Page 1

INSTALLATION INSTRUCTIONS MANUAL

PROFESSIONAL RANGES

ALL-GAS MODELS – PRG304, PRG36 AND PRG48

DUAL-FUEL MODELS - PRDS304, PRDS36 AND PRDS48

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

IMPORTANT: LOCAL CODES VARY. INSTALLATION, ELECTRICAL CONNECTIONS,

GAS CONNECTIONS, AND GROUNDING MUST COMPLY WITH ALL APPLICABLE CODES.

IMPORTANT: Save these instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these Installation Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

Gas Supply:

Natural Gas – 6 inch water column. (14.9mb) min., 8 inch (20mb) nominal

Propane Gas – 11 inch water column. (27.4 mb), 14 inch (37mb) maximum

Electrical Power Supply:

PRG304, PRG36 and PRG48 Models – 120 VAC, 60 Hz., 1Ph., 20 Amp circuit.

PRDS304 Model - 120/240 VAC, 50/60 HZ., 1Ph., 20 Amp circuit.

PRDS36 Models – 120/240 VAC, 50/60 Hz., 1Ph., 35 Amp circuit.

PRDS48 Models – 120/240 VAC, 50/60 Hz., 1Ph., 50 Amp circuit.

WARNING: Disconnect power

before installing. Before turning

N

IO

T

IA

C

O

S

S

A

S

N

A

C

®

G

N

IA

D

A

APPROVED

A

power ON, be sure that all

controls are in the OFF position.

Page 2

IMPORTANT INSTALLATION INFORMATION

INTRODUCTION

WARNING: Improper

installation, adjustment,

alteration, service or maintenance can cause injury or

property damage. Refer to

this manual. For assistance

or additional information

consult a qualified installer,

service agency, manufacturer (dealer) or the gas

supplier.

— Do not store or use

gasoline or other

flammable vapors and

liquids in the vinicity

of this or any other

appliance.

WHAT TO DO

IF YOU SMELL GAS

• Do not try to light any

appliance.

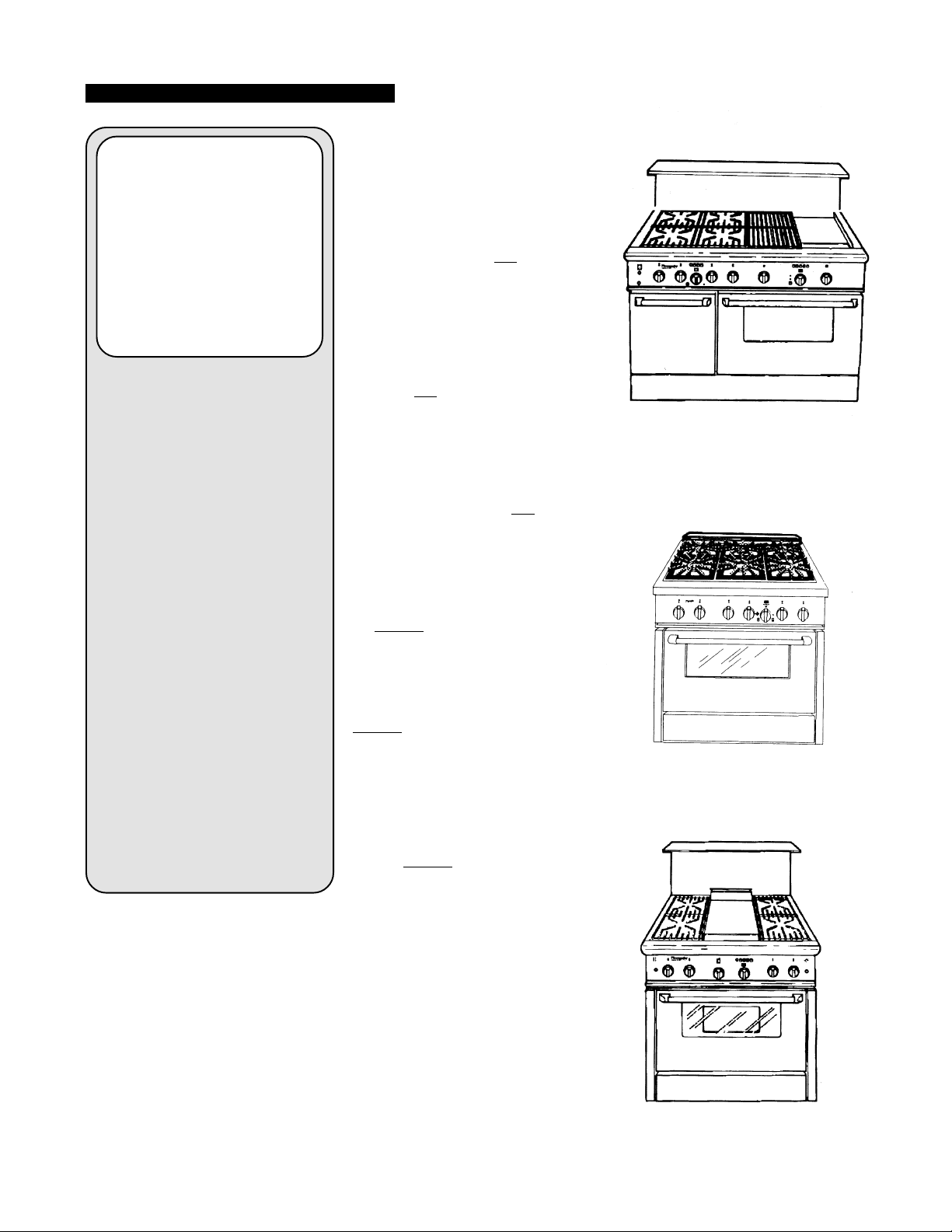

The Thermador Professional

Ranges are free standing units

available in a number of configurations. Model PRG304 is equipped

with four sealed gas surface burners, a large capacity gas oven with

gas infra-red broiler and convection

system. Models PRG364GD,

PRG364GL, and PRG366 feature a

gas cooking surface with four sealed

burners and a griddle, four sealed

burners and a grill, or six sealed

burners, in addition to a large

capacity

broiler. Models PRG484GG,

PRG486GD, and PRG486GL feature

a gas cooking surface with four

sealed burners, griddle and grill, six

sealed burners and a griddle, or six

sealed burners and a grill. PRG48

Ranges provide a large gas oven (the

same as used in the PRG36 Ranges)

and a small gas oven with broil

capability.

gas oven with gas infra-red

• Do not touch any

electrical switch; do

not use any phone in

your building.

• Immediately call your

gas supplier from a

neighbor’s phone.

Follow the gas

supplier’s instruction.

• If you cannot reach

your gas supplier, call

the fire department.

— Installation and service

must be performed by a

qualified installer,

service agency or the

gas supplier.

TABLE OF CONTENTS

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Important Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Step 1: Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Step 2: Cabinet Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Step 3: Unpacking, Moving And Placing The Range . . . . . . . . . . . . . . . . . . .8

Step 4: Install Anti-Tip Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Step 5: Gas Requirements & Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Step 6: Electrical Requirements, Connection & Grounding . . . . . . . . . . . . .16

Step 7: Backguard Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Step 8: Test And Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Installer Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Model PRDS304 is equipped with

four sealed gas surface burners and

an electric convection, self-cleaning

oven with broil capability. Models

PRDS364GD, PRDS364GL, and

PRDS366 offer the same cooking

surface configurations but are

equipped with a professional size,

electric convection, self-cleaning

oven with broil capability. Models

PRDS484GG, PRDS486GD, and

PRDS486GL feature a gas cooking

surface with four sealed burners,

griddle and grill, six sealed burners

and a griddle, or six sealed burners

and a grill. PRDS48 Ranges provide

a large electric oven (the same as

used in the PRDS36 Ranges) and a

small electric oven with a bread

proofing feature and broil capability.

®

(Shown with Low Back Guard Model PRS48LB)

Model PRDS484GG

Model PRG366

(Shown with Island Trim Model PRS36IT)

Model PRDS364GD

(Shown with High Shelf Model PRS36HS)

Inside Front Cover

Page 3

AVERTISSEMENTS EN FRANCAIS

For Residential Use Only

ALL-GAS MODELS - PRG304 AND PRG36,

DUAL FUEL MODELS PRDS304, PRDS36 AND PRDS48

CET MAN U EL CONTEN IT AVERTISSEMENTS EN FRANCAIS

AVERTISSEMENT: Couper le courant avant d'installer.

Avant de mettre EN MARCHE, soyez certain que tous les

controles sont dans la position ARRÊTE.

• Ne pas emmagasuner ou utiliser

de l'essence ou des autres vapeurs

inflammables et liquides aux endr

oits de celui-ci ou sucum autre

appareil.

AVERTISSEMENT:

DANGER DE

RENVERSEMENT

DE LA CUISINIERE

CE QUI FAIRE SI VOUS

SENTEZ LE GAZ.

• Ne pas essayer d'allumer aucun

appareil.

• Ne pas toucher aucun interrupteur

électrique; ne pas utiliser aucun

téléphone dans votre bâtiment.

• Appeler immédiatement votre four

nisseur de gaz du téléphone d'un

voisin. Suivre l'instruction du four

nisseur de gaz.

• Si vous ne pouvez pas contracter

votre four nisseur, téléphoner le

service des incendies.

• L'installation et le service doivent

être éxecutés par un installateur

qualifé, une agence de service ou

le fournisseur de gaz.

Page 1

Page 4

AVERTISSEMENTS EN FRANCAIS

AVERTISSEMENT

Page 2

Page 5

IMPORTANT INSTALLATION INFORMATION

I

MPORTANT:

All ranges must be installed with a

backguard. Models PRG304 and

PRDS304 are shipped from the

factory with a standard 9" backguard. For all other models one of

three available backguards must be

ordered separately and installed at

the back of the range. The three

backguard choices include a Low

Back Guard, High Shelf, or Island

Trim. See STEPS 2 and 6.

This appliance has been tested in accordance with ANSI Z21.1 Current Issue, Standard for Household Cooking

Appliances (USA) and in accordance

with CAN 1.1-M81 Domestic Gas

Ranges (CANADIAN).

It is strongly recommended that this

appliance be installed in conjunction

with a suitable overhead vent hood.

(See Step 1 for Ventilation Requirements.) Due to the high heat capability

It is strongly recommended that a suit-

able exhaust hood be installed above

the range. Downdraft ventilation should

not be used. The table below indicates

the Thermador hoods, by model number, that are recommended for use with

the 30", 36", and 48" ranges.

1. Select Hood and Blower Models:

• For wall installations, the hood width

must, at a minimum, equal the width of

the range cooking surface. Where space

permits, a hood larger in width than the

cooking surface may be desirable for

improved ventilation performance.

