Texas Instruments TPS6236 EVM-655 Series, TPS62360EVM-655, TPS62361BEVM-655, TPS62362EVM-655, TPS62365EVM-655 User Manual

Page 1

User's Guide

SLVU425A–April 2011–Revised July 2011

TPS6236xEVM-655

This user’s guide describes the characteristics, operation, and use of the TPS62360EVM-655

(HPA655-001), the TPS62361BEVM-655 (HPA655-002), the TPS62362EVM-655 (HPA-003), and the

TPS62365EVM-655 (HPA655-004) evaluation modules (EVMs). These EVMs demonstrate the Texas

Instruments TPS62360, TPS62361B, TPS62362, or TPS62365 Processor Supply with I2C Interface and

Remote Sense. This document includes setup instructions, a schematic diagram, bill of materials, and

PCB layout drawings for the evaluation module. The only difference between the 4 versions of the EVM is

the TPS6236x IC, U1.

Contents

1 Introduction .................................................................................................................. 2

2 Setup ......................................................................................................................... 3

3 Software Setup and Operation ............................................................................................ 6

4 Circuit Use and Modifications ............................................................................................. 8

5 Test Results ................................................................................................................. 9

6 Board Layout ............................................................................................................... 14

7 Schematic and Bill of Materials .......................................................................................... 17

List of Figures

1 TPS6236x Software Main Panel.......................................................................................... 6

2 Efficiency vs. Input Voltage (I

3 Efficiency vs. Output Current (VIN= 3.6V, V

4 Load Regulation (V

5 Line Regulation (V

6 Start-up (VIN= 3.6V, V

7 Shutdown (VIN= 3.6V, V

OUT

OUT

= 1.4V, I

= 1.4V, V

OUT

OUT

8 Output Voltage Ripple (VIN= 3.6V, V

9 Input Voltage Ripple (VIN= 3.6V, V

10 Load Transient Response (VIN= 3.6V, V

11 Thermal Performance (VIN= 3.6V, V

OUT

IN

OUT

= 1.4V, I

= 1.4V, I

= 1.5A, V

= 1.4V) ................................................................. 9

OUT

= 0.92, 1.16, 1.4, 1.7)............................................... 9

OUT

= 3.6V) ............................................................................. 10

= 1.5A).............................................................................. 10

= 1.5A) ......................................................................... 11

OUT

= 0, output cap discharge enabled)...................................... 11

OUT

OUT

OUT

OUT

= 1.4V, I

= 1.4V, I

= 1.4V, I

OUT

= 1.4V, I

= 3A)........................................................... 12

OUT

= 3A)............................................................. 12

OUT

= 1A to 2A step)......................................... 13

OUT

= 3A)........................................................... 13

OUT

12 Assembly Layer............................................................................................................ 14

13 Top Layer................................................................................................................... 15

14 Layer 2...................................................................................................................... 15

15 Layer 3 ..................................................................................................................... 16

16 Bottom Layer............................................................................................................... 16

17 TPS6236xEVM-655 Schematic.......................................................................................... 17

List of Tables

1 Performance Specification Summary..................................................................................... 2

2 Default Jumper Settings.................................................................................................... 5

3 TPS6236x Solution Required Components............................................................................ 18

4 TPS6236xEVM-655 Evaluation Components.......................................................................... 18

VeriSign is a trademark of VeriSign, Inc.

All other trademarks are the property of their respective owners.

SLVU425A–April 2011– Revised July 2011 TPS6236xEVM-655

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

1

Page 2

Introduction

1 Introduction

1.1 Requirements

To operate this EVM, connect and properly configure the following components:

A personal computer (PC) with a USB port is required to operate this EVM. The TPS6236x interface

software runs on the PC and communicates with the EVM via the PC’s USB port. Commands can be

sent to the internal registers of the TPS6236x through the USB port. The software has been tested with

the PC requirements listed below. It may work with other operating systems and configurations, but

this has not been verified.

Personal Computer Requirements

• Windows XP™ operating system

• .NET 2.0 or higher

• USB port

• 10 MB of free hard disk space

• 512 MB of RAM

USB-TO-GPIO Adapter

The USB-TO-GPIO adapter is the link that allows the PC and the EVM to communicate. One end of

the USB-TO-GPIO adapter connects to the PC with the supplied USB cable. The other end of the

USB-TO-GPIO adapter connects to the EVM with the supplied ribbon cable.

When a command is written to the EVM, the interface program running on the PC sends the

commands to the PC USB port. The USB-TO-GPIO adapter receives the USB command, converts the

signal to an I2C protocol, and sends the I2C signal to the TPS6236x EVM board.

Software

Texas Instruments provides software to assist in evaluating this EVM. This software can be

downloaded from the TPS6236xEVM-655 Product Page, located at:

http://focus.ti.com/docs/toolsw/folders/print/tps62360evm-655.html.

