Page 1

AAsssseemmbbllyy MMaannuuaall

1

Hughes 500 MD Scale Fiberglass Fuselage (TTR3834)

Distributed in North America by Ace Hobby Distributors,Inc.• 2055 Main Street,Irvine,CA 92614

Telephone:949.833.0088 • www.acehobby.com • E-mail:service@acehobby.com

Fuselage Length (less rotor):56" (1425mm)

Fueslage Width (less rotor):23.5"(595mm)

Full Equipped Weight:13~13.5 lbs (5900~6100g)

Specifications:

Warranty

This kit is guaranteed to be free from defects in material and workmanship at the date of purchase. It

does not cover any damage caused by use or modification. The warranty does not extend beyond the

product itself and is limited only to the original cost of the kit. By the act of building this user-assembled

kit,the user accepts all resulting in liability for damage caused by the final product. If the buyer is not

prepared to accept this liability,it can be returned new and unused to the place of purchase for a refund.

Notice: Adult Super vision Required

This is not a toy. Assembly and flying of this product requires adult supervision.

Read through this book completely and become familiar with the assembly and flight of this MD-500.

Inspect all parts for completeness and damage. If you encounter any problems,call us for help.

JK6001

Page 2

2

INTRODUCTION

PRE-ASSEMBLY NOTES

Congratulations on the purchase of one of our finest scale heli fuselage to date. This famous Hughes MD

500 (Military Defender),used as an antitank,multi-mission helicopter .Flown e xtensivel y during the Vietnam War

Era performing multiple missions under extreme conditions.

The venerable MD 500 has been replicated to exhibits this attack helicopter s' sleek details. The light fuselage

comes factory pre-painted with all necessary hardware.It is very easy to assemble and only takes you few hours

of enjoyable installation to put this scale body on your helicopter.

This replica MD is just like a real thing,hovering this MD that will definitely make you stand out on the flying

field.

Before beginning the assembly read the instructions thoroughly to give an understanding of the

sequence of steps and a general awareness of the recommended assembly procedures.

By following these instructions carefully and refer r ing to the corresponding pictures,the assembly of

your model will be both enjoyable and rewarding. The result will be a well built,easy to assemble scale

model,which you will be proud to display.

This MD-500 is designed for intermediate to advanced pilots,and this manual assumes a basic

knowledge of R/C model construction.

Before your assembly

1. Before you start to assemble this fuselage on your helicopter, we suggest you to first fine tune your

helicopter in the air.

2. Double-check all screws,then secure and Loctite all the loose screws.

3. The instruction manual is written for Raptor, if user should choose to install it on other branded

helicopters, then we would suggest to study thoroughly first the manual to see how it is installed on a

Raptor.

Before you begin,check the entire contents of your kit against the parts list and photos to make sure

that no parts are missing or damaged. This will also help you to become familiar with each component of

your model. If you find that any of the parts are either missing or damaged,(Customer s in North America)

please contact Ace Hobby Distributors, Inc.,Customer Service immediately for replacements.

Please read the entire manual before beginning construction.

Neither your dealer nor Ace Hobby Distributors, Inc., can accept kits for return if construction has begun.

Trial fit each part before gluing it in place. Make sure you are using the correct part and that it fits

well before assembling. No amount of glue can make up for a poor-fitting part.

TABLE OF CONTENTS

Introduction.................................................2

RecommendedTools & Materials............. 3

Item Y ou May Need.................................... 3

Parts Drawings............................................ 4-5

Parts Check List..........................................6

Assembly...................................................... 7

Test Flight..................................................... 14

MEMO...........................................................15

Page 3

3

RECOMMENDED TOOLS & MATERIALS

Adhesives:

Instant setting Cyanoacrylate adhesive (thin CA)

Slow setting Cyanoacrylate adhesive (thick CA)

10 Minute Epoxy (fast)

20-30 Minute Epoxy (slow)

Tools:

