Page 1

User's Guide

SLRU005–February 2013

TPL7407L7-Channel Relay and Inductive Load Sink Driver

EVM

1 Overview

The TPL7407LEVM is a 7-Channel Relay and Inductive Load Sink Driver evaluation module that

demonstrates the TPL7407LDR integrated circuit from Texas Instruments (TI).

The TPL7407LDR is a high-performance peripheral driver designed to drive loads of many types

including: relays, stepper motors, lamps, and light emitting diodes.

The EVM is configured with seven push buttons that supply input to the TPL7407L driver and seven

relays are driven by the TPL7407Loutputs. A four terminal block can be connected to external power

supplies to provide input and relay power. All of the TPL7407Linput and output pins are accessible for

external connection.

1.1 TPL7407LEVM Features

• Seven numbered push buttons control input for device testing.

• Seven numbered light emitting diodes indicate relay contact closure.

• Three 0.1” spaced post connector ports that allow access to all input pins, output pins, and relay

contacts.

• Three open locations, per channel, on the circuit board for user supplied components.

• Onboard relay loads that can be disconnected by removing surface mounted 0Ω resistors.

• A large device clearance area that allows the use of small profile temperature forcing equipment.

Table 1. TPL7407LEVM Specification

Key Parameters

Input Supply Voltage: 0V – 5.5V

Relay Supply Voltage: 8.5V – 24V

Output Current: 0mA to 500mA

Number of Channels: 7

Onboard Load: Seven OMRON G5NB relays

G5NB specs

• Nominal coil resistance is 2,880Ω

• Nominal coil current is 8.3mA

• Nominal coil voltage is 24V

• Pickup voltage < 75% Nominal

• Dropout voltage > 10% Nominal

• Maximum coil voltage 180% Nominal

CAUTION: Applying voltages above the limitations given in Table 1 may cause permanent damage to

your hardware.

Gerber (layout) files are available at www.ti.com.

The EVM includes mating connectors for input, output, and contact pins.

