Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

Pin-for-Pin Compatible With MAX734

D

Programming Voltage for Flash Memory

D

2.7-V to 11-V Input Operating Range

D

Output Current of 120 mA or Greater From

3.75-V or Higher Input

D

3-µA Maximum Supply Current in

Shutdown

D

Only 5 External Components Required

D

High Efficiency...85% Typical (5-V Input,

120-mA Output)

D

8-Pin SOIC and DIP Packages

D

–40°C to 85°C Free-Air Operating

T emperature Range

description

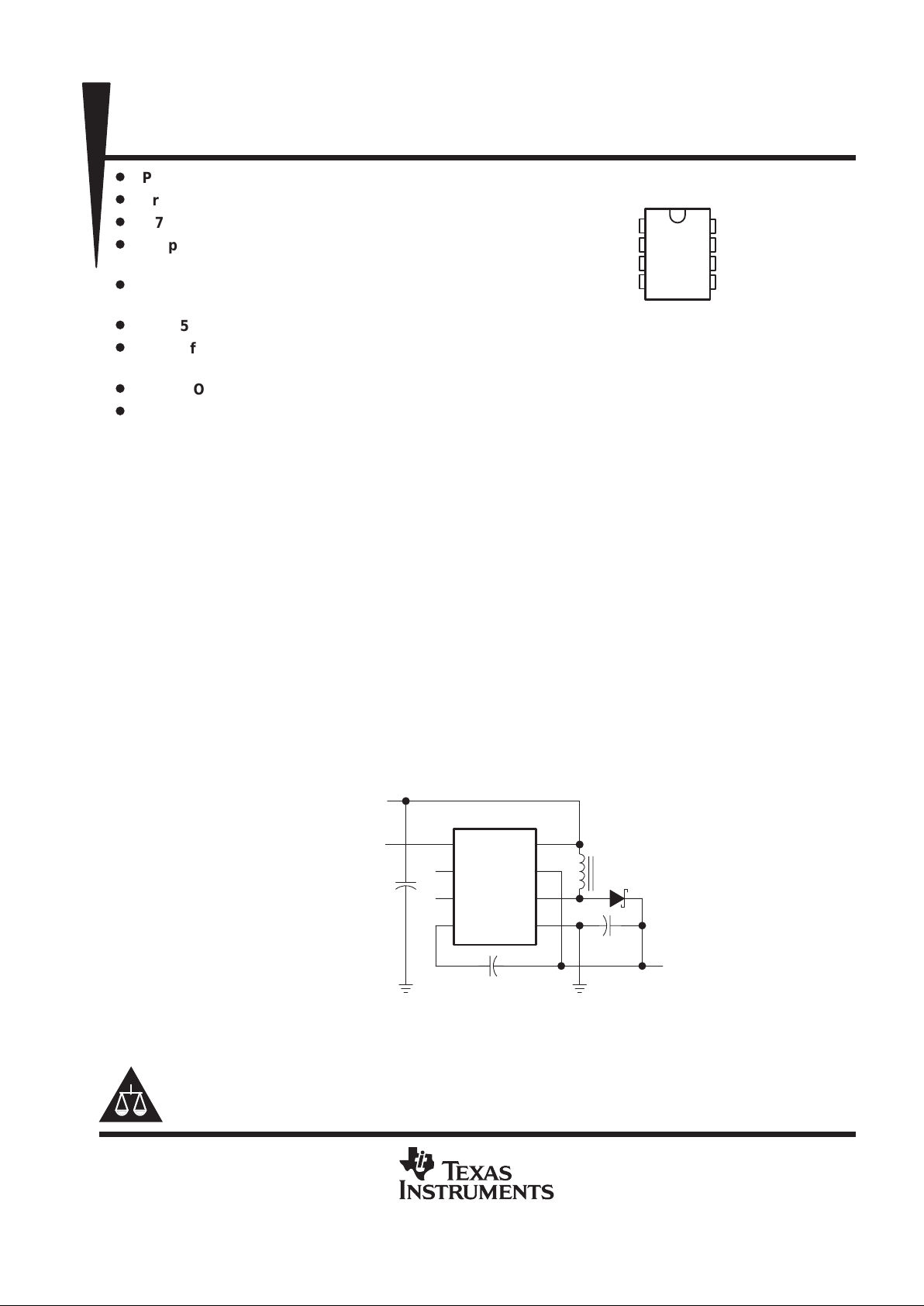

The TPS6734 is a fixed 12-V output boost converter capable of delivering 120 mA from inputs as low as

3.75 V. The device is pin-for-pin compatible with the MAX734 regulator and offers the following advantages:

lower supply current, wider operating input-voltage range, and higher output currents. As shown in Figure 1,

the only external components required are: an inductor, a Schottky rectifier, an output filter capacitor, an input

filter capacitor, and a small capacitor for loop compensation. The entire converter occupies less than 0.7 in

2

of

PCB space when implemented with surface-mount components. An enable input is provided to shut down the

converter and reduce the supply current to 3 µA when 12 V is not needed.

The TPS6734 is a 170-kHz current-mode PWM ( pulse-width modulation) controller with an n-channel MOSFET

power switch. Gate drive for the switch is derived from the 12-V output after start-up to minimize the die area

needed to realize the 0.7-Ω MOSFET and improve efficiency at input voltages below 5 V. Soft start is

accomplished with the addition of one small capacitor. A 1.22-V reference (pin 2) is brought out for external use.

