Page 1

SERVICE MANUAL

DOCUMENTATION TECHNIQUE

TECHNISCHE DOKUMENTATION

DOCUMENTAZIONE TECNICA

DOCUMENTACION TECNICA

No copying, translation, modification on other use authorized. All rights reserved worldwide. • Tous droits de reproduction, de traduction, d'adaptation et d'exécution réservés pour tous les pays. • Sämtliche Urheberrechte an diesen Texten und Zeichnungen stehen uns zu. Nachdrucke,

Vervielfältigungen - auch auszugsweise - nur mit unserer vorherigen Zustimmung zulässig. Alle Rechte vorbehalten. • I diritti di riproduzione, di traduzione, e esecuzione sono riservati per tutti i paesi. • Derechos de reproduccion, de traduccion, de adaptacion y de ejecucion reservados para todos los paises.

WARNING : Before servicing this chassis read the safety recommendations.

ATTENTION : Avant toute intervention sur ce châssis, lire les recommandations de sécurité.

ACHTUNG : Vor jedem Eingriff auf diesem Chassis, die Sicherheitsvorschriften lesen.

ATTENZIONE : Prima di intervenire sullo chassis, leggere le norme di sicurezza.

IMPORTANTE : Antes de cualquier intervención, leer las recomendaciones de seguridad.

Code : 351 400 20 - 1200 / 4,6M - DVD DTH4500 Print.

VIDEO

DTH4500

DVD DTH4500

Addition to SM

Additif au SM

Ergänzung zum SM

Aggiornamento del SM

Suplemento al SM

351 272 00

Page 2

Page Page

TECHNICAL SPECIFICATIONS .......................................... 4

SAFETY NOTICE AND PRECAUTIONS ............................... 5

ADJUSTMENT PROCEDURES

1. Handling the optical pickup ..................................... 6

2. Pickup disassembly and assembly .......................... 3

3. Disassembly and assembly

3.1 Cabinet and PCB ...........................................3

3.1.1 Removing the Top Cabinet ............................3

3.1.2 Removing the Door-Tray ............................... 3

3.1.3 Removing the Front-Panel Assembly

and Key PCB .................................................. 4

3.1.4 Removing the Deck Assembly ....................... 4

3.1.5 Removing Main PCB and Jack PCB................ 4

3.2 PCB location ................................................. 4

3.3 Deck .............................................................. 5

3.3.1 Removing PCB Deck Assembly, P/U Deck...... 5

3.3.2 Removing the Tray Disc................................. 5

3.3.3 Removing Slider Housing............................... 5

3.3.4 Removing Housing Assembly ........................ 5

3.3.5 Removing Sub Chassis .................................. 6

3.3.6 Removing Bracket Deck ................................. 6

3.4 Connector Diagram ..................................... 6

BLOCK DIAGRAMS

General Block Diagram .............................................. 7

SCHEMATIC CIRCUIT DIAGRAMS

Servo ...................................................................... 9

AV processing .........................................................13

System Control ....................................................... 17

Display and control ................................................ 21

Audio ...................................................................... 23

Keyboard.................................................................. 26

Headphone .............................................................. 26

Audio 5.1 channel ................................................... 27

Video decoder DTH4200 .......................................... 41

Power supply ........................................................... 43

CD Motor Control DTH4000-DTH4200..................... 46

PRINTED CIRCUIT BOARD LAYOUTS

Jack PCB..................................................................29

Main PCB................................................................. 33

Keyboard ................................................................. 35

CD Motor Control .................................................... 48

ABBREVIATION LIST ....................................................... 57

CONTENTS

DVD DTH4500

2 First issue 12 / 00

: Please refer to DVD DTH4000/4200 Service Manual Part N° 351 272 00

: Se référer à la documentation technique DVD DTH4000/4200 code 351 272 00

: Bitte schlagen Sie im DVD DTH4000/4200 Service Manual 351 272 00 nach

: Consultare la documentazione tecnica del telaio DVD DTH4000/4200, codice : 351 272 00

: Referirse a la documentación básica del DVD DTH4000/4200, código : 351 272 00

Page 3

DVD DTH4000/DTH4200

4 First issue 08 / 00

TECHNICAL SPECIFICATIONS

Power Source : AC 110V - 240V +/- 10%, 50Hz/60Hz

Power Consumption : 18W (approx. 2,4W when power is OFF)

Weight : 3,3 Kg

Dimension : 430 (W) x 89 (H) x 280 (D) mm (excluding protrusions)

Operating Temperature Range : +5 to +35 degrees Celsius (+41° to +95° F)

Operating Humidity Range : 10 to 75% (no condensation)

Signal system : PAL 50 - 60Hz (PAL 625/50, PAL 525/60),

NTSC or PAL 60Hz capable TV set is required to play back NTSC discs.

Disc played :

(1) DVD-Video disc :

PAL and NTSC

12/8 cm single-sided, single-layer

12/8 cm single-sided, double-layer

12/8 cm double-sided, single-layer

12/8 cm double-sided, double-layer

(2) Audio CD :

12/8 cm disc

(3 Video CD :

PAL and NTSC, 12/8 cm side

(4) S-Video CD

(5) most CD-Rs and CD-RWs (DTH4200 only)

Audio signal output :

(1) Frequency response : DVD linear audio 48KHz sampling : 4Hz to 22KHz (EIAJ)

DVD linear audio 96KHz sampling : 4Hz to 44KHz (EIAJ)

CD Audio : 4Hz to 20KHz (EIAJ)

(2) S/N ratio : 105dB (EIAJ)

(3) Dynamic range : DVD linear audio : 100dB (EIAJ)

CD audio : 100dB (EIAJ)

(4) Wow & flutter : below measurable limits

(5) Total harmonic distortion : less than 0.005%

Pickup : Wave length : 655nm, Laser power : CLASS 2

2 Laser diodes (DTH4200 only)

Page 4

DVD DTH4000/DTH4200

First issue 08 / 00 5

PREVENTION OF ELECTRO STATIC DISCHARGE (ESD) TO ELECTROSTATICALLY SENSITIVE

DEVICES (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should be used to help reduce

the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any electrostatic charge

on your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap

device, which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface such as aluminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal devices. Some solder removal devices not classified as "anti-static" can generate electrical

charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD devices.

6. Do not remove a replacement ESD device from its protective package until immediately before your are ready to install it. (Most

replacement ESD devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive materials).

7. Immediately before removing the protective materials from the leads of a replacement ESD device, touch the protective material to

the chassis or circuit assembly into which the device will be installed.

CAUTION : Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ESD devices. (Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient to damage an

ESD device).

There are special components used in this equipment which are imporant for safety, these part are marked by symbol

on the schematic circuit diagrams and replacement part list. It is essential that these safety critical components are replaced

with the manufacture’s specified parts to prevent electric shock, fire, or other hazards. do not attempt to modify the original

design without permission of the manufacturer.

DANGER : Invisible laser radiation when open and interlock failed

or defeated. Avoid direct exposure to beam.

ATTENTION : Le rayon laser est invisible. Eviter l'exposition directe

lors de la maintenance.

VORSICHT BEI Bei geöffneter Schublade und Defekt der Sicherheits -

REPARATUREN : vorrichtungen besteht die Gefahr unsichtbaren

Laserlichts. Niemals direkt in den Laserstrahl sehen.

ATTENZIONE : Il raggio laser è invisibile. Evitare l'esposizione diretta

durante la manutenzione.

IMPORTANTE : El rayo laser es invisible. Evitar la exposición directa

en el momento del mantenimiento.

CLASS 1 LASER PRODUCT

APPAREIL A LASER DE CLASSE 1

LASER KLASSE 1

APARATO CON LASER DE CLASE 1

APPARECCHIO CON LASER DI CLASSE 1

IMPORTANT SAFETY NOTICE

Page 5

DVD DTH4000/DTH4200

6 First issue 08 / 00

ADJUSTMENT PROCEDURES

1. Handling the optical pickup

The laser diode used in the optical pickup may break down due to

potential differences caused by electricity produced by clothing or

the human body, care should therefore be taken to prevent

electrostatic discharge whilst repairing the optical pickup.

The following method is recommended.

(1) Place a conductive sheet on the work bench (The black sheet

used for wrapping repair parts.)

(2) Place the set on the conductive sheet so that the chassis is

grounded to the sheet.

(3) Place your hands on the conductive sheet (doing this gives

them the same ground as the sheet.)

(4) Remove the optical pickup block

(5) Perform work on top of the conductive sheet. Be careful not to

let your clothes or any other static sources to touch the unit.

* Grounding the Human Body, use an antistatic wrist strap to

discharge static electricity from your body.

* Grounding the work place, use either an antistatic matt or a

sheet of steel on the area where the optical pickup is to be

placed and ground the matt/sheet.

Fig. 1-3

(6) Short the short terminal on the PCB, which is in-side the

Pickup Assembly, before replacing the Pickup. (The short

terminal is shorted when the Pickup Assembly is being lifted or

moved.)

(7) After replacing the Pickup, open the short terminal on the

PCB.

Page 6

DVD

DTH4500

First issue 12 / 00 3

ADJUSTMENT PROCEDURES

2. Pickup Disassembly and Assembly

2-1 Disassembly

1) Remove the power cable.

2) Switch SW3 (on Deck PCB) to "OFF" before disconnecting the

flat cable (DCN1 inserted into Main PCB see Fig. 1-4).

