Page 1

SPECIAL

SEWING MACHINE

&

FOR

CARPET

OVEREDGING

AK-2500 SERIES

(

FOR

BAGS, AND EXTRA HEAVY MATERIALS,

RUGS, BLANKETS JUTE, POLYPROPYLENE

ETC)

Page 2

INDEX

1

Setting up

Threading

Obtaining

Cutting

Carpet guide ....................................................................................................................

Adjustment

Setting

Adjustment

Adjustment

List

of

Yarns & Feed

Presser

of

of

correct

device

of

number

chain

foot

the

machine

lower

of

of

after

guides

dog

............................................................................. : ..................................... :.· 23

looper ............................................................................................... 7

sti

· ch ................................................................................................... 9

.................................................................................................................

Ioopers ............................................................. .-.......................................

of

stitches .........................................................................................

needle

replacement

......................................................................................................... 18

................................. , ..................................................... : .....................

and lubrication ...................................................................... 5

bar

............................................................................................... 15

of

hooks····························································-···········

11

12

13

14

16

22

Knives ..................................................................................... : ........................................ 24

Needles ............................................................................................................................ 25

foot

Presser

Needlebar

Feeddog

Lower

Upper looper

C

u

Crank

Fitting a puller (option) .....................................................................................................

Setting

looper

....

d . h · · 37

t

Ling

shaft

of

mechanism

movement

movement

mechanism

mechanism

ev1ce

length

mec

.......................................................................................................................

of

stitch

................................................................................................. 27

...................................................................................................... 29

........................................................................................................

.................................................. _ ..............................................

................................................................................................

an1sm

........................................................................................ ·····

device

(option) ......................................................................

31

33

35

39

41

48

Page 3

3

FITTING

INSTRUCTION

Needle

FOR

YARN

yarn~--

STAND

_

Looper

yarn

.

Page 4

27

PRESSER

FOOT

ASSEMBLY.

25773

25761

-~5590V

·

-......