SLRU005–February 2013 TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM

Submit Documentation Feedback

1

Copyright © 2013, Texas Instruments Incorporated

Page 2

Quick Setup Guide

PCB Key Map

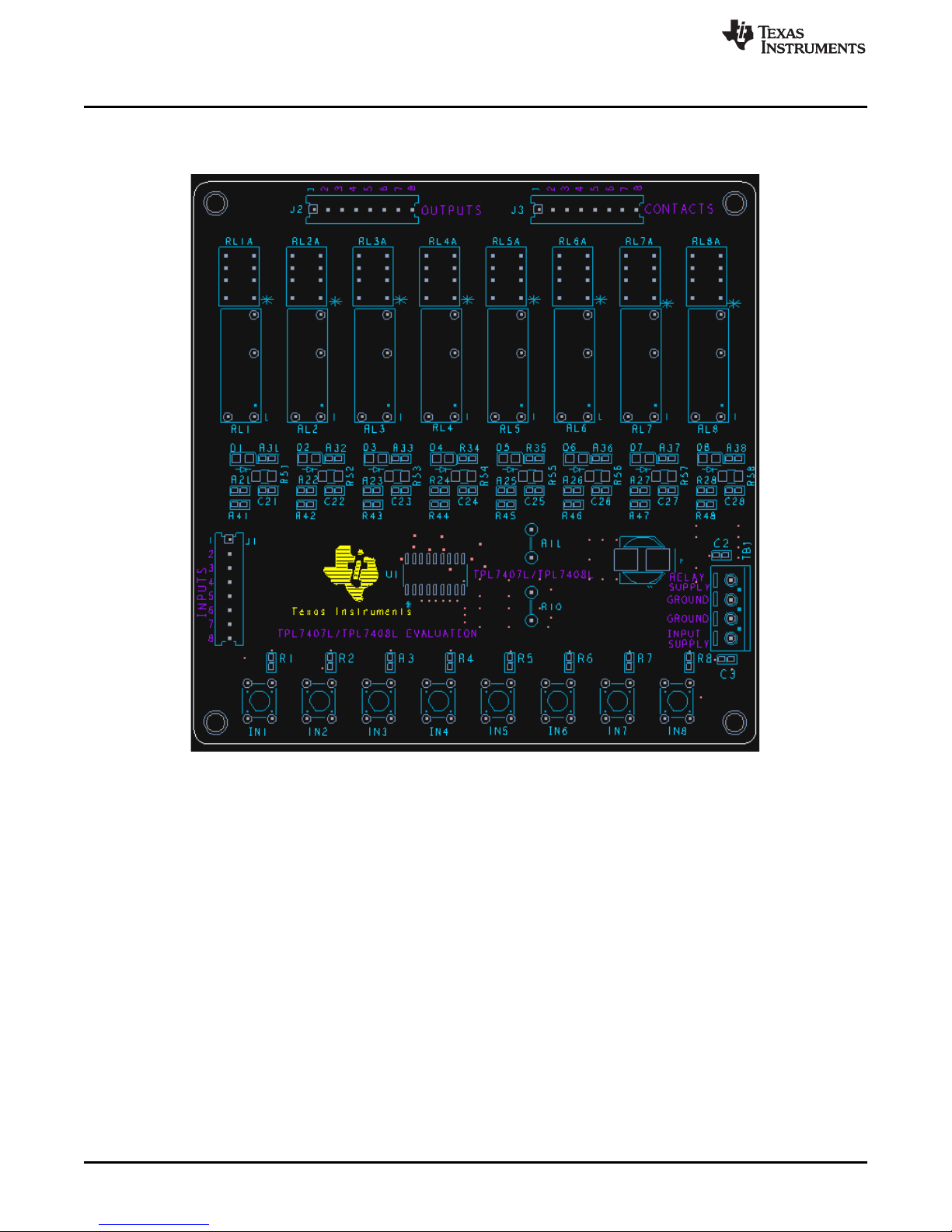

Physical structure for the TPL7407LEVM is illustrated in Figure 1.

www.ti.com

Figure 1. Physical Structure for the TPL7407LEVM (Approximate Layout)

2 Quick Setup Guide

This section describes the setup to quickly check the functionality of TPL7407LEVM.

2.1 Electrostatic Discharge Warning

Many of the components on the TPL7407LEVM are susceptible to damage by electrostatic discharge

(ESD). Customers are advised to observe proper ESD handling precautions when unpacking and handling

the EVM, including the use of a grounded wrist strap at an approved ESD workstation.

CAUTION: Failure to observe ESD handling procedures may result in damage to EVM components.

Unpacking the EVM

After opening the TPL7407LEVM package, check to ensure that the following items are included:

• 1 pc. TPL7407LEVM board using one TPL7407LDR

• 3 pc. Eight pin insulation displacement connectors that accept AWG 22 insulated wire.

2

TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM SLRU005–February 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

TB1

Relay Supply ± 4

pin 8

Ground ± 3

Ground ± 2

Input Supply ± 1

C2 0.1F

C3

0.1F

+

470F

C1

C21-27

DNI

R21-R27 DNI

0

R51-R57

10K

R31-R37

D1

J2 - Output

IN1-7

COM

R41-R47

J3 - Contact

pins 1 - 7

TPL7407L

1 of 7

Channels

OUT1 - 7

J2 - Output

pins 1 - 7

J1 - Input

pin 1 - 7

J1 - Input

pin 8

R1-7

DNI

IN1-7

1M

Shared

GND

Regulation

Circuitry

DRIVER

50.

www.ti.com

Power Supply Setup

A 8.5V - 24V power supply capable of 500 mA of current is required.

Connect the positive power supply lead to the “Input Supply” on TB1-1 and also connect it to the “Relay

Supply” on TB1-4. Connect the negative power supply lead to either of the two ground connections on

TB1-2 or TB1-3.

It is important to connect the power supply correctly because opposite supply polarity will damage

the EVM.

Turn the power supply on. At this time, the EVM light emitting diodes (LEDS) should be off and no current

should be flowing from the power supply. The TPL7407L consumes no power when all seven channels

are off.

Press the pushbuttons labeled IN1 through IN7 one at a time. When pressed the corresponding relay will

click as the contacts engage and the LED will illuminate.

Releasing a pushbutton will disengage the corresponding relay contacts and extinguish the LED.

If all seven buttons operate as previously described, then the TPL7407LEVM passes functional testing.

