Page 1

Tiva™ TM4C123GH6PM

ROM USER’S GUIDE

ROM-TM4C123GH6PM-UG-750

Copyright © 2011-2013

Texas Instruments Incorporated

Page 2

Copyright

Copyright © 2011-2013 Texas Instruments Incorporated. All rights reserved. Tiva and TivaWare are trademarks of Texas Instruments Instruments. ARM

and Thumb are registered trademarks and Cortex is a trademark of ARM Limited. Other names and brands may be claimed as the property of others.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments semicon-

ductor products and disclaimers thereto appears at the end of this document.

Texas Instruments

108 Wild Basin, Suite 350

Austin, TX 78746

www.ti.com/tiva- c

Revision Information

This is version 750 of this document, last updated on April 8, 2013.

2 April 8, 2013

Page 3

Table of Contents

Table of Contents

Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Revision Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Boot Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Serial Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 AES Data Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 Data Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 Analog Comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 Analog to Digital Converter (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 Controller Area Network (CAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7 CRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8 Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9 Floating-Point Unit (FPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9.2 API Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10 GPIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11 Hibernation Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

12 Inter-Integrated Circuit (I2C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

12.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

12.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

13 Interrupt Controller (NVIC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

13.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

13.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

14 Memory Protection Unit (MPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

14.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

14.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

15 Pulse Width Modulator (PWM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

April 8, 2013 3

Page 4

Table of Contents

15.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

15.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

16 Quadrature Encoder (QEI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

16.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

16.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

17 Synchronous Serial Interface (SSI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

17.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

17.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

18 System Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

18.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

18.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

19 System Exception Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

19.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

19.2 API Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

20 System Tick (SysTick) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

20.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

20.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

21 Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

21.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

21.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

22 UART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

22.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

22.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

23 uDMA Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

23.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

23.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

24 USB Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

24.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

24.2 Using USB with the uDMA Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

24.3 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

25 Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

25.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

25.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

IMPORTANT NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

4 April 8, 2013

Page 5

1 Introduction

The TM4C123GH6PM ROM contains the TivaWare™ Peripheral Driver Library and the TivaWare

Boot Loader. The peripheral driver library can be utilized by applications to reduce their flash

footprint, allowing the flash to be used for other purposes (such as additional features in the application). The boot loader is used as an initial program loader (when the flash is empty) as well as

an application-initiated firmware upgrade mechanism (by calling back to the boot loader).

There is a table at the beginning of the ROM that points to the entry points for the APIs that are

provided in the ROM. Accessing the API through these tables provides scalability; while the API

locations may change in future versions of the ROM, the API tables will not. The tables are split

into two levels; the main table contains one pointer per peripheral which points to a secondary table

that contains one pointer per API that is associated with that peripheral. The main table is located

at 0x0100.0010, right after the Cortex-M4 vector table in the ROM.

