Page 1

E

! "

User’s Guide

September 2003 PMP Systems Power

SLVU090

Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third−party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products & application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Secruity www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

Page 3

EVM IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation kit being sold by TI is intended for use for ENGINEERING DEVELOPMENT OR EVALUATION

PURPOSES ONLY and is not considered by TI to be fit for commercial use. As such, the goods being provided

may not be complete in terms of required design-, marketing-, and/or manufacturing-related protective

considerations, including product safety measures typically found in the end product incorporating the goods.

As a prototype, this product does not fall within the scope of the European Union directive on electromagnetic

compatibility and therefore may not meet the technical requirements of the directive.

Should this evaluation kit not meet the specifications indicated in the EVM User’s Guide, the kit may be returned

within 30 days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE

WARRANTY MADE BY SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED,

IMPLIED, OR S TATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user

indemnifies TI from all claims arising from the handling or use of the goods. Please be aware that the products

received may not be regulatory compliant or agency certified (FCC, UL, CE, etc.). Due to the open construction

of the product, it is the user’s responsibility to take any and all appropriate precautions with regard to electrostatic

discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE

TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not

exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or

infringement of patents or services described herein.

Please read the EVM User’s Guide and, specifically, the EVM Warnings and Restrictions notice in the EVM

User’s Guide prior to handling the product. This notice contains important safety information about temperatures

and voltages. For further safety concerns, please contact the TI application engineer.

Persons handling the product must have electronics training and observe good laboratory practice standards.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any

machine, process, or combination in which such TI products or services might be or are used.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

Page 4

EVM WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the input and output voltage ranges specified in the

EVM User’s Guide.

Exceeding the specified input range may cause unexpected operation and/or irreversible

damage to the EVM. If there are questions concerning the input range, please contact a TI

field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or

possible permanent damage to the EVM. Please consult the EVM User’s Guide prior to

connecting any load to the EVM output. If there is uncertainty as to the load specification,

please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than

55°C. The EVM is designed to operate properly with certain components above 60°C as long

as the input and output ranges are maintained. These components include but are not limited

to linear regulators, switching transistors, pass transistors, and current sense resistors. These

types of devices can be identified using the EVM schematic located in the EVM User’s Guide.

When placing measurement probes near these devices during operation, please be aware

that these devices may be very warm to the touch.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

Page 5

1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Background 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Performance Specification Summary 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Modifications 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Changing Output Voltage 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Switching Frequency 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Power Sequencing 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Test Setup and Results 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Input/Output Connections 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Efficiency 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Power Dissipation 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Output Voltage Regulation 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Load Transients 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Loop Characteristics 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Output Voltage Ripple 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Input Voltage Ripple 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 Power Up and Down 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Board Layout 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Layout 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Schematic and Bill of Materials 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Schematic 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Bill of Materials 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

-1

Page 6

1−1 Frequency Trimming Resistor Selection Graph 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−1 Connection Diagram 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−2 Measured Efficiency, TPS54980 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−3 Measured Circuit Losses 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−4 Load Regulation 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−5 Line Regulation 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−6 Load Transient Response, TPS54980 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−7 Measured Loop Response, TPS54980, V

2−8 Measured Loop Response, TPS54980, V

2−9 Measured Output Voltage Ripple, TPS54980 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−10 Input Voltage Ripple, TPS54980 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−11 Power Up with Tracking 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−12 Power Down With Tracking 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−13 Power Up With Ratiometric Sequencing 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−14 Power Down With Ratiometric Sequencing 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−15 Power Up With Core Voltage Rising First 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2−16 Power Up With Core Voltage Falling Second 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−1 Top-Side Layout 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−2 Internal Layer 2 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−3 Internal Layer 3 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−4 Bottom Side Layout (looking from top side) 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3−5 Top Side Assembly 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4−1 TPS54980EVM-022 Schematic 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

= 3 V 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

= 4 V 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

1−1 Input Voltage and Output Current Summary 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1−2 TPS54980EVM-022 Performance Specification Summary 1-3. . . . . . . . . . . . . . . . . . . . . . . . . .

