Page 1

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

FOR NATURAL GAS OR LP

REV. 2 9/97

MODEL

HS-3C

OWNER INSTRUCTIONS, DO NOT DESTROY

!

Recognize this symbol as an indication of important Safety Information!

NOTE: FLUE GAS TEMPERATURES MUST NOT EXCEED 285OC

(550OF)AT VENT SYSTEM INLET.

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR PROPER INSTALLATION, ADJUSTMENT AND

OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRI CAL SHOCK, CARBON MONOXIDE POISONING, EXPLOSION, PERSONAL

INJURY OR PROPERTY DAMAGE.

DO NOT DESTROY. PLEASE READ CAREFULLY AND KEEP

IN A SAFE PLACE ON JOB SITE FOR FUTURE REFERENCE.

Copyright © 1997, Tjernlund Products, Inc. All rights reserved. P/N 8504002

Page 2

TABLE OF CONTENTS

PAGE(S)

HS-3C DESCRIPTION ................................................................................................................................................. 1

SPECIFICATIONS ......................................................................................................................................................... 1

HS-3C CAPACITY.......................................................................................................................................................... 1

RESTRICTIONS............................................................................................................................................................. 2

INSTALLER CAUTIONS ............................................................................................................................................... 2

VENT HOOD LOCATION ............................................................................................................................................. 3

POWER VENTER MOUNTING .................................................................................................................................... 4

VENT PIPE INSTALLATION ..........................................................................................................................................4

FAN PROVING SWITCH INSTALLATION .................................................................................................................... 5

WIRING .....................................................................................................................................................................5 - 8

ELECTRICAL SPECIFICATIONS.................................................................................................................... 5

WIRING WITH SINGLE APPLIANCE........................................................................................................... 6-7

OPERATION SEQUENCE .............................................................................................................................. 8

DRAFT ADJUSTMENT ................................................................................................................................................. 8

SAFETY INTERLOCK TEST ...........................................................................................................................................8

MAINTENANCE ............................................................................................................................................................ 8

HOW TO OBTAIN SERVICE & LIMITED WARRANTY ..............................................................................................8-9

REPLACEMENT PARTS ............................................................................................................................................... 9

Tjernlund Products welcomes your comments and questions. Call us at 800-255-4208, Fax 612-426-9547 or write to:

Customer Service, Tjernlund Products, Inc., 1601 Ninth Street, White Bear Lake, MN 55110-6794.

DESCRIPTION

The Tjernlund Power Venter model HS-3C is designed to Side Wall or Vertically vent Natural and LP Gas appliances. The HS-3C is

supplied with a Fan Proving Switch which will disable the gas valve if a venting malfunction should occur.