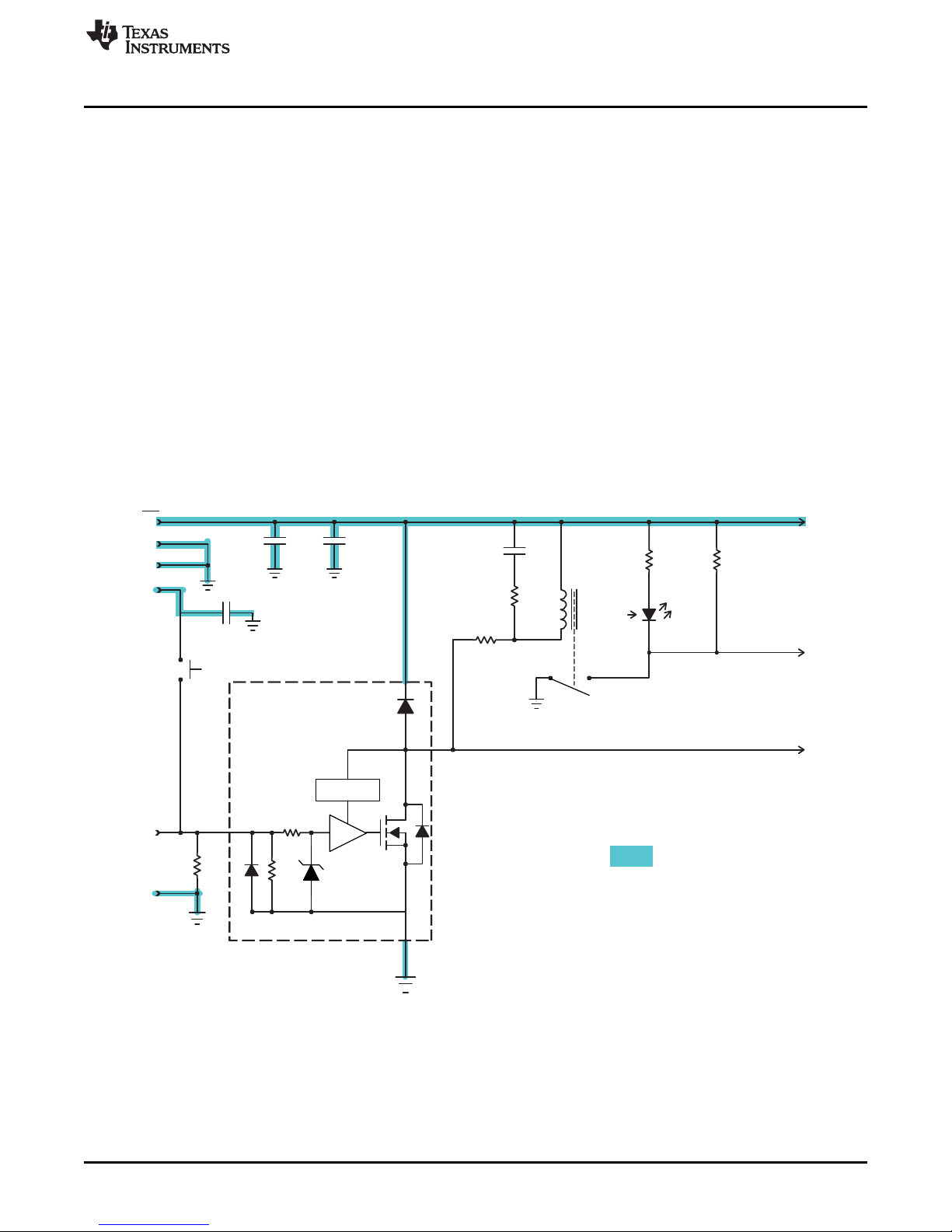

3 EVM Theory and Operation

The following single channel schematic is representative of the seven identical driver channels.

EVM Theory and Operation

The TPL7407LEVM is designed to accept an “Input Supply” on TB1-1 with a voltage range of 1.8V to 5.5V

and a “Relay Supply” on TB1-4 with a voltage range ideally set to 24V ±10%, but will still operate with a

minimum voltage of 8.5V and a maximum voltage of 40V.

