BACK COVER

TIPPMANN

• Owner’s Manual

• Le Manuel du Propriétaire

• Manual del Usuario

TM

BASIC

®

TM

MARKER

LINE

TP04110

Date: 12/06

WARNING

E

THIS IS NOT A TOY. MISUSE MAY CAUSE SERIOUS

INJURY OR DEATH. EYE, FACE AND EAR PROTECTION

N

DESIGNED FOR PAINTBALL MUST BE WORN BY THE

G

USER AND ANY PERSON WITHIN RANGE. WE

L

RECOMMEND AT LEAST 18 YEARS OLD TO PURCHASE.

PERSONS UNDER 18 MUST HAVE ADULT SUPERVISION

I

WHEN USING THIS PRODUCT. READ THE OWNER’S

S

MANUAL BEFORE USING THIS PRODUCT.

H

WARNING

SAFETY IS YOUR RESPONSIBILITY

READ, FAMILIARIZE

YOURSELF AND ANY

OTHER USER OF THIS

MARKER WITH THE

SAFETY INSTRUCTIONS

IN THIS MANUAL.

FOLLOW THESE

INSTRUCTIONS WHEN

USING, WORKING ON,

TRANSPORTING OR

STORING THIS MARKER.

ALWAYS KEEP

TRIGGER SAFETY IN

SAFE MODE =

UNLESS FIRING

AS DETAILED IN

INSTRUCTIONS

ON PAGE 4.

BARREL SLEEVE

ALWAYS KEEP

BARREL SLEEVE

INSTALLED WHEN

NOT IN SHOOTING

SITUATION AS

DETAILED IN

INSTRUCTIONS ON

PAGE 2.

E

N

G

L

I

S

H

AVERTISSEMENT

F

CE N’EST PAS UN JOUET. L’USAGE IMPROPRE PEUT

CAUSER LA BLESSURE SÉRIEUSE OU LA MORT. LA

R

PROTECTION POUR LES YEUX, LE VISAGE ET LES

A

OREILLES CONSTRUITE POUR LA BALLE DE PEINT

N

DOIT ÊTRE PORTÉE PAR L’UTILISATEUR ET N’IMPORTE

QUELLE PERSONNE DANS LE CHAMP DE TIR. NOUS

Ç

RECOMMENDONS QU’ ON A DIX – HUIT ANS AU MOINS

A

POUR L’ACHETER. LES PERSONNES SOUS L’ÂGE DE

I

DIX – HUIT ANS DOIVENT AVOIR LA SUPERVISION D’

S

UN ADULTE QUAND ON EMPLOIE CE PRODUIT. IL FAUT

LIRE TOUT DE CE MANUEL AVANT DE L’UTILISER.

ADVERTENCIA

E

ESTO NO ES UN JUGUETE. UN USO INAPROPIADO

PUEDE CAUSAR SERIAS HERIDAS O LA MUERTE.

S

OJOS, CARA Y OIDOS DEBEN SER PROTEGIDOS T ODO

P

EL TIEMPO, CON LA PROTECCIÓN DISEÑADA PARA

A

PAINTBALL TANTO POR JUGADORES COMO POR

CUALQUIER PERSONA QUE ESTE EN EL RADIO DE

Ñ

ALCANCE. RECOMENDAMOS AL MENOS 18 AÑOS

O

PARA LA COMPRA Y USO. LAS PERSONAS MENORES

L

DE 18 AÑOS DEBEN USAR ESTE PRODUCTO BAJO LA

SUPERVISIÓN DE UN ADULTO. ANTES DE USAR ESTE

PRODUCTO LEA EL MANUAL DEL USUARIO.

AVERTISSEMENT

SÉCURITÉ EST VOTRE RESPONSABILITÉ

IL FAUT LIRE, VOUS

FAMILIARISER ET TOUS

LES AUTRES UTILISATEURS

DE CE MARQUEUR

AVEC LES INSTRUCTIONS

DE SÉCURITÉ DANS CE

MANUEL. SUIVEZ CES

INSTRUCTIONS QUAND

VOUS UTILISEZ,

TRAVAILLEZ SUR,

TRANSPORTEZ, OU

ENTREPOSEZ CE

MARQUEUR.

IL FAUT TOUJOURS

GARDER LA DÉTENTE

DANS UNE MODE DE

SÉCURITÉ

SAUF QUAND ON TIRE

COMME DÉTAILLÉS

DANS LES

INSTRUCTIONS À LA

PAGE 3

=

LA CHEMISE DU CANON

IL FAUT TOUJOURS

GARDER LA

CHEMISE DU

INSTALLÉE

ON NE TIRE PAS

COMME DÉTAILLÉS

DANS LES

INSTRUCTIONS À LA

PAGE 1.

ADVERTENCIA

LA SEGURIDAD ES SU RESPONSABILIDAD

EL PROPIETARIO Y TODA

PERSONA QUE VA A USAR

ESTE MARCADOR DEBE

LEER Y FAMILIARIZARCE

CON LAS INSTRUCCIONES

DE SEGURIDAD EN ESTE

MANUAL. SIGA LAS

INSTRUCCIONES DE USO,

MANTENIMIENTO,

TRANSPORTE Y

ALMACENAJE DE ESTE

MARCADOR.

MANTENGA SIEMPRE EL

SEGURO DEL GATILLO

ACTIVADO

MENOS QUE SEA

NECESARIO HACER

DISPAROS. INMEDIATOS

COMO SE VE EN LAS

INSTRUCCIONES

DE LA PÁGINA 3.

=

FUNDA DE SEGURIDAD

A

CANON

QUAND

MANTENGA LA

FUNDA DE

SEGURIDAD

INST ALADA

CUANDO NO ESTE

HACIENDO DISPAROS

COMO SE ILUSTRA

EN LA PÁGINA 1.

F

R

A

N

Ç

A

I

S

E

S

P

A

Ñ

O

L

WARNING

E

THIS IS NOT A TOY. MISUSE MAY CAUSE SERIOUS INJURY OR

DEATH. EYE, FACE AND EAR PROTECTION DESIGNED FOR

N

PAINTBALL MUST BE WORN BY THE USER AND ANY PERSON

WITHIN RANGE. WE RECOMMEND AT LEAST 18 YEARS OLD

G

TO PURCHASE. PERSONS UNDER 18 MUST HAVE ADULT

L

SUPERVISION WHEN USING THIS PRODUCT. READ THE

OWNER’S MANUAL BEFORE USING THIS PRODUCT.

I

S

H

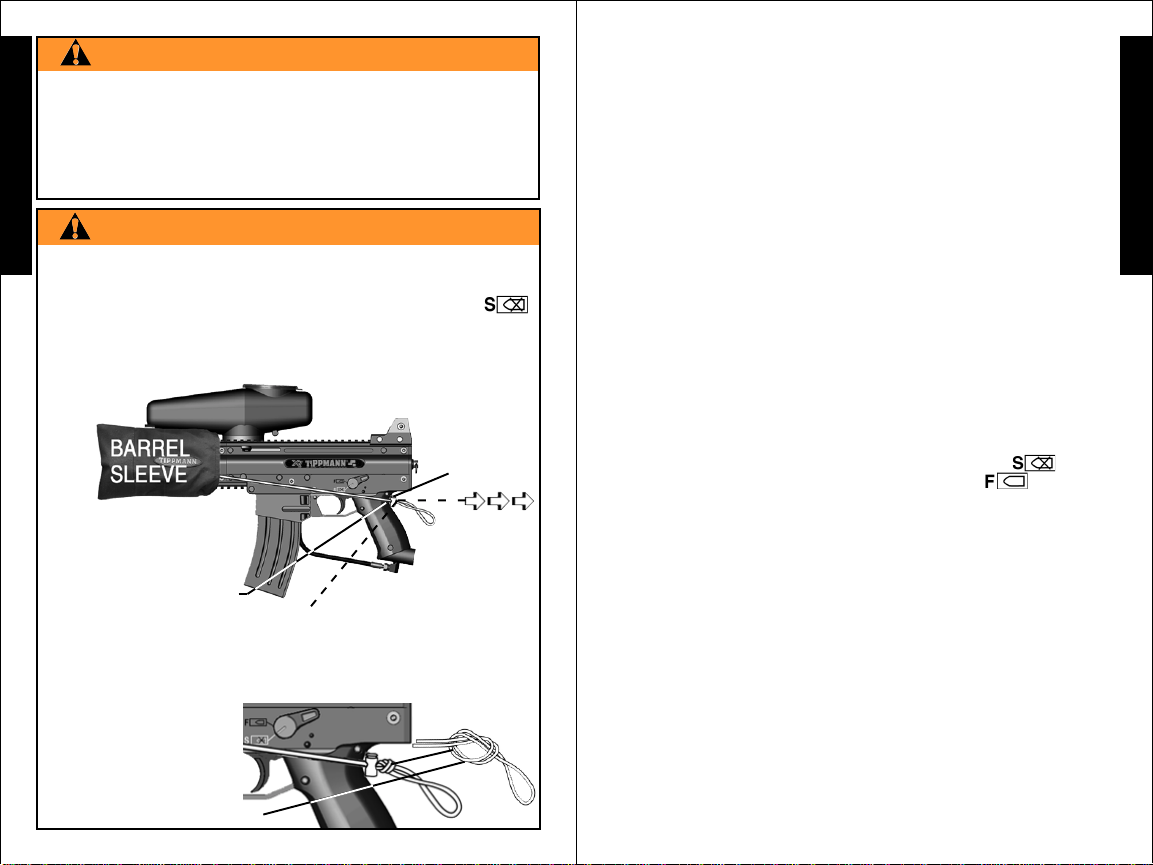

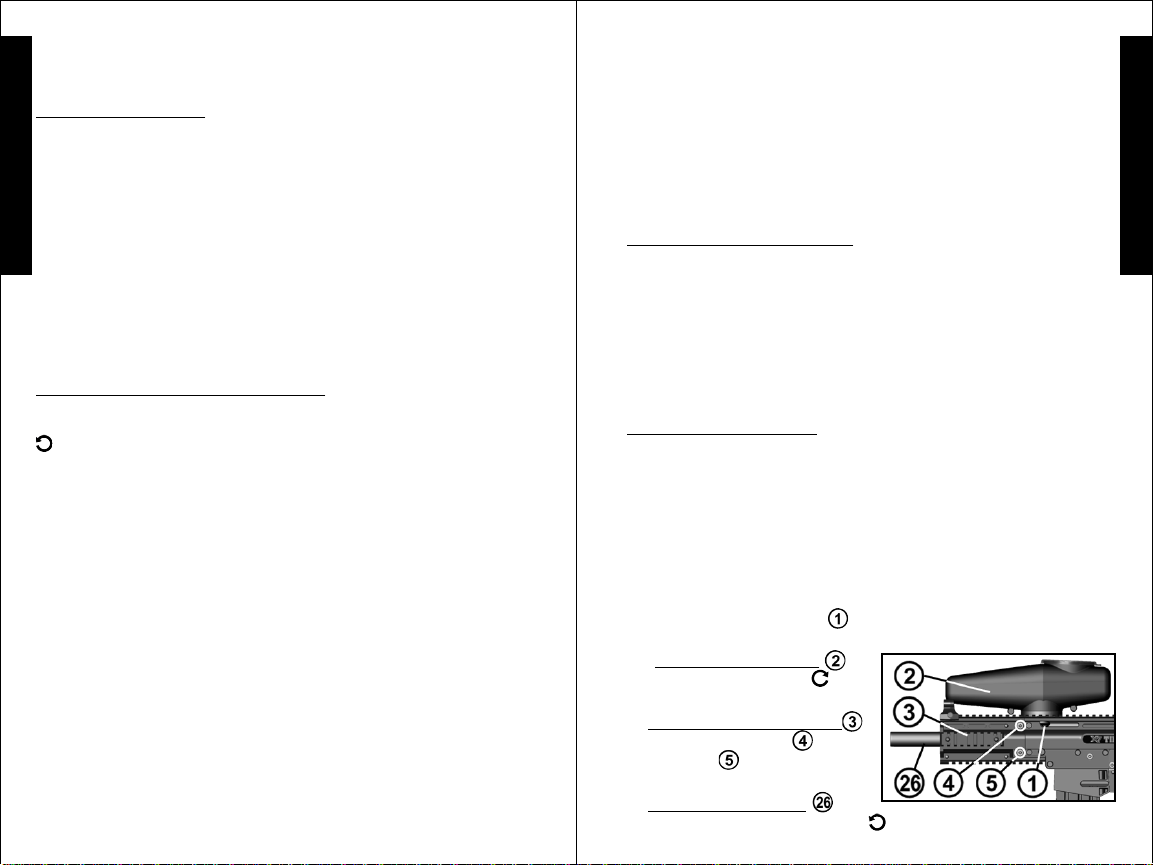

BARREL SLEEVE INSTALLATION

• EXCEPT WHEN YOUR MARKER IS IN USE, ALWAYS MAKE

SURE THAT THE TRIGGER SAFETY IS IN SAFE MODE

(SEE INSTRUCTIONS ON PAGE 4), AND THE BARREL SLEEVE

IS PROPERLY INSTALLED ON YOUR MARKER AS FOLLOWS.