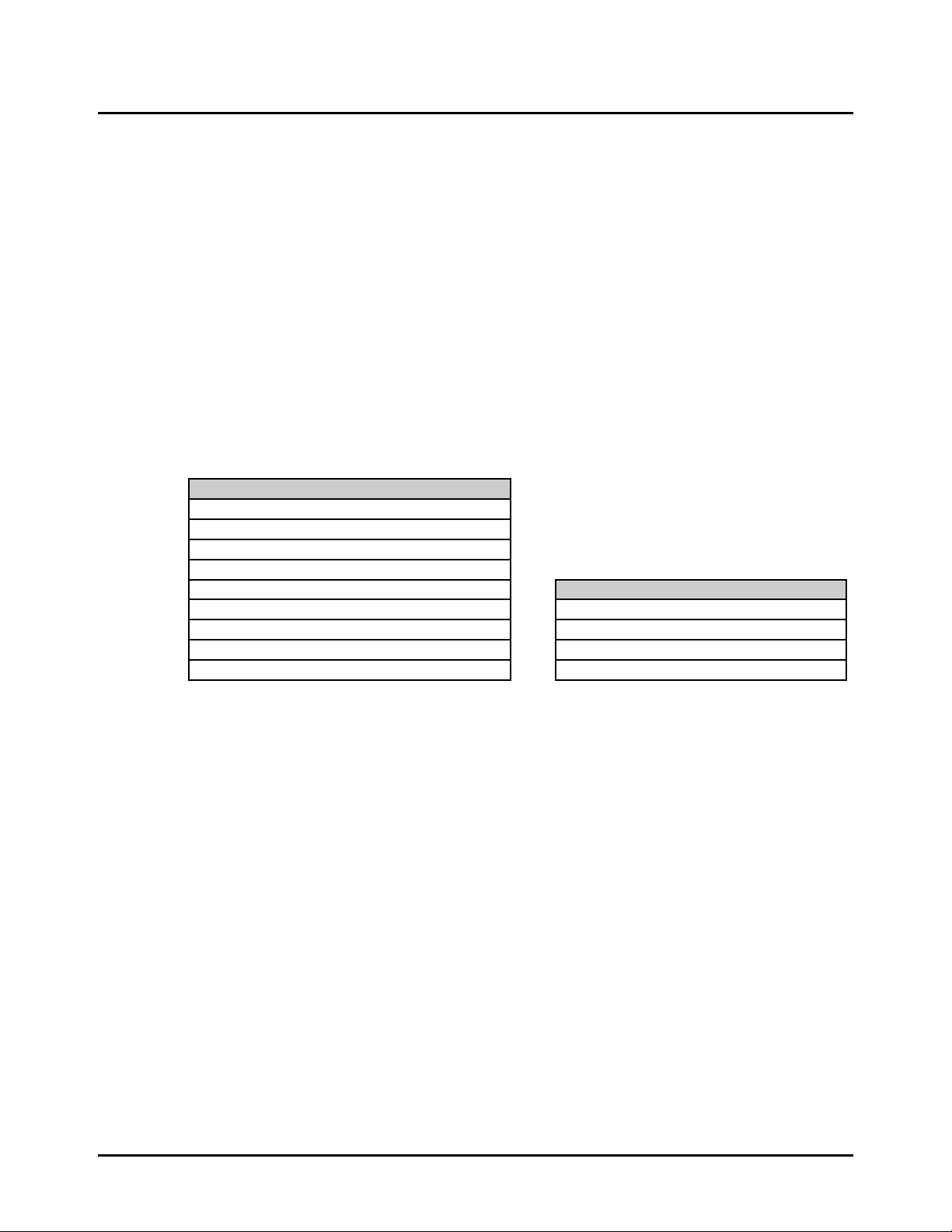

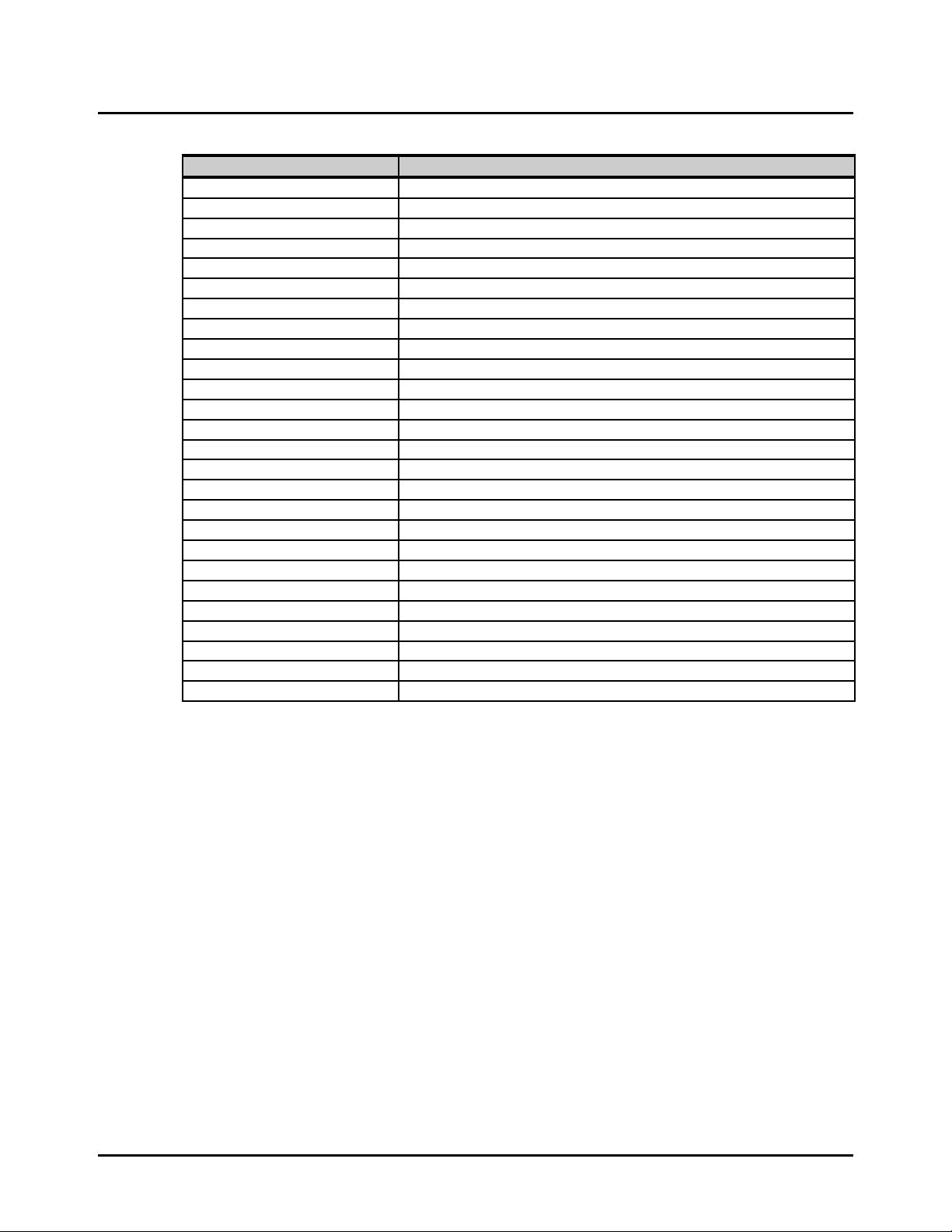

The following table shows a small portion of the API tables in a graphical form that helps to illustrate

the arrangement of the tables:

ROM_APITABLE (at 0x0100.0010)

[0] = ROM_VERSION

[1] = pointer to ROM_UARTTABLE

[2] = pointer to ROM_SSITABLE

[3] = pointer to ROM_I2CTABLE

[4] = pointer to ROM_GPIOTABLE =⇒ ROM_GPIOTABLE

[5] = pointer to ROM_ADCTABLE [0] = pointer to ROM_GPIOPinWrite

[6] = pointer to ROM_COMPARATORTABLE [1] = pointer to ROM_GPIODirModeSet

[7] = pointer to ROM_FLASHTABLE [2] = pointer to ROM_GPIODirModeGet

... ...

Introduction

From this, the address of the ROM_GPIOTABLE table is located in the memory location at

0x0100.0020. The address of the ROM_GPIODirModeSet() function is contained at offset 0x4

from that table. In the function documentation, this is represented as:

ROM_APITABLE is an array of pointers located at 0x0100.0010.

ROM_GPIOTABLE is an array of pointers located at ROM_APITABLE[4].

ROM_GPIODirModeSet is a function pointer located at ROM_GPIOTABLE[1].

The TivaWare Peripheral Driver Library contains a file called driverlib/rom.h that assists with

calling the peripheral driver library functions in the ROM. The naming conventions for the tables

and APIs that are used in this document match those used in that file.

The following is an example of calling the ROM_GPIODirModeSet() function:

#define TARGET_IS_BLIZZARD_RB1

#include <stdbool.h>

#include <stdint.h>

#include "inc/hw_memmap.h"

#include "driverlib/gpio.h"

#include "driverlib/rom.h"

int

main(void)

{

// ...

April 8, 2013 5

Page 6

Introduction

ROM_GPIODirModeSet(GPIO_PORTA_BASE, GPIO_PIN_0, GPIO_DIR_MODE_OUT);

// ....

}

See the “Using the ROM” chapter of the TivaWare Peripheral Driver Library User’s Guide for more

details on calling the ROM functions and using driverlib/rom.h.

The API provided by the ROM can be utilized by any compiler so long as it complies with the

Embedded Applications Binary Interface (EABI), which includes all recent compilers for the CortexM4 microcontroller.

Documentation Overview

The ROM-based TivaWare Boot Loader is described in chapter 2, and the ROM-based TivaWare

Peripheral Driver Library is described in chapters 3 through 25.

6 April 8, 2013

Page 7

2 Boot Loader

Introduction . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . 7

Serial Interfaces . . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .7

USB . . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . 12

2.1 Introduction

The ROM-based boot loader is executed each time the device is reset when the flash is empty.

The flash is assumed to be empty if the first two words are all ones (since the second word is the

reset vector address, it must be programmed for an application in flash to execute). When run, it

will allow the flash to be updated using one of the following interfaces:

UART0 using a custom serial protocol

SSI0 using a custom serial protocol

I2C0 using a custom serial protocol

USB using DFU protocol

The USB portion of the boot loader must run with the main PLL enabled which requires not only

that the boot loader detect if a crystal is present, but also determine the frequency of the attached

crystal to properly configure the main PLL. This crystal detection algorithm is only run when the

boot loader does not find a valid application and is not run when the boot loader is called from an

application. The device is configured to run from the PLL when there is a valid external crystal for

USB operation as specified in the data sheet.

Boot Loader

The LM Flash Programmer GUI can be used to download an application via the boot loader over

the UART or USB interface on a PC. The LM Flash Programmer utility is available for download

from www.ti.com/tiva-c.

2.2 Serial Interfaces

The serial interfaces used to communicate with the boot loader share a common protocol and differ

only in the physical connections and signaling used to transfer the bytes of the protocol.

2.2.1 UART Interface

The UART pins U0Tx and U0Rx are used to communicate with the boot loader. The device communicating with the boot loader is responsible for driving the U0Rx pin, while the microcontroller

drives the U0Tx pin.

The serial data format is fixed at 8 data bits, no parity, and one stop bit. An auto-baud feature is

used to determine the baud rate at which data is transmitted. Because the system clock must be at

least 32 times the baud rate, the maximum baud rate that can be used is 500 Kbaud (which is 16

MHz divided by 32).

When an application calls back to the ROM-based boot loader to start an update over the UART

port, the auto-baud feature is bypassed, along with UART configuration and pin configuration.

April 8, 2013 7

Page 8

Boot Loader

Therefore, the UART must be configured and the UART pins switched to their hardware function

before calling the boot loader.

2.2.2 SSI Interface

The SSI pins SSIFss, SSIClk, SSITx, and SSIRx are used to communicate with the boot loader.

