Page 1

User’ s Gu ide

April 2001 Mixed-Signal RF Products

SWRU003B

Page 2

IMPORTANT NOTICE

Texas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify , before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its products to the specifications applicable at the time of sale in accordance with

TI’s standard warranty. Testing and other quality control techniques are utilized to the extent TI deems necessary

to support this warranty . Specific testing of all parameters of each device is not necessarily performed, except

those mandated by government requirements.

Customers are responsible for their applications using TI components.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

products or services might be or are used. TI’s publication of information regarding any third party’s products

or services does not constitute TI’s approval, license, warranty or endorsement thereof.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations and notices. Representation

or reproduction of this information with alteration voids all warranties provided for an associated TI product or

service, is an unfair and deceptive business practice, and TI is not responsible nor liable for any such use.

Resale of TI’s products or services with statements different from or beyond the parameters

stated by TI for

that product or service voids all express and any implied warranties for the associated TI product or service,

is an unfair and deceptive business practice, and TI is not responsible nor liable for any such use.

Also see: Standard Terms and Conditions o f S ale for S emiconductor P roducts.

www .ti.com/sc/docs/stdterms.htm

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2001, Texas Instruments Incorporated

Page 3

EVALUATION BOARD DISCLAIMER

The enclosed evaluation boards are experimental printed circuit boards and are therefore

only intended for device evaluation.

We would like to draw your attention to the fact that these boards have been processed

through one or more of Texas Instruments’ external subcontractors which have not been production qualified.

Device parameters measured, using these boards, are not representative of any final datasheet or o f a final production version. Texas Instruments does not represent or guarantee that

a final version will be made available after device evaluation.

THE EVALUATION BOARDS ARE SUPPLIED WITHOUT W ARRANTY OF ANY KIND, EXPRESSED, IMPLIED OR STATUTORY, INCLUDING BUT NOT LIMITED TO, ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEXAS INSTRUMENTS ACCEPTS NO LIABILITY WHATSOEVER ARISING AS A RESULT

OF THE USE OF THESE BOARDS.

The fee associated with the evaluation modules (EVM) is a partial nonrecurring engineering

fee (NRE) to partially defray the engineering costs associated with the EVM development

and applications support for the RF integrated semiconductor product. The EVM is a tool for

evaluating the RF semiconductors supplied by Texas Instruments. The EVM is supplied to

prospective component customers to provide services and software allowing the prospect

customers to evaluate the RF semiconductors in products they would build.

The EVM may be operated only for product evaluation purposes and then only in nonresidential areas. TI’s understanding is that the customers’ products using the RF parts listed shall be

designed to comply with all applicable FCC and appropriate regulatory agency requirements

and will, upon testing, comply with these requirements. Operation of this device is subject to

the conditions that it not cause harmful interference and that it must accept any interference.

Page 4

About This Manual

This document is intended to introduce the TRF4900 evaluation module

(EVM) and familiarize the reader with setting up and testing the TRF4900 EVM

using the evaluation software in a typical laboratory environment.

How to Use This Manual

Information About Cautions and Warnings

Preface

This document contains the following chapters:

- Chapter 1 − Overview

- Chapter 2 − Evaluation Board

- Chapter 3 − Software User’s Guide

Information About Cautions and Warnings

This book may contain cautions and warnings.

This is an example of a caution statement.

A caution statement describes a situation that could potentially

damage your software or equipment.

This is an example of a warning statement.

A warning statement describes a situation that could potentially

cause harm to you

.

The information in a caution or a warning is provided for your protection.

Please read each caution and warning carefully.

Read This First

iii

Page 5

iv

Page 6

Running Title—Attribute Reference

1 Overview 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Purpose 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 EVM Setup 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Block Diagram 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Evaluation Board 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Schematics 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Top Side Silkscreen and Drawing 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Bottom Side Silkscreen and Drawing 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Parts List 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 EVM DC Voltage Setup 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Serial Interface and PC Port Pin Out 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Standard PC Parallel Port 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Jumper Connections 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Jumper Description 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Connectors and Test Points 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Connectors 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 Test Points (TP) 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.3 Adjustments 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.4 LED Indicators 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Software User’s Guide 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Introduction 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Main Program Screen 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Synthesizer 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Mode Options 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Output Parameters 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 PLL and MM Options 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.5 Help 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.6 Words 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.7 Operation Mode 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.8 Changing Values on the Main Program Screen 3-5. . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Chip Layout Screen 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 PLL/Modulation Options Screen 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Testing of Transmitter 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Title—Attribute Reference

v

Page 7

Running Title—Attribute Reference

1−1 TRF4900 Block Diagram 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−1 TRF4900 EVM DC Voltage Setup 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−2 TRF4900 EVM Serial Interface 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−1 Main Program Screen 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−2 Chip Layout Screen 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−3 PLL/Modulation Options Screen 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−4 Block Diagram for Testing of the TRF4900 EVM Transmitter Section 3-9. . . . . . . . . . . . . . . . .

3−5 Main Program Screen 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−6 Chip Layout Screen 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−7 Spectrum Analyzer 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−8 Input of Frequency Error 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−9 Main Panel Display After Clock Offset Is Applied 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−10 Chip Layout View for FSK Modulation Output Test 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−11 PLL/Modulation Options Screen 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−12 FSK Output From Transmitter 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−13 Block Diagram for Testing of the TRF4900 EVM Transmitter Section With an

3−14 FSK Output From Transmitter With an External Modulation 3-17. . . . . . . . . . . . . . . . . . . . . . . .

External Pulse Generator 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Page 8

Chapter 1

This chapter provides an overview of the TRF4900 evaluation module (EVM).

Topic Page

1.1 Purpose 1−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 EVM Setup 1−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Block Diagram 1−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview

1-1

Page 9

Purpose

1.1 Purpose

1.2 EVM Setup

The TRF4900 evaluation module (EVM) provides a platform for lab prototype

evaluation of the Texas Instruments TRF4900.

The TRF4900 EVM board evaluates the RF performance of the TRF4900. It

contains a PC parallel port interface and operates from 850 MHz to 950 MHz

from 2.2 V to 3.6 V. The TRF4900 EVM contains two SMA connectors that

allow the user to observe transmitted data, to test the VCO tuning range, or

to feed in an external RF input. The transmitted data can be viewed on a

spectrum analyzer as either a single output frequency or in FSK mode at data

rates up to 30 kbps. Although higher data rates are achievable with the

TRF4900, the TRF4900 EVM is designed to operate at data rates up to 30

kbps at room temperature.

The 3.5-inch diskette supplied with the TRF4900 contains the software

required to demonstrate the TRF4900. Complete the following steps to set up

the TRF4900 for evaluation.

Step 1: Place the 3.5-inch diskette into the floppy disk drive of the computer

being used to evaluate the TRF4900.

Step 2: Copy the TRF4900.exe file to the hard drive.

Step 3: Connect a DB25 female to a DB25 male cable between the TRF4900

evaluation board and the PC parallel port. The DB25 female end of

the cable is connected to the TRF4900. The DB25 male end of the

cable is connected to the desired LPT port of the PC (LPT1 or LPT2).

Step 4: Connect a dc power supply capable of 10 V 200 mA between the red

power supply pin and ground on the TRF4900 evaluation board.

Step 5: Verify that the power supply output is set to 8 V.

Step 6: Turn the power supply on.

Step 7: If the jumper at JP4 is installed, verify that LED3 (the red power on

LED) is illuminated.

Step 8: Run the TRF4900.exe file on the PC.

Step 9: Press the Send Words Now (F12) button located on the main

program screen.

Step 10: Verify that LED1 (the green lock detect LED) is illuminated. When the

lock detect LED is illuminated, the PLL is locked on frequency.