1) SLIDE BARREL INTO SLEEVE AND LOOP CORD OVER TOP

OF RECEIVER AND POSITION AT BACK OF GRIP AS SHOWN.

2) PINCH

CORD LENGTH

ADJUSTOR

BUTTON AND

HOLD TO BACK OF GRIP

AS YOU PULL CORD THROUGH IT UNTIL ADJUSTOR IS

SNUG AGAINST BACK OF GRIP, THEN RELEASE BUTTON.

3) CHECK TO BE SURE THERE IS ENOUGH CORD

ELASTICITY TO PULL CORD/ADJUSTOR OFF OF GRIP TO

REMOVE BARREL SLEEVE FOR FIRING.

4) AFTER CORD LENGTH

IS ADJUSTED, LOCK

CORD LENGTH BY TYING

A KNOT IN THE CORD

AGAINST THE BACK OF

THE ADJUSTOR AS SHOWN.

WARNING

ADJUSTOR

2

=

CORD

LENGTH

BUTTON

®

TIPPMANN

2955 Adams Center Road, Fort Wayne, IN 46803 USA

P) 260-749-6022 • F) 260-749-6619

www.tippmann.com

CONGRATULATIONS on your purchase of your Tippmann

paintball marker. We believe our X7

most accurate and durable paintball markers available, and

proudly manufactured in the USA. All Tippmann® X7TM models

will give many years of dependable service if cared for properly.

TM

line of markers to be the

E

N

G

®

L

I

S

H

Please take time to read this manual thoroughly and become

familiar with your Tippmann® X7TM markers’ parts, operation, and

safety precautions before you attempt to load or fire this marker.

If you have a missing or broken part or need assistance, please

contact Tippmann® Consumer Relations at 1-800-533-4831 for

fast friendly service.

TABLE OF CONTENTS

Warning/Caution............................................................................... 2

Warning/Caution Barrel Sleeve Installation................................... 2

Warning/Liability Statement ............................................................ 4

Safety is your Responsibility / Familiarize Yourself With Safety. 4

Safe Mode = Turning The Safety On (SAFE = white ) ....... 4

Fire Mode = Turning The Safety Off (FIRE = red ) ............. 4

Get t in g S ta r te d ................................................................................. 6

1. Prepare Marker for Air Supply Cylinder Installation............. 6

2. Air Supply Cylinder Installation .............................................. 6

3. Hopper and CycloneTM Feeder ................................................ 6

4. Velocity Adjustment ................................................................. 7

5. Rear Sight Adjustment ............................................................ 7

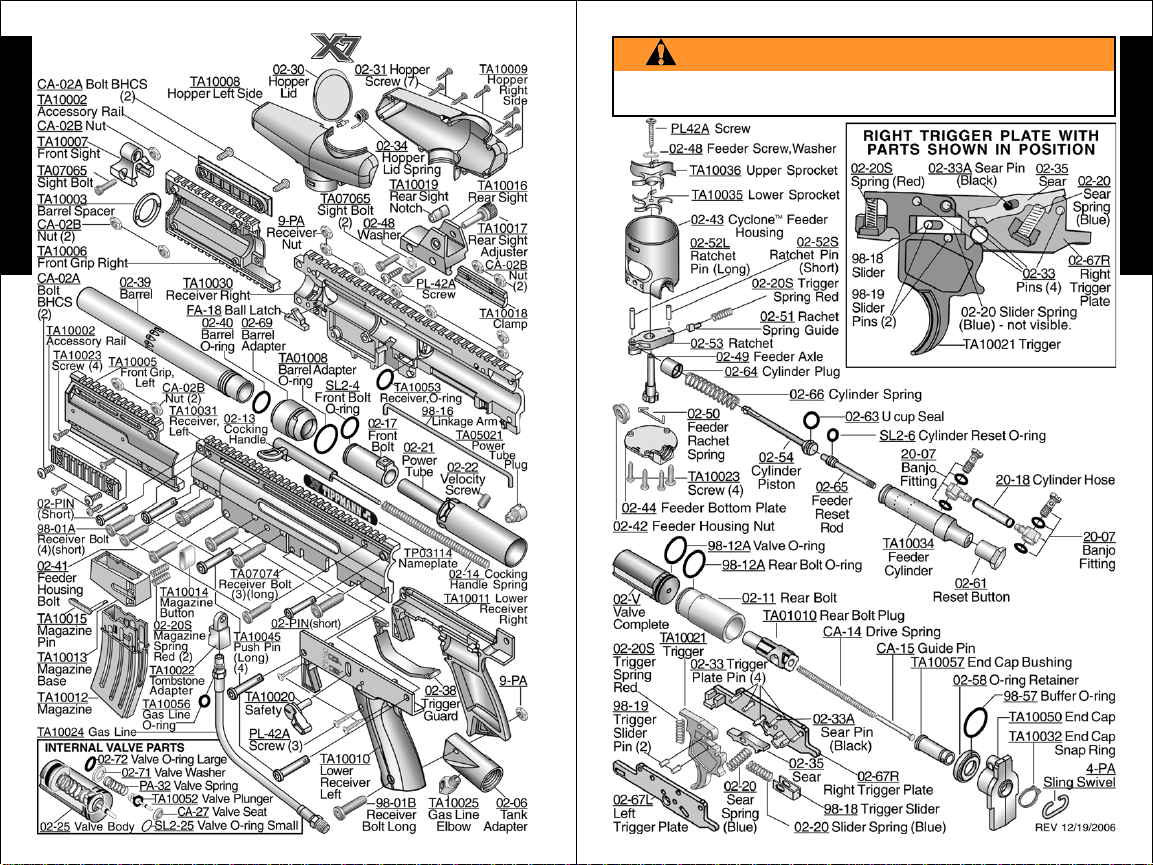

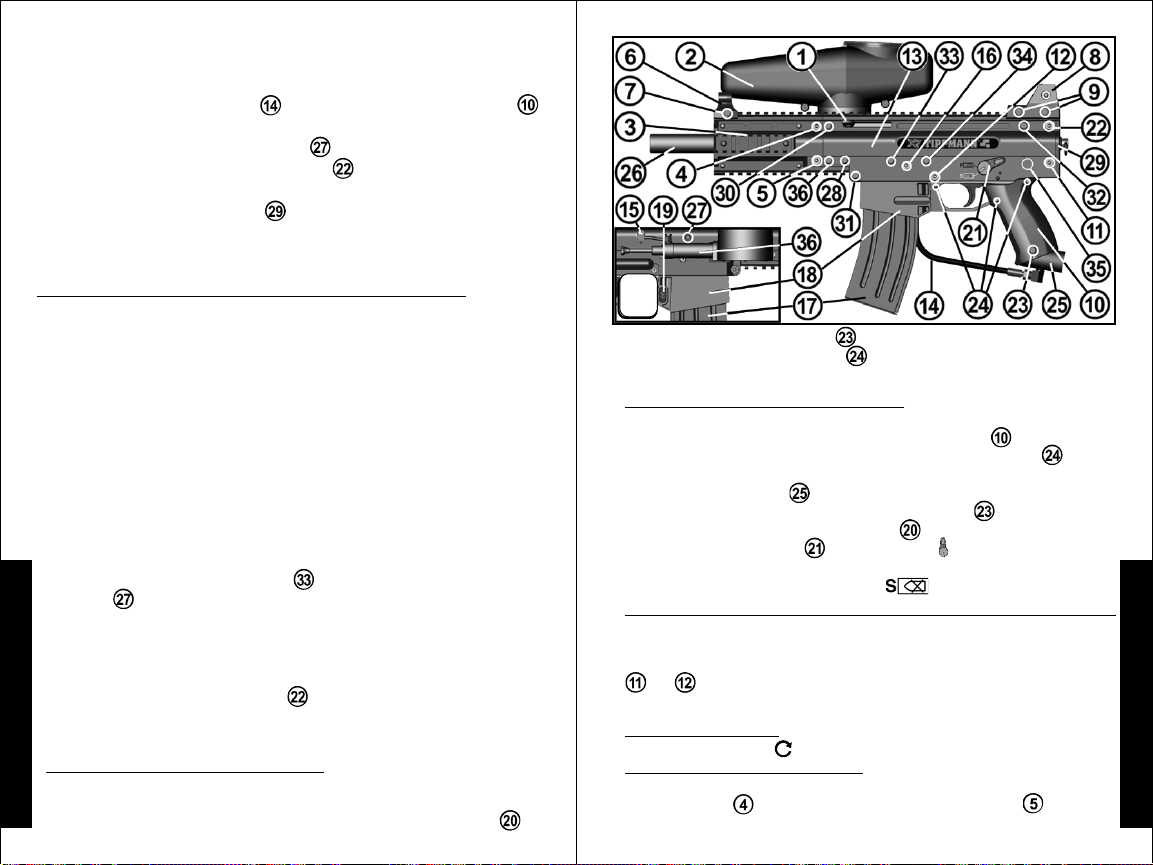

Schematic: X7TM Basic Parts List .................................................... 8

Unloading Your Marker .................................................................. 10

Air Supply Cylinder Removal ........................................................ 10

Cleaning & Maintenance ............................................................... 10

Marker / Receiver Disassembly & Assembly............................... 11

Repairing Air Supply Leaks........................................................... 17

Storage............................................................................................ 17

Marker Model Specifications......................................................... 17

Warranty and Repair Policy .......................................................... 18

Warranty or Repair Procedure...................................................... 18

Warranty Registration.................................................................... 18

3

Warning / Liability Statement

This marker is classified as a dangerous weapon and is surrendered

E

by T ippmann Sports, LLC with the understanding that the purchaser

assumes all liability resulting from unsafe handling or any action

N

that constitutes a violation of any applicable laws or regulations.

G

Tippmann Sports, LLC shall not be liable for personal injury, loss of

property or life resulting from the use of this weapon under any

L

circumstances, including the intentional, reckless, negligent or

I

accidental discharges.

S

All information contained in this manual is subject to change without

notice. Tippmann Sports, LLC reserves the right to make changes

H

and improvements to products without incurring any obligation to

incorporate such improvements in products previously sold.

If you as a user do not accept liability, Tippmann Sports, LLC

requests you do not use a Tippmann Sports, LLC marker. By using

this paintball marker you release Tippmann Sports, LLC of any and

all liability associated with its use.

SAFETY IS YOUR RESPONSIBILITY!

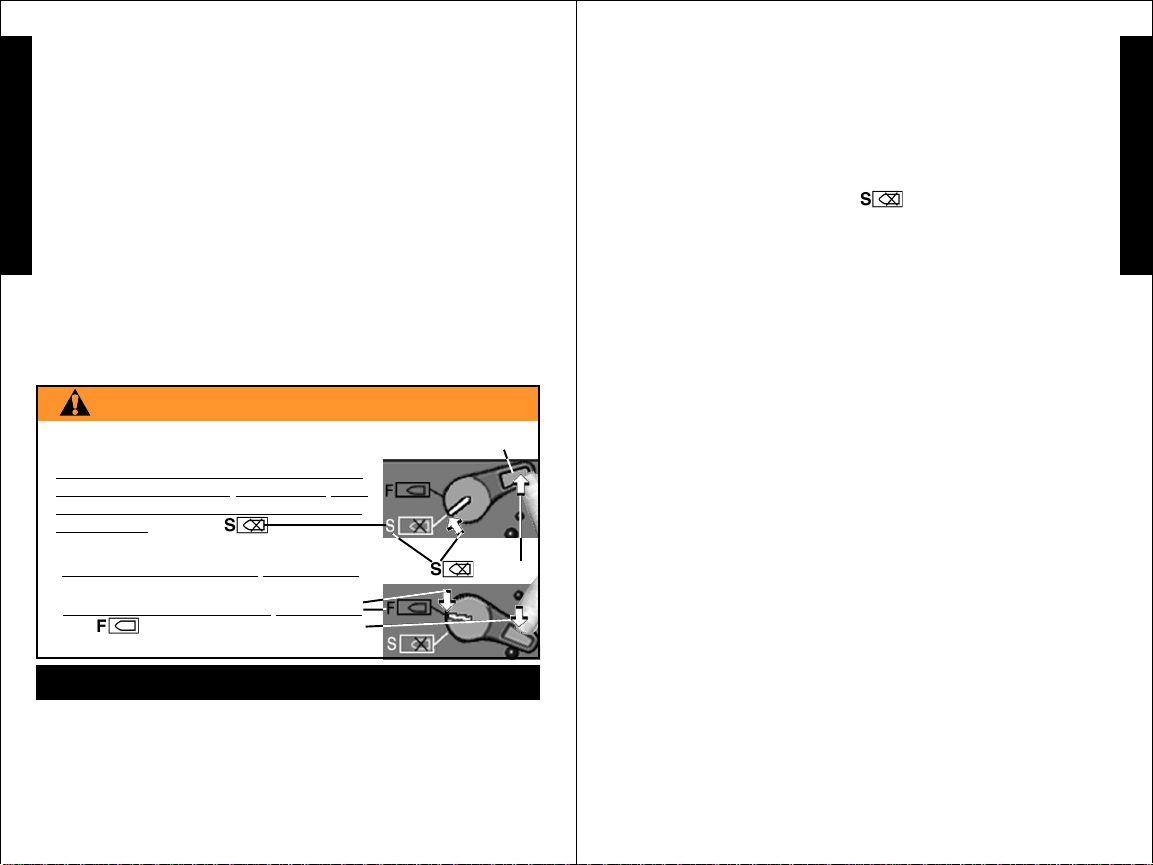

WARNING

• EXCEPT WHEN YOUR MARKER IS IN USE,

ALWAYS MAKE SURE THAT THE BARREL

SLEEVE IS INSTALLED (SEE PAGE 2) AND

THE TRIGGER SAFETY LEVER IS IN THE

SAFE MODE = WHITE

WHICH DISABLES THE TRIGGER.

