查询TPS2834供应商

TPS2834, TPS2835

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

D

Floating Bootstrap or Ground-Reference

High-Side Driver

D

Active Deadtime Control

D

50-ns Max Rise/Fall Times With 3.3-nF Load

D

2-A Min Peak Output Current

D

4.5-V to 15-V Supply Voltage Range

D

TTL-Compatible Inputs

D

Internal Schottky Bootstrap Diode

D

SYNC Control for Synchronous or

Nonsynchronous Operation

D

CROWBAR for OVP, Protects Against

ENABLE

CROWBAR

SYNC

PGND

NC – No internal connection

D OR PWP PACKAGE

1

IN

NC

DT

2

3

4

5

6

7

(TOP VIEW)

14

13

12

11

10

9

8

BOOT

NC

HIGHDR

BOOTLO

LOWDR

NC

V

CC

Faulted High-Side Power FETs

D

Low Supply Current ...3 mA Typ

D

Ideal for High-Current Single- or Multiphase

Applications

D

–40°C to 125°C Junction-Temperature

Operating Range

description

The TPS2834 and TPS2835 are MOSFET drivers for synchronous-buck power stages. These devices are ideal

for designing a high-performance power supply using a switching controller that does not include suitable

on-chip MOSFET drivers. The drivers are designed to deliver minimum 2-A peak currents into large capacitive

loads. The high-side driver can be configured as ground-reference or as floating-bootstrap. An adaptive

dead-time control circuit eliminates shoot-through currents through the main power FETs during switching

transitions, and provides high efficiency for the buck regulator. The TPS2834 and TPS2835 have additional

control functions: ENABLE, SYNC, and CROWBAR. Both high-side and low-side drivers are off when ENABLE

is low. The low-side driver is configured as a nonsynchronous-buck driver when SYNC is low . The CROWBAR

function turns on the low-side power FET, overriding the IN signal, for overvoltage protection against faulted

high-side power FETs.

The TPS2834 has a noninverting input, while the TPS2835 has an inverting input. These drivers are available

in 14-terminal SOIC and TSSOP packages and operate over a junction temperature range of –40°C to 125°C.