• For island installations, the hood width

should, at a minimum, overhang the

range cooking surface by 6" on both

sides.

of this unit, particular attention should

be paid to the hood and duct work

installation to assure it meets local building codes. To eliminate risk of burns or

fire caused by reaching over heated

surface units, cabinet storage located

above the surface units should be

avoided.

Check local building codes for the proper

method of appliance installation. Local

codes vary. Installation, electrical connections and grounding must comply

with all applicable codes. In the absence

of local codes the appliance should be

installed in accordance with the National

Fuel Gas Code ANSI Z223.1 Current

Issue and National Electrical Code ANSI/

NFPA 70-Current Issue. In Canada, installation must be in accordance with

the CAN 1-B149.1 and .2 – Installation

Codes for Gas Burning Appliances and/

or local codes.

This appliance is equipped with an inter-

STEP 1: VENTILATION REQUIREMENTS

CAUTION: Ventilation hoods and blowers are designed for use with single wall

ducting. However, some local building

codes or inspectors may require double

wall ducting. Consult local building

codes and/or local agencies, before

starting, to assure that hood and duct

installation will meet local requirements.

• Hood blower speeds should be variable to reduce noise and loss of heated

or air conditioned household air when

maximum ventilation is not required.

Normally, the maximum blower speed

is only required when using the grill.

2. Hood Placement:

• For best smoke elimination, the lower

mittent/interrupted ignition device that

cycles the two far left surface burners on

and off when in the ExtraLow

®

setting.

CAUTION:

(1) When connecting the unit to

propane gas, make certain the

propane gas tank is equipped

with its own high pressure

regulator in addition to the

pressure regulator supplied with

this unit. The maximum gas

pressure to this appliance is not

to exceed 14.0 inches (37mb)

water column from the propane

gas tank regulator.

(2) This unit is designed as a

cooking appliance. Based on

safety considerations never use it

for warming or heating a room.

edge of the hood should be installed a

minimum of 30" to a maximum of 36"

above the range cooking surface. (See

Fig. 1).

• If the hood contains any combustible

materials (i.e. a wood covering), it must

be a minimum of 42" above the cooking

surface.

3. Consider Make-Up Air:

• Due to the high volume of ventilation

air, a source of outside replacement air

is recommended. This is particularly

important for tightly sealed and insulated homes.

• A qualified heating and ventilating

contractor should be consulted.

RANGE WIDTH

30" RANGE

36" RANGE

48" RANGE

Notes: * For wall installations where adequate space is available, the installer or user may elect to use a hood that is wider than the range

cooking surface. This may be particularly beneficial for those cases, such as a long duct run or heavy usage of the grill, in which

improved capturing of the cooking exhaust is desired.

** Thermador offers a choice of remote (VTR1000Q or VTR1400q) or in-hood (VTN1000Q) blowers for use in wall installations.

WALL INSTALLATION ISLAND INSTALLATION

HOOD* BLOWER** HOOD BLOWER

PH30HQS

PHE30,36

PH36HQS

PHE36,42

PH48HQS

PHE48,60

VTR1000Q, VTR1400Q

or VTN 1000Q

VTR1000Q, VTR1400Q

or VTN 1000Q

VTR1000Q, VTR1400Q

or VTN 1000Q

Page 3

PHI48QS

PHI48QS

PHI60QS

VTR1400Q

VTR1400Q

VTR1400Q

Page 6

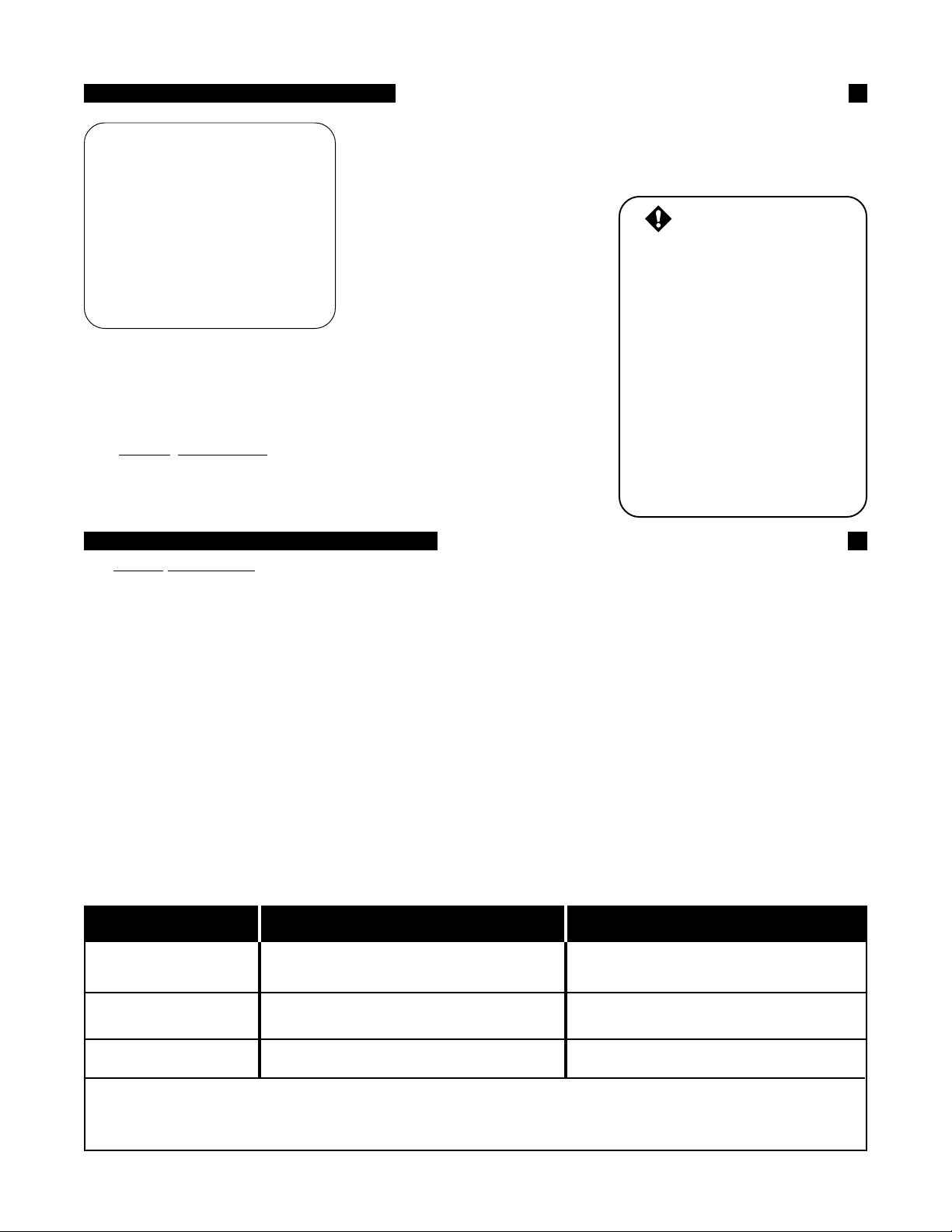

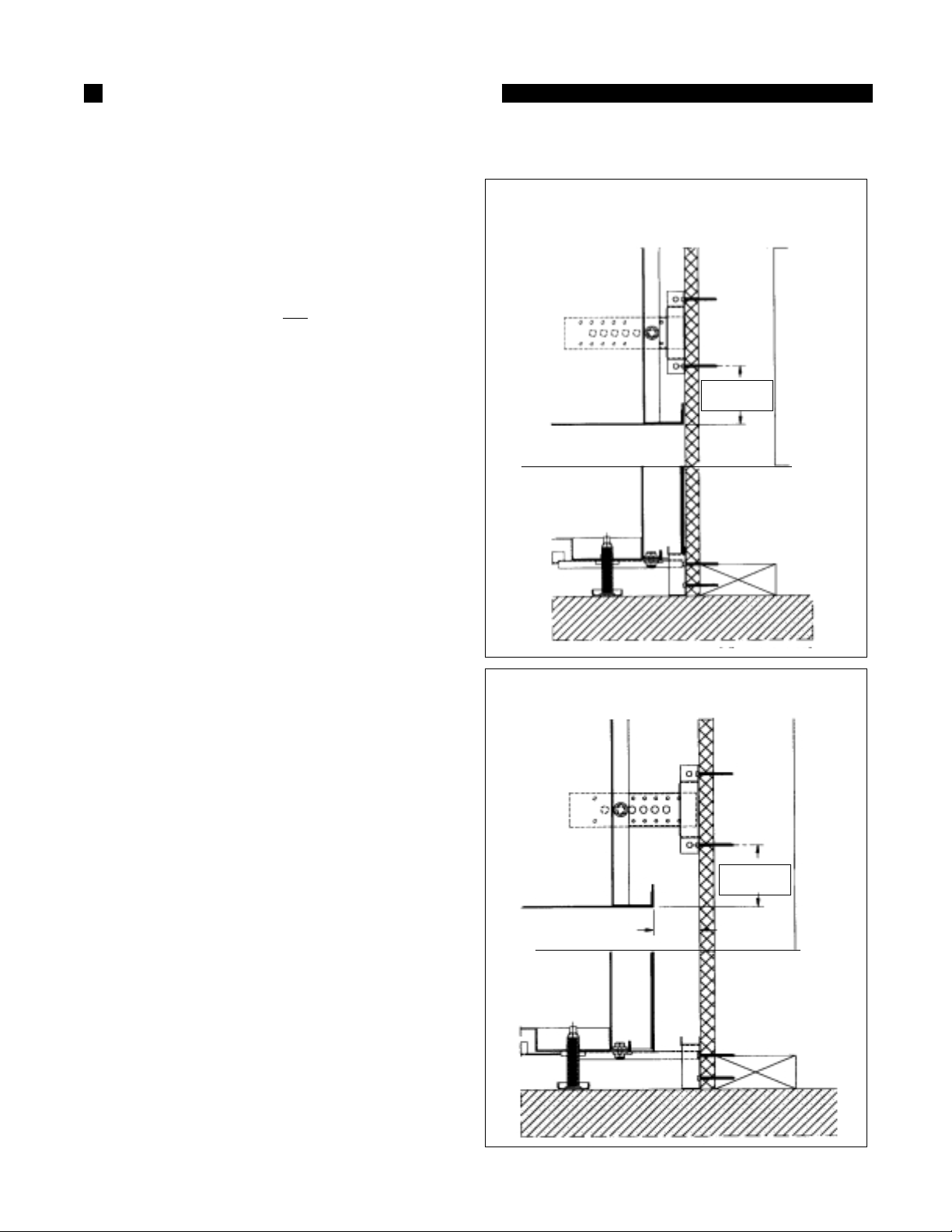

STEP 2: CABINET PREPARATION

1. The range is a free standing

unit. If the unit is to be placed

adjacent to cabinets, the

clearances shown in Fig. 1 are

required. The same clearances

apply to island installations,

except for the overhead cabinets, which must have a space

wide enough to accept the

flared island hood, as indicated

in Fig. 1.