❏

TO TURN ON THE SAFETY (SAFE MODE = WHITE ): PUSH

THE SAFETY UP AS SHOWN ABOVE.

❏

TO TURN THE SAFETY OFF (FIRE MODE

= RED ): PUSH THE SAFETY DOWN.

TRIGGER SAFETY ACTIVATION

FAMILIARIZE YOURSELF WITH SAFETY...

The ownership of this weapon places upon you the total

responsibility for its safe and lawful use. You must observe the

same safety precautions as you would any firearm to assure the

safety of not only yourself but everyone around you. The user should

at all times use caution when using this marker. The sport of

Paintball will be viewed and judged upon your safe and

sportsmanlike conduct. Always remember that the game of Paintball

4

Safety Is Your Responsibility

SAFETY

(continued on page 5)

Safety Is Your Responsibility (continued from page 4)

can only survive and grow if it remains SAFE!

• Do not load or fire this marker until you have completely read this

manual and are familiar with its safety features, mechanical

operation and handling characteristics.

• Handle this and any marker as if it were loaded at all times.

• Keep your finger off the trigger until ready to shoot.

• Do not look down the barrel of a paintball marker. Accidental

discharge into the eyes may cause permanent injury or death.

• Keep the marker on “SAFE” = until ready to shoot (see

page 4).

• Keep the barrel sleeve installed on marker when not shooting

(see page 2).

• Never point the marker at anything you do not intend to shoot.

• Never fire your marker at anything you do not intend to shoot

because there may be balls or foreign debris lodged in the

chamber, barrel and / or the marker valve.

• Do not shoot at fragile objects such as windows.

• Never fire your marker at personal property of others, the paintball

can stain the paint of automobiles and houses.

• Always keep the muzzle pointed down or in a safe direction, even

if you stumble or fall.

• Eye, face and ear protection designed specifically to stop paintballs

in the form of goggles and full face mask meeting ASTM Specification

F 1776 must be worn by the user and any person within range.

• Never shoot at a person who is not protected by eye, face and

ear protection designed for paintball.

• Pressurize and load the marker only when the marker will be

immediately used.

• NOTE: Before storing or disassembling be sure to remove

paintballs and air supply (see unloading and air supply removal

on page 10). Install the barrel sleeve (see page 2).

• Store the marker unloaded and degassed in a secure place.

• Do not field strip or otherwise disassemble this marker while

it is pressurized with air supply.

• Dress appropriately when playing the game of paintball. Avoid

exposing any skin when playing the game of paintball. Even

a light layer will absorb some of the impact and protect you

from the paintballs.

• Keep exposed skin away from escaping gas when installing

or removing air supply cylinder or if the marker or air supply

is leaking. Compressed air, CO2, and nitrogen gasses are

5

Safety Is Your Responsibility

(continued on page 6)

E

N

G

L

I

S

H

Safety Is Your Responsibility (continued from page 5)

very cold and can cause frostbite under certain conditions.

• Use only .68 caliber paintballs, never load or fire any foreign objects.

E

• Avoid alcoholic beverages before and during the use of this

marker. Handling markers while under the influence of drugs

N

or alcohol is a criminal disregard for public safety.

G

• Avoid shooting an opponent at point blank, 6 feet or less.

• Familiarize yourself with instructions listed on air supply cylinder

L

or adaptor. Contact the air supply cylinder or adaptor manufacturer

I

with any questions.

S

• Always measure your marker ’s velocity before playing paintball

and never shoot at velocities in excess of 300 feet per second

H

(see instructions on page 7).

GETTING STARTED:

❏

Eye protection designed for paintball use must be worn by the user

and any person within range.

STEP 1: Prepare Marker for Air Supply Cylinder Installation

Before installing the air supply, ❏ install the Barrel and Front Grip as

outlined on page 15 (do not install the hopper until STEP 3:).

STEP 2: Air Supply Cylinder Installation

• Do not pressurize a partially assembled paintball marker.

1)❏ Install barrel sleeve (see instructions on page 2).

2)❏ Put the trigger safety in Safe Mode = (see page 4

instructions).

3)❏ Cock the marker by sliding the bolt handle all the way back

until you hear / feel it click into place. Then release cocking handle.

Cocking handle will slide forward. Marker is now cocked. Always

keep marker in the cocked position when air supply is attached to

marker. This will help prevent an accidental discharge.

4) To install the air supply cylinder, ❏ lubricate the cylinder valve

o-ring with a little Tippmann® paintball marker oil then insert the

cylinder valve end into the air supply adapter at the back end of the

marker grip. Twist the cylinder clockwise into the adapter until it

stops. Your marker is ready to fire once you switch to the Fire

Mode = from the Safe Mode = . If the tank is full and

you do not hear the air supply engage, the pin valve could be too

short or the pin valve seal is damaged.

STEP 3: Hopper and CycloneTM Feeder

1) ❏ Barrel Sleeve must be installed (see page 2) and

6

❏

safety in

Getting Started

(continued on page 7)

Getting Started (continued from page 6)

Safe Mode= (see page 4) before filling the hopper.

2) ❏ Make sure that the CycloneTM feeder housing is clean, free of

debris, and the CycloneTM feeders turn freely when the manual

advance lever knob is pushed.

3) ❏ Make sure that the hopper is clean, free of sharp edges or

debris. This will keep the paintballs from breaking and feed the

marker smoothly.

4) ❏ Install the hopper neck into the Cyclone

TM

feeder housing

aligning the hopper neck tab to fit into the cutout in the Cyclone

feeder housing and turn counterclockwise to secure. ❏ With

the barrel sleeve installed and ❏ safety in Safe Mode = , you

E

N

G

L

I

TM

S

H

are now ready to ❏ load your hopper with paintballs. After filling

the hopper with paintballs the chamber will still be empty. You

need to push the feeder manual advance lever to chamber a

paintball. Only remove barrel sleeve and turn off the safety

when ready to shoot.

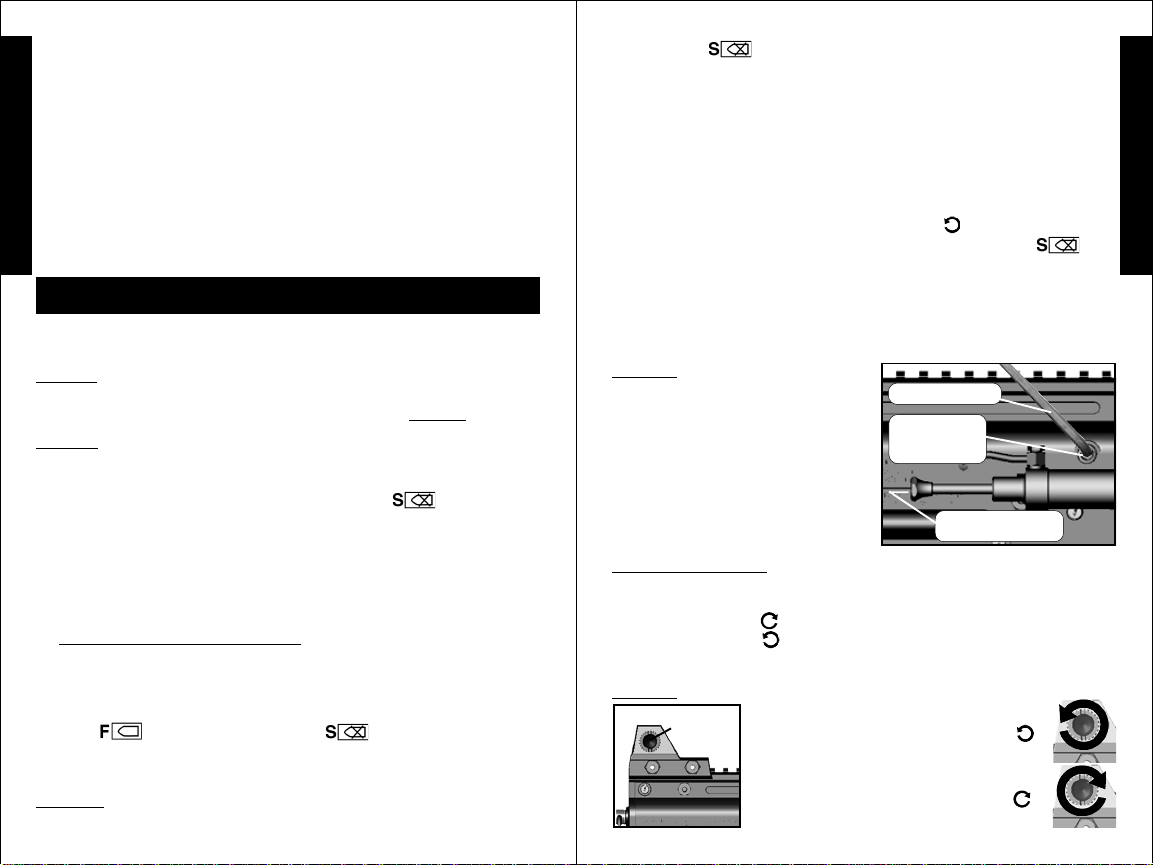

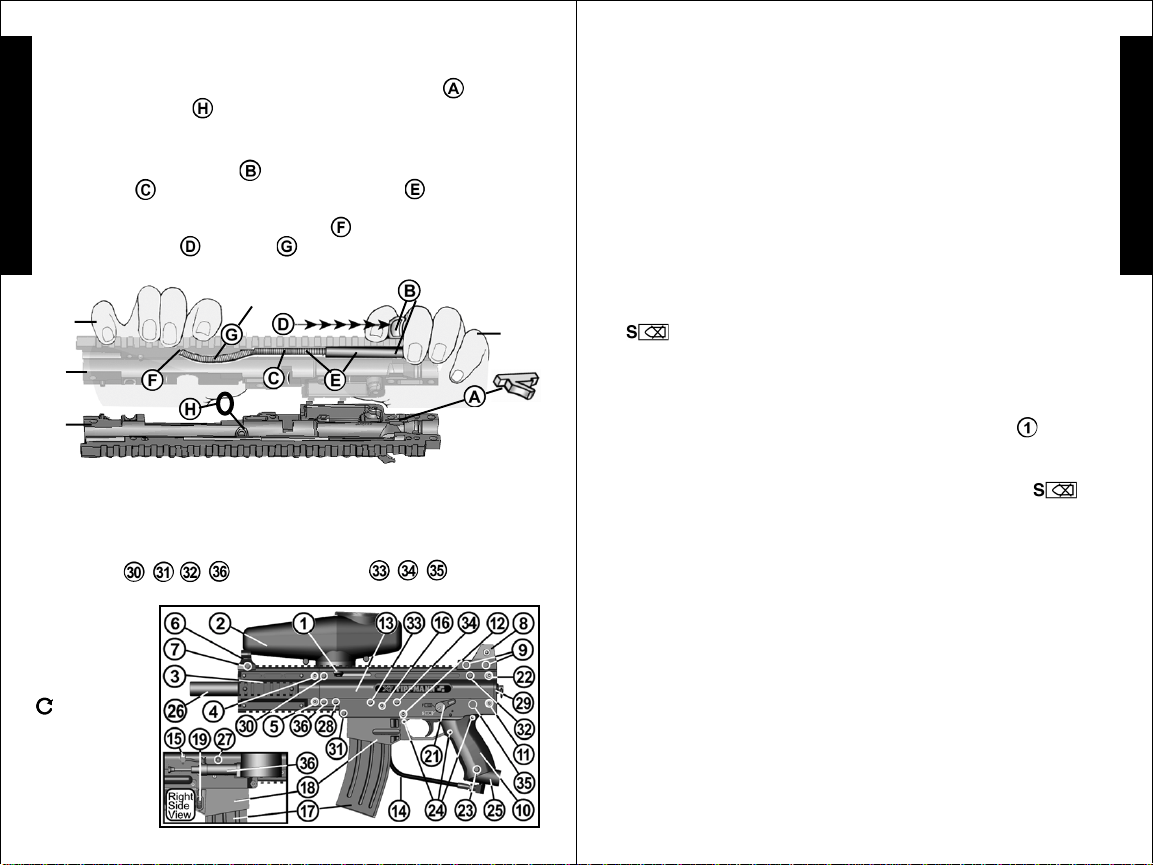

STEP 4: Velocity Adjustment

Each time you play paintball, the

velocity of your paintball marker

should be checked with a

chronograph, an instrument for

measuring velocity , prior to playing

paintball to verify that the marker’s

velocity is set below 300 feet per

second or less if required by the

playing field.