3) Remove the deck.

4) Remove the deck PCB.

2-2 Assembly

1) Replace the Pickup.

2) Refit the deck PCB.

3) Refit the deck.

4) Insert flat cable into DCN1 (Main PCB) and switch SW3 (on

deck PCB) to "ON". (see Fig. 1-4)

Note : If the assembly and disassembly are not done in correct

sequence, the Pickup may be damaged.

Fig. 1-4

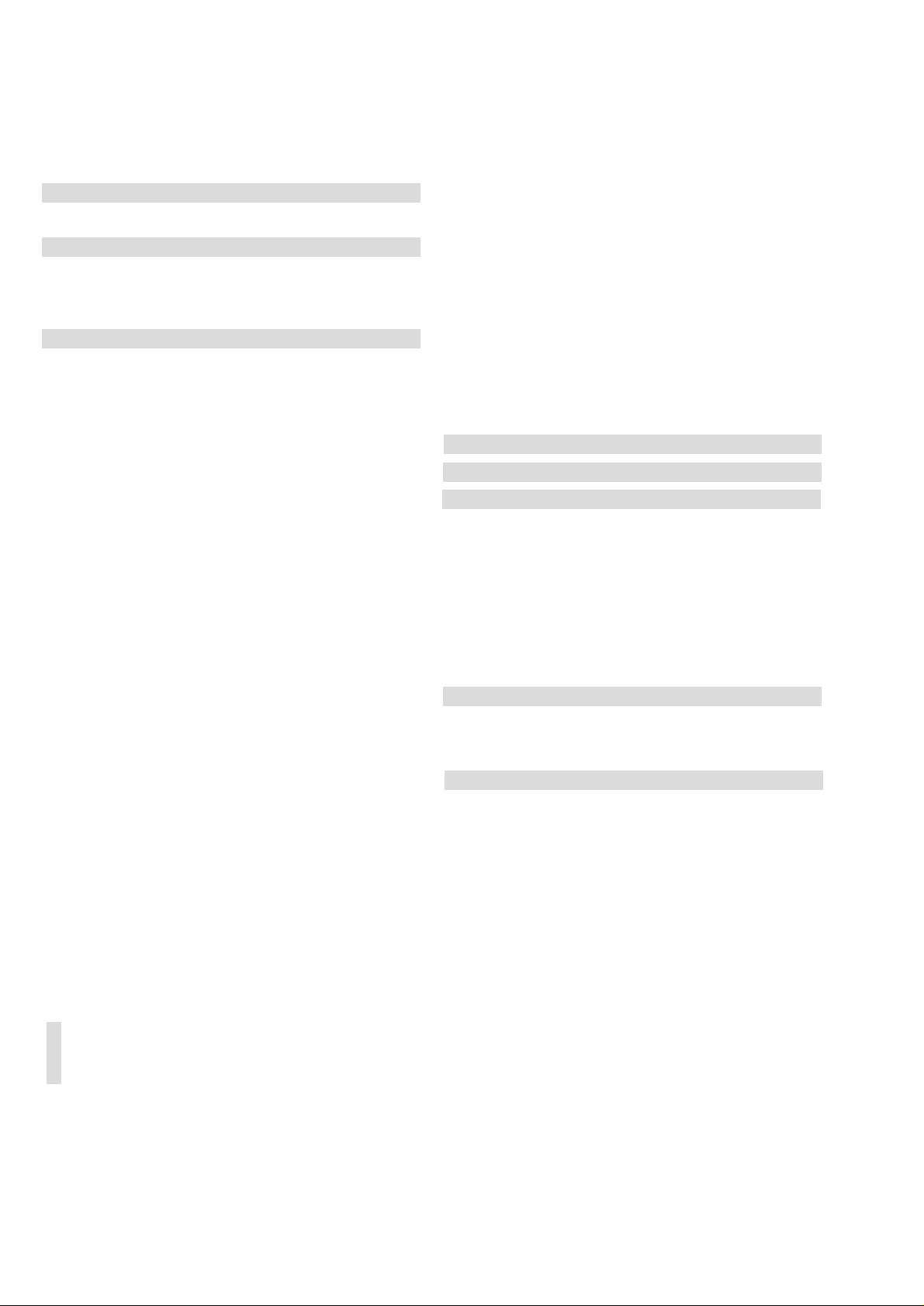

3. Disassembly and Assembly

3-1 Cabinet and PCB

Note : Reassemble in reverse order.

3-1-1 Removing the Top Cabinet

1) Remove 3 screws 1 on the back of the Top Cabinet.

2) Remove the 2 screws 2 on the left side and 3 on the right

side.

3) Lift the Top Cabinet up in the direction of the arrow.

Fig. 3-1-1

3-1-2 Removing the Door-Tray

1) Switch the power on and open Tray 1.

2) Pull Door-Tray 2 in direction of arrow "A".

3) Close Tray 1 and Switch the power off.

Note : If Tray 1 cannot be opened, insert a Screw driver 4 into

Emergency hole 3 (as shown in detailed drawing) and then turn it

in the direction of arrow "B". Open the Tray manually.

Fig. 3-1-2

FLAT-CABLE

TO MAIN PCB

(DCN1)

SW3

ON

OFF

1 3 SCREWS

2 1 SCREW

3 1 SCREW

"A"

TRAY

DOOR-TRAY

<Side View>

EMERGENCY HOLE

SCREW DRIVER

"B"

Page 7

DVD DTH4500

4 First issue 12 / 00

3-1-3 Removing the Front-Panel Assembly and Key

PCB

1) Remove Knob-Volume 1 and Knob-Shuttle 2

2) Remove Front-Panel Assembly 3.

3) Remove 5 screws 4 and Ground Rear 5.

4) Remove Key PCB 6.

Fig. 3-1-3

3-1-4 Removing the Deck Assembly

1) Remove 4 Screws 1 from the Assembly Deck and lift it up.

CAUTION :

a) When disassembling, switch SW3 to "OFF" on the Deck

PCB and remove the Flat-Cable connected to DCN1 on Main

PCB.

b) When assembling, insert the Flat-Cable into the DCN1 on

Main PCB and switch SW3 to "ON" on the Deck PCB.

Fig. 3-1-4

3-1-5 Removing Main PCB and Jack PCB

1) Remove 1 Screw 1.

2) Remove 2 screws 2 and lift Jack PCB 3 up.

3) Remove 3 screws 4 and lift Main PCB 5 up.

