Page 1

Tiva™ C Series TM4C1294 Connected

LaunchPad Evaluation Kit

EK-TM4C1294XL

User's Guide

Literature Number: SPMU365A

March 2014–Revised March 2014

Page 2

Contents

1 Board Overview ................................................................................................................... 4

1.1 Kit Contents................................................................................................................... 5

1.2 Using the Connected LaunchPad ......................................................................................... 5

1.3 Features....................................................................................................................... 5

1.4 BoosterPacks................................................................................................................. 6

1.5 Energīa........................................................................................................................ 6

1.6 Specifications................................................................................................................. 6

2 Hardware Description ........................................................................................................... 7

2.1 Functional Description ...................................................................................................... 7

2.1.1 Microcontroller....................................................................................................... 7

2.1.2 Ethernet Connectivity............................................................................................... 8

2.1.3 USB Connectivity ................................................................................................... 8

2.1.4 Motion Control....................................................................................................... 8

2.1.5 User Switches and LED's.......................................................................................... 8

2.1.6 BoosterPacks and Headers ....................................................................................... 9

2.2 Power Management........................................................................................................ 17

2.2.1 Power Supplies.................................................................................................... 17

2.2.2 Low Power Modes ................................................................................................ 18

2.2.3 Clocking ............................................................................................................ 18

2.2.4 Reset................................................................................................................ 18

2.3 Debug Interface............................................................................................................. 18

2.3.1 In-Circuit Debug Interface (ICDI)................................................................................ 18

2.3.2 External Debugger ................................................................................................ 19

2.3.3 Virtual COM Port .................................................................................................. 19

3 Software Development ........................................................................................................ 20

3.1 Software Description....................................................................................................... 20

3.2 Source Code................................................................................................................ 20

3.3 Tool Options ................................................................................................................ 20

3.4 Programming the Connected LaunchPad............................................................................... 21

4 References, PCB Layout, and Bill of Materials ....................................................................... 22

4.1 References.................................................................................................................. 22

4.2 Component Locations ..................................................................................................... 23

4.3 Bill of Materials ............................................................................................................. 24

5 Schematic ......................................................................................................................... 26

6 Revision History................................................................................................................. 27

2

Contents SPMU365A–March 2014–Revised March 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

1-1. Tiva C Series Connected LaunchPad Evaluation Board ............................................................... 4

2-1. Tiva Connected LaunchPad Evaluation Board Block Diagram........................................................ 7

2-2. Default Jumper Locations ................................................................................................. 17

4-1. Connected LaunchPad Dimensions and Component Locations ..................................................... 23

1-1. EK-TM4C1294XL Specifications........................................................................................... 6

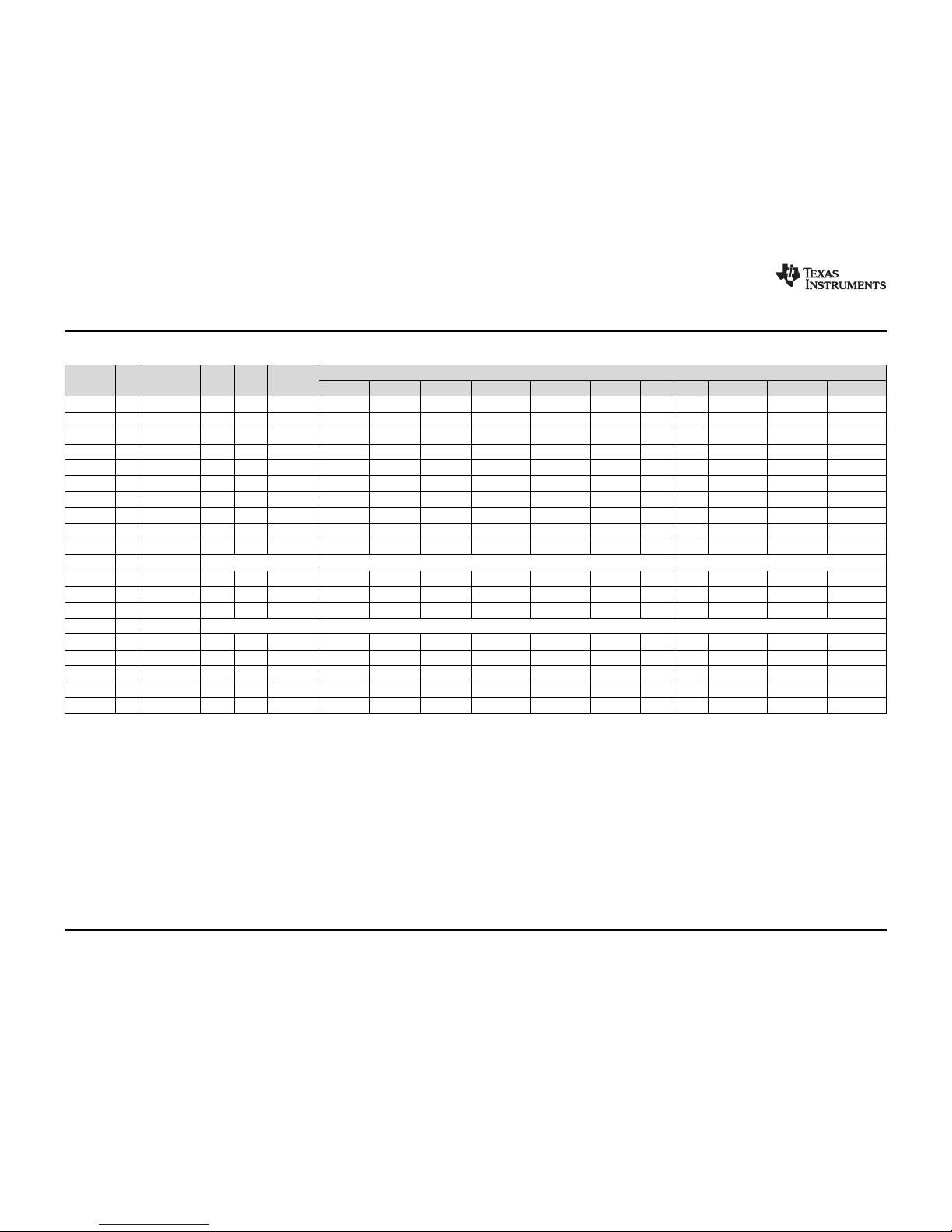

2-1. BoosterPack 1 GPIO and Signal Muxing ................................................................................. 9

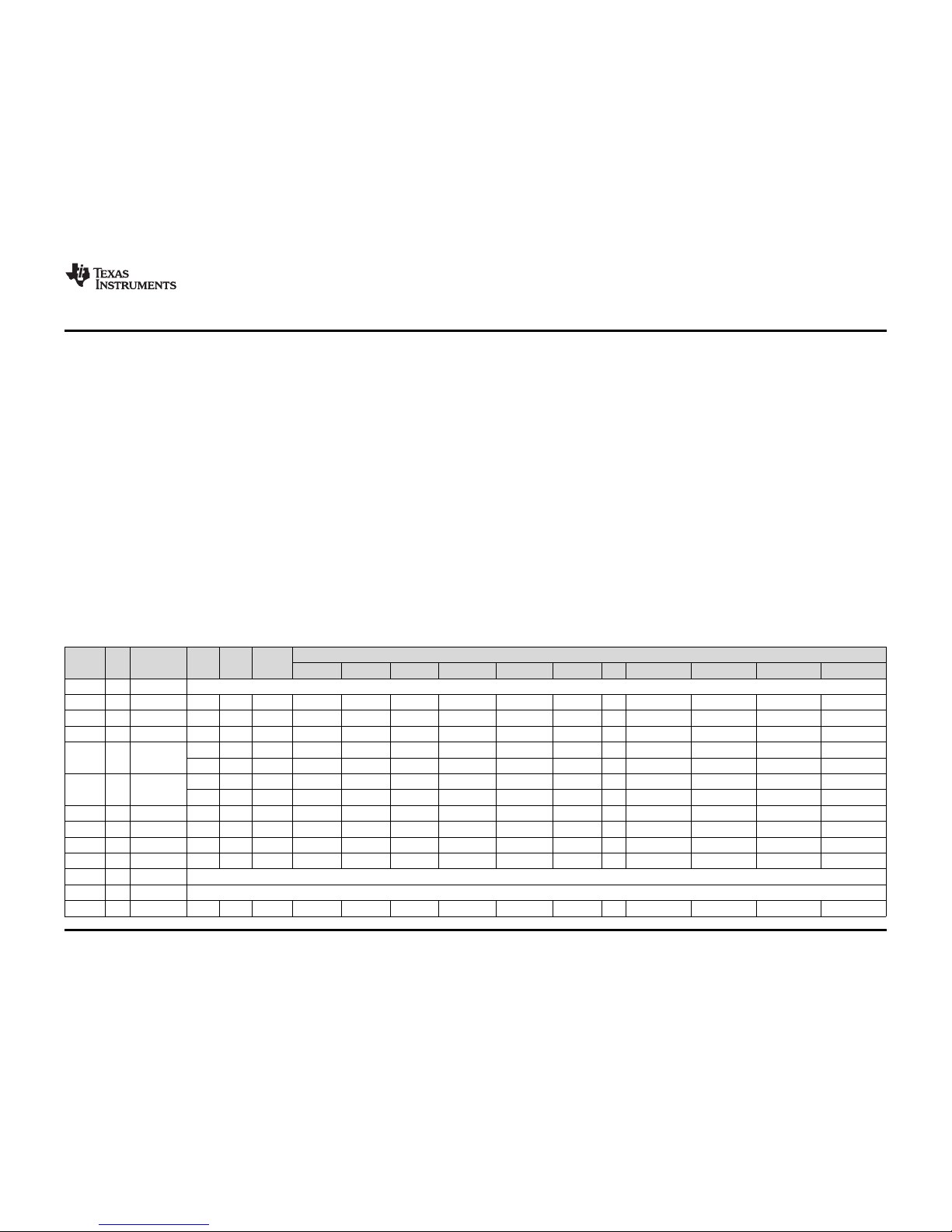

2-2. BoosterPack 2 GPIO and Signal Muxing ............................................................................... 11

2-3. X11 Breadboard Adapter Odd-Numbered Pad GPIO and Signal Muxing .......................................... 13

2-4. X11 Breadboard Adapter Even-Numbered Pad GPIO and Signal Muxing ......................................... 15

4-1. Connected LaunchPad Bill of Materials ................................................................................. 24

6-1. Revision History ............................................................................................................ 27