Model knife, 1/2” MASK tape

Small screwdrivers,medium screwdrivers

Scissors

Long nose pliers and diagonal cutting pliers

Drill and drill bits (1/16",5/64")

150 grid sand paper

Fine felt tip pen and soft lead pencil

Reamer

R/C System:

6 Channel Heli radio

GYRO system

Helicoptor:

Raptor 60~90 Suggested

TTR1115 - Precision Fueler Valve

TTR2174 - Built in Glow Plug Extension Wire

TTR4870 - Paptor 60

TTR4890 - Paptor 90

Adhesives - You will need two types of adhesives for

the MD-500 - Epoxy and Instant (cyanoacrylate)

adhesives. We recommend that you purchase both 5minute and 30-minute epoxy to cut down on assembly

time, but you can get by with only 30-minute epoxy if

time is not important.You will also need a small bottle of

both “Thick” and “Thin” instant C A adhesive.

Tools - Model assembly can be much easier if the

proper tools are used. Therefore, we have included in

our checklist to the left,a complete listing of all the tools

we used to assemble our prototype models. As you will

notice, many household tools can be utilized during

construction.

ITEMS YOU MAY NEED

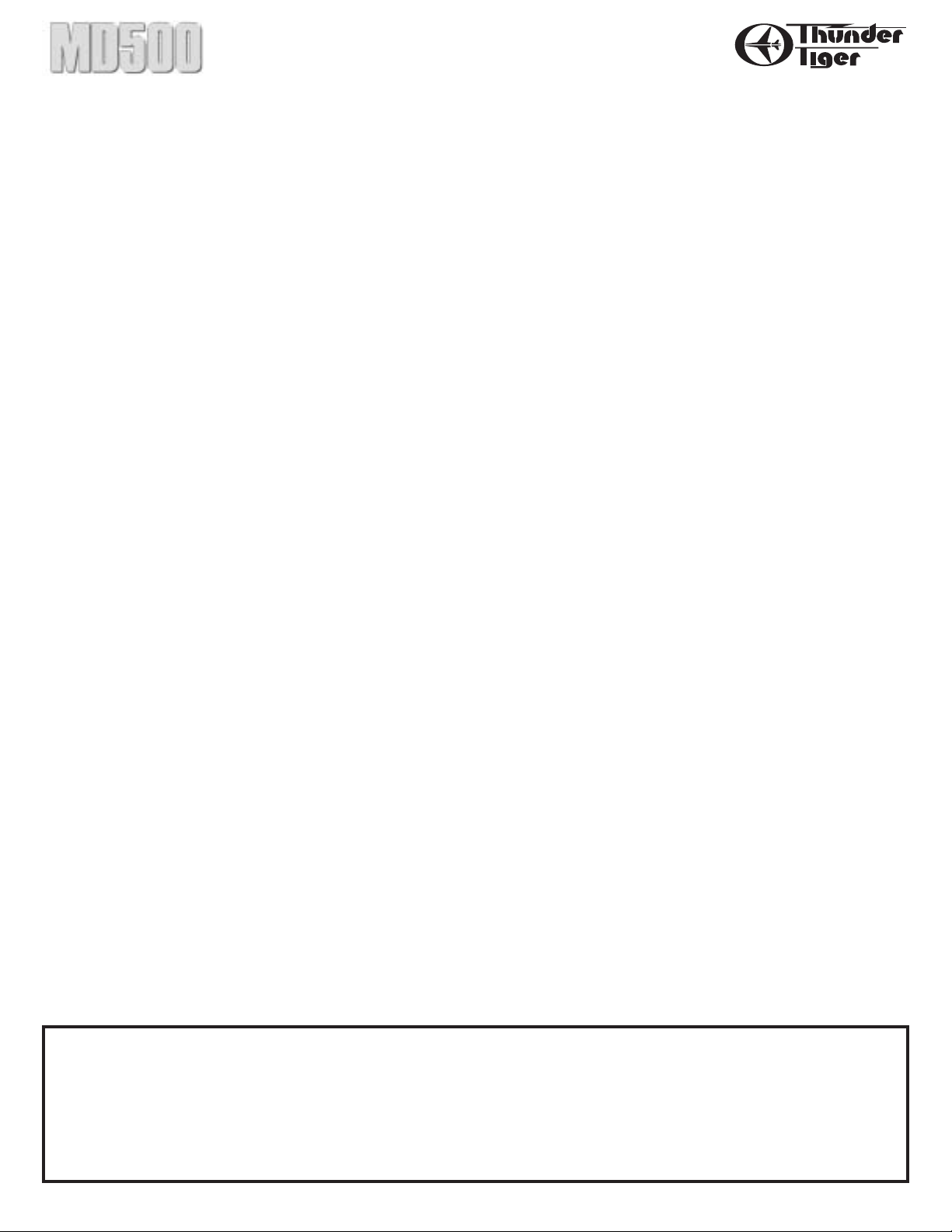

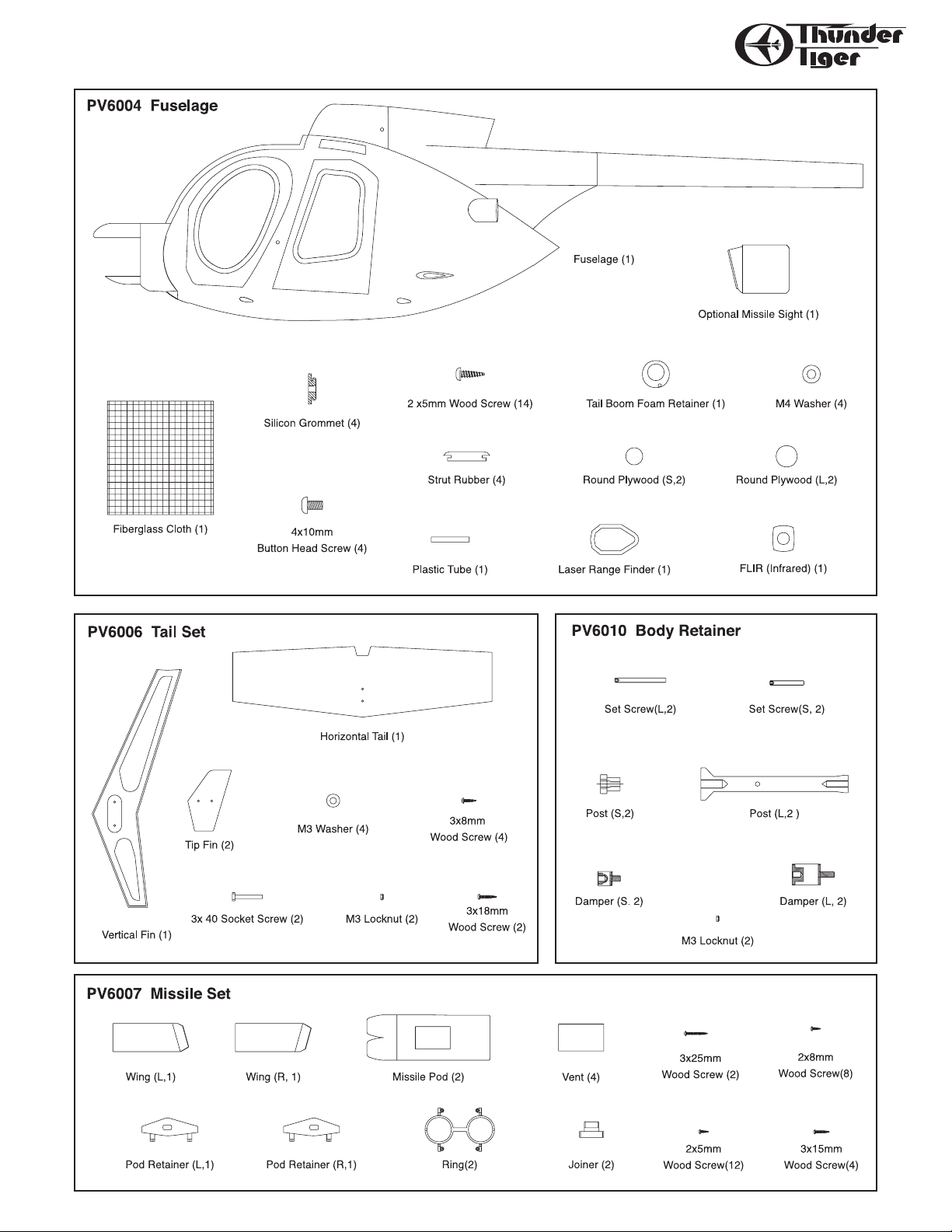