Fig. 3-1-5

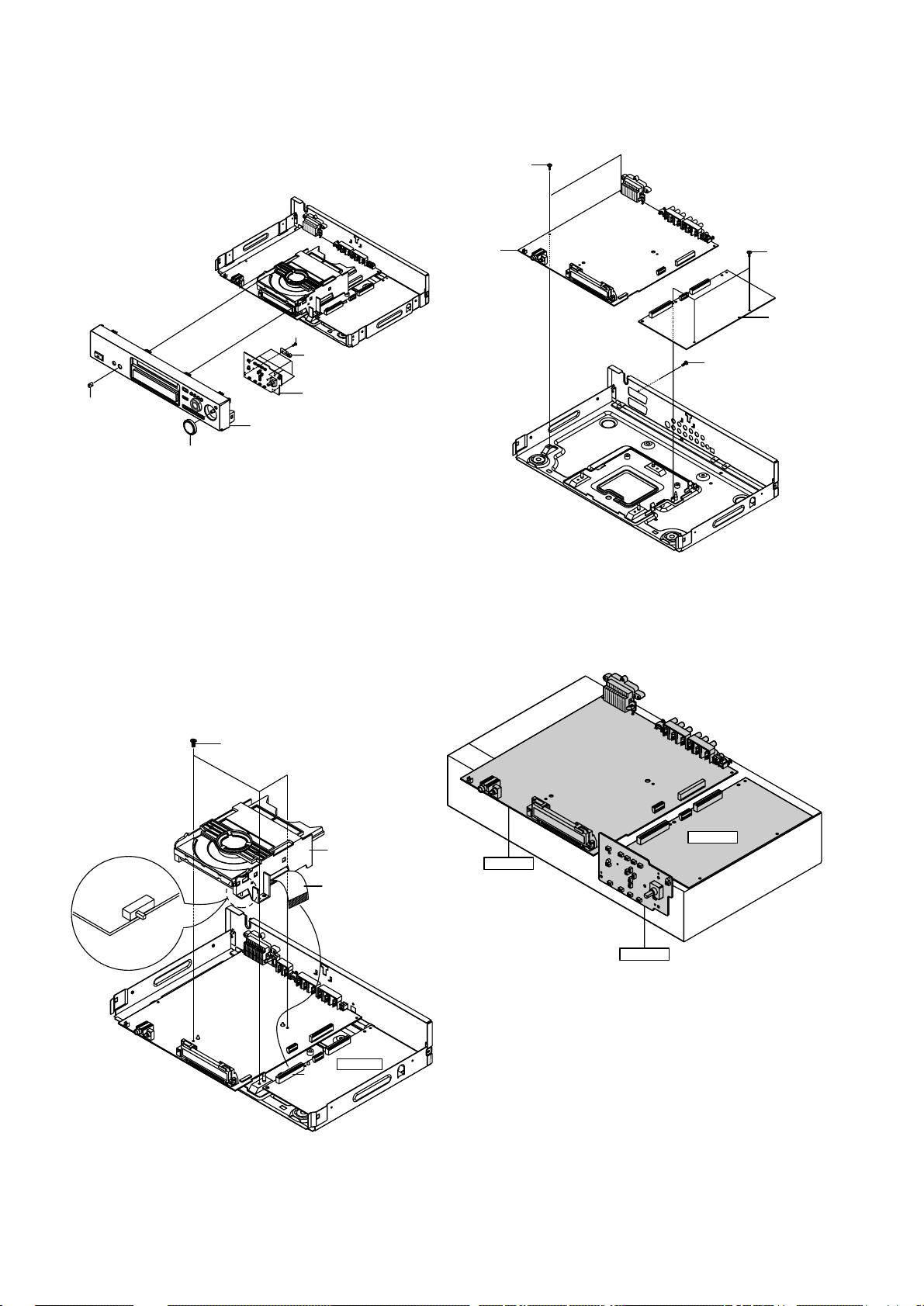

3-2 PCB Location

Fig. 3-2

DECK-ASS'Y

1 3 SCREWS

DCN1

MAIN PCB

SW3

OFF

ON

FLAT-CABLE

1 SCREW

MAIN PCB

3 SCREWS

2 SCREWS

JACK PCB

MAIN PCB

KEY PCB

JACK PCB

5 SCREWS

KEY PCB

GROUND REAR

ASS'Y FRONT-CABINET

KNOB-VOLUME

KNOB-SHUTTLE

Page 8

3-3 Deck

3-3-1 Removing PCB Deck Assembly, P/U Deck

1) Remove the soldering of SLED+, SLED- 1 and TM+, TM- 2.

2) Disconnect CN3 3, CN2 4.

3) Remove 1 Screw 5 and lift the PCB Deck 6 up.

4) Remove 1 Screw 7.

5) Push the Hook 8 in the direction of arrow "A" and lift the

P/U Deck Assembly 9 up in the direction of arrow "B".

Fig. 3-3-1

3-3-2 Removing the Tray Disc

1) Insert Screw Driver 1 into Emergency Hole 2 and push Sider

Housing 3 in the direction of arrow "A".

2) When Tray Disc 4 comes out little, pull it in the direction of

arrow "B" by hand.

3) Pull Tray Disc 4 to disassemble, while pushing 2 Stoppers 5

(left, right) in the direction of arrow "C" and "D" simultaneously.

Fig. 3-3-2

3-3-3 Removing Slider Housing

1) Push Slider Housing 1 in the direction of arrow "A".

2) Lift Slider Housing 2 up.

Fig. 3-3-3

3-3-4 Removing Housing Assembly

1) Remove Belt 1 and 1 Screw 2.

2) Remove 1 screw 3 and lift the Pulley Gear 4 up.

3) Push Hook 5 in the direction of arrow "A" and lift the

Gear Tray 6 and the Gear Housing 7 up.

4) Push the 4 Hooks 8 bottom side in the direction of arrow "B"

and lift the Motor Load Assembly 9 up.

5) Remove Clamper Assembly J.

Fig. 3-3-4

DVD

DTH4500

First issue 12 / 00 5

"A"

SLIDER HOUSING

Assembly

PUSH

BELT

1 SCREW

1 SCREW

PULLEY GEAR

HOOK

"A"

GEAR TRAY

GEAR HOUSING

MOTOR LOAD ASS'Y

CLAMPER ASS'Y

<Bottom Side>

4 HOOKS

"B"

"B"

"B"

"B"

SLED+/SLED-

TM+/TM-

1 SCREW

DECK PCB

1 SCREW

HOOK

"B"

"A"

ASS'Y P/U DECK

<Assembly Point>

CN3

CN2

5 STOPPER

4 TRAY DISC

3 SLIDER HOUSING

5 STOPPER

2 EMERGENCY HOLE

1 SCREW DRIVER

"B"

"A"

"C"

"D"

Page 9

3-3-5 Removing Sub Chassis

1) Remove 4 Screws 1.

2) Lift Assembly Braket Deck 2 up.

Fig. 3-3-5

3-4 Connector Diagram

3-3-6 Removing Bracket Deck

1) Remove Washer 1.

2) Remove Gear Feed B 2, Gear Feed A 3.

3) Remove 2 Screws 4.

4) Remove Shaft Pick-up 5 and Pick-up Assembly 6.

5) Remove screw 7.

6) Remove 2 screws 8.

7) Remove 3 Springs Spindle 9 and Motor Spindle Assembly J.

Fig. 3-3-6

DVD DTH4500

6 First issue 12 / 00

DECK-ASS'Y

CT3

KEY PCB

CT1

MAIN PCB

JACK PCB

CT2

CT4

NO. CONNECTOR NO. DIRECTION CONNECTOR NO. NO.

FCN1 KEY PCB JACK PCB CON5

PCNS1 JACK PCB MAIN PCB PCN1

FPC DECK-ASS'Y MAIN

PCB DCN1

CN1 JACK PCB MAIN PCB CN8

CT1

CT2

CT3

CT4

2 SCREW

WASHER

GEAR FEED B

2 SCREWS

1 SCREW

SHAFT PICK-UP

GEAR FEED A

PICK-UP ASS'Y

SPRING SPINDLE

MOTOR SPINDLE

4 SC REWS

ASSY-BRAK DECK

Page 10

DVD DTH4500

First issue 12 / 00 7

8

GENERAL BLOCK DIAGRAM - SYNOPTIQUE GÉNÉRAL - BLOCKSCHALTBILD ALLGEMEIN - SCHEMA A BLOCCHI GENERALE - ESQUEMA DE BLOQUES GENERAL

DECK ASS'Y (DP-5)

SIC3

(KA3017)

Actuator & Motor Driver

Spindle/Sied/Tray Motor Pick-up & I/V Amp

DIC2 4M DRAM

ZIC2/3 SDRAM X 2

MIC4 2K EEPROM

Remote Control FLT Display

MIC2 8M EPROM

Coaxial

SIC1

(KS1454)

Servo + DSP

RIC1

(KS1462)

RF Amp & DPD

MIC1

(TMP95C265F)

Main Controller

FIC1

AC3 DECODER

(uPD780232)

Front Controller

ZIC1 (ZiVA-4.1)

A/V Decoder

Lt

Rt

Post

Filter

Optical

A/V

Decoder

AC3 &

MPEG 5.1

Video

Encoder

(4DAC)

AUDIO

DSP

CSS

INPUT

FIFO

&

DEMUX

AIC1 (AK4393)

2-CH Audio DAC

Down-L/R

MIC3 1M SDRAM

SCIC3

(14053)

Switch

SCIC4

(NJM2267)

AMP

SCIC5

(14053)

Switch

SCIC6

(BA7660)

AMP

SCIC1, 2

(14053)

Switch

SCJ1 (VCR)

SCJ1 (TV)

RGB_DVD

CVBS_DVD

COMP

Y/B/Pb

L/R_DVD

CVBS_TV_IN

CVBS_TV_OUT

L/R_TV

RGB_TV

CVBS_VCR

_IN

CVBS_VCR_IN

RGB_VCR

L/R_VCR

Post Filter

Yout

Cout

CVBS

Post Filter

VIC1 (BA7660)

6dB AMP

F/L

F/R

R/L

R/R

S/W

C/T

Page 11

9

DVD DTH4500

10 First issue 12 / 00

SERVO SCHEMATIC DIA GRAM - SCHEMA DES CIRCUITS D'ASSERVISSEMENTS - SCHALTBILD SER VO - SCHEMA DEI CIRCUITI SER VO - ESQUEMA DE LOS CIRCUITOS SERV O MECANISMO

MAIN

Page 12

SERVO MEASUREMENTS - MESURES DES CIRCUITS D'ASSERVISSEMENTS - MESSUNGEN SERV O - MISURE DEI CIRCUITI SERVO - MEDIDAS DE LOS CIRCUITOS SERVO MECANISMO