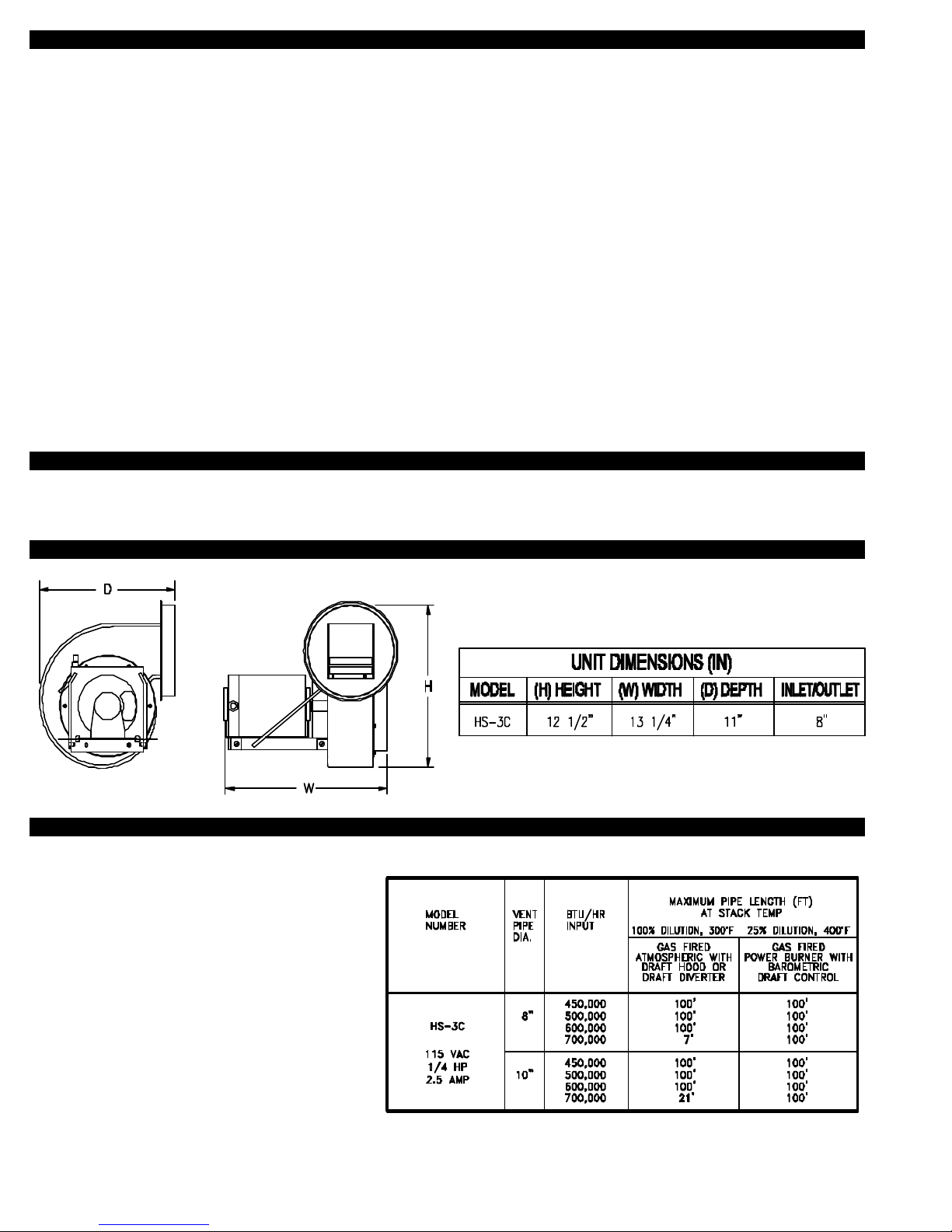

SPECIFICATIONS

CAPACITY

HS-3C CAPACITY

The installer must verify that the Power Venter is sized

properly using the capacity table to the right. The

installer may reduce the vent pipe diameter to the size

shown in the selection table immediately after the draft

hood, draft diverter or barometric draft control. The

vent pipe length shown includes all equivalent vent pipe

before and after the Power Venter. To calculate the

equivalent vent pipe length, add the straight vent pipe

plus 10 feet for every 90 degree elbow and 5 feet for

every 45 degree elbow.

If venting multiple appliances with one Power Venter,

the total combined BTU/hr. input of all appliances must

be added together to size the Power Venter.

IMPORTANT: Elbows placed directly after discharge on Power Venter may cause erratic operation of Fan Prover. If elbows are

necessary on discharge, allow for a straight section of pipe 3 times the vent diameter being used before installing an elbow.

For example, if using 8” diameter pipe, allow for 24” of straight pipe before using an elbow.

1

Page 3

INSTALLATION RESTRICTIONS

Failure to install, maintain and/or operate the Power Venter in accordance with manufacturer's instructions may result in conditions

which can produce bodily injury and property damage.

The Power Venter must be installed by a qualified installer in accordance with these instructions and all local codes or in their

absence in accordance with the latest edition of The Natural Gas Installation Code (CAN/CGA-B149.1) & The Propane Installation

Code (CAN/CGA-B149.2). Improper installation can create a hazardous condition such as an explosion, fire, electrical shock or car -

bon monoxide poisoning resulting in property damage, personal injury or death.

“Qualified Installer” shall mean (an individual properly trained and licensed) in accordance with local codes or, in their absence, in

accordance with The National Building Code of Canada & The Canadian Electrical Code (CSA Std C22.1).

Disconnect the power supply when making wiring connections or when working around the fan wheel and motor. Failure to do so can

result in electrical shock, personal injury, death or property damage.

1. The Power Venter may only be installed on Natural Gas or LP Gas appliances.

2. The Power Venter may not be installed on incinerators, incinerating toilets, condensing-type appliances or solid-fuel burning

appliances.

3. The Power Venter shall not be installed on an appliance with an automatic valve having a manual opener unless the manual

opener has been rendered inoperative or the automatic valve has been replaced with a valve not equipped with a manual opener.

4. The Power Venter may only be installed on appliance equipped with a draft hood, draft diverter or barometric draft control.

5. The Power Venter shall not be installed where the flue gas temperature exceeds 285oC (550oF). at the Power Venter inlet. Flue

gas temperature verification:

A) Consult appliance manufacturer for flue gas temperature after dilution by the draft hood, draft diverter or barometric draft control.