To adjust the velocity: ❏ use the ( 3/16” ) allen wrench included with

your marker. The velocity adjustment screw is located on the right

side of the receiver. ❏ To adjust the velocity down, turn the screw

inward or clockwise . ❏ To turn the velocity up, turn the screw out

or counterclockwise . Do not remove velocity screw. NOTE: You

must turn the velocity screw all the way in before doing any disassembly .

Allen Wrench

Velocity

Adjustment

Screw

Feeder Manual

Advance Lever

STEP 5) Rear Sight Adjustment

Rear Sight

Adjuster

If your marker fires to low: ❏ Rotate the

rear sight adjuster counterclockwise to

raise the impact point.

If your marker fires to high: ❏ Rotate

the rear sight adjuster clockwise to

lower the impact point.

7

TIPPMANN

E

N

G

L

I

S

H

®

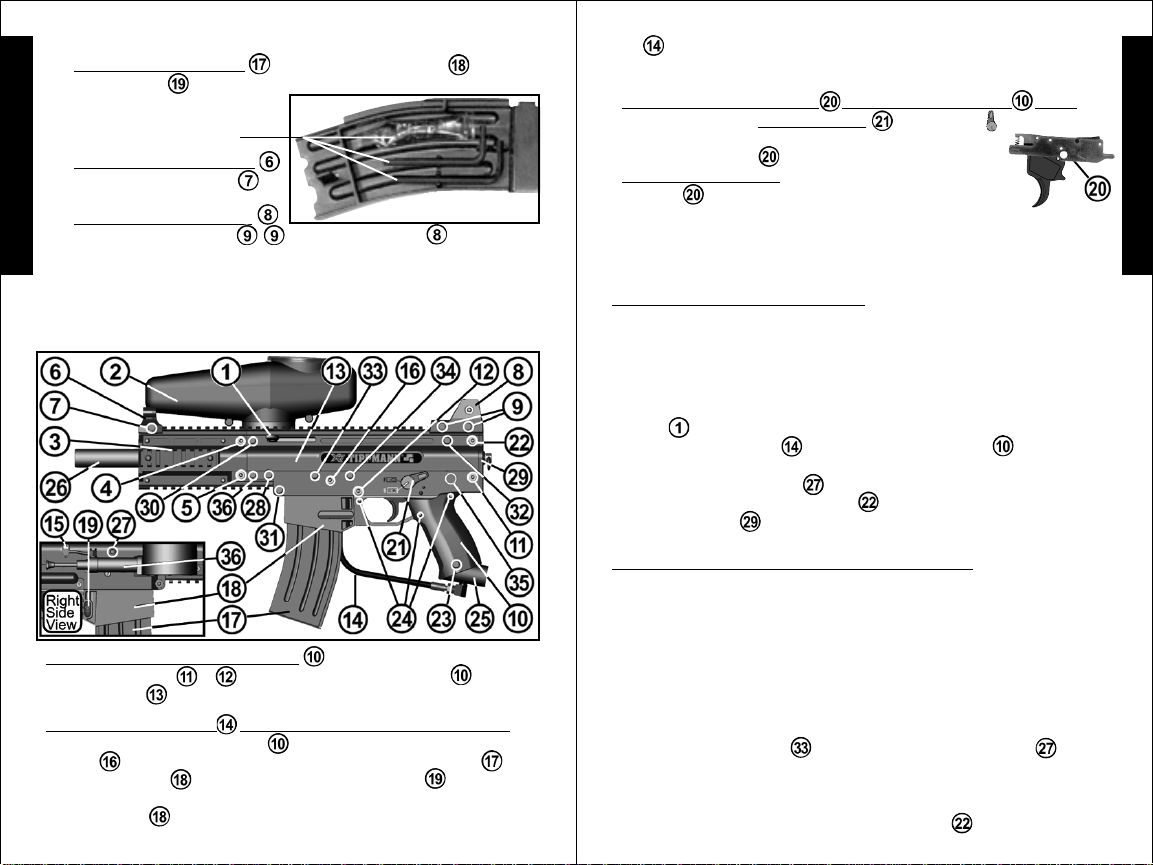

BASIC PARTS LIST

WARNING

DO NOT DISASSEMBLE THIS MARKER WHILE IT IS PRESSURIZED

WITH AIR. DO NOT PRESSURIZE A PARTIALLY ASSEMBLED MARKER.

E

N

G

L

I

S

H

8

9

Unloading Your Marker

❏

Eye protection designed for paintball use must be worn by the user

E

and any person within range.

N

To unload your marker:

❏

Install the barrel sleeve (see page 2).

1)

G

2)

❏

L

I

S

H

Empty and remove the hopper.

3)

❏

Go to a designated firing area and remove the barrel sleeve.

❏

Point your marker in a safe direction and fire several times to

4)

be sure there are no balls lodged in the chamber and / or barrel.

IMPORTANT: Do not uncock your marker as uncocking your marker

may push a ball into the chamber or down into the barrel in which

case the ball will be hidden from view.

5)

❏

Install the barrel sleeve (see page 2).

❏

Visually inspect the CycloneTM Feeder and chamber for paintballs.

6)

Air Supply Cylinder Removal

❏

Eye protection designed for paintball use must be worn by the user

and any person within range.

To remove a charged air supply cylinder:

1)

❏

Install the barrel sleeve (see page 2).

2)

❏

Turn the cylinder approximately 3/4 of a turn counterclockwise

or out. This allows the air supply pin valve to close so that no air

will enter the marker.

3)

❏

Point the marker in a safe direction and fire the remaining gas in

the marker by pulling the trigger until the marker stops firing. This may

take 4-5 shots.

• If your marker keeps firing after you have turned the tank 3/4 of a

turn, the tank pin valve has not closed yet and you may have to turn

the tank counterclockwise a little further.

• If you turn the tank 3/4 of a turn and it begins to leak before you pull the

trigger you have turned it too far and may have damaged the tank o-ring.

• Because of the variances in tank valve parts, each tank varies slightly

on exactly how far it should be turned. If this process does not work

the tank pin valve could be too long.

NOTE: Before storing or disassembling be sure to follow

Your Marker and

above).

❏

❏

Install barrel sleeve (see page 2).

Air Supply Cylinder Removal instructions (see

❏

Unloading

Cleaning & Maintenance

❏

Eye protection designed for paintball use must be worn by the user

and any person within range.

To reduce the chance of accidental discharge: First follow

10

❏

Cleaning and Maintenance

Unloading

(continued on page 11)

Cleaning and Maintenance (continued from page 10)

Your Marker and

above) and never disassemble a marker that is under pressure.

• Follow warnings listed on the air supply cylinder for handling and storage.

• Familiarize yourself with instructions listed on air supply cylinder

or adaptor. Contact the air supply cylinder or the adaptor

manufacturer with any questions.

• Do not use any petroleum based cleaning solvents.

• Do not use any cleaning solvents that come in aerosol cans.

NOTE: Petroleum based products and aerosol products can

damage your markers’ o-rings.

•

To clean your paintball marker: ❏ use a damp towel with water to

wipe off paint, oil, and debris.

oil or other premium paintball marker oil to lubricate and maintain

your marker in good working condition.

❏

Inspect and lubricate the internal drive assembly parts:

front bolt o-ring,

drive spring / guide pin (see Drive Assembly Removal and

Installation instructions on page 13).

❏

Inspect and lubricate the barrel o-ring and the air supply valve

o-ring with a few drops of oil.

•

To clean inside the barrel: ❏ remove barrel and insert metal tab

of cable squeegee into barrel, then pull squeegee through barrel

to remove debris.

❏

Air Supply Cylinder Removal instructions (see

E

N

G

L

I

S

H

❏

Use Tippmann® paintball marker

❏

❏

the rear bolt o-ring, ❏ the linkage arm and the

the

Marker / Receiver Disassembly & Assembly

❏

Eye protection designed for paintball use must be worn by the user

and any person within range.

1)

❏

First follow ❏ Unloading Your Marker and ❏ Air Supply Cylinder

Removal instructions on page 10. Remove air supply before any

disassembly . Do not pressurize a partially assembled paintball marker.

2)

❏

Put the marker in the uncocked position. To uncock the marker:

hold the bolt cocking handle

release handle forward which will uncock the marker.

❏

To remove the hopper :

3)

turn the hopper clockwise

and lift out.

❏

To remove the Front Grip :

4)

Remove short push pin

long push pin

front grip off.

5)

❏

To remove the Barrel :

Twist the barrel counterclockwise

and slide the

back 3/4 - then pull the trigger and

/ and

to remove.

11

Receiver Disassembly / Assembly

(continued on page 12)

TOOLS: The magazine contains Tools and lubricating oil for your marker.

6)

❏

E

N

G

L

S

H

To remove the magazine from the magazine base press the

magazine button

magazine down and out. Store

tools in magazine after use (shown

with 2 allen wrenches and oil.

7) ❏ To remove the Front Sight :

Remove Front Sight Screw

I

and slide the front sight off .

❏

To remove the Rear Sight :

8)

Remove 2 rear sight screws

(on right side of the magazine base, then slide

/ and the Rear Sight .

Receiver Disassembly

❏

Eye protection designed for paintball use must be worn by the user and

any person within range.

❏

FIRST: perform steps 1), 2), 3), 4), 5), 6), 7) and 8) as outlined on

pages 11 and 12 before beginning Receiver Disassembly.

• To remove the lower receiver (grip) : ❏ Remove the 2 long lower

receiver push pins

upper receiver

To remove the gas line / Tombstone from the upper receiver:

•

❏

Remove the lower receiver see above. ❏ Remove the long

push pin

the magazine base by pressing the magazine button (on right side

of magazine base), then slide magazine down and out.

magazine base

from the upper receiver. ❏ Remove the magazine from

/ and pull the lower receiver from the

.

❏

back until it stops, then down. ❏ Pull down on gas

12

Receiver Disassembly / Assembly

(continued on page 13)

Slide

Receiver Disassembly / Assembly (continued from page 12)Receiver Disassembly / Assembly (continued from page 11)

line to remove the gas line/Tombstone. NOTE: If you remove the

gasline from the Tombstone, when reinstalling, inspect and oil the o-ring

and be careful not to overtighten and strip threaded parts.

To remove trigger assembly from the lower receiver (grip):

•

❏

Rotate the Safety Selector Switch straight up

and ❏ pull it out left side of lower receiver. ❏ Pull up on

the trigger assembly

•

To access trigger parts: ❏ Pull left plate off trigger

assembly

the right plate. See trigger assembly on page 9.

. Do not remove the 5 dowel pins from

keeping it intact.

Drive Assembly Removal and Installation

NOTE: It is not necessary to disassemble the upper receiver to access

and service the drive assembly internal parts.

To remove the drive assembly parts: front bolt, power tube, valve, rear

bolt/rear bolt plug, linkage arm, drive pin guide, drive spring and end cap

(parts shown on pages 8 and 9).

❏

Remove air supply before any disassembly: Unload marker, remove

1)

the air supply as outlined on page 10 and put the marker in the uncocked

position before beginning to disassemble it. To uncock the marker, hold

the bolt cocking handle back 3/4 - then pull the trigger and release handle

forward

❏

2)

Disassembly instructions on page 12.

❏

3)

4)

❏

❏

5)

slide out the back. You may need to jiggle marker while sliding parts out.