Printed-Circuit Board Assembly

The board contains the either the TPS62360, TPS62361B, TPS62362, or TPS62365 IC and the

required external components to evaluate it as a processor power supply solution.

www.ti.com

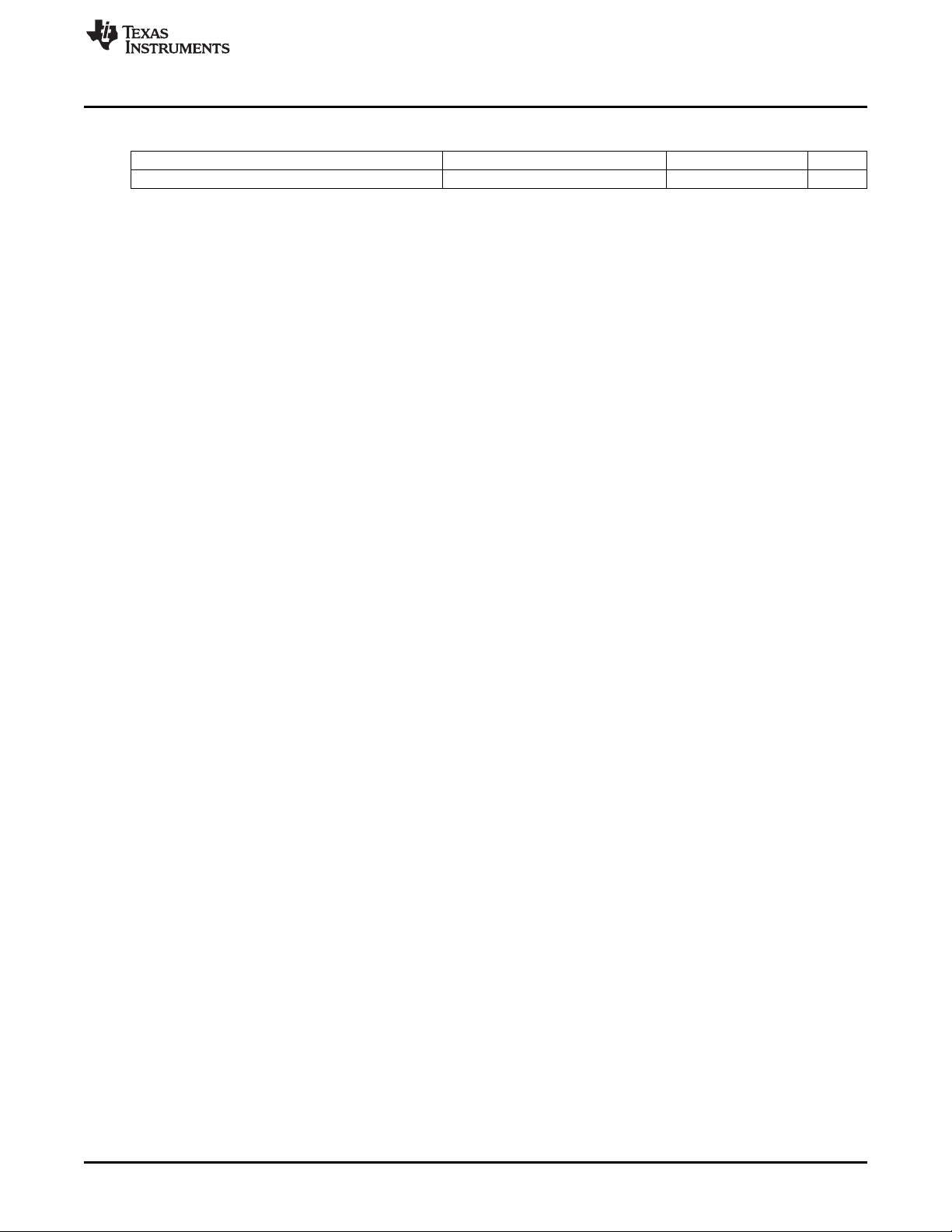

1.2 Performance Specification Summary

A summary of the performance specifications is provided in Table 1. Specifications are given for an input

voltage of 3.6V and an output voltage of 1.4V, unless otherwise specified. The TPS6236x is designed and

tested for VIN= 2.5V to 5.5V. The ambient temperature is 25°C for all measurements, unless otherwise

noted.

Table 1. Performance Specification Summary

SPECIFICATION TEST CONDITIONS MIN TYP MAX UNIT

VINvoltage range 2.5 3.6 5.5 V

Output voltage set point - TPS62360/2 Programmable in 10 mV steps 0.77 1.4 V

Output voltage set point - TPS62361B/5 Programmable in 10 mV steps 0.5 1.77 V

Output current range - TPS62360, TPS6361B, TPS62362 0 3 A

Output current range - TPS62365 0 3.5 A

Line regulation I

Load regulation VIN= 3.6V, V

Load transient response

Input ripple voltage VIN= 3.6V, V

Output ripple voltage VIN= 3.6V, V

2

TPS6236xEVM-655 SLVU425A–April 2011– Revised July 2011

Copyright © 2011, Texas Instruments Incorporated

I

I

OUT

OUT

OUT

= 1.5A, V

= 1A to 2A

= 2A to 1A

= 1.4V ±0.1%

OUT

= 1.4V ±0.15%

OUT

Voltage change 40 mV

Recovery time 10 μs

Voltage change 45 mV

Recovery time 8 μs

OUT

OUT

= 1.4V, I

= 1.4V, I

= 3A 120 mV

OUT

= 3A 10 mV

OUT

Submit Documentation Feedback

PP

PP

Page 3

www.ti.com

Table 1. Performance Specification Summary (continued)

SPECIFICATION TEST CONDITIONS MIN TYP MAX UNIT

Maximum efficiency VIN= 3.6V, V

2 Setup

This section describes the jumpers and connectors on the EVM as well as how to properly connect, set

up, and use the TPS6236xEVM-655.

