TPPM0301

400-mA LOW-DROPOUT REGULATOR

WITH AUXILIARY POWER MANAGEMENT

SLVS315 – SEPTEMBER 2000

D

Automatic Input Voltage Source Selection

D

Glitch-Free Regulated Output

D

5-V Input Voltage Source Detector With

Hysteresis

D

400-mA Load Current Capability With 5-V or

3.3-V Input Source

D

Low r

D

Thermally Enhanced Packaging Concept

for Efficient Heat Management

Auxiliary Switch

DS(on)

5VAUX

5VCC

3.3VOUT

3.3VAUX

D PACKAGE

(TOP VIEW)

1

2

3

4

8

7

6

5

GND

GND

GND

GND

description

The TPPM0301 is a low-dropout regulator with auxiliary power management that provides a constant 3.3-V

supply at the output capable of driving a 400-mA load.

The TPPM0301 provides a regulated power output for systems that have multiple input sources and require a

constant voltage source with a low-dropout voltage. This is a single output, multiple input intelligent power

source selection device with a low-dropout regulator for either 5VCC or 5VAUX inputs, and a low- resistance

bypass switch for the 3.3VAUX input.

Transitions may occur from one input supply to another without generating a glitch, outside of the specification

range, on the 3.3-V output. The device has an incorporated reverse blocking scheme to prevent excess leakage

from the input terminals in the event that the output voltage is greater than the input voltage.

The input voltage is prioritized in the following order: 5VCC, 5VAUX, and 3.3VAUX.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 2000, Texas Instruments Incorporated

