www.DataSheet4U.com

www.ti.com

1.8-V to 5-V DUAL UART WITH 64-BYTE FIFOS

TL16C2752

SLWS188 – JUNE 2006

FEATURES

• Larger FIFOs Reduce CPU Overhead

• Programmable Auto-RTS and Auto-CTS

• In Auto-CTS Mode, CTS Controls the

Transmitter

• In Auto-RTS Mode, RCV FIFO Contents, and

• Fully Programmable Serial Interface

Characteristics:

– 5-, 6-, 7-, or 8-Bit Characters

– Even-, Odd-, or No-Parity Bit Generation

and Detection

– 1-, 1 ½-, or 2-Stop Bit Generation

Threshold Control RTS – Baud Generation (dc to 1 Mbit/s)

• Serial and Modem Control Outputs Drive a • False-Start Bit Detection

RJ11 Cable Directly When Equipment is on

the Same Power Drop

• Capable of Running With All Existing

TL16C450 Software

• After Reset, All Registers Are Identical to the

TL16C450 Register Set

• Up to 48 MHz Clock Rate for up to 3-Mbps

(standard 16X sampling) Operation, or up to

6-Mbps (optional 8X sampling) Operation

With V

= 5 V Nominal

CC

• Up to 32 MHz Clock Rate for up to 2-Mbps

(standard 16X sampling) Operation, or up to

4-Mbps (optional 8X sampling) Operation

With V

= 3.3 V Nominal • Available in 44-Pin PLCC (FN) or 32-Pin QFN

CC

• Up to 24 MHz Clock Rate for up to 1.5-Mbps

• Complete Status Reporting Capabilities

• 3-State Output TTL Drive Capabilities for

Bidirectional Data Bus and Control Bus

• Line Break Generation and Detection

• Internal Diagnostic Capabilities:

– Loopback Controls for Communications

Link Fault Isolation

– Break, Parity, Overrun, and Framing Error

Simulation

• Fully Prioritized Interrupt System Controls

• Modem Control Functions ( CTS, RTS, DSR,

DTR, RI, and DCD)

(RHB) Packages

(standard 16X sampling) Operation, or up to • Each UART's Internal Register Set May Be

3-Mbps (optional 8X sampling) Operation Written Concurrently to Save Setup Time

With V

= 2.5 V Nominal

CC

• Multi-Function Output ( MF) Allows Users to

• Up to 16 MHz Clock Rate for up to 1-Mbps Select Among Several Functions, Saving

(standard 16X sampling) Operation, or up to Package Pins

2-Mbps (optional 8X sampling) Operation

With V

= 1.8 V Nominal

CC

• In the TL16C450 Mode, Hold and Shift

Registers Eliminate the Need for Precise

Synchronization Between the CPU and Serial

Data

• Programmable Baud Rate Generator Allows

Division of Any Input Reference Clock by 1 to

16

(2

- 1) and Generates an Internal 16 × Clock

APPLICATIONS

• Point-of-Sale Terminals

• Gaming Terminals

• Portable Applications

• Router Control

• Cellular Data

• Factory Automation

• Standard Asynchronous Communication Bits

(Start, Stop, and Parity) Added to or Deleted

From the Serial Data Stream

• 5-V, 3.3-V, 2.5-V, and 1.8 V Operation

• Independent Receiver Clock Input

• Transmit, Receive, Line Status, and Data Set

Interrupts Independently Controlled

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCT PREVIEW information concerns products in the

formative or design phase of development. Characteristic data and

other specifications are design goals. Texas Instruments reserves

the right to change or discontinue these products without notice.

Copyright © 2006, Texas Instruments Incorporated

www.ti.com

PRODUCT PREVIEW

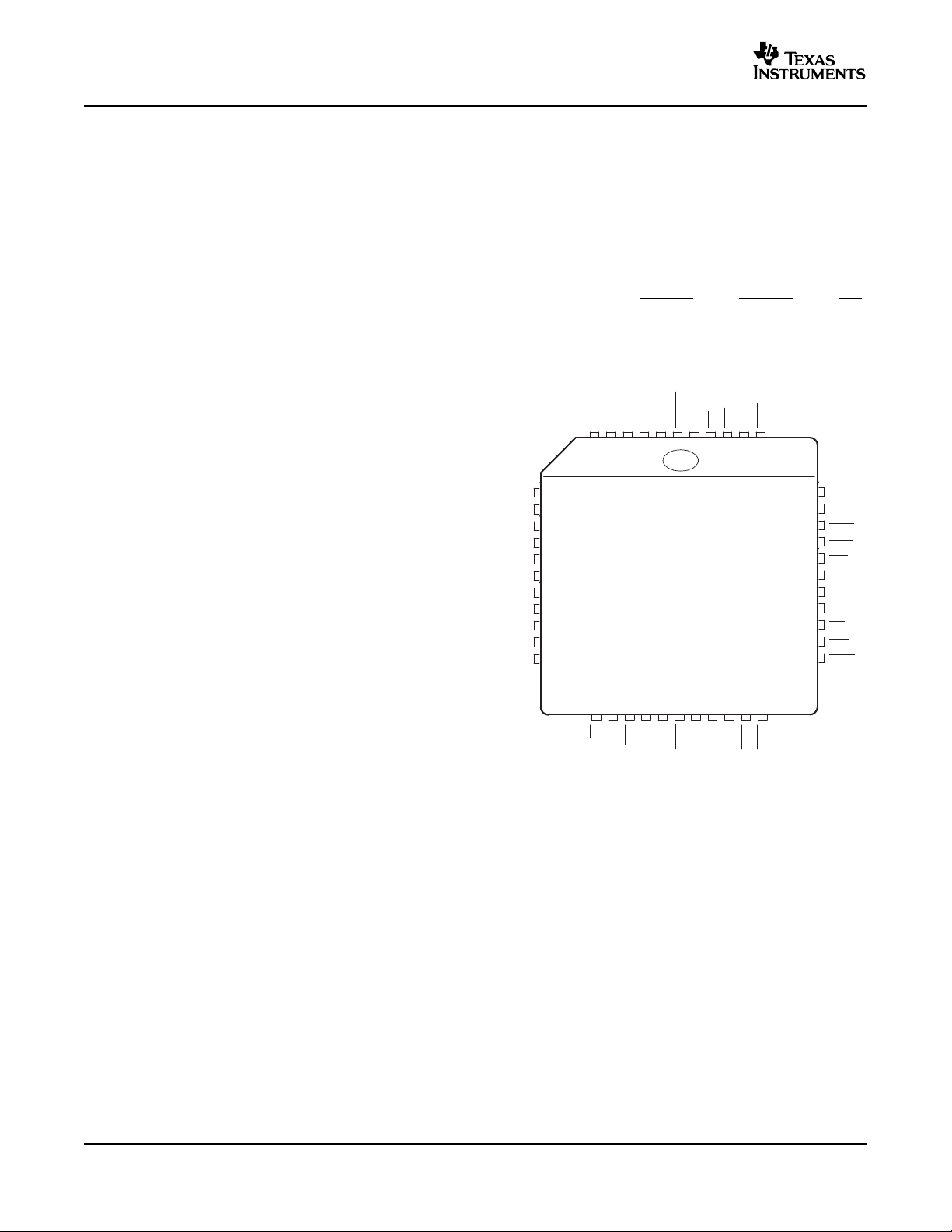

RXA

MFA

D5

D6

RIB

DSRB

CDB

TXRDYB

V

CC

INTA

RTSA

DTRA

TXA

39

35

31

29

30

32

33

34

36

37

38

246 1 42 4041434435

7

8

9

10

11

12

13

14

15

16

17

1918 26 2820 21 22 23 24 25 27

A0

XTAL1

GND

XTAL2

A1

A2

CHSEL

INTB

D7

IOW

CS

MFB

RESET

GND

RTSB

IOR

RXB

TXB

DTRB

CTSB

D4

D0

CDA

CTSA

DSRA

RIA

V

CC

TXRDYA

D1

D2

D3

TL16C2752FN

FN PACKAGE

(TOP VIEW)

TL16C2752

SLWS188 – JUNE 2006

DESCRIPTION

The TL16C2752 is a speed and functional upgrade

of the TL16C2552. Since they are pinout and

software compatible, designs can easily migrate from

the TL16C2552 to the TL16C2752 if needed. The

additional functionality within the TL16C2752 is

accessed via an extended register set. Some of the

key new features are larger receive and transmit

fifos, embedded IrDA encoders and decoders,

RS-485 transceiver controls, software flow control

(Xon/Xoff) modes, programmable transmit fifo

thresholds, extended receive and transmit threshold

levels for interrupts, and extended receive threshold

levels for flow control halt/resume operation.

The TL16C2752 is a dual universal asynchronous

receiver and transmitter (UART). It incorporates the

functionality of two independent UARTs, each UART

having its own register set and transmit and receive

FIFOs. The two UARTs share only the data bus

interface and clock source, otherwise they operate

independently. Another name for the UART function

is Asynchronous Communications Element (ACE),

and these terms will be used interchangeably. The

bulk of this document describes the behavior of each

ACE, with the understanding that two such devices

are incorporated into the TL16C2752.

Functionally equivalent to the TL16C450 on power

up or reset (single character or TL16C450 mode),

each ACE can be placed in an alternate FIFO mode.

This relieves the CPU of excessive software

overhead by buffering received and to be transmitted

characters. Each receiver and transmitter store up to

64 bytes in their respective FIFOs, with the receive

FIFO including three additional bits per byte for error

status. In the FIFO mode, selectable hardware or

software autoflow control features can significantly

reduce program overload and increase system

efficiency by automatically controlling serial data

flow.

Each ACE performs serial-to-parallel conversions on

data received from a peripheral device or modem

and stores the parallel data in its receive buffer or

FIFO, and each ACE performs parallel-to-serial

conversions on data sent from its CPU after storing

the parallel data in its transmit buffer or FIFO. The

CPU can read the status of either ACE at any time.

Each ACE includes complete modem control

capability and a processor interrupt system that can

be tailored to the application.

2

Each ACE includes a programmable baud rate

generator capable of dividing a reference clock with

divisors of from 1 to 65535, thus producing a 16× or

8× internal reference clock for the transmitter and

receiver logic. Each ACE accommodates up to a

3-Mbaud serial data rate (48-MHz input clock). As a

reference point, that speed would generate a 333-ns

bit time and a 3.33-µs character time (for 8,N,1 serial

data), with the internal clock running at 48 MHz and

16× sampling.

Each ACE has a TXRDY and RXRDY (via MF)

output that can be used to interface to a DMA

controller.