25762

25590

·

25573

25572

l

0 25579

2ssa

2557

25833

25833V

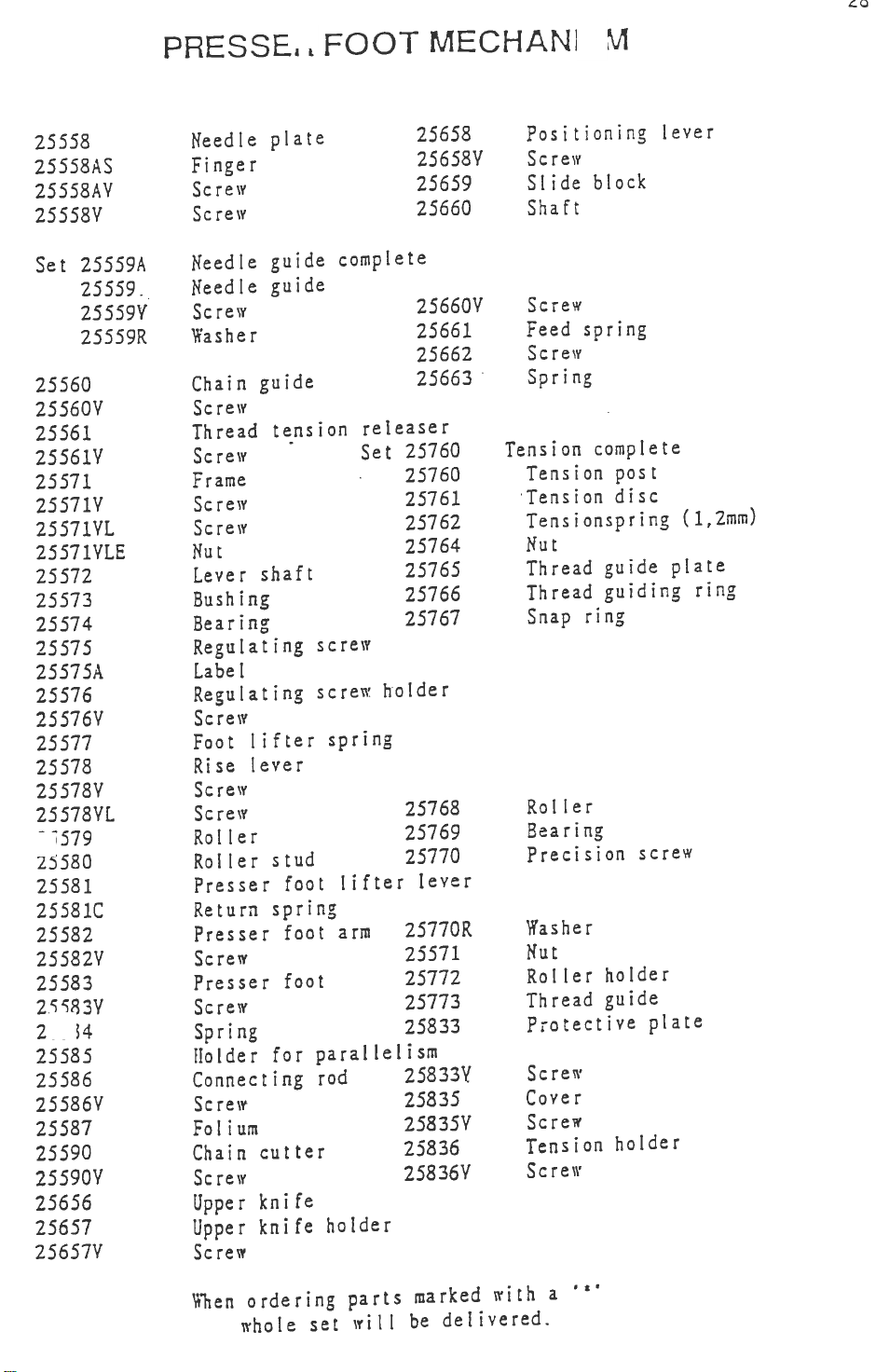

Page 5

PRESSER

FOOT

MECHANISM

25558

25558AS

25558AV

25558V

Set

25559A

25559

25559V

25559R

25560

25560V

25561

25561V

25571

25571V

25571YL

25571YLE

25572

25573

25574

25575

25575A

25576

25576V

25577

25578

25578V

25578YL

25579

25580

25581

25581C

25582

25582V

25583

25583V

25584

25585

25586

25586V

25587

25590

25590V

25656

25657

25657V

Needle

Finger

Screw

Screw

Needle

Needle

.

Screw

Washer

Chain guide

Screw

Thread

Screw

Frame

Screw

Screw

Nut

Lever

Bushing

Bearing

Regulating

Label

Regulating

Screw

Foot

Rise

Screw

Screw

Ro

Ro

Presser

Return

Presser

Screw

Presser

Screw

Spring

Holder

Connecting

Screw

Fol

Ch

Screw

Upper

Upper

Screw

l I

I I

i

a in

plate

guide

guide

tension

shaft

Ii f ter

lever

er

er

stud

spring

for

um

cutter

knife

knife

complete

screw

screw.

spring

foot Ii

foot

arm

foot

parallelism

rod

holder

25658

25658V

25659

25660

25660V

25661

25662

25663

releaser

Set

25760

25760

25761

25762

25764

25765

25766

25767

holder

25768

25769

25770

fter

lever

25770R

25571

25772

25773

25833

25833Y

25835

25835V

25836

25836V

Positioning

Screw

Slide

Shaft

Screw

Feed spring

Screw

Spring

·

Tension complete

Tension post

·Tension

Tensionspring

Nut

Thread guide

Thread guiding ring

Snap

Ro

Bearing

Precision

Washer

Nut

Roi

Thread guide

Protective

Screw

Cover

Screw

Tension holder

Screw

I I

er

!er

block

disc

ring

holder

lever

(1,2mm)

plate

screw

plate

~nen

ordering

whole set

parts

will

marked with a

be

delivered.