Page 4

4

PARTS DRAWINGS

Page 5

5

Page 6

6

PARTS CHECK LIST

Missile Set

Wing (L,1)

Wing (R,1)

Missile Pod (2)

Pod Retainer (L,1)

Pod Retainer (R,1)

Ring(2)

Joiner (2)

Vent (4)

3x25mm Wood Screw (2)

3x15mm W ood Screw(4)

2x8mm W ood Screw(8)

2x5mm W ood Screw(12)

Body Retainer

Post (L,2 )

Post (S,2)

Set Screw(L,2)

Set Screw(S,2)

Damper (L,2)

Damper (S.2)

M3 Locknut (2)

Windshield

Front Windshield (1)

Right Front Window (1)

Kit Contents:

Fuselage

Fuselage (1)

Missile Sight (1)

Round Plywood (S,2)

Round Plywood (L,2)

Laser Range Finder (1)

FLIR (infrared) (1)

Tail Boom Foam Retainer (1)

M4 Washer (4)

Silicon Grommet (4)

Strut Rubber (4)

2 x5mm Wood Screw (10)

Plastic Tube (1)

Fiberglass Cloth (1)

Tail Set

Vertical Fin (1)

Horizontal Tail (1)

Tip Fin (2)

3x 40 mm Socket Screw (2)

3x18mm Wood Screw (2)

3x8mm Wood Screw (4)

M3 Washer (4)

M3 Locknut (2)

Left Front Window (1)

Right Rear Window (1)

Left Rear Window (1)

Right T op Window (1)

Left T op Window (1)

Missile Sight Lens (1)

2x5 mm Machine Screw (16)

M2 Nut (16)

2x5 mm Wood Screw (48)

Mask T ape (1)

Landing Skid

Brace (2)

Al.Strut (4)

Skid Joiner (R,2)

Skid Joiner (L,2)

End Cap (4)

3x 30 mm Socket Screw (4)

3x3mm Set Screw (4)

2.6x 14mm Self Tapping Screw (8)

2.6x10mm Self Tapping Screw (4)

M3 Locknut (4)

Rear Frame Set

Rear Frame (L,1)

Rear Frame (R,1)

Washer (4)

Page 7

7

Assembly

1. Locate four Round Plywood pieces, glue the same sized

pieces together as shown.

2. Position the OMS (Optical Missile Sight) in place then

epoxy the two doubled round plywood inside the OMS.

Glue one side first then the other.Make sure the OMS can

be rotated.You may install a micro camera or servo making

sure that it can really do a mission at your command.If not,

then you can just epoxy the OMS in place firmly.

3. Locate the Sight Lens,position it in place, then drill 1/16"

(1.5mm) holes at the four corners.Secure the lens in place

with four 2x5mm Wood Screws.

4. Note the orientation of the wing tip and trail making sure

it can fit two Wings in the wing mount. Ascertain the two

wings are at same dihedral angles and the trailing/leading

edge of two wings are in line with each other. Adjust it

until you obtain a satisfactory result, then use pencil to

make marks on the wing at both sides as guidelines.

