Page 1

C TRANSMISSION/TRANSAXLE

A

B

SECTION

AUTOMATIC TRANSMISSION

CONTENTS

INDEX FOR DTC ........................................................ 5

Alphabetical Index .................................................... 5

DTC No. Index ......................................................... 6

PRECAUTIONS .......................................................... 7

Precautions for Supplementa l Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 7

Precautions for On Board Diagnostic (OBD) System

of A/T and Engine .................................................... 7

Precautions .............................................................. 8

Service Notice or Precautions .................................. 9

Wiring Diagrams and Trouble Diagnosis .................. 9

PREPARATION ..................................... .................... 10

Special Service Tools ............................................. 10

Commercial Service Tools ...................................... 12

A/T FLUID ................................................................. 13

Changing A/T Fluid ..................... ....... ...... ....... ....... 13

Checking A/T Fluid ................................................. 13

A/T Fluid Cooler Cleaning ...................................... 15

A/T CONTROL SYSTEM .......................................... 18

Cross-Sectional View (2WD models) ..................... 18

Cross-Sectional View (4WD models) ..................... 19

Shift Mechanism ..................................................... 20

TCM Function ........... ...... ....... ...... ....... ...... ....... ....... 33

CAN Communication .............................................. 35

Input/Output Signal of TCM .................................... 35

Line Pressure Control ........... ...... ....... ...... ....... ....... 36

Shift Control ........................................................... 37

Lock-Up Control ..................................................... 38

Engine Brake Control ............................................. 40

Control Valve ............ ...... ....... ...... ........................... 40

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 42

Introduction ............................................................ 42

OBD-II Function for A/T System ............................. 42

One or Two Trip Detection Logic of OBD-II ............ 42

OBD-II Diagnostic Trouble Code (DTC) ................. 42

Malfunction Indicator Lamp (MIL) ........................... 45

TROUBLE DIAGNOSIS ............................................ 46

DTC Inspection Priority Chart ................................ 46

Fail-Safe ................................ ................................. 46

How T o Perform Tr ouble Diagnosis For Quick and

Accurate Repair ......................................................48

A/T Electrical Parts Location ..................................53

Circuit Diagram .......................................................54

Wiring Diagram — AT — ........................................ 55

Inspections Before Trouble Diagnosis .................... 62

Check Before Engine is Started .............................. 66

Check at Idle ...........................................................66

Cruise Test - Part 1 .................................................67

Cruise Test - Part 2 .................................................69

Cruise Test - Part 3 .................................................70

Vehicle Speed When Shifting Gears ......................72

Vehicle Speed When Performing and Releasing

Complete Lock-up .................................................. 72

Vehicle Speed When Performing and Releasing

Slip Lock-up ............................................................72

Symptom Chart .......................................................73

TCM Input/Output Signal Reference Values ........... 94

CONSULT-II .............................. ...... ............. ........... 95

DTC U1000 CAN COMMUNICATION LINE ............107

Description ................... ...... ....... ...... ......................107

On Board Diagnosis Logic ....................................107

Possible Cause .....................................................107

DTC Confirmation Procedure ...............................107

Diagnostic Procedure ...........................................108

DTC P0615 START SIGNAL CIRCUIT ...................109

Description ................... ...... ....... ...... ......................109

CONSULT-II Reference Value ............... ...... ....... ..109

On Board Diagnosis Logic ....................................109

Possible Cause .....................................................109

DTC Confirmation Procedure ...............................109

Diagnostic Procedure ...........................................110

DTC P0700 TCM .....................................................112

Description ................... ...... ....... ...... ......................112

On Board Diagnosis Logic ....................................112

Possible Cause .....................................................112

DTC Confirmation Procedure ...............................112

Diagnostic Procedure ...........................................112

DTC P0705 P ARK/NEUTRAL POSITION SWITCH .113

Description ................... ...... ....... ...... ......................113

AT

D

E

F

G

H

I

J

K

L

M

Revision: April 2004 2004 Titan

AT-1

Page 2

CONSULT-II Reference Value ..............................113

On Board Diagnosis Logic ....................................113

Possible Cause .....................................................113

DTC Confirmation Procedure ................... ....... .....113

Diagnostic Procedure ...........................................114

DTC P0720 VEHICLE SPEED SENSOR A/T (REV-

OLUTION SENSOR) ...............................................116

Description ................ .......................... ..................116

CONSULT-II Reference Value ..............................116

On Board Diagnosis Logic ....................................116

Possible Cause .....................................................116

DTC Confirmation Procedure ................... ....... .....116

Diagnostic Procedure ...........................................117

DTC P0725 ENGINE SPEED SIGNAL ...................119

Description ................ .......................... ..................119

CONSULT-II Reference Value ..............................119

On Board Diagnosis Logic ....................................119

Possible Cause .....................................................119

DTC Confirmation Procedure ................... ....... .....119

Diagnostic Procedure ...........................................119

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE ............................... ...... ....... .....121

Description ................ .......................... ..................121

CONSULT-II Reference Value ..............................121

On Board Diagnosis Logic ....................................121

Possible Cause .....................................................121

DTC Confirmation Procedure ................... ....... .....121

Diagnostic Procedure ...........................................122

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) .124

Description ................ .......................... ..................124

CONSULT-II Reference Value ..............................124

On Board Diagnosis Logic ....................................124

Possible Cause .....................................................124

DTC Confirmation Procedure ................... ....... .....124

Diagnostic Procedure ...........................................125

DTC P0745 LINE PRE SSU RE SO LENO ID VALVE .127

Description ................ .......................... ..................127

CONSULT-II Reference Value ..............................127

On Board Diagnosis Logic ....................................127

Possible Cause .....................................................127

DTC Confirmation Procedure ................... ....... .....127

Diagnostic Procedure ...........................................128

DTC P1702 TRANSMISSION CONTROL MODULE

(RAM) ......................................................................130

Description ................ .......................... ..................130

On Board Diagnosis Logic ....................................130

Possible Cause .....................................................130

DTC Confirmation Procedure ................... ....... .....130

Diagnostic Procedure ...........................................130

DTC P1703 TRANSMISSION CONTROL MODULE

(ROM) ....................................... ...............................131

Description ................ .......................... ..................131

On Board Diagnosis Logic ....................................131

Possible Cause .....................................................131

DTC Confirmation Procedure ................... ....... .....131

Diagnostic Procedure ...........................................131

DTC P1705 THROTTLE POSITION SENSOR .......132

Description ................ .......................... ..................132

CONSULT-II Reference Value ..............................132

On Board Diagnosis Logic ....................................132

Possible Cause .....................................................132

DTC Confirmation Procedure ................................132

Diagnostic Procedure ............................................132

DTC P1710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT ..................................................................134

Description ............................................................134

CONSULT-II Reference Value ...............................134

On Board Diagnosis Logic ....................................134

Possible Cause .....................................................134

DTC Confirmation Procedure ................................134

Diagnostic Procedure ............................................135

Component Inspection ..........................................136

DTC P1716 TURBINE REVOLUTION SENSOR ....137

Description ............................................................137

CONSULT-II Reference Value ...............................137

On Board Diagnosis Logic ....................................137

Possible Cause .....................................................137

DTC Confirmation Procedure ................................137

Diagnostic Procedure ............................................138

DTC P1721 VEHICLE SPEED SENSOR MTR .......140

Description ............................................................140

CONSULT-II Reference Value ...............................140

On Board Diagnosis Logic ....................................140

Possible Cause .....................................................140

DTC Confirmation Procedure ................................140

Diagnostic Procedure ............................................141

DTC P1730 A/T INTERLOCK .................................142

Description ............................................................142

On Board Diagnosis Logic ....................................142

Possible Cause .....................................................142

DTC Confirmation Procedure ................................142

Judgement of A/T Interlock ...................................142

Diagnostic Procedure ............................................143

DTC P1731 A/T 1ST ENGINE BRAKING ...............145

Description ............................................................145

CONSULT-II Reference Value ...............................145

On Board Diagnosis Logic ....................................145

Possible Cause .....................................................145

DTC Confirmation Procedure ................................145

Diagnostic Procedure ............................................146

DTC P1752 INPUT CLUTCH SOLENOID VALVE ..148

Description ............................................................148

CONSULT-II Reference Value ...............................148

On Board Diagnosis Logic ....................................148

Possible Cause .....................................................148

DTC Confirmation Procedure ................................148

Diagnostic Procedure ............................................149

DTC P1754 INPUT CLUTCH SOLENOID VALVE

FUNCTION ..............................................................151

Description ............................................................151

CONSULT-II Reference Value ...............................151

On Board Diagnosis Logic ....................................151

Possible Cause .....................................................151

DTC Confirmation Procedure ................................151

Diagnostic Procedure ............................................152

DTC P1757 FRONT BRAKE SOLENOID VALVE ...154

Description ............................................................154

CONSULT-II Reference Value ...............................154

Revision: April 2004 2004 Titan

AT-2

Page 3

On Board Diagnosis Logic ................................... 154

Possible Cause .................................................... 154

DTC Confirmation Procedure ............................... 154

Diagnostic Procedure ........................................... 155

DTC P1759 FRONT BRAKE SOLENOID VALVE

FUNCTION ........................ .......................... ............ 157

Description ........................................................... 157

CONSULT-II Reference Value .............................. 157

On Board Diagnosis Logic ................................... 157

Possible Cause .................................................... 157

DTC Confirmation Procedure ............................... 157

Diagnostic Procedure ........................................... 158

DTC P1762 DIRECT CLUTCH SOLENOID VALVE . 160

Description ........................................................... 160

CONSULT-II Reference Value .............................. 160

On Board Diagnosis Logic ................................... 160

Possible Cause .................................................... 160

DTC Confirmation Procedure ............................... 160

Diagnostic Procedure ........................................... 161

DTC P1764 DIRECT CLUTCH SOLENOID VALVE

FUNCTION ........................ .......................... ............ 163

Description ........................................................... 163

CONSULT-II Reference Value .............................. 163

On Board Diagnosis Logic ................................... 163

Possible Cause .................................................... 163

DTC Confirmation Procedure ............................... 163

Diagnostic Procedure ........................................... 164

DTC P1767 HIGH AND LOW REVERSE CLUTCH

SOLENOID VALVE ................................................. 166

Description ........................................................... 166

CONSULT-II Reference Value .............................. 166

On Board Diagnosis Logic ................................... 166

Possible Cause .................................................... 166

DTC Confirmation Procedure ............................... 166

Diagnostic Procedure ........................................... 167

DTC P1769 HIGH AND LOW REVERSE CLUTCH

SOLENOID VALVE FUNCTION ............................. 169

Description ........................................................... 169

CONSULT-II Reference Value .............................. 169

On Board Diagnosis Logic ................................... 169

Possible Cause .................................................... 169

DTC Confirmation Procedure ............................... 169

Diagnostic Procedure ........................................... 170

DTC P1772 LOW COAST BRAKE SOLENOID

VALVE ............................................ ......................... 172

Description ........................................................... 172

CONSULT-II Reference Value .............................. 172

On Board Diagnosis Logic ................................... 172

Possible Cause .................................................... 172

DTC Confirmation Procedure ............................... 172

Diagnostic Procedure ........................................... 173

DTC P1774 LOW COAST BRAKE SOLENOID

VALVE FUNCTION .................. ...... ....... ...... ....... ..... 175

Description ........................................................... 175

CONSULT-II Reference Value .............................. 175

On Board Diagnosis Logic ................................... 175

Possible Cause .................................................... 175

DTC Confirmation Procedure ............................... 175

Diagnostic Procedure ........................................... 176

DTC P1815 MANUAL MODE SWITCH ..................178

Description ................... ...... ....... ...... ......................178

CONSULT-II Reference Value in Data Monitor Mode

.178

On Board Diagnosis Logic ....................................178

Possible Cause .....................................................178

DTC Confirmation Procedure ...............................178

Wiring Diagram .....................................................179

Diagnostic Procedure ...........................................180

Component Inspection ..........................................181

Position Indicator Lamp ............................... ....... ..181

DTC P1841 ATF PRESSURE SWITCH 1 ...............183

Description ................... ...... ....... ...... ......................183

CONSULT-II Reference Value ............... ...... ....... ..183

On Board Diagnosis Logic ....................................183

Possible Cause .....................................................183

DTC Confirmation Procedure ...............................183

Diagnostic Procedure ...........................................184

DTC P1843 ATF PRESSURE SWITCH 3 ...............186

Description ................... ...... ....... ...... ......................186

CONSULT-II Reference Value ............... ...... ....... ..186

On Board Diagnosis Logic ....................................186

Possible Cause .....................................................186

DTC Confirmation Procedure ...............................186

Diagnostic Procedure ...........................................187

DTC P1845 ATF PRESSURE SWITCH 5 ...............189

Description ................... ...... ....... ...... ......................189

CONSULT-II Reference Value ............... ...... ....... ..189

On Board Diagnosis Logic ....................................189

Possible Cause .....................................................189

DTC Confirmation Procedure ...............................189

Diagnostic Procedure ...........................................190

DTC P1846 ATF PRESSURE SWITCH 6 ...............192

Description ................... ...... ....... ...... ......................192

CONSULT-II Reference Value ............... ...... ....... ..192

On Board Diagnosis Logic ....................................192

Possible Cause .....................................................192

DTC Confirmation Procedure ...............................192

Diagnostic Procedure ...........................................193

TOW MODE SWITCH .............................................195

Description ................... ...... ....... ...... ......................195

Diagnostic Procedure ...........................................195

CLOSED THROTTLE POSITION AND WIDE OPEN

THROTTLE POSITION CIRCUIT .......................... ..197

CONSULT-II Reference Value ............... ...... ....... ..197

Diagnostic Procedure ...........................................197

BRAKE SIGNAL CIRCUIT ................ ....... ...... .........198

CONSULT-II Reference Value ............... ...... ....... ..198

Diagnostic Procedure ...........................................198

TROUBLE DIAGNOSIS FOR SYMPTOMS ............199

AT CHECK Indicator Lamp does not come on .....199

Engine Cannot Be Started In “P” or “N” Position ..200

In “P” Position, Vehicle Moves When Pushed ......201

In “N” Position, Vehicle Moves ..............................202

Large Shock (“N” to “D” Position) .........................203

Vehicle Does Not Creep Backward In “R” Position .206

Vehicle Does Not Creep Forward In “D” Position . 209

Vehicle Cannot Be Started From D

A/T Does Not Shift: D

1 → D2 ....................... .........214

1 .....................211

A

B

AT

D

E

F

G

H

I

J

K

L

M

Revision: April 2004 2004 Titan

AT-3

Page 4

A/T Does Not Shift: D

A/T Does Not Shift: D

A/T Does Not Shift: D

2 → D3 ........................... .....216

3 → D4 ........................... .....218

4 → D5 ........................... .....221

A/T Does Not Perform Lock-up ............................223

A/T Does Not Hold Lock-up Condition ..................225

Lock-up Is Not Released ......................................227

Engine Speed Does Not Return To Idle ................228

Cannot Be Changed to Manual Mode (Column Shift)

.229

A/T Does Not Shift: 5th gear → 4th gear ..............229

A/T Does Not Shift: 4th gear → 3rd gear ..............232

A/T Does Not Shift: 3rd gear → 2nd gear .............233

A/T Does Not Shift: 2nd gear → 1st gear .............235

Vehicle Does Not Decelerate By Engine Brake ....238

SHIFT CONTROL SYSTEM ....................................241

Control Device Removal and Installation ..............241

Adjustment of A/T Position ...................................243

Checking of A/T Position ......................................243

A/T SHIFT LOCK SYSTEM ................................ .....244

Description ................ .......................... ..................244

Shift Lock System Electrical Parts Location .........244

Wiring Diagram — A/T — Shift .............................246

Shift Lock Control Unit Reference Values .............248

DIAGNOSTIC PROCEDURE ...............................249

Component Inspection ..........................................251

KEY INTERLOCK CABLE ......................................253

Components .........................................................253

Removal ...............................................................253

Installation .............................. ...... ....... ..................254

ON-VEHICLE SERVICE ..........................................255

Control Valve With TCM and A/T Fluid Temperature

Sensor 2 ...............................................................255

Rear Oil Seal ........................................................267

AIR BREATHER HOSE ...........................................268

Removal and Installation ......................................268

TRANSMISSION ASSEMBLY ................................270

Removal and Installation (4x2) .............................270

Removal and Installation (4x4) .............................273

OVERHAUL ................................. ............................276

Components ....................... .................... ...............276

Oil Channel ...........................................................284

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ..........................286