The device communicating with the boot loader is responsible for driving the SSIRx, SSIClk, and

SSIFss pins, while the microcontroller drives the SSITx pin.

The serial data format is fixed to the Motorola format with SPH set to 1 and SPO set to 1 (see the

data sheet for more information on this format). Since the system clock must be at least 12 times

the serial clock rate, the maximum serial clock rate that can be used is 1.3 MHz (which is 16 MHz

divided by 12).

When an application calls back to the ROM-based boot loader to start an update over the SSI port,

the SSI configuration and pin configuration is bypassed. Therefore, the SSI port must be configured

and the SSI pins switched to their hardware function before calling the boot loader.

2.2.3 I2C Interface

The I2C pins I2CSCL and I2CSDA are used to communicate with the boot loader. The device

communicating with the boot loader must operate as the I2C master and provide the I2CSCL signal.

The I2CSDA pin is open-drain and can be driven by either the master or the slave I2C device.

The I2C interface can run at up to 400 KHz, the maximum rate supported by the I2C protocol. The

boot loader uses an I2C slave address of 0x42.

When an application calls back to the ROM-based boot loader to start an update over the I2C port,

the I2C configuration and pin configuration is bypassed. Therefore, the I2C port must be configured,

the I2C slave address set, and the I2C pins switched to their hardware function before calling the

boot loader. Additionally, the I2C master must be enabled since it is used to detect start and stop

conditions on the I2C bus.

2.2.4 Serial Protocol

The boot loader uses well-defined packets on the serial interfaces to ensure reliable communications with the update program. The packets are always acknowledged or not acknowledged by the

communicating devices. The packets use the same format for receiving and sending packets. This

includes the method used to acknowledge successful or unsuccessful reception of a packet. While

the actual signaling on the serial ports is different, the packet format remains independent of the

method of transporting the data.

The following steps must be performed to successfully send a packet:

1. Send the size of the packet that will be sent to the device. The size is always the number of

bytes of data + 2 bytes.

2. Send the checksum of the data buffer to help ensure proper transmission of the command.

The checksum is simply a sum of the data bytes.

3. Send the actual data bytes.

8 April 8, 2013

Page 9

Boot Loader

4. Wait for a single-byte acknowledgment from the device that it either properly received the data

or that it detected an error in the transmission.

The following steps must be performed to successfully receive a packet:

1. Wait for non-zero data to be returned from the device. This is important as the device may

send zero bytes between a sent and received data packet. The first non-zero byte received

will be the size of the packet that is being received.

2. Read the next byte which will be the checksum for the packet.

3. Read the data bytes from the device. There will be packet size - 2 bytes of data sent during

the data phase. For example, if the packet size was 3, then there is only 1 byte of data to be

received.

4. Calculate the checksum of the data bytes and ensure that it matches the checksum received

in the packet.

5. Send an acknowledge (ACK) or not-acknowledge (NAK) to the device to indicate the successful or unsuccessful reception of the packet.

An acknowledge packet is sent whenever a packet is successfully received and verified by the boot

loader. A not-acknowledge packet is sent whenever a sent packet is detected to have an error,

usually as a result of a checksum error or just malformed data in the packet. This allows the sender

to re-transmit the previous packet.

The following commands are used by the custom protocol:

COMMAND_PING

= 0x20

This command is used to receive an acknowledge from the boot

loader indicating that communication has been established. This

command is a single byte.

The format of the command is as follows:

uint8_t pui8Command[1];

pui8Command[0] = COMMAND_PING;

April 8, 2013 9

Page 10

Boot Loader

COMMAND_DOWNLOAD

= 0x21

This command is sent to the boot loader to indicate where

to store data and how many bytes will be sent by the

COMMAND_SEND_DATA commands that follow. The command

consists of two 32-bit values that are both transferred MSB first.

The first 32-bit value is the address to start programming data

into, while the second is the 32-bit size of the data that will be

sent. This command also triggers a mass erase of the flash,

which causes the command to take longer to send the ACK/NAK

in response to the command. This command should be followed

by a COMMAND_GET_STATUS to ensure that the program address and program size were valid for the microcontroller running

the boot loader.

The format of the command is as follows:

uint8_t pui8Command[9];

pui8Command[0] = COMMAND_DOWNLOAD;

pui8Command[1] = Program Address [31:24];

pui8Command[2] = Program Address [23:16];

pui8Command[3] = Program Address [15:8];

pui8Command[4] = Program Address [7:0];

pui8Command[5] = Program Size [31:24];

pui8Command[6] = Program Size [23:16];

pui8Command[7] = Program Size [15:8];

pui8Command[8] = Program Size [7:0];

COMMAND_RUN

= 0x22

This command is sent to the boot loader to transfer execution

control to the specified address. The command is followed by a

32-bit value, transferred MSB first, that is the address to which

execution control is transferred.

The format of the command is as follows:

uint8_t pui8Command[5];

pui8Command[0] = COMMAND_RUN;

pui8Command[1] = Run Address [31:24];

pui8Command[2] = Run Address [23:16];

pui8Command[3] = Run Address [15:8];

pui8Command[4] = Run Address [7:0];

10 April 8, 2013

Page 11

Boot Loader

COMMAND_GET_STATUS

= 0x23

COMMAND_SEND_DATA

= 0x24

This command returns the status of the last command that was

issued. Typically, this command should be received after every

command is sent to ensure that the previous command was successful or, if unsuccessful, to properly respond to a failure. The

command requires one byte in the data of the packet and the

boot loader should respond by sending a packet with one byte of

data that contains the current status code.

The format of the command is as follows:

uint8_t pui8Command[1];

pui8Command[0] = COMMAND_GET_STATUS;

The following are the definitions for the possible status

values that can be returned from the boot loader when

COMMAND_GET_STATUS is sent to the the microcontroller.

COMMAND_RET_SUCCESS

COMMAND_RET_UNKNOWN_CMD

COMMAND_RET_INVALID_CMD

COMMAND_RET_INVALID_ADD

COMMAND_RET_FLASH_FAIL

This command should only follow a COMMAND_DOWNLOAD command or another COMMAND_SEND_DATA command, if more data

is needed. Consecutive send data commands automatically increment the address and continue programming from the previous location. The transfer size is limited by the maximum size of

a packet, which allows up to 252 data bytes to be transferred at a

time. The command terminates programming once the number

of bytes indicated by the COMMAND_DOWNLOAD command has

been received. Each time this function is called, it should be

followed by a COMMAND_GET_STATUS command to ensure that

the data was successfully programmed into the flash. If the boot

loader sends a NAK to this command, the boot loader will not increment the current address which allows for retransmission of

the previous data.

The format of the command is as follows:

uint8_t pui8Command[9];

pui8Command[0] = COMMAND_SEND_DATA

pui8Command[1] = Data[0];

pui8Command[2] = Data[1];

pui8Command[3] = Data[2];

pui8Command[4] = Data[3];

pui8Command[5] = Data[4];

pui8Command[6] = Data[5];

pui8Command[7] = Data[6];

pui8Command[8] = Data[7];

April 8, 2013 11

Page 12

Boot Loader

COMMAND_RESET

= 0x25

The definitions for these commands are provided as part of the Tiva Peripheral Driver Library, in

boot_loader/bl_commands.h.

This command is used to tell the boot loader to reset. This is

used after downloading a new image to the microcontroller to

cause the new application to start from a reset. The normal boot

sequence occurs and the image runs as if from a hardware reset.

