Page 1

www.ti.com

VIN

NC

NC

ENA

GND

VSENSE

BOOT

PH

TPS5430/31

VIN VOUT

95

60

70

80

90

100

0 0.5 1 1.5 2.5 3 3.5

Efficiency − %

I OutputCurrent AO--

EfficiencyvsOutputCurrent

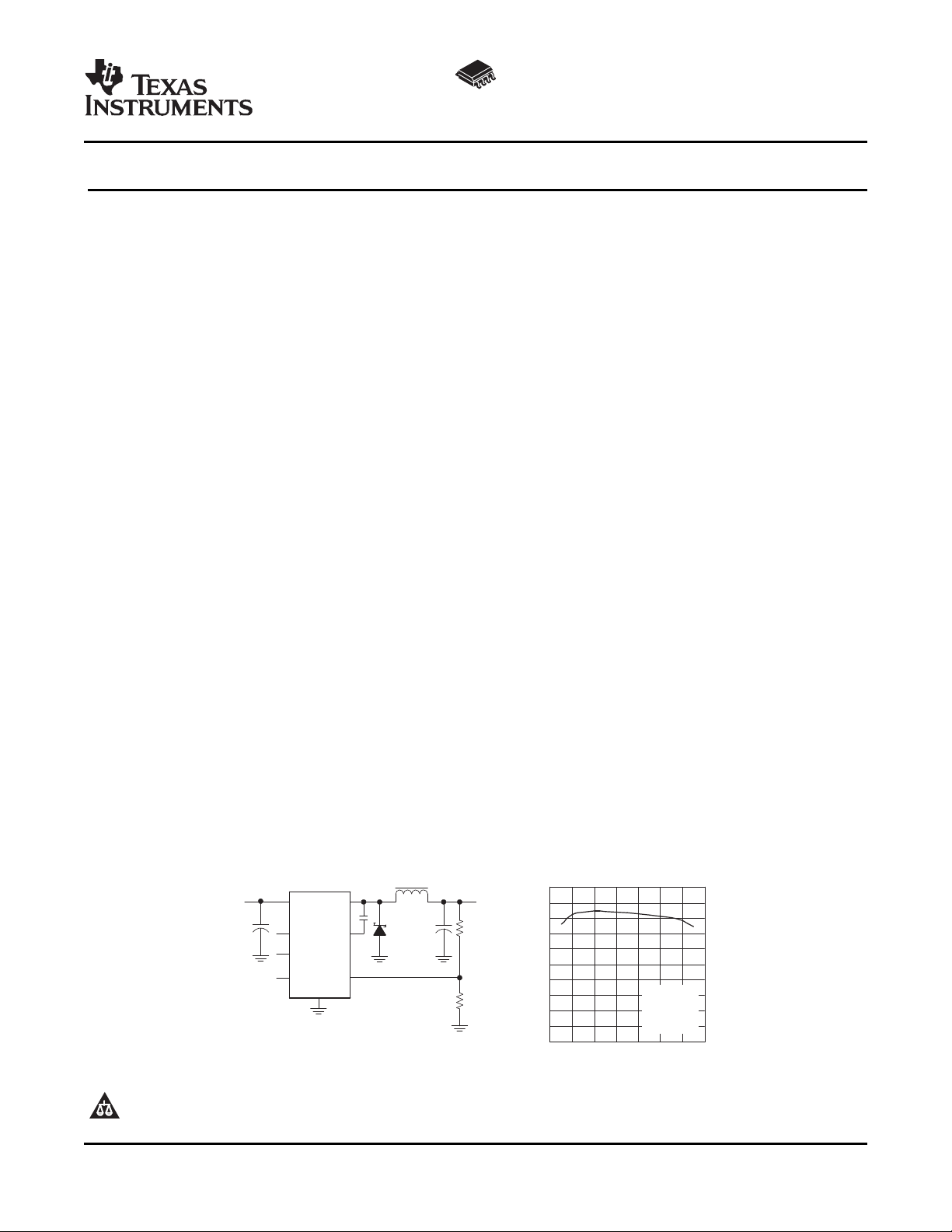

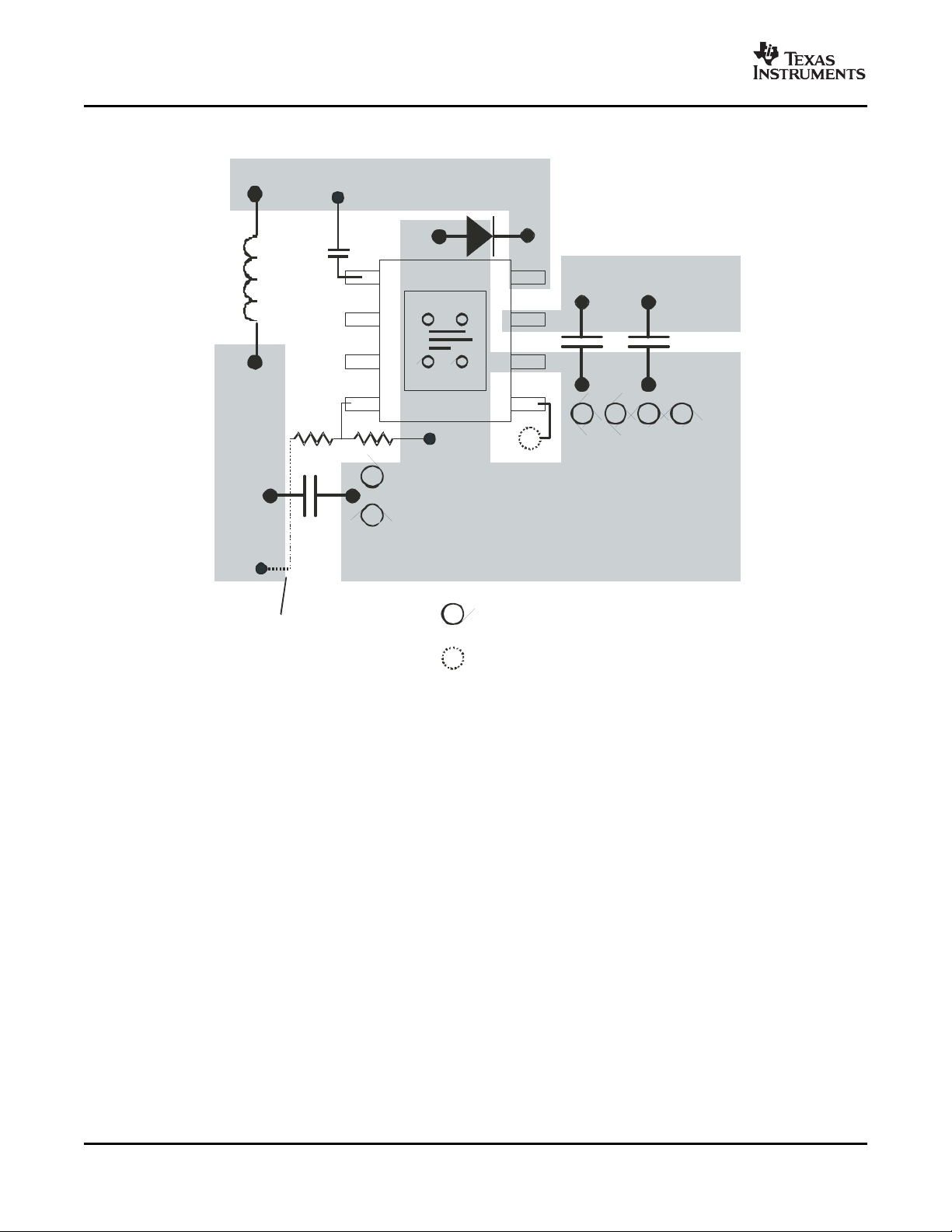

SimplifiedSchematic

VI=12V

V =5V

f =500kHz

T =25 C

O

s

A

o

2

50

55

65

75

85

3-A, WIDE INPUT RANGE, STEP-DOWN SWIFT™ CONVERTER

FEATURES APPLICATIONS

• Wide Input Voltage Range:

– TPS5430: 5.5 V to 36 V

– TPS5431: 5.5 V to 23 V

• Up to 3-A Continuous (4-A Peak) Output

Current

• High Efficiency up to 95% Enabled by 110-m Ω

Integrated MOSFET Switch

• Wide Output Voltage Range: Adjustable Down

to 1.22 V with 1.5% Initial Accuracy

• Internal Compensation Minimizes External

Parts Count

• Fixed 500 kHz Switching Frequency for Small

Filter Size

• Improved Line Regulation and Transient

Response by Input Voltage Feed Forward

• System Protected by Overcurrent Limiting,

Overvoltage Protection and Thermal

Shutdown

• –40 ° C to 125 ° C Operating Junction

Temperature Range

• Available in Small Thermally Enhanced 8-Pin

SOIC PowerPAD™ Package

• For SWIFT™ Documentation, Application

Notes and Design Software, See the TI

Website at www.ti.com/swift

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

• Consumer: Set-top Box, DVD, LCD Displays

• Industrial and Car Audio Power Supplies

• Battery Chargers, High Power LED Supply

• 12-V/24-V Distributed Power Systems

DESCRIPTION

As a member of the SWIFT™ family of DC/DC

regulators, the TPS5430/TPS5431 is a

high-output-current PWM converter that integrates a

low resistance high side N-channel MOSFET.

Included on the substrate with the listed features are

a high performance voltage error amplifier that

provides tight voltage regulation accuracy under

transient conditions; an undervoltage-lockout circuit

to prevent start-up until the input voltage reaches

5.5 V; an internally set slow-start circuit to limit inrush

currents; and a voltage feed-forward circuit to

improve the transient response. Using the ENA pin,

shutdown supply current is reduced to 18 µ A

typically. Other features include an active-high

enable, overcurrent limiting, overvoltage protection

and thermal shutdown. To reduce design complexity

and external component count, the

TPS5430/TPS5431 feedback loop is internally

compensated. The TPS5431 is intended to operate

from power rails up to 23 V. The TPS5430 regulates

a wide variety of power sources including 24-V bus.

The TPS5430/TPS5431 device is available in a

thermally enhanced, easy to use 8-pin SOIC

PowerPAD™ package. TI provides evaluation

modules and the SWIFT™ Designer software tool to

aid in quickly achieving high-performance power

supply designs to meet aggressive equipment

development cycles.

SWIFT, PowerPAD are trademarks of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2006, Texas Instruments Incorporated

Page 2

www.ti.com

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

ORDERING INFORMATION

T

J

INPUT VOLTAGE OUTPUT VOLTAGE PACKAGE

–40 ° C to 125 ° C 5.5 V to 36 V Adjustable to 1.22 V Thermally Enhanced SOIC (DDA)

–40 ° C to 125 ° C 5.5 V to 23 V Adjustable to 1.22 V Thermally Enhanced SOIC (DDA)

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

web site at www.ti.com.

(2) The DDA package is also available taped and reeled. Add an R suffix to the device type (i.e., TPS5430DDAR). See applications section

of data sheet for PowerPAD™ drawing and layout information.