DISASSEMBLY .......................................................288

Disassembly ....................... ....... ............. ............. ..288

REPAIR FOR COMPONENT PARTS ......................305

Oil Pump ...............................................................305

Front Sun Gear, 3rd One-Way Clutch ...................307

Front Carrier, Input Clutch, Rear Internal Gear .....310

Mid Sun Gear, Rear Sun Gear, High and Low

Reverse Clutch Hub ..............................................315

High and Low Reverse Clutch ..............................320

Direct Clutch .........................................................322

ASSEMBLY .............................................................324

Assembly (1) ................................... ....... ...... ....... ..324

Adjustment ............................................................337

Assembly (2) ................................... ....... ...... ....... ..339

SERVICE DATA AND SPECIFICATIONS (SDS) ....346

General Specifications ..........................................346

Vehicle Speed When Shifting Gears .....................346

Vehicle Speed When Performing and Releasing

Complete Lock-up .................................................347

Vehicle Speed When Performing and Releasing

Slip Lock-up ..........................................................347

Stall Speed ............................................................347

Line Pressure ........................................................347

A/T Fluid Temperature Sensor ..............................347

Turbine Revolution Sensor ....................................347

Vehicle Speed Sensor A/T (Revolution Sensor) ...347

Reverse brake .......................................................348

Total End Play .......................................................348

Revision: April 2004 2004 Titan

AT-4

Page 5

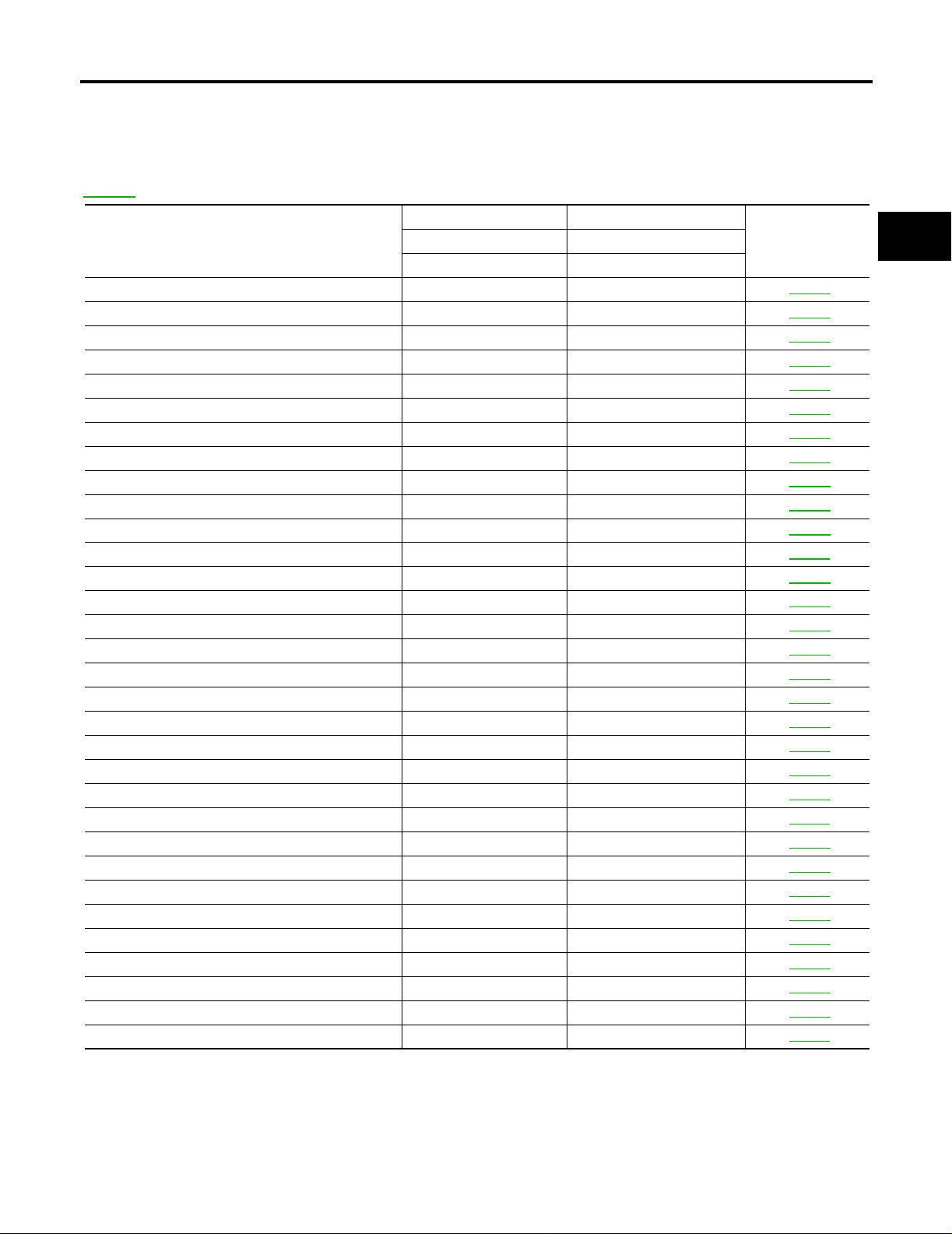

INDEX FOR DTC

INDEX FOR DTC PFP:00024

Alphabetical Index

NOTE:

If DTC U1000 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000. Refer to

AT-107

*1: These numbers are prescribed by SAE J2012.

*2: These malfunctions cannot be display ed M IL if anoth er mal fu nct io n is assig ned t o MIL.

.

DTC

Items

(CONSULT-II screen terms)

CONSULT-II GST (*1) CONSULT-II only “A/T”

A/T 1ST E/BRAKING — P1731 AT-145

ATF PRES SW 1/CIRC — P1841 AT-183

ATF PRES SW 3/CIRC — P1843 AT-186

ATF PRES SW 5/CIRC — P1845 AT-189

ATF PRES SW 6/CIRC — P1846 AT-192

A/T INTERLOCK P1730 P1730 AT-142

A/T TCC S/V FNCTN P0744 P0744 AT-124

ATF TEMP SEN/CIRC P0710 P1710 AT-134

CAN COMM CIRCUIT U1000 U1000 AT-107

D/C SOLENOID/CIRC P1762 P1762 AT-160

D/C SOLENOID FNCTN P1764 (*2 ) P1764 AT-163

ENGINE SPEED SIG — P0725 AT-119

FR/B SOLENOID/CIRC P1757 P1757 AT-154

FR/B SOLENOID FNCT P1759 P1759 AT-157

HLR/C SOL/CIRC P1767 P1767 AT-166

HLR/C SOL FNCTN P1769 (*2 ) P1769 AT-169

I/C SOLENOID/CIRC P1752 P1752 AT-148

I/C SOLENOID FNCTN P1754 (*2 ) P1754 AT-151

L/PRESS SOL/CIRC P0745 P0745 AT-127

LC/B SOLENOID/CIRC P1772 P1772 AT-172

LC/B SOLENOID FNCT P1774 P1774 AT-175

MANU MODE SW/CIR — P1815 AT-178

PNP SW/CIRC P0705 P0705 AT-113

STARTER RELAY/CIRC — P0615 AT-109

TCC SOLENOID/CIRC P0740 P0740 AT-121

TCM P0700 P0700 AT-112

TCM·RAM — P1702 AT-130

TCM·ROM — P1703 AT-131

TP SEN/CIRC A/T — P1705 AT-132

TURBINE REV S/CIRC P1716 P1716 AT-137

VEH SPD SE/CIR·MTR — P1721 AT-140

VEH SPD SEN/CIR AT P0720 P0720 AT-116

Reference pageOBD-II Except OBD-II

UCS002ME

A

B

AT

D

E

F

G

H

I

J

K

L

M

Revision: April 2004 2004 Titan

AT-5

Page 6

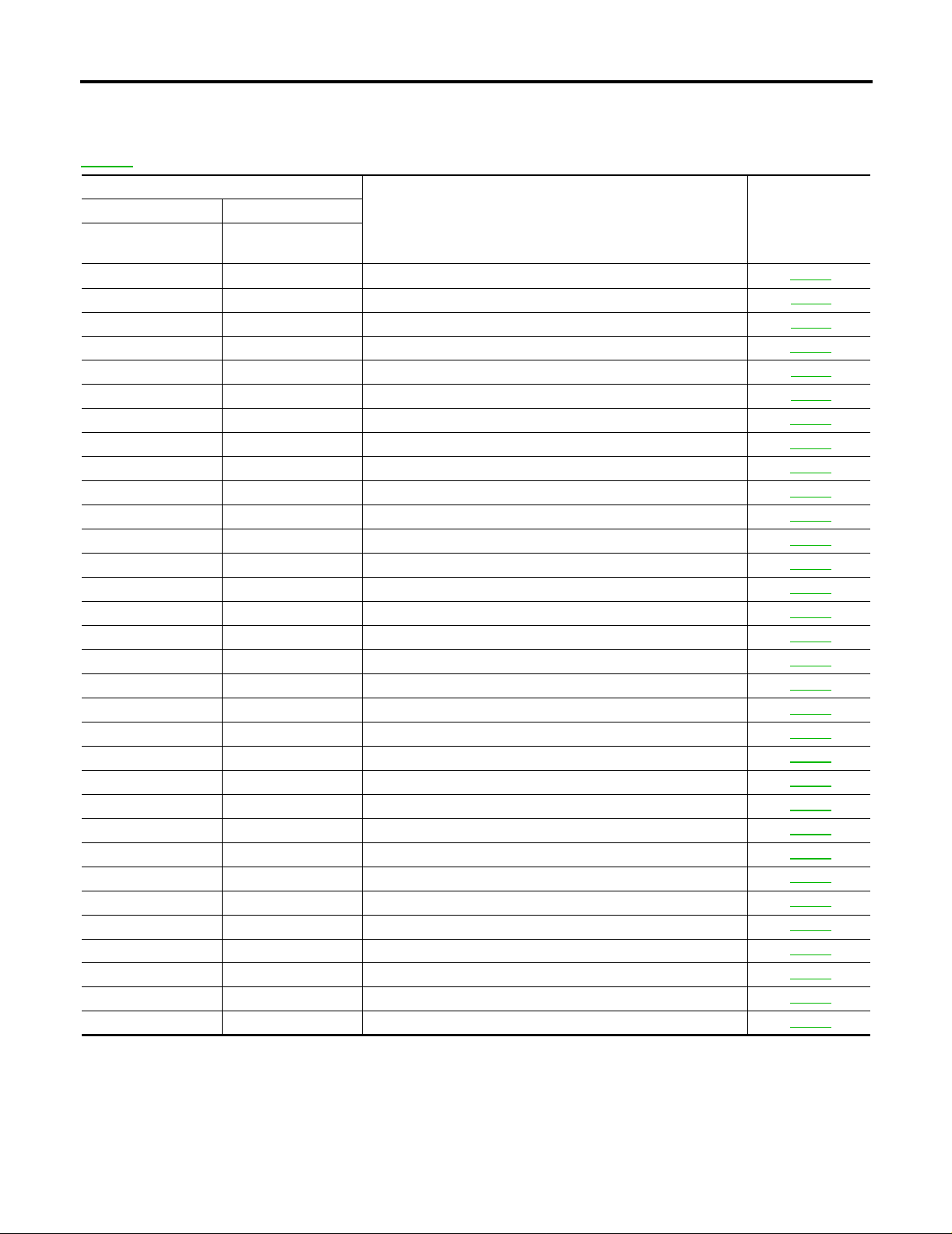

INDEX FOR DTC

DTC No. Index

UCS002MF

NOTE:

If DTC U1000 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000. Refer to

AT-107

*1: These numbers are prescribed by SAE J2012.

*2: These malfunctions cannot be displayed MIL if another malfunction is assigned to MIL.

.

DTC

OBD-II Except OBD-II

CONSULT-II

GST (*1)

— P0615 STARTER RELAY/CIRC AT-109

P0700 P0700 TCM AT-112

P0705 P0705 PNP SW/CIRC AT-113

P0710 P1710 ATF TEMP SEN/CIRC AT-134

P0720 P0720 VEH SPD SEN/CIR AT AT-116

— P0725 ENGINE SPEED SIG AT-119

P0740 P0740 TCC SOLENOID/CIRC AT-121

P0744 P0744 A/T TCC S/V FNCTN AT-124

P0745 P0745 L/PRESS SOL/CIRC AT-127

— P1702 TCM·RAM AT-130

— P1703 TCM·ROM AT-131

— P1705 TP SEN/CIRC A/T AT-132

P1716 P1716 TURBINE REV S/CIRC AT-137

— P1721 VEH SPD SE/CIR·MTR AT-140

P1730 P1730 A/T INTERLOCK AT-142

— P1731 A/T 1ST E/BRAKING AT-145

P1752 P1752 I/C SOLENOID/CIRC AT-148

P1754 (*2 ) P1754 I/C SOLENOID FNCTN AT-151

P1757 P1757 FR/B SOLENOID/CIRC AT-154

P1759 (*2 ) P1759 FR/B SOLENOID FNCT AT-157

P1762 P1762 D/C SOLENOID/CIRC AT-160

P1764 (*2 ) P1764 D/C SOLENOID FNCTN AT-163

P1767 P1767 HLR/C SOL/CIRC AT-166

P1769 P1769 HLR/C SOL FNCTN AT-169

P1772 P1772 LC/B SOLENOID/CIRC AT-172

P1774 P1774 LC/B SOLENOID FNCT AT-175

— P1815 MANU MODE SW/CIR AT-178

— P1841 ATF PRES SW 1/CIRC AT-183

— P1843 ATF PRES SW 3/CIRC AT-186

— P1845 ATF PRES SW 5/CIRC AT-189

— P1846 ATF PRES SW 6/CIRC AT-192

U1000 U1000 CAN COMM CIRCUIT AT-107

CONSULT -II

only “A/T”

(CONSULT-II screen terms )

Items

Reference page

Revision: April 2004 2004 Titan

AT-6

Page 7

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “ AIR BAG” and “SEAT BELT PRE-TENSIONER”

UCS002MG

A

The Supplemental Re straint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includ es seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

● To avoid ren dering the SRS ino perative, w hich could inc rease the ris k of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, inc luding incorrect removal and installation of the SRS, can lead to per-

sonal injury ca use d by unintentional ac tiv atio n o f the system. For remo va l of Spiral Cable and Air

Bag Module, see the SRS section.

● Do not use electrical test equ ipment o n any circu it related to the SRS unless in structed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

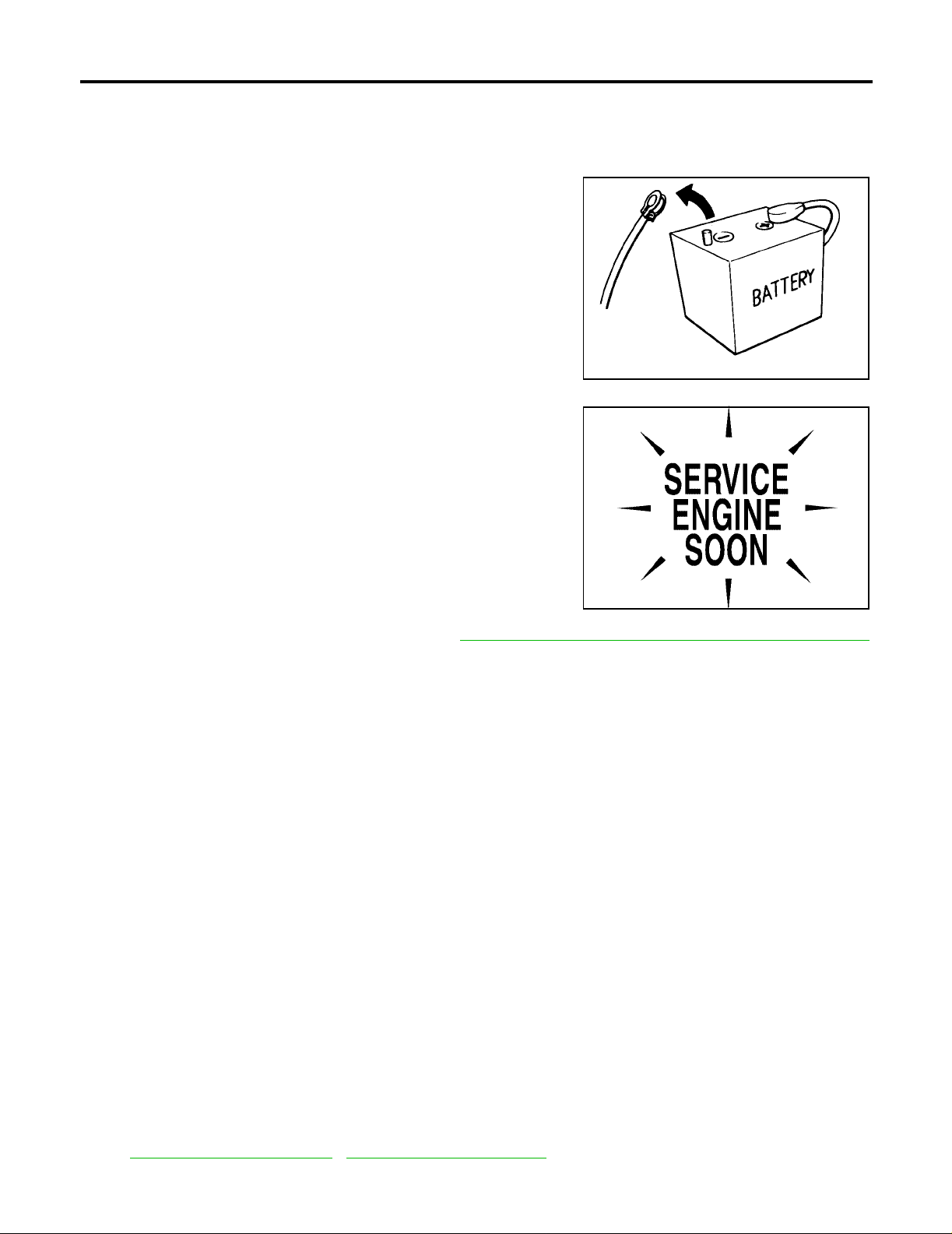

Precautions for On Board Diagnostic (OBD) System of A/T and Engine

UCS002MH

The ECM has an on boa rd diagnos tic system. It wil l light up the m alfunction indicator la mp (MIL) to warn th e

driver of a malfunction causing emission deterioration.

