TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

CHIP

0°C to 70°C

40°C to 105°C

55 C to 125 C

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

D

Outstanding Combination of dc Precision

and AC Performance:

Unity-Gain Bandwidth . . . 15 MHz Typ

V

n

3.3 nV/√Hz at f = 10 Hz Typ,. . . .

2.5 nV/√Hz at f = 1 kHz Typ

V

IO

A

VD

25 µV Max. . . .

45 V/µV Typ With RL = 2 kΩ,. . .

OFFSET N1

IN –

IN +

V

CC –

19 V/µV Typ With RL = 600 Ω

D

Available in Standard-Pinout Small-Outline

Package

D

Output Features Saturation Recovery

Circuitry

D

Macromodels and Statistical information

description

The TLE20x7 and TLE20x7A contain innovative

circuit design expertise and high-quality process

control techniques to produce a level of ac

performance and dc precision previously unavailable in single operational amplifiers. Manufactured using Texas Instruments state-of-the-art

Excalibur process, these devices allow upgrades

to systems that use lower-precision devices.

In the area of dc precision, the TLE20x7 and

TLE20x7A offer maximum offset voltages of

100 µV and 25 µV, respectively, common-mode

rejection ratio of 131 dB (typ), supply voltage

rejection ratio of 144 dB (typ), and dc gain of

45 V/µV (typ).

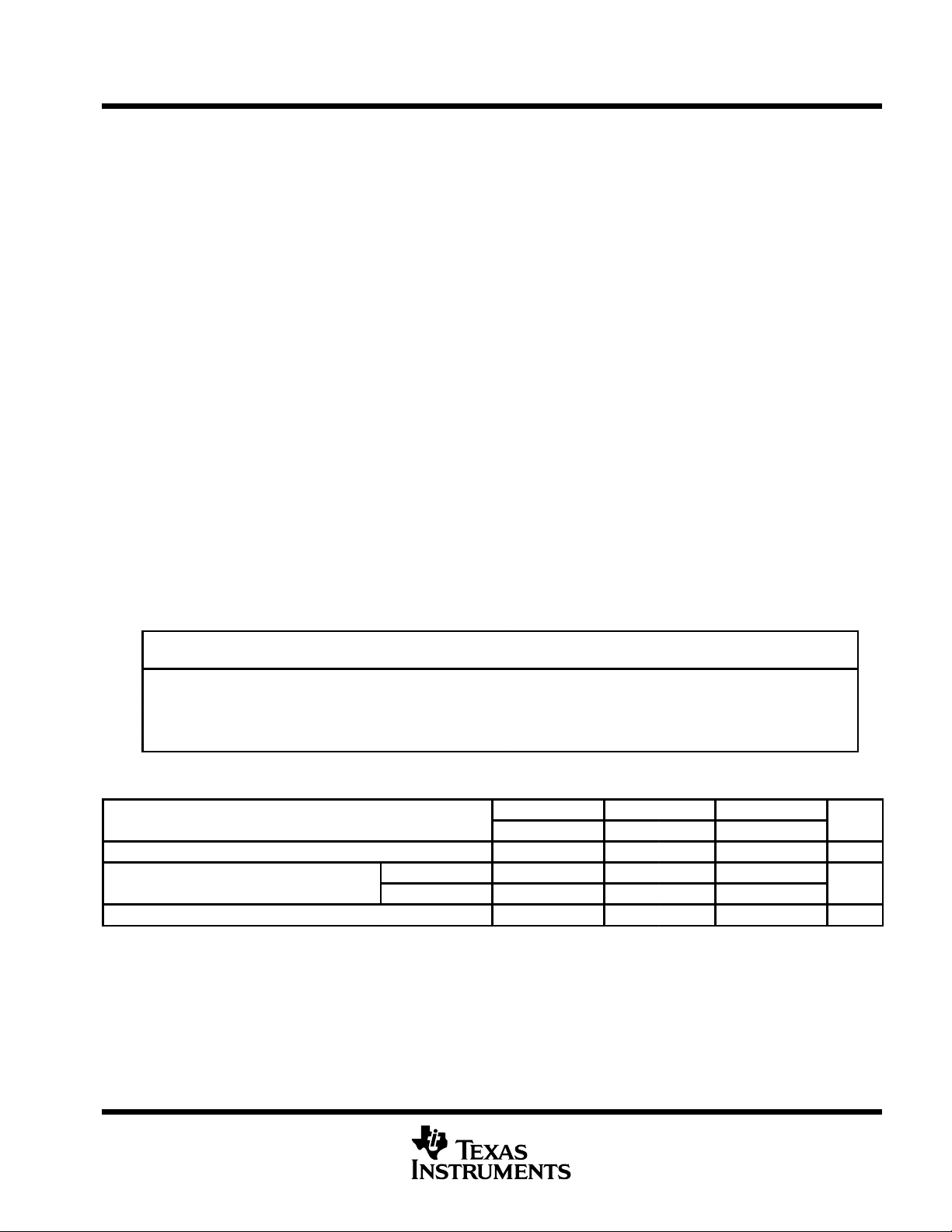

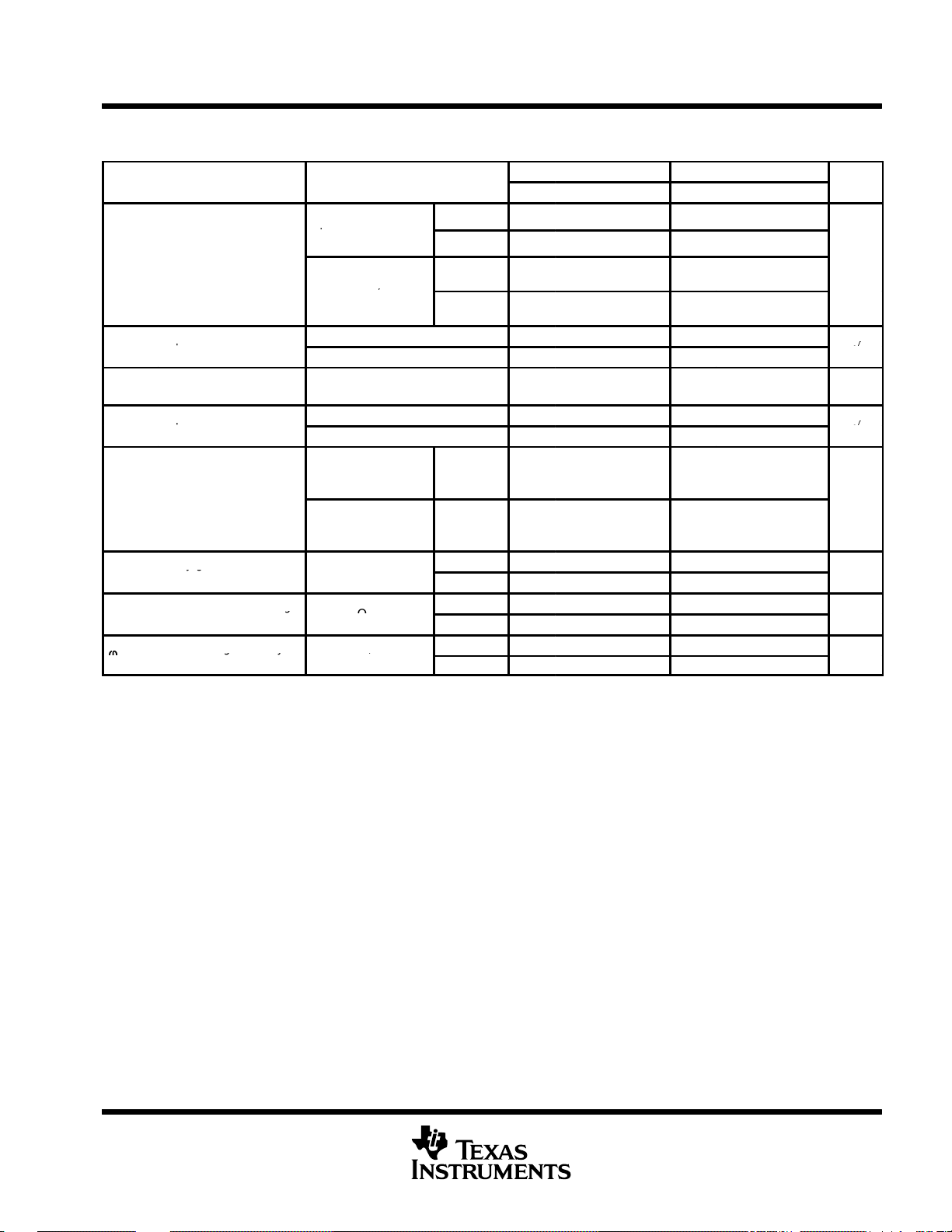

AVAILABLE OPTIONS

PACKAGED DEVICES

T

A

–

–

†

The D packages are available taped and reeled. Add R suffix to device type (e.g., TLE2027ACDR).

‡

Chip forms are tested at 25°C only.

VIOmax AT

25

°C

25 µV

100 µV

25 µV

100 µV

25 µV

100 µV

SMALL

OUTLINE

TLE2027ACD

TLE2037ACD

TLE2027CD

TLE2037CD

TLE2027AID

TLE2037AID

TLE2027ID

TLE2037ID

TLE2027AMD

TLE2037AMD

TLE2027MD

TLE2037MD

†

(D)

CHIP

CARRIER

(FK)

—

—

—

—

—

—

—

—

TLE2027AMFK

TLE2037AMFK

TLE2027MFK

TLE2037MFK

NC

IN–

NC

IN+

NC

CERAMIC

DIP

(JG)

—

—

—

—

—

—

—

—

TLE2027AMJG

TLE2037AMJG

TLE2027MJG

TLE2037MJG

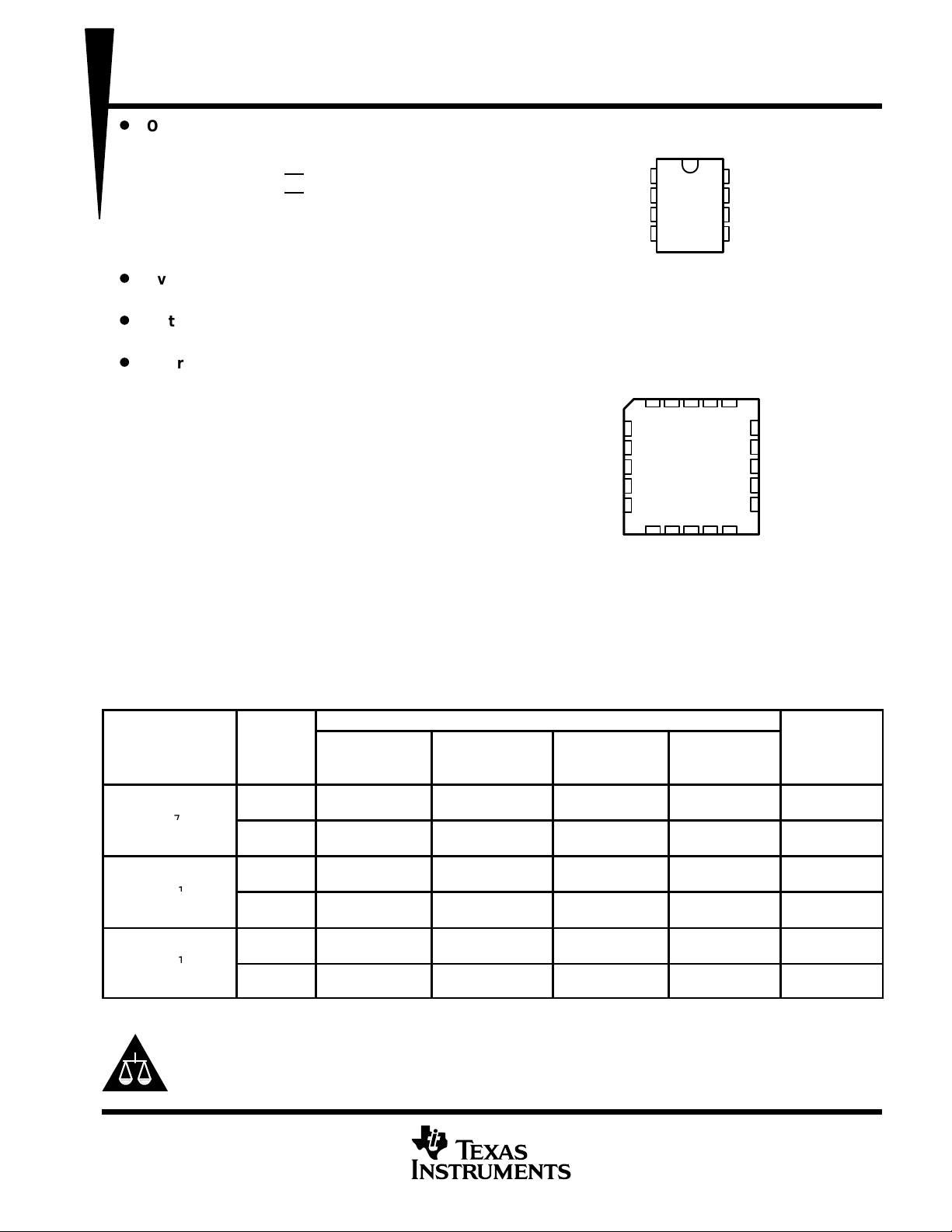

D, JG, OR P PACKAGE

(TOP VIEW)

1

2

3

4

FK PACKAGE

(TOP VIEW)

NC

OFFSET N1

3 2 1 20 19

4

5

6

7

8

910111213

NC

CC –

V

TLE2027ACP

TLE2037ACP

TLE2027CP

TLE2037CP

TLE2027AIP

TLE2037AIP

TLE2027IP

TLE2037IP

TLE2027AMP

TLE2037AMP

TLE2027MP

TLE2037MP

OFFSET N2

8

V

7

OUT

6

NC

5

NCNCNC

OFFSET N2

18

17

16

15

14

NC

NC

PLASTIC

DIP

(P)

CC +

NC

V

CC+

NC

OUT

NC

‡

FORM

(Y)

TLE2027Y

TLE2037Y

TLE2027Y

TLE2037Y

—

—

—

—

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 2002, Texas Instruments Incorporated

1

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

description (continued)

The ac performance of the TLE2027 and TLE2037 is highlighted by a typical unity-gain bandwidth specification

of 15 MHz, 55° of phase margin, and noise voltage specifications of 3.3 nV/√Hz

of 10 Hz and 1 kHz respectively . The TLE2037 and TLE2037A have been decompensated for faster slew rate

(–7.5 V/µs, typical) and wider bandwidth (50 MHz). To ensure stability, the TLE2037 and TLE2037A should be

operated with a closed-loop gain of 5 or greater.