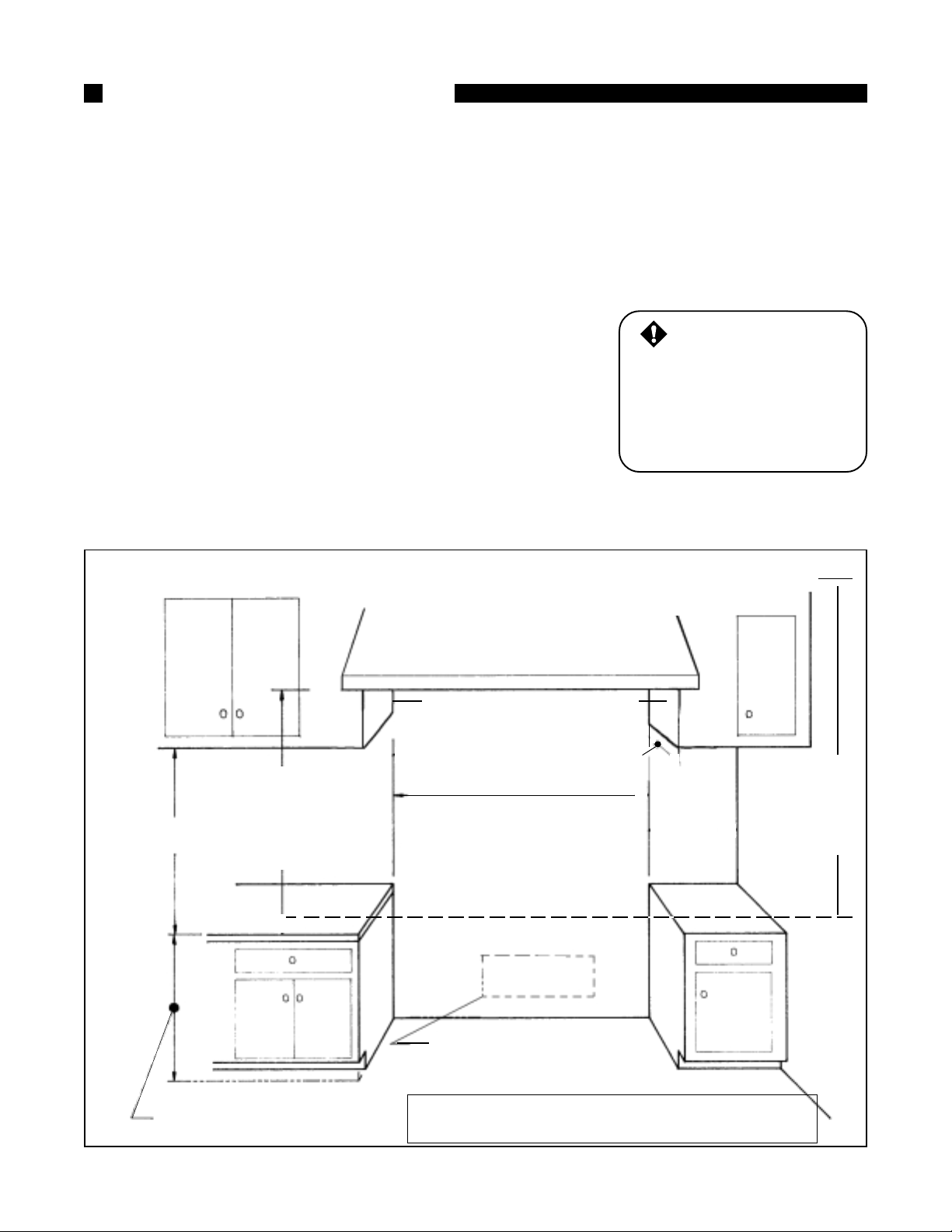

2. The PRDS48 Ranges must be

placed with the oven door

projecting out from the cabinet

face. The cabinet face should

line up with the oven front

frame, which is the surface that

the oven door closes against.

(See Fig. 2b and 2c illustrating

side views of 48" ranges.)

3. The gas and electrical supply

should be within the zones

shown in Fig. 3a, 3b and 3c.

FIG. 1 Cabinet Clearances

4. The maximum depth of over

head cabinets installed on

either side of the hood is 13".

5. Any openings in the wall behind

the range and in the floor under

the range must be sealed.

6. When there is less than a 12"

horizontal clearance between

combustible material ∆ and the

back edge of the range above

the cooking surface, a

Thermador Low Back or High

Shelf backguard must be

installed. (See Fig. 2a). When

clearance to combustible

material ∆ is over 12", a

Thermador Island Trim may be

used. (See Fig. 2b). Except in

the case of 30" Ranges,

backguards must be ordered

separately. Figures 2a, 2b

and 2c indicate the space

30" Wide Hood (Model #PH30QS)

48" for Island (Model #PHI48QS)

36" Wide Hood (Model #PH36QS)

48" for Island (Model #PHI48QS)

48" Wide Hood (Model #PH48QS)

60" for Island (Model #PHI60QS)

}

}

}

required for each type of

backguard.

7. Always keep appliance area

clear and free from combustible

materials, gasoline and other

flammable vapors and liquids.

8. Do not obstruct the flow of

combustion and ventilation air

to the unit.

CAUTION:

Do not install the Model

PRDS48 ranges such that the

oven door is flush with the

cabinet face. A flush installation could result in damage to

the cabinets due to exposure

to high heat.

∆ As defined in the “National Fuel

Gas Code” (ANSI Z223.1, Latest

Edition).

For 30" Ranges

➛

For 36" Ranges

For 48" Ranges

30" Min. to 36" Max.

bottom of overhead

Hood to cooking

surface (42" if hood

18" Min.

contains combustible

materials ∆)

➛

*35-3/8" Min. Range Height with

Leveling Legs fully retracted

*36-3/4" Max. Range Height with

Leveling Legs fully extended

➛

Min. Distance Between Overhead

Cabinets of Combustible Material ∆

30" Range – 30"

36" Range – 36"

48" Range – 48"

➛

∆ as defined in the “National Fuel Gas Code” (ANSI Z223.1, Latest

Edition). *The range height is adjustable. The level of the range top

must be at the same level or above the countertop level.

Range width

30", 36" or 48"

For Electrical and Gas Supply Zone,

see Figures 3a, 3b and 3c. Zone size

and position differ according to the

model.

13" Max.

Cabinet

Depth

Cooking

Surface

}

➛

➛

➛

➛

12" Min. to

combus-

➛

tible side

wall

material ∆,

(both

sides)

➛

CAUTION: See

Figs. 2a, 2b and

2c. 42" Min. to

combustible

material ∆,

from cooking

surface

➛

Page 4

Page 7

STEP 2: CABINET PREPARATION

Page 5

CAUTION:

Do not install the Model PRDS304 and

PRDS48 ranges such that the front

surface of the oven door is flush with

the cabinet face. A flush installation

could result in damage to the cabinets

due to high heat. The face of the

cabinet should line up with the oven

front frame. The front frame location

relative to the rear of the range is 24-3/

8" on the PRDS304 and 25" on the

PRDS48, as shown in Figures 2a and

2b.

Page 8

STEP 2: CABINET PREPARATION

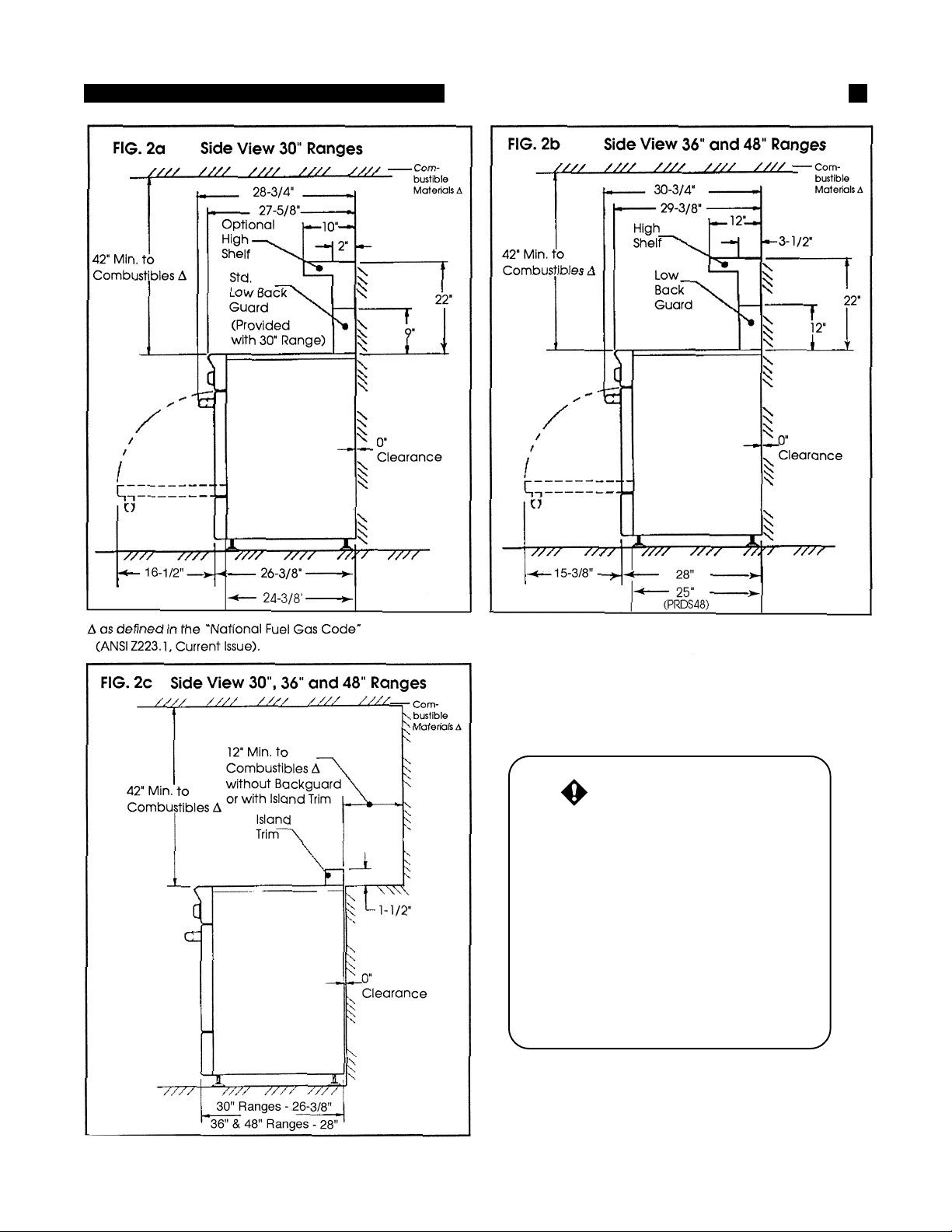

GAS AND ELECTRIC SUPPLY ZONES:

FIG. 3a

Gas & Electrical Supply Zone for PRG304, PRG36 & PRG48 All-Gas Ranges

Typical placement shown.