CAUTION:

● Be sure to turn the ignition switch “OFF” and disconnect the negative battery cable before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves,

etc. Will cause the MIL to light up.

● Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

● Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. May cause the MIL to light up due to a short circuit.

● Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system, etc.

● Be sure to eras e the u nnecess ary mal function i nformatio n (repairs compl eted) from the TC M and

ECM before returning the vehicle to the custom er.

B

AT

D

E

F

G

H

I

J

K

L

Revision: April 2004 2004 Titan

AT-7

M

Page 8

PRECAUTIONS

Precautions

UCS002MI

NOTE:

If any malfu n cti o ns oc cu r i n th e RE 5R 05A m o del t ran s mi ss ion , re pl a ce th e en ti r e transmission assembly.

● Before connecting or disconne cting the TCM harness con-

nector, turn ignition switch “OFF” and disconne ct negative

battery cable. Because battery voltage is applied to TCM

even if ignition switch is turned “OFF”.

SEF289H

● After performing each TROUBLE DIAGNOSIS, perform

“DTC (Diagnostic Trouble Code) CONFIRMATION PROCEDURE”.

If the repair is compl eted the DTC should not be display ed in

the “DTC CONFIRMATION PROCEDURE”.

SEF217U

● Always use the specified brand of ATF. Refer to MA-10, "RECOMMENDED FLUIDS AND L UBRICANTS "

.

● Use pap er rags not cloth rags during work.

● After replacing the ATF, dispose of the waste oil using the methods prescribed by law, ordinance, etc.

● Before proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other f o reign matter.

● Disassembly should be done in a clean work area.

● Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could interfere

with the operation of the trans m is si on .

● Place disassembled parts in order for easier and pro per assembly.

● All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

● Gaskets, seals and O-rings should be replaced any time the transmission is disassembled.

● It is very important to perform functional tests whenever they are indicated.

● The valve bo dy co ntains precision p a rts and requires extre me ca re w h en p ar t s ar e r em ov ed and s er v ic ed .

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent

springs and small parts from be coming scattered or lost .

● Properly installed valves, sle ev e s, plugs, etc. will slide along bores in valve body unde r thei r own we ig ht.

● Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, or hold bearings and washers in place during assembly. Do not use grease.

● Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

● After overhaul, refill the transmission with new A TF.

● When the A/T drain plug is remove d, only some of t he fluid is drai ned. O ld A/T flu id wil l remain i n torque

converter and ATF cooling system.

Always follow the procedures under “Changing A/T F luid” i n the AT section when chan ging A/T flu id. Refer

to AT-13, "

Changing A/T Fluid" , AT-13, "Checking A/T Fluid" .

Revision: April 2004 2004 Titan

AT-8

Page 9

PRECAUTIONS

Service Notice or Precautions

UCS002MJ

ATF COOLER SERVICE

● If A/T fluid contains fictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or

replaced, inspect and clean the A/T fluid cooler mounted i n the radiator or replace the ra diator. Flush

cooler lines with cleaning solvent and compressed air after repair. For A/T fluid cooler cleaning procedure,

refer to AT-15, "

A/T Fluid Cooler Cleaning" . For radiator replacement, refer to CO-10, "REMOVAL" .

CHECKING AND CHANGING A/T FLUID

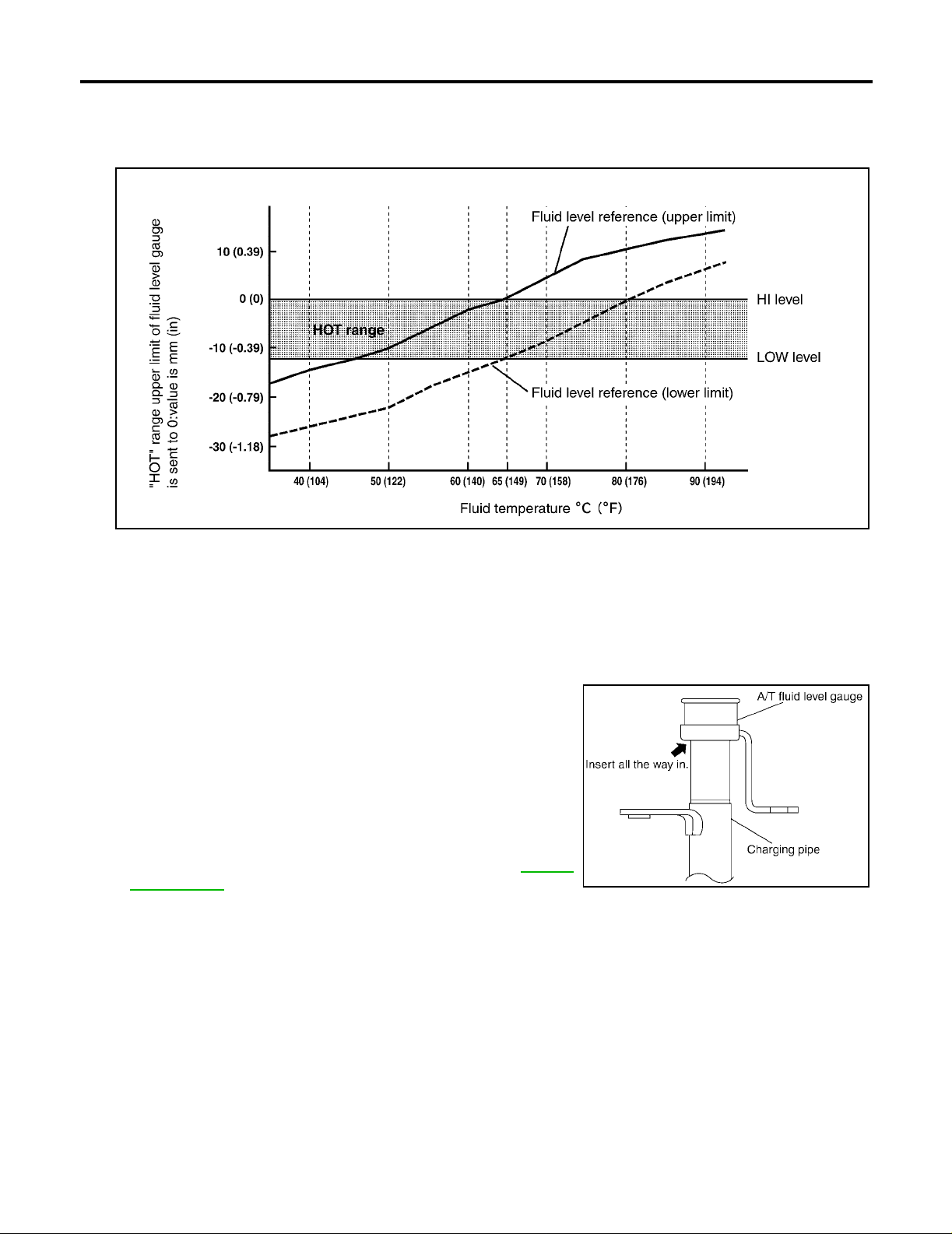

● Increase ATF oil temperature to 80°C (176°F) first, then check and adjust oil level at 65°C (149°F).

NOTE:

The A/T has both water cooling a nd air cooling systems. The air cooling system ha s a bypass valve.

When ATF oil temperatur e is at or bel ow 50 °C (122°F), it does not flow through the air cooled system. If A/

T oil level is adjusted without flow throughout the entire system, the level will be 10mm lower than

required. T herefore, all piping should be filled with oil when adjusting level.

OBD-II SELF-DIAGNOSIS

● A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the A/T CHECK indicator or the malfunction indicator lamp (MIL). Refer to the table

on AT- 9 7, "

result.

● The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM mem-

ories.

Always perform the procedure on AT-43, "

unnecessary blinking of the MIL.

For details of OBD-II, refer to AT-42, "

● Certain systems and componen ts, especially those related to OBD, may use the new s tyle slid e-

locking type harness connector. For description and how to disconnect, refer to PG-69, "

NESS CONNECTOR" .

Wiring Diagrams and Trouble Diagnosis

SELF-DIAGNOSTIC RESULT MODE" for the indicator u sed to display eac h self-diagnostic

HOW TO ERASE DTC" to complete the repair a nd avoid

ON BOARD DIAGNOSTIC (OBD) SYSTEM" .

HAR-

UCS002MK

A

B

AT

D

E

F

G

H

I

When you read wiring diagrams, refer to the following:

● GI-15, "How to Read Wiring Diagrams".

● PG-4, "POWER SUPPLY ROUTING CIRCUIT" for power distribution circuit.

When you perform trouble diagnosis, refer to the following:

● GI-9, "How to Follow Trouble Diagnoses".

● GI-27, "How to Perform Efficient Diagnosis for an Electrical Incident".

J

K

L

M

Revision: April 2004 2004 Titan

AT-9

Page 10

PREPARATION

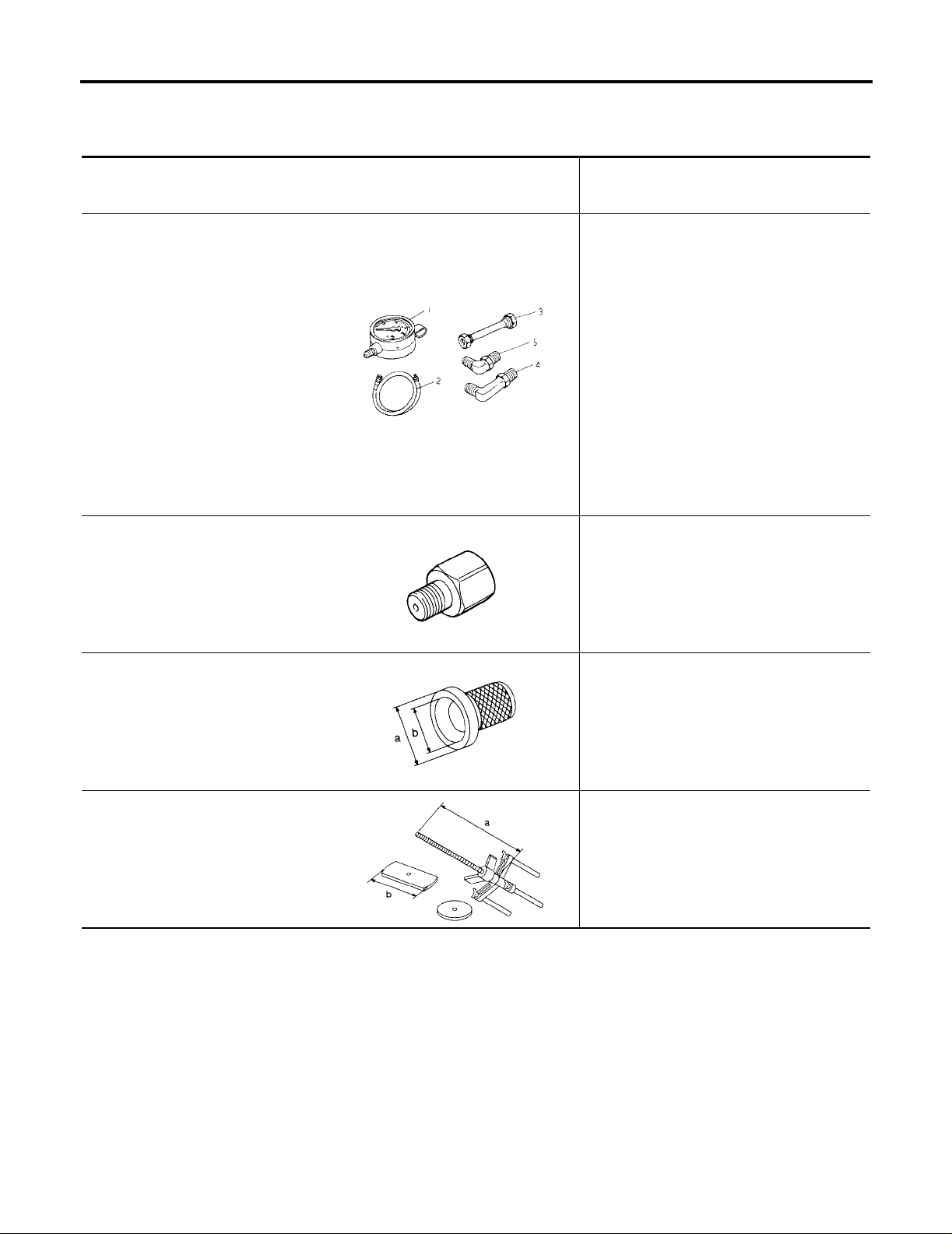

PREPARATION PFP:00002 Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of spe ci al se rvice tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

ST2505S001

(J-34301-C)

Oil pressure gauge set

1 ST25051001

( — )

Oil pressure gauge

2 ST25052000

( — )

Hose

3 ST25053000

( — )

Joint pi pe

4 ST25054000

( — )

Adapter

5 ST25055000

( — )

Adapter

KV31103600

(J-45674)

Joint pipe adapter

(With ST25054000)

ZZA0600D

Description

Measuring line pressure

Measuring line pressure

UCS002UA

ST33400001

(J-26082)

Drift

a: 60 mm (2.36 in) dia

b: 47 mm (1.85 in) dia

KV31102400

(J-34285 and J-34285-87)

Clutch spring compressor

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

ZZA1227D

● Installing rear oil seal (2WD models)

● Installing oil pump housing oil seal

NT086

Installing reverse brake return spring retainer

NT423

Revision: April 2004 2004 Titan

AT-10

Page 11

PREPARATION

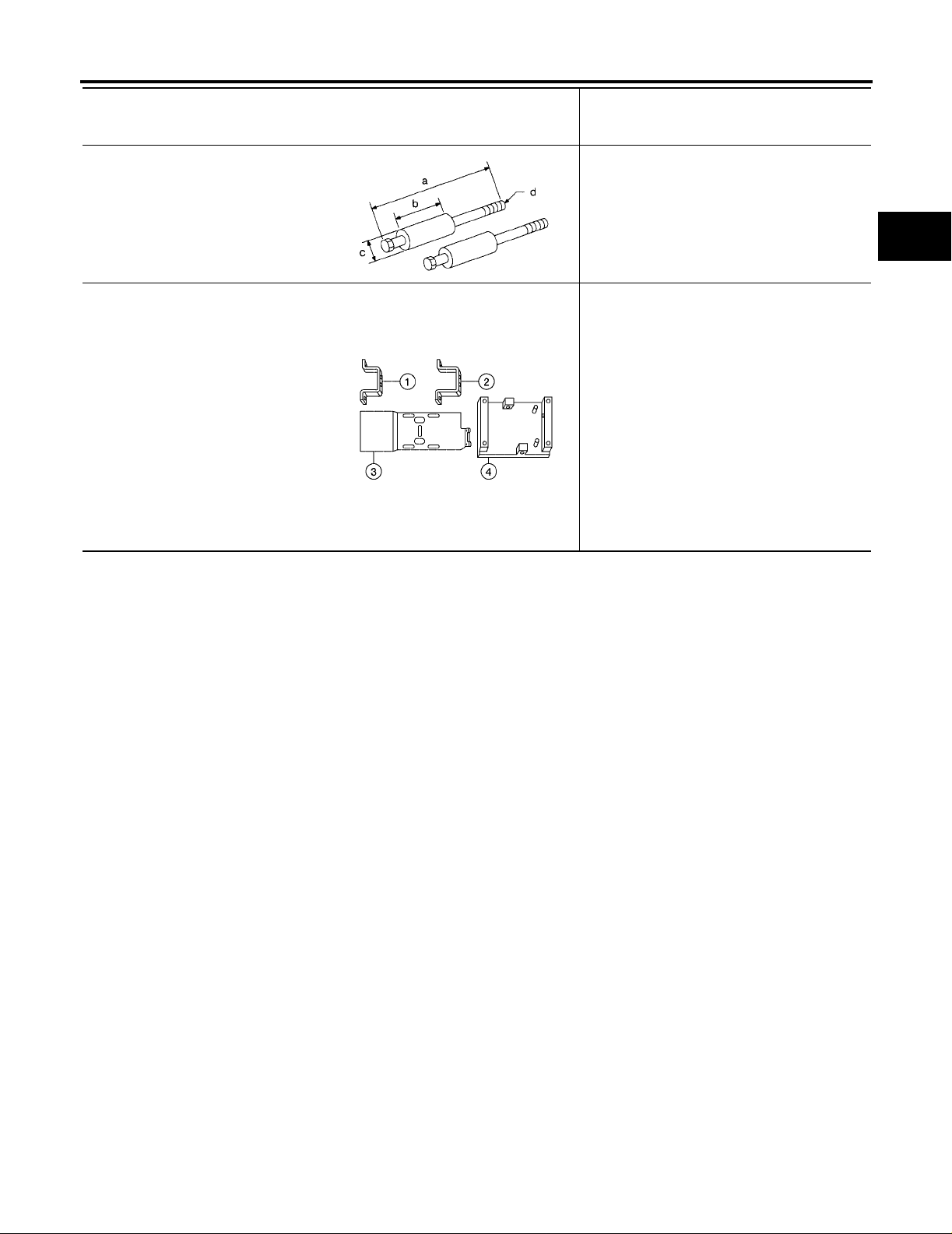

Tool number

(Kent-Moore No.)