High efficiency at low supply voltages and low supply current in shutdown make the TPS6734 particularly

attractive for flash memory programming supplies, PCMCIA cards, and operational amplifiers in

battery-powered equipment. The TPS6734 is available in 8-pin DIP and SOIC packages and operates over a

free-air temperature range of –40°C to 85°C.

V

CC

FB

OUT

GND

EN

REF

SS

COMP

1

2

3

4

8

7

6

5

TPS6734

0.001 µF

18 µH

1A, 20 V

V

I

3.75 V to 12 V

ENABLE

+

33 µF

V

O

12 V , 120 mA

Figure 1. Typical Operating Circuit

1

2

3

4

8

7

6

5

EN

REF

SS

COMP

V

CC

FB

OUT

GND

D OR P PACKAGE

(TOP VIEW)

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Copyright 1999, Texas Instruments Incorporated

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

AVAILABLE OPTIONS

PACKAGE

T

A

SMALL OUTLINE

(D)

PLASTIC DIP

(P)

–40°C to 85°C TPS6734ID TPS6734IP

The D package is available taped and reeled. Add the suffix R

to the device type (e.g., TPS6734IDR).

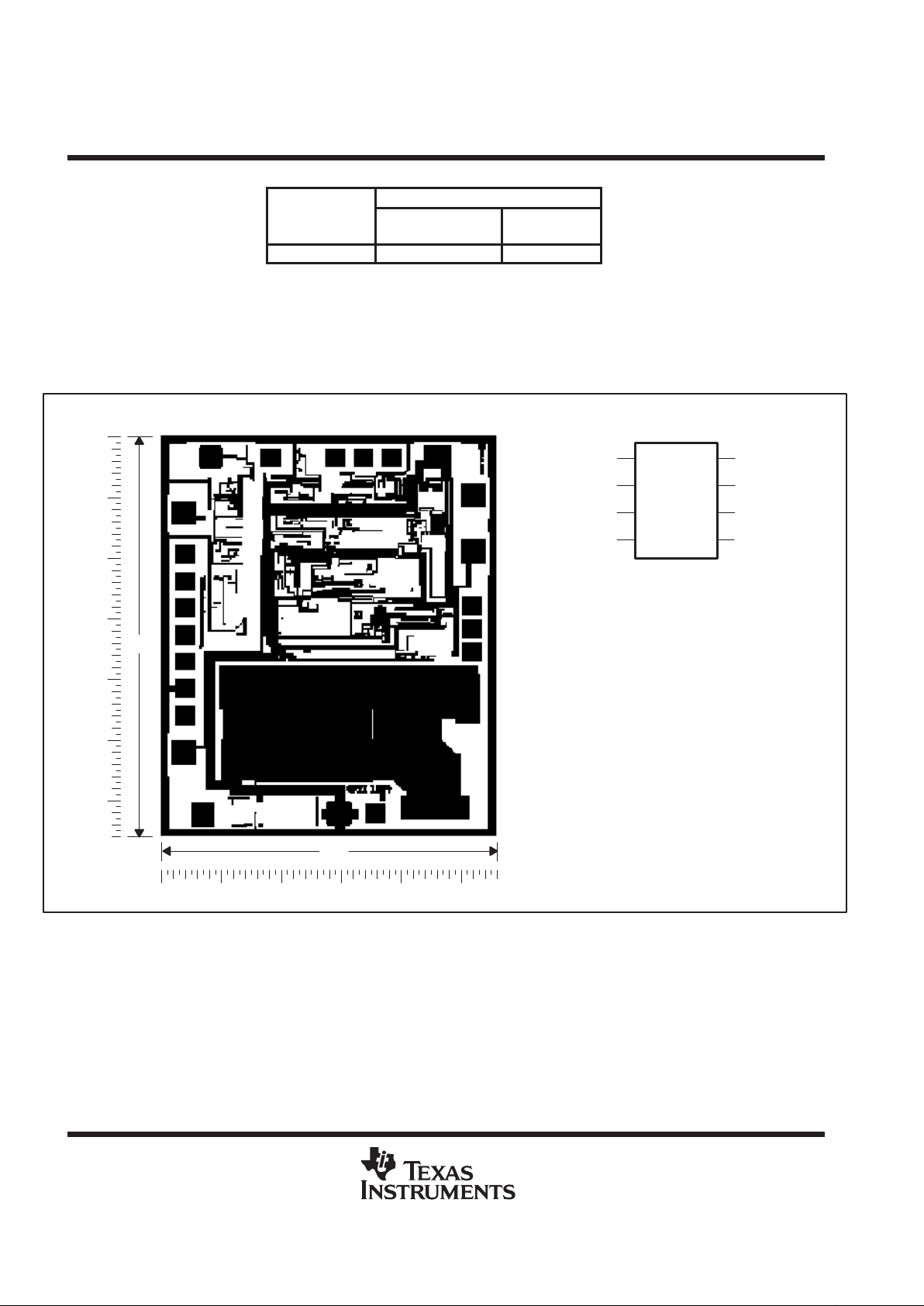

TPS6734 chip information

Thermal compression or ultrasonic bonding can be used on the doped-aluminum bonding pad. Chips can be

mounted with conductive epoxy or a gold-silicon preform. Contact factory for die sales.