1

TPPM0301

I/O

DESCRIPTION

400-mA LOW-DROPOUT REGULATOR

WITH AUXILIARY POWER MANAGEMENT

SLVS315 – SEPTEMBER 2000

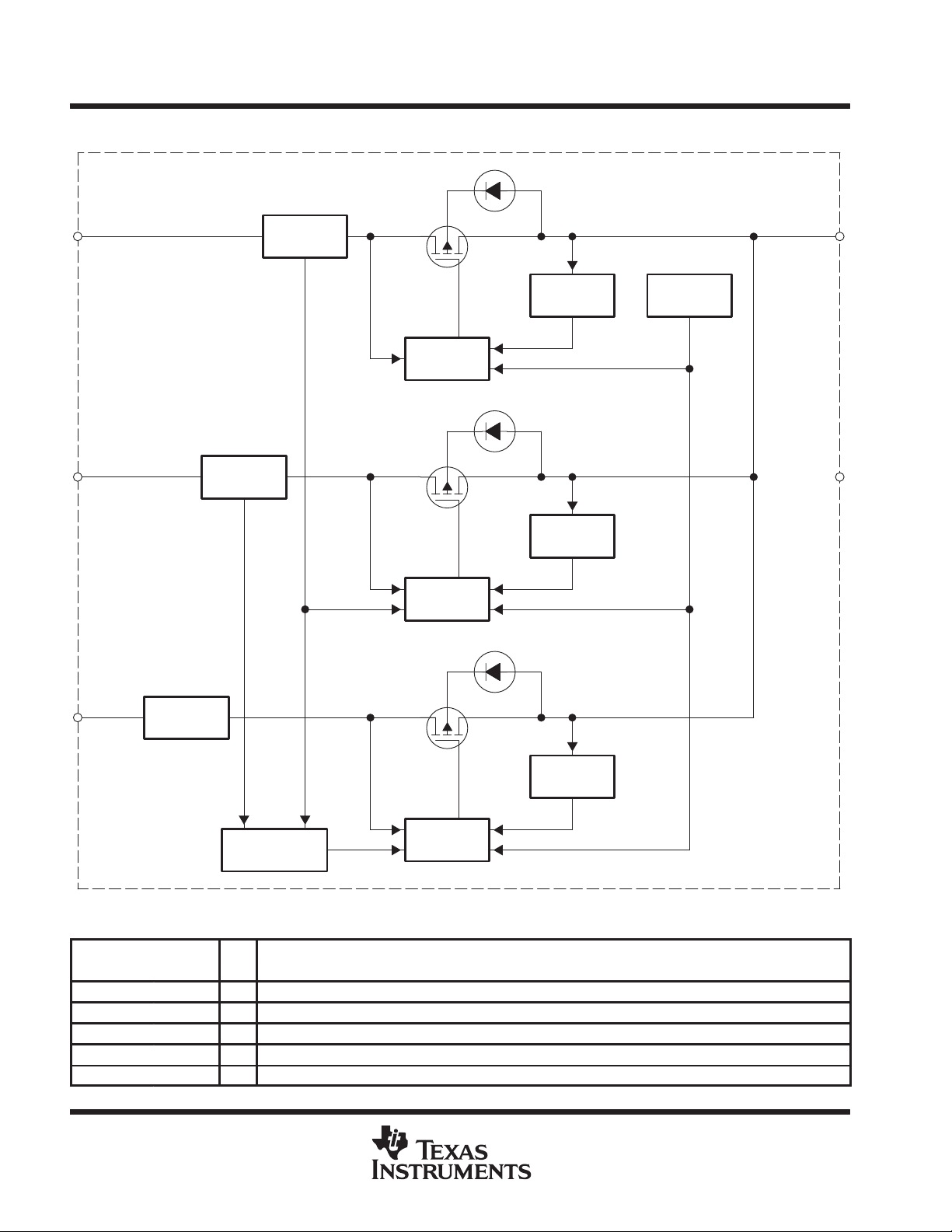

functional block diagram

Linear Regulator

5VCC

5-V

Detection

With LDO

3.3VOUT

5VAUX

3.3VAUX

3VAUX

Detection

5VAUX

Detection

Gate Drive

and Control

Linear Regulator

With LDO

Gate Drive

and Control

Low ON

Resistance

Switch

Current

Sensor

Current

Sensor

Over

Temperature

GND

5-V Detection

and Control

Gate Drive

Terminal Functions

TERMINAL

NAME NO.

