Thermador VCIN48JP, VCIN54JP, VCIB54JP, VCIB48JP Installation Manual

INSTALLATION MANUAL

For THERMADOR PROFESSIONAL® Custom Insert

MANUEL D'INSTALLATION

Pour hottes encastrées sur mesure PROFESSIONALMC

de THERMADOR

MANUAL DE INSTALACIÓN

Para campanas empotradas a medida PROFESSIONAL®

de THERMADOR

Models/

Modèles/

Modelos:

VCIN36JP

VCIN48JP

VCIN54JP

VCIB36JP

VCIB48JP

VCIB54JP

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Advance Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ductwork Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Choosing the Correct Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Blower Motor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Remote Installation (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preparing the Ceiling Cutout and Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Custom Insert Installation with Hood Trims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Custom Insert Installation with Liner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing Filters, Filter Spacers, & Grease Trays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Before Calling Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Product Data Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installer Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Service, Parts & Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . back page

Safety Definitions

WARNING

This indicates that death or serious injuries may occur as

a result of non-observance of this warning.

CAUTION

This indicates that minor or moderate injuries may occur

as a result of non-observance of this warning.

NOTICE: This indicates that damage to the appliance or property may occur as a result of non-compliance with this

advisory.

Note: This alerts you to important information and/or tips.

This THERMADOR® appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Safety

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

IMPORTANT: Save these instructions for the local

electrical inspector’s use.

INSTALLER: Please leave these instructions with this unit

for the owner. Show the owner the location of the circuit

breaker or fuse. Mark it for easy reference.

OWNER: Please retain these instructions for future

reference.

WARNING

If the information in this manual is not followed exactly, fire

or shock may result causing property damage or personal

injury.

WARNING

Turn off power circuit at service panel and lock out panel

before wiring this appliance. Requirement: 120 VAC, 60

Hz 15 A. Allow the appliance to cool after the power has

been turned off before servicing the appliance.

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

• Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer at the address or telephone number

listed on the back page.

• Before servicing or cleaning unit, switch power off at

service panel and lock the service disconnecting

means to prevent power from being switched on

accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

Electric Safety

WARNING

IMPROPER GROUNDING CAN RESULT IN A

RISK OF ELECTRIC SHOCK.

Consult a qualified electrician if the grounding

instructions are not completely understood, or if

doubt exists as to whether the appliance is

properly grounded. If the power cord is too short,

have a qualified electrician install an outlet near

the appliance.

CORD.

WARNING

ELECTRICAL SHOCK HAZARD

• DO NOT remove connections.

• DO NOT use an extension cord.

• Improper grounding can result in a risk of

electric shock.

• Failure to follow these instructions can result

in death, fire, or electrical shock.

Grounding Instructions:

This appliance must be grounded. In the event of an

electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current.

Be sure your appliance is properly installed and grounded

by a qualified technician. Installation, electrical connections

and grounding must comply with all applicable codes.

If required by the National Electrical Code (or Canadian

Electrical Code), this appliance must be installed on a

separate branch circuit.

DO NOT USE AN EXTENSION

WARNING

Do not repair or replace any part of the appliance unless

specifically recommended in the manuals. Improper

installation, service or maintenance can cause injury or

property damage. Refer to this manual for guidance. All

other servicing should be done by a qualified technician.

To reduce the risk of fire or electric shock, do not use this

appliance with any solid-state speed control devices.

English 1

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Safety Codes and Standards

This appliance complies with one or more of the following

Standards:

• UL 507, The Standard for the Safety of Electric Fans

• CSA C22.2 No. 113, Fans and Ventilators

It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

Appliance Handling Safety

CAUTION

Unit is heavy and requires at least two people

or proper equipment to move and install.

Hidden surfaces may have sharp edges. Use

caution when handling the appliance. Failure

to do so may result in property damage or

personal injury.

WARNING

State of California Proposition 65 Warnings:

This product contains chemicals known to the State of

California to cause cancer, birth defects or other

reproductive harm.

Related Equipment Safety

Never modify or alter the construction of the appliance. For

example, do not remove panels, wire covers or brackets/

screws.

CAUTION

For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors. To reduce

the risk of fire, use only metal ductwork.

When cutting or drilling into wall or ceiling, be careful not to

damage electrical wiring and other hidden utilities.

Use a quali¿ed and trained installer.

Remove all tape and packaging before using the appliance.

Destroy the packaging after install. Never allow children to

play with packaging material.

Ventilation Safety

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

• Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable

codes and standards, including fire-rated

construction.

• Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent back drafting. Follow

the heating equipment manufacturer's guideline and

safety standards such as those published by the

National Fire Protection Association (NFPA), and the

American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local

code authorities.

• USE ONLY METAL DUCTWORK.

• Ducted fans must always be vented to the outdoors.

DO NOT vent exhaust air into spaces within walls,

ceilings, attics, crawl spaces or garages.

• When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

English 2

Advance Planning

Before You Begin

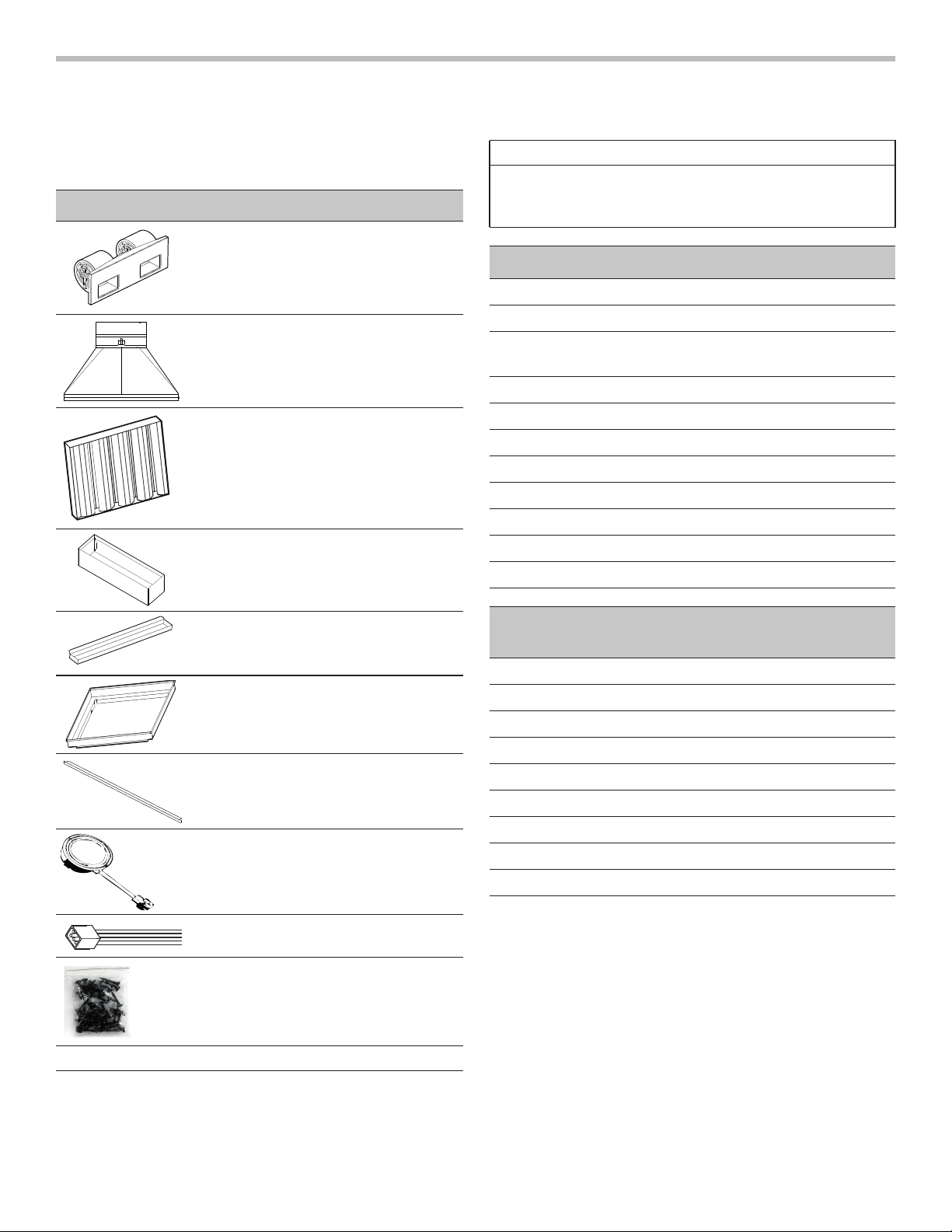

Parts Included

1 – 1000 CFM integral blower

(VCIBxxJP models only)

1 – Metal transition with backdraft

damper

2, 3, or 4 – Stainless steel baffle filters

(depending on model size)

2 – Filter spacers

CAUTION

Before installing, turn power OFF at the service panel.

Lock service panel to prevent power from being turned

ON accidentally.

Tools and Parts Needed

Blower motor (VCINxxJP models only)

Ductwork as necessary (style varies, see Table 3)

Additional sheet metal screws (as necessary for ductwork

installation)

1'' (25.4 mm) Strain relief

Aluminum tape (DO NOT use duct tape)

1/2'' (13 mm) Conduit if required (follow local codes)

Framing material (as necessary for framework)

Circular saw or jigsaw

Tape measure

Phillips head screwdriver

Protective work gloves

Literature packet

2 or 3 – Grease trays (depending on

model size)

1 – Liner (VCIBxxJP models only)

4 – Side trims (VCINxxJP models only)

2 or 4 – Halogen lights, installed

(depending on size)

1 – Remote blower adaptor

1 – Fastener assortment

Optional accessories available for separate purchase.

Refer to www.thermador.com for more details.

LINER236 – 36'' Custom Hood Liner

LINER248 – 48'' Custom Hood Liner

LINER254 – 54'' Custom Hood Liner

TRIM236 – 36'' Custom Hood Trims

TRIM248 – 48'' Custom Hood Trims

TRIM254 – 54'' Custom Hood Trims

VCI2REMKS – Remote Control Panel

EXTNCB25 – 25 ft. Blower Connection Cable

PA36JBS, PA48JBS – Backsplash

English 3

General Information

This manual provides the proper installation instructions for two styles of THERMADOR PROFESSIONAL® custom insert

hoods:

