Tippmann 98 Platinum Series User Manual

BACK COVER

®

TIPPMANN

• Owner’s Manual - For Markers with or without

• Le Manuel du Propriétaire - Pour les marqueurs avec ou sans

• Manual del Usuario - Para Marcadores con o sin

98 CUSTOM

PLATINUM SERIES

TM

TM

98 CUSTOM

PLATINUM

• BASIC NON-A.C.T.

• BASIC

98 CUSTOM

PLATINUM SERIES

• BASIC E-TRIGGER

TM

TM

TM

TM

TM

LINE

TM

TM

TM

SERIES

MARKER

98 CUSTOM

PLATINUM SERIES

• BASIC RESPONSE

98 CUSTOM

PLATINUM SERIES

TM

TM

TM

TM

TM

• BASIC DIGI CAMO

98 CUSTOM

PLATINUM SERIES

TM

TM

• PROTM

98 CUSTOM

PLATINUM SERIES

TM

TM

• PROTM E-TRIGGER

98 CUSTOM

PLATINUM SERIES

• PRO

TM

TM

DIGI CAMO

TM

TM

TP04315 Date 05-15-08

WARNING

E

THIS IS NOT A TOY. MISUSE MAY CAUSE SERIOUS

INJURY OR DEATH. EYE, FACE AND EAR PROTECTION

N

DESIGNED FOR PAINTBALL MUST BE WORN BY THE

G

USER AND ANY PERSON WITHIN RANGE. WE

L

RECOMMEND AT LEAST 18 YEARS OLD TO PURCHASE.

PERSONS UNDER 18 MUST HAVE ADULT SUPERVISION

I

WHEN USING THIS PRODUCT. READ THE OWNER’S

S

MANUAL BEFORE USING THIS PRODUCT.

H

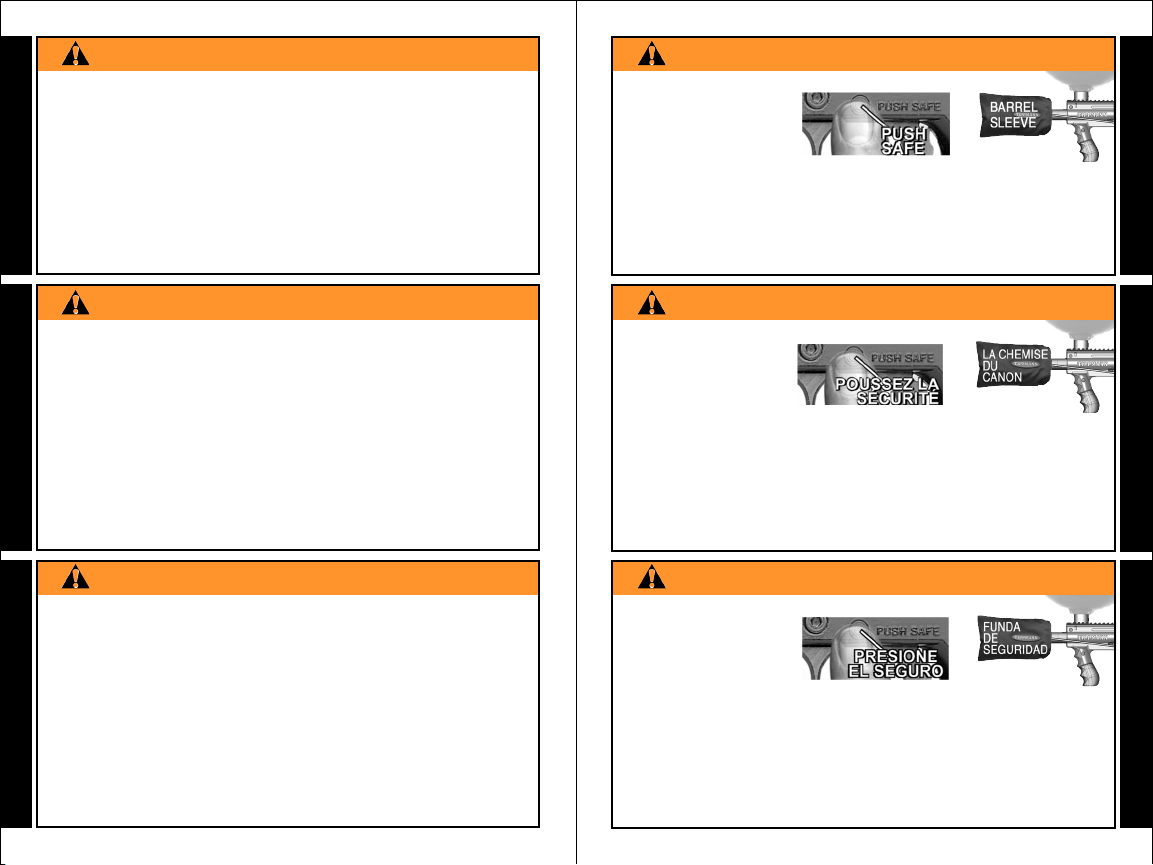

WARNING

SAFETY IS YOUR RESPONSIBILITY

READ, FAMILIARIZE

YOURSELF AND ANY

OTHER USER OF THIS

MARKER WITH THE

SAFETY INSTRUCTIONS

IN THIS MANUAL.

FOLLOW THESE

INSTRUCTIONS WHEN

USING, WORKING ON,

TRANSPORTING OR

STORING THIS MARKER.

ALWAYS KEEP

TRIGGER SAFETY

IN SAFE MODE

UNLESS FIRING

AS DETAILED IN

INSTRUCTIONS

ON PAGE 4.

ALWAYS KEEP

BARREL SLEEVE

INSTALLED WHEN

NOT IN SHOOTING

SITUATION AS

DETAILED IN

INSTRUCTIONS

ON PAGE 2.

E

N

G

L

I

S

H

AVERTISSEMENT

F

CE N’EST PAS UN JOUET. L’USAGE IMPROPRE PEUT

CAUSER LA BLESSURE SÉRIEUSE OU LA MORT. LA

R

PROTECTION POUR LES YEUX, LE VISAGE ET LES

A

OREILLES CONSTRUITE POUR LA BALLE DE PEINT

N

DOIT ÊTRE PORTÉE PAR L’UTILISATEUR ET N’IMPORTE

QUELLE PERSONNE DANS LE CHAMP DE TIR. NOUS

Ç

RECOMMENDONS QU’ ON A DIX – HUIT ANS AU MOINS

A

POUR L’ACHETER. LES PERSONNES SOUS L’ÂGE DE

I

DIX – HUIT ANS DOIVENT AVOIR LA SUPERVISION D’

S

UN ADULTE QUAND ON EMPLOIE CE PRODUIT. IL FAUT

LIRE TOUT DE CE MANUEL AVANT DE L’UTILISER.

ADVERTENCIA

E

ESTO NO ES UN JUGUETE. UN USO INAPROPIADO

PUEDE CAUSAR SERIAS HERIDAS O LA MUERTE.

S

OJOS, CARA Y OIDOS DEBEN ESTAR PROTEGIDOS

P

TODO EL TIEMPO, CON LA PROTECCIÓN DISEÑADA

A

PARA PAINTBALL TANTO PARA JUGADORES COMO

Ñ

PARA CUALQUIER PERSONA QUE ESTE EN EL RADIO

DE ALCANCE. RECOMENDAMOS AL MENOS 18 AÑOS

O

DE EDAD PARA LA COMPRA Y USO. LAS PERSONAS

L

MENORES DE 18 AÑOS DEBEN USAR ESTE PRODUCTO

BAJO LA SUPERVISIÓN DE UN ADULTO. ANTES DE

USAR ESTE PRODUCTO LEA EL MANUAL DEL USUARIO.

AVERTISSEMENT

SÉCURITÉ EST VOTRE RESPONSABILITÉ

IL FAUT LIRE, VOUS

FAMILIARISER ET

TOUS LES AUTRES

UTILISATEURS DE

CE MARQUEUR AVEC

LES INSTRUCTIONS

DE SÉCURITÉ DANS CE

MANUEL. SUIVEZ CES

INSTRUCTIONS QUAND

VOUS UTILISEZ,

TRAVAILLEZ SUR,

TRANSPORTEZ, OU

ENTREPOSEZ CE

MARQUEUR.

IL FAUT TOUJOURS

GARDER LA

DÉTENTE DANS UNE

MODE DE SÉCURITÉ

SAUF QUAND ON

TIRE COMME

DÉTAILLÉE DANS

LES INSTRUCTIONS

À LA PAGE 3.

ADVERTENCIA

LA SEGURIDAD ES SU RESPONSABILIDAD

EL PROPIETARIO Y

TODA PERSONA QUE

UTILICE ESTE

MARCADOR DEBE LEER Y

FAMILIARIZARCE

LAS INSTRUCCIONES DE

SEGURIDAD EN ESTE

MANUAL. SIGA LAS

INSTRUCCIONES DE

USO, MANTENIMIENTO,

TRANSPORTE Y

ALMACENAJE DE

ESTE MARCADOR.

MANTENGA SIEMPRE

CON

EL SEGURO DEL

GATILLO ACTIVADO

A MENOS QUE SEA

NECESARIO HACER

DISPAROS.

SE VE EN LAS

INSTRUCCIONES

DE LA PÁGINA 3.

COMO

IL FAUT

TOUJOURS

GARDER LA

CHEMISE DU

CANON INSTALLÉE

QUAND ON NE

TIRE PAS COMME

DÉTAILLÉE DANS

LES INSTRUCTIONS

À LA PAGE 1.

MANTENGA

LA FUNDA

DE

SEGURIDAD

INSTALADA

CUANDO NO

ESTE

HACIENDO

DISPAROS

COMO SE

ILUSTRA EN

LA PÁGINA 1.