3.3VAUX 4 I 3.3-V auxiliary input

3.3VOUT 3 O 3.3-V output with a typical capacitance load of 4.7 µF

5VAUX 1 I 5-V auxiliary input

5VCC 2 I 5-V main input

GND 5, 6, 7, 8 I Ground

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Current

Sensor

TPPM0301

400-mA LOW-DROPOUT REGULATOR

WITH AUXILIARY POWER MANAGEMENT

SLVS315 – SEPTEMBER 2000

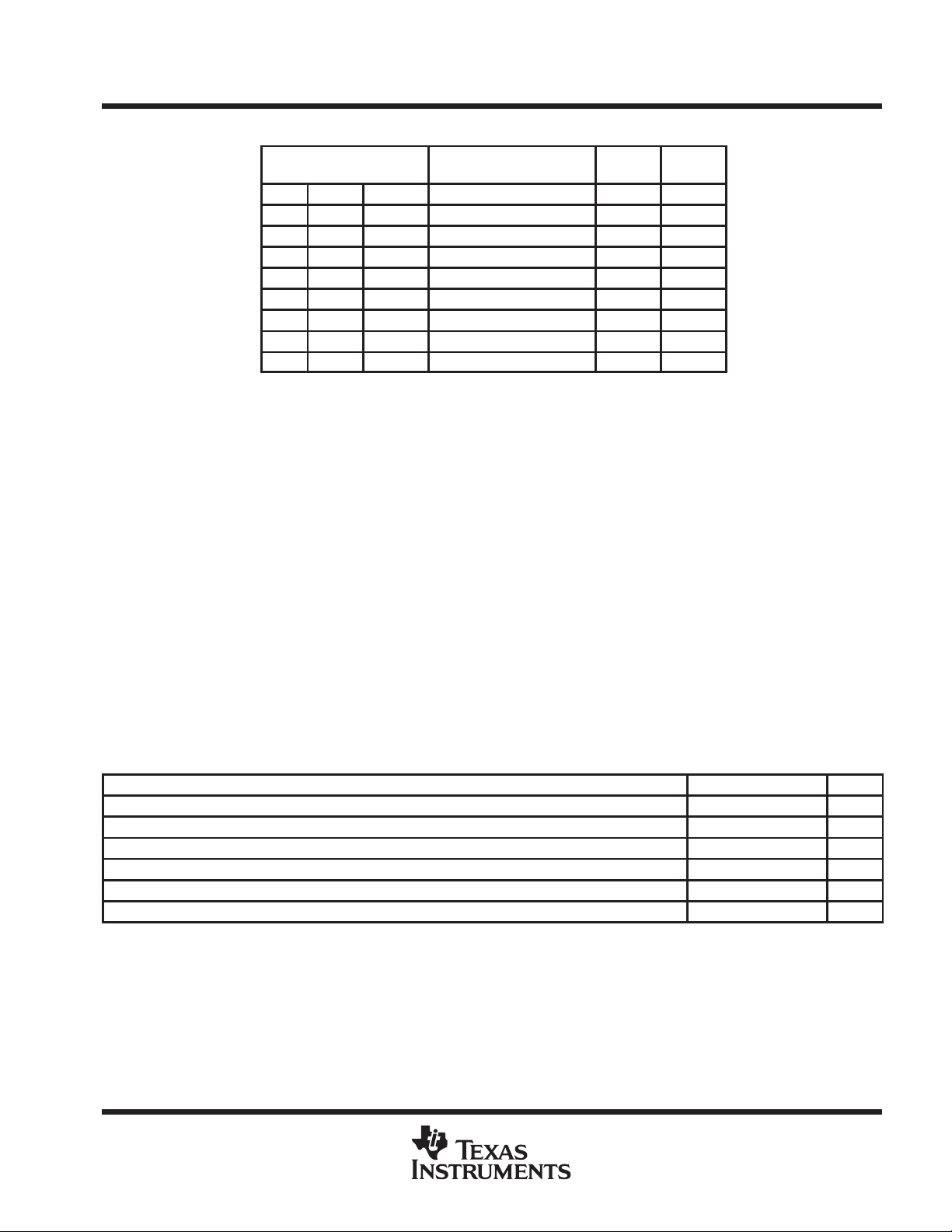

Table 1. Input Selection

INPUT VOLTAGE STATUS

5VCC 5VAUX 3.3VAUX 5VCC/5VAUX/3.3VAUX 3.3VOUT IL (mA)

0 0 0 None 0 0

0 0 3.3 3.3VAUX 3.3 375

0 5 0 5VAUX 3.3 400

0 5 3.3 5VAUX 3.3 400

5 0 0 5VCC 3.3 400

5 0 3.3 5VCC 3.3 400

5 5 0 5VCC 3.3 400

5 5 3.3 5VCC 3.3 400

(V)

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

Supply voltage, 5-V main input, V

Auxiliary voltage, 5-V input, V

Auxiliary voltage, 3.3-V input, V

3.3-V output current limit, I

(LIMIT)

(5VCC)

(5V AUX)

(see Notes 1 and 2) 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(3.3V AUX)

1.5 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INPUT SELECTED OUTPUT

(V)

OUTPUT

(I)

†

(see Notes 1 and 2) 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(see Notes 1 and 2) 5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous power dissipation, PD (see Note 3) 1 W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic discharge susceptibility, human body model, V

(HBMESD)

2 kV. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating ambient temperature range, TA 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

–55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

Operating junction temperature range, TJ –5°C to 120°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature (soldering, 10 second), T

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values are with respect to GND.

2. Absolute negative voltage on these terminal should not be below –0.5 V.

3. R

must be less than 55°C/W, typically achieved with two square inches of copper printed circuit board area connected to the GND

θJA

terminals for heat dissipation or equivalent.

260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(LEAD)

recommended operating conditions

5-V main input, V

5-V auxiliary input, V

3.3-V auxiliary input, V

Load capacitance, C

Load current, I

Ambient temperature, T

(5VCC)

(5VAUX)

(3.3VAUX)

L

L

A

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MIN TYP MAX UNIT

4.5 5.5 V

4.5 5.5 V

3 3.6 V

4.23 4.7 5.17 µF

0 400 mA

0 70 °C

3

TPPM0301

(Q)

y

A

3.3VOUT output shorted to 0 V

°C

400-mA LOW-DROPOUT REGULATOR

WITH AUXILIARY POWER MANAGEMENT

SLVS315 – SEPTEMBER 2000

electrical characteristics over recommended operating free-air temperature range, TA = 0°C to

70°C, C

V

(5VCC)

V

(5VAUX)

I

I

L

I

(LIMIT)

T

(TSD)

T

hys

V

(3.3VOUT)

C

L

I

lkg(REV)

†

Design targets only. Not tested in production.