Other placement of Gas

Supply and Electrical

Receptacle within the

Electrical and Gas Supply

Zone is acceptable.

NOTE:

A Manual Gas

Shut-Off Valve

(not shown) must

be easily accessible

through an adjacent

cabinet without moving

the range.

Three-Prong,

120 VAC

Receptacle

2"

16"

1 3/4" Maximum

Protrusion from Wall

for Gas Supply

FIG. 3b Gas & Electrical Supply Zone for PRDS304 Dual-Fuel Ranges

Typical placement shown.

Other placement of Gas Supply

and Electrical Receptacle

within the Electrical and Gas

Supply Zone is acceptable.

NOTE:

A Manual Gas

Shut-Off Valve

(not shown)

must be easily

accessible

through an

adjacent cabinet without

moving

the range.

2" Maximum Protru-

sion from Wall for Gas

5" Typ.

Both

Sides

Supply

5/8" Flex Line to

Appliance

1/2" N.P.T.

20"

5/8" Flex Line to

Appliance

Gas & Electrical

Supply Zone

1/2" N.P.T.

5"

240 VAC Receptacle

(Shown) or Junction

Box

Gas &

Electrical

Supply Zone

4-3/4"

The All-Gas Ranges are factory equipped

with a power supply cord with a three-prong

grounding plug. IT MUST BE PLUGGED

INTO A MATING, GROUNDING-TYPE, 120

VAC RECEPTACLE THAT IS CONNECTED TO A CORRECTLY POLARIZED

AND GROUNDED 120 VAC CIRCUIT.

(See STEP 6.)

The range must be connected only to the

type of gas for which it is certified.

If the range is to be connected to propane

gas, ensure that the propane gas supply

tank is equipped with its own high pressure

regulator in addition to the pressure

regulator supplied with the range. (See

STEP 5.)

The Dual-Fuel ranges may be connected

to the power supply with a 3-pole, 3conductor range supply cord kit, a 3-pole,

4-conductor range supply cord kit or by

hard-wiring to the power supply. It is the

responsibility of the installer to provide the

proper wiring components (cord or conduit

and wires) and complete the electrical

connection as dictated by local codes and

ordinances, and/or the National Electric

Code. The units must be properly

grounded. Refer to Step 6 for details.

The range must be connected only to the

type of gas for which it is certified. If the

range is to be connected to propane gas,

ensure that the propane gas supply tank

is equipped with its own high pressure

regulator in addition to the pressure

regulator supplied with the range. (See

STEP 5.)

FIG. 3c Gas & Electrical Supply Zone for PRDS36 and PRDS 48 Dual-Fuel Ranges

Typical placement shown.

Other placement of Gas Supply

and Electrical Receptacle

within the Electrical and Gas

Supply Zone is acceptable.

NOTE:

A Manual Gas

Shut-Off Valve

(not shown)

must be easily

accessible

through an

adjacent cabinet without

moving

the range.

Protrusion from Wall

Model AB

PRDS36 7" 9"

PRDS48 12" 16"

Gas

Supply

Zone

8" Typ.

Both

Sides

2" Maximum

for Gas Supply

5/8" Flex Line to

Appliance

1/2"

N.P.T.

A

4"

240 VAC Receptacle

(Shown) or Junction

Box

Page 6

Electrical

Supply Zone

B

3-1/2"

3-1/4"

The Dual-Fuel ranges may be connected

to the power supply with a 3-pole, 3conductor range supply cord kit, a 3-pole,

4-conductor range supply cord kit or by

hard-wiring to the power supply. It is the

responsibility of the installer to provide the

proper wiring components (cord or conduit

and wires) and complete the electrical

connection as dictated by local codes and

ordinances, and/or the National Electric

Code. The units must be properly

grounded. Refer to Step 6 for details.

The range must be connected only to the

type of gas for which it is certified. If the

range is to be connected to propane gas,

ensure that the propane gas supply tank is

equipped with its own high pressure

regulator in addition to the pressure regulator

supplied with the range. (See STEP 5.)

Page 9

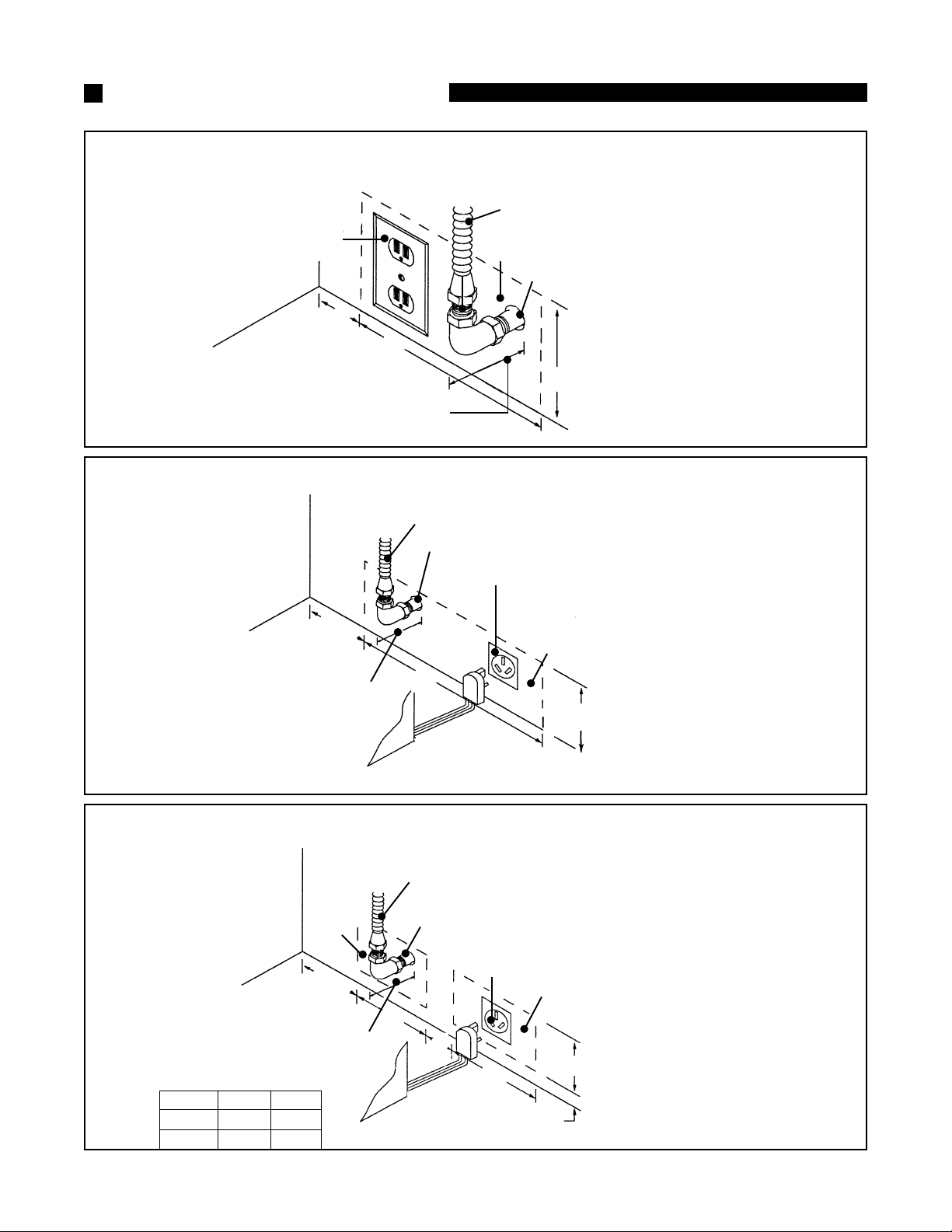

STEP 2: CABINET PREPARATION

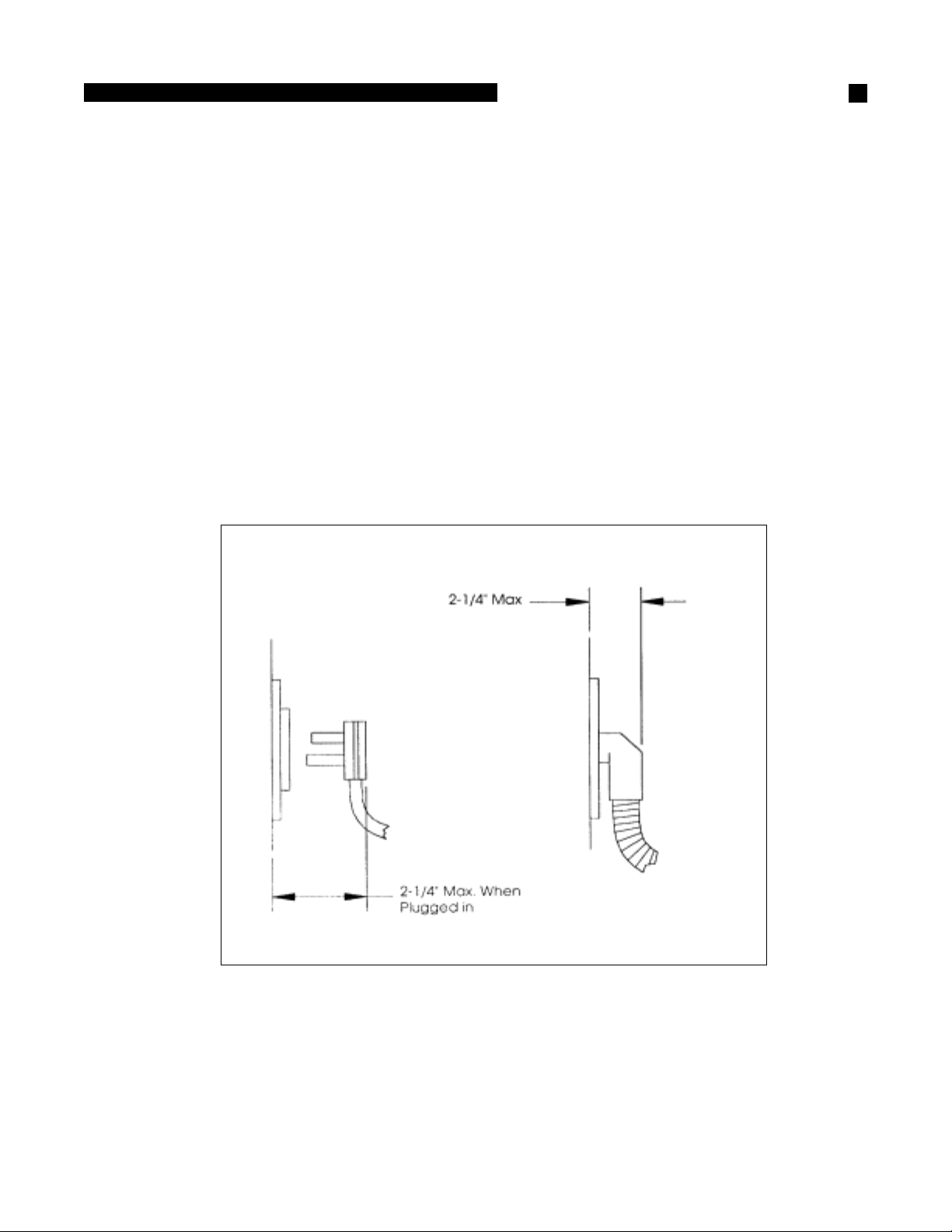

ELECTRICAL SUPPLY, DUAL FUEL RANGES

Installation of Dual Fuel ranges

must be planned so that the

rough-in of the junction box for

the receptacle or conduit connection will allow maximum clearance to the rear of the unit.