SLRU005–February 2013 TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM

Submit Documentation Feedback

Figure 2. Single Channel Schematic

Copyright © 2013, Texas Instruments Incorporated

3

Page 4

EVM Theory and Operation

When none of the buttons are pressed, the TPL7407L inputs will be open circuit and the internal resistors

in the TPL7407Lwill ensure zero volts on the inputs. With the inputs low, the TPL7407Loutput pins will set

to a high impedance state; therefore, no current will flow through the relay coils. The relay contact will not

be engaged and the voltage on the J3-Contact pins 1 to 7 will be pulled up to the relay supply voltage by a

10kΩ resistor on the PCB.

Pressing one of the input buttons, labeled IN1 to IN7, will apply the input voltage supply on TB1-1 to the

corresponding input pin on the TPL7407L. The internal resistor on the TPL7407L input pin will draw a

small current proportional to the input voltage. The nominal current is input voltage divided by 1MΩ, it can

also be expressed as the ratio, 1µA/V. The NMOS switch inside the TPL7407Lturns on providing a low

resistance path from output to ground. This completes the circuit and current flows from the relay supply

through the G5NB relay coil and through the TPL7407Loutput switch to ground and finally back through

the relay supply return lead. The relay coil current will engage the relay contacts. The relay contacts will

short the corresponding J3 “contact” pin to ground. It will also complete the corresponding LED circuit and

the LED will illuminate.

Releasing one of the input buttons, labeled IN1 to IN7, will remove the input voltage from the

corresponding input pin on the TPL7407L. The internal resistor on the TPL7407L input pin will decrease

the input voltage to zero. The NMOS switch inside the TPL7407Lturns off breaking the current path for the

relay coil. Since the coil is an inductor, the current cannot change in zero time. The coil voltage will

change polarity resulting in a TPL7407Loutput voltage that is greater than the relay supply voltage. This

will forward bias the diode inside the TPL7407Lpassing current back to the relay supply voltage. This

current will continue until the stored coil energy is depleted. The relay contacts will disengage and the

short on the J3-Contact pin will be removed and the pin voltage will increase back to the relay supply

voltage. The LED circuit will be open, thus extinguishing the LED.

The voltage on the output pins is always available on the J2-Output connector pins 1-7. Pin 8 is connected

to the COM pin on the TPL7407Land the relay supply voltage on TB1 pin 4. The J2-Output connector can

be used measure the output voltage. It can also be used to add additional loads to the TPL7407Loutput

pins. The series resistance between the J2-output connector and the TPL7407L is approximately 20 mΩ.

The onboard AGQ2003 relay coils can be removed from the TPL7407L by removing the seven 0Ω

resistors at locations R41 to R47.

The voltage on the input pins is always available on the J1-Input connector pins 1-7. Pin 8 is connected to

the GND pin on the TPL7407Land the ground voltage on TB1 pins 2 & 3. The J1-Input connector can be

used measure the input voltage. It can also be used to inject external signals onto the TPL7407Linput

pins.

Three user supplied components, per channel, can be added if needed. All three circuit board footprints

are SMD 0603 sized. The first location, R1 to R7, allows adding a resistor from each input to ground. The

second, R21 to R27, and third location, C21 to C27, are in series with each other and parallel with the

G5NB relay coils.

The terminal block, TB1, provides power for the input pushbuttons and relay coils. When directly

controlling the inputs using the J1-Input connector, the input source on TB1 pin1 may be disconnected.

The TPL7407L EVM board has seven identical channels. The single channel schematic is easier to read

then the complete schematic. The TPL7407Lsingle model functional diagram is enclosed by dotted lines.

The input pin has a 1MΩ resistor that keeps the driver off when no input is disconnected or put in to a high

impedance state. The NMOS transistor sinks to a shared ground connection when the input voltage is

applied. When the load is inductive and the NMOS turns off, the output voltage will increase beyond the

relay supply voltage and inductor current will continue to flow though the free wheeling diode to the COM

pin until the inductor is discharged.

Resistors R41 through R47 can be removed to isolate the output from the relay coils when external load

or automated test equipment is provided through the J2-Output connector.

The relay is an G5NB relay with a 2,880Ω, 24V, 8.3mA nominal coil. The pull-in voltage is less than 2.25V

(3V × 75%) and the drop out voltage is greater than 0.3V. The maximum coil voltage is 43.2V (24V ×

180%).

