Page 1

Thermostatic mixing valves

INSTALLATION AND OPERATING INSTRUCTIONS

FOR THERMOSTATIC MIXING VALVES COMPLYING WITH

N.H.S ESTATES MODEL ENGINEERING SPECIFICATION D08

THE VALVE COVERED IN THIS BOOKLET HAS BEEN DESIGNED AND MANUFACTURED

TO COMPLY WITH N.H.S ESTATES MODEL ENGINEERING SPECIFICATION D08

IT MAY PERFORM SATISFACTORILY OUTSIDE THE LIMITS SPECIFIED HOWEVER

THIS IS OUTSIDE THE SCOPE OF THE TMV2 AND TMV3 SCHEME

TEMPERATURE STABILISED

THERMOSTATIC MIXING VALVE

INTRODUCTION

It has been recognized that users of hot water in care establishments are at risk from scalding.

This risk has been reduced by the use of thermostatic mixing valves.

In order to assure the performance of thermostatic mixing valves N.H.S. Estates Model

Engineering Specification D08 was created. The valve listed in the following pages has been

designed and manufactured to this standard for use within the Build Cert scheme designated

applications.

This Thermostatic mixing valve has also been designed to the TMV2 scheme which is manufactured

to comply with BS EN 1287(LP) and BS EN 1111(HP)

The following abbreviated designation codes are used throughout this booklet. Detailed descriptions

are given below.

HP High pressure

LP Low pressure

S Shower

B Bidet

W Washbasin

T44 Bath with fill temperature of 44°C max

T46 Bath with fill temperature of 46°C max

BE Bidet with economy flow rate

SE Shower with economy flow rate

WE Washbasin with economy flow rate

DESIGNED FOR USE IN THE FOLLOWING DESIGNATIONS

CODE OPERATING PRESSURE APPLICATION

HP-B HIGH PRESSURE BIDET

HP-S HIGH PRESSURE SHOWER

HP-W HIGH PRESSURE WASH BASIN

LP-B LOW PRESSURE BIDET

LP-S LOW PRESSURE SHOWER

LP-W LOW PRESSURE WASH BASIN

HP-T44 HIGH PRESSURE BATH FILL WITH TEMPERATURE UP TO 44°C

TFC GROUP LLP Tower House, Vale Rise, Tonbridge, Kent TN9 1TB

Tel: 01732 351680 Email: sales@tfc.uk.com Web: www.tfc-group.co.uk

Page 2

Thermostatic mixing valves

NOTE: ALL INSTALLATION AND MAINTENANCE PROCEDURES SHOULD

BE CARRIED OUT IN ACCORDANCE WITH THESE GUIDELINES.

PLEASE READ THESE GUIDELINES BEFORE COMMENCING ANY

NEW INSTALLATION OR SERVICING OF EXISTING UNITS.

INSTALLATION RECOMMENDATIONS

The following general recommendations should be observed.

1) Always install isolating valves to facilitate servicing.

2) Always flush both supply pipes fully before connecting mixing valve to ensure no pipe debris

enters the inlets. Always fit filters provided.

3) All installations must comply with current local water company regulations.