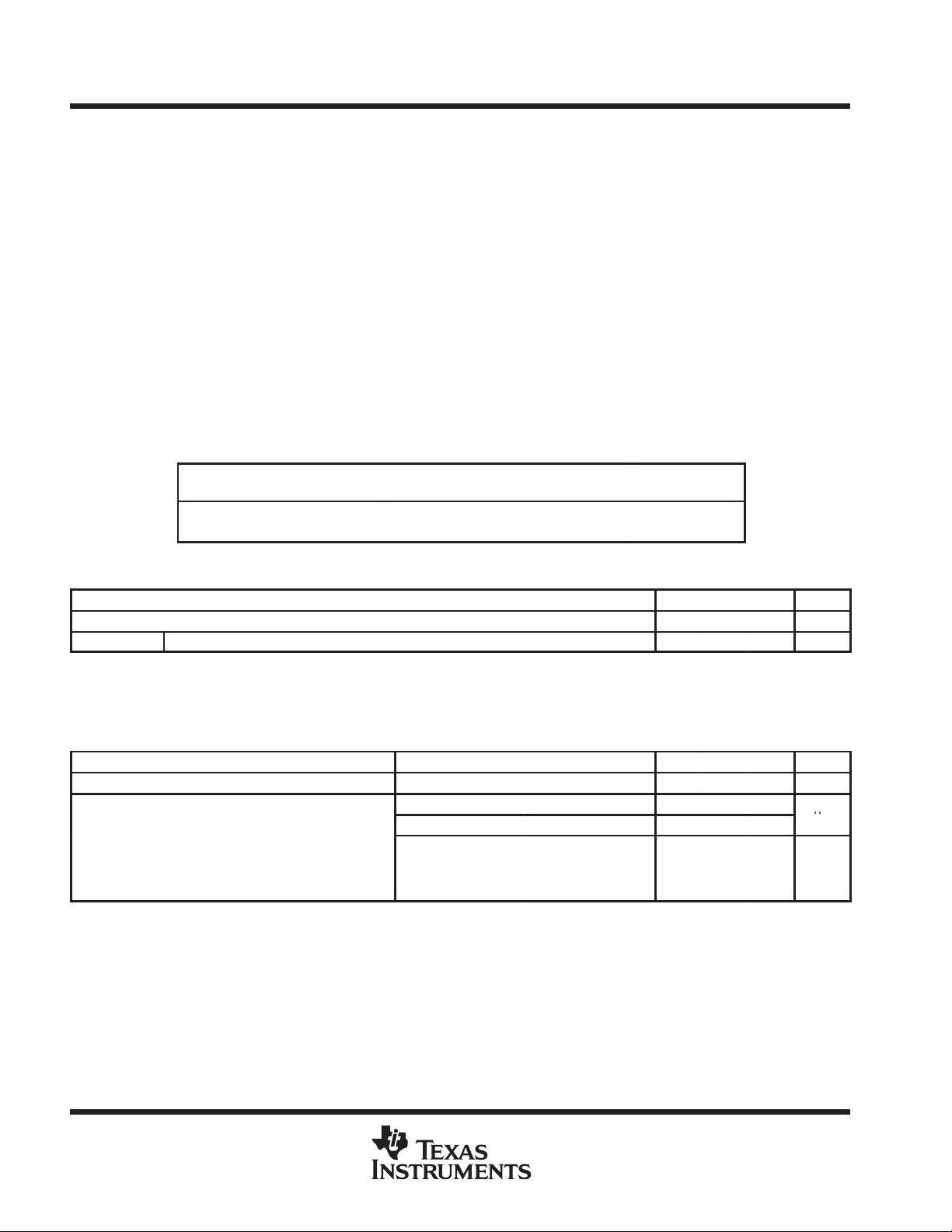

AVAILABLE OPTIONS

PACKAGED DEVICES

–40°C to 125°C

The D and PWP packages are available taped and reeled. Add R

suffix to device type (e.g., TPS2834DR)

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

T

J

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

SOIC

(D)

TPS2834D

TPS2835D

TSSOP

(PWP)