Both the TLE20x7 and TLE20x7A are available in a wide variety of packages, including the industry-standard

8-pin small-outline version for high-density system applications. The C-suffix devices are characterized for

operation from 0°C to 70°C. The I-suffix devices are characterized for operation from –40°C to 105°C. The

M-suffix devices are characterized for operation over the full military temperature range of –55°C to 125°C.

symbol

OFFSET N1

and 2.5 nV/√Hz at frequencies

IN +

IN –

OFFSET N2

+

OUT

–

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

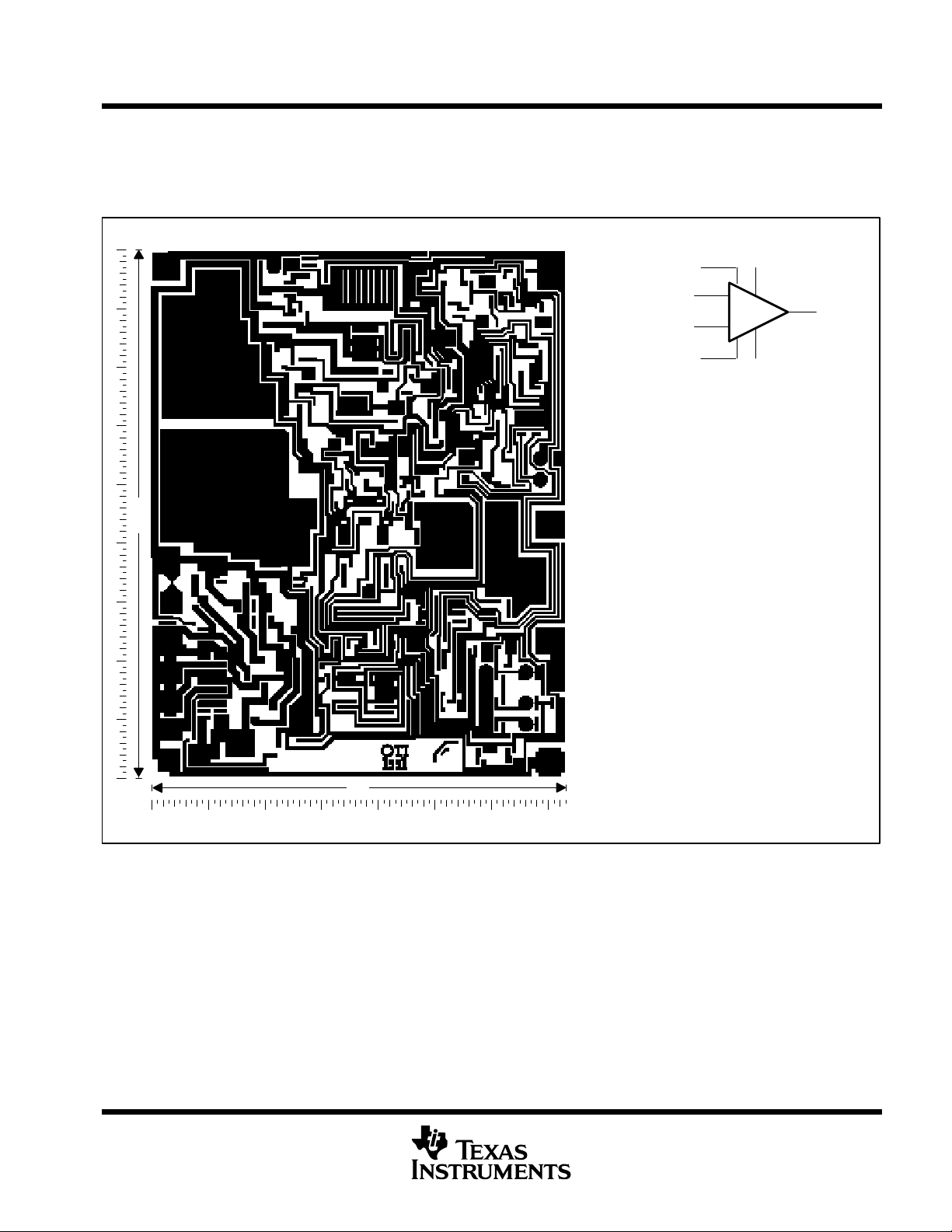

TLE202xY chip information

This chip, when properly assembled, displays characteristics similar to the TLE202xC. Thermal compression

or ultrasonic bonding may be used on the doped-aluminum bonding pads. The chip may be mounted with

conductive epoxy or a gold-silicon preform.

BONDING PAD ASSIGNMENTS

(1)

V

(6)

(4)

(7)(8)

(6)

OFFSET N1

IN+

IN–

OFFSET N2

(3)

(2)

(8)

(5)

CC+

(7)

+

–

(4)

V

CC–

(6)

OUT

90

(7)

(1) (2) (3)

(8)

73

(4)

(3)

(2)

(1)

CHIP THICKNESS: 15 MILS TYPICAL

BONDING PADS: 4 × 4 MILS MINIMUM

TJmax = 150°C

TOLERANCES ARE ±10%.

ALL DIMENSIONS ARE IN MILS.

PIN (4) IS INTERNALLY CONNECTED

TO BACKSIDE OF CHIP.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

T

l

R

l

D

7

11

94

4

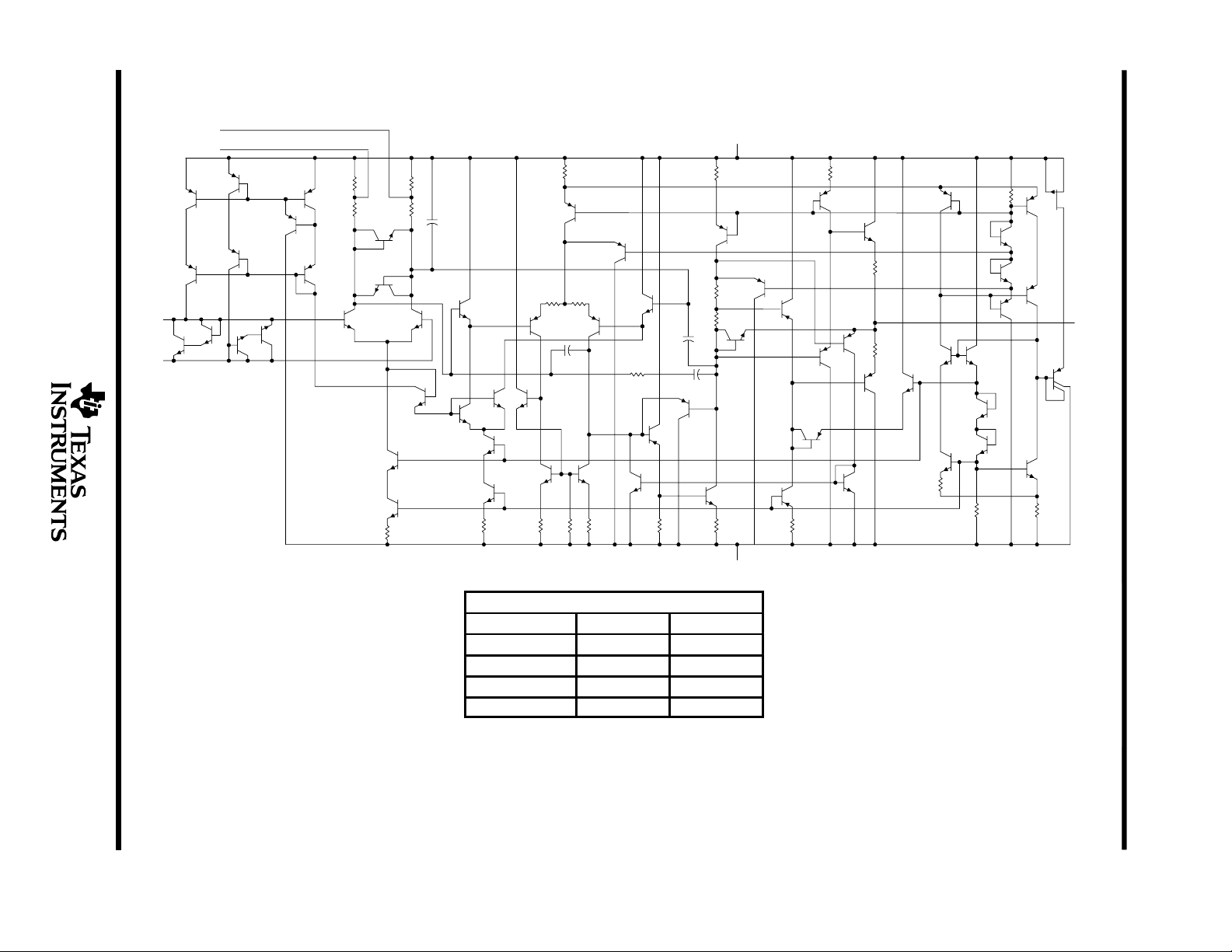

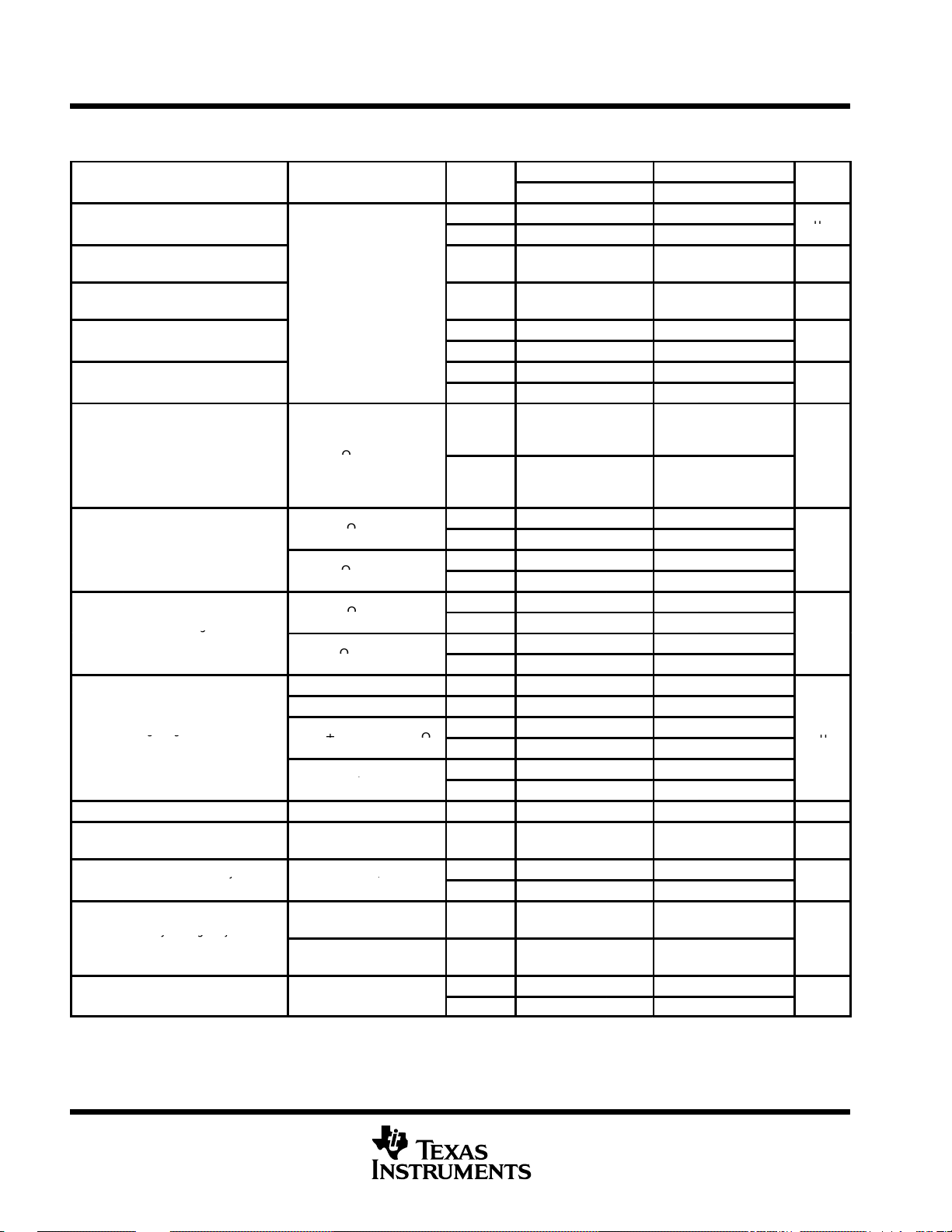

equivalent schematic

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

emp

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

•

OFFSET N2

OFFSET N1

IN +

Q1

IN –

Q2

Q3

Q4

Q5

Q6

Q7

Q8

Q9

Q10

Q11

R1

R2

Q14

Q12

Q15

Q16

R3

R4

R5

Q13

Q17

Q18

C1

Q20

Q21

Q22

R6

Q19

R9

Q27

R8 R11

Q25 Q28

C2

Q24Q23

Q26 Q29

Q30

Q32

R13

Q31

C3

Q34

Q33

R15

Q36

R16

R17

C4

R18R14R12R10R7

V

Q35

V

CC+

Q38

Q37

CC

ate

R20

Q50

Q53

Q54

R25

Q52

R24 R26

Q55

Q56

Q57

Q58

Q59

Q60

Q61

OUT

Q62

Q42

Q46

R21

Q39

Q44

Q43

Q47

Q41

Q40

R19

–

Q45

Q49

R22

Q48

Q51

R23

e

ease

ate:

–

–

ACTUAL DEVICE COMPONENT COUNT

COMPONENT TLE2027 TLE2037

Transistors 61 61

Resistors 26 26

epiFET 1 1

Capacitors 4 4

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

UNIT

Common-mode input voltage, V

V

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Supply voltage, V

Supply voltage, V

Differential input voltage, V

Input voltage range, V

Input current, I

I

Output current, I

Total current into V

Total current out of V

Duration of short-circuit current at (or below) 25°C (see Note 3) unlimited. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

Storage temperature range, T

Case temperature for 60 seconds, T

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds: D or P package 260°C. . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 60 seconds: JG package 300°C. . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values, except differential voltages, are with respect to the midpoint between V

2. Differential voltages are at IN+ with respect to IN–. Excessive current flows if a differential input voltage in excess of approximately

±1.2 V is applied between the inputs unless some limiting resistance is used.

3. The output may be shorted to either supply. Temperature and/or supply voltages must be limited to ensure that the maximum

dissipation rating is not exceeded.

(see Note 1) 19 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC+

– 19 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC–

I

(see Note 2) ±1.2 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ID

(any input) V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(each Input) ±1 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

± 50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC+

50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC–

: C suffix 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

I suffix – 40°C to 105°C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M suffix – 55°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

– 65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

: FK package 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C

CC +

and V

CC –

.

CC±

†

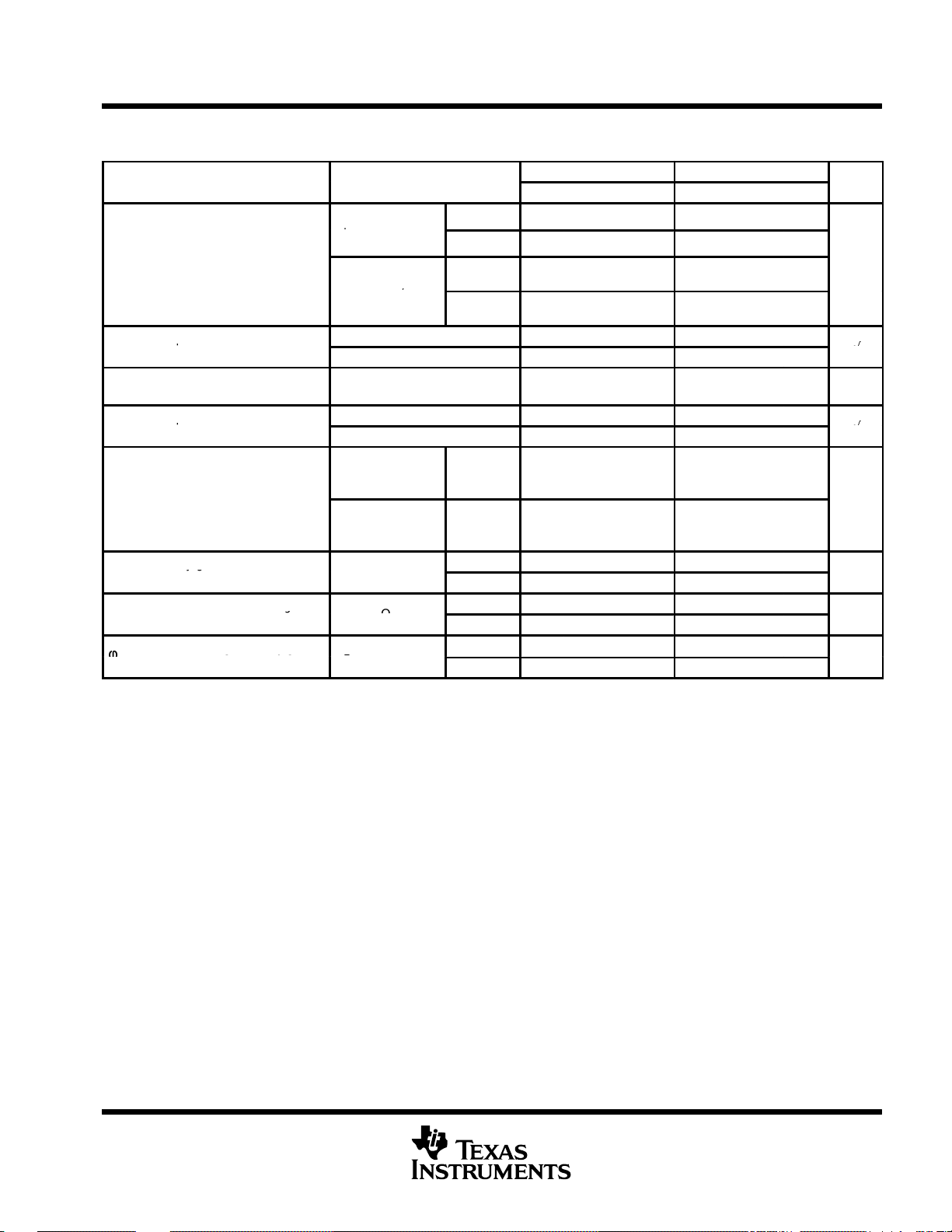

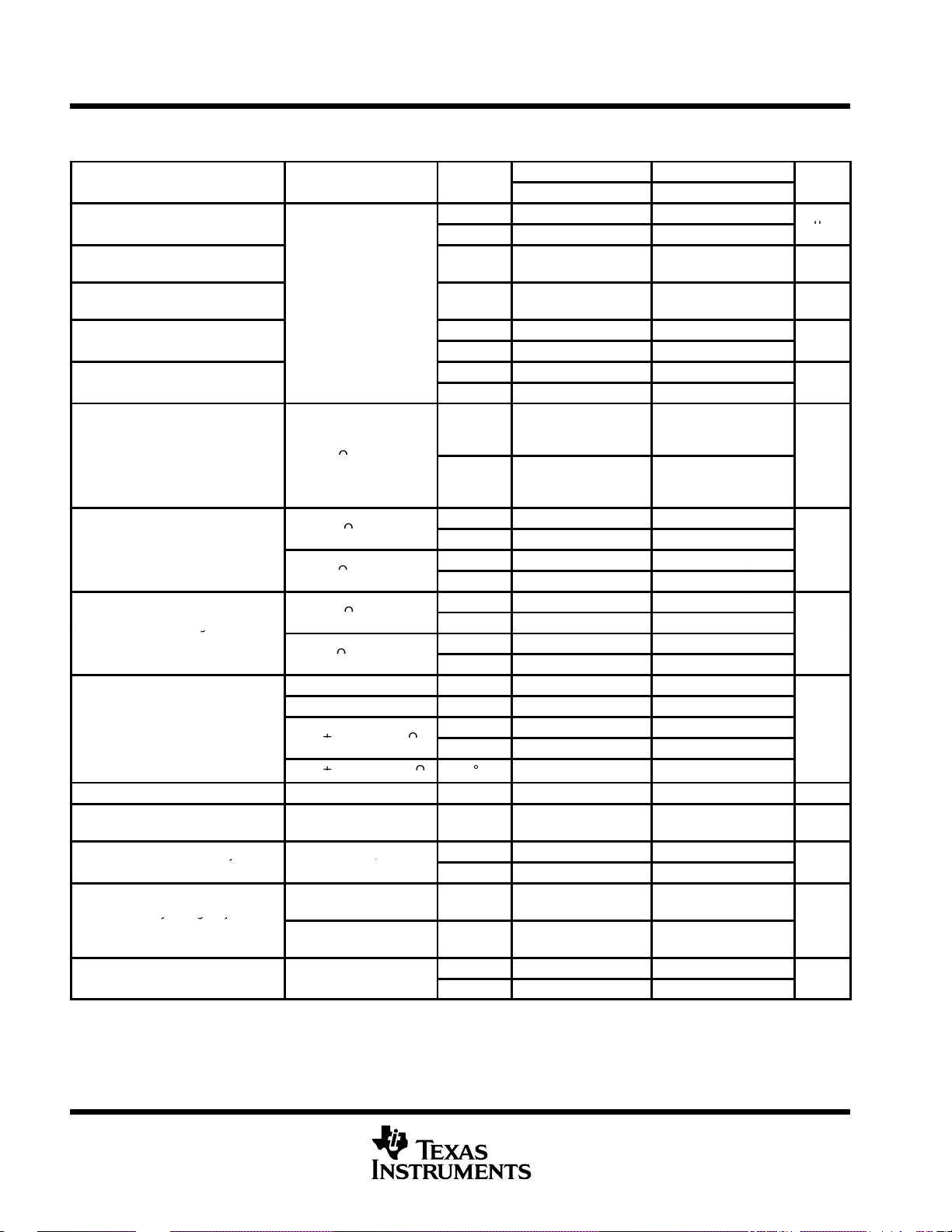

DISSIPATION RATING TABLE

PACKAGE

D 725 mW 5.8 mW/°C 464 mW 261 mW 145 mW

FK 1375 mW 11.0 mW/°C 880 mW 495 mW 275 mW

JG 1050 mW 8.4 mW/°C 672 mW 378 mW 210 mW

P 1000 mW 8.0 mW/°C 640 mW 360 mW 200 mW

TA ≤ 25°C

POWER RATING

DERATING FACTOR

ABOVE TA = 25°C

TA = 70°C

POWER RATING

TA = 105°C

POWER RATING

POWER RATING

recommended operating conditions

C SUFFIX I SUFFIX M SUFFIX

MIN MAX MIN MAX MIN MAX

Supply voltage, V

Operating free-air temperature, T

‡

Full range is 0°C to 70°C for C-suffix devices, –40°C to 105°C for I-suffix devices, and –55°C to 125°C for M-suffix devices.

