Page 1

TMS320DM335

www.ti.com

SPRS528C–JULY 2008–REVISED JUNE 2010

TMS320DM335

Digital Media System-on-Chip (DMSoC)

Check for Samples: TMS320DM335

1 Digital Media System-on-Chip (DMSoC)

1.1 TMS320DM335 Features

123

• Highlights

– High-Performance Digital Media

System-On-Chip (DMSoC)

– Up to 216-MHz ARM926EJ-S™ Clock Rate

– Digital HDTV (720p/1080i) output for

connection to external encoder – 32K-Byte RAM

– Video Processing Subsystem – 8K-Byte ROM

• Hardware IPIPE for Real-Time Image – Little Endian

Processing

• Up to 14-bit CCD/CMOS Digital Interface

• Histogram Module

• Resize Image 1/16x to 8x Processing

• Hardware On-Screen Display • Up to 14-bit CCD/CMOS Digital Interface

• Up to 75-MHz Pixel Clock • 16-/8-bit Generic YcBcR-4:2 Interface

• Composite NTSC/PAL video encoder

output • 10-/8-bit CCIR6565/BT655 Interface

– Peripherals include DDR and mDDR SDRAM, • Up to 75-MHz Pixel Clock

2 MMC/SD/SDIO and SmartMedia Flash Card

Interfaces, USB 2.0, 3 UARTs and 3 SPIs

– Enhanced Direct-Memory-Access (EDMA)

– Configurable Power-Saving Modes

– On-Chip ARM ROM Bootloader (RBL) to Boot

From NAND Flash, MMC/SD, or UART

– 3.3-V and 1.8-V I/O, 1.3-V Core

– Debug Interface Support

– Up to 104 General-Purpose I/O (GPIO) Pins

– 337-Pin Ball Grid Array at 65 nm Process

Technology

• High-Performance Digital Media

System-on-Chip (DMSoC)

– 135-, 216-MHz ARM926EJ-S™ Clock Rate

– Fully Software-Compatible With ARM™

– Extended Temperature 135- and 216-MHz

Devices are Available

• ARM926EJ-S Core

– Support for 32-Bit and 16-Bit (Thumb Mode)

Instruction Sets

– DSP Instruction Extensions and Single Cycle

MAC

– ARM® Jazelle® Technology

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2Windows is a trademark of Microsoft.

3All other trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

– EmbeddedICE-RT™ Logic for Real-Time

Debug

• ARM9 Memory Architecture

– 16K-Byte Instruction Cache

– 8K-Byte Data Cache

• Video Processing Subsystem

– Front End Provides:

• Hardware IPIPE for Real-Time Image

(BT.601)

• Histogram Module

• Resize Engine

– Resize Images From 1/16x to 8x

– Separate Horizontal/Vertical Control

– Two Simultaneous Output Paths

– Back End Provides:

• Hardware On-Screen Display (OSD)

• Composite NTSC/PAL video encoder

output

• 8-/16-bit YCC and Up to 18-Bit RGB666

Digital Output

• BT.601/BT.656 Digital YCbCr 4:2:2

(8-/16-Bit) Interface

• Digital HDTV (720p/1080i) output for

connection to external encoder

• External Memory Interfaces (EMIFs)

– DDR2 and mDDR SDRAM 16-bit wide EMIF

With 256 MByte Address Space (1.8-V I/O)

– Asynchronous16-/8-bit Wide EMIF (AEMIF)

• Flash Memory Interfaces

– NAND (8-/16-bit Wide Data)

– OneNAND(16-bit Wide Data)

• Flash Card Interfaces

Copyright © 2008–2010, Texas Instruments Incorporated

Page 2

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

www.ti.com

– Two Multimedia Card (MMC) / Secure Digital • Four Pulse Width Modulator (PWM) Outputs

(SD/SDIO)

– SmartMedia

• Four RTO (Real Time Out) Outputs

• Up to 104 General-Purpose I/O (GPIO) Pins

• Enhanced Direct-Memory-Access (EDMA) (Multiplexed with Other Device Functions)

Controller (64 Independent Channels)

• On-Chip ARM ROM Bootloader (RBL) to Boot

• USB Port with Integrated 2.0 High-Speed PHY from NAND Flash (with SPI EEPROM Boot

that Supports option), MMC/SD, or UART

– USB 2.0 Full and High-Speed Device • Configurable Power-Saving Modes

– USB 2.0 Low, Full, and High-Speed Host • Crystal or External Clock Input (typically

• Three 64-Bit General-Purpose Timers (each

24 MHz or 36 MHz)

configurable as two 32-bit timers) • Flexible PLL Clock Generators

• One 64-Bit Watch Dog Timer • Debug Interface Support

• Three UARTs (One fast UART with RTS and – IEEE-1149.1 (JTAG)

CTS Flow Control) Boundary-Scan-Compatible

• Three Serial Port Interfaces (SPI) each with two – ETB™ (Embedded Trace Buffer™) with

Chip-Selects 4K-Bytes Trace Buffer memory

• One Master/Slave Inter-Integrated Circuit (I2C) – Device Revision ID Readable by ARM

Bus®

• 337-Pin Ball Grid Array (BGA) Package

• Two Audio Serial Port (ASP) (ZCE Suffix), 0.65-mm Ball Pitch

– I2S and TDM I2S • 90nm Process Technology

– AC97 Audio Codec Interface • 3.3-V and 1.8-V I/O, 1.3-V Internal

– S/PDIF via Software • Community Resources

– Standard Voice Codec Interface (AIC12) – TI E2E Community

– SPI Protocol (Master Mode Only) – TI Embedded Processors Wiki

2 Digital Media System-on-Chip (DMSoC) Copyright © 2008–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 3

TMS320DM335

www.ti.com

1.2 Description

The DM335 processor is a low-cost, low-power processor providing advanced graphical user interface for

display applications that do not require video compression and decompression. Coupled with a video

processing subsystem (VPSS) that provides 720p display, the DM335 processor is powered by a

135/216-MHz ARM926EJ-S core so developers can create feature-rich graphical user interfaces allowing

customers to interact with their portable, electronic devices such as video-enabled universal remote

controls, Internet radio, e-books, video doorbells, and digital telescopes. The new DM335 is packed with

the same peripherals as its predecessor, the TMS320DM355 device, including high-speed USB 2.0

on-the-go, external memory interface (EMIF), mobile DDR/DDR2, two SDIO ports, three UART Ports, two

Audio Serial Ports, three SPI Ports, and SLC/MCL NAND Flash memory support. These peripherals help

customers create DM335 processor-based designs that add video and audio excitement to a wide range

of today's static user-interface applications while keeping silicon costs and power consumption low. The

new digital media processor is completely scalable with the DM355 processor and Digital Video Evaluation

Board (DVEVM), allowing customers to utilize their same code for their new DM335 processor focused

designs.

The new DM335 device delivers a sophisticated suite of capabilities allowing for flexible image capture

and display. Through its user interface technology, such as a four-level on-screen display, developers are

able to create picture-within-picture and video-within-video as well as innovative graphic user interfaces.

This is especially important for portable products that require the use of button or touch screen, such as

portable karaoke, video surveillance and electronic gaming applications. Additional advanced capture and

imaging technologies include support for CCD/CMOS image sensors, resize capability and video

stabilization. The 1280-by-960-pixel digital LCD connection runs on a 75-MHz pixel clock and supports TV

composite output for increased expandability. This highly integrated device is packaged in a 13 x 13 mm,

337 pin , 0.65 mm pitch BGA package.

SPRS528C–JULY 2008–REVISED JUNE 2010

The DM335 processor core is an ARM926EJ-S RISC processor. The ARM926EJ-S is a 32-bit processor

core that performs 32-bit and 16-bit instructions and processes 32-bit, 16-bit, and 8-bit data. The core

uses pipelining so that all parts of the processor and memory system can operate continuously. The ARM

core incorporates:

• A coprocessor 15 (CP15) and protection module

• Data and program Memory Management Units (MMUs) with table look-aside buffers.

• Separate 16K-byte instruction and 8K-byte data caches. Both are four-way associative with virtual

index virtual tag (VIVT).

The DM335 device has a Video Processing Subsystem (VPSS) with two configurable video/imaging

peripherals:

• A Video Processing Front-End (VPFE)

• A Video Processing Back-End (VPBE)

The VPFE port provides an interface for CCD/CMOS imager modules and video decoders. The VPBE

provides hardware On Screen Display (OSD) support and composite NTSC/PAL and digital LCD output.

The DM335 peripheral set includes:

• An inter-integrated circuit (I2C) Bus interface

• Two audio serial ports (ASP)

• Three 64-bit general-purpose timers each configurable as two independent 32-bit timers

• A 64-bit watchdog timer

• Up to 104-pins of general-purpose input/output (GPIO) with programmable interrupt/event generation

modes, multiplexed with other peripherals

• Three UARTs with hardware handshaking support on one UART

• Three serial port Interfaces (SPI)

• Four pulse width modulator (PWM) peripherals

• Four real time out (RTO) outputs

Copyright © 2008–2010, Texas Instruments Incorporated Digital Media System-on-Chip (DMSoC) 3

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 4

Peripherals

64bitDMA/DataBus

JTAG

24MHz

or36MHz

27MHz

(optional)

CCD/

CMOS

Module

DDR2/mDDR16

CLOCK

PLL

CLOCKctrl

PLLs

JTA

JTAG

I/F

Clocks

ARM

z )

ARM926EJ-S_Z8

I-

cach

e

16 K

B

l-cache

16KB

B

RA

M

32 K

B

RAM

32KB

B

D-

cach

e

8K

D-cache

8KB

RO

M

8 K

ROM

8KB

CCD

C

3A

H3A

DMA / Dataandconfigurationbus

DMA/Dataandconfigurationbus

DDR

MH

z )

DDR

controller

DL

DLL/

PHY

16bit

32bitConfigurationBus

CCDC

IPIPE

VPBE

Vide

o

Encod

er

Video

Encoder

10b

DAC

OS

D

OSD

er

c

ARM

ARMINTC

Enhanced

channels

3PCC /TC

(100 MHz

EnhancedDMA

64channels

Compositevideo

DigitalRGB/YUV

Nand /

Nand/SM/

Async/OneNand

(AEMIF)

USB 2 .0

USB2.0PHY

Speaker

microphone

ASP (2x)

BufferLogic

VPSS

MMC/SD(x2)

SPII/F(x3)

UART (x3)

I2C

Timer/

WDT (x4-64)

GIO

PWM(x4)

RTO

VPFE

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

• Two Multi-Media Card / Secure Digital (MMC/SD/SDIO) interfaces

• Wireless interfaces (Bluetooth, WLAN, WUSB) through SDIO

• A USB 2.0 full and high-speed device and host interface

• Two external memory interfaces:

– An asynchronous external memory interface (AEMIF) for slower memories/peripherals such as

NAND and OneNAND,

– A high speed synchronous memory interface for DDR2/mDDR.

For software development support the DM335 has a complete set of ARM development tools which

include: C compilers, assembly optimizers to simplify programming and scheduling, and a Windows™

debugger interface for visibility into source code execution.