It can also be used to reset the boot loader if a critical error

occurs and the host device wants to restart communication with

the boot loader.

The boot loader responds with an ACK signal to the host device

before actually executing the software reset on the microcontroller running the boot loader. This informs the updater application that the command was received successfully and the part

will be reset.

The format of the command is as follows:

uint8_t pui8Command[1];

pui8Command[0] = COMMAND_RESET;

2.3 USB Interface

The USB boot loader allows programming the flash over USB using the standard USB DFU update

method. To use the USB boot loader, the system running the boot loader must be capable of acting

as a USB device and have the proper USB B or USB AB connector. The boot loader does not support firmware update of systems which operate solely as USB hosts. The USB update mechanism

allows the boot loader to either be called from a functioning application or from startup when no

firmware has been downloaded to the microcontroller. When the USB boot loader is called from an

application, the application can customize some of the descriptors that are used for enumeration.

This customization option is not available when the microcontroller is being programmed and there

is no application present on the microcontroller.

When the USB boot loader is invoked from a running application, the boot loader reconfigures the

USB controller to publish the required descriptor set for a Device Firmware Upgrade (DFU) class

device and merge in any custom values that the application provides. Before calling the boot loader

from an application, the main application is responsible for the following: enable the main PLL and

configure it as the system clock, enable the USB PLL, enable the USB controller, and enable the

USB D+ and D- pins on the microcontroller. If the main application is already acting as a USB

device, then the application must remove the device from the bus by calling the DriverLib function

ROM_USBDevDisconnect() prior to entering the boot loader.

2.3.1 USB Device Firmware Upgrade Overview

The USB boot loader enumerates as a Device Firmware Upgrade (DFU) class device.

This standard device class specifies a set of class-specific requests and a state machine that can be used to download and flash firmware images to a device and, op-

12 April 8, 2013

Page 13

Boot Loader

tionally, upload the existing firmware image to the USB host. The full specification for

the device class can be downloaded from the USB Implementer’s Forum web site at

http://www.usb.org/developers/devclass_docs#approved.

All communication with the DFU device takes place using the USB control endpoint, endpoint 0. The

device publishes a standard device descriptor with vendor, product, device revisions and strings. It

also publishes a single configuration descriptor and a single interface descriptor where the interface

class of 0xFE indicates an application-specific class and the subclass of 0x01 indicates “Device

Firmware Upgrade”. Attached to the interface descriptor is a DFU Functional Descriptor which

provides information to the host on DFU-specific device capabilities such as whether the device can

perform upload operations and what the maximum transfer size for upload and download operations

is.

DFU functions are initiated by means of a set of class-specific requests. Each request, which follows

the standard USB request format, performs some operation and moves the DFU device between

a series of well-defined states. Additional requests allow the host to query the current state of the

device to determine whether, for example, it is ready to receive the next block of download data.

A DFU device may operation in either “Run Time” mode or “DFU” mode. In “Run Time” mode, the

device publishes the DFU interface and functional descriptors along with any other descriptors that

the device requires for normal operation. However, it is not required to respond to any DFU classspecific requests other than DFU_DETACH which indicates that it should switch to “DFU” mode.

The “Run Time” mode support is not part of the USB boot loader but can be added to a USB

device application to provide simple switching to “DFU” mode. If a main application wishes to

publish DFU descriptors and respond to the DFU_DETACH request, it can cause a switch to “DFU”

mode on receiving a DFU_DETACH request by removing itself from the USB bus using a call to

ROM_USBDevDisconnect() before transferring control to the USB boot loader by making a call

to ROM_UpdateUSB(). Once in “DFU” mode in the boot loader, the device supports all DFU

functionality and can perform upload and download operations as specified in its DFU functional

descriptor.

2.3.2 DFU Requests

Requests supported by the USB boot loader are as follow:

DFU_DNLOAD This OUT request is used to send a block of binary data to the

device. The DFU class specification does not define the content and format of the binary data but typically it is either binary

data to be written to some position in the device’s flash memory or a device-specific command. The request payload size is

constrained by the maximum packet size specified in the DFU

functional descriptor. In this implementation, that maximum is

set to 1024 bytes.

After sending a DFU_DNLOAD request, the host must poll the device status and wait until the state reverts to DNLOAD_IDLE before sending another request. If the host wishes to indicate that

it has finished sending download data, it sends a DFU_DNLOAD

request with a payload length of 0.

April 8, 2013 13

Page 14

Boot Loader

DFU_UPLOAD This IN request is used to request a block of binary data from

the device. The data returned is device-specific but is typically the contents of a region of the device’s flash memory or

a device-specific response to a command previously sent via

a DFU_DNLOAD request. As with DFU_DNLOAD, the maximum

amount of data that can be requested is governed by the maximum packet size specified in the DFU functional descriptor, here

1024 bytes.

DFU_GETSTATUS This IN request allows the host to query the current status of the

DFU device. It is typically used during download operations to

determine when it is safe to send the next block of data. Depending upon the state of the DFU device, this request may also

trigger a state change. During download, for example, the device enters DNLOAD_SYNC state after receiving a block of data

and remains there until the data has been processed and a

DFU_GETSTATUS request is received at which point the state

changes to DNLOAD_IDLE.

DFU_CLRSTATUS This request is used to reset any error condition reported by

the DFU device. If an error is reported via the response to a

DFU_GETSTATUS request, that error condition is cleared when

this request is received and the device returns to IDLE state.

DFU_GETSTATE This IN request is used to query the current state of the device

without triggering any state change. The single byte of data returned indicates the current state of the DFU device.

DFU_ABORT This request cancels any partially complete upload or download

operation and returns the device to IDLE state in preparation for

some other request.