TPS2834PWP

TPS2835PWP

Copyright 1999, Texas Instruments Incorporated

1

TPS2834, TPS2835

I/O

DESCRIPTION

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

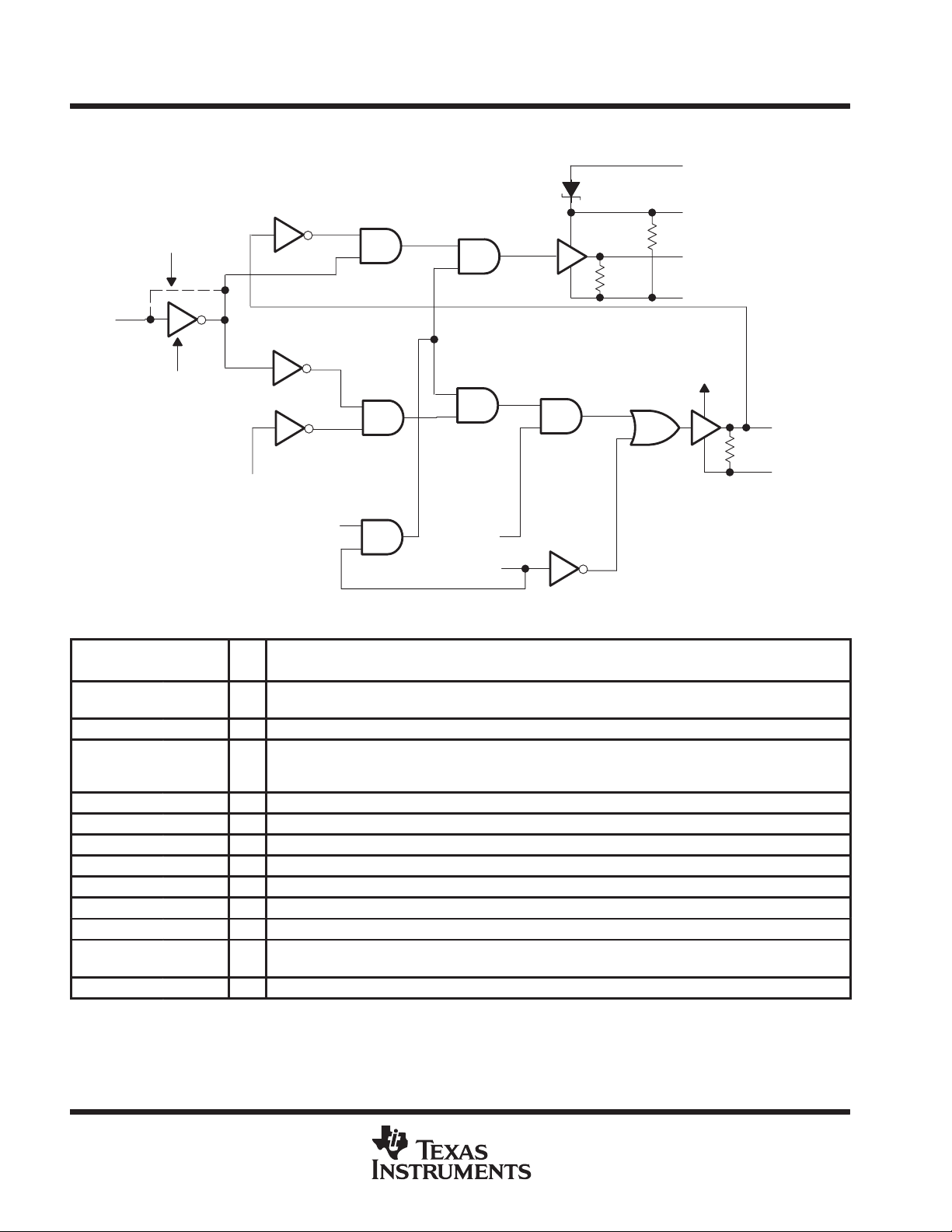

functional block diagram

(TPS2834 Only)

2

IN

(TPS2835 Only)

6

DT

200 kΩ

200 kΩ

8

14

12

11

V

CC

BOOT

HIGHDR

BOOTLO

V

CC

10

200 kΩ

7

LOWDR

PGND

ENABLE

1

SYNC

CROWBAR

5

3

Terminal Functions

TERMINAL

NAME NO.

BOOT 14 I Bootstrap terminal. A ceramic capacitor is connected between BOOT and BOOTLO to develop the floating

BOOTLO 11 O This terminal connects to the junction of the high-side and low-side MOSFETs.

CROWBAR 3 I CROWBAR can to be driven by an external OVP circuit to protect against a short across the high-side

DT 6 I Deadtime control terminal. Connect DT to the junction of the high-side and low-side MOSFETs.

ENABLE 1 I If ENABLE is low, both drivers are off.

HIGHDR 12 O Output drive for the high-side power MOSFET

IN 2 I Input signal to the MOSFET drivers (noninverting input for the TPS2834; inverting input for the TPS2835).

LOWDR 10 O Output drive for the low-side power MOSFET

NC 4, 9, 13

PGND 7 Power ground. Connect to the FET power ground

SYNC 5 I Synchronous rectifier enable terminal. If SYNC is low, the low-side driver is always off; If SYNC is high, the

V

CC

8 I Input supply. Recommended that a 1-µF capacitor be connected from VCC to PGND.

bootstrap voltage for the high-side MOSFET. The capacitor value is typically between 0.1 µF and 1 µF.

MOSFET. If CROWBAR is driven low, the low-side driver will be turned on and the high-side driver will be

turned off, independent of the status of all other control terminals.

low-side driver provides gate drive to the low-side MOSFET.

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

detailed description

low-side driver

TPS2834, TPS2835

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

The low-side driver is designed to drive low r

source and sink.

high-side driver

The high-side driver is designed to drive low r

source and sink. The high-side driver can be configured as a GND-reference driver or as a floating bootstrap

driver. The internal bootstrap diode is a Schottky, for improved drive ef ficiency. The maximum voltage that can

be applied from BOOT to ground is 30 V.

dead-time (DT) control

Dead-time control prevents shoot-through current from flowing through the main power FETs during switching

transitions by controlling the turnon times of the MOSFET drivers. The high-side driver is not allowed to turn

on until the gate drive voltage to the low-side FET is low, and the low-side driver is not allowed to turn on until

the voltage at the junction of the power FETs (Vdrn) is low; the TTL-compatible DT terminal connects to the

junction of the power FETs.

ENABLE

The ENABLE terminal enables the drivers. When enable is low, the output drivers are low. ENABLE is a

TTL-compatible digital terminal.

IN

The IN terminal is a TTL-compatible digital terminal that is the input control signal for the drivers. The TPS2834

has a noninverting input; the TPS2835 has an inverting input.

SYNC

N-channel MOSFET s. The current rating of the driver is 2 A,

DS(on)

N-channel MOSFET s. The current rating of the driver is 2 A,

DS(on)

The SYNC terminal controls whether the drivers operate in synchronous or nonsynchronous mode. In

synchronous mode, the low-side FET is operated as a synchronous rectifier. In nonsynchronous mode, the

low-side FET is always off. SYNC is a TTL-compatible digital terminal.

CROWBAR

The CROWBAR terminal overrides the normal operation of the driver. When CROWBAR is low, the low-side

FET turns on to act as a clamp, protecting the output voltage of the dc/dc converter against overvoltages due

to a short across the high-side FET. VIN should be fused to protect the low-side FET. CROWBAR is a

TTL-compatible digital terminal.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

TPS2834, TPS2835

A

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

Supply voltage range, V

(see Note 1) –0.3 V to 16 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC

†

Input voltage range:BOOT to PGND (high-side driver ON) –0.3 V to 30 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BOOTLO to PGND –0.3 V to 16 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BOOT to BOOTLO –0.3 V to 16 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENABLE, SYNC, and CROWBAR (see Note 2) –0.3 V to 16 V. . . . . . . . . . . . . . . . . . . . .