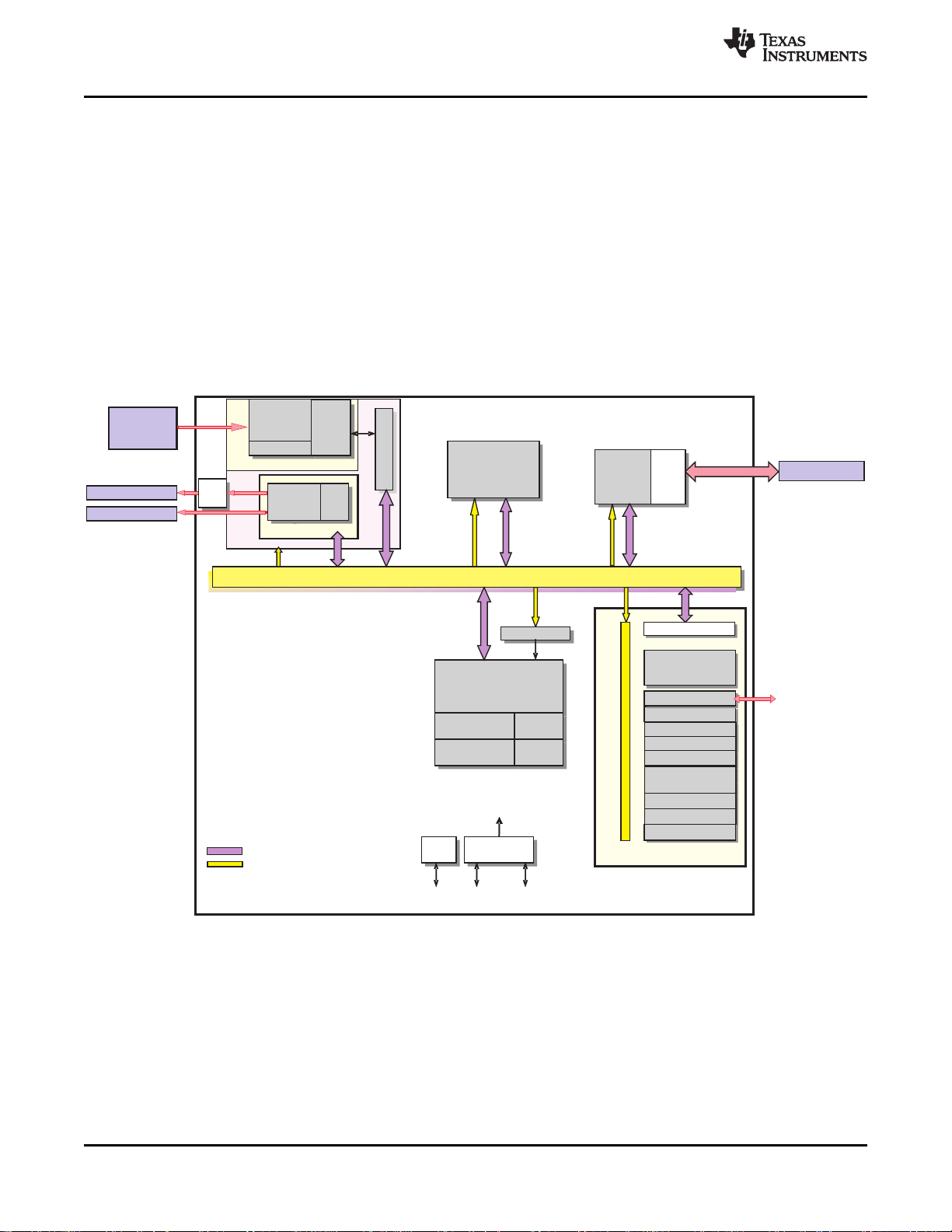

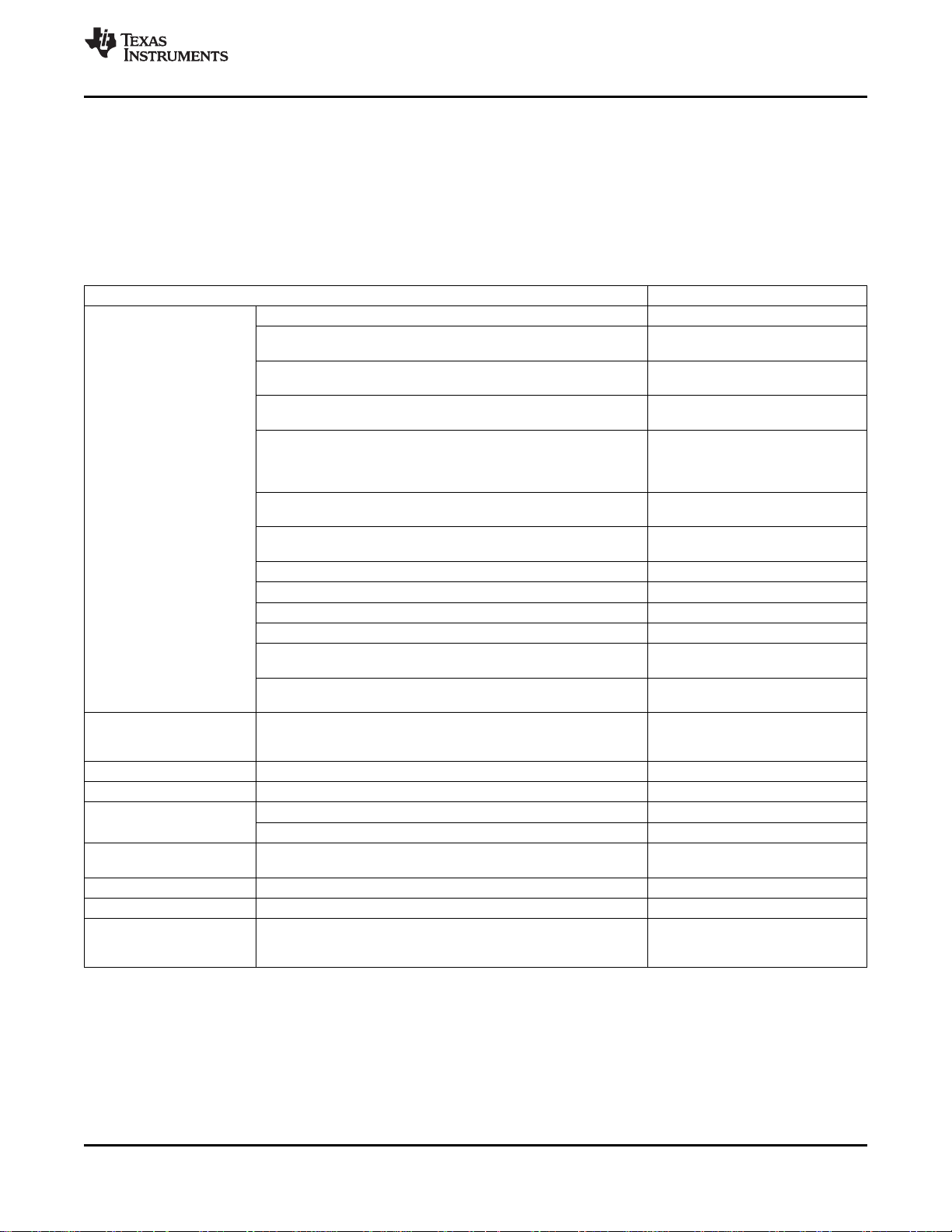

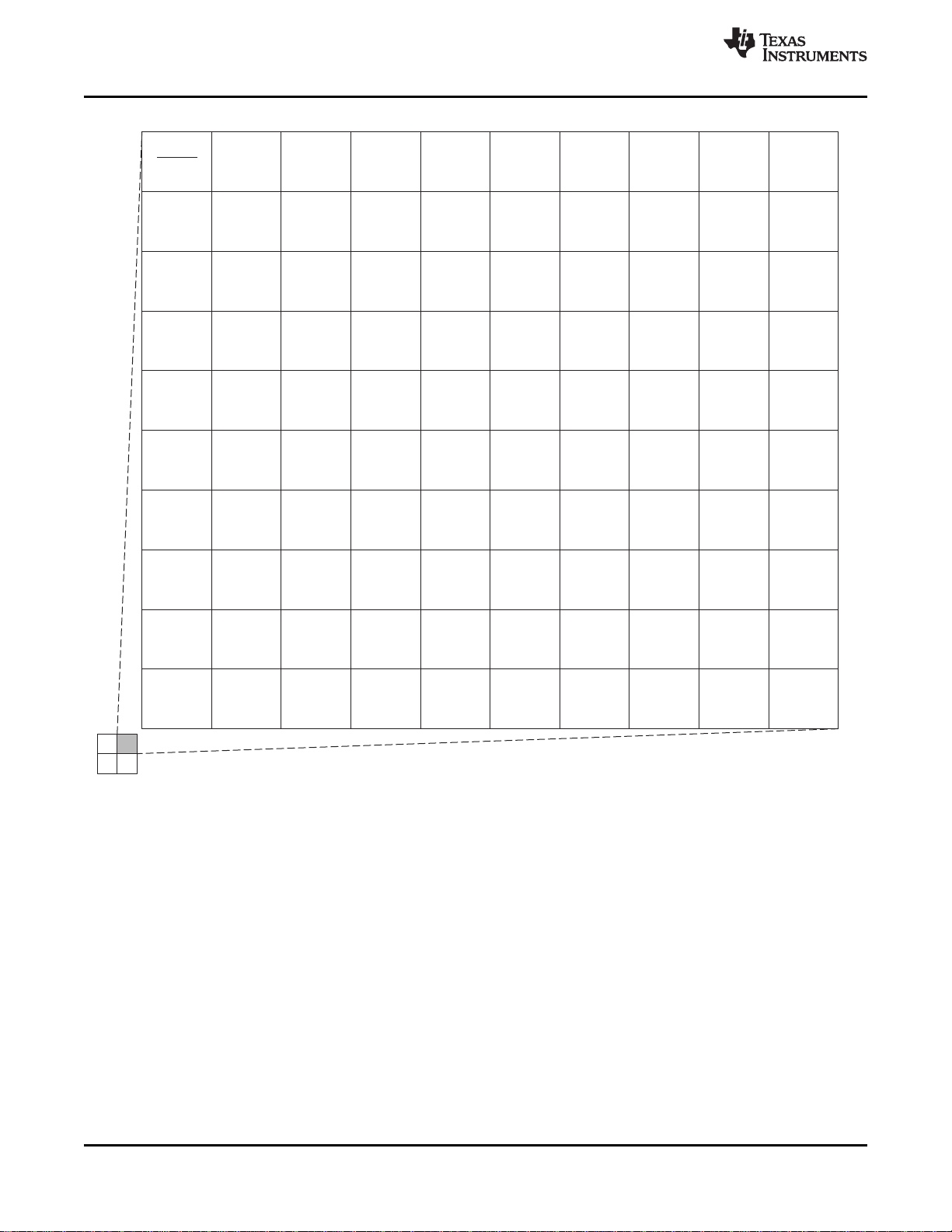

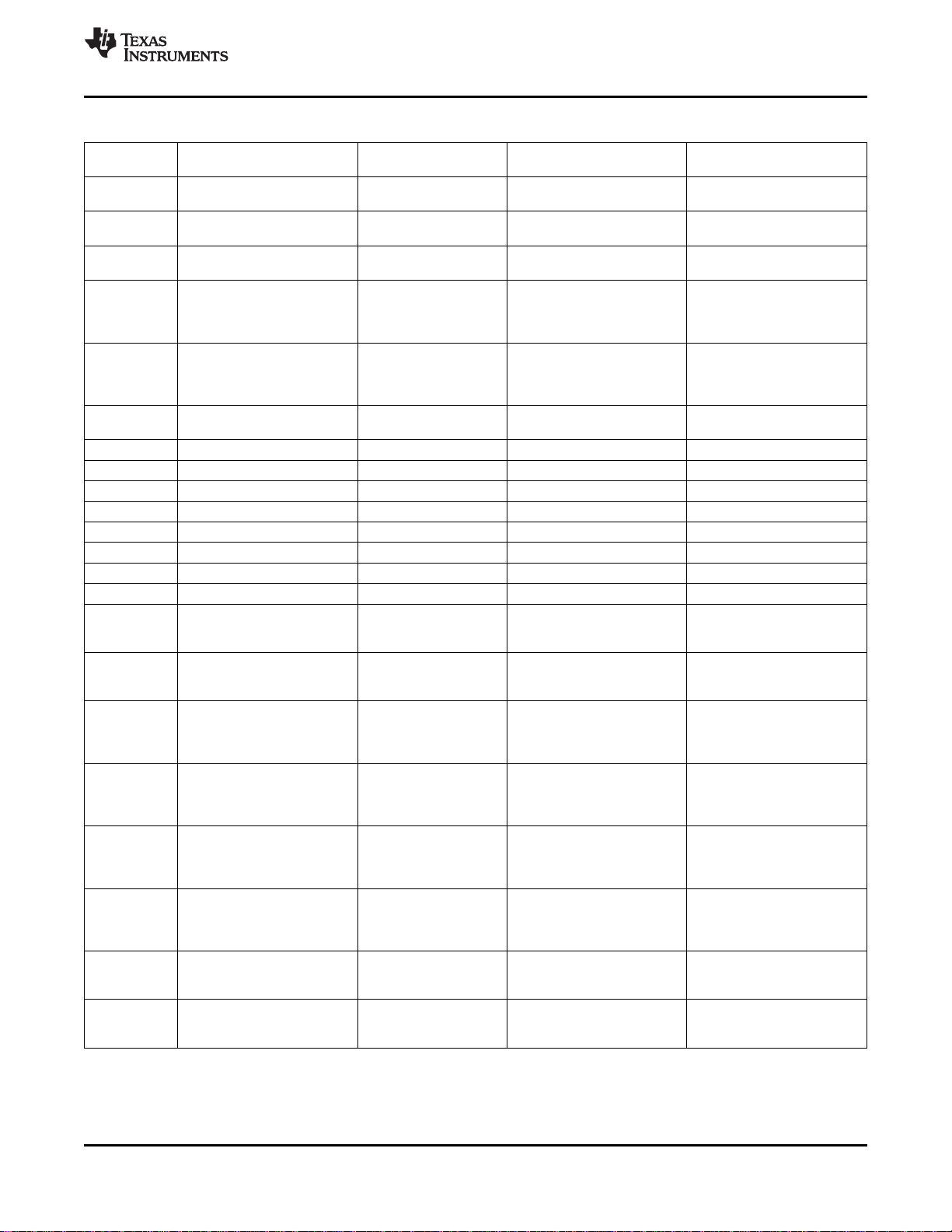

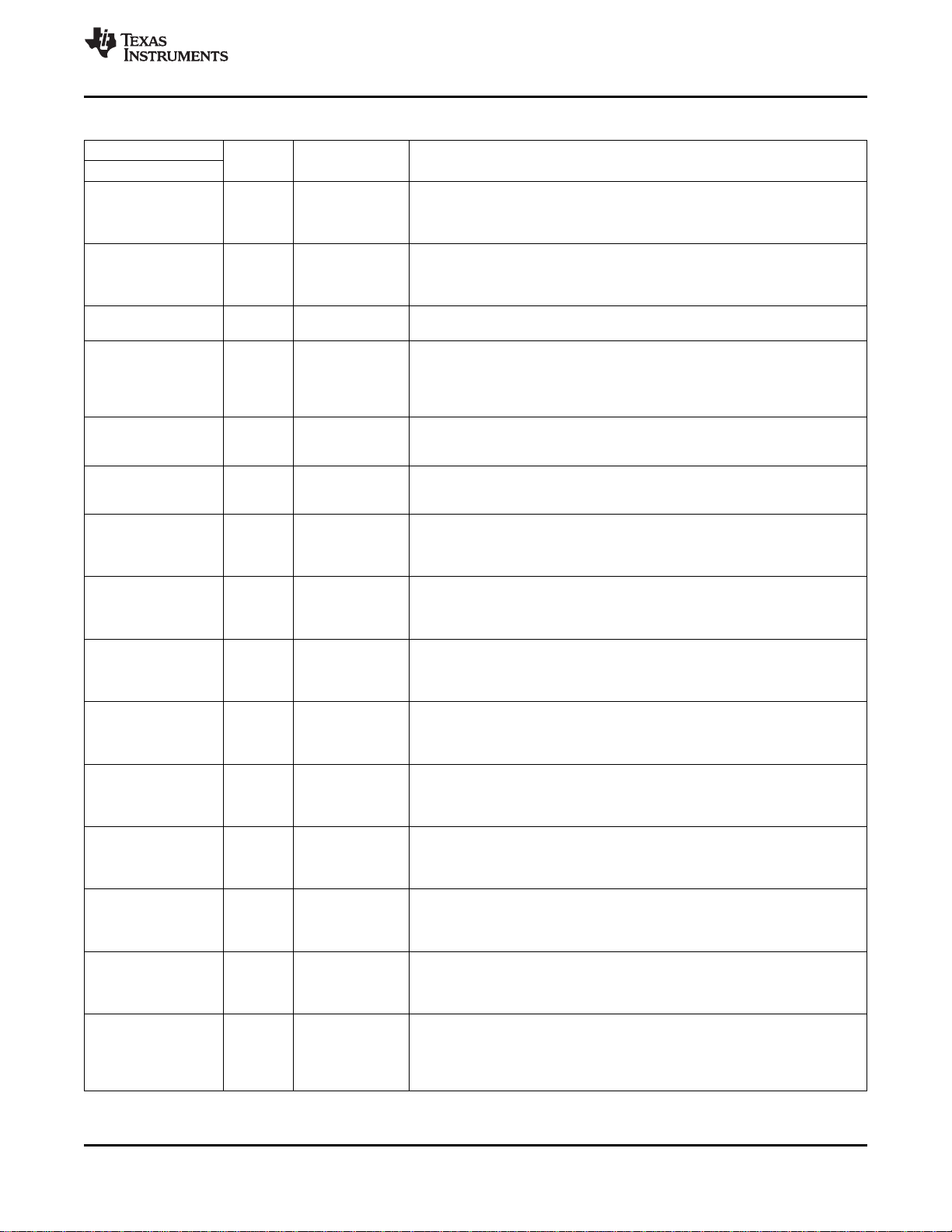

1.3 Functional Block Diagram

The below figure shows the functional block diagram of the DM335 device.

www.ti.com

4 Digital Media System-on-Chip (DMSoC) Copyright © 2008–2010, Texas Instruments Incorporated

Figure 1-1. Functional Block Diagram

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 5

TMS320DM335

www.ti.com

1 Digital Media System-on-Chip (DMSoC) ............ 1

1.1 TMS320DM335 Features ............................ 1 3.9 Pin Multiplexing ..................................... 79

1.2 Description ........................................... 3 3.10 Device Reset ....................................... 80

1.3 Functional Block Diagram ............................ 4

Revision History .............................................. 6

2 Device Overview ........................................ 7

2.1 Device Characteristics ............................... 7

2.2 Memory Map Summary .............................. 8

2.3 Pin Assignments .................................... 10

2.4 Pin Functions ....................................... 14

2.5 Image Data Output - Video Processing Back End

(VPBE) .............................................. 16

2.6 Asynchronous External Memory Interface (AEMIF)

...................................................... 19

2.7 DDR Memory Interface ............................. 21

2.8 GPIO ................................................ 23

2.9 Multi-Media Card/Secure Digital (MMC/SD)

Interfaces ........................................... 28

2.10 Universal Serial Bus (USB) Interface ............... 29

2.11 Audio Interfaces .................................... 30

2.12 UART Interface ..................................... 31

2

2.13 I

C Interface ........................................ 32

2.14 Serial Interface ..................................... 32

2.15 Clock Interface ...................................... 33

2.16 Real Time Output (RTO) Interface ................. 34

2.17 Pulse Width Modulator (PWM) Interface ........... 34

2.18 System Configuration Interface ..................... 35

2.19 Emulation ........................................... 36

2.20 Pin List .............................................. 37

2.21 Device Support ..................................... 56

3 Detailed Device Description ......................... 61

3.1 ARM Subsystem Overview ......................... 61

3.2 ARM926EJ-S RISC CPU ........................... 62

3.3 Memory Mapping ................................... 64

3.4 ARM Interrupt Controller (AINTC) .................. 65

3.5 Device Clocking .................................... 67

3.6 PLL Controller (PLLC) .............................. 74

3.7 Power and Sleep Controller (PSC) ................. 78

3.8 System Control Module ............................. 78

3.11 Default Device Configurations ...................... 81

3.12 Device Boot Modes ................................. 85

3.13 Power Management ................................ 89

3.14 64-Bit Crossbar Architecture ....................... 91

4 Device Operating Conditions ....................... 95

4.1 Absolute Maximum Ratings Over Operating Case

Temperature Range

(Unless Otherwise Noted) ................................. 95

4.2 Recommended Operating Conditions .............. 96

4.3 Electrical Characteristics Over Recommended

Ranges of Supply Voltage and Operating Case

Temperature (Unless Otherwise Noted) ............ 97

5 DM335 Peripheral Information and Electrical

Specifications .......................................... 98

5.1 Parameter Information Device-Specific Information

...................................................... 98

5.2 Recommended Clock and Control Signal Transition

Behavior ............................................ 99

5.3 Power Supplies ..................................... 99

5.4 Reset .............................................. 101

5.5 Oscillators and Clocks ............................ 102

5.6 General-Purpose Input/Output (GPIO) ............ 107

5.7 External Memory Interface (EMIF) ................ 109

5.8 MMC/SD ........................................... 117

5.9 Video Processing Sub-System (VPSS) Overview

..................................................... 119

5.10 USB 2.0 ........................................... 131

5.11 Universal Asynchronous Receiver/Transmitter

(UART) ............................................ 133

5.12 Serial Port Interface (SPI) ......................... 135

5.13 Inter-Integrated Circuit (I2C) ...................... 138

5.14 Audio Serial Port (ASP) ........................... 141

5.15 Timer .............................................. 149

5.16 Pulse Width Modulator (PWM) .................... 150

5.17 Real Time Out (RTO) ............................. 152

5.18 IEEE 1149.1 JTAG ................................ 153

6 Mechanical Data ...................................... 156

6.1 Thermal Data for ZCE ............................. 156

6.2 Packaging Information ............................ 156

SPRS528C–JULY 2008–REVISED JUNE 2010

Copyright © 2008–2010, Texas Instruments Incorporated Contents 5

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 6

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

This data sheet revision history highlights the technical changes made to the SPRS528B device-specific

data sheet to make it an SPRS528C revision.

Scope: Applicable updates to the DM335 device family, specifically relating to the DM335 device, have

been incorporated. The A135 and A216 DM335 devices both support extended temperature.

Global Added SPI EEPROM Boot option to NAND.

Section 1.1 Changed Feature bullet from NAND Flash to NAND Flash (with SPI EEPROM Boot option).

Section 2.4 Table 2-9 and Table 2-11:

Section 2.20 Updated Table 2-23, changed Reset State values.

Section 2.21.2 Updated Figure 2-5 Device Nomenclature.

Section 3.2.4 Changed NAND to NAND (with SPI EEPROM Boot option).

Section 3.5 Table 3-4:

Table 3-15 Updated BTSEL Function and NAND configuration in table.

Table 3-16 Updated table:

Section 3.12 Added Section 3.12.2, "RBL NAND Boot Process" and associated Standard and Compatibility

Section 3.12.1 Added ARM ROM Boot - SPI boot in NAND Mode bullet and sub-bullets.

Figure 3-6 Added SPI Flash to Diagram.

Section 4.2 Added last row to table including table note.

Section 4.3 Updated/Changed the following values in Section 4.3:

Table 5-5 Changed parameter 4 on table and added table note.

Table 5-6 Changed parameter 4 on table and added table note.

Table 5-45 Changed parameter 4 on table and added table note.

Section 5.7.1.3 Added note to Table 5-14.

www.ti.com

Revision History

Revision C Updates

ADDS/CHANGES/DELETES

• Added "Used to drive boot status LED signal (active low) in ROM boot modes." to pin number

P16.

• Deleted "Used to drive boot status LED signal (active low) in ROM boot modes." from pin

number V19.

• Updated/Changed "(/2 or /1 programmable)" to "POSTDIV" and added "(/2 or /1

programmable)" to 2nd row.