1 2.5 2.5 2.5 2.5

2 2.5 2.5 2.5 2.5

3 2.5 2.5 2.5 2.5

4 2.5 2.5 2.5 2.5

5 2.5 2.5 2.5 2.5

6 1.3 1.3 1.3 1.3

7 1.3 1.3 1.4 1.5

8 1.3 1.3 1.3 1.3

9 2.5 2.5 2.5 2.5

10 2.5 2.5 2.7 2.5

11 2.5 2.5 2.7 2.5

12 2.5 2.5 2.6 2.5

13 2.5 2.5 2.6 2.5

14 5 5 5 5.1

15 2.5 2.5 2.5 2.5

16 2.5 2.5 2.8 2.5

17 2.5 2.5 2.8 2.5

181111

195555

200000

21 4.9 0 3.8 5

22 0 0 0.2 0

230000

24 1.6 1.7 1.7 1.7

25 1.7 1.7 1.7 1.7

26 1.7 1.7 1.7 1.7

27 3.3 3.3 3.3 3.3

28 1.7 1.7 1.7 1.7

29 2.6 1.4 2.5 1.4

30 2.5 2.5 2.5 2.5

31 3.3 2.5 3.3 2.5

32 1.6 2.4 1.6 2.5

33 1.6 0 1.5 0

340000

35 0 5 0 5.1

36 3.5 2.5 3.4 2.5

37 3.5 2.6 3.5 2.8

38 3.4 2.5 3.4 2.5

39 3.5 2.6 3.4 2.6

40 5.1 5.1 5.1 5.1

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

41 0 0 0 0

42 0 0 0 0

43 2.5 2.5 2.5 2.5

44 0 0 0 0

45 5 5 5 5.1

46 0 5.1 0 5.1

47 2.5 2.5 0.1 0.1

48 2.5 2.5 0.1 0.1

49 0 5.1 5.1 5.1

50 2.5 2.5 1.4 1.5

51 1.3 1.3 0 0

52 0 0 0 0

53 2.5 2.5 1.4 1.5

54 1.3 1.3 0 0

55 0 0 0 0

56 5.1 5.1 5.1 5.2

57 0 0 0 0

58 5.1 5.1 5.1 5.1

59 2.4 0.5 2 1.2

60 5 5 5 5

61 2.6 0.3 2.2 1.1

62 3.3 0.2 2.3 1.3

63 2 2.5 2.1 2.5

64 3.1 2.6 2.8 2.6

65 2.5 2.5 2.5 2.5

66 5 5 5 5.1

67 1.6 1.6 1.7 1.7

68 4.7 4.7 4.6 4.7

69 2.5 2.5 2.5 2.5

70 1.6 1.6 1.7 1.7

71 2.5 2.6 2.5 2.5

72 2.5 2.6 2.5 2.5

73 2.4 2.4 3.9 4

74 0 0 0 0

75 1.3 1.3 1.3 1.3

76 2.2 2.5 2.3 2.5

77 3 2.5 2.9 2.5

78 1.1 1.2 1.1 1.2

79 5 5 5 5.1

80 2.5 2.5 2.5 2.5

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

RIC1 (KS1462)

10 0 0 0

2 1.2 1.2 1.2 1.2

3 3.4 3.4 3.4 3.4

4 3.4 3.4 3.4 3.4

5 1.5 3.4 1.5 3

6 1.5 2.5 1.5 3

7 1.2 1.2 1.2 1.7

8 0 0 0 1.7

9 1.4 0.7 0.7 0.7

10 1.7 1.7 1.7 1.7

110000

12 1.7 1.7 1.7 1.7

13 1.7 1.7 1.7 1.7

14 1.7 1.7 1.7 1.7

15 1.7 1.7 1.7 1.7

16 1.8 1.6 1.7 1.6

17 1.9 1.7 1.7 1.7

18 3.4 3.4 3.4 3.4

19 1.7 0.1 1.7 0

20 1.7 1.7 1.7 1.7

21 1.7 1.7 1.7 1.6

22 1.7 1.7 1.7 1.6

23 1.7 1.7 1.7 1.7

24 1.7 3.3 1.7 0.1

25 1.7 1.7 1.7 1.7

26 1.7 1.7 1.7 1.7

27 1.7 1.7 1.7 1.6

28 1.9 1.7 1.8 1.7

29 0.2 1.7 1 1.1

30 0 0.1 0 0

31 1.7 1.7 1.7 1.7

32 1.7 1.7 1.9 1.7

33 1.6 1.6 1.6 1.6

34 1.7 1.7 1.7 1.7

35 1.8 1.6 1.8 1.6

360000

370000

380000

390000

400000

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

41 0 0 0 0

42 0 0 0 0

43 1.6 1.5 1.5 1.4

44 0 0 0 0

45 1.5 1.4 1.4 1.5

46 0.2 0 0.2 0.4

47 0.2 0 0.2 0.4

48 0.2 0 0.2 0.4

49 0.2 0 0.1 0.2

50 0.2 0 0.2 0.4

51 0.2 0 0.1 0.2

52 0.2 0 0.2 0.4

53 0.2 0 0.1 0.2

54 0.2 0 0 0

55 3.2 3.2 3.2 3.2

56 5.1 5.2 5.1 5.2

57 2.4 2.4 4.9 4.8

58 5 5.2 5 5

59 5.1 5.2 5.1 5.2

60 5 5.2 5.1 5

61 5.1 5.2 5.2 5.2

62 3.8 3.8 5 5

63 3.9 3.8 5 5

64 5.1 5.2 5.2 5.2

65 3.2 3.2 3.2 3.2

66 1.4 1.5 2.4 2.5

67 1.4 1.6 0 0

68 1.4 1.6 2.4 2.7

69 1.4 1.6 0 0

70 1.4 1.6 2.4 2.5

71 1.4 1.4 0 0

72 1.4 1.5 2.4 2.1

73 1.4 1.5 0 0

74 1.4 1.5 2.4 2.3

75 1.4 1.5 0 0

76 1.4 1.5 2.4 2.4

77 1.4 1.5 0 0

78 1.4 1.6 2.4 2.6

79 1.4 1.5 0 0

80 0 0 0 0

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

810000

82 1.5 1.6 2.4 2.5

83 1.5 1.5 0 0

840000

850000

860000

87 1.3 1.5 2.5 2.5

88 5.1 0 0 0

89 3.2 3.2 3.2 3.2

90 2.6 2.6 2.6 2.6

91 2.6 2.6 2.6 2.6

92 2.5 2.5 2.5 2.5

93 3.2 3.2 3.2 3.2

94 2.5 2.5 2.5 2.5

95 2.5 2.5 2.5 2.5

96 0 0 0 2.6

97 2.5 2.5 2.5 5.2

98 3.2 3.2 3.2 3.2

99 5.1 5.2 5.1 5.2

100 0 0 0 0

101 4.7 5.2 5.1 0.1

102 5 5.2 5.1 5.2

103 3.2 3.2 3.2 3.2

104 1.8 1.8 1.5 1.5

105 2.3 2.3 2 1.9

106 2 2 2 2

107 1.7 1.6 1.9 1.9

108 1.7 1.7 1.9 1.9

109 1.7 2.1 2.2 2.2

110 2.5 2.6 3.1 3.1

111 1.7 1.8 1.9 2

112 0 0 0 0

113 5.1 5.1 5.1 5.2

114 2.5 2.4 2.5 2.5

115 5.1 5.2 5.1 5.2

116 5.1 5.2 5.1 5.2

117 5.1 5.2 5.1 5.2

118 5.1 5.2 5.1 5.2

119 5.1 5.2 5.1 5.2

120 0 0 0 0

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

121 5.1 5.1 5.1 5.2

122 2.1 5.1 5.1 2.1

123 5.1 5.1 5.1 5.2

124 0 0 0 0

125 0 0 0 0

126 4.4 5.1 5.1 5.2

127 2.4 5.1 5.1 5.2

128 2.4 0 0 0

129 3.2 3.2 3.2 3.2

130 2.5 2.8 2.8 2.7

131 2.5 0.1 0.1 0

132 2.5 2.6 2.6 2.6

133 2.5 0.1 0.1 2.6

134 2.5 0 0 5.2

135 2.5 2.5 2.5 2.5

136 2.5 2.6 2.6 2.6

137 2.5 1.7 1.7 0

138 0 0 0

139 0 0 0 0

140 0 0 0 0

141 0 0 0 0

142 0 0 0 0

143 0 0 0 0

144 0 0 0 0

145 0 0 0 0

146 0 0 0 0

147 3.2 3.2 3.2 3.2

148 5.1 5.1 5.1 5.2

149 5.1 0 0 0

150 0 0 0 0

151 5.1 5.1 5.1 0

152 5.1 5.1 5.1 0

153 1.9 1.7 1.7 1.7

154 1.9 2 2 1.7

155 0 0 0 5.1

156 0 0 0 0

157 0 0 0 0

158 1.5 1.5 1.5 1.3

159 0 0 0 0

160 0 0 0 0

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

SIC1 (KS1454)

1 0.1 0.1 0.1 0.1

2 2.3 5.0 2.3 5.0

3 2.5 2.5 2.5 2.5

4 2.7 2.5 2.7 2.5

5 5.0 5.0 5.0 5.0

6 0.0 0.0 0.0 0.0

7 0.0 0.0 0.0 0.0

8 7.9 8.0 7.9 8.0

9 7.9 8.0 7.9 8.0

10 5.0 0.0 5.0 0.0

11 0.0 5.0 0.0 5.0

12 0.0 0.0 0.0 0.0

13 0.0 0.0 0.0 0.0

14 5.9 0.0 6.6 0.0

15 6.0 0.0 6.6 0.0

16 5.9 0.0 6.6 0.0

17 2.5 2.5 2.5 2.5

18 2.5 2.5 2.5 2.5

19 2.5 2.5 2.5 2.5

20 7.9 8.0 7.9 8.0

21 7.9 8.0 7.9 8.0

22 2.5 2.5 2.5 2.5

23 2.5 2.5 2.5 2.5

24 2.5 2.5 2.5 2.5

25 2.5 2.5 2.5 2.5

26 3.7 4.0 3.5 4.0

27 4.2 4.0 4.2 4.0

28 4.0 4.0 4.0 4.0

29 4.0 4.0 4.0 4.0

30 0.0 0.0 0.0 0.0

31 0.0 0.0 0.0 0.0

32 3.9 4.0 3.9 4.0

33 3.9 4.0 3.9 4.0

34 7.9 8.0 7.9 8.0

35 4.0 4.0 4.0 4.0

36 3.9 3.9 3.9 3.9

37 0.0 0.0 0.0 0.0

38 0.0 0.0 0.0 0.0

39 0.0 0.0 0.0 0.0

40 7.9 8.0 7.9 8.0

41 2.5 2.5 2.5 2.5

42 0.0 0.0 0.0 0.0

43 2.5 2.6 2.5 2.6

44 2.5 2.5 2.5 2.5

45 2.5 2.6 2.5 2.6

46 2.5 2.4 2.5 2.4

47 2.5 2.4 2.5 2.4

48 2.5 2.4 2.5 2.4

PLAY STOP PLAY STOP

DVD CD

SIC3 (KA3017)

