based on appliance interlock voltage 24V or 115V. If using the “DRY” contact activation method, use terminals A & B on UC1 control and position the RED voltage jumper tab in the “DRY” position. See millivolt appliance interlock diagram for further information. IMPORTANT: Only one interlock method (i.e. 24V, 115V or “Dry”) can be used with the UC1. Multiple

appliance interlocks require the use of our MAC-Series multiple appliance controls.

The steps listed under each diagram are intended as a supplement to the diagram. Wiring colors or designations may vary by manufacturer. If you are unable to wire the UC1 as outlined in these instructions, call Tjernlund’s Customer Service Department toll free at

1-800-255-4208 for assistance.

IMPORTANT: If the call for heat interlock signal or 115 VAC power is removed, the UC1 board will reset and any fault, if present, will

be stored in memory instead of displayed. See page 5, “Checking Memory for Last Fault Code”.

10

(UPFLOW APPLIANCE)

IMPORTANT: MORE THAN ONE INTERLOCK METHOD MAY BE APPLICABLE

In many cases it is easier to interlock with the thermostat/aquastat portion of the heater control circuit vs. the ignition module /

primary control portion of the heater control circuit. Review all of the wiring diagram options prior to choosing the best method.

Page 12

11

IMPORTANT:

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

CALL

RELAY

INTERLOCK

COMMON

NEUTRAL

PRODUCTS,

INC.

MOTOR

1 H.P. MAX @ 115 VAC

SUPPLY

115 VAC

50/60 Hz

R

TJERNLUND

9183006

NO

MTRM

MOTOR

RELAY

N

COM

NO

115 VAC

24 VAC

D/N 1303958-1

DO NOT SUPPLY VOLTAGE

TO "A" OR "B".

DO NOT SUPPLY POWER!

5 VDC BOARD-GENERATED POWER

HOT

24 VAC

USER-PROVIDED

CALL SWITCH

LINE

OR

"DRY"

OR

115V

J2

COM

24V

DRY

LEGEND:

115 VAC

5

POST-PURGE SETTINGS

FOR TJERNLUND

TO P1, P2, C, GND

AUXILIARY

OR F. DOING SO

WILL DAMAGE THE

CONNECT POWER

OPEN PROVER OPTION

(9)

(3 - 8)

9

786

CONTROL.

DEVICES. DO NOT

FGND

ON

LED1

PRE-PURGE SETTINGS

LED5 LED4 LED2LED3

(1 - 2)

243

1

CP1P2

PROVER

J1

XL

XN

115 OR 24 VAC FROM CALL JUMPER

OR USER-PROVIDED VOLTAGE

FROM TERMINAL 3 TO 4 WITH CALL

JUMPER REMOVED

K2

K1

APPROVED

MAC1E OR MAC4E

JUMPER

RED

RED

GREEN

GREEN

AMBER

WARNING: Disconnect power supply from the UC1 and heating equipment when making wiring connections and servicing the

Venter. Failure to do so may result in personal injury and/or equipment damage. LED #5 (RED) should be off with

power removed.

GREEN

BLUE

YELLOW

WHITE

BLACK

GREEN

WHITE

BLACK

GROUNDING STUD

2 FT. WHIP FROM UC1

HSJ, 1, 2 ELECTRICAL BOX

FAN PROVER

INSERT PROVIDED

HOLE PLUG

UC1 UNIVERSAL CONTROL WIRING SCHEMATIC

The Ground lead, Venter motor and Fan Prover leads are factory connected to the UC1 circuit board. Venter Ground, motor and Fan

Prover wiring connections are made at the free end of the 2 foot whip in HS-Series junction box.

WIRING CONNECTIONS FROM UC1 UNIVERSAL CONTROL MADE IN

HS-SERIES JUNCTION BOX

1. Connect ground from UC1 whip to grounding stud in Venter.

2. Connect Black and White leads from UC1 whip to Venter motor leads.

3. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals

in Venter. Yellow lead should be on switch terminal closest to Venter junction box wall.

4. Insert provided hole plug in HS-Series junction box in opening

opposite UC1 whip.

MULTIPLE APPLIANCE INTERLOCKS

To interlock with one additional 24/115 VAC heater add the MAC1E. It is a stripped

down auxiliary board version of the UC1 and is powered by and communicates with

the UC1 through a factory wired whip.

To interlock more than two 24/115 VAC heaters, add the MAC4E for a total of up to

5 heaters. It is powered by and communicates with the UC1 through a factory wired

whip. Consult factory for installations with more than 5 heaters.

To interlock a millivolt water heater and a 24/115 VAC furnace or boiler, add the

WHKE and MAC1E.