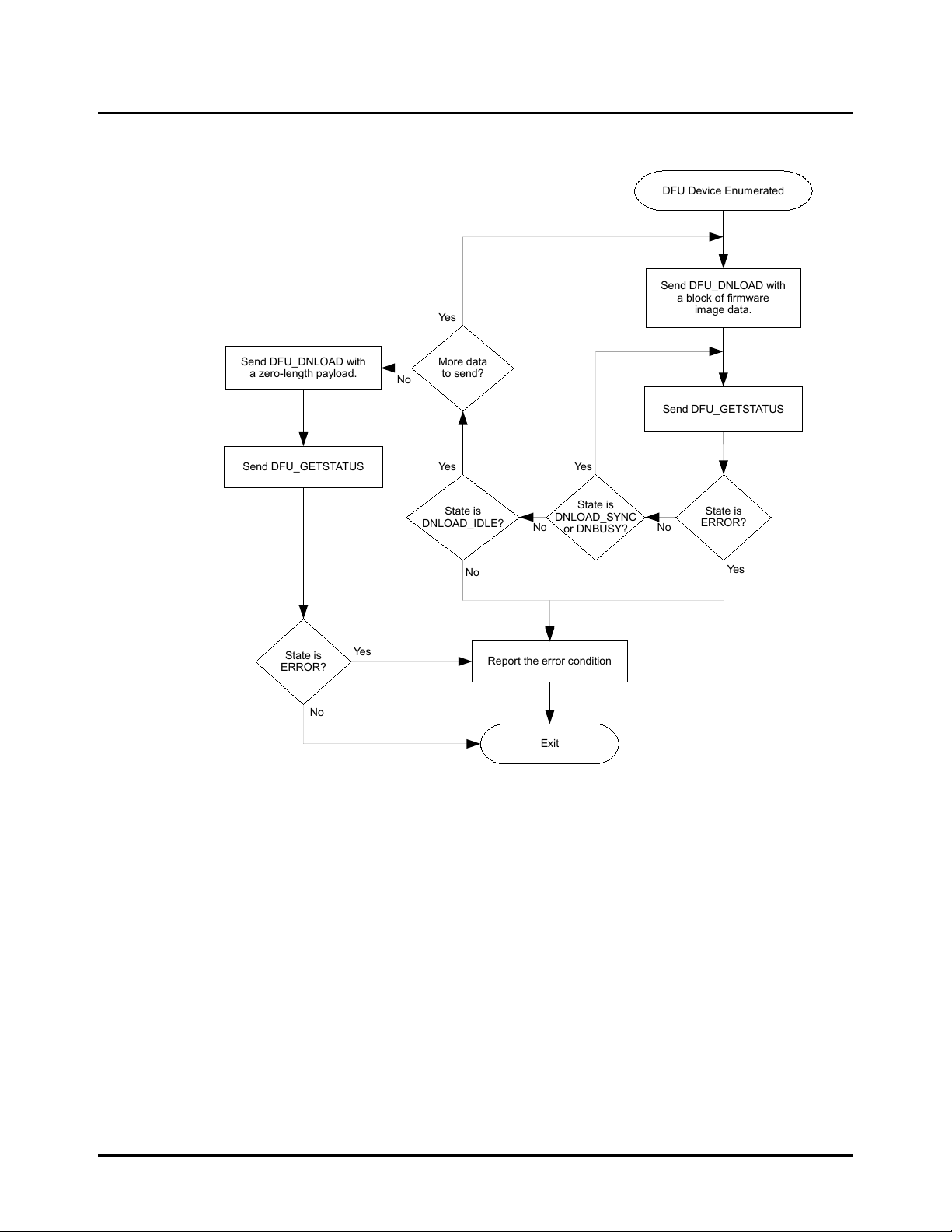

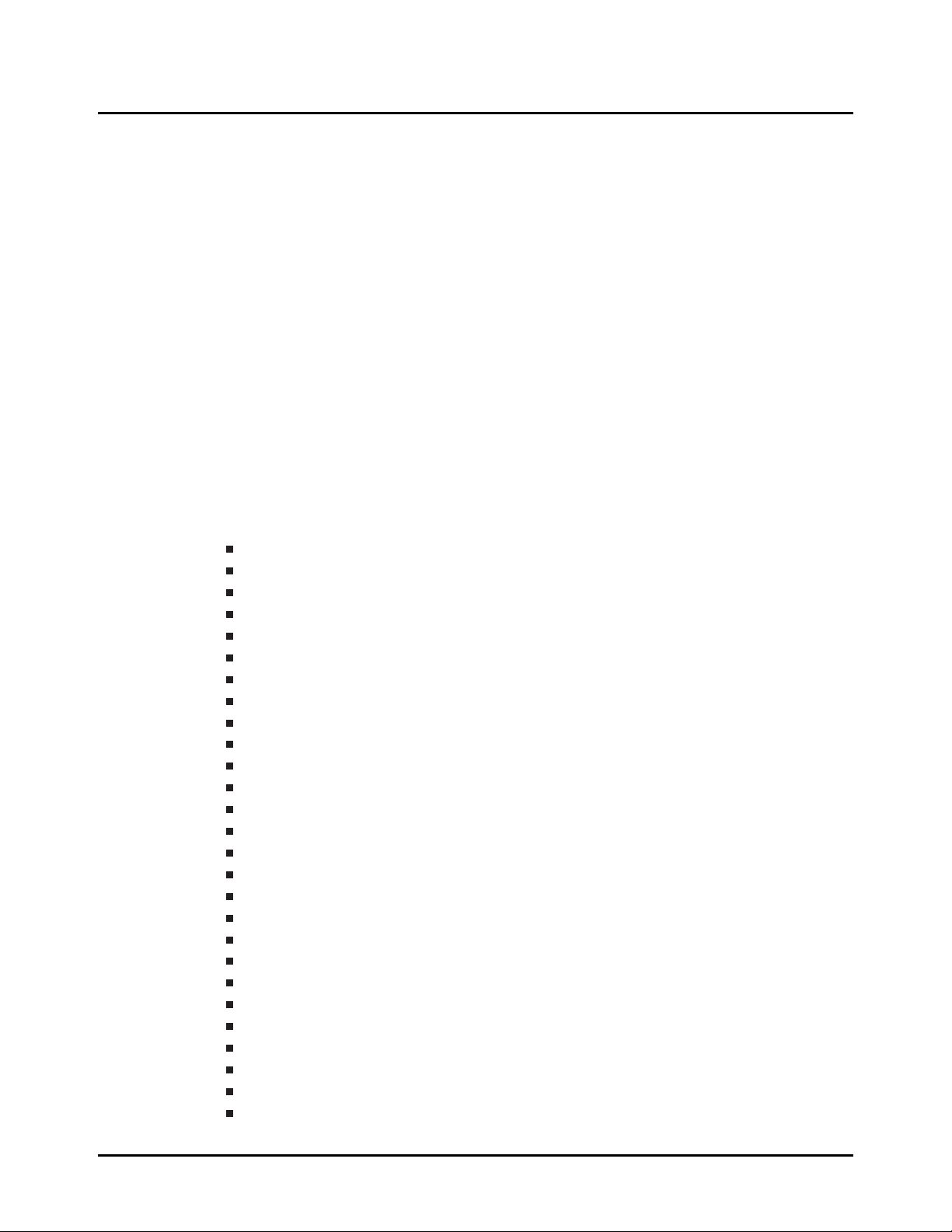

2.3.3 Typical Firmware Download Sequence

The following flow chart illustrates a typical firmware image download sequence from the perspective of the host application.

14 April 8, 2013

Page 15

DFU Device Enumerated

Exit

Send DFU_GETSTATUS

No

Send DFU_DNLOAD with

a block of firmware

image data.

State is

ERROR?

Yes

State is

DNLOAD_SYNC

or DNBUSY?

State is

DNLOAD_IDLE?

More data

to send?

No

No

YesYes

Send DFU_DNLOAD with

a zero-length payload.

Report the error condition

Send DFU_GETSTATUS

Yes

No

State is

ERROR?

Yes

No

Boot Loader

April 8, 2013 15

Page 16

Boot Loader

2.3.4 Tiva-Specific USB Download Commands

The DFU class specification provides the framework necessary to download and upload firmware

files to the USB device but does not specify the actual format of the binary data that is transferred.

As a result, different device implementations have used different methods to perform operations

that are not defined in the standard such as:

Setting the address to flash a downloaded binary.

Setting the address and size of the area of flash with contents to be uploaded.

Erasing sections of the flash.

Querying the size of flash and writeable area addresses.

The USB boot loader implementation employs a small set of commands which can be sent to the

DFU device via a DFU_DNLOAD request when the device is in IDLE state. Each command takes

the form of an 8-byte structure that defines the operation to carry out and provides any required

additional parameters.

To ensure that a host application that does not have explicit support for Tiva-specific commands can

still be used to download binary firmware images to the device, the protocol is defined such that only

a single 8-byte header structure must be placed at the start of the binary image being downloaded.