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

VIN –0.3 to 40

TPS5430 BOOT –0.3 to 50

V

Input voltage range

I

TPS5431 BOOT –0.3 to 35

I

O

I

lkg

T

T

Source current PH Internally Limited

Leakage current PH 10 µ A

Operating virtual junction temperature range –40 to 150 ° C

J

Storage temperature –65 to 150 ° C

stg

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltage values are with respect to network ground terminal.

(3) Approaching the absolute maximum rating for the VIN pin may cause the voltage on the PH pin to exceed the absolute maximum rating.

PH (steady-state) –0.6 to 40

VIN –0.3 to 25

PH (steady-state) –0.6 to 25

ENA –0.3 to 7

BOOT-PH 10

VSENSE –0.3 to 3

PH (transient < 10 ns) –1.2

(1) (2)

(1)

VALUE UNIT

PART NUMBER

(2)

(2)

TPS5430DDA

TPS5431DDA

(3)

(3)

V

DISSIPATION RATINGS

8 Pin DDA (2-layer board with solder)

8 Pin DDA (4-layer board with solder)

(1) (2)

PACKAGE

(3)

(4)

THERMAL IMPEDANCE

JUNCTION-TO-AMBIENT

33 ° C/W

26 ° C/W

(1) Maximum power dissipation may be limited by overcurrent protection.

(2) Power rating at a specific ambient temperature TAshould be determined with a junction temperature of 125 ° C. This is the point where

distortion starts to substantially increase. Thermal management of the final PCB should strive to keep the junction temperature at or

below 125 ° C for best performance and long-term reliability. See Thermal Calculations in applications section of this data sheet for more

information.

(3) Test board conditions:

a. 3 in x 3 in, 2 layers, thickness: 0.062 inch.

b. 2 oz. copper traces located on the top and bottom of the PCB.

c. 6 thermal vias in the PowerPAD area under the device package.

(4) Test board conditions:

a. 3 in x 3 in, 4 layers, thickness: 0.062 inch.

b. 2 oz. copper traces located on the top and bottom of the PCB.

c. 2 oz. copper ground planes on the 2 internal layers.

d. 6 thermal vias in the PowerPAD area under the device package.

2

Submit Documentation Feedback

Page 3

www.ti.com

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

RECOMMENDED OPERATING CONDITIONS

MIN NOM MAX UNIT

VIN Input voltage range V

T

Operating junction temperature –40 125 ° C

J

ELECTRICAL CHARACTERISTICS

TJ= –40 ° C to 125 ° C, VIN = 12.0 V (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SUPPLY VOLTAGE (VIN PIN)

VSENSE = 2 V, Not switching,

I

Q

UNDERVOLTAGE LOCK OUT (UVLO)

VOLTAGE REFERENCE

OSCILLATOR

ENABLE (ENA PIN)

CURRENT LIMIT

THERMAL SHUTDOWN

OUTPUT MOSFET

r

DS(on)

Quiescent current

Start threshold voltage, UVLO 5.3 5.5 V

Hysteresis voltage, UVLO 330 mV

Voltage reference accuracy V

Internally set free-running frequency 400 500 600 kHz

Minimum controllable on time 150 200 ns

Maximum duty cycle 87 89 %

Start threshold voltage, ENA 1.3 V

Stop threshold voltage, ENA 0.5 V

Hysteresis voltage, ENA 450 mV

Internal slow-start time (0~100%) 6.6 8 10 ms

Current limit 4 5 6 A

Current limit hiccup time 13 16 20 ms

Thermal shutdown trip point 135 162 ° C

Thermal shutdown hysteresis 14 ° C

High-side power MOSFET switch m Ω

PH pin open

Shutdown, ENA = 0 V 18 50 µ A

TJ= 25 ° C 1.202 1.221 1.239

IO= 0 A – 3 A 1.196 1.221 1.245

VIN = 5.5 V 150

TPS5430 5.5 36

TPS5431 5.5 23

3 4.4 mA

110 230

Submit Documentation Feedback

3

Page 4

www.ti.com

1

2

3

4

8

7

6

5

PowerPAD

(Pin9)

BOOT

NC

NC

VSENSE

PH

VIN

GND

ENA

DDAPACKAGE

(TOPVIEW)

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

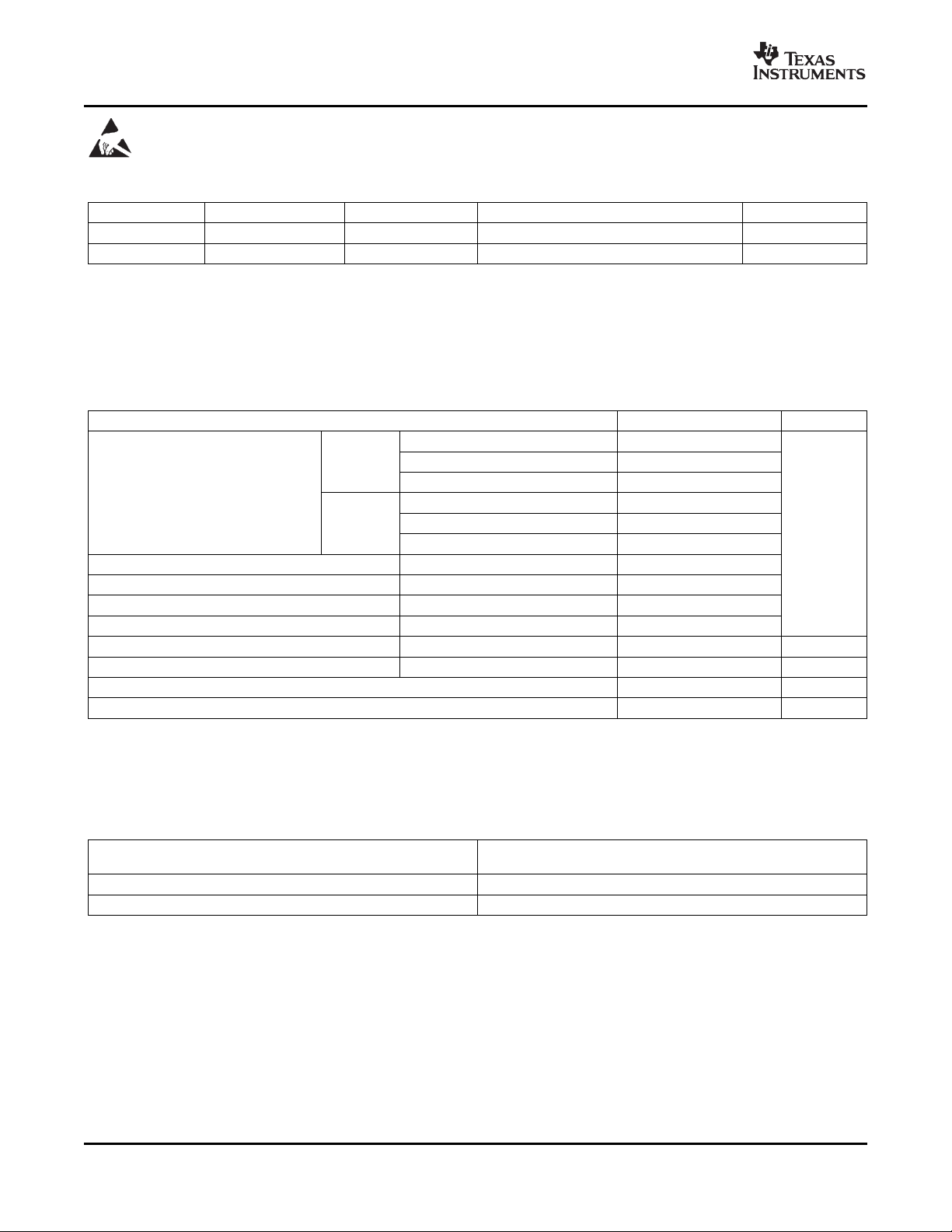

PIN ASSIGNMENTS

TERMINAL FUNCTIONS

TERMINAL

NAME NO.

BOOT 1 Boost capacitor for the high-side FET gate driver. Connect 0.01 µ F low ESR capacitor from BOOT pin to PH pin.

NC 2, 3 Not connected internally.

VSENSE 4 Feedback voltage for the regulator. Connect to output voltage divider.

ENA 5 On/off control. Below 0.5 V, the device stops switching. Float the pin to enable.

GND 6 Ground. Connect to PowerPAD.

VIN 7

PH 8 Source of the high side power MOSFET. Connected to external inductor and diode.

PowerPAD 9 GND pin must be connected to the exposed pad for proper operation.

Input supply voltage. Bypass VIN pin to GND pin close to device package with a high quality, low ESR ceramic

capacitor.

DESCRIPTION

4

Submit Documentation Feedback

Page 5

www.ti.com

2.5

2.75

3

3.25

3.5

−50 −25 0 25 50 75 100 125

T

J

−JunctionT emperature − °C

I

Q

−QuiescentCurrent

−mA

V =12V

I

460

470

480

490

500

510

520

530

−50 −25 0 25 50 75 100 125

f − OscillatorFrequency − kHz

T − JunctionTemperature − °C

1.210

1.215

1.220

1.225

1.230

-50 -25 0 25 50 75 100 125

T -JunctionTemperature-°C

J

V -VoltageReference-V

REF

5

10

15

20

25

0 5 10 15 20 25 30 35 40

T

J

=125

°C

T

J

=27°C

TJ=

– °40 C

ENA=0V

VI−InputV oltage −V

I

SD

−ShutdownCurrent

−

Aµ

7

7.5

8

8.5

9

−50 −25 0 25 50 75 100 125

T

J

− JunctionTemperature − °C

T

S

S

− InternalSlowStartT

ime − ms

80

90

100

110

120

130

140

150

160

170

180

−50 −25 0 25 50 75 100 125

mΩ

−OnResistance

−

r

DS(on)