Submit Documentation Feedback

www.ti.com

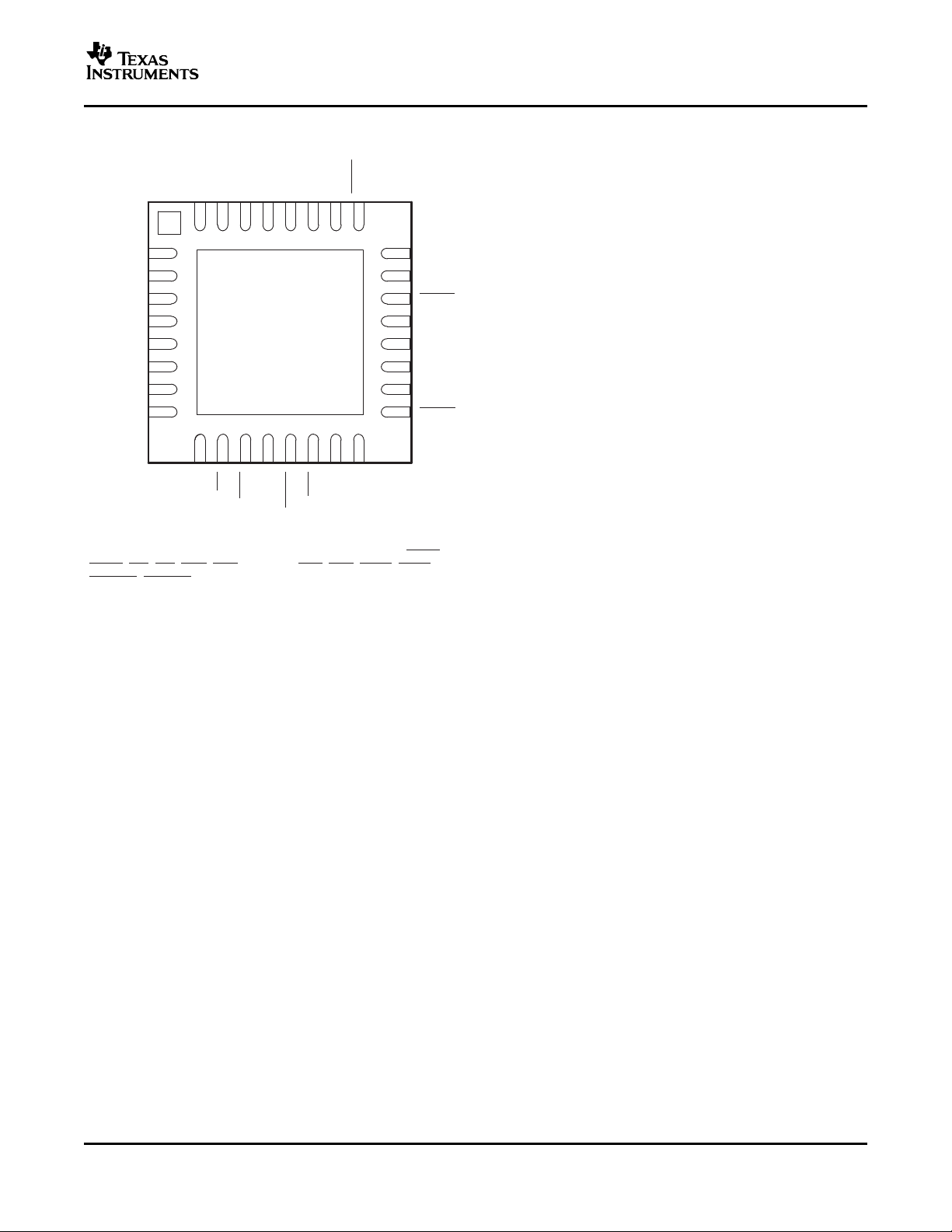

INTB

CS

IOW

RESET

RTSB

IOR

RXB

TXB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

24

23

22

21

20

19

18

17

D6

D7

A0

XTAL1

XTAL2

A1

A2

CHSEL

RXA

TXA

RTSA

INTA

GND

NC

NC

CTSB

32

31

30

29

28

27

26

25

D5D4D3D2D1D0V

CC

CTSA

RHB PACKAGE

(TOP VIEW)

NC − No internal connection

NOTE: The 32-pin RHB package does not provide access to DSRA

,

DSRB, RIA, RIB, CDA, CDB inputs and MFA, MFB, DTRA , DTRB,

TXRDYA

, TXRDYB outputs.

TL16C2752RHB

TL16C2752

SLWS188 – JUNE 2006

Submit Documentation Feedback

3

www.ti.com

PRODUCT PREVIEW

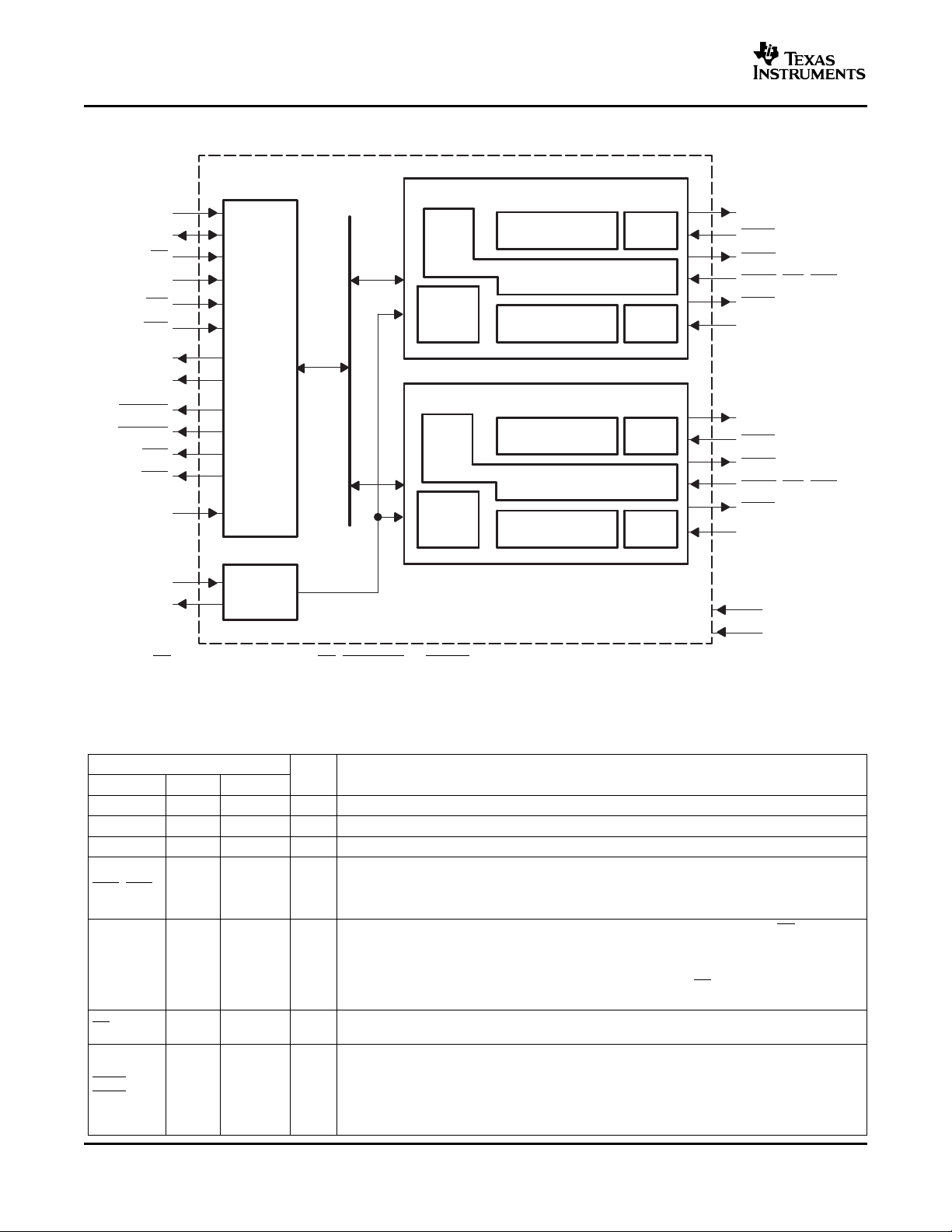

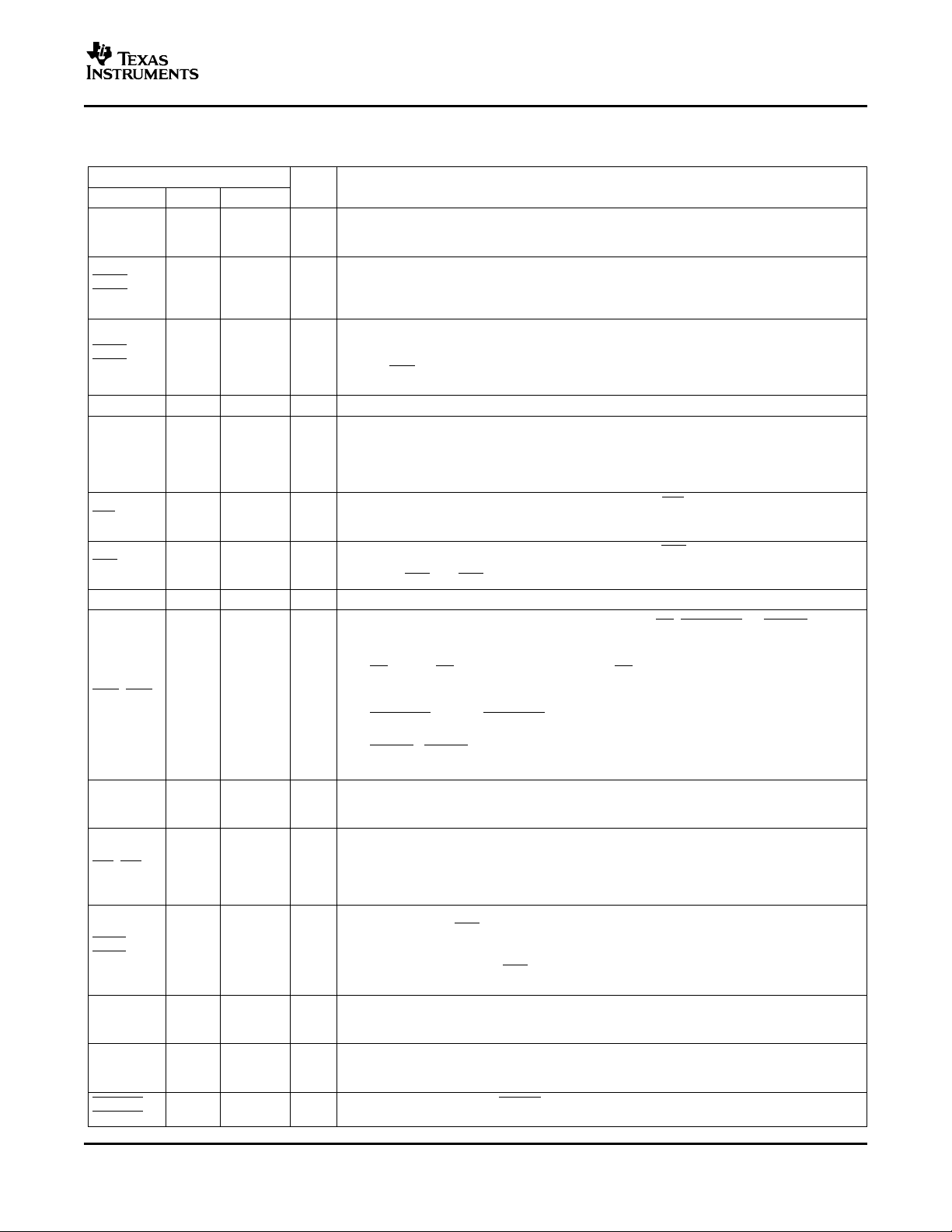

Crystal

OSC

Buffer

Data Bus

Interface

A2 − A0

D7 − D0

CS

CHSEL

IOR

IOW

INTA

INTB

TXRDYA

TXRDYB

MFA

MFB

RESET

XTAL1

XTAL2

BAUD

Rate

Gen

64 Byte Tx FIFO

64 Byte Rx FIFO

Tx

IR ENC

UART Channel A

BAUD

Rate

Gen

64 Byte Tx FIFO

64 Byte Rx FIFO

UART Channel B

CTSA

DTRA

DSRA, RIA, CDA

RTSA

CTSB

DTRB

DSRB, RIB, CDB

RTSB

V

CC

GND

TXA

RXA

TXB

RXB

UART Regs

UART Regs

Rx

IR DEC

Tx

IR ENC

Rx

IR DEC

TL16C2752

SLWS188 – JUNE 2006

TL16C2752 Block Diagram

A. MF output allows selection of OP, BAUDOUT, or RXRDY per channel.

TERMINAL

NAME FN NO. RHB NO.