MODE

PIN

0

DTH4500

DVD

First issue 12 / 00 11

12

Page 13

13

DVD DTH4500

14 First issue 12 / 00

14

13 12 11 10 9 8

7654321

MAIN

AV PROCESSING SCHEMATIC DIAGRAM - SCHEMA DU TRAITEMENT AV - SCHALTBILD AV-VERARBEITUNG - SCHEMA ELABORAZIONE AV - ESQUEMA DEL TRATAMIENTO AV

Page 14

DVD DTH4500

First issue 12 / 00 15

16

AV PROCESSING MEASUREMENTS - MESURES DU TRAITEMENT AV - MESSUNGEN AV-VERARBEITUNG - MISURE ELABORAZIONE AV - MEDIDAS DEL TRATAMIENTO AV

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

1 2.4 2.4 2.4 2.4

2 4.9 4.9 4.9 4.9

3 3.2 3.2 3.2 3.2

4 3.2 3.2 3.2 3.2

5 5.0 5.0 5.0 5.0

6 0.0 0.0 0.0 0.0

7 3.2 3.2 3.2 3.2

8 3.2 3.2 3.2 3.2

9 2.7 2.7 2.7 2.7

10 2.7 2.7 2.7 2.7

11 2.7 2.7 2.7 2.7

12 2.7 2.7 2.7 2.7

13 2.4 2.4 2.4 2.4

14 0.0 0.0 0.0 0.0

15 2.7 2.7 2.7 2.7

16 2.7 2.7 2.7 2.7

17 2.7 2.7 2.7 2.7

18 2.7 2.7 2.7 2.7

19 0.0 0.0 0.0 0.0

20 3.2 3.2 3.2 3.2

21 0.2 0.2 0.2 0.2

22 0.2 0.2 0.2 0.2

23 0.2 0.2 0.2 0.2

24 0.2 0.2 0.2 0.2

25 0.2 0.2 0.2 0.2

26 0.2 0.2 0.2 0.2

27 0.2 0.2 0.2 0.2

28 0.2 0.2 0.2 0.2

29 3.2 3.2 3.2 3.2

30 2.7 2.7 2.7 2.7

31 0.0 0.0 0.0 0.0

32 3.2 3.2 3.2 3.2

33 3.2 3.2 3.2 3.2

34 3.2 3.2 3.2 3.2

35 3.2 3.2 3.2 3.2

36 3.2 3.2 3.2 3.2

37 0.0 0.0 0.0 0.0

38 3.2 3.2 3.2 3.2

39 3.2 3.2 3.2 3.2

40 3.2 3.2 3.2 3.2

41 3.2 3.2 3.2 3.2

42 3.2 3.2 3.2 3.2

43 0.0 0.0 0.0 0.0

44 0.0 0.0 0.0 0.0

45 3.2 3.2 3.2 3.2

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

46 0.0 0.0 0.0 0.0

47 0.0 0.0 0.0 0.0

48 0.0 0.0 0.0 0.0

49 0.0 0.0 0.0 0.0

50 0.0 0.0 0.0 0.0

51 0.0 0.0 0.0 0.0

52 0.0 0.0 0.0 0.0

53 0.8 0.8 0.8 0.8

54 1.0 1.0 1.0 1.0

55 3.2 3.2 3.2 3.2

56 0.0 0.0 0.0 0.0

57 1.2 0.9 1.2 0.9

58 1.2 0.9 1.2 0.9

59 1.2 0.9 1.2 0.9

60 1.2 0.9 1.2 0.9

61 1.2 0.9 1.2 0.9

62 1.2 0.9 1.2 0.9

63 1.2 0.9 1.2 0.9

64 3.2 3.2 3.2 3.2

65 0.0 0.0 0.0 0.0

66 1.4 0.9 1.4 0.9

67 2.4 2.4 2.4 2.4

68 0.0 0.0 0.0 0.0

69 1.4 0.9 1.4 0.9

70 1.4 0.9 1.4 0.9

71 1.4 0.9 1.4 0.9

72 1.4 0.9 1.4 0.9

73 1.4 0.9 1.4 0.9

74 3.2 3.2 3.2 3.2

75 0.0 0.0 0.0 0.0

76 1.4 0.9 1.4 0.9

77 0.0 0.0 0.0 0.0

78 1.6 1.6 1.6 1.6

79 3.2 3.2 3.2 3.2

80 0.8 0.5 0.6 0.5

81 0.8 0.5 0.6 0.4

82 3.2 3.2 3.2 3.2

83 0.0 0.0 0.0 0.0

84 1.4 0.9 1.4 0.9

85 1.4 0.9 1.4 0.9

86 1.4 0.9 1.4 0.9

87 3.2 3.2 3.2 3.2

88 0.0 0.0 0.0 0.0

89 1.3 1.5 1.3 1.5

90 3.1 3.1 3.1 3.1

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

ZIC1 (ZIVA4.1)

91 1.5 1.5 1.5 1.5

92 3.2 3.2 3.2 3.2

93 0.0 0.0 0.0 0.0

94 2.7 2.4 2.7 2.4

95 2.1 2.3 2.1 2.3

96 3.1 3.1 3.0 3.0

97 1.2 1.3 1.2 1.3

98 0.3 0.3 0.3 0.3

99 0.4 0.7 0.4 0.7

100 3.2 3.2 3.2 3.2

101 0.0 0.0 0.0 0.0

102 1.4 1.2 1.4 1.2

103 1.4 1.4 1.4 1.4

104 1.4 1.4 1.4 1.4

105 0.0 0.0 0.0 0.0

106 0.0 0.0 0.0 0.0

107 0.0 0.0 0.0 0.0

108 0.0 0.0 0.0 0.0

109 0.2 0.2 0.2 0.2

110 0.0 0.0 0.0 0.0

111 3.2 3.2 3.2 3.2

112 3.2 3.2 3.2 3.2

113 1.6 1.6 1.6 1.6

114 1.6 1.6 1.6 1.6

115 3.2 3.2 3.2 3.2

116 0.0 0.0 0.0 0.0

117 0.0 0.0 0.0 0.0

118 0.0 0.0 0.0 0.0

119 0.0 0.0 0.0 0.0

120 1.6 0.0 1.6 0.0

121 1.6 0.0 1.6 0.0

122 1.6 1.6 1.6 1.6

123 3.2 3.2 3.2 3.2

124 0.0 0.0 0.0 0.0

125 1.6 1.6 1.6 1.6

126 1.6 1.6 1.6 1.6

127 1.6 1.6 1.6 1.6

128 2.4 2.4 2.4 2.4

129 0.0 0.0 0.0 0.0

130 0.0 0.0 0.0 0.0

131 0.0 0.0 0.0 0.0

132 0.0 0.0 0.0 0.0

133 0.6 0.5 0.6 0.5

134 3.2 3.2 3.2 3.2

135 3.2 3.2 3.2 3.2

136 0.0 0.0 0.0 0.0

137 0.0 0.0 0.0 0.0

138 0.0 0.0 0.0 0.0

139 0.6 0.5 0.6 0.5

140 3.2 3.2 3.2 3.2

141 3.2 3.2 3.2 3.2

142 0.0 0.0 0.0 0.0

143 0.0 0.0 0.0 0.0

144 0.0 0.0 0.0 0.0

145 0.7 0.5 0.7 0.5

146 3.2 3.2 3.2 3.2

147 3.2 3.2 3.2 3.2

148 0.0 0.0 0.0 0.0

149 0.0 0.0 0.0 0.0

150 0.0 0.0 0.0 0.0

151 0.5 0.5 0.5 0.5

152 3.2 3.2 3.2 3.2

153 3.2 3.2 3.2 3.2

154 0.0 0.0 0.0 0.0

155 1.3 1.3 1.3 1.3

156 3.2 3.2 3.2 3.2

157 0.0 0.0 0.0 0.0

158 3.2 3.2 3.2 3.2

159 1.6 1.6 1.6 1.6

160 3.2 3.2 3.2 3.2

161 2.5 0.0 2.5 0.0

162 2.5 0.0 2.5 0.0

163 2.5 0.0 2.5 0.0

164 2.5 0.0 2.5 0.0

165 2.5 0.0 2.5 0.0

166 0.0 0.0 0.0 0.0

167 3.2 3.2 3.2 3.2

168 2.5 0.0 2.5 0.0

169 2.5 0.0 2.5 0.0

170 2.5 0.0 2.5 0.0

171 4.0 5.0 5.0 5.0

172 2.5 2.0 2.5 1.6

173 2.4 2.4 2.4 2.4

174 0.0 0.0 0.0 0.0

175 3.2 3.2 3.2 3.2

176 0.0 0.0 0.0 0.0

177 3.2 3.2 3.2 3.2

178 0.0 0.0 0.0 0.0

179 3.2 3.2 3.2 3.2

180 0.0 0.0 0.0 0.0

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

181 3.2 3.2 3.2 3.2

182 2.5 2.5 2.5 2.5

183 2.5 2.5 2.5 2.5

184 2.5 2.5 2.5 2.5

185 3.2 3.2 3.2 3.2

186 3.2 3.2 3.2 3.2

187 3.2 3.2 3.2 3.2

188 0.0 0.0 0.0 0.0

189 3.2 3.2 3.2 3.2

190 3.2 3.2 3.2 3.2

191 0.0 0.0 0.0 0.0

192 3.2 3.2 3.2 3.2

193 3.2 3.2 3.2 3.2

194 3.2 3.2 3.2 3.2

195 3.2 3.2 3.2 3.2

196 3.2 3.2 3.2 3.2

197 2.4 2.3 2.4 2.3

198 0.0 0.0 0.0 0.0

199 2.2 2.2 2.2 2.2

200 2.0 2.0 2.0 2.0

201 1.6 1.6 1.6 1.6

202 1.6 1.6 1.6 1.6

203 1.8 2.0 1.8 2.0

204 3.2 3.2 3.2 3.2

205 0.0 0.0 0.0 0.0

206 1.6 1.6 1.6 1.6

207 1.6 1.6 1.6 1.6

208 4.9 5.0 4.9 5.0

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

ZIC1 (ZIVA4.1)