When the power supply cord (not

supplied) or conduit is connected

to the mating receptacle or

junction box cover, the combined

plug/receptacle or junction box

cover/conduit connector should

protrude no more than 2-1/4

inches from the rear wall. See

Figure 3d.

FIG. 3d Wall Connection

This is especially critical if the

junction box in the wall will be

directly behind the junction box

on the unit when the unit is

installed. Refer to Figures 16

and 16a for location of junction

box on unit. Orient the receptacle or conduit connector to

minimize binding when the unit

is connected to the receptacle or

junction box and slid back in

position.

Power Cord & Receptacle

Junction Box & Conduit

Page 7

Page 10

STEP 3: UNPACKING, MOVING AND PLACING THE RANGE

CAUTION:

Proper equipment and

adequate manpower must

be used in moving the

range to avoid damage to

the unit or the floor. The

unit is heavy and rests on

adjustable steel legs.

• The range has an approximate

shipping weight as shown in

Chart A. It is recommended that

the door(s), grates, burner caps,

front kick panel and oven racks be

removed to facilitate handling.

This will reduce the weight as

shown in Chart A and allow the

range to pass through 30" doorways. See Chart B and Fig. 2a and

2b. Do not remove the grill or

griddle assemblies.

• Remove the outer carton and

packing material from the shipping base. Remove the front kick

panel (see Fig. 4) by removing two

(2) screws at the top and pulling

forward. The dual fuel ranges are

held to the skid by four (4) bolts,

the front two (2) are behind the

kick panel (see Fig. 4) and the

rear two (2) are located on the

bottom flange of the range back

(see Fig. 5). All-gas ranges are

held in place by 4 bolts, two (2)

as shown in Fig. 4 and two (2) at

the rear as shown in Fig. 5. After

removing the bolts the range

must be lifted and removed from

the skid.

Chart A 30" Range 36" Range 48" Range

Shipping Weight 335 lbs. 444 lbs. 584 lbs.

Weight without 285 lbs. 390 lbs. 524 lbs.

packing materials

After removing door(s), 215 lbs. 295 lbs. 395 lbs.

burner caps, front kick

panel and oven racks

Chart B 30" Range 36" Range 48" Range

Doorway Width Required 28-7/8" 30-7/8" 30-7/8"

(Unit Assembled)

Doorway Width Required 27-3/4" 29-1/2" 29-1/2"

(Oven Door(s) Removed)

FIG. 4 All Ranges – Removal of

Kick Panel and Two Front

Shipping Bolts

Front

Kick

Panel

FIG. 5 All-Gas and Dual Fuel

Ranges –Removal of Two Rear

Shipping Bolts

Left Rear

Shipping

Bolt

➛

FIG. 6 All Ranges –

Door Removal

Hinge Latch

• To remove the door, open the

door to the fully open position.

Close the hinge latches (See Fig.

6) by rotating towards the door

top. The door can then be removed by gently lifting and

pulling the door, with the hinges

up and out of the frame. Do not

lift the range by the door

handle(s).

Page 8

Hinge Clip In

Locked Position

Lower Clip After

Replacing Door

Page 11

STEP 3: UNPACKING, MOVING AND PLACING THE RANGE

• Due to the weight, a dolly with soft

wheels should be used to move this

unit. The weight must be supported

uniformly across the bottom (See

Fig. 7).

• After transporting the professional

range by dolly close to its final

location, the range can be tipped

back and supported on the rear

legs while the dolly is carefully

removed. THE FLOOR UNDER

THE LEGS SHOULD BE PROTECTED (WOOD STRIPS, CARPET, PANELING, ETC.) BEFORE

PUSHING THE UNIT INTO

POSITION. The anti-tip device (30"

and 36" ranges) must be installed

(STEP 4), gas and electric connections should be made (STEPS 5 and

6), and the backguard installed

(STEP 7) before the range is placed

in its final position.

wires.

Griddle Level Adjustments

• For proper performance the professional range must be level. The

range is leveled by adjusting the

legs with a wrench. Replace the

kick panel and oven doors by

reversing the procedure described

above. It is important that the

two (2) screws retaining the

kick panel are secure to prevent accidental access to live

electrical components and

The griddle should be level or tilted slightly forward

and should not rock. Screws are installed in the back

ledge to eliminate rocking and to adjust the level of

the griddle. To access these screws (A) (see Fig. 8),

carefully remove the black aluminum trim strips

running front to back alongside the griddle, then lift

the back of the griddle.

Page 9

Page 12

STEP 4: INSTALLING ANTI-TIP DEVICE

For all 30" and 36" ranges, an anti-tip device must be installed as per these instructions.

WARNING

RANGE TIPPING HAZARD

• All ranges can tip and injury could

result. To prevent accidental tipping

of the range, attach it to the wall, floor

or cabinet by installing the Anti-Tip

Device supplied.

• A risk of tip-over may exist if the

appliance is not installed in accordance with these instructions.

• If the range is pulled away from the

wall for cleaning, service, or any other

reason, ensure that the Anti-Tip Device is properly reengaged when the

range is pushed back against the wall.

In the event of abnormal usage (such

as a person standing, sitting, or leaning on an open door), failure to take

this precaution could result in tipping

of the range. Personal injury might

result from spilled hot liquids or from

the range itself.

WARNING

ELECTRICAL SHOCK HAZARD

• Use extreme caution when drilling

holes into the wall or floor. There may

be concealed electrical wires located

behind the wall or under the floor.

• Identify the electrical circuits that

could be effected by the installation of

the Anti-Tip Device, then turn off

power to these circuits.

• Failure to follow these instructions

may result in electrical shock or other

WARNING

• ALL RANGES CAN TIP

• INJURY TO PERSONS

COULD RESULT

• INSTALL ANTI-TIP

DEVICES PACKED

WITH RANGE

• SEE INSTRALLATION

INSTRUCTIONS

personal injury.

CAUTION

PROPERTY DAMAGE

• Contact a qualified installer or contractor to determine the proper method for

drilling holes through the wall or floor

material (such as ceramic tile, hardwood, etc.)

• Do not slide the range across an unprotected floor.

• Failure to follow these instructions

may result damage to wall or floor

coverings.

Tools Needed for Installation of Anti-Tip Device:

- Screwdriver, Phillips - Hammer

- Drill, electric or hand - Pencil or other marker

- Measuring tape or ruler - Wrench, 7/16" (PRG Ranges only)

- 1/8" drill bit (wood or metal wall or floor) - Wrench adjustable (PRG Ranges only)

- 3/16" carbide-tipped masonry drill bit (concrete or concrete block wall or floor)

- 3/16" anchors, drywall or concrete, 2 each (not required if mounting bracket is being attached to solid

wood or metal)

Page 10

Page 13

STEP 4: INSTALLING ANTI-TIP DEVICE

Parts Required for Installation of Anti-Tip Device:

PRG304 and PRG36 All Gas Ranges (Figures 9 and 10)

Thermador Part No. Qty Description

15-10-916 4 Screw, Phillips,#10 x 1-1/2"

15-10-771 1 Anti-Tip Channel, Adjust

able, PRG

15-10-772 1 Mounting Bracket, PRG

15-10-909 1 Bolt, Hex Head, 1/4"-20 x

1/2"

15-10-910 1 Nut, Hex, 1/4-20

15-10-911 2 Washer, Flat, 1/4-20

15-10-948 2 Screw, Phillips, #10 x 1/2"

FIG. 9 Mounting Kit for PRG304 and PRG36

All-Gas Ranges

Mounting Bracket

15-10-772 (1 Each)

15-10-909 (1 Each)

15-10-916 (4 Each)

15-10-771 (1 Each)

FIG. 10 Adjustable Anti-Tip Channel PRG304

and PRG36 All-Gas Ranges

5-1/2"

This Hole

For Flush

Mount of

PRG304

1-9/32"

This Hole

For Flush

Mount of

PRG36

1-17/32"

FIG. 11 Mounting Kit for PRDS304 and PRDS36

Dual Fuel Ranges

15-10-770 (1 Each)

15-10-916 (4 Each)

15-10-911 (2 Each)

15-10-910 (1 Each)

15-10-948 (2 Each)

PRDS304 and PRDS36 Dual

Fuel Ranges (Figure 11)

Thermador Part No. Qty Description

15-10-916 4 Screw, Phillips,#10 x 1-1/2"

15-10-770 1 Anti-Tip Channel, Adjustable,

IMPORTANT INSTALLATION INFORMATION:

• The anti-tip bracket may be attached to a

solid wood cabinet having a minimum wall

thickness of 3/4".

• The thickness of the wall or floor may

require use of longer screws, available at

your local hardware store.

• In all cases, at least two (2) of the bracket

mounting screws must be fastened to solid

wood or metal.

• Use appropriate anchors when fastening the

mounting bracket to any material other

than hardwood or metal.

• Prepare holes at fastener locations as

identified below:

- For walls, wall studs, or floors composed

of solid wood or metal, drill 1/8" pilot

holes.

- For walls or floors composed of drywall,

sheet-rock or other soft materials, drill 3/

16" holes to a minimum depth of 1-3/4",

then tap plastic anchors into each of the

holes using a hammer.

- For walls or floors composed of concrete or

concrete block, drill 3/16" holes to a

minimum depth of 1-3/4", then tap con

crete anchors into each of the holes using

a hammer.

- For walls or floors having ceramic tile

covering, drill 3/16" holes through the tile

only, then drill into the material behind

the tile as indicated immediately above.

• If the range is moved to a new location, the

Anti-Tip Device must be removed and reinstalled.

Page 11

Page 14

STEP 4: INSTALLING ANTI-TIP DEVICE

PRG304 AND PRG36 All-Gas Ranges (Figures 9, 10, 12a 12b and 13)

STEP A: Determine the best location for the

PRG Mounting Bracket. The bracket may be

mounted to the wall or floor behind the

range, offset from either the left or right side

wall by 2-3/4" for model PRG304 or

4-5/8" for Model PRG36.

