Page 1

User’s Guide

UCC3817 BiCMOS Power Factor

Preregulator Evaluation Board

User’ s Gu ide

1

Page 2

SLUU077C – September 2000 – Revised November 2002

UCC3817 BiCMOS Power Factor Preregulator

Evaluation Board

Mike O’Loughlin Power Supply Control Products

Contents

1 Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Description 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Operating Guidelines 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Step 1: Load Connections 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Step 2: Applying Input Power 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Step 3: Measuring the Evaluation Board’s Performance 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Evaluation Board Layouts 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Evaluation Board Components 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Typical Performance 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Additional Information 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

UCC3817 BiCMOS Power Factor Preregulator

Page 3

SLUU077C – September 2000 – Revised November 2002

1 Introduction

This user’s guide details the Texas Instruments (TI) UCC3817–EVM BiCMOS Power Factor Preregulator

Evaluation Module (EVM) SLUU077. It includes a list of EVM features, a brief description of the module

illustrated with pictorial and schematic diagrams and EVM specifications.

The UCC3817 evaluation board is designed to illustrate the performance of the controller in a 250 W boost

converter with power factor correction. The board is designed to handle a universal input operating voltage

range (i.e. 85–265 V ac) with a regulated 385 V dc output.

Proper precautions must be taken

when working with the board

CAUTION:

D High voltage levels are present on the evaluation board whenever it is energized.

D The output capacitor has high levels of energy storage and it must be discharged before the load is removed.

Improper handling of the evaluation board could cause serious injury.

D It is important to maintain the ambient temperature around the evaluation board to below 40°C during

operation

1.1 Evaluation Module Features

D

Designed for Compliance with IEC 1000-3-2 (Low Total Harmonic Distortion)

D Worldwide Line Operation 85 V

RMS

to 265 V

RMS

D Regulated 385-V, 250-W(max), dc Output

D Accurate Power Limiting

D Accurate Overvoltage Protection

1.2 Description

The UCCx817 provides all the functions necessary for active power-factor-corrected preregulators. The

controller achieves near-unity power factor by shaping the ac input-line current waveform to correspond to that

of the ac input-line voltage. Average current-mode control maintains stable, low-distortion, sinusoidal line

current.

The controller’s operation is similar to previously designed Unitrode preregulators with an added feature to

reduce the RMS-current in the boost capacitor. The controller uses leading-edge modulation that, when

synchronized properly with a downstream dc-to-dc converter, reduces the RMS current in the boost capacitor.

UCC3817 BiCMOS Power Factor Preregulator

3

Page 4

SLUU077C – September 2000 – Revised November 2002

V

LINE

85–265

V

RMS

AC2

AC1

IAC

F1

C14

1.5µF

400 V

R21

383

k

R16

Ω

R8 12

Ω

k

D6

100

C13

0.47µF

600 V

R14

0.25Ω5

W

R9

4.02

Ω

k

C8 270 pF

R15

51

Ω

k

R10

4.02

Ω

k

(OPTIONAL)

C9 1.2 nF

C7 150 nF

R7

100

Ω

k

C6 2.2µF

R6 30

C15

3.3µF

Ω

k

SEE EVM WARNINGS

AND RESTRICTIONS

VCC

R13

383

Ω

Ω

k

D3

6 A

600 V

R12

2

Ω

k

R11

10

Ω

k

V

REF

(OPTIONAL)

C10

1µF

D7

D8

L1

1 mH

HIGH VOLTAGE –

1

2

IAC

3

4

5

6

7

8

PKLIMIT

CAOUT

CAI

MOUT

IAC

VAOUT

VFF

D5

C11

1µF

D2

8 A, 600 V

UCC3817

VCC

CT

SS

RT

VSENSE

OVP/EN

VREF

HIGH TEMPERATURE –

SEE EVM WARNINGS

AND RESTRICTIONS

Q1

R17

D4

R3 20

Ω

k

VREF

20

C5 1µF

16GND DRVOUT

15

14

13

12

11

10

9

NOTE: High-Voltage component. See EVM Warnings and Restrictions at the back of this document.

NOTE: High-Temperature component. See EVM Warnings and Restrictions at the back of this document.