·•·

Page 6

29

25556

BV

NEEDLE

25553

25556 8

BAR

MECHANISM

Page 7

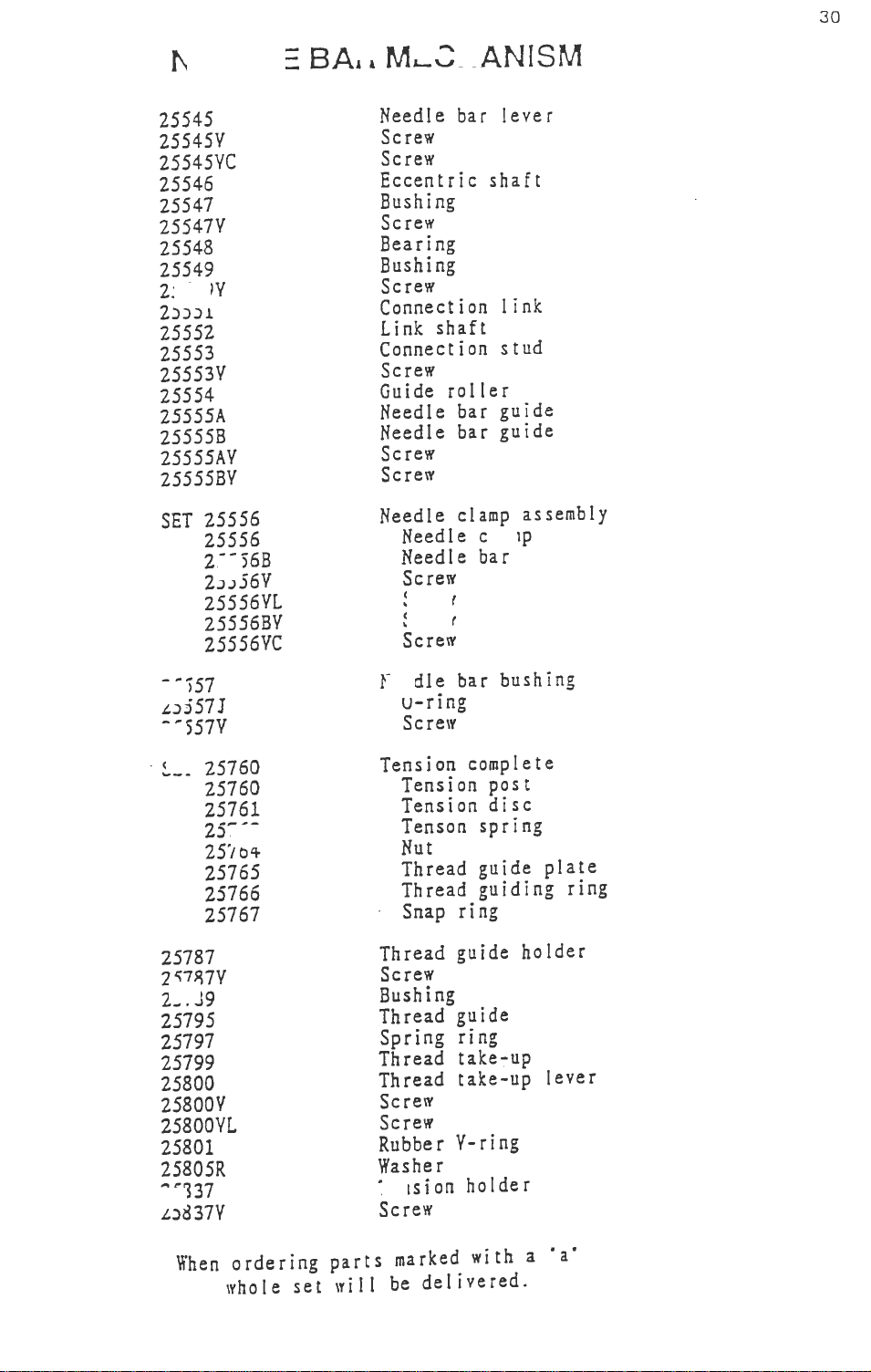

30

NEEDLE

25545

25545V

25545YC

25546

25547

25547V

25548

25549

.

25549V

25551

25552

25553

25553V

25554

25555A

25555B

25555AV

25555BV

SET

25556

25556

25556B

25556V

25556VL

25556BV

25556YC

BAR

MECHANISM

Needle bar lever

Screw

Screw

Eccentric

Bushing

Screw

Bearing

Bushing

Screw

Connection link.

Link.

Connection

Screw

Guide

Needle bar guide

Needle bar guide

Screw

ScrelY

Needle

Needle

Needle bar

ScrelY

Screw

Screw

Scre1Y

shaft

roller

clamp

clamp

shaft

stud

assembly

25557

255571

25557V

·

SET

25760

25760

25761

25763

25764

25765

25766

25767

25787

25787V

25789

25795

25797

25799

25800

25800V

25800VL

25801

25805R

25837

25837V

Needle bar bushing

0-r i ng

Screw

Tension complete

Tension post

Tension

Tens

Nut

Thread guide

Thread guiding ring

Snap

Thread guide holder

Screw

Bushing

Thread guide

Spring ring

Thread

Thread take-up lever

ScrelY

Screw

Rubber Y-ring

Washer

Tension holder

Screw

disc

on

spring

ring

take-:-up

plate

When

ordering

whole set

parts

wil I be

marked

delivered.

with a

·a·

Page 8

31

N

_,.