IN –0.3 V to 16 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DT –0.3 V to 30 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating virtual junction temperature range, T

Storage temperature range, T

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

–40°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J

Lead temperature soldering 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. Unless otherwise specified, all voltages are with respect to PGND.

DISSIPATION RATING TABLE

PACKAGE

D 760 mW 7.6 mW/°C 420 mW 305 mW

PWP 2400 mW 25 mW/°C 1275 mW 900 mW

TA ≤ 25°C

POWER RATING

DERATING FACTOR

ABOVE TA = 25°C

TA = 70°C

POWER RATING

TA = 85°C

POWER RATING

recommended operating conditions

MIN NOM MAX UNIT

Supply voltage, V

Input voltage BOOT to PGND 4.5 28 V

CC

4.5 15 V

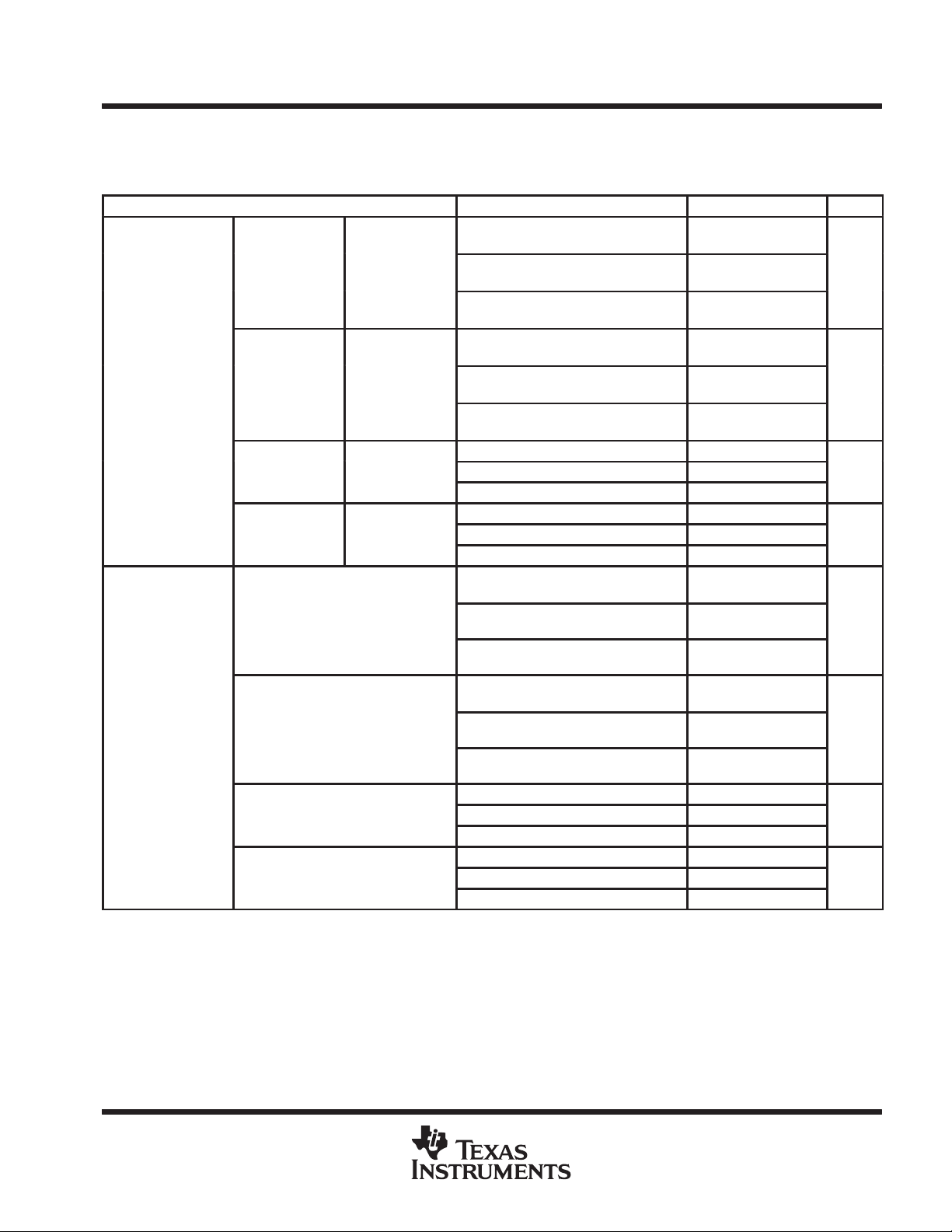

electrical characteristics over recommended operating virtual junction temperature range,

= 6.5 V, ENABLE = High, CL = 3.3 nF (unless otherwise noted)

V

CC

supply current

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

CC

V

CC

NOTE 2: Ensured by design, not production tested.