1 3.2 3.2 3.2 3.2

2 1.0 0.7 1.0 0.7

3 1.0 0.7 1.0 0.7

4 0.0 0.0 0.0 0.0

5 1.0 1.0 1.0 1.0

6 0.9 0.9 0.9 0.9

7 3.2 3.2 3.2 3.2

8 1.3 0.7 0.6 0.8

9 1.0 1.0 0.8 1.2

10 0.0 0.0 0.0 0.0

11 1.0 1.0 0.6 1.1

12 1.6 1.0 0.6 1.2

13 3.2 3.2 3.2 3.2

14 0.0 0.0 0.0 0.0

15 3.0 3.1 3.0 3.1

16 1.4 1.5 1.4 1.5

17 2.7 2.4 3.2 2.6

18 2.2 2.3 2.2 2.3

19 1.2 1.1 1.2 1.1

20 0.5 0.7 0.5 0.7

21 0.5 0.7 0.5 0.7

22 1.4 1.2 1.4 1.2

23 1.4 1.4 1.4 1.4

24 1.3 1.3 1.3 1.3

25 3.2 3.2 3.2 3.2

26 0.0 0.0 0.0 0.0

27 1.4 1.5 1.4 1.5

28 1.5 1.5 1.5 1.5

29 1.4 1.2 1.4 1.2

30 1.4 1.3 1.4 1.3

31 0.7 0.6 0.7 0.6

32 0.0 0.0 0.0 0.0

33 0.0 0.0 0.0 0.0

34 3.2 3.2 3.2 3.2

35 1.6 1.6 1.6 1.6

36 0.0 0.0 0.0 0.0

37 0.0 0.0 0.0 0.0

38 3.2 3.2 3.2 3.2

39 1.2 0.7 1.2 0.7

40 1.3 0.8 1.2 0.8

41 0.0 0.0 0.0 0.0

42 1.1 0.4 1.1 0.4

43 1.1 0.5 1.1 0.5

44 3.2 3.2 3.2 3.2

45 1.3 1.0 1.3 1.0

46 1.4 1.0 1.4 1.0

47 0.0 0.0 0.0 0.0

48 1.0 0.9 1.0 0.9

49 1.0 0.7 1.0 0.7

50 0.0 0.0 0.0 0.0

PLAY STOP PLAY STOP

DVD CD

ZIC2,3 (KM416S1120D)

MODE

PIN

Page 15

17

DVD DTH4500

18 First issue 12 / 00

SYSTEM CONTROL SCHEMATIC DIAGRAM - SCHEMA DES CIRCUITS DE GESTION - SCHALTBILD GERÄTESTEUERUNG - SCHEMA DEI CIRCUITI CONTROLLO MECCANICA ESQUEMA DE LOS CIRCUITOS GESTIÓN

MAIN

Page 16

DVD

DTH4500

First issue 12 / 00 19

SYSTEM CONTROL MEASUREMENTS - MESURES DES CIRCUITS DE GESTION MESSUNGEN GERÄTESTEUERUNG - MISURE DEI CIRCUITI CONTROLLO MECCANICA MEDIDAS DE LOS CIRCUITOS GESTIÓN

1 0.0 0.0 0.0 0.0

2 0.0 0.0 0.0 0.0

3 4.9 4.9 4.9 4.9

4 0.0 0.0 0.0 0.0

5 0.0 0.0 0.0 0.0

6 4.9 4.9 4.9 4.9

7 2.5 4.9 4.9 4.9

8 2.5 4.9 4.9 4.9

9 2.5 2.5 4.9 4.9

10 4.9 4.9 0.0 0.0

11 2.5 4.9 2.5 4.9

12 2.5 0.0 0.0 0.0

13 2.5 0.0 0.0 0.0

14 2.5 4.9 4.9 4.9

15 4.9 4.9 4.9 4.9

16 0.0 0.0 0.0 0.0

17 4.9 4.9 4.9 4.9

18 2.5 4.9 2.5 4.9

19 2.5 4.9 2.5 4.9

20 2.5 2.5 2.5 2.5

21 2.5 2.5 2.5 2.5

22 2.5 2.5 2.5 2.5

23 2.5 2.5 2.5 2.5

24 2.5 2.5 2.5 2.5

25 4.9 4.9 4.9 4.9

26 0.0 0.0 0.0 0.0

27 2.5 2.5 2.5 2.5

28 2.5 2.5 2.5 2.5

29 0.0 0.0 0.0 0.0

30 4.9 4.9 4.9 4.9

31 0.0 0.0 0.0 0.0

32 2.5 4.9 2.5 4.9

33 4.9 4.9 4.9 4.9

34 4.9 4.9 4.9 4.9

35 0.0 0.0 0.0 0.0

36 4.9 4.9 4.9 4.9

37 2.5 4.9 2.5 4.9

38 0.0 0.0 0.0 0.0

39 4.9 0.0 0.0 0.0

40 4.9 4.9 4.9 4.9

41 2.5 2.5 2.5 2.5

42 2.5 2.5 2.5 2.5

43 4.9 4.9 4.9 4.9

44 4.9 4.9 4.9 4.9

45 2.5 2.5 2.5 2.5

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

51 2.5 2.5 2.5 2.5

52 2.5 2.5 2.5 2.5

53 0.0 0.0 0.0 0.0

54 4.9 4.9 4.9 4.9

55 0.0 0.0 0.0 0.0

56 0.0 0.0 0.0 0.0

57 0.0 0.0 0.0 0.0

58 0.0 0.0 0.0 0.0

59 4.9 0.0 0.0 0.0

60 2.5 0.0 2.5 0.0

61 4.9 4.9 4.9 4.9

62 0.0 0.0 0.0 0.0

63 4.9 4.9 4.9 4.9

64 2.5 2.5 2.5 2.5

65 2.5 2.5 2.5 2.5

66 2.5 2.5 2.5 2.5

67 2.5 2.5 2.5 2.5

68 2.5 2.5 2.5 2.5

69 2.5 2.5 2.5 2.5

70 2.5 2.5 2.5 2.5

71 2.5 2.5 2.5 2.5

72 2.5 2.5 2.5 2.5

73 2.5 2.5 2.5 2.5

74 2.5 2.5 2.5 2.5

75 2.5 2.5 2.5 2.5

76 2.5 2.5 2.5 2.5

77 2.5 2.5 2.5 2.5

78 2.5 2.5 2.5 2.5

79 2.5 2.5 2.5 2.5

80 2.5 2.5 2.5 2.5

81 2.5 2.5 2.5 2.5

82 2.5 2.5 2.5 2.5

83 2.5 2.5 2.5 2.5

84 2.5 2.5 2.5 2.5

85 2.5 2.5 2.5 2.5

86 2.5 2.5 2.5 2.5

87 2.5 2.5 2.5 2.5

88 2.5 2.5 2.5 2.5

89 2.5 2.5 2.5 2.5

90 4.9 4.9 4.9 4.9

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

MIC1 (TMP95C265)

91 0.0 0.0 0.0 0.0

92 3.2 0.4 3.7 1.1

93 0.0 0.0 0.0 0.0

94 4.9 4.9 4.9 4.9

95 2.5 4.9 4.9 4.9

96 0.0 4.9 0.0 4.9

97 4.9 0.0 4.9 0.0

98 0.0 4.9 0.0 4.9

99 2.8 1.9 2.7 1.8

100 4.9 4.9 4.9 4.9

MIC3 (KM681000C)