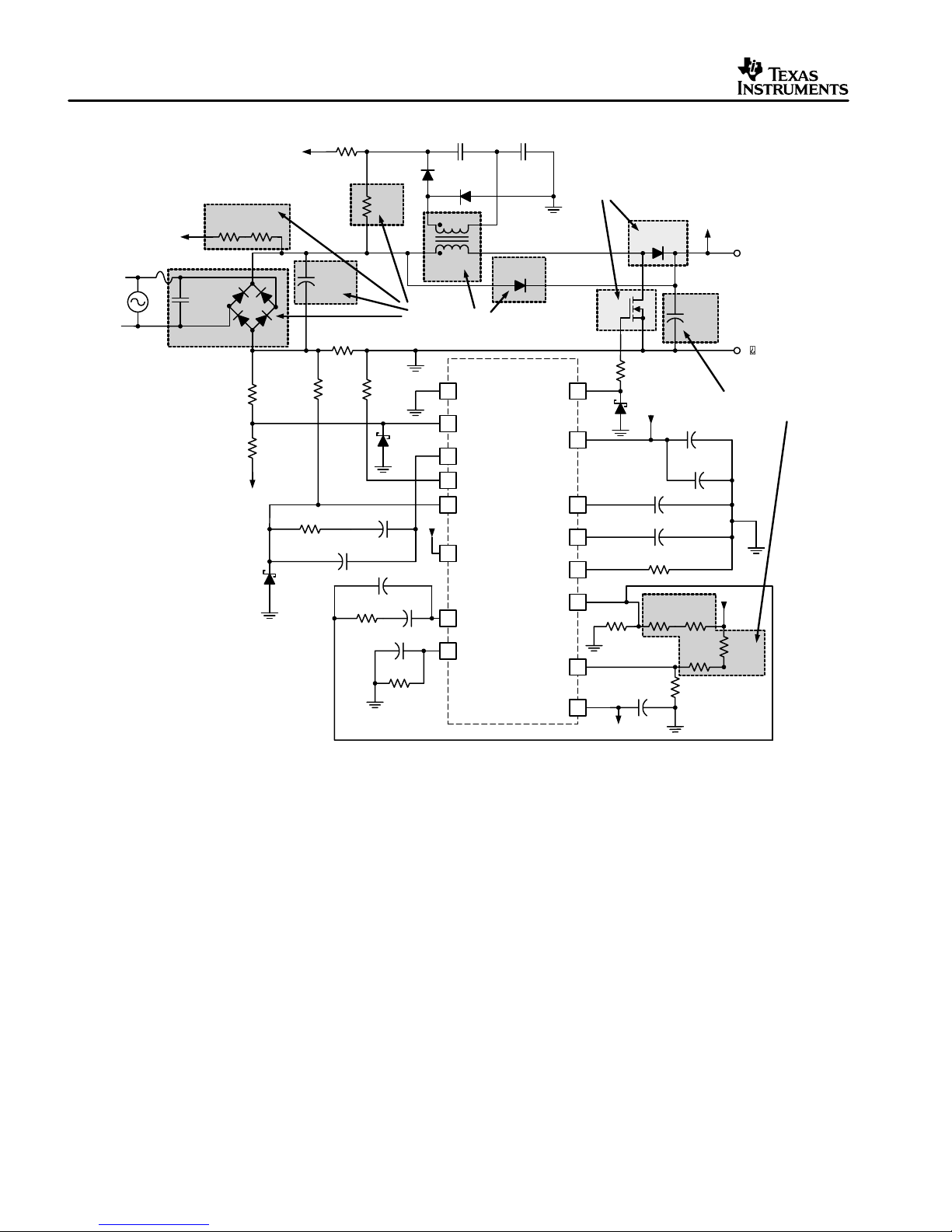

Figure 1. Evaluation Board Schematic

D1

6 A, 600 V

Ω

VCC

C1 560 pF

C4 0.01µF

R1 12

Ω

k

R2

499

Ω

k

V

C12

220µF

450 V

C3

1µF CER

C2

100µF AI EI

R19

499

Ω

k

R20

274

Ω

k

R5 10

Ω

k

O

V

O

+

V

OUT

385V

DC

GND

HIGH VOLTAGE –

SEE EVM WARNINGS

AND RESTRICTIONS

V

O

R4

249

Ω

k

UDG-01001

2 Operating Guidelines

The operating guidelines for the evaluation board are provided with reference to the schematic in Figure 1.