Supply voltage range 4.5 15 V

Quiescent current

V

(ENABLE)

V

(ENABLE)

V

(ENABLE)

f

(SWX)

C

(HIGHDR)

See Note 2

= LOW, VCC =15 V 100

= HIGH, VCC =15 V 300 400

= HIGH,

= 200 kHz,

= 50 pF,

VCC =12 V,

BOOTLO grounded,

C

(LOWDR)

= 50 pF,

3 mA

µ

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

(see Note 2)

(see Note 2)

Duty cycle < 2%

(see Note 3)

Duty cycle < 2%

(see Note 3)

TPS2834, TPS2835

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

electrical characteristics over recommended operating virtual junction temperature range,

= 6.5 V, ENABLE = High, CL = 3.3 nF (unless otherwise noted) (continued)

V

CC

output drivers

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-side sink

(see Note 3)

Peak output current

Output resistance

NOTES: 2: Ensured by design, not production tested.

3. The pullup/pulldown circuits of the drivers are bipolar and MOSFET transistors in parallel. The peak output current rating is the

combined current from the bipolar and MOSFET transistors. The output resistance is the r

the voltage on the driver output is less than the saturation voltage of the bipolar transistor.

High-side source

(see Note 3)

Low-side sink

Low-side source

High-side sink (see Note 3)

High-side source (see Note 3)

Low-side sink (see Note 3)

Low-side source (see Note 3)

Duty cycle < 2%,

tpw < 100 µs

Duty cycle < 2%,

tpw < 100 µs

tpw < 100 µs

(see Note 2)

tpw < 100 µs

(see Note 2)

V

V

V

V

V

V

V

V

V

V

V

V

VCC = 4.5 V, V

,

VCC = 6.5 V, V

VCC = 12 V, V

VCC = 4.5 V, V

,

VCC = 6.5 V, V

VCC = 12 V, V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

– V

(BOOT)

(HIGHDR)

– V

(BOOT)

(HIGHDR)

– V

(BOOT)

(HIGHDR)

– V

(BOOT)

(HIGHDR)

– V

(BOOT)

(HIGHDR)

– V

(BOOT)

(HIGHDR)

– V

(BOOT)

(HIGHDR)

– V

(BOOT)

(HIGHDR)

– V

(BOOT)

(HIGHDR)

– V

(BOOT)

(HIGHDR)

– V

(BOOT)

(HIGHDR)

– V

(BOOT)

(HIGHDR)

= 4.5 V, V

(DRV)

= 6.5 V, V

(DRV)

= 12 V, V

(DRV)

= 4.5 V, V

(DRV)

= 6.5 V, V

(DRV)

= 12 V, V

(DRV)

(BOOTLO)

= 4 V

(BOOTLO)

= 5 V

(BOOTLO)

= 10.5 V

(BOOTLO)

= 0.5V

(BOOTLO)

= 1.5 V

(BOOTLO)

= 1.5 V

(LOWDR)

(LOWDR)

(LOWDR)

LOWDR))

(LOWDR))

(LOWDR0)

(BOOTLO)

= 0.5 V

(BOOTLO)

= 0.5 V

(BOOTLO)

= 0.5 V

(BOOTLO)

= 4 V

(BOOTLO)

= 6 V

(BOOTLO)

=11.5 V

(LOWDR)

(LOWDR)

(LOWDR)

(LOWDR)

(LOWDR

(LOWDR)

= 4.5 V,

= 6.5 V,

= 12 V,

= 4.5 V,

= 6.5 V,

= 12 V,

= 4 V 1.3 1.8

= 5 V 2 2.5

= 10.5 V 3 3.5

= 0.5V 1.4 1.7

= 1.5 V 2 2.4

= 1.5 V 2.5 3

= 4.5 V,

= 6.5 V,

= 12 V,

= 4.5 V,

= 6.5 V,

= 12 V,

= 0.5 V 9

= 0.5 V 7.5

= 0.5 V 6

= 4 V 75

)= 6 V 75

= 11.5 V 75

0.7 1.1

1.1 1.5

2 2.4

1.2 1.4

1.3 1.6

2.3 2.7

of the MOSFET transistor when

DS(on)