CHIP THICKNESS: 15 TYPICAL

BONDING PADS: 4X4 MINIMUM

TJmax = 150°C

TOLERANCES ARE ±10%

ALL DIMENSIONS ARE IN MILS.

BONDING PAD ASSIGNMENTS

4

3

5

5

6

7

7

8

2

1

(1)

(2)

(3)

(4)

(5)

(5)

(6)

(7)

(7)

92

75

(8)

V

CC

FB

OUT

GND

EN

REF

SS

COMP

1

2

3

4

8

7

6

5

TPS6734

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

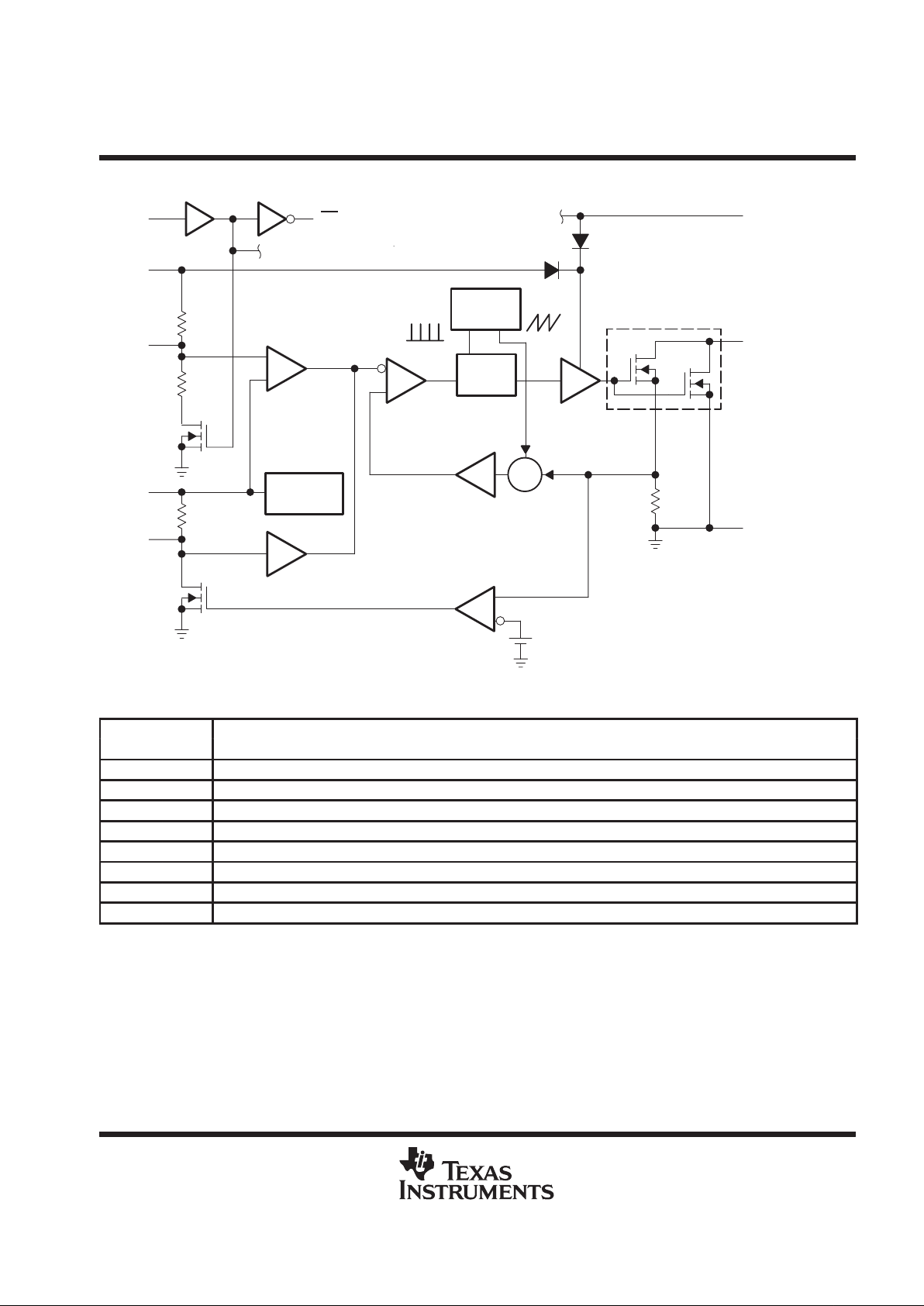

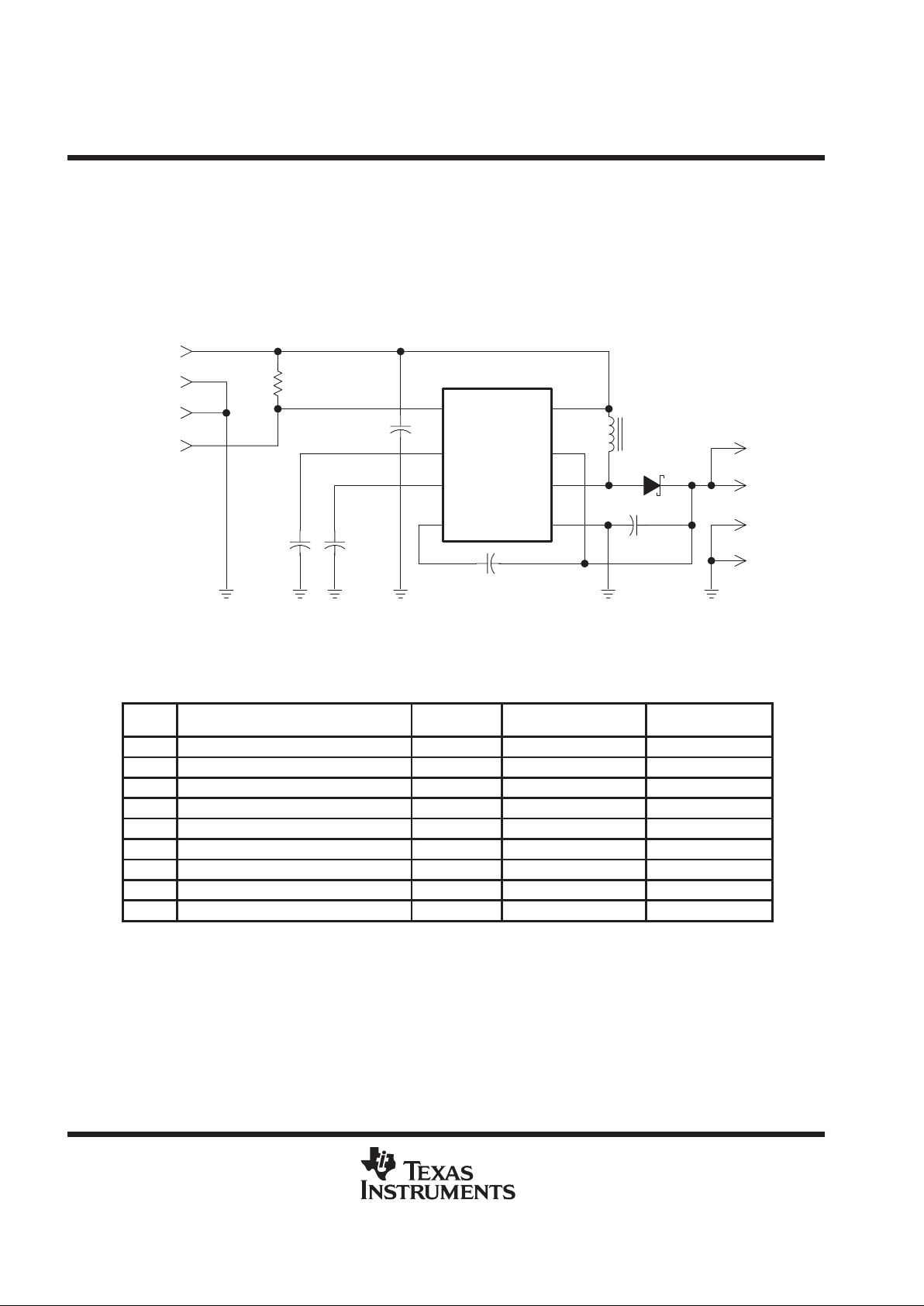

functional block diagram

EN

1

EN

7

EN

FB

_

+

4

COMP

Voltage

Reference

x3.5

SS

Clamp

Error

Amplifier

PWM

Comparator

R

S

170-kHz

Oscillator

V

CC

Power Switch

Drive Latch

Σ

2

REF

3

SS

x6

Current

Sense Amplifier

Overcurrent

Comparator

Driver

V

CC

OUT

GND

8

6

5

+

1 MΩ

–

Q

Terminal Functions

TERMINAL

NAME NO.

DESCRIPTION

EN 1 Enable. EN ≥2 V turns on the TPS6734. EN ≤ 0.4 V turns it off and reduces the supply current to 3 µA max.

REF 2 1.22-V reference voltage output. REF can source 100 µA for external loads.

SS 3 Soft Start. A capacitor between SS and GND brings the output voltage up slowly at power-up.

COMP 4 Compensation connection. A 0.001-µF capacitor between COMP and FB stabilizes the feedback loop.

GND 5 Ground

OUT 6 N-channel MOSFET drain connection

FB 7 Feedback voltage. FB is connected to the converter output for the feedback loop.

V

CC

8 Supply voltage input

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

detailed description

The following descriptions refer to the functional block diagram.

reference

The internal 1.22-V reference is brought out on REF and can source 100 µA maximum to external loads. A

0.01-µF to 0.1-µF decoupling capacitor connected between REF and GND is recommended to minimize noise

pickup.