MILLIVOLT INSTALLATIONS

Each millivolt appliance interlocked with the UC1 must have its own WHKE kit

installed. The WHKE Gas Pressure Switch actuates the Venter through the A - B Dry

contacts. The Linear Limit switch disables the heater in the event of a venting malfunction. IMPORTANT: Each millivolt appliance interlocked with the UC1 must have

its own Linear Limit spill switch.

MULTIPLE MILLIVOLT HEATER INSTALLATIONS

Multiple millivolt heaters can be installed by using the A-B dry contact terminals of

the UC1, MAC1E or MAC4E. Wire each WHKE gas pressure switch in parallel

across A-B terminals of UC1, MAC1E or MAC4E. Wire Linear Limit safety switch

into each individual millivolt heater. For further information consult factory or WHKE

instructions.

Page 13

12

UC1 UNIVERSAL CONTROL CONNECTED WITH A 24 VAC ELECTRONIC IGNITION MODULE

XN

R

UNIVERSAL CONTROLLER

D/N 9183046-8

115 VAC

24 VAC

LEGEND:

HONEYWELL IGNITION

CONTROL

MV

MV

PV

CALL

AS APPLIANCE INTERLOCK VOLTAGE.

RED JUMPER POSITION MUST BE THE SAME

XL

J1J2

DRY

115V

24V

IMPORTANT:

PV

MV / PV (2)

MV (1)

PV (3)

BNR GND (4)

24V GND (5)

24V (6)

(7)

(8)

SPARK (9)

OR

PI

YE

GR

YE

WH

OR

YE

WH

OR

GR

GAS VALVE

JUMPER

50/60 Hz

SUPPLY

115 VAC

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

1. Remove the wire on MV at gas valve and connect it on #1 on UC1 terminal block.

2. Connect #2 on UC1 terminal block to MV/PV.

3. Connect #4 on UC1 terminal block to MV on gas valve.

4. Make sure RED voltage jumper on UC1 is on 24V.

5. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

6. If not previously completed, connect ground from UC1 whip to grounding stud in Venter. Connect Black and White leads

from UC1 whip to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals in

Venter. Yellow lead should be on switch terminal closest to Venter junction box wall.

UC1 UNIVERSAL CONTROL CONNECTED WITH A 24 OR 115 VAC STANDING PILOT

115V

24V

DRY

OF FURNACE/BOILER

INTERNAL CONTROLS

24V OR 115V GAS VALVE

HOT

COM

B2

COM

TR

Aquastat

T-stat

TH

HOT

B1

XL

UNIVERSAL CONTROLLER

XN

J1J2

D/N 9183046-1

24 OR 115 VAC

LEGEND:

CALL

JUMPER

115 VAC

50/60 Hz

SUPPLY

115 VAC

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

IMPORTANT:

1. Remove the wire on TH or HOT of gas valve and connect it on #1 on UC1 terminal block.

2. Connect #2 on UC1 terminal block to TR or Common.

3. Connect #4 on UC1 terminal block to TH or HOT on gas valve.

4. Make sure RED voltage jumper on UC1 is on 24V or 115V depending on control voltage.

5. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

6. If not previously completed, connect ground from UC1 whip to grounding stud in Venter. Connect Black and White leads

from UC1 whip to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals in

Venter. Yellow lead should be on switch terminal closest to Venter junction box wall.

NOTE: If burner safety control goes out on lockout, the Venter will continue to run as long as a call for heat is present.

Page 14

13

UC1 UNIVERSAL CONTROL CONNECTED WITH A SINGLE ZONE 24 VAC THERMOSTAT

XN

R

UNIVERSAL CONTROLLER

THERMOSTAT

GG

INTERNAL CONTROL

OF FURNACE

W

C

Y

R

R

Y

AS APPLIANCE INTERLOCK VOLTAGE.

RED JUMPER POSITION MUST BE THE SAME

XL

J1J2

W

DRY

115V

24V

IMPORTANT:

D/N 9183046-5

115 VAC

24 VAC

LEGEND:

CALL

JUMPER

50/60 Hz

SUPPLY

115 VAC

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

1. Connect W from t-stat to #1 on terminal block of UC1.

2. Connect #2 on UC1 terminal block to C on internal control terminal strip of furnace/boiler.

3. Connect #4 on UC1 terminal block to W on internal control terminal strip of furnace/boiler.

4. Make sure RED voltage jumper on UC1 is on 24V.

5. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

6. If not previously completed, connect ground from UC1 whip to grounding stud in Venter. Connect Black and White leads

from UC1 whip to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals in

Venter. Yellow lead should be on switch terminal closest to Venter junction box wall.

NOTE: If burner safety control goes out on lockout, the Venter will continue to run as long as a call for heat is present.