5

5

5

75

75

75

A

A

A

A

Ω

Ω

Ω

Ω

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

TPS2834, TPS2835

LOWDR

Over the V

range (see Note 2)

V

DT

Over the V

range

Over the V

range

Rise time

Fall time

deadtime) (see Note 2)

Propagation delay time

deadtime) (see Note 2)

deadtime) (see Note 2)

HIGHDR (see Note 2)

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

electrical characteristics over recommended operating virtual junction temperature range,

= 6.5 V, ENABLE = High, CL = 3.3 nF (unless otherwise noted) (continued)

V

CC

deadtime control

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-level input voltage, V

Low-level input voltage, V

High-level input voltage, V

Low-level input voltage, V

NOTE 2: Ensured by design, not production tested.

IH

IL

IH

IL

CC

CC

digital control terminals (IN, CROWBAR, SYNC, ENABLE)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-level input voltage, V

Low-level input voltage, V

IH

IL

CC

switching characteristics over recommended operating virtual junction temperature range,

ENABLE = High, C

p

Propagation delay time

Driver nonoverlap time

NOTE 2: Ensured by design, not production tested.

= 3.3 nF (unless otherwise noted)

L

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

HIGHDR output (see Note 2)

LOWDR output (see Note 2)

HIGHDR output (see Note 2)

LOWDR output (see Note 2)

HIGHDR going low (excluding

LOWDR going high (excluding

LOWDR going low (excluding

DT to LOWDR and LOWDR to

V

V

V

VCC = 4.5 V 40

VCC = 6.5 V 30

VCC = 12 V 30

V

V

V

VCC = 4.5 V 40

VCC = 6.5 V 30

VCC = 12 V 30

V

V

V

V

V

V

VCC = 4.5 V 80

VCC = 6.5 V 70

VCC = 12 V 60

VCC = 4.5 V 40 170

VCC = 6.5 V 25 135

VCC = 12 V 15 85

(BOOT)

(BOOT)

(BOOT)

(BOOT)

(BOOT)

(BOOT)

(BOOT)

(BOOT)

(BOOT)

(BOOT)

(BOOT)

(BOOT)

= 4.5 V, V

= 6.5 V, V

= 12 V, V

= 4.5 V, V

= 6.5 V, V

= 12 V, V

= 4.5 V, V

= 6.5 V, V

= 12 V, V

= 4.5 V, V

= 6.5 V, V

= 12 V, V

(BOOTLO)

(BOOTLO)

(BOOTLO)

(BOOTLO)

(BOOTLO)

(BOOTLO)

(BOOTLO)

(BOOTLO)

(BOOTLO)

(BOOTLO)

(BOOTLO)

(BOOTLO)