List of Figures

List of Tables

SPMU365A–March 2014–Revised March 2014 List of Figures

Submit Documentation Feedback

3

Copyright © 2014, Texas Instruments Incorporated

Page 4

Chapter 1

SPMU365A–March 2014–Revised March 2014

Board Overview

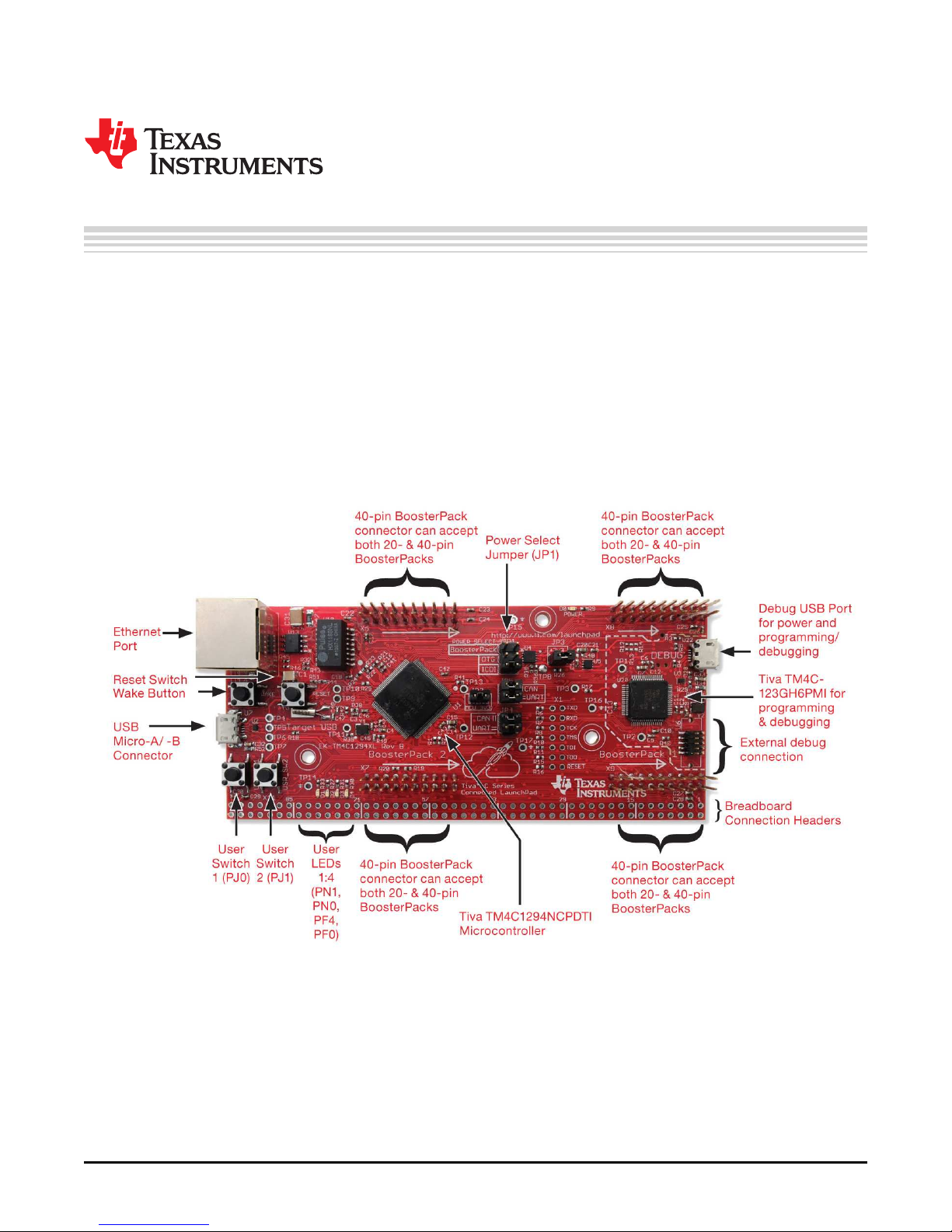

The Tiva™ C Series TM4C1294 Connected LaunchPad Evaluation Board (EK-TM4C1294XL) is a low-cost

evaluation platform for ARM® Cortex™-M4F-based microcontrollers. The Connected LaunchPad design

highlights the TM4C1294NCPDT microcontroller with its on-chip 10/100 Ethernet MAC and PHY, USB 2.0,

hibernation module, motion control pulse-width modulation and a multitude of simultaneous serial

connectivity. The Connected LaunchPad also features two user switches, four user LEDs, dedicated reset

and wake switches, a breadboard expansion option and two independent BoosterPack XL expansion

connectors. The pre-programmed quickstart application on the Connected LaunchPad also enables

remote monitoring and control of the evaluation board from an internet browser anywhere in the world.

The web interface is provided by 3rd party, Exosite. Each Connected LaunchPad is enabled on the

Exosite platform allowing users to create and customize their own Internet-of-Things applications.

Figure 1-1 shows a photo of the Connected LaunchPad with key features highlighted.

Figure 1-1. Tiva C Series Connected LaunchPad Evaluation Board

Tiva is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

4

Board Overview SPMU365A–March 2014–Revised March 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

1.1 Kit Contents

The Connected LaunchPad Evaluation Kit contains the following items:

• Tiva™ C Series TM4C1294 Evaluation Board (EK-TM4C1294XL)

• Retractable Ethernet cable

• USB Micro-B plug to USB-A plug cable

• README First document

1.2 Using the Connected LaunchPad

The recommended steps for using the Connected LaunchPad Evaluation Kit are:

1. Follow the README First document included in the kit. The README First helps you get the

Connected LaunchPad up and running in minutes. Within just a few minutes you can be controlling and

monitoring the Connected LaunchPad through the internet using Exosite and the pre-programmed

quickstart application.

2. Experiment with BoosterPacks. This evaluation kit conforms to the latest revision of the BoosterPack

pinout standard. It has two independent BoosterPack connections to enable a multitude of expansion

opportunities.

3. Take the first step towards developing your own applications. The Connected LaunchPad is

supported by TivaWare for C Series. After installing TivaWare, look in the installation directory for

examples\boards\ek-tm4c1294xl. You can find pre-configured example applications for this board as

well as for this board with selected BoosterPacks. Alternately, use Energīa for a wiring frameworkbased cross-platform, fast-prototyping environment that works with this and other TI LaunchPads. See

Chapter 3 of this document for more details about software development. TivaWare can be

downloaded from the TI website at http://www.ti.com/tool/sw-tm4c. Energīa can be found at

http://energia.nu.

4. Customize and integrate the hardware to suit your end application. This evaluation kit can be

used as a reference for building your own custom circuits based on Tiva C microcontrollers or as a

foundation for expansion with your custom BoosterPack or other circuit. This manual can serve as a

starting point for this endeavor.

5. Get Trained. You can also download hours of written and video training materials on this and related

LaunchPads. Visit the Tiva C Series LaunchPad Workshop Wiki for more information.

6. More Resources. See the TI MCU LaunchPad web page for more information and available

BoosterPacks. (http://www.ti.com/tiva-c-launchpad)

Kit Contents

1.3 Features

Your Connected LaunchPad includes the following features:

• Tiva TM4C1294NCPDTI microcontroller

• Ethernet connectivity with fully integrated 10/100 Ethernet MAC and PHY Motion Control PWM

• USB 2.0 Micro A/B connector

• 4 user LEDs

• 2 user buttons

• 1 independent hibernate wake switch

• 1 independent microcontroller reset switch

• Jumper for selecting power source:

– ICDI USB

– USB Device

– BoosterPack

• Preloaded Internet-of-Things Exosite quickstart application

• I/O brought to board edge for breadboard expansion

• Two independent BoosterPack XL standard connectors featuring stackable headers to maximize

expansion through BoosterPack ecosystem

SPMU365A–March 2014–Revised March 2014 Board Overview

Submit Documentation Feedback

5

Copyright © 2014, Texas Instruments Incorporated

Page 6

BoosterPacks

– For a complete list of BoosterPacks, see the TI MCU LaunchPad web page:

http://www.ti.com/launchpad

1.4 BoosterPacks

The Connected LaunchPad provides an easy and inexpensive way to develop applications with the

TM4C1294NCPDTI microcontroller. BoosterPacks are add-on boards that follow a pin-out standard

created by Texas Instruments. The TI and third-party ecosystem of BoosterPacks greatly expands the

peripherals and potential applications that you can easily explore with the Connected LaunchPad.

You can also build your own BoosterPack by following the design guidelines on TI’s website. Texas

Instruments even helps you promote your BoosterPack to other members of the community. TI offers a

variety of avenues for you to reach potential customers with your solutions.

1.5 Energīa

Energīa is an open-source electronics prototyping platform started in January of 2012 with the goal of

bringing the Wiring and Arduino framework to the TI LaunchPad community. Energīa includes an

integrated development environment (IDE) that is based on Processing.

Together with Energīa, LaunchPads can be used to develop interactive objects, taking inputs from a

variety of switches or sensors, and controlling a variety of lights, motors, and other physical outputs.

LaunchPad projects can be stand-alone (only run on the target board, i.e. your LaunchPad), or they can

communicate with software running on your computer (Host PC). Energīa projects are highly portable

between supported LaunchPad platforms. Projects written for your Connected LaunchPad can be run on

other LaunchPads with little or no modifications.

More information is available at http://energia.nu.

www.ti.com

1.6 Specifications

Table 1-1 summarizes the specifications for the Connected LaunchPad.

Parameter Value

Board Supply Voltage

Dimensions 4.9 in x 2.2 in x .425 in (12.45 cm x 5.59 cm x 10.8 mm) (L x W x H)

Break-out Power Output

RoHS Status Compliant

Table 1-1. EK-TM4C1294XL Specifications

4.75 VDCto 5.25 VDCfrom one of the following sources:

• Debug USB U22 (ICDI) USB Micro-B cable connected to PC or other compatible

power source.

• Target USB (U7) USB Micro-B cable connected to PC or other compatible power

source.

• BoosterPack 1 (X8-4)

• BoosterPack 2 (X6-4)

• Breadboard expansion header (X11-2 or X11-97).

See schematic symbol JP1 for power input selection.

• 5 VDCto BoosterPacks, current limited by TPS2052B. Nominal rating 1 Amp.

Board input power supply limitations may also apply.

• 3.3 VDCto BoosterPacks, limited by output of TPS73733 LDO. This 3.3-V plane is

shared with on-board components. Total output power limit of TPS73733 is 1

Amp.

6

Board Overview SPMU365A–March 2014–Revised March 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