= 4.7 µF (unless otherwise noted)

L

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

/

†

†

5-V inputs 4.5 5 5.5 V

Quiescent supply current

Output load current 0.4

Output current limit 3.3VOUT = 0 V 1 1.5

Thermal shutdown

Thermal hysteresis

3.3-V output IL = 400 mA 3.135 3.3 3.465 V

Load capacitance

Reverse leakage output current

From 5VCC or 5VAUX terminals, IL = 0 to

400 mA

From 3.3VAUX terminal, IL = 0 A 250 500 µA

p

Minimal ESR to insure stability of regulated

output

Tested for input that is grounded.

3.3VAUX, 5VAUX or 5VCC = GND,

3.3VOUT = 3.3 V

150 180

2.5 5 mA

15

4.7 µF

°

50 µA

5-V detect

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

(TO_LO)

V

(TO_HI)

Threshold voltage, low 5VAUX or 5VCC ↓ 3.85 4.05 4.25 V

Threshold voltage, high 5VAUX or 5VCC ↑ 4.1 4.3 4.5 V

auxiliary switch

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

R

(SWITCH)

∆V

O(∆VI)

∆V

O(∆IO)

VI – V

O

Auxiliary switch resistance

Line regulation voltage 5VAUX or 5VCC = 4.5 V to 5.5 V 2 mV

Load regulation voltage 20 mA < IL < 400 mA 40 mV

Dropout voltage IL < 400 mA 1 V

thermal characteristics

R

Thermal impedance, junction-to-case 38 °C/W

θJC

R

Thermal impedance, junction-to-ambient 97 °C/W

θJA

5VAUX = 5VCC = 0 V,

3.3VAUX = 3.3 V, IL = 150 mA

PARAMETER MIN TYP MAX UNIT

0.4 Ω

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPPM0301

400-mA LOW-DROPOUT REGULATOR

WITH AUXILIARY POWER MANAGEMENT

SLVS315 – SEPTEMBER 2000

THERMAL INFORMATION

T o ensure reliable operation of the device, the junction temperature of the output device must be within the safe

operating area (SOA). This is achieved by having a means to dissipate the heat generated from the junction

of the output structure. There are two components that contribute to thermal resistance. They consist of two

paths in series. The first is the junction to case thermal resistance, R

thermal resistance, R

R

θJA

= R

θJC

+ R

. The overall junction to ambient thermal resistance, R

θCA

θCA

The ability to efficiently dissipate the heat from the junction is a function of the package style and board layout

incorporated in the application. The operating junction temperature is determined by the operating ambient

temperature, T

The junction temperature, T

TJ = TA + PJ (R

TJ = TA + PJ (R

, and the junction power dissipation, PJ.

A

, is equal to the following thermal equation:

J

θJC

θJA

) + PJ (R

)

θCA

)

This particular application uses the enhanced 8-pin SO package with an integral fused lead frame (terminals

5 to 8). By incorporating a dedicated heat spreading copper plane of at least two square inches on a double-side

printed-circuit board (PCB), a thermal resistance of junction to ambient, R

Alternatively, if no dedicated copper plane is incorporated for this device and the PCB has a multilayer

construction, the ground terminals (5 to 8) could be electrically connected to the ground plane of the board. This

will provide a means for heat spreading through the copper plane associated within the PCB (GND layer). This

concept could provide a thermal resistance from junction to ambient, R

Hence, maximum power dissipation allowable for an operating ambient temperature of 70°C, and a maximum

junction temperature of 150°C is determined as:

; the second is the case to ambient

θJC

θJA

, of 70°C/W if implemented correctly .

θJA

, is determined by:

θJA

, of 50°C/W can be obtained.