A0 10 3 I Address 0 select bit. Internal registers address selection

A1 14 6 I Address 1 select bit. Internal registers address selection

A2 15 7 I Address 2 select bit. Internal registers address selection

CDA, CDB 42, 30 – I

CHSEL 16 8 I

CS 18 10 I

CTSA, data from the 2552. Status can be tested by reading MSR bit 4. These pins only affect the

CTSB transmit and receive operations when auto CTS function is enabled through the enhanced

40, 28 25, 17 I

DEVICE INFORMATION

TERMINAL FUNCTIONS

I/O DESCRIPTION

Carrier detect (active low). These inputs are associated with individual UART channels A and

B. A low on these pins indicates that a carrier has been detected by the modem for that

channel. The state of these inputs is reflected in the modem status register (MSR). These

inputs should be pulled high if unused.

Channel select. UART channel A or B is selected by the state of this pin when CS is a logic 0.

A logic 0 on the CHSEL selects the UART channel B while a logic 1 selects UART channel A.

CHSEL could just be an address line from the user CPU such as A3. Bit 0 of the alternate

function register (AFR) can temporarily override CHSEL function, allowing the user to write to

both channel register simultaneously with one write cycle when CS is low. It is especially

useful during the initialization routine.

UART chip select (active low). This pin selects channel A or B in accordance with the state of

the CHSEL pin. This allows data to be transferred between the user CPU and the 2552.

Clear to send (active low). These inputs are associated with individual UART channels A and

B. A logic low on the CTS pins indicates the modem or data set is ready to accept transmit

feature register (EFR) bit 7, for hardware flow control operation. These inputs should be

pulled high if unused.

4

Submit Documentation Feedback

www.ti.com

TL16C2752

SLWS188 – JUNE 2006

DEVICE INFORMATION (continued)

TERMINAL FUNCTIONS (continued)

TERMINAL

NAME FN NO. RHB NO.

D0-D4 2 - 6 27 - 31 Data bus (bidirectional). These pins are the eight bit, 3-state data bus for transferring

D5-D7 7 - 9 32, 1, 2

DSRA, and B. A logic low on these pins indicates the modem or data set is powered on and is ready

DSRB for data exchange with the UART. The state of these inputs is reflected in the modem status

DTRA,

DTRB

GND 12, 22 20 Signal and power ground.

INTA, INTB 34, 17 21, 9 O the interrupt enable register (IER). Interrupt conditions include: receiver errors, available

IOR 24 14 I internal register defined by address bits A0-A2 onto the TL16C2552 data bus (D0-D7) for

IOW 20 11 I data bus (D0-D7) from the external CPU to an internal register that is defined by address bits

NC – 18, 19 No internal connection

MFA, MFB 35, 19 – O

RESET 21 12 I output and the receiver input will be disabled during reset time. See TL16C2552 external

RIA, RIB 43, 31 – I telephone line. A low to high transition on these input pins generates a modem status

RTSA, Writing a 1 in the modem control register (MCR bit 1) sets these pins to low, indicating data is

RTSB available. After a reset, these pins are set to high. These pins only affects the transmit and

RXA, RXB 39, 25 24, 15 I 2552. During the local loopback mode, these RX input pins are disabled and TX data is

TXA, TXB 38, 26 23, 16 O the 2552. During the local loopback mode, the TX input pin is disabled and TX data is

TXRDYA, Transmit ready (active low). TXRDY A and B go low when there are at least a trigger level

TXRDYB numbers of spaces available. They go high when the TX buffer is full.

41, 29 – I

37, 27 – O These pins can be controlled through the modem control register. Writing a 1 to MCR bit 0

36, 23 22, 13 O

1, 32 – O

I/O DESCRIPTION

I/O information to or from the controlling CPU. D0 is the least significant bit and the first data bit in

a transmit or receive serial data stream.

Data set ready (active low). These inputs are associated with individual UART channels A

register (MSR). These inputs should be pulled high if unused.

Data terminal ready (active low). These outputs are associated with individual UART channels

A and B. A logic low on these pins indicates that theTLl16C2552 is powered on and ready.

sets the DTR output to low, enabling the modem. The output of these pins is high after writing

a 0 to MCR bit 0, or after a reset.

Interrupt A and B (active high). These pins provide individual channel interrupts, INT A and B.

INT A and B are enabled when MCR bit 3 is set to a logic 1, interrupt sources are enabled in

receiver buffer data, available transmit buffer space or when a modem status flag is detected.

INTA-B are in the high-impedance state after reset.

Read input (active low strobe). A high to low transition on IOR will load the contents of an

access by an external CPU.

Write input (active low strobe). A low to high transition on IOW will transfer the contents of the

A0-A2 and CSA and CSB

Multi-function output. This output pin can function as the OP, BAUDOUT, or RXRDY pin. One

of these output signal functions can be selected by the user programmable bits 1-2 of the

alternate function register (AFR). These signal functions are described as follows:

1. OP - When OP (active low) is selected, the MF pin is a logic 0 when MCR bit 3 is set to

a logic 1 (see MCR bit 3). MCR bit 3 defaults to a logic 1 condition after a reset or

power-up.

2. BAUDOUT - When BAUDOUT function is selected, the 16× baud rate clock output is

available at this pin.

3. RXRDY - RXRDY (active low) is intended for monitoring DMA data transfers.

If it is not used, leave it unconnected.

Reset. RESET will reset the internal registers and all the outputs. The UART transmitter

reset conditions for initialization details. RESET is an active-high input.

Ring indicator (active low). These inputs are associated with individual UART channels A and

B. A logic low on these pins indicates the modem has received a ringing signal from the

interrupt, if enabled. The state of these inputs is reflected in the modem status register (MSR).

These inputs should be pulled high if unused.

Request to send (active low). These outputs are associated with individual UART channels A

and B. A low on the RTS pin indicates the transmitter has data ready and waiting to send.

receive operation when auto RTS function is enabled through the enhanced feature register

(EFR) bit 6, for hardware flow control operation.

Receive data input. These inputs are associated with individual serial channel data to the

internally connected to the UART RX input internally.

Transmit data. These outputs are associated with individual serial transmit channel data from

internally connected to the UART RX input.

Submit Documentation Feedback

5

www.ti.com

PRODUCT PREVIEW

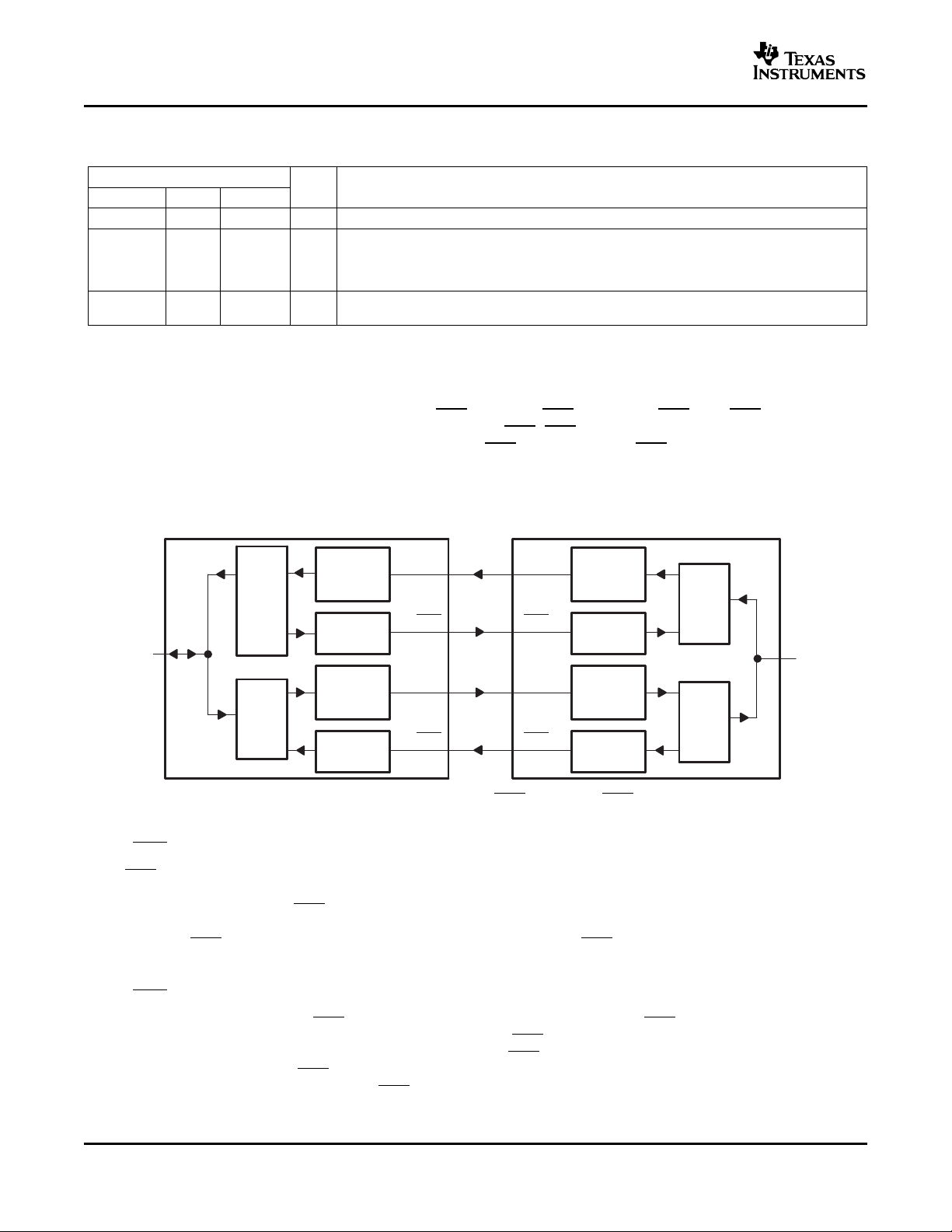

RCV

FIFO

Serial to

Parallel

Flow

Control

XMT

FIFO

Parallel

to Serial

Flow

Control

Parallel

to Serial

Flow

Control

Serial to

Parallel

Flow

Control

XMT

FIFO

RCV

FIFO

ACE1 ACE2

D7−D0

RX TX

RTS CTS

TX RX

CTS RTS

D7−D0

TL16C2752

SLWS188 – JUNE 2006

DEVICE INFORMATION (continued)

TERMINAL FUNCTIONS (continued)

TERMINAL

NAME FN NO. RHB NO.

V

CC

XTAL1 11 4 I

XTAL2 13 5 O

33, 44 26 I Power supply inputs.