Note:

The actual icons/windows on the computer screen may differ from those

shown in the user’s guide, due to software version upgrades.

The schematics shown in this user’s guide may not match the current

revision, due to PCB and component upgrades.

Always check the TI website for the latest schematics and software.

1-2

Page 10

1.3 Block Diagram

Figure 1−1 shows the block diagram for the TRF4900.

Figure 1−1.TRF4900 Block Diagram

Block Diagram

PD_OUT1

PLL_VCC

PD_SET

VCO_TANK1

VCO_TANK2

PLL_GND

DIG_GND

CLOCK

DATA

STROBE

MODE

STDBY

1

2

3

PLL

24

PD_OUT2

23

LOCKDET

22

PA_OUT

Power

4

VCO

5

6

7

8

9

Serial

Interface

10

11

12

TRF4900

Direct Digital Synthesizer

Power-Down Logic

Amplifier

and

21

PA_GND

20

PA_VCC

19

GND

18

DIG_GND

17

XOSC2

16

XOSC1

15

DIG_GND

14

TX_DATA

13

NC

Overview

1-3

Page 11

1-4

Page 12

Chapter 2

This chapter describes the EVM and its operation.

Topic Page

2.1 Schematics 2−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Parts List 2−6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 EVM DC Voltage Setup 2−10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Serial Interface and PC Port Pin Out 2−11. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Standard PC Parallel Port 2−12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Jumper Connections 2−13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Connectors and Test Points 2−14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Evaluation Board

2-1

Page 13

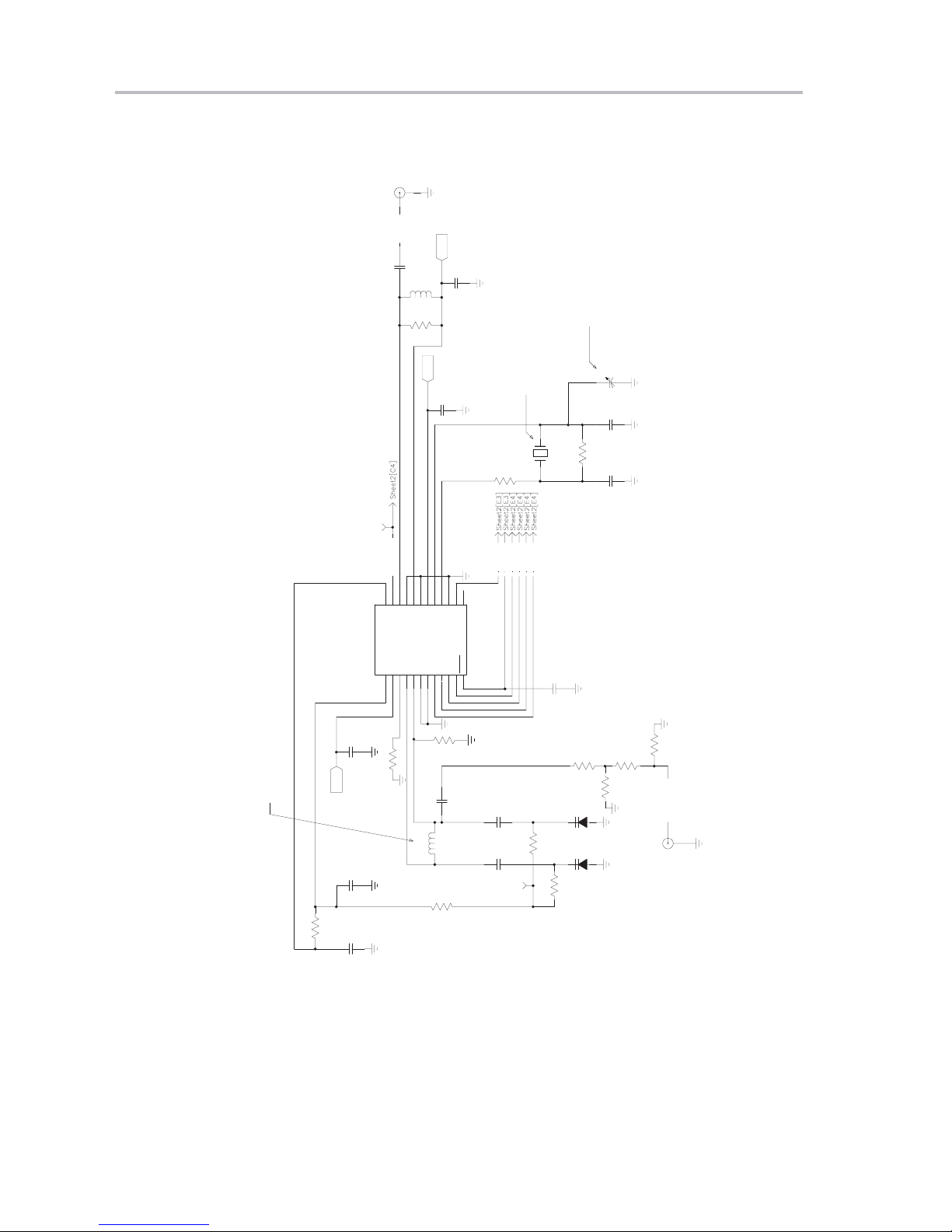

Schematics

2.1 Schematics

J1

TX_OUTTX_OUT

C4

3.3pF

LDET

LOCKDET

20

21

22

23

24

PA_VCC

PA_O UT

PA_G ND

PD_OUT2

LOCKDET

IC1

PD_SET2PLL_VCC

PD_OUT14VCO_TANK15VCO_TANK26PLL_GND7DIG_GND8CLOCK

3

1

R3

19

6.8nHL1LQW1608

51

18

GND

VCC1

C5

16

DIG_VCC

DATA

9

VCC1

C7

0.1uF

15

XOSC117XOSC2

DIG_GND

STROBE11MODE12STDBY

10

0.1uF

13NC14

TRF4900

TXDATA

R4

100

STDBY

MODE

FUNDAMENTAL MODE

CQ1

DATA

STROBE

INITIAL TOLERANCE +/− 7 PPM

CLOCK

STAB OVER TEMP +/− 20 PPM

C10

TEMP RANGE −40TO +85 DEG C

25.6MHz

1000pF

DNP

SELECT FOR OUTPUT

FREQUENCY AT J1

1.5 − 10pF

C13

DNP

SAT

10pF

C12

R7

1.0M

10pF

C11

2-2

NOTES:

DNP: DO NOT PLACE

TBD: TO BE DETERMINED

123

0.1uF

C3

R2

SELECT L2 FOR CENTER FREQUENCY.

SELECT C8, C9 FOR TUNING RANGE.

TYPICAL TUNING RANGE (Vcc=3.3V)

