Texas Instruments TPS60123PWPR, TPS60123PWP, TPS60122PWPR, TPS60121PWPR, TPS60122PWP Datasheet

...

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

features

D

High Average Efficiency Over Input Voltage

Range Because of Special Switching

Topology

D

Up to 200-mA Output Current (TPS60120

and TPS60121) From an Input Voltage

Range of 1.8-V to 3.6-V

D

No Inductors Required, Low EMI

D

Regulated 3.3-V ± 4% Output

D

Only Four External Components Required

D

55-µA Quiescent Supply Current

D

0.05-µA Shutdown Current

D

Load Disconnected in Shutdown

D

Space-saving, Thermally-Enhanced

PowerPADt Package

D

Evaluation Module Available

(TPS60120EVM-142)

applications

D

Battery-Powered Applications

D

Two Battery Cells to 3.3-V Conversion

D

Portable Instruments

D

Battery-Powered Microprocessor Systems

D

Miniature Equipment

D

Backup-Battery Boost Converters

D

PDA’s, Organizers, Laptops

D

MP-3 Portable Audio Players

D

Handheld Instrumentation

D

Medical Instruments (e.g., Glucose Meters)

D

Cordless Phones

·

description

The TPS6012x step-up, regulated charge pumps

generate a 3.3-V ±4% output voltage from a 1.8-V

to 3.6-V input voltage (two alkaline, NiCd, or NiMH

batteries). The output current is 200 mA for the

TPS60120/TPS60121 and 100 mA for the

TPS60122/TPS60123, all from a 2-V input. Four

external capacitors are needed to build a

complete high efficiency dc/dc charge pump

converter. To achieve the high efficiency over a

wide input voltage range, the charge pump

automatically selects between a 1.5x or doubler

conversion mode. From a 2-V input, all ICs can

start with full load current.

The devices feature the power-saving pulse-skip

mode to extend battery life at light loads.

TPS60120 and TPS60122 include a low battery

comparator. TPS60121 and TPS60123 feature a

power-good output. The logic shutdown function

reduces the supply current to a maximum of 1 µA

and disconnects the load from the input. Special

current-control circuitry prevents excessive current from being drawn from the battery during

start-up. This dc/dc converter requires no

inductors, therefore EMI is of low concern. It is

available in the small, thermally enhanced 20-pin

PowerP ADt package (PWP).

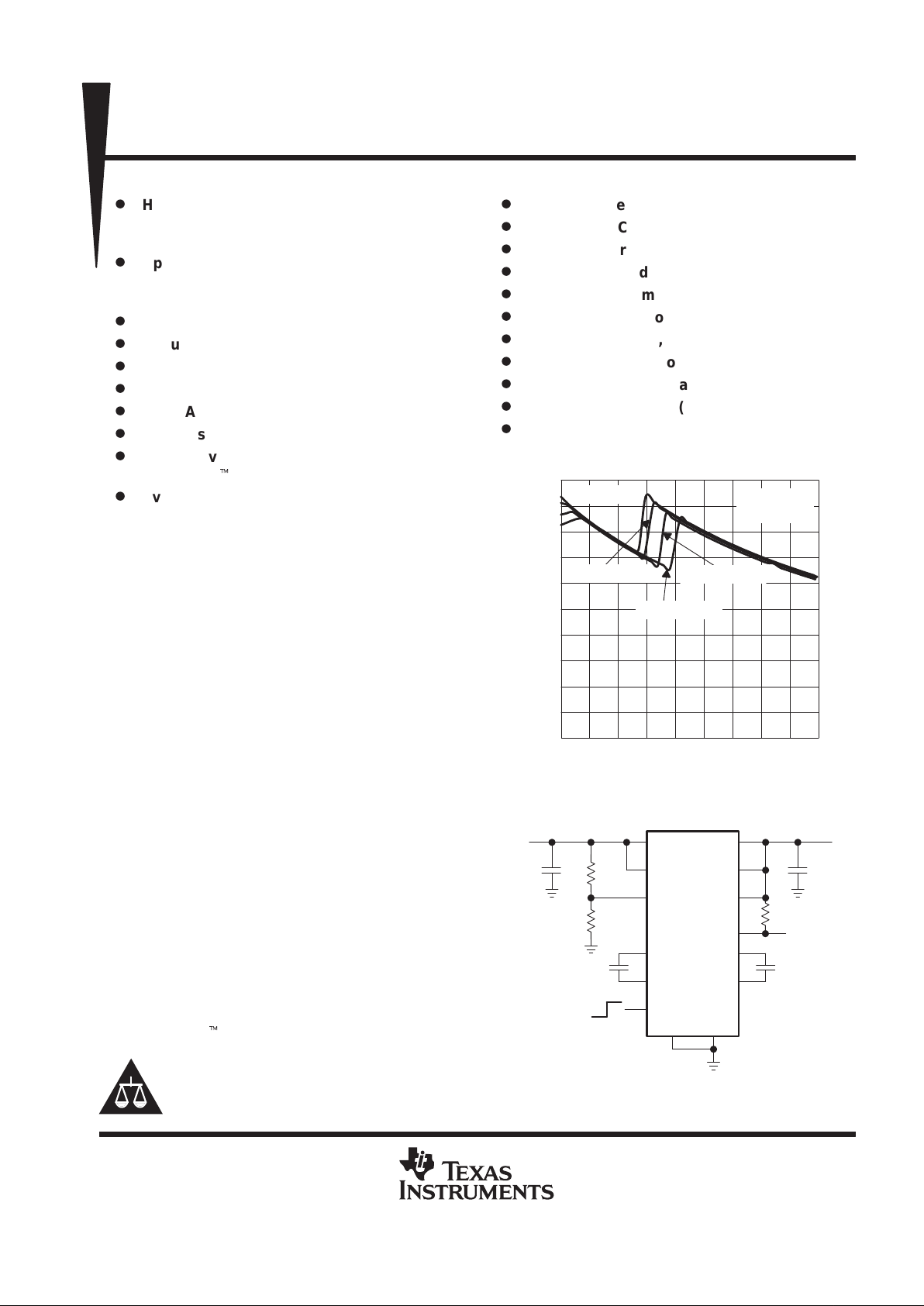

IO = 66 mA

0

10

20

30

40

50

60

70

80

90

100

1.8 2 2.2 2.4 2.6 2.8 3 3.2 3.4 3.6

VI – Input Voltage – V

Efficiency – %

IO = 164 mA

IO = 216 mA

IO = 116 mA

VO = 3.3 V

TC = 25°C

IN

IN

LBI

C1+

C1–

ENABLE

PGND GND

OUT

OUT

FB

LBO

C2+

C2–

C

O

22 µF

C

i

10 µF

Output

3.3 V , 200 mA

C2

2.2 µF

C1

2.2 µF

R1

R2

Input

1.8 V to 3.6 V

OFF/ON

efficiency (TPS60120, TPS60121)

typical operating circuit

R3

TPS60120

Copyright 1999, Texas Instruments Incorporated

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

PowerPAD is a trademark of Texas Instruments Incorporated.