Tool name

ST25850000

(J-25721-A)

Sliding h a mmer

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in)

d: M12X1.75P

—

(J-47002)

Transmission jack adapter kit

—

(J-47002-1)

Center bracket (Pathfinder with AllMode 4WD)

—

(J-47002-2)

Center bracket (Titan and Armada)

—

(J-47002-3)

Adapter plate

—

(J-47002-4)

Adapter block

NT422

LCIA0364E

Description

Remove oil pump assembly

Assist in removal of transmission and transfer

case as one assembly using only one transmission jack.

A

B

AT

D

E

F

G

H

K

M

I

J

L

Revision: April 2004 2004 Titan

AT-11

Page 12

PREPARATION

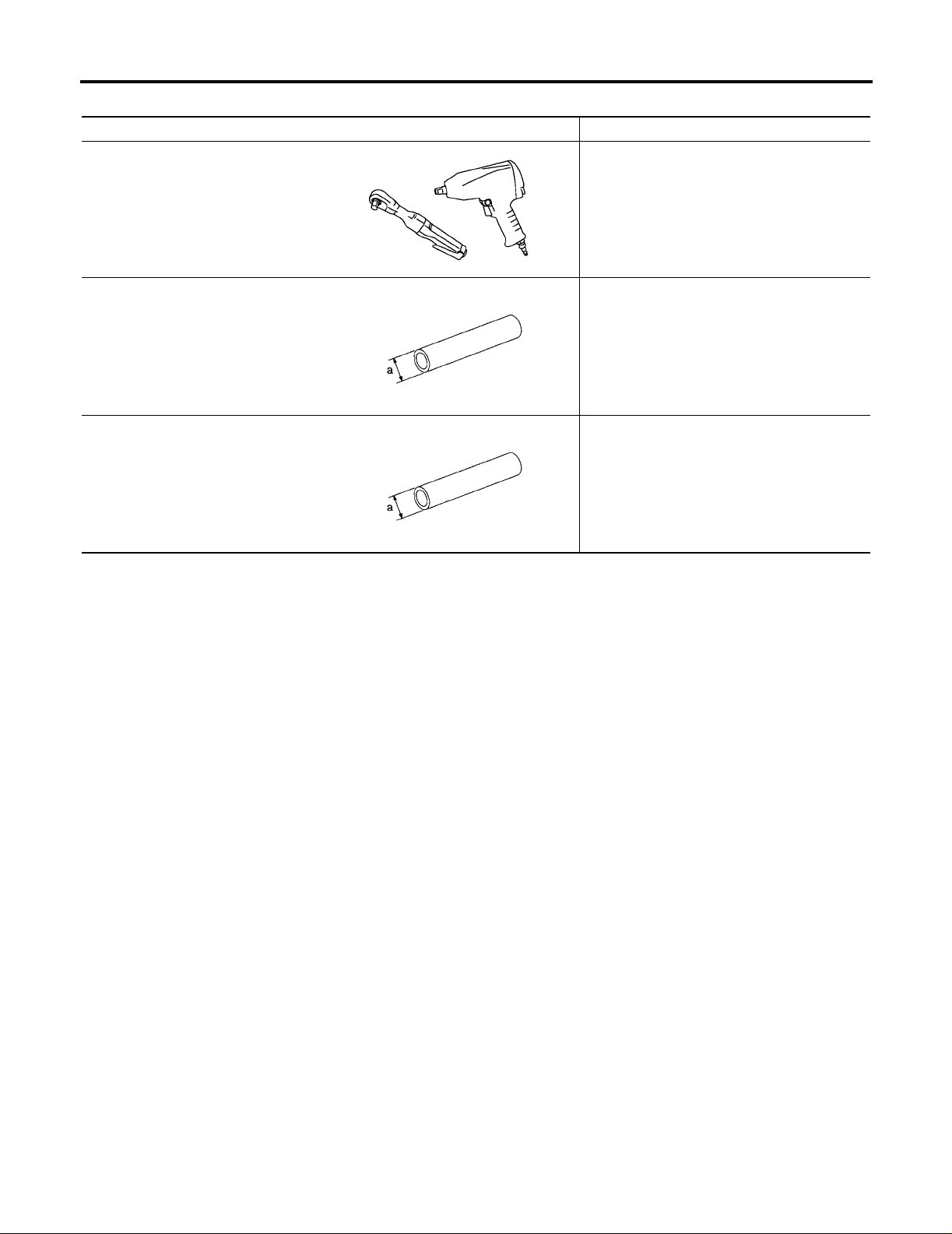

Commercial Service Tools

Tool name Description

Power tool Loosening bolts and nuts

PBIC0190E

Drift

a: 22 mm (0.87 in)

NT083

Drift

a: 64 mm (2.52 in)

NT083

Installing manual shaft seal

Installing rear oil seal (4WD models)

UCS002UB

Revision: April 2004 2004 Titan

AT-12

Page 13

A/T FLUID

A/T FLUID PFP:KLE40

Changing A/T Fluid

1. Increase ATF oil temperature to 80°C (176°F) once.

2. Stop engine.

3. Remove the tightening bolt for ATF level gauge.

4. Drain ATF from drain plug and refill with new ATF. Always refill same volume with drained fluid.

● To replace the ATF, pour in new fluid at the charging pipe with the engine idling and at the same time

drain the old fluid from the radiator cooler hose return side.

● When the color o f the fluid coming out is abo ut th e s a me a s the c ol or of the new fl ui d, the replacement

is complete. The amount of new transmis sion fluid to use should b e 30 to 50% i ncrease of t he stipulated amount .

UCS002MN

A

B

AT

D

ATF: NISSAN Matic Fluid J

Fluid capacity: 10.6 (1 1-1/4 US qt, 9-3/8 lmp qt)

CAUTION:

● Use only Genuine NISSAN ATF Matic Fluid J. Do not mix with other fluid.

● Using automatic transmissi on fluid other than Genuine NISSAN ATF Matic Fluid J will cause

deterioration in driveabi lity and automatic transmission dura bility, and may damage the automatic transmission, which is not covered by the warranty.

● When filling ATF, take care not to splash ATF on heat generating parts such as exhaust.

● Do not reuse drain plug gasket.

Drain plug: : 34 N·m (3.5 kg-m, 25 ft-lb)

5. Increase ATF oil temperature to 80°C (176°F) once.

6. Check fluid leve l and condition . Refer to MA-21, "

Checking A/T Fluid" . If fluid is still dirty, repeat step 2.

through 5.

7. Install the removed ATF level gauge in the fluid charging pipe.

8. Tighten the level gauge bolt.

Level gauge bolt: : 5.1 N·m (0.52 kg-m, 45 in-lb)

Checking A/T Fluid

UCS002MO

1. Wa rm up engine.

2. Check for fluid leakage.

3. Remove the tightening bolt for ATF level gauge.

4. Before driving, fluid level can be checked at fluid temperatures of 30° to 50°C (86° to 122°F) using

“COLD” range on ATF level gauge as follows.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear position. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove ATF level gauge and wipe clean with lint-free paper.

CAUTION:

When wiping away the fluid level gauge, always use lint-free paper, not a cloth one.

e. Re-inser t ATF leve l gauge into charging pipe as far as it will go.

CAUTION:

To check fluid level, insert the ATF level gauge until the cap contacts the end of the charging pipe,

with the gauge reversed from the normal attachment conditions.

f. Remove ATF level gauge and note reading. If reading is at low side of range, add fluid to th e charging

pipe.

CAUTION:

Do not overfill.

5. Increase ATF oil temperature to 80°C (176°F) once.

E

F

G

H

I

J

K

L

M

Revision: April 2004 2004 Titan

AT-13

Page 14

A/T FLUID

6. Make the fluid temperature approximately 65°C (149°F).

NOTE:

Fluid level will be greatly affected by temperatu re as shown in figure. The refore, be certain to perform operation while checking data with CONSULT-II.

SLIA0016E

a. Connect CONSULT-II to data link connector.

b. Select “MAIN SIGNALS” in “DATA MONITOR ” mode for “A/T” with CONSULT-II.

c. Read ou t the value of “ATF TEMP 1”.

7. Re-check fluid leve l at fluid tempe ratures of app roximately 65 °C (149°F) using “HOT” range on A/T fluid

level gauge.

CAUTION:

● When wiping away the fluid level gauge, always use lint-free paper, not a cloth one.

● To chec k fluid level, insert the ATF level gauge until the

cap contacts the end of the charging pipe, with the gauge

reversed from the normal attachment conditions as

shown.

8. Check fluid condition.

● If fluid is ve ry dark or smells burned, check operation of A/T.

Flush cooling system after repair of A/T.

● If ATF contains frictional material (clutches, bands, etc.),

replace radiat or and flush cooler line using cl eaning solvent

and compressed air after repair of A/T. Refer to CO-10,

"RADIATOR" .

SCIA1684E

9. Install the removed ATF level gauge into the fluid charging pipe.

10. Tighten the level gauge bolt.

Level gauge bolt: : 5.1 N·m (0.52 kg-m, 45 in-lb)

Revision: April 2004 2004 Titan

AT-14

Page 15

A/T FLUID

A/T Fluid Cooler Cleaning

UCS002MP

Whenever an au to ma tic tra ns m is si on is repai red, overhauled, or replaced, the A/T flu id co oler mounted in th e

radiator must be inspected and cleaned.

Metal debris and fri ct ion ma teri al, i f pres ent, can beco me trapp ed i n the A/T fl uid c oole r. This debris ca n co ntaminate the newly serviced A/T or, in severe cases, can block or restrict the flow of A/T fluid. In either case,

malfunction of the newly serviced A/T may result.

Debris, if present, may build up as A/T fluid enters the cooler inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

A/T FLUID COOLER CLEANING PROCEDURE

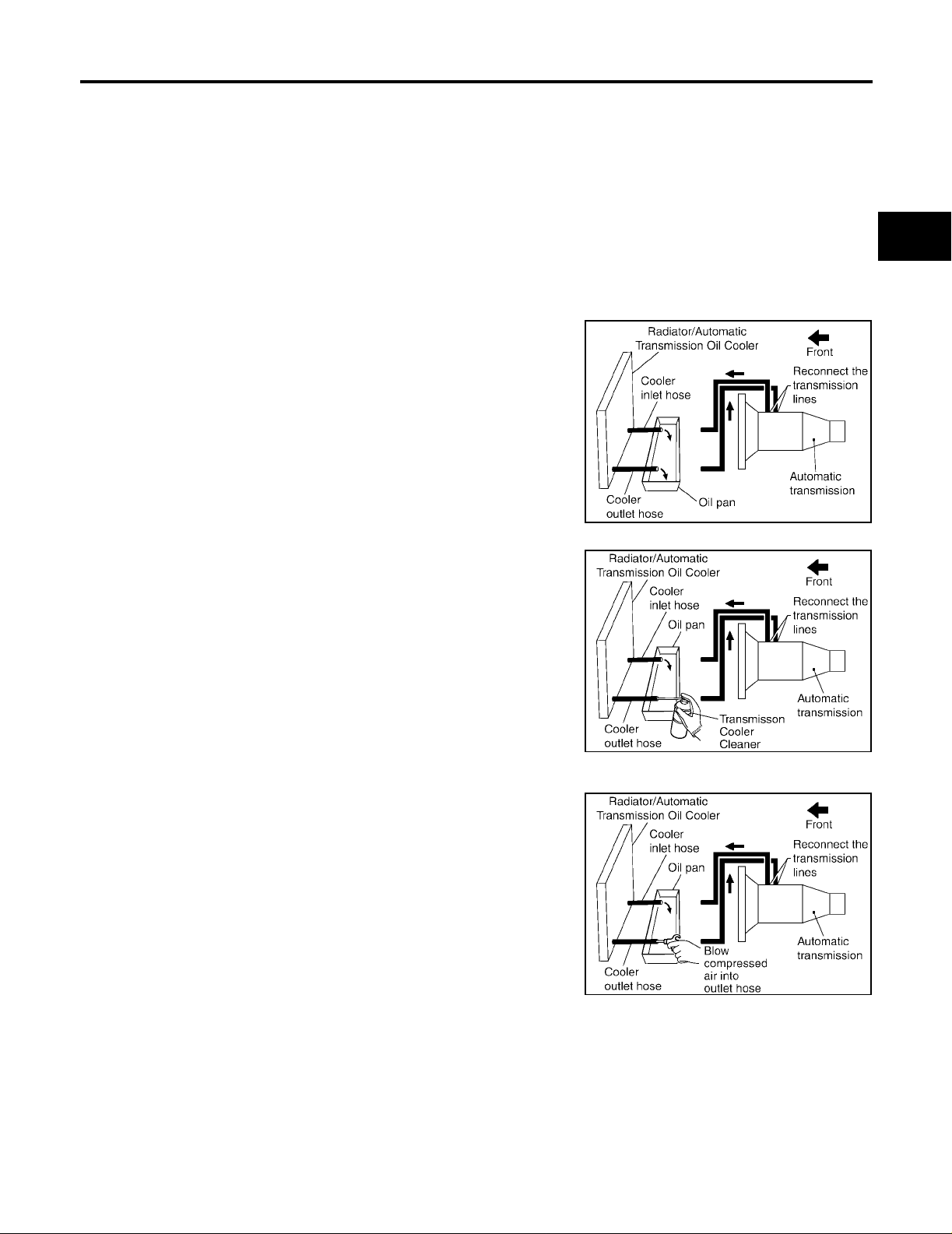

1. Position an oil pan under the aut omatic transmission's inlet and outlet cooler hoses.

2. Identify the inlet and outlet fluid cooler hoses.

3. Disconnect the fluid cooler inlet and outlet rubber hoses from the

steel cooler tubes or bypass valve.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

4. Allow any A/T fluid that remains in the cooler hoses to drain into

the oil pan.

SCIA3830E

5. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 99 9MP-AM00 6) into the coole r outlet hose.

CAUTION:

● Wear safety glasses and rubber gloves when spraying

the Transmission Cooler Cleaner .

● Spray cooler cleaner only with ad equ ate venti lation.

● Avoid contact with eyes and skin.

● Do not breat h vapors or spray mis t.

6. Hold the hose and can as high as possible and spray Transmission Cooler Cleaner in a continuous stream into the cooler outlet

hose until fluid flows out of the cooler inlet hose for 5 seconds.

7. Insert the tip of an air gun into the end of the cooler outle t hose.

8. Wrap a shop rag a round the ai r gun tip and of the cool er outlet

hose.

SCIA3831E

A

B

AT

D

E

F

G

H

I

J

K

L

M

SCIA3832E

9. Blow compressed air regulated to 5 - 9 kg/cm

2

(70 - 130 psi) th rough th e cooler outlet hose fo r 10 sec-

onds to force out any remaining fluid.

10. Repeat steps 5 through 9 three additional times.

11. Position an oil pan under the banjo bolts that connect the fluid cooler steel lines to the transmission.

12. Remove the banjo bolts.

13. Flush each steel li ne fr om th e coo ler sid e bac k towa rd th e transm issi on by sp rayin g Transmissio n Cool er

Cleaner in a continuous stream for 5 seconds.

Revision: April 2004 2004 Titan

AT-15

Page 16

A/T FLUID

14. Blow compre ssed air regulated to 5 - 9 kg/cm2 (70 - 130 psi) through each steel line from the cooler side

back toward the transmission for 10 seconds to force out any re maining fluid.

15. Ensure all debris is removed from the steel cooler lines.

16. Ensure all debris is removed from the banjo bolts and fittings.

17. Perform A/T fliud cooler inspection procedure. Refer to AT-17, "

CEDURE" .

A/T FLUID COOLER DIAGNOSIS PROCEDURE

NOTE:

Insufficient cleaning of the cooler inlet hose exterior may lead to inaccurate debris identification.