To reinstall drive assembly parts and lower receiver:

1)

❏

❏

2)

o-ring,

guide pin with a few drops of Tippmann

premium paintball marker oil) before reinstalling them.

❏

3)

match power tube cutout. (Insert tombstone adapter to check fit).

❏

4)

bolt plug, with linkage arm facing up, until tombstone adapter can be

inserted, long push pin

accessed. You may need to jiggle marker while sliding parts in.

❏

5)

rear bolt plug.

in it.

which will uncock the marker.

Remove gas line and lower receiver (grip) see Receiver

Screw velocity screw in past receiver.

Remove last push pin (short) holding end cap in place.

Pull end cap out and tilt marker up, drive assembly parts should

Clean inside upper receiver and removed parts.

Inspect and replace any damaged parts. Lubricate

❏

the rear bolt o-ring, ❏ the linkage arm and the drive spring/

Insert valve into power tube with Tombstone cutout aligned down to

Insert reassembled parts - front bolt, power tube/valve, rear bolt/rear

replaced and velocity screw can be

Insert the guide pin into the drive spring and

❏

❏

Install the upper end cap short push pin .

Insert the end cap, while keeping the guide pin centered

®

paintball marker oil (or other

13

Receiver Disassembly / Assembly

❏

the front bolt

❏

drive spring into the

(continued on page 14)

E

N

G

L

I

S

H

Receiver Disassembly / Assembly (continued from page 13)

Lower Receiver Disassembly/Assembly:

• To disassemble the lower receiver:

E

1) ❏ Follow the Marker / Receiver Disassembly instructions on pages

11, 12 and 13 until you have ❏ detached the lower receiver and

N

❏

G

L

removed the trigger assembly from the grip.

2) ❏ Remove the tank adapter bolt .

3) ❏ Remove the 3 grip screws holding the two lower

receiver grip halves together.

I

S

H

• To reassemble the lower receiver (grip):

1)

❏

Make sure the trigger guard is in place.

2)

❏

Replace left grip half .

3) ❏ Secure the grip halves with 3 grip screws .

4) ❏ Attach Tank Adapter: Slide tank adapter into the

lower receiver and align holes;

and tighten.

5)

❏

Insert trigger group into the grip. ❏ Rotate the

Safety Selector Switch straight up and ❏ insert it into

the left side of the grip and then rotate it to the “SAFE” =

position.

• To attach the lower receiver (grip) to the upper receiver.

❏

Line up lower receiver front push pin holes with upper

receiver holes then gently rock rear of grip until you can

insert the two long lower receiver push pins & to attach.

❏

Insert receiver bolt

14

Receiver Disassembly/Assembly:

❏

(continued on page 15)

Receiver Disassembly / Assembly (continued from page 14)

Barrel and Front Grip:

• To install Barrel: Insert barrel and turn clockwise .

• To install Front Grip: Slide front grip onto barrel/upper receiver

and insert short push pin in top and long push pin in

bottom to attach.

CycloneTM Feed System Removal

FIRST: Remove air supply before any disassembly:

marker, ❏ remove the air supply as outlined on page 10 and

the marker in the uncocked position before beginning to disassemble

it. To uncock the marker, hold the bolt cocking handle back 3/4 then pull the trigger and release handle forward which will uncock

the marker.

❏

Remove banjo fitting bolt from upper receiver. ❏ Remove

CycloneTM housing bolt from left front side of upper receiver and

remove feed system . To install reverse the process.

❏

Unload

❏

put

E

N

G

L

I

S

H

Upper Receiver Disassembly:

NOTE: It is only necessary to disassemble upper receiver halves

to access the ball latch, cocking handle, cocking handle spring and

(receiver o-ring - the receiver o-ring is glued in place, only

remove it if it is damaged. To replace the receiver o-ring: 1) pull it

out; 2) clean receiver groove of glue; 3) place 4 equally spaced

drops of CA glue (cyanoacrylate - super glues) into bottom of groove

and press new o-ring into place. 4) Allow the glue to dry before

reassembling.)

To disassemble the Upper Receiver:

1) ❏ Follow Marker / Receiver Disassembly instructions on

pages 1 1 and 12 until you have removed the gas line/Tombstone

from the upper receiver.

2) ❏ Remove the 4 short Receiver Bolts

the 3 long Receiver Bolts

receiver halves together and lift the left half off of the right

receiver half. NOTE: long receiver bolt is not visible until

the lower receiver (grip) has been removed.

/ /

Upper Receiver Disassembly/Assembly:

15

/ / /

holding the 2 upper

(continued on page 16)

and

Upper Receiver Disassembly / Assembly (continued from page 15)

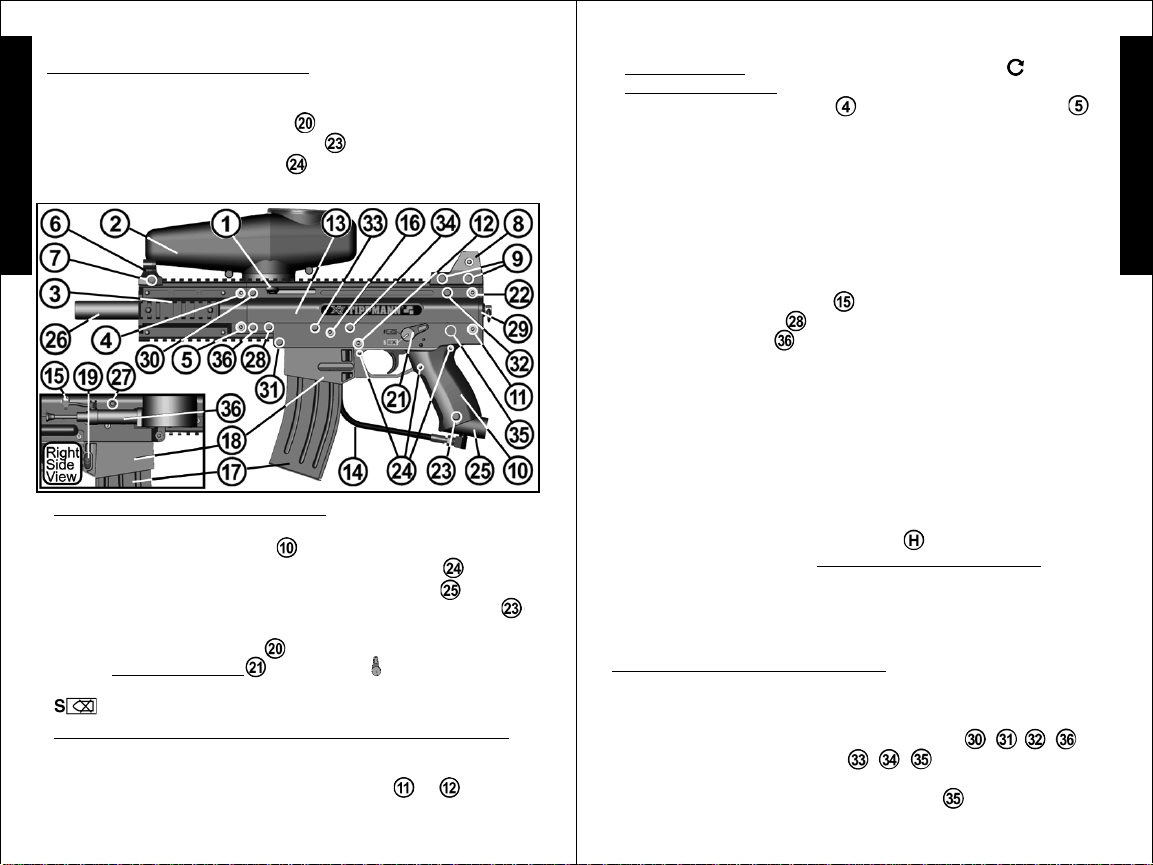

Upper Receiver Assembly:

1) ❏ Make sure all parts are cleaned and oiled before reassembling.

E

Place right upper receiver half flat with (Ball Latch inserted)

and (receiver o-ring glued) in position as shown below.

N

2) ❏ With left hand, grip left

G

upper receiver half as shown

L

to hold Cocking Handle

I

and spring in place by

applying side pressure with

S

index finger pushing in

H

direction of arrows against

Cocking Handle.

Right

Hand

Left

Half

Right

Half

4) ❏ Use your finger tips to guide the left half straight down on to right

half until receiver halves fit flush. If it does not fit flush the first time,

check to make sure the spring and other parts have stayed in place

and repeat until halves fit flush.

5) ❏ Oil the Barrel/adapter o-rings. Follow the illustration and Insert 4

short bolts

spots and tighten them just enough to hold halves flush yet loose

enough to allow

you to now

insert and twist

Barrel / Adapter

unit clockwise

to reinstall.

6) ❏ Carefully

tighten all 7

bolts (do not

overtighten and

strip threaded

parts).

Cocking Handle Spring

/ / /

3) ❏ With left hand holding as

shown below, use right hand to seat

cocking handle with spring into

receiver cutout then position

edge of spring in end of spring

cutout bowed as shown below

. Then grip left receiver with

right hand as shown.

will be bowed.

and 3 long bolts

16

Cocking Handle

/ /

into correct

Left

Hand

Ball

Latch

Repairing Air Supply Cylinder Leaks

The most common leak occurs from a bad air supply valve o-ring.

To replace a valve o-ring you must first remove the bad o-ring and

then install a new one. This o-ring is located on the tip of your air

supply valve. The best valve o-rings are made of urethane.

The urethane o-rings are not affected by high air supply

pressures. These may be purchased from Tippmann® or your

local paintball dealer.

NOTE: If new valve o-ring does not resolve air supply leak, do not

attempt to repair air supply cylinder. Contact Tippmann Sports,

LLC or your local paintball dealer.

E

N

G

L

I

S

H

Storage

Before storage, unload and remove air supply (see page 10). Install

the Barrel Sleeve (see page 2) and put your marker in Safe Mode

= (see page 4). (You should store your marker in a dry area.)

Before storing your marker make sure that the marker is cleaned

and oiled (see Cleaning and Maintenance on page 10) so that it

does not rust. Store your marker with the bolt in the forward position,

uncocked. To uncock the marker, hold the bolt cocking handle back

3/4 - then pull the trigger and release handle forward which will

uncock the marker.

When removing your marker out of storage make sure Barrel Sleeve

is installed (see page 2) and safety is in Safe Mode = (see

page 4). You should re-oil the rear bolt and the front bolt o-ring before

use (see Drive Assembly Removal and Installation on page 13).

MODEL SPECIFICATIONS

Model Basic ......................................................... TIPPMANN® X7

Caliber.............................................................................................68

Action .................................Semi-Automatic (open bolt blow-back)

Power/Air Supply .......... compressed air, nitrogen or CO2 cylinder

Hopper Capacity ........................................................ 200 Paintballs

Ball Feed.........................................TIPPMANN® CycloneTM System

Standard Barrel Length .............................................8. 5 ” /2 1 . 59 c m

Length (with standard barrel & no tank) .................19.2” / 48.8 cm

Effective Range ...................................... 150+ feet / 45.72+ meters

Weight (without tank)............................................ 4 . 11 lb s / 1 . 8 6 kg

Velocity................. Always measure your marker ’s velocity before

playing paintball and never shoot at velocities in excess of 300

feet / 91.44 meters per second (see instructions on page 7).

17

TM

WARRANTY AND REPAIR POLICY

E

Tippmann Sports, LLC warrants that this product is found free from

defects in materials and workmanship for a period of 1 year from

N

the original date of purchase by the initial owner/purchaser. This

G

warranty does not apply to defects discovered after purchase which

were caused by the unauthorized modifications and alterations of

L

our product. Tippmann Sports, LLC will repair or replace, without

I

charge, any of its markers that have failed through defect in

S

material or workmanship. Tippmann

with the ultimate paintball marker and the quality support necessary

H

for satisfactory play.

®

is dedicated to providing you

WARRANTY OR REPAIR PROCEDURE

If you should encounter any problems with your marker and you

have aftermarket parts on your marker, please test it with the

original stock parts before sending it in.

Always unload and remove air supply before shipping a marker (see

page 10). Do not ship your air supply tank if it is not completely empty .

For warranty and non-warranty repair:

1. Ship or deliver your product(s) to:

Tippmann Sports, LLC

2955 Adams Center Road

Fort Wayne, IN 46803

2. Postage or delivery charges must be prepaid.

3. Include a brief statement regarding the requested repair,

your name, return address and telephone number where

you can be reached during normal business hours, if possible.

Our policy is to complete the necessary repair work within 24 hours

and return it to you via regular ground UPS. If you wish to have it

returned using a faster service, you can request for NEXT DAY

AIR UPS OR SECOND DAY AIR UPS. You will be charged for this

service and must include your credit card number with the

expiration date. Your card will be charged the difference in

additional cost over regular ground shipping service.