~

.....

,.r,

N

:;

..r,

'°

"'

......

......

"'

..r,

'°

......

C,

,.,

.....

..r,

N

......

,D

N

.....

..r,

....

.....

0

,..,

.....

..r,

"'

"'

N

.....

..r,

.....

>

=

,.r,

.....

c:,

,.r,

......

Page 9

SET

•

25641

25640

25641

FEEDDOG

Lower

Bearing

Lower

MECHANISM

knife

driving

knife

driving

link complete

link

25641V

25642

25643

25645

25699

25721

25.722

25722E

25724

25725

25726

25728

25728V

25728YL

25730

25730V

25731

25734

257341/

. 25735

25735V

25736

25737

25737P

25737V

25739

ScrelY

Driving link

Lower

Stud

Pin

Feed

Washer

Nut

Bearing bushing

Bearing

Feed

Feed

Screw

Screw

Bushing

Screw

Bearing

Thrust

Screw

Feed

Screw

Stud

Base

Protect

Screw

Feeddog

·

shaft

across

driving

driving

co

11

driving

ion

shaft

regulator

a r

·

rod

lever

lever

SET

25743

• 25742

25743

•

25743YP

25744

25744V

25845

26010

26011

26012

26014

~nen

ordering

whole

Complete feeddog

Shutter

Feeddog

Clamp

Feeddog

Screw

Plug

Shaft

Bushing

Bearing

0-r

i

ng

parts

set will

shaft

screw

marked with a

be

de!

shaft

guide

ivered.

guide

·•·

Page 10

w

w

25690V

\

2s 5 2ovr-_____

2S5

22

25516

ZIIIIVL

I

1

t;~

'

~

~

~

SET

~ -

('.§,.,.

'· \

•

~(

---._~:I

~-t\

• iy.l \

25520

\

~".J

,,

'·"'

'

"'-.,.

'

"---

'"-."',

11121

~\

2551SV

2 5

690y______ ~ .