1−3 Output Voltage Programming 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4−1 TPS54980EVM-022 Bill of Materials 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-2

Page 7

About This Manual

This user’s guide describes the characteristics, operation, and the use of the

TPS54980EVM-022 evaluation module. It covers all pertinent areas involved

to properly use this EVM board along with the devices that it supports. The

physical PCB layout, schematic diagram, and circuit descriptions are included.

How to Use This Manual

This document contains the following chapters:

- Chapter 1—Introduction

Preface

FCC Warning

Trademarks

- Chapter 2—Test Setup and Results

- Chapter 3—Board Layout

- Chapter 4—Schematic and Bill of Materials

This equipment is intended for use in a laboratory test environment only. It generates, uses, and can radiate radio frequency energy and has not been tested

for compliance with the limits of computing devices pursuant to subpart J of

part 15 of FCC rules, which are designed to provide reasonable protection

against radio frequency interference. Operation of this equipment in other environments may cause interference with radio communications, in which case

the user at his own expense will be required to take whatever measures may

be required to correct this interference.

- SWIFT and PowerPAD are trademarks of Texas Instruments.

Read This First

-3

Page 8

-4

Page 9

Chapter 1

This chapter contains background information for the TPS54980 as well as

support documentation for the TPS54980EVM-022 evaluation module

(HPA022). The TPS54980EVM-022 performance specifications are given, as

well as modifications.

Topic Page

1.1 Background 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Performance Specification Summary 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Modifications 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

1-1

Page 10

Background

TPS54980EVM−022

3.0 V to 4.0 V

1.1 Background

The TPS54980 tracking dc/dc converter is designed to provide accurate

power sequencing in applications where two or more voltages are required for

a load. These types of applications include core and I/O power supplies for

microprosessors, DSPs, and FPGAs. Typically, some specific relation

between the core and I/O supply voltages has to be provided during the power

up and power down sequences. The TPS54980 tracking dc/dc converter is

capable of direct tracking, ratiometric tracking, and voltage sequencing with

a second power source.

The TPS54980EVM−022 is a two-channel EVM demonstrating the flexibility

inherent in the TPS54980 design for tracking and sequencing core and I/O

voltages. The TPS54980 is used to generate the core voltage and is nominally

set at 1.8 V. The nominal 3.3-V I/O voltage is provided by a TPS2013

distribution switch. Rated input voltage and output current range are listed in

Table 1−1.

Table 1−1.Input Voltage and Output Current Summary

EVM Input Voltage Range Output Current Range

Core, −9 A to 9 A

I/O, 0 to 1.5 A

This evaluation module is designed to demonstrate the small PCB areas that

may be achieved when designing with the TPS54980 regulator . The switching

frequency is set at a nominal 700 kHz, allowing the use of a small footprint

0.65-µH output inductor.

The MOSFETs of the TPS54980 are incorporated inside the TPS54980

package. This eliminates the need for external MOSFETs and their associated

drivers. The low drain-to-source on resistance of the MOSFETs provides the

TPS54980 high efficiency and helps to keep the junction temperature low at

high output currents.The compensation components are provided external to

the IC and allow for an adjustable output voltage and a customizable loop

response.

The TPS54980 device uses the TRACKIN pin to access the tracking and

sequencing capabilities. An internal multiplexer circuit compares the voltage

at this pin with the internal reference voltage and uses the lesser of the two as

the reference for the output voltage regulation. When the output of another

power supply or distribution switch is connected to the TRACKIN pin of the

TPS54980, the output of the TPS54980 tracks the output of this other channel

during power up or power down, until the voltage at the TRACKIN pin becomes

higher than the internal reference voltage. By applying the other power supply

output to the TRACKIN pin through an appropriate resistor divider network,

any required power up and power down relation between the two output

voltages of the regulators can be set by changing the ratio of the divider

network.