oscillator and ramp generator

The oscillator circuit provides a 170-kHz clock, to set the converter operating frequency , and a timing ramp for

slope compensation. The clock waveform is a pulse, a few hundred nanoseconds in duration, that is used to

limit the maximum power-switch duty cycle to 95%. The timing ramp is summed with the current-sense signal

at the input to the current-sense amplifier.

driver latch

The latch, which consists of a set/reset flip-flop and associated logic, is used to control the state of the power

switch by turning the driver on and off. A high output from the latch turns the switch on; a low output from the

latch turns it off. In normal operation, the flip-flop is set high during the clock pulse, but gating keeps the latch

output low until the clock pulse is over. The latch is reset when the PWM comparator output goes high.

current-sense amplifier

The current-sense amplifier has a fixed gain of 6. It amplifies the slope-compensated current-sense voltage (a

summation of the voltage on the current-sense resistor and the oscillator ramp) and feeds it to the PWM

comparator.

error amplifier

The error amplifier is a high-gain differential amplifier used to regulate the converter output voltage. The

amplifier generates an error signal, which is fed to the PWM comparator. The error signal is generated when

a sample of the output voltage is compared to the internal reference and the difference is amplified. The output

sample is obtained from a resistive divider connected between FB and GND. FB is externally connected to the

converter output, and the divider output is connected to both the error amplifier input and COMP. A 0.001-µF

capacitor connected between FB and COMP stabilizes the voltage control loop.