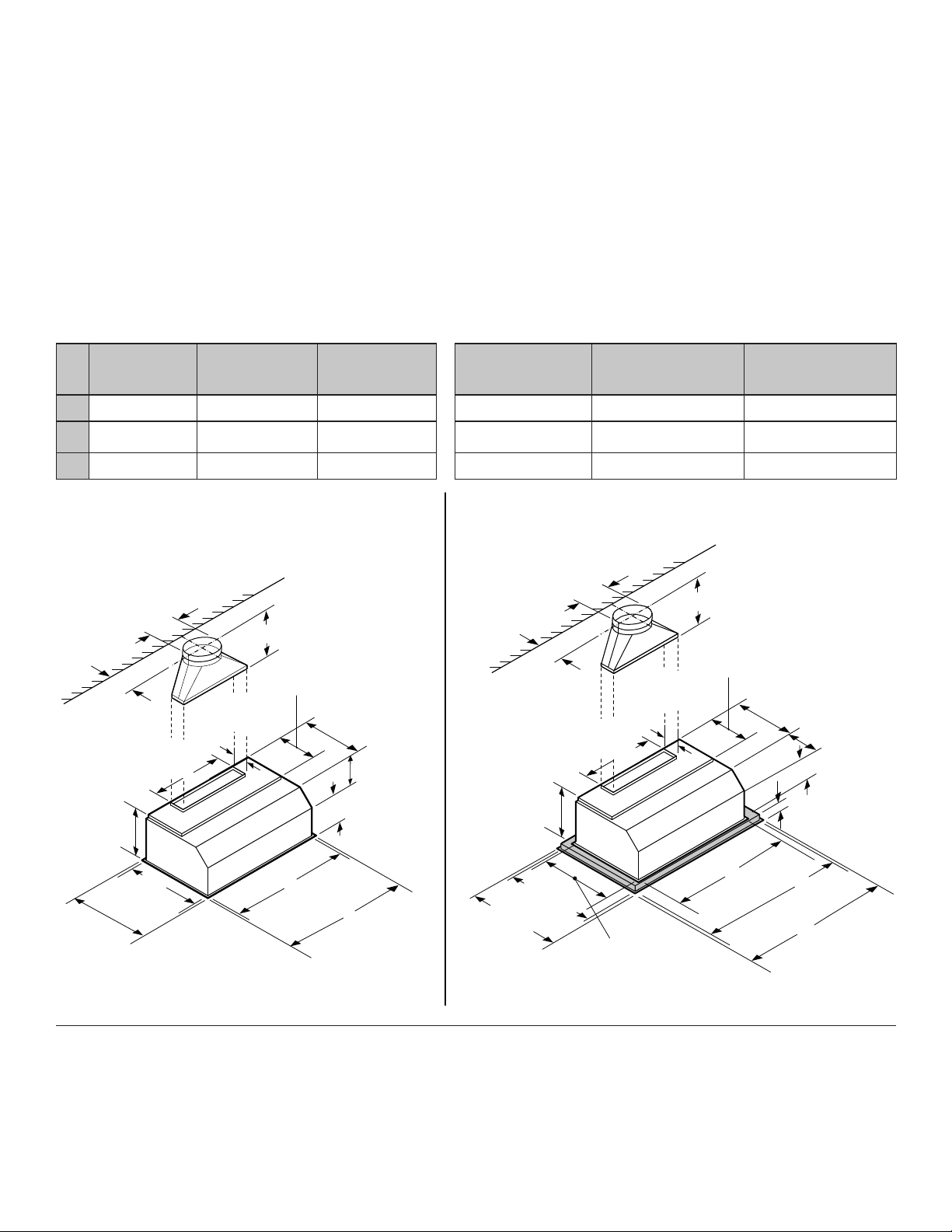

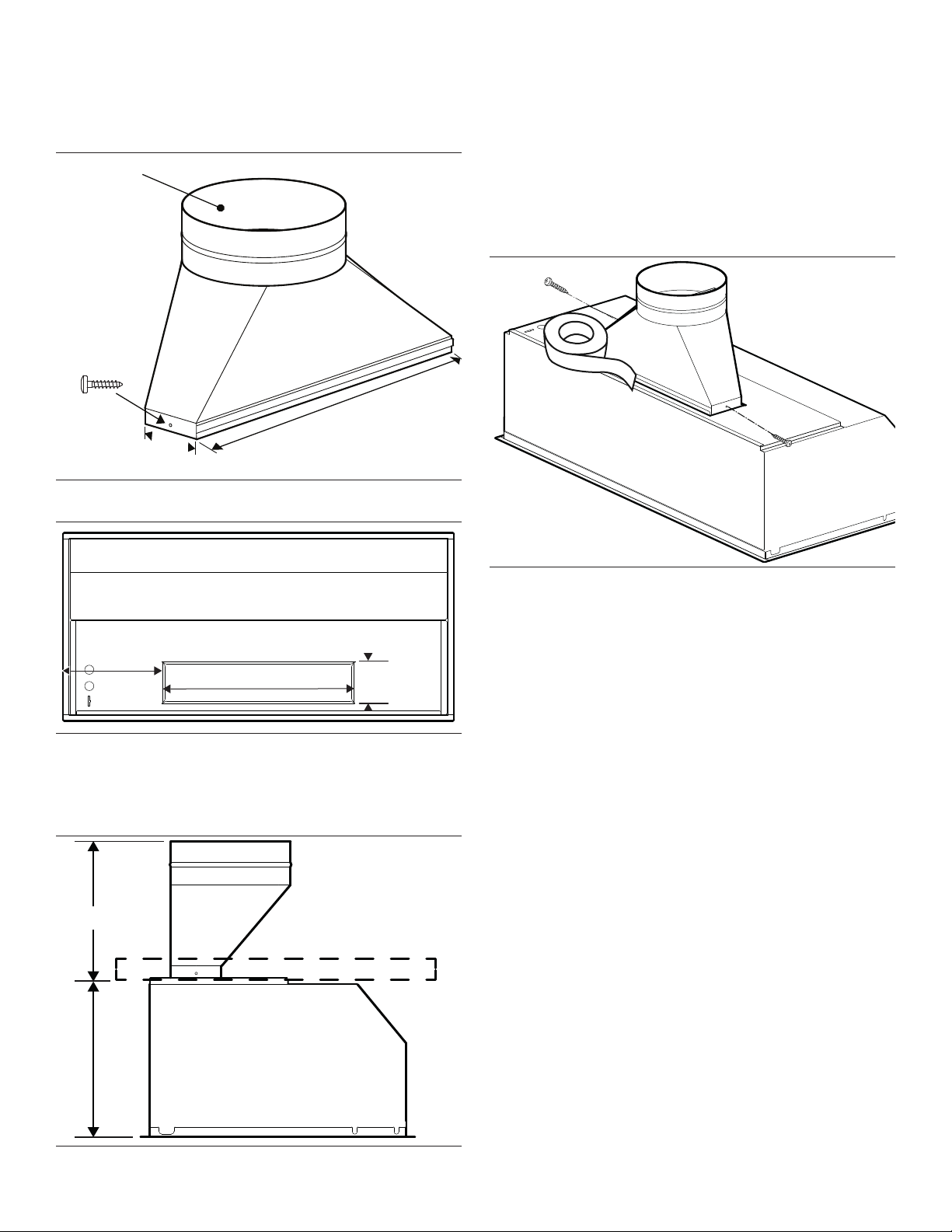

Overall Dimensions

VCINxxJP — This model series features brushed stainless-steel filters, halogen lights, and side trims.

VCIBxxJP — This model series features brushed stainless-steel filters, halogen lights, optional hood liner, and an integral

blower.

NOTE: Installation without option hood liner requires Accessory Custom Insert Hood Trims, TRIM2xx.

36'' (914)

without liner

A 32Ǫ'' (822) 44Ǫ'' (1,127) 50'' (1,280) 32Ǫ'' (822) 44Ǫ'' (1,127) 50Ǫ'' (1,280)

33¾'' (856) 45¾'' (1,162) 51¾'' (1,315)

B

C — — — 40½'' (1,029) 52½'' (1,344) 58½'' (1,486)

Custom Insert – without liner

48'' (1,219)

without liner

54'' (1,372)

without liner

36'' (914)

with liner

393/16'' (995) 513/16'' (1,300) 573/16'' (1,453)

48'' (1,219)

with liner

54'' (1,372)

with liner

Custom Insert – with liner

dia. 10"

dia. 10"

(dia. 254)

13/

5

16

(148)

13/

16

12

"

(325)

"

3/

21

(553)

(dia. 254)

1

10

/4" (260)

1

11

/8"

(283)

5

4

/16"

(110)

"

4

5

16

/8"

(422)

51/8"

13/

16

5

(148)

"

3/

21

(553)

4

"

(130)

5/

14

16

11/

16

7

"

"

(364)

(195)

10

5

/16"

4

(110)

1

/4" (260)

11

(283)

1

/8"

5

16

/8"

(422)

1

"

5

/

8

11/

16

7

1/

2

"

1

(38)

(130)

"

(195)

5/

20

"

8

(524)

22"

(559)

NOTE: Transition is centered.

English 4

A

A

5/

16

23

"

B

24

(629)

3/

4

"

(592)

20

5/

8

"

B

C

(524)

inches (millimeters)

Table 1: Custom Insert Overall Dimensions

Installation Preparation

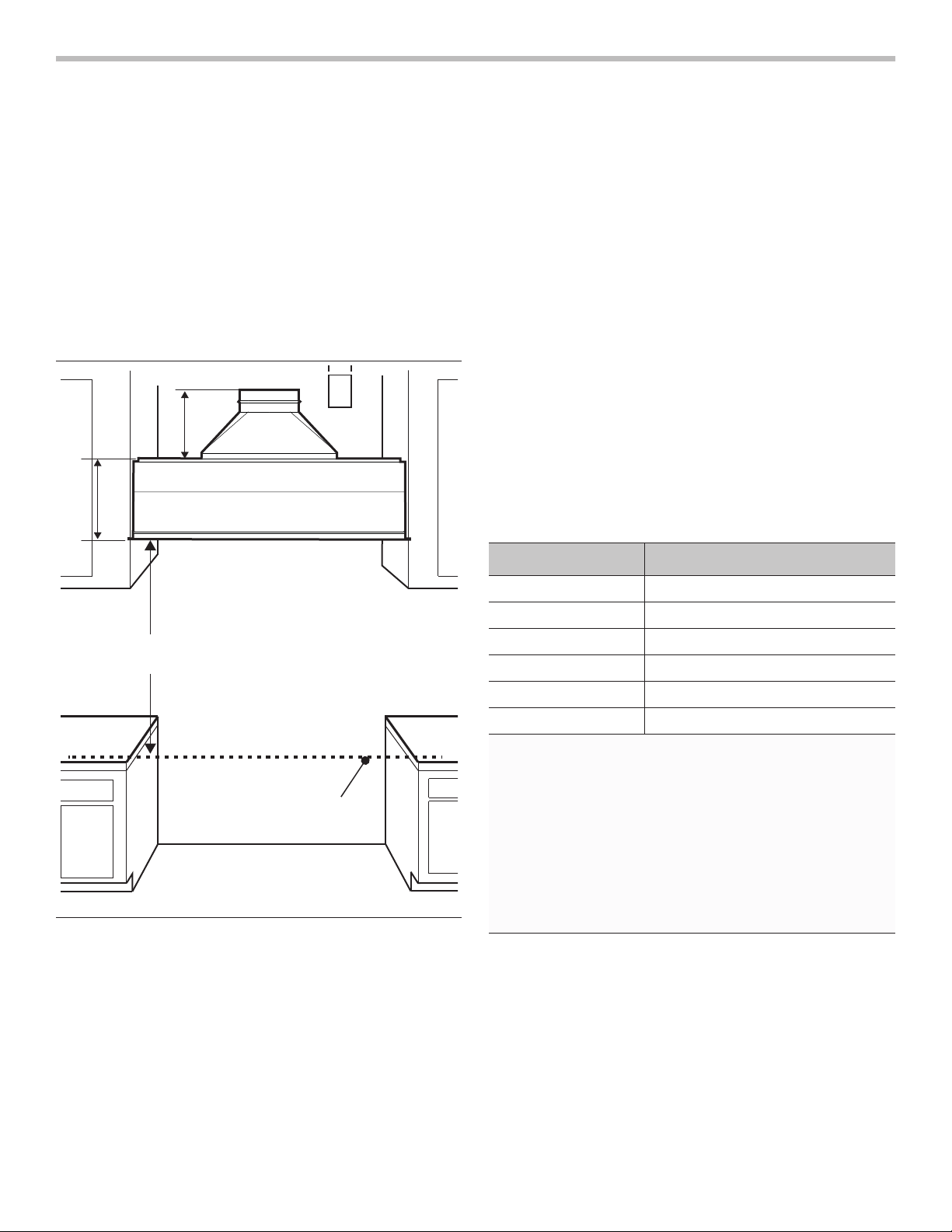

* 30" (762) min.

40" (1,016) max.

to Cooking Surface

18"

(457)

10¼"

(260)

Installation Considerations

The custom insert unit is designed for installation inside a

custom-built hood assembly. It is for ducting to the outside.

It cannot be used in conjunction with a recirculation unit.

Hood installation height above a cooktop, rangetop or

range can vary. To obtain the necessary installation height

above a cooktop, rangetop or range, consult the

appliance's installation manual.

E

10¼"

10¼"

(260)

(260)

18"

18"

(457)

* Hood width should be no less

than the width of the cooking

surface.

* 30" (762) min.

* 30" (762) min.

40" (1,016) max.

40" (1,016) max.

to Cooking Surface

to Cooking Surface

Hood Width

The hood width should be no less than the width of the

cooking surface. For proper performance, the housing must

cover the entire cooking surface.

Where space is not restricted, a wider hood can be used to

increase capture area.

Distance From Cooking Surface

The installation height ranges from a minimum height of

30'' (762 mm) to a maximum height of 40'' (1,016 mm);

however, it is necessary to follow the cooking appliance

manufacturer’s installation instructions for proper hood

height.

Unit Weight

When calculating the load for the housing support system,

be sure to consider the weight of the ventilation unit.

Model Weight

VCIN36JP 60 lb (27.22 kg)

VCIN48JP 73 lb (33.11 kg)

VCIN54JP 82 lb (37.20 kg)

VCIB36JP 96 lb (43.54 kg)

VCIB48JP 111 lb (50.35 kg)

Cooking

Surface

* Follow cooking appliance

manufacturer’s recommendations

meters)

Figure 1: Typical Hood Installation

NOTICE:

The hood could incur some damage from heat if a

THERMADOR PROFESSIONAL

is operated with multiple burners at high settings under a

hood that is installed at minimum clearances.

®

series range or rangetop

VCIB54JP 122 lb (55.34 kg)

IMPORTANT:

The supplied weights address only the ventilation unit and

blower. Installer must account for weight of any materials

of construction when calculating the total dead weight

load of installation, including but not limited to: wall, tile,

mortar, plaster, brick, finishes, partitions, and other

similarly incorporated architectural and structural items. It

is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

Table 2: Unit Weight with Blowers

English 5

Blower Motors

VCIN models are shipped without the blower motor.

Internal, in-line and remote blowers are available through

your authorized THERMADOR

information, visit the Find a Dealer section of our website at

www.thermador.com.

®

dealer. For local dealer

MAKE-UP AIR: Local building codes may require the use

of make-up air systems when using ducted ventilation

systems greater than specified CFM of air movement. The

specified CFM varies from locale to locale. It is the

responsibility of the owner and the installer to determine if

additional requirements and/or standards apply to specific

installations.

The blower will vary in size and is dictated by the cooking

surface, the volume of air that needs to be moved and the

length of the duct run. Refer to “Blower Motor Installation”

on page 10 for detailed blower motor information.

Backsplash

Optional stainless steel backsplashes are available for

purchase in widths to match all custom insert hoods

through your authorized THERMADOR

dealer information, visit the Find a Dealer section of our

website at www.thermador.com.

®

dealer. For local

Ductwork Preparation

Discharge Direction

The exhaust air is discharged upwards through a duct.

Ducting Recommendations

Proper performance is dependent upon proper ducting.

Local building codes may require the use of make-up air

systems when using ducted ventilation systems greater

than speci¿ed cubic feet per minute (CFM) of air

movement. The speci¿ed CFM varies from locale to locale.

It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

For safety reasons, ducting should vent directly outdoors

(not into an attic, underneath the house, into the garage or

into any enclosed space). The unit cannot be used in

conjunction with a recirculation unit.

®

THERMADOR

(15.24 m) of duct.