1-2

Page 11

Performance Specification Summary

Load transient

IO = 2.25 A to 6.75 A

Load transient

response

IO = 6.75 A to 2.25 A

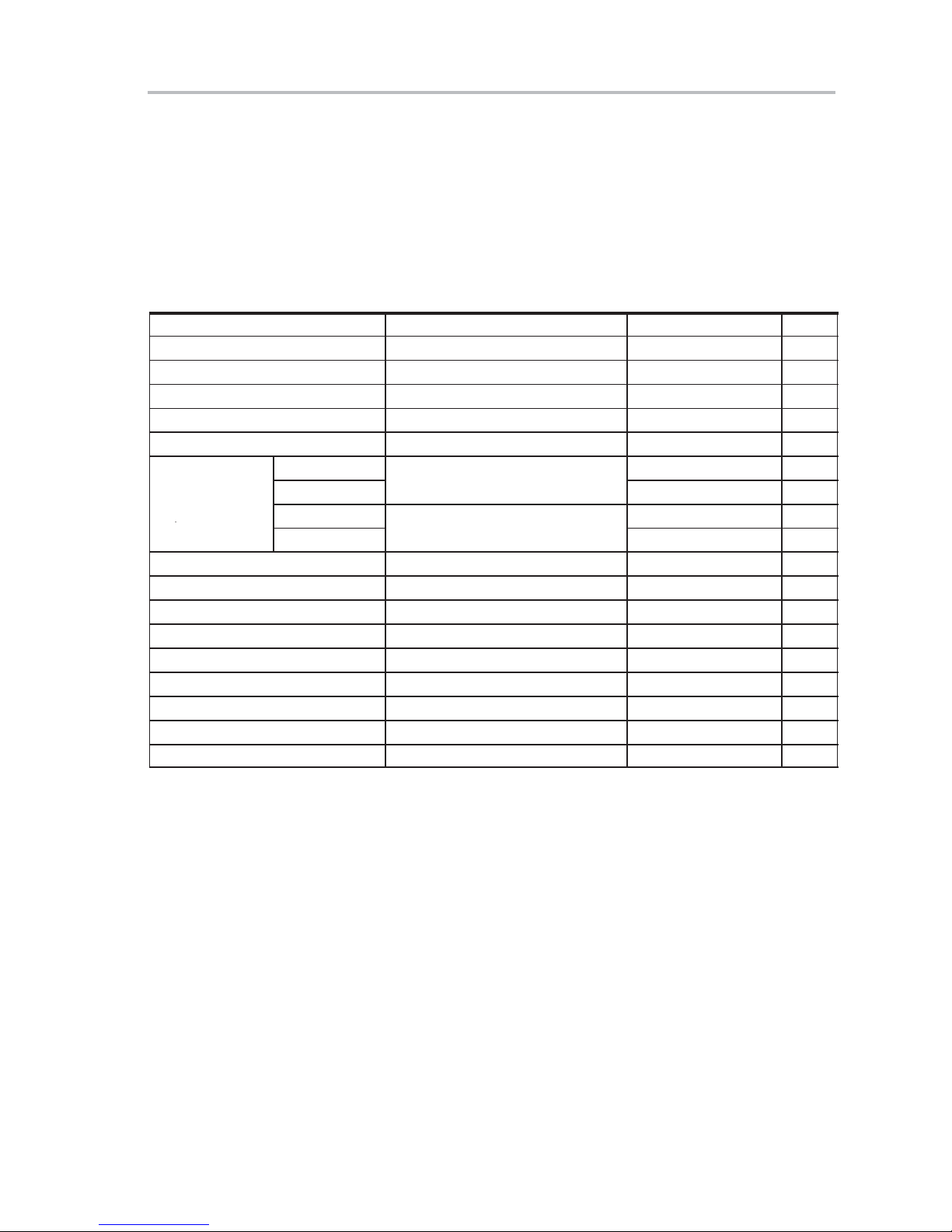

1.2 Performance Specification Summary

A summary of the TPS54980EVM−022 performance specifications is

provided in Table 1−2. Specifications are given for an input voltage of 3.3 V and

an output voltage of 1.8 V unless otherwise specified. The ambient

temperature is 25°C for all measurements, unless otherwise noted. The data

presented in Table 1−2 was compiled with no load on the I/O output. The

maximum input voltage for the TPS54980 is 4 V.