F

R

A

N

Ç

A

I

S

E

S

P

A

Ñ

O

L

WARNING

E

THIS IS NOT A TOY. MISUSE MAY CAUSE SERIOUS

INJURY OR DEATH. EYE, FACE AND EAR PROTECTION

N

DESIGNED FOR PAINTBALL MUST BE WORN BY THE

G

USER AND ANY PERSON WITHIN RANGE. WE

L

RECOMMEND AT LEAST 18 YEARS OLD TO PURCHASE.

PERSONS UNDER 18 MUST HAVE ADULT SUPERVISION

I

WHEN USING THIS PRODUCT. READ THE OWNER’S

S

MANUAL BEFORE USING THIS PRODUCT.

H

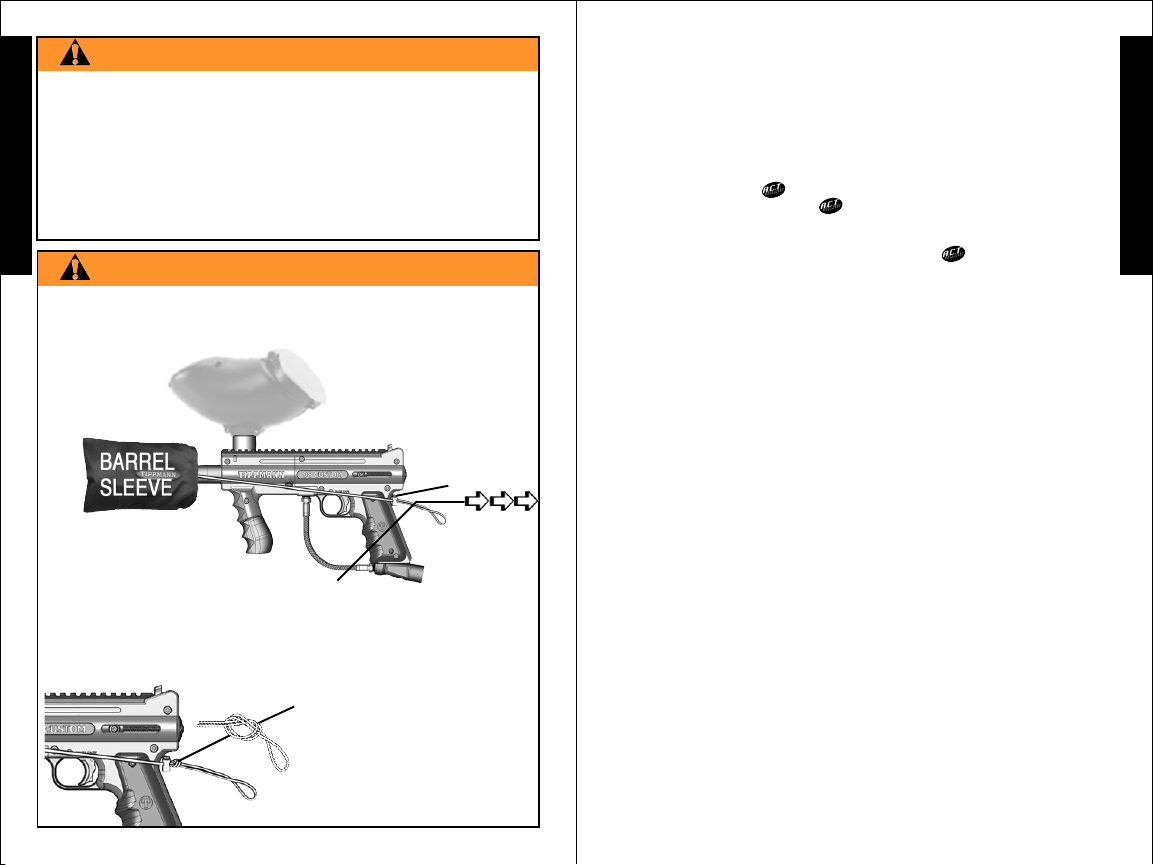

WARNING

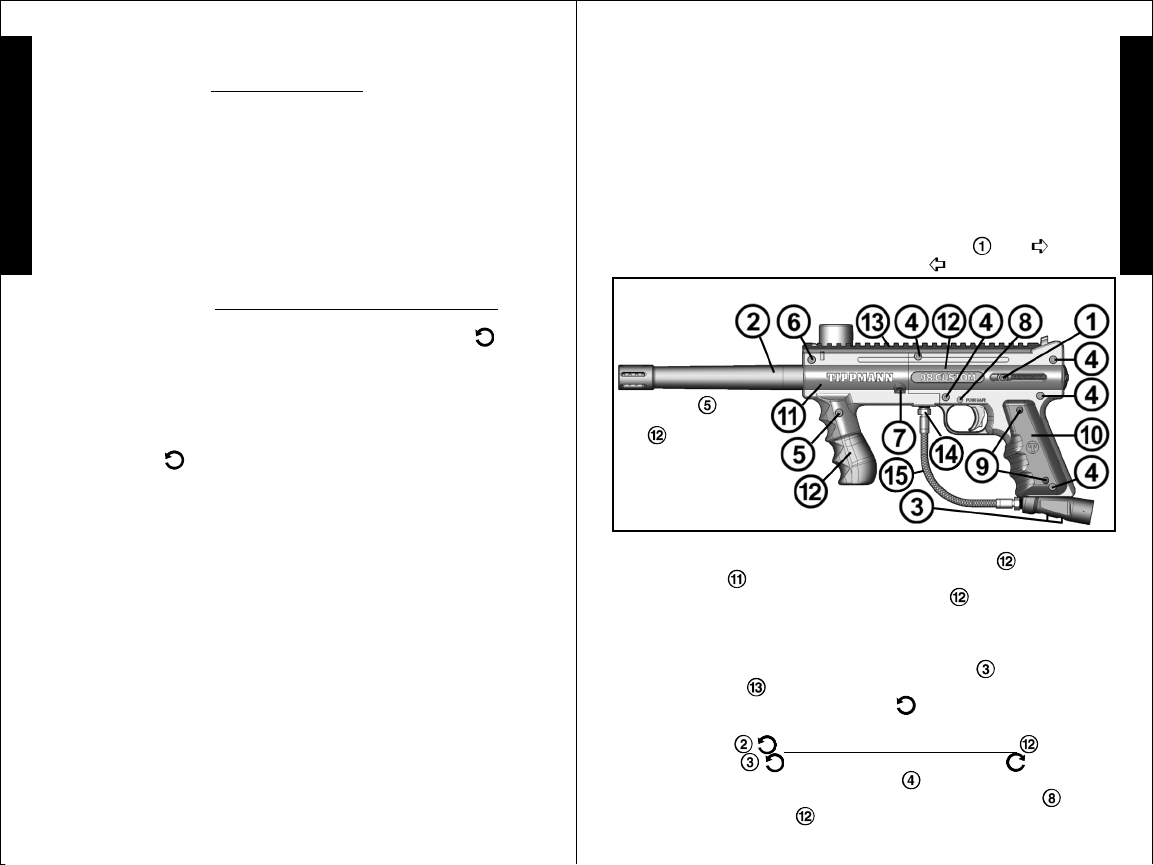

BARREL SLEEVE INSTALLATION

• EXCEPT WHEN YOUR MARKER IS IN USE, ALWAYS MAKE

SURE THAT THE TRIGGER SAFETY IS IN SAFE MODE (SEE

INSTRUCTIONS ON PAGE 4), AND THE BARREL SLEEVE IS

PROPERLY INSTALLED ON YOUR MARKER AS SHOWN BELOW.

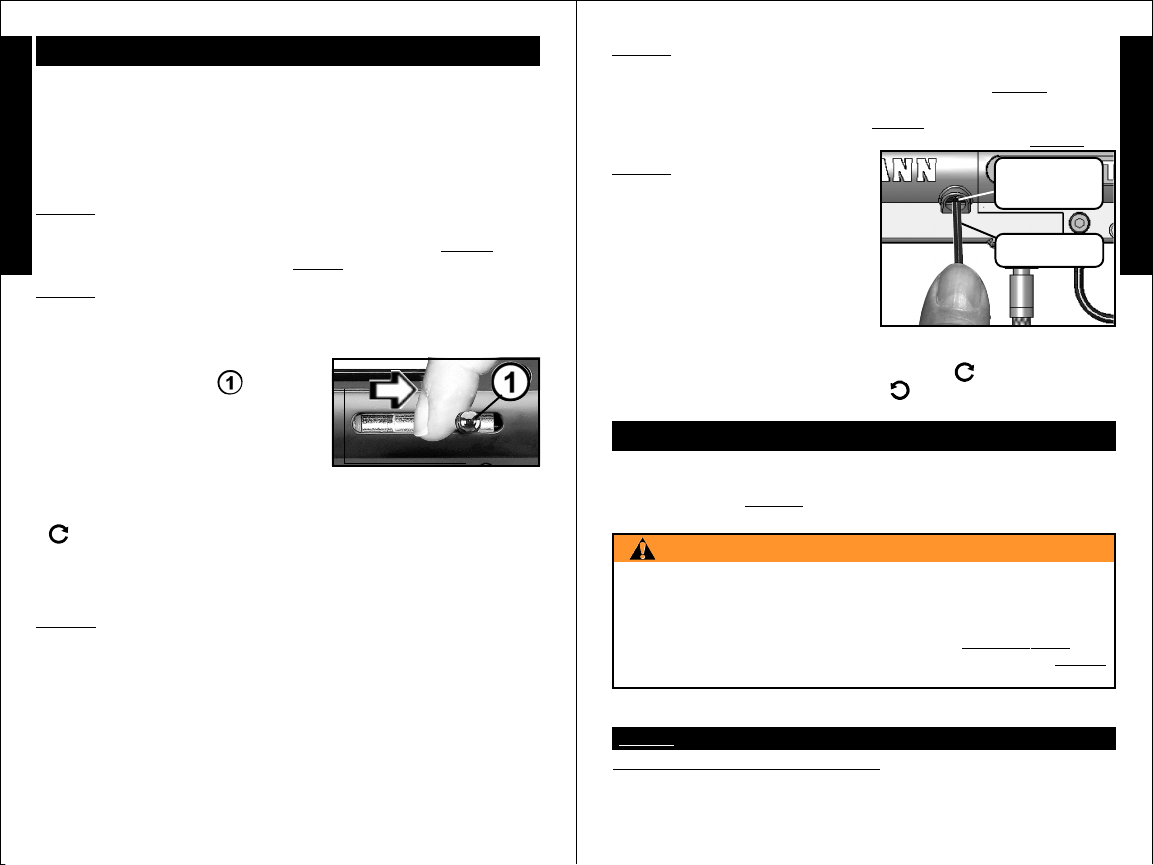

1) SLIDE BARREL INTO SLEEVE AND LOOP THE CORD OVER

THE TOP OF THE RECEIVER AND POSITION AT THE

BACK OF THE GRIP AS SHOWN BELOW.