Detailed Description

Hardware Autoflow Control (see Figure 1 )

Hardware Autoflow control is comprised of auto- CTS and auto- RTS. With auto- CTS, the CTS input must be

active before the transmitter FIFO can emit data. With auto- RTS, RTS becomes active when the receiver needs

more data and notifies the sending serial device. When RTS is connected to CTS, data transmission does not

occur unless the receiver FIFO has space for the data; thus, overrun errors are eliminated using ACE1 and

ACE2 from a TLC16C2752 with the autoflow control enabled. If not, overrun errors can occur when the transmit

data rate exceeds the receiver FIFO read latency.

I/O DESCRIPTION

Crystal or external clock input. XTAL1 functions as a crystal input or as an external clock

input. A crystal can be connected between XTAL1 and XTAL2 to form an internal oscillator

circuit (see Figure 4 ). Alternatively, an external clock can be connected to XTAL1 to provide

custom data rates.

Output of the crystal oscillator or buffered clock. See also XTAL1. XTAL2 is used as a crystal

oscillator output or buffered a clock output.

Figure 1. Autoflow Control (Auto- RTS and Auto- CTS) Example

Auto- RTS (See Figure 2 and Figure 3 )

Auto- RTS data flow control originates in the receiver timing and control block (see functional block diagram) and

is linked to the programmed receiver FIFO trigger level. When the receiver FIFO level reaches the defined halt

trigger level 8 (see Figure 3 ), RTS is deasserted. The sending ACE may send an additional byte after the trigger

level is reached (assuming the sending ACE has another byte to send) because it may not recognize the

deassertion of RTS until after it has begun sending the additional byte. RTS is automatically reasserted once the

defined resume trigger level is reached.

Auto- CTS (See Figure 2 )

The transmitter circuitry checks CTS before sending the next data byte. When CTS is active, it sends the next

byte. To stop the transmitter from sending the following byte, CTS must be released before the middle of the last

stop bit that is currently being sent (see Figure 2 ). The auto- CTS function reduces interrupts to the host system.

When flow control is enabled, CTS level changes do not trigger host interrupts because the device automatically

controls its own transmitter. Without auto- CTS, the transmitter sends any data present in the transmit FIFO and

a receiver overrun error may result.

6

Submit Documentation Feedback

www.ti.com

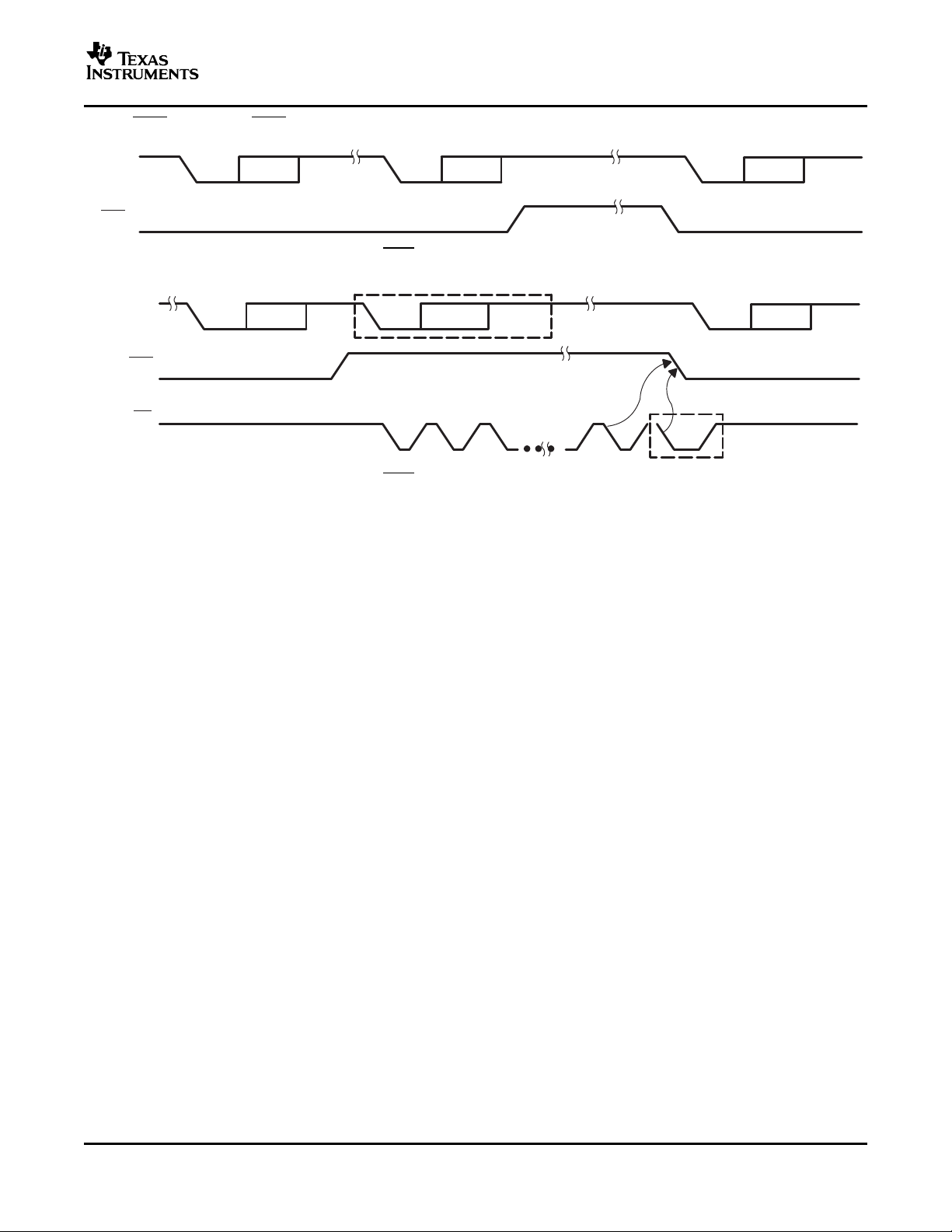

Auto- CTS and Auto- RTS Functional Timing

Start Bits 0−7 Start Bits 0−7 Start Bits 0−7

Stop Stop Stop

SOUT

CTS

Start Byte N Start Byte N+1 Start Byte

Stop Stop Stop

SIN

RTS

RD

(RD RBR)

1 2

N N+1

Figure 2. CTS Functional Timing Waveforms

Figure 3. RTS Functional Timing Waveforms

TL16C2752

SLWS188 – JUNE 2006

Submit Documentation Feedback

7

www.ti.com

PRODUCT PREVIEW

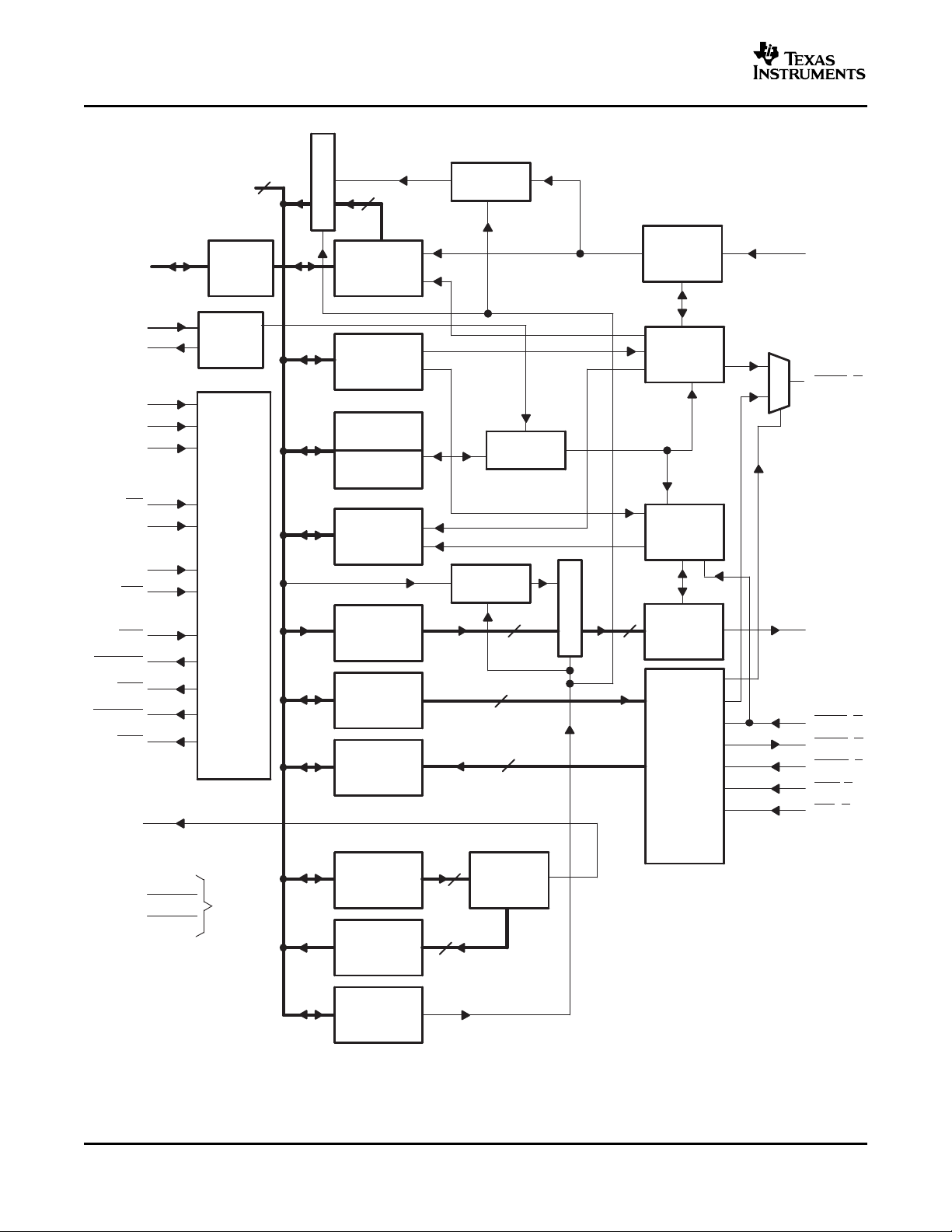

Receiver

Buffer

Register

Divisor

Latch (LS)

Divisor

Latch (MS)

Baud

Generator

Receiver

FIFO

Line

Status

Register

Transmitter

Holding

Register

Modem

Control

Register

Modem

Status

Register

Line

Control

Register

Transmitter

FIFO

Interrupt

Enable

Register

Interrupt

Identification

Register

FIFO

Control

Register

Select

and

Control

Logic

Interrupt

Control

Logic

S

e

l

e

c

t

Data

Bus

Buffer

RXA, B

TXA, B

CTSA, B

DTRA, B

DSRA, b

CDA,B

RIA, B

INTA, B

40, 28

37, 27

41, 29

42, 30

43, 31

34, 17

38, 26

39, 25

A0

10

D(7−0)

9−2

Internal

Data Bus

14

15

18

16

13

21

24

20

11

1

35

A1

A2

CS

CHSEL

XTAL2

RESET

IOR

IOW

XTAL1

TXRDYA

MFA

S

e

l

e

c

t

Receiver

Shift

Register

IrDA Decoder

Receiver

Timing and

Control

Transmitter

Timing and

Control

Modem

Control

Logic

8

33, 44

12, 22

V

CC

GND

Power

Supply

RTSA, B

36, 23

Autoflow

Control

(AFE)