Keep duct runs as short and straight as possible. Elbows

and transitions fittings reduce air flow efficiency. Back to

back elbows and “S” turns give very poor delivery and are

not recommended.

A short, straight length of duct at the inlet of a remote

blower gives the best delivery.

Hoods are supplied with a 10" (254 mm) round transition. A

locally supplied transition is required for other sizes.

Use Table 3 on page 7 to compute permissible lengths for

duct runs to outdoors.

recommends not exceeding 50 ft

DO NOT USE FLEXIBLE DUCT; it creates back pressure/

air turbulence and reduces performance.

Always install a metal vent cover where the ductwork exits

the house.

COLD WEATHER installations should have an additional

backdraft damper installed to minimize backward cold air

flow and a nonmetallic thermal break to minimize

conduction of outside temperatures as part of the ductwork.

The damper should be on the cold air side of the thermal

break. The break should be as close as possible to where

the ducting enters the heated portion of the house.

English 6

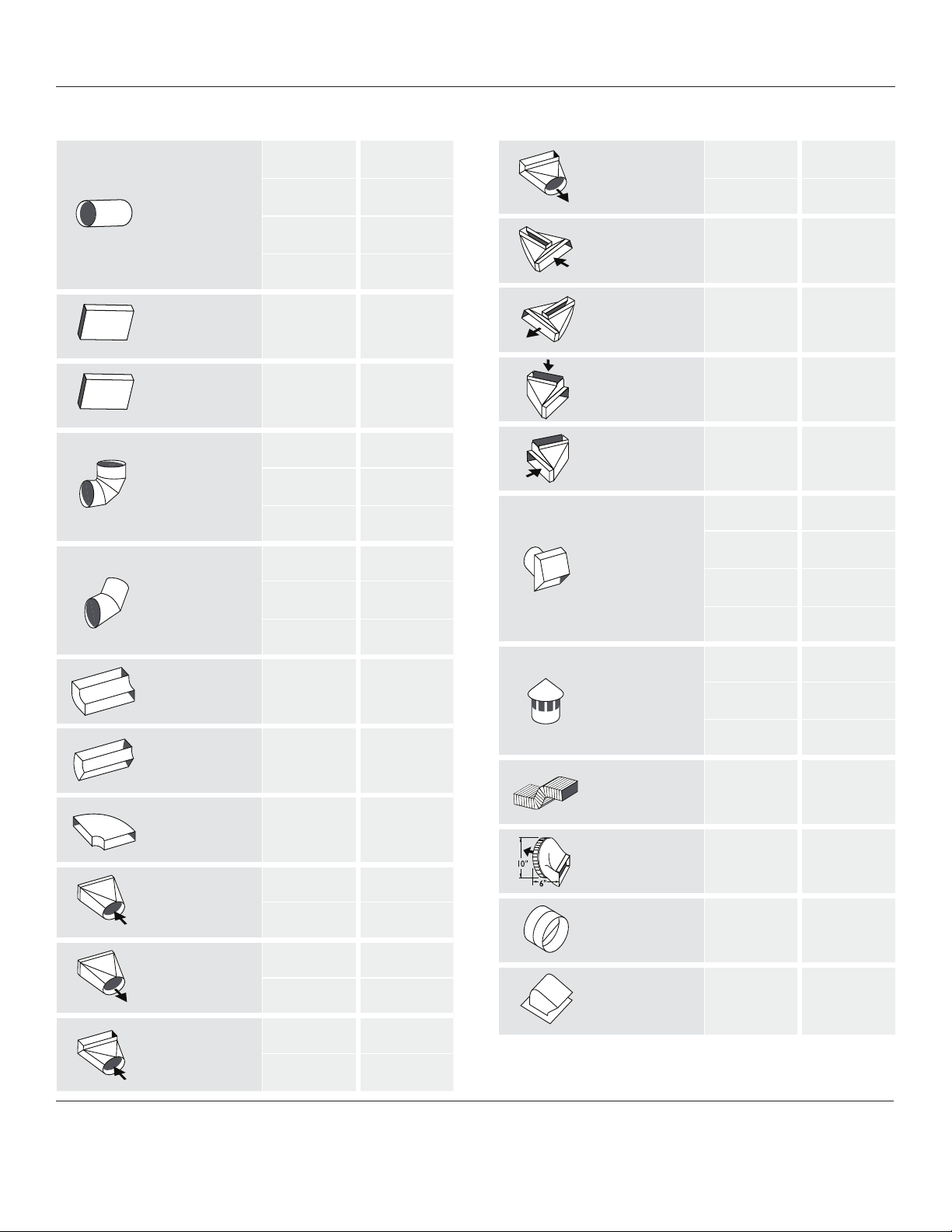

Equivalent Duct Lengths for Commonly Used Transitions

Duct Piece

Smooth

Straight

3¼" x 10"

Straight

3¼" x 14"

Straight

90° Elbow

Round

45° Elbow

Round

Size of Duct

Piece (in)

6 1.2

7 0.95

8 0.7

10 0.6

N/A 1

N/A 0.7

612

78

86

65

74

83

Equivalent

Length (ft)

Duct Piece

3¼" x 10"

to Round

90° Elbow

3¼" x 10"

Center Reverse

Elbow Left

3¼" x 10"

Center Reverse

Elbow Right

3¼" x 10" Left

Reverse Elbow

3¼" x 10"

Right Reverse

Elbow

Round

Wall Cap

Size of Duct

Piece (in)

610

75

N/A 15

N/A 25

N/A 15

N/A 25

62

72

82

10 2

Equivalent

Length (ft)

3¼" x 10"

90° Elbow

Round

3¼” x 10"

45° Elbow

Round

3¼" x 10"

Flat Elbow

Round to

3¼" x 10"

3¼" x 10"

to Round

Round to

3¼" x 10"

90° Elbow

N/A 5

N/A 15

N/A 20

61

71

65

73

610

78

62

Round

Roof Cap

2' Long

3¼" x 10"

Flex

3¼" x 10"

to Round

7" Inline

Backdraft

Damper

3¼" x 10"

Roof Jack

and Shutter

NOTE: These commonly used installation parts can be purchased

at a local hardware store. THERMADOR® does not manufacture all

these parts.

72

82

N/A 20

10 1

7

N/A

Table 3: Duct Lengths

English 7

Hood Transition

21¾" (

553 mm)

4

5/

"

(502 mm)

21¾ʺ

(552 mm)

17½ʺ

(444 mm)

10¼ʺ

(260 mm)

12

/

ʺ

(325 mm)

Assembly of the Transition

10" (254 mm)

Duct

1" (25.4 mm)

x 2

21¾" (553 mm)

21¾" (553 mm)

5

4

/ "

16

(110 mm)

Figure 2: Transition Dimensions

2. Remove transition from inside of hood. Discard

brackets attaching transition to the inside of hood.

3. Align mounting holes at base of transition with the

mounting holes of the 1/2'' (13 mm) flange located at

the top or rear of the hood (Figure 5).

4. Fasten transition to hood using two (2) 1'' (25.4 mm)

sheet metal screws included with hood (Figure 5).

5. Seal connection between transition and hood with

aluminum tape. DO NOT use duct tape (Figure 5).

1. A minimum height clearance of 10¼'' (260 mm) is

17½ʺ

17½ʺ

(444 mm)

(444 mm)

Figure 3: Hood Transition Dimensions

21¾ʺ

21¾ʺ

(552 mm)

(552 mm)

needed above the hood for transition mounting.

10¼ʺ

10¼ʺ

(260 mm)

(260 mm)

5/

"

4

161616

(502 mm)

(502 mm)

Figure 5: Transition Connection

6. Remove tape holding damper closed.

English 8

131313

ʺ

12

12

/

161616

(325 mm)

(325 mm)

Figure 4: Transition Height

Electrical Requirements

Choosing the Correct

The unit requires a 120V AC, 60Hz. 15A branch circuit.

The hood should only be connected to a grounded socket

that has been installed according to relevant regulations. If

possible, place the grounded socket directly behind the

chimney paneling. Attach the grounded socket as close to

the appliance as possible and in an accessible location.

• The grounded socket should be connected to its own

circuit.

• If the grounded socket is no longer accessible following

installation of the hood, make sure that an electrical

switch is permanently installed for turning off the

appliance.

When connected to a GFCI-protected supply,

THERMADOR PROFESSIONAL

suitable for use in damp locations that are protected from

outside weather conditions and not subject to saturation

with water and other liquids, but can be subject to

moderate degrees of moisture (such as an outdoor covered

patio or lanai area). Refer to local codes, NEC/CEC, and or

the Authority Having Jurisdiction (AHJ) for additional

information.

®

custom insert hoods are

Blower

A variety of interior and exterior blower options (Remote,

Inline or Integral) are available for THERMADOR

PROFESSIONAL® Custom Insert series hoods. If the unit

you have selected does not have a blower included, one

must be purchased separately.

It is recommended to use only THERMADOR blowers with

THERMADOR ventilation hoods. See the Ventilation

Planning Guide for recommended blowers. Contact

Customer Service for additional options (see the back page

for contact information).

Blower selection will vary based on the volume of air that

needs to be moved and the length and location of the duct

run. For long duct runs with multiple turns and bends,

consider using a more powerful blower. For the most

efficient air-Àow exhaust, use a straight run or as few

elbows as possible (refer to “Ductwork Preparation” on

page 6).

Integral Blowers

Check your local building codes for proper method of

installation. In the U.S., if there are no applicable local

codes, this unit should be installed in accordance with the

National Electric Code ANSI/NFPA No. 70, Current Issue.

In Canada, installation must be in accordance with the CAN

1- B149.1 and .2 - Installation Codes for Gas Burning

Appliances and/or local codes.

The appliance must be grounded. In the event of an

electrical short circuit, grounding reduces the risk of electric

shock by providing a wire that allows the electric current to

escape. This appliance has a cord with a ground wire and

grounded plug. The plug must be plugged into an outlet

that is properly installed and grounded.

WARNING

The appliance must be grounded.

Electrical Data

Data, including the model and serial number, is located on

the product data rating plate inside the appliance, visible

after removal of the filter frame (see Figure 39 on page 23).

These blowers are integrated into the hood at the time of

installation (included with the VCIB model units).

Remote Blowers

Depending on preference and ducting situation, these

blowers can be mounted on the roof or exterior wall of the

home. An exterior installation may be more appealing to

reduce noise in the kitchen.

Inline Blowers

To minimize noise in the kitchen, these blowers are

mounted along the duct line anywhere between the kitchen

and the exterior wall. If there is easy access to duct line (in

an attic, for example), this may be an appealing option.

English 9

Installation Instructions

Blower Motor Installation

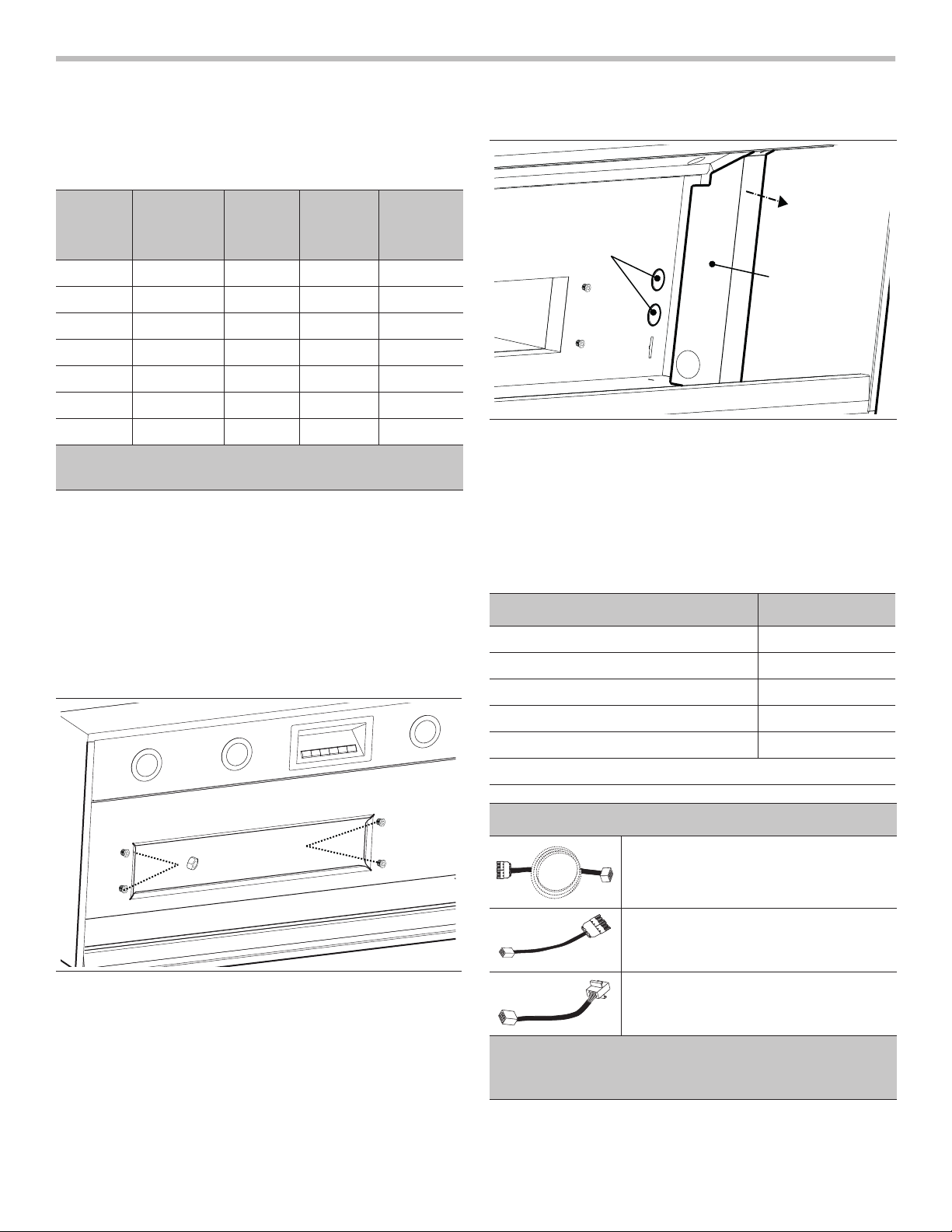

Blower SKU

Integral VTN630* 120 2.7 15

Integral VTN1030* 120 5.4 15

Remote VTR630* 120 4.2 15

Remote VTR1030* 120 5.7 15

Remote VTR1330* 120 8.5 15

Inline VTI610* 120 4.2 15

Inline VTI1010* 120 5.7 15

* Indicates a letter designating the release year.