LENGTH

ADJUSTOR

BUTTON

2) PINCH THE CORD

LENGTH ADJUSTOR

BUTTON AND HOLD THE

ADJUSTOR TO THE BACK OF THE

GRIP AS YOU PULL THE CORD THROUGH IT UNTIL THE

ADJUSTOR IS SNUG AGAINST THE BACK OF THE GRIP, THEN

RELEASE THE BUTTON.

3) CHECK TO BE SURE YOU LEAVE ENOUGH CORD ELASTICITY

TO PULL THE CORD/ADJUSTOR UP OVER THE TOP OF THE

MARKER TO REMOVE THE BARREL SLEEVE FOR FIRING.

4) AFTER THE CORD LENGTH

IS ADJUSTED, LOCK THE

CORD LENGTH BY TYING A

KNOT IN THE CORD

AGAINST THE BACK OF THE

ADJUSTOR AS SHOWN.

2

CORD

®

TIPPMANN

2955 Adams Center Road, Fort Wayne, IN 46803 USA

P) 260-749-6022 • F) 260-749-6619 • www.tippmann.com

CONGRATULATIONS on your purchase of a Tippmann® paintball marker. We

believe our 98 Custom

and durable paintball markers available, and are proudly manufactured by

Tippmann

nonservice if cared for properly . The

Anti-Chop Technology, a patent pending design to help eliminate ball chopping

and ensure consistent performance. Using a new technology that has the front

and rear bolt working independently of each other,

chopping and improves ball accuracy with less barrel cleaning; and unlike other

anti-chop systems, our system maintains consistent ball velocity shot after shot

and does not have to be re-cocked if the anti-chop technology had to be engaged.

The 98 Custom

receiver technology which seperates the left receiver half into two parts for

improved ease of service and installation of accessories.

Please take time to read this manual thoroughly and become familiar with your

98 Custom

before you attempt to load or fire this marker. If you have a missing or broken

part or need assistance, please contact Tippmann

at 1-800-533-4831 for fast friendly service.

®

. All Tippmann

A.C.T model to our enabled models will give many years of dependable

TM

Platinum Series

TM

Platinum SeriesTM line of markers to be the most accurate

®

98 CustomTM Platinum SeriesTM markers from the Basic

enabled markers contain our exclusive new

virtually eliminates ball

TM

Platinum SeriesTM markers feature Tippmann®'s exclusive split

TM

marker’s parts, operation, and safety precautions

®

Consumer Relations

E

N

G

L

I

S

H

TABLE OF CONTENTS

Warning/Caution ......................................................................................................... 2

Warning/Caution Barrel Sleeve Installation ......................................................... 2

Warning/Liability Statement..................................................................................... 4

Safety is your Responsibility / Familiarize Yourself With Safety .................... 4

Safe Mode = Turning The Safety On (PUSH SAFE).......................................... 4

Fire Mode = Turning The Safety Off (PUSH FIRE) ............................................ 4

Getting Started ........................................................................................................... 6

1. Prepare Marker for Air Supply Cylinder Installation ................................. 6

2. Air Supply Cylinder Installation ..................................................................... 6

3. Hopper Installation........................................................................................... 7

4. Rate of Fire Adjustments and Troubleshooting ......................................... 7

5. Velocity Adjustment ......................................................................................... 7

Schematics ................................................................................................................ 14

Unloading Your Marker ........................................................................................... 20

Air Supply Cylinder Removal ................................................................................ 20

Cleaning & Maintenance ........................................................................................ 20

Marker Disassembly / Assembly ........................................................................... 21

Repairing Air Supply Leaks ................................................................................... 24

Storage ....................................................................................................................... 24

Specifications ........................................................................................................... 24

Warranty and Repair Policy................................................................................... 25

Warranty or Repair Procedure .............................................................................. 25

Warranty Registration .............................................................................................25

3

Warning/Liability Statement

This marker is classified as a dangerous weapon and is surrendered by

E

Tippmann Sports, LLC with the understanding that the purchaser assumes

all liability resulting from unsafe handling or any action that constitutes a

N

violation of any applicable laws or regulations. Tippmann Sports, LLC shall

G

not be liable for personal injury , loss of property or life resulting from the use

of this weapon under any circumstances, including the intentional, reckless,

L

negligent or accidental discharges.

I

All information contained in this manual is subject to change without notice.

S

Tippmann Sports, LLC reserves the right to make changes and improvements

to products without incurring any obligation to incorporate such improvements

H

in products previously sold.

If you as a user do not accept liability , Tippmann Sports, LLC requests you

do not use a Tippmann Sports, LLC marker. By using this paintball marker

you release Tippmann Sports, LLC of any and all liability associated with its use.

SAFETY IS YOUR RESPONSIBILITY!

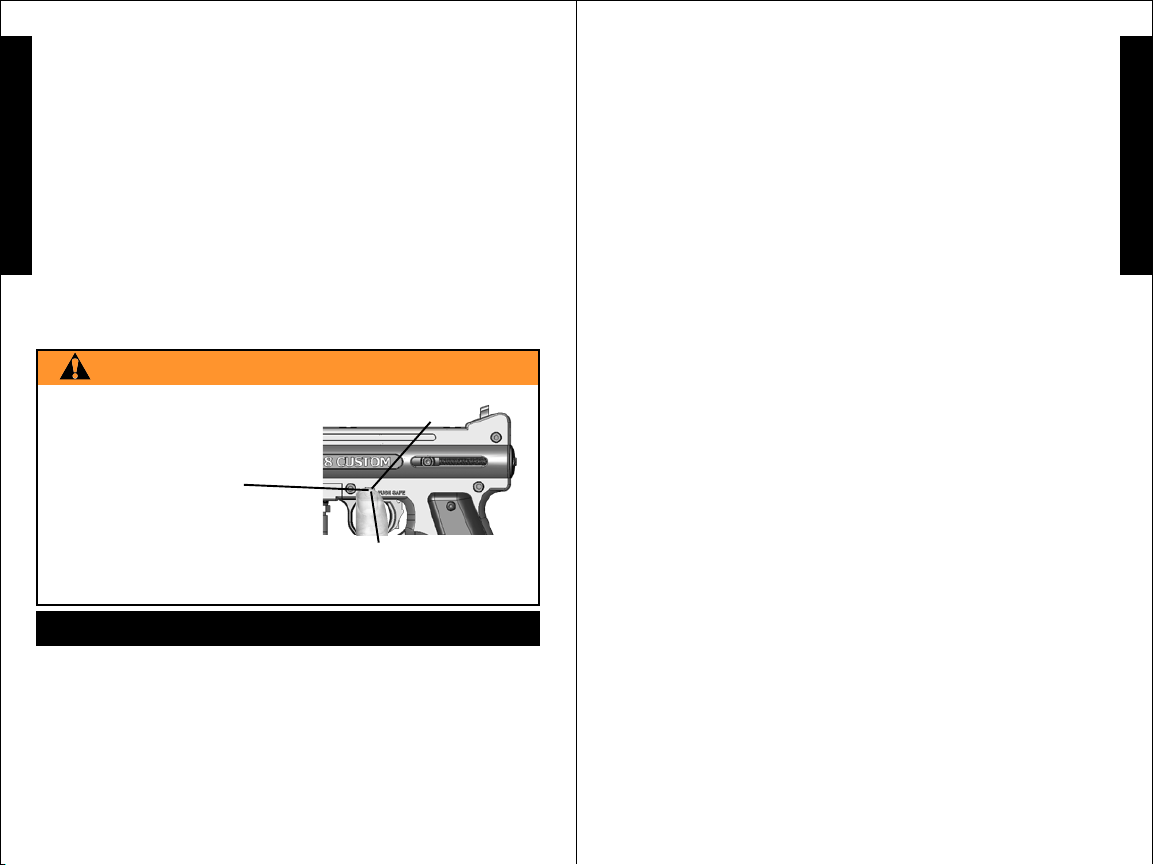

WARNING

• EXCEPT WHEN YOUR MARKER

TRIGGER SAFETY ACTIVATION

IS IN USE, ALWAYS MAKE

SURE THAT THE BARREL SLEEVE

IS INSTALLED (SEE PAGE 2) AND

THE TRIGGER SAFETY

IS IN SAFE MODE WHICH

DISABLES THE TRIGGER.

• TO TURN ON THE SAFETY (SAFE MODE): PUSH THE SAFETY

IN AS SHOWN ABOVE.

• TO TURN SAFETY OFF (FIRE MODE): PUSH SAME BUTTON

ON OPPOSITE SIDE OF RECEIVER.

FAMILIARIZE YOURSELF WITH SAFETY...

The ownership of this weapon places upon you the total responsibility for its

safe and lawful use. You must observe the same safety precautions as you

would any firearm to assure the safety of not only yourself but everyone

around you. The user should at all times use caution when using this marker.

The sport of Paintball will be viewed and judged upon your safe and

sportsmanlike conduct. Always remember that the game of Paintball can

only survive and grow if it remains SAFE!

• Do not load or fire this marker until you have completely read this

manual and are familiar with its safety features, mechanical operation

and handling characteristics.