The relay contact when open will allow the J3-Contact pin to rise to the Relay supply voltage. The voltage

on J3-Contact connector can be measured by any high impedance (>100kΩ) measuring device. When the

contacts close the J2-Contact pin will be pulled down to ground potential.

www.ti.com

4

TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM SLRU005–February 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

TPL7407LEVM Performance Testing Using Lab Equipment

The TPL7407Loutput pins 16 to 10 are connected to relays RL1 to RL7 and J2-Output port pins 1 -7 (pin 8

is relay coil power sense).

The TPL7407LCOM, pin 9, is connected to the relay supply on TB1. This pin connects to the cathodes of

free wheeling diodes for each output. It provides a discharge path when the inductive load is turned off.

The inputs can be fully controlled by external test equipment using the J1-Input Port. The outputs can be

measured by external test equipment using the J2-Output Port. If relay supply voltage, TPL7407L COM

pin, exceeds 40V or full external control is required, then the relay coils should be disconnected by

removing the zero ohm resistors labeled R41 to R47.

The TPL7407LEVM has open 0603 foot prints for input resistors to ground as R11 to R17, coil wave

shaping resistor and capacitors as R31 to R37 and C31 to C37. The TPL7407L does not require these

components.

Increasing output load using onboard relays: Shorting two or more of the J2 pins 1-7 (output port) will

parallel the TPL7407Loutputs and relay coils. By activate just one of the inputs for the shorted output

channels will cause a single output to drive multiple relay coil loads. Two coils typically uses 16.6mA and

three coils typically use 24.9mA.

4 TPL7407LEVM Performance Testing Using Lab Equipment

Datasheet electrical characterization parameters can be measured using the following test setups. Setups

for both standard EVM boards and modified EVM boards that have R41 to R47 removed to disconnect the

onboard relay loads. It is acceptable to keep some channels “standard” (R4x installed) and other channels

“modified” (R4x removed). The capacitors (470µF & 0.1µF) on the TPL7407L COM pin are connected

regardless of R41 to R47 presence. Therefore the charging, discharging, and leakages of the capacitors

must be considered. Each output pin has an internal diode to the COM pin. Testing for channel 1 will be

described; test other channels by using a different pin on the J1(input) and J2(output) connectors.

Channel Tested J1(Input)-pin J2(Output)-pin

CH 1 J1–1 J2–1

CH 2 J1–2 J2–2

CH 3 J1–3 J2–3

CH 4 J1–4 J2–4

CH 5 J1–5 J2–5

CH 6 J1–6 J2–6

CH 7 J1–7 J2–7

Relay supply is connected to TB1 pin 4; the Relay supply sense line can also be connected to TB1-pin4.

Alternatively the sense line can be connected to J2 pin 8. The relay supply is the same node as the

TPL7407LCOM (pin 9).

Ground power and ground sense connection can be made to TB1 pins 2 and 3. An alternative ground

sense can be made at J1 pin 8.

Warning: All tests that supply current should be limited to the data sheet limit of 600mA. Input pin

voltage should be limited to 30V and output pin voltage should be limited to 40V.

SLRU005–February 2013 TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM

Submit Documentation Feedback

5

Copyright © 2013, Texas Instruments Incorporated

Page 6

I

24V

Current

Limit 10 mA

TB1-4

Measure

Current

J1-1

IN

1/7

COM

OUT

J2-1

TPL7407L

Sweep

Voltage

0 to 1.5V

GND

TB1-2

TPL7407LEVM Performance Testing Using Lab Equipment

Input parameter VI(on) and VI(off) Channel 1 Test Setup and Typical Results

Board setup: Sweep input voltage on J1-1; Set Output J2-1 and Relay Supply to 24V, measure output

current on J2-1 [current clamp on measurement range of 10mA is recommended].