• Changed BTSEL[1:0] = 00 – Enable (NAND) to BTSEL[1:0] = 00 – Enable (NAND, SPI)

Changed SPI0 Module State from SyncRst to:

• BTSEL[1:0] = 00 – Enable (NAND, SPI)

• BTSEL[1:0] = 01 – SyncRst (OneNAND)

• BTSEL[1:0] = 10 – Enable (MMC/SD)

• BTSEL[1:0] = 11 – Enable (UART)

mode references throughout the document.

• IOHMAX value from "-100 mA" to "-4000 mA"

• IOZTYP (IPU disabled) value from "±10 µA" to "±20 µA"

• IOZTYP (IPU enabled) added value of ±100 µA"

Added "Test Conditions" for IOHand IOLparameters

6 Contents Copyright © 2008–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 7

TMS320DM335

www.ti.com

SPRS528C–JULY 2008–REVISED JUNE 2010

2 Device Overview

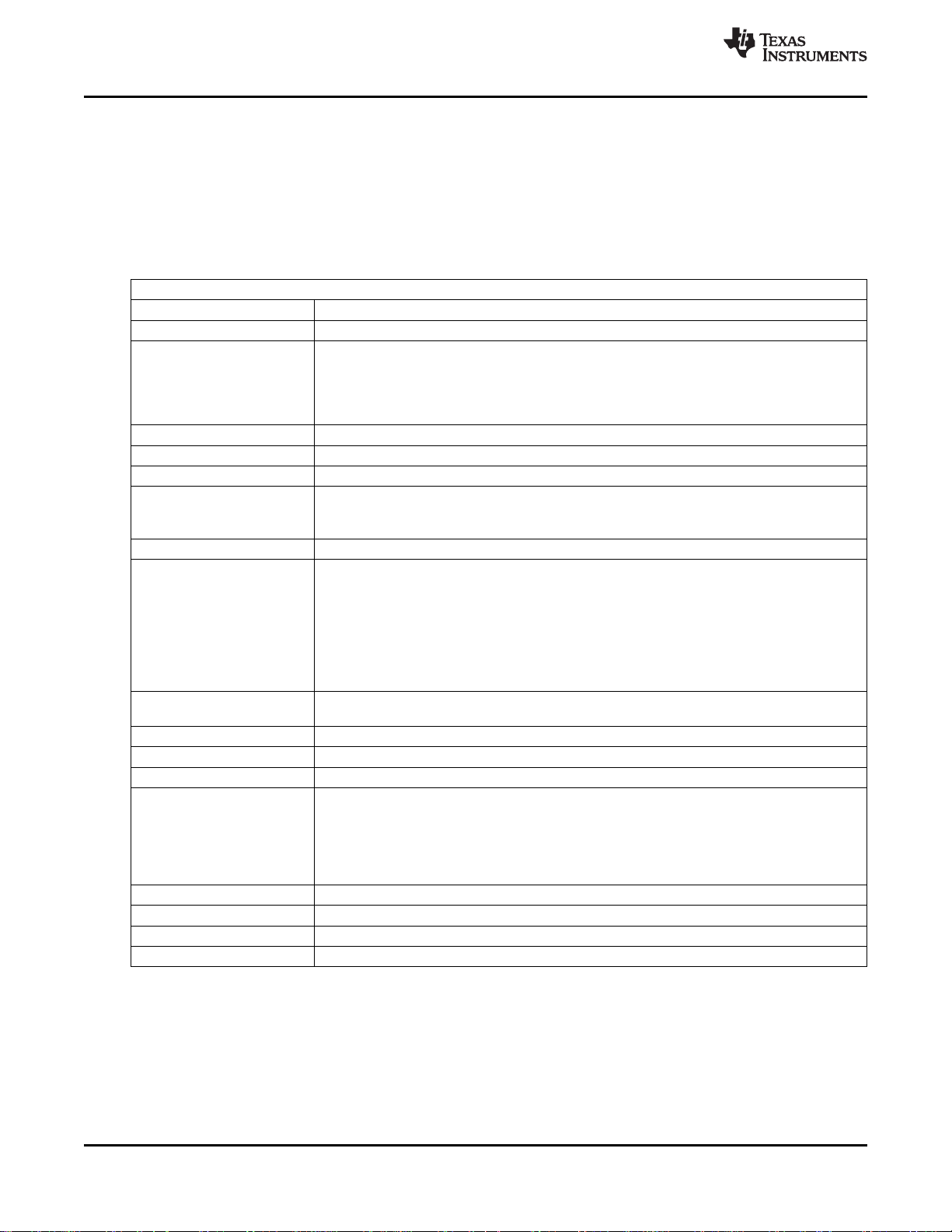

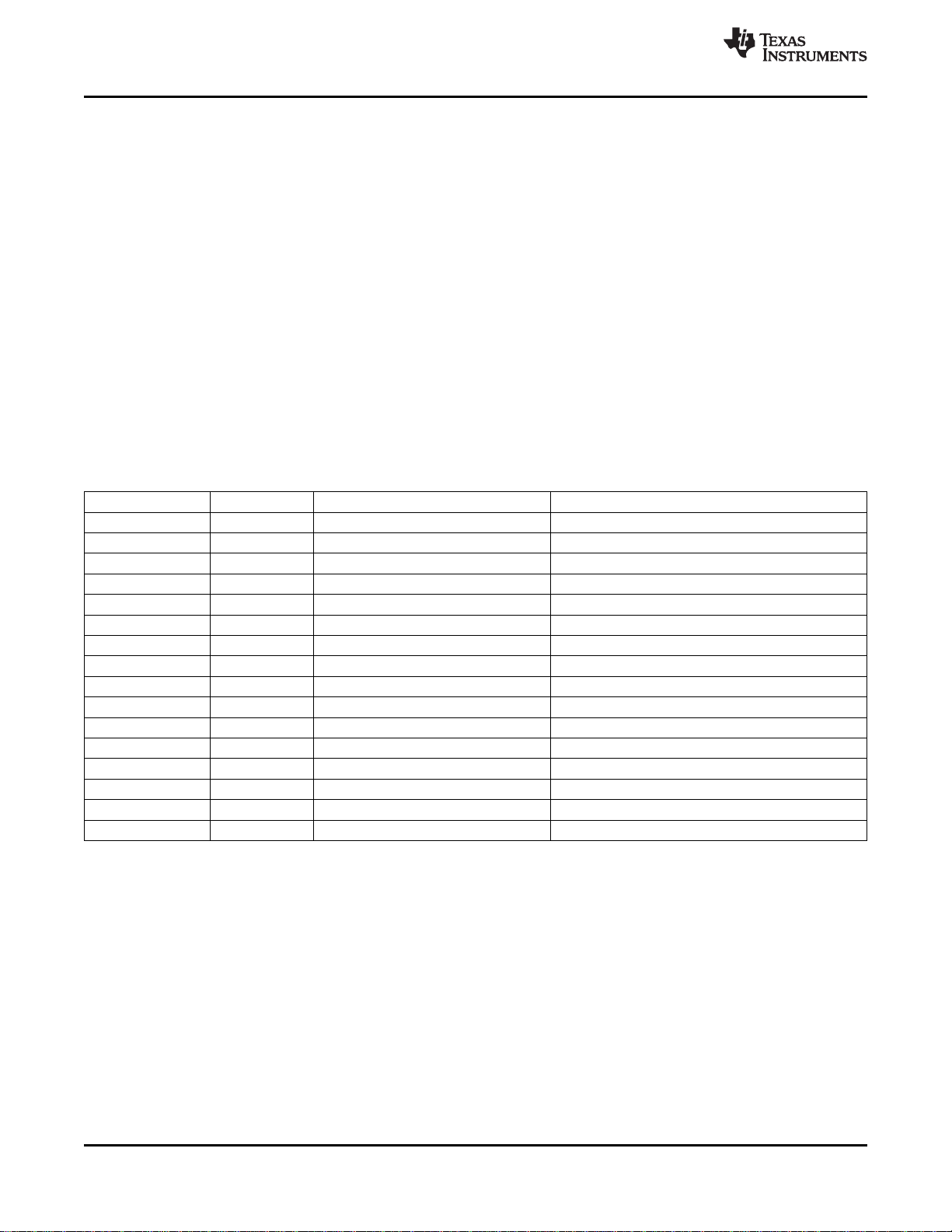

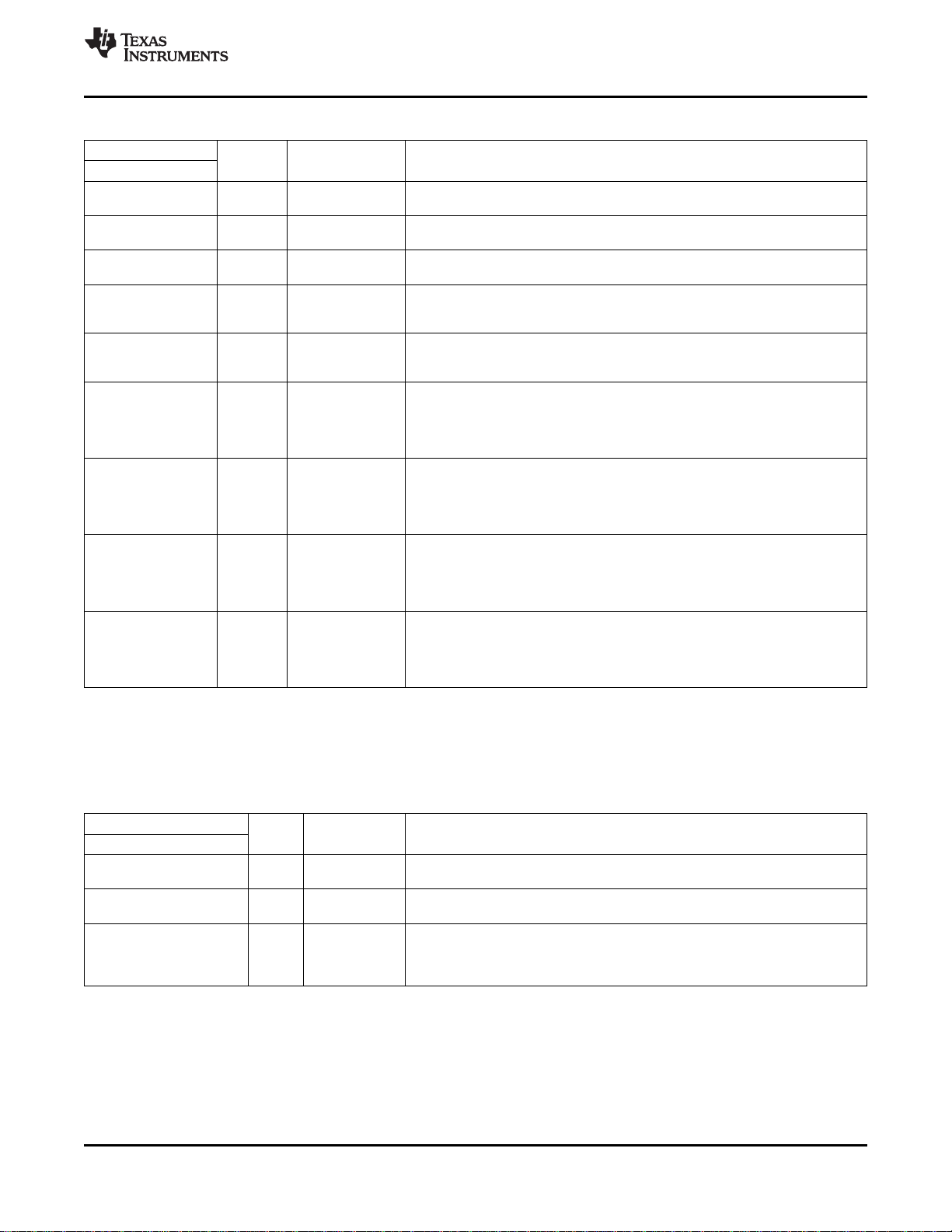

2.1 Device Characteristics

Table 2-1 provides an overview of the DMSoC. The table shows significant features of the device,

including the peripherals, capacity of on-chip RAM, ARM operating frequency, the package type with pin

count, etc.

Table 2-1. Characteristics of the Processor

HARDWARE FEATURES DM335

DDR2 / mDDR Memory Controller DDR2 / mDDR (16-bit bus width)

Asynchronous EMIF (AEMIF)

Flash Card Interfaces

EDMA

Peripherals

Not all peripherals pins are

available at the same time

(For more detail, see the

Device Configuration

section).

On-Chip CPU Memory Organization 16-KB I-cache, 8-KB D-cache,

JTAG BSDL_ID JTAGID register (address location: 0x01C4 0028) 0x0B73B01F

CPU Frequency (Maximum) MHz ARM 135, 216 MHz

Voltage

PLL Options

BGA Package 13 x 13 mm 337-Pin BGA (ZCE)

Process Technology 90 nm

Product Status

(1) PRODUCTION DATA information is current as of publication date. Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not necessarily include testing of all parameters.

(1)

Timers

UART

SPI

I2C One (Master/Slave)

Audio Serial Port [ASP] Two ASP

General-Purpose Input/Output Port Up to 104

Pulse width modulator (PWM) Four outputs

Configurable Video Ports

USB 2.0

Core (V) 1.3 V

I/O (V) 3.3 V, 1.8 V

Reference frequency options 24 MHz (typical), 36 MHz

Configurable PLL controller PLL bypass, programmable PLL

Product Preview (PP),

Advance Information (AI), PD

or Production Data (PD)

Asynchronous (8/16-bit bus width)

RAM, Flash (NAND, OneNAND)

Two MMC/SD

One SmartMedia/xD

64 independent DMA channels

Eight EDMA channels

Three 64-Bit General Purpose (each

configurable as two separate 32-bit

timers)

One 64-Bit Watch Dog

Three (one with RTS and CTS flow

control)

Three (each supports two slave

devices)

One Input (VPFE)

One Output (VPBE)