TJ−JunctionTemperature − °C

VI=12V

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

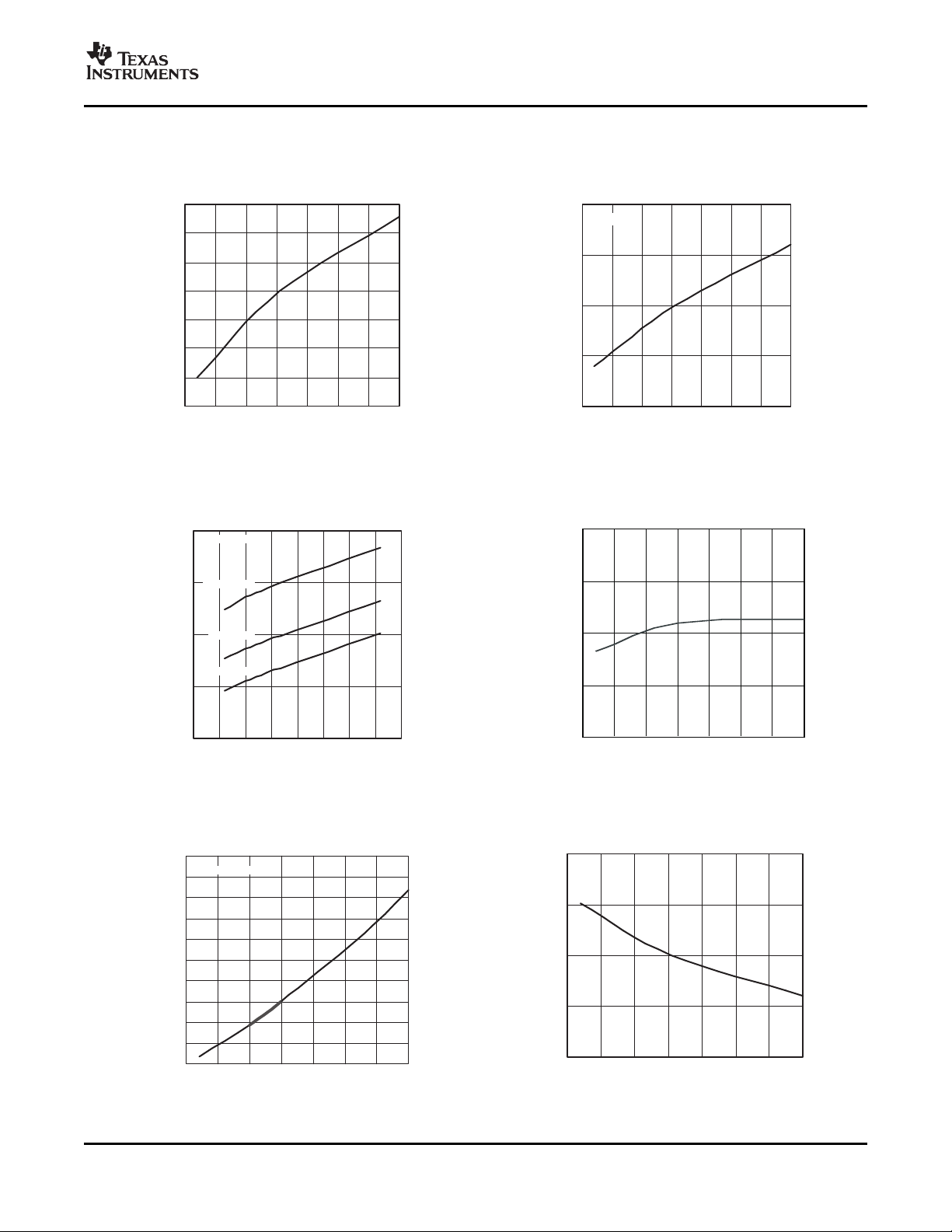

TYPICAL CHARACTERISTICS

OSCILLATOR FREQUENCY NON-SWITCHING QUIESCENT CURRENT

vs vs

JUNCTION TEMPERATURE JUNCTION TEMPERATURE

Figure 1. Figure 2.

SHUTDOWN QUIESCENT CURRENT VOLTAGE REFERENCE

vs vs

INPUT VOLTAGE JUNCTION TEMPERATURE

JUNCTION TEMPERATURE JUNCTION TEMPERATURE

Figure 3. Figure 4.

ON RESISTANCE INTERNAL SLOW START TIME

vs vs

Figure 5. Figure 6.

Submit Documentation Feedback

5

Page 6

www.ti.com

7

7.25

7.50

7.75

8

-50 -25 0 25

50

75 100 125

T -JunctionTemperature-°C

J

MinimumDutyRatio-%

120

130

140

150

160

170

180

−50 −25 0 25 50 75 100 125

T

J

− JunctionTemperature − °C

MinimumControllableOnT

ime

− ns

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

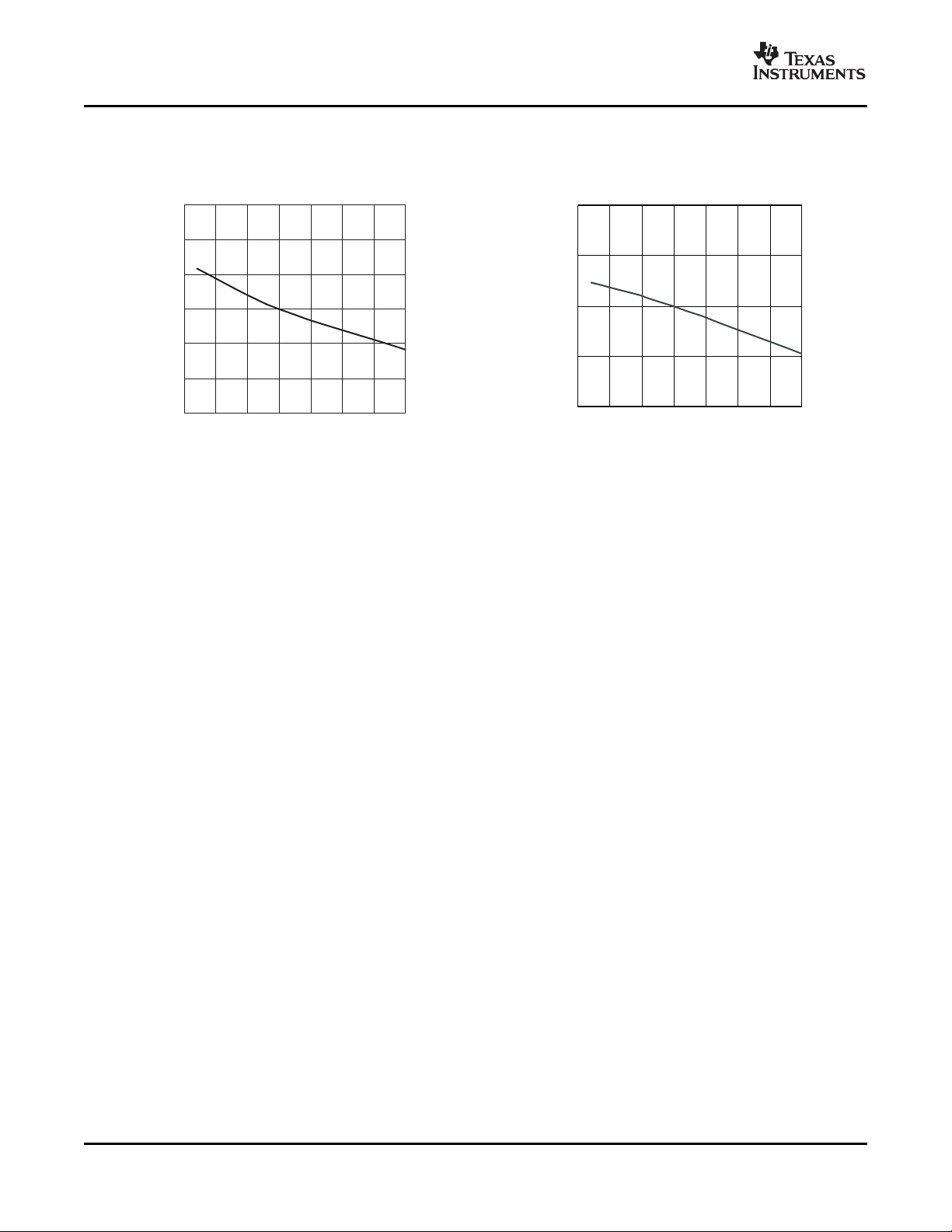

TYPICAL CHARACTERISTICS (continued)

MINIMUM CONTROLLABLE ON TIME MINIMUM CONTROLLABLE DUTY RATIO

vs vs

JUNCTION TEMPERATURE JUNCTION TEMPERATURE

Figure 7. Figure 8.