CC±

p

IC

A

TA = 25°C –11 11 –11 11 –11 11

TA = Full range

‡

±4 ± 19 ±4 ±19 ±4 ±19 V

–10.5 10.5 –10.4 10.4 –10.2 10.2

0 70 –40 105 –55 125 °C

TA = 125°C

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

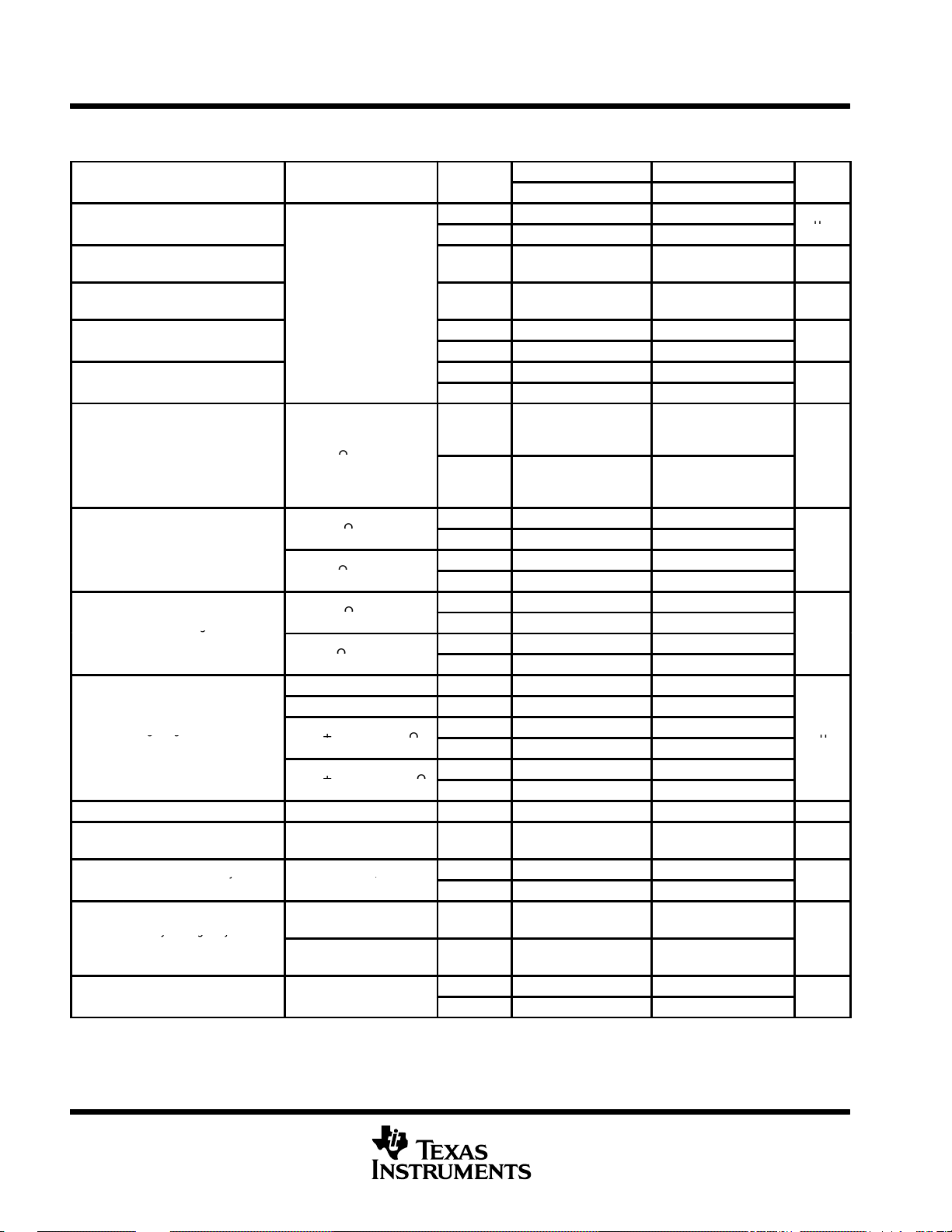

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

PARAMETER

TEST CONDITIONS

T

†

UNIT

VIOInput offset voltage

V

IIOInput offset current

nA

IIBInput bias current

nA

V

R

50 Ω

V

R

600 Ω

V

V

R

2 kΩ

R

600 Ω

V

g

V

R

2 kΩ

A

gg

V

±10 V, R

1 kΩ

V/µV

O

,

CMRR

j

IC ICR

,

dB

k

ygj

dB

ICCSupply current

V

0

No load

mA

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

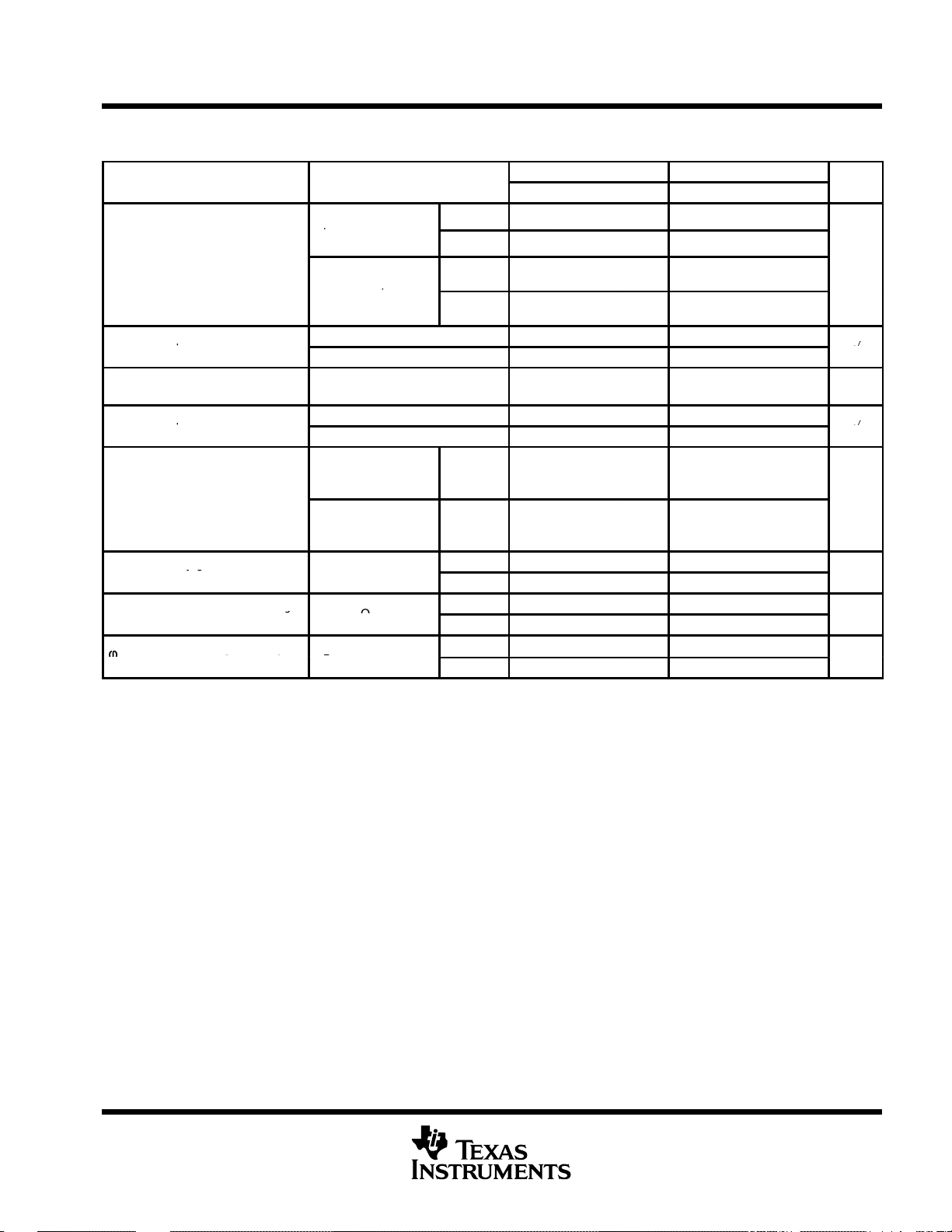

TLE20x7C electrical characteristics at specified free-air temperature, V

= ±15 V (unless

±

CC

otherwise noted)

A

p

α

C

z

o

SVR

†

Full range is 0°C to 70°C.

NOTE 4: Typical values are based on the input offset voltage shift observed through 168 hours of operating life test at TA = 150°C extrapolated

Temperature coefficient of

VIO

input offset voltage

Input offset voltage

long-term drift (see Note 4)

p

p

Common-mode input

ICR

voltage range

Maximum positive peak

OM +

output voltage swing

Maximum negative peak

OM –

output voltage swing

Large-signal differential

VD

voltage amplification

Input capacitance 25°C 8 8 pF

i

Open-loop output

impedance

Common-mode rejection V

ratio

Supply-voltage rejection

ratio (∆V

pp

to TA = 25°C using the Arrhenius equation and assuming an activation energy of 0.96 eV .

CC

/∆V

IO

±

VIC = 0, RS = 50 Ω

=

S

=

L

=

L

=

L

=

L

VO = ±11 V, RL = 2 kΩ 25°C 5 45 10 45

VO = ±10 V, RL = 2 kΩ Full range 2 4

=

O

V

= ±10 V,

RL = 600 Ω

IO = 0 25°C 50 50

= V

RS = 50 Ω

V

= ±4 V to ±18 V,

CC±

RS = 50 Ω

V

)

= ±4 V to ±18 V,

CC±

RS = 50 Ω

,

=

O

min,

=

L

25°C 20 100 10 25

Full range 145 70

Full range 0.4 1 0.2 1 µV/°C

25°C 0.006 1 0.006 1 µV/mo

25°C 6 90 6 90

Full range 150 150

25°C 15 90 15 90

Full range 150 150

25°C

Full range

25°C 10.5 12.9 10.5 12.9

Full range 10 10

25°C 12

Full range 11 11

25°C –10.5 –13 –10.5 –13

Full range –10 –10

25°C – 12 –13.5 – 12 –13.5

Full range – 11 – 11

25°C 3.5 38 8 38

Full range 1 2.5

25°C 2 19 5 19

Full range 0.5 2

25°C 100 131 117 131

Full range 98 114

25°C 94 144 110 144

Full range 92 106

25°C 3.8 5.3 3.8 5.3

Full range 5.6 5.6

TLE20x7C TLE20x7AC

MIN TYP MAX MIN TYP MAX

–11

11

–10.5

10.5

–13

to

to

13

to

13.2

–11

to

11

–10.5

to

10.5

12 13.2

–13

to

13

µ

Ω

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

PARAMETER

TEST CONDITIONS

UNIT

C

100 pF

L

,

V

q

V/√H

I

q

A/√H

THD

Total harmonic distortion

B

yg

L

,

MHz

g

B

g

R

2 kΩ

kHz

φ

gyg

L

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TLE20x7C operating characteristics at specified free-air temperature, V

(unless otherwise specified)

TLE20x7C TLE20x7AC

MIN TYP MAX MIN TYP MAX

RL = 2 kΩ,

See Figure 1

SR Slew rate at unity gain

n

V

N(PP)

n

1

OM

m

NOTE 5: Measured distortion of the source used in the analysis was 0.002%.

Equivalent input noise voltage (see Figure 2)

Peak-to-peak equivalent input noise voltage

Equivalent input noise current

Unity-gain bandwidth R

(see Figure 3)

Maximum output-swin

bandwidth

Phase margin at unity gain RL = 2 kΩ,

(see Figure 3)

RL = 2 kΩ,

C

TA = 0°C to 70°C,

See Figure 1

RS = 20 Ω, f = 10 Hz 3.3 8 3.3 4.5

RS = 20 Ω, f = 1 kHz

f = 0.1 Hz to 10 Hz 50 250 50 130 nV

f = 10 Hz 10 25 10 25

f = 1 kHz

VO = +10 V,

AVD = 1,

See Note 5

VO = +10 V,

AVD = 5,

See Note 5

CL = 100 pF

CL = 100 pF

=

L

= 100 pF,

= 2 kΩ,

=

L

p

,

TLE2027 1.7 2.8 1.7 2.8

TLE2037 6 7.5 6 7.5

TLE2027 1.2 1.2

TLE2037 5 5

2.5 4.5 2.5 3.8

0.8 1.8 0.8 1.8

TLE2027 <0.002% <0.002%

TLE2037 <0.002% <0.002%

TLE2027 7 13 9 13

TLE2037 35 50 35 50

TLE2027 30 30

TLE2037 80 80

TLE2027 55° 55°

TLE2037 50° 50°

= ±15 V, TA = 25°C

CC ±

n

p

V/µs

z

z

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

PARAMETER

TEST CONDITIONS

T

†

UNIT

VIOInput offset voltage

V

IIOInput offset current

nA

IIBInput bias current

nA

V

R

50 Ω

V

R

600 Ω

V

V

R

2 kΩ

R

600 Ω

V

g

V

R

2 kΩ

A

gg

V

±10 V, R

1 kΩ

V/µV

V

±10 V, R

600 Ω

CMRR

j

IC ICR

,

dB

k

ygj

dB

ICCSupply current

V

0

No load

mA

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TLE20x7I electrical characteristics at specified free-air temperature, V

= ±15 V (unless

CC±

otherwise noted)

A

p

α

C

z

o

SVR

†

Full range is – 40°C to 105°C.

NOTE 4: Typical values are based on the input offset voltage shift observed through 168 hours of operating life test at TA = 150°C extrapolated

Temperature coefficient of

VIO

input offset voltage

Input offset voltage

long-term drift (see Note 4)

p

p

Common-mode input

ICR

voltage range

Maximum positive peak

OM +

output voltage swing

Maximum negative peak

OM –

output voltage swing

Large-signal differential

VD

voltage amplification

Input capacitance 25°C 8 8 pF

i

Open-loop output

impedance

Common-mode rejection V

ratio

Supply-voltage rejection

ratio (∆V

pp

to TA = 25°C using the Arrhenius equation and assuming an activation energy of 0.96 eV .

CC

/∆VIO)

±

VIC = 0, RS = 50 Ω

=

S

=

L

=

L

=

L

=

L

VO = ±11 V, RL = 2 kΩ 25°C 5 45 10 45

VO = ±10 V, RL = 2 kΩ Full range 2 3.5

=

O

=

O

IO = 0 25°C 50 50

= V

RS = 50 Ω

V

= ±4 V to ±18 V,

CC±

RS = 50 Ω

V

= ±4 V to ±18 V,

CC±

RS = 50 Ω

,

=

O

min,

=

L

=

L

25°C 20 100 10 25

Full range 180 105

Full range 0.4 1 0.2 1 µV/°C

25°C 0.006 1 0.006 1 µV/mo

25°C 6 90 6 90

Full range 150 150

25°C 15 90 15 90

Full range 150 150

25°C

Full range

25°C 10.5 12.9 10.5 12.9

Full range 10 10

25°C 12

Full range 11 11

25°C –10.5 –13 –10.5 –13

Full range –10 –10

25°C – 12 –13.5 – 12 –13.5

Full range – 11 – 11

25°C 3.5 38 8 38

Full range 1 2.2

25°C 2 19 5 19

Full range 0.5 1.1

25°C 100 131 117 131

Full range 96 113

25°C 94 144 110 144

Full range 90 105

25°C 3.8 5.3 3.8 5.3

Full range 5.6 5.6

TLE20x7I TLE20x7AI

MIN TYP MAX MIN TYP MAX

–11

–10.4

10.4

–13

to

11

to

to

13

13.2

–11

to

11

–10.4

to

10.4

12 13.2

–13

to

13

µ

Ω

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

PARAMETER

TEST CONDITIONS

UNIT

C

100 pF

L

,

V

q

V/√H

I

q

A/√H

THD

Total harmonic distortion

B

yg

L

,

MHz

g

B

g

R

2 kΩ

kHz

y

φ

gy

L

,

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TLE20x7I operating characteristics at specified free-air temperature, V

(unless otherwise specified)

TLE20x7I TLE20x7AI

MIN TYP MAX MIN TYP MAX

RL = 2 kΩ,

See Figure 1

SR Slew rate at unity gain

n

V

N(PP)

n

1

OM

m

NOTE 5: Measured distortion of the source used in the analysis was 0.002%.