THIS PAGE INTENTIONALLY LEFT BLANK

E

N

G

L

I

S

H

WARRANTY REGISTRATION

Register your marker either:

1. On line at www.tippmann.com.

2. Complete attached registration card and mail to the above address.

18

19

AVERTISSEMENT

CE N'EST PAS UN JOUET. L'USAGE IMPROPRE PEUT CAUSER LA

BLESSURE SÉRIEUSE OU LA MORT. LA PROTECTION POUR LES YEUX,

LE VISAGE ET LES OREILLES CONSTRUITE POUR LA BALLE DE PEINT

DOIT ÊTRE PORTÉE PAR L'UTILISATEUR ET N'IMPORTE QUELLE

PERSONNE DANS LE CHAMP DE TIR. NOUS RECOMMENDONS QU' ON

A DIX - HUIT ANS AU MOINS POUR L'ACHETER. LES PERSONNES SOUS

L'ÂGE DE DIX - HUIT ANS DOIVENT AVOIR LA SUPERVISION D' UN

ADULTE QUAND ON EMPLOIE CE PRODUIT. IL FAUT LIRE TOUT DE CE

MANUEL AVANT DE L'UTILISER.

AVERTISSEMENT

• SAUF QUAND VOTRE MARQUEUR EST EN USAGE, SOYEZ CERTAIN

TOUJOURS QUE LA SÉCURITÉ DE DÉTENTE EST EN MODE DE

F

SÉCURITÉ= BLANC

ET QUE LA CHEMISE DU CANON EST BIEN INSTALLÉE SUR VOTRE

R

MARQUEUR COMME MONTRÉ AUDESSOUS.

A

1) GLISSEZ LE CANON DANS LA CHEMISE ET FORMEZ UNE

BOUCLE AUDESSUS DU RECEVEUR ET METTEZ EN ARRIÈRE

N

DE LA POIGNÉE COMME MONTRÉ AUDESSOUS.

Ç

A

I

S

2) PINCEZ LE RÉGLEUR

DU LONGEUR DE CORDE

ET TENEZ L'ARRIÈRE

DE POIGNÉE PENDANT

QUE VOUS TIREZ LA

CORDE JUSQU'À LE

RÉGLEUR EST JUSTE À CÔTÉ DE L'ARRIÈRE DE POIGNÉE.

3) VÉRIFIEZ QUE VOUS LAISSEZ ASSEZ DE CORDE POUR

TIRER LA CORDE DU MARQUEUR POUR ENLEVER LA CHEMISE

DU CANON POUR DÉCHARGER.

4) APRÈS QUE LE LONGEUR

DE CORDE EST AJUSTÉ, IL

FAUT IMMOBILISER LA

CORDE EN FAISANT UN

NOEUD CONTRE L'ARRIÈRE

DU RÉGLEUR COMME MONTRÉ.

INSTALLATION DE LA CHEMISE DU CANON

(VOYEZ LES INSTRUCTIONS À LA PAGE 3),

LE BOUTON DU

RÉGLEUR DU

LONGUEUR

DE CORDE

1

®

TIPPMANN

2955 Adams Center Road, Fort Wayne, IN 46803 USA

P) 260-749-6022 • F) 260-749-6619 • www.tippmann.com

FÉLICITATIONS sur votre achat d'un marqueur de balle de peint,

Tippmann®. Nous croyons que la ligne des marqueurs X7

plus précise et résistante disponible et c'est fabriquée fièrement

aux Etats - Unis. Tous les modèles X7TM donnéront des années du

service confiant si c'est bien tenu.

S'il vous plaît, prenez le temps de lire entièrement ce manuel et

familiarisez - vous avec les parties, l' opération, et les précautions

de sécurité de votre Tippmann® X7TM modèle avant de charger et de

tirer ce marqueur. Si vous avez quelque chose manquante ou

quelque chose cassée ou si vous avez besoin d’ assistance, veuillez

contacter Tippmann® Consumer Relations à 1-800-533-4831 pour

l’assistance amicale et vite.

TABLE DES MATIÈRES

Avertissement / Caution................................................................ 1

Avertissement, l’installation de la chemise du canon ............ 1

Avertissement/communiqué official de responsabilité ........... 3

Sécurité est votre responsabilité / Familiarisez – Vous Avec

Les Précautions.............................................................................. 3

Mode de sécurité = mettre la sécurité (sécurité = blanc ).. 3

Mode de tirer = fermer la sécurité (tirer = rouge ) .............. 3

Pour commencer ............................................................................ 5

1. Préparez le marqueur pour l'installation du cylindre d'air.. 5

2. L’installation du cylindre d’air ............................................... 5

3. La trémie d’les balles de peint ............................................. 6

4. Le réglage de vélocité............................................................ 7

5. Le réglage de vue arrière ...................................................... 7

Modèle Spécifications ................................................................... 7

Décharger votre marqueur ........................................................... 8

Enlever le cylindre d’air ................................................................ 8

Schématique X7TM de base ........................................................... 9

Nettoyer et la maintenance........................................................ 11

Désassemblage / Assemblage du marqueur.......................... 11

Réparation de la fuite de réserve d’aire .................................. 18

Entreposer ..................................................................................... 18

Garantie et la policie de réparations ........................................ 19

Garantie et le procès de réparer .............................................. 19

D’enregistrement de garantie .................................................... 19

2

TM

sont la

F

R

A

N

Ç

A

I

S

Avertissement/Communiqué Officiel de Responsabilité

Ce marqueur est classifié comme une arme dangéreuse et est donné

par Tippmann Sports, LLC avec la compréhension que l’acheteur

assume toute la responsabilité résultante d’une manipulation

dangéreuse ou n’ importe quelle action qui constitue une violation des

lois et des régulations applicables. Tippmann Sports, LLC ne sera

pas responsable pour la blessure personnelle, la perte de propriété

ou la perte de vie comme un résultat d’usage de cette arme sous les

circonstances, compris les décharges accidentals, négligeants,

imprudents et intentionnels.

Tout le renseignement contenu dans ce manuel est soumis au

change sans notification. Tippmann Sports, LLC réserve le droit

de faire les changes et des améliorations aux produits sans être obligé

d’incorporer telles améliorations dans les produits déjà vendus.

Si vous, comme un utilisateur, n’acceptez pas la responsabilité,

F

Tippmann Sports, LLC pose que vous n’utilisez pas un marqueur

R

de Tippmann Sports, LLC. En utilisant ce marqueur de balle de

peint, vous libérez Tippmann Sports, LLC de toute la responsabilité

A

associée avec son usage.

N

Ç

A

S

LA SÉCURITÉ EST VOTRE RESPONSABILITÉ!

AVERTISSEMENT

POUSSEZ LA SÉCURITÉ DANS LE MODE DE SÉCURITÉ.

I

• SAUF QUAND VOTRE MARQUEUR EST EN

USAGE, SOYEZ CERTAIN TOUJOURS QUE LA

CHEMISE DU CANON EST INSTALLÉE (VOYEZ

PAGE 1) ET QUE LA SÉCURITÉ DE DETENTE EST

AU MODE DE SÉCURITÉ = BLANC

QUI MET HORS D’ACTION LA DÉTENTE.

❏

POUR METTRE LA SÉCURITÉ (LE MODE DE SÉCURITÉ): (SÉCURITÉ =

BLANC ) POUSSEZ LA SÉCURITÉ EN HAUT.

❏

POUR FERMER LA SÉCURITÉ

(LE MODE DE TIRER): (TIRER = ROUGE )

POUSSEZ LA SÉCURITÉ EN BASE.

SÉCURITÉ

FAMILIARISEZ – VOUS AVEC LES PRÉCAUTIONS

La possession de cette arme met sur vous la responsabilité totale

pour son usage en sécurité et légal. Vous devez observer les

mêmes précautions de sécurité que vous observez avec n’importe

quelle arme pour assurer la sécurité de vous – même et de toutes

les autres personnes autour de vous. L’utilisateur devrait toujours

3

Sécurité est votre responsabilité!

(continué à la page 4)

Sécurité est votre responsabilité! (continué de la page 3)

utliser la caution en utilisant ce marquer. On regardera et jugera le

sport de balle de peint selon votre sécurité et votre conduite sportive.

Il faut vous rappeler que le jeu de balle de peint peut seulement

survivre et grandir si le sport continue à être en sécurité!

• Ne pas charger ou tirer ce marqueur jusqu’à vous avez

complètement lu ce manuel et vous êtes familiarisé avec

les traits de sécurité, l’opération méchanique et les

charactéristiques de manipulation.

• Il faut manipuler ce marqueur et tous les autres marqueurs

comme si c’est chargé toujours.

• Ne mettez pas votre doigt sur la détente jusqu’à vous êtes prêt à tirer.

• Ne regardez pas le long du canon d’un marqueur de balle de

peint. Le décharge accidental aux yeux peut causer la

blessure permanente ou la mort.

• Retenez le marqueur en sécurité = jusqu’à prêt à tirer

(voyez page 3).

• Retenez la chemise du canon installée sur le marqueur

quand on ne tire pas (voyez page 1).

• Ne braquez jamais le marqueur à une chose que vous n’avez

pas l’intention de tirer.

• Ne tirez jamais le marqueur à une chose que vous n’avez pas

l’intention de tirer parce qu’il peut avoir des balles ou le débris

étranger logé dans la chambre, le canon et/ou la valve du marqueur.

• Ne tirez pas aux objets fragiles comme les fenêtres.

• Ne tirez pas à la propriété personnelle des autres, la balle

de peint peut tâcher le peint des automobiles et les maisons.

F

R

A

N

Ç

A

I

S

• Il faut toujours retenir la gueule braqué en bas ou dans une

direction sans danger, même si vous trébuchez ou tombez.

• La protection pour les yeux, le visage et les oreilles fait exprès pour

arrêter une balle de peint dans la forme des lunettes protectrices, et

une masque en accord aux spécifications d' ASTM F 1776 et doit

être portée pour l'utilisateur et les autres personnes au champ de tir.

• No tirez jamais à une personne sans la protection pour les

yeux, le visage et les oreilles qui sont faite exprès pour la

balle de peint.

• Pressurisez et chargez le marqueur seulement quand le

marqueur sera utilisé immédiatement.

• NOTE: Avant d'entreposer et de désassembler, soyez certain

d'enlever les balles de peint et la réserve d'air. Suivez les instructions

de décharger et d’enlever la réserve d’air à la page 8. D’abord

installez la chemise du canon (voyez les instructions sur la page 1).

4

Sécurité est votre responsabilité!

(continué à la page 5)

Sécurité est votre responsabilité! (continué de la page 4)

• Entreposez le marqueur déchargé et sans gaz dans un endroit

sans danger.

• Familiarisez-vous avec des instructions énumérées sur le cylindre

ou l'adapteur d'air. Contactez le fabricant de cylindre ou

d'adapteur d'air avec toutes les questions.

• N’enlevez jamais au champ ni désassemblez ce marqueur

pendant que ce soit pressurisé avec la réserve d’air.

• Habillez – vous à propos quand on joue le sport de balle de peint.

Evitez d’exposer la peau en jouant le jeu de balle de peint. Même

un peu de vêtements légers peut absorber un peu d’impact et

peut vous proteger des balles de peint.

• Gardez la peau exposée loin du gaz échappant en installant ou

en enlevant le cylindre réserve d'air ou si le marqueur ou la

réserve d'air fuit. L'air comprimé, CO2, l'azote sont vraiment froids

et peuvent causer la gelure sous les conditions certaines.

F

• N’utilisez que .68 calibre des balles de peint. Ne chargez jamais

R

ni tirez aux objets étrangers.

A

• Evitez les boissons alcooliques avant et pendant l’usage de ce

marqueur. La manipulation des marqueurs sous l’influence des

N

drogues ou d’alcool est un abus criminel pour la sécurité publique.

Ç

• Evitez de tirer une adversaire à bout portant (six pieds ou moins).

A

• Si vous avez acheté une cartouche de 12 grammes ou n’importe

quelle autre forme d’adapteur avec ce marqueur, il faut lire et

I

suivre les instructions qui etaient inclues avec l’adapteur.

S

• Il faut toujours mesurer la velocité de votre marqueur avant de

jouer à la balle de peint et ne tirez jamais aux velocités à l’excès de

(300 pieds) 91.44 mètres/sec. (voyez les instructions sur la page 7).

POUR COMMENCER:

❏

La protection des yeux faite exprès pour la balle de peint doit être portée

par tous les joueurs et par toutes les personnes dans le champ à tir .

PAS 1: Préparez le marqueur pour l'installation du cylindre

de la réserve d’air

Avant d'installer le réserve d'air, ❏ installez le canon et la poignée

avant comme décrit à la page 16 (n'installez pas la trémie jusqu'à PAS 3:).