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

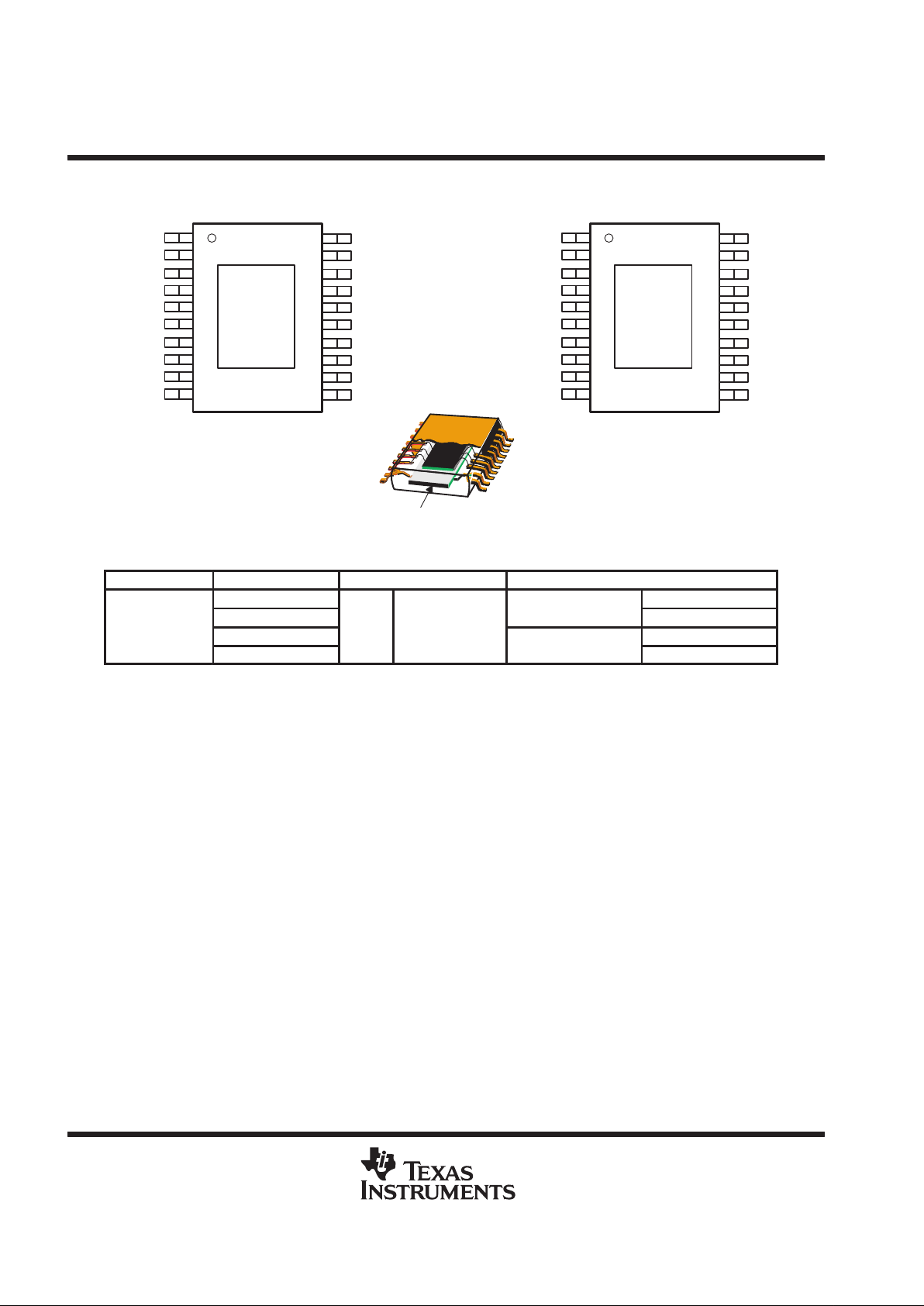

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

GND

GND

ENABLE

FB

OUT

C1+

IN

C1–

PGND

PGND

GND

GND

LBI

LBO

OUT

C2+

IN

C2–

PGND

PGND

PWP PACKAGE

(TPS60120/TPS60122)

(TOP VIEW)

Thermal Pad

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

GND

GND

ENABLE

FB

OUT

C1+

IN

C1–

PGND

PGND

GND

GND

NC

PG

OUT

C2+

IN

C2–

PGND

PGND

PWP PACKAGE

(TPS60121/TPS60123)

(TOP VIEW)

AVAILABLE OPTIONS

T

A

PART NUMBER

†

PACKAGE DEVICE FEATURES

TPS60120PWP

Low battery detector

°

°

TPS60121PWP

20-Pin thermally

2-Cell to 3.3 V, 200 mA

Power good detector

–

40°C to 85°C

TPS60122PWP

PWP

y

enhanced TSSOP

Low battery detector

TPS60123PWP

2-Cell to 3.3 V, 100 mA

Power good detector

†

The PWP package is available taped and reeled. Add R suffix to device type (e.g. TPS60120PWPR) to order quantities of 2000

devices per reel.