** With blower installed.

Voltage

(Ac)

Blower

Current

(Amps)

**Circuit

Breaker

(Amps)

Integral blower installation only

1. The blower is attached to the hood using weld studs on

the mounting plate. Figure 6 exhibits the weld stud

locations.

2. Guide the motor mounting plate over the studs.

3. Attach four (4) nuts (included with hood) to the weld

studs. Tighten nuts to secure the blower to the hood.

Knockouts

Junction Box

Figure 7: Junction Box Location

25 ft. Blower Cable Connection Accessory

(optional)

Kit

The blower extension cable is compatible with the

following Inline & Remote blowers:

Blower SKU

Remote Blower VTR630*

Remote Blower VTR1030*

Remote Blower VTR1330*

Weld Studs

x 4

Figure 6: Weld Stud Location

Inline Blower VTI610*

Inline Blower VTI1010*

*Indicates a letter designating the release year.

EXTNCB25 Parts Included

1 – 25 ft. cable

1 – Adapter Cable No. 1

(NOT NEEDED FOR VCIN OR

VCIB MODEL CONNECTIONS)

1 – Adapter Cable No. 2

(NOT NEEDED FOR VCIN OR

VCIB MODEL CONNECTIONS)

IMPORTANT: CUTTING OFF A CONNECTOR TO THE

APPLIANCE OR TO THE EXTENSION CABLE KIT

WILL VOID THE WARRANTY.

English 10

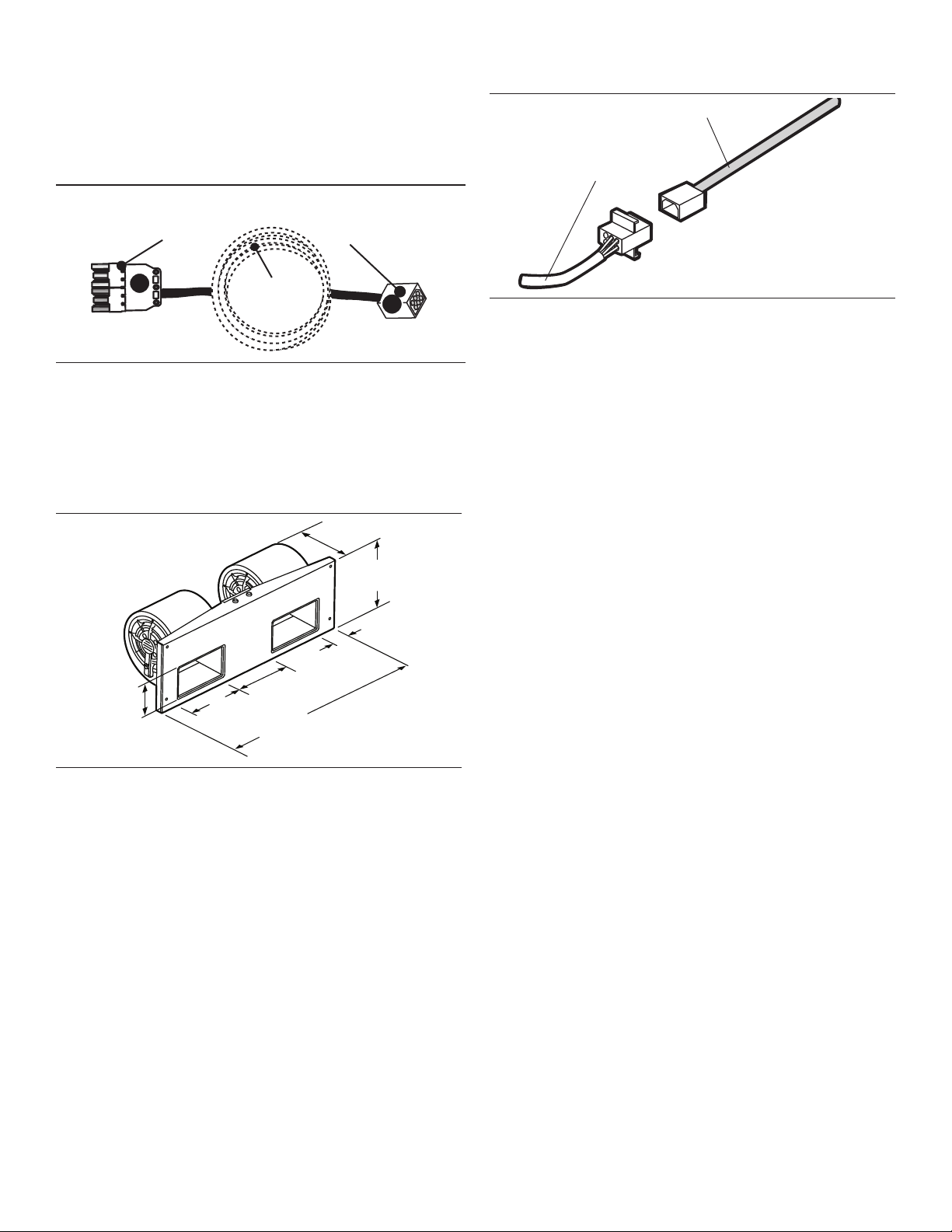

Blower Extension Cable Connection

Figure 10.

The internal blower harness should be routed through the

knockout and secured with a 1'' (25.4 mm) strain relief. The

remote harness can then be connected to the blower

harness outside the unit.

Connects to

Remote or

Inline blower

A

25ft cable

Connects to

VCIxxJP hood

B

Figure 8: 25ft Cable

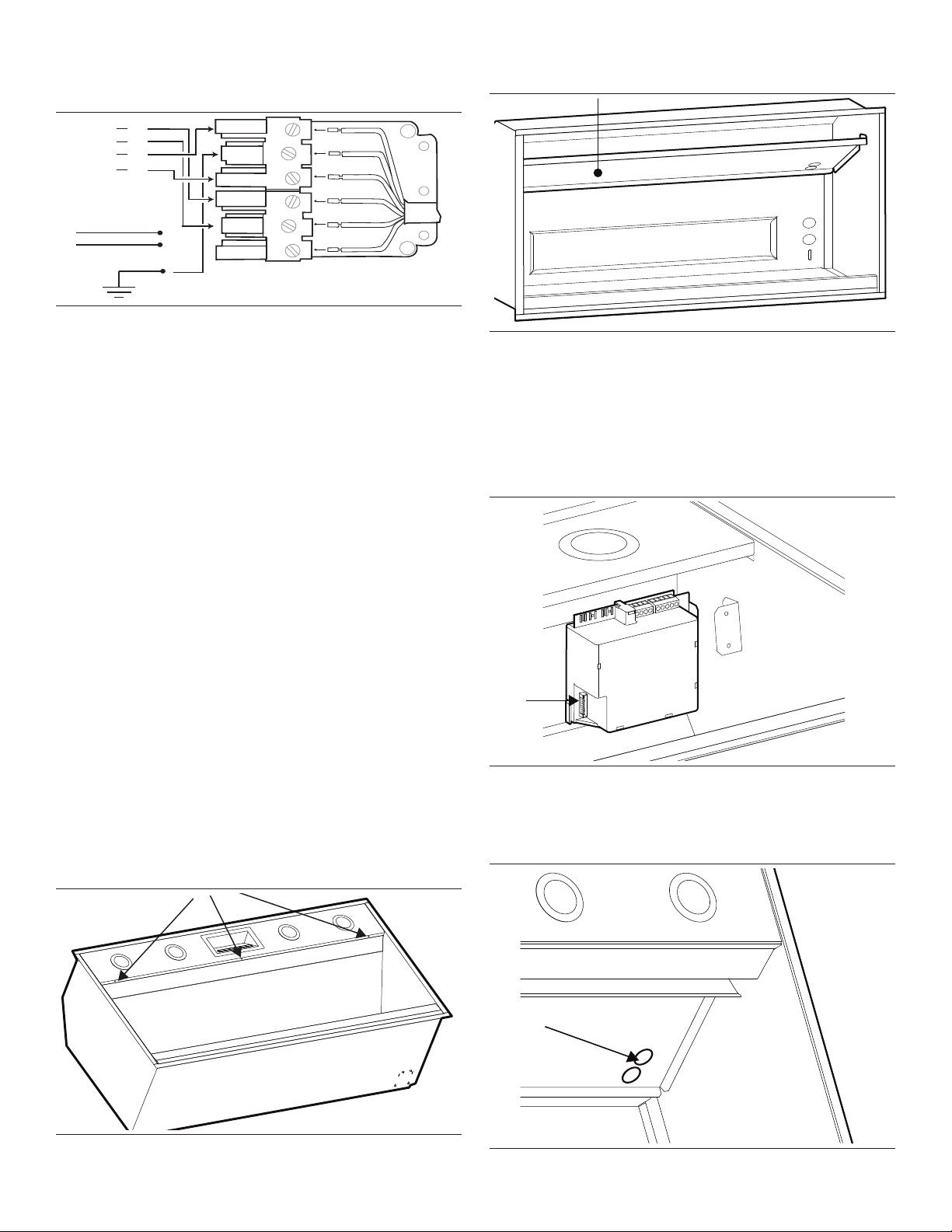

Wiring the Hood with an

Integral Blower

1/

4

8

" (210)

7/

8

"

8

(225)

From Blower

From Control Panel

Figure 10: Wiring the Hood with an Integral Blower

4. Install 1'' (25.4 mm) conduit connector in junction box.

5. Run black, white, and green wires (#12 AWG) in 1''

(25.4 mm) conduit from the power supply to the

junction box.

6. Connect the power supply wires to the hood wires in

the following order: black to black, white to white, and

green wire to green ground screw on chassis. Use

spring type wire nuts.

• Spring type wire nuts rated for a minimum of two

(2) #18 gauge wires and maximum of four (4) #14

gauge wires, UL & CSA rated to 600V and 302°F

(150°C.)

7. Close the junction box cover.

1/

4

2

"

3/

6

(171)

7/

8

6

1/

4

8

"

(105)

Figure 9: Integral Blower Model VTN1030

Integral Blower models VTN630 and VTN1030 are

integrated into the hood at the time of installation (VCIN

models). For complete installation instructions see the

instructions supplied with the blower unit.

1. Remove junction box channel covering the wires (see

Figure 7 on page 10).

2. Remove circular knockouts (Figure 7 on page 10).

3. Connect the blower’s Molex plug connector to the

connector present inside the hood, as shown in

(175)

"

25"

(635)

(57)

4

"

English 11

Wiring the Hood with a

Brown

Green/Yellow

White

Red

Blue

Orange

Remote Blower

5/

13

"

8

(346)

1/

2

"

8

7/

12

(327)

7/

1

(48)

8

"

8

1/

6

(165)

"

2

1/

2

(54)

"

(54)

"

8

12

(308)

dia. 9

(251)

10"

(254)

1/

8

7/

19

(505)

"

"

8

3/

20

(527)

7/

"

8

7. Close the junction box cover.

8. Run five (5) #14 AWG wires in 1'' (25.4 mm) conduit

from the remote blower to the second conduit

connector.

9. Connect the remote blower to the pigtail wires as

shown in Figure 12. Connect the remote blower green

(ground) wire to the ground screw in the junction box.

Refer to the blower installation instructions for further

wiring details.

4

"

Wiring the Hood with an

Inline Blower

12

12

(308)

1/

8

"

(305)

"

7/

8

" (22)

Figure 11: VTR1330 Remote Blower

Custom insert models can be installed with remote blowers

(VCIN models). For complete installation instructions see

the instructions supplied with the blower unit.

1. Remove junction box channel covering the wires (see

Figure 7 on page 10).

2. Remove circular knockouts (Figure 7 on page 10).

3. Install 1'' (25.4 mm) conduit connectors.

4. Run black, white, and green wires (#12 AWG) in 1''

(25.4 mm) conduit from the power supply to the

junction box.

5. Connect the power supply wires to the hood wires in

the following order: black to black, white to white, and

green wire to green ground screw on chassis. Use

spring type wire nuts.

• Spring type wire nuts, rated for a minimum of two

(2) #18 gauge wires and maximum of four (4) #14

gauge wires, UL & CSA rated to 600V and 302°F

(150°C).

6. Connect the “pigtail” to the connector inside the

junction box.