Chapter 2

SPMU365A–March 2014–Revised March 2014

Hardware Description

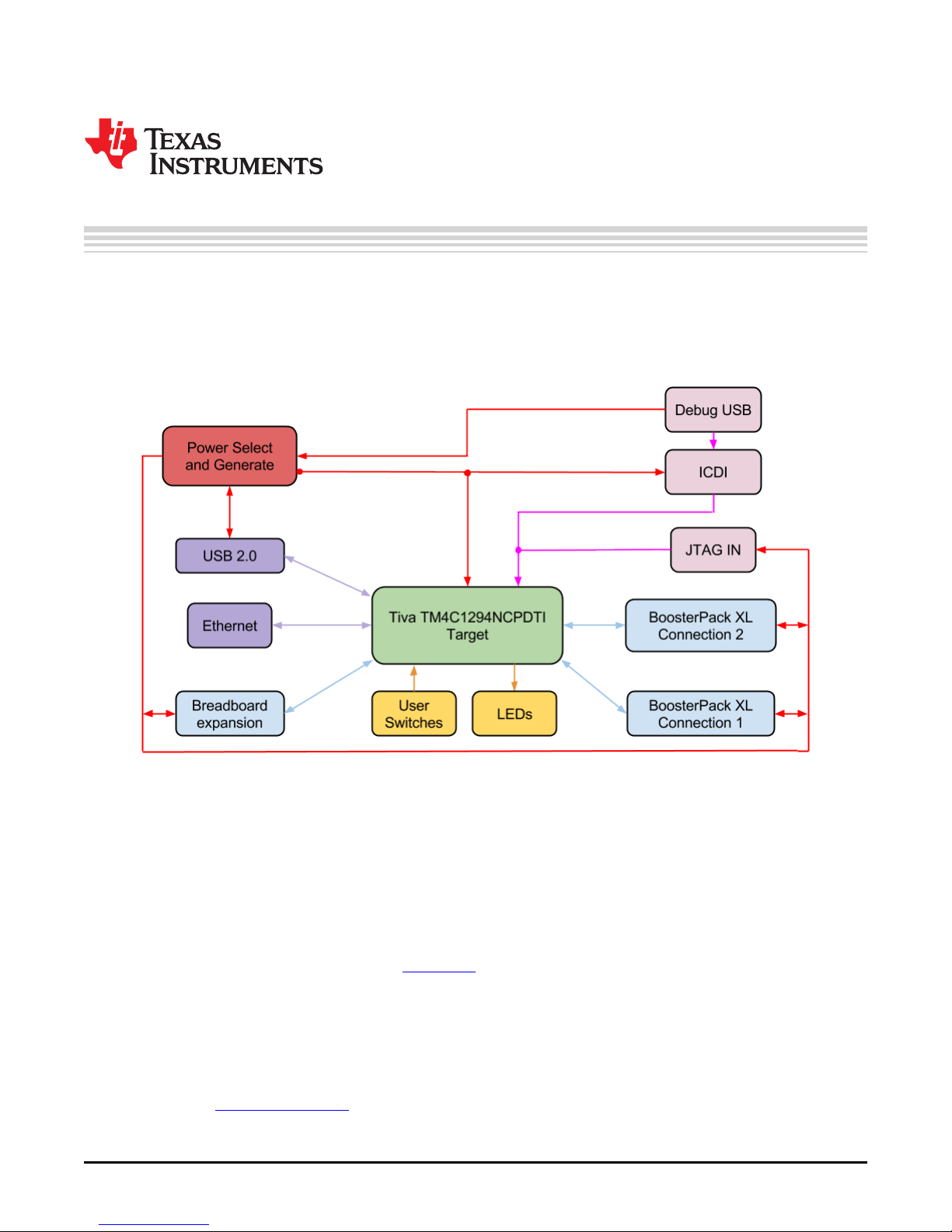

The Connected LaunchPad includes a TM4C1294NCPDTI microcontroller with an integrated 10/100

Ethernet MAC and PHY. This advanced ARM® Cortex™ M4F MCU has a wide range of peripherals that

are made available to users via the on-board accessories and the BoosterPack connectors. This chapter

explains how those peripherals operate and interface to the microcontroller.

Figure 2-1 provides a high-level block diagram of the Connected LaunchPad.

Figure 2-1. Tiva Connected LaunchPad Evaluation Board Block Diagram

2.1 Functional Description

2.1.1 Microcontroller

The TM4C1294NCPDTI is a 32-bit ARM Cortex-M4F based microcontroller with 1024-kB Flash memory,

256-kB SRAM, 6-kB EEPROM, and 120 MHz operation; integrated 10/100 Ethernet MAC and PHY;

integrated USB 2.0 connectivity with external high-speed USB 3.0 PHY capability; a hibernation module, a

multitude of serial connectivity and motion control PWM; as well as a wide range of other peripherals. See

the TM4C1294NCPDTI microcontroller data sheet for more complete details.

Most of the microcontroller’s signals are routed to 0.1-in (2.54-mm) pitch headers or through-hole solder

pads. An internal multiplexor allows different peripheral functions to be assigned to each of these GPIO

pads. When adding external circuitry, consider the additional load on the evaluation board power rails.

The TM4C1294NCPDTI microcontroller is factory-programmed with a quickstart demo program. The

quickstart program resides in on-chip Flash memory and runs each time power is applied, unless the

quickstart application has been replaced with a user program. The quickstart application automatically

connects to http://ti.exosite.com when an internet connection is provided through the RJ45 Ethernet jack

on the evaluation board.

SPMU365A–March 2014–Revised March 2014 Hardware Description

Submit Documentation Feedback

7

Copyright © 2014, Texas Instruments Incorporated

Page 8

Functional Description

2.1.2 Ethernet Connectivity

The Connected LaunchPad is designed to connect directly to an Ethernet network using RJ45 style

connectors. The microcontroller contains a fully integrated Ethernet MAC and PHY. This integration

creates a simple, elegant and cost-saving Ethernet circuit design. Example code is available for both the

uIP and LwIP TCP/IP protocol stacks. The embedded Ethernet on this device can be programmed to act

as an HTTP server, client or both. The design and integration of the circuit and microcontroller also enable

users to synchronize events over the network using the IEEE1588 precision time protocol.

When configured for Ethernet operation, it is recommended that the user configure LED D3 and D4 to be

controlled by the Ethernet MAC to indicate connection and transmit/receive status.

2.1.3 USB Connectivity

The Connected LaunchPad is designed to be USB 2.0 ready. A TPS2052B load switch is connected to

and controlled by the microcontroller USB peripheral, which manages power to the USB micro A/B

connector when functioning in a USB host. When functioning as a USB device, the entire Connected

LaunchPad can be powered directly from the USB micro A/B connector. Use JP1 to select the desired

power source.

USB 2.0 functionality is provided and supported directly out of the box with the target USB micro A/B

connector. High-speed USB 3.0 functionality can be enabled by adding an external USB PHY. The USB

external PHY control and data signals are provided on the breadboard expansion header X11.

2.1.4 Motion Control

The Connected LaunchPad includes the Tiva C Series Motion Control PWM technology, featuring a PWM

module capable of generating eight PWM outputs. The PWM module provides a great deal of flexibility

and can generate simple PWM signals – for example, those required by a simple charge pump – as well

as paired PWM signals with dead-band delays, such as those required by a half-H bridge driver. Three

generator blocks can also generate the full six channels of gate controls required by a 3-phase inverter

bridge.

A quadrature encoder interface (QEI) is also available to provide motion control feedback.

See the BoosterPacks and Headers section of this document for details about the availability of these

signals on the BoosterPack interfaces.

www.ti.com

2.1.5 User Switches and LED's

Two user switches are provided for input and control of the TM4C1294NCPDTI software. The switches

are connected to GPIO pins PJ0 and PJ1.

A reset switch and a wake switch are also provided. The reset switch initiates a system reset of the

microcontroller whenever it is pressed and released. Pressing the reset switch also asserts the reset

signal to the BoosterPack and Breadboard headers. The wake switch is one way to bring the device out of

hibernate mode.

Four user LEDs are provided on the board. D1 and D2 are connected to GPIOs PN1 and PN0. These

LEDs are dedicated for use by the software application. D3 and D4 are connected to GPIOs PF4 and

PF0, which can be controlled by user’s software or the integrated Ethernet module of the microcontroller.

A power LED is also provided to indicate that 3.3 volt power is present on the board.

8

Hardware Description SPMU365A–March 2014–Revised March 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

Functional Description

2.1.6 BoosterPacks and Headers

2.1.6.1 BoosterPack 1

The Connected LaunchPad features two fully independent BoosterPack XL connectors. BoosterPack 1, located around the ICDI portion of the

board, is fully compliant with the BoosterPack standard with the single exception of GPIO pin PA6 (X8-16), which does not provide analog

capability. PA6 is located near the bottom of the inner left BoosterPack XL header.

I2C is provided in both the original BoosterPack standard configuration as well as the updated standard location. Use of I2C on the bottom left of

the BoosterPack connections per the updated standard is highly encouraged whenever possible.

Motion control advanced PWM connections are provided on the inner right connector for motion control applications.

Table 2-1 provides a complete listing of the BoosterPack pins and the GPIO alternate functions available on each pin. The TM4C1294NCPDTI

GPIO register GPIOPCTL values are shown for each configuration. The headers in this table are labeled from left to right in ten pin columns. ‘A’

and ‘D’ make up the outer BoosterPack standard pins, ‘B’ and ‘C’ make up the inner BoosterPack XL standard pins.

Table 2-1. BoosterPack 1 GPIO and Signal Muxing

Digital Function (GPIOPCTL Bit Encoding)

Standard MCU

Header Pin GPIO Analog

Function Pin

1 2 3 5 6 7 8 11 13 14 15

A1 1 +3.3 volts 3.3V

A1 2 Analog PE4 123 AIN9 U1RI - - - - - - - - - SSI1XDAT0

A1 3 UART RX PC4 25 C1- U7Rx - - - - - - - - - EPI0S7

A1 4 UART TX PC5 24 C1+ U7Tx - - - - RTCCLK - - - - EPI0S6

A1 5 GPIO PC6 23 C0+ U5Rx - - - - - - - - - EPI0S5

A1 6 Analog PE5 124 AIN8 - - - - - - - - - - SSIXDAT1

A1 7 SPI CLK PD3 4 AIN12 - I2C8SDA T1CCP1 - - - - - - - SSI2CLk

A1 8 GPIO PC7 22 C0- U5Tx - - - - - - - - - EPI0S4

A1 9 I2C SCL PB2 91 - - I2C0SCL T5CCP0 - - - - - - USB0STP EPI0S27

A1 10 I2C SDA PB3 92 - - I2C0SDA T5CCP1 - - - - - - USB0CLK EPI0S28

B1 1 +5 volts 5V

B1 2 ground GND

B1 3 Analog PE0 15 AIN3 U1RTS - - - - - - - - - B1 4 Analog PE1 14 AIN2 U1DSR - - - - - - - - - B1 5 Analog PE2 13 AIN1 U1DCD - - - - - - - - - B1 6 Analog PE3 12 AIN0 U1DTR - - - - - - - - - B1 7 Analog PD7 128 AIN4 U2CTS - T4CCP1 USB0PFLT - - NMI - - - SSI2XDAT2

B1 8 Analog PA6 40 - U2Rx I2C6SCL T3CCP0 USB0EPEN - - - - SSI0XDAT2 - EPI0S8

B1 9 A out PM4 74 TMPR3 U0CTS - T4CCP0 - - - - - - - B1 10 A out PM5 73 TMPR2 U0DCD - T4CCP1 - - - - - - - -

9

SPMU365A– March 2014 –Revised March 2014 Hardware Description

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 10

Functional Description

www.ti.com

Table 2-1. BoosterPack 1 GPIO and Signal Muxing (continued)

Digital Function (GPIOPCTL Bit Encoding)

Standard MCU

Header Pin GPIO Analog

Function Pin

1 2 3 5 6 7 8 11 13 14 15

C1 1 PWM PF1 43 - - - - EN0LED2 M0PWM1 - - - - SSI3XDAT0 TRD1

C1 2 PWM PF2 44 - - - - - M0PWM2 - - - - SSI3Fss TRD0

C1 3 PWM PF3 45 - - - - - M0PWM3 - - - - SSI3Clk TRCLK

C1 4 PWM PG0 49 - - I2C1SCL - EN0PPS M0PWM4 - - - - - EPI0S11

C1 5 Capture PL4 85 - - - T0CCP0 - - - - - - USB0D4 EPI0S26

C1 6 Capture PL5 86 - - - T0CCP1 - - - - - - USB0D5 EPI0S33

C1 7 GPIO PL0 81 - - I2C2SDA - - M0FAULT3 - - - - USB0D0 EPI0S16

C1 8 GPIO PL1 82 - - I2C2SCL - - PhA0 - - - - USB0D1 EPI0S17

C1 9 GPIO PL2 83 - - - - C0o PhB0 - - - - USB0D2 EPI0S18

C1 10 GPIO PL3 84 - - - - C1o IDX0 - - - - USB0D3 EPI0S19

D1 1 ground GND

D1 2 PWM PM3 75 - - - T3CCP1 - - - - - - - EPI0S12

D1 3 GPIO PH2 31 - U0DCD - - - - - - - - - EPI0S2

D1 4 GPIO PH3 32 - U0DSR - - - - - - - - - EPI0S3

D1 5 reset RESET

D1 6 SPI MOSI PD1 2 AIN14 - I2C7SDA T0CCP1 C1o - - - - - - SSI2XDAT0

D1 7 SPI MISO PD0 1 AIN15 - I2C7SCL T0CCP0 C0o - - - - - - SSI2XDAT1

D1 8 GPIO PN2 109 - U1DCD U2RTS - - - - - - - - EPI0S29

D1 9 GPIO PN3 110 - U1DSR U2CTS - - - - - - - - EPI0S30

D1 10 GPIO PP2 103 - U0DTR - - - - - - - - USB0NXT EPI0S29

10

Hardware Description SPMU365A–March 2014–Revised March 2014

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 11

www.ti.com

Functional Description

2.1.6.2 BoosterPack 2

The second BoosterPack XL interface is located near the middle of the board. This interface is fully compliant with the BoosterPack standard, and

adds features not covered by the BoosterPack standard that enable operation with additional BoosterPacks.