Equivalent input noise

voltage (see Figure 2)

Peak-to-peak equivalent

input noise voltage

Equivalent input noise

current

Unity-gain bandwidth R

(see Figure 3)

Maximum output-swin

bandwidth

Phase margin at unit

gain (see Figure 3)

RL = 2 kΩ,

C

TA = –40°C to 85°C,

See Figure 1

RS = 20 Ω, f = 10 Hz 3.3 8 3.3 4.5

RS = 20 Ω, f = 1 kHz

f = 0.1 Hz to 10 Hz 50 250 50 130 nV

f = 10 Hz 10 25 10 25

f = 1 kHz

VO = +10 V,

AVD = 1,

See Note 5

VO = +10 V,

AVD = 5,

See Note 5

CL = 100 pF

R

CL = 100 pF

=

L

= 100 pF,

= 2 kΩ,

=

L

= 2 kΩ,

p

,

TLE2027 1.7 2.8 1.7 2.8

TLE2037 6 7.5 6 7.5

TLE2027 1.1 1.1

TLE2037 4.7 4.7

2.5 4.5 2.5 3.8

0.8 1,8 0.8 1.8

TLE2027 < 0.002% < 0.002%

TLE2037 < 0.002% < 0.002%

TLE2027 7 13 9 13

TLE2037 35 50 35 50

TLE2027 30 30

TLE2037 80 80

TLE2027 55° 55°

TLE2037 50° 50°

= ±15 V, TA = 25°C

CC ±

n

p

V/µs

z

z

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

PARAMETER

TEST CONDITIONS

T

†

UNIT

VIOInput offset voltage

V

IIOInput offset current

nA

IIBInput bias current

nA

V

R

50 Ω

V

R

600 Ω

V

V

R

2 kΩ

R

600 Ω

V

g

V

R

2 kΩ

VD

voltage am lification

V

±10 V, R

1 kΩ

µ

V

±10 V, R

600 Ω

25°C219519

CMRR

j

IC ICR

,

dB

k

ygj

dB

ICCSupply current

V

0

load

mA

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TLE20x7M electrical characteristics at specified free-air temperature, V

= ±15 V (unless

±

CC

otherwise noted)

A

p

α

A

Ci

z

o

SVR

* On products compliant to MIL-PRF-38535, this parameter is not production tested.

†

Full range is – 55°C to 125°C.

NOTE 4: Typical values are based on the input offset voltage shift observed through 168 hours of operating life test at TA = 150°C extrapolated

Temperature coefficient of

VIO

input offset voltage

Input offset voltage

long-term drift (see Note 4)

p

p

Common-mode input

ICR

voltage range

Maximum positive peak

OM +

output voltage swing

Maximum negative peak

OM –

output voltage swing

Large-signal differential

VD

Input capacitance 25°C 8 8 pF

Open-loop output

impedance

Common-mode rejection V

ratio

Supply-voltage rejection

ratio (∆V

to TA = 25°C using the Arrhenius equation and assuming an activation energy of 0.96 eV .

pp

CC

p

/∆V

IO

±

VIC = 0, RS = 50 Ω

=

S

=

L

=

L

=

L

=

L

VO = ±11 V, RL = 2 kΩ 25°C 5 45 10 45

VO = ±10 V, RL = 2 kΩ Full range 2.5 3.5

=

O

=

O

IO = 0 25°C 50 50

= V

RS = 50 Ω

V

= ±4 V to ±18 V,

CC±

RS = 50 Ω

V

)

= ±4 V to ±18 V,

CC±

RS = 50 Ω

, No

=

O

min,

=

L

=

L

25°C 20 100 10 25

Full range 200 105

Full range 0.4 1* 0.2 1* µV/°C

25°C 0.006 1* 0.006 1* µV/mo

25°C 6 90 6 90

Full range 150 150

25°C 15 90 15 90

Full range 150 150

25°C

Full range

25°C 10.5 12.9 10.5 12.9

Full range 10 10

25°C 12 13.2 12 13.2

Full range 11 11

25°C –10.5 –13 –10.5 –13

Full range –10 –10

25°C – 12 –13.5 – 12 –13.5

Full range – 11 – 11

25°C 3.5 38 8 38

Full range 1.8 2.2

25°C 100 131 117 131

Full range 96 113

25°C 94 144 110 144

Full range 90 105

25°C 3.8 5.3 3.8 5.3

Full range 5.6 5.6

TLE20x7M TLE20x7AM

MIN TYP MAX MIN TYP MAX

–11

–10.3

10.3

–13

to

11

to

to

13

–11

11

–10.4

10.4

–13

to

to

to

13

µ

V/µV

Ω

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

PARAMETER

TEST CONDITIONS

UNIT

C

100 pF

L

,

V

q

V/√H

I

q

A/√H

THD

Total harmonic distortion

B

yg

L

,

MHz

g

B

g

R

2 kΩ

kHz

φ

gy

L

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TLE20x7M operating characteristics at specified free-air temperature, V

(unless otherwise specified)

TLE20x7M TLE20x7AM

MIN TYP MAX MIN TYP MAX

RL = 2 kΩ,

See Figure 1

SR Slew rate at unity gain

n

V

N(PP)

n

1

OM

m

* On products compliant to MIL-PRF-38535, this parameter is not production tested.

NOTE 5: Measured distortion of the source used in the analysis was 0.002%.

Equivalent input noise

voltage (see Figure 2)

Peak-to-peak equivalent

input noise voltage

Equivalent input noise

current

Unity-gain bandwidth R

(see Figure 3)

Maximum output-swin

bandwidth

Phase margin at unity RL = 2 kΩ,

gain (see Figure 3)

RL = 2 kΩ,

C

TA = –55°C to 125°C,

See Figure 1

RS = 20 Ω, f = 10 Hz 3.3 8* 3.3 4.5*

RS = 20 Ω, f = 1 kHz

f = 0.1 Hz to 10 Hz 50 250* 50 130* nV

f = 10 Hz 1.5 4* 1.5 4*

f = 1 kHz

VO = +10 V,

AVD = 1,

See Note 5

VO = +10 V,

AVD = 5,

See Note 5

CL = 100 pF

CL = 100 pF

=

L

= 100 pF,

= 2 kΩ,

=

L

p

,

TLE2027 1.7 2.8 1.7 2.8

TLE2037 6* 7.5 6* 7.5

TLE2027 1 1

TLE2037 4.4* 4.4*

2.5 4.5* 2.5 3.8*

0.4 0.6* 0.4 0.6*

TLE2027 < 0.002% < 0.002%

TLE2037 < 0.002% < 0.002%

TLE2027 7* 13 9* 13

TLE2037 35 50 35 50

TLE2027 30 30

TLE2037 80 80

TLE2027 55° 55°

TLE2037 50° 50°

= ±15 V, TA = 25°C

CC ±

n

p

V/µs

z

z

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

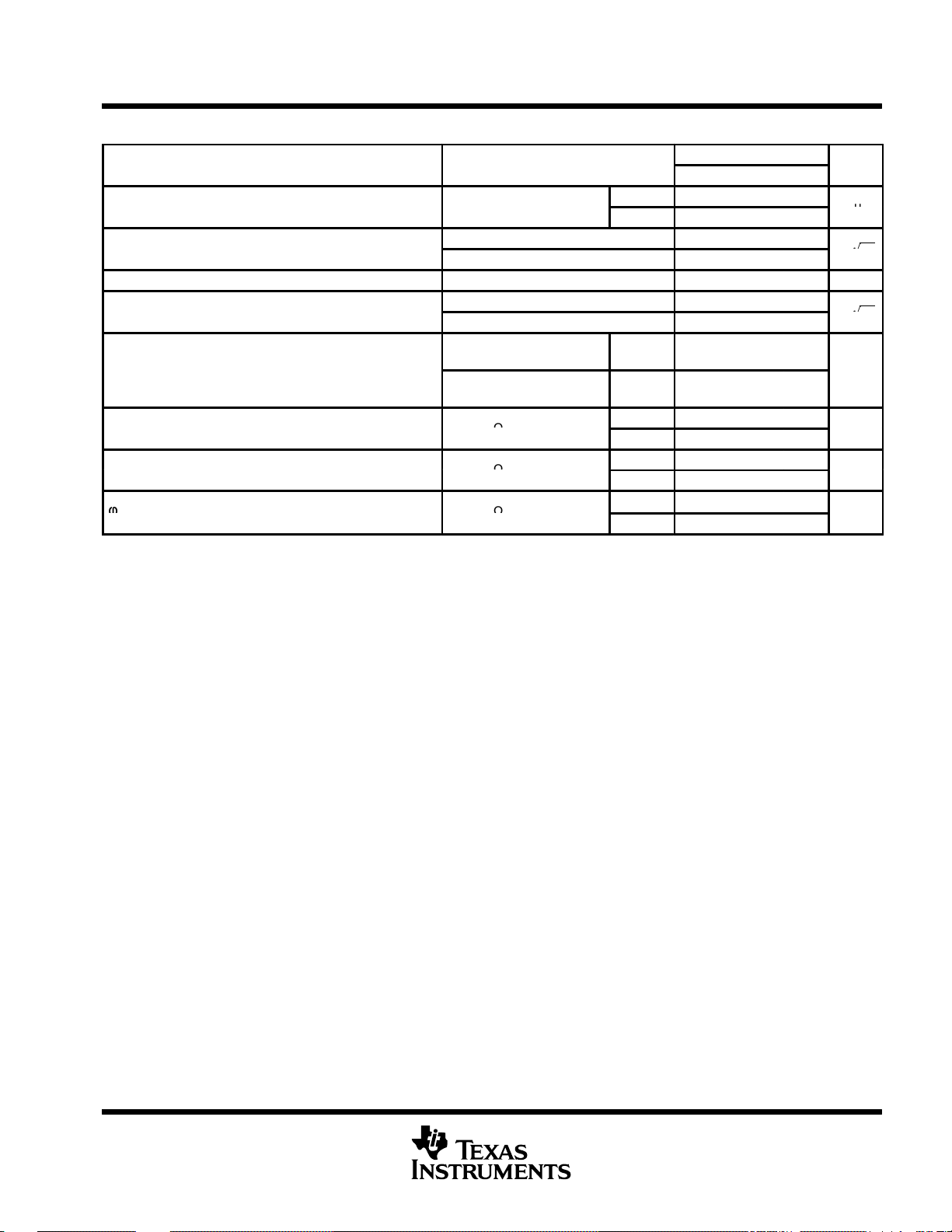

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

PARAMETER

TEST CONDITIONS

UNIT

IC

,

S

V

Maximum positive peak output voltage swing

V

V

Maximum negative peak output voltage swing

V

AVDLarge-signal differential voltage am lification

V/µV

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TLE20x7Y electrical characteristics, V

V

I

IO

I

IB

V

C

z

o

CMRR Common-mode rejection ratio

k

SVR

I

CC

NOTE 4: Typical values are based on the input offset voltage shift observed through 168 hours of operating life test at TA = 150°C extrapolated

Input offset voltage 20 µV

IO

Input offset voltage

long-term drift (see Note 4)

Input offset current

Input bias current 15 nA

Common-mode input voltage range RS = 50 Ω

ICR

p

OM +

OM –

Input capacitance 8 pF

i

Open-loop output impedance IO = 0 50

Supply-voltage rejection ratio (∆V

Supply current VO = 0, No load 3.8 mA

to TA = 25°C using the Arrhenius equation and assuming an activation energy of 0.96 eV .

p

p

p

p

p

/∆V

CC

±

= ±15 V, TA = 25°C (unless otherwise noted)

±

CC

MIN TYP MAX

V

IO

= 0, R

R

= 600 Ω 12.9

L

RL = 2 kΩ

RL = 600 Ω –13

RL = 2 kΩ –13.5

VO = ±11 V, RL = 2 kΩ 45

VO = ±10 V, RL = 1 kΩ 38

VO = ±10 V,

RL = 600 Ω

VIC = V

ICR

RS = 50 Ω

V

= ±4 V to ±18 V,

)

CC±

RS = 50 Ω

= 50 Ω

min,

TLE20x7Y

0.006 µV/mo

6 nA

–13

to

13

13.2

19

131 dB

144 dB

V

Ω

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

PARAMETER

TEST CONDITIONS

UNIT

SR

Slew rate at unity gain

L

,

L

,

V/µs

VnEquivalent input noise voltage (see Figure 2)

V/√H

InEquivalent input noise current

A/√H

THD

Total harmonic distortion

B1Unity-gain bandwidth (see Figure 3)

R

2 kΩ,C

100 pF

MHz

BOMMaximum output-swing bandwidth

R

2 kΩ

kHz

φ

Phase margin at unity gain (see Figure 3)

R

L

C

L

100 F

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TLE20x7Y operating characteristics at specified free-air temperature, V

R

= 2 kΩ,C

See Figure 1

p

V

N(PP)

m

NOTE 5: Measured distortion of the source used in the analysis was 0.002%.