B) Measure flue gas temperature at the Power Venter inlet after installation. Temperature should be measured after appliance and

Power Venter have operated for at least 15 minutes, allowing the flue gas temperature to stabilize.

6. The Power Venter must be mounted so that the shaft of the motor remains horizontal to prevent motor bearing wear.

7. Power Venter electrical box must be mounted with the Fan Proving Switch in a vertical position.

8. Ambient temperature surrounding Power Venter must not exceed 40oC (104o F).

4

F444444

444444444444444 CAUTIONS

INSTALLER CAUTIONS

1. Plan the vent system so that the code required clearances are maintained from plumbing and wiring.

2. To prevent personal injury and equipment damage, disconnect power supply when working on Power Venter.

3. Make certain the power supply is adequate for Power Venter motor requirements. Do not add the Power Venter to a circuit where

the total load is unknown.

4. The installer must verify that the appliance on which the Power Venter will be installed is in a safe operating condition. Consult

appliance manufacturer’s Instructions for details.

5. Plan the vent system layout so that the Power Venter is as close to the point of termination as possible. Vent pipe between the

Power Venter and Vent Hood is acceptable. However, all vent pipe connections after the Power Venter discharge will be under

positive pressure during operation and must be sealed with high-temperature caulk or aluminum vent pipe tape to prevent flue gas

leakage into the structure.

2

Page 4

VENT HOOD LOCATION

NOTE: Termination of a Side Wall Vent System with a device other than the Tjernlund VH1 Series Vent Hood could affect system

performance and result in a possible safety hazard. Consult Vent Hood instructions for complete installation details.

If possible, locate the Vent Hood on a wall that does not face the direction of prevailing winds. This will diminish the possi bility of appliance interruption during periods of extreme winds.

CODE REQUIREMENTS

• A venting system shall not terminate underneath a veranda, porch, or deck, or above a paved sidewalk or a paved driveway that is

located between two buildings, and that serves both buildings.

• The exit terminals of mechanical draft systems shall not be less than 2.13m (7ft) above grade when located adjacent to a paved

sidewalk or driveway.

• A venting system shall not direct flue gases towards brickwork, siding, or other construction, in such a manner that may cause

damage from heat or condensate from the flue gases.

• A vent system shall not direct flue gases so as to jeopardize people, overheat combustible structures, or enter buildings.

A venting system shall not terminate within 1.8 m (6ft) of the following:

• A window, door or mechanical air supply inlet of any building, including soffit openings

• A gas service regulator vent outlet

• A combustion air inlet

• A property line

• A direction facing combustible materials or openings of surrounding buildings

A venting system shall not terminate within 1m (3ft) of the following:

• Above a gas meter/regulator assembly within 1m (3ft) horizontally of the vertical centreline of the regulator

• A oil tank or an oil tankfill inlet

• The inside corner of an L-shaped structure

A venting system shall not terminate within .3m (1ft) of the following:

• Above grade level or any surface that may support snow, ice, or debris

Page 5

POWER VENTER MOUNTING

The installer must supply plumber’s strap or 1/4” threaded rod with nuts

and washers for mounting. The Power Venter may be mounted in any

position as long as the shaft of the motor remains horizontal. The Power

Venter housing is single wall, 15.2 CM (6”) must be maintained from all

combustible materials. It is recommended that the Power Venter be

mounted as close as possible to the point of termination.

VENT PIPE INSTALLATION

If Installing the Power Venter on an appliance not equipped with a draft hood or draft diverter (e.g. Power Burners, Induced Draft), a

barometric draft control must be added. The barometric draft control must be the same size as the flue outlet and installed as close

as possible to the appliance. After the draft hood, draft diverter or barometric draft control, a tapered reducer should be installed to

reduce the flue to the size shown in the capacity table on page 1 of these instructions. After the tapered reducer, install the appropriate type of vent pipe to the inlet of the Power Venter. The vent pipe chosen must be in compliance with local codes. The Power

Venter inlet and outlet are designed to accept single wall vent pipe. If using vent pipe other than single wall, the installer must supply

adapters to connect to the Power Venter. While it is recommended that the Power Venter be mounted at the point of termination, it is

acceptable to install vent pipe between the outlet of the Power Venter and the point of termination. The Installer must seal all vent

pipe connections after the Power Venter with high-temperature caulk or aluminum vent pipe tape to prevent flue gas leakage during

operation. The size of the vent pipe between the Power Venter and point of termination should be the same size shown on the selection table. Support the vent pipe as recommended by it’s manufacturer. Examples of proper vent pipe installation are shown below.

IMPORTANT: Elbows placed directly after discharge on Power Venter may cause erratic operation of Fan Prover. If elbows are

necessary on discharge, allow for a straight section of pipe 3 times the vent diameter being used before installing an elbow.