4

PUSH SAFE

Safety Is Your Responsibility

(continued on page 5)

Safety Is Your Responsibility (continued from page 4)

• Handle this and any marker as if it were loaded at all times.

• Keep your finger off the trigger until ready to shoot.

• Do not look down the barrel of a paintball marker. Accidental discharge into

the eyes may cause permanent injury or death.

• Keep the marker on safe until ready to shoot (see page 4).

• Keep the barrel sleeve installed on marker when not shooting.

• Never point the marker at anything you do not intend to shoot.

• Never fire you r m arker at anything you do not intend to shoot because there

may be balls or foreign debris lodged in the chamber, barrel and / or the

marker valve.

• Do not shoot at fragile objects such as windows.

• Never fire your marker at personal property of others, the paintball can stain

the paint of automobiles and houses.

• Always keep the muzzle pointed down or in a safe direction, even if you

stumble or fall.

• Eye, face and ear protection designed specifically to stop paintballs in the

form of goggles and full face mask meeting ASTM Specification F 1776

must be worn by the user and any person within range.

• Never shoot at a person who is not protected by eye, face and ear protection

designed for paintball.

• Pressurize and load the marker only when the marker will be immediately used.

• NOTE: Before storing or disassembling be sure to remove paintballs and

air supply (see unloading and air supply removal instructions on page 20).

Install barrel sleeve (see page 2).

• Store the marker unloaded and degassed in a secure place.

• Do not field strip or otherwise disassemble this marker while it is pressurized

with air supply .

• Dress appropriately when playing the game of paintball. A void exposing

any skin when playing the game of paintball. Even a light layer will absorb

some of the impact and protect you from the paintballs.

• Keep exposed skin away from escaping gas when installing or removing

air supply cylinder or if the marker or air supply is leaking. Compressed

air, CO

2, and nitrogen gasses are very cold and can cause frostbite

under certain conditions.

• Use only .68 caliber paintballs, never load or fire any foreign objects.

• Avoid alcoholic beverages before and during the use of this marker .

Handling markers while under the influence of drugs or alcohol is a

criminal disregard for public safety .

• Avoid shooting an opponent at point blank, 6 feet or less.

• Familiarize yourself with instructions listed on air supply cylinder or

adaptor. Contact the air supply cylinder or adaptor manufacturer with

any questions.

• Always measure your marker’s velocity before playing paintball

and never shoot at velocities in excess of 300 feet per second

(see instructions on page 7).

5

E

N

G

L

I

S

H

GETTING STARTED

❏

Eye protection designed for paintball use must be worn by the user and

E

any person within range. Do not disassemble this marker while it is

N

pressurized with air. Do not pressurize a partially assembled marker.

G

Read each step completely before performing the step.

NOTE: Carefully hand start all threaded parts and do not overtighten and

L

strip threaded parts when assembling.

I

STEP 1) Prepare Marker for Air Supply Cylinder Installation

S

• For markers with E-TriggerTM - You must first read and follow E-T rigger

H

Operating Instructions (on pages 7-12) before performing

• For mark ers w ithout E-Trigger

TM

go to STEP 2.

STEP 2) Air Supply Cylinder Installation

• Do not pressurize a partially assembled paintball marker .

• First install barrel sleeve (see instructions on page 2).

• Next put trigger safety in Safe Mode

(see instructions on page 4).

• Next you need to cock the marker

by sliding the bolt handle

all the way

back until it locks into place. Always

keep marker in the cocked position when

air supply is attached to the marker. This

will help prevent an accidental discharge.

• To install the air supply cylinder, lubricate the cylinder valve o-ring with

a little marker oil then insert the cylinder valve end into the air supply

adapter at the back end of the marker grip. Turn the cylinder clockwise

into the marker until it stops. Your marker is ready to fire once you

switch to Fire Mode from Safe Mode. If the tank is full and you do not

hear the air supply engage, the pin valve could be too short or the pin

valve seal is damaged.

STEP 3) Hopper Installation

• Barrel Sleeve must be installed (see page 2) and safety in Safe Mode (see

page 4) before filling the hopper .

• Make sure that the feed elbow and hopper are clean and free of any sharp

edges to keep paintballs feeding into the marker smoothly .

• Install the hopper neck into the feed elbow of your marker and tighten the

hopper down with a 3/16” allen wrench.

NOTE: Do not overtighten or the elbow may break. With the barrel sleeve

installed and safety in Safe Mode, you are now ready to load your hopper

with paintballs. Fill the hopper and only remove barrel sleeve and turn off

the safety when ready to shoot.

6

Getting Started (continued on page 7)

STEP 2.

Getting Started (continued from page 6)

STEP 4) Rate of Fire Adjustments and Troubleshooting

• For RESPONSE

of Fire instructions (on page 13) before performing

• For E-TRIGGER

(on pages 7-12); before performing

• For Basic Non-A.C.T., Basic A.C.T. and Pro

STEP 5) Velocity Adjustment

Each time you play paintball, the

velocity of your paintball marker should

be checked with a chronograph, an

instrument for measuring velocity , prior

to playing paintball to verify that the

TM

markers - complete Tuning The Response T rigger Rate

TM

markers - read and follow E-TriggerTM Operating Instructions

STEP 5.

TM

markers - Go to STEP 5.

STEP 5.

Velocity

Adjustment

Screw

5/32”Allen

Wrench

E

N

G

L

I

S

H

marker’s velocity is set below 300 feet

per second or less if required by

playing field.

To adjust the velocity use the 5/32” allen wrench included with your marker .

The velocity adjustment screw is located on left side receiver. To adjust the

velocity down, turn the screw inward or clockwise

up, turn the screw out or counterclockwise

E-TRIGGERTM OPERATING INSTRUCTIONS

Read And Follow E-Trigger

TM

Operating Instructions completely (on

. Do not remove velocity screw .

. To turn the velocity

pages 7-12) before installing the air supply cylinder as outlined in Getting Started -

READ EACH STEP COMPLETELY BEFORE PERFORMING THE STEP:

STEP 2: on page 6.

WARNING

INSTALL THE AIR SUPPLY AND LOAD THE HOPPER WITH PAINTBALLS

ONLY AFTER YOU:

❏ ❏

❏

HAVE THE BARREL SLEEVE INSTALLED (SEE PAGE 2);

❏ ❏

❏ ❏

❏

HAVE THE SAFETY IN THE "SAFE" POSITION (SEE PAGE 4);

❏ ❏

❏ ❏

❏

HAVE SUCCESSFULLY INSTALLED THE BATTERY (STEP 2: - PAGE 8) AND

❏ ❏

❏ ❏

❏

ARE FAMILIAR WITH THE E-TRIGGERTM NORMAL OPERATION (STEP 3:

❏ ❏

- PAGE 8).

❏

Eye protection designed for paintball use must be worn by the user and

any person within range.

STEP 1: Prepare the marker for safety before any programming:

Prepare the marker for disassembly. First follow ❏ Unloading Your

Marker and

20. Do not disassemble this marker while it is pressurized with air.

Do not pressurize a partially assembled marker.

❏

Air Supply Cylinder Removal instructions on page

E-TRIGGERTM OPERATING INSTRUCTIONS

7

(continued on page 8)

TM

E-Trigger

Operating Instructions (continued from page 7)

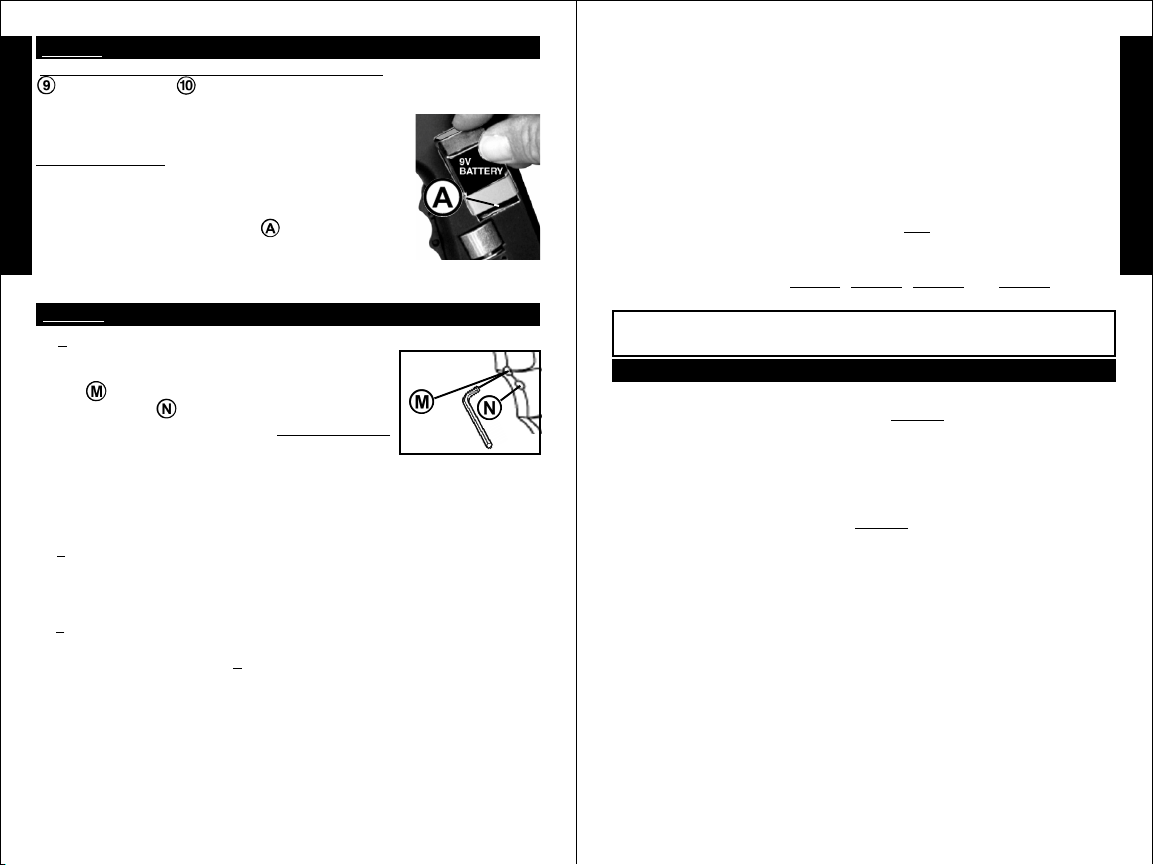

STEP 2: E-TRIGGERTM Battery Installation or Replacement

Remove the Battery Clip/old battery (from marker). ❏ Remove the 2 bolts

E

and the left grip . ❏ Carefully work battery out of receiver cutout

bringing non-connected end out first. As you remove battery from receiver, do

N

not pull wires off of internal components.