Peak-to-peak equivalent input noise voltage f = 0.1 Hz to 10 Hz 50 nV

p

p

RS = 20 Ω, f = 10 Hz 3.3

RS = 20 Ω, f = 1 kHz 2.5

f = 10 Hz 10

f = 1 kHz 0.8

VO = +10 V, AVD = 1,

See Note 5

VO = +10 V, AVD = 5,

See Note 5

=

L

=

L

= 2 kΩ,

= 100 pF,

=

L

=

TLE2027 2.8

TLE2037 7.5

TLE2027 <0.002%

TLE2037 <0.002%

TLE2027 13

p

TLE2037 50

TLE2027 30

TLE2037 80

TLE2027 55°

p

TLE2037 50°

= ±15 V

CC ±

TLE20x7Y

MIN TYP MAX

n

z

p

z

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

13

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

PARAMETER MEASUREMENT INFORMATION

R

f

15 V

–

R

I

+

V

I

– 15 V

NOTE A: CL includes fixture capacitance.

CL =

100 pF

(see Note A)

Figure 1. Slew-Rate Test Circuit Figure 2. Noise-Voltage Test Circuit

10 kΩ

100 Ω

V

I

15 V

–

+

–15 V

(see Note A)

CL =

100 pF

V

O

RL = 2 kΩ

V

O

2 kΩ

R

20 Ω

I

2 kΩ

15 V

–

V

O

+

– 15 V

20 Ω

R

f

15 V

–

V

O

+

V

I

– 15 V

NOTES: A. CL includes fixture capacitance.NOTE A: CL includes fixture capacitance.

B. For the TLE2037 and TLE2037A,

CL =

100 pF

(see Note A)

AVD must be ≥ 5.

2 kΩ

Figure 3. Unity-Gain Bandwidth and Figure 4. Small-Signal Pulse-

Phase-Margin Test Circuit (TLE2027 Only) Response Test Circuit

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

typical values

Typical values presented in this data sheet represent the median (50% point) of device parametric performance.

initial estimates of parameter distributions

In the ongoing program of improving data sheets and supplying more information to our customers, Texas

Instruments has added an estimate of not only the typical values but also the spread around these values. These

are in the form of distribution bars that show the 95% (upper) points and the 5% (lower) points from the

characterization of the initial wafer lots of this new device type (see Figure 5). The distribution bars are shown

at the points where data was actually collected. The 95% and 5% points are used instead of ± 3 sigma since

some of the distributions are not true Gaussian distributions.

The number of units tested and the number of different wafer lots used are on all of the graphs where distribution

bars are shown. As noted in Figure 5, there were a total of 835 units from two wafer lots. In this case, there is

a good estimate for the within-lot variability and a possibly poor estimate of the lot-to-lot variability . This is always

the case on newly released products since there can only be data available from a few wafer lots.

The distribution bars are not intended to replace the minimum and maximum limits in the electrical tables. Each

distribution bar represents 90% of the total units tested at a specific temperature. While 10% of the units tested

fell outside any given distribution bar, this should not be interpreted to mean that the same individual devices

fell outside every distribution bar.

4.5

3.5

– Supply Current – mA

CC

I

2.5

SUPPLY CURRENT

FREE-AIR TEMPERATURE

5

V

= ±15 V

CC

±

VO = 0

No Load

Sample Size = 835 Units

From 2 Water Lots

4

3

TA – Free-Air Temperature –

Figure 5. Sample Graph With Distribution Bars

vs

95% point on the distribution bar

(5% of the devices fell above this point.)

90% of the devices were within the upper

and lower points on the distribution bar.

5% point on the distribution bar

(5% of the devices fell below this point.)

1501251007550250– 25– 50– 75

°C

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

15

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

IIBInput bias current

V

(g)

,

vsvsSu ly voltage

20

AVDLarge-signal differential voltage amplification

yg

,

OS

ICCSupply current

yg

Voltage-follower pulse response

g

,

B1Unity-gain bandwidth

yg

Gain bandwidth product

yg

φ

yg

,

φ

m

g

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

Table of Graphs

V

IO

∆V

I

IO

I

I

V

O(PP)

OM

z

o

CMRR Common-mode rejection ratio vs Frequency 28

k

SVR

I

OS

V

n

SR Slew rate vs Free-air temperature 48, 49

m

Input offset voltage Distribution 6, 7

Input offset voltage change vs Time after power on 8, 9

IO

Input offset current vs Free-air temperature 10

p

Input current vs Differential input voltage 13

Maximum peak-to-peak output voltage vs Frequency 14, 15

Maximum (positive/negative) peak output vs Load resistance 16, 17

voltage vs Free-air temperature

p

Output impedance vs Frequency 27

Supply-voltage rejection ratio vs Frequency 29

Short-circut output current

pp

p

Equivalent input noise voltage vs Frequency 42

Noise voltage (referred to input) Over 10-second interval 43

p

Phase margin

Phase shift vs Frequency 22 – 25

p

vs Free-air temperature 11

vs Common-mode input voltage 12

vs Supply voltage 20

Load resistance

vs Frequency 22 – 25

vs Free-air temperature 26

vs Supply voltage 30, 31

vs

Elapsed time

vs Free-air temperature 34, 35

vs Supply voltage 36

vs

Free-air temperature 37

Small signal 38, 40

Large signal

vs Supply voltage 44

vs

Load capacitance 45

vs Supply voltage 46

vs

Load capacitance 47

vs Supply voltage 50, 51

vs

Load capacitance

vs Free-air temperature 54, 55

FIGURE

18, 19

21

32, 33

39, 41

52, 53

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

DISTRIBUTION

INPUT OFFSET VOLTAGE

16

1568 Amplifiers Tested From 2 Wafer Lots

= +15 V

V

CC

14

12

10

8

6

±

TA = 25°C

D Package

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

INPUT OFFSET VOLTAGE CHANGE

TIME AFTER POWER ON

12

µV

10

8

6

vs

Percentage of Amplifiers – %

4

2

0

VIO – Input Offset Voltage – µV

0 120906030– 30– 60– 90– 120

Figure 6

INPUT OFFSET VOLTAGE CHANGE

vs

TIME AFTER POWER ON

6

µV

5

4

3

2

50 Amplifiers Tested From 2 Wafer Lots

= ±15 V

V

CC

1

IO

AVIO – Change in Input Offset Voltage –

∆V

0

0 20 40 60 80 100 120 140 160 180

±

TA = 25°C

P Package

t – Time After Power On – s

Figure 8

AVIO – Change in Input Offset Voltage –

∆V

IO

I

IIO – Input Offset Current – nA

IO

30

25

20

15

10

4

50 Amplifiers Tested From 2 Wafer Lots

V

2

0

0

= ±15 V

CC

±

TA = 25°C

D Package

10 20 30 40 50 60

t – Time After Power On – s

Figure 7

INPUT OFFSET CURRENT

vs

FREE-AIR TEMPERATURE

V

= ±15 V

CC

±

VIC = 0

Sample Size = 833 Units

From 2 Wafer Lots

5

0

– 75

TA – Free-Air Temperature – °C

Figure 9

†

1501251007550250– 25– 50

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

17

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

IB

IIB – Input Bias Current – nA

I

0.8

0.6

60

50

40

30

20

10

–10

–20

1

INPUT BIAS CURRENT

†

vs

FREE-AIR TEMPERATURE

V

= ± 15 V

CC

±

VIC = 0

Sample Size = 836 Units

From 2 Wafer Lots

0

–75

–50 –25 0 25 50 75 100 125 150

TA – Free-Air Temperature – °C

Figure 10

INPUT CURRENT

DIFFERENTIAL INPUT VOLTAGE

V

= ± 15 V

CC

±

VIC = 0

TA = 25°C

vs

IB

IIB – Input Bias Current – nA

I

INPUT BIAS CURRENT

vs

COMMON-MODE INPUT VOLTAGE

40

= ± 15 V

V

CC

35

30

25

20

15

10

5

0

–12

±

TA = 25°C

– 8 – 40 4 812

VIC – Common-Mode Input Voltage – V

Figure 11

TLE2027

MAXIMUM PEAK-TO-PEAK

OUTPUT VOLTAGE

vs

FREQUENCY

30

25

†

V

= ±15 V

CC±

RL = 2 kΩ

0.4

0.2

0

– 0.2

– 0.4

I

II – Input Current – mA

I

– 0.6

– 0.8

– 1

– 1.8

– 1.2 – 0.6 0 0.6 1.2 1.8

VID – Differential Input Voltage – V

Figure 12

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

– Maximum Peak-to-Peak Output Voltage – V

O(PP)

V

20

15

10

5

0

10 k

TA = 125

TA = – 55°C

f – Frequency – Hz

Figure 13

°C

10 M1 M100 k

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

ÁÁ

ÁÁ

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

O(PP)