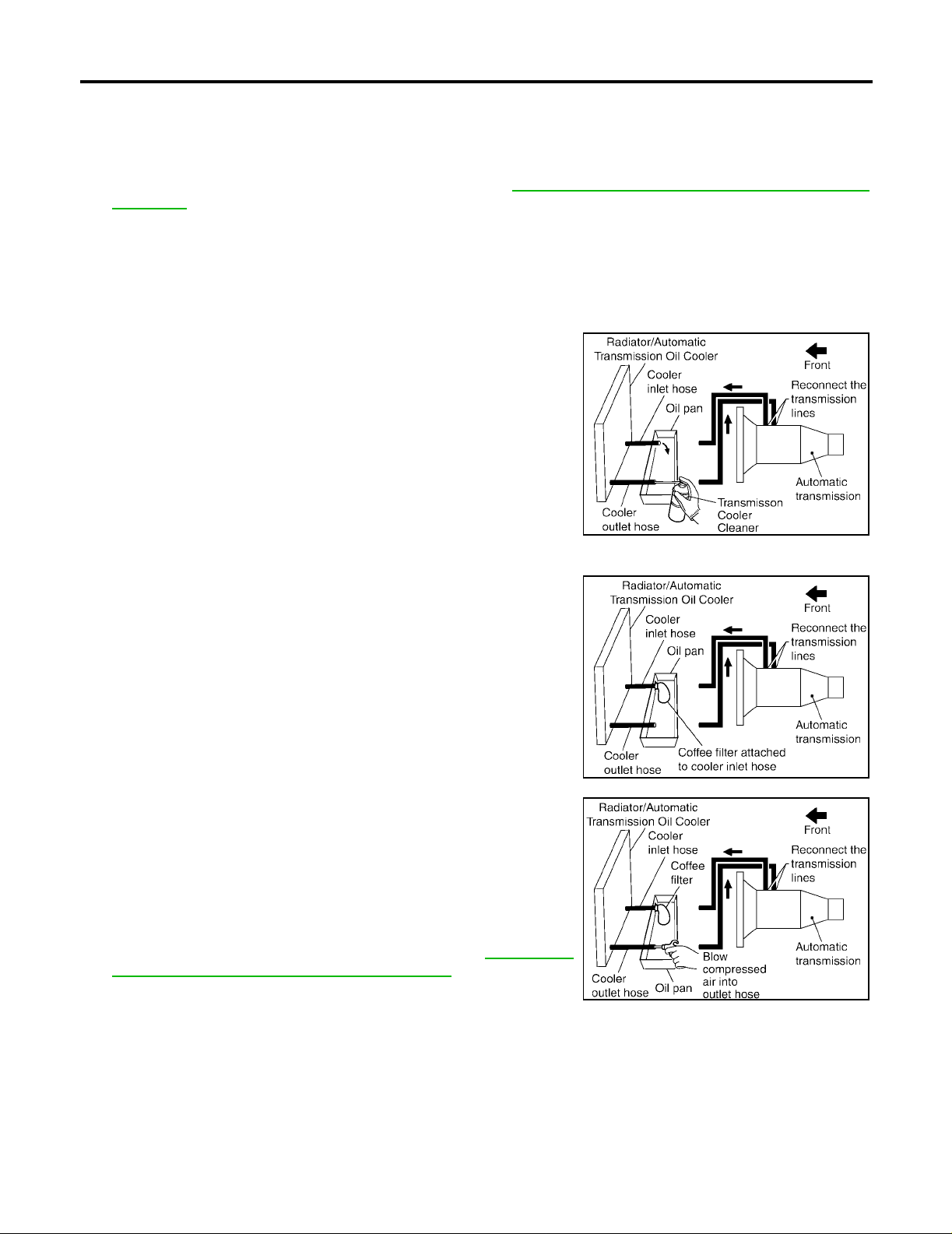

1. Position an oil pan under the automatic transmission's inlet and outlet cooler hoses.

2. Clean the exterior and tip of the cooler inlet hose.

3. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissa n P/N 999M P-AM0 06) into the co oler ou tlet hose.

CAUTION:

● Wear safety glasses and rubber gloves when spraying

the Transmission Cooler Cleaner.

● Spray cooler cleaner only with adequate ventilation.

● Avoid contact with eyes and skin.

● Do not breath vapors or spray mist.

4. Hold the hose and can as high as possible and spray Transmission Cooler Cleaner in a continuous stream into the cooler outlet

hose until fluid flows out of the cooler inlet hose for 5 seconds.

5. Tie a common white, basket-type coffee filter to the end of the

cooler inlet hose.

A/T FLUID COOLER INSPECTION PRO-

SCIA3831E

SCIA3833E

6. Insert the tip of an air gun into the end of the cooler outl et hose.

7. Wrap a shop rag around the air gun tip an d end of cooler ou tlet

hose.

2

8. Blow compressed air regulated to 5 - 9 kg/cm

(70 - 130 psi)

through the cooler outlet hose to force any remaining A/T fluid

into the coffee filter.

9. Remove the coffee filter from the end of the cooler inlet hose.

10. Perform A/T fliud cooler inspection procedure. AT-17, "

A/T

FLUID COOLER INSPECTION PROCEDURE" .

SCIA3834E

Revision: April 2004 2004 Titan

AT-16

Page 17

A/T FLUID

A/T FLUID COOLER INSPECTION PROCEDURE

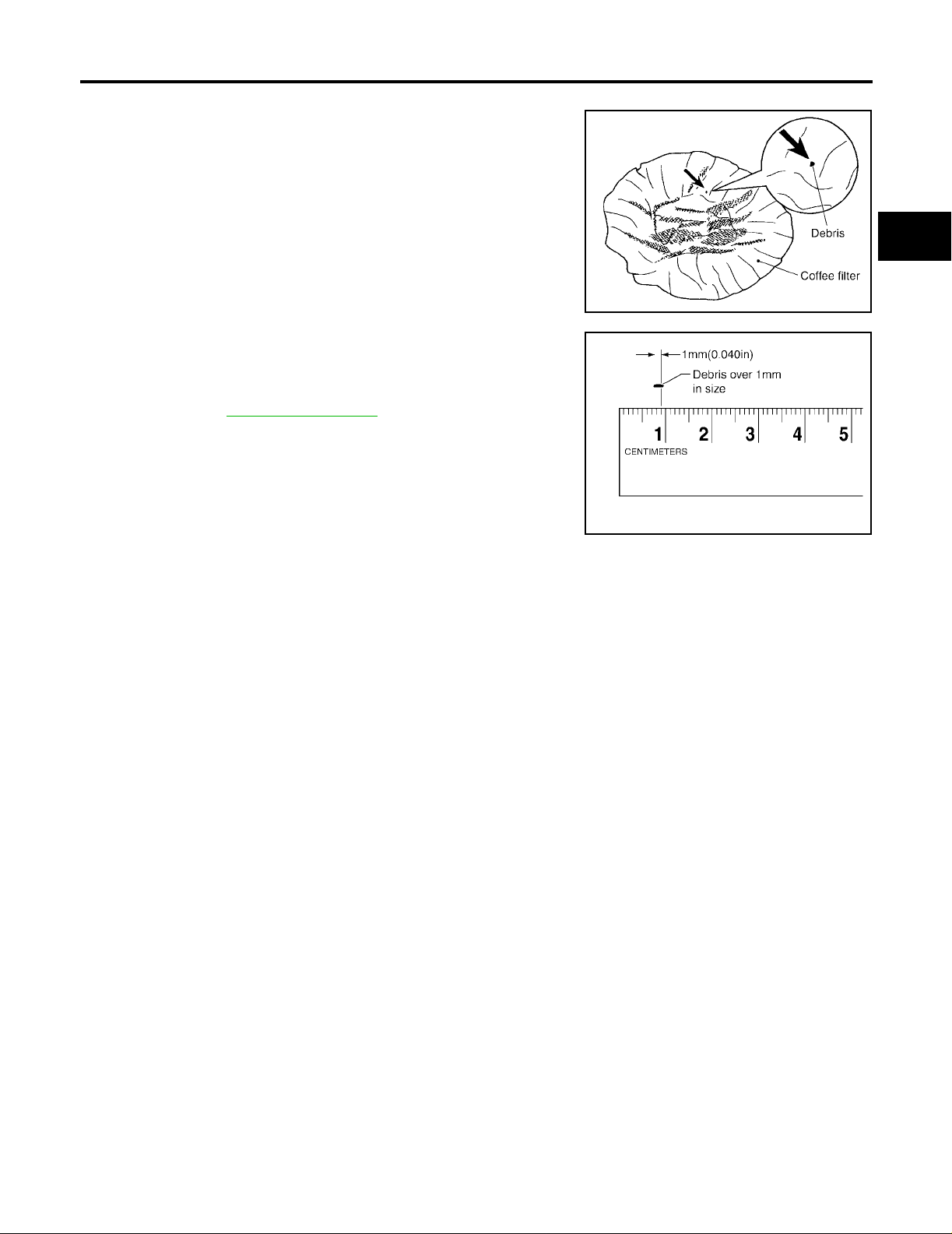

1. Inspect the coffee filter for debris.

a. If small metal debri s less than 1mm (0.040 in) in size or metal

powder is found in the coffee filter, this is normal. If normal

debris is found, the A/T fluid cooler/radiator can be re-used and

the procedur e is ended.

A

B

AT

b. If one or more pieces of debris are found that are over 1mm

(0.040 in) in siz e an d/or peeled clutch facing material is fo un d in

the coffee filter, the fluid cooler is not servicea ble. The A/T fluid

cooler/radiator must be replaced and the inspection procedure is

ended.Refer to CO-10, "

RADIATOR" .

A/T FLUID COOLER FINAL INSPECTION

After performing all procedures, ensure that all remaining oi l is cleaned from all components.

SCIA2967E

SCIA5257E

D

E

F

G

H

I

J

K

Revision: April 2004 2004 Titan

AT-17

L

M

Page 18

A/T CONTROL SYSTEM

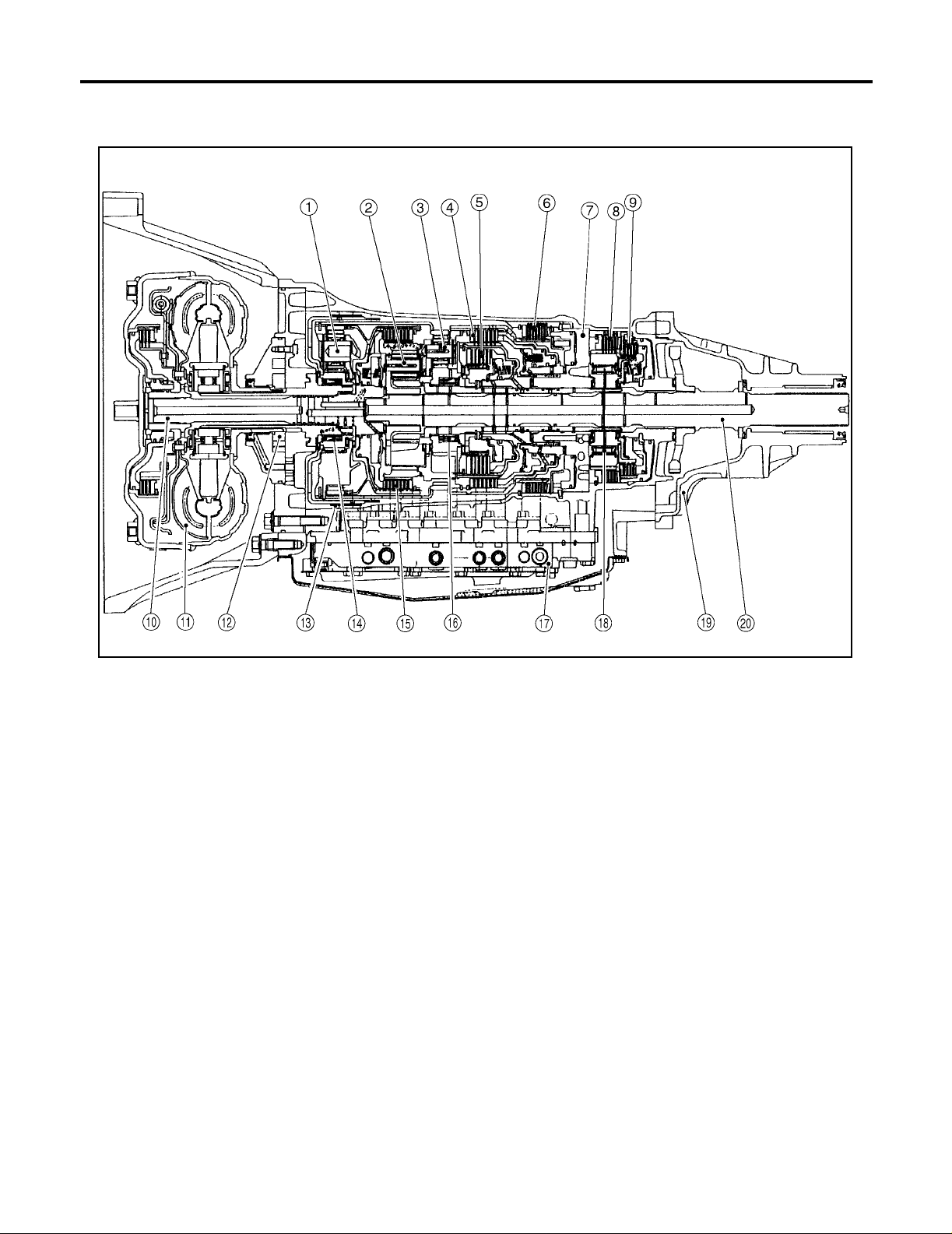

A/T CONTROL SYSTEM PFP:31036 Cross-Sectional View (2WD models)

UCS002MQ

1. Front planetary gear 2. Mid planetary gear 3. Rear planetary gear

4. Direct clutch 5. High & low reverse clutch 6. Reverse brake

7. Drum support 8. Forward brake 9. Low coast brake

10. Input shaft 11. Torque converter 12. Oil pump

13. Front brake 14 . 3rd one-way clut ch 15. Input clutch

16. 1st one-way clutch 17. Control valve with TCM 18. Forward one-way clutch

19. Rear extension 20. Output shaft

SCIA5267E

Revision: April 2004 2004 Titan

AT-18

Page 19

A/T CONTROL SYSTEM

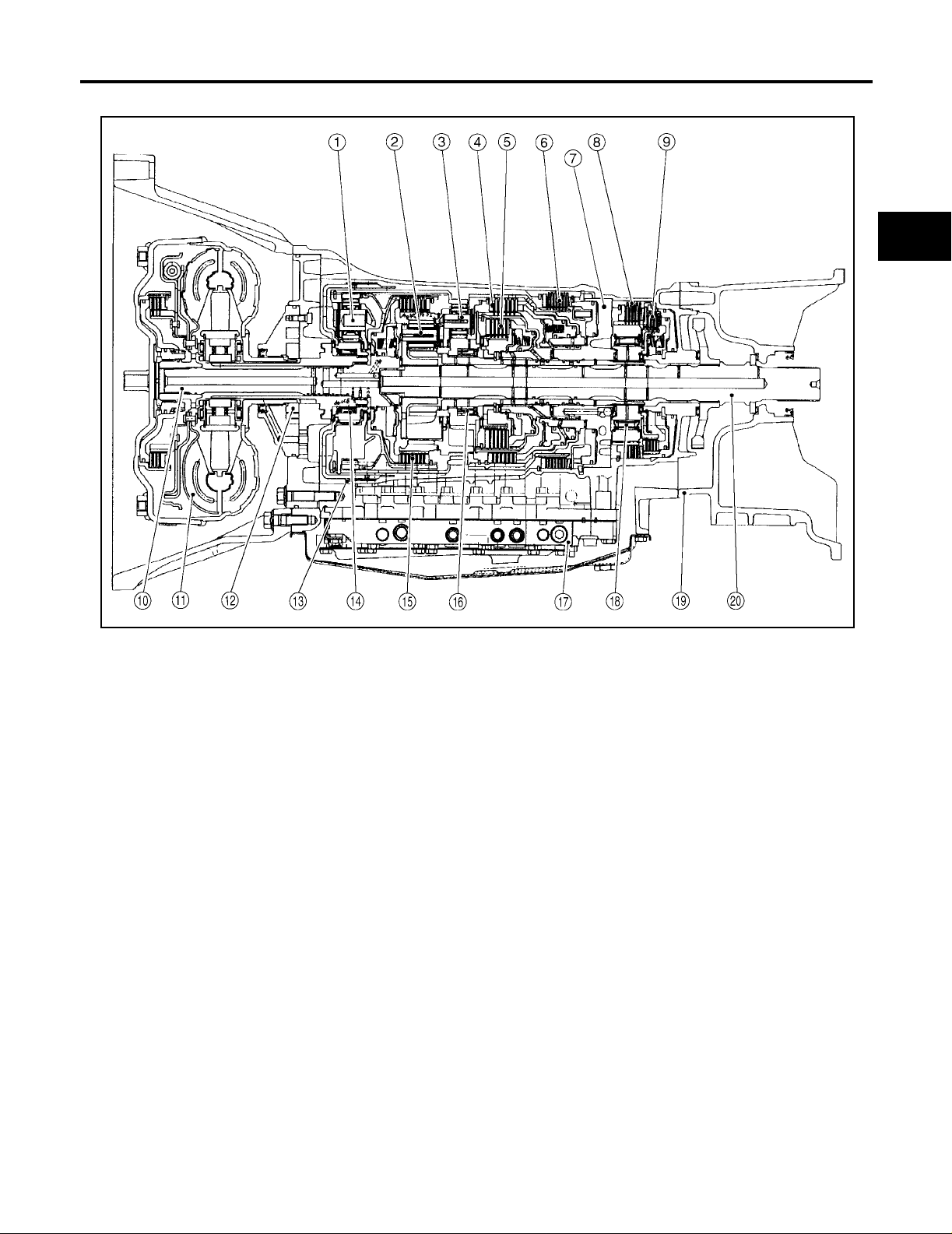

Cross-Sectional View (4WD models)