Table 1−2.TPS54980EVM-022 Performance Specification Summary

Parameters Test Conditions Min Typ Max Units

Input voltage range 3.0 3.3 4.0 V

Output voltage set point 1.8 V

Output current range VI = 3 to 5.5 V −9 9 A

Line regulation IO = 0 A to 3 A, VI = 3 V to 5.5 V ±0.1%

Load regulation VI = 3.3 V, IO = 0 to 3 A ±0.2%

Voltage change

Recovery time

response

Loop bandwidth VI = 3 V 63 kHz

Phase margin VI = 3 V 56 _

Loop bandwidth VI = 4 V 75 kHz

Phase margin VI = 4 V 49 _

Input ripple voltage 50 200 mV

Output ripple voltage 6 10 mV

Output rise time N/A ms

Operating frequency 280 700 700 kHz

Max efficiency VI = 3.3 V, VO = 1.8 V, IO = 1.0 A 89%

Voltage change

Recovery time

−50 mV

400 µs

50 mV

400 µs

PK

PK

PP

PP

Introduction

1-3

Page 12

Modifications

1.3 Modifications

The TPS54980EVM-022 is designed to demonstrate the small size that can

be attained when designing with the TPS54980, however many of the

features, which allow for extensive modifications, have been omitted from this

EVM.

1.3.1 Changing Output Voltage

By changing the value of R2, the output voltage can be set to a value in the

range of 0.9 V to 2.5 V. The value of R

calculated by using Equation 1−1. Table 1−3 lists the values for R

common output voltages.

Equation 1−1.

for a specific output voltage can be

2

for some

2

R2+ 10 kW

VO* 0.891 V

Table 1−3.Output Voltage Programming

Output Voltage (V) R

0.9 1000

1.2 28.7

1.5 14.7

1.8 9.76

2.5 5.49

The minimum output voltage is limited by the minimum controllable on-time of

the device, 200 ns, and is dependent upon the duty cycle and operating

frequency. The approximate minimum output voltage can be calculated using

Equation 1−2:

Equation 1−2.

V

OUTMIN

+ 200 nsec ƒs V

1.3.2 Switching Frequency

0.891 V

Value (kW)

2

INMAX

Switching frequency can be trimmed to any value between 280 kHz and

700 kHz by changing the value of R4. Decreasing the switching frequency

results in increased output ripple unless the value of L1 is increased. A plot of

the value of RT versus the switching frequency is shown in Figure 1−1.

1-4

Page 13

Figure 1−1.Frequency Trimming Resistor Selection Graph

R6

R1

750

700

650

600

550

500

450

400

Switching Frequency − kHz

350

300

250

60 80 100 120 140 160 180

R − Resistance − kΩ

An onboard electrolytic input capacitor may be added at C1.

Modifications

1.3.3 Power Sequencing

By selecting different R6−R7 resistor divider ratios, different power

sequencing scenarios can be set. The Equations 1−3, 1−4, and 1−5 show how

to select the different ways of power sequencing.

Equation 1−3.

R6

R7

Equation 1−4.

R6

R7

Equation 1−5.

R7

+

+

t

R1

* Core voltage tracks IńO voltage

R2

ǒ

V

* 0.891

IńO

0.891

− Core voltage rises first at power up and falls second

R2

Ǔ

− Ratiometric relation between core and I/O

voltage

at power down

Introduction

1-5

Page 14

1-6

Page 15

Chapter 2

This chapter describes how to properly connect, setup, and use the

TPS54980EVM-022 evaluation module. The chapter also includes test results

typical for the TPS54980EVM-022 and covers efficiency, output voltage

regulation, load transients, loop response, output ripple, input ripple, and

startup.