TO CLEAN

1. Soak all metal parts in de-scaler, wash off in clean water.

2. Lightly grease all metal parts with silicone grease.

3. Replace worn and damaged ‘O’ rings.

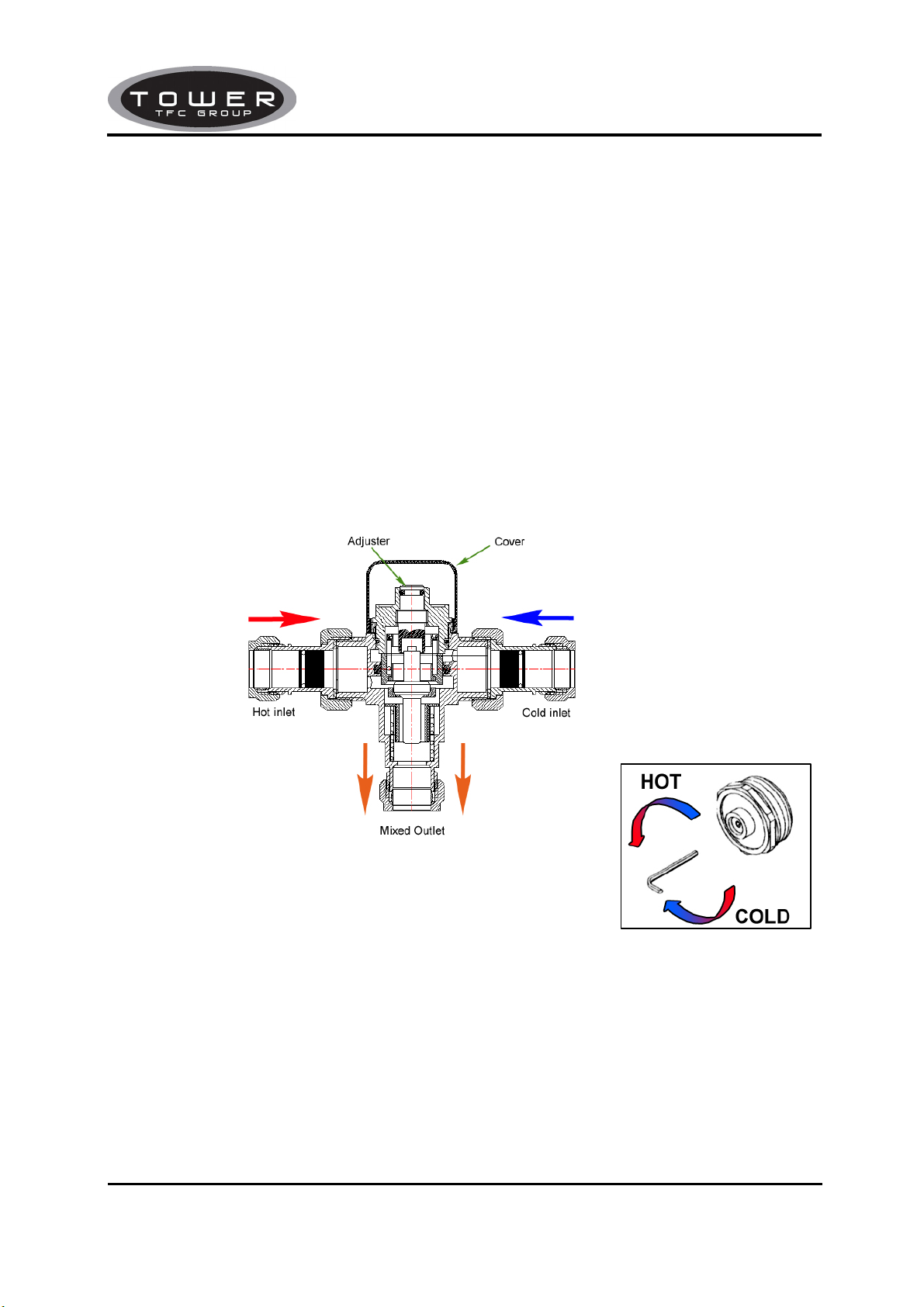

TEMPERATURE SETTING

1. Turn adjustment screw clockwise for cooler temperature,

Anti-clockwise for warmer temperature. Replace head cover.

CONDITIONS FOR NORMAL USE

In order to give compliance with N.H.S. specification D08 and TMV2 scheme, the table below lists

the conditions for normal use, the valves may perform adequately outside these parameters but the

scope of the TMV2 and TMV3 scheme does not apply. If they are required to work with other supply

conditions an engineer must carry out a risk assessment and satisfy themselves that the units are

still suitable for use.

TFC GROUP LLP Tower House, Vale Rise, Tonbridge, Kent TN9 1TB

Tel: 01732 351680 Email: sales@tfc.uk.com Web: www.tfc-group.co.uk

Page 3

Thermostatic mixing valves

Table 1: Conditions for normal use

Operating pressure range Low pressure High pressure

Maximum static pressure-bar 10 10

Flow pressure, hot and cold-bar 0.2 to 1 1 to 5

Hot supply temperature-°C

Cold supply temperature-°C

Minimum Temperature Differential

Between Mixed Temperature &

Either Supply

COMMISSIONING

Since the installed supply conditions may differ from those used in testing and setting the valves

during final inspection and a valve may have several designations, it is necessary to reset the mix

temperature. The following procedure should be used after ensuring:

a) The designation of the thermostatic mixing valve matches the intended application (i.e. if a

shower is to be supplied at 2 bar then the valve must have a HP-S designation).

b) The supply pressures match those for which the valve has been approved, see table1 and

valve details.

c) The supply temperatures are such that they are within the permitted range (see table1) and

comply with guidance information on the prevention of legionella.

Note:- If the supply conditions are not within the parameters for normal use the valve may still

be suitable, but individual engineers must carry out their own risk assessment and satisfy

themselves that the units are still suitable for use.

Adjust the mixed water temperature in accordance with table 2, the method of adjustment is

covered in the section temperature setting.

Table 2: Mixed Water Temperature

Application Abbreviated Designation

Bidet -HP-B,BE,-LP-B,BE 38 max

Shower -HP-S,SE,-LP-S,SE 41 max

Washbasin -HP-W,WE,-LP-W,WE 41 max

Bath (44°C fill)

Bath (46°C fill)

-HP-T44,-LP-T44 44 max

-HP-T46,-LP-T46 46 max

Note 1: For washbasins, washing under running water is assumed.