Vt: 0.5 TO 3.0V f: 845−965MHz

SAT: SELECT AT TEST

VCC1

470pF

C2

R1

6.2k

4700pF

C1

100k

R38

100k

C6

DNP

L2

10nH

LQW1608

0

JP1

4.7pF

C9

R5

4.7pF

C8

TP1

TBDR8DNP

R10

SMV1247−079

V2

1

2

10k

1

2

V1

R6

10k

SMV1247−079

TBD

DNP

R9

DNP

TBD

R11

TBD

DNP

VCO_TANK

J2

VCO_TANK

Page 14

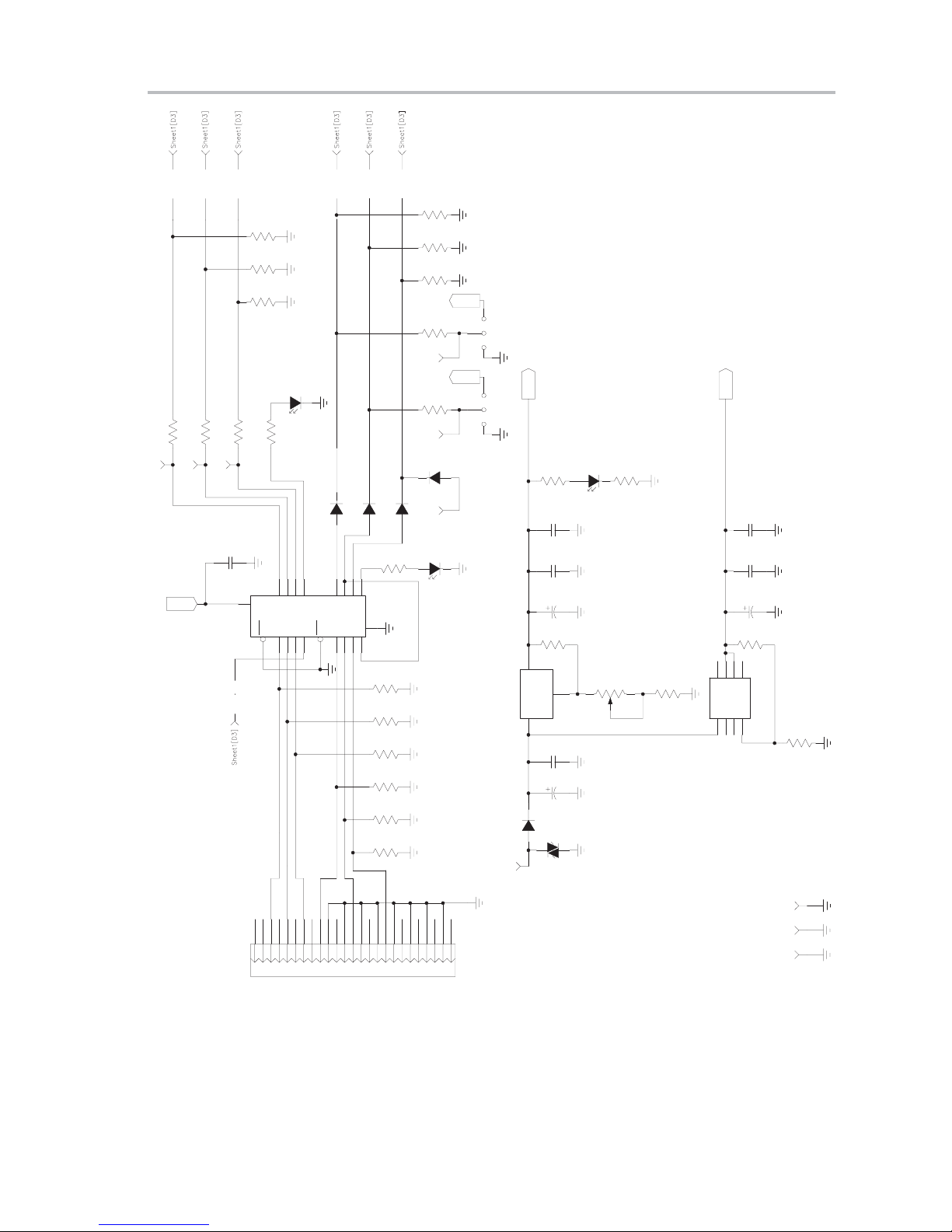

Schematics

MODE

STDBY

CLOCK

DATA

100

R12

DATA

CLOCK

STROBE

10k

R17

10k

R16

10k

R15

LED1

LDET

LN1371SG−(TR)

100

100

R14

R13

STROBE

510

R18

TXDATA

10k

R30

10k

R29

10k

R28

VCC2

100

R27

JP3

2

3 1

MODESTDBYTXDATA

VCC2

100

R26

JP2

2

3 1

LL4148

CR4

VCC1

LN1271R−(TR)

VCC

LED3

220

JP4

0

2.0 − 3.8V (3.0V TYP)

R33

3.3V

VCC2

VCC2

0.1uF

C14

LOCKDET

CR2

LL4148

2Y252Y332Y4

2A2152A3172A4

CR3

LL4148

LL4148

LED2

ENABLE

R25

510

10

SN74LVT244BDW

10k

R24

10k

R23

10k

R22

10k

R21

10k

R20

10k

R19

LN1471SY−(TR)

POWER

13251224112310229218207196185

DB25M

VR1

RED

+8.0V

2

VOUT

VIN

LM317MDT

3

CR5

C19

0.01uF

C18

0.1uF

1.0uF

C17

360

R31

500

1

ADJ

C16

0.1uF

10uF

C15

S1JB

ZR1

SMBJ8.5CA

R32

1

2

220

R34

3

VR2

NC

1VI3VO2VO4

5NC6VO7VO8

ADJ

C22

0.01uF

C21

0.1uF

C20

220

R35

1.0uF

LM317LBD

GROUND CLIPS

R36

360

TP4

TP2 TP3

CR1

9

12

18

20

1Y1161Y2141Y3

IC2

1OE

1A141A261A381A4

1

2

1

P1

7

2Y1

1Y4

2OE112A1

19

13

17416315214

Evaluation Board

2-3

Page 15

Top Side Silkscreen and Drawing

2.1.1 Top Side Silkscreen and Drawing

2-4

Page 16

2.1.2 Bottom Side Silkscreen and Drawing

Top Side Silkscreen and Drawing

Evaluation Board

2-5

Page 17

Parts List

2

7

2

3

2

18 MHz CX−1 SMI

C19 0.01 µF 0603 Ceramic chip capacitor Venkel C0603X7R500−103KNB Venkel C0603X7R500−103KNB

C22 0.01 µF 0603 Ceramic chip capacitor Venkel C0603X7R500−103KNB Venkel C0603X7R500−103KNB

C3 0.1 µF 0603 Ceramic chip capacitor Venkel C0603Y5V160−104ZNB Venkel C0603Y5V160−104ZNB

C5 0.1 µF 0603 Ceramic chip capacitor Venkel C0603Y5V160−104ZNB Venkel C0603Y5V160−104ZNB

C7 0.1 µF 0603 Ceramic chip capacitor Venkel C0603Y5V160−104ZNB Venkel C0603Y5V160−104ZNB

C14 0.1 µF 0603 Ceramic chip capacitor Venkel C0603Y5V160−104ZNB Venkel C0603Y5V160−104ZNB

C16 0.1 µF 0603 Ceramic chip capacitor Venkel C0603Y5V160−104ZNB Venkel C0603Y5V160−104ZNB

C18 0.1 µF 0603 Ceramic chip capacitor Venkel C0603Y5V160−104ZNB Venkel C0603Y5V160−104ZNB

C21 0.1 µF 0603 Ceramic chip capacitor Venkel C0603Y5V160−104ZNB Venkel C0603Y5V160−104ZNB

C17 1 µF 1206 Tantalum Tantalum capacitor

C20 1 µF 1206 Tantalum Tantalum capacitor

C4 3.3 pF 0603 Ceramic chip capacitor Venkel C0603COG500−3R3CNB Venkel C0603COG500−3R3CNB

C8 3.3 pF 0603 Ceramic chip capacitor Venkel C0603COG500−3R3CNB Venkel C0603COG500−3R3CNB

C9 3.3 pF 0603 Ceramic chip capacitor Venkel C0603COG500−3R3CNB Venkel C0603COG500−3R3CNB

C11 10 pF 0603 Ceramic chip capacitor Venkel C0603COG500−100JNB Venkel C0603COG500−100JNB

C12 10 pF 0603 Ceramic chip capacitor Venkel C0603COG500−100JNB Venkel C0603COG500−100JNB

products)

Fast switching diode Diode INC LL4148 Digi-Key LL4148CT−ND

(MINIMELF)

2

Count RefDes Value PatternName Description Manufacturer Part Number Distributor Distributor P/N