This header and the DFU-defined suffix structure can both be added using the “dfuwrap” commandline application supplied with TivaWare, thus providing a single binary that can be sent to a device

running the Tiva USB boot loader using a standard sequence of DFU_DNLOAD requests with no

other embedded commands or device-specific operations required. An application which does

understand the Tiva-specific commands may make use of them to offer additional functionality that

would not otherwise be available.

Querying Command Support

Because the device-specific commands defined here are sent to the DFU device in DFU_DNLOAD

requests, the possibility exists that sending them to a device which does not understand the protocol

could result in corruption of that device’s firmware. To guard against this possibility, the USB boot

loader supports an additional USB request which is used to query the device capabilities and allow

a host to determine whether or not the device supports the Tiva commands. A device which does

not support the commands either stalls the request or returns unexpected data.

To determine whether a target DFU device supports the Tiva-specific DFU commands, send the

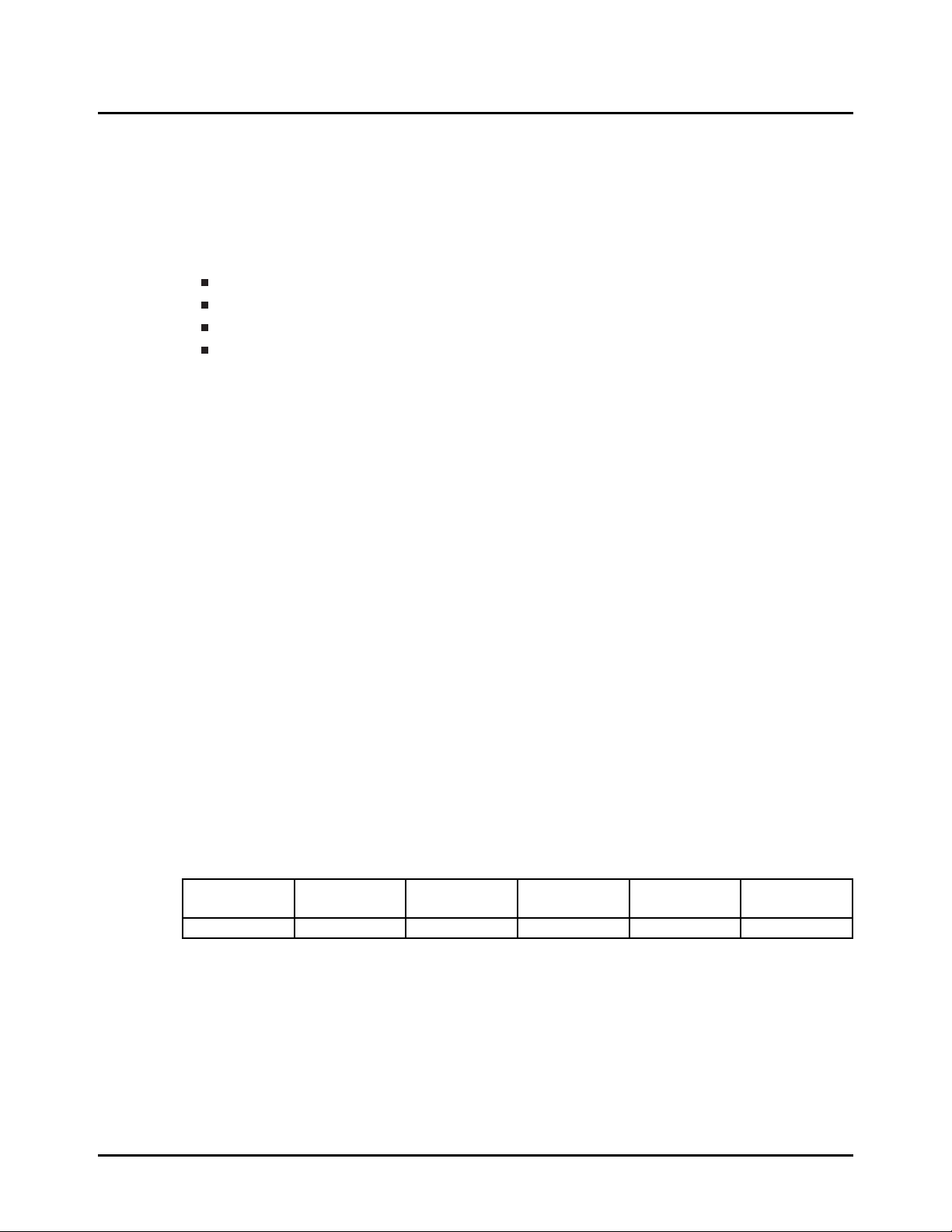

following IN request to the DFU interface:

bmRequestType

10100001b 0x42 0x23 Interface 4 Protocol Info

where the protocol information returned is a 4-byte structure, the first two bytes of which are 0x4D,

0x4C and the second two bytes indicates the protocol version supported, currently 0x01 and 0x00

respectively.

bRequest wValue wIndex wLength Data

Download Command Definitions

The following commands may be sent to the USB boot loader as the first 8 bytes of the payload to

a DFU_DNLOAD request. The boot loader expects any DFU_DNLOAD request received while in the

16 April 8, 2013

Page 17

Boot Loader

IDLE state to contain a command header but does not look for a command unless the state is IDLE.

This protocol allows an application that is unaware of the command header to download a DFUwrapped binary image using a standard sequence of multiple DFU_DNLOAD and DFU_GETSTATUS

requests without the need to insert additional command headers during the download.

The commands defined here and their parameter block structures can be found in header file

usbdfu.h provided with TivaWare. In all cases where multi-byte numbers are specified, the numbers are stored in little-endian format with the least significant byte in the lowest addressed location.

The following definitions specify the command byte ordering unambiguously but care must be taken

to ensure correct byte swapping if using the command structure types defined in usbdfu.h on bigendian systems.

DFU_CMD_PROG This command is used to provide the USB boot loader with the address at which

the next download should be written and the total length of the firmware image

that follows. This structure forms the header that is written to the DFU-wrapped

file generated by the dfuwrap tool.

The start address is provided in terms of 1024-byte flash blocks. To convert a

byte address to a block address, merely divide by 1024. The start address must

always be on a 1024-byte boundary.

This command may be followed by up to 1016 bytes of firmware image data,

this number being the maximum transfer size minus the 8 bytes of the command

structure.

The format of the command is as follows:

uint8_t pui8Data[8];

pui8Data[0] = DFU_CMD_PROG (0x01)

pui8Data[1] = Reserved - set to 0x00

pui8Data[2] = Start Block Number [7:0];

pui8Data[3] = Start Block Number [15:8];

pui8Data[4] = Image Size [7:0];

pui8Data[5] = Image Size [15:8];

pui8Data[6] = Image Size [23:16];

pui8Data[7] = Image Size [31:24];

April 8, 2013 17

Page 18

Boot Loader

DFU_CMD_READ This command is used to set the address range of the content to be returned

on subsequent DFU_UPLOAD requests from the host.

The start address is provided in terms of 1024-byte flash blocks. To convert a

byte address to a block address, divide by 1024. The start address must always

be on a 1024-byte boundary.

To read back a the contents of a region of flash, the host should send a

DFU_DNLOAD request with command DFU_CMD_READ, start address set to the

1KB block start address and length set to the number of bytes to read. The

host should then send one or more DFU_UPLOAD requests to receive the current flash contents from the configured addresses. Data returned includes an

8-byte DFU_CMD_PROG prefix structure unless the prefix has been disabled by

sending a DFU_CMD_BIN command with the bBinary parameter set to 1. The

host should, therefore, be prepared to read 8 bytes more than the length specified in the READ command if the prefix is enabled.