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

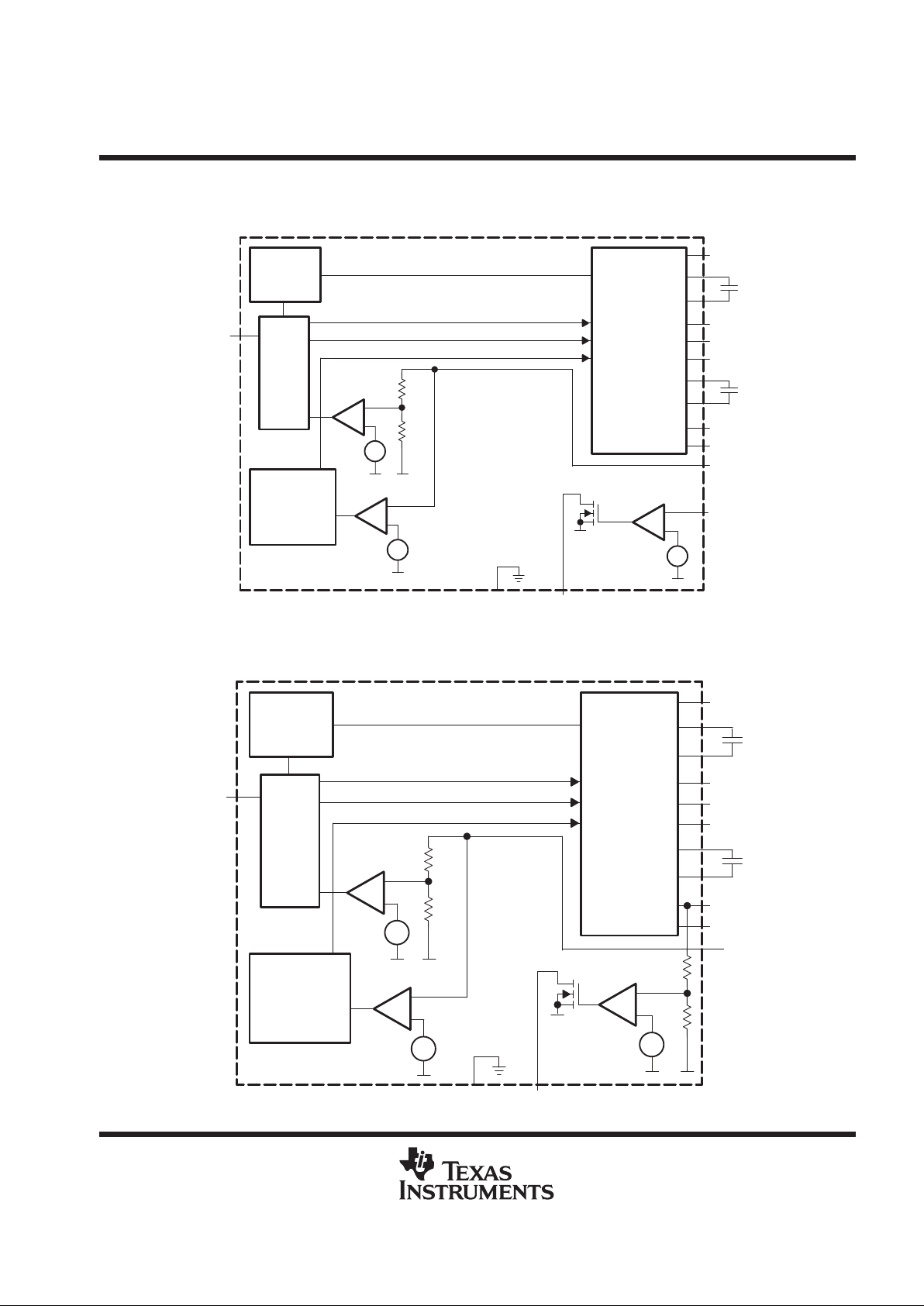

functional block diagram

_

+

Charge Pump

Power Stages

IN

C1+

C1–

OUT

PGND

IN

C2+

C2–

OUT

PGND

FB

Oscillator

Control

Circuit

_

+

+

–

V

REF

_

+

+

–

Shutdown/

Start-Up

Control

0.8 V

I

+

–

V

REF

LBI

GND LBO

ENABLE

C1F

C2F

TPS60120/TPS60122

_

+

Charge Pump

Power Stages

IN

C1+

C1–

OUT

PGND

IN

C2+

C2–

OUT

PGND

FB

Oscillator

Control

Circuit

_

+

+

–

V

REF

_

+

+

–

Shutdown/

Start-Up Control

0.8 V

I

+

–

V

REF

GND PG

ENABLE

C1F

C2F

TPS60121/TPS60123

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

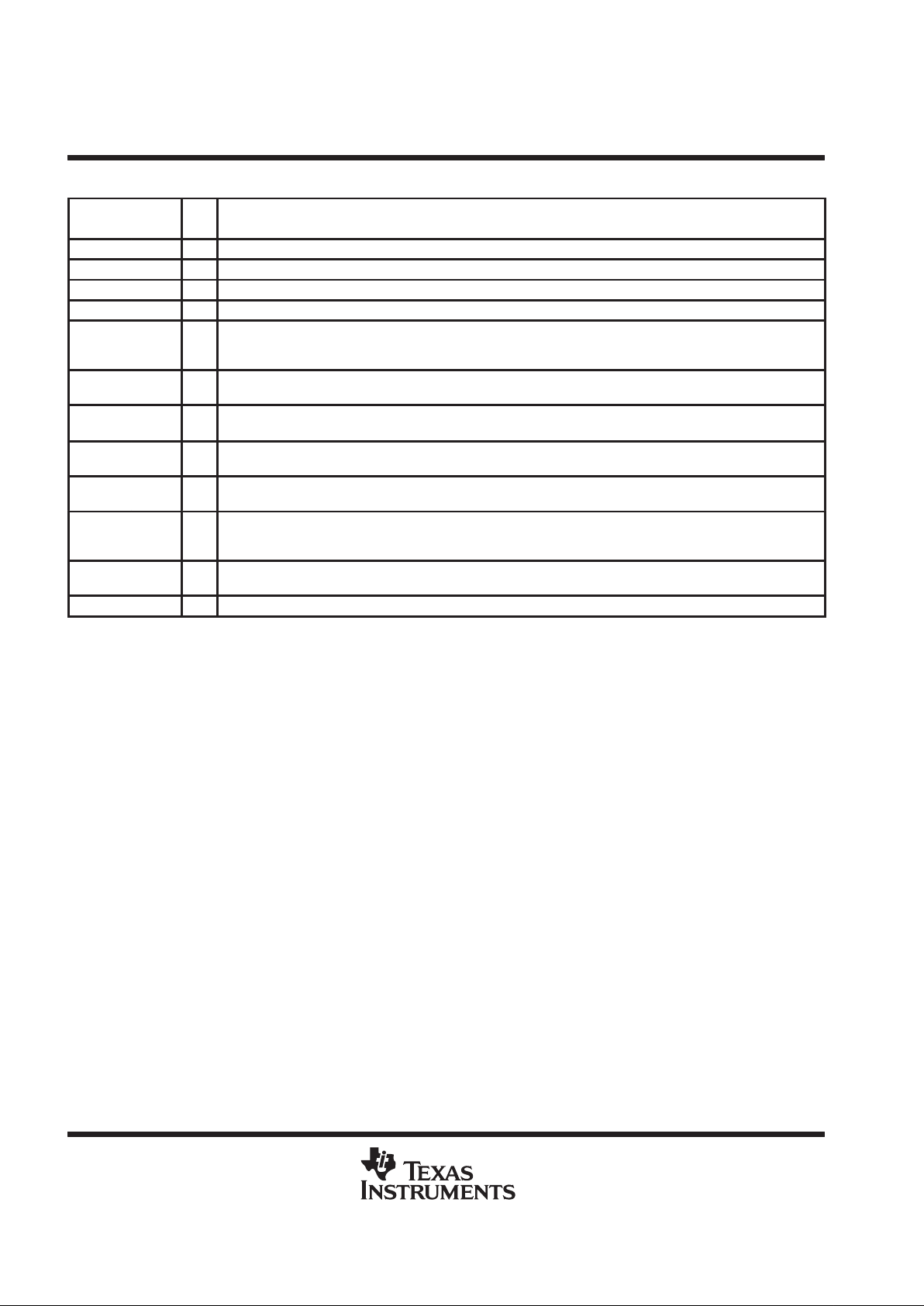

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

C1+ 6 Positive terminal of the flying capacitor C1

C1– 8 Negative terminal of the flying capacitor C1

C2+ 15 Positive terminal of the flying capacitor C2

C2– 13 Negative terminal of the flying capacitor C2

ENABLE 3 I

ENABLE input. Connect ENABLE to IN for normal operation. When ENABLE is a logic low, the device turns off and

the supply current decreases to 0.05 µA. The output is disconnected from the input when the device is placed in

shutdown.

FB 4 I

Feedback input. Connect FB to OUT as close to the load as possible to achieve best regulation. Resistive divider

is on the chip to match the internal reference voltage of 1.21 V .

GND

1, 2,

19, 20

Ground. Analog ground for internal reference and control circuitry. Connect to PGND through a short trace.

IN 7,14 I

Supply input. Connect to an input supply in the 1.8-V to 3.6-V range. Bypass IN to PGND with a (CO/2) µF capacitor.

Connect both IN through a short trace.

LBO/PG 17 O

Low battery detector output or power good output. Open drain output of the low battery or power-good comparator.

It can sink 1 mA. A 100-kΩ to 1-MΩ pullup is recommended. Leave terminal unconnected if not used.

LBI/NC 18 I

Low battery detector input (TPS60120/TPS60122 only). The input is compared to the internal 1.21-V reference

voltage. Connect terminal to ground if the low-battery detector function is not used. On the TPS60121 and

TPS60123, this terminal is not connected.

OUT 5, 16 O

Regulated 3.3-V power output. Connect both OUT terminals through a short trace and bypass OUT to GND with

the output filter capacitor C

O.

PGND 9–12 Power ground. Charge-pump current flows through this pin. Connect all PGND pins together.

detailed description

operating principle

The TPS6012x charge pumps provide a regulated 3.3-V output from a 1.8-V to 3.6-V input. They deliver a

maximum load current of 200 mA or 100 mA, respectively. Designed specifically for space-critical, batterypowered applications, the complete charge pump circuit requires only four external capacitors. The circuit is

optimized for efficiency over a wide input voltage range.

The TPS6012x charge pumps consist of an oscillator, a 1.21-V bandgap reference, an internal resistive

feedback circuit, an error amplifier, high current MOSFET switches, a shutdown/start-up circuit, a low-battery

or power-good comparator, and a control circuit (see the functional block diagram).

The device consists of two single-ended charge pumps. The power stages of the charge pump are automatically

configured to amplify the input voltage with a conversion factor of 1.5 or 2. The conversion ratio depends on

input voltage and output current. With input voltages lower than approximately 2.4 V, the convertor will run in

a voltage doubler mode with a gain of two. With a higher input voltage, the converter operates with a gain of

1.5 V. This assures high efficiency over the wide input voltage range of a two-cell battery stack and is further

described in the

adaptive mode switching

section.

adaptive mode switching

The ON-resistance of the MOSFETs that are in the charge path of the flying capacitors is regulated when the

charge pump operates in voltage doubler-mode. It is changed depending on the output voltage that is fed back

into the control loop. This way, the time-constant during the charging phase can be modified and increased

versus a time-constant for fully switched-on MOSFETs. The ON-resistance of both switches and the

capacitance of the flying capacitor define the time constant. The MOSFET switches in the discharge path of the

charge pump are always fully switched on to their minimum r

DS(on)

. With the time-constant during charge phase

being larger than the time constant in discharge phase, the voltage on the flying capacitors stabilizes to the

lowest possible value necessary to get a stable VO.

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

adaptive mode switching (continued)

The voltage on the flying capacitors is measured and compared with the supply voltage V

I

. If the voltage across

the flying capacitors is smaller than half of the supply voltage, then the charge pump switches into the 1.5x

conversion-mode. The charge pump switches back from a 1.5x conversion-mode to a voltage doubler mode

if the load current in 1.5x conversion-mode can no more be delivered.

With this control mode the device runs in doubler-mode at low V

I

and in 1.5x conversion-mode at high VI to

optimize the efficiency. The most desirable doubler mode is automatically selected depending on both VI and

IL. This means that at light loads the device selects the 1.5x conversion-mode already at smaller supply voltages

than at heavy loads.

The TPS60120 output voltage is regulated using the

ACTIVE-CYCLE

regulation. An active cycle controlled

Charge pump utilizes two methods to control the output voltage. At high load currents it varies the on resistances

of the internal switches and keeps the ratio ON/OFF time (=frequency) constant. That means the charge pump

runs at a fixed frequency. It also keeps the output voltage ripple as low as in linear-mode. At light loads the

internal resistance and also the amount of energy transferred per pulse is fixed and the charge pump regulates

the voltage by means of a variable ratio of ON-to-OFF time. In this operating point, it runs like a skip mode

controlled charge pump with a very high internal resistance, which also enables a low ripple in this operation

mode. Since the charge pump does effectively switch at lower frequencies at light loads, it achieves a low

quiescent current.

pulse-skip mode

In pulse-skip mode the error amplifier disables switching of the power stages when it detects an output higher

than 3.3 V. The oscillator halts and the IC then skips switching cycles until the output voltage drops below 3.3

V . Then the error amplifier reactivates the oscillator and starts switching the power stages again. The pulse-skip

regulation mode minimizes operating current because it does not switch continuously and deactivates all

functions except bandgap reference, error amplifier, and low-battery/power-good comparator when the output

is higher than 3.3 V . When switching is disabled from the error amplifier , the load is also isolated from the input.

In pulse-skip mode, a special current control circuitry limits the peak current. This assures moderate output

voltage ripple and also prevents the device from drawing excessive current spikes out of the battery.

start-up procedure

During start-up, i.e., when ENABLE is set from logic low to logic high, the output capacitor is charged up with

a limited current until the output voltage V

O

reaches 0.8 × VI. When the start-up comparator detects this voltage

limit, the IC begins switching. This start-up charging of the output capacitor ensures a short start-up time and

eliminates the need of a Schottky diode between IN and OUT. The IC starts with a maximum load, which is

defined by a 16-Ω resistor or 33-Ω resistor, respectively.

shutdown

Driving ENABLE low places the device in shutdown mode. This disables all switches, the oscillator, and control

logic. The device typically draws 0.05 µA (1 µA max) of supply current in this mode. Leakage current drawn from

the output is as low as 1 µA max. The device exits shutdown once ENABLE is set to a high level. The typical

no-load shutdown exit time is 10 µs. When the device is in shutdown, the load is isolated from the input.

undervoltage lockout

The TPS6012x devices have an undervoltage lockout feature that deactivates the device and places it in

shutdown mode when the input voltage falls below 1.6 V.