SPEED 1

SPEED 2

SPEED 3

NEUTRAL

WH / BC / BL (16 AWG)

BK / N / NE (16 AWG)

RD

BU

BN

WH

SP4

GROUND

N

SP1

SP2

SP3

L1NT1T2S3

Brown

Brown

Green/Yellow

Green/Yellow

White

White

Red

Red

Blue

Blue

Orange

Orange

14

19

(486)

3/

8

1/

1

(44)

"

8

"

3/

"

4

ø9

(251)

7/

"

8

7/

12

"

8

(327)

(365)

Figure 13: VTI1010 Inline Blower

Both VCIN and VCIB custom insert models can be installed

with inline blowers. For complete installation instructions

see the instructions supplied with the blower unit.

1. Remove junction box channel covering the wires (see

Figure 7 on page 10).

2. Remove circular knockouts (Figure 7 on page 10).

3. Install 1'' (25.4 mm) conduit connectors.

4. Run black, white, and green wires (#12 AWG) in 1''

(25.4 mm) conduit from power supply to junction box.

5. Connect the power supply wires to the hood wires in

the following order: black to black, white to white, and

green wire to green ground screw on chassis. Use

spring type wire nuts.

• Spring type wire nuts, rated for a minimum of two

(2) #18 gauge wires and maximum of four (4) #14

gauge wires, UL & CSA rated to 600V and 302°F

(150°C).

English 12

120V, 60HZ, 20A

POWER SUPPLY

Figure 12: Wiring the Hood with a Remote Blower

6. Connect the “pigtail” to the connector inside the

Brown

Green/Yellow

White

Red

Blue

Orange

junction box.

d) Remove core partition (Figure 16).

SPEED 1

SPEED 2

SPEED 3

NEUTRAL

WH / BC / BL (16 AWG)

BK / N / NE (16 AWG)

RD

BU

BN

WH

120V, 60HZ, 20A

POWER SUPPLY

SP4

GROUND

N

SP1

SP2

SP3

L1NT1T2S3

Brown

Brown

Green/Yellow

Green/Yellow

White

White

Red

Red

Blue

Blue

Orange

Orange

Figure 14: Wiring the Hood with an Inline Blower

7. Close the junction box cover.

8. Run five (5) wires (#14 AWG) in 1'' (25.4 mm) conduit

from the inline blower to the second conduit connector.

9. Connect the inline blower to the pigtail wires as per

Figure 14. Connect the inline blower green (ground)

wire to the ground screw in the junction box.

Remote Control Installation

(optional)

Figure 16: Remove core partition

2. Connecting the harness to the relay board.

a) Unplug harness from the remote control to the

relay board (Figure 17).

b) Plug in harness included in the remote kit

(Figure 17).

NOTE: When using the Custom Insert with the optional

remote control, the unit loses the “AUTO” function and

the over-temperature heat sensor described in the Use

& Care Guide.

It is recommended that the Remote Control be wired to the

hood after the hood is installed.

1. Access wiring

a) Remove filters, spacers and grease trays.

b) Remove the junction box cover (refer to Figure 7

on page 10).

c) Remove three screws holding stainless steel panel

to the canopy.

Figure 17: Relay Board Hookup

c) Run harness through core partition hole

(Figure 18).

Figure 15: Remove stainless steel panel

Figure 18: Wire Routing through Partition

English 13

d) Reinstall core partition after running the harness

Remote

Harness

Harness

Mounting

Hole

1½ʺ

(40 mm)

(17 mm)

5

/

8

ʺ

1½ʺ

(40 mm)

(23 mm)

/

ʺ

1

(35 mm)

3

/

8

ʺ

1

(35 mm)

3

/

8

ʺ

(10 mm)

3

/

8

ʺ

(5 mm)

3

/

ʺ

through the access hole.

e) Insert remote harness end into the mounting hole,

as indicated in Figure 19, until it clicks.

Harness

Harness

Remote

Remote

Harness

Harness

Mounting

Mounting

Hole

Hole

f) Connect the extension harness to the connector

inside the junction box.

Figure 20: Pigtail Remote Connection

Figure 19: Remote Harness Mounting Hole

(298 mm)

11

ʺ

(17 mm)

/

16

3

ʺ

/

(5 mm)

(5 mm)

161616

1½ʺ

1½ʺ

(40 mm)

(40 mm)

151515

ʺ

/

161616

(23 mm)

(23 mm)

1

1

(35 mm)

(35 mm)

2¾ʺ

(69 mm)

3

ʺ

(10 mm)

(10 mm)

/

8

3

ʺ

/

8

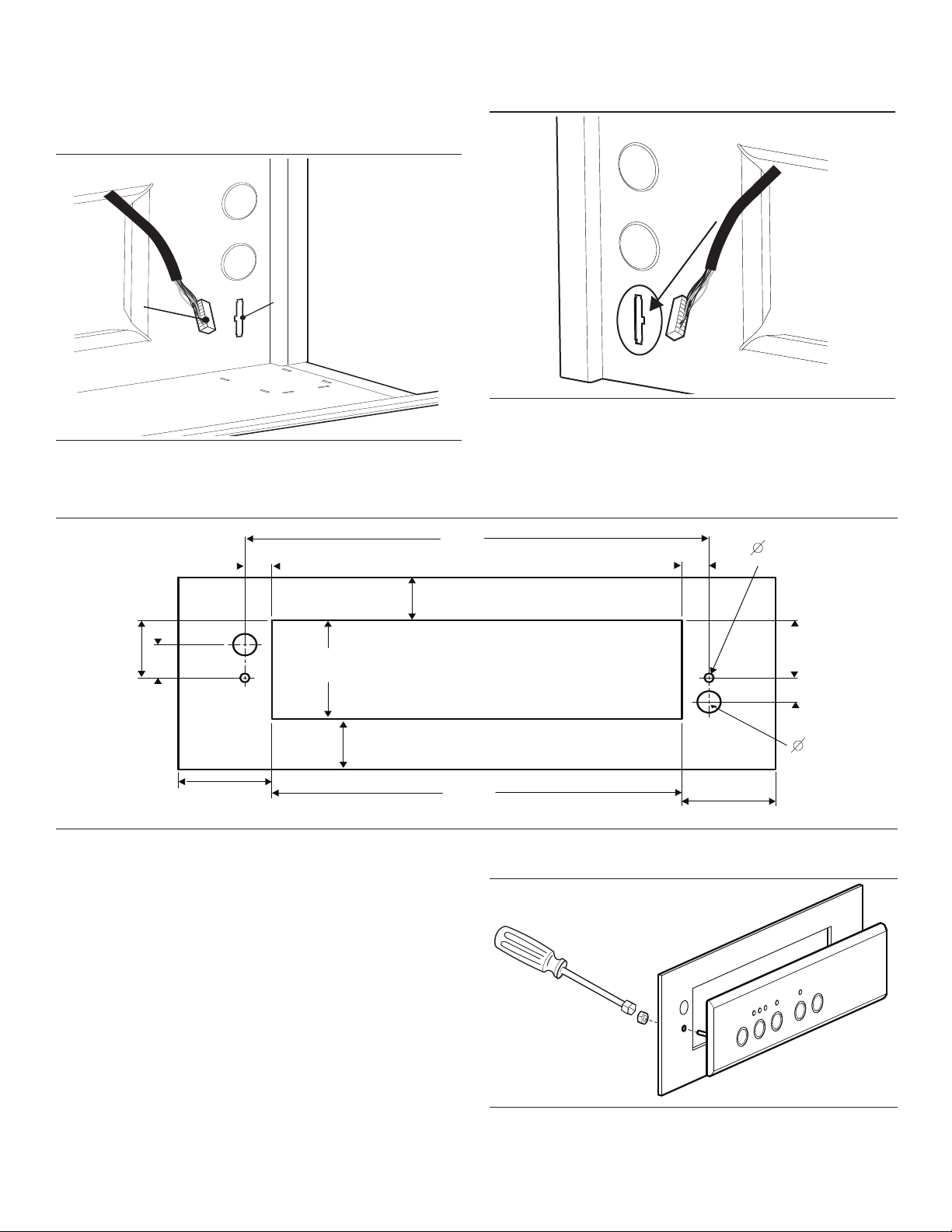

4. Connect the remote control to extension harness with

the included 30 ft (914.4 cm) cable.

5. Insert remote control into cutout. Secure from behind

with two (2) nuts onto the weld studs (Figure 22).

6. Reinstall hood components from Figure 15 and

Figure 16.

3. Prepare wall (or similar surface) cutout for installation

as shown below in Figure 21.

11¾ʺ

3

ʺ

10

/

8

(263 mm)

11

ʺ

/

(17 mm)

16

3

/

1

1

8

(35 mm)

(35 mm)

Figure 21: Wall Cutout (view is shown facing wall)

ʺ

¼ʺ

(6 mm)

1½ʺ

1½ʺ

(40 mm)

(40 mm)

5

ʺ

/

(17 mm)

(17 mm)

8

9

ʺ

/

16

(15 mm)