PWM comparator

The PWM comparator resets the drive latch and turns off the power switch whenever the slope-compensated

current-sense signal from the current-sense amplifier exceeds the error signal.

power switch

The power switch is a 0.7-Ω n-channel MOSFET with current-sensing. The drain is connected to OUT and the

current sense is connected to a resistor. The voltage across the resistor is proportional to the current in the

power switch and is tied to the overcurrent comparator and the current-sense amplifier. In normal operation,

the power switch is turned on at the start of each clock cycle and turned off when the PWM comparator resets

the drive latch.

SS clamp

The SS (soft-start) clamp circuit limits the signal level on error-amplifier output during start-up. The voltage on

SS is amplified and used to momentarily override the error-amplifier output until it rises above that output, at

which point the error-amplifier takes over. This prevents the input to the PWM comparator from exceeding its

common-mode range (the error-amplifier output too high to be reached by the current ramp) by limiting the

maximum voltage on the error-amplifier output during start-up.

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

soft start

Soft start causes the output voltage to increase to the regulation point at a controlled rate of rise. The voltage

on the charging soft-start capacitor gradually raises the clamp on the error-amplifier output voltage, limiting

surge currents at power-up by increasing the current-limit threshold on a cycle-by-cycle basis. Even if SS has

no capacitor installed, some distributed capacitance will always be present. A soft-start cycle is initiated when

either the enable signal (EN) is switched high, or an overcurrent fault condition triggers the discharge of the

soft-start capacitor.

overcurrent comparator

The overcurrent comparator monitors the current in the power switch. The comparator trips and initiates a

soft-start cycle if the power-switch current exceeds 1.5-A peak. On each clock cycle, the power switch turns on

and attempts to deliver current until the overcurrent limits are exceeded.

enable (EN)

A logic low on EN puts the TPS6734 in shutdown mode. In shutdown, the output power switch, voltage

reference, and other functions are shut off, the supply current is reduced to 3 µA maximum, and the soft-start

capacitor is discharged through a 1-MΩ resistance. The output voltage falls to a diode drop below the input

voltage because of the current path from input to output through the inductor and diode.

DISSIPATION RATING TABLE

PACKAGE

TA ≤ 25°C

POWER RATING

DERATING FACTOR

ABOVE TA = 25°C

TA = 70°C

POWER RATING

TA = 85°C

POWER RATING

D 725 mW 5.8 mW/°C 464 mW 377 mW

P 1175 mW 9.4 mW/°C 752 mW 611 mW

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

†

Pin voltages: V

CC,

OUT (see Note 1) –0.3 V to 15 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SS, COMP, EN (see Note 1) –0.3 V to V

CC

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Peak switch current 1.5 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference current 2.5 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous power dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

A

–40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 s 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: All voltage values are with respect to network terminal ground.

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

recommended operating conditions

MIN NOM MAX UNIT

Supply voltage 2.7 5 12 V

Compensation capacitor 0.001 µF

Output current at REF 0 100 µA

Reference capacitor 0.01 µF

Operating free-air temperature, T

A

–40 85 °C

electrical characteristics over recommended operating free-air temperature range, V

CC

= 5 V,

I

O(LOAD)

= 0 mA, EN = 5 V , typical values are at T

A

= 25°C (unless otherwise noted) (refer to circuit

shown in Figure 13)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Operating Entire circuit 1.2 2.5 mA

Supply current

EN = 0.4 V , entire circuit 3 µA

Standb

y

EN = 0.4 V, into V

CC

3 µA

High-level input threshold voltage at EN 2 V

Low-level input threshold voltage at EN 0.4 V

Shutdown input leakage current at EN –1 1 µA

On resistance at OUT Current at OUT = 500 mA 0.7 Ω

Leakage current at OUT VDS = 12 V 1 µA

Reference voltage 1.22 V

Reference drift TA = –40°C to 85°C 6.7 ppm/°C

Oscillator frequency 170 kHz

Compensation pin impedance 7500 Ω

performance characteristics over recommended operating free-air temperature range, typical

circuit connected as shown in Figure 13, typical values are at T

A

= 25°C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Output voltage VCC = 4.75 V , 0 mA < I

O(LOAD)

< 120 mA 11.64 12.12 12.6 V

VCC = 3.75 V 120 150

Load current

VCC = 3.0 V, Figure 11 150

mA

Line regulation VCC = 5 V to 12 V, I

O(LOAD)

= 50 mA 0.20%

Load regulation I

O(LOAD)

= 0 mA to 120 mA 0.0042%

Efficiency VCC = 5 V, I

O(LOAD)