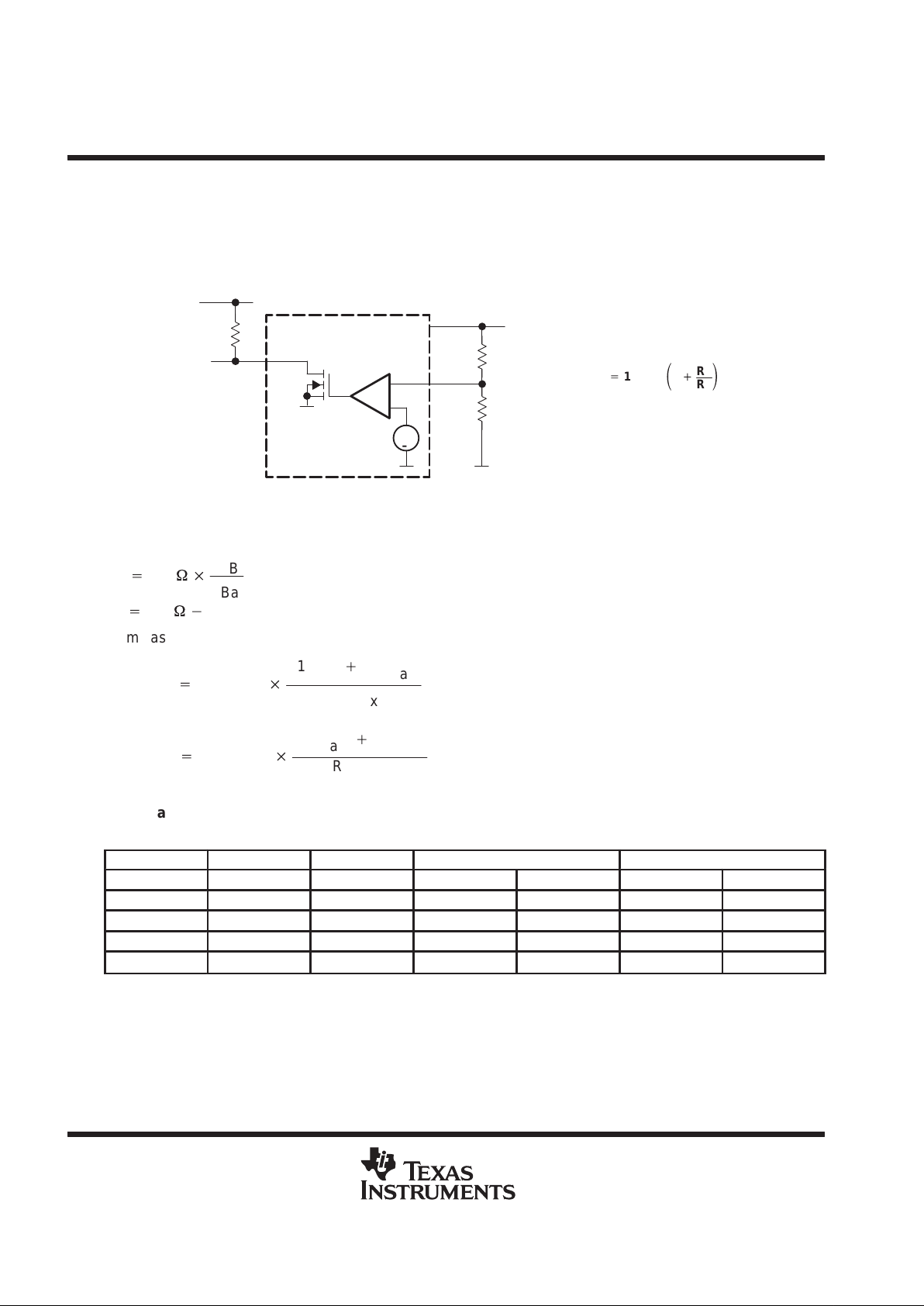

low-battery detector (TPS60120 and TPS60122)

The internal low-battery comparator trips at 1.21 V ± 5% when the voltage on LBI ramps down. The battery

voltage at which the comparator initiates a low battery warning at the LBO output can easily be programmed

with a resistive divider as shown in Figure 1. The sum of resistors R1 and R2 is recommended to be in the 100

kΩ to 1 MΩ range.

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

low-battery detector (TPS60120 and TPS60122) (continued)

LBO is an open drain output. An external pullup resistor to OUT , in the 100 kΩ to 1 MΩ range, is recommended.

During start-up, the LBO output signal is invalid for the first 500 µs. LBO is high impedance when the device

is disabled.

If the low-battery comparator function is not used, connect LBI to ground and leave LBO unconnected.

V

(TRIP)

+

1.21 Vǒ1

)

R1

R2

Ǔ

_

+

+

–

V

REF

V

BAT

IN

R1

LBI

R2

LBO

R3

V

O

Figure 1. Programming of the Low-Battery Comparator Trip Voltage

Formulas to calculate the resistive divider for low battery detection, with V

LBI

= 1.15 V – 1.27 V:

R2+1MW

V

LBI

V

Bat

R1+1MW*

R2

Formulas to calculate the minimum and maximum battery voltage that triggers the low battery detector:

V

Bat(min)

+

V

LBI(min)

R1

(min)

)

R2

(max)

R2

(max)

V

Bat(max)

+

V

LBI(max)

R1

(max)

)

R2

(min)

R2

(min)

Table 1. Recommended Values for the Resistive Divider From the E96 Series (±1%),

V

LBI

= 1.15 V – 1.27 V

V

BAT

/V R1/kΩ R2/kΩ V

BAT (MIN)

/V V

BAT(MAX)

/V

1.8 357 732 1.700 –5.66% 1.902 5.67%

1.9 365 634 1.799 –5.32% 2.016 6.11%

2.0 412 634 1.883 –5.86% 2.112 5.6%

2.1 432 590 1.975 –5.95% 2.219 5.67%

2.2 442 536 2.080 –5.45% 2.338 6.27%

Using ±1% accurate resistors, the total accuracy of the trip voltage is about ±6%, considering the ±4% accuracy

the integrated voltage reference adds and considering that not every calculated resistor value is available.

A 100 nF bypass capacitor should be connected in parallel to R2 if large line transients are expected. These

voltage drops can inadvertently trigger the low-battery comparator and produce a wrong low-battery warning

signal at the LBO terminal.