PJ = (TJ – TA) / R

θJA

PJ = (150 – 70) / 50 = 1.6 W

Using two square inches of dedicated copper plane on double-sided PCB,

= (150 – 70) / 70 = 1.14 W

P

J

Using a multilayer board and utilizing the ground plane for heat spreading, worst case maximum power

dissipation is determined by:

= (5.5 – 3) × 0.4 = 1 W

P

D

Normal operating maximum power dissipation is (see Figure 1):

PD = (5 – 3.3) × 0.4 = 0.68 W

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

TPPM0301

400-mA LOW-DROPOUT REGULATOR

WITH AUXILIARY POWER MANAGEMENT

SLVS315 – SEPTEMBER 2000

THERMAL INFORMATION

Power Dissipation Derate Curve Using

Two Square Inches of Copper Heat

Spreader on a Double-Sided PCB

2.5

1.78

Power – W

1

0.68

Power Dissipation Derate Curve Using

Multilayer Board With The Ground

Plane for Heat Spreader

25

Ambient Temperature – °C

NOTE: These curves are to be used for guideline purposes only . For a particular application, a more specific thermal characterization is required.

80 100

116 150

103

Figure 1. Power Dissipation Derating Curves

APPLICATION INFORMATION

1

5VAUX GND

4.7 µF

4.7 µF

0.1 µF

0.1 µF4.7 µF

4.7 µF

0.1 µF

5VCC GND

TPPM0301

3.3VOUT GND

3.3VAUX GND

Figure 2. Typical Application Schematic

8

72

63

54

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TPPM0301

400-mA LOW-DROPOUT REGULATOR

WITH AUXILIARY POWER MANAGEMENT

SLVS315 – SEPTEMBER 2000

MECHANICAL DATA

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PINS SHOWN

0.050 (1,27)

14

1

0.069 (1,75) MAX

0.020 (0,51)

0.014 (0,35)

8

7

A

0.010 (0,25)

0.004 (0,10)

DIM

0.157 (4,00)

0.150 (3,81)

PINS **

0.010 (0,25)

0.244 (6,20)

0.228 (5,80)

8

M

Seating Plane

0.004 (0,10)

14

0.008 (0,20) NOM

0°–8°

16

Gage Plane

0.010 (0,25)

0.044 (1,12)

0.016 (0,40)

A MAX

A MIN

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion, not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-012

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0.197

(5,00)

0.189

(4,80)

0.344

(8,75)

0.337

(8,55)

0.394

(10,00)

0.386

(9,80)

4040047/D 10/96

7

PACKAGE OPTION ADDENDUM

www.ti.com

6-Dec-2006

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TPPM0301DR ACTIVE SOIC D 8 2500 Green(RoHS &

no Sb/Br)

TPPM0301DRG4 ACTIVE SOIC D 8 2500 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

(3)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com

17-May-2007

TAPE AND REEL INFORMATION

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com

Device Package Pins Site Reel

Diameter

(mm)

TPPM0301DR D 8 FMX 330 0 6.4 5.2 2.1 8 12 PKGORN

Reel

Width

(mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)W(mm)

17-May-2007

Pin1

Quadrant

T1TR-MS

P

TAPE AND REEL BOX INFORMATION

Device Package Pins Site Length (mm) Width (mm) Height (mm)

TPPM0301DR D 8 FMX 342.9 336.6 20.6

Pack Materials-Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements,

improvements, and other changes to its products and services at any time and to discontinue any product or service without notice.

Customers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All products are sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s

standard warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this

warranty. Except where mandated by government requirements, testing of all parameters of each product is not necessarily

performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should

provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask

work right, or other TI intellectual property right relating to any combination, machine, or process in which TI products or services

are used. Information published by TI regarding third-party products or services does not constitute a license from TI to use such

products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under

the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without alteration and is

accompanied by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an

unfair and deceptive business practice. TI is not responsible or liable for such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service

voids all express and any implied warranties for the associated TI product or service and is an unfair and deceptive business

practice. TI is not responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would

reasonably be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement

specifically governing such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications

of their applications, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related

requirements concerning their products and any use of TI products in such safety-critical applications, notwithstanding any

applications-related information or support that may be provided by TI. Further, Buyers must fully indemnify TI and its

representatives against any damages arising out of the use of TI products in such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is

solely at the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in

connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products

are designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any

non-designated products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

Low Power www.ti.com/lpw Video & Imaging www.ti.com/video

Wireless

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2007, Texas Instruments Incorporated

Loading...

Loading...