Topic Page

2.1 Input/Output Connections 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Efficiency 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Power Dissipation 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Output Voltage Regulation 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Load Transients 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Loop Characteristics 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Output Voltage Ripple 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Input Voltage Ripple 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 Power Up and Down 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Setup and Results

2-1

Page 16

Input/Output Connections

2.1 Input/Output Connections

The TPS54980EVM−022 has the following three input/output connectors: VIN

J1, VOUT I/O J2, and VOUT CORE J3. A diagram showing the connection

points is shown in Figure 2−1. A power supply capable of supplying 8 A should

be connected to J1 through a pair of 20 AWG wires. The load should be

connected to J2 through a pair of 16 AWG wires. The maximum load current

capability should be 9 A. Wire lengths should be minimized to reduce losses

in the wires. Test point TP7 provides a place to easily connect an oscilloscope

voltage probe to monitor the output voltage. The TPS54980 is intended to be

used as a point of load regulator. In typical applications it is usually located

close to the input voltage source. When using the TPS54980EVM−022 with

an external power supply as the source for VIN, an additional bulk capacitor

may be required, depending upon the output impedance of the source and

length of the hook-up wires. The test results presented were obtained using

an additional 470-µF, 16-V input capacitor. Alternately, C1 may be populated

with an input filter capacitor. Connection is shown for no load on the I/O voltage

output. The I/O voltage may supply up to 1.5 A into an external load.

Figure 2−1.Connection Diagram

2-2

Page 17

2.2 Efficiency

The TPS54980EVM−022 efficiency peaks at a load current of about 1 A to 2 A

and then decreases as the load current increases towards full load. Figure 2−2

shows the efficiency of the TPS54980 at an ambient temperature o f 25°C. The

efficiency is lower at higher ambient temperatures due to temperature

variation in the drain-to-source resistance of the MOSFETs. Efficiency is

slightly lower at 700 kHz than at lower switching frequencies due to the gate

and switching losses in the MOSFETs.

Figure 2−2.Measured Efficiency, TPS54980

OUTPUT CURRENT

100

VI = 3.3 V

95

90

85

80

Efficiency

EFFICIENCY

vs

75

70

Efficiency − %

65

60

55

50

012345678910

IO − Output Current − A

Test Setup and Results

2-3

Page 18

Power Dissipation

2.3 Power Dissipation

The low junction-to-case thermal resistance of the PWP package, along with

well designed board layout, allows the TPS54980EVM-022 EVM to output full

rated load current while maintaining safe junction temperatures. With a 3.3-V

input source and a 9-A load, the junction temperature is approximately 60°C,

while the case temperature is approximately 55°C. The total circuit losses at

25°C are shown in Figure 2−3. Power dissipaton is shown for an input voltage

of 3.3 V. For additional information on the dissipation ratings of the devices,

see the individual product data sheets.

Figure 2−3.Measured Circuit Losses

4

VI = 3.3 V

3.5

3

2.5

POWER DISSIPATION

vs

OUTPUT CURRENT

2

1.5

− Power Dissipation − W

D

P

1

0.5

0

012345678910

IO − Output Current − A

2-4

Page 19

2.4 Output Voltage Regulation

The output voltage load regulation of the TPS54980EVM−022 is shown in

Figure 2−4, while the output voltage line regulation is shown in Figure 2−5.

Measurements are shown for an ambient temperature of 25°C.

Figure 2−4.Load Regulation

1

Output Voltage Regulation

OUTPUT VOLTAGE

vs

OUTPUT CURRENT

0.8

0.6

0.4

0.2

−0.2

− Output Voltage Change − %V

−0.4

O

−0.6

−0.8

−1

Figure 2−5.Line Regulation

VI = 3.3 V

0

012345678910

IO − Output Current − A

OUTPUT VOLTAGE

vs

INPUT VOLTAGE

0.5

0.4

0.3

0.2

0.1

0

−0.1

−0.2

− Output Voltage Change − %V

O

−0.3

−0.4

−0.5

3 3.2 3.4 3.6 3.8 4

IO = 0 A

IO = 4.5 A

IO = 4.5 A

IO = 9 A

VI − Input Voltage − V

Test Setup and Results

2-5

Page 20

Load Transients

2.5 Load Transients

The TPS54980EVM−022 response to load transients is shown in Figure 2−6.