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

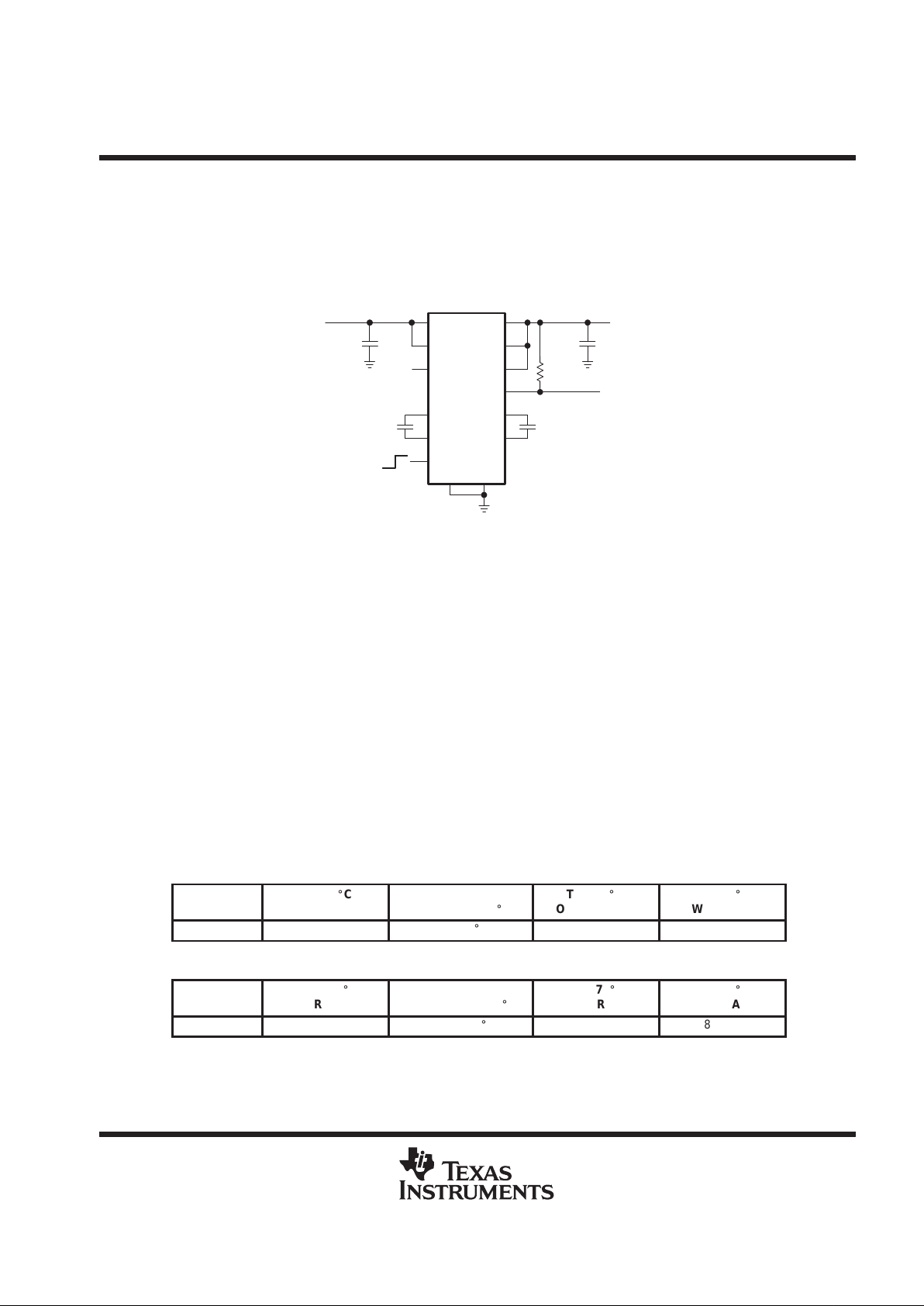

power-good detector (TPS60121 and TPS60123)

The PG terminal is an open-drain output that is pulled low when the output is out of regulation. When the output

voltage rises to about 90% of its nominal voltage, the power-good output is released. PG is high impedance

when the device is disabled. A pullup resistor must be connected between PG and OUT. The pullup resistor

should be in the 100 kΩ to 1 MΩ range. If the power-good function is not used, then PG should remain

unconnected.

C

O

22 µF

Output

3.3 V, 200 mA

Input

1.8 V to 3.6 V

IN

IN

NC

C1+

C1–

ENABLE

PGND GND

OUT

OUT

FB

PG

C2+

C2–

C2

2.2 µF

C1

2.2 µF

Off/On

C

I

10 µF

R1

1 MΩ

TPS60121

Power-Good Output

Figure 2. Typical Operating Circuit Using Power-Good Comparator

absolute maximum ratings (see Note 1)

†

Input voltage range, VI (IN, OUT, ENABLE, FB, LBI, LBO/PG) –0.3 V to 5.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential input voltage, V

ID

(C1+, C2+ to GND) –0.3 V to (VO + 0.3 V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential input voltage, VID (C1–, C2– to GND) –0.3 V to (VI + 0.3 V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation See dissipation rating table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous output current TPS60120, TPS60121 300 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous output current TPS60122, TPS60123 150 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10s 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum junction temperature, T

J

150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: V

(ENABLE)

, V

(LBI)

and V

(LBO/PG)

can exceed VI up to the maximum rated voltage without increasing the leakage current drawn by these

inputs.

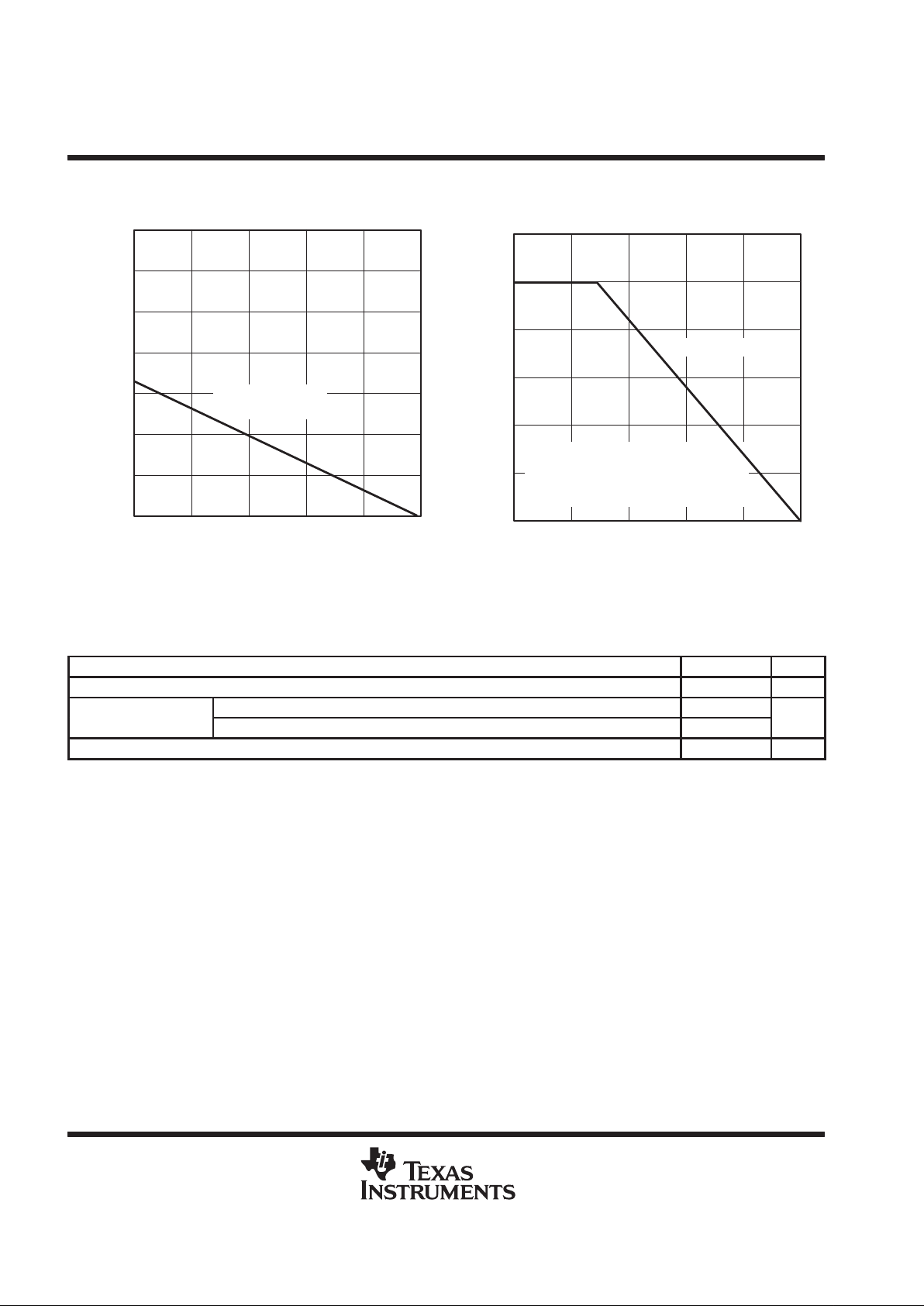

DISSIPATION RATING TABLE 1 FREE-AIR TEMPERATURE (see Figure 3)

PACKAGE

TA ≤ 25_C

POWER RATING

DERATING FACTOR

ABOVE TA = 25_C

TA = 70_C

POWER RATING

TA = 85_C

POWER RATING

PWP 700 mW 5.6 mW/_C 448 mW 364 mW

DISSIPATION RATING TABLE 2 FREE-AIR TEMPERATURE (see Figure 4)

PACKAGE

TC ≤ 62.5_C

POWER RATING

DERATING FACTOR

ABOVE TC = 62.5_C

TC = 70_C

POWER RATING

TC = 85_C

POWER RATING

PWP 25 mW 285.7 mW/_C 22.9 mW 18.5 mW

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Figure 3

800

600

400

0

25 50 75 100

– Maximum Continuous Dissipation – mW

1000

1200

DISSIPATION DERATING CURVE

†

vs

FREE-AIR TEMPERATURE

1400

125 150

200

TA – Free-Air Temperature – °C

P

D

PWP Package

R

θJA

= 178°C/W

Figure 4

15

10

5

0

25 50 75 100

20

25

MAXIMUM CONTINUOUS DISSIPATION

†

vs

CASE TEMPERATURE

30

125 150

Measured with the exposed thermal pad

coupled to an infinite heat sink with a

thermally conductive compound (the thermal

conductivity of the compound is 0.815 W/m°C)

The R

θJC

is 3.5°C/W

PWP package

TC – Case Temperature – °C

– Maximum Continuous Dissipation – WP

D

†

Dissipation rating tables and figures are provided for maintenance of junction temperature at or below absolute maximum temperature of 150°C.