High, Full Speed Device

High, Full, Low Speed Host

ARM

32-KB RAM, 8-KB ROM

Copyright © 2008–2010, Texas Instruments Incorporated Device Overview 7

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 8

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

www.ti.com

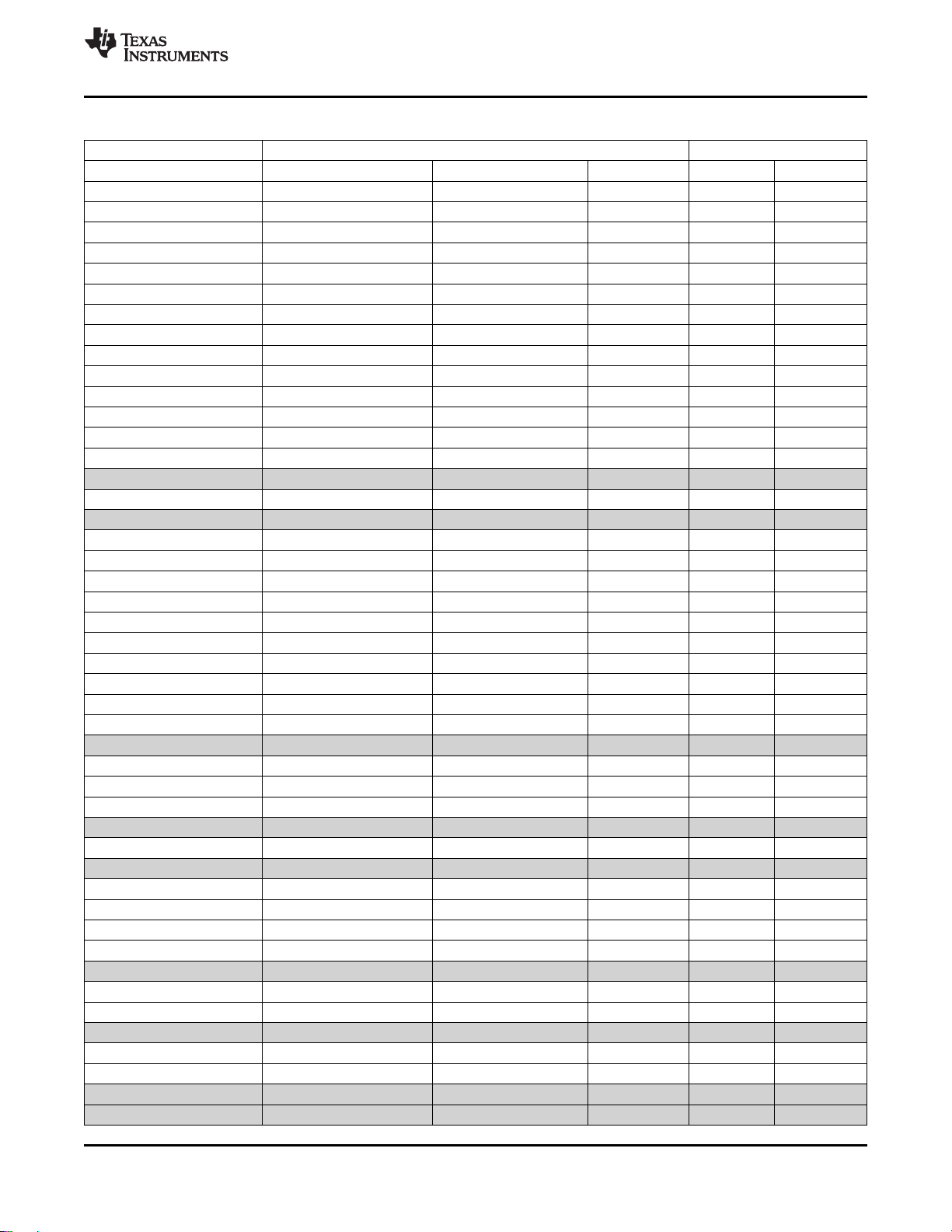

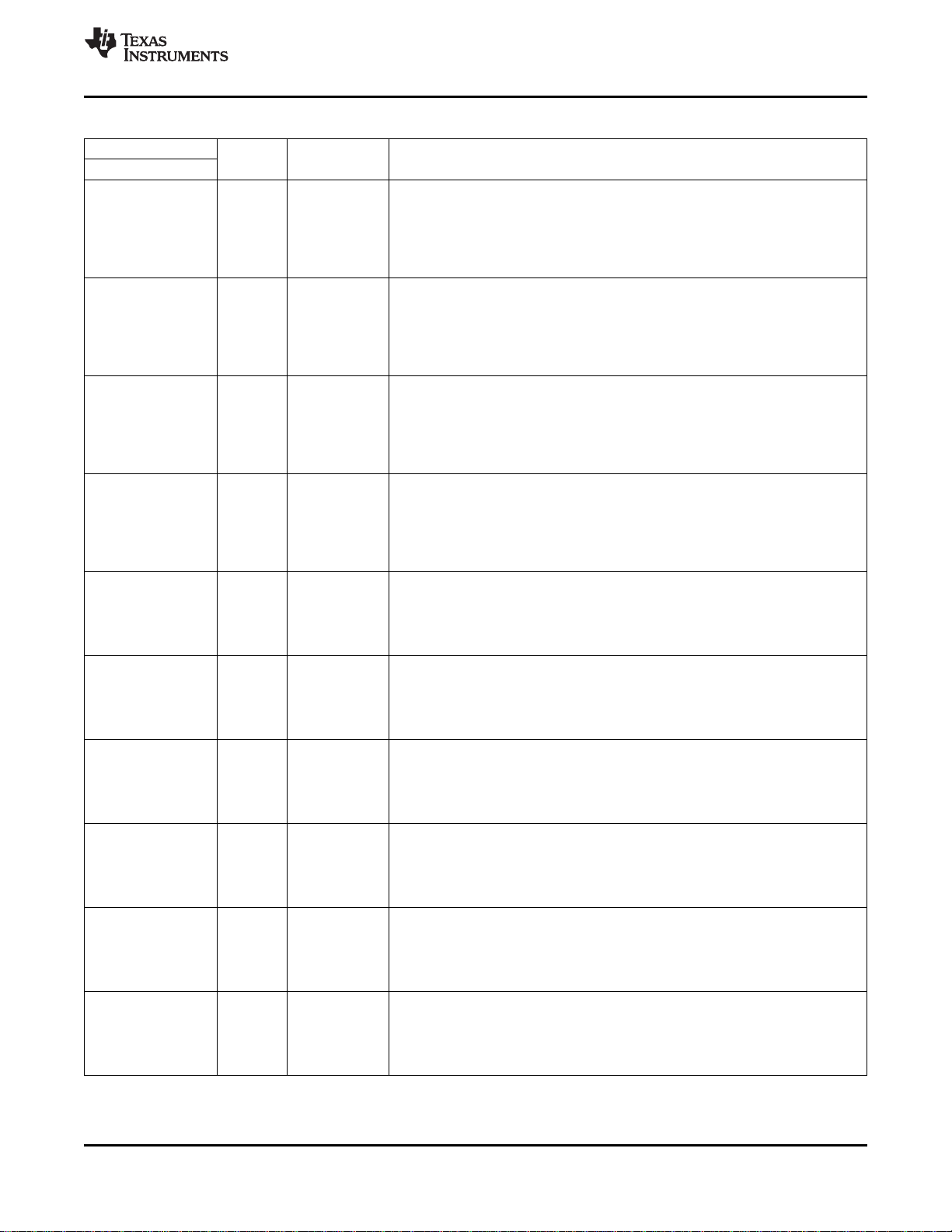

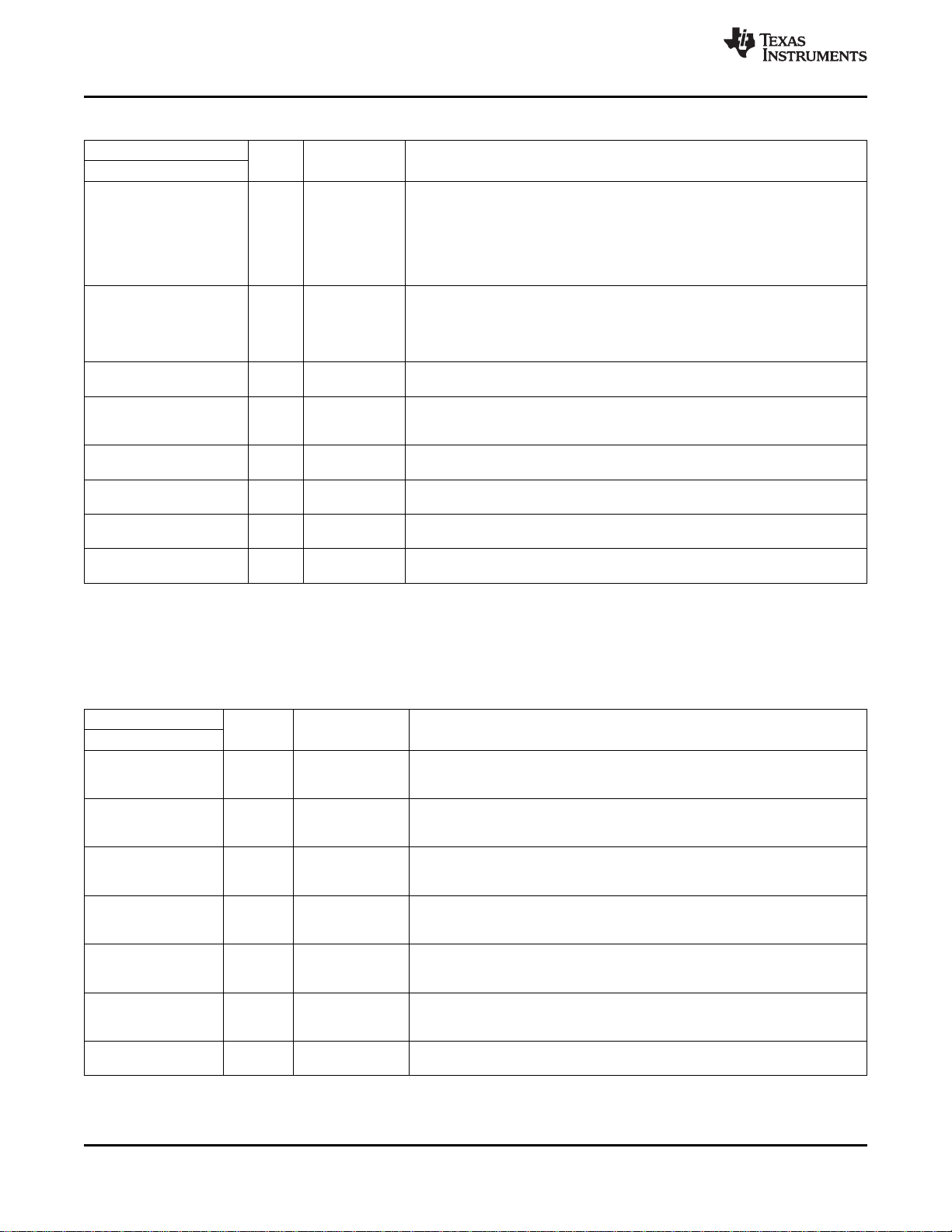

2.2 Memory Map Summary

Table 2-3 shows the memory map address ranges of the device. Table 2-3 depicts the expanded map of

the Configuration Space (0x01C0 0000 through 0x01FF FFFF). The device has multiple on-chip memories

associated with its processor and various subsystems. To help simplify software development a unified

memory map is used where possible to maintain a consistent view of device resources across all bus

masters. The bus masters are the ARM, EDMA, USB, and VPSS.

Table 2-2. DM335 Memory Map

Start Address End Address Size (Bytes) ARM EDMA USB VPSS

0x0000 0000 0x0000 3FFF 16K ARM RAM0

0x0000 4000 0x0000 7FFF 16K ARM RAM1

0x0000 8000 0x0000 FFFF 32K ARM ROM

0x0001 0000 0x0001 3FFF 16K ARM RAM0 (Data) ARM RAM0 ARM RAM0

0x0001 4000 0x0001 7FFF 16K ARM RAM1 (Data) ARM RAM1 ARM RAM1

0x0001 8000 0x0001 FFFF 32K ARM ROM (Data) ARM ROM ARM ROM

0x0002 0000 0x000F FFFF 896K Reserved

0x0010 0000 0x01BB FFFF 26M

0x01BC 0000 0x01BC 0FFF 4K ARM ETB Mem

0x01BC 1000 0x01BC 17FF 2K ARM ETB Reg Reserved

0x01BC 1800 0x01BC 18FF 256 ARM IceCrusher Reserved

0x01BC 1900 0x01BC FFFF 59136 Reserved

0x01BD 0000 0x01BF FFFF 192K

0x01C0 0000 0x01FF FFFF 4M CFG Bus CFG Bus

0x0200 0000 0x09FF FFFF 128M ASYNC EMIF (Data) ASYNC EMIF (Data)

0x0A00 0000 0x11EF FFFF 127M - 16K

0x11F0 0000 0x11F1 FFFF 128K Reserved Reserved

0x11F2 0000 0x1FFF FFFF 141M-64K

0x2000 0000 0x2000 7FFF 32K DDR EMIF Control DDR EMIF Control

0x2000 8000 0x41FF FFFF 544M-32K Reserved

0x4200 0000 0x49FF FFFF 128M Reserved Reserved

0x4A00 0000 0x7FFF FFFF 864M Reserved

0x8000 0000 0x8FFF FFFF 256M DDR EMIF DDR EMIF DDR EMIF DDR EMIF

0x9000 0000 0xFFFF FFFF 1792M Reserved Reserved Reserved Reserved

Mem Map Mem Map Mem Map Mem Map

(Instruction)

(Instruction)

(Instruction)

- only 8K used

- only 8K used

Peripherals Peripherals

Regs Regs

Reserved Reserved

Reserved

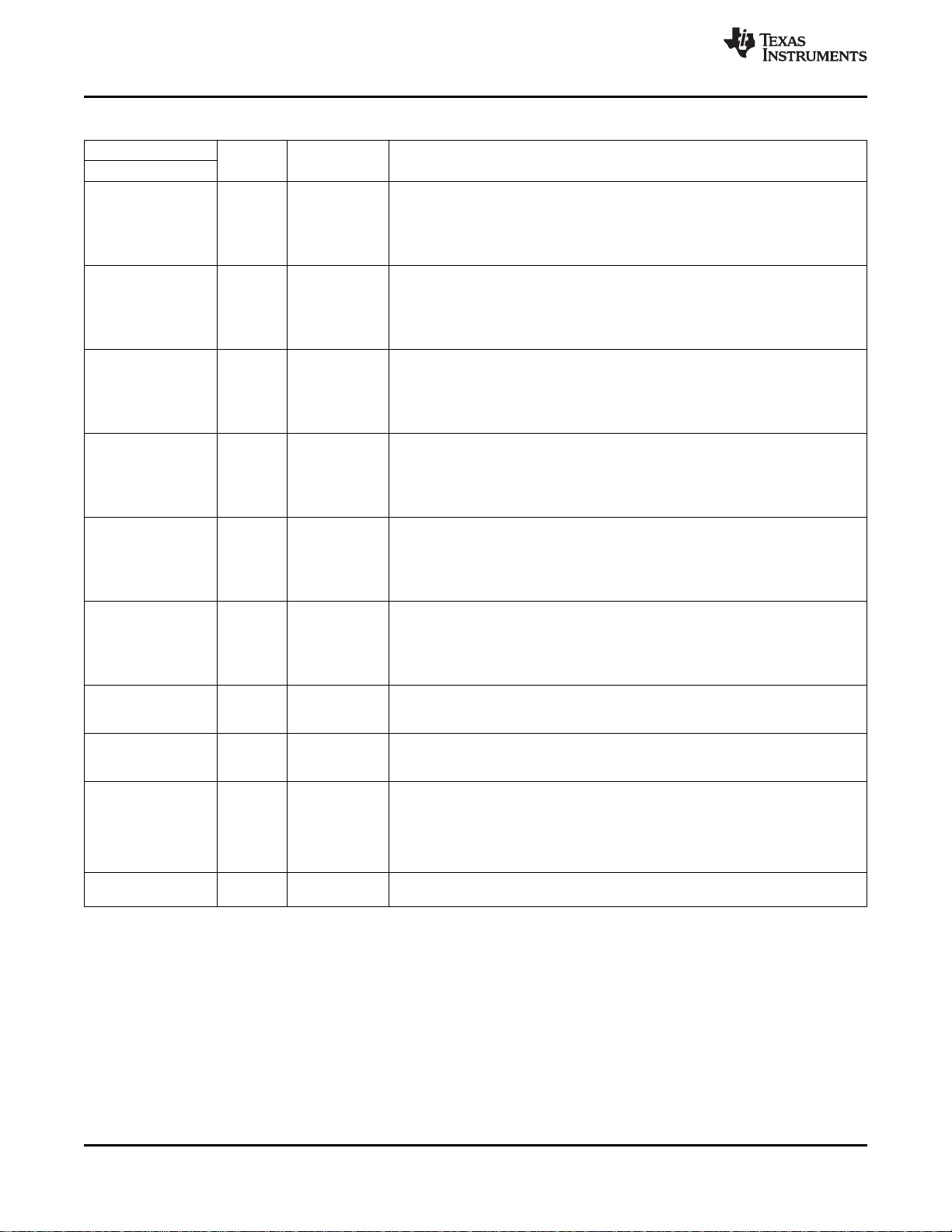

Table 2-3. DM335 ARM Configuration Bus Access to Peripherals

Address Accessibility

Region Start End Size ARM EDMA

EDMA CC 0x01C0 0000 0x01C0 FFFF 64K √ √

EDMA TC0 0x01C1 0000 0x01C1 03FF 1K √ √

EDMA TC1 0x01C1 0400 0x01C1 07FF 1K √ √

Reserved 0x01C1 0800 0x01C1 9FFF 38K √ √

Reserved 0x01C1 A000 0x01C1 FFFF 24K √ √

UART0 0x01C2 0000 0x01C2 03FF 1K √ √

8 Device Overview Copyright © 2008–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 9

TMS320DM335

www.ti.com

SPRS528C–JULY 2008–REVISED JUNE 2010

Table 2-3. DM335 ARM Configuration Bus Access to Peripherals (continued)

Address Accessibility

UART1 0x01C2 0400 0x01C2 07FF 1K √ √

Timer4/5 0x01C2 0800 0x01C2 0BFF 1K √ √

Real-time out 0x01C2 0C00 0x01C2 0FFF 1K √ √

I2C 0x01C2 1000 0x01C2 13FF 1K √ √

Timer0/1 0x01C2 1400 0x01C2 17FF 1K √ √

Timer2/3 0x01C2 1800 0x01C2 1BFF 1K √ √

WatchDog Timer 0x01C2 1C00 0x01C2 1FFF 1K √ √

PWM0 0x01C2 2000 0x01C2 23FF 1K √ √

PWM1 0x01C2 2400 0x01C2 27FF 1K √ √

PWM2 0x01C2 2800 0x01C2 2BFF 1K √ √

PWM3 0x01C2 2C00 0x01C2 2FFF 1K √ √

System Module 0x01C4 0000 0x01C4 07FF 2K √ √

PLL Controller 0 0x01C4 0800 0x01C4 0BFF 1K √ √

PLL Controller 1 0x01C4 0C00 0x01C4 0FFF 1K √ √

Power/Sleep Controller 0x01C4 1000 0x01C4 1FFF 4K √ √

Reserved 0x01C4 2000 0x01C4 7FFF 24K √ √

ARM Interrupt Controller 0x01C4 8000 0x01C4 83FF 1K √ √

Reserved 0x01C4 8400 0x01C6 3FFF 111K √ √

USB OTG 2.0 Regs / RAM 0x01C6 4000 0x01C6 5FFF 8K √ √

SPI0 0x01C6 6000 0x01C6 67FF 2K √ √

SPI1 0x01C6 6800 0x01C6 6FFF 2K √ √

GPIO 0x01C6 7000 0x01C6 77FF 2K √ √

SPI2 0x01C6 7800 0x01C6 FFFF 2K √ √

VPSS Subsystem 0x01C7 0000 0x01C7 FFFF 64K √ √

VPSS Clock Control 0x01C7 0000 0x01C7 007F 128 √ √

Hardware 3A 0x01C7 0080 0x01C7 00FF 128 √ √

Image Pipe (IPIPE) Interface 0x01C7 0100 0x01C7 01FF 256 √ √

On Screen Display 0x01C7 0200 0x01C7 02FF 256 √ √

Reserved 0x01C7 0300 0x01C7 03FF 256 √ √

Video Encoder 0x01C7 0400 0x01C7 05FF 512 √ √

CCD Controller 0x01C7 0600 0x01C7 07FF 256 √ √

VPSS Buffer Logic 0x01C7 0800 0x01C7 08FF 256 √ √

Reserved 0x01C7 0900 0x01C7 09FF 256 √ √

Image Pipe (IPIPE) 0x01C7 1000 0x01C7 3FFF 12K √ √

Reserved 0x01C7 4000 0x01CD FFFF 432K √ √

Multimedia / SD 1 0x01E0 0000 0x01E0 1FFF 8K √ √

ASP0 0x01E0 2000 0x01E0 3FFF 8K √ √

ASP1 0x01E0 4000 0x01E0 5FFF 8K √ √

UART2 0x01E0 6000 0x01E0 63FF 1K √ √

Reserved 0x01E0 6400 0x01E0 FFFF 39K √ √

ASYNC EMIF Control 0x01E1 0000 0x01E1 0FFF 4K √ √

Multimedia / SD 0 0x01E1 1000 0x01E1 FFFF 60K √ √

Reserved 0x01E2 0000 0x01FF FFFF 1792K √ √

ASYNC EMIF Data (CE0) 0x0200 0000 0x03FF FFFF 32M √ √

ASYNC EMIF Data (CE1) 0x0400 0000 0x05FF FFFF 32M √ √

Reserved 0x0600 0000 0x09FF FFFF 64M √ √

Reserved 0x0A00 0000 0x0BFF FFFF 32M √ √

Copyright © 2008–2010, Texas Instruments Incorporated Device Overview 9

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 10

9

J

8

V

SSA_PLL2

7

V

DDA33_USB

6

5

4

31

H

G

V

DDA13_USB

V

SS

F

E

D

CIN2

C

B

A

VREF

CIN3CIN0

V

DDA_PLL2

V

SS

LCD_OE

FIELDVCLK

V

SS

V

SS

CV

DD

VSYNCEXTCLKVFB

V

DD_VOUT

V

DD_VOUT

V

DD_VOUT

HSYNCCOUT0COUT1TVOUT

TDOEMU0EMU1

V

SS_USB

USB_VBUS

COUT2COUT3IOUT

TDITMS

V

SS_USB

USB_IDCOUT4

V

SS

TRST

V

SS_USB_REF

USB_R1

V

DDD13_USB

USB_DRV

VBUS

CV

DD

YOUT7COUT5

MXO1

V

SS

V

SS_USB

V

DDA33_USB_

PLL

V

SS

YOUT5YOUT4YOUT0

MXI1

V

SS

USB_DPUSB_DM

V

SS

YOUT6YOUT2

CV

DD

2

V

SS

V

SS

V

SS

IBIAS

V

SS

COUT6

COUT7

YOUT3

YOUT1

RSV01

V

DD

V

DD

NC

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

Table 2-3. DM335 ARM Configuration Bus Access to Peripherals (continued)