UC1 UNIVERSAL CONTROL AND WHKE INTERLOCK KIT

CONNECTED WITH A MILLIVOLT APPLIANCE

XN

R

UNIVERSAL CONTROLLER

D/N 9183046-9

CALL

AS APPLIANCE INTERLOCK VOLTAGE.

RED JUMPER POSITION MUST BE THE SAME

XL

J1J2

DRY

115V

24V

IMPORTANT:

JUMPER

GENERATED

5 VDC

LEGEND:

115 VAC

WHKE GAS

SAFETY CIRCUIT ACROSS P1 & P2 OF UC1 IS NOT UTILIZED

WITH HEATING EQUIPMENT AS SHOWN.

IN THIS APPLICATION. SPILL SWITCH MUST BE INTERLOCKED

MILLIVOLT

PRESSURE

SWITCH

JUNCTION ADAPTER

THERMOCOUPLE

950-0470 (JA1)

LINEAR LIMIT

SPILL SWITCH

GAS

VALVE

30 MILLIVOLT WATER HEATERS REQUIRE USE OF THE

(ECO) OF WATER HEATER. LINEAR LIMIT SPILL SWITCH,

ON 750 MILLIVOLT (POWER PILE) WATER HEATERS WIRE

LINEAR LIMIT SPILL SWITCH IN SERIES WITH HIGH LIMIT

950-0470 THERMOCOUPLE JUNCTION ADAPTER.

950-0470 JUNCTION ADAPTER AND GAS PRESSURE

SWITCH ARE INCLUDED WITH WHKE KIT.

DO NOT

SUPPLY

POWER.

POWER!

BOARD-

50/60 Hz

SUPPLY

115 VAC

ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING SPADE TERMINAL IN

IMPORTANT:

Each millivolt appliance interlocked with the UC1 must have its own WHKE kit installed. The WHKE Gas Pressure Switch actuates the

Venter through the A - B Dry contacts. The Linear Limit switch disables the heater in the event of a venting malfunction. IMPORTANT:

Each millivolt appliance interlocked with the UC1 must have its own Linear Limit spill switch.

1. Wire WHKE Gas Pressure Switch across A and B terminals on UC1. Do not supply voltage to A and B terminals.

2. Wire WHKE Linear Limit in series with thermocouple junction adapter or high limit ECO of water heater.

3. Make sure RED voltage jumper on UC1 is in the DRY position.

4. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

5. If not previously completed, connect ground from UC1 whip to grounding stud in Venter. Connect Black and White leads

from UC1 whip to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals in

Venter. Yellow lead should be on switch terminal closest to Venter junction box wall.

Page 15

14

UC1 UNIVERSAL CONTROL CONNECTED TO A HONEYWELL R7184 SERIES OR EQUIVALENT

PRIMARY CONTROL WITH A LINE VOLTAGE THERMOSTAT OR AQUASTAT

Burner

Alarm

Cad Cell

A

Interrupted

Intermittant

Motor

A

IGNITION TRANS

BURNER MOTOR

R

Oil Valve

Limit

R7184

L1

T

T

L2

OIL VALVE

115 VAC

60 Hz

SUPPLY

Limit

24V

DRY

115V

XL

UNIVERSAL CONTROLLER

XN

J1J2

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

IMPORTANT:

D/N 9183046-6

115 VAC

LEGEND:

CALL

JUMPER

Ignitor

Line Voltage Thermostat

or Aquastat Control

Low Voltage

Jumper

50/60 Hz

SUPPLY

115 VAC

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

1. Disconnect burner motor wire off the R7184.

2. Connect burner motor terminal of R7184 to #1 on UC1 terminal block.

3. Connect #2 on UC1 terminal block to L2 or N.

4. Connect #4 on UC1 terminal block to burner motor wire removed from R7184.

5. Make sure RED voltage jumper on UC1 is on 115V.

6. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

7. If not previously completed, connect ground from UC1 whip to grounding stud in Venter. Connect Black and White leads

from UC1 whip to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals in

Venter. Yellow lead should be on switch terminal closest to Venter junction box wall.

UC1 UNIVERSAL CONTROL CONNECTED TO A GAS OR OIL BURNER WITH AN AQUASTAT

XN

R

UNIVERSAL CONTROLLER

LINE VOLTAGE OIL BURNER

PRIMARY CONTROL, BURNER

L1

N

XL

J1J2

115V

DRY

24V

AQUASTAT

B2

B1

C1

C2

L1

L2

D/N 9183046-7

115 VAC

LEGEND:

CALL

JUMPER

RELAY OR GAS VALVE

50/60 Hz

SUPPLY

115 VAC

RED JUMPER POSITION MUST BE THE SAME

IMPORTANT:

AS APPLIANCE INTERLOCK VOLTAGE.