8

8

8

8

8

8

8

32

19

TXRDYB

MFB

Crystal

OSC

Buffer

Transmitter

Shift

Register

IrDA Encoder

TL16C2752

SLWS188 – JUNE 2006

A. Pin numbers shown are for 44-pin PLCC FN package.

8

Figure 4. Functional Block Diagram

Submit Documentation Feedback

www.ti.com

SLWS188 – JUNE 2006

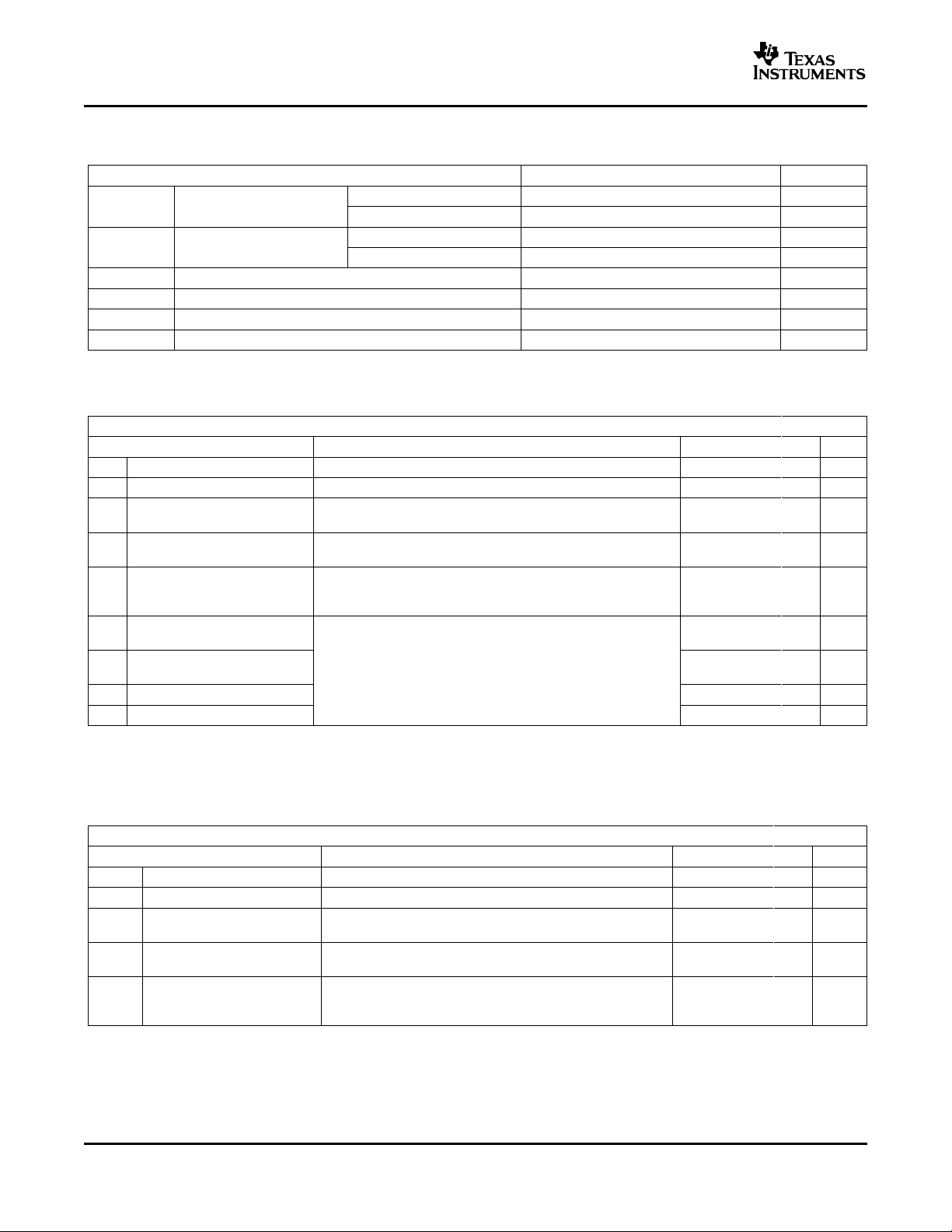

ABSOLUTE MAXIMUM RATINGS

(1)

over operating free-air temperature range (unless otherwise noted)

UNIT

Supply voltage range, V

Input voltage range at any input, V

Output voltage range, V

(2)

CC

I

O

-0.5 V to 7 V

-0.5 V to 7 V

-0.5 V to 7 V

Operating free-air temperature, TA, TL16C2552 0°C to 70°C

Operating free-air temperature, TA, TL16C2552I -40°C to 85°C

Storage temperature range, T

stg

-65°C to 150°C

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltage values are with respect to VSS.

RECOMMENDED OPERATING CONDITIONS

over operating free-air temperature range (unless otherwise noted)

1.8 V ±10% MIN NOM MAX UNIT

V

CC

V

I

V

IH

V

IL

V

O

I

OH

I

OL

Supply voltage 1.62 1.8 1.98 V

Input voltage 0 V

CC

High-level input voltage 1.4 1.98 V

Low-level input voltage -0.3 0.4 V

Output voltage 0 V

CC

High-level output current (all outputs) 0.5 mA

Low-level output current (all outputs) 1 mA

Oscillator/clock speed 10 MHz

TL16C2752

V

V

2.5 V ±10% MIN NOM MAX UNIT

V

CC

V

I

V

IH

V

IL

V

O

I

OH

I

OL

Supply voltage 2.25 2.5 2.75 V

Input voltage 0 V

CC

High-level input voltage 1.8 2.75 V

Low-level input voltage -0.3 0.6 V

Output voltage 0 V

CC

High-level output current (all outputs) 1 mA

Low-level output current (all outputs) 2 mA

Oscillator/clock speed 16 MHz

3.3 V ±10% MIN NOM MAX UNIT

V

CC

V

I

V

IH

V

IL

V

O

I

OH

I

OL

Supply voltage 3 3.3 3.6 V

Input voltage 0 V

High-level input voltage 0.7V

CC

Low-level input voltage 0.3V

Output voltage 0 V

CC

CC

CC

High-level output current (all outputs) 1.8 mA

Low-level output current (all outputs) 3.2 mA

Oscillator/clock speed 20 MHz

5 V ±10% MIN NOM MAX UNIT

V

CC

V

I

Supply voltage 4.5 5 5.5 V

Input voltage 0 V

CC

V

V

V

V

V

V

V

Submit Documentation Feedback

9

www.ti.com

PRODUCT PREVIEW

TL16C2752

SLWS188 – JUNE 2006

RECOMMENDED OPERATING CONDITIONS (continued)

over operating free-air temperature range (unless otherwise noted)

5 V ±10% MIN NOM MAX UNIT

V

IH

V

IL

V

O

I

OH

I

OL

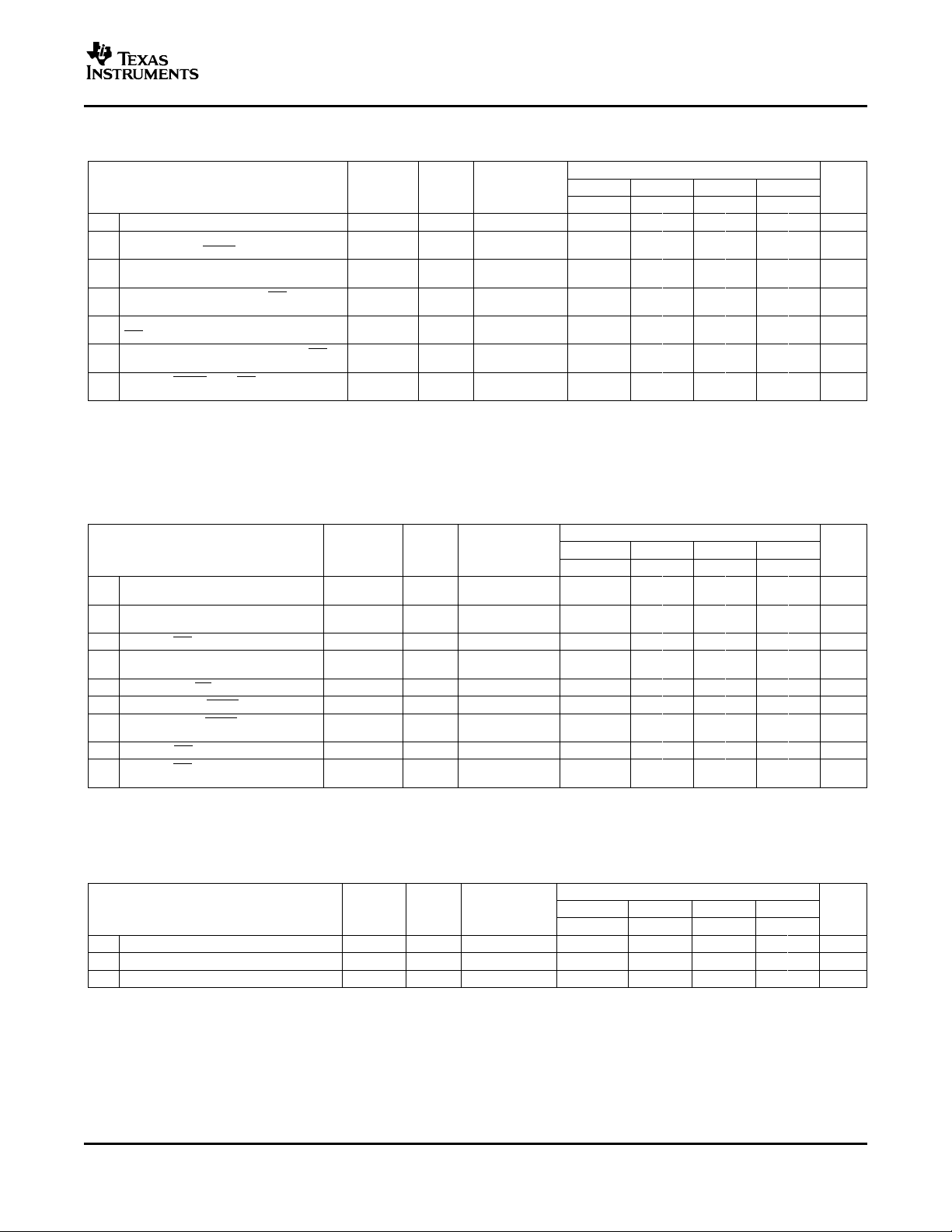

ELECTRICAL CHARACTERISTICS

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

V

High-level output voltage

OH

V

Low-level output voltage

OL

I

Input current V

I

I

High-impedance-state output V

OZ

current mode or chip deselected

I

Supply current V

CC

C

Clock input impedance 15 20 pF

i(CL

K)

C

Clock output impedance 20 30 pF

O(C

LK)

C

Input impedance 6 10 pF

I

C

Output impedance 10 20 pF

O

(1) All typical values are at V

(2) These parameters apply for all outputs except XTAL2.

High-level input voltage All except XTAL1, XTAL2 2 V

XTAL1, XTAL2 0.7V

CC

Low-level input voltage All except XTAL1, XTAL2 0.8 V

XTAL1, XTAL2 0.3V

Output voltage 0 V

High-level output current (all outputs) 4 mA

Low-level output current (all outputs) 4 mA

Oscillator/clock speed 24 MHz

1.8 V Nominal

PARAMETER TEST CONDITIONS MIN TYP

(2)

(2)

IOH= -0.5 mA 1.3 V

IOL= 1 mA 0.5 V

= 1.98 V, V

CC

floating

= 1.98 V, V

CC

= 1.98 V, TA= 0°C, RXA, RXB, DSRA, DSRB, CDA, CDB, mA

CC

CTSA, CTSB, RIA, and RIB at 1.4 V, All other inputs at 0.4 V,

= 0, VI= 0 to 1.98 V, All other terminals 10 µA

SS

= 0, VI= 0 to 1.98 V, Chip selected in write ±20 µA

SS

XTAL1 at 16 MHz, No load on outputs

V

CC

TA= 25°C, All other terminals grounded

= 1.8 V and TA= 25°C.