Note 2: Bath fill temperatures of more than 44°C should only be available when the bather is

always under the supervision of a competent person (e.g. nurse or care assistant)

Note 3: A thermostatic mixing valve having multiple designations (i.e. it is capable of satisfying

the requirements of this specification for more than one application) should be reset on site to

suit be designation required.

The following set of tests should be carried out.

1) Record the temperature of the hot and cold water supplies.

2) record the temperature of the mixed water at the largest draw-off flow rate.

3) record the temperature of the mixed water at a smaller draw-off rate, which shall be

measured.

4) Isolate the cold water supply to the mixing valve and monitor the mixed water temperature.

5) record the maximum temperature achieved as a result of (d) and the final temperature.

6) record the equipment, thermometer etc. used for the measurements.

TFC GROUP LLP Tower House, Vale Rise, Tonbridge, Kent TN9 1TB

Tel: 01732 351680 Email: sales@tfc.uk.com Web: www.tfc-group.co.uk

52-65 52-65

5 to 20 5 to 20

10°C 10°C

Mixed water temperature °C

Page 4

Thermostatic mixing valves

IN-SERVICE TESTING

The purpose of in-service testing is to regularly monitor the thermal performance of the

thermostatic mixing valve. Deterioration in performance can indicate the need for service work

to be carried out on the system.

If the authority concerned does not have a planned test and maintenance schedule then the

suggestions below should form the basis of a new system.

At intervals of 6-8 weeks and 12-15 weeks after commissioning:

a. Check supply parameters are still within the expected values if not check system for faults.

b. Carry out commissioning procedures 1) to 6) using the same test equipment, if the mixed

water temperature has changed a significant amount (by more than 1K) check to ensure

in-line filters are clean, that the check valves are working and all isolating valves are fully

open. If no fault can be found check and record the mixed water temperatures and

re-adjust mixed water temperature to the values in table 2.Complete the commissioning

procedure 1) to 6) if the mixed water temperature exceeds the values of the maximum

recorded temperature by more than 2K the need for service work is indicated.

Depending on the results of these two tests the following should be adopted.

I. If a small change (e.g.1K to 2K) occurs in one of these tests or there is no significant change

(e.g.1K maximum) then the next in service test should be 24 to 28 weeks after

commissioning.

II. If small changes occur in both test or a larger change occurs in one test (exceeding 2K) then

the next in service test should be carried out 18 to 21 weeks after commissioning.

These results can then be used to set a service interval which tests have shown can be used

with no more than a small change in mixed water temperature. This method of determining

service intervals is used to take into account various in-service conditions (i.e. water condition)

that the valve may experience.

CONNECTIONS SPECIFICATIONS

134

44.70

H

C

56

INLETS 15mm Compression

OUTLET 15mm Compression

TFC GROUP LLP Tower House, Vale Rise, Tonbridge, Kent TN9 1TB

Tel: 01732 351680 Email: sales@tfc.uk.com Web: www.tfc-group.co.uk

Page 5

Thermostatic mixing valves

SPECIFICATIONS

Minimum pressure drop through fitting for correct mixing 0.1bar (1 Metre head)

Maximum pressure drop through fitting for correct mixing 5.0bar (50 Metre head)

Maximum static pressure to be applied to fitting 10.0 bar (100 Metre head)

Maximum pressure loss ratio 20:1 either supply

Temperature stability with normal variation of supply

Temperatures and pressures

Factory set standard blend temperature Not Pre-set

Maximum hot supply temperature 80°C

The sensitive wax capsule will shut down the operation of the valve if either the hot or cold water

supply fails, provided a minimum differential of 10°C exists between the mixed water temperature

and the remaining supply.

PERFORMANCE

PRESSURE

DROP(BARS)

FLOW RATE

(LITRES/MIN)

0.1 0.2 0.4 0.6 0.8 1 1.5 2 3 4 5

5.9 9.8 14.7 18.2 21.3 23.8 30.5 35.0 42.5 49.5 55.2

Flow rates are open outlet with equal pressure drops, fitted with Check valves and Filter as

supplied.

Product Support & Guarantee

This product is guaranteed against faulty materials and workmanship for 1 year from date of

purchase. For the guarantee to be valid, the unit must be installed by a competent person, in

accordance with the instruction booklet.

This guarantee does not affect your statutory rights.

±2°C from set temperature

TFC GROUP LLP Tower House, Vale Rise, Tonbridge, Kent TN9 1TB

Tel: 01732 351680 Email: sales@tfc.uk.com Web: www.tfc-group.co.uk

Loading...

Loading...