Reserved 0x0C00 0000 0x0FFF FFFF 64M √ √

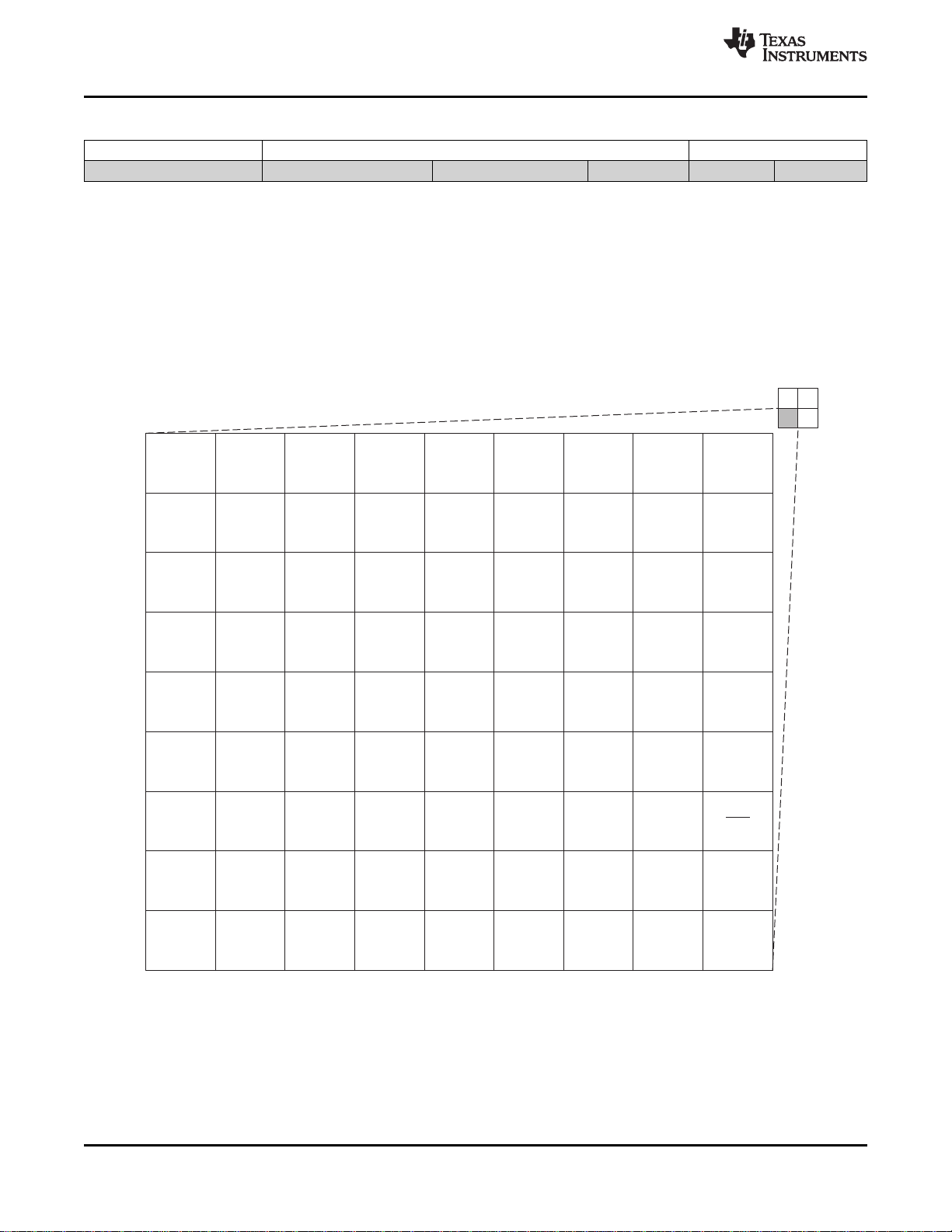

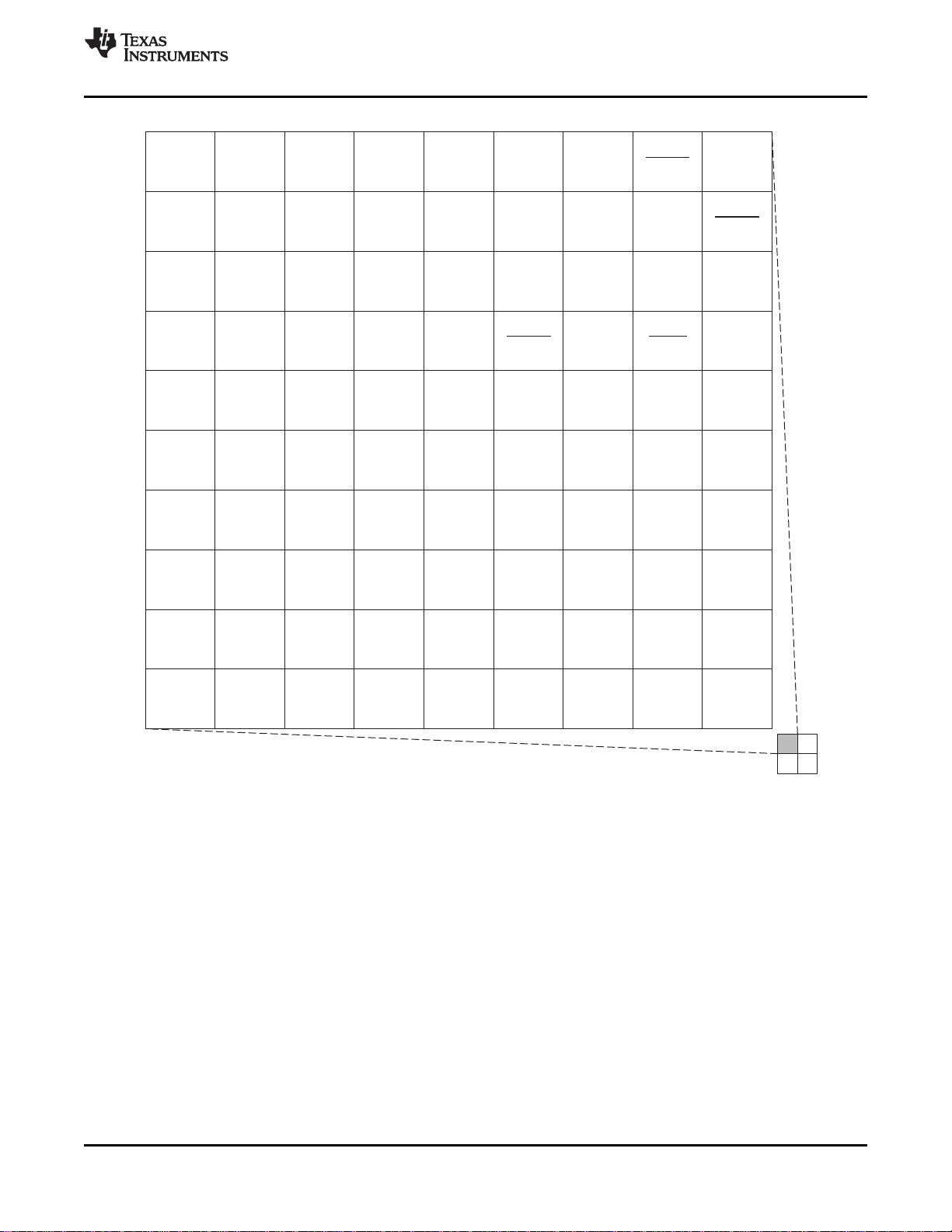

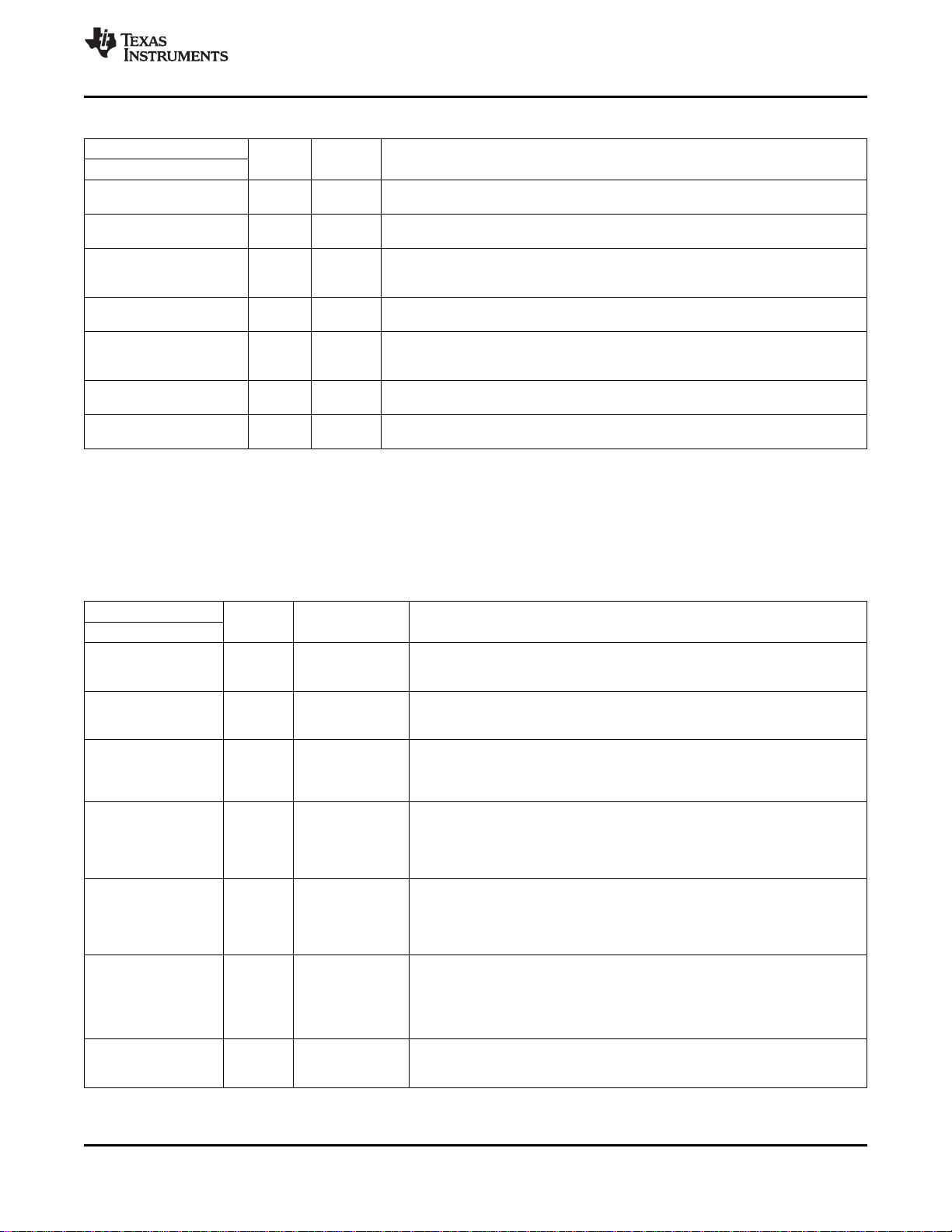

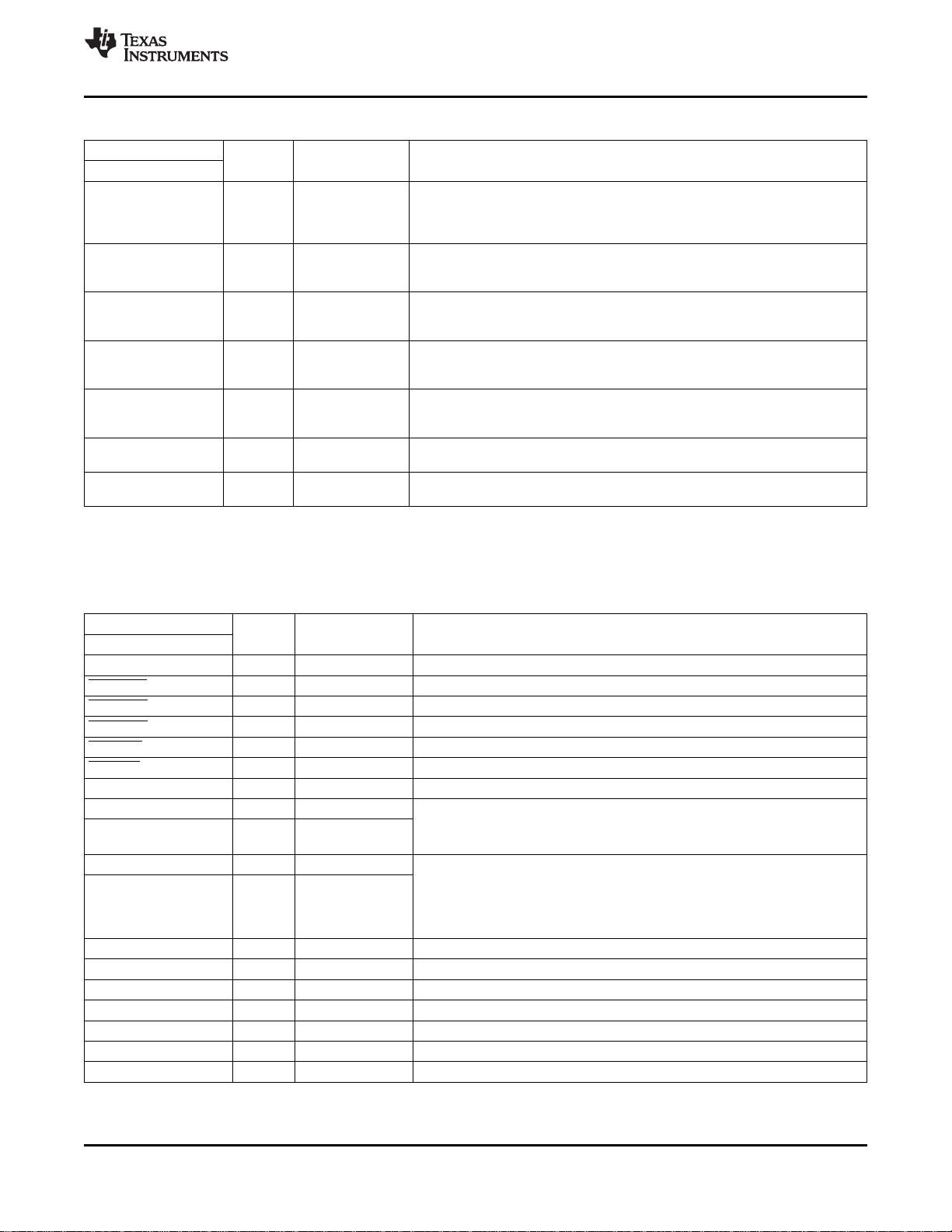

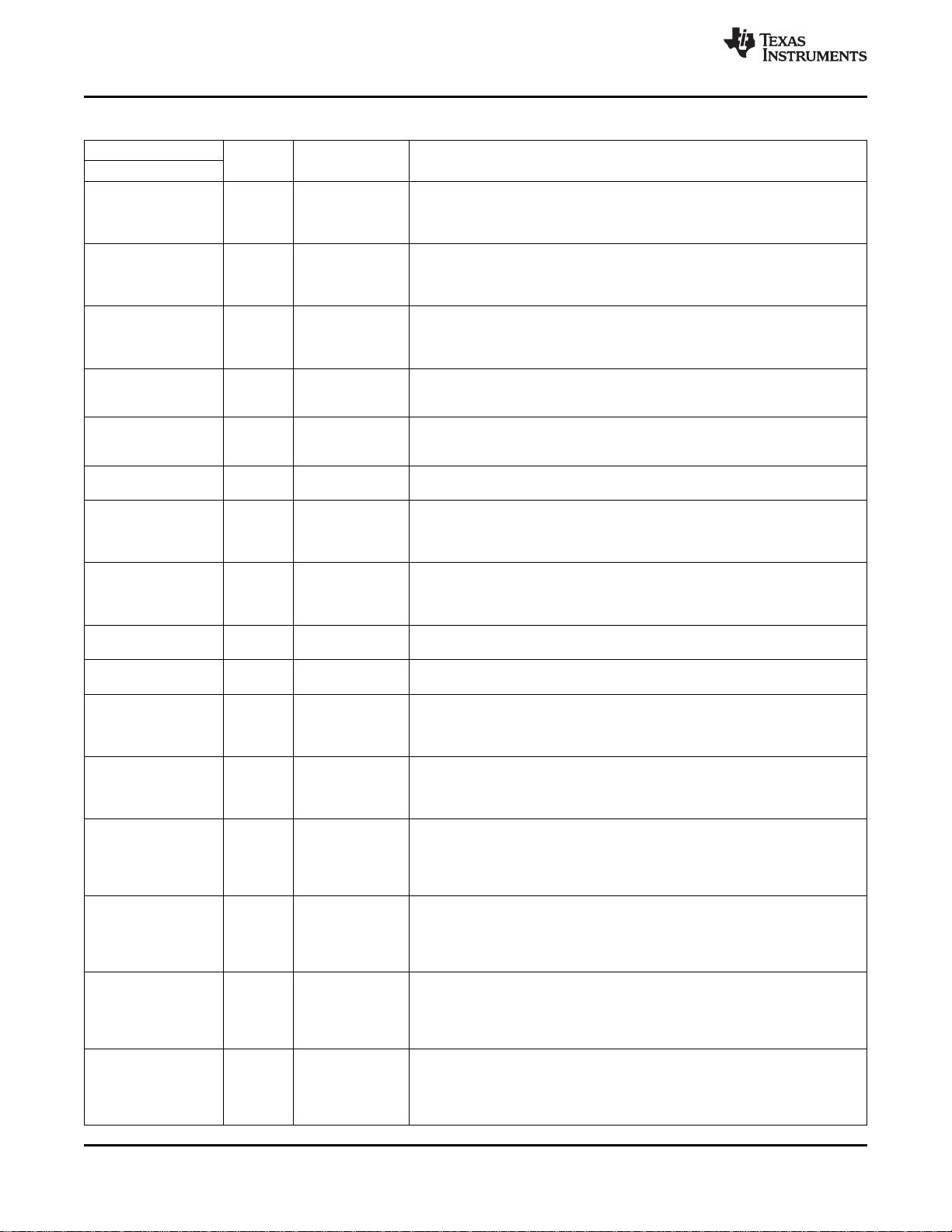

2.3 Pin Assignments

Extensive use of pin multiplexing is used to accommodate the largest number of peripheral functions in