= 0 V 60

= 0 V 50

= 0 V 50

= 0 V 50

= 0 V 40

= 0 V 40

= 0 V 95

= 0 V 80

= 0 V 70

= 0 V 80

= 0 V 70

= 0 V 60

0.7V

CC

0.7V

CC

2 V

1

V

1 V

1 V

ns

ns

ns

ns

ns

ns

ns

ns

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS2834, TPS2835

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

TYPICAL CHARACTERISTICS

50

45

40

35

30

– Rise Time – ns

25

r

t

20

15

10

50

45

RISE TIME

vs

SUPPLY VOLTAGE

CL = 3.3 nF

TJ = 25 °C

High Side

Low Side

5791112

46 810

VCC – Supply Voltage – V

Figure 1

RISE TIME

vs

JUNCTION TEMPERATURE

VCC = 6.5 V

CL = 3.3 nF

13

FALL TIME

vs

SUPPLY VOLTAGE

50

CL = 3.3 nF

45

40

35

30

– Fall Time – ns

f

25

t

20

15

1514

10

46 810

5791112

High Side

Low Side

VCC – Supply Voltage – V

TJ = 25 °C

13

1514

Figure 2

FALL TIME

vs

50

45

JUNCTION TEMPERATURE

VCC = 6.5 V

CL = 3.3 nF

40

35

30

25

– Rise Time – ns

r

t

20

15

10

High Side

Low Side

0 50 100

25 75–50 –25

TJ – Junction Temperature – °C

Figure 3

125

40

35

30

25

– Fall Time – ns

f

t

20

15

10

–50 –25

High Side

Low Side

25 75

0 50 100

TJ – Junction Temperature – °C

Figure 4

125

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

TPS2834, TPS2835

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

TYPICAL CHARACTERISTICS

150

140

130

120

110

100

90

80

70

60

50

40

– Low-to-High Propagation Delay Time – ns

30

PLH

t

20

150

140

130

120

110

100

90

80

70

60

50

40

– Low-to-High Propagation Delay Time – ns

30

PLH

t

20

LOW-TO-HIGH PROPAGATION DELAY TIME

vs

SUPPLY VOLTAGE, LOW TO HIGH LEVEL

CL = 3.3 nF

TJ = 25 °C

Low Side

5791112

46 810

VCC – Supply Voltage – V

13

Figure 5

LOW-TO-HIGH PROPAGATION DELAY TIME

vs

JUNCTION TEMPERATURE

VCC = 6.5 V

CL = 3.3 nF

High Side

Low Side

–25–50

TJ – Junction Temperature – °C

25 75

0 50 100

1514

125

HIGH-TO-LOW PROPAGATION DELAY TIME

vs

SUPPLY VOLTAGE, HIGH TO LOW LEVEL

150

140

130

120

110

100

90

80

70

60

50

40

– High-to-Low Propagation Delay Time – ns

30

PHL

t

20

46 810

5791112

VCC – Supply Voltage – V

High Side

Low Side

Figure 6

HIGH-TO-LOW PROPAGATION DELAY TIME

vs

150

140

130

120

110

100

90

80

70

60

50

40

– High-to-Low Propagation Delay Time – ns

30

PHL

t

20

JUNCTION TEMPERATURE

VCC = 6.5 V

CL = 3.3 nF

High Side

Low Side

–25–50

0 50 100

25 75

TJ – Junction Temperature – °C

CL = 3.3 nF

TJ = 25 °C

13

1514

125

Figure 7

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Figure 8

TPS2834, TPS2835

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

TYPICAL CHARACTERISTICS

DRIVER-OUTPUT RISE TIME

vs

LOAD CAPACITANCE

1000

VCC = 6.5 V

TJ = 25 °C

100

High Side

– Rise Time – ns

r

10

t

1

0.01 1 10 100

0.1

CL – Load Capacitance – nF

Low Side

Figure 9

SUPPLY CURRENT

vs

SUPPLY VOLTAGE

500 kHz

300 kHz

200 kHz

100 kHz

50 kHz

25 kHz

12

VCC – Supply Voltage – V

I Supply Current – –Aµ

CC

6000

5500

5000

4500

4000

3500

3000

2500

2000

1500

1000

500

TJ = 25 °C

CL = 50 pF

0

46 810

14

16

DRIVER-OUTPUT FALL TIME

vs

LOAD CAPACITANCE

1000

VCC = 6.5 V

TJ = 25 °C

100

High Side

– Fall Time – ns

f

10

t

1

0.01 1 10 100

0.1

CL – Load Capacitance – nF

Low Side

Figure 10

SUPPLY CURRENT

vs

SUPPLY VOLTAGE

2 MHz

1 MHz

12

VCC – Supply Voltage – V

CC

I Supply Current – mA–

25

TJ = 25 °C

CL = 50 pF

20

15

10

5

0

46 810 14

16

Figure 11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Figure 12

9

TPS2834, TPS2835

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

TYPICAL CHARACTERISTICS

PEAK SOURCE CURRENT

vs

DRIVE VOLTAGE

4

TJ = 25 °C

3.5

3

2.5

2

1.5

1

Peak Source Current – A

0.5

0

46 810

Low Side

High Side

12

VCC – Supply Voltage – V

14

16

4

TJ = 25 °C

3.5

3

2.5

2

1.5

Peak Sink Current – A

1

0.5

0

46 810

Figure 13

INPUT THRESHOLD VOLTAGE

vs

2.00

TJ = 25 °C

SUPPLY VOLTAGE

2.00

VCC = 6.5 V

PEAK SINK CURRENT

vs

DRIVE VOLTAGE

Low Side

High Side

12

VCC – Supply Voltage – V

Figure 14

INPUT THRESHOLD VOLTAGE

vs

JUNCTION TEMPERATURE

14

16

1.80

1.60

1.40

– Input Threshold Voltage – V

1.20

IT

V

1.00

4.00 6.00 8.00 10.00 12.00 14.00 16.00

VCC – Supply Voltage – V

Figure 15

1.80

1.60

1.40

– Input Threshold Voltage – V

1.20

IT

V

1.00

–50.00 –25.00 0.00 25.00 50.00 75.00 100.00 125.00

TJ – Junction Temperature – °C

Figure 16

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS2834, TPS2835

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

APPLICATION INFORMATION

Figure 17 shows the circuit schematic of a 100-kHz synchronous-buck converter implemented with a TL5001A

pulse-width-modulation (PWM) controller and a TPS2835 driver. The converter operates over an input range from

4.5 V to 12 V and has a 3.3-V output. The circuit can supply 3 A continuous load. The converter achieves an efficiency

of 94% for V

V

IN

IN

= 5 V, I

=1 A, and 93% for V

load

= 5 V, I

IN

load

= 3 A.