1 0.0 0.0 0.0 0.0

2 1.3 1.3 1.2 1.9

3 2.0 2.0 1.4 0.9

4 2.3 2.7 1.7 1.7

5 2.3 2.4 2.8 2.4

6 2.6 2.6 2.5 2.8

7 2.4 2.4 2.4 2.2

8 2.5 2.5 2.5 2.5

9 2.4 2.4 2.4 2.3

10 2.4 2.4 2.4 2.4

11 2.3 2.3 2.3 2.4

12 2.1 2.2 2.0 2.2

13 1.7 1.7 1.8 1.6

14 2.4 2.5 2.5 2.4

15 1.9 1.8 2.0 2.0

16 0.0 0.0 0.0 0.0

17 1.8 1.8 2.1 2.0

18 1.6 1.6 0.0 1.5

19 2.0 2.0 2.4 2.0

20 2.2 2.2 2.0 2.0

21 1.8 1.8 2.1 1.8

22 4.7 4.7 4.9 4.9

23 2.6 2.7 2.7 2.8

24 2.4 2.4 2.5 2.4

25 1.9 1.9 1.7 2.0

26 3.5 3.5 3.4 3.5

27 2.8 2.8 2.7 2.9

28 2.7 2.6 2.2 2.0

29 5.0 5.0 5.0 5.0

30 5.0 5.0 5.0 5.0

31 3.0 3.0 2.0 1.9

32 5.0 5.0 5.0 5.0

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

1 0.0 0.0 0.0 0.0

2 0.0 0.0 0.0 0.0

3 0.0 0.0 0.0 0.0

4 0.0 0.0 0.0 0.0

5 5.0 5.0 5.0 5.0

6 5.0 5.0 5.0 5.0

7 0.0 0.0 0.0 0.0

8 5.0 5.0 5.0 5.0

PLAY STOP PLAY STOP

DVD CD

MIC4 (KS24C021)

MODE

PIN

MIC2 (M27C801)

1 0.0 0.0 0.0 0.0

2 1.3 1.4 1.2 1.9

3 2.7 2.7 2.0 1.9

4 2.4 2.7 1.7 1.7

5 2.3 2.4 2.8 2.4

6 2.7 2.6 2.5 2.8

7 2.4 2.4 2.4 2.2

8 2.6 2.5 2.5 2.5

9 2.4 2.4 2.4 2.3

10 2.4 2.4 2.4 2.4

11 2.3 2.4 2.3 2.3

12 2.1 2.2 2.0 2.2

13 1.7 1.7 1.8 1.6

14 2.5 2.6 2.5 2.4

15 1.8 1.8 2.0 2.0

16 0.0 0.0 0.0 0.0

17 1.8 1.8 2.1 2.0

18 1.6 1.6 1.5 1.5

19 2.0 2.0 2.3 2.0

20 2.2 2.2 2.0 2.0

21 1.8 1.8 2.1 1.8

22 1.1 1.1 1.2 1.0

23 2.6 2.6 2.8 3.0

24 2.4 2.4 2.5 2.4

25 1.9 1.9 1.7 2.0

26 3.5 3.5 3.3 3.3

27 2.8 2.8 2.7 2.9

28 2.7 2.6 2.3 2.0

29 2.2 2.1 1.4 1.0

30 1.8 2.2 2.2 1.5

31 0.0 0.0 1.3 0.6

32 5.0 5.0 5.0 5.0

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

46 2.5 2.5 2.5 2.5

47 2.5 2.5 2.5 2.5

48 2.5 2.5 2.5 2.5

49 2.5 2.5 2.5 2.5

50 2.5 2.5 2.5 2.5

Page 17

DVD DTH4500

20 First issue 12 / 00

DISPLAY & CONTROL MEASUREMENTS - MESURES DES CIRCUITS

COMMANDES/AFFICHEUR - MESSUNGEN BEDIENTEIL/ANZEIGE - MISURE DEI

CIRCUITI DISPLAY E COMANDI - MEDIDAS DE LOS CIRCUITOS

MANDOS/VISUALIZADOR

1 5.0 5.0 5.0 5.0

2 0.0 0.0 0.0 0.0

3 2.3 2.3 2.3 2.3

4 4.4 4.4 4.4 4.4

5 0.0 0.0 0.0 0.0

6 5.0 5.0 5.0 5.0

7 4.9 4.9 4.9 4.9

8 5.0 5.0 5.0 5.0

9 0.0 0.0 0.0 0.0

10 0.0 0.0 0.0 0.0

11 0.0 0.0 0.0 0.0

12 0.0 0.0 0.0 0.0

13 0.0 0.0 0.0 0.0

14 4.5 4.5 4.5 4.5

15 1.5 1.5 1.5 1.5

16 5.0 5.0 5.0 5.0

17 5.0 5.0 5.0 5.0

18 0.0 0.0 0.0 0.0

19 0.0 0.0 0.0 0.0

20 0.0 0.0 0.0 0.0

21 0.0 0.0 0.0 0.0

22 0.0 0.0 0.0 0.0

23 0.0 0.0 0.0 0.0

24 5.0 5.0 5.0 5.0

25 5.0 5.0 5.0 5.0

26 0.0 0.0 0.0 0.0

27 4.7 4.7 4.7 4.7

28 4.9 4.9 4.9 4.9

29 4.5 4.5 4.5 4.5

30 4.5 4.5 4.5 4.5

31 4.5 4.5 4.5 4.5

32 4.5 4.5 4.5 4.5

33 4.5 4.5 4.5 4.5

34 4.5 4.5 4.5 4.5

350000

360000

370000

380000

390000

400000

410000

42 4.9 4.9 4.9 4.9

43 5.0 5.0 5.0 5.0

44 4.9 4.9 4.9 4.9

45 4.9 4.9 4.9 4.9

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

46 4.9 4.9 4.9 4.9

47 0.0 4.9 0.0 4.9

48 0.0 4.9 0.0 4.9

49 0.0 0.0 0.0 0.0

50 0.0 0.0 0.0 0.0

51 -28.0 -23.7 -28.0 -23.7

52 -28.0 -23.7 -28.0 -23.7

53 -29.0 -23.7 -29.0 -23.7

54 -29.0 -23.7 -29.0 -23.7

55 -29.0 -23.7 -29.0 -23.7

56 -28.0 -23.7 -28.0 -23.7

57 -29.0 -23.7 -29.0 -23.7

58 -29.0 -23.7 -29.0 -23.7

59 3.5 4.9 3.5 4.9

60 -29.0 -28.3 -29.0 -28.3

61 -27.0 -26.6 -27.0 -26.6

62 -26.0 -23.3 -26.0 -23.3

63 -27.5 -26.6 -27.5 -26.6

64 -27.5 -26.6 -27.5 -26.6

65 -27.5 -26.6 -27.5 -26.6

66 -26.6 -23.7 -26.6 -23.7

67 -27.5 -26.6 -27.5 -26.6

68 -27.5 -26.6 -27.5 -26.6

69 -27.5 -26.6 -27.5 -26.6

70 -26.3 -23.7 -26.3 -23.7

71 -26.3 -23.7 -26.3 -23.7

72 -26.3 -23.3 -26.3 -23.3

73 -26.3 -23.7 -26.3 -23.7

74 -26.3 -23.7 -26.3 -23.7

75 -26.3 -23.7 -26.3 -23.7

76 -26.3 -23.7 -26.3 -23.7

77 -26.3 -23.7 -26.3 -23.7

78 -26.3 -23.7 -26.3 -23.7

79 -26.3 -23.7 -26.3 -23.7

80 -26.3 -23.7 -26.3 -23.7

PLAY STOP PLAY STOP

DVD CD

MODE

PIN

FIC1 (uPD780232)

Page 18

DISPLAY & CONTROL SCHEMATIC DIAGRAM - SCHEMA DES CIRCUITS COMMANDES/AFFICHEUR - SCHALTBILD BEDIENTEIL/ANZEIGE - SCHEMA DEI CIRCUITI DISPLAY

E COMANDI - ESQUEMA DE LOS CIRCUITOS MANDOS/VISUALIZADOR

SKC

DVD DTH4500

First issue 12 / 00 21

22

Page 19

23

DVD DTH4500

24 First issue 12 / 00

AUDIO SCHEMATIC DIAGRAM - SCHEMA DES CIRCUITS AUDIO - SCHALTBILD AUDIOSIGNALVERARBEITUNG - SCHEMA DEI CIRCUITI AUDIO - ESQUEMA DE LOS CIRCUITOS AUDIO

SKC

Page 20

DVD

DTH4500

First issue 12 / 00 25

AUDIO MEASUREMENTS - MESURES DES CIRCUITS AUDIO MESSUNGEN AUDIOSIGNALVERARBEITUNG - MISURE DEI CIRCUITI AUDIO MEDIDAS DE LOS CIRCUITOS AUDIO

1 0.0 0.0 0.0 0.0

2 3.2 3.2 3.2 3.2

3 1.6 1.6 1.6 1.6

4 3.0 3.0 3.0 3.0

5 1.6 1.6 1.6 1.6

6 1.3 0.0 1.3 0.0

7 1.6 1.6 1.6 1.6

8 3.0 3.0 3.0 3.0

9 0.0 0.0 0.0 0.0

10 3.0 3.0 3.0 3.0

11 0.0 3.0 0.0 3.0

12 0.0 0.0 0.0 0.0

13 0.0 0.0 0.0 0.0

14 0.0 0.0 0.0 0.0

15 0.0 0.0 0.0 0.0

16 0.0 0.0 0.0 0.0

17 5.0 5.0 5.0 5.0

18 5.0 5.0 5.0 5.0

19 0.0 0.0 0.0 0.0

20 2.6 2.6 2.6 2.6

21 2.6 2.6 2.6 2.6

22 2.6 2.6 2.6 2.6

23 2.6 0.0 2.6 0.0

24 2.6 0.0 2.6 0.0

25 0.0 0.0 0.0 0.0

26 0.0 0.0 0.0 0.0

27 0.0 0.0 0.0 0.0

28 0.0 0.0 0.0 0.0

PLAY STOP PLAY STOP

DVD CD

AIC1 (AK4393)