the smallest possible package. Pin multiplexing is controlled using a combination of hardware

configuration at device reset and software programmable register settings.

2.3.1 Pin Map (Bottom View)

Figure 2-1 through Figure 2-4 show the pin assignments in four quadrants (A, B, C, and D). Note that

micro-vias are not required. Contact your TI representative for routing recommendations.

www.ti.com

Address Accessibility

Figure 2-1. Pin Map [Quadrant A]

10 Device Overview Copyright © 2008–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 11

W

9

DDR_CLK

8

DDR_CLK

7654

DDR_A05

32

DDR_A02

1

V

DDR_A07DDR_A04DDR_A00

U

V

SS

T

PCLK

R

P

N

M

L

K

DDR_A11DDR_A09DDR_A08

V

SS

DDR_CAS

DDR_BA[2]

DDR_A12DDR_A10DDR_A01

V

SS

DDR_BA[0]DDR_BA[1]

DDR_A13DDR_A06

DDR_A03

V

SS

V

SS

V

SS

V

SS

DDR_ZNDDR_CSDDR_RAS

V

SS

V

SS

MXO2

V

DD_DDR

CV

DD

CV

DD

V

SS

CAM_WEN_

FIELD

CAM_VDYIN3

V

SS

MXI2

V

DD_DDR

V

DD_VIN

YIN0YIN2YIN4YIN1V

SS_MX2

V

SS

V

SS

CV

DD

CAM_HDCIN7

RSV05

V

SS

V

DD_DDR

V

SS

V

SS

V

SS

YIN5

YIN6CIN5

RSV06

RSV04

V

SS

V

SS_DAC

V

DDA18V_DAC

V

DD

YIN7CIN4CIN1

V

SS

RSV03

V

SS

V

DD

CV

DD

CIN6

V

SS

RSV07RSV02

V

DD_VIN

V

DD_VIN

TMS320DM335

www.ti.com

SPRS528C–JULY 2008–REVISED JUNE 2010

Figure 2-2. Pin Map [Quadrant B]

Copyright © 2008–2010, Texas Instruments Incorporated Device Overview 11

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 12

CV

DD

19

W

18

DDR_

DQGATE0

17

DDR_DQ15

16

DDR_DQ13

15

DDR_DQ11

14

DDR_DQ10

13

DDR_DQ07

12

DDR_DQ05

11

DDR_DQ01

10

DDR_WE

EM_A13

V

V

SS

DDR_

DQGATE1

DDR_DQ14DDR_DQS[1]

DDR_DQ09DDR_DQ06

DDR_DQS[0]DDR_DQ00

DDR_CKE

EM_A12

U

UART0_RXD

V

SS

DDR_DQ12DDR_DQM[1]

V

SS

DDR_DQ08DDR_DQ04DDR_DQ02

DDR_VREF

EM_A08

T

UART0_TXD

CV

DD

V

SS

V

DD_DDR

DDR_DQM[0]

DDR_DQ03

EM_A05

R

EM_A10

UART1_TXD

EM_A11

UART1_RXD

I2C_SCLI2C_SDA

V

DD_DDR

V

SSA_DLL

V

DDA33_DDRDLL

EM_BA1

P

EM_A06

EM_A09EM_A07EM_A04

V

DD_DDR

EM_BA0

N

EM_A03EM_A01EM_A02

V

SS

V

DD

V

DD

EM_D14

M

EM_D15

V

SS

EM_A00EM_D13

V

SS

V

DD

EM_D10

L

EM_D12EM_D11EM_D08EM_D04

CV

DD

V

SS

EM_D07

K

EM_D09EM_D06

V

DD_DDR

V

DD_DDR

V

DD_DDR

V

DD_DDR

V

DD

V

DD

V

DD

CV

DD

V

DD

V

SS

CV

DD

CV

DD

V

SS

V

SS

V

DD

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

www.ti.com

Figure 2-3. Pin Map [Quadrant C]

12 Device Overview Copyright © 2008–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 13

19181716151413121110

EM_D05

J

EM_D02

H

EM_CE1

G

F

E

D

C

V

DD

B

A

EM_D03EM_D01EM_CE0EM_WE

V

SS

EM_D00

EM_ADV

ASP0_DX

V

SSA_PLL1

CV

DD

EM_WAIT

ASP0_FSX

GIO003

V

DDA_PLL1

EM_OE

ASP0_CLKXASP0_CLKRASP0_FSR

GIO002

EM_CLK

ASP0_DRASP1_FSRASP1_FSX

GIO001

SPI1_

SDENA[0]

SPI1_SDORTCKTCK

ASP1_CLKXASP1_CLKRASP1_CLKS

GIO005

MMCSD0_

DATA1

CLKOUT1RESET

ASP1_DRASP1_DX

GIO007GIO000

MMCSD1_CLK

MMCSD0_CMDSPI1_SCLKSPI0_SCLK

CLKOUT3

V

SS_MX1

GIO006

MMCSD1_

DATA0

MMCSD1_

DATA3

MMCSD1_

DATA2

GIO004

MMCSD1_

CMD

MMCSD1_

DATA1

MMCSD0_

CLK

MMCSD0_

DATA0

MMCSD0_

DATA3

MMCSD0_

DATA2

SPI1_SDI

SPI0_

SDENA[0]

SPI0_SDI

SPI0_SDO

CLKOUT2

V

SS

CV

DD

CV

DD

CV

DD

V

SS

CV

DD

V

SS

CV

DD

CV

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

CV

DD

V

SS

V

SS

CV

DD

TMS320DM335

www.ti.com

SPRS528C–JULY 2008–REVISED JUNE 2010

Figure 2-4. Pin Map [Quadrant D]

Copyright © 2008–2010, Texas Instruments Incorporated Device Overview 13

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 14

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

2.4 Pin Functions

The pin functions tables (Table 2-4 through Table 2-22) identify the external signal names, the associated

pin (ball) numbers along with the mechanical package designator, the pin type, whether the pin has any

internal pullup or pulldown resistors, and a functional pin description. For more detailed information on

device configuration, peripheral selection, multiplexed/shared pins, and debugging considerations, see

Section 3. For the list of all pin in chronological order see Section 2.20

2.4.1 Image Data Input - Video Processing Front End

The CCD Controller module in the Video Processing Front End has an external signal interface for image

data input. It supports YUV (YC) inputs as well as Bayer RGB and complementary input signals (I.e.,

image data input).

The definition of the CCD controller data input signals depend on the input mode selected.

• In 16-bit YCbCr mode, the Cb and Cr signals are multiplexed on the Cl signals and the order is

configurable (i.e., Cb first or Cr first).

• In 8-bit YCbCr mode, the Y, Cb, and Cr signals are multiplexed and not only is the order selectable,

but also the half of the bus used.

Table 2-4. CCD Controller Signals for Each Input Mode

PIN NAME CCD 16-BIT YCbCr 8-BIT YCbCr

Cl7 Cb7,Cr7 Y7,Cb7,Cr7

Cl6 Cb6,Cr6 Y6,Cb6,Cr6

Cl5 CCD13 Cb5,Cr5 Y5,Cb5,Cr5

Cl4 CCD12 Cb4,Cr4 Y4,Cb4,Cr4

Cl3 CCD11 Cb3,Cr3 Y3,Cb3,Cr3

Cl2 CCD10 Cb2,Cr2 Y2,Cb2,Cr2

Cl1 CCD9 Cb1,Cr1 Y1,Cb1,Cr1

Cl0 CCD8 Cb0,Cr0 Y0,Cb0,Cr0

Yl7 CCD7 Y7 Y7,Cb7,Cr7

Yl6 CCD6 Y6 Y6,Cb6,Cr6

Yl5 CCD5 Y5 Y5,Cb5,Cr5

Yl4 CCD4 Y4 Y4,Cb4,Cr4

Yl3 CCD3 Y3 Y3,Cb3,Cr3

Yl2 CCD2 Y2 Y2,Cb2,Cr2

Yl1 CCD1 Y1 Y1,Cb1,Cr1

Yl0 CCD0 Y0 Y0,Cb0,Cr0

www.ti.com

14 Device Overview Copyright © 2008–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 15

TMS320DM335

www.ti.com

SPRS528C–JULY 2008–REVISED JUNE 2010

Table 2-5. CCD Controller/Video Input Terminal Functions

TERMINAL

NAME NO.

CIN7/

GIO101/ N3 I/O/Z

SPI2_SCLK

CIN6/

GIO100/ K5 I/O/Z

SPI2_SDO

CIN5/ • YCC 16-bit: Time multiplexed between chroma: CB/SR[05]

GIO099/ PD

SPI2_SDEN V

M3 I/O/Z

A[0]

CIN4/ • YCC 16-bit: Time multiplexed between chroma: CB/SR[04]

GIO098/ PD

SPI2_SDEN V

L4 I/O/Z

A[1]

CIN3/ PD

GIO097/ V

CIN2/ PD

GIO096/ V

CIN1/ PD

GIO095/ V

CIN0/ PD

GIO094/ V

YIN7/ PD

GIO093 V

YIN6/ PD

GIO092 V

J4 I/O/Z

J5 I/O/Z

L3 I/O/Z

J3 I/O/Z

L5 I/O/Z

M4 I/O/Z

TYPE

(1)

OTHER

(2) (3)

DESCRIPTION

Standard CCD/CMOS input: NOT USED

• YCC 16-bit: Time multiplexed between chroma: CB/SR[07]

PD

V

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[07]

SPI: SPI2 Clock

GIO: GIO[101]

Standard CCD/CMOS input: NOT USED

• YCC 16-bit: Time multiplexed between chroma: CB/SR[06]

PD

V

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[06]

SPI: SPI2 Data Out

GIO: GIO[100]

Standard CCD/CMOS input: Raw[13]

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

DD_VIN

multiplexed between luma and chroma of the upper channel. Y/CB/CR[05]

SPI: SPI2 Chip Select

GIO: GIO[099]

Standard CCD/CMOS input: Raw[12]

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

DD_VIN

multiplexed between luma and chroma of the upper channel. Y/CB/CR[04]

SPI: SPI2 Data In

GIO: GIO[098]

Standard CCD/CMOS input(AFE): Raw[11]

• YCC 16-bit: Time multiplexed between chroma: CB/SR[03]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[03]

GIO: GIO[097]

Standard CCD/CMOS input: Raw[10]

• YCC 16-bit: Time multiplexed between chroma: CB/SR[02]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[02]

GIO: GIO[097]

Standard CCD/CMOS input: Raw[09]

• YCC 16-bit: Time multiplexed between chroma: CB/SR[01]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[01]

GIO: GIO[095]

Standard CCD/CMOS input: Raw[08]

• YCC 16-bit: Time multiplexed between chroma: CB/SR[00]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[00]

GIO: GIO[094]

Standard CCD/CMOS input: Raw[07]

• YCC 16-bit: Time multiplexed between chroma: Y[07]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[07]

GIO: GIO[093]

Standard CCD/CMOS input: Raw[06]

• YCC 16-bit: Time multiplexed between chroma: Y[06]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[06]

GIO: GIO[092]

(1) I = Input, O = Output, Z = High impedance, S = Supply voltage, GND = Ground, A = Analog signal.

(2) PD = internal pull-down, PU = internal pull-up. (To pull up a signal to the opposite supply rail, a 1 kΩ resistor should be used.)

(3) Specifies the operating I/O supply voltage for each signal. See Section 5.3 , Power Supplies for more detail.

Copyright © 2008–2010, Texas Instruments Incorporated Device Overview 15

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 16

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

Table 2-5. CCD Controller/Video Input Terminal Functions (continued)

TERMINAL

NAME NO.

YIN5/ PD

GIO091 V

YIN4/ PD

GIO090 V

YIN3/ PD

GIO089 V

YIN2/ PD

GIO088 V

YIN1/ PD

GIO087 V

YIN0/ PD

GIO086 V

CAM_HD/ PD

GIO085 V

CAM_VD PD

GIO084 V

M5 I/O/Z

P3 I/O/Z

R3 I/O/Z

P4 I/O/Z

P2 I/O/Z

P5 I/O/Z

N5 I/O/Z output (master mode). Tells the CCDC when a new line starts.

R4 I/O/Z (master mode). Tells the CCDC when a new frame starts.

CAM_WEN

_FIELD\ R5 I/O/Z

GIO083

PCLK/ PD Pixel clock input (strobe for lines C17 through Y10)

GIO082 V

T3 I/O/Z

TYPE

(1)

OTHER

(2) (3)

DESCRIPTION

Standard CCD/CMOS input: Raw[05]

• YCC 16-bit: Time multiplexed between chroma: Y[05]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[05]

GIO: GIO[091]

Standard CCD/CMOS input: Raw[04]

• YCC 16-bit: Time multiplexed between chroma: Y[04]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[04]

GIO: GIO[090]

Standard CCD/CMOS input: Raw[03]

• YCC 16-bit: Time multiplexed between chroma: Y[03]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[03]

GIO: GIO[089]

Standard CCD/CMOS input: Raw[02]

• YCC 16-bit: Time multiplexed between chroma: Y[02]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[02]

GIO: GIO[088]

Standard CCD/CMOS input: Raw[01]

• YCC 16-bit: Time multiplexed between chroma: Y[01]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[01]

GIO: GIO[087]

Standard CCD/CMOS input: Raw[00]

• YCC 16-bit: Time multiplexed between chroma: Y[00]

DD_VIN

• YCC 8-bit (which allows for two simultaneous decoder inputs), it is time

multiplexed between luma and chroma of the upper channel. Y/CB/CR[00]

GIO: GIO[086]

Horizontal synchronization signal that can be either an input (slave mode) or an

DD_VIN

GIO: GIO[085]

Vertical synchronization signal that can be either an input (slave mode) or an output

DD_VIN

GIO: GIO[084]

Write enable input signal is used by external device (AFE/TG) to gate the DDR

output of the CCDC module. Alternately, the field identification input signal is used

PD by external device (AFE/TG) to indicate which of two frames is input to the CCDC

V

DD_VIN

module for sensors with interlaced output. CCDC handles 1- or 2-field sensors in

hardware.

GIO: GIO[083]

DD_VIN

GIO: GIO[0082]

www.ti.com

2.5 Image Data Output - Video Processing Back End (VPBE)

The Video Encoder/Digital LCD interface module in the video processing back end has an external signal

interface for digital image data output as described in Table 2-7 and Table 2-8.

The digital image data output signals support multiple functions / interfaces, depending on the display

mode selected. The following table describes these modes. Parallel RGB mode with more than RGB565

signals requires enabling pin multiplexing to support (i.e., for RGB666 mode).