6

Submit Documentation Feedback

Page 7

www.ti.com

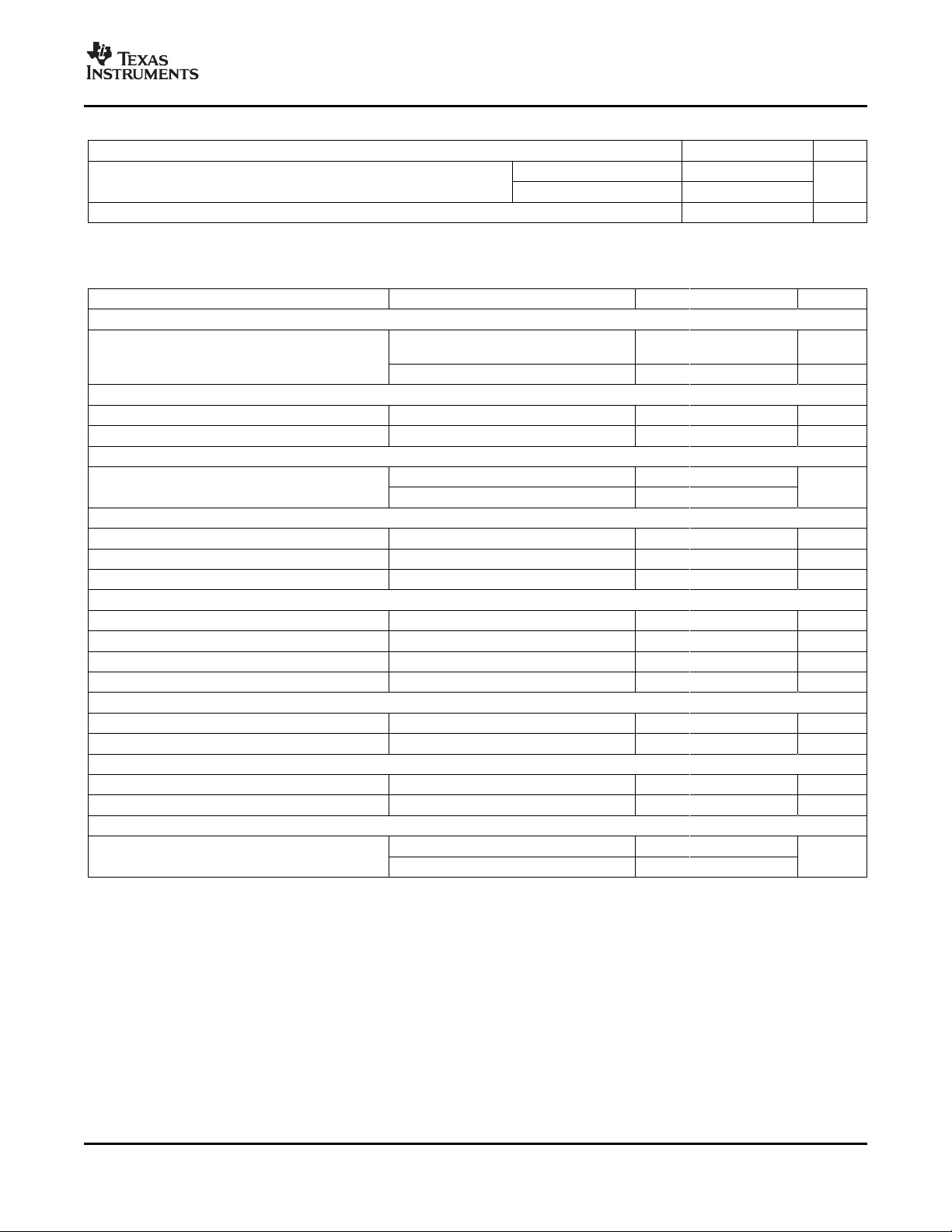

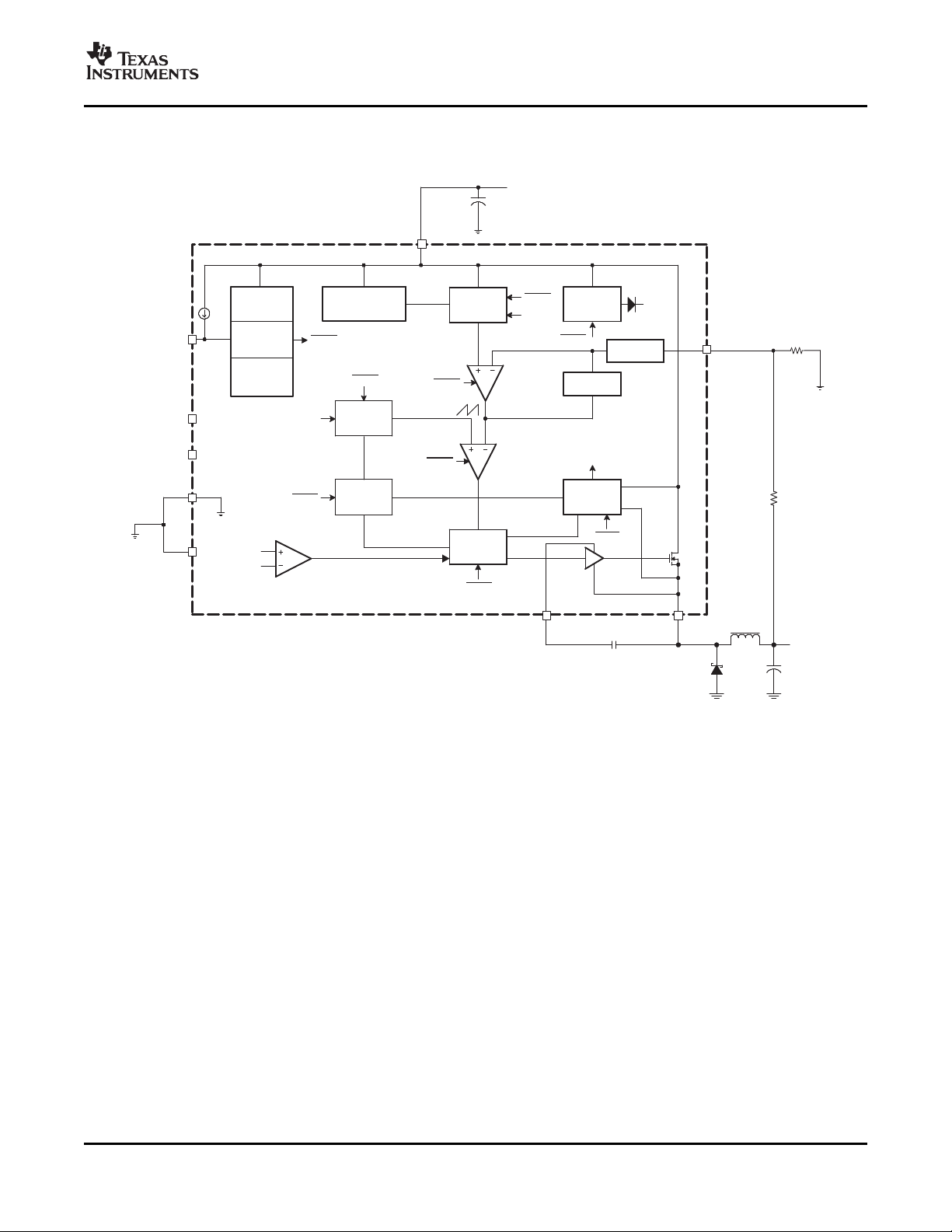

FUNCTIONAL BLOCK DIAGRAM

VIN

UVLO

ENABLE

Thermal

Protection

Reference

Overcurrent

GateDrive

Oscillator

Ramp

Generator

VREF

PH

ENA

GND

BOOT

Z1

Z2

SHDN

SHDN

SHDN

SHDN

SHDN

SHDN

SHDN

SHDN

VIN

112.5%VREF

VSENSE

OVP

HICCUP

HICCUP

SHDN

NC

FeedForward

BOOT

NC

POWERPAD

VIN

VOUT

5 µA

1.221VBandgap

SlowStart

Boot

Regulator

Error

Amplifier

Gain=25

PWM

Comparator

Protection

Gate

Driver

Control

VSENSE

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

APPLICATION INFORMATION

DETAILED DESCRIPTION

Oscillator Frequency

The internal free running oscillator sets the PWM switching frequency at 500 kHz. The 500 kHz switching

frequency allows less output inductance for the same output ripple requirement resulting in a smaller output

inductor.

Voltage Reference

The voltage reference system produces a precision reference signal by scaling the output of a temperature

stable bandgap circuit. The bandgap and scaling circuits are trimmed during production testing to an output of

1.221 V at room temperature.

Enable (ENA) and Internal Slow Start

The ENA pin provides electrical on/off control of the regulator. Once the ENA pin voltage exceeds the threshold

voltage, the regulator starts operation and the internal slow start begins to ramp. If the ENA pin voltage is pulled

below the threshold voltage, the regulator stops switching and the internal slow start resets. Connecting the pin

to ground or to any voltage less than 0.5 V will disable the regulator and activate the shutdown mode. The

quiescent current of the TPS5430/TPS5431 in shutdown mode is typically 18 µ A.

The ENA pin has an internal pullup current source, allowing the user to float the ENA pin. If an application

requires controlling the ENA pin, use open drain or open collector output logic to interface with the pin. To limit

the start-up inrush current, an internal slow-start circuit is used to ramp up the reference voltage from 0 V to its

final value, linearly. The internal slow start time is 8 ms typically.

Submit Documentation Feedback

7

Page 8

www.ti.com

Feed Forward Gain +

VIN

Ramp

pk*pk

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

APPLICATION INFORMATION (continued)

Undervoltage Lockout (UVLO)

The TPS5430/TPS5431 incorporates an undervoltage lockout circuit to keep the device disabled when VIN (the

input voltage) is below the UVLO start voltage threshold. During power up, internal circuits are held inactive and

the internal slow start is grouded until VIN exceeds the UVLO start threshold voltage. Once the UVLO start

threshold voltage is reached, the internal slow start is released and device start-up begins. The device operates

until VIN falls below the UVLO stop threshold voltage. The typical hysteresis in the UVLO comparator is 330

mV.

Boost Capacitor (BOOT)

Connect a 0.01 µ F low-ESR ceramic capacitor between the BOOT pin and PH pin. This capacitor provides the

gate drive voltage for the high-side MOSFET. X7R or X5R grade dielectrics are recommended due to their

stable values over temperature.

Output Feedback (VSENSE) and Internal Compensation

The output voltage of the regulator is set by feeding back the center point voltage of an external resistor divider

network to the VSENSE pin. In steady-state operation, the VSENSE pin voltage should be equal to the voltage

reference 1.221 V.

The TPS5430/TPS5431 implements internal compensation to simplify the regulator design. Since the

TPS5430/TPS5431 uses voltage mode control, a type 3 compensation network has been designed on chip to

provide a high crossover frequency and a high phase margin for good stability. See the Internal Compensation

Network in the applications section for more details.

Voltage Feed Forward

The internal voltage feed forward provides a constant dc power stage gain despite any variations with the input

voltage. This greatly simplifies the stability analysis and improves the transient response. Voltage feed forward

varies the peak ramp voltage inversely with the input voltage so that the modulator and power stage gain are

constant at the feed forward gain, i.e.

The typical feed forward gain of TPS5430/TPS5431 is 25.

Pulse-Width-Modulation (PWM) Control

The regulator employs a fixed frequency pulse-width-modulator (PWM) control method. First, the feedback

voltage (VSENSE pin voltage) is compared to the constant voltage reference by the high gain error amplifier and

compensation network to produce a error voltage. Then, the error voltage is compared to the ramp voltage by

the PWM comparator. In this way, the error voltage magnitude is converted to a pulse width which is the duty

cycle. Finally, the PWM output is fed into the gate drive circuit to control the on-time of the high-side MOSFET.

Overcurrent Limiting

Overcurrent limiting is implemented by sensing the drain-to-source voltage across the high-side MOSFET. The

drain to source voltage is then compared to a voltage level representing the overcurrent threshold limit. If the

drain-to-source voltage exceeds the overcurrent threshold limit, the overcurrent indicator is set true. The system

will ignore the overcurrent indicator for the leading edge blanking time at the beginning of each cycle to avoid

any turn-on noise glitches.

Once overcurrent indicator is set true, overcurrent limiting is triggered. The high-side MOSFET is turned off for

the rest of the cycle after a propagation delay. The overcurrent limiting mode is called cycle-by-cycle current

limiting.

(1)

8

Submit Documentation Feedback

Page 9

www.ti.com

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

APPLICATION INFORMATION (continued)

Sometimes under serious overload conditions such as short-circuit, the overcurrent runaway may still happen

when using cycle-by-cycle current limiting. A second mode of current limiting is used, i.e. hiccup mode

overcurrent limiting. During hiccup mode overcurrent limiting, the voltage reference is grounded and the

high-side MOSFET is turned off for the hiccup time. Once the hiccup time duration is complete, the regulator

restarts under control of the slow start circuit.

Overvoltage Protection

The TPS5430/TPS5431 has an overvoltage protection (OVP) circuit to minimize voltage overshoot when

recovering from output fault conditions. The OVP circuit includes an overvoltage comparator to compare the

VSENSE pin voltage and a threshold of 112.5% x VREF. Once the VSENSE pin voltage is higher than the

threshold, the high-side MOSFET will be forced off. When the VSENSE pin voltage drops lower than the

threshold, the high-side MOSFET will be enabled again.

Thermal Shutdown

The TPS5430/TPS5431 protects itself from overheating with an internal thermal shutdown circuit. If the junction

temperature exceeds the thermal shutdown trip point, the voltage reference is grounded and the high-side

MOSFET is turned off. The part is restarted under control of the slow start circuit automatically when the junction

temperature drops 14 ° C below the thermal shutdown trip point.