English 14

Figure 22: Remote Install

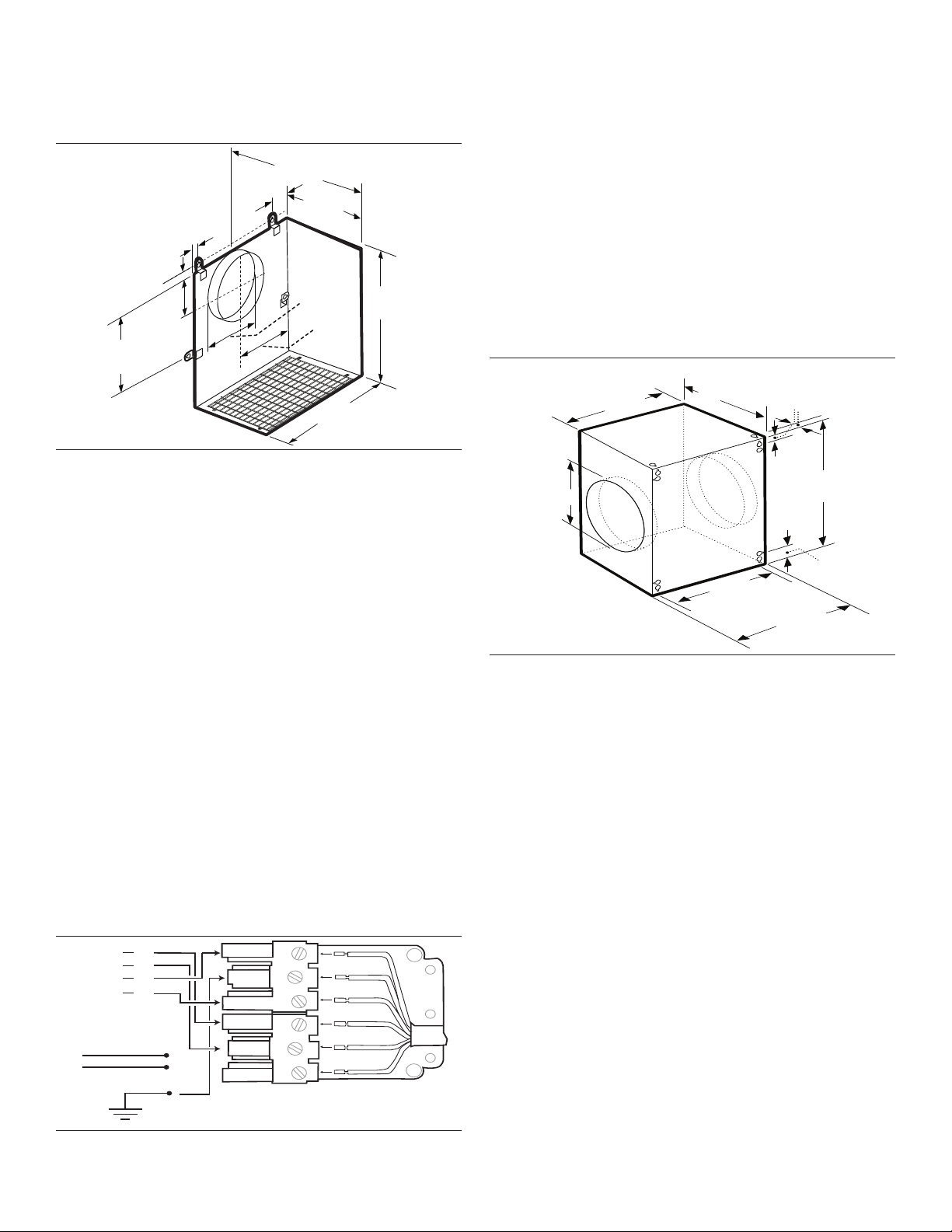

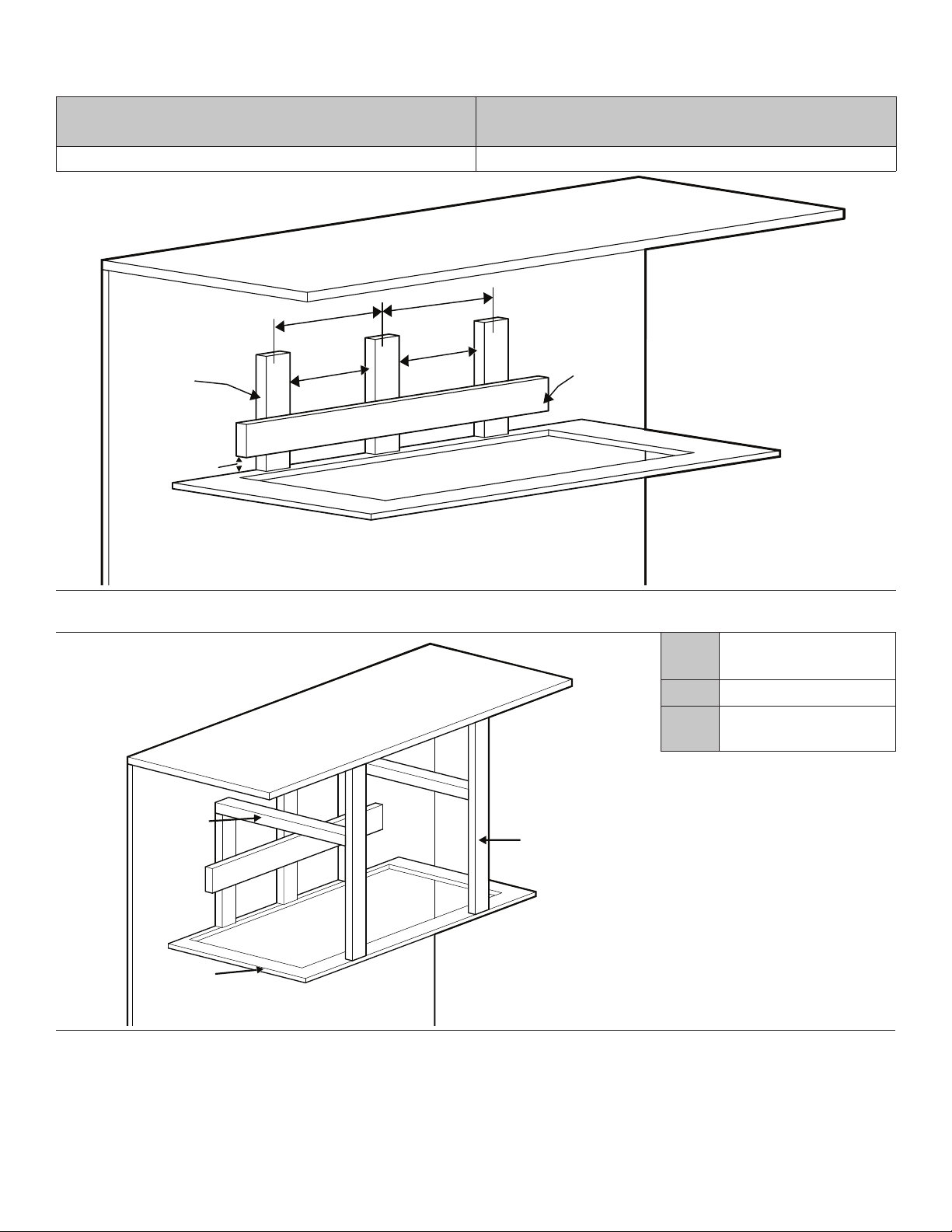

Preparing the Ceiling Cutout and Housing

2

3/

8

"

(86)

Back of Trim or Liner

C

L

B

10¼"

(260)

3

"

(81 )

7

7/

8

"

(200)

Dia. clearance holes for 1

"

(25.4) conduit to junction box

23" (584)

A

1

7/

"

(48)

8

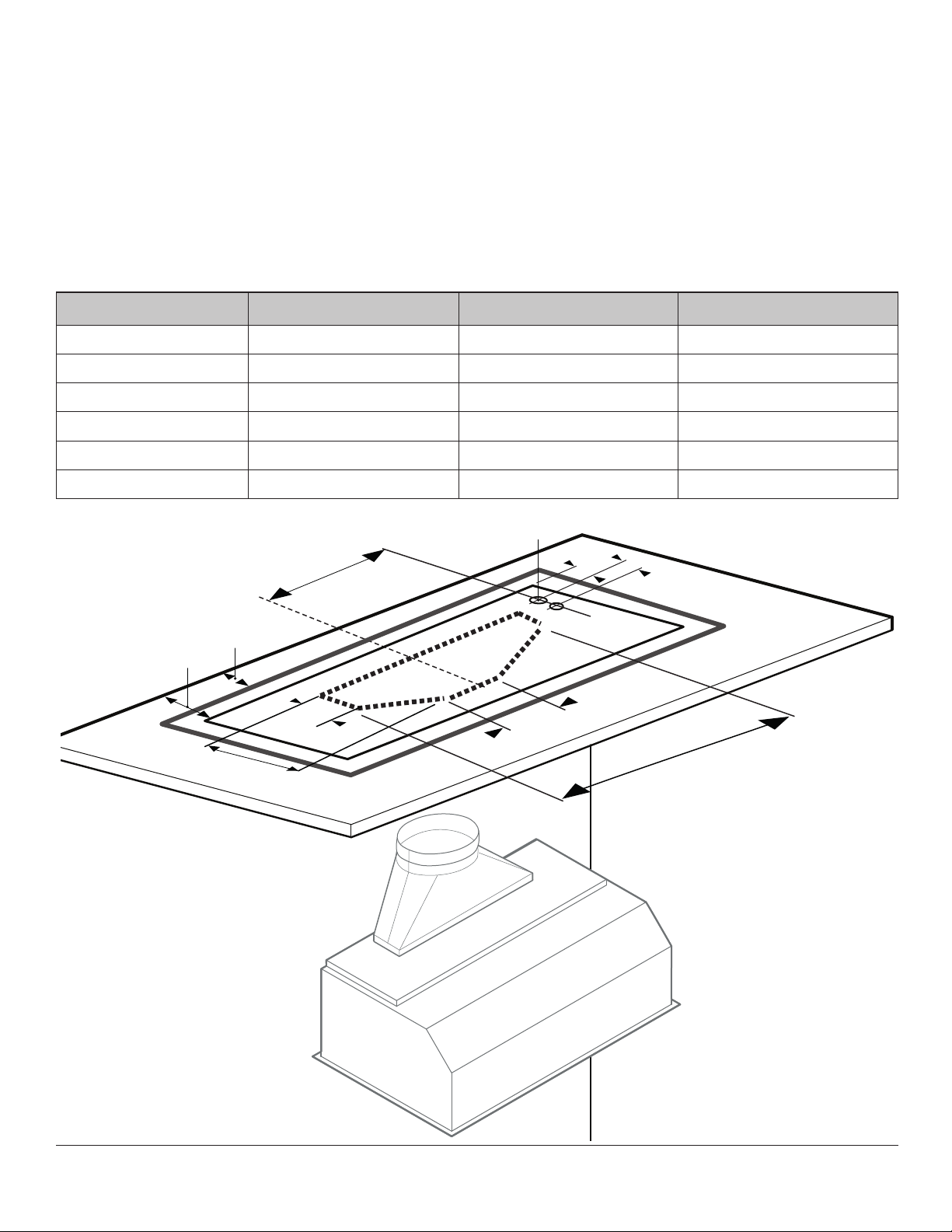

The unit must be mounted to the surrounding housing. See “Installation Preparation” on page 5 for suggestions on

determining hood height.

When calculating the load for the housing support system, be sure to include the weight of the ventilation unit. See Table 2

on page 5 for unit weight by model.

Build housing in accordance with the dimensions noted in Figure 26 thru Figure 28.

Transition and Conduit Cutout Dimensions

Model A B C

36'' without Liner 14

48'' without Liner 19

54'' without Liner 22

36'' with LINER236 14

48'' with LINER248 19

54'' with LINER254 22

3

/

'' (360 mm) 1ǩ'' (29 mm) 1Ǭ'' (47 mm)

16

13

/

'' (503 mm) 1ǩ'' (29 mm) 1Ǭ'' (47 mm)

16

13

/

'' (579 mm) 1ǩ'' (29 mm) 1Ǭ'' (47 mm)

16

3

/

'' (360 mm) 3

16

13

/

'' (503 mm) 3

16

13

/

'' (579 mm) 3

16

3

/

'' (81 mm) 1ǩ'' (29 mm)

16

3

/

'' (81 mm) 1ǩ'' (29 mm)

16

3

/

'' (81 mm) 1ǩ'' (29 mm)

16

Back of Trim or Liner

Back of Trim or Liner

C

Back of Hood

B

10¼"

10¼"

(260)

(260)

7/

7

A

" (200)

(200)

8

C

C

Dia. clearance holes for 1

Dia. clearance holes for 1

(25.4) conduit to junction box

(25.4) conduit to junction box

L

L

3/3/3/

3

161616

(81 )

(81 )

"

"

3/

3/

"

"

2

2

8

8

7/

"

(48)

(48)

1

8

(86)

(86)

"

23" (584)

23" (584)