NOTE: In order for the output voltage to regulate, a load of 10 W must be applied to the evaluation

board’s output. In order to maintain power factor near unity , the voltage loop is designed with a slow

frequency response. Large transient steps in output current can cause the evaluation module to go

out of regulation.

4

UCC3817 BiCMOS Power Factor Preregulator

Page 5

SLUU077C – September 2000 – Revised November 2002

2.1 Step 1. Load Connections

A resistive or electronic load should be applied to the output connections of VO and GND.

NOTE: For safety reasons the load should be connected before power is supplied to the evaluation

board.

2.2 Step 2. Applying Input Power

A 50- or 60-Hz ac power source not exceeding 265 V

needs be applied across terminals AC1 and AC2 for

RMS

proper operation.

2.3 Step 3. Measuring the Evaluation Board’s Performance

With the ac source set between 85 V

current should track the input-voltage shape with near-unity power factor. The operation of the circuit is verified

over the line and load range and shows efficiency in the 90–95% range. At lighter loads, there may be some

distortion in the line current due to DCM operation. Please refer to Figure 3 and Figure 4 for typical evaluation

board performance.

RMS

and 265 V

, the output voltage should be regulated and the input

RMS

3 Evaluation Board Layouts

R18

R15

D7

D2

R14

HS1

D1

Q1

V0

GND

HIGH TEMPERATURE

SEE EVM WARNINGS

AND RESTRICTIONS

HIGH VOLTAGE

SEE EVM WARNINGS

AND RESTRICTIONS

D8

AC2

XC12

AC1

XL1

L1

C13

UCC3817 EVALUATION BOARD

NOTE: High-Voltage component. See EVM Warnings and Restrictions at the back of this document.

NOTE: High-Temperature component. See EVM Warnings and Restrictions at the back of this document.