5. Remove the Wing to sand away the paint base on the

guideline you drew, this is the glue area that you could

sand with 150 grid sand paper to enhance the adhesion.

Remove the paint in the wing mount,you may use hobby

knife to scratch the surface in the well.

Page 8

8

6. Fit the wing in place again, drill two 5/64"(2mm) holes

through the wing mount to the wing from the inside of the

fuselage. Remove the wing again,apply epoxy at glue area

and secured it with two 3x15mm Wood Screws. Either

wipe off the excess epoxy or use masking tape to tape the

guideline to keep the wing clean after the masking tape

removal.

7. Repeat the same procedure on the other wing,make sure

the two wings are at same dihedral angles.If you see from

the top the trailing/ leading edge should be in line with

each other.

8. Locate the Laser Range Finder, position it right after the

Windshield at the center bottom of fuselage. Drill

1/16"(1.5mm) holes and secure it with six 2x5mm Wood

Screws.

9. Locate the molded marks for landing strut and engine

cooling openings at the bottom of the fuselage. Note these

marks are only for reference of Raptors,shall you install it

on other branded helicopters then you will have to find

out the correct opening position for landing strut before

you drill or trim the fuselage.

Note: For Raptor Owners, it is recommended to offset by

2mm to the center line when you trim the landing skid

opening. This will get more space between the collective

pitch frame and windshield where servo horn and ball link

might contact.

Center Line

Page 9

10.Locate four Rubber Rings, trim away the flashing and

center portion.Place the Rubber Rings at the four landing

strut openings. It might be necessary to trim the opening

larger to fit the rubber ring with the inserted Aluminum

strut.For the rear strut opening,you may cut the ring for

easier access.

11.Put the scale fuselage aside for a moment and get your

heli prepared. For Raptor owners, please remove the

Landing Skid, Muffler, Tail Fins, Boom Supports and Tail

Rotor Assembly. Locate the new Rear Frames,which are

specially designed for this MD fuselage. Use the new

washers and secure the Rear Frame in place with the

same screws you used previously. Also use the same

screw and locknut to secure the Rear Frame at the tail

boom mounting hole. Use the same Tank Rubber

grommets and install the Fuel Tank.

9

12.Assemble the Landing Skid as shown.Temporarily install

the Brace under the side frame. Adjust the Landing Skid

as shown and make sure it sits on the table firmly. Secure

the Joiner & Skid Pipe with the furnished 3x3mm Set

Screws. Do not over-tighten the setscrews;just make sure

the skid pipe will not rotate. Then secure the Joiner and

the Aluminum Strut with 2.6x10mm Self-Tapping Screws.

13.Remove the landing skid assembly from Heli. Remove the

brace from the aluminum strut. Do not remove the strut

and skid pipe as they are already adjusted and secured.

Apply masking tape on the strut that is going to make

contact with the fuselage, since the masking tape will

protect the paint from scratching. Place the brace on the

fuselage and install the strut and skid pipe onto the brace.

You may apply Vaseline on rubber ring to increase the

lubrication for easier installation.

Page 10

14.Secure the Aluminum Strut and Brace with 2.6x14mm

Socket Screws. Hint: Install the left Aluminum Strut

Assembly and Brace first ( Left side is the side of the

fuselage with Optical Missile Sight). Pull the brace out and

secure the socket screws then push it back and pull the

right side out then install the right aluminum strut

assembly.

15.Before fitting your helicopter into the fuselage, you may

trim all Windows and trails to better fit them into the

fuselage.It might be necessary to trim the FRP fuselage to

match the windows as well.Once you obtain satisfactory

result, proceed to drill 1/16"(1.5mm) openings through

the fiberglass the fuselage and window and secure the

window with 2x5mm Wood Screws. After finishing all the

windows, remove all the windows and clean the inside

fuselage entirely. (You can skip the rear side window for

easy operation)

10

16.Trial sit on the landing skid assembly. For Raptor owner,

position the Front Windshield in place and check if the

ball links on aileron servo horn contacts the front

windshield when it is in maximum positive pitch.Lower

the Raptor by enlarging the landing strut opening to the

fuselage center liner if the servo horn contacts the

windshield. It might be necessary to try several times

before obtaining a desirable result.