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

CAUTION:

WHEN INTERLOCKING WITH AQUASTAT

DO NOT

DISCONNECT BURNER MOTOR

FROM PRIMARY CONTROL / CAD CELL RELAY.

1. Disconnect B1 from L1 of oil burner primary control, burner relay or hot of gas valve and reconnect to #1 on UC1 terminal block.

2. Connect #2 on UC1 terminal block to B2 or N.

3. Connect #4 on UC1 terminal block to the L1 on line voltage oil burner primary control, burner relay or gas valve.

4. Make sure RED voltage jumper on UC1 is on 115V.

5. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

6. If not previously completed, connect ground from UC1 whip to grounding stud in Venter. Connect Black and White leads

from UC1 whip to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals in

Venter. Yellow lead should be on switch terminal closest to Venter junction box wall.

NOTE: If burner safety control goes out on lockout, the Venter will continue to run as long as a call for heat is present.

Page 16

15

UC1 UNIVERSAL CONTROL CONNECTED TO A HONEYWELL

R8184 SERIES OR EQUIVALENT PRIMARY CONTROL

50/60 Hz

R

WHITE

ORANGE

BLACK

HONEYWELL

R8184 SERIES

OR EQUIVALENT

IGNITION TRANS

BURNER MOTOR

WHITE

SUPPLY

115 VAC

BLACK

UNIVERSAL CONTROLLER

XN

RED JUMPER POSITION MUST BE THE SAME

IMPORTANT:

AS APPLIANCE INTERLOCK VOLTAGE.

J1

XL

J2

115V

DRY

24V

115 VAC

LEGEND:

CALL

JUMPER

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

D/N 9183046-2 10/16/03

L1 OR B1

CONNECT TO

CONNECT TO

L2 OR B2

WHITE

1. Separate the Black burner motor wire from the Orange wire of R8184 Primary Control.

NOTE: Do not separate the ignition transformer wire from the Orange.

2. Connect Orange wire of R8184 to #1 on UC1 terminal block.

3. Connect #2 on UC1 terminal block to White on R8184 and L2 or B2.

4. Connect Black of burner motor to #4 on UC1 terminal block.

5. Make sure RED voltage jumper on UC1 is on 115V.

6. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

7. If not previously completed, connect ground from UC1 whip to grounding stud in Venter. Connect Black and White leads

from UC1 whip to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals in

Venter. Yellow lead should be on switch terminal closest to Venter junction box wall.

UC1 UNIVERSAL CONTROL CONNECTED WITH A CARLIN 40200, 42230, 48245, 50200, 60200

SERIES OR EQUIVALENT AND A LINE VOLTAGE THERMOSTAT OR AQUASTAT

Alarm

A Violet

0.3 A, AC

OIL VALVE

R

ABlue

OrangeF

FWhite

TBlack

Red/WhiteT

115 VAC

BURNER MOTOR

IGNITION TRANS

500 VA

10 FLA / 60 LRA

Line Voltage Thermostat

60 Hz

SUPPLY

J2

UNIVERSAL CONTROLLER

XNXL

J1

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

IMPORTANT:

115V

DRY

24V

D/N 9183046-3

115 VAC

LEGEND:

CALL

JUMPER

Limit

or Aquastat Control

Low Voltage

Jumper

50/60 Hz

SUPPLY

115 VAC

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

1. Disconnect burner motor wire off the Orange on Carlin.

2. Connect burner motor terminal Orange of Carlin to #1 on UC1 terminal block.

3. Connect #2 on UC1 terminal block to L2 or N

4. Connect #4 on UC1 terminal block to burner motor wire removed from Orange of Carlin.

5. Make sure RED voltage jumper on UC1 is on 115V.

6. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

7. If not previously completed, connect ground from UC1 whip to grounding stud in Venter. Connect Black and White leads

from UC1 whip to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals in

Venter. Yellow lead should be on switch terminal closest to Venter junction box wall.

Page 17

16

UC1 UNIVERSAL CONTROL OPERATIONAL CHECK

1. Confirm power is supplied to the Control. LED #5 (RED) should be on.

2. Activate the UC1 by initiating an appliance call for heat. LED #1 (AMBER) should be on.

3. The motor relay will close and activate the Venter motor. LED #3 (GREEN) should be on and

Venter motor should be running.

4. If the safety circuit across P1 & P2 (Venter Prover) is closed, indicating an approved condition, the

appliance interlock relay will close making terminal #3 closed to terminal #4 & LED #2 (GREEN).

Appliance burner should fire.