UCS002MR

A

B

AT

D

E

F

G

H

1. Front planetary gear 2. Mid planetary gear 3. Rear planetary gear

4. Direct clutch 5. High & low reverse clutch 6. Reverse brake

7. Drum support 8. Forward brake 9. Low coast brake

10. Input shaft 11. Torque converter 12. Oil pump

13. Front brake 14. 3rd one-way clutch 15. Input clutch

16. 1st one-way clutch 17. Control valve with TCM 18. Forward one-way clutch

19. Adapter case 20. Output shaft

SCIA5268E

I

J

K

L

M

Revision: April 2004 2004 Titan

AT-19

Page 20

A/T CONTROL SYSTEM

Shift Mechanism

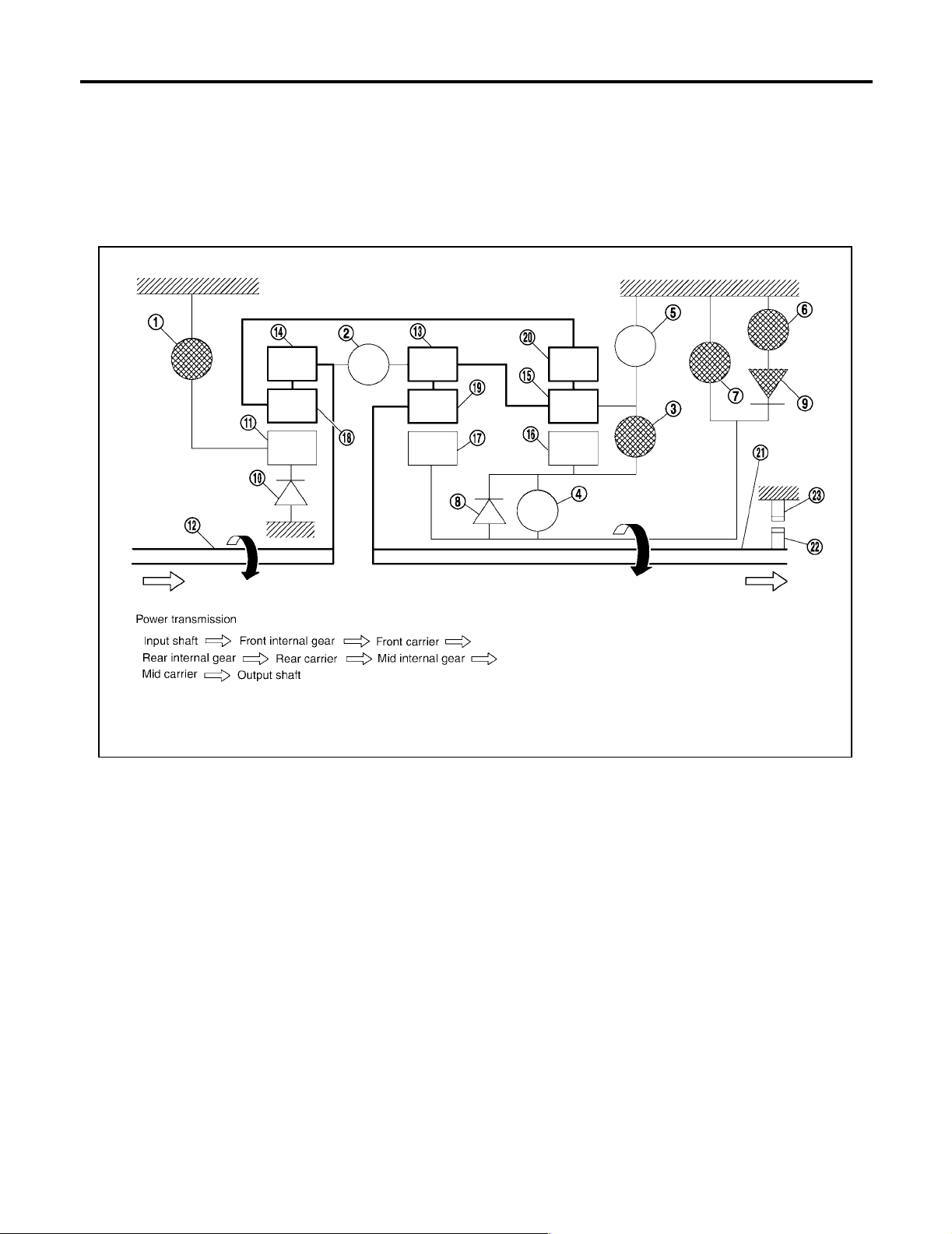

UCS002MS

The automatic tra nsmission uses compact dual plan etary gear systems to improve powe r-transmission efficiency, simplify construction and reduce weight.

It also empl oys an o ptimum shi ft control and supe r wide ge ar ratios. They imp rove starti ng perform ance and

acceleration during medium and high-speed operation.

CONSTRUCTION

1. Front brake 2. Input clutch 3. Direct clutch

4. High and low reverse clutch 5. Reverse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input sha ft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. Front car rier

19. Mid carrier 20. Rear internal gear 21. Outpu t sha ft

22. Parking gear 23. Parking pawl

FUNCTION OF CLUTCH AND BRAKE

Name of the Part Abbreviati on Function

Front brake (1) FR/B Fastens t he front sun gear (11).

Input clutch (2) I/C

Direct clutch (3) D/C Connects the rear carrier (15) and the rear sun gear (16).

High and low reverse clutch (4) HLR/C Connects the mid sun gear (17) and the rear sun gear (16).

Reverse brake (5) R/B Fastens the rear carrier (15).

Forward brake (6) F/B Fastens the mid sun gear (17).

Low coast brake (7) LC/B Fastens the mid sun gear (17).

1st one-way clutch (8) 1st/O.C

Forward one-way clutch (9) F/O.C

3rd one-way clutch (10) 3rd/O.C

Connects the input shaft (12), the front internal gear (14) and the mid internal

gear (13).

Allows the rear sun gear (16) to turn freely forward relative to the mid sun gear

(17) but fastens it for reverse rotation.

Allows the mid sun gear (17) to turn freely in the forward direction but fastens it

for reverse rotat i o n.

Allows the front sun gear (11) to turn freely in the forward direction but fastens

it for reverse rotat ion.

PCIA0002J

Revision: April 2004 2004 Titan

AT-20

Page 21

A/T CONTROL SYSTEM

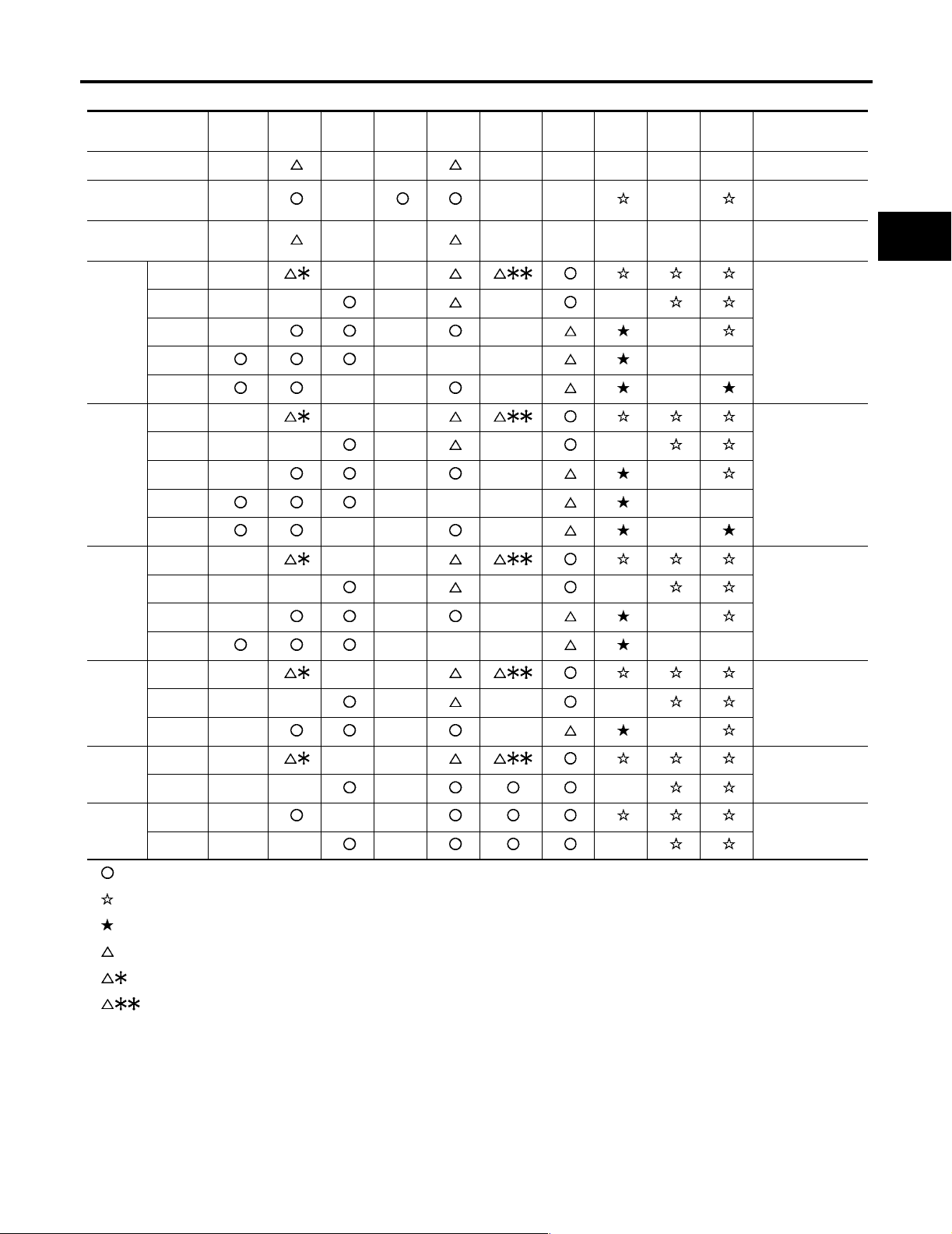

CLUTCH AND BAND CHART (FLOOR SHIFT MODELS)

Shift position I/C HLR/C D/C R/B FR/B LC/B Fwd/B

P PARK POSITION

R

N

1st

2nd

D

3rd

4th

5th

1st

OWC

Fwd

OWC

3rd

OWC

Remarks

REVERSE

POSITION

NEUTRAL POSI-

TION

Automatic shift

1⇔2⇔3⇔4⇔5

A

B

AT

D

E

1st

4

2nd

3rd

4th

1st

2nd

3

3rd

4th

1st

2nd

2

3rd

4th

1st

2nd

1

3rd

4th

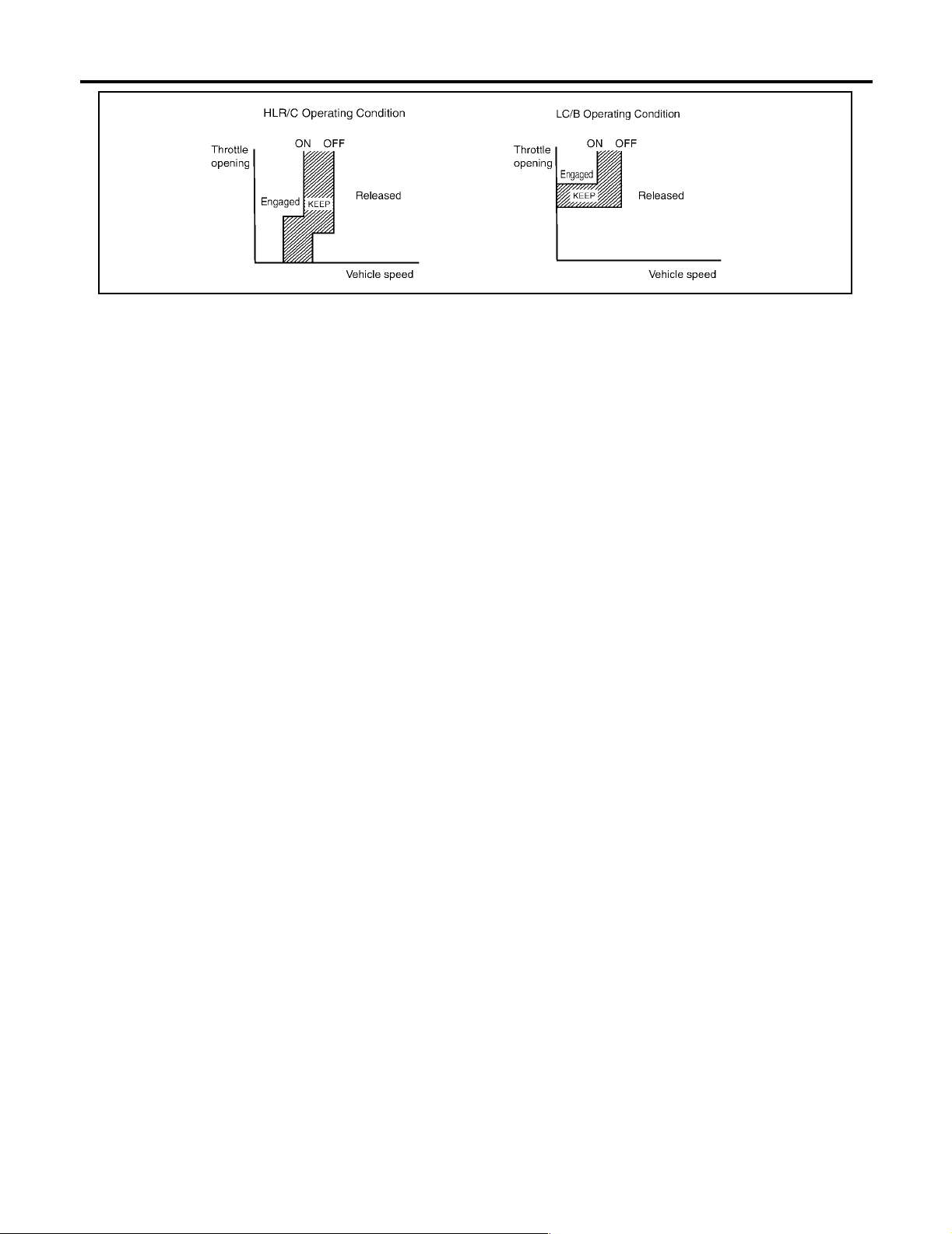

● —Operates

● —Operates during “progressive” accel era tion.

● —Operates and effects power transmission while coasting.

● —Line pressure is applied but does not affect power transmiss io n.

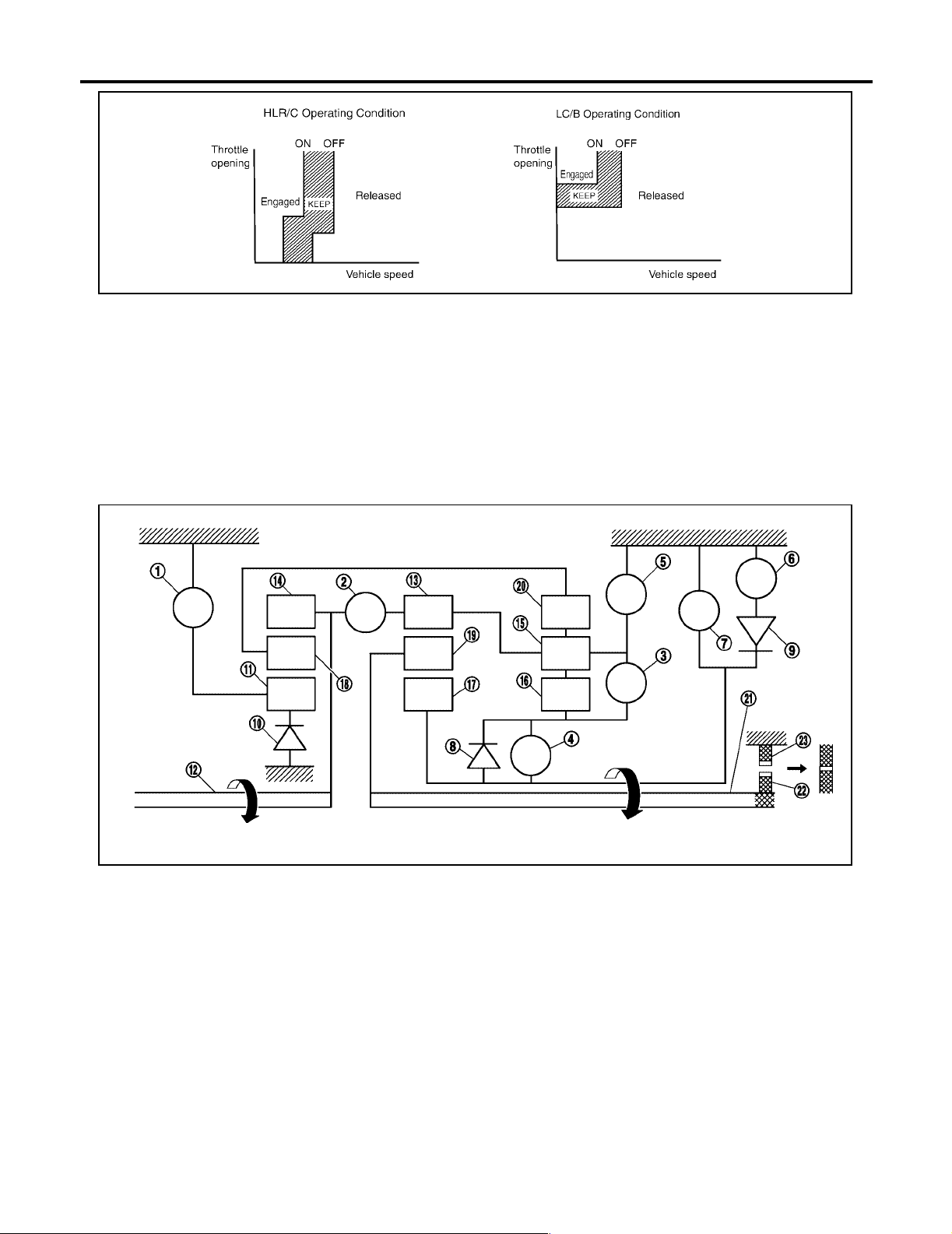

● —Operates under conditions shown in HLR/C Op era ting C ond iti on

● —Operates under conditions show n in LC/B Op era ting Condition. Delay control is applied during D (4,3,2,1) ÞN shift.