An additional analog signal is provided on the outer left header (X6-9). This signal can be used to monitor the touch panel on the popular Kentec

EB-LM4F120-L35 BoosterPack.

Using the jumpers JP4 and JP5, Controller Area Network (CAN) digital receive and transmit signals can be optionally routed to the BoosterPack 2

interface. The location of these signals is consistent with the CAN interface on the Tiva C Series TM4C123G LaunchPad and the Stellaris

LM4F120 LaunchPad. In the default configuration, UART0 is used for the ICDI virtual UART and CAN is not present on the BoosterPack headers.

In this configuration, the ROM serial bootloader can be used over the ICDI virtual UART. When the jumpers are configured for CAN on the

BoosterPack, then UART4 must be used for the ICDI virtual UART.

To comply with both the original and the new BoosterPack standard, I2C is provided on both sides of the BoosterPack connection. Use of I2C on

the bottom left of the BoosterPack connection is highly encouraged where possible, to be in compliance with the new BoosterPack standard. To

provide I2C capability on the right side of the connector, per the original standard, two zero-ohm resistors (R19 and R20) are used to combine the

SPI and I2C signals. These signals are not shared with any other pins on the LaunchPad and therefore removal of these zero-ohm resistors

should not be required. Software should be certain that unused GPIO signals are configured as inputs.

Table 2-2 provides a complete listing of the BoosterPack pins and the GPIO alternate functions available at each pin. The TM4C1294NCPDT

GPIO register GPIOPCTL values are shown for each configuration. The headers in this table are labeled from left to right in ten pin columns. ‘A’

and ‘D’ make up the outer BoosterPack standard pins, ‘B’ and ‘C’ make up the inner BoosterPack XL standard pins.

Table 2-2. BoosterPack 2 GPIO and Signal Muxing

Digital Function (FPIOPCTL Bit Encoding)

Standard MCU

Header Pin GPIO Analog

Function Pin

1 2 3 5 6 7 8 11 13 14 15

A2 1 3.3V

A2 2 Analog PD2 3 AIN13 - I2C8SCL T1CCP0 C2o - - - - - - SSI2Fss

A2 3 UART RX PP0 118 C2+ U6Rx - - - - - - - - - SSI3XDAT2

A2 4 UART TX PP1 119 C2- U6Tx - - - - - - - - - SSI3XDAT3

PD4 125 AIN7 U2Rx - T3CCP0 - - - - - - - SSI1XDAT2

GPIO

A2 5

(See JP4)

PA0 33 - U0Rx I2C9SCL T0CCP0 - - CANORx - - - - PD5 126 AIN6 U2Tx - T3CCP1 - - - - - - - SSI1XDAT3

Analog

A2 6

(See JP5)

PA1 34 - U0Tx I2C9SDA T0CCP1 - - CAN0Tx - - - - A2 7 SPI CLK PQ0 5 - - - - - - - - - - SSI3Clk EPI0S20

A2 8 GPIO PP4 105 - U3RTS U0DSR - - - - - - - USB0D7 A2 9 I2C SCL PN5 112 - U1RI U3CTS I2C2SCL - - - - - - - EPIO0S35

A2 10 I2C SDA PN4 111 - U1DTR U3RTS I2C2SDA - - - - - - - EPIO0S34

B2 1 5V

B2 2 GND

B2 3 Analog PB4 121 AIN10 U0CTS I2C5SCL - - - - - - - - SSI1Fss

11

SPMU365A– March 2014 –Revised March 2014 Hardware Description

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 12

Functional Description

www.ti.com

Table 2-2. BoosterPack 2 GPIO and Signal Muxing (continued)

Digital Function (FPIOPCTL Bit Encoding)

Standard MCU

Header Pin GPIO Analog

Function Pin

1 2 3 5 6 7 8 11 13 14 15

B2 4 Analog PB5 120 AIN11 U0RTS I2C5SDA - - - - - - - - SSI1Clk

B2 5 Analog PK0 18 AIN16 U4Rx - - - - - - - - - EPI0S0

B2 6 Analog PK1 19 AIN17 U4Tx - - - - - - - - - EPI0S1

B2 7 Analog PK2 20 AIN18 U4RTS - - - - - - - - - EPI0S2

B2 8 Analog PK3 21 AIN19 u4CTS - - - - - - - - - EPI0S3

B2 9 A out PA4 37 - U3Rx I2C7SCL T2CCP0 - - - - - - - SSI0XDAT0

B2 10 A out PA5 38 - U3Tx I2C7SDA T2CCP1 - - - - - - - SSI0XDAT1

C2 1 PWM PG1 50 - - I2C1SDA - - M0PWM5 - - - - - EPI0S10

C2 2 PWM PK4 63 - - I2C3SCL - EN0LED0 M0PWM6 - - - - - EPI0S32

C2 3 PWM PK5 62 - - I2C3SDA - EN0LED2 M0PWM7 - - - - - EPI0S31

C2 4 PWM PM0 78 - - - T2CCP0 - - - - - - - EPI0S15

C2 5 Capture PM1 77 - - - T2CCP1 - - - - - - - EPI0S14

C2 6 Capture PM2 76 - - - T3CCP0 - - - - - - - EPI0S13

C2 7 GPIO PH0 29 - U0RTS - - - - - - - - - EPI0S0

C2 8 GPIO PH1 30 - U0CTS - - - - - - - - - EPI0S1

C2 9 GPIO PK6 61 - - I2C4SCL - EN0LED1 M0FAULT1 - - - - - EPI0S25

C2 10 GPIO PK7 60 - U0RI I2C4SDA - RTCCLK M0FAULT2 - - - - - EPI0S24

D2 1 GND

D2 2 PWM PM7 71 TMPR0 U0RI - T5CCP1 - - - - - - - D2 3 GPIO PP5 106 - U3CTS I2C2SDL - - - - - - - USB0D6 D2 4 GPIO PA7 41 - U2Tx I2C6SDA T3CCP1 USB0PFLT - - - USB0EPEN SSI0XDAT3 - EPI0S9

D2 5 RESET

SPI MOSI PQ2 11 - - - - - - - - - - SSI3XDAT0 EPI0S22

D2 6

I2C PA3 36 - U4Tx I2C8SDA T1CCP1 - - - - - - - SSI0Fss

SPI MISO PQ3 27 - - - - - - - - - - SSI3XDAT1 EPI0S23

D2 7

I2C PA2 35 - U4Rx I2C8SCL T1CCP0 - - - - - - - SSI0Clk

D2 8 GPIO PP3 104 - U1CTS U0DCD - - - - - - - USB0DIR EPI0S30

D2 9 GPIO PQ1 6 - - - - - - - - - - SSI3Fss EPI0S21

D2 10 GPIO PM6 72 TMPR1 U0DSR - T5CCP0 - - - - - - - -

12

Hardware Description SPMU365A–March 2014–Revised March 2014

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 13

www.ti.com

Functional Description

2.1.6.3 Breadboard Connection

The breadboard adapter section of the board is a set of 98 holes on a 0.1 inch grid. Properly combined with a pair of right angle headers, the

entire Connected LaunchPad can be plugged directly into a standard 300 mil (0.3 inch) wide solder-less breadboard. The right angle headers and

breadboard are not provided with this kit. Suggested part numbers are Samtec TSW-149-09-L-S-RE and TSW-149-08-L-S-RA right angle pin

headers and Twin industries TW-E40-1020 solder-less breadboard. Samtec TSW-149-09-F-S-RE and TSW-149-09-F-S-RA may be substituted.

A detailed explanation of how to install the headers is available on the TI LaunchPad Wiki or at

http://users.ece.utexas.edu/~valvano/EE345L/Labs/Fall2011/LM3S1968soldering.pdf.

Nearly all microcontroller signals are made available at the breadboard adapter holes (X11). These signals are grouped by function where

possible. For example, all EPI signals are grouped on one side of the connector. Many of the analog signals are grouped near VREF, and UART,

SSI and I2C signals are grouped by peripheral to make expansion and customization simpler.

Table 2-3 and Table 2-4 show the GPIO pin and signal muxing for the X11 breadboard adapter pads.

Table 2-3. X11 Breadboard Adapter Odd-Numbered Pad GPIO and Signal Muxing

Digital Function (GPIOPCTL Bit Encoding)

MCU

Pin Port Analog

PIN

1 2 3 5 6 7 8 11 13 14 15

1 3V3

3 GND

5 PB4 121 AIN10 U0CTS I2C5SCL - - - - - - - - SSI1Fss

7 PB5 120 AIN11 U0RTS I2C5SDA - - - - - - - - SSI1Clk

9 PH0 29 - U0RTS - - - - - - - - - EPI0S0

11 PH1 30 - U0CTS - - - - - - - - - EPI0S1

13 PH2 31 - U0DCD - - - - - - - - - EPI0S2

15 PH3 32 - U0DSR - - - - - - - - - EPI0S3

17 PC7 22 C0- U5Tx - - - - - - - - - EPI0S4

19 PC6 23 C0+ U5Rx - - - - - - - - - EPI0S5

21 PC5 24 C1+ U7Tx - - - - RTCCLK - - - - EPI0S6

23 PC4 25 C1- U7Rx - - - - - - - - - EPI0S7

25 PA6 40 - U2Rx I2C6SCL T3CCP0 USB0EPEN - - - - SSI0XDAT2 - EPI0S8

27 PA7 41 - U2Tx I2C6SDA T3CCP1 USB0PFLT - - - USB0EPEN SSI0XDAT3 - EPI0S9

29 PG1 50 - - I2C1SDA - - M0PWM5 - - - - - EPI0S10

31 PG0 49 - - I2C1SCL - EN0PPS M0PWM4 - - - - - EPI0S11

33 PM3 75 - - - T3CCP1 - - - - - - - EPI0S12

35 GND

37 PM2 76 - - - T3CCP0 - - - - - - - EPI0S13

39 PM1 77 - - - T2CCP1 - - - - - - - EPI0S14

41 PM0 78 - - - T2CCP0 - - - - - - - EPI0S15

13

SPMU365A– March 2014 –Revised March 2014 Hardware Description

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 14

Functional Description

www.ti.com

Table 2-3. X11 Breadboard Adapter Odd-Numbered Pad GPIO and Signal Muxing (continued)

Digital Function (GPIOPCTL Bit Encoding)