G

remove old battery from battery clip connector.

Install new battery. ❏ Attach a 9 volt battery to

L

battery connector and be sure wires lay flat inside

I

the cutout area of receiver (as shown on page 22).

❏

Carefully tilt and insert your new battery , wire attached

S

end first, into receiver as shown

H

grip with 2 grip bolts. Battery installation is complete.

NOTE: The E-Trigger

TM

Low Battery Indicator feature: the “Ready To Fire” solid

❏

Carefully

. ❏ Reinstall the left

Green LED will turn to blinking red when the battery is low and needs replaced.

STEP 3: NORMAL OPERATION:

❏ ❏

❏

1) To Turn ON the TRIGGERTM to normal operation - Ready T o Fire:

❏ ❏

• Without holding the trigger: Use a small object like

an allen wrench to

button

for 1/2 second and then release the power

button. The LED

seconds, flash Red once and then

to show normal operation - “Ready To Fire” mode.

Your E-Trigger

❏

press and hold the power

should light solid Orange for 2

light solid Green

TM

is now ready for normal operation in the SEMI-AUTO = 1

Power

Button

LED

pull / release of the trigger fires 1 time (Factory set Default Firing Mode).

NOTE: If pressing the power button failed to turn on the LED light, see

troubleshooting on page 9.

❏ ❏

❏

2) T o turn OFF the E-T riggerTM electronics. ❏ Press and hold the power

❏ ❏

button for 2 seconds as the LED turns solid Red, then release the Power

Button and the LED will turn OFF. NOTE: The trigger electronics are set to

shut-off automatically after a prolonged period of inactivity (120 minutes).

❏❏

❏

3) To select a new firing mode:

❏❏

❏

1) Turn ON the E-T riggerTM to normal operation (solid Green LED - Ready

To Fire) as instructed in step

❏

2) Press / hold the power button in one time for more than 1/4 but less

than 2 seconds and release the power button.

1 above.

❏

Count the LED Orange

flashes to identify your new setting, the LED light will return to solid Green Ready To Fire - in the new firing mode. You can program your marker for

any one of 5 firing modes. The orange flashes = firing mode options are:

• 1 orange flash = SEMI-AUTO MODE – 1 pull/release of the trigger fires

1 time (default firing mode). (This adheres to the 2005 NPPL rules).

• 2 orange flashes = 3 SHOT RAMPING MODE – 3 trigger pulls are

required (semi-auto) and the consecutive trigger pulls will fire 3 shots

8

TM

E-Trigger

Operating Instructions

(continued on page 9)

TM

E-Trigger

Operating Instructions (continued from page 8)

per pull as long as the trigger is pulled at least 5 times per second.

(This adheres to the 2005 PSP rules).

• 3 orange flashes = 3 SHOT FULL AUTO MODE – 3 trigger pulls are

required (semi-auto) after which the trigger can he held to achieve full auto

firing. (This adheres to the 2005 NXL rules).

• 4 orange flashes = AUTO RESPONSE MODE – Fires one shot for each

pull or release of the trigger. If the trigger is held for more than 1/4 of a

second,when the trigger is released no shot is fired.

• 5 orange flashes = TURBO MODE – Fires one shot for each pull of the

trigger until the time between trigger pulls is less than 1/4 of a second at

which point it will fire on each trigger pull

❏

Repeat step 2) until you have the firing mode you want.

and trigger release.

E

N

G

L

I

S

H

• Y ou are now ready to go back to page 6 and complete the GETTING

ST ARTED section steps:

NOTE: If marker does not fire see E-Trigger

❏

TOURNAMENT LOCK: Because the E-TriggerTM board requires a tool

STEP 2:, STEP 3:, STEP 4:and STEP 5:.

TM

Troubleshooting - below.

to turn it on and off, no tournament lock is necessary for competition paintball.

E-TRIGGER

❏

PROBLEM: The LED light does not light when you push the power button

and attempt to turn ON the E-Trigger

1) Battery may be disconnected.

2) Battery may be bad -

TM

TROUBLESHOOTING

TM

in STEP 2: Normal Operation.

❏

❏

Check battery clip connection.

Check the battery, replace if bad.

3) Internal wire may be disconnected. Do NOT disassemble a marker while

it is pressurized with air.

❏

Inspect wire connections inside the receiver:

follow disassembly / wire inspection and assembly instructions on pages

21-23 then continue on page 8 with

❏

PROBLEM: Y ou have successfully installed the battery, turned on the E-

TM

Trigger

, installed the air supply and loaded the paintballs and the marker

will not fire.

❏

Check to be sure safety is in "FIRE" position and

STEP 2: Normal Operation.

❏

make

sure sufficient air supply is hooked up to the marker .

❏

PROBLEM: the “Ready To Fire” solid Green LED has turned to blinking

red.

❏

Low battery condition - While performance will vary while the LED is

blinking red, the E-Trigger

battery has lost power to the point that it will not cycle the marker.

TM

will still function under this condition until the

❏

The

battery is low and needs replaced.

❏

PROBLEMS WHEN FIRING: Y ou can fine tune how your marker fires by

making adjustments to the Dwell, Debounce

TM

and Rate Of Fire Cap modes.

Read and become familiar with detailed descriptions of problems you may

have when firing and instructions for troubleshooting, tuning and

programming to correct them in the Dwell, Debounce

TM

and Rate Of Fire

sections on pages 10, 1 1and 12.

❏

If a problem still exists, call Tippmann® Service Department at 1-800-533-4831.

9

TM

E-Trigger

Operating Instructions

(continued on page 10)

TM

E-Trigger

Operating Instructions (continued from page 9)

STEP 4: How to program a new Dwell, Debounce

Cap or Firing mode setting In the TRIGGER PROGRAMMING

E

MODE. (Example: Shows how to select a new firing mode).

N

1) FIRST YOU MUST ENTER INTO THE “TRIGGER PROGRAMMING

MODE:” to access the Trigger Programming Menu:

G

is turned off (page 8 step 2).

L

❏

Pull the trigger and hold it in the back position - as you press and hold the

power button for 1 second (the LED will light red) - then release first the

I

power button and then the trigger. The LED will stay solid red indicating the

S

marker is now in the “Trigger Programming Mode” - at Menu Item number 1.

In the “Trigger Programming Mode”, there are 4 Menu Items, each

H

❏

Press the trigger safety to the FIRE position.

TM

, Rate Of Fire

❏

Make sure the power

identifiable by its LED color which creates the “Programming Menu” sequence:

• Menu Item 1 - Solid Red LED = Dwell (programming mode).

• Menu Item 2 - Solid Green LED = Debounce (programming mode).

• Menu Item 3 - Flickering Green LED = Rate of Fire (ROF) Cap (programming mode).

• Menu Item 4 - Alternating Green/Orange LED = Firing Mode (programming mode).

2) TO SELECT A MENU ITEM:

❏

Pull and release the trigger to advance to the next menu item until you

get to the item you want to change. After last item, an additional trigger pull

will restart the menu item sequence. (EXAMPLE:

❏

To program a new

Firing Mode, advance to: Alternating Green/Orange LED=Firing Mode).

3) TO CHECK THE MENU ITEM’S CURRENT SETTING:

❏

Pull the trigger and hold it until the LED goes out and then release the

trigger. There will be a 2 second pause and then the LED will flash green -

❏

count the number of green flashes to determine the current setting.

EXAMPLE-Firing Mode settings (green LED flashes =):

• 1 LED flash = Semi-auto (2005 NPPL legal).

• 2 LED flashes = 3 shot Ramping (2005 PSP legal).

• 3 LED flashes = 3 shot Full Auto (2005 NXL legal).

• 4 LED flashes = Auto Response.

• 5 LED flashes = Turbo.

If you decide not to change the item’s setting,

❏

simply do not touch the

trigger at all for 5 seconds. The LED will then blink green/red alternately to

indicate there was no reprogramming, and then it will go back to the

programming menu and the menu item’s setting will not have changed.

❏

Y ou can exit the programming mode by pressing the power button until the LED

turns solid red (

❏

then stop pressing the power button) and the LED will turn off.

4) TO CHANGE A MENU ITEM’S SETTING:

Once the LED is done flashing the current setting, there is a 5 second time

period to begin programming the new setting (Note: you do not have to wait and

count the flashes for the current setting, any trigger input immediately bypasses

the flashes and begins programming the new setting).

the number of times equal to how you wish to program the item. On each pull of

❏

Pull and release the trigger

TM

E-Trigger

Operating Instructions

(continued on page 11)

TM

E-Trigger

Operating Instructions (continued from page 10)

the trigger , the LED will light up red (indicating that the pull has been detected).

❏

Once you have pulled and released the trigger the number of times necessary

to set the function, wait a few seconds for Programming Verification.

PROGRAMMING VERIFICATION:

If the programming was successful: The LED will flash red/green/orange

•

in rapid succession (numerous times) to let you know that the new setting

has been saved. After this, the LED will return to the color representing

what the current programming menu item is.

❏

At this point, you can exit

the programming mode (see below) or you can program other features by

once again pulling and releasing the trigger to toggle between Dwell,

Debounce

™

, ROF Cap, and Firing Mode. (Dwell, Debounce

™

and Rate of

E

N

G

L

I

S

H

Fire Cap Programming is described in detail on pages 1 1and 12).