5. Remove power to the UC1 and any interlocked appliances. The LED #5 (RED) or any LED’s

should not be on. Test the safety circuit by removing the Blue or Yellow Lead from Fan Proving

Switch. Do not let the opened LEAD touch a ground or damage may occur to the control when

power is Reestablished. Reestablish power to the UC1 and interlocked appliances and initiate

a call for heat. After 60 seconds a Prover Start Up fault should arise with LED #4 flashing 3 times.

6. Remove appliance call for heat and power to the UC1 and any interlocked appliances. The LED #5

(RED) or any LED’s should not be on. Reconnect Blue or Yellow Fan Prover lead to Fan Proving

Switch terminal removed from in step 5.

7. Reestablish power to UC1 and interlocked appliances and initiate a call for heat to confirm proper operation of UC1 and appliance.

RESETTING FAULT CODE CREATED BY STEP 5 OF OPERATIONAL CHECK

IMPORTANT: Prior to accessing the fault code memory, note the settings of the dip switches so that they can be returned to their

original Pre / Post-Purge positions. When power is supplied to the UC1 use caution when moving dip switches.

The last fault code can be retrieved at any time by setting all dip switches 1-8 to the up, or “on” position. The last fault code, or lack

there of, will be indicated by counting the number of times LED 4 flashes. By moving any of the dip switches back to their original

position, the fault code will be cleared. NOTE: The UC1 board must have its 115 VAC power supply present when any of the (1-8) dip

switches are moved back to their original position for the fault code to clear.

1 9

LED 1 AMBER

LED 2 GREEN

LED 3 GREEN

LED 4 RED

LED 5 RED

ON

UC1 UNIVERSAL CONTROL CONNECTED TO AN OIL-FIRED FURNACE WITH A

HONEYWELL T87 OR EQUIVALENT NON-POWERED THERMOSTAT

XN

R

UNIVERSAL CONTROLLER

REMOVE JUMPER TO AVOID

AS APPLIANCE INTERLOCK VOLTAGE.

RED JUMPER POSITION MUST BE THE SAME

XL

J1J2

DRY

115V

24V

IMPORTANT:

BACKFEEDS OR SHORT

50/60 Hz

SUPPLY

115 VAC

NON-POWERED THERMOSTAT

F

F

T

T

D/N 9183047-1

PRIMARY CONTROL

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

OR EQUIVALENT

5 VDC BOARD-GENERATED

LEGEND:

115 VAC

DO NOT SUPPLY POWER!

POWER.

LOW VAC

HONEYWELL T87 OR EQUIVALENT

W

O

WHITE

ORANGE

B

BLACK

HONEYWELL

R8184 SERIES

IMPORTANT:

FACTORY-

WIRED

CIRCUITS.

1. IMPORTANT: Remove J1 & J2 Call Jumper on UC1 to avoid backfeeds or short circuits.

2. Connect T87 or Equivalent non-powered thermostat to A and B terminals on UC1.

3. Remove T T Jumper from R8184 or equivalent Primary Control.

4. Connect #3 on UC1 terminal block to T terminal of Primary Control.

5. Connect #4 on UC1 terminal block to remaining T terminal of Primary Control.

6. Make sure RED voltage jumper on UC1 is on DRY.

7. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

8. If not previously completed, connect ground from UC1 whip to Venter ground. Connect Black and White leads from UC1 whip

to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch. Prover Leads are not polarity sensitive.

NOTE: If burner safety control goes out on lockout, the Venter will continue to run as long as a call for heat is present.

Page 18

17

DRAFT CHECK, SAFETY INTERLOCK & COMBUSTION AIR TEST

The Power Venter Fan Proving Switch is designed to disable the appliance gas valve or burner motor upon Power Venter failure only!

It is not designed and cannot replace, regular vent system inspection, appliance servicing and combustion testing.

1. Close all doors and windows of the building. If the appliance is installed in a

utility room or closet, close the entrance door to this room. Close fireplace

dampers.

2. Turn on clothes dryer and all exhaust fans such as range hoods, bathroom

exhausts and whole house fans to maximum speeds. Do not operate a fan

used strictly for Summer exhausting.

3. Following the appliance manufacturer’s instructions, place the appliance in

operation, set thermostat for continuous operation.

4. Verify that Power Venter operates first, prior to burner ignition. Watch to make

sure burner lights off properly.

GAS

After allowing appliance(s) to operate for 15 minutes, follow the appliance manufacturers instructions to verify that the recommended

draft is present. In general, most gas appliances will operate safely with flue outlet draft levels from -0.02 to -0.05" W.C.. If the draft

is excessive, make necessary adjustments to the barometric control and/or follow the, “Power Venter Air Flow Damper Adjustment”

procedure outlined below. As a cross check, a candle or match can be held adjacent to the draft hood or barometric control to verify

flame/smoke is being drawn into, and not rolling out of edge of the relief opening, (See Diagram I). If exhaust gases are escaping

from the relief opening of the draft hood or barometric control, the equipment should not be operated until proper adjustments or

repairs are made to provide adequate draft levels.