+

C10

100 µF

C5

100 µF

+

R1

1 kΩ

GND

C9

0.22 µF

1

ENABLE

2

IN

3

CROWBAR

4

NC

5

SYNC

6

DT

7

PGND

R8

121 kΩ

U1

TPS2835

BOOTLO

C14

1 µF

C1

1 µF

BOOT

NC

HIGHDR

LOWDR

NC

V

CC

C8

0.1 µF

1

OUT

6

DTC

5

SCP

V

CC

GND

14

13

12

11

10

9

8

2

COMP

8

U2

TL5001A

3

4

FB

7

RT

R9

90.9 kΩ

C15

1.0 µF

C2

0.033 µF

R6

1 MΩ

C3

0.0022 µF

R2

1.6 kΩ

R10

1.0 kΩ

R5

0 Ω

Q1

Si4410

R11

4.7 Ω

Q2

Si4410

C4

0.022 µFR3180 Ω

R4

2.32 kΩ

C11

0.47 µF

R7

3.3 Ω

C6

1000 pF

L1

27 µH

100 µF

C12

C7

100 µF

+

C13

10 µF

+

3.3 V

RTN

Figure 17. 3.3-V 3-A Synchronous-Buck Converter Circuit

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

TPS2834, TPS2835

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

APPLICATION INFORMATION

Great care should be taken when laying out the pc board. The power-processing section is the most critical and

will generate large amounts of EMI if not properly configured. The junction of Q1, Q2, and L1 should be very

tight. The connection from Q1 drain to the positive sides of C5, C10, and C1 1 and the connection from Q2 source

to the negative sides of C5, C10, and C11 should be as short as possible. The negative terminals of C7 and

C12 should also be connected to Q2 source.

Next, the traces from the MOSFET driver to the power switches should be considered. The BOOTLO signal from

the junction of Q1 and Q2 carries the large gate drive current pulses and should be as heavy as the gate drive

traces. The bypass capacitor (C14) should be tied directly across V

The next most sensitive node is the FB node on the controller (terminal 4 on the TL5001A). This node is very

sensitive to noise pick-up and should be isolated from the high-current power stage and be as short as possible.

The ground around the controller and low-level circuitry should be tied to the power ground as the output. If these

three areas are properly laid out, the rest of the circuit should not have other EMI problems and the power supply

will be relatively free of noise.

and PGND.

CC

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPS2834, TPS2835

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

MECHANICAL DATA

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PIN SHOWN

0.050 (1,27)

14

1

0.069 (1,75) MAX

A

0.020 (0,51)

0.014 (0,35)

0.010 (0,25)

0.004 (0,10)

DIM

8

7

PINS **

0.010 (0,25)

0.157 (4,00)

0.150 (3,81)

M

0.244 (6,20)

0.228 (5,80)

Seating Plane

0.004 (0,10)

8

14

0.008 (0,20) NOM

0°–8°

16

Gage Plane

0.010 (0,25)

0.044 (1,12)

0.016 (0,40)

A MAX

A MIN

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion, not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-012

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0.197

(5,00)

0.189

(4,80)

0.344

(8,75)

0.337

(8,55)

0.394

(10,00)

0.386

(9,80)

4040047/D 10/96

13

TPS2834, TPS2835

SYNCHRONOUS-BUCK MOSFET DRIVERS

WITH DEADTIME CONTROL

SLVS223 – NOVEMBER 1999

MECHANICAL DATA

PWP (R-PDSO-G**) PowerPAD PLASTIC SMALL-OUTLINE PACKAGE

20-PIN SHOWN

0,65

20

1

1,20 MAX

0,30

0,19

11

4,50

4,30

10

A

0,15

0,05

PINS **

DIM

M

0,10

6,60

6,20

Seating Plane

0,10

1614

Thermal Pad

(See Note D)

20

0,15 NOM

0°–8°

Gage Plane

0,25

0,75

0,50

2824

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusions.

D. The package thermal performance may be enhanced by bonding the thermal pad to an external thermal plane. This pad is electrically

and thermally connected to the backside of the die and possibly selected leads.

E. Falls within JEDEC MO-153

PowerPAD is a trademark of Texas Instruments Incorporated.

5,10

4,90

5,10

4,90

6,60

6,40

7,90

7,70

9,80

9,60

4073225/E 03/97

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...