•

If the programming was unsuccessful, the LED will toggle green/red

alternately to indicate there was a programming error, and it will then return

to the programming menu. If this happens the setting will not have changed

and you will need to

❏

begin programming again at STEP 3: 2). (NOTE:

When adjusting the Firing Mode, if you pull and release the trigger more

than 5 times it will cause a programming error.)

•

To exit the Trigger Programming Mode: Turn off the E-TriggerTM,

❏

press and hold the power button until the LED first flickers red then

becomes solid red, and then release the button.

DWELL, DEBOUNCE

TM

and RATE OF FIRE (ROF) CAP MODES:

The firing mode controls how the marker fires regardless of these 3 mode

settings. Adjust these 3 mode features to fine tune your markers firing as follows.

DWELL troubleshooting and tuning / programming: Dwell is the amount of

time that the solenoid will be activated. This time is measured in milliseconds (1/

th

1000

of a second). The default dwell is 6.0ms. The lowest allowable dwell time

is 4.0ms and the longest allowable time is 50.0ms. According to the solenoid

manufacturer, the dwell should never be below 5.0ms for proper operation. Too

short of a dwell time will not release the sear mechanism. Too long of a dwell

time will reduce battery life. T o adjust the Dwell:

❏

Perform STEP 3: 1) then

❏

select the Dwell programming feature (= Solid Red LED), ❏ pull and hold trigger

until LED light goes out and release the trigger. When LED comes back on -

❏

count the number of green flashes to determine the current setting and once the

LED stops flashing, you have 5 seconds to

❏

begin pulling and releasing the

trigger once for every FULL 1ms of time you want the dwell to be. On each pull

of the trigger, the LED will light up red (indicating that the pull has been detected).

Once you have pulled and released the trigger the number of times necessary to

set the function,

Programming Verification - above).

DEBOUNCE

amount of time the trigger switch must be stable before checking for

❏

wait a few seconds for Programming Verification (See

TM

troubleshooting and tuning/programming: Debounce

TM

E-Trigger

1110

Operating Instructions

(continued on page 12)

TM

is the

TM

E-Trigger

Operating Instructions (continued from page 11)

another trigger pull. This time is measured in milliseconds. (The default Debounce

setting is 20ms). If th e marker has been double firing, increase the Debounce

time. To make your marker fire faster, reduce the trigger response time by

E

decreasing the Debounce

N

STEP 3 1) then ❏ select the DebounceTM programming feature (= Solid Green

❏ ❏

LED),

❏

G

L

I

S

H

pull and hold trigger until LED light goes out and

❏ ❏

When LED comes back on the current setting and once the LED stops flashing, you have 5 seconds to

❏ ❏

begin

❏

pulling and releasing the trigger once for every FULL 1 ms of time you

❏ ❏

want the Debounce

(indicating that the pull has been detected). Once you have pulled and released

the trigger the number of times necessary to set the function,

TM

time. To adjust the DebounceTM time: ❏ Perform

❏ ❏

❏

release the trigger.

❏ ❏

❏

count the number of green flashes to determine

❏ ❏

TM

to be. On each pull of the trigger, the LED will light up red

❏ ❏

❏ ❏

❏

❏ ❏

TM

TM

wait a few

seconds for Programming V erification (See Programming Verification on page 11).

THE RA TE OF FIRE (ROF) CAP troubleshooting and tuning/programming:

(ROF) Cap sets the maximum cycle speed of the marker. (The default ROF

Cap is 15 bps). Setting this value too low will reduce the usable speed of the

marker. Setting this value too high can cause misfires and “chops” if the hopper

can not keep up. T o adjust the Rate of Fire cap:

❏

select the (ROF) programming feature (=Flickering Green LED), ❏ pull and

hold trigger until LED light goes out and

comes back on -

❏

count the number of green flashes to determine the current

setting and once the LED stops flashing, you have 5 seconds to begin

❏

Perform STEP 3 1) then

❏

release the trigger. When LED

❏

pulling

and releasing the trigger once for every bps you want the Rate of Fire (ROF) cap

to be. For example, 20 pulls/releases would be 20 bps. On each pull of the

trigger, the LED will light up red (indicating that the pull has been detected).

Once you have pulled and released the trigger the number of times necessary to

set the function,

❏

wait a few seconds for Programming Verification (See

Programming Verification on page 11).

To Perform A Complete E-Trigger

TM

Reset To the Default Settings:

With the E-Trigger turned off, press and hold the power button for 10 full seconds

as the LED turns on solid orange and at 10 seconds it turns solid red. At this

point, you release the power button and the LED will turn off and the board will

be reset to the factory default settings. Your marker is now ready for normal

operation with the Factory Default Mode Settings: Firing Mode = Semi-auto (1

pull/release of the trigger fires 1 time); Dwell = 6.0 ms; Debounce

TM

= 20 ms;

Rate of Fire (ROF) Cap = 15 bps.

NOTE: You can increase your 98 Custom

Basic or 98 CustomTM Platinum SeriesTMPro

adding a Cyclone

The Cyclone

Order the Cyclone

TM

Feeder Adapter to your marker.

TM

Adapter works well with the E-TriggerTM markers.

TM

Adapter Kit PN. T205030.

TM

Platinum Series

TM

rate of fire by

TM

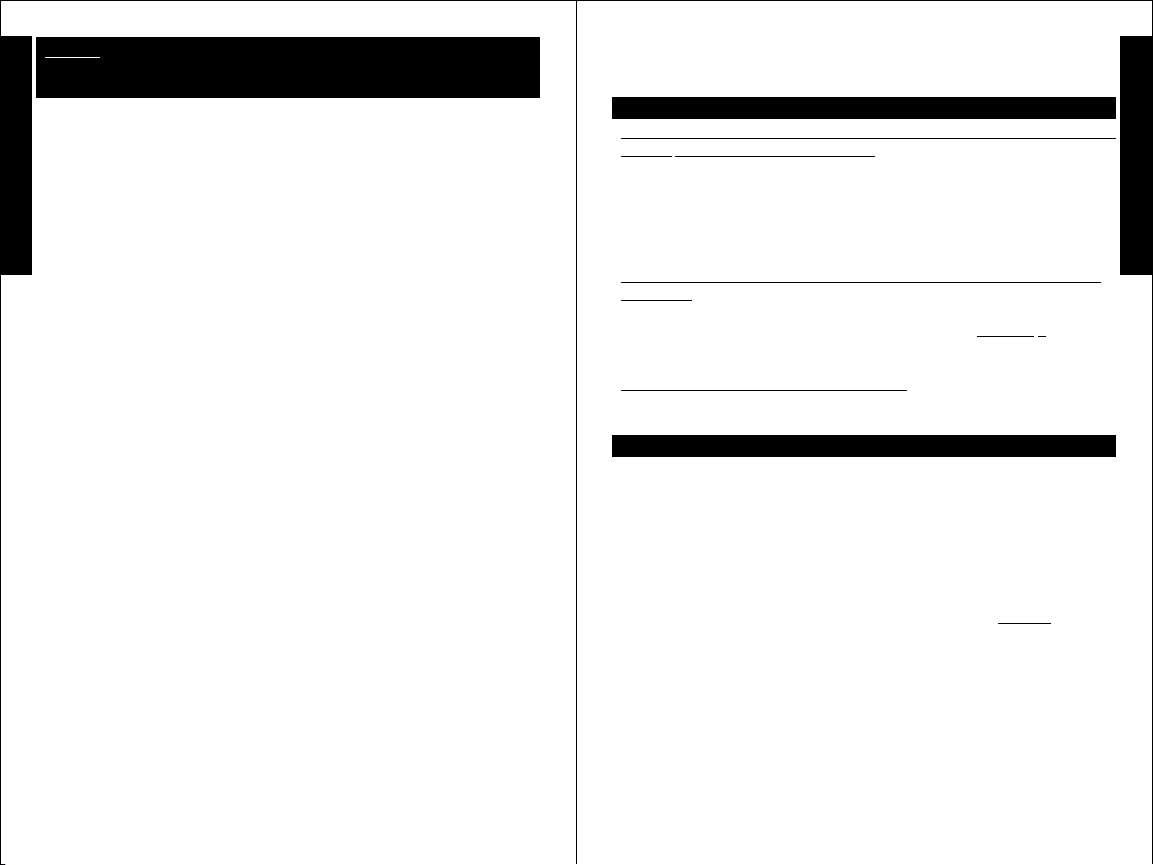

TUNING THE RESPONSE

❏

Eye protection designed for paintball use must be worn by the user and

any person within range.

With a screwdriver, turn the Flow Control Adjustor to the desired speed.

clockwise

to slow the

rate of fire.

Tuning - Troubleshooting A:

If tuning the Response

rate of fire, reset the Flow Control as follows:

TM

Trigger produces little or no response in the

TM

TRIGGER RATE OF FIRE

counterclockwise to increase

rate of fire to the

desired speed.

E

N

G

L

I

S

H

1) With marker properly unloaded (see page 21), begin adjusting rate of

fire by turning flow control clockwise

completely (Do not over tighten

or damage will occur). In a safe direction fire 2 to 4 shots. Trigger should

become very hard to pull or even unable to be pulled. If this occurs, the

response trigger system is functioning properly. Go to step 2. If it does

not occur, go to Troubleshooting B.

2) Now while firing in a safe direction with marker still unloaded, slowly

turn the flow control adjustor counterclockwise

until desired rate of

fire is achieved.

Tuning - Troubleshooting B:

If the trigger remains easy to pull after adjusting the flow control, there

may be a leak in the system. Double check installation making sure all

fittings are tight and o-rings are properly seated. If you need to

disassemble to check that all fittings are tight and o-rings are properly

seated (see Response

while it is pressurized with air, follow

disassembly / assembly instructions

on pages 21-23. If a problem still

exists, call Tippmann

Department at 1-800-533-4831.