OIL

After allowing equipment to operate for 15 minutes, make necessary adjustments to the primary air intake and barometric draft control

to comply with the manufacturer recommended over-fire draft and CO

2 requirements of the burner. In most cases, the over-fire draft

should be in a range of -.02” to -.04” W.C. If adjustments to the primary air intake and barometric draft control do not provide the

required over-fire draft, the Power Venter draft adjustment must be repositioned accordingly. Measure over-fire draft after repositioning Power Venter draft adjustment, (See Diagram J).

5. Next, turn on all other fuel-burning appliances within the same room so they will operate at their full input. Repeat Step 3 above,

checking the draft on each appliance.

POWER VENTER AIR FLOW DAMPER ADJUSTMENT

The Air Flow Damper Adjustment on the Power Venter is factory set for maximum air flow. Operating a properly sized Power Venter at

its maximum setting will assure that combustion gases are safely removed to the outside. If the Power Venter has excess venting

capacity than what is required for this application, operating the Power Venter with the air-flow adjustment at the maximum setting

may draw more dilution air than necessary.

The Air Flow Damper Adjustment may be set by use of a combustion analyzer, inclined manometer or draft gauge. Alternatively, the

damper adjustment can be set using a smoke candle or taper, as follows:

1. With all exhaust fans operating, air inlets closed and all appliances firing

(as instructed above), hold a lighted match or taper around the edge of the

relief opening of the draft hood(s) or barometric draft control, (See Diagram I).

2. Set Air Flow Adjustment by loosening locknut and turning damper rod

handle. CAUTION: HANDLE MAY BE HOT, use pliers to move handle.

Position of rod handle indicates the position of Air Flow Adjustment inside

housing, (See Diagram J).

3. Using pliers, move handle towards minimum draft setting until spillage is

detected at draft hood relief opening, then re-open Air Flow Adjustment just

enough to eliminate spillage.

4. Lock Air Flow Adjustment at desired setting by tightening locknut.

5. Return doors, windows, exhaust fans, fireplace dampers and appliances to their previous conditions of use.

COMBUSTION AIR

Adequate combustion air is vital for proper combustion and for safe venting. Likewise, for proper Power Venter performance, adequate combustion air must be available to the appliance. Many installers assume adequate combustion air is present, especially in

older homes. In some cases this is a false assumption, because many older homes have been made "tight" due to weatherization.

Size the combustion air opening(s) into the appliance room as outlined local or national codes. Tjernlund’s IN-FORCER

TM

Combustion

Air Intake Systems provide a convenient interlocked way to provide combustion air to the equipment room. When installing a Power

Venter it is not necessary to supply any more combustion air than normally required when conventional venting. Common symptoms

of inadequate combustion air include: Fan Proving Switch short cycling, odor present at end of burner cycle, outside air enters the

structure through the Power Venter during appliance off cycle.

DIAGRAM I

PROPER

DRAFT

ESTABLISHED

PROPER

DRAFT

ESTABLISHED

DIAGRAM J

Page 19

18

MAINTENANCE

1. The HSJ,1,2 motors are permanently lubricated and do not need to be oiled.

2. The end-user must semiannually inspect the Vent Hood and vent pipe for blockage, corrosion and leaks.

3. A vent system inspection must be performed annually by a qualified service agency. The inspection should include the operation

circuit check, safety interlock test, combustion air test and a visual inspection of the complete vent system for corrosion, blockage or leaks.

Any corrosion, blockage or leaks detected must be repaired or replaced immediately.

TROUBLESHOOTING

The following guide is intended to be used if a problem occurs during the use of the Venter and UC1. It may be necessary to measure voltage during

troubleshooting. Extreme caution must be exercised to prevent injury. If you are unable to determine the defective part with the use of this guide,

call your Tjernlund distributor or Tjernlund Products at 1-800-255-4208 for further assistance.

IMPORTANT: If the call for heat interlock signal or 115 VAC power is removed, the UC1 board will reset and any fault, if present, will be stored in

memory instead of displayed. See page 5, “Checking Memory for Last Fault Code”.

LED STATUS & FAULT INDICATORS

LED INDICATOR LIGHTS

LED #1 (Amber) Appliance call for heat.

LED #2 (Green) Safety circuit through P1 & P2 (Venter Fan Prover) is verified “Open” upon start-up. Indicates Venter prover is

closed during run cycle. Burner circuit is energized with contact closure from terminal 3 to 4.