2.2 Parts List

2-6

7

Evaluation Board

2

1 C13 1.5 −10 pF 9341 SERIES Trimmer capacitor Johanson 9341−3SL Newark 95F9901

3

2

1 C15 10 µF 6032 C case Tantalum capacitor

1 C6 120 pF 0603 Ceramic chip capacitor Venkel C0603COG500−121JNB Venkel C0603COG500−121JNB

1 C2 470 pF 0603 Ceramic chip capacitor Venkel C0603X7R500−471JNB Venkel C0603X7R500−471JNB

1 C10 1000 pF 0603 Ceramic chip capacitor Venkel C0603X7R500−102KNB Venkel C0603X7R500−102KNB

1 C1 4700 pF 0603 Ceramic chip capacitor Venkel C0603X7R500−472KNB Venkel C0603X7R500−472KNB

1 CQ1 25.6 MHz HC45/U gull wing Resistance weld miniature crystal International Crystal Mfg. 865842

1 CQ1_A1 CX−1−SM Surface-mount quartz crystal CFP − (CMAC frequency

1 CQ1_B1 ATS−SM series Crystal CTS Reeves ATS256SM−T Digi-Key CTX51?TR−ND

4 CR1 MELF3

Page 18

Parts List

2

Fast switching diode Diode INC LL4148 Digi-Key LL4148CT−ND

Fast switching diode Diode INC LL4148 Digi-Key LL4148CT−ND

(MINIMELF)

(MINIMELF)

CR2 MELF3

CR3 MELF3

Fast switching diode Diode INC LL4148 Digi-Key LL4148CT−ND

(MINIMELF)

CR4 MELF3

Texas Instruments SN74LVT244BDW Digi-Key 296−1707−5−ND

Johnson Components 142−0701−801 Newark 90F2624

Johnson Components 142−0701−801 Newark 90F2624

with 3-state outputs

horizontal/PC mount

J1 SMA_H SMA brass connector −

J2 SMA_H SMA brass connector −

horizontal/PC mount

JP2 Jumper−3 pin Breakaway headers AMP 4−103239−0 Newark 90F77252JP3 Jumper−3 pin Breakaway headers AMP 4−103239−0 Newark 90F7725

Panasonic LN1371SG−(TR) Digi-Key P516CT−ND

Panasonic LN1471SY−(TR) Digi-Key P517CT−ND

type-green

type-amber

Panasonic LN1271R−(TR) Digi-Key P490CT−ND

type-red

JP1 0 0603 Chip resistor Venkel CR0603−16W−000B Venkel CR0603−16W−000B

JP4 0 0603 Chip resistor Venkel CR0603−16W−000B Venkel CR0603−16W−000B

4

Count Distributor P/NDistributorPart NumberManufacturerDescriptionPatternNameValueRefDes

1 CR5 SMB Rectifier Diode INC S1JBT Digi-Key S1JBDICT−ND

1 IC1 TSSOP24_M Single chip RF transmitter Texas Instruments TRF4900

1 IC2 SO20WB Octal buffers and line drivers

2

2

1 L1 6.8 nH 0603 Surface-mount inductor Murata LQW1608

1 L2 10 nH 0603 Surface-mount inductor Murata LQW1608

1 LED1 LDET LED, S type Surface-mount LED-Gull wing-S

1 LED2 Enable LED, S type Surface-mount LED-Gull wing-S

1 LED3 VCC LED, S type Surface-mount LED-Gull wing-S

1 P1 DB25M Subminiature D connector AMP 745783−4 Newark 90F5485

2

1 R7 1.0M 0603 Chip resistor Venkel CR0603−16W−105JB Venkel CR0603−16W−105JB

1 R1 6.2k 0603 Chip resistor Venkel CR0603−16W−622JB Venkel CR0603−16W−622JB

Evaluation Board

2-7

Page 19

Parts List

14

6

3

2

R5 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R6 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R15 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R16 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R17 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R19 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R20 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R21 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R22 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R23 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R24 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R28 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R29 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R30 10k 0603 Chip resistor Venkel CR0603−16W−103JB Venkel CR0603−16W−103JB

R4 100 0603 Chip resistor Venkel CR0603−16W−101JB Venkel CR0603−16W−101JB

R12 100 0603 Chip resistor Venkel CR0603−16W−101JB Venkel CR0603−16W−101JB

R13 100 0603 Chip resistor Venkel CR0603−16W−101JB Venkel CR0603−16W−101JB

R14 100 0603 Chip resistor Venkel CR0603−16W−101JB Venkel CR0603−16W−101JB

R26 100 0603 Chip resistor Venkel CR0603−16W−101JB Venkel CR0603−16W−101JB

R27 100 0603 Chip resistor Venkel CR0603−16W−101JB Venkel CR0603−16W−101JB

R33 220 0603 Chip resistor Venkel CR0603−16W−221JB Venkel CR0603−16W−221JB

R34 220 0603 Chip resistor Venkel CR0603−16W−221JB Venkel CR0603−16W−221JB

R35 220 0603 Chip resistor Venkel CR0603−16W−221JB Venkel CR0603−16W−221JB

Panasonic #EVM−1SSX50BXX Digi-Key P1S501CT−ND

potentiometer

R31 360 0603 Chip resistor Venkel CR0603−16W−361JB Venkel CR0603−16W−361JB

R36 360 0603 Chip resistor Venkel CR0603−16W−361JB Venkel CR0603−16W−361JB

R18 510 0603 Chip resistor Venkel CR0603−16W−511JB Venkel CR0603−16W−511JB2R25 510 0603 Chip resistor Venkel CR0603−16W−511JB Venkel CR0603−16W−511JB

14

Count Distributor P/NDistributorPart NumberManufacturerDescriptionPatternNameValueRefDes

2-8

Evaluation Board

1 R3 51 0603 Chip resistor Venkel CR0603−16W−510JB Venkel CR0603−16W−510JB

6

2 R2, R38 100k 0603 Chip resistor Venkel CR0603−16W−104JB Venkel CR0603−16W−104JB

3

2

1 R32 500 P1S Panasonic Surface-mount trimmer

2

Page 20

Parts List

SMV1247−079

SMV1247−079

Electronic

Corp.

Electronic

Corp.

On Semiconductor LM317MDT Newark 06F9320

On Semicondictor LM317LBD Newark 06F9304

70070107373 Digi-Key SJ5303−7−ND

Electronic Specialty

Markets/3M

R8 TBD 0603 Chip resistor Venkel Venkel4R9 TBD 0603 Chip resistor Venkel Venkel

R10 TBD 0603 Chip resistor Venkel Venkel

4

Count Distributor P/NDistributorPart NumberManufacturerDescriptionPatternNameValueRefDes

R11 TBD 0603 Chip resistor Venkel Venkel

2 V1 SC−79 Hyperabrupt tuning varactor Alpha Industries SMV1247−079 Nu Horizons

V2 SC−79 Hyperabrupt tuning varactor Alpha Industries SMV1247−079 Nu Horizons

Three-terminal adustable output

positive voltage regulator

positive voltage regulator

CASE369A−13

CLOCK WHT PC test point Color coded PC test point (white) Components Corp. TP−105−01−09 Newark 97B32538DATA WHT PC test point Color coded PC test point (white) Components Corp. TP−105−01−09 Newark 97B3253

1 VR1 DPAK

1 VR2 SO8NB Three-terminal adustable output

1 ZR1 SMBJ−BI Transient voltage suppressor Vishay/Liteon SMBJ8.5CA Digi-Key SMBJ8.5AGICT−ND

1 8.0V RED PC test point Color coded PC test point (red) Components Corp. TP−105−01−02 Newark 97B3257

8

LDET WHT PC test point Color coded PC test point (white) Components Corp. TP−105−01−09 Newark 97B3253

MODE WHT PC test point Color coded PC test point (white) Components Corp. TP−105−01−09 Newark 97B3253

STDBY WHT PC test point Color coded PC test point (white) Components Corp. TP−105−01−09 Newark 97B3253

STROBE WHT PC test point Color coded PC test point (white) Components Corp. TP−105−01−09 Newark 97B3253

TXDATA WHT PC test point Color coded PC test point (white) Components Corp. TP−105−01−09 Newark 97B3253

TP1 WHT PC test point Color coded PC test point (white) Components Corp. TP−105−01−09 Newark 97B32533TP2 SMD test point Surface-mount test point Components Corp. TP−107−01 Newark 97B26473TP3 SMD test point Surface-mount test point Components Corp. TP−107−01 Newark 97B2647

Evaluation Board

clear

TP4 SMD test point Surface-mount test point Components Corp. TP−107−01 Newark 97B2647

4 FOOT1 Hardware Bumpon hemisphere 0.44 × 20

2-9

Page 21

2.3 EVM DC Voltage Setup

The evaluation board should be used with a dc power supply voltage of 8 V

nominal. Figure 2−1 details the dc voltage supply setup for the TRF4900 EVM.