= 120 mA 86%

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

0

0246810

– Load Current – mA

50

150

t – Time – ms

LOAD TRANSIENT RESPONSE

200

12 14 16 18

100

– Output Voltage – V

12.1

12

I

L

V

O

VI = 5 V

VO = 12 V

IL = 0 mA to 120 mA

11.9

Figure 2

0

0246810

– Input Voltage – V

2

6

t – Time – ms

LINE TRANSIENT RESPONSE

8

12 14 16 18

4

– Output Voltage – V

12.05

12

11.95

V

I

V

O

Figure 3

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

8

6

2

0

012345

Voltage – V

10

14

t – Time – mS

EN RESPONSE TIME

6789

4

12

Output

Voltage

EN Voltage

VI = 5 V

VO = 5 V to 12 V

IL = 120 mA at 12 V

170

160

150

140

345

– Oscillator Frequency – kHz

180

190

OSCILLATOR FREQUENCY

vs

SUPPLY VOLTAGE

200

67 9

108

F

osc

VCC – Supply Voltage – V

Figure 4 Figure 5

10

6

4

0

0.1 0.5 0.9 1.3 1.7 2.1 2.5

– Input Supply Current – mA

12

16

INPUT SUPPLY CURRENT

vs

SUPPLY VOLTAGE

18

2.9 4.5 6.5 8.5

14

8

2

Bootstrap

Typical

IO = 0

Á

I

CC

VCC – Supply Voltage – V

120

60

40

0

3 3.5 4

– Maximum Output Current – mA

140

160

MAXIMUM OUTPUT CURRENT

vs

SUPPLY VOLTAGE

180

4.5 5

100

80

20

I

O

VCC – Supply Voltage – V

Figure 6 Figure 7

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

The TPS6734 operates in a boost circuit as shown in Figures 1 and 1 1. Figure 1 shows the typical application

circuit, which generates 12 V from a nominal 5-V source. The circuit is ideal for processor interface for energy

management, because EN can be controlled by logic signals to place the 12-V source into the shutdown mode

(3-µA current drain) when 12 V is not needed. An example of such an application is a flash memory device that

requires 12 V for the erase cycle.

discontinuous mode

The circuit shown in Figure 1 operates in discontinuous mode over most of the range of input voltage and output

current. In discontinuous mode, current through the inductor begins at zero, rises to a peak value, then ramps

down to zero each cycle as shown by the voltage and current waveforms in Figure 8. The ringing in the voltage

waveform on OUT results from a resonance between the inductor and the power switch capacitance and is

normal for discontinuous operation.

0

0246810

5

15

DISCONTINUOUS MODE

20

12 14 16 18

10

1

0.5

0

I – Inductor Current – A

t – Time – µs

VI = 5 V

VO = 12 V

IL = 50 mA

Voltage at Out – V

Figure 8

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

continuous mode

When the converter is delivering heavy loads from low voltage sources, it operates in continuous mode. As

shown in Figure 9, the inductor current does not drop to zero and the ringing is gone from the OUT voltage

waveform.

0

0246810

Voltage at Out – V

5

15

CONTINUOUS MODE

20

12 14 16 18

10

1

0.5

0

I– Inductor Current – A

t – Time –µs

VI = 5 V

VO = 12 V

IL = 150 mA

Figure 9

pulse-skipping mode

At very light load currents, the TPS6734 cannot generate drive pulses sufficiently narrow to maintain regulation

and operate at 170 kHz. Under these circumstances, the converter operates in a pulse-skipping mode, in which

cycles are skipped. In pulse-skipping mode, the waveforms are irregular and the output ripple contains a

low-frequency component that may exceed 50 mV peak-to-peak.

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

efficiency

Typical ef ficiency for the converter circuit shown in Figure 13 is plotted in Figure 10. The efficiency falls off rapidly

at very light currents because the supply current is a significant percentage of the load.

82

80

76

74

10 20 30 40 50 60 70

% – Efficiency

84

86

EFFICIENCY

vs

OUTPUT CURRENT

88

80 90 100 140

78

110120 130

IO – Output Current – mA

VCC = 5.5 V

VCC = 5 V

VCC = 4.5 V

Figure 10

inductor selection

Inductance value is directly proportional to the input voltage and inversely proportional to the output power. The

18 µH shown in the typical circuit is the proper value for operation from 5-V sources up to 2-W loads. A lower

inductance value should be used when operating from 3-V sources. Operation from 7 V and higher sources may

require inductance values greater than 18 µH. The inductor’s saturation current rating should be greater than

three times the dc load current for 5-V inputs and five times the dc load for 3-V inputs.

output filter capacitor selection

The output filter capacitor should be selected for minimum ESR (equivalent series resistance). Capacitor

ESR × ∆I

L

(change in inductor current) determines the amplitude of the high-frequency ripple on the output

voltage. The ESR of the capacitor should be less than 0.25 Ω to keep the output ripple less than 50 mV

peak-to-peak over the entire current range (using 18-µH inductor).

diode

A Schottky diode or a high-speed silicon rectifier should be used. The continuous current rating of the diode

should be at least 300 mA for full load (120 mA) operation.

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

soft-start capacitor

Soft-start timing is controlled by the value of the SS capacitor. Table 1 lists soft-start time intervals for selected

capacitor values and circuit conditions. If the circuit starts up with no load (e.g. in flash-memory programming

supplies), no soft start is needed. Omitting the soft-start capacitor provides a minimum output-voltage rise time

from the shutdown state, improving the output start-up time.