PAS 2: L’enlevage du cylindre de la réserve d’air

• Ne pas pressuriser un marqueur de balle de peint qui n'est pas

complètement assemblé.

1)❏ D’abord installez la chemise du canon (voyez page 1).

Pour commencer (continué à la page 6)

5

Pour commencer (continué de la page 5)

2)❏ Mettez la sécurité de détente dans la mode de sécurité =

(voyez page 3 pour les instructions).

3)❏ Il faut armer le marqueur en glissant le boulon de poigne

complètement jusqu'a vous entendez une clique / vous vous sentez

une clique en place. Et puis relâchez la poigne armante. La poigne

armante glissera en avant. Le marqueur est armé maintenant. Il

faut toujours retenir le marqueur dans la position armée quand le

réserve d’air est attachée au marqueur. Ceci aidera empêcher un

décharge accidental.

4)❏ Pour installer le cylindre d’air, ❏ lubrifiez la valve cercle d’O

du cylindre avec un peu Tippmann® huile de marqueur, et puis

insérez le bout de valve du cylindre dans l’adapteur de réserve d’air

en arrière de la poignée du marqueur. Pivotez le cylindre dans une

direction de l’horloge dans le marqueur jusqu’à il s’arrête. Ajustez

la crosse de plaque si nécessaire. Votre marqueur est prêt à tirer

aussitot que vous avez changé le mode de sécurité à tirer = rouge

. Si la réserve est plein et vous n’entendez pas que la réserve

s’engage, la goupille de valve peut être trop petite ou la groupille de

valve est endommagée.

PAS 3: Trémie et le conducteur Cyclone

1)❏ La chemise du canon doit être

installée (voyez page 1) et ❏ la sécurité

au mode de sécurité = (voyez

page 3) avant de remplir la trémie.

2)❏ Soyez certain que le boîtier du conducteur CycloneTM est

propre, sans les fils affûtés et sans débris. Soyez certain que le

boîtier du conducteur CycloneTM tourne facilement quand on pousse

le bouton manuel avance.

3)❏ Soyez certain que la trémie est propre, sans les fils affûtés et

sans débris. Ceci empêchera casser les balles et conduira le

marqueur sans à coups.

4)❏ Installez le cou de trémie dans le boîtier du conducteur de

CycloneTM en alignant le trou du cou de trémie pour convener dans

le trou du boîtier conducteur de Cyclone

contre l'horloge pour sécurer. ❏ Avec la chemise du canon

installée et ❏ la sécurité est en position de sécurité = , vous

êtes prêts à ❏ charger votre trémie avec les balles de peint. Après

remplir la trémie avec les balles de peint la chambre sera encore

vide. Vous aurez besoin d'appuyer sur le levier du conducteur

avance manuel pour chambrer une balle de peint. N'enlevez que la

chemise du canon et fermez la sécurité quand vous êtes prêts à tirer.

6

TM

le bouton manuel

avance

TM

et tournez dans un sens

Pour commencer (continué à la page 7)

F

R

A

N

Ç

A

I

S

Pour commencer (continué de la page 6)

PAS 4: Le réglage de vélocité

Chaque fois que vous jouez à la

balle de peint, la vélocité de votre

marqueur de balle de peint devrait

être vérifié avec un chronographe,

un instrument pour mesurer la

vélocité. Avant de jouer à la balle

de peint pour vérifier que la vélocité

du marqueur s’est mis sous (300

pieds) 91.44 mètres par seconde ou

moins si réglé par le champ.

Pour régler la vélocité: utilisez la 3/16” clé inclue avec votre marqueur .

La vis de réglage de vélocité se trouve à droite du marqueur.

baisser la vélocité, tournez la vis à droite ou dans un sens d’horloge

❏

Pour augmenter la vélocité, tournez la vis à gauche ou contre

F

l’horloge

vis de vélocité entièrement à droite avant de désassembler.

R

PAS 5: Le réglage de vue arrière

A

N

Ç

A

I

S

(n’enlevez pas la vis de vélocité). NOTE: Il faut tourner la

le régleur de

vue arrière

Si votre marqueur tire trop bas: ❏ Faites

tourner le régleur de vue avant dans un sens

contre l'horloge

Si votre marqueur tire trop haut:

tourner le régleur de vue arrière dans un sens

d'horloge

pour baisser le point d'impact.

clé de 3/16

vis de vélocité

le bouton

manuel avance

❏

pour lever le point d'impact.

❏

Faites

Pour

MODÈLE SPÉCIFICATIONS

Modèle d e b a se ........................................................ T I PPMANN® X7

Munitions............................................................................................. .68

Action.......................... Semi-Automatic (boulon ouvert – coup arrière)

Pouvoir/réserve d’air .............................. air comprimé, l’azote ou CO

Capacité du Trémie ........................................... 200 les balles de peint

Balles - Chargement ........................... Tippmann

Le longueur du canon standard ....................................... 8.5” /21.59 cm

Le longueur (avec le canon standard & sans réserve) ...19.2” / 48.4 cm

Le champ efficace ..................................... 150+ pieds / 45.72+ mètres

Le poids (sans réserve) ..............................................4.11 lbs / 1.86 kg

Vélocité... ............................................................... Toujours mesurez la

vélocité de votre marqueur avant de jouer à la balle de peint et ne tirez

jamais aux vélocités à excès de (300 pieds) 91.44 mètres par seconde

(voyez les instructions à la page 7).

7

®

CycloneTM Système

TM

Décharger le marqueur

❏

La protection des yeux faite exprès pour la balle de peint doit être

portée par le joueur et d'autres personnes dans le champ à tir.

Pour désarmer votre marqueur:

1)

❏

Installez la chemise du canon (voyez page 1).

2)

❏

Enlevez la boîte d’ammunition et videz complètement la boîte

d’ammunition.

3)

❏

Allez à un endroit/champ à tir et enlevez la chemise du canon.

4)

❏

Braquez votre marqueur dans une direction sans danger et tirez

plusieurs fois pour être certain qu’il n’y a pas de balles logées dans la

chambre et/ ou le canon. IMPORT ANT: Ne désarmez pas votre marqueur

parce que le désarmage de votre marqueur peut pousser une balle dans

la chambre ou dans le canon dans lequel la balle sera cachée de la vue.

5)

❏

.

2

Installez la chemise du canon (voyez page 1).

6)

❏

Inspectez visuellement le conducteur Cyclone

les balles de peint.

L’enlevage du cylindre de la réserve d’air

❏

La protection des yeux faite exprès pour la balle de peint doit être

portée par le joueur et d'autres personnes dans le champ à tir.

Pour enlever un cylindre chargé de la réserve d'air:

1)❏ Installez la chemise du canon (voyez page 1).

2)

❏

Tournez le cylindre approximativement 3/4 d'un tour contre

l'horloge

goupille de fermer pour que l'air n'entre pas le marqueur.

3)

❏

jusqu'à tout l'air dans le réservoir sera vide en tirant la détente. La détente

s'arrêtera quand le réservoir est vide. (Ça peut faire 4 ou 5 coups.)

• Si votre marqueur continue à tirer après avoir tourné le réservoir 3/4

d’un tour, la goupille de valve de réservoir n’a pas encore fermé et vous

devrez tourner le réservoir un peu plus dans la direction à gauche ou

au sens contre l’horloge

• Si vous tournez le réservoir 3/4 d’un tour et il commence à s’échapper

avant de tirer sur la détente, vous avez tourné trop et c’est possible que

vous avez fait mal au cercle d’O du réservoir.

•À cause des variances aux parties de la valve réservoir , chaque réservoir

varie un peu et c’est un peu difficile de savoir exactement à tel point de

le tourner. Si ce procès ne marche pas, la valve de la goupille du

réservoir peut être trop longue.

NOTE: Avant d'entreposer ou désassembler, soyez certain de suivre les

instructions sur le

de la réserve d'air sur la page 8 (voyez en haut).

du canon (voyez les instructions sur la page 1.

ou à gauche. Cela permet la valve de la réservoir d'air de

Braquez le marqueur dans une direction sans danger et tirez

.

❏

Décharger du marqueur et

8

TM

et la chambre pour

❏

L'enlevage du cylindre

❏

Installez la chemise

F

R

A

N

Ç

A

I

S

TIPPMANN

®

PARTIES DE BASE

AVERTISSEMENT

NE PAS DÊSASSEMBLER CE MARQUEUR PENDANT QUE C’EST PRESSURISÉ

AVEC L’AIR. NE PAS PRESSURISER UN MARQUEUR MOITIÉ ASSEMBLÉ.

F

R

A

N

Ç

A

S

F

R

A

N

Ç

I

A

I

S

9

10

La maintenance et le nettoyage

❏

La protection des yeux faite exprès pour la balle de peint doit

être portée par le joueur et d'autres personnes dans le champ à tir.

❏

Pour réduire la chance d’un décharge accidental:

suivez les instructions

cylindre de la réserve d'air à la page 8 - et ne désassemblez jamais un

marqueur qui est pressurisé.

• Familiarisez-vous avec des instructions énumérées sur le cylindre

ou l'adapteur d'air. Contactez le fabricant de cylindre ou d'adapteur

d'air avec toutes les questions.

• N’utilisez pas les solvents de nettoyage qui sont basé sur le pétrole.

• N’utilisez pas les solvents de nettoyage qui sont dans une boîte d’aérosol.

NOTE: Les produits basés sur le pétrol et les produits d’aérosol peuvent

faire mal aux cercles d’O sur votre marqueur.

F

Pour nettoyer votre marqueur de balle de peint:

•

❏

R

A

N

Ç

A

S

utilisez une serviette mouillée d'eau pour effacer le peint, l'huile et

❏

le débris.

huile de marqueur de qualité supérieure pour maintenir votre

marqueur en bonne condition.

d'assemblage du conducteur interne:

❏

le boulon cercle d'O arrière, ❏ l'arme liée et ❏ l'arme liée / l'épingle

guidant d'actionnement et le ressort d'actionnement (voyez les

instructions pour l'enlevage de l'assemblé du conducteur et l'installation

I

à la page 14).

du cercle d'O du réservoir d'air avec quelque gouttes d'huile.

Pour nettoyer à l'intérieur du canon:

•

enlevez le canon et insérez le trou métal du cable raclette dans le

canon, et puis tirez la raclette à travers le canon pour enlever le débris.

Utilisez Tippmann® l'huile de marqueur ou une autre

❏

Décharger le marqueur et ❏ L'enlevage du

❏

Inspectz et lubrifiez les parties

❏

le boulon cercle d'O avant,

❏

Inspectez et lubrifiez le cercle d'O du canon et la valve

Pour commencer,

Désassemblage / Assemblage du marqueur (continué de la page 11)

3)❏ Pour enlever la trémie : tournez la trémie dans un sens

l'horloge

4)

❏

avant : Enlevez l'épingle

courte

et glissez la poignée avant pour

l'enlever.

❏

5)

Faites tourner le canon dans un sens

contre l'horloge

LES OUTILS: le magasin contient les outils et l'huile lubrifiante pour votre

marqueur.

❏

6)

de la base du magasin appuyez

le bouton du magasin

de la base du magasin, et puis

glissez le magasin en bas et puis

sortez - le.

Entreposez les outils dans le magasin après l'usage (montré avec 2

clés à pans et de l'huile).

7) ❏ Pour enlever la vue avant : Enlevez le vis de la vue avant

et glissez la vue avant et sortez - la.

❏

8)

arrière

et enlevez - la.

Pour enlever la poignée

/ et l'épingle longue

Pour enlever le canon :

pour enlever.

Pour enlever le magasin

(à droite

Pour enlever la vue arrière : Enlevez les 2 vis de la vue

/ et la vue arrière .

F

R

A

N

Ç

A

I

S

Désassemblage / Assemblage du marqueur et d’receveur

❏

La protection des yeux faite exprès pour la balle de peint doit être

portée par le joueur et d'autres personnes dans le champ à tir.

❏

Pour commencer, suivez les instructions ❏ Décharger le

1)

marqueur et ❏ L'enlevage du cylindre de la réserve d'air à la page 8 et ne désassemblez jamais un marqueur qui est pressurisé. Ne pas

pressuriser un marqueur moitié assemblé.

❏

Mettez le marqueur dans une position de sécurité. Si votre

2)

marqueur est armé, tenez la poignée du boulon 3/4 en arrière - puis

tirez la détente et relâchez la poignée

qui désarmera le marqueur.

Désassemblage / Assemblage du marqueur

11

(continué à la page 12)

La Vue

du Côté

Droite

Désassemblage / Assemblage du marqueur

12

(continué à la page 13)

Désassemblage / Assemblage du marqueur (continué de la page 12)

Désassemblage d’receveur

❏

La protection des yeux faite exprès pour la balle de peint doit être portée

par le joueur et d'autres personnes dans le champ à tir.