The current step is from 25 to 75 percent of maximum rated load. Total

peak-to-peak voltage variation is as shown, including ripple and noise on the

output.

Figure 2−6.Load Transient Response, TPS54980

VO (ac) 50 mV/div

IO 2 A/div

t − Time − 200 µs/div

2.6 Loop Characteristics

The TPS54980EVM−022 loop response characteristics are shown in

Figure 2−7 and Figure 2−8. Gain and phase plots are shown for each device

at minimum and maximum operating voltage.

Figure 2−7.Measured Loop Response, TPS54980, V

MEASURED LOOP RESPONSE

60

50

40

30

20

10

0

Gain − dB

−10

−20

−30

−40

−50

−60

100 1 k 10 k 100 k 1 M

Gain

f − Frequency − Hz

= 3V

I

Phase

180

150

120

90

60

30

0

−30

−60

−90

−120

−150

−180

Phase − deg

2-6

Page 21

Output Voltage Ripple

Figure 2−8.Measured Loop Response, TPS54980, V

MEASURED LOOP RESPONSE

60

50

40

30

20

10

0

Gain − dB

−10

−20

−30

−40

−50

−60

100 1 k

Gain

10 k 100 k

f − Frequency − Hz

2.7 Output Voltage Ripple

= 4

I

Phase

1 M

180

150

120

90

60

30

0

−30

−60

−90

−120

−150

−180

Phase − deg

The TPS54980EVM−022 output voltage ripple is shown in Figure 2−9. The

input voltage is 3.3 V for the TPS54980. Output current is the rated full load

of 9 A. Voltage is measured directly across output capacitors.

Figure 2−9.Measured Output Voltage Ripple, TPS54980

VO (ac) 10 mV/div

V

1 V/div

phase

t − Time − 1 µs/div

Test Setup and Results

2-7

Page 22

Input Voltage Ripple

2.8 Input Voltage Ripple

The TPS54980EVM−022 output voltage ripple is shown in Figure 2−10. The

input voltage is 3.3 V for the TPS54980. Output current for each device is the

rated full load of 9 A.

Figure 2−10. Input Voltage Ripple, TPS54980

VO (ac) 20 mV/div

V

1 V/div

phase

t − Time − 1 µs/div

2-8

Page 23

2.9 Power Up and Down

The TPS54980 regulator provides different modes for power up and power

down sequencing of the core and I/O voltages. By selecting different ratios for

the resistor divider R6/R7 (see Figure 4−1), the slope of the core voltage during

power up and down can be set equal to, higher than, or lower than the slope

of the I/O voltage. If the resistors R6 = R1 and R7 = R2, then the core voltage

tracks the I/O voltage. The start up voltage waveform of the

TPS54980EVM-022 for this condition is shown in Figure 2−11. The waveform

shows that the core voltage regulator tracks the output of the I/O regulator until

the core regulator reaches its nominal 1.8-V level. After that, the core regulator

starts to regulate its output at the preset 1.8-V level. The I/O regulator

continues its ramp up until the voltage reaches the nominal 3.3-V level. The

output voltage waveforms during power up do not depend on load currents.

The output voltage waveforms are powered up by asserting the ENABLE

signal while the input voltage is already applied.

Figure 2−11. Power Up with Tracking

VO I/O 500 mV/div

Power Up and Down

VO Core 500 mV/div

t − Time − 500 µs/div

The power down waveform is shown in Figure 2−12. During power down, the

output voltage fall time is defined by the output capacitance and load

resistance. In t h i s case the I/O output load resistance has been set to 20 Ω and

the core output load resistance set to 1 Ω. With the I/O output voltage falling

with a slew rate of about 1.25 V/ms, there is essentially no difference between

the core voltage and I/O voltage.