- Locate the bracket on the side of the

range that will not interfere with the

gas supply line, electrical wiring,

conduit or any other item.

- Select either the rear wall or the floor

for mounting the bracket, based

upon which will provide the greatest

holding strength.

STEP B: Set the bracket on the floor and turn it

until it is oriented properly. The bracket should

be standing up on end. The set of mounting

flanges having one (1) hole per side should be

resting on the floor, and the other set of

mount

ing flanges having two (2) holes per side

should be positioned vertically facing the rear.

FIG. 12a PRG36 Wall Mount (0" Clearance)

PLAN VIEW

PRG304: 2-3/4"

PRG36: 4-5/8"

May Be Used On Either Left

or Right Side (Right Shown)

SIDE VIEW

STEP C: Slide the bracket left or right to the

correct position for the model that you are

installing. The distance from the side wall to the

center line of the closest mounting hole is 2-3/4"

for model PRG304 or 4-5/8" for Model PRG36.

STEP D: If you plan to mount the bracket to the

rear wall, slide the bracket back until it is

positioned against the rear wall. If you plan to

mount the bracket to the floor, position the

bracket such that the center line of the mounting holes in the horizontal bracket flanges are

7/16" in front of the rear edge of the range

side panel when the range is in its final installed position.

STEP E: With the bracket properly positioned,

use the bracket as a template and mark the

location of the selected mounting holes in

either the rear wall l (4 holes) or the floor (2

holes) with a pencil.

STEP F: Drill holes at the marked locations.

FIG. 12b PRG Wall Mount (Max 2" Clearance)

PLAN VIEW

PRG304: 2-3/4"

PRG36: 4-5/8"

May Be Used On Either Left

or Right Side (Right Shown)

Maxi-

mum

Up to 2"

SIDE VIEW

STEP G: Using the screws provided, securely

fasten the bracket to the rear wall (4 screws) or

floor (2 screws).

Page 12

Page 15

STEP 4: INSTALLING ANTI-TIP DEVICE

STEP H: Using the 1/4"-20 x 1/2" Hex Head

Bolt, Hex Nut and two (2) Flat Washers,

securely attach the Adjustable Anti-Tip

Channel to the existing hole in the flange

located at the bottom rear of the range.

(There are two (2) holes in the range flange,

so be certain to select the hole that is on the

same side as the mounting bracket.) The

flat face of the channel should be flush

against the underside of the range flange.

From the bottom of the channel, screw the

two (2) #10 x 1/2" Phillips Screws up

through the first pair of holes extending

beyond the rear edge of the range flange.

These screws will prevent rotation of the

channel. Note: A number of mounting

holes are provided in the Adjustable

Anti-Tip Channel. Be certain to use

the hole that enables the channel to

engage the mounting bracket when the

range is in its final installed position.

For ranges that are to be installed flush

against a rear wall, use the first hole in

the Adjustable Anti-Tip Channel, such

that the short portion of the channel

extends out from the bottom of the

range flange and the long portion is

hidden beneath the range. Refer to

Figure 10.

STEP I: Carefully slide the range into posi-

tion. FOR THE ANTI-TIP CHANNEL TO

ENGAGE THE MOUNTING BRACKET, THE

REAR EDGE OF THE RANGE SIDE PANEL

MUST BE WITHIN 2" OF THE VERTICAL

FIG. 13 PRG36 Floor Mount

PLAN VIEW

➝

Anti-Tip Channel

➝

Mounting Bracket

PRG304: 2-3/4"

PRG36: 4-5/8"

May Be Used On Either Left

or Right Side (Right Shown)

SIDE VIEW

➝

Anti-Tip Channel

Leveling Leg

➝

➝

Mounting Bracket

MOUNTING FLANGE OF THE ANTI-TIP

BRACKET, AND THE ADJUSTABLE

MOUNTING CHANNEL MUST BE ATTACHED TO THE APPROPRIATE MOUNTING HOLE. REMOVE ANY LOOSE ITEMS

SUCH AS GRATES AND BURNER CAPS

FROM THE TOP OF THE RANGE, THEN

CAREFULLY TILT THE RANGE FORWARD

TO ENSURE THAT THE ANTI-TIP DEVICE

ENGAGES TO PREVENT TIPPING.

PRDS304 AND PRDS36 Dual-Fuel Ranges (Figures 11, 14 and 15)

STEP A: Determine the best location for Anti-

Tip Channel Mounting Bracket. The bracket

may be mounted to the wall or floor behind

the range, offset from side wall as indicated

in the chart below and in Figures 14 and 15:

Model No. "A", Min. "B", Max.

PRDS304 5-1/2" 16-1/2"

PRDS36 6-1/2" 13-1/2"

Page 13

- For Model PRDS304, the dimensions

shown are from the left side wall only.

- For Model PRDS36, the dimensions

shown are from either the left or right

side wall. Locate the bracket on the

side of the range that will not interfere

with the gas supply line, electrical

wiring, conduit or any other item.

- Select either the rear wall or the

floor for mounting the bracket,

based upon which will provide the

greatest holding strength.

Page 16

STEP 4: INSTALLING ANTI-TIP DEVICE

STEP B: Set the bracket on the floor and

turn it

until it is oriented properly. The long

channel should be on the top with the free

end facing towards you,

flanges should be

the floor, and the other set of mount

one set of mounting

resting horizontally on

ing

flanges should be positioned vertically

facing the rear.

STEP C: Slide the bracket to the desired

position. Note that the minimum (dim. "A")

and maximum (dim. "B") spacing from the

side wall to the center line of the closest

bracket mounting hole is as shown in the

chart above and in Figures 14 and 15.

STEP D: If you plan to mount the bracket to

the rear wall, slide the bracket back until it

is positioned against the rear wall. If you

plan to mount the bracket to the floor,

position the bracket such that the center

line of the mounting holes in the horizontal

bracket flanges are 7/16" in front of the

rear edge of the range side panel when the

range is in its final installed position.

FIG. 14 PRDS Wall Mount

PLAN VIEW

Min. A

Max.B

Shown from

Left Side Wall

SIDE VIEW

Max,

up to 2"

STEP E: With the bracket properly posi-

tioned, use the bracket as a template and

mark the location of the selected four (4)

mounting holes.

STEP F: Drill four (4) holes at the marked

locations.

STEP G: Using the four (4) screws provided,

securely fasten the bracket.

STEP H: Carefully slide the range into

position. FOR THE ANTI-TIP DEVICE

TO ENGAGE THE RANGE, THE REAR

EDGE OF THE RANGE SIDE PANEL

MUST BE WITHIN 2" OF THE VERTICAL MOUNTING FLANGE OF THE

ANTI-TIP BRACKET, REMOVE ANY

LOOSE ITEMS SUCH AS GRATES AND

BURNER CAPS FROM THE TOP OF

THE RANGE, THEN CAREFULLY TILT

THE RANGE FORWARD TO ENSURE

THAT THE ANTI-TIP DEVICE ENGAGES TO PREVENT TIPPING.

FIG.15 PRDS Floor Mount

PLAN VIEW

Min. A

Max.B

Shown from

Left Side Wall

SIDE VIEW

716"

Page 14

Page 17

STEP 5: GAS REQUIREMENTS AND HOOKUP

Verify the type of gas being used at the installation site.

As shipped from the factory, all units are configured for

use on natural gas. For use with propane gas, the unit

must be converted. Field conversion for use with propane

must only be done by qualified service personnel. Contact

the dealer where the unit was purchased or Thermador

(800/735-4328). The field conversion kit for all

Professional Gas (PRG series) ranges is Thermador Model

PROGASLPKIT. The field conversion kit for all Professional

Dual Fuel (PRDS series) ranges is Thermador Model

STARLPKIT.

For installation of the appliance at high altitude,

please consult your local gas company for their

recommendation of the correct orifice sizes and any

other necessary adjustments that will provide proper

gas combustion at specified altitudes.

CAUTION:

When connecting unit to propane gas, make

certain the propane gas tank is equipped with

its own high pressure regulator in addition to

the pressure regulator supplied with the

appliance. The pressure of the gas supplied to

the appliance regulator must not exceed 14"

(37mb) water column.

HOOK UP

• A manual gas shut-off valve must be installed

external to the appliance, in an accessible location

from the front, for the purpose of shutting off the gas

supply. The supply line must not interfere with the

back of the unit. Make sure the gas supply is turned

off at the manual shut-off valve before connecting the

appliance.

• The range is supplied with its own pressure regulator

that has been permanently mounted within the range

body.

• Use 5/8" flex line to connect between the gas supply

and the appliance manifold pipe, which exits the

upper left rear of the appliance. The appliance

manifold pipe connection is 1/2" NPT. (See Fig. 3a,

3b, or 3c.) Use caution to avoid crimping the 5/8" flex

line when making bends.

• The gas supply connections should be made by a

competent technician and in accordance with local

codes or ordinances. In the absence of a local code,

the installation must conform to the National Fuel

Gas Code ANSI Z223.1, Current Issue.

• Always use pipe dope or Teflon® tape on the pipe

threads, and be careful not to apply excessive pressure when tightening the fittings.

• Turn on gas and check supply line connections for

leaks using a soap solution. Do not use a flame of

any sort to check for leaks.

Natural Gas Requirements:

Inlet Connection: 1/2" N.P.T. (Minimum 5/8" dia.

flex line.)

Supply Pressure: 6" to 14" water column. (14.9 to

37 mb)

Manifold Pressure: 5" water column (12.5 mb)

Propane Gas Requirements:

Inlet Connection: 1/2" N.P.T. (Minimum 5/8" dia.

flex line.)

Supply Pressure: 11" to 14" water column. (27.4

mb to 37 mb)

Manifold Pressure: 10" water column (24.9 mb)

For Massachusetts Installations:

1. Shut-off valve must be a “T” handle gas

cock.

2. Flexible gas connector must not be

longer than 36 inches.

3. Not approved for installation in a bedroom or a bathroom unless unit is

direct vent.

CAUTION:

“The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less

than 1/2 psig (3.5kPa.).”

“The appliance and its individual shut off valve must be disconnected from the gas supply piping system

during any pressure testing of the system at test pressures in excess of 1/2 psig (3.5kPa.).”

When checking the manifold gas pressure, the inlet pressure to the regulator should be at least

6.0" (14.9 mb) W.C. for natural gas or 11.0" (27.4 mb) for propane.

Do not attempt any adjustment of the pressure regulator.