NOTE: To disable the Response

System:

❏ ❏

❏

❏ ❏

unloading and air supply removal

TM

parts below), do not disassemble this marker

TM

20-20 Banjo Fitting

TA0519 1/16”

®

Service

TM

Model Specific RESPONSE

Shown on parts pages 14-19).

TA05021 Shut Off Plug

First follow the

02-103 Flow Control

Parts Not

Hose

instructions on page 20 and never

disassemble a marker that is under

pressure.

fitting (

❏ ❏

❏

Remove the banjo

❏ ❏

20-20) attached to the power

tube/valve and replace it with the

shut off plug

(TA05021).

20-04 90 Degree Fitting

20-19 1/8” Hose

20-05 Cylinder Fitting

20-02N RT Cylinder

12

13

PLATINUM SERIES

E

N

G

L

I

S

H

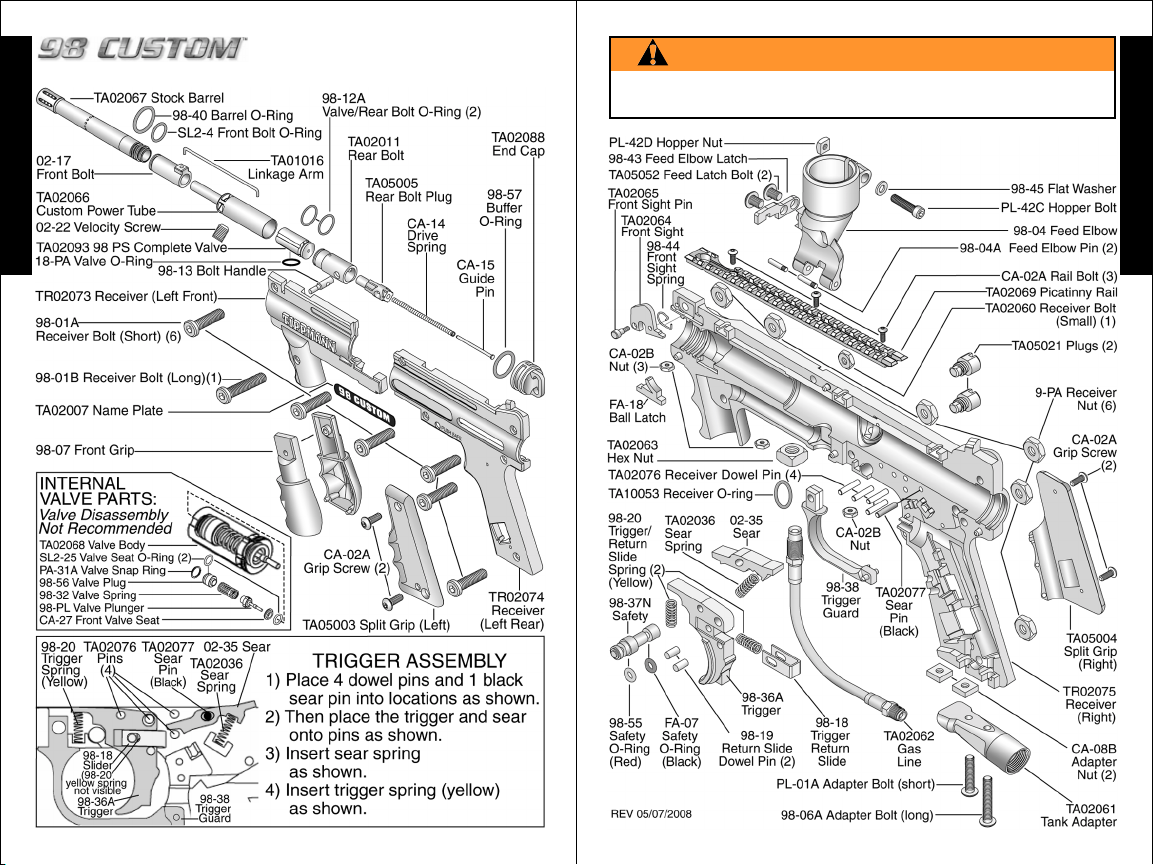

• BASIC NON-A.C.T.

TM

Basic Parts List

WARNING

DO NOT DISASSEMBLE THIS MARKER WHILE IT IS PRESSURIZED

WITH AIR. DO NOT PRESSURIZE A PARTIALLY ASSEMBLED MARKER.

TIPPMANN

1-800-533-4831

www.tippmann.com

E

N

TM

G

L

I

S

H

14

15

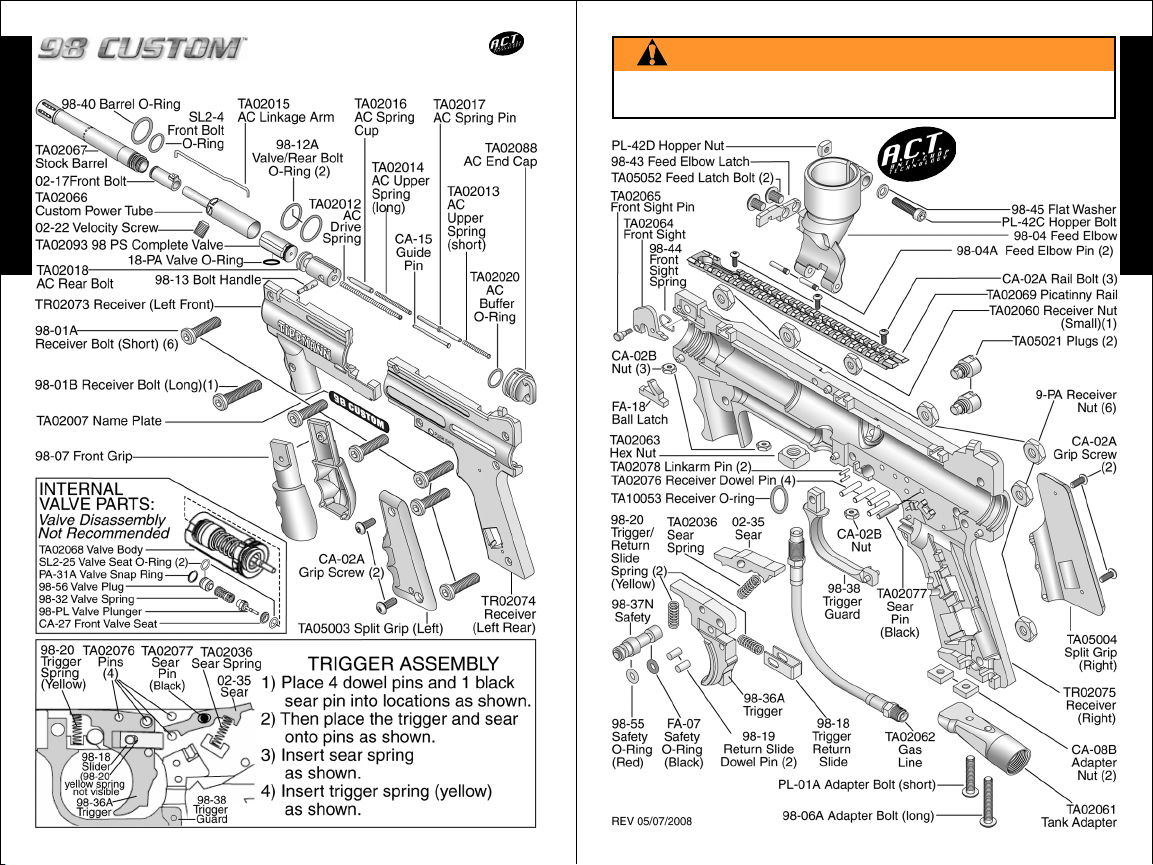

PLATINUM SERIES

E

• RESPONSE

TM

Parts Shown on page 13. • E-Trigger

N

G

L

I

S

H

TM

• BASIC

Basic Parts List

TM

Parts Shown on page 23).

DO NOT DISASSEMBLE THIS MARKER WHILE IT IS PRESSURIZED

WITH AIR. DO NOT PRESSURIZE A PARTIALLY ASSEMBLED MARKER.