CC

= 0, V

= 0, f = 1 MHz,

SS

CC

CC

(1)

V

MAX UNIT

ELECTRICAL CHARACTERISTICS

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

2.5 V Nominal

PARAMETER TEST CONDITIONS MIN TYP

V

V

I

I

I

OZ

I

CC

(1) All typical values are at V

(2) These parameters apply for all outputs except XTAL2.

10

High-level output voltage

OH

Low-level output voltage

OL

Input current V

High-impedance-state output V

current write mode or chip deselected

Supply current V

CC

ADDED SPACE

(2)

IOH= -1 mA 1.8 V

(2)

IOL= 2 mA 0.5 V

= 2.75 V, V

CC

floating

= 2.75 V, V

CC

= 2.75 V, TA= 0°C, RXA, RXB, DSRA, DSRB, CDA, mA

CC

CDB, CTSA, CTSB, RIA, and RIB at 1.8 V, All other inputs at

0.6 V, XTAL1 at 24 MHz, No load on outputs

= 2.5 V and TA= 25°C.

= 0, VI= 0 to 2.75 V, All other terminals 10 µA

SS

= 0, VI= 0 to 2.75 V, Chip selected in ±20 µA

SS

Submit Documentation Feedback

(1)

MAX UNIT

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

2.5 V Nominal

PARAMETER TEST CONDITIONS MIN TYP

C

C

C

C

Clock input impedance 15 20 pF

i(CLK)

Clock output impedance 20 30 pF

O(CLK)

Input impedance 6 10 pF

I

Output impedance 10 20 pF

O

V

= 0, V

CC

TA= 25°C, All other terminals grounded

= 0, f = 1 MHz,

SS

ELECTRICAL CHARACTERISTICS

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

3.3 V Nominal

PARAMETER TEST CONDITIONS MIN TYP

V

OH

V

OL

I

I

I

OZ

I

CC

C

i(CLK)

C

O(CLK)

C

I

C

O

High-level output voltage

Low-level output voltage

Input current V

High-impedance-state output V

current write mode or chip deselected

Supply current V

Clock input impedance 15 20 pF

Clock output impedance 20 30 pF

Input impedance 6 10 pF

Output impedance 10 20 pF

(1) All typical values are at V

(2) These parameters apply for all outputs except XTAL2.

(2)

(2)

= 3.3 V and TA= 25°C.

CC

IOH= -1.8 mA 2.4 V

IOL= 3.2 mA 0.5 V

= 3.6 V, V

CC

floating

= 3.6 V, V

CC

= 3.6 V, TA= 0°C, RXA, RXB, DSRA, DSRB, CDA, mA

CC

CDB, CTSA, CTSB, RIA, and RIB at 2 V, All other inputs

= 0, VI= 0 to 3.6 V, All other terminals 10 µA

SS

= 0, VI= 0 to 3.6 V, Chip selected in ±20 µA

SS

at 0.8 V, XTAL1 at 32 MHz, No load on outputs

V

= 0, V

CC

TA= 25°C, All other terminals grounded

= 0, f = 1 MHz,

SS

TL16C2752

SLWS188 – JUNE 2006

(1)

MAX UNIT

(1)

MAX UNIT

Submit Documentation Feedback

11

www.ti.com

PRODUCT PREVIEW

TL16C2752

SLWS188 – JUNE 2006

ELECTRICAL CHARACTERISTICS

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

5 V Nominal

PARAMETER TEST CONDITIONS MIN TYP

V

V

I

I

I

OZ

I

CC

C

C

C

C

High-level output voltage

OH

Low-level output voltage

OL

Input current V

High-impedance-state output V

current write mode or chip deselected

Supply current V

Clock input impedance 15 20 pF

i(CLK)

Clock output impedance 20 30 pF

O(CLK)

Input impedance 6 10 pF

I

Output impedance 10 20 pF

O

(1) All typical values are at V

(2) These parameters apply for all outputs except XTAL2.

(2)

(2)

= 5 V and TA= 25°C.

CC

IOH= -4 mA 4 V

IOL= 4 mA 0.4 V

= 5.5 V, V

CC

terminals floating

= 5.5 V, V

CC

= 5.5 V, TA= 0°C, RXA, RXB, DSRA, DSRB, mA

CC

CDA, CDB, CTSA, CTSB, RIA, and RIB at 2 V, All

= 0, VI= 0 to 5.5 V, All other 10 µA

SS

= 0, VI= 0 to 5.5 V, Chip selected in ±20 µA

SS

other inputs at 0.8 V, XTAL1 at 48 MHz, No load on

outputs

V

= 0, V

CC

TA= 25°C, All other terminals grounded

= 0, f = 1 MHz,

SS

(1)

MAX UNIT

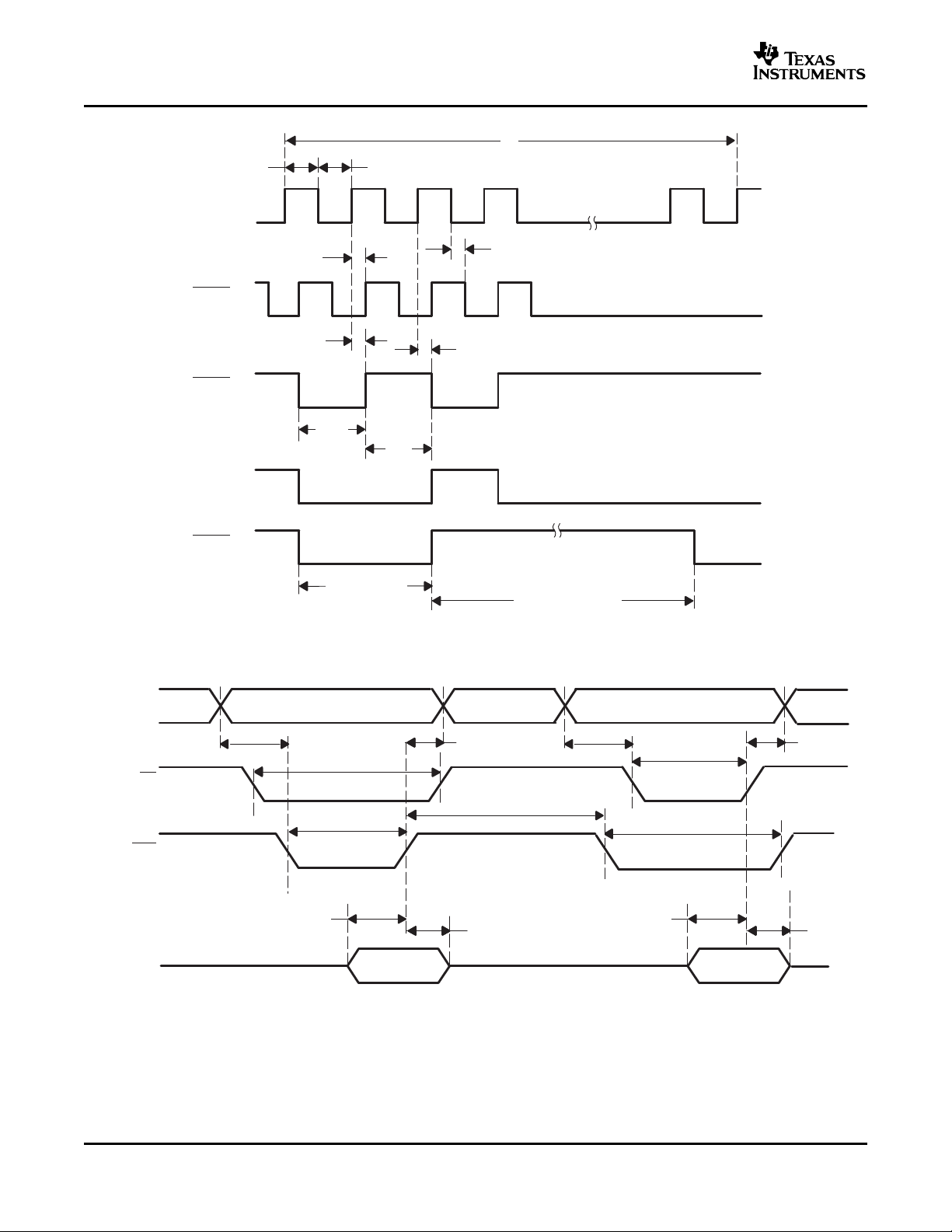

TIMING REQUIREMENTS

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER FIGURE 1.8 V 2.5 V 3.3 V 5 V UNIT

t

Pulse duration, RESET t

w8

t

Pulse duration, clock high t

w1

t

Pulse duration, clock low t

w2

t

Cycle time, read (tw7+ td8+ th7) RC 8 115 80 62 57 ns

cR

t

Cycle time, write (tw6+ td5+ th4) WC 7 115 80 62 57 ns

cW

t

Pulse duration, IOW or CS t

w6

t

Pulse duration, IOR or CS t

w7

t

Setup time, data valid before IOW↑ or CS↑ t

SU3

t

Hold time, address valid after IOW↑ or CS↑ t

h4

t

Hold time, data valid after IOW↑ or CS↑ t

h5

t

Hold time, data valid after IOR↑ or CS↑ t

h7

t

Delay time, address valid before IOW↓ or CS↓ t

d5

t

Delay time, address valid to IOR↓ or CS↓ t

d8

t

Delay time, IOR↓ or CS↓ to data valid t

d10

t

Delay time, IOR↑ or CS↑ to floating data t

d11

t

Write cycle to write cycle delay 7 100 75 60 50 ns

d12

t

Read cycle to read cycle delay 8 100 75 60 50 ns

d13

BAUD GENERATOR SWITCHING CHARACTERISTICS

over recommended ranges of supply voltage and operating free-air temperature, CL= 30 pF (for FN package only)

PARAMETER FIGURE 1.8 V 2.5 V 3.3 V 5 V UNIT

t

Pulse duration, BAUDOUT low t

w3

t

Pulse duration, BAUDOUT high t

w4

t

Delay time, XIN ↑ to BAUDOUT↑ t

d1

t

Delay time, XIN ↑ ↓ to BAUDOUT↓ t

d2

ALT. TEST

SYMBOL CONDITIONS

RESET

XH

XL

IOW

IOR

DS

WA

DH

RA

AW

AR

RVD

HZ

ALT. TEST

SYMBOL CONDITIONS

LW

HW

BLD

BHD

6 25 16 12 8 ns

7 80 55 45 40 ns

8 80 55 45 40 ns

7 25 20 15 15 ns

7 20 15 10 10 ns

7 15 10 5 5 ns

8 20 15 10 10 ns

7 15 10 7 7 ns

8 15 10 7 7 ns

8 CL= 30 pF 55 35 25 20 ns

8 CL= 30 pF 40 30 20 20 ns

6 CLK ÷ 2 50 35 27 16 ns

6 CLK ÷ 2 50 35 27 16 ns

6 35 25 20 15 ns

6 35 25 20 15 ns

LIMITS

MIN MAX MIN MAX MIN MAX MIN MAX

1 1 1 1 µs

LIMITS

MIN MAX MIN MAX MIN MAX MIN MAX

12

Submit Documentation Feedback

www.ti.com

RECEIVER SWITCHING CHARACTERISTICS

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER FIGURE 1.8 V 2.5 V 3.3 V 5 V UNIT

t

Delay time, RCLK to sample t

d12

t

Delay time, stop to set INT or read RBR to LSI t

d13

interrupt or stop to RXRDY↓ 11, 12 cycle

t

Delay time, read RBR/LSR to reset INT t

d14

t

Delay time, RCV threshold byte to RTS↑ 19 CL= 30 pF 2 baudout

d26

t

Delay time, read of last byte in receive FIFO to 19 CL= 30 pF 2 baudout

d27

RTS↓ cycles

t

Delay time, first data bit of 16th character to RTS↑ 20 CL= 30 pF 2 baudout

d28

t

Delay time, RBRRD low to RTS↓ 20 CL= 30 pF 2 baudout

d29

ALT. TEST

SYMBOL CONDITIONS

SCD

SINT

RINT

9 20 15 10 10 ns

8, 9, 10, 1 1 1 1 RCLK

8, 9, 10, CL= 30 pF 100 90 80 70 ns

11, 12

MIN MAX MIN MAX MIN MAX MIN MAX

(1) In the FIFO mode, the read cycle (RC) = 1 baudclock (min) between reads of the receive FIFO and the status registers (interrupt

identification register or line status register).