It is recommended not to exceed a junction temperature of 125°C.

recommended operating conditions

MIN MAX UNIT

Input voltage, V

I

1.8 3.6 V

p

TPS60120 and TPS60121 200

Output current, I

O

TPS60122 and TPS60123 100

mA

Operating junction temperature, T

J

125 °C

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics at C

I

= 10 µF, C1F = C2F = 2.2 µF, CO = 22 µF, TC = –40°C to 85°C, VI = 2 V,

V

FB

= VO and V

(ENABLE)

= VI (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

I

Input voltage 1.8 3.6 V

V

(UVLO)

Input undervoltage lockout threshold TC = 25°C 1.6 1.8 V

p

TPS60120/TPS60121 200 mA

I

O(MAX)

Maximum output current

TPS60122/TPS60123 100 mA

1.8 V < VI < 2 V,

0 < IO < I

O(MAX)

/2

TC = 0°C to 70°C

3.17 3.43

V

O

Output voltage

2 V < VI < 3.3 V,

0 < IO < I

O(MAX)

3.17 3.43

V

3.3 V < VI < 3.6 V,

0 < IO < I

O(MAX)

3.17 3.47

I

lkg(OUT)

Output leakage current VI = 2.4 V, V

(ENABLE)

= 0 V 1 µA

I

Q

Quiescent current (no-load input current) VI = 2.4 V 55 90 µA

I

Q(SDN)

Shutdown supply current VI = 2.4 V, V

(ENABLE)

= 0 V 0.05 1 µA

f

OSC(INT)

Internal switching frequency VI = 2.4 V 210 320 450 kHz

V

IL

Enable input voltage low VI = 1.8 V 0.3 x V

I

V

V

IH

Enable input voltage high VI = 3.6 V 0.7 x V

I

V

I

lkg(ENABLE)

Enable input leakage current V

(ENABLE)

= V

GND

or V

I

0.01 0.1 µA

Output load regulation

VI = 2.4 V,

1 mA < IO < I

O(MAX)

TC = 25°C

0.003% /mA

Output line regulation

2 V < VI < 3.3 V,

IO = 100 mA,

TC = 25°C

0.3% /V

Short circuit current limit

VI < 2.4 V, VO = 0 V,

TC = 25°C

115 mA

V

(LBITRIP)

Low battery trip voltage TPS60120/TPS60122

VI = 1.8 V to 2.2 V,

Hysteresis 0.8% for rising

LBI, TC = 0°C to 70°C

1.15 1.21 1.27 V

I

I(LBI)

LBI input current TPS60120/TPS60122 V

(LBI)

= 1.3 V 100 nA

V

O(LBO)

LBO output voltage low

(see Note 2)

TPS60120/TPS60122

V

(LBI)

= 0 V,

I

(LBO,SINK)

= 1 mA

0.4 V

I

lkg(LBO)

LBO leakage current TPS60120/TPS60122

V

(LBI)

= 1.3 V,

V

(LBO)

= 3.3 V

0.01 0.1 µA

V

(PGTRIP)

Power-good trip voltage TPS60121/TPS60123 TC = 0°C to 70°C

0.86 ×

V

O

0.90 ×

V

O

0.94 ×

V

O

V

V

hys(PG)

Power-good trip voltage

hysteresis

TPS60121/TPS60123

VO ramping negative,

TCA = 0°C to 70°C

0.8%

V

O(PG)

Power-good output

voltage low (see Note 2)

TPS60121/TPS60123 VO = 0 V, I

(PG,SINK)

= 1 mA 0.4 V

I

lkg(PG)

Power-good leakage

current

TPS60121/TPS60123 VO = 3.3 V, V

(PG)

= 3.3 V 0.01 0.1 µA

NOTE 2: During start-up the LBO and PG output signal is invalid for the first 500 µs.

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

IN

IN

LBI

C1+

C1–

ENABLE

PGND GND

OUT

OUT

FB

LBO

C2+

C2–

Ci

10 µF

C2

2.2 µF

C1

2.2 µF

R1

R2

Off/On

R3

TPS6012x

Co

2 x 10 µF

Used capacitor types:

Ci: Ceramic, X7R

Co: Ceramic, X7R

C1, C2: Ceramic, X7R

Figure 5. Circuit Used For Typical Characteristics Measurements

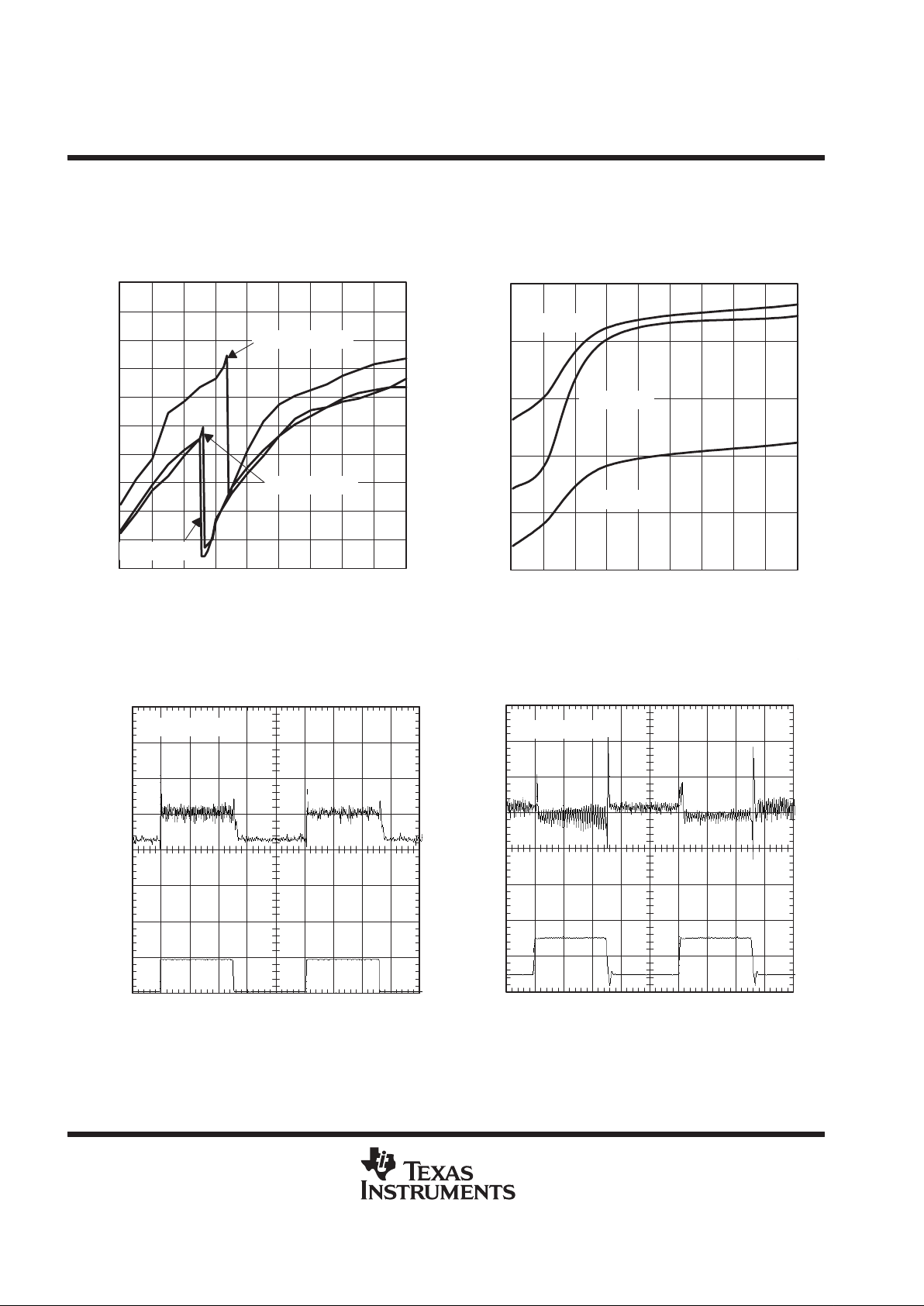

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

vs Output Current (TPS60120 and TPS60122) 6, 7

η

Efficienc

y

vs Input Voltage (TPS60120 and TPS60122)

8, 9

I Supply Current vs Input Voltage 10

V

O

Output Voltage vs Output Current (TPS60120 and TPS60122) 11, 12

V

O

Output Voltage vs Input Voltage (TPS60120 and TPS60122) 13, 14

V

O

Output Voltage Ripple vs Time 15 – 17

V

PP

Output Voltage Ripple Amplitude vs Input Voltage 18

f

(OSC)