2.1 Connector/Jumper Descriptions

OUT

= 1.7V, I

= 750mA 91.4%

OUT

Setup

2.1.1 J1 – V

IN

This header is for the positive input supply voltage to the converter. The leads to the input supply should

be twisted and kept as short as possible to minimize EMI transmission and reduce inductive voltage droop

at a load transient event. This voltage should be between 2.5V and 5.5V.

2.1.2 J2 – S+/S-

Sense connector for VIN. Connect input supply's sense leads to this point. Monitor the VINvoltage at this

point.

2.1.3 J3 – GND

This is the return connection for the input power supply of the converter. The leads to the input supply

should be twisted and kept as short as possible to minimize EMI transmission and reduce inductive

voltage droop at a load transient event.

2.1.4 J4 – V

OUT

This header connects to V

below 1A. If the load current will exceed 1A, use terminal block J7 instead. The leads to the load should

be twisted and kept as short as possible to minimize EMI transmission and reduce inductive voltage droop

at a load transient event.

2.1.5 J5 – SNS+/SNS-

Remote sense connector for the IC. For proper regulation, this must be connected at the load. This is

a high impedance connection back to the TPS6236x's remote sense inputs and is required for output

regulation. Monitor the output voltage at this point.

. Connect the load (processor) at this point if the load current will remain

OUT

2.1.6 J6 – GND

This is the return connection for the load. If the load current will exceed 1A, do not use headers J4 and J6,

but use terminal block J7 instead. The leads to the load should be twisted and kept as short as possible to

minimize EMI transmission and reduce inductive voltage droop at a load transient event.

2.1.7 J7 – V

/GND Terminal Block

OUT

This terminal block should be used to connect to the load (processor) if the load current will exceed 1A. If

the load current will remain below 1A, the J4/J6 headers may be used instead. The leads to the load

should be twisted and kept as short as possible to minimize EMI transmission and reduce inductive

voltage droop at a load transient event.

2.1.8 J8 – I2C Connection from USB-TO-GPIO Adaptor

This connects the USB-TO-GPIO adaptor to the TPS6236xEVM-655. It provides the I2C signals and a

3.3V supply for powering VDD. If the USB-TO-GPIO adaptor is not used, do not connect to J8, but connect

the I2C signals to the J9 header instead. This connector is keyed to prevent incorrect installation.

SLVU425A–April 2011– Revised July 2011 TPS6236xEVM-655

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

3

Page 4

Setup

2.1.9 J9 – I2C Monitor Point and Alternate Connection

This header is provided to connect to or monitor the I2C signals on the TPS6236xEVM-655. If the I2C

signals are being sent via this header (and not via the USB-TO-GPIO adaptor), do not plug into the J8

header and provide a separate VDDsupply on JP1 without any jumper installed.

2.1.10 J10 – Load Step Signal Input

This SMA connector accepts a signal input from a function generator that drives Q1 in order to evaluate

the TPS6236x's transient response.

2.1.11 JP1 – VDDControl

This jumper is used to connect VDDto either a 3.3V rail provided by the USB-TO-GPIO adaptor (jumper

across pins 1 and 2) or to GND to reset the I2C registers (jumper across pins 2 and 3). Alternatively, the

user can provide their own VDDvoltage (1.15 - 3.6V) between pins 2 and 3 of JP1. No jumper should be

installed in this case. For normal operation without an external supply voltage, the jumper should be

installed between pins 1 and 2.

2.1.12 JP2 – VSEL0

This jumper sets the VSEL0 pin to either a logic high (jumper across pins 1 and 2) or a logic low (jumper

across pins 2 and 3).

2.1.13 JP3 – VSEL1

This jumper sets the VSEL1 pin to either a logic high (jumper across pins 1 and 2) or a logic low (jumper

across pins 2 and 3).

www.ti.com

2.1.14 JP4 – EN

This jumper sets the EN pin to either a logic high (jumper across pins 1 and 2) or a logic low (jumper

across pins 2 and 3). When EN is low, the TPS6236x output will be off and not switching. Set EN to high

to turn on the output voltage.

2.2 Software Setup

The software is available at the TI website,

http://focus.ti.com/docs/toolsw/folders/print/tps62360evm-655.html.

Download and unzip the file. Run setup.exe and follow the on screen instructions to complete the

installation.