Figure 2−1.TRF4900 EVM DC Voltage Setup

for LM317 voltage regulator is equal to:

V

out

Vout = 1.25(1+((R32+R34)/R31))

V at terminal 3 of LM317 should be 2 V to 3 V

higher than V

out

V

is equal to 8 V

in

nominal.

With V

V = 7.2 V

GROUND CLIPS

equal to 8 V,

in

POWER

8.0V

RED

TP4TP2 TP3

CR5

S1JB

ZR1

SMBJ8.5CA

C15

10µ F

C16

0.1µ F

R36

360Ω

3

LM317MDT

VIN2VOUT

1

VI

2

VO

3

VO

4

ADJ

LM317LBD

2

VR2

ADJ

1

VR1

3

NC

VO

VO

NC

R32

500Ω

R34

220Ω

2.0 − 3.8 V (3.0 V TYP)

C17 C18

R31

1µ F 0.1µ F 0.01µ F

360Ω

V

Used to Change

adj

V

From 2.2 V to 3.6 V

out

8

7

6

5

R35

C20

220Ω

1µ F 0.1µ F 0.01µ F

C19

C22C21

JP4

0

LED3

VCC

LN1271R−(TR)

R33

220Ω

VCC2

VCC1

3.3V

2-10

Page 22

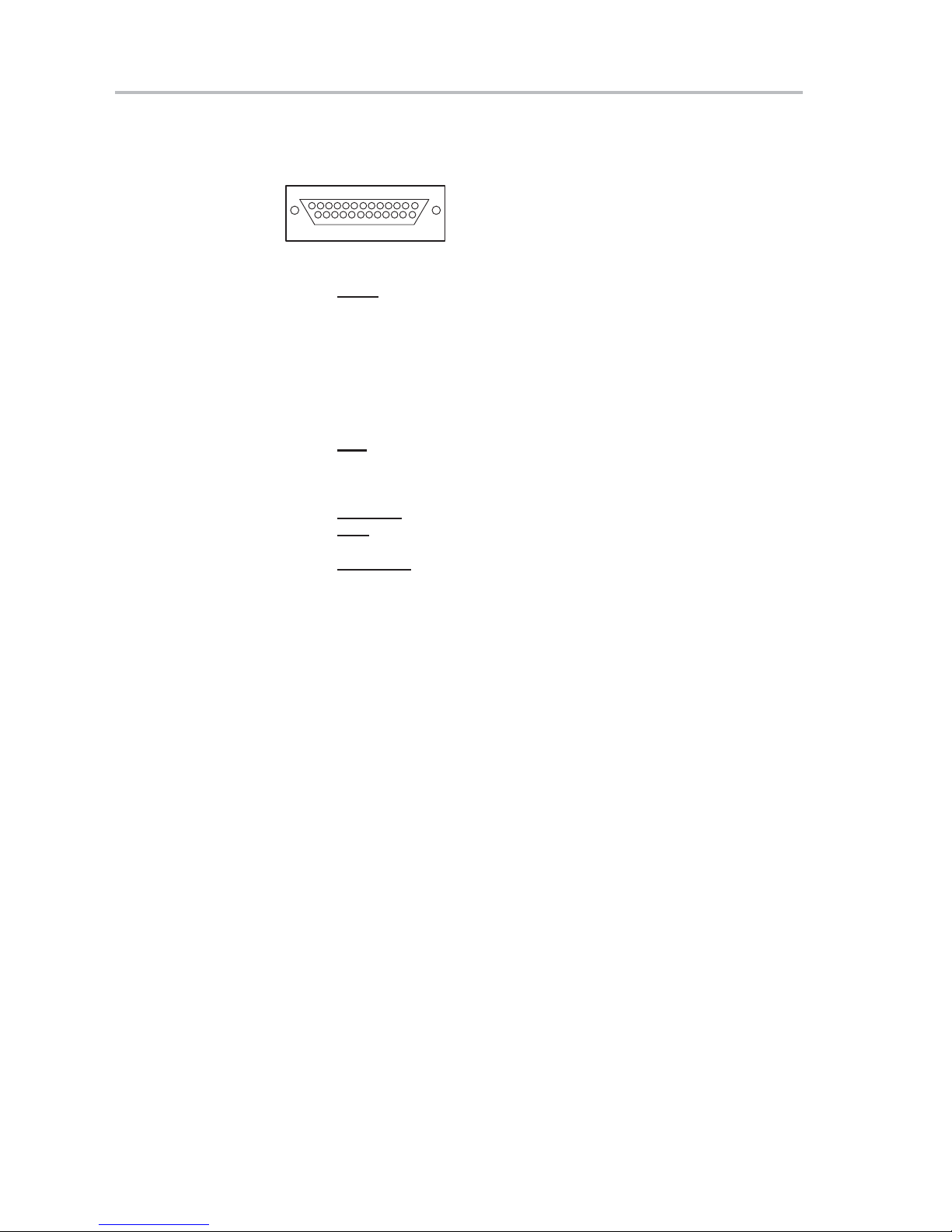

2.4 Serial Interface and PC Port Pin Out

Figure 2−2 details the serial interface portion of the TRF4900 EVM.

Figure 2−2.TRF4900 EVM Serial Interface

VCC2

P1

DB25M

1

14

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

13

R19

R20

10k

R21

10k

10k

LOCKDET

R23

R22

10k

10k

R24

10k

IC2

1

1OE

2

1A1

4

1A2

6

1A3

8

1A4

19

2OE

11

2A192Y1

13

2A2

15

2A3

17

2A4

10

SN74LVT244BDW

C14

0.1uF

20

18

1Y1

16

1Y2

14

1Y3

12

1Y4

7

2Y2

5

2Y3

3

2Y4

R25

510

LED2

ENABLE

LN1471SY−(TR)

CR1

LL4148

CR2

LL4148

CR3

LL4148

DATA

CLOCK

STROBE

CR4

LL4148

Serial Interface and PC Port Pin Out

R12

100

R13

100

R14

100

R18

510

JP2

2

3 1

LED1

LDET

LN1371SG−(TR)

R26

100

VCC2

MODESTDBYTXDATA

3 1

R27

100

JP3

2

R15

10k

VCC2

R16

R17

10k

10k

R29

R28

10k

10k

R30

10k

DATA

CLOCK

STROBE

MODE

STDBY

TXDATA

P1 Computer Interface Connector Pin Number Function

2 DATA

3 CLOCK

4 STROBE

5 MODE

7 STDBY

9 TXDATA

18 thru 25 Ground

Evaluation Board

2-11

Page 23

Standard PC Parallel Port

2.5 Standard PC Parallel Port

A standard PC parallel port is configured as follows:

113

14 25

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Note: The TRF4900 EVM uses pins 2–9 for signals from the PC to the EVM.