(2) A baudout cycle is equal to the period of the input clock divided by the programmed divider in DLL, DLM.

LIMITS

TRANSMITTER SWITCHING CHARACTERISTICS

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER ALT. SYMBOL FIGURE 1.8 V 2.5 V 3.3 V 5 V UNIT

t

Delay time, initial write to transmit start t

d15

t

Delay time, start to INT t

d16

t

Delay time, IOW (WR THR) to reset INT t

d17

t

Delay time, initial write to INT (THRE

d18

t

Delay time, read IOR↑ to reset INT (THRE

d19

t

Delay time, write to TXRDY inactive t

d20

t

Delay time, start to TXRDY active t

d21

t

Setup time, CTS↑ before midpoint of stop bit 18 30 20 10 10 ns

SU4

t

Delay time, CTS low to TX ↓ 18 CL= 30 pF 24 24 24 24 baudout

d25

(1)

) t

(1)

) t

IRS

STI

HR

SI

IR

WXI

SXA

14 8 24 8 24 8 24 8 24 baudout

14 8 10 8 10 8 10 8 10 baudout

14 CL= 30 pF 70 60 50 50 ns

14 16 34 16 34 16 34 16 34 baudout

14 CL= 30 pF 70 50 35 35 ns

15, 16 CL= 30 pF 60 45 35 35 ns

15, 16 CL= 30 pF 9 9 9 9 baudout

TEST

CONDITIONS

MIN MAX MIN MAX MIN MAX MIN MAX

(1) THRE = Transmitter Holding Register Empty; IIR = Interrupt Identification Register.

LIMITS

TL16C2752

SLWS188 – JUNE 2006

(1)

(2)

cycles

cycles

cycles

cycles

cycles

cycles

cycles

cycles

MODEM CONTROL SWITCHING CHARACTERISTICS

over operating free-air temperature range (unless otherwise noted)

PARAMETER FIGURE 1.8 V 2.5 V 3.3 V 5 V UNIT

t

Delay time, WR MCR to output t

d22

t

Delay time, modem interrupt to set INT t

d23

t

Delay time, RD MSR to reset INT t

d24

ALT. TEST

SYMBOL CONDITIONS

MDO

SIM

RIM

Submit Documentation Feedback

LIMITS

MIN MAX MIN MAX MIN MAX MIN MAX

17 CL= 30 pF 90 70 60 50 ns

17 CL= 30 pF 60 50 40 35 ns

17 CL= 30 pF 80 60 50 40 ns

13

www.ti.com

PRODUCT PREVIEW

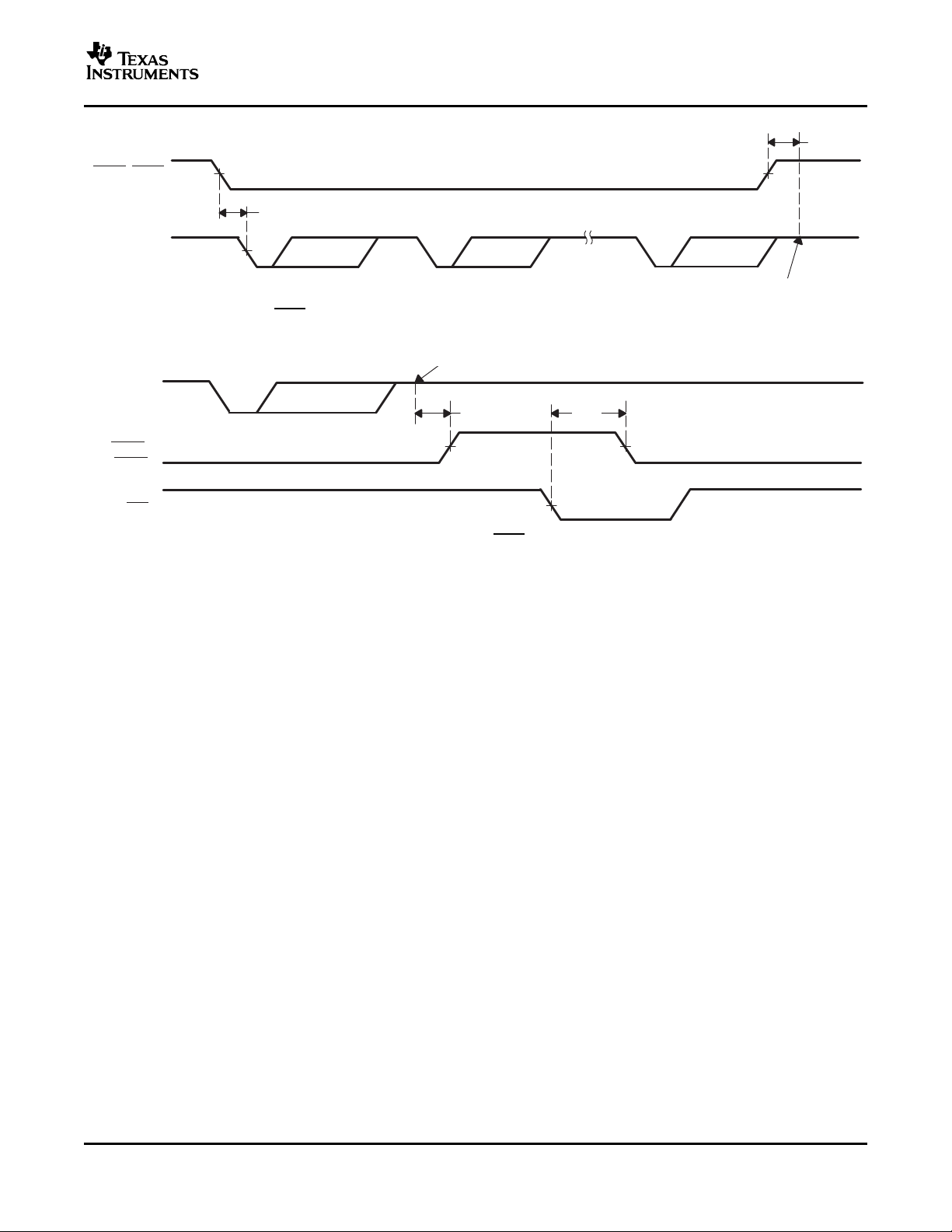

MFA,B

(1/1)

XTAL

MFA,B

(1/2)

MFA,B

(1/3)

MFA,B

(1/N)

(N > 3)

t

d2

t

d1

t

d2

t

w1

t

w2

t

d1

2 XIN Cycles

t

w3

t

w4

N

(N−2) XIN Cycles

t

su3

t

h5

Valid Data

Valid Address

CHSEL,

A2−A0

D7−D0

IOW

CS

t

d5

t

w6

t

d12

t

h4

t

su3

t

h5

Valid Data

t

d5

t

h4

t

w6

t

w6

Valid Address

t

w6

TL16C2752

SLWS188 – JUNE 2006

Figure 5. Input Clock and Baud Generator Timing Waveforms

(For FN Package Only) (When AFR2:1 = 01)

Figure 6. Write Cycle Timing Waveforms

14

Submit Documentation Feedback

www.ti.com

t

d10

t

d11

Valid Data

Valid Address

CHSEL,

A2−A0

D7−D0

IOR

CS

t

d8

t

w7

t

d13

t

h7

t

h11

Valid Data

t

d8

t

h7

t

w7

t

w7

Valid Address

t

w7

t

d10

t

d13

Active

Active

IOR

(read RBR)

RCLK

(Internal)

t

d14

t

d14

t

d12

Parity StopStart Data Bits 5−8

Sample Clock

(Internal)

TL16C450 Mode:

Sample Clock

RXA, RXB

INT

(data ready)

INT

(RCV error)

IOR

(read LSR)

50%50%

50%

50%

50%

50%

8 CLKs

Figure 7. Read Cycle Timing Waveforms

TL16C2752

SLWS188 – JUNE 2006

Figure 8. Receiver Timing Waveforms

Submit Documentation Feedback

15

www.ti.com

PRODUCT PREVIEW

t

d13

(see Note A)

t

d14

Stop

Data Bits 5−8

Sample Clock

(Internal)

RXA, RXB

Trigger Level

INT

(FCR6, 7 = 0, 0)

INT

Line Status

Interrupt (LSI)

t

d14

IOR

(RD LSR)

IOR

(RD RBR)

Active

Active

(FIFO at or above

trigger level)

(FIFO below

trigger level)

50%50%

50%

50%

50%

50%

t

d13

(see Note A)

t

d14

Stop

Top Byte of FIFO

Sample Clock

(Internal)

RXA, RXB

Time-Out or

Trigger Level

Interrupt

Line Status

Interrupt (LSI)

t

d13

(FIFO at or above

trigger level)

(FIFO below

trigger level)

IOP

(RD LSR)

IOR

(RD RBR)

Active Active

t

d14

Previous Byte

Read From FIFO

50%

50%

50%50%

50%

50% 50%

TL16C2752

SLWS188 – JUNE 2006

Figure 9. Receive FIFO First Byte (Sets DR Bit) Waveforms

Figure 10. Receive FIFO Bytes Other Than the First Byte (DR Internal Bit Already Set) Waveforms

16

Submit Documentation Feedback

www.ti.com

t

d13

(see Note B)

t

d14

Stop

Sample Clock

(Internal)

RXA, RXB

(first byte)

Active

IOR

(RD RBR)

RXRDYA, RXRDYB

See Note A

50%

50%

50%

t

d13

(see Note B)

t

d14

Sample Clock

(Internal)

RXA, RXB

(first byte that reaches

the trigger level)

Active

IOR

(RD RBR)

RXRDYA, RXRDYB

See Note A

50%

50%50%

t

d16

Parity Stop

Start

Data Bits

TXA, TXB

Start

t

d15

t

d17

t

d17

t

d18

t

d19

INT

(THRE)

IOW

(WR THR)

IOR

50% 50% 50% 50% 50%

50%

50%

50%

50%

50%

50%

TL16C2752

SLWS188 – JUNE 2006

Figure 11. Receiver Ready ( RXRDY) Waveforms, FCR0 = 0 or FCR0 = 1 and FCR3 = 0 (Mode 0)