NOTE: This installation page is best viewed with Microsoft Internet Explorer browser (it may not

work correctly with other browsers)

The Microsoft .Net Framework 2.0 is required for the software to run.

After installation, the software should automatically run. To run the software later, go to

Start→All Programs→Texas Instruments→TPS6236x EVM→TPS6236x EVM.

During future use of the software, it may prompt you to install a new version if one becomes available on

the Web.

NOTE: VeriSign™ Code Signing is used to prevent any malicious code from changing this

application. If at any time in the future the binaries are modified, the code will no longer

attempt to run.

4

TPS6236xEVM-655 SLVU425A–April 2011– Revised July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

Host

Computer

USBCable

USB

Interface

Adapter

GreenLED

Indicates

Power

10-Pin

Ribbon

Cable

EVMBoard

USBInterface AdaptorQuickConnectionDiagram

www.ti.com

2.3 Hardware Setup

Table 2 shows the board default jumper settings.

Connect the USB-TO-GPIO adapter to your PC using the supplied USB cable. Connect the

TPS6236xEVM connector J8 to the USB-TO-GPIO adapter using the supplied 10-pin ribbon cable. The

connectors on the ribbon cable are keyed to prevent incorrect installation.

Setup

Table 2. Default Jumper Settings

JUMPER DEFAULT

JP1 Installed across pins 1 and 2

JP2 Installed across pins 2 and 3

JP3 Installed across pins 2 and 3

JP4 Installed across pins 1 and 2

Connect the load (processor) to either the output headers J4 and J6 (for currents below 1A) or to the

output terminal block J7 (for currents greater than 1A). The leads should be short and twisted.

Connect the SNS+ and SNS- signals from header J5 to the load. For proper regulation, these must be

connected to the output.

Install jumpers, JP1 through JP4 to the desired positions. Jumper JP1 must be across pins 1 and 2 for the

TPS6236x to operate.

Connect at least a 3 A rated input power supply, set to provide between 2.5V and 5.5V, between J1 and

J3. The leads should be short and twisted. Turn on the power supply.