Oscillator Frequency vs Input Voltage 19

Load Transient Response 20

Line Transient Response 21

V

O

Output Voltage vs Time (Start-Up Timing) 22

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 6

Efficiency – %

0

10

20

30

40

50

60

70

80

90

100

IO – Output Current – mA

TPS60120

EFFICIENCY

vs

OUTPUT CURRENT

100.1 1 10 100 1000

VI = 2.0 V

VI = 2.4 V

VI = 2.7 V

Figure 7

Efficiency – %

0

10

20

30

40

50

60

70

80

90

100

IO – Output Current – mA

TPS60122

EFFICIENCY

vs

OUTPUT CURRENT

100.1 1 10 100 1000

VI = 2.0 V

VI = 2.4 V

VI = 2.7 V

Figure 8

IO = 66 mA

0

10

20

30

40

50

60

70

80

90

100

1.8 2 2.2 2.4 2.6 2.8 3 3.2 3.4 3.6

VI – Input Voltage – V

Efficiency – %

IO = 164 mA

IO = 216 mA

IO = 116 mA

VO = 3.3 V

TC = 25°C

TPS60120

EFFICIENCY

vs

INPUT VOLTAGE

Figure 9

IO = 66 mA

0

10

20

30

40

50

60

70

80

90

100

1.8 2 2.2 2.4 2.6 2.8 3 3.2 3.4 3.6

VI – Input Voltage – V

Efficiency – %

IO = 116 mA

VO = 3.3 V

TC = 25°C

TPS60122

EFFICIENCY

vs

INPUT VOLTAGE

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 10

y

VI – Input Voltage – V

SUPPLY CURRENT

vs

INPUT VOLTAGE

Supply Current –

A

µ

0.00

10.00

20.00

30.00

40.00

50.00

60.00

1.60 2.00 2.40 2.80 3.20 3.60

IO = 0 mA

100.1 1 10 100 1000

3.30

3.31

3.32

3.33

3.34

3.35

3.36

3.37

3.38

3.39

3.40

VI = 1.8 V

VI = 2.4 V

VI = 2.7 V

VI = 3.6 V

Figure 11

IO – Output Current – mA

TPS60120

OUTPUT VOLTAGE

vs

OUTPUT CURRENT

V

O

– Output Voltage – V

Figure 12

IO – Output Current – mA

TPS60122

OUTPUT VOLTAGE

vs

OUTPUT CURRENT

V

O

– Output Voltage – V

3.30

3.31

3.32

3.33

3.34

3.35

3.36

3.37

3.38

3.39

3.40

100.1 1 10 100

VI = 1.8 V

VI = 2.4 V

VI = 2.7 V

VI = 3.6 V

Figure 13

3.05

3.10

3.15

3.20

3.25

3.30

3.35

3.40

1.8 2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6

VI – Input Voltage – V

1 mA

TPS60120

OUTPUT VOLTAGE

vs

INPUT VOLTAGE

50 mA

200 mA

100 mA

V

O

– Output Voltage – V

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 14

VI – Input Voltage – V

TPS60122

OUTPUT VOLTAGE

vs

INPUT VOLTAGE

V

O

–

O

u

tp

u

t

Voltage

–

V

3.30

3.32

3.34

3.36

3.38

3.40

1.80 2.00 2.20 2.40 2.60 2.80 3.00 3.20 3.40 3.60

1 mA

50 mA

100 mA

Figure 15

3.3

3.32

3.34

3.36

3.38

3.40

0 200 400 600 800 10001200140016001800 2000

t – TIME – µs

OUTPUT VOLTAGE RIPPLE

vs

TIME

VI = 2.4 V

IO = 1 mA

V

O

– Output Voltage – V

Figure 16

3.3

3.32

3.34

3.36

3.38

3.40

0 20 40 60 80 100 120 140 160 180 200

t – TIME – µs

OUTPUT VOLTAGE RIPPLE

vs

TIME

VI = 2.4 V

IO = 10 mA

V

O

– Output Voltage – V

Figure 17

3.3

3.32

3.34

3.36

3.38

3.40

02468101214161820

t – TIME – µs

OUTPUT VOLTAGE RIPPLE

vs

TIME

VI = 2.4 V

IO = 100 mA

V

O

– Output Voltage – V

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 18

0

10

20

30

40

50

60

70

80

90

100

1.8 2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6

VI – Input Voltage – V

OUTPUT VOLTAGE RIPPLE AMPLITUDE

vs

INPUT VOLTAGE

IO = 100 mA

IO = 10 mA

IO = 1 mA

V

O

– Output Voltage Ripple – V

pp

– mV

295

300

305

310

315

320

1.8 2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6

Figure 19

VI – Input Voltage – V

OSCILLATOR FREQUENCY

vs

INPUT VOLTAGE

T = –40°C

T = 85 °C

T = 25°C

f – Frequency – kHz

t – Time – ms

LOAD TRANSIENT RESPONSE

VI = 2.4 V

020

0

200

3.38

3.40

3.36

3.34

21816141210 46 8

Figure 20

I

O

V

O

– Output Voltage – V

– Output Current – mA

010198765 23 4

t – Time – ms

LINE TRANSIENT RESPONSE

2.7

3.35

3.36

3.34

3.33

2.2

Figure 21

V

I

V

O

– Output Voltage – V

– Input Voltage – V

IO = 50 mA

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

–0.5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

–0.2 –0.1 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

t – Time – ms

OUTPUT VOLTAGE

vs

TIME

(START-UP TIMING)

VO – V

VI = 2.4 V

R

LOAD

= 16.5 Ω

ENABLE – V

V

O

– Output Voltage and Enable Signal – V

Figure 22

APPLICATION INFORMATION

capacitor selection

The TPS6012x charge pumps require only four external capacitors as shown in the basic application circuit.

Their values and types are closely linked to the output current and output noise/ripple requirements. For lowest

noise and ripple, low ESR (<0.1 Ω) capacitors should be used for input and output capacitors.

The input capacitor improves system efficiency by reducing the input impedance. It also stabilizes the input

current of the power source. The input capacitor should be chosen according to the power supply used and the

distance from the power source to the converter IC. The input capacitor also has an impact on the output ripple

requirements. The lower the ESR of the input capacitor Ci, the lower is the output ripple. Ci is recommended

to be about two to four times as large as C

(xF)

.

The output capacitor Co can be selected from 5-times to 50-times larger than C

(xF)

, depending on the ripple

tolerance. The larger Co and the lower its ESR, the lower will be the output voltage ripple. Ci and Co can be either

ceramic or low-ESR tantalum; aluminum capacitors are not recommended.

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

capacitor selection (continued)

Generally , the flying capacitors C

(xF)

will be the smallest. Only ceramic capacitors are recommended because

they are low ESR and because they retain their capacitance at the switching frequency. Because the device

regulates the output voltage with the pulse-skip technique, a larger flying capacitor will lead to a higher output

voltage ripple if the size of the output capacitor is not increased. Be aware that, depending on the material used

to manufacture them, ceramic capacitors might lose their capacitance over temperature and voltage. Ceramic

capacitors of type X7R or X5R material will keep their capacitance over temperature and voltage, whereas Z5U

or Y5V-type capacitors will decrease in capacitance. Table 2 lists recommended capacitor values.

Table 2. Recommended Capacitor Values

V

I

C

i

(µF)

C

(xF)

(µF)

C

o

(µF)

V

TYP

PART

I

(V)

O

(mA)

TANTALUM

CERAMIC

(X7R)

CERAMIC

(X7R)

TANTALUM

CERAMIC

(X7R)

PP

(mV)

4.7

22 4.7 65

TPS60120

150

4.7

2.2

22 40

TPS60121

2.4

10 4.7

22 4.7 80

200102.2

22 35

TPS60122

50 2.2

70

TPS60123

2.4

100 4.7

1

10

80

The TPS6012x devices are charge pumps that regulate the output voltage using the pulse-skip operating mode.

The output voltage ripple is therefore dependent on the values and the ESR of the input, output and flying

capacitors. The only possibility to reduce the output voltage ripple is to choose the appropriate capacitors. The

lowest output voltage ripple can be achieved with ceramic capacitors due to their low ESR and their frequency

characteristic.

Ceramic capacitors typically have an ESR that is more than 10 times lower than tantalum capacitors and they

retain their capacitance at frequencies more than 10 times higher than tantalum capacitors. Many different

tantalum capacitors act as an inductance for frequencies higher than 200 kHz. This behavior increases the

output voltage ripple. Therefore the best choice for a minimized ripple is the ceramic capacitor. For applications

that do not need higher performance in output voltage ripple, tantalum capacitors with a low ESR are a possibility

for input and output capacitor, but a ceramic capacitor should be connected in parallel. Be aware that the ESR

of tantalum capacitors is indirectly proportional to the physical size of the capacitor.

Table 2 is a good starting point for choosing the capacitors. If the output voltage ripple is too high for the

application, it can be improved by selecting the appropriate capacitors. The first step is to increase the

capacitance at the output. If the ripple is still too high, the second step would be to increase the capacitance

at the input.

For the TPS60120 and TPS60121, the smallest board space can be achieved using Sprague’s 595D-series

tantalum capacitors for input and output. However, with the trend towards high capacitance ceramic capacitors

in smaller size packages, these types of capacitors may become more competitive in size. The smallest size

for the TPS60122 and TPS60123 can be achieved using the recommended ceramic capacitors.

Tables 3 and 4 lists the manufacturers of recommended capacitors. In most applications surface-mount

tantalum capacitors will be the right choice. However, ceramic capacitors provide the lowest output voltage

ripple due to their typically lower ESR.