Table 1. Typical Soft-Start Times

SUPPLY

SOFT-START TIME† (ms) VERSUS CAPACITANCE (µF)

SUPPLY

VOLTAGE (V)

NO. CAP 0.047 0.1 0.47 1.0

5 0.70 22 42 220 400

7 0.46 15 37 185 225

9 0.38 10 17 88 155

†

Soft-start times are ±35%

printed-circuit layout

Printed-circuit-board (PCB) layout is critical to quiet operation. A ground plane is recommended. Special

attention should be given to minimizing the lengths of the switching loops. The first loop is formed by OUT, the

diode, the output capacitor, and GND, the length of which can be minimized by connecting the anode of the diode

close to OUT . The output capacitor should be connected directly between the diode cathode and GND with the

shortest possible path. The second loop is formed by OUT , the inductor , the input capacitor, and GND. This loop

is less critical than the first; however, the connection of OUT, the inductor and the anode of the diode must be

minimized. Bypass capacitors should be located as close to the device as possible to prevent instability and

noise pickup. If a large V

CC

-to-GND bypass capacitor cannot be placed adjacent to the IC pins, the pins should

be bypassed directly with a small ceramic capacitor (e.g., 0.1 µF). The recommended layout, shown in

Figures 14 through 17, can provide guidance for PCB configuration (the ground plane beneath the TPS6734

and the short loops should be noted).

Plastic plug-in-type proto boards, or any construction scheme that allows long leads and the possibility of noise

pickup, should not be used when assembling a breadboard or prototype application circuit implementing the

TPS6734.

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

bootstrapped output circuit

For operation below 2.7 V , the TPS6734 may be connected in a bootstrap configuration as shown in Figure 1 1.

The bootstrap configuration is less efficient (requires more supply current and suffers a loss in efficiency at

voltages below 5 V; see Figure 12) and is not recommended except for very low voltage operating conditions.

Because the output-driver stage, which benefits most from higher voltages, is diode-coupled to the output

voltage (see Figure 2), the bootstrapped configuration provides no benefit except at very low voltages. In the

shutdown mode (EN = low), no-load quiescent current is unchanged (3 µA max) whether in the bootstrap or the

typical configuration.