SLVU425A–April 2011– Revised July 2011 TPS6236xEVM-655

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

5

Page 6

Software Setup and Operation

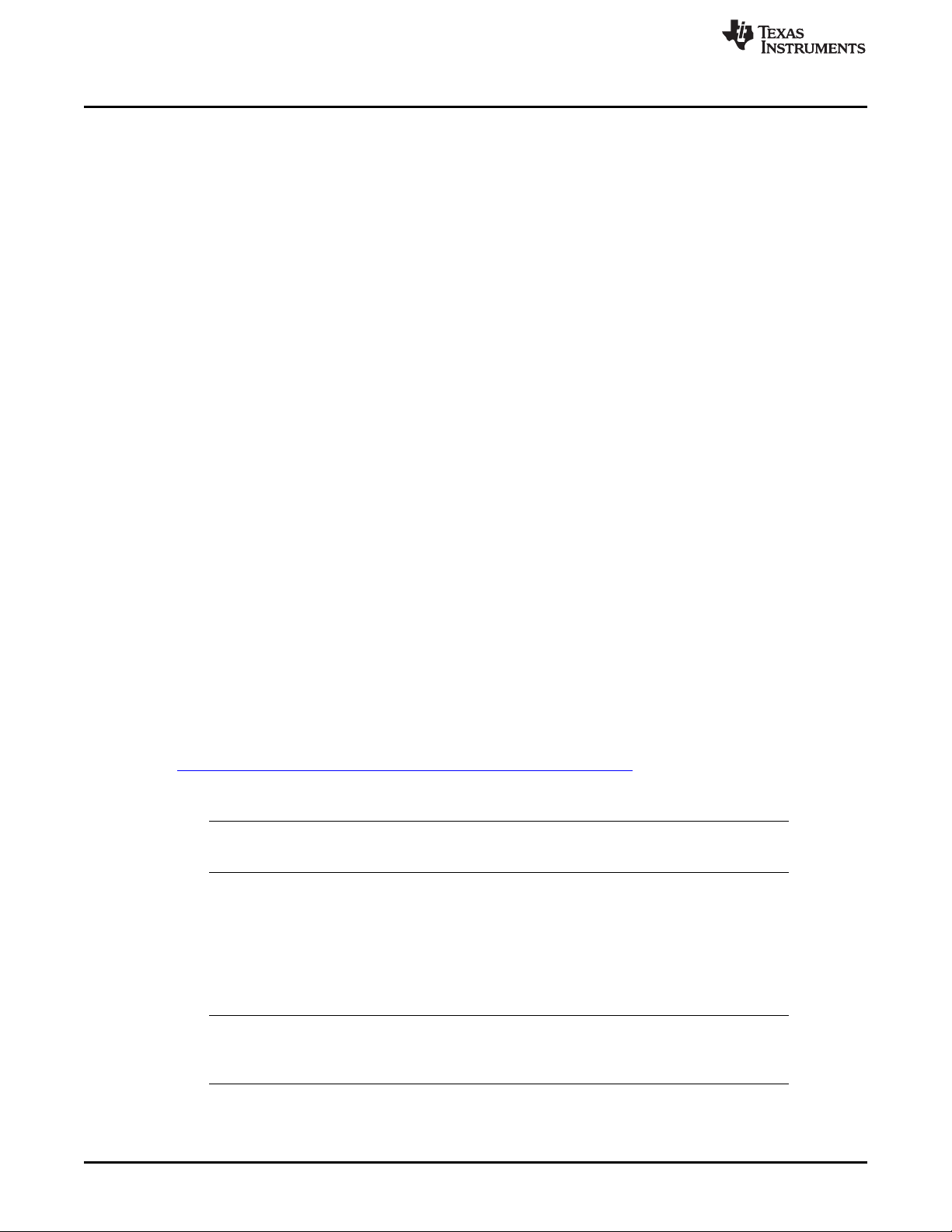

3 Software Setup and Operation

This section provides descriptions of the EVM software and functionality.

The supplied software is used to communicate with the TPS6236xEVM. Click on the icon on the host PC

to start the software. The host PC software first checks the firmware version of the USB-TO-GPIO

adapter. If an incorrect firmware version is installed, the software automatically searches on the Internet (if

connected) for updates. If a new update is available, the software notifies the user of the update,

downloads and installs the software. Note that after the firmware is updated, the user must disconnect and

then reconnect the USB cable between the adapter and PC, as instructed during the install process. The

host PC software also automatically searches on the Internet (if connected) for updates to the EVM

software. If a new update is available, the software notifies the user of the update, downloads and installs

the update.

VINand VDDmust be supplied for the software to detect the TPS6236x and run.

The software reads the registers on the TPS6236x and automatically determines which version of the IC is

installed. Even if the IC is disabled via the EN pin (JP4), the user can still communicate with the

TPS6236x if VINand VDDare supplied. If no IC is detected, the software will abort loading.

The software displays the main panel for the user interface, shown in Figure 1.

www.ti.com

Figure 1. TPS6236x Software Main Panel

6

TPS6236xEVM-655 SLVU425A–April 2011– Revised July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

It is recommended that the user press the 'READ' button at the top of the screen immediately after loading

the software to confirm that the software and cable connections are working properly. The message box at

the top right of the main panel (I2C Activity) displays all I2C activity. The message box at the bottom (USB

Bridge Connected) displays whether or not the USB-TO-GPIO connection is functional.

The software itself performs no calculations or computations and simply reads and writes to and from the

IC's registers through the I2C interface. Each register's bits can either be changed manually by changing

the boxes corresponding to each bit in the panel's bottom left half (REGISTERS section), or they can be

changed through the drop-down boxes and buttons in the rest of the panel. Some bits are reserved and

not writeable. These will not allow you to click on them to change their setting. For example, since the

TPS62360 does not have an operational register bit at bit 6 of registers 0x00h through 0x03h, the

TPS62360's main panel will not allow writes to those bits. The I2C bus speed is fixed at 100 kbps and this

is noted at the bottom of the screen.

Following any change to an individual bit, drop-down box, or button, the user must write the new values to

the registers by either clicking the 'W' button to the left of each affected register or by clicking the 'WRITE'

button at the top of the screen.

In order to reduce the amount of manual reading and writing required, the two drop-downs at the top left of

the screen have been provided to do this automatically. The 'Auto Read' drop down allows the option of

automatically reading all the registers at specific time intervals. The 'Write On Changes' drop-down allows

the option of automatically writing a change to the registers as soon as it is made in the software.

The TPS6236x datasheet is available via the 'Help' menu (Internet access is required). The datasheet

discusses the functionality of the various register bits, which is also briefly repeated here.

The drop-downs in the top left section of the software (SET0-SET3 section) correspond to registers 0x00h

thought 0x03h in the TPS6236x. These registers set the target output voltage and operating mode

(PFM/PWM or forced PWM). The output voltage on the TPS62360/2 is settable in 10 mV steps between

0.77V and 1.4V. The output voltage on the TPS62361B/5 is settable in 10 mV steps between 0.5V and

1.77V. The operating mode is either PFM/PWM, in which the IC is allowed to skip switching pulses at light

loads to keep the converting efficiency high, or forced PWM mode, in which the IC allows negative

inductor current at light loads to maintain a specific switching frequency and output noise. The TPS6236x

only runs at the settings of one of these four registers at a time. This operating register is selected by the

VSEL0 and VSEL1 jumpers and can be changed during operation.

The top right section of the software (CONTROLS section) contains the functionality of registers 0x04h

and 0x06h and some of the functionality of register 0x05h. The first 3 check boxes enable an internal

resistor on any of the EN, VSEL0, or VSEL1 pins. This resistor, which is internal to the TPS6236x, would

keep that pin in a defined state if it were left floating. The 'Disable Temperature shutdown feature' bit

disables the temperature shutdown internal to the IC, if selected. The 'Enable Active output capacitor

discharge at shutdown' forces the IC to actively discharge the output capacitor during shutdown. The first

drop-down sets the output voltage ramp timing and the final drop-down describes the ramp behavior when

the TPS6236x is changing its output voltage in PFM mode.