MCU

Pin Port Analog

PIN

1 2 3 5 6 7 8 11 13 14 15

43 PL0 81 - - I2C2SDA - - M0FAULT3 - - - - USB0D0 EPI0S16

45 PL1 82 - - I2C2SCL - - PhA0 - - - - USB0D1 EPI0S17

47 PL2 83 - - - - C0o PhB0 - - - - USB0D2 EPI0S18

49 PL3 84 - - - - C1o IDX0 - - - - USB0D3 EPI0S19

51 PQ0 5 - - - - - - - - - - SSI3Clk EPI0S20

53 PQ1 6 - - - - - - - - - - SSI3Fss EPI0S21

55 PQ2 11 - - - - - - - - - - SSI3XDAT0 EPI0S22

57 PQ3 27 - - - - - - - - - - SSI3XDAT1 EPI0S23

59 PK7 60 - U0RI I2C4SDA - - - - - - EPI0S24

61 GND

63 PK6 61 - - I2C4SCL - EN0LED1 M0FAULT1 - - - - - EPI0S25

65 PL4 85 - - - T0CCP0 - - - - - - USB0D4 EPI0S26

67 PB2 91 - - I2C0SCL T5CCP0 - - - - - - USB0STP EPI0S27

69 PB3 92 - - I2C0SDA T5CCP1 - - - - - - USB0CLK EPI0S28

71 PP2 103 - U0DTR - - - - - - - - USB0NXT EPI0S29

73 PP3 104 - U1CTS U0DCD - - - RTCCLK - - - USB0DIR EPI0S30

75 PK5 62 - - I2C3SDA - EN0LED2 M0PWM7 - - - - - EPI0S31

77 PK4 63 - - I2C3SCL - EN0LED0 M0PWM6 - - - - - EPI0S32

79 PL5 86 - - - T0CCP1 - - - - - - USB0D5 EPI0S33

81 PN4 111 - U1DTR U3RTS I2C2SDA - - - - - - - EPI0S34

83 PN5 112 - U1RI U3CTS I2C2SCL - - - - - - - EPI0S35

85 PN0 107 - U1RTS - - - - - - - - - 87 PN1 108 - U1CTS - - - - - - - - - 89 PN2 109 - U1DCD U2RTS - - - - - - - - EPI0S29

91 PN3 110 - U1DSR U2CTS - - - - - - - - EPI0S30

93 PQ4 102 - U1Rx - - - - - DIVSCLK - - - 95 WAKE

97 5V

14

Hardware Description SPMU365A–March 2014–Revised March 2014

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 15

www.ti.com

Functional Description

Table 2-4. X11 Breadboard Adapter Even-Numbered Pad GPIO and Signal Muxing

Digital Function (GPIOPCTL Bit Encoding)

MCU

Pin Port Analog

PIN

1 2 3 5 6 7 8 11 13 14 15

2 5V

4 GND

6 PA2 35 - U4Rx I2C8SCL T1CCP0 - - - - - - - SSI0Clk

8 PA3 36 - U4Tx I2C8SDA T1CCP1 - - - - - - - SSI0Fss

10 PA4 37 - U3Rx I2C7SCL T2CCP0 - - - - - - - SSI0XDAT0

12 PA5 38 - U3Tx I2C7SDA T2CCP1 - - - - - - - SSI0XDAT1

14 PE0 15 AIN3 U1RTS - - - - - - - - - 16 PE1 14 AIN2 U1DSR - - - - - - - - - 18 PE2 13 AIN1 U1DCD - - - - - - - - - 20 PE3 12 AIN0 U1DTR - - - - - - - - - 22 PE4 123 AIN9 U1RI - - - - - - - - - SSI1XDAT0

24 PE5 124 AIN8 - - - - - - - - - - SSI1XDAT1

26 PK0 18 AIN16 U4Rx - - - - - - - - - EPI0S0

28 PK1 19 AIN17 U4Tx - - - - - - - - - EPI0S1

30 PK2 20 AIN18 U4RTS - - - - - - - - - EPI0S2

32 PK3 21 AIN19 U4CTS - - - - - - - - - EPI0S3

34 VREF

36 GND

38 PD5 126 AIN6 U2Tx - T3CCP1 - - - - - - - SSI1XDAT3

40 PD4 125 AIN7 U2Rx - T3CCP0 - - - - - - - SSI1XDAT2

42 PD7 128 AIN4 U2CTS - T4CCP1 USB0PFLT - - NMI - - - SSI1XDAT2

44 PD6 127 AIN5 U2RTS - T4CCP0 USB0EPEN - - - - - - SSI1XDAT3

46 PD3 4 AIN12 - I2C8SDA T1CCP1 - - - - - - - SSI2Clk

48 PD1 2 AIN14 - I2C7SDA T0CCP1 C1o - - - - - - SSI1XDAT0

50 PD0 1 AIN15 - I2C7SCL T0CCP0 C0o - - - - - - SSI1XDAT1

52 PD2 3 AIN13 - I2C8SCL T1CCP0 C2o - - - - - - SSI2Fss

54 PP0 118 C2+ U6Rx - - - - - - - - - SSI1XDAT2

56 PP1 119 C2- U6Tx - - - - - - - - - SSI1XDAT3

58 PB0 95 USB0ID U1Rx I2C5SCL T4CCP0 - - CAN1Rx - - - - 60 PB1 96 USB0VBUS U1Tx I2C5SDA T4CCP1 - - CAN1Tx - - - - 62 GND

64 PF4 46 - - - - EN0LED1 M0FAULT0 - - - - SSI3XDAT2 TRD3

66 PF0 42 - - - - EN0LED0 M0PWM0 - - - - SSI3XDAT1 TRD2

15

SPMU365A– March 2014 –Revised March 2014 Hardware Description

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 16

Functional Description

www.ti.com

Table 2-4. X11 Breadboard Adapter Even-Numbered Pad GPIO and Signal Muxing (continued)

Digital Function (GPIOPCTL Bit Encoding)

MCU

Pin Port Analog

PIN

1 2 3 5 6 7 8 11 13 14 15

68 PF1 43 - - - - EN0LED2 M0PWM1 - - - - SSI3XDAT0 TRD1

70 PF2 44 - - - - - M0PWM2 - - - - SSI3Fss TRD0

72 PF3 45 - - - - - M0PWM3 - - - - SSI3Clk TRCLK

74 PA0 33 - U0Rx I2C9SCL T0CCP0 - - CAN0Rx - - - - 76 PA1 34 - U0Tx I2C9SDA T0CCP1 - - CAN0Tx - - - - 78 PP4 105 - U3RTS U0DSR - - - - - - - USB0D7 80 PP5 106 - U3CTS I2C2SCL - - - - - - - USB0D6 82 PJ0 116 - U3Rx - - - - - - - - 84 PJ1 117 - U3Tx - - - - - - - - - 86 PM7 71 TMPR0 U0RI - T5CCP1 - - - - - - - 88 PM6 72 TMPR1 U0DSR - T5CCP0 - - - - - - - 90 PM5 73 TMPR2 U0DCD - T4CCP1 - - - - - - - 92 PM4 74 TMPR3 U0CTS - T4CCP0 - - - - - - - 94 RESET

96 GND

98 3V3

16

Hardware Description SPMU365A–March 2014–Revised March 2014

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 17

www.ti.com

2.1.6.4 Other Headers and Jumpers

JP1 is provided to select the power input source for the Connected LaunchPad. The top position is for

BoosterPack power; this position also disconnects both USB voltages from the board’s primary 5-volt

input. In the top position, the TPS2052B does not limit current so additional care should be exercised. The

middle position draws power from the USB connector on the left side of the board near the Ethernet jack.

The bottom position is the default, in which power is drawn from the ICDI (Debug) USB connection.

JP2 separates the MCU 3.3-volt power domain from the rest of the 3.3-volt power on the board allowing

an ammeter to be used to obtain more accurate measurements of microcontroller power consumption.

JP3 isolates the output of the TPS73733 LDO from the board’s 3.3-V power domain.

JP4 and JP5 are used to configure CAN signals to the BoosterPack 2 interface. In the default horizontal

configuration, CAN is not present on the BoosterPack. UART 4 goes to the BoosterPack and UART 0

goes to the ICDI virtual serial port to provide ROM serial bootloader capability. In the vertical CAN-enabled

configuration, UART 4 goes to the ICDI virtual serial port and CAN signals are available on the

BoosterPack. The ROM serial bootloader is not available to the ICDI virtual serial port while the jumpers

are in the CAN position.

Figure 2-2 shows the default configuration and relative location of the jumpers on the board.

Power Management

2.2 Power Management

2.2.1 Power Supplies

The Connected LaunchPad can be powered from three different input options:

• On-board ICDI USB cable (Debug, Default)

• Target USB cable

• BoosterPack or Breadboard adapter connection

The JP1 power-select jumper is used to select one of the power sources.

In addition, the JP3 power jumper can be used to isolate the 3.3-volt output of the TPS73733 from the

board’s 3.3-volt rail.

A TPS2052B load switch is used to regulate and control power to the Target USB connector when the

microcontroller is acting in USB host mode. This load switch also limits current to the BoosterPack and

Breadboard adapter headers when the JP1 jumper is in the ICDI position.

SPMU365A–March 2014–Revised March 2014 Hardware Description

Submit Documentation Feedback

Figure 2-2. Default Jumper Locations

17

Copyright © 2014, Texas Instruments Incorporated

Page 18

Power Management

2.2.2 Low Power Modes

The Connected LaunchPad demonstrates several low power microcontroller modes. In run mode, the

microcontroller can be clocked from several sources such as the internal precision oscillator or an external

crystal oscillator. Either of these sources can then optionally drive an internal PLL to increase the effective

frequency of the system up to 120 MHz. In this way, the run mode clock speed can be used to manage

run mode current consumption.

The microcontroller also provides sleep and deep sleep modes and internal voltage adjustments to the

flash and SRAM to further refine power consumption when the processor is not in use but peripherals

must remain active. Each peripheral can be individually clock gated in these modes so that current

consumption by unused peripherals is minimized. A wide variety of conditions from internal and external

sources can trigger a return to run mode.

The lowest power setting of the microcontroller is hibernation, which requires a small amount of supporting

external circuitry available on the Connected LaunchPad. The Connected LaunchPad can achieve

microcontroller current consumption modes under 2 micro-Amps using hibernate VDD3ON mode.

Hibernation with VDD3ON mode is not supported on this board. The Connected LaunchPad can be woken

from hibernate by several triggers including the dedicated wake button, the reset button, an internal RTC

timer and a subset of the device GPIO pins. The hibernation module provides a small area of internal

SRAM that can preserve data through a hibernate cycle.

2.2.3 Clocking

The Connected LaunchPad uses a 25 MHz crystal (Y1) to drive the main TM4C1294NCPDTI internal

clock circuit. Most software examples use the internal PLL to multiply this clock to higher frequencies up to

120 MHz for core and peripheral timing. The 25-MHz crystal is required when using the integrated

Ethernet MAC and PHY.

The Hibernation module is clocked from an external 32.768-KHz crystal (Y3).

www.ti.com

2.2.4 Reset

The RESET signal to the TM4C1294NCPDTI microcontroller connects to the RESET switch, BoosterPack

connectors, Breadboard adapter and to the ICDI circuit for a debugger-controller reset.

External reset is asserted (active low) under the following conditions:

• Power-on reset (filtered by and R-C network)

• RESET switch is held down.

• By the ICDI circuit when instructed by the debugger (this capability is optional, and may not be

supported by all debuggers)

• By an external circuit attached to the BoosterPack or Breadboard connectors.

2.3 Debug Interface

2.3.1 In-Circuit Debug Interface (ICDI)

The Connected LaunchPad comes with an on-board ICDI. The ICDI allows for the programming and

debugging of the TM4C1294NCPDTI using LM Flash Programmer and/or any of the supported tool

chains. Note that ICDI only supports JTAG debugging at this time. It is possible to use other JTAG

emulators instead of the on board ICDI, by connecting to U6. When the ICDI detects an external debug

adapter connection on the JTAG connector U6 and disables the ICDI outputs to allow the external debug

adapter to drive the debug circuit. For more information, see Section 2.3.2.