Page 15

Page 18

STEP 6: ELECTRICAL REQUIREMENTS, CONNECTION & GROUNDING

• Prior to servicing appliance, always

disconnect appliance electrical

supply cord, if so equipped, from

wall receptacle. If appliance is hardwired to power supply, disconnect

power to unit by turning off the

Chart C: ELECTRICAL SUPPLY CIRCUIT REQUIREMENTS

MODEL NUMBER VOLTAGE CIRCUIT RATING FREQUENCY PHASE

PRG304, PRG36 120 VAC 15 Amps 50/60 Hz. Single

and PRG48

PRDS304 120/240 VAC 20 Amps 50/60 Hz. Single

PRDS36 120/240 VAC 35 Amps 50/60 Hz. Single

PRDS48 120/240 VAC 50 Amps 50/60 Hz. Single

• For the PRG All-Gas Ranges,

improper polarization of the

120 VAC electrical supply

circuit will cause malfunction

(such as continuous sparking

of the burner igniters), may

damage this appliance, and

could create a condition of

shock hazard at the igniter of

each burner. If the circuit is

not correctly polarized, it is

the responsibility and obligation of the installer or user to

have the existing receptacle

changed to a properly polarized receptacle in accordance

with all applicable local codes

and ordinances by a qualified

electrician. In the absence of

local codes and ordinances,

the receptacle replacement

shall be

Na

tional Electric Code.

in accordance with the

proper circuit breaker or

disconnecting the proper fuse.

• Gas range models PRG304,

PRG36 and PRG48 must be

plugged into a 3-prong

grounding type receptacle.

• For the PRDS Dual-Fuel

Ranges, a neutral supply wire

must be provided from the

power source (breaker/fuse

panel) because critical range

components, including the

surface burner spark

reignition module, require

120 VAC to operate safely and

properly. An improper

120/240 VAC power supply

will cause malfunction,

damage this appliance, and

possibly create a condition of

shock hazard. If the correct

power supply circuit is not

provided, it is the responsibility and obligation of the

installer or user to have proper

power supply connected. This

must be accomplished in

accordance with all applicable

local codes and ordinances by

a qualified electrician. In the

• Dual Fuel range models

PRDS304. PRDS36 and

PRDS48 can be cord-connected or hard-wired to the

power supply, as described on

Page 17.

absence of local codes and

ordinances, the power supply

connection shall be in accordance with the National

Electric Code.

• Observe all governing codes

and ordinances when grounding. In the absence of these

codes or ordinances observe

National Electrical Code ANSI/

NFPA No. 70 Current Issue.

See pages 17 and 18 for

grounding method.

• Electrical wiring diagrams and

schematics have been placed in

the toe kick area of the range

for access by a qualified service

technician.

• The PRDS Dual Fuel Ranges

may be connected to a 120/

208 VAC power supply.

Chart D: POWER SUPPLY WIRE - RATING AND SIZE REQUIREMENTS

MODEL VOLTAGE TEMPERATURE CONDUCTOR SIZE, AWG

NUMBER RATING, MIN. RATING L1, L2 NEUT GROUND

PRDS304 300 VAC 105°C 10 12 10

PRDS36 300 VAC 105°C 10 12 10

PRDS48 300 VAC 105°C 8 10 8

Page 16

Page 19

STEP 6: ELECTRICAL REQUIREMENTS, CONNECTION & GROUNDING

Dual Fuel models PRDS304, PRDS36 and PRDS48 must be connected to the power supply utilizing one of the

following methods. For all methods of connection, the length of the cord or conduit/wiring must allow the unit to

be slid completely out of the cabinet without having to unplug or disconnect the unit from the power supply.

Recommended minimum free length of cord or conduit is four feet. Electrical installations and grounding must

be in accordance with all local codes and ordinances, and/or the National Electric Code, as applicable.

• 3-CONDUCTOR CORD - Where

local codes and ordinances

permit grounding through

neutral, unit may be connected

to the power supply with a 3pole, 3-conductor cord kit rated

125/250 volts, 50 amperes, and

marked for use with ranges. The

cord kit must be attached to the

range junction box with a strain

relief which will fit a 1-3/8"

diameter hole. If not already

equipped, the cord must have

#10 closed-loop lugs attached to

the free ends of the individual

conductors, preferably soldered

in place.

Locate the junction box on the

rear of the unit and remove

cover. Refer to Fig. 16 for

PRDS304 range and Fig. 16a for

PRDS36 and PRDS48 ranges.

Remove the knock out ring in

the junction box to provide a 13/8" diameter hole. Install the

cord to the junction box, and

make the connections to the

terminal block provided. Refer

to Figures 17 and 17a. The cord

kit must be plugged into a

mating NEMA 10-50R receptacle

provided in the gas and electrical

supply zone, as shown in

Figures 3b, and 3c on Page 6.

•

4-CONDUCTOR CORD - Where

local codes and ordinances DO

NOT PERMIT GROUNDING

THROUGH NEUTRAL, unit

must be connected to the power

supply with a 3-pole, 4-conductor cord kit rated 125/250 volts,

50 amperes, and marked for use

with ranges. The cord kit must

be attached to the range junction box with a strain relief

which will fit a 1-3/8" diameter

hole. If not already equipped,

the cord must have #10 closedloop lugs attached to the free

ends of the individual conductors, preferably soldered in place.

Locate the junction box on the

rear of the unit and remove

cover. Refer to Fig. 16 for

PRDS304 range and Fig. 16a for

PRDS36 and PRDS48 ranges.

Remove the knock out ring in the

junction box to provide a 1-3/8"

diameter hole. Remove the

ground strap retaining screw and

bend the ground strap up. Refer

to Fig. 18. Install the cord to the

junction box, and make the

connections to the terminal block

provided. Secure the ground

lead from the cord to the junction box with the screw previously used to secure the ground

strap. Refer to Fig. 18a. The

cord kit must be plugged into a

mating NEMA 10-50R receptacle

provided in the gas and electrical

supply zone, as shown in Figures

3b, and 3c on Page 6.

• PERMANENT CONNECTION

(HARD WIRING) - Units may be

hard wired to the power supply.

The installer must provide

approved flexible aluminum

conduit, 3/4" trade size, maximum 6 feet long. Locate the

junction box on the rear of the

unit and remove cover. Refer to

Fig. 16 for PRDS304 range and

Fig. 16a for PRDS36 and

PRDS48 ranges. Remove the

ground strap retaining screw and

bend the ground strap up. Refer

to Fig. 18. The conduit must be

installed to the junction box

using an approved conduit

connector.

Wiring for the unit is to be

brought into the junction box

through the conduit. Refer to

Chart D on Page 16 for rating of

wiring and sizing of individual

conductors. The ends of the

wiring must have #10 closedloop lugs attached, preferably

soldered in place. Make the

connections to the terminal

block provided. Secure the

ground lead to the junction box

with the screw previously used

to secure the ground strap.

Refer to Fig. 18a. The free end

of the conduit must be connected to a junction box provided in the gas and electrical

supply zone, as shown in

Figures 3b and 3c on Page 6.

FIG. 16 Location of Junction Box

on PRDS304 Range

FIG. 16a Location of Junction Box

on PRDS36, 48

Hole for Connection of Cord

or Conduit

MODEL DIM “A”

PRDS36 13-1/4"

PRDS48 19"

Page 17

Page 20

STEP 6: ELECTRICAL REQUIREMENTS, CONNECTION & GROUNDING

A 3 or 4 conductor supply may be connected to

the terminal block. A 4 conductor supply shall

be used only when the range is installed in a

mobile home or where local codes do not

permit grounding through the neutral.

3 WIRE LEAD CONNECTION

1. Remove upper nuts only from the terminal

block studs. Do not remove nuts which

secure range internal wiring leads.

2. Secure the neutral, grounded wire of the

supply circuit, to the center stud of the

terminal block with nut. (See Fig. 17a).

3. Secure the L1 (black) and L2 (red) power leads

to the outside terminal block studs (brass

colored) with nuts.

4. Tighten nuts securely.

4 WIRE CONNECTION

1. Remove upper nuts only from the termina

block studs. Do not remove lower nuts

which secure range internal wiring

leads.

2. Remove ground strap screw and bend the

strap up as shown in Fig. 18)

l

FIG.17

FIG. 17a

FIG. 18

Conductor Securement

➝

3 Wire Connection

Neutral White

➛

L1 Black

Ground Strap

➝

Upper Nut

➝

Cupped Washer

➝

Supply Wire

Flat Washer

➛

➛

L2 Red

3. Secure the neutral wire to the center stud of

the terminal block with nut. Tape neutral

wire and connector, as shown in Fig. 18a to

insure strap does not contact a grounded

surface.

4. Secure the L1 (black) and L2 (red) power

leads to the outside terminal studs (brass

colored) with nuts.

5. Secure the bare copper ground lead to the

range chassis using the ground screw previously used for the ground strap.

6. Tighten all connections securely.

Page 18

Bend Ground Strap Up

FIG. 18a

Secure Neutral Wire

L1 Black

➛

L2 Red

➛

➛

Ground Wire

Page 21

STEP 6: ELECTRICAL REQUIREMENTS, CONNECTION & GROUNDING

Recommended Grounding Method – All-Gas

Models PRG304, PRG36 and PRG48

The 30," 36" and 48" all-gas ranges are factory equipped with a power

supply cord with a three-prong grounding plug (with polarized parallel

blades). IT MUST BE PLUGGED INTO A MATING GROUNDING TYPE

RECEPTACLE THAT IS CONNECTED TO A CORRECTLY POLARIZED 120

VOLT CIRCUIT. (See Fig. 19). Improper grounding will cause malfunc-

tion (such as continuous sparking of the burner igniters), may

damage this appliance, and could create a condition of shock

hazard at the igniter of each burner. If the circuit does not have a

grounding type receptacle, it is the responsibility and obligation of the

installer or user to have the existing receptacle changed to a properly

grounded receptacle in accordance with all applicable local codes and

ordinances by a qualified electrician. In the absence of local codes and

ordinances, the receptacle replacement shall be in accordance with the

National Electric Code. THE THIRD GROUND PRONG SHOULD NOT,

UNDER ANY CIRCUMSTANCES, BE CUT OR REMOVED.

Alternate Grounding Method – All-Gas

Models PRG304, PRG36 and PRG48

If installing a properly grounded wall receptacle is impossible at the time of

installation, consult your local electrical inspector for permission to

connect a temporary adapter (with polarized blades) which could be

plugged into your present 2-wire receptacle.

(See Fig. 20). This method is not recommended.

FIG. 19 Recommended

Grounding Method –

Models PRG304, PRS36

and PRG48

RECEPTACLE

BOX COVER

PLATE

THREE-PRONG

RECEPTACLE

THREE-PRONG

PLUG

FIG. 20 Alternate

Grounding Method –

Models PRG304, PRG36

and PRSG48

TWO-PRONG

RECEPTACLE

COVER

PLATE

GROUND

WIRE

If this is done, you must attach the lug and/or the green adapter wire to

the receptacle cover plate screw. Ground from it to a grounded metal cold

water pipe. (See Fig. 21).