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

capacitor selection (continued)

Table 3. Recommended Capacitors

MANUFACTURER PART NUMBER CAPACITANCE CASE SIZE TYPE

Taiyo Yuden

LMK212BJ105KG–T 1 µF 0805 Ceramic

LMK212BJ225MG–T 2.2 µF 0805 Ceramic

LMK316BJ475KL–T 4.7 µF 1206 Ceramic

LMK325BJ106MN–T 10 µF 1210 Ceramic

LMK432BJ226MM–T 22 µF 1812 Ceramic

AVX

0805ZC105KAT2A 1 µF 0805 Ceramic

1206ZC225KAT2A 2.2 µF 1206 Ceramic

TPSC475035R0600 4.7 µF Case C Tantalum

TPSC106025R0500 10 µF Case C Tantalum

TPSC226016R0375 22 µF Case C Tantalum

Sprague

595D106X0016B2T 10 µF Case B T antalum

595D226X06R3B2T 22 µF Case B Tantalum

595D226X0020C2T 22 µF Case B Tantalum

Kemet

T494C156K010AS 10 µF Case C Tantalum

T494C226M010AS 22 µF Case C Tantalum

NOTE: Case code compatibility with EIA 535BAAC and CECC30801 molded chips.

Table 4. Recommended Capacitor Manufacturers

MANUFACTURER CAPACITOR TYPE INTERNET SITE

Taiyo Yuden X7R/X5R ceramic http://www.t–yuden.com/

AVX X7R/X5R ceramic

TPS-series tantalum

http://www.avxcorp.com/

Sprague 595D-series tantalum

593D-series tantalum

http://www.vishay.com/

Kemet T494-series tantalum http://www.kemet.com/

power dissipation

The power dissipated in the TPS6012x depends on output current and mode of operation (1.5x or doubler

voltage conversion mode). It is described by the following:

P

DISS

=

ǒ

1

h

–

1

Ǔ

V

O

× IO (Efficiency η mainly depends on VI and also on IO. See efficiency graphs.)

P

DISS

must be less than that allowed by the package rating. See the absolute maximum ratings for 20-pin PWP

package power-dissipation limits and deratings.

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

board layout

Careful board layout is necessary due to the high transient currents and switching frequency of the converter.

All capacitors should be soldered in close proximity to the IC. Connect ground and power ground pins through

a short, low-impedance trace. A PCB layout proposal for a two-layer board is given in Figure 23. The bottom

layer of the board carries only ground potential for best performance. The layout also provides improved

performance as the exposed frame is soldered to the PCB.

An evaluation module for the TPS60120 is available and can be ordered under product code

TPS60120EVM–142. The EVM uses the layout shown in Figure 23. The layout also provides improved thermal

performance as the exposed leadframe of the PowerPAD package can be soldered to the PCB.

Figure 23. Recommended PCB Layout for

TPS6012X

Figure 24. Component Placement

Table 5. Component Identification

IC1 TPS6012x

C1, C2 Flying capacitors

C3, C6 Input capacitors

C4, C5 Onput capacitors

C7 Stabilization capacitor for LBI

R1, R2 Resistive divider for LBI

R3 Pullup resistor for LBO

The best performance of the converter is achieved with the additional bypass capacitors C5 and C6 at input and

output. Capacitor C7 should be included if the large line transients are expected. The capacitors are not

required. They can be omitted in most applications.

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

application proposals

paralleling of two TPS6012x to deliver 400 mA total output current

Two TPS6012x devices can be connected in parallel to yield higher load currents. The circuit of Figure 25 can

deliver up to 400 mA at an output voltage of 3.3 V . The devices can share the output capacitors, but each one

requires its own transfer capacitors and input capacitor. If both a TPS60120 and a TPS60121 are used, it is

possible to monitor the battery voltage with the TPS60120 using the low-battery comparator function and to

supervise the output voltage with the TPS60121 using the power-good comparator. Make the layout of the

charge pumps as similar as possible, and position the output capacitor the same distance from both devices.

IN

IN

LBI

C1+

C1–

ENABLE

PGND GND

OUT

OUT

FB

LBO

C2+

C2–

C

O

47 µF

Ci

10 µF

Output

3.3 V, 400 mA

C2

2.2 µF

C1

2.2 µF

R1

357 kΩ

R2

732 kΩ

Input

1.8 V to 3.6 V

Off/On

IN

IN

NC

C1+

C1–

ENABLE

PGND GND

OUT

OUT

FB

PG

C2+

C2–

C2

2.2 µF

C1

2.2 µF

C

i

10 µF

R3

1 MΩ

Low Battery

Warning

Power-Good

Signal

R4

1 MΩ

TPS60120 TPS60121

Figure 25. Paralleling of Two TPS6012x Charge Pumps

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

TPS6012x operated with ultra-low quiescent current

Because the output of the TPS6012x is isolated from the input when the devices are disabled, and because the

internal resistive divider is disconnected in shutdown, an ultra-low quiescent current mode can be implemented.

In this mode, the output voltage is sustained because the converter is periodically enabled to refresh the output

capacitor. The necessary external control signal that is applied to the ENABLE pin is generated from a

microcontroller like the ultra-low power microcontroller MSP430. For a necessary supply current for the system

of 1 mA and a minimum supply voltage of 3 V with a 22-µF output capacitor, the refresh has to be done after

a maximum of 3.5 ms. Longer refresh periods can be achieved with a larger output capacitor.

IN

IN

LBI

C1+

C1–

ENABLE

PGND GND

OUT

OUT

FB

LBO

C2+

C2–

C2

22 µF

C

i

10 µF

Output

3.3 V , 100 mA

C2

2.2 µF

C1

2.2 µF

R1

R2

Input

1.8 V to 3.6 V

ON

OFF

C3

1 µF

R4

1 MΩ

R3

1 MΩ

I

O

MCU

e.g.

MSP430

TPS60122

Figure 26. TPS60122 in Ultra-Low Quiescent Current Mode

regulated discharge of the output capacitors after disabling of the TPS6012x

During shutdown of the charge pump TPS6012x, the output is isolated from the input. Therefore, the discharging

of the output capacitor depends on the load and on the leakage current of the capacitor. In certain applications

it is necessary to completely remove the supply voltage from the load in shutdown mode. That means the output

capacitor of the charge pump has to be actively discharged when the charge pump is disabled. Figure 27 shows

one solution to this problem.

TPS601xx

OUT

IN

GND

ENABLE

+

C

O

SN74AHC1G04

A

Y

VCC

GND

IN

ENABLE

GND

OUT

BSS138

Figure 27. Block Diagram of the Regulated Discharge of the Output Capacitor

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

21

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

related information

application reports

For more application information see:

D

PowerPAD Application Report, Literature Number SLMA002

D

TPS6010x/TPS6011x Charge Pump Application Report

, Literature Number SLVA070

D

Designer Note Page: Powering the TMS320C5420 Using the TPS60100, TPS76918, and the TPS3305-18,

Literature Number SLVA082.

device family products

Other devices in this family are:

PART NUMBER

DATASHEET

LITERATURE

CODE

DESCRIPTION

TPS60100 SLVS213B Regulated 3.3-V, 200-mA low-noise charge pump dc-dc converter

TPS60101 SL VS214A Regulated 3.3-V, 100-mA low-noise charge pump dc-dc converter

TPS60110 SLVS215A Regulated 5-V, 300-mA low-noise charge pump dc-dc converter

TPS60111 SLVS216A Regulated 5-V, 150-mA low-noise charge pump dc-dc converter

TPS60130 SLVS258 Regulated 5-V, 300-mA high efficiency charge pump dc-dc converter with low-battery comparator

TPS60131 SLVS258 Regulated 5-V, 300-mA high efficiency charge pump dc-dc converter with power-good comparator

TPS60132 SLVS258 Regulated 5-V, 150-mA high efficiency charge pump dc-dc converter with low-battery comparator

TPS60133 SLVS258 Regulated 5-V, 150-mA high efficiency charge pump dc-dc converter with power-good comparator

TPS60120, TPS60121, TPS60122, TPS60123

REGULATED 3.3 V, 200-mA HIGH EFFICIENCY CHARGE PUMP

DC/DC CONVERTERS

SLVS257A – NOVEMBER 1999 – REVISED DECEMBER 1999

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

PWP (R-PDSO-G**) PowerPAD PLASTIC SMALL-OUTLINE

4073225/F 10/98

0,50

0,75

0,25

0,15 NOM

Thermal Pad

(See Note D)

Gage Plane

2824

7,70

7,90

20

6,40

6,60

9,60

9,80

6,60

6,20

11

0,19

4,50

4,30

10

0,15

20

A

1

0,30

1,20 MAX

1614

5,10

4,90

PINS **

4,90

5,10

DIM

A MIN

A MAX

0,05

Seating Plane

0,65

0,10

M

0,10

0°–8°

20 PINS SHOWN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusions.

D. The package thermal performance may be enhanced by bonding the thermal pad to an external thermal plane.

This pad is electrically and thermally connected to the backside of the die and possibly selected leads.

E. Falls within JEDEC MO-153

PowerPAD is a trademark of Texas Instruments Incorporated.

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...