Test Setup and Results

2-9

Page 24

Power Up and Down

Figure 2−12. Power Down With Tracking

VO Core 500 mV/div

t − Time − 1 ms/div

The TPS54980EVM-022 EVM provides the ability to change the slew rate of

the output voltage of the core regulator by using jumper JP2 (see schematic

in Figure 4−1). If jumper JP2 is set so that R8 is connected in parallel to R7,

ratiometric power sequencing is implemented. For ratiometric sequencing, the

following condition must to be met: if R6 = 10 kΩ then R8 II R7 = (R7 ×

0.891)/(V

nominal values at the same time. The waveforms for ratiometric power up and

down are shown in Figure 2−13 and Figure 2−14.

− 0.891). In this case, the I/O and core voltages reach their

I/O

VO I/O 500 mV/div

Figure 2−13. Power Up With Ratiometric Sequencing

VO I/O 500 mV/div

VO Core 500 mV/div

t − Time − 500 µs/div

2-10

Page 25

Figure 2−14. Power Down With Ratiometric Sequencing

VO I/O 500 mV/div

VO Core 500 mV/div

t − Time − 1 ms/div

If jumper JP2 is set so that R8 is connected in parallel to R6, the core voltage

rises first during power up and falls second during power down. The

waveforms with this type of sequencing are shown in Figure 2−15 and

Figure 2−16.

Power Up and Down

Figure 2−15. Power Up With Core Voltage Rising First

VO I/O 500 mV/div

VO Core 500 mV/div

t − Time − 1 ms/div

Test Setup and Results

2-11

Page 26

Power Up and Down

Figure 2−16. Power Up With Core Voltage Falling Second

VO I/O 500 mV/div

VO Core 500 mV/div

t − Time − 1 ms/div

2-12

Page 27

Chapter 3

This chapter provides a description of the TPS54980EVM-022 board layout

and layer illustrations.

Topic Page

3.1 Layout 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Board Layout

3-1

Page 28

Layout

3.1 Layout

The board layout for the TPS54980EVM−022 is shown in Figure 3−1 through

Figure 3−6. The topside layer of the TPS54980EVM−022 is laid out in a

manner typical of a user application. The top and bottom layers are 1.5-oz.

copper, while the two internal ground plane layers are 1-oz. copper.

The top layer contains the main power traces for V

the top layer are connections for the remaining pins of the TPS54980 and a

large area filled with ground. The bottom layer contains ground and some

signal routing. The top and bottom ground traces are connected with multiple

vias placed around the board including 12 directly under the TPS54980 device

to provide a thermal path from the PowerPAD land to ground.

The input decoupling capacitors (C5, C9, and C19), bias decoupling capacitor

(C4), and bootstrap capacitor (C3) are all located as close to the IC as

possible. In addition, the compensation components are also kept close to the

IC. The compensation circuit ties to the output voltage at the point of

regulation, adjacent to the high frequency bypass output capacitor.

Figure 3−1.Top-Side Layout

, VO, and V

I

phase

. Also on

3-2

Page 29

Figure 3−2.Internal Layer 2

Figure 3−3.Internal Layer 3

Layout

Board Layout

3-3

Page 30

Layout

Figure 3−4.Bottom Side Layout (looking from top side)

Figure 3−5.Top Side Assembly

3-4

Page 31

Chapter 4

The TPS54980EVM-022 schematic and bill of materials are presented in this

chapter.

Topic Page

4.1 Schematic 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Bill of Materials 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Schematic and Bill of Materials

4-1

Page 32

Schematic

4.1 Schematic

The schematic for the TPS54980EVM−022 is shown in Figure 4−1.

Figure 4−1.TPS54980EVM-022 Schematic

+

4-2

Page 33

Bill of Materials

4.2 Bill of Materials

The bill of materials for the TPS54980EVM−022 is listed in Table 4−1.