Note: any difference between voltage on J2-1 and Relay Supply(TB1-4) will affect low current accuracy

with Standard board.

www.ti.com

6

TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM SLRU005–February 2013

Figure 3. VI(on) and VI(off) Schematic

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

24 V

TB1-4

Measure

Current

J1-1

IN

1/7

COM

OUT

J2-1

I

Sweep

Voltage

0 to 5.5V

TPL7407L

GND

TB1-2

www.ti.com

TPL7407LEVM Performance Testing Using Lab Equipment

Input Parameter II(on) Channel 1 Test Setup and Typical Results

Input current is a function of input voltage alone. The output load impedance and termination voltage have

no impact on the results.

Board setup: Sweep input voltage on J1-1. Measure input current on J1-1. Optionally, Relay supply can be

connected to 24V.

SLRU005–February 2013 TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM

Submit Documentation Feedback

Figure 4. II(on) Schematic

Copyright © 2013, Texas Instruments Incorporated

7

Page 8

24 V

TB1-4

Measure

Current

J1-1

IN

1/7

COM

OUT

J2-1

I

TPL7407L

GND

TB1-2

TB1-3

TPL7407LEVM Performance Testing Using Lab Equipment

Input Parameter II(off) Channel 1 Test Setup and Typical Results

Input current with zero input voltage will be very low. A pico-amp meter is recommended. This is a signal

point test.

Standard board setup: Set input voltage on J1-1 to 0V. Measure input current on J1-1. Optionally, output

J2-1 and Relay Supply can be set to 24V.

Modified board setup: Sweep CH1 voltage on J1-1; Set Output J2-1 and Relay Supply to 24V, measure

current on J1-1. The return lead of the pico-amp meter must be at board ground potential.

www.ti.com

8

TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM SLRU005–February 2013

Figure 5. II(off) Schematic

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

V

OPEN

TB1-4

J1-1

IN

1/7

COM

OUT

J2-1

Sweep

Current

TPL7407L

GND

Kelvin

0 to 500 mA

1.8V ± 5.0V

TB1-2

Connection

Measure

Voltage

TB-3

www.ti.com

TPL7407LEVM Performance Testing Using Lab Equipment

Output Parameter VOL Channel 1 Test Setup and Typical Results

This parameter was called collector emitter saturation voltage on the original TPL7407L device.

The data sheet has specifications for input voltages of 1.8V - 5V.

Board setup: Sweep output current on J2-1. Set desired input voltage on J1-1 [1.8V - 5V, and other

voltages]. Disconnect the relay supply on TB1-4. Measure output voltage on J2-1 (kelvin connections at

J2-1 and ground are highly recommended for accurate results).

SLRU005–February 2013 TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM

Submit Documentation Feedback

Figure 6. VOL Schematic

Copyright © 2013, Texas Instruments Incorporated

9

Page 10

0.00

0.20

0.40

0.60

0.80

1.00

1.20

1.40

1.60

0 100 200 300 400 500 600 700

VOL (V)

Output Drain Current IDS(mA)

VOL at Various Temperatures

25C

70C

105C

-40C

TPL7407LEVM Performance Testing Using Lab Equipment

www.ti.com

Figure 7. VOL vs IOL

10

TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM SLRU005–February 2013

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

OPEN

TB1-4

J1-1

IN

1/7

COM

OUT

J2-1

Measure

Current

Sweep

Voltage

0 V to 5.5 V

TPL7407L

GND

TB1-2

I

SENSE

0.4 V

SENSE

TB1-3

www.ti.com

TPL7407LEVM Performance Testing Using Lab Equipment

Output Parameter IOUT(on) Channel 1 Test Setup and Typical Results

Board setup: Sweep input voltage on J1-1. Set output voltage on J2-1 to 0.4V. Disconnect the relay supply

on TB1-4. Measure output current on J2-1 (sense connections at J2-1 and ground are highly

recommended to keep 0.4V on the EVM regardless of line losses in wires and current meter).