Description

Strobe

Data 0

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

ACK

Busy

Paper Empty

Select

Auto Feed

Error

Initialize Printer

Select Input

View Is Looking at

Connector Side of

DB-25 Male Connector

PC Output

PC Output

PC Output

PC Output

PC Output

PC Output

PC Output

PC Output

PC Output

PC Input

PC Input

PC Input

PC Input

PC Output

PC Input

PC Output

PC Output

Pin Assignments

Note: 8 Data Outputs

4 Misc Other Outputs

5 Data Inputs

Note: Pins 18−25 Are

Ground

2-12

Page 24

2.6 Jumper Connections

The default position of the jumpers on the TRF4900 EVM are configured as

shown below.

Standard PC Parallel Port

JP1

1

2

JP1 is a 0-Ω 0603 resistor

JP3

1

2

3

JP3 Default is not installed

To R1 and C2 (Loop Filter)

To R5 and R6 (VCO Tank)

To V

CC2

To Mode Test Point

To Ground

2.6.1 Jumper Description

The jumpers on the TRF4900 EVM are used for the following purposes:

- JP1

Jumper JP1 connects the VCO tank circuit to the loop filter of the PLL

circuit. The only reason to remove jumper JP1 is to test the tuning range

of the VCO tank circuit with an external power supply. The default state for

jumper JP1 is JP1-1 to JP1-2. Jumper JP1 is a 0-Ω 0603 resistor.

JP2

1

2

3

JP2 Default is not installed

JP4

1

2

JP4 is a 0-Ω 0603 resistor

To V

CC2

To STDBY Test Point

To Ground

VR1 output (VCC1)

To LED3 anode (Power on LED)

Denotes Default Connection

- JP2

Jumper JP2 can be used to pull the STDBY line up to VCC (JP2-1 to JP2-2)

or pull down to ground (JP2-2 to JP2-3), if a computer connection is not

installed. The primary purpose for JP2 is as a test point to monitor the state

of the STDBY line. The default state for jumper JP2 is not connected.

- JP3

Jumper JP3 can be used to pull the MODE line up to V

(JP3-1 to JP3-2)

CC

or pull down to ground (JP3-2 to JP3-3), if a computer connection is not

installed. The primary purpose for JP3 is as a test point to monitor the state

of the MODE line. The default state for jumper JP3 is not connected.

- JP4

Jumper JP4 connects the Power-On LED to the output of the VR2 voltage

regulator. The default state for jumper JP4 is JP4-1 to JP4-2. Jumper JP4

is a 0-Ω, 0603 resistor.

Evaluation Board

2-13

Page 25

Connectors and Test Points

2.7 Connectors and Test Points

The following information describes the TRF4900 EVM connectors and test

points.

2.7.1 Connectors

- P1

P1 is the PC parallel port interface and is a male DB25 connector. P1 is

connected to the LPT1 or LPT2 port of the computer on which the

TRF4900 software is running.

- J1

TX_OUT is an SMA female connector which is connected to the

transmitter output of the TRF4900.

- J2 VCO_TANK

VCO_T ANK i s a n SMA female connector used with resistors R8, R9, R10,

R11, and capacitor C6 to directly feed in an external VCO signal. Resistors

R8, R9, R10, and R11 are used to form a T attenuator. The components

for this option are not installed on the EVM.

2.7.2 Test Points (TP)

- TP1

- LDET TP

- MODE TP

- STDBY TP

- CLOCK TP

- DATA TP

- STROBE TP

Test point TP1 is used to monitor the tuning voltage applied to the VCO

circuit by the PLL circuit.

The LDET test point is used to monitor the lock detect line of the TRF4900.

The MODE test point is used to monitor the MODE line.

The STDBY test point is used to monitor the STDBY line.

The CLOCK test point is used to monitor the CLOCK signal from the PC.

The DATA test point is used to monitor the DATA signal from the PC.

The STROBE test point is used to monitor the STROBE signal from

the PC.

- TXDATA TP

The TXDATA test point is used to monitor the transmitted data. Transmit

data from an external source can also be applied at this point.

2-14

Page 26

2.7.3 Adjustments

2.7.4 LED Indicators

Connectors and Test Points

Resistor R32 is varied to adjust the VCC1 voltage applied to IC1 (TRF4900).

- VCC LED

If JP4 is installed, the VCC LED is illuminated when voltage is applied to

IC1.

- LDET LED

The LDET LED is illuminated when the lock detect line IC1−23 (TRF4900)

is high, indicating that the PLL circuit is locked.

- ENABLE LED

The ENABLE LED is illuminated when the STDBY line from the computer

is in the high state.

Evaluation Board

2-15

Page 27

2-16

Page 28

Chapter 3

This chapter describes the Windows-based software application that

accompanies the EVM.

Topic Page

3.1 Introduction 3−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Main Program Screen 3−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Chip Layout Screen 3−6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 PLL/Modulation Options Screen 3−7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Testing of Transmitter 3−9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software User’s Guide

3-1

Page 29

Introduction

3.1 Introduction

A Windows-based software application accompanies the evaluation board.

The software is intended for use in either a Windows 95/98 or Windows NT

environment. If the Windows NT environment is used, the Windows NT driver

software must accompany the software. However, if the operating system is

Windows 95/98, the software application can run on its own.

Both the Windows NT Driver and the TRF4900 software are provided on

diskette. Your system administrator must install the Windows NT Driver if you

do not have administrative privileges on your computer. The TRF4900

software can run from the floppy disk by following these steps:

1) Click on the Start button on the desktop

2) Click on the Run button

3) Type − A:\ TRF4900.exe and press OK

3-2

Page 30

3.2 Main Program Screen

Double Click Here With the

n

The screen shown in Figure 3−1 appears on your monitor.

Figure 3−1.Main Program Screen

Main Program Screen

Crystal or Clock

Frequency

Computer Printer Port

LPT1 or LPT2

Transmit Frequency

Press to Program the TRF4900

Left Mouse Button to Obtai

Chip Layout Screen

NOTE: When word bits are displayed in RED, the Send Words Now (F12) button on the main program screen must be pressed

for changes to be updated.

The main program screen is divided into seven main sections as follows:

3.2.1 Synthesizer

This section is used to set the crystal/clock (CLK) frequency, the Desired Freq.,

and the PreScaler value of the divide-by-N of the PLL. From these inputs, the

actual frequency and bit values of Words A and B are calculated.

Software User’s Guide

3-3

Page 31

Main Program Screen

3.2.2 Mode Options

This section allows the user to control various features of the TRF4900. The

following is a brief summary of the four controls.

1) PLL Turns the phase-locked loop on or off.

2) VCO The voltage controlled oscillator (VCO) is always on.

3) Pwr Amp Allows the power amp to be set to off, 20-dB attenuation,

4) LPT Port Allows the user to change between the LPT1 and the

3.2.3 Output Parameters

This section allows the user to turn the TRF4900 Enable, TXData, and Mode

control lines on and off. When the mode control line is off, Mode 0 is defaulted.

When the mode control line is on, Mode 1 is defaulted. Mode 0 initializes using

Words A and D; Mode 1 initializes using Words B and C.

Clock Width and Strobe Width allow the clock and strobe pulse widths to be

increased or decreased.

10-dB attenuation, or 0-dB attenuation states.

LPT2 ports of the controlling computer.

3.2.4 PLL and MM Options

Allows the change of the APLL value (0, 20, 40...140), the NPLL value (256,

512), and the Modulation Mode (FSK).

3.2.5 Help

Gives a brief description of each control box. For example, after clicking the

PLL box in the Mode Options section on the main program screen, the Help

box will read:

Phase-Lock Loop

0: Off

1: On

Valid in Mode 0 or 1.