WARNING

TIPPMANN

1-800-533-4831

www.tippmann.com

E

N

TM

G

L

I

S

H

16

17

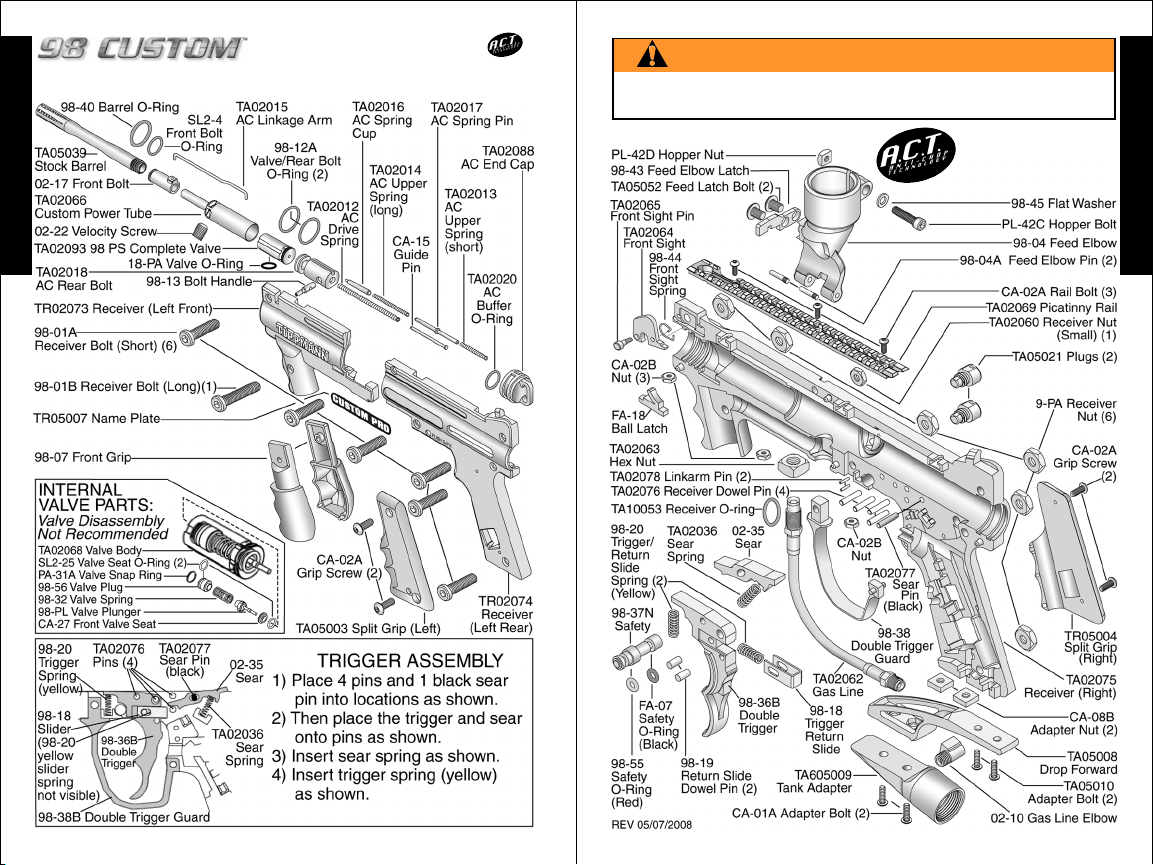

PLATINUM SERIES

E

• RESPONSE

TM

Parts Shown on page 13. • E-Trigger

N

G

L

I

S

H

TM

• PROTM

Basic Parts List

TM

Parts Shown on page 23).

DO NOT DISASSEMBLE THIS MARKER WHILE IT IS PRESSURIZED

WITH AIR. DO NOT PRESSURIZE A PARTIALLY ASSEMBLED MARKER.

WARNING

TIPPMANN

1-800-533-4831

www.tippmann.com

E

N

TM

G

L

I

S

H

18

19

Unloading Your Marker

❏

Eye protection designed for paintball use must be worn by the user and

E

any person within range.

1)

❏

N

G

L

S

H

Install the barrel sleeve (see page 2).

2)

❏

Empty and remove the hopper.

3)

❏

Go to a designated firing area and remove the barrel sleeve.

4)

❏

Point your marker in a safe direction and fire several times to be sure

there are no balls lodged in the chamber and / or barrel. IMPORTANT: Do

I

not uncock your marker as uncocking your marker may push a ball into the

chamber or down into the barrel in which case the ball will be hidden from view.

5)

❏

Install the barrel sleeve (see page 2).

6)

❏

Visually inspect the chamber for paintballs.

To unload your marker:

Air Supply Cylinder Removal

❏

Eye protection designed for paintball use must be worn by the user and

any person within range.

1)

❏

Follow the Unloading Your Marker instructions above.

2)

❏

T urn the cylinder approximately 3/4 of a turn counterclockwise or out.

This allows the air supply pin valve to close so that no air will enter the marker.

❏

Point the marker in a safe direction and fire the remaining gas in the marker

by pulling the trigger until the marker stops firing. This may take 4-5 shots.

• If your marker continues to fire, the tank pin valve has not closed yet (because

of the variances in tank pin valve parts, each tank varies slightly on exactly

how far it should be turned) and

counterclockwise

not fire,

❏

and it began to leak before you pulled the trigger, the tank o-ring should be

checked for damage before reassembly .)

3) After air tank is removed,

stored air is completely discharged.

NOTE: Before storing or disassembling be sure to follow

Marker and

Install barrel sleeve (see page 2).

then remove the tank. (If during this step - you turned the tank

❏

Air Supply Cylinder Removal instructions (see above).

To remove a charged air supply cylinder:

❏

a little further and repeat this step until the marker does

❏

you will have to turn the tank

point & fire the marker in a safe direction until

❏

Unloading Y our

❏

Cleaning & Maintenance

❏

Eye protection designed for paintball use must be worn by the user and

any person within range.

follow unloading and air supply removal instructions above and never disassemble a

marker that is under pressure.

• Follow warnings listed on the air supply cylinder for handling and storage.

• Familiarize yourself with instructions listed on air supply cylinder or adaptor.

Contact the air supply cylinder or adaptor manufacturer with any questions.

• Do not use any petroleum based cleaning solvents.

• Do not use any cleaning solvents that come in aerosol cans. NOTE: Petroleum

based products and aerosol products can damage your markers’ o-rings.

• T o clean your paintball marker use a damp towel with water to wipe off paint,

❏

To reduce the chance of accidental discharge: First

20

Cleaning & Maintenance

(continued on page 21)

Cleaning & Maintenance (continued from page 20)

oil, and debris. Use T ippmann

your marker in good working condition. Re-oil with a few drops to the front bolt

o-ring and rear bolt o-ring. Oil the barrel o-ring and air supply valve o-ring.

• To clean the barrel. Depress front sight and tip out feed elbow. Insert

tab of cable squeegee into breach, then pull squeegee through barrel

to remove debris.

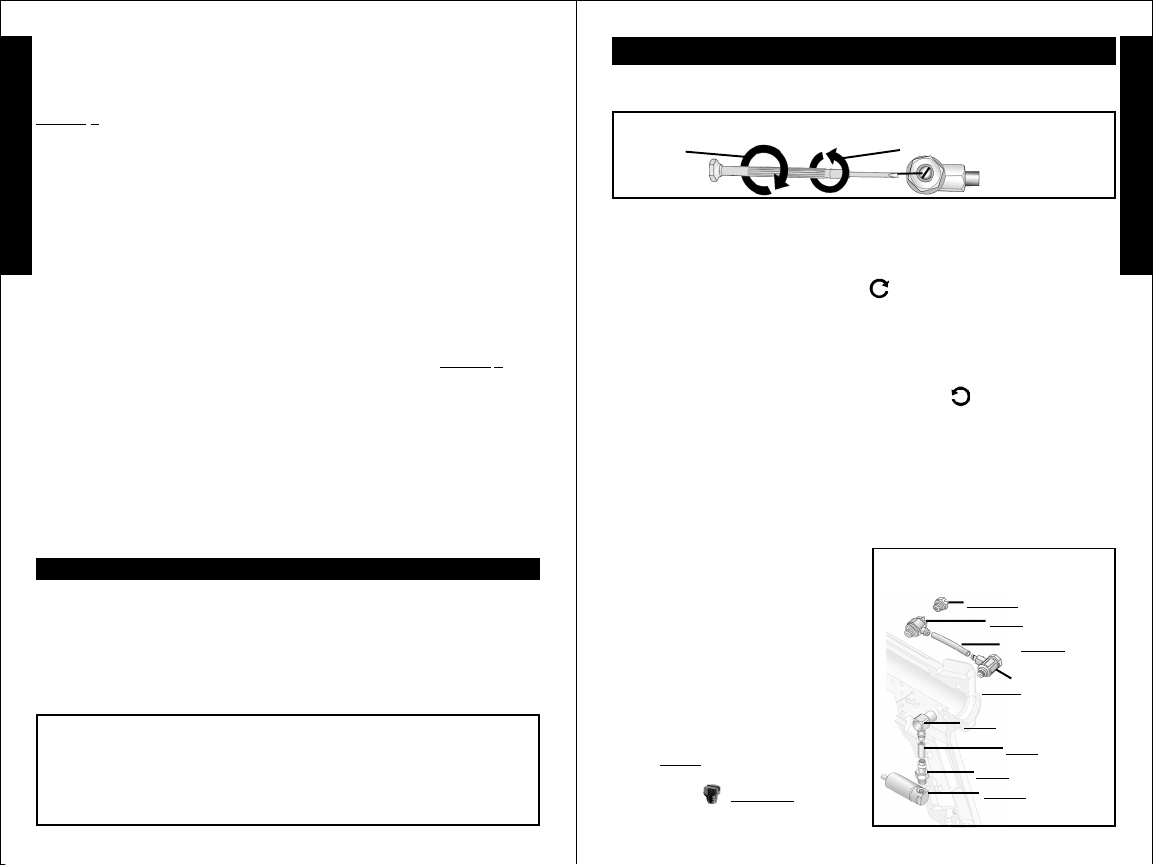

Marker Disassembly / Assembly

❏

Eye protection must be worn during disassembly / assembly .

❏

First follow unloading and air supply removal instructions on page 20. Do not

disassemble a pressurized paintball marker. Do not pressurize a partially

assembled paintball marker. Put the marker in the uncocked position. If your

marker is cocked, pull and hold the bolt cocking handle

the trigger and slowly release the handle forward

NOTE: Carefully hand start all threaded parts and do not overtighten

and strip

threaded parts

when assembling.

Longest bolt

attaches the front

grip when

reassembling.

NOTE : To aid in service and the installation of accessories the Left Side

Receiver is split into 2 parts : ( the Rear-left side receiver

left side receiver

• For most repairs, only the Rear-Left side Receiver

• Only the Front Sight, Front Sight Spring, Front Sight Pin and Ball Latch require

removal of the Front-left side Receiver. It is not necessary to remove the front

sight pin unless broken or the front sight and / or spring need replaced.

• It is not necessary to remove the tank adapter bolts

• The Picatinny Rail

remove the Picatinny Rail:

Picatinny Rail to the top of the marker.

Remove the barrel . To remove the rear-left side receiver : ❏ Loosen

the 2 adapter bolts

❏

Unscrew the 5 receiver connection bolts and ❏ carefully lift the rearleft side receiver to access the internal parts. NOTE: The Safety

on the rear-left side receiver

®

marker oil or other premium marker oil to maintain

back - then pull

to uncock the marker.

).

does not need to be removed for regular service. To

❏

unscrew the 3 screws securing the

. ❏ turn the velocity screw (7) in until it stops.

and should be reassembled the same way .

21

and the Front-

needs to be removed.

for most service.

will stay

Marker Disassembly

(continued on page 22)

E

N

G

L

I

S

H

Loading...

Loading...