The bottom right section of the software (STATUS section) contains the remaining bits in register 0x05h.

The top indicator is green if the IC die temperature is low enough and turns red when the bit is set

corresponding to a die temperature exceeding 120°C typical. The indicator on the bottom turns red if

thermal shutdown has occurred. When this does occur, the TPS6236x will latch off and the temperature

must decrease below a hysteresis amount and the TJTemp shutdown bit needs to be reset by the user.

The button at the bottom of this section is provided for this purpose.

Software Setup and Operation

SLVU425A–April 2011– Revised July 2011 TPS6236xEVM-655

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

7

Page 8

Circuit Use and Modifications

4 Circuit Use and Modifications

Besides the required circuitry to operate the TPS6236x (outlined in a white silk screen border on the

PCB), there are additional circuits present on the TPS6236xEVM-655 that assist in evaluating the

TPS6236x as a processor power supply solution. Additionally, there are modifications that can be made to

adapt the circuit's performance to the needs of a particular application.

4.1 Load Step Circuit

The TPS6236xEVM-655 contains a simple circuit that can produce fast load current steps at the output of

the TPS6236x. This can evaluate the response of the TPS6236x to various load transients. To operate

this circuit, connect a function generator to SMA connector J10 or TP4. The output of the function

generator should be a square wave with a small duty cycle. The output high level controls the gate to

source voltage of the power transistor, Q1, and should be adjusted to generate the desired step current

high level. The output low level sets the step current low level. Good settings to start with are a square

wave signal running at 100 Hz and 5% duty cycle going from 0V to 1.5V. These settings can be adjusted

in order to generate the desired load step.

Resistor R6 is present to observe the load step current by measuring the voltage across TP2 and TP3.

Oscilloscope settings of 100mV / div translate to a current in R6 of 1A / div.

4.2 Output Voltage Buffer

The output voltage buffer circuit simply buffers the SNS+/- output with a unity gain op amp. This

transforms SNS+ and SNS- to a lower impedance signal that can be measured by high impedance

measurement equipment, such as an oscilloscope. The op amp, U2, is powered from the USB-TO-GPIO

adaptor. The USB-TO-GPIO adaptor must be installed for the output voltage buffer circuit to operate.

C13 is provided to reduce the bandwidth and noise of the input signal to the operational amplifier.

www.ti.com

4.3 Circuit Modifications

Modifications may be made to the circuit. Any modifications will affect the performance of the EVM and

must remain within the limits of the TPS6236x IC, as detailed in the datasheet.

4.3.1 Output Capacitors

There are 3 locations for extra output capacitors to be installed in order to reduce output ripple or lessen

the voltage drop due to a load transient. C7 allows an extra capacitor to be installed near the TPS6236x

IC, while C10 and C11 allow extra capacitors to be installed closer to the point of load, which is simulated

by the load step circuit. The total output capacitance must remain below the maximum capacitance

allowed in the datasheet.

4.3.2 Input Capacitors

C9 is provided to locate additional input capacitance near the TPS6236x input. Additional capacitance at

C9 will decrease the input voltage ripple.

C8 is provided to form a complete 'PI'-type filter for the AVIN input. With the change of R1 to some small

value (around 10 Ω), the C-R-C filter is complete. This filter is not necessary for operation of the

TPS6236x.

4.3.3 I2C Pull-up Resistors

R2 and R3 are locations for optional pull-up resistors for the I2C signals. They are required when not using

the USB-TO-GPIO adaptor but are not recommended when using the adaptor. If used, their typical value

is around 2.2kΩ.

8

TPS6236xEVM-655 SLVU425A–April 2011– Revised July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

80

82

84

86

88

90

92

94

96

98

100

2.5 3 3.5 4 4.5 5 5.5

V - Input Voltage - V

I

Efficiency - %

0

10

20

30

40

50

60

70

80

90

100

0.1 1 10 100 1k 10k

I - Load Current - mA

O

0.92 V

1.4 V

1.7 V

1.16 V

Efficiency - %

www.ti.com

5 Test Results

This section provides typical performance waveforms for the TPS6236xEVM-655.

Test Results

Figure 2. Efficiency vs. Input Voltage (I

Figure 3. Efficiency vs. Output Current (VIN= 3.6V, V

= 1.5A, V

OUT

= 1.4V)

OUT

= 0.92, 1.16, 1.4, 1.7)

OUT

SLVU425A–April 2011– Revised July 2011 TPS6236xEVM-655

Submit Documentation Feedback

9

Copyright © 2011, Texas Instruments Incorporated

Page 10

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

0.1 1 10 100 1k 10k

I - Load Current - mA

O

Load Regulation - %

-0.1

-0.08

-0.06

-0.04

-0.02

0

0.02

0.04

0.06

0.08

0.1

2.5 3 3.5 4 4.5 5 5.5

V - Input Voltage - V

I

Line Regulation - %

Test Results

www.ti.com

Figure 4. Load Regulation (V

Figure 5. Line Regulation (V

= 1.4V, VIN= 3.6V)