MODE

PIN

Page 21

DVD DTH4500

26 First issue 12 / 00

KEYBOARD SCHEMATIC DIAGRAM - SCHEMA DES CIRCUITS COMMANDE SCHALTBILD BEDIENTEIL - SCHEMA DEI CIRCUITI TASTIERA ESQUEMA DE LOS CIRCUITOS MANDOS

HEADPHONE SCHEMATIC DIAGRAM - SCHEMA DES CIRCUITS CASQUE SCHALTBILD KOPFHÖRERANSCHLUSS - SCHEMA DEI CIRCUITI CUFFIA ESQUEMA DE LOS CIRCUITOS AURICULARES

KB

SKC

Page 22

DVD DTH4500

First issue 12 / 00 27

28

AUDIO 5.1 CHANNEL SCHEMATIC DIAGRAM - SCHEMA DES CIRCUITS AUDIO 5.1 - SCHALTBILD 5.1 MULTIKANAL AUDIO - SCHEMA DEI CIRCUITI AUDIO 5.1 ESQUEMA DE LOS CIRCUITOS AUDIO 5.1

SKC

Page 23

DVD DTH4000/DTH4200

First issue 08 / 00 41

42

VIDEO DECODER SCHEMATIC DIAGRAM - SCHEMA DES DECODEURS VIDEO - VIDEO VERARBEITUNG - SCHEMA DEI CIRCUITI VIDEO - ESQUEMA DE LOS CIRCUITOS VÍDEO

DTH4200

SKC

Page 24

43

DVD DTH4000/DTH4200

44 First issue 08 / 00

POWER SUPPLY SCHEMATIC DIAGRAM - SCHEMA DES CIRCUITS D’ALIMENTATIONS - SCHALTBILD NETZTEIL - SCHEMA DEI CIRCUITI DI ALIMENTAZIONE - ESQUEMA DE LOS

CIRCUITOS DE ALIMENTACIÓN

SKC

Page 25

DVD DTH4000/DTH4200

First issue 08 / 00 45

46

CD MOTOR CONTROL SCHEMATIC DIAGRAM - SCHEMA DE LA PLATINE COMMANDES MOTEURS CD - CD WECHSLER-MOTOR SCHALTBILD SCHEMA DELLA PIASTRA COMANDI MOTORI CD - ESQUEMA DE LA PLATINA MANDOS MOTORES CD

DTH4000

DTH4200 / DTH4500

SKC

SKC

Page 26

29

DVD DTH4500

30 First issue 12 / 00

JACK PRINTED CIRCUIT BOARD - CIRCUIT IMPRIME PLATINE PRISES - LEITERPLATTE ANSCHLUSS - PIASTRA PRESE - PLATINA TOMAS

COMPONENT SIDE - COTÉ COMPOSANTS - BESTÜCKUNGSSEITE - LATO COMPONENTI - LADO COMPONENTES

Page 27

DVD DTH4500

First issue 12 / 00 31

32

JACK PRINTED CIRCUIT BOARD - CIRCUIT IMPRIME PLATINE PRISES - LEITERPLATTE ANSCHLUSS - PIASTRA PRESE - PLATINA TOMAS

SOLDER SIDE - COTÉ CUIVRE - LÖTSEITE - LATO SALDATURE - LADO DEL COBRE

Page 28

33

DVD DTH4500

34 First issue 12 / 00

COMPONENT SIDE - COTÉ COMPOSANTS - BESTÜCKUNGSSEITE - LATO COMPONENTI - LADO COMPONENTES

MAIN PRINTED CIRCUIT BOARD - CIRCUIT IMPRIME PLATINE PRINCIPALE - GRUNDPLATTE - PIASTRA PRINCIPALE - PLATINA PRINCIPAL

Page 29

DVD

DTH4500

First issue12 / 00 35

KEYBOARD CIRCUIT BOARDS - CIRCUITS IMPRIMES PLATINES COMMANDES LETERPLATTE BEDIENTEIL - PIASTRE TASTIERA - PLATINAS MANDOS

COMPONENT SIDE - COTÉ COMPOSANTS - BESTÜCKUNGSSEITE LATO COMPONENTI - LADO COMPONENTES

Page 30

CD MOTOR CONTROL CIRCUIT BOARD CIRCUIT IMPRIME DE LA PLATINE COMMANDES MOTEURS CD CD WECHSLER-MOTOR LETERPLATTE PIASTRE COMANDI MOTORI CD - PLATINAS MANDOS MOTORES CD

DTH4000

COMPONENT SIDE - COTÉ COMPOSANTS BESTÜCKUNGSSEITE LATO COMPONENTI - LADO COMPONENTES

DTH4200

COMPONENT SIDE - COTÉ COMPOSANTS BESTÜCKUNGSSEITE LATO COMPONENTI - LADO COMPONENTES

DVD DTH4000/DTH4200

48 First issue 08 / 00

Page 31

AC Alternative Current

AGC Automatic Gain Control

ALPC Automatic Laser Power Control

CD Compact Disc

CLV Constant Linear Velocity

CSS Contents Scramble System

DTS Digital Theater System

DVD Digital Versatile Disc

EFM Eight to Fourteen Modulation

EQ Equalizer

FE Focusing Error

FG Frequency Generator

LD Laser Diode

LPCM Linear Pulse Code Modulation

MIRR Mirror

MPEG Moving Picture Expert Group

PCB Printed Circuit Board

PLL Phase Locked Loop

PWM Pulse Width Modulation

RF Radio Frequency

S/N Signal to Noise

SMPS Switching Mode Power Supply

TE Tracking Error

TZC Track Zero Cross

VBR Variable Bit Rate

Abbreviations - Abreviations - Abkürzungen - Abbreviazioni - Abreviaciones

Page 32

The description and characteristics given here are of informative significance only, and non committal. To keep up the high quality of our products, we reserve the right to

make any changes or improvement without previous notice. • Les descriptions et caractéristiques figurant sur ce document sont données à titre d'information et non

d'engagement. En effet, soucieux de la qualité de nos produits, nous nous réservons le droit d'effectuer, sans préavis, toute modification ou amélioration. • Die

Beschreibungen und Daten in dieser Anleitung dienen nur zur Information und sind nicht bindend. Um die Qualität unserer Produkte ständig zu verbessern, behalten wir uns

das Recht auf Änderungen vor. • Le descrizioni e le caratteristiche date su questo documento sono fornite a semplice titolo informativo e senza impegno. Ci riserviamo il

diritto di eseguire, senza preavviso, qualsiasi modifica o miglioramento. • Las descripciones y características que figuran en este documento se dan a título de información y

no de compromiso. En efecto, en bien de la calidad de nuestros productos, nos reservamos el derecho de efectuar, sin previo aviso, cualquier modificación o mejora.

THOMSON multimedia Sales Europe - S.A. au capital de 30 000 000 - Siège : 46, quai Alphonse Le Gallo 92100 Boulogne France - RCS Nanterre B 322 019 464

THOMSON multimedia

Sales France

46, quai Alphonse Le Gallo

92648 Boulogne cedex

Tel.

: 01 41 86 60 00

Minitel : 3616 ou 3623 TCEDS

Internet : http://www.thomson.fr

THOMSON multimedia

Sales UK Limited

30 T ower Vie w

Kings Hill, West Malling

Kent ME19 4NQ (England)

Tel. : 44 (0) 173 252 0920

THOMSON multimedia

Sales Italy S.p.A.

Via Leonardo da Vinci,43

20090 Trezzano sul naviglio (Milano)

Tel.

: (02) 48 414 111

THOMSON multimedia

Scandinavia AB

Florettgatan 29 C

S-25467 Helsingborg (Sweden)

Tel. : 042 25 75 00

THOMSON multimedia

Switzerland

Seewenweg 5

CH-4153 Reinach

Tel.

: (61) 716 96 60

THOMSON

Consumer Electronics Poland

ul.Gen.L. Okulickiego 7/9

05-500 Piaseczno (Varsovie)

Tel.

: (22) 757 10 80

THOMSON multimedia

Hungary KFT

Lajos u. 78. II.em.

H-1036 Budapest

Tel. : 00 36 14 5334/80

THOMSON multimedia

Czech s.r.o.

ul. Dopravaku - dum Genius 1

Dolni Chabry

CZ - 18400 Prague 8

Tel. : (2) 688 67 70

THOMSON multimedia

Sales Germany GmbH & Co oHG

Karl-Wiechert-Allee 74

30625 Hannover

THOMSON multimedia

Sales Spain

Avenida de Burgos 8A

28036 Madrid

Tel. : (91) 384 14 19

THOMSON multimedia

Sales Portugal

Avenida da Boavista, 3521

4106 Porto

Tel. : (2) 26 18 76 41

This technical documentation is for use by maintenance technicians only

Documentation technique exclusivement destinée aux professionnels de la maintenance

Diese Angaben und Hinweise sind ausschließlich für den Service des Fachhändlers bestimmt

Documentazione tecnica destinata esclusivamente ai tecnici dell'assistenza

Documentación técnica destinada exclusivamente a los profesionales de mantenimiento

Loading...

Loading...