V

VO(PP) – Maximum Peak-to-Peak Output Voltage – V

30

25

20

15

10

5

0

– 14

– 12

– 10

10 k

TLE2037

TYPICAL CHARACTERISTICS

MAXIMUM PEAK-TO-PEAK

OUTPUT VOLTAGE

vs

FREQUENCY

TA = 125°C

TA = – 55°C

100 k 1 M 100 M

f – Frequency – Hz

Figure 14

MAXIMUM NEGATIVE PEAK

OUTPUT VOLTAGE

vs

LOAD RESISTANCE

†

V

= ± 15 V

CC

±

RL = 2 kΩ

10 M

MAXIMUM POSITIVE PEAK

OUTPUT VOLTAGE

vs

LOAD RESISTANCE

14

12

10

8

6

4

V

2

0

OM +

VOM+ – Maximum Positive Peak Output Voltage – V

100

V

= ± 15 V

CC

±

TA = 25°C

RL – Load Resistance – Ω

1 k 10 k

Figure 15

13.5

13.4

13.3

MAXIMUM POSITIVE PEAK

OUTPUT VOLTAGE

vs

FREE-AIR TEMPERATURE

V

= ± 15 V

CC

±

RL = 2 kΩ

Sample Size = 832 Units

From 2 Wafer Lots

†

– 8

13.2

– 6

13.1

– 4

VOM+ – Maximum Positive Peak Output Voltage – V

V

12.9

OM +

13

– 50 – 25 0 25 50 75 100 125 150

– 75

TA – Free-Air Temperature – °C

Figure 17

V

= ± 15 V

CC

– 2

0

OM –

VOM– – Maximum Negative Peak Output Voltage – V

100

V

±

TA = 25°C

1 k 10 k

RL – Load Resistance – Ω

Figure 16

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

19

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

LARGE-SIGNAL DIFFERENTIAL

VOLTAGE AMPLIFICATION

TA = 25°C

– 13

– 13.2

MAXIMUM NEGATIVE PEAK

OUTPUT VOLTAGE

†

vs

FREE-AIR TEMPERATURE

V

= ± 15 V

CC

±

RL = 2 kΩ

Sample Size = 831 Units

From 2 Wafer Lots

50

Vµ

40

V/

SUPPLY VOLTAGE

vs

RL = 2 kΩ

RL = 1 kΩ

– 13.4

– 13.6

– 13.8

OM –

VOM– – Maximum Negative Peak Output Voltage – V

V

– 14

– 50 – 25 0 25 50 75 100 125 150

– 75

TA – Free-Air Temperature – °C

Figure 18

50

V

CC

±

TA = 25°C

Vµ

40

V/

30

20

Voltage Amplification –

VD

10

A

AVD – Large-Signal differential

0

0

LARGE-SIGNAL DIFFERENTIAL

VOLTAGE AMPLIFICATION

vs

LOAD RESISTANCE

= ± 15 V

RL = 600 Ω

4 8 12 16 20

V

– Supply Voltage – V

CC±

Figure 19

30

20

Voltage Amplification –

VD

A

AVD – Large-Signal differential

10

0

100 200 400 1 k 4 k 10 k2 k

RL – Load Resistance – Ω

Figure 20

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

Á

Á

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

TLE2027

LARGE-SIGNAL DIFFERENTIAL VOLTAGE

AMPLIFICATION AND PHASE SHIFT

vs

FREQUENCY

160

75°

120

A

100

80

60

Voltage Amplification – dB

VD

40

A

AVD – Large-Signal Differential

20

0

0.1

V

CC±

RL = 2 kΩ

CL = 100 pF

TA = 25

VD

= ± 15 V

°C

LARGE-SIGNAL DIFFERENTIAL VOLTAGE

AMPLIFICATION AND PHASE SHIFT

160

Phase Shift

100 k100

f – Frequency – Hz

Figure 21

TLE2037

vs

FREQUENCY

100 M

100°140

125°

150°

175°

200°

225°

250°

275°

75°

Phase Shift

140

120

A

100

80

60

Voltage Amplification – dB

VD

A

AVD – Large-Signal Differential

V

40

20

CC

RL = 2 kΩ

CL = 100 pF

TA = 25°C

0

0.1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

VD

= ± 15 V

±

Phase Shift

100 100 k

f – Frequency – MHz

Figure 22

100 M

100°

125°

150°

175°

200°

225°

250°

275°

Phase Shift

21

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

TLE2027

LARGE-SIGNAL DIFFERENTIAL VOLTAGE

AMPLIFICATION AND PHASE SHIFT

vs

FREQUENCY

6

100°

3

0

– 3

– 6

Phase Shift

– 9

– 12

Voltage Amplification – dB

VD

A

AVD – Large-Signal Differential

– 15

– 18

V

CC±

RL = 2 kΩ

CL = 100 pF

TA = 25

10

= ± 15 V

°C

LARGE-SIGNAL DIFFERENTIAL VOLTAGE

AMPLIFICATION AND PHASE SHIFT

30

f – Frequency – MHz

Figure 23

TLE2037

vs

FREQUENCY

125°

150°

100

175°

200°

225°

250°

275°

300°

100

Phase Shift

°

A

VD

704020

22

25

20

15

10

5

V

0

Voltage Amplification – dB

VD

A

AVD – Large-Signal Differential

RL = 2 kΩ

CL = 100 pF

– 5

TA = 25°C

–10

1 2 4 10 40 100

CC

A

VD

= ± 15 V

±

f – Frequency – MHz

Phase Shift

20

Figure 24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

125

150

175

200

225

250

275

300

°

°

°

°

Phase Shift

°

°

°

°

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

LARGE-SIGNAL DIFFERENTIAL

VOLTAGE AMPLIFICATION

FREE-AIR TEMPERATURE

60

V

= ± 15 V

CC ±

Vµ

V/

50

40

Voltage Amplification –

VD

A

AVD – Large-Signal differential

30

–75

–50 –25 0 25 50 75 100 125

TA – Free-Air Temperature – °C

vs

Figure 25

†

RL = 2 kΩ

RL = 1 kΩ

150

OUTPUT IMPEDANCE

vs

FREQUENCY

100

V

= ± 15 V

CC ±

TA = 25°C

Ω

10

AVD = 100

1

AVD = 10

o

z

zo – Output Impedance –

–10

–100

10

100 1 k 10 k 100 k 1 M 10 M

f – Frequency – Hz

NOTE A: For this curve, the TLE2027 is AVD = 1 and the

TLE2037 is AVD = 5.

See Note A

100 M

Figure 26

COMMON-MODE REJECTION RATIO

vs

FREQUENCY

– Supply-Voltage Rejection Ratio – dB

SVR

K

140

120

100

140

120

100

CMRR – Common-Mode Rejection Ratio – dB

80

60

40

20

V

= ± 15 V

CC ±

TA = 25°C

0

10

100 1 k 10 k 100 k 1 M 10 M

f – Frequency – Hz

100 M

Figure 27

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

SUPPLY-VOLTAGE REJECTION RATIO

vs

FREQUENCY

V

TA = 25°C

k

SVR–

80

60

k

40

20

0

10

100 1 k 10 k 100 k 1 M 10 M

SVR+

f – Frequency – Hz

Figure 28

CC ±

= ± 15 V

100 M

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

23

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

БББББ

БББББ

БББББ

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

OS

IOS – Short-Circuit Output Current – mA

I

– 45

– 43

–42

–40

–38

–36

–34

–32

–30

SHORT-CIRCUIT OUTPUT CURRENT

vs

SUPPLY VOLTAGE

VID = 100 mV

VO = 0

TA = 25°C

P Package

0

2 4 6 8 10 12 14 16 18 20

V

– Supply Voltage – V

CC±

Figure 29

SHORT-CIRCUIT OUTPUT CURRENT

vs

ELAPSED TIME

V

= ± 15 V

CC ±

VID = 100 mV

VO = 0

TA = 25°C

P Package

OS

IOS – Short-Circuit Output Current – mA

I

44

42

44

42

40

38

36

34

32

30

0

SHORT-CIRCUIT OUTPUT CURRENT

vs

SUPPLY VOLTAGE

VID = – 100 mV

VO = 0

TA = 25°C

P Package

2 4 6 8 10 12 14 16 18 20

V

– Supply Voltage – V

CC±

Figure 30

SHORT-CIRCUIT OUTPUT CURRENT

vs

ELAPSED TIME

V

= ± 15 V

CC ±

VID = 100 mV

VO = 0

TA = 25°C

P Package

– 41

– 39

– 37

OS

IOS – Short-Circuit Output Current – mA

I

– 35

24

0

30 60 90 120 150

t – Elasped Time – s

Figure 31

40

38

36

OS

IOS – Short-Circuit Output Current – mA

I

180

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

34

0

30 60 90 120 150

t – Elasped Time – s

Figure 32

180

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

ÁÁ

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

OS

IOS – Short-Circuit Output Current – mA

I

ICC – Supply Current – mA

I

– 48

– 44

– 40

– 36

– 32

– 28

– 24

CC

SHORT-CIRCUIT OUTPUT CURRENT

vs

FREE-AIR TEMPERATURE

– 75

– 50 – 25 0 25 50 75 100 125

TA – Free-Air Temperature – °C

Figure 33

SUPPLY CURRENT

SUPPLY VOLTAGE

6

VO = 0

No Load

5

4

3

2

1

vs

V

= ± 15 V

CC ±

VID = 100 mV

VO = 0

P Package

†

TA = 125°C

TA = 25°C

TA = – 55°C

†

SHORT-CIRCUIT OUTPUT CURRENT

†

vs

FREE-AIR TEMPERATURE

46

V

= ± 15 V

CC ±

VID = –100 mV

VO = 0

P Package

1251007550250– 25– 50 150– 75

150

OS

IOS – Short-Circuit Output Current – mA

I

42

38

34

30

26

TA – Free-Air Temperature – °C

Figure 34

†

CC

ICC – Supply Current – mA

I

FREE-AIR TEMPERATURE

5

V

= ± 15 V

CC ±

VO = 0

No Load

4.5

Sample Size = 836 Units

From 2 Wafer Lots

4

3.5

3

SUPPLY CURRENT

vs

0

0

2 4 6 8 10 12 14 16 18 20

V

– Supply Voltage – V

CC

±

Figure 35

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

2.5

– 75

– 50 – 25 0255075 100 125

TA – Free-Air Temperature – °C

Figure 36

150

25

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

– Output Voltage – mV

O

V

– 50

– 100

100

50

TLE2027

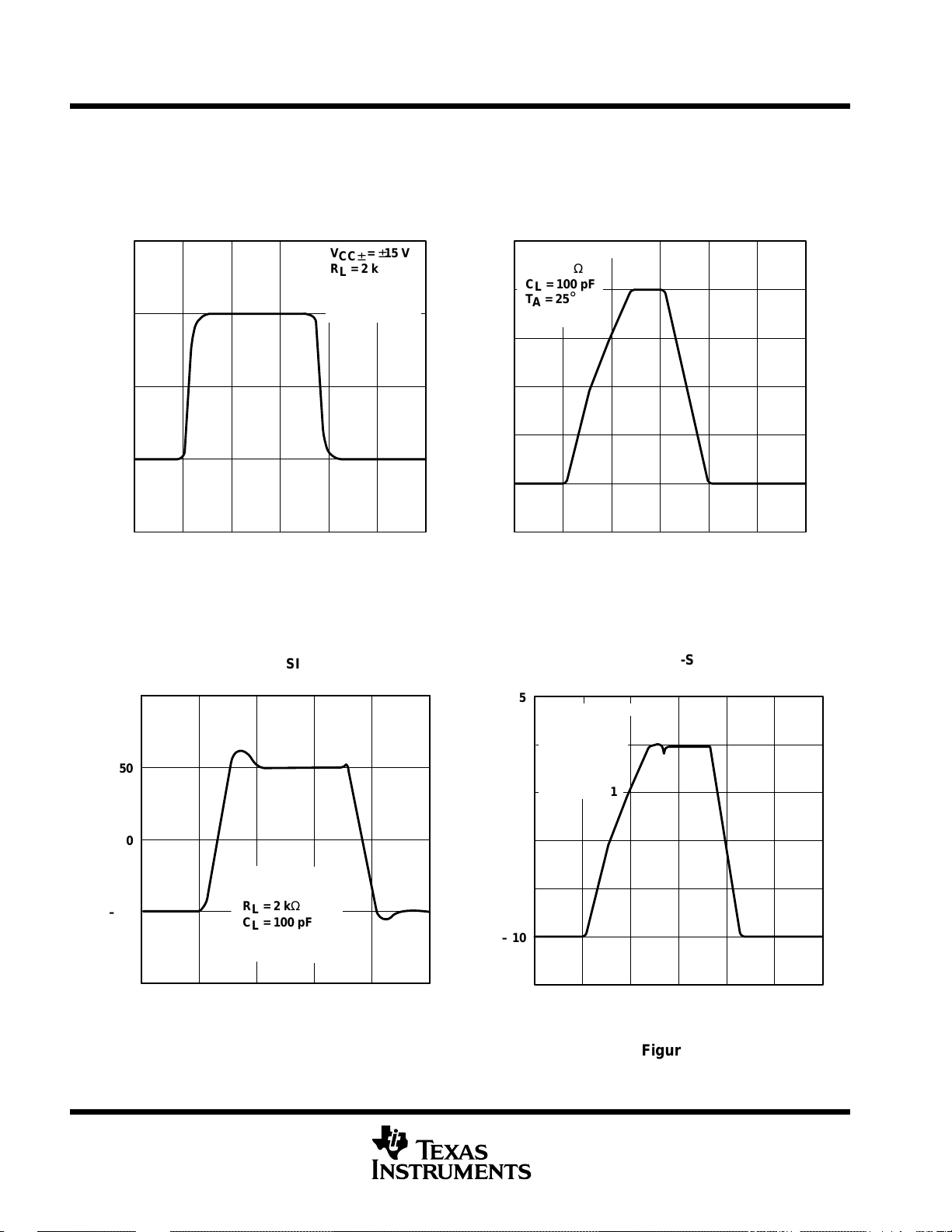

VOLTAGE-FOLLOWER

VOLTAGE-FOLLOWER

SMALL-SIGNAL

PULSE RESPONSE

V

= ±15 V

CC±

RL = 2 kΩ

CL = 100 pF

°C

TA = 25

See Figure 4

0

1000

8006004002000

t – Time – ns

15

V

= ±15 V

CC±

RL = 2 kΩ

CL = 100 pF

10

5

0

– Output Voltage – V

– 5

O

V

– 10

– 15

°C

TA = 25

See Figure 1

Figure 37

TLE2027

LARGE-SIGNAL

PULSE RESPONSE

250 5 10 15 20

t – Time – µs

Figure 38

O

VO – Output Voltage – mV

V

– 100

100

50

– 50

TLE2037

VOLTAGE-FOLLOWER

VOLTAGE-FOLLOWER

SMALL-SIGNAL

PULSE RESPONSE

15

V

= ± 15 V

CC ±

AVD = 5

RL = 2 kΩ

10

CL = 100 pF

TA = 25°C

See Figure 1

5

0

V

= ± 15 V

CC ±

AVD = 5

RL = 2 kΩ

CL = 100 pF

TA = 25°C

See Figure 4

2001000

t – Time – ns

300

400

0

– 5

O

VO – Output Voltage – V

V

– 10

– 15

Figure 39

TLE2037

LARGE-SIGNAL

PULSE RESPONSE

8642010

t – Time – µs

Figure 40

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

БББББББ

БББББББ

БББББББ

БББББББ

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

10

nV/ Hz

8

6

4

2

n

V

Vn – Equivalent Input Noise Voltage – nVHz

0

EQUIVALENT INPUT NOISE VOLTAGE

vs

FREQUENCY

V

= ± 15 V

CC ±

RS = 20 Ω

TA = 25°C

See Figure 2

Sample Size = 100 Units

From 2 Wafer Lots

1

10 100 1 k 10 k

f – Frequency – Hz

Figure 41

100 k

Noise Voltage – nV

50

40

30

20

10

– 10

– 20

– 30

– 40

– 50

0

0

NOISE VOLTAGE

(REFERRED TO INPUT)