DO NOT GROUND TO A GAS SUPPLY PIPE.

Grounding Method – Dual-Fuel

Models PRDS304, PRDS36 and PRDS48

All ranges must be properly grounded. See the grounding instructions for

your installation case, as follows. Refer also to the instructions and

Figures on Pages 17 and 18.

CASE 1: Electrical Connection and Grounding with a 3 Conductor Power

Supply (To be used when local codes permit grounding through

the neutral.) Secure the neutral, grounded wire of the supply

circuit to the neutral terminal of the NEMA 10-50R receptacle.

Connect the L! (black) and the L2 (red) hot heads to the other

terminals on the NEMA 10-50R receptacle. A separate ground

wire is not required. Ensure that the house supply wires and all

electrical connections meet the requirements of all applicable

codes.

GROUND

THREE-PRONG

THREE-PRONG

PLUG

ADAPTER

WIRE

GROUNDED

COLD WATER

FIG. 21 Grounding Method –

Models PRDS304,

PRDS36 and PRDS48

NO. 4 WIRE

CLAMP

METER

CLAMP

METAL WATER PIPE

PIPE

Page 19

Page 22

STEP 6: ELECTRICAL REQUIREMENTS, CONNECTIONS & GROUNDING

CASE 2: Electrical Connections and Grounding

with a 4-Conductor Power Supply (to be

used only when local codes do not permit grounding through the neutral).

Secure the neutral (white) wire of the supply

circuit to the neutral terminal of the NEMA

14-50R receptacle. Connect the L1 (black)

and the L2 (red) hot leads to the other terminals on the NEMA 14-50R receptacle. Connect a separate ground (green) wire to the

grounding terminal of the NEMA 14-50R

receptacle.

If range is hard-wired to power supply, follow

the instructions for permanent connection on

pages 17 and 18. The ground wire must be

STEP 7: BACKGUARD INSTALLATION

The backguard must be attached

before sliding the range into the

final installed position. A Low Back

or High Shelf backguard must be

installed when there is less than a

12" clearance between combustibles

and the back of the range above

the cooking surface. (See Fig. 2a

and 2b).

FIG. 22

Front of Unit

brought out to the junction box on the

range and connected to the box, per the

instructions.

Ensure that the house supply wires and

all electrical connections meet requirements of all applicable codes.

DO NOT GROUND TO A GAS SUPPLY PIPE.

Improper grounding will cause malfunction (such

as continuous sparking of the burner igniters),

may damage this appliance, and could create a

condition of shock hazard at the igniter of each

burner. It is the responsibility and obligation of

the installer or user to ensure that the appliance

is properly grounded.

An Island Trim is available for

covering the backguard mounting

flanges for island installations,

where there is a minimum of 12" of

horizontal clearance between

combustibles and the back of the

range. (See Fig. 2c).

The backguard is inserted, as

shown in Fig. 22, into the guide

channels on the back of the range.

Secure the backguard with the (4)

sheet metal screws provided.

For installation of backguards

on all models, refer to the following

instructions on Page 21.

Chart D: BACKGUARD KIT MODEL NUMBERS

RANGE MODEL NO. 9" STD. LOW BACK 12" LOW BACK 22" HIGH SHELF 1-1/2" ISLAND TRIM

PRDS304/PRG304 Included with Range N/A PHS30T PRS30ITS

PRDS36/PRG36 N/A PRS36LBS PHS36T PRS36ITS

PRDS48/PRG48 N/A PRS48LBS PHS48T PRS48ITS

Page 20

Page 23

INSULATION AND RETAINER REMOVAL

Before the backguard can be assembled onto Model

PRDS304, PRDS36 and PRDS48 Ranges, the insulation

retainer and the insulation must be removed to avoid

interference. This insulation is not required on the

PRDS304, PRDS36 and PRDS48 models.

The High Shelf Back Trim is shown. The procedure is

the same for Island Trim or Low Back Trim

STEP 7: BACKGUARD INSTALLATION

FIG. 22a

Step 1

Remove the four (4) screws holding in insulation

retainer. See Fig. 22a.

Step 2

Slide insulation retainer and insulation out and

discard. See Fig. 22b.

NOTE: DO NOT REMOVE INSULATION WHEN

INSTALLING A BACKGUARD ON MODELS PRG304,

PRG36 AND PRG48 ALL-GAS RANGE.

Install any loose components, such as burner caps and grates, that may

CAUTION

Thermador recommends that

burner adjustments be made by

a qualified technician at the

time of installation. Extreme

care should be used when

adjustments are made after

installation. Improper or lack of

adjustments may void your

warranty.

have been removed earlier. Be certain that burner caps seat properly into

the alignment slots in the burner bases. Before testing operation of the

appliance, verify that the unit and the gas supply have been carefully

checked for leaks and that the unit has been connected to the electric

power supply. Turn the manual gas shut-off valve to the open position.

Check operation of the sealed gas burners and grill by pushing and

turning each knob counterclockwise to “HI”. The burner igniters will click

until the flame ignites. The two far left sealed burners feature XLO®,

causing the flame to cycle on and off when the knob is set to the XLO

range. This is normal operation.

Burner flames should be blue and stable with no yellow tips, excessive

noise, or lifting of the flame from the burner. If any of these conditions

exist, check that the air shutter (grill, griddle and gas oven only) or burner

ports are not blocked or clogged. Remove any blockages that exist.

➝

Screws

FIG. 22b

Insulation

Retainer

STEP 8: TEST AND ADJUSTMENT

If the flame is too yellow, indicating insufficient air, adjust the shutter

counterclockwise to increase air inlet (grill, griddle and gas oven only).

The

sealed top burner flames should be approximately 1" to 1-1/4" high. The

griddle, grill, gas oven and infrared broiler burner flames should be as shown

in Fig. 23).

NOTE: No air shutter or low flame adjustment is necessary or possible with

the sealed top burners.

Page 21

Page 24

STEP 8: TEST AND ADJUSTMENT

FIG. 23

PROPER FLAME (APPROX.)

Griddle, Grill, & Gas Oven Burners

➛

H

➛

Burner Natural Gas Propane Gas

Griddle 3/4" 3/4" to 1"

Grill 1/4" 1/2"

Gas oven 1-1/2" to 2 " 1-1/2" to 3"

Gas Oven Infra-Red Broiler Flame Characteristics should be Visually Inspected

Screen should be

to Resemble Diagram. (Looking at Front of Burner).

Glowing Red

Flame should be approximately 1/8"

thick and should be blue in color

Flame Height "H"

1/8" Plume

* The gas oven infra-red broiler

burner has no air shutter and

is not adjustable when used

with natural gas. When used

on propane gas, an air shutter

is attached, but it is not

adjustable. It is necessary to

operate the oven broiler for 45

minutes to eliminate the harsh

odor of the insulation binder.

This must be done before

broiling food in the range for

the first time and with proper

ventilation.

TO CLEAN AND PROTECT

EXTERIOR SURFACES

The stainless steel surfaces may be cleaned by wiping

with a damp soapy cloth, rinsing with clear water and

drying with a soft cloth to avoid water marks. Any mild

glass cleaner will remove fingerprints and smears.

For discolorations or deposits that persist, refer to the

Care and Use Manual.

To polish and protect the stainless steel, use a cleaner/

polish such as Stainless Steel Magic®.

Page 22

DO NOT allow deposits to remain for long periods of

time.

DO NOT use ordinary steel wool or steel brushes.

Small bits of steel may adhere to the surface causing

rust.

DO NOT allow salt solutions, disinfectants, bleaches or

cleaning compounds to remain in contact with stainless steel for extended periods. Many of these compounds contain chemicals which could prove harmful.

Rinse with water after exposure and wipe dry with a

clean cloth.

Page 25

FINAL CHECK LIST

❑ Placement of unit.

❑ Specified clearances maintained

to cabinet surfaces.

❑ Unit Level – front to back –

side to side.

❑ Burner caps positioned properly

on sealed burner bases.

❑ Manual gas shut off valve

installed in an accessible

location (without requiring

removal of range).

❑ Unit tested and free of gas leaks.

❑ Gas supply pressure does not

exceed 14" (37mb) W.C.

ELECTRICAL

INSTALLER CHECKLIST

❑ Burner caps properly seated

into burner bases with alignment pins engaged.

❑ Grill components properly

seated (not all models). Refer to

Use & Care Manual for Grill

details.

❑ Bezels centered on burner

knobs, and knobs turn freely.

❑ All packaging material removed.

❑ Backguard attached (if horizon-

tal clearance to combustible

materials behind cooking

surface is less than 12").

❑ Ceramic briquettes bag placed

in grill unit (if equipped) per

instructions enclosed.

❑ The stainless steel grill housing

(if equipped) is in place. The

ceramic briquettes are placed

on grill tray per instruction

enclosed.

GAS SUPPLY

❑ Connection: 1/2" N.P.T. with

a minimum 5/8" diameter

flex line.

❑ The appliance is connected only

to the type of gas for which it is

certified for use.

❑ Receptacle with correct over-

current protection is provided

for service cord connection.

❑ Proper ground connection.

❑ Proper polarity at receptacle.

❑ Kick panel in place and two (2)

screws secure.

OPERATION

❑ All internal packing materials

removed. Check below grates

and grill pans and within

oven(s).

❑ If used on propane gas, verify

that the propane gas supply is

equipped with its own high

pressure regulator in addition

to the pressure regulator

supplied with the appliance.

❑ Each burner lights satisfacto-

rily, both individually and with

other burners operating.

❑ Air Shutter adjustment for

proper flame made for Grill,

Griddle and Gas Oven. See

Step 8 and Fig.23.

❑ Griddle is level or tilted slightly

forward and does not rock (not

all models).

❑ Oven door hinges seated and

hinge locks in proper position.

Door opens and closes properly.

(Two doors on Model PRDS48.)

❑ Burner grates correctly posi-

tioned, level, and do not rock.

Page 23

Page 26

NOTES

Page 24

Page 27

NOTES

Page 25

Page 28

Specifications are for planning purposes only. Refer to installation instructions and consult your countertop supplier

prior to making counter opening. Consult with a heating and ventilating engineer for your specific ventilation

requirements. For the most detailed information, refer to installation instructions accompanying product or write

Thermador indicating model number.

We reserve the right to change specifications or design without notice. Some models are certified for use in Canada.

Thermador is not responsible for products which are transported from the United States for use in Canada. Check with

your local Canadian distributor or dealer.

For the most up to date critical installation dimensions by fax, use your fax handset and call 702/833-3600. Use code

#8030.

ECO 14028 • 15-12-596C • © BSH Home Appliances Corp • Litho U. S. A. 4/01

5551 McFadden Avenue, Huntington Beach, CA • 800/735-4328

Loading...

Loading...