Most of the other control boxes follow this format. The first line indicates what

portion of the TRF4900 is being controlled. The next two lines indicate the bit

value. If the PLL is off, bit 12 of Words C and D are equal to 0. If it is on, bit 12

is equal to 1. The last line indicates this control works in both Mode 0 and

Mode 1.

Double clicking in the Help box on the main program screen activates the chip

layout screen.

3-4

Page 32

3.2.6 Words

This section updates the binary words after changes are made to the control

options. Clicking on the box next to the word can individually send each word.

Clicking on the Send Words Now (F12) button on the main program screen or

pressing F12 on the keyboard, sends all the words to the TRF4900.

3.2.7 Operation Mode

Operation mode shows whether the TRF4900 is enabled, which mode (0 or

1) is selected, and whether the transmit (TX) data line is on or off.

3.2.8 Changing Values on the Main Program Screen

- Synthesizer Section

CLK Type the desired clock frequency inside the box or use

the arrows located at the right side of the box.

Desired Freq. Type the desired transmit or LO receive frequency inside

the box or use the arrows located at the right side of the

box.

PreScaler Click inside the box to change divide-by-N value

between 256 and 512. The value of NPLL under PLL and

MM Options changes when the PreScaler value

changes.

Main Program Screen

- Mode Options

PLL Click inside the box to turn the PLL on or off (turn on for

transmit).

VCO The VCO is always on. Clicking has no effect.

Pwr Amp Use the arrow at the side of the box to select the desired

power amplifier attenuation.

- Output Parameters

Enable Click inside the box to turn the TRF4900 on or off.

TXData Click inside the box to switch the TXData line between

high and low.

Mode Click inside the box to switch the mode line between 0

and 1.

Clock Width Type inside the box to increase or decrease the clock

pulse width (this should not be changed during normal

use).

Strobe Width Type inside the box to increase or decrease the strobe

pulse width (this should not be changed during normal

use).

Software User’s Guide

3-5

Page 33

Chip Layout Screen

PLL and MM Options

-

APLL: Use the arrows beside the box to select from values of 0,

20, 40, 60, 80, 100, 120, and 140.

NPLL: Click inside the box to change the divide-by-N value

between 256 and 512. The value of PreScaler under

Synthesizer changes when the NPLL value changes.

MM: Modulation Mode is fixed to FSK Modulation Mode.

- LPT Port

LPT_x: Click inside the box to chose between PC parallel ports

LPT 1 or LPT 2.

- Help

Help: When any box on the main program screen is selected

(clicked inside of box with mouse), the Help screen

displays the valid selections for that box. Double clicking

inside the Help box cause the chip layout screen to be

displayed as shown in Figure 3−2.

3.3 Chip Layout Screen

The chip layout screen can be accessed by double clicking on the left mouse

button in the Help section of the main program screen. The chip layout screen

appears as a simplified internal schematic of the TRF4900 as shown in

Figure 3−2.

3-6

Page 34

Figure 3−2.Chip Layout Screen

Press to Turn PLL and VCO On or Off

Mode Select 0 or 1

Enable or Standby.

IC is Disabled in

Standby Mode.

PLL/Modulation Options Screen

Clicking Here Sets

Power Amp

Attenuation (0 dB,

10 dB, 20 dB) or

Turn the Power

Amp Off

Press to Start

FSK Test

Turn TX Data On or Off

Press to Program the TRF4900

- The Mode Options (e.g., the Power Amp, PLL, etc.) may be controlled

from the chip layout screen, as well as from the main program screen.

Changes made in either the main program screen or the chip layout

screen simultaneously update both screens. The user can also control the

chip enable, TXData, and mode control lines from the chip layout screen.

- The user can select FSK Modulation. The FSK T est button, located on the

chip layout screen, will allow the user to transmit data using the TRF4900.

Options for use with the FSK Test button are the pulse repetition frequency

(PRF), which is defaulted to 100 Hz, and the Run Time (Min), which can

be set in minutes. For example, if you want the test to run for five minutes,

set Run Time (Min) to 5.

- The PLL/Modulation Options button brings up the PLL/Modulation

Options screen as shown in Figure 3−3. This button is activated only when

the PLL is on.

3.4 PLL/Modulation Options Screen

Press to Select

PLL/Modulation

Options Screen

The PLL/Modulation Options screen is accessed by pressing the

PLL/Modulation Option button, located on the chip layout screen, and is

displayed as shown in Figure 3−3.

Software User’s Guide

3-7

Page 35

PLL/Modulation Options Screen

Figure 3−3.PLL/Modulation Options Screen

The PLL/Modulations Options screen is divided into the following four

sections:

DV6 Display

Set to 1 by

Double Clicking

f1 Frequency

915 MHz

f

Frequency

2

915.10 MHz

FSK Deviation

of 100 kHz

Send Bits

Button

- APLL

Controls the acceleration factor for the PLL. The values are 0, 20, 40, 60,

80, 100, 120, and 140. Any changes are automatically updated in the PLL

and MM Options section of the main program screen after pressing the

Send Bits button located on the PLL screen.

- NPLL

Controls the N-Divider of the PLL. The NPLL can be set to either 256 or

512. Any changes are automatically updated in the NPLL box on the main

program screen after pressing the Send Bits button located on the PLL

screen.

- Modulation Mode

Allows the user to select FSK modulation. Any changes are automatically

updated in the MM box on the main program screen after pressing the

Send Bits button located on the PLL screen.

- FSK Frequency Register

This section acts as a calculator and sets bits 20−13 of Word D to the user

defined bits. The bits of the FSK deviation register (DV7−DV0) can be set

individually by double clicking inside each DVx box. After setting all bits,

press the Send Bits button located on the PLL/Modulation Options screen.

The bits of the frequency register will be mapped to Word D on the main

program screen, and highlighted in green. Furthermore, Fout: TX_Data

High (MHz), Fout: TX_Data Low (MHz) frequencies, and their difference

(Delta Fout kHz), are calculated and displayed.

Press the Send Bits button located on the PLL/Modulation Options screen to

program the TRF4900. Press the Close button to return to the chip layout

screen.

3-8

Page 36

Testing of Transmitter

3.5 Testing of Transmitter

To test the transmitter section of the TRF4900, perform the following steps:

Step 1: Test Setup:

Set up the test bench as shown in Figure 3−4.

Figure 3−4.Block Diagram for Testing of the TRF4900 EVM Transmitter Section

PC with

TRF4900 software

installed

PC printer port

(LPT1 or LPT2)

Frequency Counter

Spectrum Analyzer

Cable DB25M to DB25F

P1

DB25M

(Male)

TRF4900

Evaluation

Board

Coupled Port

J1

Directional

Coupler

Software User’s Guide

3-9

Page 37

Testing of Transmitter

Step 2: Software Programming:

To test the TRF4900 transmitter section, set the main program screen and the

chip layout screen as shown in Figure 3−5 and Figure 3−6.

Figure 3−5.Main Program Screen

Transmit Frequency

Double Click Here With Left Mouse

Button to Obtain Chip Layout View

3-10

Page 38

Chip Layout Screen of TRF4900 Software for Transmitter Testing

n

ff

Figure 3−6.Chip Layout Screen

Testing of Transmitter

Clicking Here Sets

Power Amp Attenuatio

(0 dB, 10 dB, 20 dB) or

Turn the Power Amp O

Press to Program

TRF4900

After setup is complete, press the Send Words button on the chip layout screen

or the Send Words Now (F12) button on the main program screen to send the

programming words to the TRF4900.