Debug out of the ICDI is possible by removing resistors R6, R7, R8, R10, R11, R15, R16 and R40 from

the Connected LaunchPad and use the ICDI to drive JTAG signals out on U6 for the purpose of

programming or debugging other boards. To restore the connection to the on-board TM4C1294NCPDTI

microcontroller, install jumpers from the odd to even pins of X1 or re-install the resistors. Removal of R40

disables the detection of an attached external debugger. R40 must be installed to use an external debug

adapter to program or debug the Connected LaunchPad.

18

Hardware Description SPMU365A–March 2014–Revised March 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

2.3.2 External Debugger

The connector U6 is provided for the attachment of an external debug adapter such as the IAR J-Link or

Keil ULINK. This connector follows the ARM standard 10-pin JTAG pinout. This interface can use either

JTAG or SWD if supported by the external debug adapter.

2.3.3 Virtual COM Port

When plugged into a USB host, the ICDI enumerates as both a debugger and a virtual COM port. JP4 and

JP5 control the selection of which UART from the TM4C1294NCPDTI is connected to the virtual COM

port. In the default configuration, UART0 maps to the virtual COM port of the ICDI. In the CAN jumper

configuration, UART4 maps to the virtual COM port of the ICDI.

Debug Interface

SPMU365A–March 2014–Revised March 2014 Hardware Description

Submit Documentation Feedback

19

Copyright © 2014, Texas Instruments Incorporated

Page 20

This chapter provides general information on software development as well as instructions for flash

memory programming.

3.1 Software Description

The TivaWare software provides drivers for all of the peripheral devices supplied in the design. The Tiva C

Series Peripheral Driver Library is used to operate the on-chip peripherals as part of TivaWare.

TivaWare includes a set of example applications that use the TivaWare Peripheral Driver Library. These

applications demonstrate the capabilities of the TM4C1294NCPDTI microcontroller, as well as provide a

starting point for the development of the final application for use on the Connected LaunchPad evaluation

board. Example applications are also provided for the Connected LaunchPad when paired with selected

BoosterPacks.

3.2 Source Code

The complete source code including the source code installation instructions are provided at

http://www.ti.com/tool/sw-tm4c. The source code and binary files are installed in the TivaWare software

tree.

Chapter 3

SPMU365A–March 2014–Revised March 2014

Software Development

3.3 Tool Options

The source code installation includes directories containing projects, makefiles, and binaries for the

following tool-chains:

• Keil ARM RealView®Microcontroller Development System

• IAR Embedded Workbench for ARM

• Sourcery Codebench

• Generic GNU C Compiler

• Texas Instruments' Code Composer Studio™ IDE

Download evaluation versions of these tools from the Tools & Software section of www.ti.com/tiva. Due to

code size restrictions, the evaluation tools may not build all example programs. A full license is necessary

to re-build or debug all examples.

For detailed information on using the tools, see the documentation included in the tool chain installation or

visit the website of the tools supplier.

20

Software Development SPMU365A–March 2014–Revised March 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

3.4 Programming the Connected LaunchPad

The Connected LaunchPad software package includes pre-built binaries for each of the example

applications. If you installed the TivaWare™ software to the default installation path of

C:\ti\TivaWare_C_Series_<version>, you can find the example applications in C:\ti\TivaWare_C_Series<version>\examples\boards\ek-tm4c129xl. The on-board ICDI is used with the LM Flash Programmer tool

to program applications on the Connected LaunchPad.

Follow these steps to program example applications into the Connected LaunchPad evaulation board

using the ICDI:

1. Install LM Flash Programmer on a PC running Microsoft Windows.

2. Place JP1 into the ICDI position on the Connected LaunchPad.

3. Connect the USB-A cable plug in to an available USB port on the PC and plug the Micro-B plug to the

Debug USB port (U22) on the Connected LaunchPad.

4. Verify that LED D0 at the top of the board is illuminated.

5. Install Windows ICDI and Virtual COM Port drivers if prompted. Installation instructions can be found at

http://www.ti.com/lit/pdf/spmu287.

6. Run the LM Flash Programmer application on the PC.

7. In the Configuration tap, use the Quick Set control to select “TM4C1294XL LaunchPad”.

8. Move to the Program tab and click the Browse button. Navigate to the example applications directory

(the default location is C:\ti\TivaWare_C_Series_<version>\examples\boards\ek-tm4c1294xl\)

9. Each example application has its own directory. Navigate to the example directory that you want to

load and then into the sub-directory for one of the supported tool chains which contains the binary

(*.bin) file. Select the binary file and click Open.

10. Set the Erase Method to Erase Necessary Pages, check the Verify After Program box, and check

Reset MCU After Program. The example program starts execution once the verify process is complete.

Programming the Connected LaunchPad

SPMU365A–March 2014–Revised March 2014 Software Development

Submit Documentation Feedback

21

Copyright © 2014, Texas Instruments Incorporated

Page 22

4.1 References

In addition to this document the following references are available for download at www.ti.com.

• TivaWare for C Series (http://www.ti.com/tool/sw-tm4c)

• TivaWare Peripheral Driver Library Users' Guide (literature number SPMU298)

• EK-TM4C1294XL Getting Started Guide (literature number SPMZ858)

• LM Flash Programmer Tool (http://www.ti.com/lmflashprogrammer)

• TPS73733 Low-Dropout Regulator with Reverse Current Protection

(http://www.ti.com/product/tps79733)

• Texas Instruments Code Composer Studio website (http://www.ti.com/ccs)

• Tiva C Series TM4C1294NCPDT Microcontroller Data Sheet (http://www.ti.com/lit/gpn/tm4c1294ncpdt)

• Build Your Own BoosterPack information regarding the BoosterPack standard (http://www.ti.com/byob)

• ICDI Driver Installation Guide (literature number SPMU287)

Additional Support:

• Keil RealView MDK-ARM (http://www.keil.com/arm/mdk.asp)

• IAR Embedded Workbench for ARM (http://iar.com/ewarm/)

• Sourcery CodeBench development tools (http://www.mentor.com/embedded-software/sourcery-

tools/sourcery-codebench/overview)

• Exosite (http://ti.exosite.com)

Chapter 4

SPMU365A–March 2014–Revised March 2014

References, PCB Layout, and Bill of Materials

22

References, PCB Layout, and Bill of Materials SPMU365A–March 2014–Revised March 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

4.2 Component Locations

Figure 4-1 is a dimensioned drawing of the Connected LaunchPad. This figure shows the location of

selected features of the board as well as the component locations.

Component Locations

Figure 4-1. Connected LaunchPad Dimensions and Component Locations

SPMU365A–March 2014–Revised March 2014 References, PCB Layout, and Bill of Materials

Submit Documentation Feedback

23

Copyright © 2014, Texas Instruments Incorporated

Page 24

Bill of Materials

4.3 Bill of Materials

Table 4-1 is the Connected LaunchPad bill of materials list.

Item Ref Qty Description Mfg Part Number

1 C1 1 Kemet C1210C102MGRACTU

C3, C4, C5, C10, C11, C12,

C13, C16, C17, C18, C19,

2 C21, C22, C23, C24, C25, 26 Taiyo Yuden EMK105B7104KV-F

C26, C27, C28, C29, C30,

C40, C41, C42, C43, C46

3 C31 1 AVX 1812GC472KAT1A

4 C32, C33 2 TDK C1608X7R1H332K

5 C6, C14 2 100R07X105KV4T

6 C7, C15, C20 3 Murata GRM188R61C225KE15D

7 6 Murata GRM1555C1H120JZ01D

8 D0, D1, D2, D3, D4 5 Green LED 0603 Everlight 19-217/G7C-AL1M2B/3T

9 7

10 JP1 1 Vertical Unshrouded, FCI 67996-206HLF

11 JP2, JP3 2 Vertical Unshrouded, 0.220 FCI 68001-102HLF

12 JP4, JP5 2 Vertical Unshrouded, 0.230

13 8 Yageo RC0402FR-0710KL

14 R17, R26, R36 3 100k 5% 0402 resistor smd Rohm MCR01MRTJ104

15 R18, R51 2 Resistor 0402 100 ohm 5% Rohm MCR1MRTJ101

16 R23, R21, R22, R24 4 Resistor 49.9 ohm 0402. 1 % Rohm MCR01MRTF49R9

17 R25 1 Resistor 4.87k 1% 0402 smd Rohm MCR01MRTF4871

18 R28 1 Panasonic ERJ-2GEJ562X

19 R32, R43, R45, R46 4 resistor 75 ohm 0402 5% Rohm MCR01MRTJ750

20 R34, R52 2 Panasonic ERJ-3GEYJ105V

21 R38 1 Panasonic ERJ-2GEJ510X

22 R42 1 Rohm MCR01MRTF1004

23 R47 1 RES 1M OHM 5% 1206 TF Panasonic ERJ-8GEYJ105V

24 R49, R50 2 Panasonic ERJ-3GEYJ202V

25 R15, R16, R19, R20, R39, 12 Panasonic ERJ-2GE0R00X

26 R9, R27, R30, R31, R33 5 Yageo RC0402FR-07330RL

C8, C9, C44, Capacitor, 12pF, 50V,

C45, C47, C48 5%, 0402, COG

J1, J2, J3, Jumper, 0.100, Gold,

J4, J5, J6, J7 Black, Open

R1, R2, R3, R4, Resistor, 10k ohm, 1/10W,

R5, R29, R35, R44 5%, 0402 Thick Film

R6, R7, R8, R10, R11,

R40, R41

Table 4-1. Connected LaunchPad Bill of Materials

Capacitor, 1000pF, 2kV,

20%, X7R, 1210

Capacitor, 0.1uF 16V,

10%,0402 X7R

Capacitor, 4700pF, 2kV,

10%,X7R, 1812

Capacitor, 3300pF, 50V,

10%, X7R, 0603

Capacitor, 1uF , X5R, 10V, Johanson

Low ESR, 0402 Dielectrics Inc

Capacitor, 2.2uF, 16V,

10%, 0603, X5R

3M 969102-0000-DA

Kobiconn 151-8000-E

Header, 2x3, 0.100, T-Hole,

0.230 Mate, gold

Header, 1x2, 0.100, T-Hole,

Mate

Header, 2x2, 0.100, T-Hole, FCI 67997-104HLF

Mate

Resistor, 5.6k ohm,

1/10W, 5%, 0402

Resistor, 1M OH,

1/10W, 5% 0603 SMD

Resistor, 51 ohm,

1/10W, 5%, 0402

Resistor, 1M Ohm,

1/10W, 5%, 0402

Resistor, 2.0k ohm,

1/10W, 5%, 0402

Resistor, 0 ohm,

1/10W, 5%, 0402

Resistor, 330 ohm,

1/10W, 5%, 0402

3M 961102-6404-AR

Anyone 1x2-head

4UCON 00998

www.ti.com

24

References, PCB Layout, and Bill of Materials SPMU365A–March 2014–Revised March 2014

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 25

www.ti.com

Bill of Materials

Table 4-1. Connected LaunchPad Bill of Materials (continued)

Item Ref Qty Description Mfg Part Number

27 4 Omron B3S-1000

28 U1 1 128 QFP with Ethernet MAC

29 U10 1 Pulse Electronics HX1198FNL

30 U13 1 Semtech SLVU2.8-4.TBT

31 U14 1 TE Connectivity 1-406541-5

32 U2, U3 2 Texas Instruments TPD4S012DRYR

33 U20 1 Texas Instruments TM4C123GH6PMI

34 U22 1 FCI 10118194-0001LF

35 U4 1 Texas Instruments TPS2052BDRBR

36 U5 1 Texas Instruments TPS73733DRV

37 U6 1

38 U7 1 Right angle with through Hirose ZX62D-AB-5P8

39 X6, X7, X8, X9 4

40 Y1 1 Crystal 25 MHz 3.2 x 2.5 mm NDK nx3225ga-25.000m-std-crg-2

41 Y2 1 NDK NX3225GA-16.000M-STD-CRG-2

42 Y3 1 CMR200T-32.768KDZY-UT

43 C2 1 Taiyo Yuden EMK105B7104KV-F

44 H1, H4, H6 3 McMaster 90077A112

45 R12, R13, R14 3 Panasonic ERJ-2GEJ562X

46 R48 1 Resistor 0402 1% 52.3k Rohm TRR01MZPF5232

47 17 Keystone 5000

48 X1 1 Vertical, Unshrouded, 0.230 FCI 67997-114HLF

49 X11A 1 connect. Right Angle Samtec TSW-149-09-F-S-RE

50 X11B 1 Samtec TSW-149-08-F-S-RA

RESET, USR_SW1, Switch, Tact 6mm SMT,

USR_SW2, WAKE 160gf

Tiva, MCU TM4C1294NCPDT Texas Instruments TM4C1294NCPDT

+ PHY

Transformer, ethernet, 1 to 1.