OUT

= 1.4V, I

OUT

OUT

= 1.5A)

10

TPS6236xEVM-655 SLVU425A–April 2011– Revised July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

t - Time - 20 s/divm

0.5 A/div

0.5 V/div

5 V/div

EN

V

OUT

I

inductor

t - Time - 2 ms/div

0.5 V/div

5 V/div

0.5 A/div

EN

V

OUT

I

inductor

www.ti.com

Test Results

Figure 6. Start-up (VIN= 3.6V, V

Figure 7. Shutdown (VIN= 3.6V, V

OUT

= 1.4V, I

= 1.4V, I

OUT

= 0, output cap discharge enabled)

OUT

OUT

= 1.5A)

SLVU425A–April 2011– Revised July 2011 TPS6236xEVM-655

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

11

Page 12

t - Time - 200 ns/div

0.5 A/div

20 mV/div

5 V/div

SW

I

inductor

V (AC COUPLED)

OUT

t - Time - 200 ns/div

0.5 A/div

50 mV/div

5 V/div

SW

I

inductor

V (AC COUPLED)

IN

Test Results

www.ti.com

Figure 8. Output Voltage Ripple (VIN= 3.6V, V

Figure 9. Input Voltage Ripple (VIN= 3.6V, V

OUT

OUT

= 1.4V, I

= 1.4V, I

OUT

OUT

= 3A)

= 3A)

12

TPS6236xEVM-655 SLVU425A–April 2011– Revised July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

t - Time - 5 s/divm

50 mV/div

1 A/div

I

1A to 2A load Step

OUT

V (AC COUPLED)

OUT

www.ti.com

Test Results

Figure 10. Load Transient Response (VIN= 3.6V, V

OUT

= 1.4V, I

= 1A to 2A step)

OUT

Figure 11. Thermal Performance (VIN= 3.6V, V

OUT

= 1.4V, I

OUT

= 3A)

SLVU425A–April 2011– Revised July 2011 TPS6236xEVM-655

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

13

Page 14

Board Layout

6 Board Layout

This section provides the TPS6236xEVM-655 board layout and illustrations.

Board layout is critical for all high-frequency, switch-mode power supplies. Figure 12 through Figure 15

show the board layout for the TPS6236xEVM-655 PCB. The nodes with high-switching frequencies and

currents are kept as short as possible to minimize trace inductance. Careful attention has been given to

the routing of high-frequency current loops and a single-point grounding scheme is used. Also, the

majority of the heatsinking for this device occurs through the top layer traces and vias pulled from the IC's

solder bumps that carry high currents. See the data sheet for specific layout guidelines.

www.ti.com

14

Figure 12. Assembly Layer

TPS6236xEVM-655 SLVU425A–April 2011– Revised July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

Board Layout

Figure 13. Top Layer

Figure 14. Layer 2

SLVU425A–April 2011– Revised July 2011 TPS6236xEVM-655

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

15

Page 16

Board Layout

www.ti.com

Figure 15. Layer 3

16

Figure 16. Bottom Layer

TPS6236xEVM-655 SLVU425A–April 2011– Revised July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

www.ti.com

7 Schematic and Bill of Materials

This section provides the TPS6236xEVM-655 schematic and bill of materials. The bill of materials is provided in two tables. Table 3 are the

components required to build the TPS6236x solution. Table 4 are the components used only to evaluate the TPS6236xEVM-655 solution.

7.1 Schematic

Schematic and Bill of Materials

Figure 17. TPS6236xEVM-655 Schematic

SLVU425A–April 2011– Revised July 2011 TPS6236xEVM-655

Submit Documentation Feedback

Copyright © 2011, Texas Instruments Incorporated

17

Page 18

Schematic and Bill of Materials

7.2 Bill of Materials

www.ti.com

Table 3. TPS6236x Solution Required Components

Count

-001 -002 -003 -004

3 3 3 3 C1, C4, C5 0.1 µF Capacitor, Ceramic, 10V, X5R, 20% 0402 Std Std

2 2 2 2 C2, C6 10 µF Capacitor, Ceramic, 6.3V, X5R, 20% 0603 Std Std

1 1 1 1 L1 1.0 µH Inductor, Power, 5.4 A, 10.8 mΩ, ±20% 0.157 x 0.157 inch XFL4020-102ME Coilcraft