17.If you use Raptor 60 then it is required to trim off the

fuselage tail for about 1"( 2.5cm ). However, it is not

necessary for those using the 80/90 conversion kit, R90

STD Kit or R90 SE Kit since the tail gear case is longer than

the fuselage tail.Install the tail rotor assembly in place and

check if holes on the landing brace matches the side

frame landing skid-mounting holes. If it cannot reach the

holes then trim the tail until it is able to do so. Unthread

the ball link, insert a Plastic Tube then thread the ball link

back to pushrod at the original position.

Page 11

11

18.Remove the tail rotor assembly once again and proceed to

extract the Raptor from fuselage. Replace a M3 Locknut

from the old body post. Remove the socket screws and

replace the long setscrews,then secure the new retaining

post in place. The upper post goes with long setscrew and

the lower post goes with short setscrew. Remember to

apply Loctite then secure the posts firmly. Place the

Raptor into the fuselage again, the long post should be

located between front and rear window where we will

drill hole later. If not,try to move the Raptor backward by

trimming the strut opening and trial fit it again.

19.Locate a sponge as the Tail Boom Retainer, install the

sponge on the tail boom section where the plastic tube

for the sponge insertion. Be careful not to apply any glue

inside the plastic tube and make sure the pushrod can

move freely. Push the sponged tube into the fuselage tail

and make sure there is no binding of the pushrod

movement and the heli sit on the landing brace just right.

Glue the sponge inside the fuselage tail with CA.

Note: do not glue sponge and tail boom in case you had to

remove the heli from fuselage. Install the tail rotor assembly

in place firmly and snap on the ball link.

20.Secure the helicopter onto the landing brace with four

3x30mm Socket Screws and M3 Locknuts.Secure the rear

brace first then the front.

21.Secure the Vertical Fin in place with two 3x40 Socket

Screws,two M3 Washer s and two M3 Locknuts.

Page 12

12

22.Trial fit the Horizontal Tail onto the vertical fin,note that

flat surface should be facing up and the other side with

the air foil facing down. It might be necessary to file/sand

the contact area on the vertical fin so that they make

perfect contact. Apply epoxy at the contact area and

make sure it is perpendicular after securing it with two

3x18mm Wood Screws and two M3 Washers. Secure two

vertical Tip Fins onto horizontal tail with four 3x8mm

Wood Screws.

23.Install the big Damper in place as shown then drill 3/8"

(9mm) hole.Never drill the hole on the molded mark as it

is only for reference, please drill the hole and aim to the

damper screw hole.

24.Remove the damper temporarily and insert the Silicon

Grommet from the inside fuselage then re-install the

damper again. Note the bigger diameter side should be

facing the Damper. Secure the fuselage with 4x10mm

Button Head Screw and M4 Washer. Do the same

procedure at the other side.

25.Locate the small Damper and do the same way you did for

the last two steps.

26.Secure the fuselage with 4x10mm Button Head Screw and

M4 Washer as shown.

Page 13

13

30.Locate the Joiner and insert it into the pod retainer,next

trial fit the missile pod assembly onto the wing. Make sure

two missile pod are angled just right, if not then trim it

until it will. Remove the missile pod assembly then apply

epoxy at the joint area in the wing then secure the wing

with 3x25mm Wood Screw. Make sure again that the two

missile pods are at same angle.

31.Install the muffler on the Raptor and try to install a

diverter. It is recommended to drill an exit hole at the

bottom of the fuselage and it will enable your beautiful

MD to be less oily.If you do not care about the smoke oil

then you may customer built a Y splitter and exhaust at

the two exhaust vent to obtain a more scale-like look.