❏

Première: faites les pas 1), 2), 3), 4), 5), 6), 7), et 8) comme souligné

aux pages 1 1 et 12 avant de commencer le Désassemblage du Receveur .

Pour enlever le receveur inférieur (la poignée) : ❏ Enlevez les 2

•

épingles longues du receveur inférieur

inférieur

Pour enlever la ligne à gaz / la Pierre Tombale du receveur supérieur:

•

❏

Enlevez le receveur inférieur voyez en haut. ❏ Enlevez l'épingle

longue

du magasin

la base du magasin), et puis glissez le magasin en bas et sortez - le.

Glissez la base du magasin en arrière jusqu'à elle s'arrête, ensuite en

bas.

Tombale. NOTE: Si vous enlevez la ligne à gaz de la Pierre Tombale, en

F

réinstallant inspectez et lubrifiez le cercle d'O et soyez certain de ne pas

R

surserrer et arracher les parties aux filets.

du receveur supérieur .

du receveur supéreur. ❏ Enlevez le magasin de la base

en poussant le bouton du magasin (au côté droite de

❏

Tirez en bas la ligne à gaz pour enlever la ligne à gaz / Pierre

et tirez le receveur

❏

A

N

Ç

A

I

S

La Vue

du Côté

Droite

Pour enlever l’assemblé de détente du receveur inférieur (la poignée) :

•

❏

Faites tourner la sécurité verticalement et ❏ tirez - la et sortez la du côté gauche du receveur inférieur.

l'assemblé de détente

• Pour avoir accès aux parties de détente: ❏ Tirez la

plaque gauche de l’assemblé de détente

pas les 5 goupilles de la plaque droite voyez page 10.

en la gardant intact.

❏

Enlevez soigneusement

. N’enlevez

Désassemblage / Assemblage du marqueur

13

(continué à la page 14)

Désassemblage / Assemblage du marqueur (continué de la page 13)

L'Enlevage et L'installation de l'assemblé d'actionnement

NOTE: Ce n'est pas nécessaire de désassembler le receveur supérieur

pour accéder et réviser les parties internes de l'assemblé.

Pour enlever les parties de l'assemblé d'actionnement: le boulon avant, le

tube puissant, la valve, le boulon arrière/introduction de boulon arrière,

l'arme liée, l'épingle guidant d'actionnement, le ressort d'actionnement et

l'assemblé d'amorce à la fin (les parties montrées aux pages 9 et 10).

1)❏ Enlevez la réserve d’air avant de désassembler: ❏ Déchargez le

marqueur,

mettez le marqueur dans la position désarmée avant de commencer à

enlever au champ. Si votre marqueur est armé, tenez la poignée du boulon

3/4 en arrière - puis tirez la détente et relâchez la poignée

le marqueur.

2)

❏

3)

❏

4)

❏

5)

❏

parties d’assemblé d’actionnement devraient glisser de l’arrière du

marqueur. C'est peut - être nécessaire de secouer légèrement le marqueur

en glissant les parties.

Pour installer les parties d’assemblé d’actionnement et le receveur inférieur:

1)

❏

❏

2)

boulon du cercle d'O avant, ❏ le boulon cercle d'O arrière, ❏ l'arme liée et

❏

l'huile Tippmann

supérieure pour les marqueurs de balle de peint) avant de les réinstaller.

❏

3)

Pierre tombale aligné avec la forme de bouchon du tube puissant. Insérez

l’adapteur de Pierre tombale pour vérifier le match.

4)

❏

la valve, le boulon arrière/introduction de boulon arrière, avec l’arme liée

face visible) jusqu’à l’adapteur de Pierre tombale peut être inséré, l’épingle

(longue)

– être nécessaire de secouer légèrement le marqueur en re-mettant les

parties dans le marqueur.)

5)

❏

ressort d'actionnement dans

guidant au centre.

❏

enlevez le réserve d’air comme décrit à la page 8 et

qui désarmera

Enlevez la ligne à gaz et détachez le receveur inférieur (la poignée)

(voyez des instructions pour Désassemblage du receveur à la page 13).

Serrez la vis de vélocité passé le receveur.

Enlevez la dernière épingle (courte) en tenant l'amorce en place.

Tirez l’amorce à la fin et inclinez le marqueur au dessus, les

❏

F

R

A

N

Ç

A

❏

I

S

le

Nettoyez l’ intérieure du receveur supérieur et les parties enlevées.

Inspectez et remplacez les parties endommagées. Lubrifiez ❏ le

le ressort d'actionnement/l'épingle guidant avec quelque gouttes de

Insérez la valve dans le tube puissant avec la forme de bouchon de

Insérez les parties ré-assemblées (le boulon avant, le tube puissant/

Insérez l'épingle guidant dans le ressort d'actionnement et

®

pour les marqueurs de balle de peint (ou une autre huile

remplacé et on a accès à la vis de vélocité . (C’est peut

❏

❏

Installez l'épingle courte du bouchon supérieur .

Insérez le bouchon, en tenant l'épingle

Désassemblage / Assemblage du marqueur

14

(continué à la page 15)

Désassemblage / Assemblage du marqueur (continué de la page 14)

Le Receveur Inférieur Désassembler/Assembler:

❏

La protection des yeux faite exprès pour la balle de peint doit être

portée par le joueur et d'autres personnes dans le champ à tir.

Pour désassembler le receveur inférieur:

•

❏

Suivez les instructions pour désassembler le Marqueur/Receveur

1)

aux page 11, 12, et 13 jusqu'à vous avez

l'assemblé de détente

❏

Ensuite enlevez le boulon du réservoir adapteur.

2)

3)

❏

Enlevez les 3 vis de poignée qui tiennent les deux moitiés du

receveur inférieur ensemble.

de la poignée.

❏

détaché et enlevé

F

R

A

N

Ç

A

La Vue

du Côté

I

Droite

S

Pour rassembler le receveur inférieur (la poignée) :

•

❏

Soyez certain que la garde de détente soit en place.

1)

2)

❏

Remplacez la moitié gauche de poignée .

3)

❏

Attachez les moitiés de poignée avec 3 vis de poignée .

❏

Attachez l'adapteur de réservoir de Poignée: Glissez l'adapteur

4)

de réservoir

Insérez le boulon de l'adapteur et serrez.

5)

❏

Ré-installez le groupe de détente dans la poignée. ❏ Faites

tourner la sécurité du commutateur sélecteur

insérez - le au côté gauche et puis faites le tourner à la position de

sécurité = blanc

Pour attacher le receveur inférieur (la poignée) au receveur supérieur:

•

❏

Alignez le trou de l'épingle avant du receveur inférieur avec le

trou du receveur supérieur et puis bercez doucement la poignée jusqu'à

le trou de l'épingle arrière

deux épingles longues

dans le receveur inférieur et alignez les trous;

verticale et

.

aligne aussi et vous pouvez ❏ insérer les

et pour attacher.

Désassemblage / Assemblage du marqueur

(continué à la page 16)

❏

❏

Désassemblage / Assemblage du marqueur (continué de la page 15)

Le Canon et la Poignée Avant:

• Pour installer le canon: Insérez le canon et tournez dans un sens

l'horloge

•

Pour installer la poignée avant: Glissez la poignée avant dans le

canon/le receveur supérieur et insérez l'épingle courte

l'épingle longue

L'enlevage Du Cyclone

1)❏ Enlevez la réserve d'air avant de désassembler: ❏ Déchargez le

marqueur et

❏

2)

au champ. Pour désarmer votre marqueur, tenez la poignée du boulon

3/4 en arrière - puis tirez la détente et relâchez la poignée

désarmera le marqueur.

❏

3)

❏

4)

du receveur supérieur et enlevez le système de conduire

❏

5)

.

en bas pour l'attacher.

TM

Système Du Conducteur De Balle

❏

enlevez la réserve d'air comme décrit à la page 8.

Mettez le marqueur dans la position désarmée avant d'enlever

Enlevez le boulon banjo d'installations du receveur supérieur.

Enlevez le boulon de boîtier Cyclone

Pour installer, faites l'inverse.

TM

du moitié gauche avant

en haut et

qui

.

F

R

A

N

Ç

Le Receveur Supérieur Désassembler/Assembler:

Note: Il est seulement nécessaire de désassembler les quartiers

du receveur supérieur pour avoir accès aux 4 parties; le loquet de

balle, la poignée armée, le ressort poignée armée et le ( Le cercle

d'O du receveur est collé en place, ne l'enlevez que c'est

endommagél.

tirez - le ; 2) ❏ nettoyez la colle du trou du receveur ; 3)

mettez 4 gouttes de la colle CA (cyanoacrylate - superglue) placées

également en bas du trou et appuyez en place le nouveau cercle

d'O ; 4)

•

Pour Désassembler le Receveur Supérieur:

❏

Suivez les instructions de désassembler le marqueur/le

1)

receveur aux page 11, 12, et 13 jusqu'à vous avez enlevé la ligne

à gaz/ Pierre Tombale du receveur supérieur.

❏

Enlevez les 4 boulons courts du receveur

2)

les 3 boulons longs du receveur

supérieurs du receveur ensemble et levez le moitié gauche du

moitié du receveur droite. NOTE: le boulon longue du receveur

n'est pas visible jusqu'à le receveur inférieur (poignée) a été enlevé.

❏

Pour remplacer le cercle d'O du receveur: 1)

❏

il faut faire sècher avant de rassembler.)

/ /

en tenant les 2 moitiés

1615

Assemblée De Receveur Supérieure

/ / /

(continué à la page 17)

A

I

S

❏

❏

et

Assemblée De Receveur Supérieure (continué de la page 16)

Assemblée De Receveur Supérieure:

❏

Soyez certain que toutes les parties sont propres et lubrifiées

1)

avant de ré-assembler. Mettez plat le moitié droite du receveur

supérieur en haut avec

et

❏

le cercle d'O du receveur supérieur et collé en position

comme montré audessous..

2)❏ Avec la main gauche,

saisissez le moitié gauche du

receveur supérieur comme

montré pour tenir la poignée

armante

et le ressort

en place en appliquant la

pression à côté avec le doigt

d'index poussant dans un sens

de fleches

F

armante.

R

La

A

main

droite

N

Ç

Le côté

gauche

A

I

Le côté

S

droite

4)

❏

contre la poignée

Le ressort de poignée armante

Utilisez vos bouts de doigts pour guider la moitié gauche

directement en bas sur la moitié droite jusqu'à les moitiés du

receveur conviennent proprement. Si ça ne se convient pas la

première fois, vérifiez pour être certain que le ressort et les autres

parties sont restés en place et répétez jusqu'à les moitiés se

conviennent exactement.

5) ❏ Lubrifiez le canon/les

cercle d'O de l'adapteur. Suivez

l'illustration et

❏

boulons courts

et les 3 boulons longs

de receveur aux endroits

correctes et serrez -les assez

pour garder les moitiés au

❏

le loquet de balle insérez en position

sera courbé.

Insérez les 4

/ / /

/ /

❏

Avec la main gauche qui tient

3)

comme montré audessous, utilisez la

main droite pour mettre en place la

poignée armante avec le ressort dans

la rainure du receveur

, ensuite

positionnez le bord du ressort dans le

bout de la rainure du ressort courbé

comme montré audessous . Ensuite,

saisissez le receveur gauche avec la

main droite comme montré.

La poignée armante

La Vue

du Côté

Droite

17

Assemblée De Receveur Supérieure

(continué à la page 18)

La

main

gauche

Le loquet

de balle

Assemblée De Receveur Supérieure (continué de la page 17)

même niveau mais encore assez desserré pour vous permettre d'insérer

maintenant et de tordre l'unité de canon/adapteur dans un sens de

l'horloge

pour ré-installer.

6) Maintenant soyez certain que tous les 7 boulons sont serrés mais

pas surserrés pour ne pas arracher le filet des parties.

Réparer les échappes du cylindre du réserve d’air

L’échappe le plus commun c’est l’un d’un mauvais cercle d’O valve

d’un réserve d’air. Pour remplacer un cercle d’O de valve, il faut

enlever d-abord le mauvais cercle d’O de valve et puis installez le

nouveau. Ce cercle d’O se trouve au bout de votre valve de la

réserve d’air. Les meilleurs cercles d’O de valve sont fait

d’urethane. Les cercles d’O d’urethane ne sont pas affecté par

les pressions élévées du réserve d’air. Ceux peuvent être achetés

de Tippmann

le nouveau cercle d’O ne résoud pas l’échappe du réserve d’air,

n’essayez pas de réparer le cylindre d’air. Il faut contacter