OVER A

V

= ± 15 V

CC ±

f = 0.1 to 10 Hz

TA = 25°C

10-SECOND INTERVAL

246 8

t – Time – s

Figure 42

10

20

18

16

14

– Unity-Gain Bandwidth – MHz

12

1

B

10

RL = 2 kΩ

CL = 100 pF

TA = 25

See Figure 3

0

TLE2027

UNITY-GAIN BANDWIDTH

vs

SUPPLY VOLTAGE

°C

| V

| – Supply Voltage – V

CC

±

Figure 43

TLE2037

GAIN-BANDWIDTH PRODUCT

vs

SUPPLY VOLTAGE

52

f = 100 kHz

RL = 2 kΩ

CL = 100 pF

TA = 25°C

51

50

49

Gain-Bandwidth Product – MHz

48

0

201816141210864222

2 468 10 12 14 16 18 20

V

– Supply Voltage – V

CC±

Figure 44

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

27

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

TLE2027

UNITY-GAIN BANDWIDTH

16

12

vs

LOAD CAPACITANCE

V

= ±15 V

CC±

RL = 2 kΩ

TA = 25°C

See Figure 3

52

51

GAIN-BANDWIDTH PRODUCT

TLE2037

vs

LOAD CAPACITANCE

V

= ±15 V

CC±

RL = 2 kΩ

TA = 25°C

– Unity-Gain Bandwidth – MHz

1

B

2.8

µ

2.6

3

8

4

0

100

1000

CL – Load Capacitance – pF

Figure 45

TLE2027

SLEW RATE

FREE-AIR TEMPERATURE

†

vs

10000

sµ

50

49

Gain-Bandwidth Product – MHz

48

10

9

8

100

FREE-AIR TEMPERATURE

V

= ± 15 V

CC ±

AVD = 5

RL = 2 kΩ

CL = 100 pF

See Figure 1

1000

CL – Load Capacitance – pF

Figure 46

TLE2037

SLEW RATE

†

vs

10000

2.4

SR – Slew Rate – V/ s

V

= ±15 V

CC±

AVD = 1

2.2

RL = 2 kΩ

CL = 100 pF

See Figure 1

2

– 75

TA – Free-Air Temperature – °C

1251007550250– 25– 50

150

Figure 47

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

28

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

SR – Slew Rate – V/

7

6

5

– 75

– 50 – 25 0 25 50 75 100 125

TA – Free-Air Temperature – °C

Figure 48

150

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

58°

RL = 2 kΩ

CL = 100 pF

56°

TA = 25

See Figure 3

54°

52°

50°

48°

– Phase Margin

m

φ

46°

44°

42°

0

TLE2027

PHASE MARGIN

SUPPLY VOLTAGE

°C

| – Supply Voltage – V

| V

CC

±

Figure 49

vs

TLE2037

PHASE MARGIN

vs

SUPPLY VOLTAGE

52°

AVD = 5

RL = 2 kΩ

50°

CL = 100 pF

TA = 25°C

48°

46°

44°

– Phase Margin

m

φ

42°

40°

38°

0

2018161412108642

22

2 468 10 12 14 16 18 20

V

– Supply Voltage – V

CC±

Figure 50

60°

50°

40°

30°

– Phase Margin

m

20°

φ

10°

0°

100

TLE2027

PHASE MARGIN

vs

LOAD CAPACITANCE

V

CC±

RL = 2 kΩ

TA = 25°C

See Figure 3

1000

CL – Load Capacitance – pF

Figure 51

= ±15 V

60°

50°

40°

30°

20°

m

φ – Phase Margin

10°

0°

100

TLE2037

PHASE MARGIN

vs

LOAD CAPACITANCE

V

CC ±

RL = 2 kΩ

TA = 25

1000

CL – Load Capacitance – pF

Figure 52

= ± 15 V

°C

10000

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

29

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

TYPICAL CHARACTERISTICS

TLE2027

PHASE MARGIN

†

vs

65°

60°

55°

50°

– Phase Margin

m

45°

φ

40°

35°

– 75

FREE-AIR TEMPERATURE

V

CC±

RL = 2 kΩ

TA = 25

See Figure 3

TA – Free-Air Temperature –

= ±15 V

°C

°C

55°

53°

51°

49°

m

φ – Phase Margin

47°

45°

150

1251007550250– 25– 50

– 75

FREE-AIR TEMPERATURE

TA – Free-Air Temperature – °C

Figure 53

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

TLE2037

PHASE MARGIN

vs

Figure 54

†

V

= ± 15 V

CC ±

AVD = 5

RL = 2 kΩ

CL = 100 pF

150– 50 – 25 0 25 50 75 100 125

30

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

APPLICATION INFORMATION

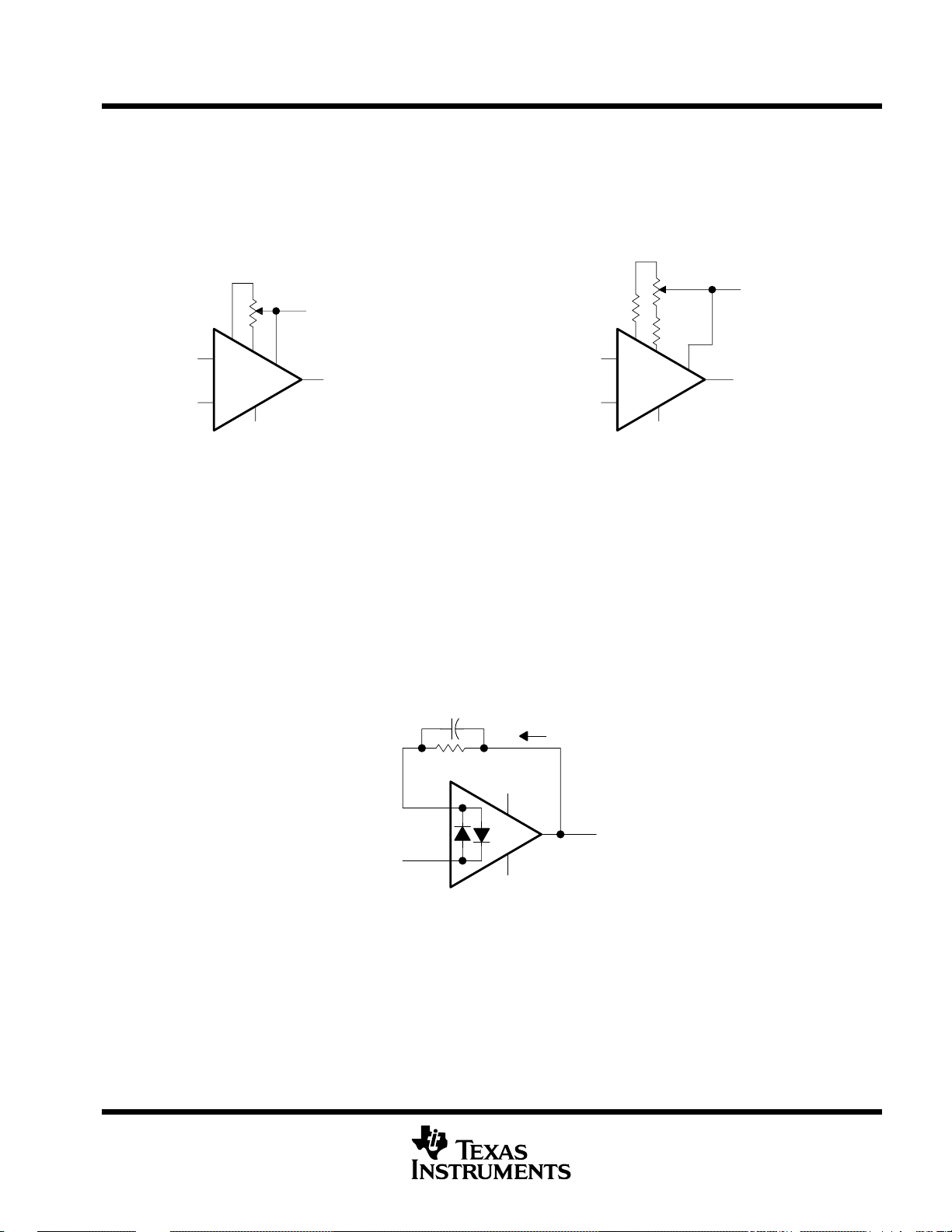

input offset voltage nulling

The TLE2027 and TLE2037 series offers external null pins that can be used to further reduce the input offset

voltage. The circuits of Figure 55 can be connected as shown if the feature is desired. If external nulling is not

needed, the null pins may be left disconnected.

1 kΩ

10 kΩ

IN –

IN +

(a) STANDARD ADJUSTMENT (b) ADJUSTMENT WITH IMPROVED SENSITIVITY

–

+

V

CC –

V

CC +

OUT

IN –

IN +

4.7 kΩ

4.7 kΩ

–

+

V

CC –

V

CC +

OUT

Figure 55. Input Offset Voltage Nulling Circuits

voltage-follower applications

The TLE2027 circuitry includes input-protection diodes to limit the voltage across the input transistors; however,

no provision is made in the circuit to limit the current if these diodes are forward biased. This condition can occur

when the device is operated in the voltage-follower configuration and driven with a fast, large-signal pulse. It

is recommended that a feedback resistor be used to limit the current to a maximum of 1 mA to prevent

degradation of the device. Also, this feedback resistor forms a pole with the input capacitance of the device.

For feedback resistor values greater than 10 kΩ, this pole degrades the amplifier phase margin. This problem

can be alleviated by adding a capacitor (20 pF to 50 pF) in parallel with the feedback resistor (see Figure 56).

CF = 20 to 50 pF

IF

R

F

V

CC

–

V

I

+

V

CC–

Figure 56. Voltage Follower

≤ 1 mA

V

O

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

31

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

APPLICATION INFORMATION

macromodel information

Macromodel information provided was derived using Microsim Parts, the model generation software used

with Microsim PSpice . The Boyle macromodel (see Note 6) and subcircuit in Figure 57, Figure 58, and

Figure 59 were generated using the TLE20x7 typical electrical and operating characteristics at 25°C. Using this

information, output simulations of the following key parameters can be generated to a tolerance of 20% (in most

cases):

• Maximum positive output voltage swing

• Maximum negative output voltage swing

• Slew rate

• Quiescent power dissipation

• Input bias current

• Open-loop voltage amplification

NOTE 6: G. R. Boyle, B. M. Cohn, D. O. Pederson, and J. E. Solomon, “Macromodeling of Integrated Circuit Operational Amplifiers”, IEEE Journal

of Solid-State Circuits, SC-9, 353 (1974).

V

CC +

rc1

c1

11

13

re1 re2

14

lee

4

V

IN +

IN –

CC –

rp

1

2

dp

3

rc2

12

Q2Q1

ree

cee

10

54

– +

ve

+

vc

–

53

dc

de

9

r2

6

gcm

• Gain-bandwidth product

• Common-mode rejection ratio

• Phase margin

• DC output resistance

• AC output resistance

• Short-circuit output current limit

99

vb

+

fb

–

C2

ga

7

vlim

ro2

hlim

8

OUT

90

+ dip

–

+

–

ro1

5

egnd

+

–

dln

92

91

vip

–

vin

+

+

–

Figure 57. Boyle Macromodel

PSpice and Parts are trademarks of MicroSim Corporation.

32

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

APPLICATION INFORMATION

macromodel information (continued)

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

.subckt TLE2027 1 2 3 4 5

*

c1 11 12 4.003E-12

c2 6 7 20.00E-12

dc 5 53 dz

de 54 5 dz

dlp 90 91 dz

dln 92 90 dx

dp 4 3 dz

egnd 99 0 poly(2) (3,0)

(4,0) 0 5 .5

fb 7 99 poly(5) vb vc

ve vlp vln 0 954.8E6 –1E9 1E9 1E9

–1E9

ga 6 0 11 12

2.062E-3

gcm 0 6 10 99

531.3E-12

iee 10 4 dc 56.01E-6

hlim 90 0 vlim 1K

q1 11 2 13 qx

Figure 58. TLE2027 Macromodel Subcircuit

.subckt TLE2037 1 2 3 4 5

*

c1 11 12 4.003E–12

c2 6 7 7.500E–12

dc 5 53 dz

de 54 5 dz

dlp 90 91 dz

dln 92 90 dx

dp 4 3 dz

egnd 99 0 poly(2) (3,0)

(4,0) 0 .5 .5

fb 7 99 poly(5) vb vc

ve vip vln 0 923.4E6 A800E6

800E6 800E6 A800E6

ga 6 0 11 12 2.121E–3

gcm 0 6 10 99 597.7E–12

iee 10 4 dc 56.26E–6

hlim 90 0 vlim 1K

q1 11 2 13 qx

q2 12 1 14 qx

r2 6 9 100.0E3

rc1 3 11 530.5

rc2 3 12 530.5

re1 13 10 –393.2

re2 14 10 –393.2

ree 10 99 3.571E6

ro1 8 5 25

ro2 7 99 25

rp 3 4 8.013E3

vb 9 0 dc 0

vc 3 53 dc 2.400

ve 54 4 dc 2.100

vlim 7 8 dc 0

vlp 91 0 dc 40

vln 0 92 dc 40

.modeldx D(Is=800.0E-18)

.modelqx NPN(Is=800.0E-18

Bf=7.000E3)

.ends

q2 12 1 14 qz

r2 6 9 100.0E3

rc1 3 11 471.5

rc2 3 12 471.5

re1 13 10 A448

re2 14 10 A448

ree 10 99 3.555E6

ro1 8 5 25

ro2 7 99 25

rp 3 4 8.013E3

vb 9 0 dc 0

vc 3 53 dc 2.400

ve 54 4 dc 2.100

vlim 7 8 dc 0

vlp 91 0 dc 40

vln 0 92 dc 40

.model dxD(Is=800.0E–18)

.model qxNPN(Is=800.0E–18

Bf=7.031E3)

.ends

Figure 59. TLE2037 Macromodel Subcircuit

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

33

TLE2027, TLE2037, TLE2027A, TLE2037A, TLE2027Y, TLE2037Y

EXCALIBUR LOW-NOISE HIGH-SPEED

PRECISION OPERATIONAL AMPLIFIERS

SLOS192A – FEBRUARY 1997 REVISED MARCH 2002

34

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty . Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. T o minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third–party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party , or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Loading...

Loading...