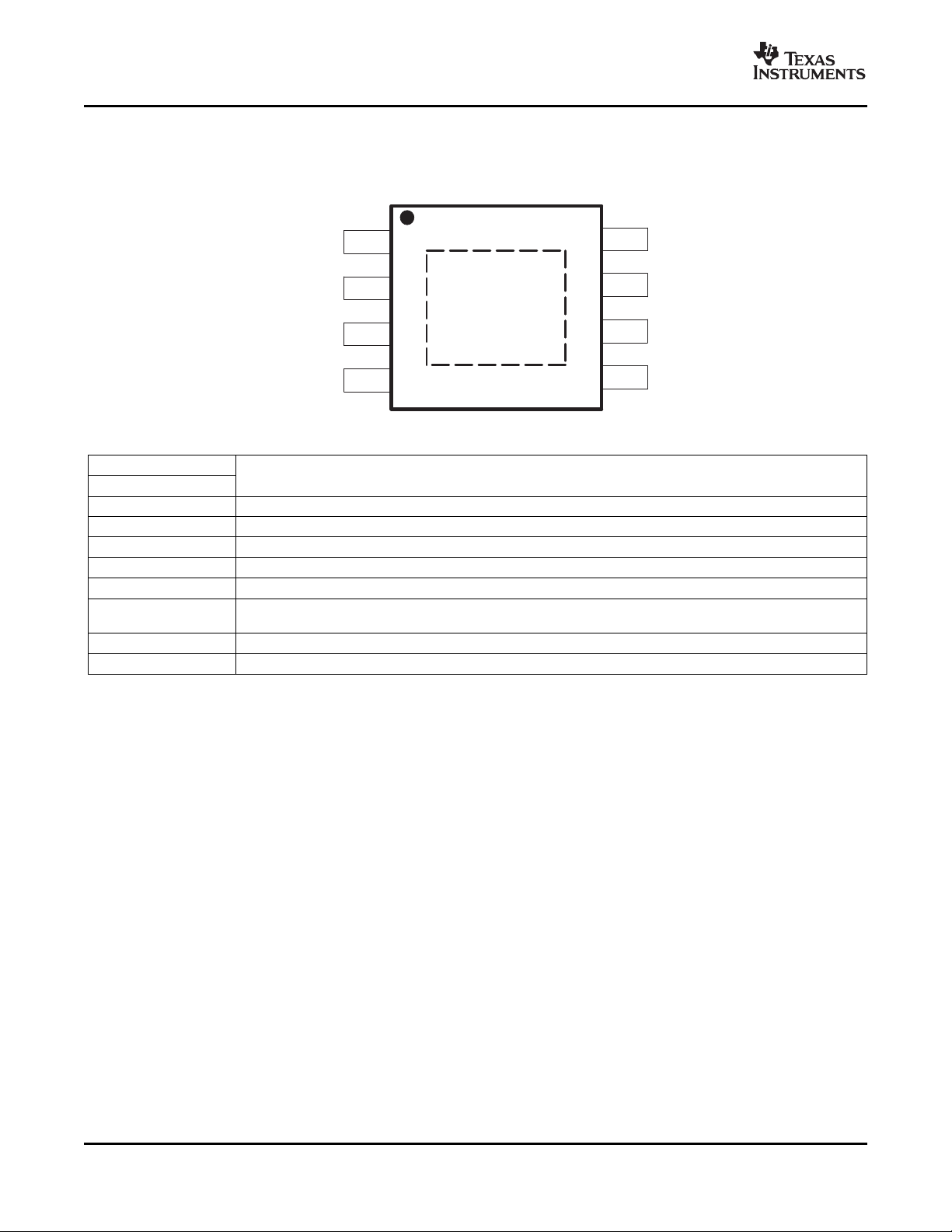

PCB Layout

Connect a low ESR ceramic bypass capacitor to the VIN pin. Care should be taken to minimize the loop area

formed by the bypass capacitor connections, the VIN pin, and the TPS5430/TPS5431 ground pin. The best way

to do this is to extend the top side ground area from under the device adjacent to the VIN trace, and place the

bypass capacitor as close as possible to the VIN pin. The minimum recommended bypass capacitance is 4.7 µ F

ceramic with a X5R or X7R dielectric.

There should be a ground area on the top layer directly underneath the IC, with an exposed area for connection

to the PowerPAD. Use vias to connect this ground area to any internal ground planes. Use additional vias at the

ground side of the input and output filter capacitors as well. The GND pin should be tied to the PCB ground by

connecting it to the ground area under the device as shown below.

The PH pin should be routed to the output inductor, catch diode and boot capacitor. Since the PH connection is

the switching node, the inductor should be located very close to the PH pin and the area of the PCB conductor

minimized to prevent excessive capacitive coupling. The catch diode should also be placed close to the device

to minimize the output current loop area. Connect the boot capacitor between the phase node and the BOOT pin

as shown. Keep the boot capacitor close to the IC and minimize the conductor trace lengths. The component

placements and connections shown work well, but other connection routings may also be effective.

Connect the output filter capacitor(s) as shown between the VOUT trace and GND. It is important to keep the

loop formed by the PH pin, Lout, Cout and GND as small as is practical.

Connect the VOUT trace to the VSENSE pin using the resistor divider network to set the output voltage. Do not

route this trace too close to the PH trace. Due to the size of the IC package and the device pin-out, the trace

may need to be routed under the output capacitor. Alternately, the routing may be done on an alternate layer if a

trace under the output capacitor is not desired.

If using the grounding scheme shown in Figure 9 , use a via connection to a different layer to route to the ENA

pin.

Submit Documentation Feedback

9

Page 10

www.ti.com

BOOT

NC

NC

VSENSE

PH

VIN

GND

ENA

VOUT

PH

Vin

TOPSIDEGROUND AREA

VIA toGroundPlane

OUTPUT

INDUCTOR

OUTPUT

FILTER

CAPACITOR

BOOT

CAPACITOR

INPUT

BYPASS

CAPACITOR

INPUT

BULK

FILTER

CATCH

DIODE

SignalVIA

Routefeedback

traceunderoutput

filtercapacitororon

otherlayer

RESISTOR

DIVIDER

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

APPLICATION INFORMATION (continued)

Figure 9. Design Layout

10

Submit Documentation Feedback

Page 11

www.ti.com

0.080

0.026

0.098

0.118

0.050

0.110

0.220

0.050

0.040

0.013DIA 4PL

Alldimensionsininches

+

PwPd

10.8-19.8V

L1

15 Hm

6

4

9

5

2

3

GND

VSNS

VIN

NC

NC

ENA

BOOT

PH

7

1

8

C1

10 Fm

C3

220 Fm

D1

B340A

C2

0.01 Fm

VOUT

5V

R2

3.24kW

R1

10kW

VIN

EN

U1

TPS5430DDA

APPLICATION INFORMATION (continued)

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

Figure 10. TPS5430 Land Pattern

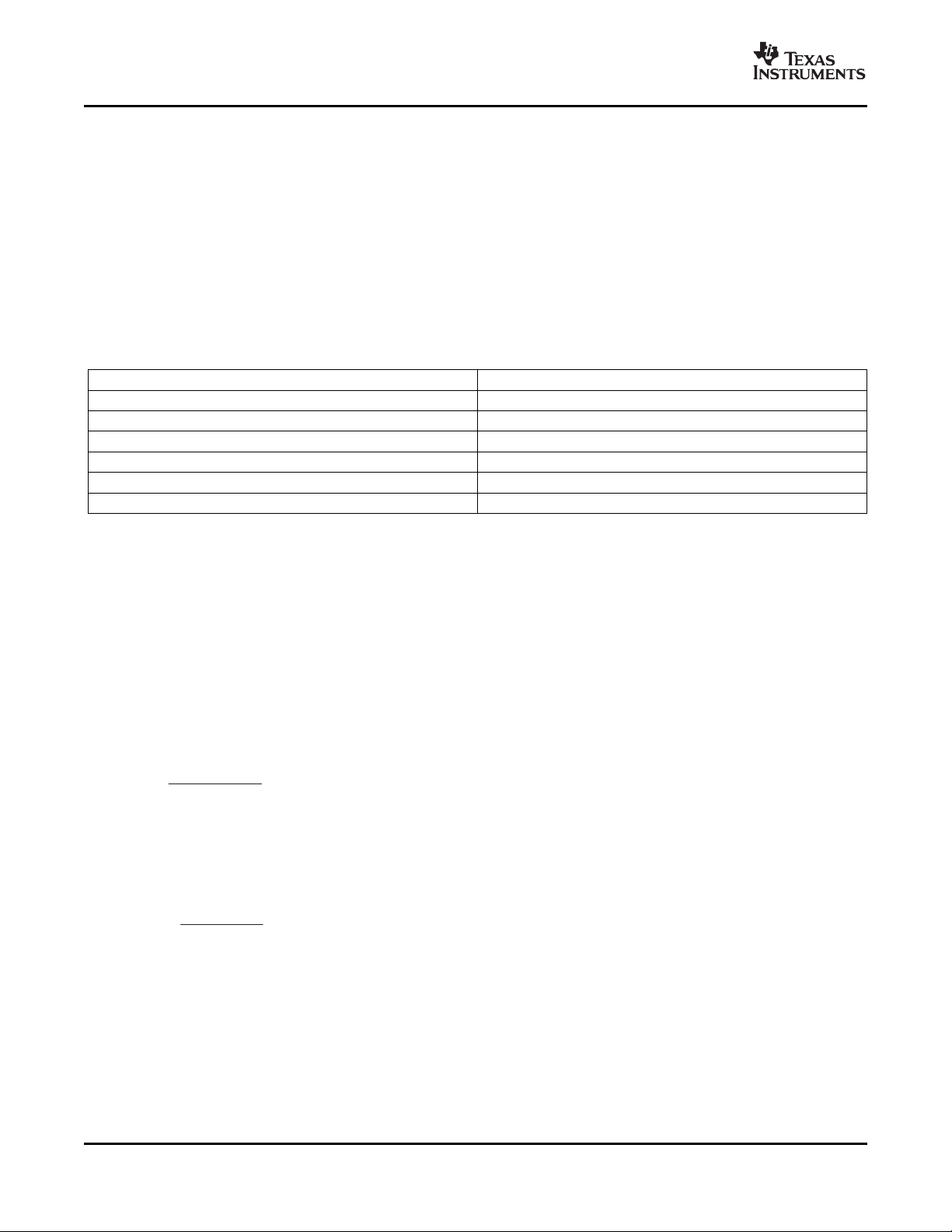

Application Circuits

Figure 11 shows the schematic for a typical TPS5430 application. The TPS5430 can provide up to 3-A output

current at a nominal output voltage of 5 V. For proper thermal performance, the exposed PowerPAD™

underneath the device must be soldered down to the printed-circuit board.

Figure 11. Application Circuit, 12-V to 5.0-V

Design Procedure

The following design procedure can be used to select component values for the TPS5430. Alternately, the

SWIFT™ Designer Software may be used to generate a complete design. The SWIFT™ Designer Software

uses an iterative design procedure and accesses a comprehensive database of components when generating a

design. This section presents a simplified discussion of the design process.