By default, the 8-byte prefix is enabled for all upload operations. This prefix

is required by the DFU class specification which states that uploaded images

must be formatted to allow them to be directly downloaded back to the device

at a later time.

The format of the command is as follows:

uint8_t pui8Data[8];

pui8Data[0] = DFU_CMD_READ (0x02)

pui8Data[1] = Reserved - set to 0x00

pui8Data[2] = Start Block Number [7:0];

pui8Data[3] = Start Block Number [15:8];

pui8Data[4] = Image Size [7:0];

pui8Data[5] = Image Size [15:8];

pui8Data[6] = Image Size [23:16];

pui8Data[7] = Image Size [31:24];

18 April 8, 2013

Page 19

Boot Loader

DFU_CMD_CHECK This command is used to check a region of flash to ensure that it is completely

erased.

The start address is provided in terms of 1024-byte flash blocks. To convert a

byte address to a block address, divide by 1024. The start address must always

be on a 1024-byte boundary. The length must also be a multiple of 4.

To check that a region of flash is erased, the DFU_CMD_CHECK command

should be sent with the required start address and region length set then the

host should issue a DFU_GETSTATUS request. If the erase check was successful, the returned bStatus value is OK (0x00), otherwise it is errCheckErased

(0x05).

The format of the command is as follows:

uint8_t pui8Data[8];

pui8Data[0] = DFU_CMD_CHECK (0x03)

pui8Data[1] = Reserved - set to 0x00

pui8Data[2] = Start Block Number [7:0];

pui8Data[3] = Start Block Number [15:8];

pui8Data[4] = Region Size [7:0];

pui8Data[5] = Region Size [15:8];

pui8Data[6] = Region Size [23:16];

pui8Data[7] = Region Size [31:24];

DFU_CMD_ERASE This command is used to erase a region of flash.

The start address is provided in terms of 1024-byte flash blocks. To convert a

byte address to a block address, divide by 1024. The start address must always

be on a 1024-byte boundary. The length must also be a multiple of 4.

The size of the region to erase is expressed in terms of flash blocks. The block

size can be determined using the DFU_CMD_INFO command.

The format of the command is as follows:

uint8_t pui8Data[8];

pui8Data[0] = DFU_CMD_ERASE (0x04)

pui8Data[1] = Reserved - set to 0x00

pui8Data[2] = Start Block Number [7:0];

pui8Data[3] = Start Block Number [15:8];

pui8Data[4] = Number of Blocks [7:0];

pui8Data[5] = Number of Blocks [15:8];

pui8Data[6] = Reserved - set to 0x00

pui8Data[7] = Reserved - set to 0x00

April 8, 2013 19

Page 20

Boot Loader

DFU_CMD_INFO This command is used to query information relating to the target de-

vice and programmable region of flash. The device information structure,

tDFUDeviceInfo, is returned on the next DFU_UPLOAD request following this

command.

The format of the command is as follows:

uint8_t pui8Data[8];

pui8Data[0] = DFU_CMD_INFO (0x05)

pui8Data[1] = Reserved - set to 0x00

pui8Data[2] = Reserved - set to 0x00

pui8Data[3] = Reserved - set to 0x00

pui8Data[4] = Reserved - set to 0x00

pui8Data[5] = Reserved - set to 0x00

pui8Data[6] = Reserved - set to 0x00

pui8Data[7] = Reserved - set to 0x00

//

*******************************************************************

//

// Payload returned in response to the DFU_CMD_INFO command.

//

// This is structure is returned in response to the first DFU_UPLOAD

// request following a DFU_CMD_INFO command. Note that byte ordering

// of multi-byte fields is little-endian.

//

//

*******************************************************************

typedef struct

{

//

// The size of a flash block in bytes.

//

uint16_t ui16FlashBlockSize;

//

// The number of blocks of flash in the device. Total

// flash size is usNumFlashBlocks*usFlashBlockSize.

//

uint16_t ui16NumFlashBlocks;

//

// Information on the part number, family, version and

// package as read from SYSCTL register DID1.

//

uint32_t ui32PartInfo;

//

// Information on the part class and revision as read

// from SYSCTL DID0.

//

uint32_t ui32ClassInfo;

//

// Address 1 byte above the highest location the boot

// loader can access.

//

uint32_t ui32FlashTop;

//

// Lowest address the boot loader can write or erase.

//

uint32_t ui32AppStartAddr;

}

PACKED tDFUDeviceInfo;

20 April 8, 2013

Page 21

Boot Loader

DFU_CMD_BIN By default, data returned in response to a DFU_UPLOAD request includes an

8-byte DFU_CMD_PROG prefix structure. This ensures that an uploaded image

can be directly downloaded again without the need to further wrap it but, in

cases where pure binary data is required, can be awkward. The DFU_CMD_BIN

command allows the upload prefix to be disabled or enabled under host control.

The format of the command is as follows:

uint8_t pui8Data[8];

pui8Data[0] = DFU_CMD_BIN (0x06)

pui8Data[1] = 0x01 to disable upload prefix, 0x00 to enable

pui8Data[2] = Reserved - set to 0x00

pui8Data[3] = Reserved - set to 0x00

pui8Data[4] = Reserved - set to 0x00

pui8Data[5] = Reserved - set to 0x00

pui8Data[6] = Reserved - set to 0x00

pui8Data[7] = Reserved - set to 0x00

DFU_CMD_RESET This command may be sent to the USB boot loader to cause it to perform a

soft reset of the board. This reboots the system and, assuming that the main

application image is present, runs the main application. Note that a reboot also

takes place if a firmware download operation completes and the host issues a

USB reset to the DFU device.

The format of the command is as follows:

uint8_t pui8Data[8];

pui8Data[0] = DFU_CMD_RESET (0x07)

pui8Data[1] = Reserved - set to 0x00

pui8Data[2] = Reserved - set to 0x00

pui8Data[3] = Reserved - set to 0x00

pui8Data[4] = Reserved - set to 0x00

pui8Data[5] = Reserved - set to 0x00

pui8Data[6] = Reserved - set to 0x00

pui8Data[7] = Reserved - set to 0x00

2.3.5 Customizing the USB Device Firmware Upgrade

The USB boot loader provides a method to pass a set of custom values to the boot loader when

called from a running application. When the USB boot loader is entered because the flash was

empty, the boot ROM offers no customization and provides generic “Texas Instruments” and “Device

Firmware Update” strings to the host as identifiers. The USB boot loader is called by an application

via a call to ROM_UpdateUSB(), which takes a single pointer as an argument that is a pointer to

an array containing the values that the boot loader uses for customization. This pointer can also be

0 to indicate that the application wishes to use the defaults provided by the ROM boot loader. The

application can place the customization structure anywhere in flash or SRAM.

April 8, 2013 21

Page 22

Boot Loader

The actual values that can be customized are the following:

Vendor ID (default 0x1CBE)

Product ID (default 0x00FF)

Bus/Self Power (default Self Powered)

Max Power (default 0)

Device Version (default 0x110)

All strings in multiple languages

The defaults for the strings are a Manufacturer set to “Texas Instruments”, Product set to “Device

Firmware Update”, and serial number set to “1.0”.