16 Device Overview Copyright © 2008–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 17

TMS320DM335

www.ti.com

SPRS528C–JULY 2008–REVISED JUNE 2010

Table 2-6. Signals for VPBE Display Modes

PIN NAME YCC16 YCC8/ PRGB SRGB

HSYNC HSYNC HSYNC HSYNC HSYNC

GIO073

VSYNC VSYNC VSYNC VSYNC VSYNC

GIO072

LCD_OE As needed As needed As needed As needed

GIO071

FIELD As needed As needed As needed As needed

GIO070

R2

PWM3C

EXTCLK As needed As needed As needed As needed

GIO069

B2

PWM3D

VCLK VCLK VCLK VCLK VCLK

GIO068

YOUT7 Y7 Y7,Cb7,Cr7 R7 Data7

YOUT6 Y6 Y6,Cb6,Cr6 R6 Data6

YOUT5 Y5 Y5,Cb5,Cr5 R5 Data5

YOUT4 Y4 Y4,Cb4,Cr4 R4 Data4

YOUT3 Y3 Y3,Cb3,Cr3 R3 Data3

YOUT2 Y2 Y2,Cb2,Cr2 G7 Data2

YOUT1 Y1 Y1,Cb1,Cr1 G6 Data1

YOUT0 Y0 Y0,Cb0,Cr0 G5 Data0

COUT7 C7 LCD_AC G4 LCD_AC

GIO081

PWM0

COUT6 C6 LCD_OE G3 LCD_OE

GIO080

PWM1

COUT5 C5 BRIGHT G2 BRIGHT

GIO079

PWM2A

RTO0

COUT4 C4 PWM B7 PWM

GIO078

PWM2B

RTO1

COUT3 C3 CSYNC B6 CSYNC

GIO077

PWM2C

RTO2

COUT2 C2 - B5 GIO076

PWM2D

RTO3

COUT1 C1 - B4 GIO075

PWM3A

COUT0 C0 - B3 GIO074

PWM3B

REC656

Copyright © 2008–2010, Texas Instruments Incorporated Device Overview 17

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 18

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

www.ti.com

Table 2-7. Digital Video Terminal Functions

TERMINAL

NAME NO.

YOUT7-R7 C3 I/O/Z V

YOUT6-R6 A4 I/O/Z V

YOUT5-R5 B4 I/O/Z V

YOUT4-R4 B3 I/O/Z V

YOUT3-R3 B2 I/O/Z V

YOUT2-G7 A3 I/O/Z V

YOUT1-G6 A2 I/O/Z V

YOUT0-G5 B1 I/O/Z V

COUT7-

G4/GIO081 C2 I/O/Z V

/PWM0

COUT6-G3

/GIO080 D2 I/O/Z V

/PWM1

COUT5-G2

/ GIO079 /

PWM2A /

C1 I/O/Z V

RTO0

COUT4-B7 /

GIO078 /

PWM2B /

D3 I/O/Z V

RTO1

COUT3-B6 /

GIO077 /

PWM2C /

E3 I/O/Z V

RTO2

COUT2-B5 /

GIO076 /

PWM2D /

E4 I/O/Z V

RTO3

COUT1-B4 / Digital Video Out: VENC settings determine function

GIO075 / F3 I/O/Z V

PWM3A PWM3A

COUT0-B3 / Digital Video Out: VENC settings determine function

GIO074 / F4 I/O/Z V

PWM3B PWM3B

HSYNC / PD Video Encoder: Horizontal Sync

GIO073 V

VSYNC / PD Video Encoder: Vertical Sync

GIO072 V

F5 I/O/Z

G5 I/O/Z

FIELD / Video Encoder: Field identifier for interlaced display formats

GIO070 / GIO: GIO[070]

R2 / Digital Video Out: R2

H4 I/O/Z V

PWM3C PWM3C

EXTCLK /

GIO069 / PD

B2 / V

G3 I/O/Z GIO: GIO[069]

PWM3D

VCLK / Video Encoder: Video Output Clock

GIO068 GIO: GIO[068]

H3 I/O/Z V

(1) I = Input, O = Output, Z = High impedance, S = Supply voltage, GND = Ground, A = Analog signal.

(2) Specifies the operating I/O supply voltage for each signal. See Section 5.3 , Power Supplies for more detail.

(3) PD = pull-down, PU = pull-up. (To pull up a signal to the opposite supply rail, a 1 kΩ resistor should be used.)

(4) To reduce EMI and reflections, depending on the trace length, approximately 22 Ω to 50 Ω damping resistors are recommend on the

following outputs placed near the DM335: YOUT(0-7),COUT(0-7), HSYNC,VSYNC,LCD_OE,FIELD,EXTCLK,VCLK. The trace lengths

should be minimized.

TYPE

(1)

OTHER

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

(2) (3)

DESCRIPTION

(4)

Digital Video Out: VENC settings determine function

Digital Video Out: VENC settings determine function

Digital Video Out: VENC settings determine function

Digital Video Out: VENC settings determine function

Digital Video Out: VENC settings determine function

Digital Video Out: VENC settings determine function

Digital Video Out: VENC settings determine function

Digital Video Out: VENC settings determine function

Digital Video Out: VENC settings determine function GIO: GIO[081] PWM0

Digital Video Out: VENC settings determine function GIO: GIO[080] PWM1

Digital Video Out: VENC settings determine function GIO: GIO[079] PWM2A RTO0

Digital Video Out: VENC settings determine function GIO: GIO[078] PWM2B RTO1

Digital Video Out: VENC settings determine function GIO: GIO[077] PWM2C RTO2

Digital Video Out: VENC settings determine function GIO: GIO[076] PWM2D RTO3

GIO: GIO[075]

GIO: GIO[074]

GIO: GIO[073]

GIO: GIO[072]

Video Encoder: External clock input, used if clock rates > 27 MHz are needed, e.g.

74.25 MHz for HDTV digital output

DD_VOUT

Digital Video Out: B2

PWM3D

DD_VOUT

18 Device Overview Copyright © 2008–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 19

TMS320DM335

www.ti.com

SPRS528C–JULY 2008–REVISED JUNE 2010

Table 2-8. Analog Video Terminal Functions

TERMINAL

NAME NO.

VREF J7 A I/O/Z

IOUT E1 A I/O/Z

IBIAS F2 A I/O/Z configuration. When the DAC is not used, the IBIAS signal should be connected to

VFB G1 A I/O/Z

TVOUT F1 A I/O/Z V circuit connection). When the DAC is not used, the TVOUT signal should be left as a

V

DDA18_DAC

V

SSA_DAC

L7 PWR

L8 GND

(1) I = Input, O = Output, Z = High impedance, S = Supply voltage, GND = Ground, A = Analog signal. Specifies the operating I/O supply

voltage for each signal. See Section 5.3 , Power Supplies for more detail.

(2) PD = pull-down, PU = pull-up. (To pull up a signal to the opposite supply rail, a 1 kΩ resistor should be used.)

TYPE

(1)

OTHER

(2)

DESCRIPTION

Video DAC: Reference voltage output (0.45V, 0.1uF to GND). When the DAC is not

used, the VREF signal should be connected to VSS.

Video DAC: Pre video buffer DAC output (1000 ohm to VFB). When the DAC is not

used, the IOUT signal should be connected to VSS.

Video DAC: External resistor (2550 Ohms to GND) connection for current bias

VSS.

Video DAC: Pre video buffer DAC output (1000 Ohms to IOUT, 1070 Ohms to

TVOUT). When the DAC is not used, the VFB signal should be connected to VSS.

Video DAC: Analog Composite NTSC/PAL output (SeeFigure 5-31 andFigure 5-32 for

No Connect or connected to VSS.

Video DAC: Analog 1.8V power. When the DAC is not used, the V

should be connected to VSS.

Video DAC: Analog 1.8V ground. When the DAC is not used, the V

should be connected to VSS.

DDA18_DAC

SSA_DAC

signal

signal

2.6 Asynchronous External Memory Interface (AEMIF)

The Asynchronous External Memory Interface (AEMIF) signals support AEMIF, NAND, and OneNAND.

Table 2-9. Asynchronous EMIF/NAND/OneNAND Terminal Functions

TERMINAL

NAME NO.

EM_A13/ Async EMIF: Address bus bit[13]

GIO067/ V19 I/O/Z GIO: GIO[67]

BTSEL[1] System: BTSEL[1:0] sampled at power-on-reset to determine boot method.

EM_A12/ Async EMIF: Address bus bit[12]

GIO066/ U19 I/O/Z GIO: GIO[66]

BTSEL[0] System: BTSEL[1:0] sampled at power-on-reset to determine boot method.

EM_A11/

GIO065/ R16 I/O/Z

AECFG[3]

EM_A10/ GIO: GIO[64]

GIO064/ R18 I/O/Z AECFG[3:0] sampled at power-on-reset to AECFG configuration. AECFG[2:1]

AECFG[2] sets default for PinMux2_EM_BA0: AEMIF EM_BA0 definition (EM_BA0,

EM_A09/ GIO: GIO[63]

GIO063/ P17 I/O/Z AECFG[3:0] sampled at power-on-reset to AECFG configuration. AECFG[2:1]

AECFG[1] sets default for PinMux2_EM_BA0: AEMIF EM_BA0 definition (EM_BA0,

EM_A08/

GIO062/ T19 I/O/Z

AECFG[0] • PinMux2_EM_A0_BA1: AEMIF address width (OneNAND or NAND)

EM_A07/

GIO061

P16 I/O/Z V

(1) I = Input, O = Output, Z = High impedance, S = Supply voltage, GND = Ground, A = Analog signal.

(2) Specifies the operating I/O supply voltage for each signal. See Section 5.3 , Power Supplies for more detail.

(3) PD = pull-down, PU = pull-up. (To pull up a signal to the opposite supply rail, a 1 kΩ resistor should be used.)

TYPE

(1)

OTHER

(2) (3)

DESCRIPTION

PD

V

DD

PD

V

DD

Async EMIF: Address bus bit[11]

PU GIO: GIO[65]

V

DD

AECFG[3:0] sampled at power-on-reset to AECFG configuration. AECFG[3] sets

default for PinMux2_EM_D15_8: AEMIF default bus width (16 or 8 bits)

Async EMIF: Address bus bit[10]

PU

V

DD

EM_A14, GIO[054], rsvd)

Async EMIF: Address bus bit[09]

PD

V

DD

EM_A14, GIO[054], rsvd)

Async EMIF: Address bus bit[08]

GIO: GIO[62]

AECFG[0] sets default for:

V

PD

DD

• PinMux2_EM_A13_3: AEMIF address width (OneNAND or NAND)

Async EMIF: Address bus bit[07]

DD

GIO: GIO[61]

Used to drive boot status LED signal (active low) in ROM boot modes.

Copyright © 2008–2010, Texas Instruments Incorporated Device Overview 19

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 20

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

Table 2-9. Asynchronous EMIF/NAND/OneNAND Terminal Functions (continued)

TERMINAL

NAME NO.

EM_A06/ Async EMIF: Address bus bit[06]

GIO060 GIO: GIO[60]

EM_A05/ Async EMIF: Address bus bit[05]

GIO059 GIO: GIO[59]

EM_A04/ Async EMIF: Address bus bit[04]

GIO058 GIO: GIO[58]

EM_A03/ Async EMIF: Address bus bit[03]

GIO057 GIO: GIO[57]

P18 I/O/Z V

R19 I/O/Z V

P15 I/O/Z V

N18 I/O/Z V

EM_A02/ N15 I/O/Z V

EM_A01/ N17 I/O/Z V

EM_A00/ Async EMIF: Address bus bit[00]

GIO056 GIO: GIO[56]

EM_BA1/ • In 16-bit mode, lowest address bit.

GIO055

M16 I/O/Z V

P19 I/O/Z V

EM_BA0/

GIO054 N19 I/O/Z V

EM_A14

EM_D15/ Async EMIF: Data bus bit 15

GIO053 GIO: GIO[053]

EM_D14/ Async EMIF: Data bus bit 14

GIO052 GIO: GIO[052]

EM_D13/ Async EMIF: Data bus bit 13

GIO051 GIO: GIO[051]

EM_D12/ Async EMIF: Data bus bit 12

GIO050 GIO: GIO[050]

EM_D11/ Async EMIF: Data bus bit 11

GIO049 GIO: GIO[049]

EM_D10/ Async EMIF: Data bus bit 10

GIO048 GIO: GIO[048]

EM_D09/ Async EMIF: Data bus bit 09

GIO047 GIO: GIO[047]

EM_D08/ Async EMIF: Data bus bit 08

GIO046 GIO: GIO[046]

EM_D07/ Async EMIF: Data bus bit 07

GIO045 GIO: GIO[045]

EM_D06/ Async EMIF: Data bus bit 06

GIO044 GIO: GIO[044]

EM_D05/ Async EMIF: Data bus bit 05

GIO043 GIO: GIO[043]

EM_D04/ Async EMIF: Data bus bit 04

GIO042 GIO: GIO[042]

EM_D03/ Async EMIF: Data bus bit 03

GIO041 GIO: GIO[041]

EM_D02/ Async EMIF: Data bus bit 02

GIO040 GIO: GIO[040]

EM_D01/ Async EMIF: Data bus bit 01

GIO039 GIO: GIO[039]

EM_D00/ Async EMIF: Data bus bit 00

GIO038 GIO: GIO[038]

M18 I/O/Z V

M19 I/O/Z V

M15 I/O/Z V

L18 I/O/Z V

L17 I/O/Z V

L19 I/O/Z V

K18 I/O/Z V

L16 I/O/Z V

K19 I/O/Z V

K17 I/O/Z V

J19 I/O/Z V

L15 I/O/Z V

J18 I/O/Z V

H19 I/O/Z V

J17 I/O/Z V

H18 I/O/Z V

TYPE

(1)

OTHER

DD

DD

DD

DD

DD

DD

DD

(2) (3)

DESCRIPTION

Async EMIF: Address bus bit[02]

NAND/SM/xD: CLE - Command latch enable output

Async EMIF: Address bus bit[01]

NAND/SM/xD: ALE - Address latch enable output

Async EMIF: Bank address 1 signal - 16-bit address:

DD

• In 8-bit mode, second lowest address bit.

GIO: GIO[055]

Async EMIF: Bank address 0 signal - 8-bit address:

DD

• In 8-bit mode, lowest address bit. or can be used as an extra address line

(bit14) when using 16-bit memories.

GIO: GIO[054]

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

www.ti.com

20 Device Overview Copyright © 2008–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 21

TMS320DM335

www.ti.com

SPRS528C–JULY 2008–REVISED JUNE 2010

Table 2-9. Asynchronous EMIF/NAND/OneNAND Terminal Functions (continued)

TERMINAL

NAME NO.

EM_CE0/ standard asynchronous memories (example: flash), OneNAND, or NAND

GIO037 memory. Used for the default boot and ROM boot modes.

EM_CE1/

GIO036

EM_WE/

GIO035

EM_OE/

GIO034

EM_WAIT/

GIO033

EM_ADV/ OneNAND: Address valid detect for OneNAND interface

GIO032 GIO: GIO[032]

EM_CLK/ OneNAND: Clock for OneNAND flash interface

GIO031 GIO: GIO[031]

J16 I/O/Z V

G19 I/O/Z V

J15 I/O/Z V

F19 I/O/Z V

G18 I/O/Z V

H16 I/O/Z V

E19 I/O/Z V

TYPE

(1)

OTHER

(2) (3)

DESCRIPTION

Async EMIF: Lowest numbered chip select. Can be programmed to be used for

DD

GIO: GIO[037]

Async EMIF: Second chip select. Can be programmed to be used for standard

DD

asynchronous memories(example: flash), OneNAND, or NAND memory.

GIO: GIO[036]

Async EMIF: Write Enable

DD

NAND/SM/xD: WE (Write Enable) output

GIO: GIO[035]

Async EMIF: Output Enable

DD

NAND/SM/xD: RE (Read Enable) output

GIO: GIO[034]

Async EMIF: Async WAIT

DD

DD

DD

NAND/SM/xD: RDY/ BSY input

GIO: GIO[033]

2.7 DDR Memory Interface

The DDR EMIF supports DDR2 and mobile DDR.

Table 2-10. DDR Terminal Functions

TERMINAL

NAME NO.

DDR_CLK W9 I/O/Z V

DDR_CLK W8 I/O/Z V

DDR_RAS T6 I/O/Z V

DDR_CAS V9 I/O/Z V

DDR_WE W10 I/O/Z V

DDR_CS T8 I/O/Z V

DDR_CKE V10 I/O/Z V

DDR_DQM[1] U15 I/O/Z V

DDR_DQM[0] T12 I/O/Z V

DDR_DQS[1] V15 I/O/Z V

DDR_DQS[0] V12 I/O/Z V

DDR_BA[2] V8 I/O/Z V

DDR_BA[1] U7 I/O/Z V

DDR_BA[0] U8 I/O/Z V

DDR_A13 U6 I/O/Z V

DDR_A12 V7 I/O/Z V

DDR_A11 W7 I/O/Z V

DDR_A10 V6 I/O/Z V

TYPE

(1)

OTHER

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

(2) (3)

DESCRIPTION

DDR Data Clock

DDR Complementary Data Clock

DDR Row Address Strobe

DDR Column Address Strobe

DDR Write Enable

DDR Chip Select

DDR Clock Enable

Data mask outputs:

• DDR_DQM[1] - For DDR_DQ[15:8]

• DDR_DQM[0] - For DDR_DQ[7:0]

Data strobe input/outputs for each byte of the 16-bit data bus used to

synchronize the data transfers. Output to DDR when writing and inputs when

reading.

• DDR_DQS[1] - For DDR_DQ[15:8]

• DDR_DQS[0] - For DDR_DQ[7:0]

Bank select outputs. Two are required for 1Gb DDR2 memories.

Bank select outputs. Two are required for 1Gb DDR2 memories.

Bank select outputs. Two are required for 1Gb DDR2 memories.

DDR Address Bus bit 13

DDR Address Bus bit 12

DDR Address Bus bit 11

DDR Address Bus bit 10

(1) I = Input, O = Output, Z = High impedance, S = Supply voltage, GND = Ground, A = Analog signal.

(2) Specifies the operating I/O supply voltage for each signal. See Section 5.3 , Power Supplies for more detail.

(3) PD = pull-down, PU = pull-up. (To pull up a signal to the opposite supply rail, a 1 kΩ resistor should be used.)