Submit Documentation Feedback

11

Page 12

www.ti.com

DV

IN

+

I

OUT(MAX)

0.25

C

BULK

ƒ

sw

)

ǒ

I

OUT(MAX)

ESR

MAX

Ǔ

I

CIN

+

I

OUT(MAX)

2

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

APPLICATION INFORMATION (continued)

To begin the design process a few parameters must be decided upon. The designer needs to know the

following:

• Input voltage range

• Output voltage

• Input ripple voltage

• Output ripple voltage

• Output current rating

• Operating frequency

Design Parameters

For this design example, use the following as the input parameters:

DESIGN PARAMETER

Input voltage range 10.8 V to 19.8 V

Output voltage 5 V

Input ripple voltage 300 mV

Output ripple voltage 30 mV

Output current rating 3 A

Operating frequency 500 kHz

(1) As an additional constraint, the design is set up to be small size and low component height.

Switching Frequency

The switching frequency for the TPS5430 is internally set to 500 kHz. It is not possible to adjust the switching

frequency.

(1)

EXAMPLE VALUE

Input Capacitors

The TPS5430 requires an input decoupling capacitor and, depending on the application, a bulk input capacitor.

The recommended value for the decoupling capacitor, C1, is 10 µ F. A high quality ceramic type X5R or X7R is

required. For some applications, a smaller value decoupling capacitor may be used, so long as the input voltage

and current ripple ratings are not exceeded. The voltage rating must be greater than the maximum input voltage,

including ripple.

This input ripple voltage can be approximated by Equation 2 :

Where I

ESR

MAX

OUT(MAX)

is the maximum series resistance of the input capacitor.

is the maximum load current, fSWis the switching frequency, C

is the input capacitor value and

IN

The maximum RMS ripple current also needs to be checked. For worst case conditions, this can be

approximated by Equation 3 :

In this case the input ripple voltage would be 156 mV and the RMS ripple current would be 1.5 A. The maximum

voltage across the input capacitors would be VIN max plus delta VIN/2. The chosen input decoupling capacitor

is rated for 25 V and the ripple current capacity is greater than 3 A, providing ample margin. It is very important

that the maximum ratings for voltage and current are not exceeded under any circumstance.

Additionally some bulk capacitance may be needed, especially if the TPS5430 circuit is not located within about

2 inches from the input voltage source. The value for this capacitor is not critical but it also should be rated to

handle the maximum input voltage including ripple voltage and should filter the output so that input ripple voltage

is acceptable.

(2)

(3)

12

Submit Documentation Feedback

Page 13

www.ti.com

L

MIN

+

V

OUT(MAX)

ǒ

V

IN(MAX)

* V

OUT

Ǔ

V

IN(max)

K

IND

I

OUT

F

SW

I

L(RMS)

+ I

2

OUT(MAX)

)

1

12

ǒ

V

OUT

ǒ

V

IN(MAX)

* V

OUT

Ǔ

V

IN(MAX)

L

OUT

FSW 0.8

Ǔ

2

Ǹ

I

L(PK)

+ I

OUT(MAX)

)

V

OUT

ǒ

V

IN(MAX)

* V

OUT

Ǔ

1.6 V

IN(MAX)

L

OUT

F

SW

f

CO

+

f

LC

2

85 V

OUT

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

Output Filter Components

Two components need to be selected for the output filter, L1 and C2. Since the TPS5430 is an internally

compensated device, a limited range of filter component types and values can be supported.

Inductor Selection

To calculate the minimum value of the output inductor, use Equation 4 :

K

is a coefficient that represents the amount of inductor ripple current relative to the maximum output current.

IND

Three things need to be considered when determining the amount of ripple current in the inductor: the peak to

peak ripple current affects the output ripple voltage amplitude, the ripple current affects the peak switch current

and the amount of ripple current determines at what point the circuit becomes discontinuous. For designs using

the TPS5430, K

with the proper output capacitor, the peak switch current will be well below the current limit set point and

relatively low load currents can be sourced before discontinuous operation.

For this design example use K

highest standard value is 15 µ H, which is used in this design.

For the output filter inductor it is important that the RMS current and saturation current ratings not be exceeded.

The RMS inductor current can be found from Equation 5 :

of 0.2 to 0.3 yields good results. Low output ripple voltages can be obtained when paired

IND

= 0.2 and the minimum inductor value is calculated to be 12.5 µ H. The next

IND

(4)

and the peak inductor current can be determined with Equation 6 :

For this design, the RMS inductor current is 3.003 A, and the peak inductor current is 3.31 A. The chosen

inductor is a Sumida CDRH104R-150 15 µ H. It has a saturation current rating of 3.4 A and a RMS current rating

of 3.6 A, easily meeting these requirements. A lesser rated inductor could be used, however this device was

chosen because of its low profile component height. In general, inductor values for use with the TPS5430 are in

the range of 10 µ H to 100 µ H.

Capacitor Selection

The important design factors for the output capacitor are dc voltage rating, ripple current rating, and equivalent

series resistance (ESR). The dc voltage and ripple current ratings cannot be exceeded. The ESR is important

because along with the inductor ripple current it determines the amount of output ripple voltage. The actual value

of the output capacitor is not critical, but some practical limits do exist. Consider the relationship between the

desired closed loop crossover frequency of the design and LC corner frequency of the output filter. Due to the

design of the internal compensation, it is desirable to keep the closed loop crossover frequency in the range 3

kHz to 30 kHz as this frequency range has adequate phase boost to allow for stable operation. For this design

example, it is assumed that the intended closed loop crossover frequency will be between 2590 Hz and 24 kHz

and also below the ESR zero of the output capacitor. Under these conditions the closed loop crossover

frequency is related to the LC corner frequency by:

(5)

(6)

(7)

And the desired output capacitor value for the output filter to:

Submit Documentation Feedback

13

Page 14

www.ti.com

C

OUT

+

1

3357 L

OUT

fCO V

OUT

ESR

MAX

+

1

2p C

OUT

f

CO

V (MAX)=

PP

()

ESR xV xV -V

MAX OUT IN(MAX) OUT

N xV xL

C IN(MAX) OUT

xF

SW

I

COUT(RMS)

+

1

12

Ǹ

ȧ

ȡ

Ȣ

V

OUT

ǒ

V

IN(MAX)

* V

OUT

Ǔ

V

IN(MAX)

L

OUT

FSW N

C

ȧ

ȣ

Ȥ

R2 +

R1 1.221

V

OUT

* 1.221

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

For a desired crossover of 18 kHz and a 15- µ H inductor, the calculated value for the output capacitor is 220 µ F.

The capacitor type should be chosen so that the ESR zero is above the loop crossover. The maximum ESR

should be:

The maximum ESR of the output capacitor also determines the amount of output ripple as specified in the initial

design parameters. The output ripple voltage is the inductor ripple current times the ESR of the output filter.

Check that the maximum specified ESR as listed in the capacitor data sheet results in an acceptable output

ripple voltage:

Where:

∆ V

is the desired peak-to-peak output ripple.

PP

N

is the number of parallel output capacitors.

C

F

is the switching frequency.

SW

For this design example, a single 220- µ F output capacitor is chosen for C3. The calculated RMS ripple current is

143 mA and the maximum ESR required is 40 m Ω . A capacitor that meets these requirements is a Sanyo

Poscap 10TPB220M, rated at 10 V with a maximum ESR of 40 m Ω and a ripple current rating of 3 A. An

additional small 0.1- µ F ceramic bypass capacitor may also used, but is not included in this design.

The minimum ESR of the output capacitor should also be considered. For good phase margin, the ESR zero

when the ESR is at a minimum should not be too far above the internal compensation poles at 24 kHz and 54

kHz.

The selected output capacitor must also be rated for a voltage greater than the desired output voltage plus one

half the ripple voltage. Any derating amount must also be included. The maximum RMS ripple current in the

output capacitor is given by Equation 11 :

(8)

(9)

(10)

Where:

N

is the number of output capacitors in parallel.

C

F

is the switching frequency.

SW

Other capacitor types can be used with the TPS5430, depending on the needs of the application.

Output Voltage Setpoint

The output voltage of the TPS5430 is set by a resistor divider (R1 and R2) from the output to the VSENSE pin.

Calculate the R2 resistor value for the output voltage of 5 V using Equation 12 :

For any TPS5430 design, start with an R1 value of 10 k Ω . R2 is then 3.24 k Ω .

Boot Capacitor

The boot capacitor should be 0.01 µ F.

14

Submit Documentation Feedback

(11)

(12)

Page 15

www.ti.com

+

10-35V

VIN

C1

4.7 Fm

C4

4.7 Fm

ENA

VIN

ENA

NC

NC

GND

PwPd

BOOT

PH

VSNS

U1

TPS5430DDA

C2

0.01 Fm

L1

22 Hm

D1

B340A

C3

220 Fm

R2

3.24kW

5V

VOUT

R1

10kW

C3=SanyoPOSCAP 10TP220M

+

9-21V

VIN

C1

ENA

VIN

ENA

NC

NC

GND

PwPd

BOOT

PH

VSNS

U1

TPS5431DDA

C2

0.01 Fm

L1

18 Hm

D1

B340A

C3

220 Fm

R2

3.24kW

5V

VOUT

R1

10kW

C3=SanyoPOSCAP 10TP220M

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

Catch Diode

The TPS5430 is designed to operate using an external catch diode between PH and GND. The selected diode

must meet the absolute maximum ratings for the application: Reverse voltage must be higher than the maximum

voltage at the PH pin, which is VINMAX + 0.5 V. Peak current must be greater than IOUTMAX plus on half the

peak to peak inductor current. Forward voltage drop should be small for higher efficiencies. It is important to

note that the catch diode conduction time is typically longer than the high-side FET on time, so attention paid to

diode parameters can make a marked improvement in overall efficiency. Additionally, check that the device

chosen is capable of dissipating the power losses. For this design, a Diodes, Inc. B340A is chosen, with a

reverse voltage of 40 V, forward current of 3 A, and a forward voltage drop of 0.5 V.