I

i

25852

/

25690

25686

25516

·

~~~

25511,

Page 11

34

LOWER

SET

25511

"

25514

25515

25515V

25515VL

25516

25518

25518V

25518VL

SET

25520

25519

"

•

25520

25520YP

25521

25522

25523

LOOPER

Connecting

Bal

I

Small

Screw

Sere\\'

Washer

Driving

Screw

Screw

Complete

Lower

driving

Looper

Ba

I l

Precision

Nut

Bal

I

joint

looper

MECHANISM

rod

complete

lever

lever

ball

ball

joint

joint

screw

guide

fork

SET

25525

"

25524

"

25525

25525YP

25686

25690

25690V

25692

25802

25803

25803V

25804

25804V

25804YL

25852

25852A

25852V

~nen

ordering

n·hole

set

Under

Needle bearing

Bushing

Screw

Shaft

Thread guide

Thread guide supporting

ScrelY

Thread guide

Screw

Sc

Plug

Washer

Sc

parts

will

looper guide complete

Ba

11

Under looper

Screw

re,,·

re1Y

marked with

be

delivered.

ball

holder

joint

a···

shaft

Page 12

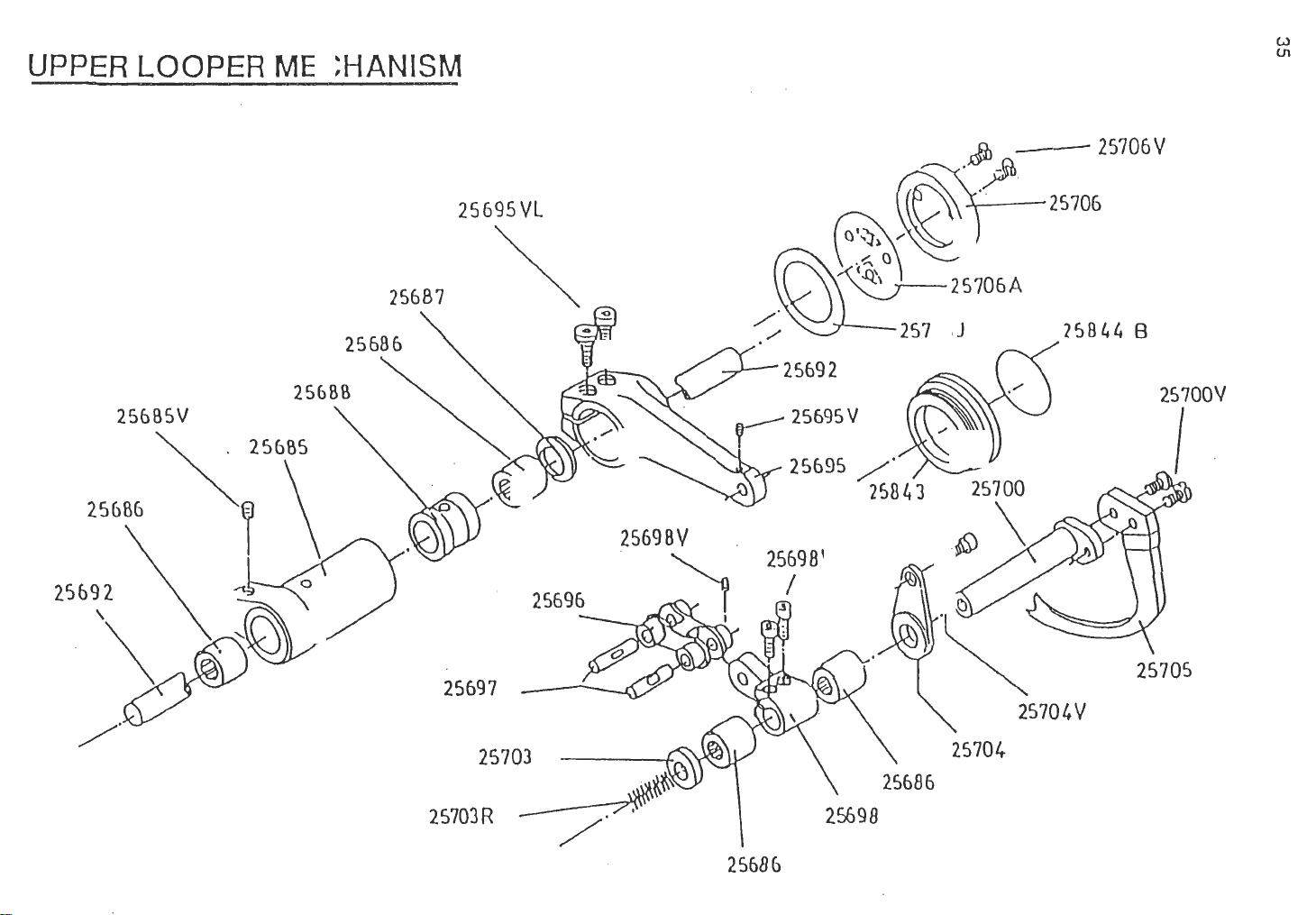

UPPER LOOPER MECHANISM

--25706V

w

Ul

25692

25GBB

25687

25695

VL

25695

/'

2S84

1S844 B

3

25704V

25704

25686

25698

25686

Page 13

36

UPPER

SET

25685

*

25685

25685V

25686

25687

25688

25692

25695

25695V

25695YL

25696

25697

25698

25698V

25698YL

25700

25700V

25703

25703R

25704

25704V

25705

25706

25706A

257061

25706V

25843

25844B

LOOPER

Complete intermediary assembly

Intermediate

Screw

Bearing

Washer

Bushing

Shaft

lever

Big

Screw

Screw

Connection

I:.ink

pin

Smal I lever

Screw

Screw

Upper

Sc re.

Washer

Spring

Thrust

Sc

Upper

on

Sticker

Packing

Screw

Plug

Sticker

looper

11·

rel\'

I oope r

window

MECHANISM

lever

link

shaft

plate

~nen

ordering

whole

set

parts

will

marked with a

be

delivered.

...

Page 14

37

25653

25650

CU

TT

ING

------

~

DEVICE

'p---

y·

\

®--25652

25650V

/

.

J----

25652

V

25546

255!.~

ZSSl~

~

----

<:;~

,,,D----___ 2 5 6 4 5

-~25647V

OVEREDGING MACHINE

Page 15

38

CUTTING

25546

255468

255468V

25645

SET

25647V

25650

25650V

25652

25652V

25653

25654

25654V

25655

25655V

25697

. Stud

25647

•

25647

25648

DEVICE

Eccentric

Co

11

a r

Screw

Lower

Screw

Slide

Screw

SI i de

Screw

Lower

Lower

Screw

Lower

Screw .

Link

knife

Lo\\'er

Bearing

block

block

knife

knife

knife

pin

MECHANISM

shaft

lever

knife

guide

shaft

bushing

complete

lever

~nen

ordering

whole

set

parts

will

marked with a

be

delivered.

...

Page 16

Crank

shaft.

w

ill

Page 17

40

SET

25511

•

25511

25511V

25511

25512

•

25513

•

25514

25604

SET

25511A

25511A

25511B

25604