LED #3 (Green) Power switched to Venter motor from L to MTR & M.

LED #4 (Red) Status / Fault indicator.

LED #5 (Red) 115 VAC power supplied to board. Also used as a status indicator.

LED STATUS INDICATORS

LED #4 & #5 (Red) Flashing Alternately = Venter in Pre-purge. (Pre-Purge options 0, 5, 20, 35 seconds)

LED #4 & #5 (Red) Flashing in Unison = Venter in Post-Purge. (Post-Purge options 0, 30 seconds or 1, 2, 4, 8, 16 minutes)

LED #4 Flashes Continuously* = Fan Prover opened for more than 10 seconds during burner cycle.

(Venter will run for 10 minutes, attempting to make Fan Prover)

LED FAULT INDICATORS

Fault conditions are indicated by counting the number of times LED #4 (Red) flashes.

LED #4 Flashes 2 Times Fan Prover was in electrically closed position prior to venter operation.

LED #4 Flashes 3 Times* Fan Prover does not close within 60 seconds after call for heat.

LED #4 Flashes 4 Times* Fan Prover did not re-close after 10 minutes of Venter operation.

LED #4 Flashes 5 Times* Fan Prover opened for more than 10 seconds during burner cycle but closed within 10 minutes.

* Investigate causes of Fan Prover not making, i.e; Firing burner at capacities or temperatures exceeding Venter limits, excessive

vent pipe runs, elbows directly on venter discharge, high winds, plugged / kinked Fan Prover sensing tube or a faulty Fan Prover.

SYMPTOM 1: VENTER OPERATES CONTINUOUSLY

Verify that Venter is not in post-purge mode which could last up to 16 minutes. A factory post-purge has been set for 2 minutes. LED #4 & #5 (Red)

will flash in unison during post-purge. A Venter pre-purge could also be set for up to 35 seconds. LED #4 & #5 (Red) will flash alternately during prepurge. See “Pre / Post-Purge Settings” on page 5.

Verify that LED #1 (Amber) is not lit.

Yes, LED #1 (Amber) is lit: Check interlock wiring. Confirm burner control(s) are functioning properly. UC1 control is receiving constant call for heat

signal.

LED #1 (Amber) is not lit: Replace UC1 circuit board part number 950-8804.

SYMPTOM 2: VENTER MOTOR DOES NOT OPERATE

Verify that UC1 control has power, LED #5 (Red) should be lit. Verify that LED# 4 (Red) is not flashing. See “LED Status & Fault Indicators” above if

flashing. Verify RED voltage selection jumper corresponds with interlock voltage (i.e 24V, 115V or “Dry”).

No: Check circuit breaker, disconnect switches and wiring. Confirm that Venter motor leads are connected to N & MTR terminals.

Yes, LED #5 (Red) is lit: Verify that the interlocked burner is calling for heat, LED #1 (Amber) should be lit.

No, LED #1 (Amber) is not lit: Verify interlock wiring and that thermostat/aquastat is adjusted to call for heat. Verify that the RED

voltage selection jumper is installed so that it matches the voltage of the interlocked burner.

Yes, LED #1 (Amber) is lit: Verify Prover safety circuit fault does not exist. See, “LED Status & Fault Indicators” above.

If faults exist check Prover P1 & P2 safety circuit.

If no faults exist, check for 115 VAC across terminals N and MTR.

Voltage present: Confirm Black and White leads from UC1 whip are securely fastened to Venter motor leads. If so, replace Venter motor.

No voltage present: Replace UC1 circuit board part number 950-8804.

IMPORTANT: Fault codes will automatically be displayed after a fault condition occurs. If the call for heat interlock signal or 115 VAC

power is removed, the UC1 board will reset and the fault will be stored in memory instead of displayed. Any new fault will replace

any previous fault. See page 5, “Checking Memory for Last Fault Code”.

Page 20

19

SYMPTOM 3: VENTER OPERATES, BUT BURNER DOES NOT

For any newly established call for heat the UC1 will run for 60 seconds to try to close the fan prover circuit (P1 to P2). If circuit can not be made within

60 seconds, LED #4 (Red) will flash 3 times, indicating a prover check circuit fault on UC1 start up. NOTE: The UC1 safety circuit and LED #4 (Red)

will be reset if the call for heat interlock signal or 115 VAC power is removed. If the fan prover makes on start up, but breaks for more than 10 seconds during the burner cycle, LED #4 will flash continuously indicating a prover circuit fault. The Venter will continue to run for 10 minutes to try to

make the prover circuit as long as a call for heat exists. If Prover does not make within 10 minutes, the UC1 will shut down and LED #4 (Red) will

flash 4 times indicating a prover circuit fault. Remove the call for heat and then reestablish to reset the UC1 prover safety circuit (P1 to P2) & LED #4

(Red).