Figure 2. UCC3817 Evaluation Board Layout Assembly

FA1

C12

C10

C11

R21

D3

R13

R12

R11

R8

D5 D6

R10

R16

R9

C9

C8

C15

C6

U1

C14

C7

R7

R6

C2

C3

C5

R20

GND

R17

D4

VCC

R22

C1

C4

SYNC

R1

R2

R19

R3

R4

R5

HIGH VOLTAGE

SEE EVM WARNINGS

AND RESTRICTIONS

UCC3817 BiCMOS Power Factor Preregulator

5

Page 6

SLUU077C – September 2000 – Revised November 2002

Ca acitors

Resistors

4 Evaluation Board Components

. Bill of Materials

Reference Qty DESCRIPTION Manufacturer Part Number

C1 1 560 pF, 50 V, ceramic Panasonic ECU–S1H561JCA

C2 1 100 µF, 25 V, electronic Panasonic EEU–FC1V101S

C3, C5 2 1 µF, 50 V, ceramic Panasonic ECU–S1H105MEB

C4 1 0.01 µF, 50 V, ceramic Panasonic ECU–S1H103KBA

C6, C15 2 2.2 µF, 50 V, ceramic Panasonic ECU–S1H225MEB

C7 1 150 nF, 50 V, ceramic, ±10% Panasonic ECU–S1H154KBB

Capacitors

Diodes

Fuses

Heat Sink

Inductors L1 1 1 mH, 5.5 A, 20:1 TR

MOSFETs Q1 1 International Rectifier IRFP450

Resistors

C8

C9 1 1.2 nF, 50 V, ceramic, ±10% Panasonic ECU–S1H122JCB

C10, C11 2 1 µF, 50 V, stacked metal poly Panasonic ECQ–V1H105JL

C12 1 220 µF, 450 V electronic Panasonic ECO–S2WB221DA

C13 1 0.47 µF, 600 V (optional for user, not used on EVM) Panasonic ECQ–E6474KF

C14 1 1.5 µF, 400 V Poly Panasonic ECW–F4155JB

C16 1 Not used Panasonic ECU–S2A330JCA

D1 1 6 A, 600 V, ultra fast diode International Rectifier HFA08TB60

D2 1 8 A, 600 V, 400 A surge General Instruments GI756CT

D3 1 6 A, 600 V, bridge General Instruments PB66

D4, D5,

D7, D8

D6 1 100 mA, 20 V, schottky BAT85

D9 1 Not used

F1 1 6 A, 250 V, 3 AG glass fast acting cartridge type

FH1, FH2

HS1 1 Heat sink for Q1 Aavid 513201

HS2

R1 1 12.1 kΩ, 1/4 W

R3 1 20 kΩ

R4 1 249 kΩ

R5, R11 2 10 kΩ

R6 1 30.1 kΩ

R7 1 100 kΩ

R8

R9, R10 2 4.02 kΩ

R12 1 2 kΩ

R13, R21 2 383 kΩ

R14 1 0.25 Ω, 3 W

R15, R18 2 24 kΩ, 1W, metal oxide/metal film Panasonic ERG 1S G 243

R16 1 100 Ω

1 270 pF, 50 V, ceramic, ±10% Panasonic ECU–S1H271JCA

4 1 A, 40 V, schottky 1N5819

2 3AG fuse clip

1 Heat sink for D1 Aavid 579302 B 0 00 00

Cooper Electronic

Technologies

1 12.1 kΩ

CTX08–13679–02

6

UCC3817 BiCMOS Power Factor Preregulator

Page 7

SLUU077C – September 2000 – Revised November 2002

Resistors

Hardware

Reference Qty DESCRIPTION Manufacturer Part Number

R17 1 20 Ω

R18 1 24 kΩ, 1W, metal oxide/metal film ERX 1S G 243

Resistors

Integrated

Curcuit

Sockets X @ U1 1 16 pin DIP socket

Board PCB 1 UCC3817 BARE PC BOARD

Hardware

NOTE: Unless otherwise specified, all resistors are 0.25 W metal film with a 1% tolerance.

R2, R19

R20 1 274k

R22 1 Zero Ohm jumper or 26AWG wire

U1 1 UCC3817N Texas Instruments UCC3817N

X1 @ Q1 1 Thermal Pad Silicone TO220

X2 @ HS1

X3 @ HS1 1 Nut #6X32

2 499 kΩ

1 Screw Pan Hd #6–32 X 3/8

5 Typical Performance

EFFICIENCY vs. OUTPUT POWER

100

VIN = 265 V

95

VIN = 175 V

90

Efficiency (%)

85

80

75

25 50 75 100 125 150 175 200 225 250

VIN = 85 V

P

– Output Power – W

OUT

Figure 3.

UCC3817 BiCMOS Power Factor Preregulator

7

Page 8

SLUU077C – September 2000 – Revised November 2002

POWER FACTOR

OUTPUT POWER

1.1

VIN = 85 V

1.0

vs.

0.9

0.8

0.7

Power Factor

0.6

0.5

0.4

25 50 75 100 125 150 175 200 225 250

VIN = 175 V

VIN = 265 V

P

– Output Power – W

OUT

Figure 4.

6 Additional Information

For more information, pin description and specifications for the UCC3817 PFC Controller, please refer to the

UCC3817 datasheet, TI Literature Number SLUS395, or contact the Texas Instruments Semiconductor Product

Information Center at 1–800–336–5236 or 1–972–644–5580. Product information can also be found on the at

http://www.ti.com.

This evaluation module can also be used to evaluate the performance of the UCC3818 PFC control IC by

removing R16 and applying the bias voltage to the VCC pin through a separate bias supply.

8

UCC3817 BiCMOS Power Factor Preregulator

Page 9

SLUU077C – September 2000 – Revised November 2002

DYNAMIC WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the input voltage range of 85 V to 265 V ac and the output voltage of

385 V +/– 10%.

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM.

If there are questions concerning the input range, please contact a TI field representative prior to connecting

the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible

permanent damage to the EVM. Please consult the EVM User’s Guide prior to connecting any load to the EVM

output. If there is uncertainty as to the load specification, please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than 50°C. The EVM

is designed to operate properly with certain components above 50°C as long as the input and output ranges are

maintained. These components include but are not limited to linear regulators, switching transistors, pass

transistors, and current sense resistors. These types of devices can be identified using the EVM schematic

located in the EVM User’s Guide. When placing measurement probes near these devices during operation,

please be aware that these devices may be very warm to the touch.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2001, Texas Instruments Incorporated

UCC3817 BiCMOS Power Factor Preregulator

9

Page 10

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty . Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. T o minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third–party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party , or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Page 11

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

UCC3817EVM

Loading...

Loading...