25608

25601

25601A

25602

25602V

25603

25605

25605P

25605V

25605YL

25607

25607V

25608

25610

25610V

25612

25612V

25612YL

25615

25615V

25617

25620

256201

25620V

25621

25621V

25640A

SET

25641

25640

*

25641

25641V

25720

25720P

25720V

25721

25721V

25722

25722E

25844A

YL

CRANK

Connecting

Connecting rod

Clamp

Clamp

Ball

Bal

I

Ba

I I

Bearing

Complete rod

Rod

Stud

Bearing

Pin

Bearing

Bearing ·

Crank ·

Screw

Pin

Crank

Protection

Screw

Screw

Crank

Screw

P·in

Crank

Screw

Crank

Screw

Sc

re,r

Crank

Screw

Ring

Flange

0-ring

Screw

Pu!

ley

Screw

Washer

Lower

Bearing

Lower

Screw

Eccentric

Proection

Screw

Feed across

Screw

Washer

Nut

Plug

SHAFT

rod

complete

.screw

screw

joint

knife

guide fork

driving

knife

regulator

driving

link complete

link

When

ordering

whole

set

parts

\l'i

11

marked with

be

de!

ivered.

a···

Page 18

PULLER

260)7

160\6

Page 19

PULLER

44

25573

25575

255

76

25576V

25577

25

734

2573

4V

2

6010

2

6011

2

601

2

26

014

26016

26016

V

26016

VL

260

17

26018

260019

26020

26020V

26020VL

26021

26021V

26022

26023

26023V

26025

26026

26027

26027V

26027YL

26028

26029

26030

26031

26031V

26032

26033

26033V

26033YL

26034

26036

26037

26038

26041R

26041V

26041L

26042

26043

26043A

26043AY

26044

25576L

25577L

Bushing

Regulating screw

Regulating screw holder

Screw

Foot

Thru

lifter

st

co

11

a r

spring

Screw

Big axle

Bushing

Bearing

Sea l

-Ri

ng

Lever

Scre,r

Screw

Lever

Bushing

Pin

Lever

Screw

Sc

r.ew

Lever

Screw

Wheel

Washer

Screw

Lower

Upper

shaft

shaft

Frame

Screw

Screw

Bearing

Bushing

Bearing

Gear cover

Srew

Pin

Fixation

support

Screw

Screw

Block

Snap

ring

Bushing

Cardan

Lever

Screw

Lever

Bearing

Shaft for levers

Thrust

collar

Screw

Bushing

Page 20

45

SET

SET

26045

26047

26050

26050V

26051

26051V

26060

26060V

26062

26062V

26054

25916A

26052

26053

26054

26055

26056

26056V

26057

26057E

26057R

26050L

Bearing

Block

Piston

frame

Screw

Cover

Screw

Upper

feed

Screw

Lower

feed

Screw

Pneumatic

Elbow

0-Ring

0-Ring

Piston

0-Ring

Lever

Screw

Pin ·

Nut

Washer

n·heel

wheel

cylinder

(OPTION)

Page 21

)0':>66

25B~~S 258440

2500

@,R~

J0566V

TAPE

WITH

INSERTION

OR

WITHOUT

KNIVES

SERVICING WORKST AND

Page 22

0

cc

~

~

0

f-

....J

w

co

47

1..f")

N

<.D

i.n

N

Page 23

-

~

,-

.

-

a.,

Ol

0

r-

--

- > -

~

a.,

- ·

-0

0 ..c

01

0 0

c

::=

-

0

-

Q.;

48

Loading...

Loading...