Figure 12. Receiver Ready ( RXRDY) Waveforms, FCR0 = 1 and FCR3 = 1 (Mode 1)

Figure 13. Transmitter Timing Waveforms

Submit Documentation Feedback

17

www.ti.com

PRODUCT PREVIEW

t

d20

IOW

(WR THR)

t

d21

Parity

Stop

Data

Start

Byte 1

TXA, TXB

TXRDYA, TXRDYB

50%

50%

50%

50%

IOW

(WR THR)

Parity

Stop

Data

Start

Byte 16

TXA, TXB

TXRDYA

, TXRDYB

FIFO Full

t

d20

t

d21

50%

50%

50%

50%

IOW

(WR MCR)

RTSA, RTSB, DTRA,

DTRB, OPA, OPB

CTSA, CTSB, DSRA,

DSRB, CDA, CDB

t

d23

t

d24

t

d23

INT

(modem)

IOR

(RD MSR)

RI

50% 50%

50% 50%

50%

50%

50%

50%

50%

50%

t

d22

t

d22

TL16C2752

SLWS188 – JUNE 2006

Figure 14. Transmitter Ready ( TXRDY) Waveforms, FCR0 = 0 or FCR0 = 1 and FCR3 = 0 (Mode 0)

Figure 15. Transmitter Ready ( TXRDY) Waveforms, FCR0 = 1 and FCR3 = 1 (Mode 1)

18

Figure 16. Modem Control Timing Waveforms

Submit Documentation Feedback

www.ti.com

Midpoint of Stop Bit

t

d25

t

su4

CTSA, CTSB

TXA, TXB

50% 50%

50%

t

d27

RXA, RXB

50%

t

d26

50%

50%

Midpoint of Stop Bit

RTSA

,

RTSB

IOR

Figure 17. CTS and TX Autoflow Control Timing (Start and Stop) Waveforms

TL16C2752

SLWS188 – JUNE 2006

Figure 18. Auto- RTS Timing

Submit Documentation Feedback

19

www.ti.com

PRODUCT PREVIEW

Buffer

(Optional)

Address

Decoder

A0−A23

AD0−AD15

RSI/ABT

PHI1 PHI2

PHI1 PHI2

CPU

RSTO

A0−A2

CHSEL

CS

RESET

D0−D7

D0−D7

IOR

IOW

XTAL1

XTAL2

DTRA, B

RTSA, B

RIA, B

CDA, B

DSRA, B

CTSA, B

RXA, B

TXA, B

INTA, B

GND

(VSS)

V

CC

12, 22

33, 44

Alternate

Crystal Control

TL16C2752

EIA-232-D

Connector

20

1

8

6

5

2

3

7

1

11

13

37, 27

36, 23

43, 31

42, 30

41, 29

40, 28

39, 25

34, 17

38, 26

20

24

21

16

18

TCU

WR

RD

(Optional)

10, 14, 15

2−9

33 pF

33 pF

TL16C2752

SLWS188 – JUNE 2006

APPLICATION INFORMATION

A. Pin numbers shown are for 44-pin PLCC FN package.

UART Internal Registers

Each of the UART channel in the 2752 has its own set of configuration registers selected by address lines A0,

A1, and A2 with CS# and CHSEL selecting the channel. The complete register set is shown in Table 1 and

Table 2 .

20

Figure 19. Typical TL16C2752 Connection

PRINCIPLES OF OPERATION

Submit Documentation Feedback

www.ti.com

Table 1. UART Channel A and B UART Internal Registers

ADDRESS RESET (HEX) COMMENTS REGISTER READ/WRITE

A2 - A0

0 0 0 XX RHR = Receive Holding Register Read-only

0 0 0 XX DLL - Div Latch Low Byte Read/Write

0 0 1 XX LCR[7] = 1, LCR ≠ 0xBF DLM - Div Latch High Byte Read/Write

0 1 0 00 AFR - Alternate Function REgister Read/Write

0 0 0 00 DREV - Device Revision Code Read-only

0 0 1 0A DVID - Device Identification Code Read-only

0 0 1 00 LCR[7] = 0 IER - Interrupt Enable Register Read/Write

0 1 0 01 ISR - Interrupt Status Register Read-only

0 1 1 00 LCR = Line Control Register Read/Write

1 0 0 00 MCR - Modem Control Register Read/Write

1 0 1 60 LSR - Line Status Register Read-only

1 1 0 X0 MSR - Modem Status Register Read-only

1 1 1 FF LCR ≠ 0xBF, FCTR[6] = 0 SPR - Scratch Pad Register Read/Write

1 1 1 00 LCR ≠ 0xBF, FCTR[6] = 1 FLVL - RX/TX FIFO Level Counter Register Read-only

1 1 1 80 EMSR - Enhanced Mode Select Register Write-only

0 0 0 00 TRG - RX/TX FIFO Trigger Level Register Write-only

0 0 1 00 FCTR - Feature Control Register Read/Write

0 1 0 00 EFR - Enhanced Function Register Read/Write

1 0 0 00 Xon-1 - Xon Character 1 Read/Write

1 0 1 00 Xon-2 - Xon Character 2 Read/Write

1 1 0 00 Xoff-1 - Xoff Character 1 Read/Write

1 1 1 00 Xoff-2 - Xoff Character 2 Read/Write

VALUE

16C550 Compatible Registers

XX THR - Transmit Holding Register Write-only

00 FCR - FIFO Control Register Write-only

00 FC - RX/TX FIFO Level Counter Register Read-only

LCR[7] = 0

DLL, DLM = 0x00,

LCR[7] = 1, LCR ≠ 0xBF

LCR[7] = 0

LCR ≠ 0xBF Reserved Write-only

Reserved Write-only

Enhanced Registers

LCR = 0xBF

TL16C2752

SLWS188 – JUNE 2006

Table 2. Internal Registers Description

Address Reg Read/

A2 - A0 NAME Write

0 0 0 RHR RD LCR[7] = 0 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 0 THR WR Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 1 IER RD/WR 0/ 0/ 0/ 0/ Modem Stat. RX Line Stat. TX Empty Int. RX Data Int.

0 1 0 ISR RD FIFOs FIFOs 0/ 0/ INT Source INT Source INT Source INT Source

0 1 0 FCR WR RXFIFO RXFIFO 0/ 0/ DMA Mode TX FIFO RX FIFO FIFOs Enable

0 1 1 LCR RD/WR Divisor Set TX Break Set Parity Even Parity Parity Enable Stop Bits Word Length Word Length

1 0 0 MCR RD/WR 0/ 0/ 0/ Internal OP2# Output Rsrvd (OP1#) RTS# Output DTR# Output

1 0 1 LSR RD RX FIFO THR & TSR THR Empty RX Break RX Framing RX Parity RX Overrun RX Data

1 1 0 MSR RD CD# Input RI# Input DSR# Input CTS# Input Delta CD# Delta RI# Delta DSR# Delta CTS#

1 1 1 SPR RD/WR LCR ≠ 0xBF Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1 1 1 EMSR WR 16X Sampling LSR Error Auto RTS Auto RTS Auto RS485 Rsrvd Rx/Tx FIFO Rx/Tx FIFo

1 1 1 FLVL RD Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Comments Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

16C550 Compatible Registers

CTS Int. RTS Int. Xoff Int. Sleep Mode

Enable Enable Enable Enable

LCR ≠ 0xBF

FCTR Bit 6 = 0

LDR ≠ 0xBF

FCTR Bit 6 = 1

Enabled Enabled Bit 3 Bit 2 Bit 1 Bit 0

Trigger Trigger Enable Reset Reset

Enable Bit 1 Bit 0

BRG IR Mode XonAny

Prescaler Enable

Global Error Empty Error Error Error Ready

Rate Mode Interrupt Hyst. Bit 3 Hyst Bit 2 Output Count Count

Imd/Dly# Inversion

INT Source INT Source

Bit 5 Bit 4

TXFIFO TXFIFO

Trigger Trigger

Loopback Control Control Control

Enable

(1)

Int. Enable Int. Enable Enable Enable

(1) Shaded bits are accessible when EFR Bit 4 = 1.

Submit Documentation Feedback

21

www.ti.com

PRODUCT PREVIEW

TL16C2752

SLWS188 – JUNE 2006

Table 2. Internal Registers Description (continued)

Address Reg Read/

A2 - A0 NAME Write

0 0 0 DLL RD/WR Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 1 DLM RD/WR LCR[7] = 1 LCR Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 1 0 AFR RD/WR Rsvd Rsvd Rsvd Rsvd Rsvd RXRDY# Baudout# Concurrent

0 0 0 DREV RD LCR[7] = 1 LCR Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 1 DVID RD 0 0 0 0 1 0 1 0

0 0 0 TRG WR LCR = 0xBF Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 0 FC RD Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 1 FCTR RD/WR RX/TX Mode SCPAD Swap Trig Table Bit Trig Table Bit Auto RS485 RX IR Input Auto RTS Auto RTS

0 1 0 EFR RD/WR Auto CTS Auto RTS Special Char Enable Software Flow Software Flow Software Flow Software Flow

1 0 0 XON1 RD/WR Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1 0 1 XON2 RD/WR Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1 1 0 XOFF1 RD/WR Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

1 1 1 XOFF2 RD/WR Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Comments Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Baud Rate Generator Divisor

≠ 0xBF

Select Select Write

≠ 0xBF DLL =

0x00 DLM =

0x00

Enhanced Registers

1 0 Direction Inv. Hyst Bit 1 Hyst Bit 0

Enable Enable Select IER[7:4], Cntl Bit 3 Cntl Bit 2 Cntl Bit 1 Cntl Bit 0

ISR[5:4],

FCT[5:4],

MCR[7:5]

Control

22

Submit Documentation Feedback

MECHANICAL DATA

MPLC004A – OCT OBER 1994

FN (S-PQCC-J**) PLASTIC J-LEADED CHIP CARRIER

20 PIN SHOWN

Seating Plane

0.004 (0,10)

D

D1

13

4

E1E

8

9

NO. OF

PINS

**

D/E

19

13

18

14

0.032 (0,81)

0.026 (0,66)

0.050 (1,27)

0.008 (0,20) NOM

D1/E1

MINMAXMIN

MAX

D2/E2

MIN

0.180 (4,57) MAX

0.120 (3,05)

0.090 (2,29)

0.020 (0,51) MIN

D2/E2

D2/E2

0.021 (0,53)

0.013 (0,33)

0.007 (0,18)

MAX

M

20

28

44

52

68

84

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS-018

0.385 (9,78)

0.485 (12,32)

0.685 (17,40)

0.785 (19,94)

0.985 (25,02)

1.185 (30,10)

0.395 (10,03)

0.495 (12,57)

0.695 (17,65)

0.795 (20,19)

0.995 (25,27)

1.195 (30,35)

0.350 (8,89)

0.450 (11,43)

0.650 (16,51)

0.750 (19,05)

0.950 (24,13)

1.150 (29,21)

0.356 (9,04)

0.456 (11,58)

0.656 (16,66)

0.756 (19,20)

0.958 (24,33)

1.158 (29,41)

0.141 (3,58)

0.191 (4,85)

0.291 (7,39)

0.341 (8,66)

0.441 (11,20)

0.541 (13,74)

0.169 (4,29)

0.219 (5,56)

0.319 (8,10)

0.369 (9,37)

0.469 (11,91)

0.569 (14,45)

4040005/B 03/95

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Low Power Wireless www.ti.com/lpw Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2006, Texas Instruments Incorporated

Loading...

Loading...