Automatic shift

1⇔2⇔3⇔4

Automatic shift

1⇔2⇔3⇐4

Automatic shift

1⇔2⇐3⇐4

Locks (held sta-

tionary in 1st

gear)

1⇐2⇐3⇐4

F

G

H

I

J

K

L

M

Revision: April 2004 2004 Titan

AT-21

Page 22

A/T CONTROL SYSTEM

SCIA5642E

Revision: April 2004 2004 Titan

AT-22

Page 23

A/T CONTROL SYSTEM

CLUTCH AND BAND CHART (COLUMN SHIFT MODELS)

Shift position I/C HLR/C D/C R/B FR/B LC/B Fwd/B

P PARK POSITION

R

N

1st

2nd

D

3rd

4th

5th

1st

OWC

Fwd

OWC

3rd

OWC

Remarks

REVERSE

POSITION

NEUTRAL POSI-

TION

Automatic shift

1⇔2⇔3⇔4⇔5

A

B

AT

D

E

1st

2nd

M5

M4

M3

M2

M1

● —Operates

● —Operates during “progressive” accel era tion.

● —Operates and effects power transmission while coasting.

● —Line pressure is applied but does not affect power transmiss io n.

● —Operates under conditions shown in HLR/C Op era ting C ond iti on

● —Operates under conditions show n in LC/B Op era ting Condition. Delay control is applied during D (4,3,2,1) ÞN shift.

3rd

4th

5th

1st

2nd

3rd

4th

1st

2nd

3rd

1st

2nd

1st

2nd

Automatic shift

1⇔2⇔3⇔4⇔5

Automatic shift

1⇔2⇔3⇔4

Automatic shift

1⇔2⇔3

Automatic shift

1⇔2

Locks (held sta-

tionary in 1st

gear)

F

G

H

I

J

K

L

M

Revision: April 2004 2004 Titan

AT-23

Page 24

A/T CONTROL SYSTEM

SCIA5642E

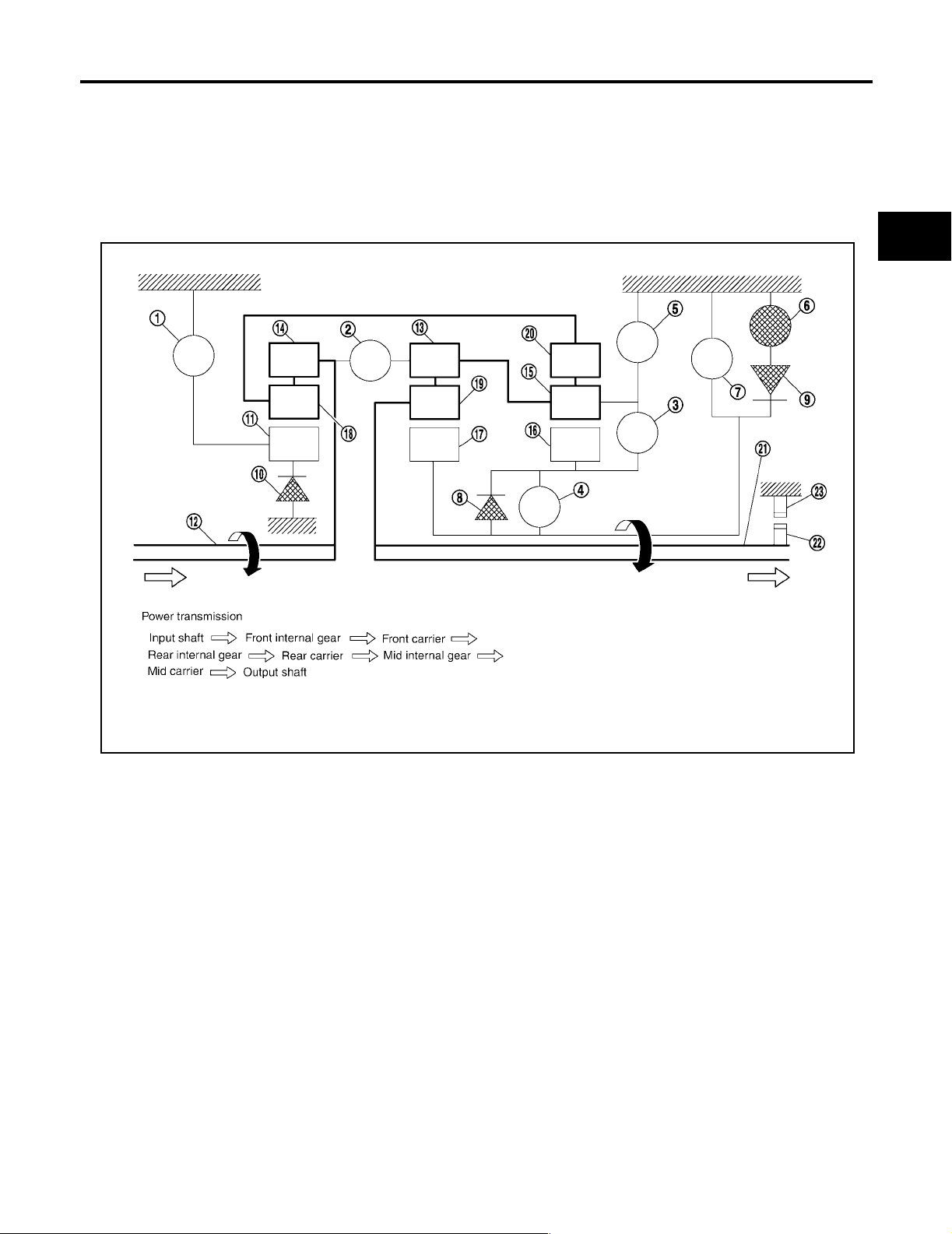

POWER TRANSMISSION

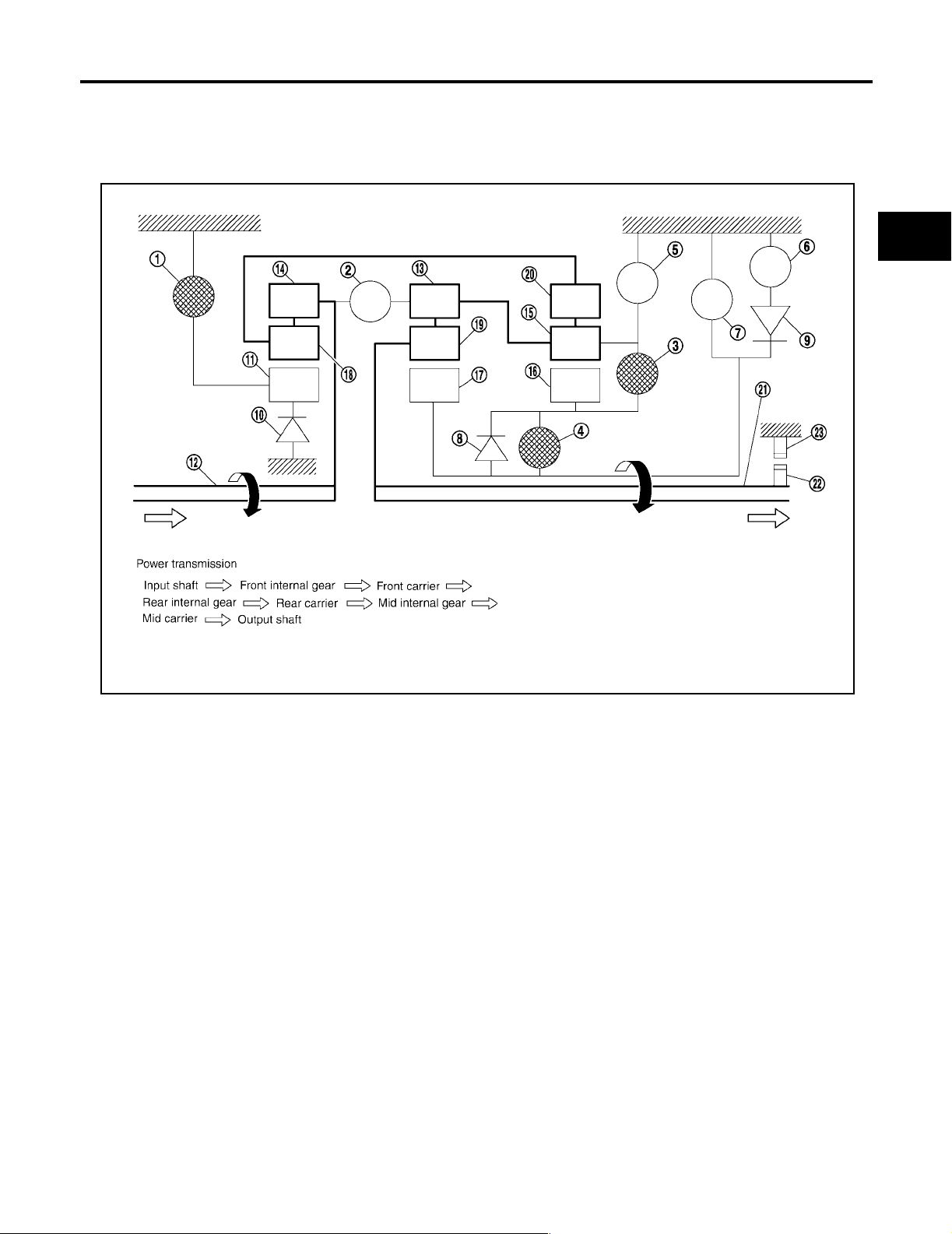

“N” position

Since both the forward brake and the reverse brake are released, torque from the input shaft drive is not transmitted to the output shaft.

“P” position

● The same as for the “N” position, both the forward brake and the reverse brake are released, so torque

from the input shaft drive is not transmitted to the output shaft.

● The parking pawl linked w ith the se lect lever mes hes with the parking gear a nd fastens the output sh aft

mechanically.

PCIA0003J

1. Fr ont brak e 2. I nput clutch 3. Direct clutch

4. H i gh and l ow reverse clutch 5. R everse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. Front carrie r

19. Mid carrier 20. Rear internal gea r 2 1. Output shaft

22. Parking gear 23. Parking pawl

Revision: April 2004 2004 Titan

AT-24

Page 25

A/T CONTROL SYSTEM

“D”, “M5”, “M4”, “M3”, “M2” positions (column sh ift), “D”, “4”, “3”, “2” positions (floor shift)

1st gear

● The forward brake and the forward one-way clutch regulate reverse rotation of the mid sun gear.

● The 1st one-way clutch regulates reverse rotation of the rear sun gear.

● The 3rd one-way clutch regulates rever s e rotation of the front sun gear .

● During deceleration, the mid sun gear turns forward, so the forward one-way clutch idles and the engine

brake is not act ivated.

A

B

AT

D

E

F

G

1. Front brake 2. Input clutch 3. Dir ect clutch

4. High and low reverse clutch 5. Reverse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. F ron t carrier

19. Mid carrier 20. Rear internal gear 21. Output shaft

22. Parking gear 23. Parking pawl

H

I

J

K

SCIA1512E

L

M

Revision: April 2004 2004 Titan

AT-25

Page 26

A/T CONTROL SYSTEM

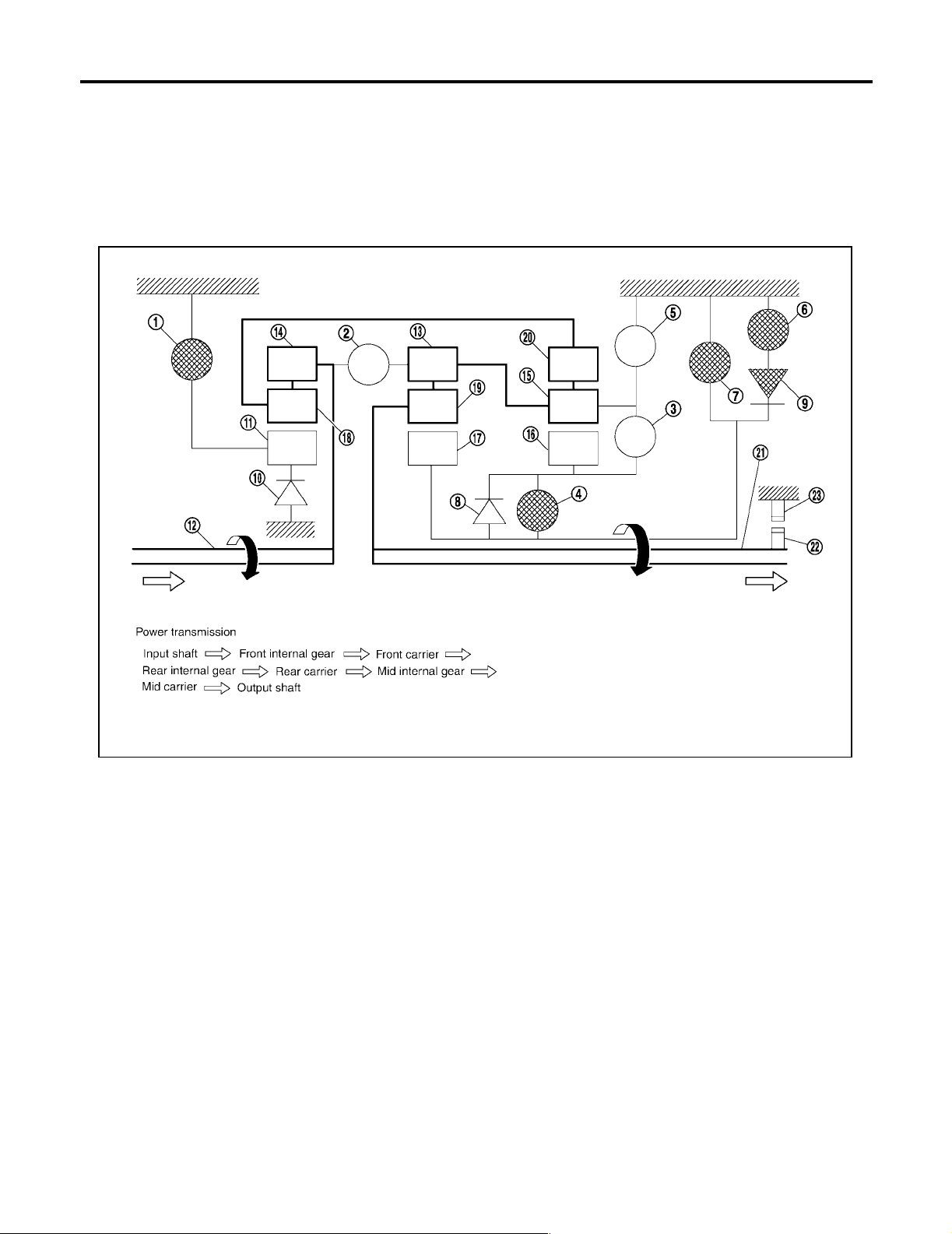

“M1” position (column shift), “1 ” position (floor shift) 1st gear

● The front brake fastens the front sun gear.

● The forward brake and the forward one-way clutch regulate reverse rotation of the mid sun gear.

● High and low reverse clutch connects the rear sun gear and the mid sun gear.

● The low coast brake fastens the mid sun gear.

● During deceleration, the low coast brake regulates forward rotation of the mid sun gear and the engine

brake functions.

1. Fr ont brak e 2. I nput clutch 3. Direct clutch

4. H i gh and l ow reverse clutch 5. R everse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. Front carrie r

19. Mid carrier 20. Rear internal gea r 2 1. Output shaft

22. Parking gear 23. Parking pawl

SCIA1513E

Revision: April 2004 2004 Titan

AT-26

Page 27

A/T CONTROL SYSTEM

“D”, “M5”, “M4”, “M3” positions (column shift), “D”, “4”, “3” positions (column shift) 2nd gear

● The forward brake and the forward one-way clutch regulate reverse rotation of the mid sun gear.

● The 3rd one-way clutch regulates rever s e rotation of the front sun gear .

● The direct clutch is coupled and the rear carrier and rear sun gear are connected.

● During deceleration, the mid sun gear turns forward, so the forward one-way clutch idles and engine

brake is not act ivated.