Verify that LED #2 (Green) is lit.

Yes, LED #2 (Green) is lit: Verify that "call jumper" is connected from J1 to J2 on UC1 circuit board if using typical wiring where supply voltage from

terminal 1 is routed to terminal 3 through “call jumper” then to 4 when appliance interlock relay makes. With call for heat established, verify that wiring

is correct by measuring voltage between terminals 1 & 2 and 2 & 4 of UC1 terminal strip. Voltage should be the same in both cases, if not rewire per

appropriate diagram or confirm burner control(s) are functioning properly. NOTE: If a different voltage source is provided to terminal 3 which is

switched to terminal 4 or when using the A-B dry contacts, voltage measurements may not apply. For millivolt installations make sure system Limits

are reset and relight pilot.

No, LED #2 (Green) is not lit: Remove power from UC1 and push dip switch #9 up or “on” to deactivate Fan Prover status check. Remove P1 and

P2 prover leads off of Fan Prover switch and jumper together. Reestablish power and call for heat. After Venter pre-purge, if set (up to 35 seconds),

LED #2 (Green) should light.

No, LED #2 (Green) does not light: Replace UC1 circuit board, part number 950-8804.

Yes, LED #2 (Green) lights up: The fan proving switch may not be closing, wiring connections are incorrect/broken or burner control(s) are not functioning properly. With Venter running, verify that Venter performance is sufficient to close Fan Prover contacts by checking for continuity across switch.

IMPORTANT: After continuity check push dip switch #9 back down to “activate” Fan Prover status check. Replace Fan Prover leads from P1 and P2

back on Fan Proving switch.

No, continuity is not present: Confirm that burner is not firing at capacities or temperatures exceeding Venter limits. Check for excessive vent pipe

runs, elbows directly on venter discharge, high winds, plugged / kinked Fan Prover sensing tube or a faulty Fan Prover switch. If everything checks

out okay, replace fan prover.

Yes, continuity present: Recheck wiring and burner control(s).

HOW TO OBTAIN SERVICE ASSISTANCE

If you have any questions about your Venter or if it requires adjustment or repair, we suggest you contact your installer, contractor or service agency.

If you require technical information contact Tjernlund Products, Inc. at 1-800-255-4208 with the following information.

Model of the Venter the UC1 is interlocked with as shown on the label attached to Venter.

Name and address of installer and any service agency who performed work on Venter.

Date of original installation and dates any service work was performed.

Details of the problem as you can best describe them.

LIMITED PARTS WARRANTY AND CLAIM PROCEDURE

Tjernlund Products, Inc. warrants the components of the Venter and UC1 for 1 year from date of installation. This warranty covers defects in material

and workmanship. This warranty does not cover normal maintenance, transportation or installation charges for replacement parts or any other service

calls or repairs. This warranty DOES NOT cover the complete Venter if it is operative, except for the defective part.

1.) Follow troubleshooting guide to determine defective component. If unable to determine faulty component, contact your Tjernlund distributor or

Tjernlund Products Technical Customer Service Department at 1-800-255-4208 for troubleshooting assistance.

2.) After the faulty component is determined, return it to your Tjernlund distributor for replacement. Please include Venter date code component was

taken from. The date code is located on the Electrical Box coverplate. If the date code is older than 1 year, you will need to provide a copy of the

original installation receipt to your distributor. Credit or replacement will only be issued to a Tjernlund distributor after the defective part has been

returned prepaid to Tjernlund and verified defective.

WHAT IS NOT COVERED

Product installed contrary to our installation instructions, altered, neglected, misused or wired incorrectly.

Product that has been damaged by a malfunctioning or maladjusted burner.

Any freight charges related to the return of the defective part.

Any labor charges related to evaluating and replacing the defective part

MODEL HSJ

DESCRIPTION PART NUMBER

MOTOR KIT 950-1020

WHEEL KIT 950-1010

FAN PROVER KIT 950-1030

UC1 CIRCUIT BOARD 950-8804

MODEL HS2

DESCRIPTION PART NUMBER

MOTOR KIT W/WHEEL 950-1021

WHEEL KIT 3/8” BORE 950-1012

FAN PROVER KIT 950-1031

UC1 CIRCUIT BOARD 950-8804

MODEL HS1

DESCRIPTION PART NUMBER

MOTOR KIT 950-1020

WHEEL KIT 950-1011

FAN PROVER KIT 950-1030

UC1 CIRCUIT BOARD 950-8804

TJERNLUND ONE YEAR LIMITED WARRANTY