Software User’s Guide

3-11

Page 39

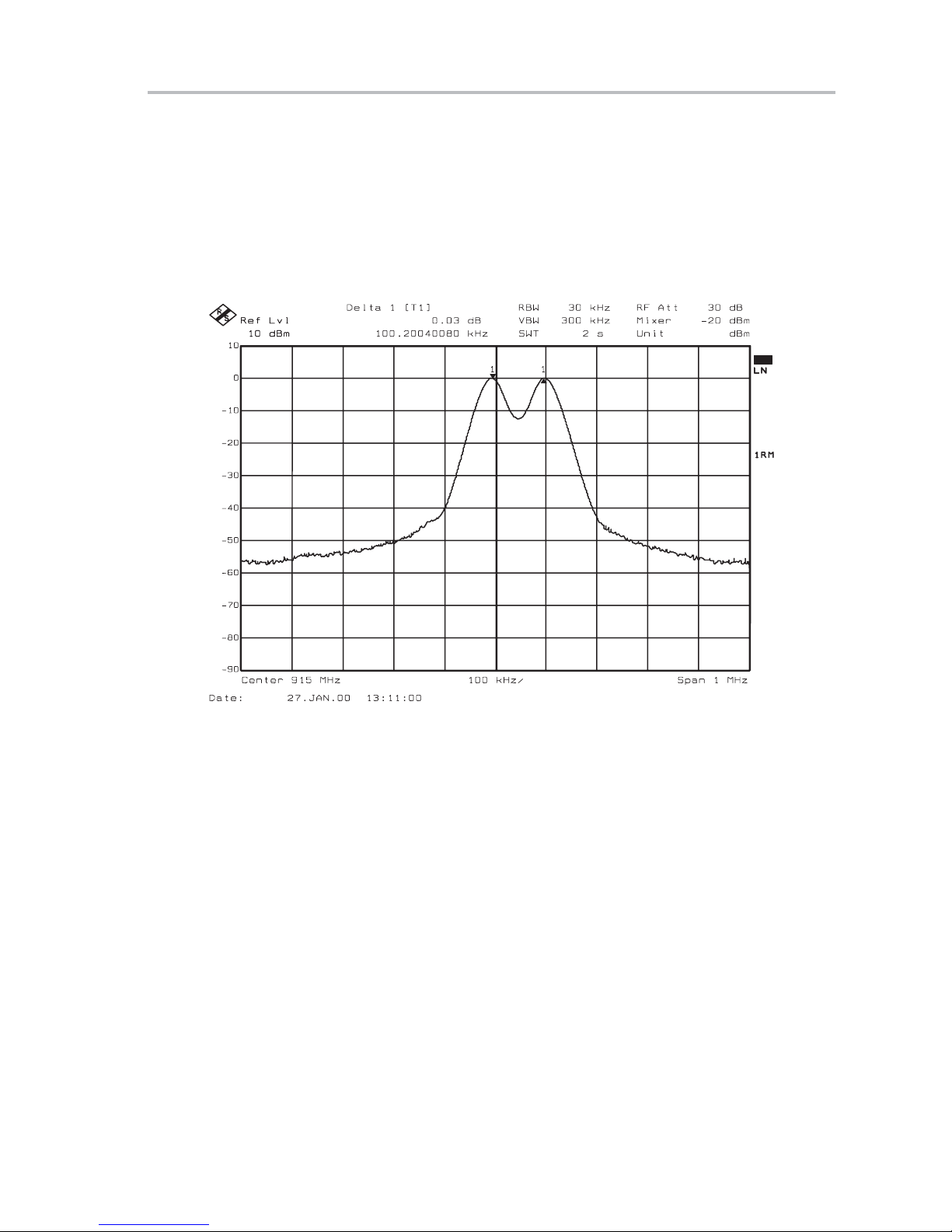

Testing of Transmitter

Step 3: Spectrum Analyzer Setup and Clock Offset Procedure

Setup the spectrum analyzer to observe the following:

Figure 3−7.Spectrum Analyzer

Clock Offset Procedure

1) Use the test setup as shown in Figure 3−4 and transmitter software setup

2) Observe the frequency reading on the frequency counter.

3) Subtract 915.000000 MHz from the frequency counter reading.

4) Enter the difference value in the Freq. Error box in the main program

5) Note: If the difference value is negative, enter – sign, followed by the differ-

6) Press the Update CLK button on the main program screen.

7) Verify that clock frequency is updated as shown in Figure 3−9.

8) Pressing the Update CLK button twice clears the frequency offset.

shown in Figure 3−5 and Figure 3−6.

screen as shown in Figure 3−8.

ence value.

Example: Frequency counter reading is 914.996000 MHz

Subtracting 915.000 MHz from 914.996 MHz will yield

a difference of –4000 Hz. This difference is entered in the Freq. Error

block as −0.004 MHz (see Figure 3−8).

3-12

Page 40

Figure 3−8.Input of Frequency Error

Frequency Error is entered here Press Update CLK button

Testing of Transmitter

Figure 3−9.Main Panel Display After Clock Offset Is Applied

Software User’s Guide

3-13

Page 41

Testing of Transmitter

Step 4: FSK Modulation Output Test

On the chip layout screen press the PLL/Modulation Options button.

The PLL/Modulation Options View Is Set Up as Shown in Figure 3−11.

Figure 3−10. Chip Layout View for FSK Modulation Output Test

Select This Button

to Start the FSK

Modulation Test

Select to Program

the TRF4900

Select This Button

With Mouse to Set

FSK Frequency

Set the DVx bits, as shown in Figure 3−11, by double clicking inside each

-

DVx box to set the value to either a 1 or 0. For this example only DV6 is

set to a 1.

- Press the Send Bits button located on the PLL/Modulation Options screen,

to obtain the results shown in Figure 3−11.

- Press the Close button located on the PLL/Modulation Options screen.

3-14

Page 42

Figure 3−11. PLL/Modulation Options Screen

-

Press the Send Words button on the chip layout screen or the Send Words

Now (F12) on the main program screen.

Testing of Transmitter

DV6 Display

Set to 1

f

Frequency

1

915 MHz

f

Frequency

2

915.10 MHz

FSK Deviation

of 100 kHz

Send Bits

Button

- Press the FSK Test button on the chip layout screen, as shown in Figure

3−10, to start the FSK test.

- Set up the spectrum analyzer to observe the spectrum analyzer display

as shown in Figure 3−12.

Software User’s Guide

3-15

Page 43

Testing of Transmitter

.

Figure 3−12. FSK Output From Transmitter

Note: This is FSK modulation with f1 equal to 915.0 MHz, f2 equal to 915.10-MHz and 100-Hz data rate

The f1 frequency is the 0 frequency. The f2 frequency is the 1 frequency.

Figure 3−13. Block Diagram for Testing of the TRF4900 EVM Transmitter Section With an

External Pulse Generator

PC With

TRF4900 Software

Installed

Cable DB25M to DB25F

3 V

Pulse Generator Output Waveform

1 kHz

PC Printer

(LPT1 or LPT2)

P1

DB25M

(Male)

Pulse

Generator

Power

Supply

TRF4900

Evaluation

Board

J1

Spectrum Analyzer

TXDATA TP

GND TP

Coaxial Cable With

Clip Lead Ends

3-16

Page 44

To use an external pulse generator to supply transmit data, set up the test

bench as shown in Figure 3−13.

- Perform the FSK modulation output test as described in the previous

section. In this new setup, an external pulse generator is providing the

modulation. The FSK Test button on the chip layout screen does not need

to be pressed to start the FSK test.

Figure 3−14. FSK Output From Transmitter With an External Modulation

Testing of Transmitter

Note: This is FSK modulation with f1 equal to 915.0 MHz, f2 equal to 915.10-MHz and 1000-Hz data rate.

The f1 frequency is the 0 frequency. The f2 frequency is the 1 frequency.

Software User’s Guide

3-17

Page 45

3-18

Loading...

Loading...