A

B

AT

D

E

F

G

1. Front brake 2. Input clutch 3. Dir ect clutch

4. High and low reverse clutch 5. Reverse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. F ron t carrier

19. Mid carrier 20. Rear internal gear 21. Output shaft

22. Parking gear 23. Parking pawl

H

I

J

K

SCIA1514E

L

M

Revision: April 2004 2004 Titan

AT-27

Page 28

A/T CONTROL SYSTEM

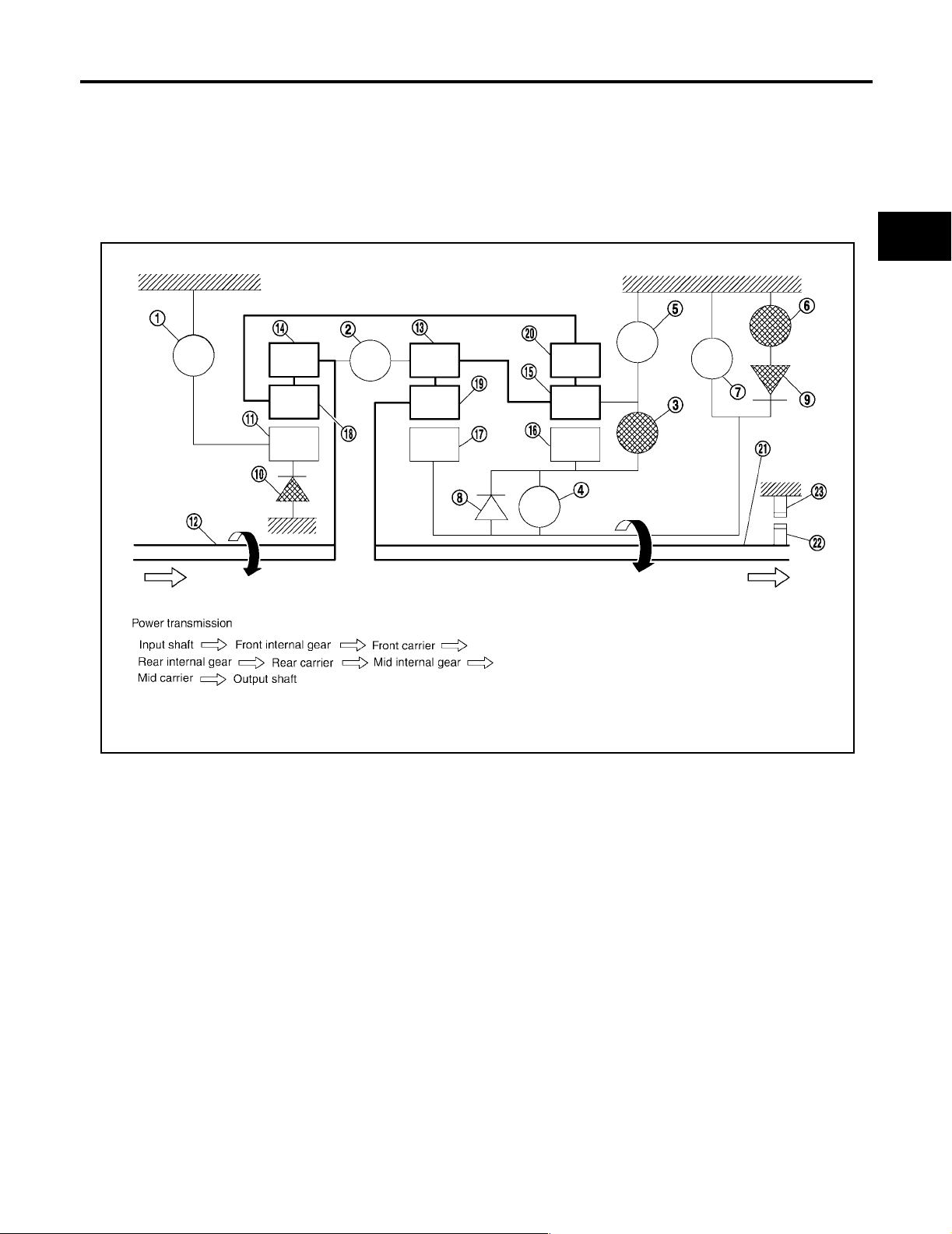

“M2”, “M1” positions (column shift), “2”, “1” positions (floor shift) 2nd gear

● The front brake fastens the front sun gear.

● The forward brake and the forward one-way clutch regulate reverse rotation of the mid sun gear.

● The direct clutch is coupled, and the rear carrier and rear sun gear are connected.

● The low coast brake fastens the mid sun gear.

● During deceleration, the low coast brake regulates forward rotation of the mid sun gear and the engine

brake functions.

1. Fr ont brak e 2. I nput clutch 3. Direct clutch

4. H i gh and l ow reverse clutch 5. R everse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. Front carrie r

19. Mid carrier 20. Rear internal gea r 2 1. Output shaft

22. Parking gear 23. Parking pawl

SCIA1515E

Revision: April 2004 2004 Titan

AT-28

Page 29

A/T CONTROL SYSTEM

“D”, “M5”, “M4”, “M3” positions (column shift), “D”, “4”, “3” positions (floor shift) 3rd gear

● The front brake fastens the front sun ge ar.

● The direct clutch is coupled, and the rear carrier and rear sun gear are connected.

● The high and low reverse clutch is coupled and the mid sun gear and rear sun gear are connected.

A

B

AT

D

E

F

G

1. Front brake 2. Input clutch 3. Dir ect clutch

4. High and low reverse clutch 5. Reverse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. F ron t carrier

19. Mid carrier 20. Rear internal gear 21. Output shaft

22. Parking gear 23. Parking pawl

H

I

J

SCIA1516E

K

L

M

Revision: April 2004 2004 Titan

AT-29

Page 30

A/T CONTROL SYSTEM

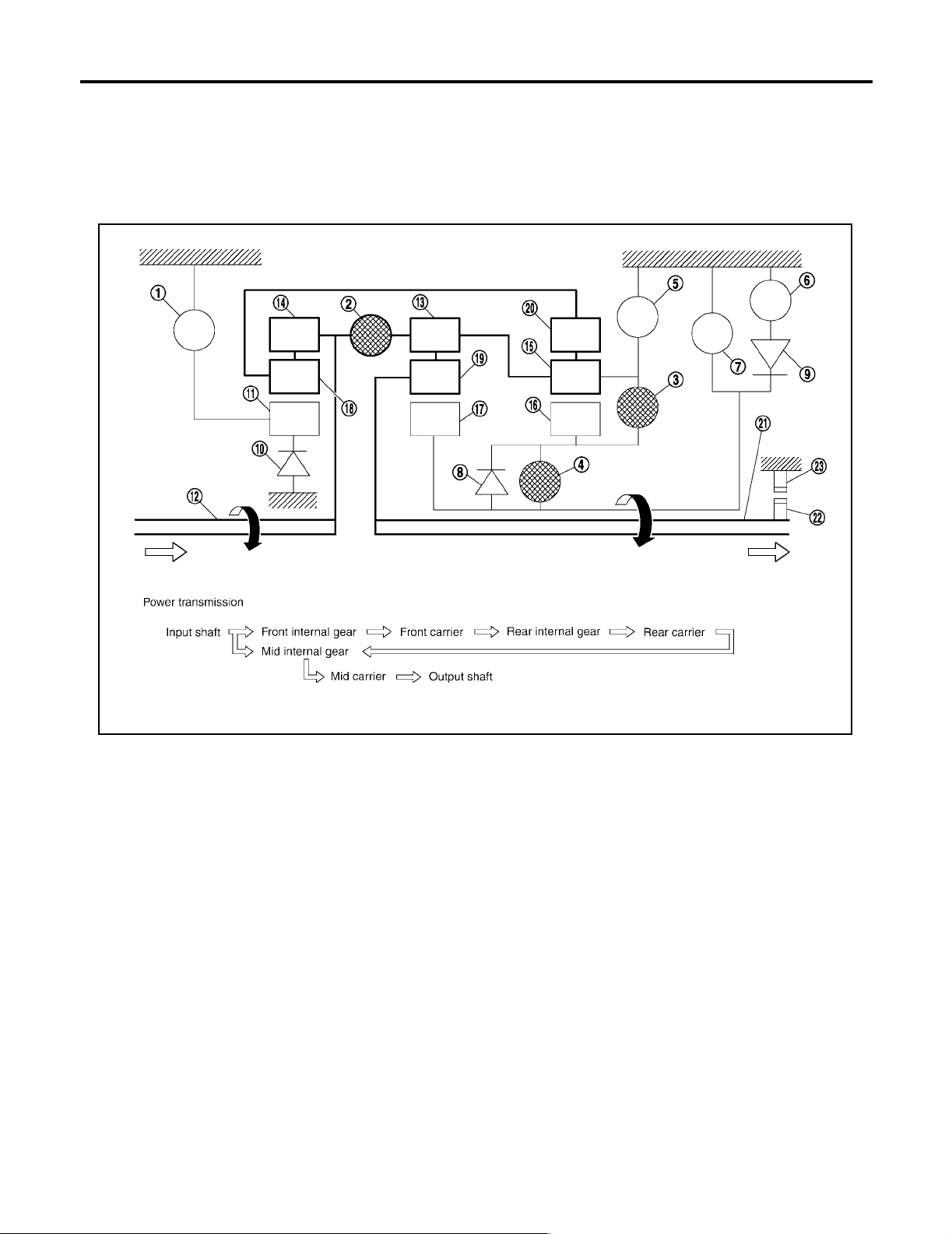

“D”, “M5”, “M4” positions (column shift), “D”, “4” positions (floor shift) 4th gear

● The direct clutch is coupled, and the rear carrier and rear sun gear are connected.

● The high an d low reverse clutch is coupled and the mid sun gear and rear sun gear are connected.

● The input clutch is coupled and the front internal gear and mid internal gear are connected.

● The drive power is co nveyed to the front in ternal gear, mid internal gear, and rear carrier an d the three

planetary gears rotate forward as one unit.

1. Fr ont brak e 2. I nput clutch 3. Direct clutch

4. H i gh and l ow reverse clutch 5. R everse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. Front carrie r

19. Mid carrier 20. Rear internal gea r 2 1. Output shaft

22. Parking gear 23. Parking pawl

SCIA1517E

Revision: April 2004 2004 Titan

AT-30

Page 31

A/T CONTROL SYSTEM

“D”, “M5” positions (column shift), “D” position (floor shift) 5th gear

● The front brake fastens the front sun ge ar.

● The input clutch is coupled and the front internal gear and mid internal gear are connected.

● The high and low reverse clutch is coupled and the mid sun gear and rear sun gear are connected.

A

B

AT

D

E

F

G

1. Front brake 2. Input clutch 3. Dir ect clutch

4. High and low reverse clutch 5. Reverse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. F ron t carrier

19. Mid carrier 20. Rear internal gear 21. Output shaft

22. Parking gear 23. Parking pawl

H

I

J

SCIA4984E

K

L

M

Revision: April 2004 2004 Titan

AT-31

Page 32

A/T CONTROL SYSTEM

“R” position

● The front brake fastens the front sun gear.

● The high and low reverse clutch is coupled, and the mid sun gear and rear sun gear are connected.

● The reverse brake fastens the rear carrier.

1. Fr ont brak e 2. I nput clutch 3. Direct clutch

4. H i gh and l ow reverse clutch 5. R everse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. Front carrie r

19. Mid carrier 20. Rear internal gea r 2 1. Output shaft

22. Parking gear 23. Parking pawl

SCIA1519E

Revision: April 2004 2004 Titan

AT-32

Page 33

A/T CONTROL SYSTEM

TCM Function

UCS002MT

The function of the TCM is to:

● Receive input signals sent from various switches and sensors.

● Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

● Send required output signals to the respective solenoids.

CONTROL SYSTEM OUTLIN E ( FLOOR SHIFT)

The automatic transmission se ns es v eh ic le op era ting conditions thro ugh various sens o r s o r s ig nals. It always

controls the optimum shift position and reduces shifting and lock-up shocks.

SENSORS (or SIGNALS)

PNP switch

Accelerator pedal position sensor

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed signal

Stop lamp switch signal

Turbine revolution sensor

1st position switch signal

4th position switch signal

ATF pressure switch

Tow mode switch signal

Þ

Shift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

Duet-EA control

CAN system

TCM

Þ

ACTUATORS

Input clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High & low reverse clutch solenoid valve

Low coast brake solenoid valve

T orque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Starter relay

Back-up lamp relay

CONTROL SYSTEM DIAGRAM

A

B

AT

D

E

F

G

H

K

M

I

J

L

SCIA5624E

Revision: April 2004 2004 Titan

AT-33

Page 34

A/T CONTROL SYSTEM

CONTROL SYSTEM OUTLINE (COLUMN SHIFT)

The automatic transmission senses vehicle operating conditions through various sensors or signals. It always

controls the optimum shift position and reduces shifting and lock-up shocks.

SENSORS (or SIGNALS)

PNP switch

Accelerator pedal position sensor

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed signal

Stop lamp switch signal

Turbine revolution sensor

Manual mode switch

Tow mode switch signal

CONTROL SYSTEM DIAGRAM

Þ

Shift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

Duet-EA control

CAN system

TCM

Þ

ACTUATORS

Input clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High & low reverse clutch solenoid valve

Low coast brake solenoid valve

T orque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Start e r relay

Back-up lamp relay

SCIA5625E

Revision: April 2004 2004 Titan

AT-34

Page 35

A/T CONTROL SYSTEM

CAN Communication

UCS002MU

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle multiplex communication line with high data communication speed and excellent error detection ability. Many electronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during opera tion (not independent). In CA N communication, cont rol units are connected with 2

communicatio n lines ( CAN H lin e, CAN L li ne) al lowi ng a high rate of in forma tio n trans missi on wi th less w iring .

Each control unit transm its/receives da ta but selectively read s required data only. For details, refer to LAN-8,

"CAN COMMUNICATION" .

Input/Output Signal of TC M

Line

Control item

Accelerator pedal position signal

Vehicle speed sensor A/T

(revolution sensor)

Vehicle speed sensor MTR

Closed throttle position signal

Wide open throttle position signal

Turbine revolution sensor 1 X X X X X

Turbine revolution sensor 2

Input

(for 4th speed only)

Engine speed signals

PNP switch XXXXXXX

A/T fluid temperature sensors 1, 2XXXXXXX

Operation signal

ASCD

TCM power supply voltage signal XXXXX X

Direct clutch solenoid (ATF pres-

sure switch 5)

Input clutch solenoid (ATF pressure

switch 3)

High & low reverse clutch solenoid

(ATF pressure switch 6)

Front brake solenoid (ATF pressure

Out-

switch 1)

put

Low coast brake solenoid (ATF

pressure switch 2)

Line pressure solenoid XXXX XXX

TCC solenoid X X X

Self-diagnostics table

Starter relay XX

*1: Spare for vehicle speed sensor·A/T (revolu tion sensor)

*2: Spare for accelerator pedal position signal

*3: If these input and output signals are different, the TCM triggers th e fail -s afe function.

*4: CAN communications

Overdrive cancel

signal

(*1) (*4)

(*4)

(*4)

(*4)

(*4)

(*4)

pressure

control

(*4)

(*4)

XXXXXXX

XXXX XX

XXXX X

(*2) X (*2) X X (*2) X X

(*2) X (*2) X (*2) X X

XX X XX

Vehicle

speed

control

XXXX

XXX

XX XX

XX XX

XX XX

XX XX

XX XXX

Shift

control

Lock-up

control

XX

Engine

brake

control

Fail-safe

function

(*3)

UCS002MV

Self-diag-

nostics

function

X

A

B

AT

D

E

F

G

H

I

J

K

L

M

Revision: April 2004 2004 Titan

AT-35

Page 36

A/T CONTROL SYSTEM

Line Pressure Control

● When an input torque signal equivalent to the engine drive force is sent from the ECM to the TCM, the

UCS002MW

TCM controls the line pressure solenoid.

● This line pressure s olenoid controls the pressure regu lator valve as the signal press ure and adjusts the

pressure of the o perating oil dischar ged from the oil pump to the line pressur e most appropriate to t he

driving state.

PCIA0007E

LINE PRESSURE CONTROL IS BASED ON THE TCM LINE PRESSURE CHARACTERISTIC PATTERN

● The TCM has store d in memory a n umb er of patterns for t he o ptimum line pr essure ch arac terist ic fo r the

driving state.

● In order to obtain the most app ropriate line pres sure characteristi c to meet the current d riving state, the

TCM controls the line pressure solenoid current valve and thus controls the line pressur e.

Normal control

Each clutch is adjusted to the necessary pressure to match the

engine drive force.

Back-up control (Engine brake)

When the select operation is performed during driving and the transmission is shifted down, the line pressure is set according to the

vehicle speed.

PCIA0008E

PCIA0009E

Revision: April 2004 2004 Titan

AT-36

Page 37

A/T CONTROL SYSTEM

During shift change

The necessary a nd adequate line pressure for sh ift change is set.

For this reason, line pressure pattern setting corresponds to input

torque and gearshift selection. Also, line pressure characteristic is

set according to engine speed, during engine brake operation.

A

B

AT

D

E

F

G

PCIA0010E

At low fluid temperature

When the A/T fluid temperature drops below the prescribed temperature, in order to speed up the action of each friction element, the line

pressure is set higher than the no rma l lin e pre ss ure char ac te ris tic .

PCIA0011E

Shift Control

The clutch pressure control solenoid is controlled by the signals from the switches and sensors. Thus, the

clutch pressure is adjusted to be appropriate to the engine load state and vehicle driving state. It becomes

possible to finely control the clutch hydraulic pressure with high precision and a smoother shift change characteristic is attained.

UCS002MX

H

I

J

K

L

M

PCIA0012E

SHIFT CHANGE

The clutch is contro lle d w it h th e op tim um tim in g a nd oil pres su re by th e en gi ne spe ed , en gine torque information, etc.

Revision: April 2004 2004 Titan

AT-37

Page 38

Shift change system diagram

A/T CONTROL SYSTEM

*1: Full phase real-time feedback control monitors movement of gear ratio at gear change, and controls oil

PCIA0013E

pressure at real-time to achieve the best gear ratio.