V

CC

FB

OUT

GND

EN

REF

SS

COMP

1

2

3

4

8

7

6

5

TPS6734

0.001 µF

18 µH

1 A, 20 V

V

I

2 V to 12 V

ENABLE

+

33 µF

V

O

12 V , 120 mA

0.0047 µF

Figure 11. TPS6734 Bootstrap Configuration

82

80

76

74

10 20 30 40 50 60 70

% – Efficiency

72

84

EFFICIENCY

vs

OUTPUT CURRENT FOR TYPICAL AND BOOTSTRAP

86

80 90 100 140

78

110120 130

IO – Output Current – mA

70

68

66

Typical

Bootstrap

VCC = 5 V

Figure 12

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

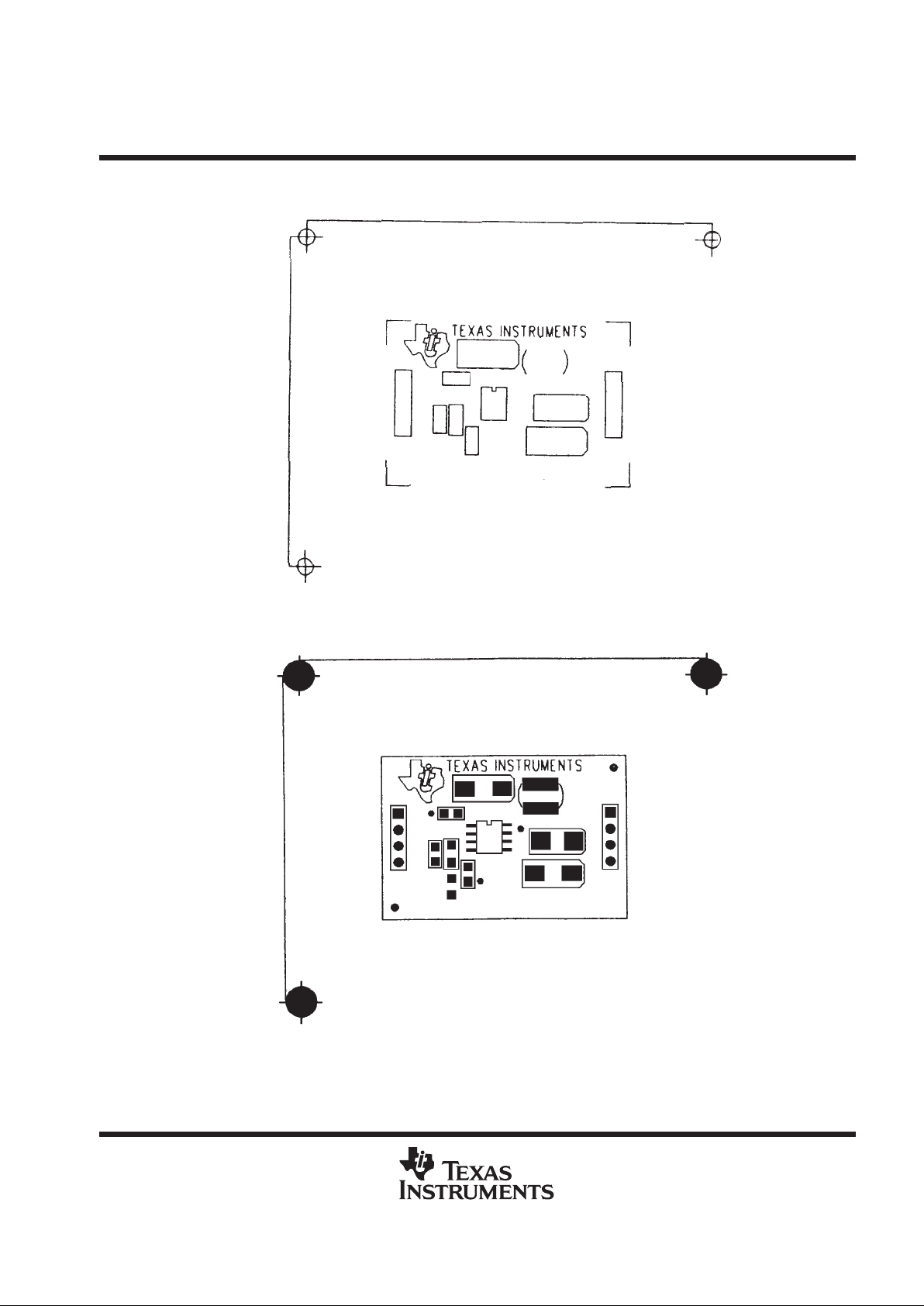

TPS6734 converter design with recommended layout

The following schematic (Figure 13) and a required-components table are provided for a 12-V-output boost

converter. The converter is capable of delivering 120 mA of output current over an input voltage range of 3.75 V

to 12 V. Recommended layout and detailed artwork for a PCB are provided in Figures 14 through 17.

NOTE A: A jumper between pins P1-3 and P1-4 shuts off the TPS7634. Remove the jumper to resume normal operation.

V

CC

FB

OUT

GND

EN

REF

SS

COMP

1

2

3

4

8

7

6

5

TPS6734

V

I

ENABLE

+

33 µF, 20 V

L1

18 µH

SS12

1

2

3

4

V

O

V

O

GND

GND

C5

D1

U1

C4 0.001 µF

+

C1

C3

0.047 µF

C2

0.01 µF

R1

10 kΩ

1

2

3

4

GND

GND

33 µF, 20 V

P1

P2

Figure 13. Schematic for Printed Circuit Board (shown in Figures 14 through 17)

Required Components

QTY. DESCRIPTION REF DES

MANUFACTURER’S

PART NO.

MANUFACTURER

1 IC, power supply, 12 V for flash memory U1 TPS6734ID Texas Instruments

1 Diode, Schottky D1 SS12 General Instruments

1 Inductor, 18 µH, 150 mΩ, 1.23 A(DC) L1 CD54180MC Sumida

2 Capacitor, 33 µF, 20 V, tantalum C1,5 TAPSD336M020R0200 AVX

1 Capacitor, 0.01 µF, 50 V, ceramic, 0805 C2

1 Capacitor, 0.047 µF, 50 V, ceramic, 1206 C3

1 Capacitor, 0.001 µF, 50 V, ceramic, 0805 C4

2 Connector, header, 4-pin P1,2 Molex

1 PCB, TPS6734

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

1

4

P1 R1

C2 C3

C1

D1

C5

C4

U1

1

4

L1

P2

SLVP081

TPS6734 EVALUATION BOARD

REDUCE TO 2.000 +/– .005

REDUCE TO 2.500 +/– .005

SILKSCREEN – TOP

Figure 14. Component Placement

1

4

P1

C2

C3

SS

JMPR

C4

U1

C1

R1

L1

D1

C5

P2

1

4

SL VP081

REDUCE TO 2.000 +/– .005

REDUCE TO 2.500 +/– .005

SILKSCREEN – TOP

TPS6734 EVALUATION BOARD

Figure 15. Solder Paste Mask

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

REDUCE TO 2.000 +/– .005

REDUCE TO 2.500 +/– .005

COMPONENT SIDE

Figure 16. Printed Circuit, Component Side

REDUCE TO 2.500 +/– .005

REDUCE TO 2.000 +/– .005

Figure 17. Printed Circuit, Wiring Side

(Viewed from Component Side)

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PIN SHOWN

4040047/D 10/96

0.228 (5,80)

0.244 (6,20)

0.069 (1,75) MAX

0.010 (0,25)

0.004 (0,10)

1

14

0.014 (0,35)

0.020 (0,51)

A

0.157 (4,00)

0.150 (3,81)

7

8

0.044 (1,12)

0.016 (0,40)

Seating Plane

0.010 (0,25)

PINS **

0.008 (0,20) NOM

A MIN

A MAX

DIM

Gage Plane

0.189

(4,80)

(5,00)

0.197

8

(8,55)

(8,75)

0.337

14

0.344

(9,80)

16

0.394

(10,00)

0.386

0.004 (0,10)

M

0.010 (0,25)

0.050 (1,27)

0°–8°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion, not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-012

TPS6734I

FIXED 12-V 120-mA BOOST-CONVERTER SUPPLY

SLVS127A – AUGUST 1995 – REVISED JANUAR Y 1999

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

P (R-PDIP-T8) PLASTIC DUAL-IN-LINE PACKAGE

4040082/B 03/95

0.310 (7,87)

0.290 (7,37)

0.010 (0,25) NOM

0.400 (10,60)

0.355 (9,02)

58

41

0.020 (0,51) MIN

0.070 (1,78) MAX

0.240 (6,10)

0.260 (6,60)

0.200 (5,08) MAX

0.125 (3,18) MIN

0.015 (0,38)

0.021 (0,53)

Seating Plane

M

0.010 (0,25)

0.100 (2,54)

0°–15°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS-001

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...