SOIC 16

Diode, 8 chan, +/-15KV, ESD

Protection Array, SO-8

Connector, RJ45 NO MAG,

shielded THRU HOLE

IC 4CH ESD SOLUTION

W/CLAMP 6SON

Stellaris TIVA MCU

TM4C123GH6PMI

USB Micro B receptacle

right angle with guides

Fault protected power switch,

dual channel, 8-SON

3.3V LDO TI TPS73733DRV

fixed out 5V in

Header 2x5, 0.050, SM,

Vertical Shrouded

USB Micro AB receptacle.

guides

Header, 2x10, T-Hole Vertical

unshrouded stacking

Crystal 16 MHz 3.2 x 2.5 mm

4 pin

Crystal, 32.768 KHz Radial Citizen Finetech

Can Miyota

PCB Do Not Populate List (Shown for information only)

Capacitor, 0.1uF 16V,

10%, 0402 X7R

Screw, #4 x 0.625" Pan

Head, Sheet Metal,

Phillips/Slotted

(for fan)

Resistor, 5.6k ohm,

1/10W, 5%, 0402

TP1, TP2, TP3, TP4, TP5,

TP6, TP7, TP8, TP9, Terminal, Test Point Miniature

TP10, TP11, TP12, TP13, Loop, Red, T-Hole

TP14, TP15, TP16, TP17

Header, 2x7, 0.100, T-Hole,

Mate

Valvano style bread board

extended, 1 x 49 0.100 pitch.

valvano style breadboard

header.

Texas Instruments XM4C1294NCPDT

Samtec SHF-105-01-S-D-SM

Don Connex

Electronics

Samtec SSW-110-23-S-D

Major League

Electronics

C44-10BSA1-G

SSHQ-110-D-08-F-LF

SPMU365A–March 2014–Revised March 2014 References, PCB Layout, and Bill of Materials

Submit Documentation Feedback

25

Copyright © 2014, Texas Instruments Incorporated

Page 26

Chapter 5

SPMU365A–March 2014–Revised March 2014

Schematic

This section contains the complete schematics for the Tiva C Series TM4C1294 Connected LaunchPad.

• Microcontroller, USB, Buttons, and LED's

• BoosterPack connectors

• Breadboard connector

• Ethernet and Ethernet LED's

• Power

• In-Circuit Debug Interface

26

Schematic SPMU365A–March 2014–Revised March 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 27

GND

330

GND

GND

SWITCH_TACTILE

SWITCH_TACTILE

GND

330

GND

TPD4S012_DRY_6

GND

100

GND

1M

3300pF

TP4

TP5

TP6

TP7

D1

R33

USR_SW1

USR_SW2

D2

R27

D+

1

D-

2

GND

4

ID

3

N.C.

5

VBUS

6

U2

R18

DM

P2

DP

P3

GND

P5

ID

P4

VBUS

P1

TP14

TP15

TP16

TP17

PA0

P$33

PA1

P$34

PA2

P$35

PA3

P$36

PA4

P$37

PA5

P$38

PA6

P$40

PA7

P$41

PB0

P$95

PB1

P$96

PB2

P$91

PB3

P$92

PB4

P$121

PB5

P$120

PC0

P$100

PC1

P$99

PC2

P$98

PC3

P$97

PC4

P$25

PC5

P$24

PC6

P$23

PC7

P$22

PD0

P$1

PD1

P$2

PD2

P$3

PD3

P$4

PD4

P$125

PD5

P$126

PD6

P$127

PD7

P$128

PE0

P$15

PE1

P$14

PE2

P$13

PE3

P$12

PE4

P$123

PE5

P$124

PF0

P$42

PF1

P$43

PF2

P$44

PF3

P$45

PF4

P$46

PG0

P$49

PG1

P$50

PH0

P$29

PH1

P$30

PH2

P$31

PH3

P$32

PJ0

P$116

PJ1

P$117

PK0

P$18

PK1

P$19

PK2

P$20

PK3

P$21

PK4

P$63

PK5

P$62

PK6

P$61

PK7

P$60

PL0

P$81

PL1

P$82

PL2

P$83

PL3

P$84

PL4

P$85

PL5

P$86

PL6

P$94

PL7

P$93

PM0

P$78

PM1

P$77

PM2

P$76

PM3

P$75

PM4

P$74

PM5

P$73

PM6

P$72

PM7

P$71

PN0

P$107

PN1

P$108

PN2

P$109

PN3

P$110

PN4

P$111

PN5

P$112

PP0

P$118

PP1

P$119

PP2

P$103

PP3

P$104

PP4

P$105

PP5

P$106

PQ0

P$5

PQ1

P$6

PQ2

P$11

PQ3

P$27

PQ4

P$102

R52

C32

GPIO

PA0

PA1

PA2

PA3

PA5

PA6

PA7

PA4

PB0

PB0/3.2C

TARGET_VBUS/3.2C

TARGET_VBUS/3.2C

TARGET_VBUS/3.2C

PB2

PB3

PB4

PB5

PC4

PC5

PC6

PC7

PD0

PD1

PD2

PD3

PD4

PD5

PD6

PD7

PF0

PF1

PF2

PF3

PF4

PE0

PE1

PE2

PE3

PE4

PE5

PG0

PG1

PH0

PH1

PH2

PH3PJ0

PJ0/3.2D

PJ1

PJ1/3.2D

PK0

PK1

PK2

PK3

PK4

PK5

PK6

PK7

PL0

PL1

PL2

PL3

PL4

PL5

USBD_P

USBD_P

USBD_P

USBD_N

USBD_N

USBD_N

PM0

PM1

PM2

PM3

PM4

PM5

PM6

PM7

PP0

PP1

PP2

PP3

PP4

PP5

PN0

PN0/3.4D

PN1

PN1/3.4D

PN2

PN3

PN4

PN5

PQ0

PQ1

PQ2

PQ3

PQ4

TARGET_TCK/SWCLK/6.1A

TARGET_TMS/SWDIO/6.1A

TARGET_TDI/6.1E

TARGET_TDO/SWO/6.1E TARGET_ID

TARGET_ID

A

B

C

D

E

A

B

C

D

E

1 2 3 4 5 6

U7G$1

U1G$1

TM4C1294NCPDT

See PF0 and PF4 for additional LED's used for

Ethernet or user application

NOTE: TPD4S012 all protection circuits are identical.

Connections chosen for simple routing.

convienence test points for ground

Page 28

TSW-110-02-S-D

TSW-110-02-S-D

TSW-110-02-S-D

TSW-110-02-S-D

0

0

+3V3

+3V3

+5V

+5V

0.1uF 0.1uF

0.1uF

0.1uF

GNDGND

GND

GND

X6-1 X6-2

X6-3

X6-4

X6-5 X6-6

X6-7 X6-8

X6-9 X6-10

X6-11 X6-12

X6-13 X6-14

X6-15 X6-16

X6-17 X6-18

X6-19 X6-20

X7-1

X7-2

X7-3

X7-4

X7-5

X7-6

X7-7

X7-8

X7-9

X7-10

X7-11

X7-12

X7-13

X7-14

X7-15

X7-16X7-17

X7-18X7-19

X7-20

X8-1

X8-2

X8-3

X8-4

X8-5 X8-6

X8-7 X8-8

X8-9 X8-10

X8-11 X8-12

X8-13 X8-14

X8-15 X8-16

X8-17 X8-18

X8-19 X8-20

X9-1

X9-2

X9-3 X9-4

X9-5 X9-6

X9-7 X9-8

X9-9 X9-10

X9-11

X9-12X9-13

X9-14X9-15

X9-16X9-17

X9-18X9-19

X9-20

R19

R20

JP4

1 2

3 4

JP5

1 2

3 4

C23 C24

C25

C26

PB2

PB3

PL0

PP2

PH2

GND/1.6B

GND/1.6B

GND/1.6B

GND/1.6B

TARGET_RESET/3.2D

TARGET_RESET/3.2D

PA0/3.2C

BP2_A2.5BP2_A2.5

TARGET_RXD/6.1D

TARGET_TXD/6.1D PA1/3.2C

BP2_A2.6

BP2_A2.6

PE4

PE5

PC5

PC4

PM3

PM4

PM5

PL4

PD5/1.4B

PC6

PD3

PC7

PE0

PE1

PE2

PE3

PD4/1.4B

PD7

PF1

PF2

PF3

PG0

PL5

PL1

PL2

PL3

PH3

PD1

PD0

PN2

PN3

PD2

PP0

PP1

PQ0

PP4

PN5

PN4

PB4

PB5

PK0

PK1

PK2

PK3

PA4

PA5

PG1

PK4

PK5

PM0

PM1

PM2

PH0

PH1

PK6

PK7

PM7

PA7

PA3

PA2

PQ3

PQ2

PP3

PQ1

PM6

PP5

PA6

BoosterPack 2 Interface

BoosterPack 1 Interface

A

B

C

D

E

A

B

C

D

E

1 2 3 4 5 6

JP4 and JP5 CAN and ICDI UART Selection:

Populate Jumpers from 1-2 and 3-4 for Default Mode

This enables ROM UART boot loader. UART 0 to ICDI

Populate from 1-3 and 2-4 for controller area network

on the boosterpack. UART2 is then availabe to ICDI.

R19 and R20 can be populated to enable I2C on

Right side of BP2 interface. This is for legacy

support and the Sensor Hub BoosterPack.

I2C and SSI are available on the corresponding

BoosterPack 1 interface pins without modification to

the board.

PA6 and PA7 are also used by the onboard radio.

Configure the radio to tri-state these GPIO before

using them on the boosterpack interface.