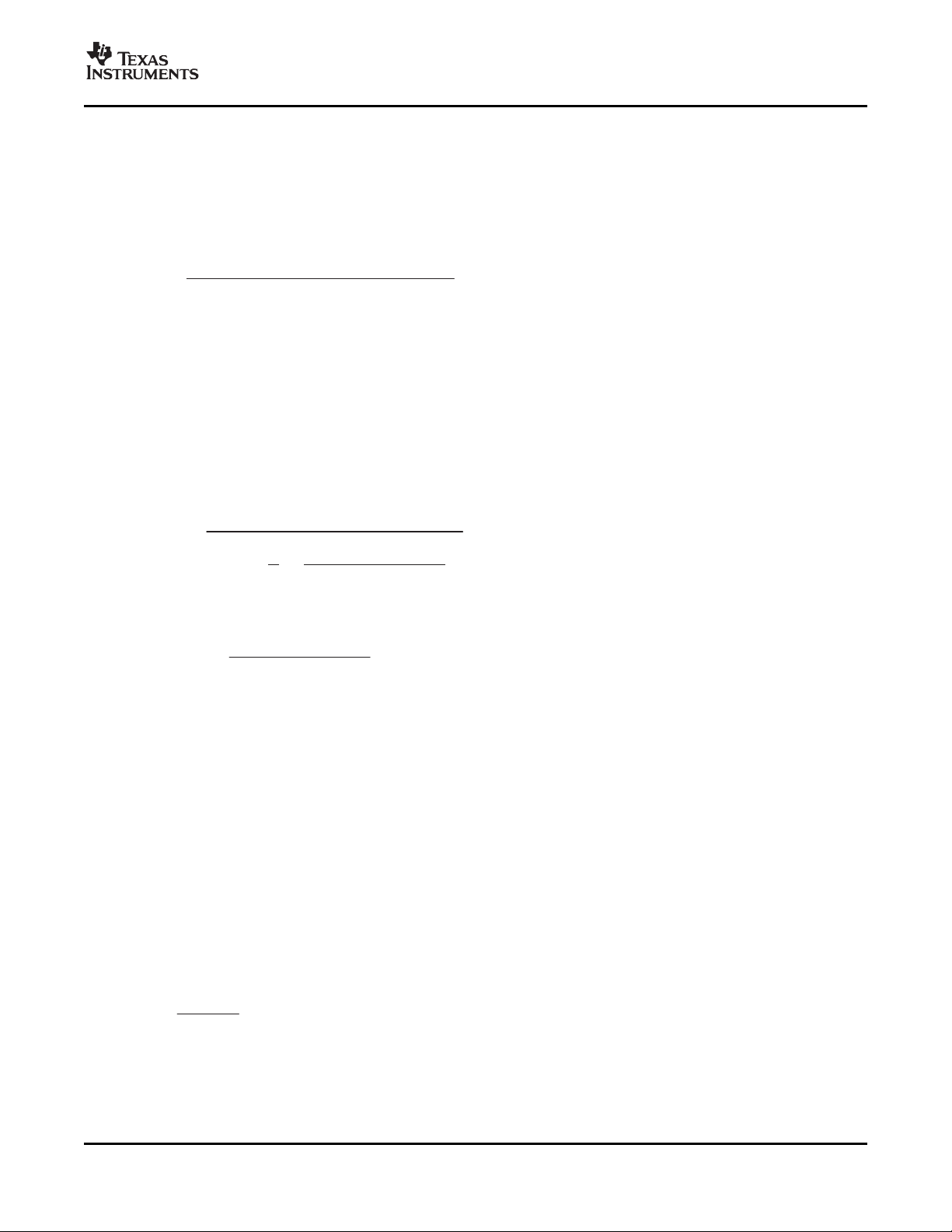

Additional Circuits

Figure 12 and Figure 13 show application circuits using wide input voltage ranges. The design parameters are

similar to those given for the design example, with a larger value output inductor and a lower closed loop

crossover frequency.

Figure 12. 10–35 V Input to 5 V Output Application Circuit

Figure 13. 9–21 V Input to 5 V Output Application Circuit

Circuit Using Ceramic Output Filter Capacitors

Figure 14 shows an application circuit using all ceramic capacitors for the input and output filters which

generates a 3.3-V output from a 10-V to 24-V input. The design procedure is similar to those given for the

design example, except for the selection of the output filter capacitor values and the design of the additional

compensation components required to stabilize the circuit.

Submit Documentation Feedback

15

Page 16

www.ti.com

VIN10 24V-

C1

4.7 Fm

L1

15 Hm

R1

10kW

R2

5.9kW

R3

549 W

C6

1500pF

U1

TPS5430DDA

VIN

GND

VSNS

PH

BOOT

PwPd

EN

3.3V

VOUT

C2

0.01 Fm

D1

MRBS340

C3

100 Fm

C7

0.1 Fm

C4

150pF

VIN

7

1

2

4

5

8

3

6

9

ENA

NC

NC

C (MIN)

O

³

1

2

(2 x7000)xLp

O

F =

LC

1

2 Lp

O O

xC (EFF)Ö

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

Figure 14. Ceramic Output Filter Capacitors Circuit

Output Filter Component Selection

Using Equation 11 , the minimum inductor value is 12 µ H. A value of 15 µ H is chosen for this design.

When using ceramic output filer capacitors, the recommended LC resonant frequency should be no more than

7 kHz. Since the output inductor is already selected at 15 µ H, this limits the minimum output capacitor value to:

The minimum capacitor value is calculated to be 34 µ F. For this circuit a larger value of capacitor yields better

transient response. A single 100- µ F output capacitor is used for C3. It is important to note that the actual

capacitance of ceramic capacitors decreases with applied voltage. In this example, the output voltage is set to

3.3 V, minimizing this effect.

External Compensation Network

When using ceramic output capacitors, additional circuitry is required to stabilize the closed loop system. For

this circuit, the external components are R3, C4, C6, and C7. To determine the value of these components, first

calculate the LC resonant frequency of the output filter:

For this example the effective resonant frequency is calculated as 4109 Hz

The network composed of R1, R2, R3, C5, C6, and C7 has two poles and two zeros that are used to tailor the

overall response of the feedback network to accommodate the use of the ceramic output capacitors. The pole

and zero locations are given by the following equations:

16

Submit Documentation Feedback

(13)

(14)

Page 17

www.ti.com

Fp1=500000x

V

O

F

LC

Fz1=0.7xF

LC

Fz2=2.5xF

LC

C7=

1

2 xFp1x(R1||R2)p

R3=

1

2 xFz1xC7p

C6=

1

2 xFz2xR1p

V

OUTMAX

+ 0.87 ǒǒV

INMIN

* I

OMAX

0.230Ǔ) V

D

Ǔ

*

ǒ

I

OMAX

R

L

Ǔ

* V

D

V

OUTMIN

+ 0.12 ǒǒV

INMAX

* I

OMIN

0.110Ǔ) V

D

Ǔ

*

ǒ

I

OMIN

R

L

Ǔ

* V

D

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

The final pole is located at a frequency too high to be of concern. The second zero, Fz2 as defined by

Equation 17 uses 2.5 for the frequency multiplier. In some cases this may need to be slightly higher or lower.

Values in the range of 2.3 to 2.7 work well. The values for R1 and R2 are fixed by the 3.3-V output voltage as

calculated usingEquation 12 . For this design R1 = 10 k Ω and R2 = 5.90 k Ω . With Fp1 = 401 Hz, Fz1 = 2876 Hz

and Fz2 = 10.3 kHz, the values of R3, C6 and C7 are determined using Equation 18 , Equation 19 , and

Equation 20 :

For this design, using the closest standard values, C7 is 0.1 µ F, R3 is 549 Ω , and C6 is 1500 pF. C4 is added to

improve load regulation performance. It is effectively in parallel with C6 in the location of the second pole

frequency, so it should be small in relationship to C6. C4 should be less the 1/10 the value of C6. For this

example, 150 pF works well.

For additional information on external compensation of the TPS5430, TPS5431 or other wide voltage range

SWIFT devices, see SLVA237 Using TPS5410/20/30/31 With Aluminum/Ceramic Output Capacitors

(15)

(16)

(17)

(18)

(19)

(20)

ADVANCED INFORMATION

Output Voltage Limitations

Due to the internal design of the TPS5430, there are both upper and lower output voltage limits for any given

input voltage. The upper limit of the output voltage set point is constrained by the maximum duty cycle of 87%

and is given by:

Where

V

= minimum input voltage

INMIN

I

= maximum load current

OMAX

V

= catch diode forward voltage.

D

RL= output inductor series resistance.

This equation assumes maximum on resistance for the internal high side FET.

The lower limit is constrained by the minimum controllable on time which may be as high as 200 ns. The

approximate minimum output voltage for a given input voltage and minimum load current is given by:

Where

V

I

V

RL= output inductor series resistance.

This equation assumes nominal on resistance for the high side FET and accounts for worst case variation of

operating frequency set point. Any design operating near the operational limits of the device should be

carefully checked to assure proper functionality.

= maximum input voltage

INMAX

= minimum load current

OMIN

= catch diode forward voltage.

D

(21)

(22)

Submit Documentation Feedback

17

Page 18

www.ti.com

H(s) +

ǒ

1 )

s

2p Fz1

Ǔ ǒ

1 )

s

2p Fz2

Ǔ

ǒ

s

2p Fp0

Ǔ ǒ

1 )

s

2p Fp1

Ǔ ǒ

1 )

s

2p Fp2

Ǔ ǒ

1 )

s

2p Fp3

Ǔ

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

Internal Compensation Network

The design equations given in the example circuit can be used to generate circuits using the

TPS5430/TPS5431. These designs are based on certain assumptions and will tend to always select output

capacitors within a limited range of ESR values. If a different capacitor type is desired, it may be possible to fit

one to the internal compensation of the TPS5430/TPS5431. Equation 23 gives the nominal frequency response

of the internal voltage-mode type III compensation network:

Where

Fp0 = 2165 Hz, Fz1 = 2170 Hz, Fz2 = 2590 Hz

Fp1 = 24 kHz, Fp2 = 54 kHz, Fp3 = 440 kHz

Fp3 represents the non-ideal parasitics effect.

Using this information along with the desired output voltage, feed forward gain and output filter characteristics,

the closed loop transfer function can be derived.

Thermal Calculations

The following formulas show how to estimate the device power dissipation under continuous conduction mode

operations. They should not be used if the device is working at light loads in the discontinuous conduction mode.

Conduction Loss: Pcon = I

Switching Loss: Psw = V

Quiescent Current Loss: Pq = V

Total Loss: Ptot = Pcon + Psw + Pq

Given TA=> Estimated Junction Temperature: TJ= TA+ Rth x Ptot

Given T

= 125 ° C => Estimated Maximum Ambient Temperature: T

JMAX

2

x Rds(on) x V

OUT

x I

IN

x 0.01

OUT

x 0.01

IN

/V

OUT

IN

= T

AMAX

– Rth x Ptot

JMAX

(23)

18

Submit Documentation Feedback

Page 19

www.ti.com

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0 0.5 1 1.5

2

2.5 3

I -OutputCurrent- A

O

OutputRegulation-%

75

80

85

90

95

100

0 0.5 1 1.5 2 2.5 3 3.5

I -OutputCurrent- A

O

Efficiency-%

V =15V

I

V =10.8V

I

V =12V

I

V =18V

I

V =19.8V

I

t-Time-500ns/Div

PH=5V/Div

V =100mV/Div(ACCoupled)