27.Locate the FLIR and place it at the center of the tail

section either at the top or bottom. Drill four 1/16"

(1.5mm) mounting holes and secure the FLIR with four

2x5mm W ood Screws.

28.Locate the Pod Retainer and center it on the missile pod

(the missile pod with square molded line should face

down). Drill 1/16" (1.5mm) holes then secure it with

2x8mm Wood Screws.Note the orientation of the retainer.

29.Locate the Vents (fiberglass tube) and rings, position the

two vents at the tail of missile pod then secure the ring on

the tail with four 2x5mm Wood Screws. The vents should

stay firmly in the place. Drill 1/16"(1.5mm) holes on the

vent then secure the vent firmly with 2x5mm wood

screw.

Front

Rear

Page 14

14

32.You will have to install the remote glow plug adaptor

(TTR3803). With the opening for engine cooling located

at the bottom of the engine,you can either use the glow

starter from the opening or install a Built in Glow Plug

Extension Wire (TTR2174) and secure the connector on

the fuselage for easy glow ignition. Also suggested is the

use of Precision Fueler Valve (TTR1115) which is very

convenient for both re-fueling or de-fueling and could filer

the fuel when fueling.

33. Install all the windows on. It is recommended to secure

the front windshield first then the front side windows.

You may skip the installation of the rear side windows,as

it is easier for you in case of tuning engine or adjustment.

Shall you decide to install the rear side window then you

might need to cut a hole for your index finger's insertion

allowing easier securing of the windows. Remember if

rear windows are installed,a needle valve extension and a

small hole for tuning the mixture metering screw ( idle

screw) are required. Even the RX battery on/off switch

should be installed on fuselage.

Test Flight

1. When hovering you MD, try to keep rotor speed at

approximately 1350~1400 RPM.The higher RPM will cause

vibration at the small tip fins.

2.Check the helicopter and fuselage to see if there is any loose

screw after each flight.

3. It is easy to get nose up in speed flight, please trim the

elevator down when swith on the Idle.Suggest to off set at

about 15%~20%.

Page 15

MEMO

Page 16

16

THUNDER TIGER CORP . www.thundertiger.com

Introducing the pinnacle heli of the Raptor family,

the RAPTOR 90 SE. Designed and engineered by the

world-renowned F3C champion Mr. Shigetada Taya.

Thanks to all the feedbacks provided by Raptor

owners and customers worldwide, Thunder Tiger

heli design team has successfully combined today's

advanced technologies with previously successful

designs, R90 SE is the machine that everyone has

ever dreamed of.

Additional to R90, the R90 SE is a value-added

machine utilizing all the desired Hop-Up parts. R90

SE is only available in kit version without engine.

Specification:

Full Length of Fuselage: 1410mm(55.5")

Full Width of Fuselage: 190mm(7.5")

Total Height: 476mm(18.75")

Main Rotor Dia: 1580mm(62.25")

Tail Rotor Dia: 260mm(10.25")

Gear Ratio: 8.45:1:4.6

Fully Equipped Weight: 4650g(10.65lbs)

90 CLASS RC HELI

No.4890 R90 SE Key Features:

* Metal Button Head Main Rotor Hub

* Metal Grips

* Metal Swashplate

* Metal Washout Base

* Metal Side Frame Stiffener

* Metal Cooling Fan

* Metal Fork

* Metal Upper/Lower Bearing Block

* Metal Elevator Control Lever

* Metal Flybar Control Arm

* Carbon Graphite Collective Control Arm Set

* Carbon Side Frames

* Carbon Tail Fins

* Carbon Tail Boom

* Carbon Tail Boom Support

* Carbon T orque Tube

* 550 cc Fuel Tank

* Header Tank

* New Decal

PRO-90H(R) ENGINE

Loading...

Loading...