1 0 0 0 U1 TPS62360YZH IC, 3A Processor Supply Converter BGA TPS62360YZH TI

0 1 0 0 U1 TPS62361BYZH IC, 3A Processor Supply Converter BGA TPS62361BYZH TI

0 0 1 0 U1 TPS62362YZH IC, 3A Processor Supply Converter BGA TPS62362YZH TI

0 0 0 1 U1 TPS62365YZH IC, 3.5A Processor Supply Converter BGA TPS62365YZH TI

RefDes Value Description Size Part Number MFR

Table 4. TPS6236xEVM-655 Evaluation Components

Count

-001 -002 -003 -004

1 1 1 1 C12 0.1 µF Capacitor, Ceramic, 10V, X5R, 20% 0402 Std Std

1 1 1 1 C3 100 µF Capacitor, Ceramic, 6.3V, X5R, 20% 1210 Std Std

0 0 0 0 C7, C10, C11 Open Capacitor, Ceramic, 6.3V, X5R, 20% 0805 Std Std

0 0 0 0 C8, C9 Open Capacitor, Ceramic, 6.3V, X5R, 20% 0603 Std Std

0 0 0 0 C13 Open Capacitor, Ceramic, 25V, X7R, 10% 0603 Std Std

1 1 1 1 Q1 IRLR3715 MOSFET, N-ch, 20V, 49A, 11 mΩ DPAK IRLR3715ZCPBF IR

1 1 1 1 R1 0 Resistor, Chip, 1/10W 0603 Std Std

0 0 0 0 R2, R3 Open Resistor, Chip, 1/16W, 1% 0603 Std Std

2 2 2 2 R4, R5 10 Resistor, Chip, 1/16W, 1% 0603 Std Std

1 1 1 1 R6 0.1 Resistor, Chip, 1W, 1% 2512 Std Std

1 1 1 1 R7 100 Resistor, Chip, 1/16W, 1% 0603 Std Std

5 5 5 5 R8, R9, R10, R11, 10.0K Resistor, Chip, 1/16W, 1% 0603 Std Std

1 1 1 1 U2 OPA334 IC, 0.05 µV/°C Max, Single Supply Op Amp, Zero-Drift SOT23-6 OPA334AIDBV TI

RefDes Value Description Size Part Number MFR

R12

7.3 Related Documentation From Texas Instruments

Processor Supply with I2C Compatible Interface and Remote Sense data sheet (SLVSAU9)

18

TPS6236xEVM-655 SLVU425A–April 2011– Revised July 2011

Copyright © 2011, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

Evaluation Board/Kit Important Notice

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION

PURPOSES ONLY and is not considered by TI to be a finished end-product fit for general consumer use. Persons handling the

product(s) must have electronics training and observe good engineering practice standards. As such, the goods being provided are

not intended to be complete in terms of required design-, marketing-, and/or manufacturing-related protective considerations,

including product safety and environmental measures typically found in end products that incorporate such semiconductor

components or circuit boards. This evaluation board/kit does not fall within the scope of the European Union directives regarding

electromagnetic compatibility, restricted substances (RoHS), recycling (WEEE), FCC, CE or UL, and therefore may not meet the

technical requirements of these directives or other related directives.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30

days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY

SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all

claims arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to

take any and all appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER

FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or infringement of

patents or services described herein.

Please read the User’s Guide and, specifically, the Warnings and Restrictions notice in the User’s Guide prior to handling the

product. This notice contains important safety information about temperatures and voltages. For additional information on TI’s

environmental and/or safety programs, please contact the TI application engineer or visit www.ti.com/esh.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used.

FCC Warning

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION

PURPOSES ONLY and is not considered by TI to be a finished end-product fit for general consumer use. It generates, uses, and

can radiate radio frequency energy and has not been tested for compliance with the limits of computing devices pursuant to part 15

of FCC rules, which are designed to provide reasonable protection against radio frequency interference. Operation of this

equipment in other environments may cause interference with radio communications, in which case the user at his own expense

will be required to take whatever measures may be required to correct this interference.

EVM Warnings and Restrictions

It is important to operate this EVM within the input voltage range of 2.5 V to 5.5 V and the output voltage range of 0.5 V to 1.77 V .

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM. If there are

questions concerning the input range, please contact a TI field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible permanent damage to the

EVM. Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the load

specification, please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than 85°C. The EVM is designed to

operate properly with certain components above 85°C as long as the input and output ranges are maintained. These components

include but are not limited to linear regulators, switching transistors, pass transistors, and current sense resistors. These types of

devices can be identified using the EVM schematic located in the EVM User's Guide. When placing measurement probes near

these devices during operation, please be aware that these devices may be very warm to the touch.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2011, Texas Instruments Incorporated

Page 20

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Audio www.ti.com/audio Communications and Telecom www.ti.com/communications

Amplifiers amplifier.ti.com Computers and Peripherals www.ti.com/computers

Data Converters dataconverter.ti.com Consumer Electronics www.ti.com/consumer-apps

DLP® Products www.dlp.com Energy and Lighting www.ti.com/energy

DSP dsp.ti.com Industrial www.ti.com/industrial

Clocks and Timers www.ti.com/clocks Medical www.ti.com/medical

Interface interface.ti.com Security www.ti.com/security

Logic logic.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Power Mgmt power.ti.com Transportation and www.ti.com/automotive

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com Wireless www.ti.com/wireless-apps

RF/IF and ZigBee® Solutions www.ti.com/lprf

TI E2E Community Home Page e2e.ti.com

Automotive

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2011, Texas Instruments Incorporated

Page 21

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

TPS62360EVM-655 TPS62361BEVM-655 TPS62362EVM-655

Loading...

Loading...