IN

-0.1

-0.08

-0.06

-0.04

-0.02

0

0.02

0.04

0.06

0.08

0.1

10.8 13.8 16.8 19.8

V -InputVoltage-V

I

InputRegulation-%

I =0 A

O

I =3 A

O

I =1.5 A

O

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

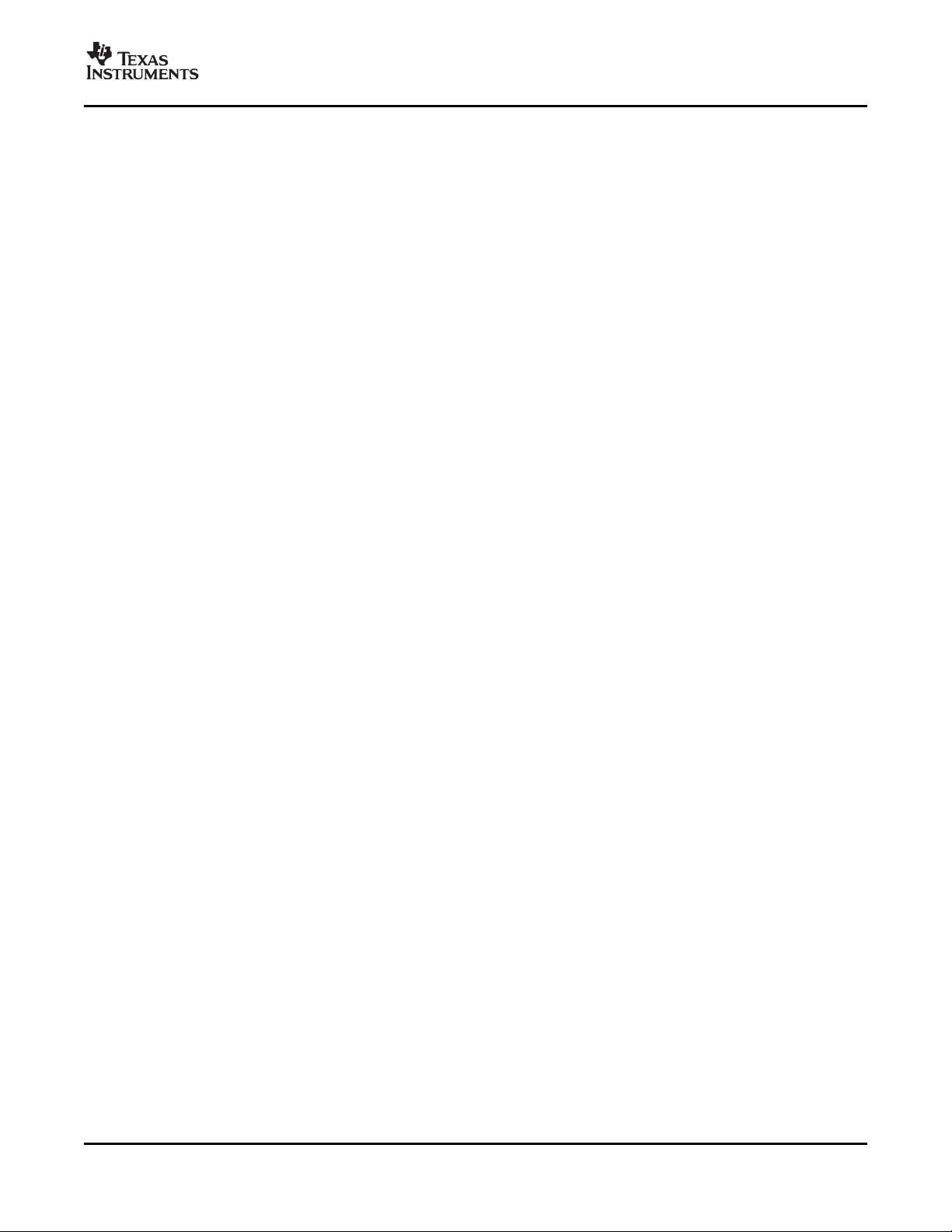

PERFORMANCE GRAPHS

The performance graphs (Figure 15 through Figure 21 ) are applicable to the circuit in Figure 11 . Ta = 25 ° C.

unless otherwise specified.

Figure 15. Efficiency vs. Output Current Figure 16. Output Regulation % vs. Output Current

Figure 17. Input Regulation % vs. Input Voltage Figure 18. Input Voltage Ripple and PH Node, Io = 3 A.

Submit Documentation Feedback

19

Page 20

www.ti.com

t-Time=500ns/Div

PH=5V/Div

V =20mV/Div(ACCoupled)

OUT

t-Time=200 μs/Div

I =1 A /Div

OUT

V =50mV/Div(ACCoupled)

OUT

t-Time=2ms/Div

V =2V/Div

OUT

V =5V/Div

IN

TPS5430

TPS5431

SLVS632C – JANUARY 2006 – REVISED NOVEMBER 2006

Figure 19. Output Voltage Ripple and PH Node, Io = 3 A Figure 20. Transient Response, Io Step 0.75 to 2.25 A.

20

Figure 21. Startup Waveform, Vin and Vout.

Submit Documentation Feedback

Page 21

PACKAGE OPTION ADDENDUM

www.ti.com

31-Oct-2008

PACKAGING INFORMATION

Orderable Device Status

TPS5430DDA ACTIVE SO

(1)

Package

Type

Power

Package

Drawing

Pins Package

Qty

Eco Plan

DDA 8 100 Green (RoHS &

no Sb/Br)

PAD

TPS5430DDAG4 ACTIVE SO

Power

DDA 8 100 Green (RoHS &

no Sb/Br)

PAD

TPS5430DDAR ACTIVE SO

Power

DDA 8 2500 Green (RoHS &

no Sb/Br)

PAD

TPS5430DDARG4 ACTIVE SO

Power

DDA 8 2500 Green (RoHS &

no Sb/Br)

PAD

TPS5431DDA ACTIVE SO

Power

DDA 8 100 Green (RoHS &

no Sb/Br)

PAD

TPS5431DDAG4 ACTIVE SO

Power

DDA 8 100 Green (RoHS &

no Sb/Br)

PAD

TPS5431DDAR ACTIVE SO

Power

DDA 8 2500 Green (RoHS &

no Sb/Br)

PAD

TPS5431DDARG4 ACTIVE SO

Power

DDA 8 2500 Green (RoHS &

no Sb/Br)

PAD

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

Addendum-Page 1

Page 22

PACKAGE OPTION ADDENDUM

www.ti.com

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

OTHER QUALIFIED VERSIONS OF TPS5430 :

Automotive: TPS5430-Q1

•

NOTE: Qualified Version Definitions:

Automotive - Q100 devices qualified for high-reliability automotive applications targeting zero defects

•

31-Oct-2008

Addendum-Page 2

Page 23

PACKAGE MATERIALS INFORMATION

www.ti.com

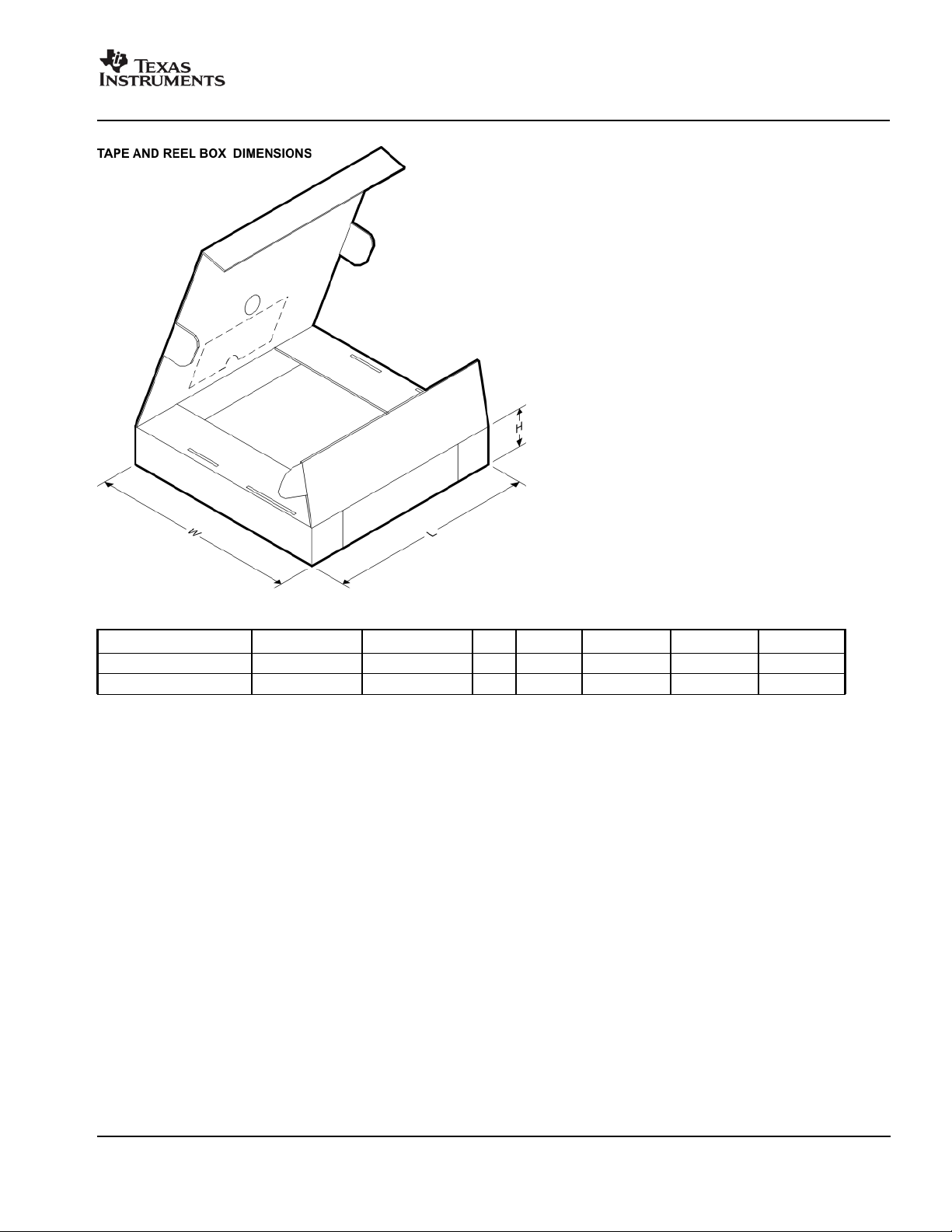

TAPE AND REEL INFORMATION

31-Oct-2008

*All dimensions are nominal

Device Package

TPS5430DDAR SO

TPS5431DDAR SO

Type

Power

PAD

Power

PAD

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

DDA 8 2500 330.0 12.4 6.4 5.2 2.1 8.0 12.0 Q1

DDA 8 2500 330.0 12.4 6.4 5.2 2.1 8.0 12.0 Q1

Reel

Width

W1 (mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 24

PACKAGE MATERIALS INFORMATION

www.ti.com

31-Oct-2008

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TPS5430DDAR SO PowerPAD DDA 8 2500 346.0 346.0 29.0

TPS5431DDAR SO PowerPAD DDA 8 2500 346.0 346.0 29.0

Pack Materials-Page 2

Page 25

Page 26

Page 27

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Clocks and Timers www.ti.com/clocks Digital Control www.ti.com/digitalcontrol

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

RF/IF and ZigBee® Solutions www.ti.com/lprf Video & Imaging www.ti.com/video

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2008, Texas Instruments Incorporated

Wireless www.ti.com/wireless

Loading...

Loading...