Copyright © 2008–2010, Texas Instruments Incorporated Device Overview 21

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 22

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

www.ti.com

Table 2-10. DDR Terminal Functions (continued)

TERMINAL

NAME NO.

DDR_A09 W6 I/O/Z V

DDR_A08 W5 I/O/Z V

DDR_A07 V5 I/O/Z V

DDR_A06 U5 I/O/Z V

DDR_A05 W4 I/O/Z V

DDR_A04 V4 I/O/Z V

DDR_A03 W3 I/O/Z V

DDR_A02 W2 I/O/Z V

DDR_A01 V3 I/O/Z V

DDR_A00 V2 I/O/Z V

DDR_DQ15 W17 I/O/Z V

DDR_DQ14 V16 I/O/Z V

DDR_DQ13 W16 I/O/Z V

DDR_DQ12 U16 I/O/Z V

DDR_DQ11 W15 I/O/Z V

DDR_DQ10 W14 I/O/Z V

DDR_DQ09 V14 I/O/Z V

DDR_DQ08 U13 I/O/Z V

DDR_DQ07 W13 I/O/Z V

DDR_DQ06 V13 I/O/Z V

DDR_DQ05 W12 I/O/Z V

DDR_DQ04 U12 I/O/Z V

DDR_DQ03 T11 I/O/Z V

DDR_DQ02 U11 I/O/Z V

DDR_DQ01 W11 I/O/Z V

DDR_DQ00 V11 I/O/Z V

DDR_ DDR: Loopback signal for external DQS gating. Route to DDR and back to

DQGATE0 DDR_DQGATE1 with same constraints as used for DDR clock and data.

DDR_ DDR: Loopback signal for external DQS gating. Route to DDR and back to

DQGATE1 DDR_DQGATE0 with same constraints as used for DDR clock and data.

W18 I/O/Z V

V17 I/O/Z V

DDR_VREF U10 I/O/Z V

V

SSA_DLL

V

DDA33_DDRDL

L

R11 I/O/Z V

R10 I/O/Z V

DDR_ZN T9 I/O/Z V

TYPE

(1)

OTHER

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

DD_DDR

(2) (3)

DESCRIPTION

DDR Address Bus bit 09

DDR Address Bus bit 08

DDR Address Bus bit 07

DDR Address Bus bit 06

DDR Address Bus bit 05

DDR Address Bus bit 04

DDR Address Bus bit 03

DDR Address Bus bit 02

DDR Address Bus bit 01

DDR Address Bus bit 00

DDR Data Bus bit 15

DDR Data Bus bit 14

DDR Data Bus bit 13

DDR Data Bus bit 12

DDR Data Bus bit 11

DDR Data Bus bit 10

DDR Data Bus bit 09

DDR Data Bus bit 08

DDR Data Bus bit 07

DDR Data Bus bit 06

DDR Data Bus bit 05

DDR Data Bus bit 04

DDR Data Bus bit 03

DDR Data Bus bit 02

DDR Data Bus bit 01

DDR Data Bus bit 00

DDR: Voltage input for the SSTL_18 I/O buffers. Note even in the case of

mDDR an external resistor divider connected to this pin is necessary.

DDR: Ground for the DDR DLL

DDR: Power (3.3 V) for the DDR DLL

DDR: Reference output for drive strength calibration of N and P channel

outputs. Tie to ground via 50 ohm resistor @ 0.5% tolerance.

22 Device Overview Copyright © 2008–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 23

TMS320DM335

www.ti.com

2.8 GPIO

The General Purpose I/O signals provide generic I/O to external devices. Most of the GIO signals are

multiplexed with other functions.

Table 2-11. GPIO Terminal Functions

TERMINAL

NAME NO.

GIO000 C16 I/O/Z V

GIO001 E14 I/O/Z V

GIO002 F15 I/O/Z V

GIO003 G15 I/O/Z V

GIO004 B17 I/O/Z V

GIO005 D15 I/O/Z V

GIO006 B18 I/O/Z V

GIO007 /

SPI0_SDE C17 I/O/Z V

NA[1]

SPI1_SD

O / E12 I/O/Z V

GIO008

SPI1_SDI

/ GIO009 /

SPI1_SDE

A13 I/O/Z V

NA[1]

SPI1_SCL

K / C13 I/O/Z V

GIO010

SPI1_SDE

NA[0] / E13 I/O/Z V

GIO011

UART1_T

XD / R17 I/O/Z V

GIO012

UART1_R

XD / R15 I/O/Z V

GIO013

I2C_SCL / I2C: Serial Clock GIO:

GIO014 GIO[014]

I2C_SDA / I2C: Serial Data

GIO015 GIO: GIO[015]

CLKOUT3 CLKOUT: Output Clock 3

/ GIO016 GIO: GIO[016]

CLKOUT2 CLKOUT: Output Clock 2

/ GIO017 GIO: GIO[017]

CLKOUT1 CLKOUT: Output Clock 1

/ GIO018 GIO: GIO[018]

R14 I/O/Z V

R13 I/O/Z V

C11 I/O/Z V

A11 I/O/Z V

D12 I/O/Z V

MMCSD1

_DATA0 / MMCSD1: DATA0

GIO019 / A18 I/O/Z V

UART2_T UART2: Transmit Data

XD

TYPE

(1)

OTHER

(2) (3)

DESCRIPTION

GIO:GIO[000] is sampled at reset and stored in the GIO0_RESET bit of the

BOOTCFG register.

DD

Active low during MMC/SD boot (can be used as MMC/SD power control).

Can be used as external clock input for Timer 3.

Note: The GIO000 pin must be held high during NAND boot for the boot

process to fuction properly.

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

GIO: GIO[001] Can be used as external clock input for Timer 3.

GIO: GIO[002] Can be used as external clock input for Timer 3.

GIO: GIO[003] Can be used as external clock input for Timer 3.

GIO: GIO[004]

GIO: GIO[005]

GIO: GIO[006]

GIO: GIO[007]

SPI0: Chip Select 1

SPI1: Data Out

GIO: GIO[008]

SPI1: Data In -OR- SPI1: Chip Select 1 GIO: GIO[009]

SPI1: Clock GIO:

GIO[010]

SPI1: Chip Select 0

GIO: GIO[011]

UART1: Transmit Data

GIO: GIO[012]

UART1: Receive Data

GIO: GIO[013]

GIO: GIO[019]

SPRS528C–JULY 2008–REVISED JUNE 2010

(1) I = Input, O = Output, Z = High impedance, S = Supply voltage, GND = Ground, A = Analog signal.

(2) Specifies the operating I/O supply voltage for each signal. See Section 5.3 , Power Supplies for more detail.

(3) PD = pull-down, PU = pull-up. (To pull up a signal to the opposite supply rail, a 1 kΩ resistor should be used.)

Copyright © 2008–2010, Texas Instruments Incorporated Device Overview 23

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 24

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

www.ti.com

Table 2-11. GPIO Terminal Functions (continued)

TERMINAL

NAME NO.

MMCSD1

_DATA1 / MMCSD1: DATA1

GIO020 / B15 I/O/Z V

UART2_R UART2: Receive Data

XD

MMCSD1

_DATA2 / MMCSD1: DATA2

GIO021 / A16 I/O/Z V

UART2_C UART2: CTS

TS

MMCSD1

_DATA3 / MMCSD1: DATA3

GIO022 / B16 I/O/Z V

UART2_R UART2: RTS

TS

MMCSD1

_CMD / A17 I/O/Z V

GIO023

MMCSD1

_CLK / C15 I/O/Z V

GIO024

ASP0_FS

R / F16 I/O/Z V

GIO025

ASP0_CL

KR / F17 I/O/Z V

GIO026

ASP0_DR ASP0: Receive Data

/ GIO027 GIO: GIO[027]

E18 I/O/Z V

ASP0_FS

X / G17 I/O/Z V

GIO028

ASP0_CL

KX / F18 I/O/Z V

GIO029

ASP0_DX ASP0: Transmit Data

/ GIO030 GIO: GIO[030]

EM_CLK /

GIO031

EM_ADV / PD OneNAND: Address Valid Detect for OneNAND interface

GIO032 V

EM_WAIT PU Async EMIF: Async WAIT NAND/SM/xD: RDY/_BSY input

/ GIO033 V

EM_OE /

GIO034

EM_WE /

GIO035

EM_CE1 /

GIO036

EM_CE0 / standard asynchronous memories (example: flash), OneNand or NAND memory.

GIO037 Used for the default boot and ROM boot modes.

EM_D00 / Async EMIF: Data Bus bit[00]

GIO038 GIO: GIO[038]

H15 I/O/Z V

E19 I/O/Z V

H16 I/O/Z

G18 I/O/Z

F19 I/O/Z V

J15 I/O/Z V

G19 I/O/Z V

J16 I/O/Z V

H18 I/O/Z V

TYPE

(1)

OTHER

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

(2) (3)

DESCRIPTION

GIO: GIO[020]

GIO: GIO[021]

GIO: GIO[022]

MMCSD1: Command

GIO: GIO[023]

MMCSD1: Clock

GIO: GIO[024]

ASP0: Receive Frame Synch

GIO: GIO[025]

ASP0: Receive Clock

GIO: GIO[026]

ASP0: Transmit Frame Synch

GIO: GIO[028]

ASP0: Transmit Clock

GIO: GIO[029]

OneNAND: Clock signal for OneNAND flash interface GIO: GIO[031]

GIO: GIO[032]

GIO: GIO[033]

Async EMIF: Output Enable

DD

NAND/SM/xD: RE (Read Enable) output

GIO: GIO[034]

Async EMIF: Write Enable

DD

NAND/SM/xD: WE (Write Enable) output

GIO: GIO[035]

Async EMIF: Second Chip Select., Can be programmed to be used for standard

DD

asynchronous memories (example: flash), OneNand or NAND memory.

GIO: GIO[036]

Async EMIF: Lowest numbered Chip Select. Can be programmed to be used for

DD

GIO: GIO[037]

DD

24 Device Overview Copyright © 2008–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 25

TMS320DM335

www.ti.com

Table 2-11. GPIO Terminal Functions (continued)

TERMINAL

NAME NO.

EM_D01 / Async EMIF: Data Bus bit[01]

GIO039 GIO: GIO[039]

EM_D02 / Async EMIF: Data Bus bit[02]

GIO040 GIO: GIO[040]

EM_D03 / Async EMIF: Data Bus bit[03]

GIO041 GIO: GIO[041]

EM_D04 / Async EMIF: Data Bus bit[04]

GIO042 GIO: GIO[042]

EM_D05 / Async EMIF: Data Bus bit[05]

GIO043 GIO: GIO[043]

EM_D06 / Async EMIF: Data Bus bit[06]

GIO044 GIO: GIO[044]

EM_D07 / Async EMIF: Data Bus bit[07]

GIO045 GIO: GIO[045]

EM_D08 / Async EMIF: Data Bus bit[08]

GIO046 GIO: GIO[046]

EM_D09 / Async EMIF: Data Bus bit[09]

GIO047 GIO: GIO[047]

EM_D10 / Async EMIF: Data Bus bit[10]

GIO048 GIO: GIO[048]

EM_D11 / Async EMIF: Data Bus bit[11]

GIO049 GIO: GIO[049]

EM_D12 / Async EMIF: Data Bus bit[12]

GIO050 GIO: GIO[050]

EM_D13 / Async EMIF: Data Bus bit[13]

GIO051 GIO: GIO[051]

EM_D14 / Async EMIF: Data Bus bit[14]

GIO052 GIO: GIO[052]

EM_D15 / Async EMIF: Data Bus bit[15]

GIO053 GIO: GIO[053]

J17 I/O/Z V

H19 I/O/Z V

J18 I/O/Z V

L15 I/O/Z V

J19 I/O/Z V

K17 I/O/Z V

K19 I/O/Z V

L16 I/O/Z V

K18 I/O/Z V

L19 I/O/Z V

L17 I/O/Z V

L18 I/O/Z V

M15 I/O/Z V

M19 I/O/Z V

M18 I/O/Z V

EM_BA0 /

GIO054 / N19 I/O/Z V

EM_A14

EM_BA1 /

GIO055

EM_A00 /

GIO056

EM_A03 / Async EMIF: Address Bus bit[03]

GIO057 GIO: GIO[057]

EM_A04 / Async EMIF: Address Bus bit[04]

GIO058 GIO: GIO[058]

EM_A05 / Async EMIF: Address Bus bit[05]

GIO059 GIO: GIO[059]

EM_A06 / Async EMIF: Address Bus bit[06]

GIO060 GIO: GIO[060]

EM_A07 /

GIO061

P19 I/O/Z V

M16 I/O/Z V

N18 I/O/Z V

P15 I/O/Z V

R19 I/O/Z V

P18 I/O/Z V

P16 I/O/Z V

EM_A08 /

GIO062 / T19 I/O/Z

AECFG[0]

TYPE

(1)

OTHER

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

DD

(2) (3)

DESCRIPTION

Async EMIF: Bank Address 0 signal = 8-bit address. In 8-bit mode, lowest

DD

address bit. Or, can be used as an extra Address line (bit[14] when using 16-bit

memories.

GIO: GIO[054]

Async EMIF: Bank Address 1 signal = 16-bit address. In 16-bit mode, lowest

DD

address bit. In 8-bit mode, second lowest address bit

GIO: GIO[055]

Async EMIF: Address Bus bit[00] Note that the EM_A0 is always a 32-bit

DD

DD

DD

DD

DD

address

GIO: GIO[056]

Async EMIF: Address Bus bit[07]

DD

GIO: GIO[061] - Used to drive Boot Status LED signal (active low) in ROM boot

modes

Async EMIF: Address Bus bit[08]

PU GIO: GIO[062] AECFG[0] sets default for - PinMux2.EM_A0_BA1: AEMIF

V

DD

Address Width (OneNAND or NAND) - PinMux2.EM_A13_3: AEMIF Address

Width (OneNAND or NAND)

SPRS528C–JULY 2008–REVISED JUNE 2010

Copyright © 2008–2010, Texas Instruments Incorporated Device Overview 25

Submit Documentation Feedback

Product Folder Link(s): TMS320DM335

Page 26

TMS320DM335

SPRS528C–JULY 2008–REVISED JUNE 2010

www.ti.com

Table 2-11. GPIO Terminal Functions (continued)

TERMINAL

NAME NO.

EM_A09 /

GIO063 / P17 I/O/Z

AECFG[1]

EM_A10 /

GIO064 / R18 I/O/Z

AECFG[2]

EM_A11 /

GIO065 / R16 I/O/Z

AECFG[3]

EM_A12 / Async EMIF: Address Bus bit[12]

GIO066 / U19 I/O/Z GIO: GIO[066] System: BTSEL[1:0] sampled at Power-on-Reset to determine

BTSEL[0] Boot method

EM_A13 / Async EMIF: Address Bus bit[13]

GIO067 / V19 I/O/Z GIO: GIO[067] System: BTSEL[1:0] sampled at Power-on-Reset to determine

BTSEL[1] Boot method.

VCLK / Video Encoder: Video Output Clock

GIO068 GIO: GIO[068]

H3 I/O/Z V

EXTCLK /

GIO069 / PD

B2 / V

G3 I/O/Z e.g. 74.25 MHz for HDTV digital output

PWM3D

FIELD /

GIO070 / Video Encoder: Field identifier for interlaced display formats

R2 / GIO: GIO[070] Digital Video Out: R2 PWM3C

H4 I/O/Z V

PWM3C

VSYNC / PD Video Encoder: Vertical Sync

GIO072 V

HSYNC / PD Video Encoder: Horizontal Sync

GIO073 V

G5 I/O/Z

F5 I/O/Z

COUT0-

B3 / Digital Video Out: VENC settings determine function GIO: GIO[074]

GIO074 / PWM3B

F4 I/O/Z V

PWM3B

COUT1-

B4 / Digital Video Out: VENC settings determine function GIO: GIO[075]

GIO075 / PWM3A

F3 I/O/Z V

PWM3A

COUT2-

B5 /

GIO076 / E4 I/O/Z V

PWM2D /

RTO3

COUT3B6 /

GIO077 / E3 I/O/Z V

PWM2C /

RTO2

COUT4B7 /

GIO078 / D3 I/O/Z V

PWM2B /

RTO1

COUT5G2 /

GIO079 / C1 I/O/Z V

PWM2A /

RTO0

TYPE

(1)

OTHER

(2) (3)

DESCRIPTION

Async EMIF: Address Bus bit[09]

PD GIO: GIO[063] System: AECFG[3:0] sampled at Power-on-Reset to set AEMIF

V

DD

Configuration AECFG[2:1] sets default for PinMux2.EM_BA0: AEMIF EM_BA0

Definition (EM_BA0, EM_A14, GIO[054], rsvd)

Async EMIF: Address Bus bit[10]

PU GIO: GIO[064] System: AECFG[3:0] sampled at Power-on-Reset to set AEMIF

V

DD

Configuration AECFG[2:1] sets default for PinMux2.EM_BA0: AEMIF EM_BA0

Definition (EM_BA0, EM_A14, GIO[054], rsvd)

Async EMIF: Address Bus bit[11]

PU GIO: GIO[065] System: AECFG[3:0] sampled at Power-on-Reset to set AEMIF

V

DD

Configuration AECFG[3] sets default for PinMux2.EM_D15_8: AEMIF Default

Bus Width (16 or 8 bits)

PD

V

DD

PD

V

DD

DD_VOUT

Video Encoder: External clock input, used if clock rates > 27 MHz are needed,

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

DD_VOUT

GIO: GIO[069] Digital Video Out: B2 PWM3D

GIO: GIO[072]

GIO: GIO[073]

Digital Video Out: VENC settings determine function GIO: GIO[076] PWM2D

RTO3