SLRU005–February 2013 TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM

Submit Documentation Feedback

Figure 8. IOUT(on) Schematic

Copyright © 2013, Texas Instruments Incorporated

11

Page 12

TEE

24V

Rising Edge

Slope

Trigger

50

J1-8

GND

J1-1

IN

1/7

TB1-4

COM

OUT

J2-8

COM

J2-1

50

10x Scope

3UREH³,QSXW´

GND

TB1-2

10x Scope

Probe

³2XWSXW´

3.3 V

Pulse Generator

100 kHz

0V

10% Duty Cycle

TPL7407L

TPL7407LEVM Performance Testing Using Lab Equipment

www.ti.com

Switching Parameter t

Board setup: The TPL7407Land TPL7407LEVM are primarily designed for slow responding loads like

relays, stepper motors, and DC lab equipment; however, the TPL7407Lrise/fall times and propagation

delays are short. Therefore line termination and short wires are important for signal quality. The waveform

below uses a 50 ohm cable “T” tapped within 3 cm of the J1-Input connector and terminated at the

oscilloscope set to 50 ohm input impedance. This input is used as the scope trigger. A locally grounded

10X scope probe is used to measure the input signal and the same probe was used to measure the output

on J2-1. A pull up resistor of 50Ω is connected between the output (J2-1) and Relay supply (J2-8). Set

scope trigger for rising edge. Pulse generator is 10% duty cycle 100kHz 3.3V logic level signal.

3.3V 50Ω Channel 1 Test Setup and Typical Results

PHL

Switching Parameter t

3.3V 50Ω Channel 1 Test Setup and Typical Results

PLH

Board setup: The TPL7407Land TPL7407LEVM are primarily designed for slow responding loads like

relays, stepper motors, and DC lab equipment; however, the TPL7407Lrise/fall times and propagation

delays are quite short. Therefore line termination and short wires are important for signal quality. The

waveform below uses a 50 ohm cable “T” tapped within 3 cm of the J1-Input connector and terminated at

the oscilloscope set to 50 ohm input impedance. This input is used as the scope trigger. A locally

grounded 10X scope probe is used to measure the input signal and the same probe was used to measure

the output on J2-1. A pull up resistor of 50Ω is connected between the output (J2-1) and Relay supply (J2-

8). Set scope trigger for falling edge. Pulse generator is 10% duty cycle 100kHz 3.3V logic level signal.

12

TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM SLRU005–February 2013

Figure 9. T

Copyright © 2013, Texas Instruments Incorporated

Schematic

PHL

Submit Documentation Feedback

Page 13

TEE

24V

Falling Edge

Slope

Trigger

50

J1-8

GND

J1-1

IN

1/7

TB1-4

COM

OUT

J2-8

COM

J2-1

50

10x Scope

3UREH³,QSXW´

GND

TB1-2

10x Scope

Probe

³2XWSXW´

3.3 V

Pulse Generator

100 kHz

0V

10% Duty Cycle

TPL7407L

www.ti.com

TPL7407LEVM Performance Testing Using Lab Equipment

Switching Parameter RINChannel 1 Test Setup and Typical Results.

The data to calculate RIN, the DC input resistance, was recorded during the II(on) test. The input

resistance is simply input voltage divided by input current.

SLRU005–February 2013 TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM

Submit Documentation Feedback

Figure 10. T

Copyright © 2013, Texas Instruments Incorporated

Schematic

PLH

13

Page 14

J1-1

IN

1/7

TB1-4

COM

OUT

Measure

Voltage

V

J2-1

OPEN

Sweep

GND

TB1-2

Current

0 to 600 mA

TPL7407L

TPL7407LEVM Performance Testing Using Lab Equipment

Free-wheeling Diode Parameter VF channel 1 Test Setup and Typical Results

Board setup: Sweep output current on J2-1. Set Relay supply voltage to 0V. On standard boards the X

axis (output current) will need to be compensated for coil current flow. The real diode current is

approximately X-VF/2,880Ω. Measure output current on J2-1 (Kelvin connections at J2-1 and relay supply

are highly recommended for accurate results).

www.ti.com

14

TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM SLRU005–February 2013

Figure 11. VF Schematic

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

0.000

0.100

0.200

0.300

0.400

0.500

0.600

0.700

0.800

0.000 0.200 0.400 0.600 0.800 1.000 1.200 1.400 1.600

IF (A)

VF (V)

Fly-back Diode Forward Voltage

www.ti.com

TPL7407LEVM Performance Testing Using Lab Equipment

Figure 12. VF = Diode(V) vs Diode(I)