Table 4−1.TPS54980EVM-022 Bill of Materials

Count Ref Des Description Size MFR Part Number

C1 Capacitor, POSCAP, 220 µF, 10 V,

−

C10, C14, C17 Capacitor, ceramic, 0.1 µF, 25 V,

3

C16 Capacitor, ceramic, 1000 pF, 25 V,

1

C2, C5, C9,

7

C11, C12, C13,

C19

C3 Capacitor, ceramic, 0.047 µF, 25 V,

1

C4 Capacitor, ceramic, 1.0 µF, 10 V,

1

C6, C15 Capacitor, ceramic, 3300 pF, 50 V,

2

C7 Capacitor, ceramic, 120 pF, 50 V,

1

C8 Capacitor, ceramic, 1200 pF, 50 V,

1

J1, J3 Terminal block, 2 pin, 15 A, 5,1 mm 148830 OST ED1609

2

J2 Terminal block, 2 pin, 6 A, 3,5 mm 75525 OST ED1514

1

JP1 Header, 2 pin, 100 mil spacing,

1

JP2 Header, 3 pin, 100 mil spacing,

1

— Shunt, 100 mil, black 0.100 3M 929950-00

2

L1 Inductor, 0.65 µH, 12 A 0.340 × 0.250 Pulse PA0277

1

R1 Resistor, chip, 10.0 kΩ, 1/16 W, 1% 603 Std Std

1

R10 Resistor, chip, 0 Ω, 1/16 W, 1% 603 Std Std

1

R11 Resistor, chip, 2.4 Ω, 1/8 W, 1% 1206 Std Std

1

R2, R7 Resistor, chip, 9.76 kΩ, 1/16 W, 1% 603 Std Std

2

R3 Resistor, chip, 4.02 kΩ, 1/16 W, 1% 603 Std Std

1

F4 Resistor, chip, 71.5 kΩ, 1/16 W, 1% 603 Std Std

1

R5 Resistor, chip, 383 Ω, 1/16 W, 1% 603 Std Std

1

R6 Resistor, chip, 10.0 kΩ, 1/16 W, 1% 603 Std Std

1

R8 Resistor, chip, 6.04 kΩ, 1/16 W, 1% 603 Std Std

1

R9 Resistor, chip, 10 kΩ, 1/16 W, 1% 603 Std Std

1

S1 Switch, 1P2T, slide, PC mount,

1

TP1, TP3,

5

TP4, TP5, TP6

TP10 Test point, black, 1 mm 0.038 Farnell 240-333

1

TP2, TP8 Test point, black, 1 mm 0.038I, 6400I Farnell 240-333

2

45 mΩ, 20%

X7R, 10%

X7R, 10%

Capacitor, ceramic, 22 µF, 6.3 V,

X5R, 20%

X7R, 10%

X5R, 20%

X7R, 10%

NPO, 5%

X7R, 10%

(36-pin strip)

(36-pin strip)

200 mA

Test point, red, 1 mm 0.038I, 6400I Farnell 240-345

7343 (D) Sanyo 10TPB220M

603 Std Std

603 Std Std

1210 Taiyo Yuden JMK325BJ226MN

603 Std Std

603 Std Std

603 Std Std

603 Std Std

603 Std Std

0.100 × 2I Sullins PTC36SAAN

0.100 × 3I Sullins PTC36SAAN

0.46 × 0.16 E_Switch EQ1218

Schematic and Bill of Materials

4-3

Page 34

Bill of Materials

Count Part NumberMFRSizeDescriptionRef Des

TP7 Adaptor, 3,5 mm probe clip (or

1

TP9 Test point, red, 1 mm 0.038 Farnell 240-345

1

U1 IC, high−side power distribution SW

1

U2 IC, tracking synchronous PWM

1

— PCB, 3 in. × 3 in. × 0.062 in. Any HPA022

1

Notes: 1) These assemblies are ESD sensitive, ESD precautions should be observed.

2) These assemblies must be clean and free from flux and all contaminants, Use of no clean flux is not acceptable.

3) These assemblies must comply with workmanship standards IPC-A-610 Class 2.

4) Reference designators marked with an asterisk (**) cannot be substituted. All other components can be substituted

with equivalent manufacturers components.

131-5031-00)

with current limit

switcher

72900 Tektronix 131-4244-00

SO8 TI TPS201xD

PWP28 TI TPS54980PWP

4-4

Loading...

Loading...