Page 29

TSW-149-02-S-D

+3V3

+3V3

+5V

+5V

0.1uF0.1uF

0.1uF 0.1uF

GNDGND

GNDGND

X11-1X11-2

X11-3X11-4

X11-5X11-6

X11-7X11-8

X11-9X11-10

X11-11X11-12

X11-13X11-14

X11-15X11-16

X11-17X11-18

X11-19X11-20

X11-21X11-22

X11-23X11-24

X11-25X11-26

X11-27X11-28

X11-29X11-30

X11-31X11-32

X11-33X11-34

X11-35X11-36

X11-37X11-38

X11-39X11-40

X11-41X11-42

X11-43X11-44

X11-45X11-46

X11-47X11-48

X11-49X11-50

X11-51X11-52

X11-53X11-54

X11-55X11-56

X11-57X11-58

X11-59X11-60

X11-61X11-62

X11-63X11-64

X11-65X11-66

X11-67X11-68

X11-69X11-70

X11-71X11-72

X11-73X11-74

X11-75X11-76

X11-77X11-78

X11-79X11-80

X11-81X11-82

X11-83X11-84

X11-85X11-86

X11-87X11-88

X11-89X11-90

X11-91X11-92

X11-93X11-94

X11-95X11-96

X11-97X11-98

C27C28

C29 C30

VREF+/5.5B

TARGET_RESET/2.4D

GND/2.3C

GND/4.1A

GND/2.3C

GND/4.1AGND/2.3C

PB4

PB5

PH0

PH1

PH2

PH3

PC7

PC6

PC5

PC4

PA6

PA7

PG1

PM3

PM2

PM1

PM0

PL0

PL2

PL3

PQ0

PQ1

PK7

PK6

PL4

PB2

PB3

PP2

PP3

PK5

PK4

PL5

PN4

PN5

PG0

PL1

PQ2

PQ3

PN0

PN1

PN2

PN3

PQ4

WAKE/5.5A

PA2

PA3

PA4

PA5

PE0

PE1

PE2

PE3

PE4

PE5

PK0

PK1

PK2

PK3

PD5

PD4

PD7

PD6

PD3

PD1

PD0

PD2

PP0

PP1

PB0

TARGET_VBUS/1.6B

PF4

PF0

PF1

PF2

PF3

PA0

PA1

PP4

PP5

PJ0

PJ1

PM7

PM6

PM5

PM4

A

B

C

D

E

A

B

C

D

E

1 2 3 4 5 6

NOTE: PB0 and PB1 are used in some

configurations with 5V signals especially in USB

Host or OTG mode. Be aware the 5V may be

present on these pins depending on system jumper

configuration

These pins are only 5V tolerant when configured for

USB mode applications.

This is the breadboard connection header.

Samtec TSW-149-08-F-S-RA and TSW-149-09-F-S-RE

can be used together to create a breadboard

connector

see the Users Manual for more information.

Page 30

49.9

49.9

49.4

49.9

330

GND

330

GND

0.1uF0.1uF

GNDGND

0.1uF0.1uF

75

75

GNDGND

75

75

GND

4700pF

1M

1000pF

R21

R22

R23

R24

D4

R30

D3

R31

C16C17

C18C22

P$1

P$1

P$2

P$2

P$3

P$3

P$6

P$6

P$7

P$7

P$8

P$8

P$9

P$9

P$10

P$10

P$11

P$11

P$14

P$14

P$15

P$15

P$16

P$16

P$1

1

P$2

2

P$3

3

P$44P$5

5

P$6

6

P$7

7

P$8

8

R32

R43

CHASSIS

9

CHASSIS

10

RX+

3

RX-

6

TERM1A

4

TERM1B

5

TERM2A

7

TERM2B

8

TX+

1

TX-

2

R45

R46

C31

R47

C1

EN0RXI_N/5.3B

EN0RXI_P/5.3B

EN0TXO_N/5.3B

EN0TXO_P/5.3B

PF4/3.2C PF0/3.2C

MCU_3V3/5.2A

A

B

C

D

E

A

B

C

D

E

1 2 3 4 5 6

U10

U13

U14

For Ethernet example Applications:

LED4 is default configured as Ethernet Link OK

LED3 is default configured as Ethernet TX/RX activity

User may re-configure these pins / LED's for any

application usage.

Place pull up resistors and C16-C17 near TM4C MCU.

Place C18 and C22 near pin 2 and pin 7 of U$10

U10 May be populated with either HX1188FNL or HX1198FNL.

HX1198FNL preferred for best Ethernet performance.

Page 31

+3V3

+5V

GND

0.1uF

2.2uF

0.1uF

GND

330

GND

100k

4.87k 1%

GND

GND

0.1uF 1.0uF 2.2uF

0.1uF 0.1uF 0.1uF 0.1uF

GND

0

0

GND

1M

SWITCH_TACTILE

12pF

12pF

10k

0.1uF

12pF 12pF

SWITCH_TACTILE

GND

MOUNT-HOLE3.2

MOUNT-HOLE3.2

GND

GND

GND

GND GND

TPS2052B_DRB_8

+5V

10k

100k

GND

51

0.1uF

GND

+3V3

100k

TPS73733_DRV_6

OMIT

2k

MOUNT-HOLE3.2

100

CRYATL_32K_SMD

C19

C20

C21

D0

R9

R17

TP3

R25

C4 C14 C15

C40 C41 C42 C43

TP9

TP10

TP11

TP12

R39

TP13

R41

R42

RESET

C44

C45

NC2

P$2

NC4

P$4

OSC0

P$1

OSC1

P$3

R44

C46

C47 C48

WAKE

H4

H6

*EN1

3

*EN2

4

*OC1

8

*OC2

5

EPAD

9

GND

1

IN

2

OUT1

7

OUT2

6

VIAVVIA

V_2

VIA

V_3

VIA

V_4

VIA

V_5

VIA

V_6

U4

JP1

1 2

3 4

5 6

JP2

1

2

JP3

1

2

R35

R36

TP8

R38

C3

R26

EN

4

EPAD

7

GND

3

IN

6

NC

5

NR/FB

2

OUT

1

VIAVVIA

V_2

U5

R48

R49

H1

R51

HIB

P$65

RESET

P$70

WAKE

P$64

EN0RXIN

P$53

EN0RXIP

P$54

EN0TXON

P$56

EN0TXOP

P$57

GND

P$17

GND

P$48

GND

P$55

GND

P$58

GND

P$80

GND

P$114

GNDA

P$10

OSC0

P$88

OSC1

P$89

RBIAS

P$59

VBAT

P$68

VDD

P$7

VDD

P$16

VDD

P$26

VDD

P$28

VDD

P$39

VDD

P$47

VDD

P$51

VDD

P$52

VDD

P$69

VDD

P$79

VDD

P$90

VDD

P$101

VDD

P$113

VDD

P$122

VDDA

P$8

VDDC

P$87

VDDC

P$115

VREFA+

P$9

XOSC0

P$66

XOSC1

P$67

P$1

P$1

P$2

P$2

Y3

TARGET_VBUS/3.2C

TARGET_VBUS/3.2C

DEBUG_VBUS/6.4A

EN0RXI_N

EN0RXI_P

EN0TXO_N

EN0TXO_P

RBIAS

WAKE/3.3D

MCU_3V3/6.2A

MCU_3V3/4.1A

VBUS

VBUS

VBUS

PQ4/3.4D

PD6/3.2B

TARGET_RESET/3.2D

A

B

C

D

E

A

B

C

D

E

1 2 3 4 5 6

Y1

25Mhz

U1G$2

Power Control Jumper:

1) To power from Debug install jumper on pins 5 - 6

2) To power from Target USB install jumper on pins 3 - 4

3) To power from BoosterPack 5V install jumper on pins 1 - 2

This is also the off position if BoosterPack does not

supply power

When powered from BoosterPack TPS2052B does not

provide current limit protection.

When powered by BoosterPack, USB host mode does not

supply power to connected devices

Primary 3.3V regulator

Disconnect JP3 to power device from 3V3 BoosterPack

JP2 can be used to measure MCU current

consumption with a multi-meter.

TPS2052B provides current limit for main 5V power.

Also provides power switching for USB host/OTG modes

For Host/OTG:

PD6 configured as USB0EPEN peripheral function.

PQ4 configure as individual pin interrupt. Indicates

power fault on the USB bus. USB0PFLT peipheral pin

not available due to pin mux and use on BoosterPacks.

USB Host mode does not supply power to devices

when powered from a BoosterPack

For Applications that do not use USB:

Configure PD6 as input with internal pull-down

enabled. Turns off power to TARGET_VBUS

R38 and C3 Used to meet

VBAT rise time requirements

R41 may be removed and precision

reference applied to TP13

Page 32

OMIT

TSW-107-02-S-D

OMIT

+3V3

10k

0.1uF

OMIT

0.1uF 1.0uF

12pF

12pF

0.1uF 0.1uF 0.1uF 0.1uF

+3V3

+3V3

2.2uF

5.6k

OMIT

5.6k

OMIT

5.6k

OMIT

10k

10k

10k

10k

+3V3

0

0

0

0

0

0

0

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

0

+3V3

TPD4S012_DRY_6

5.6k 10k

GND

2k

GND

1M

3300pF

GND

TRST

9

GND

3

NC

5

RESET

10

RTCK

7

TCK

4

TDI

8

TDO

6

TMS

2

VTREF

1

U21

X1-1X1-2

X1-3X1-4

X1-5X1-6

X1-7X1-8

X1-9X1-10

X1-11X1-12

X1-13X1-14

R3

C2

C5 C6

C8

C9

C10 C11 C12 C13

NC2

P$2

NC4

P$4

OSC0

P$1

OSC1

P$3

C7

R12

R13

R14

R1

R2

R4

R5

TP2

TP1

R6

R7

R8

R10

R11

R15

R16

EXTDBG

P3

RESET

P10

GND

P5

GND1

P9

P$7

P7

TCK

P4

TDI

P8

TDO

P6

TMS

P2

VTARGET

P1

R40

HIB

P$33

RESET

P$38

WAKE

P$32

GND0

P$12

GND1

P$27

GND2

P$39

GND3

P$55

GNDA

P$3

GNDX

P$35

OSC0

P$40

OSC1

P$41

PA0

P$17

PA1

P$18

PA2

P$19

PA3

P$20

PA4

P$21

PA5

P$22

PA6

P$23

PA7

P$24

PB0

P$45

PB1

P$46

PB2

P$47

PB3

P$48

PB4

P$58

PB5

P$57

PB6

P$1

PB7

P$4

PC0/TCK

P$52

PC1/TMS

P$51

PC2/TDI

P$50

PC3/TDO

P$49

PC4

P$16

PC5

P$15

PC6

P$14

PC7

P$13

PD0

P$61

PD1

P$62

PD2

P$63

PD3

P$64

PD4

P$43

PD5

P$44

PD6

P$53

PD7

P$10

PE0

P$9

PE1

P$8

PE2

P$7

PE3

P$6

PE4

P$59

PE5

P$60

PF0

P$28

PF1

P$29

PF2

P$30

PF3

P$31

PF4

P$5

VBAT

P$37

VDD0

P$11

VDD1

P$26

VDD2

P$42

VDD3

P$54

VDDA

P$2

VDDC0

P$25

VDDC1

P$56

XOSC0

P$34

XOSC1

P$36

DM

P2

DP

P3

GND

P5

ID

P4

VBUS

P1

D+

1

D-

2

GND

4

ID

3

N.C.

5

VBUS

6

U3

R28 R29

R50

R34

C33

ICDI_TDI

ICDI_TMS

ICDI_TMS

ICDI_TCK

ICDI_TCK

ICDI_TDO

ICDI_TDO

ICDI_RESET

ICDI_RESET

VCP_RXD

VCP_RXD

VCP_RXD

VCP_TXD

VCP_TXD

VCP_TXD

DEBUG_PC1/TMS/SWDIO

DEBUG_PC1/TMS/SWDIO

DEBUG_PC1/TMS/SWDIO

DEBUG_PC1/TMS/SWDIO

DEBUG_PC1/TMS/SWDIO

DEBUG_PC3/TDO/SWO

DEBUG_PC3/TDO/SWO

DEBUG_PC3/TDO/SWO

DEBUG_PC3/TDO/SWO

DEBUG_PC3/TDO/SWO

DEBUG_PC2/TDI

DEBUG_PC2/TDI