SLRU005–February 2013 TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM

Submit Documentation Feedback

15

Copyright © 2013, Texas Instruments Incorporated

Page 16

OUT4

OUT7

OUT1

OUT2

OUT3

OUT5

OUT6

OUT8

IN1

IN2

IN3

IN4

IN5

IN6

IN7

IN8

OUT8

OUT7

OUT6

OUT5

OUT4

OUT3

OUT2

OUT1

V_RELAY

V_RELAY

V_IN

V_IN

V_IN

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

CONTACT1

CONTACT2

CONTACT3

CONTACT4

CONTACT5

CONTACT6

CONTACT7

CONTACT8

R3R

DNI

R3R

DNI

IN8

SPST

DNI

IN8

SPST

DNI

142

3

R5R

DNI

R5R

DNI

R7R

DNI

R7R

DNI

+

C1

470UF

+

C1

470UF

J3

8 HEADERJ38 HEADER

1234567

8

U1

ULN2003LVDR

U1

P11P22P33P44P55P66P77P88P9

9

P1010P1111P1212P1313P1414P1515P1616P1717P18

18

R1R

DNI

R1R

DNI

MTG4MTG4

MTG3MTG3

IN5

SPST

IN5

SPST

142

3

MTG2MTG2

TB1

TERM BLOCK

TB1

TERM BLOCK

123

4

C2

0.1UFC20.1UF

MTG1MTG1

C3

0.1UFC30.1UF

R4R

DNI

R4R

DNI

J2

8 HEADERJ28 HEADER

1234567

8

R100R10

0

R6R

DNI

R6R

DNI

R11 0R11 0

IN1

SPST

IN1

SPST

142

3

R8R

DNI

R8R

DNI

R2R

DNI

R2R

DNI

IN7

SPST

IN7

SPST

142

3

IN2

SPST

IN2

SPST

142

3

IN3

SPST

IN3

SPST

142

3

IN4

SPST

IN4

SPST

142

3

IN6

SPST

IN6

SPST

142

3

J1

8 HEADERJ18 HEADER

1234567

8

TPL7407LEVM Performance Testing Using Lab Equipment

www.ti.com

16

TPL7407L7-Channel Relay and Inductive Load Sink Driver EVM SLRU005–February 2013

Figure 13. Full Schematic

Copyright © 2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

Evaluation Board/Kit Important Notice

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION PURPOSES

ONLY and is not considered by TI to be a finished end-product fit for general consumer use. Persons handling the product(s) must have

electronics training and observe good engineering practice standards. As such, the goods being provided are not intended to be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including product safety and environmental

measures typically found in end products that incorporate such semiconductor components or circuit boards. This evaluation board/kit does

not fall within the scope of the European Union directives regarding electromagnetic compatibility, restricted substances (RoHS), recycling

(WEEE), FCC, CE or UL, and therefore may not meet the technical requirements of these directives or other related directives.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30 days from

the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY SELLER TO BUYER

AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or infringement of patents or

services described herein.

Please read the User’s Guide and, specifically, the Warnings and Restrictions notice in the User’s Guide prior to handling the product. This

notice contains important safety information about temperatures and voltages. For additional information on TI’s environmental and/or

safety programs, please contact the TI application engineer or visit www.ti.com/esh.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used.

FCC Warning

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION PURPOSES

ONLY and is not considered by TI to be a finished end-product fit for general consumer use. It generates, uses, and can radiate radio

frequency energy and has not been tested for compliance with the limits of computing devices pursuant to part 15 of FCC rules, which are

designed to provide reasonable protection against radio frequency interference. Operation of this equipment in other environments may

cause interference with radio communications, in which case the user at his own expense will be required to take whatever measures may

be required to correct this interference.

EVM Warnings and Restrictions

It is important to operate this EVM within the input voltage range of and the output voltage range of .

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM. If there are questions

concerning the input range, please contact a TI field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible permanent damage to the EVM.

Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the load specification,

please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than . The EVM is designed to operate properly

with certain components above as long as the input and output ranges are maintained. These components include but are not limited to

linear regulators, switching transistors, pass transistors, and current sense resistors. These types of devices can be identified using the

EVM schematic located in the EVM User's Guide. When placing measurement probes near these devices during operation, please be

aware that these devices may be very warm to the touch.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2014, Texas Instruments Incorporated

Page 18

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2014, Texas Instruments Incorporated

Page 19

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

TPL7407LEVM

Loading...

Loading...