4

Page 6

FAN PROVINGSWITCH INSTALLATION

As viewed from the opposite end of the shaft, the motor should rotate clockwise.

NOTE: It is important that the electrical box is mounted with

the Fan Proving Switch in a vertical position.

1. Mount supplied electrical box to a flat surface within 2 feet

of the Power Venter with Proving Switch in a vertical

position.

2. Connect the 1/4” aluminum tubing from the Fan Proving

Switch to the Power Venter housing using supplied fittings.

The factory calibrated sensing tube length and compression

fittings are critical for proper operation of the Fan Proving

Switch. If it is necessary to alter the sensing tube length,

ONLY trim sensing tube portion that is on the exterior of the

housing. DO NOT trim the sensing tube portion that will be

mounted in the interior of the housing. No attempts should

be made to substitute the specified materials. See Fan

Proving Switch installation diagram.

All wiring from the Power Venter to the appliance must be in compliance with the local codes or in their absence, The Canadian

Electrical Code (CSA Std C22.1).

All wiring from the Power Venter to the appliance must be appropriate class 1 wiring as follows: Installed in rigid metal conduit, inter mediate metal conduit, rigid non-metallic conduit, electrical metallic tubing, Type MI Cable, MC cable or be otherwise suitably protected

from physical damage.

NOTE:

WIRING

ELECTRICAL SPECIFICATIONS

5

Page 7

MODEL HS-3C WIRING WITH SINGLE APPLIANCE

The HS-3C Power Venter is equipped with 2 relays. One is used to activate the Power Venter while the other is used to isolate the

Fan Proving Switch from the load of the appliance. The relays and Fan Proving Switch are factory wired for easy installation. The

installer needs to complete 3 steps to wire the Power Venter as noted below:

1. Route the metal conduit from the electrical box to the Power Venter motor and connect the Black, White and Ground wires to the

motor.

2. Connect the Red, Blue and Orange wires in the electrical box to the appliance.

3. Supply 115 VAC to the input wires in the electrical box.

NOTE: The HS-3C as viewed from the opposite end of the shaft should rotate clockwise.

FACTORY WIRING OF HS-3C ELECTRICAL BOX

O

LADDER DIAGRAM OF HS-3C

6

Page 8

MODELS HS-3C CONNECTION DIAGRAMS WITH SINGLE APPLIANCE

The diagrams below represent common ways in which the HS-3C Power Venter is interlocked to 24V controlled appliances. Variations

of these diagrams are acceptable as long as the Fan Proving Switch isolation circuit is wired to disable the gas valve if a venting mal function should occur.

HS-3C CONNECTED TO APPLIANCE WITH SPARK IGNITION

HS-3C CONNECTED TO A BOILER

7

Page 9

SEQUENCE OF OPERATION FOR HS-3C ON A SINGLE APPLIANCE

The following sequence of operation gives guidance as to how the Power Venter should operate with the appliance.

1. The call for heat will be routed through the Motor Relay and to one side of the Fan Proving Switch. The Power Venter motor is

energized.

2. When the Power Venter has achieved full RPM and maximum draft has been established, the Fan Proving Switch will close

allowing the 24V signal to energize the Isolation Relay coil.

3. When the Isolation Relay contacts close, the 24V signal will then be allowed to reach the gas valve.

DRAFT ADJUSTMENT

DRAFT ADJUSTMENT FOR GAS APPLIANCES EQUIPPED W ITH A DRAFT HOOD OR DRAFT DIVERTER

1. With the appliance(s) and Power Venter operating for at least 15 minutes, hold a taper, cigarette or other smoke producing device

at the draft hood or draft diverter.

2. Determine that the smoke is being drawn into the vent system.

3. If the draft appears to be excessive, the damper on the Power Venter may be adjusted to reduce the Power Venter’s performance

as long as the smoke is still being drawn into the draft hood after damper adjustment.

DRAFT ADJUSTMENT FOR GAS APPLIANCES EQUIPPED WITH A BAROMETRIC DRAFT CONTROL

1. With the appliance(s) and Power Venter operating for at least 15 minutes, insert a draft gauge into the vent pipe between the

barometric draft control and the appliance flue outlet.

2. Make necessary draft adjustments with the barometric draft control, appliance burner air intake and the damper located on the

outlet of the Power Venter until the appliance manufacturer’s recommended draft is present.

SAFETY INTERLOCK TEST

1. Adjust the appliance thermostat(s) or aquastat(s) to call for heat.

2. Determine that the Power Venter operates before the gas valve becomes energized.

3. With the appliance(s) and Power Venter operating, disrupt power to the Power Venter and determine that the appliance gas valve

shuts off.