Figure 23: Transition and Conduit Cutout Dimensions

English 15

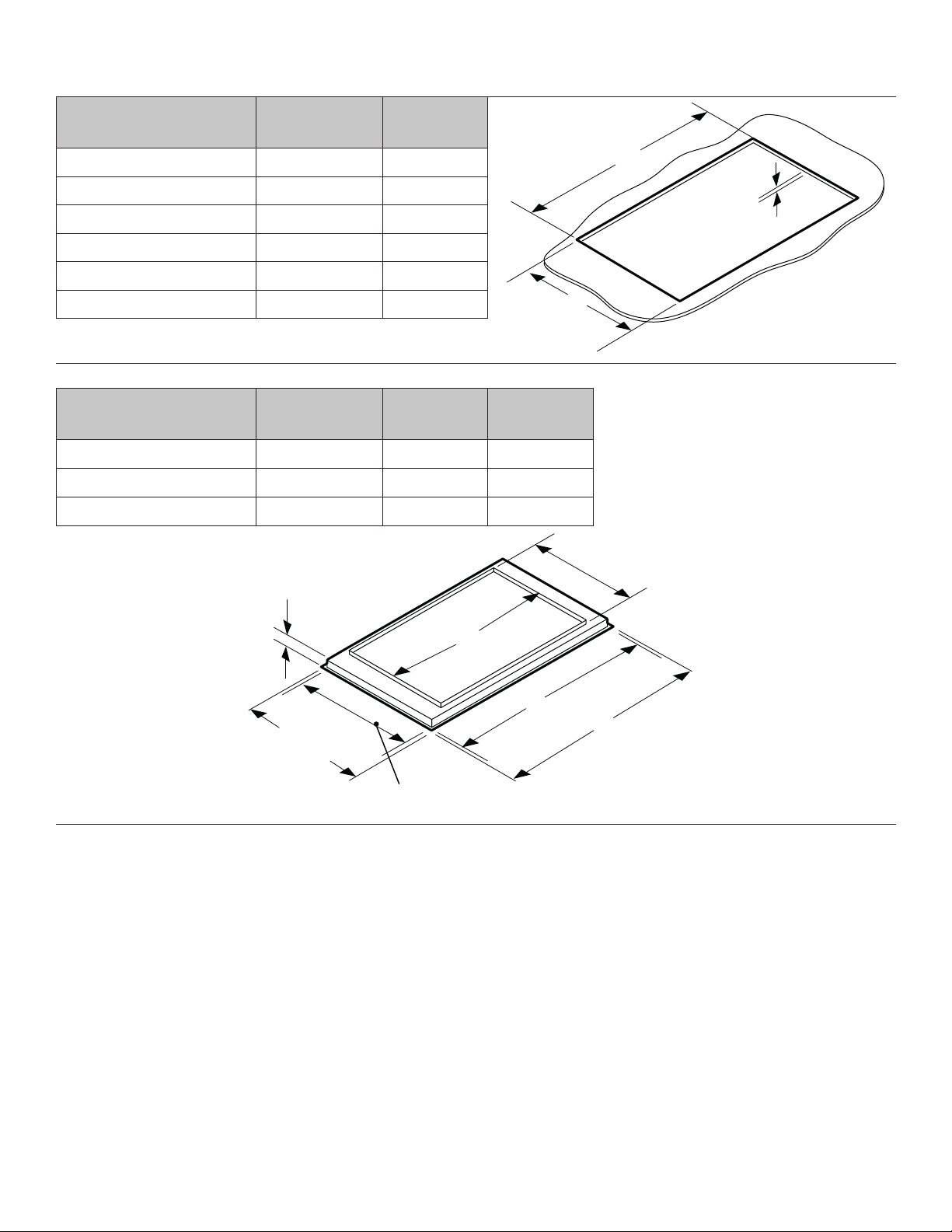

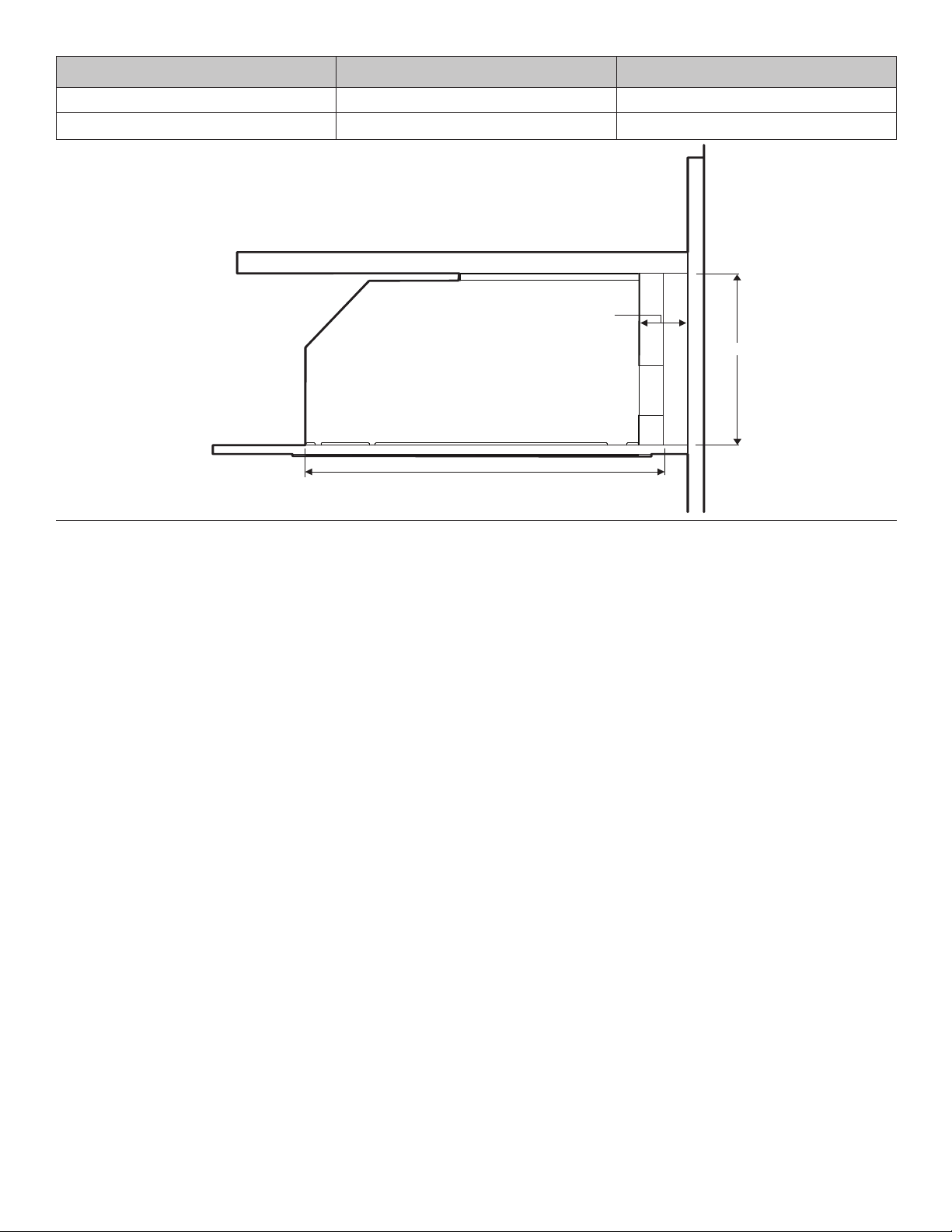

Ceiling Cutout Dimensions

Cutout for Hood

36'' without Liner 32

36'' with LINER236

48'' without Liner 44

48'' with LINER248

54'' without Liner 50

54'' with LINER254

inches (mm)Binches (mm)

15

39¾'' (1010)

15

51¾'' (1315)

15

57¾'' (1467)

Dimensions for Optional

Liner Accessory

inches (mm)Dinches (mm)Einches (mm)

36'' LINER236 32

48'' LINER248 44

54'' LINER254 50

A

/

'' (836)

16

/

'' (1141)

16

/

'' (1294)

16

C

7

/

'' (824) 39

16

7

/

'' (1129) 51

16

7

/

'' (1281) 57

16

21¼'' (540)

23Ǭ'' (606)

21¼'' (540)

23Ǭ'' (606)

21¼'' (540)

23

Ǭ'' (606)

3

/

'' (995)

16

3

/

'' (1300)

16

3

/

'' (1453)

16

40½'' (1029)

52½'' (1304)

58½'' (1486)

B

205/8

(524 mm)

A

5/

8"

(16 mm)

Figure 24: Cutout Dimensions

"

1½"

(38 mm)

24¾"

(629 mm)

235/16

(592 mm)

C

D

E

"

Figure 25: Liner Dimensions

English 16

Supporting Stud Housing Dimensions

1½” x 3½” x 44½”

(38 x 89 x 1,130 mm)

12½"

(318)

16" (407)

16" (407)

12½"

(318)

Hood without Liner

Dimension A

2ǩ'' (54 mm) 4ǫ'' (117 mm)

To be placed on 16"

(407) stud centers

A

16" (407)

16" (407)

12½"

12½"

(318)

(318)

16" (407)

16" (407)

12½"

12½"

(318)

(318)

Hood with Liner

Dimension A

1½” x 3½” x 44½”

1½" x 3½" x 44½"

(38 x 89 x 1,130 mm)

(38 x 89 x 1,130 mm)

Figure 26: Back Stud Dimensions

A

1½'' x 3½'' x 27

(38 x 89 x 707 mm)

13

/

''

16

B ǫ'' (16 mm)

C

A

C

B

1½'' x 3½'' x 23Ǫ''

(38 x 89 x 594 mm)

Figure 27: Stud Dimensions

English 17

Model Dimension A Dimension B

A

B

Hood without Liner 12¼'' (311 mm) 22ǩ'' (562 mm)

Hood with Liner

14

5

/

'' (364 mm)

16

B

24¾'' (629 mm)

3ʺ

(76 mm)

Figure 28: Side View

English 18

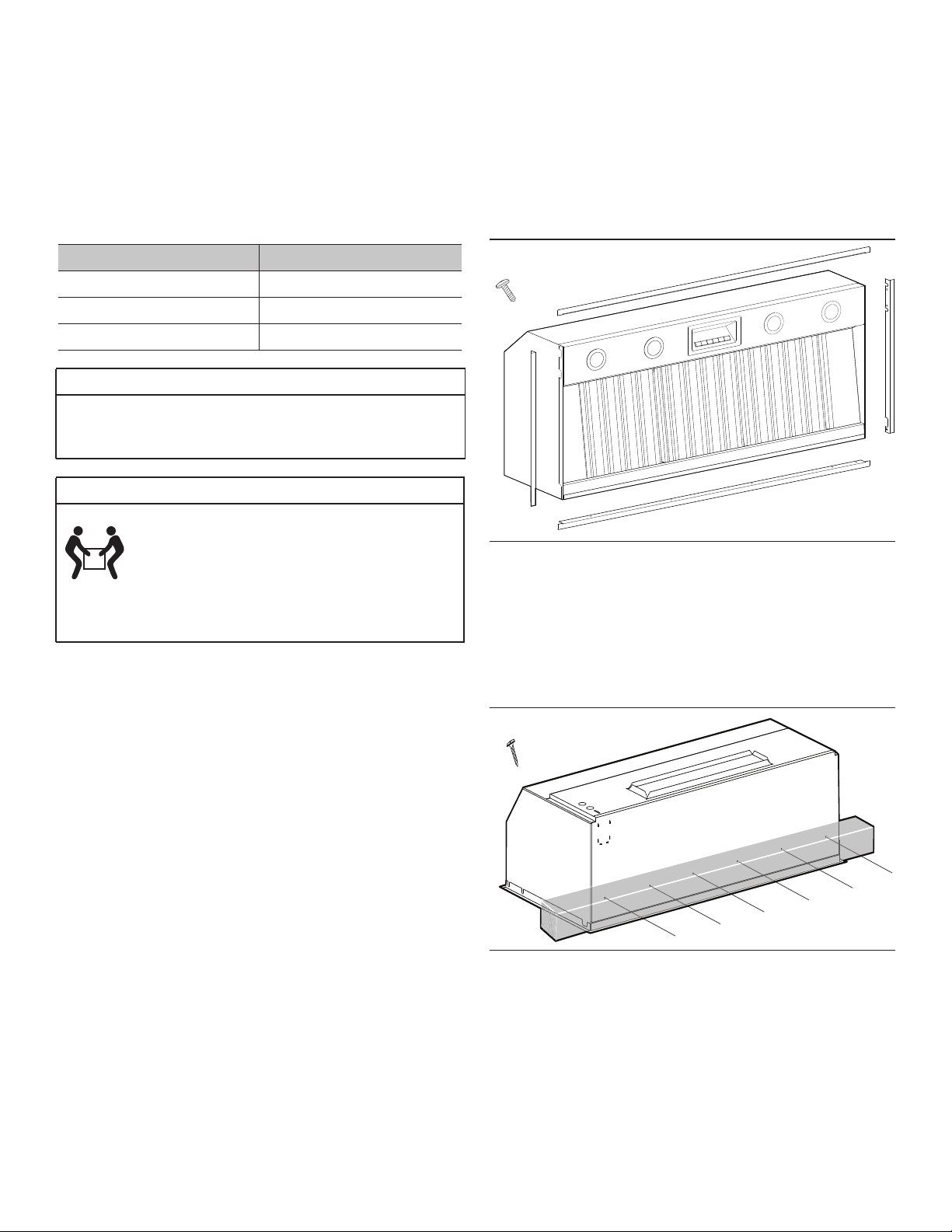

Custom Insert Installation

with Hood Trims

NOTE: VCIN Custom Insert models have the Hood Trim

pieces included. VCIB Custom Insert model installations

that do not use the included Liner, must order the Hood

Trim pieces separately.

Trim Model Insert Model

TRIM236 VCIx36JP

TRIM248 VCIx48JP

TRIM254 VCIx54JP

WARNING

To avoid electrical shock hazard, before installing, switch

power off at the service panel and lock the panel to

prevent the power from being switched on accidentally.

CAUTION

The hood weighs at least 60 lbs; therefore, it

requires at least two people to lift it safely.

Hidden surfaces may have sharp edges. Use

caution when handling the appliance. Failure

to do so may result in property damage or

personal injury.

Turn power OFF at the service panel. Lock service panel to

prevent power from being turned ON.

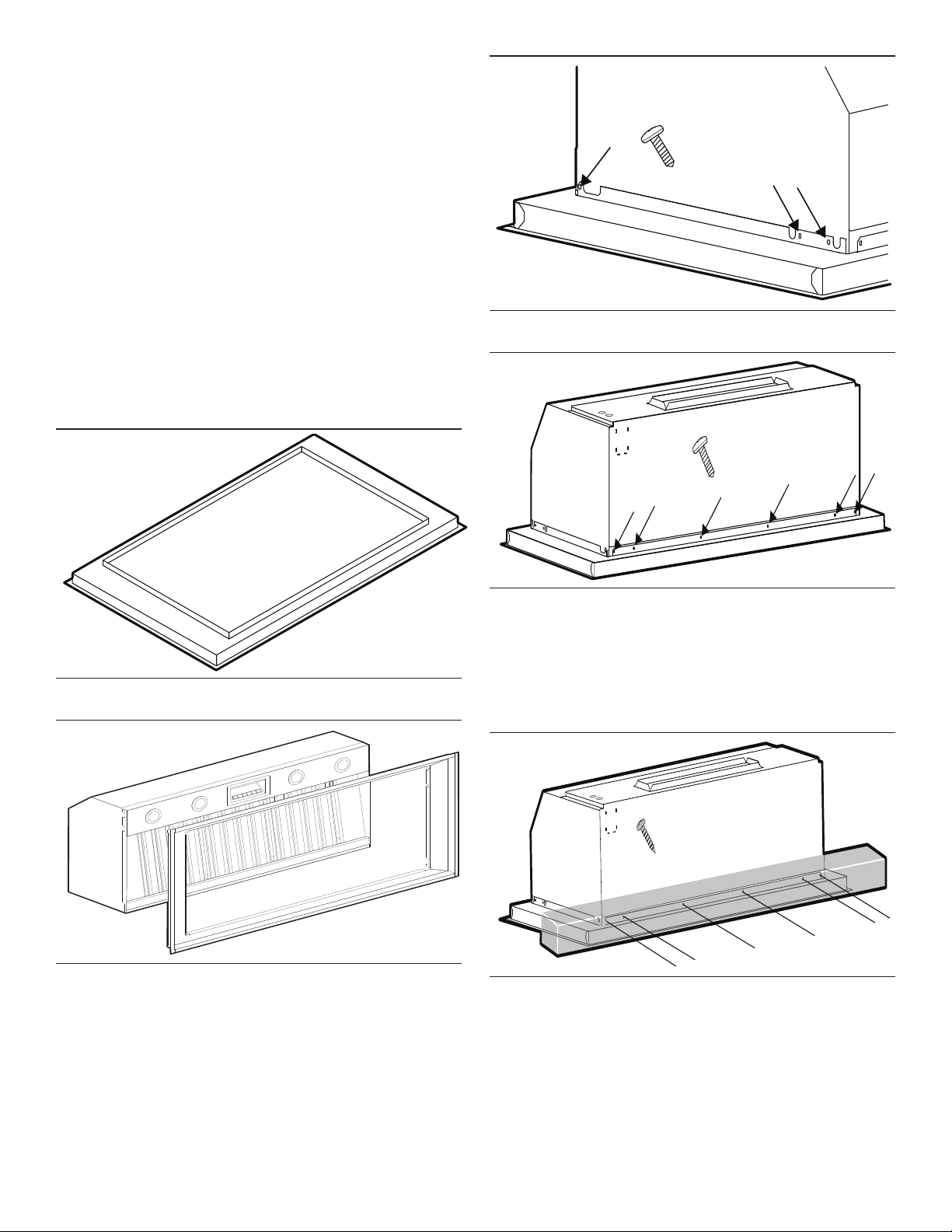

4. Install hood trim

Trim is only installed in models that do not use the optional

Custom Insert Liner. See “Custom Insert Installation with

Liner (optional)” on page 20 for liner installation

instructions.

a) Hold trim flush to the bottom of the housing.

Secure the trim to the hood with eighteen (18) x Ǫ''

(9.5 mm) screws, as indicated in Figure 29.

⅜" (9.5 mm)

x 18

Figure 29: Trim Installation

6. Install the unit

a) Install the custom insert inside the custom housing.

b) Secure to the rear of the housing framework using

six (6) x 1'' (25.4 mm) mounting screws, as

indicated in Figure 30.

1. Prepare ductwork

a) Refer to “Ductwork Preparation” on page 6.

b) Install metal transition with backdraft damper so

that the flap opens up toward the ceiling. If

necessary, install thermal break and additional

backdraft damper (refer to “Hood Transition” on

page 8).

2. Build housing framework

a) Refer to “General Information” on page 4 for the

applicable model dimensions.

b) Refer to “Installation Preparation” on page 5 for

clearance specifications.

c) Build housing framework for applicable model

according to dimensions in “Preparing the Ceiling

Cutout and Housing” beginning on page 15.

3. Install blower motor

a) Refer to “Choosing the Correct Blower” on page 9.

b) Refer to “Blower Motor Installation” beginning on

page 10.

1" (25.4 mm)

x 6

Figure 30: Rear Screws

English 19

c) Secure to the sides of the housing framework using

six (6) x 1'' (25.4 mm) mounting screws, 3 per side

as indicated in Figure 31.

Custom Insert Installation

with Liner (optional)

1" (25.4 mm)

x 6

Figure 31: Side Screws

7. Connect to ductwork

8. Connect electrical wiring

a) Remove the junction box cover (see Figure 7 on

page 10).

b) Remove circular knock-out holes located on back

side of the insert (see Figure 7 on page 10).

c) Connect wiring for applicable blower motor (see

blower instructions beginning on page 10).

d) Ensure all controls are in the OFF position. Plug

electrical cord into grounded outlet.

9. Install hood filters, filter spacers, and grease trays

a) Refer to “Installing Grease Trays, Filter Spacers,

and Filters” on page 22.

10. Test the installation

a) Test the operation of the blower and the lights.

b) Be sure to check for backdraft. With the blower on

high, close the windows and doors to the area to

ensure that fan does not cause back drafting in any

outlet vent for another appliance.

The Custom Insert Liner is an optional accessory which,

when used in conjunction with a Custom Insert, will

increase the overall capture area and protect surrounding

building materials.

The liner must be installed before the custom insert.

NOTE: If optional Liner is installed, trim pieces

included with the VCIN Custom Insert are not used.

VCIB Custom Insert model installations that do not use the

included Liner, must order the Hood Trim pieces (TRIMxx)

separately.

CAUTION

Before installing, remove the protective plastic film from

all parts.

Liner Model Insert Model

LINER236 VCIx36JP

LINER248 VCIx48JP

LINER254 VCIx54JP

WARNING

To avoid electrical shock hazard, before installing, switch

power off at the service panel and lock the panel to

prevent the power from being switched on accidentally.

CAUTION

The hood weighs at least 60 lbs; therefore, it

requires at least two people to lift it safely.

Hidden surfaces may have sharp edges. Use

caution when handling the appliance. Failure

to do so may result in property damage or

personal injury.

English 20

1. Turn power OFF at the service panel. Lock service

panel to prevent power from being turned ON.

2. Prepare ductwork

a) See “Ductwork Preparation” on page 6.

b) Install metal transition with backdraft damper so

that the flap opens up toward the ceiling. If

necessary, install thermal break and additional

backdraft damper (refer to “Hood Transition” on

page 8).

3. Build housing framework

a) Refer to “General Information” on page 4 for the

applicable model dimensions.

b) Refer to “Installation Preparation” on page 5 for

clearance specifications.

c) Build housing framework for applicable model

according to dimensions in “Preparing the Ceiling

Cutout and Housing” beginning on page 15.

4. Install blower motor

a) Refer to “Blower Motor Installation” beginning on

page 10.

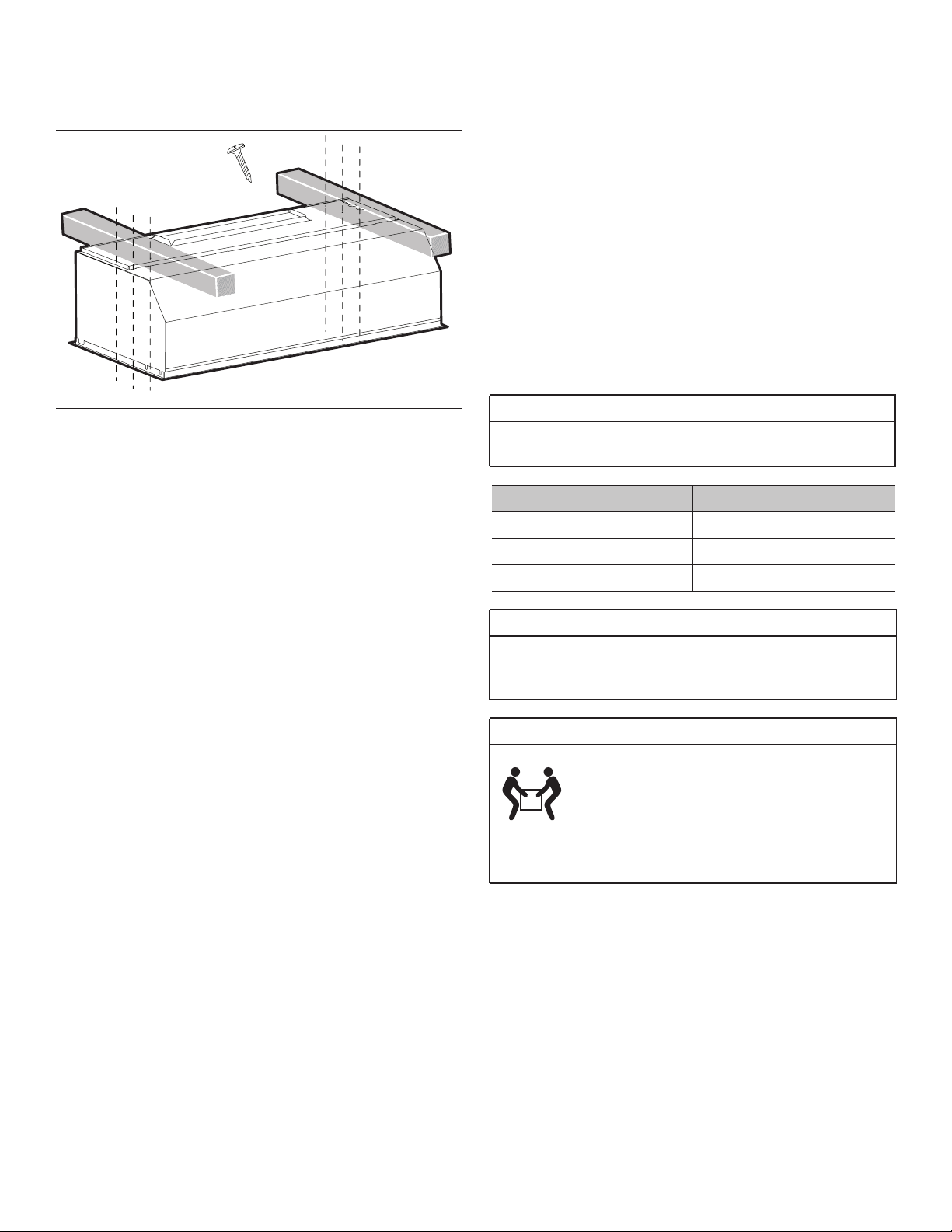

5. Hood liner installation

a) Slide the liner onto the hood (Figure 33).

b) Hold liner flush to the bottom of the housing.

Secure the liner to the hood with eighteen (18) x Ǫ''

(9.5 mm) screws, as indicated in Figure 34 and

Figure 35.

⅜" (9.5 mm)

x 3 each side

Figure 34: Secure Liner Sides

⅜" (9.5 mm)

X 6 each front

& back side

Figure 32: Liner

Figure 33: Liner Installation

Figure 35: Secure Liner Front & Back

6. Install the unit

a) Install the custom insert inside the custom housing.

b) Secure to the rear of the frame using six (6) 1''

(25.4 mm) mounting screws provided (Figure 36).

1'' (25.4 mm) X 6

mounting screws

Figure 36: Rear Screws

English 21

c) Secure to the sides of the frame using six (6) 1''

Filters

(25.4 mm) mounting screws provided (Figure 37).

Installing Grease Trays,

Filter Spacers, and Filters

1" (25.4 mm)

mounting screws

X 3 per side

Figure 37: Side Screws

7. Connect to Ductwork

8. Connect electrical wiring

a) Remove the junction box cover (see Figure 7 on

page 10).

b) Remove circular knock-out holes located on back

side of the insert (see Figure 7 on page 10).

c) Connect wiring for blower motor (see blower

instructions beginning on page 10).

d) Ensure all controls are in the OFF position. Plug

electrical cord into grounded outlet.

9. Install hood filters and grease trays

a) Refer to “Installing Grease Trays, Filter Spacers,

and Filters” on page 22.

10. Test the installation.

a) Test the operation of the blower and the lights.

b) Be sure to check for backdraft. With the blower on

high, close the windows and doors to the area to

ensure that fan does not cause back drafting in any

outlet vent for another appliance.

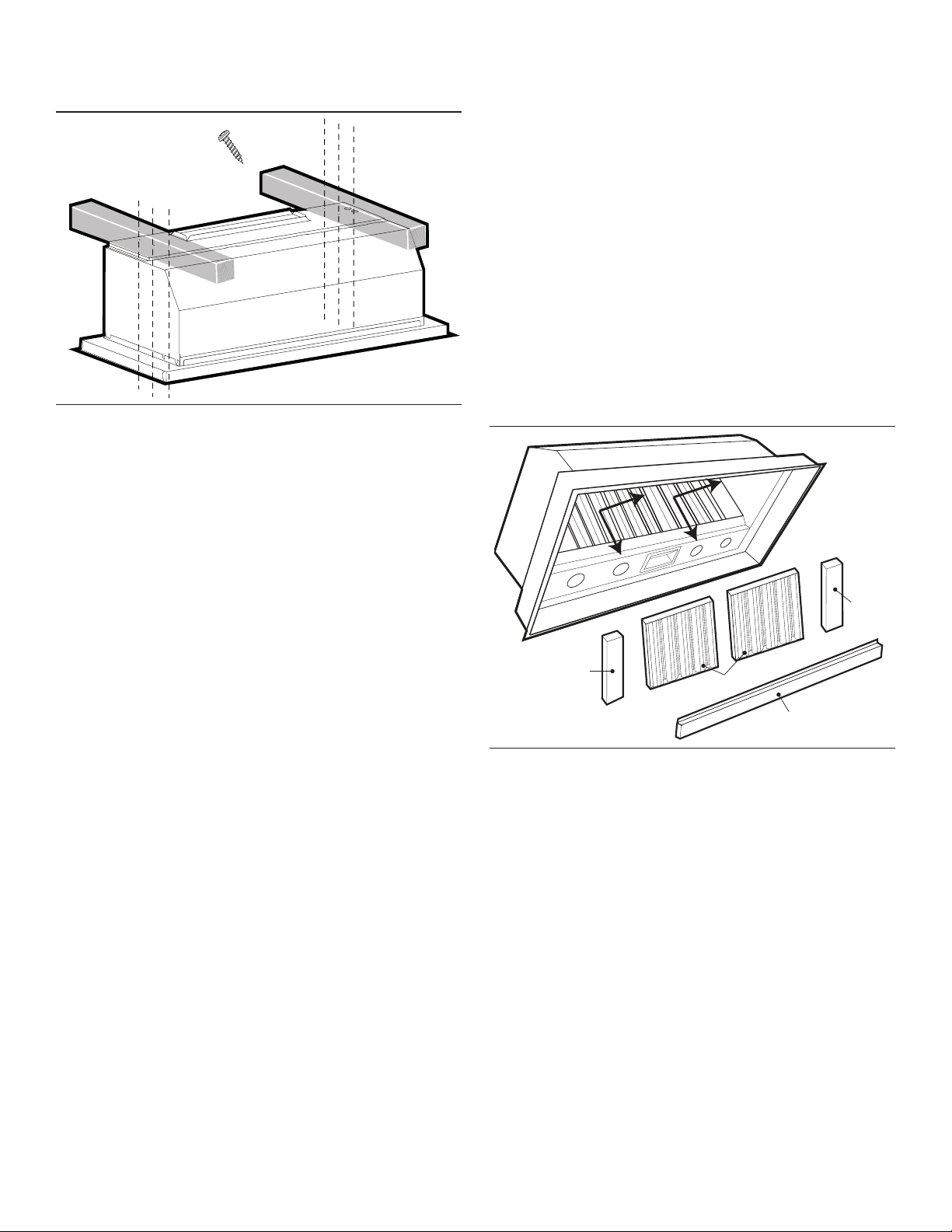

1. Remove all plastic from hood pieces.

2. Insert in the following order:

a) Grease trays — push down and in. The grease

trays must be in place before installing the filters.

Depending upon the size and model of hood, there

will be from 2 or 3 grease trays per hood.

b) Filter spacers — push down and in at the bottom.

c) Filters — start with center filters, push

push in at the bottom.

Depending upon the size

down, then

and model of hood, there will be from 2 to 4 filters

per hood.

3. Reverse the above directions to remove the grease

trays, filter spacers, and filters.

Filters

Filters

Filter

Spacers

Filter

Spacers

Filters

Grease Tray

Figure 38: Hood and parts

NOTE: DO NOT use rangetop burners, elements, or oven

while hood is disassembled.

English 22

Loading...

Loading...