DONOT OPERATE AN APPLIANCE THAT DOES NOTSHUTOFF WITH THE VENTER DISABLED.

MAINTENANCE

1. Oil every six months with 2 drops of S.A.E. #20. The oil ports are located at both ends of the motor.

2. A vent pipe inspection must be performed annually. The inspection should include checking all vent pipe and connections for

blockage and leaks. A safety interlock test should also be performed.

HOW TO OBTAIN SERVICE ASSISTANCE

1. If you have any questions about your Power Venter or if it requires adjustment, repair or routine maintenance, we suggest that

you contact your installer, contractor or service agency.

2. If you require technical information contact Tjernlund Products, Inc. at 1-800-255-4208.

When contacting Tjernlund Products, Inc., please have the following information available:

1. Model number of the Power Venter

2. Name and address of installer and service agency

3. Date of original installation and dates any service work was performed

4. Details of the problem

8

Page 10

LIMITED PARTS WARRANTY AND CLAIM PROCEDURE

Tjernlund Products, Inc. warrants the components of its products for one year from date of installation. This warranty covers defects

in material and workmanship. This warranty does not cover normal maintenance, transportation or installation charges for replacement parts or any other service calls or repairs. Products that are tampered with, damaged, or defective due to malfunctioning appliances are not covered under this warranty. This warranty DOES NOT cover the complete Power Venter if it is operative, except for

the defective part.

Tjernlund Products, Inc. will issue credit to the original distributor or provide a free part to replace one that becomes defective during the

one year warranty period. If the part is over 18 months old, proof of date of the installation in the form of the contractor sales/installation receipt is necessary to prove the unit has been in service for under one year. All receipts should include the date code of the Power

Venter to ensure that the defective component corresponds with the complete unit. This will help preclude possible credit refusal.

1.) Determine defective component. If unable to determine faulty component, contact your Tjernlund distributor or Tjernlund Products

Technical Customer Service Department at 1-800-255-4208 for troubleshooting assistance.

2.) After the faulty component is determined, return it to your Tjernlund distributor for replacement. Please include Power Venter date

code component was taken from. The date code is located on the Electrical Box cover plate. If Power Venter date code is older

than 18 months you will need to provide a copy of the original installation receipt to your distributor. Credit or replacement will only

be issued to a Tjernlund distributor after the defective part has been returned prepaid to Tjernlund.

COVERED PARTS

Motor Proving Switch Relays Wheel Housing

WHAT IS NOT COVERED

Product installed contrary to our installation instructions

Product that has been altered, neglected or misused

Product that has been wired incorrectly

Product that has been damaged by a malfunctioning or mistuned burner

Any freight charges related to the return of the defective part

Any labor charges related to evaluating and replacing the defective part

TJERNLUND LIMITED ONE YEAR WARRANTY

Tjernlund Products, Inc. warrants to the original purchaser of this product that the product will be free from defects due to faulty material or workmanship for a

period of (1) year from the date of original purchase or delivery to the original purchaser, whichever is earlier. Remedies under this warranty are limited to

repairing or replacing, at our option, any product which shall, within the above stated warranty period, be returned to Tjernlund Products, Inc. at the address

listed below, postage prepaid. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF, AND TJERNLUND

PRODUCTS, INC. EXPRESSLY DISCLAIMS LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF THIS PRODUCT. THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES AND NO AGENT IS AUTHORIZED TO ASSUME FOR US ANY LIABILITY

ADDITIONAL TO THOSE SET FORTH IN THIS LIMITED WARRANTY. IMPLIED WARRANTIES ARE LIMITED TO THE STATED DURATION OF THIS LIMITED WARRANTY. Some states do not allow limitation on how long an implied warranty lasts, so that limitation may not apply to you. In addition, some states

do not allow the exclusion or limitation of incidental or consequential damages, so that above limitation or exclusion may not apply to you. This warranty gives

you specific legal rights and you may also have other rights which may vary from State to State. Send all inquiries regarding warranty work to Tjernlund

Products, Inc. 1601 9th Street, White Bear Lake, MN 55110-6794. Phone (612) 426-2993 • (800) 255-4208 • Fax (612) 426-9547.

REPLACEMENT PARTS

MODEL HS-3C

MOTOR KIT 950-1022

WHEEL KIT 950-1013

FAN PROVER KIT 950-1032

HOUSING 950-1014

ISOLATION OR 950-1040

MOTOR RELAY

9

Loading...

Loading...