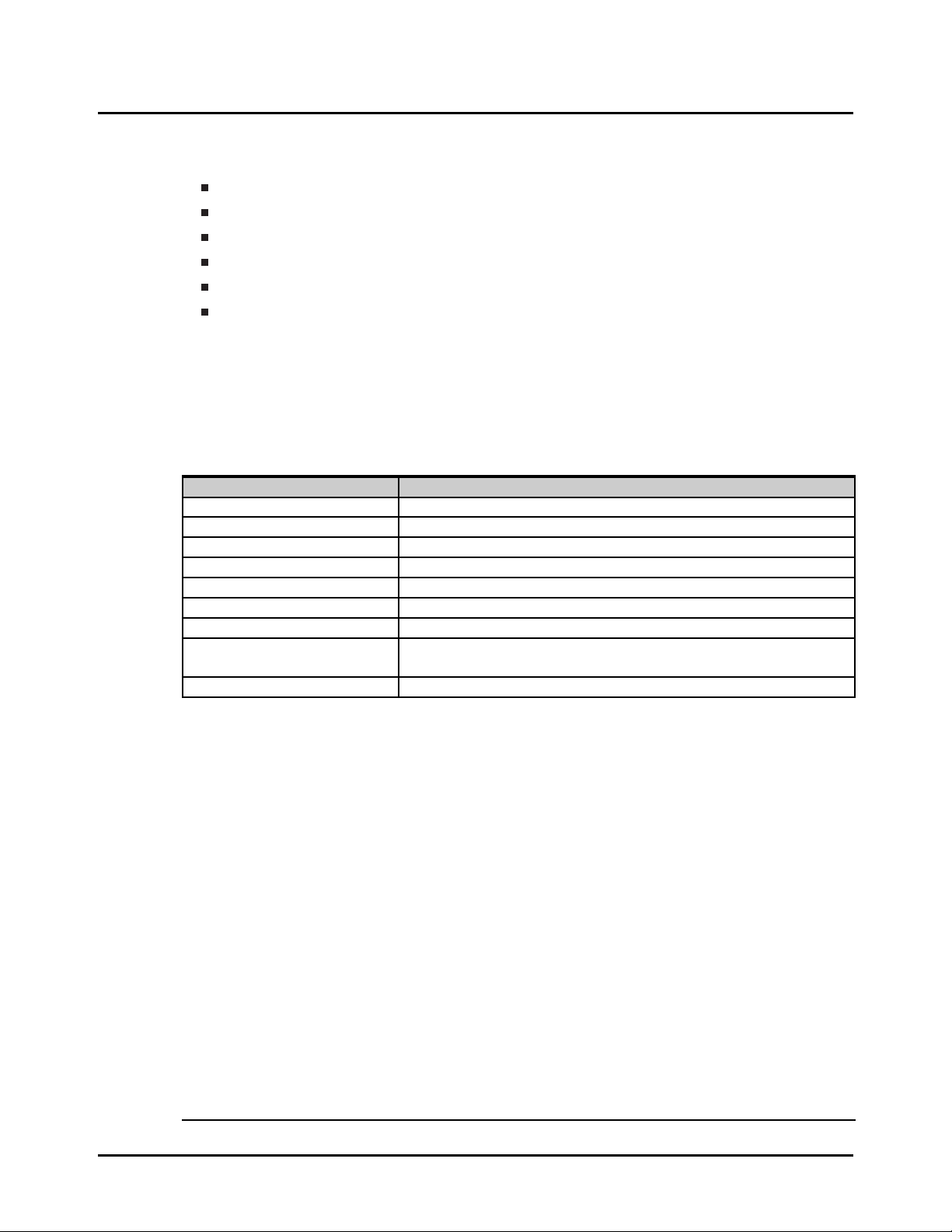

If the application is providing a structure to the boot loader with custom values, then the first 12

bytes must contain valid data. The values in the structure that is passed to the boot loader have the

following meaning and are merged directly to the device and configuration descriptor for the boot

loader:

Byte Value

0 VID bits 7:0

1 VID bits 15:8

2 PID bits 7:9

3 PID bits 15:8

4 Device Version(BCD) bits 7:9

5 Device Version(BCD) bits 15:8

6 Power in 2mA Increments(250 maximum)

7 USB Configuration Descriptor bmAttributes (Self powered 0xC0,

Bus powered 0x80).

8-11 Pointer to the string table

The values for the custom strings are contained in a pointer at the end of the structure passed to

the boot loader. If the application wants to use the default strings, this pointer should be set to 0.

The string table provided supports custom strings for Manufacturer, Product, and Serial Number in

multiple languages. The string table is optimized to not require that a string be provided for every

language in case there is not a unique string for every language. This is most likely the case for the

Serial Number string but it could be any string that is provided.

The string table has a header that describes the number of languages provided and the language

identifiers for each followed by a set of strings for each language. Each entry in the table has a size

header that specifies the size of the string in bytes plus a byte for the size itself and a one byte tag

of USB_DTYPE_STRING(0x03). This size and ID padding is included for ease of string handling in

the boot loader and is required. It is very important for the application to provide the correct size

values because the boot loader uses these to skip through the array and find the requested strings

requested by the USB host. If these sizes are incorrect, the boot loader may fail to enumerate, so

care should be taken when building the string table. The application must provide all three strings

in the first language because these strings are treated as the default if a string is left blank in

other languages. In other languages, a string can be left blank for strings that do not change per

language. A blank entry in the table consists of a two byte entry with a byte size value of 2 followed

by the USB_DTYPE_STRING value.

The string table has the following format:

22 April 8, 2013

Page 23

Byte Description

0 Size of the header(Number of Languages * 2) + 2

1 USB_DTYPE_STRING

2 Language ID 0 bits[7:0]

3 Language ID 0 bits[15:8]

... ...

. Language ID n bits[7:0]

. Language ID n bits[15:8]

. Language 0 Manufacturer string size in bytes + 2

. USB_DTYPE_STRING

. Language 0 Manufacturer Unicode String

. Language 0 Product string size in bytes + 2

. USB_DTYPE_STRING

. Language 0 Product Unicode String

. Language 0 Serial Number size in bytes + 2

. USB_DTYPE_STRING

. Language 0 Serial Number Unicode String

... ...

. Language n Manufacturer string size in bytes + 2

. USB_DTYPE_STRING

. Language n Manufacturer Unicode String

. Language n Product string size in bytes + 2

. USB_DTYPE_STRING

. Language n Product Unicode String

. Language n Serial Number size in bytes + 2

. USB_DTYPE_STRING

. Language n Serial Number Unicode String

Boot Loader

The next three examples show an example customization structure for a no string case, a single

language case and a multiple language case.

Example: No strings but custom descriptor.

uint8_t pui8USBBootROMInfo[] =

{

0xbe, 0x1c, // TI VID

0xff, 0x00, // Tiva DFU PID

0x00, 0x02, // USB version 2.0

0x00, // 0mA of Bus power

0xC0, // Self powered using no bus power

0 // Address of the string table

}

//

// Call to ROM USB boot loader.

//

ROM_UpdateUSB(pui8USBBootROMInfo);

Example: Single US English string set.

April 8, 2013 23

Page 24

Boot Loader

uint8_t pui8Strings[] =

{

(1*2) + 2, // One Language (1*2) + 2

USB_DTYPE_STRING,

0x09, 0x04, // Language code for US English.

(17*2) + 2, // Size of Manufacturer String.

// "Texas Instruments"

USB_DTYPE_STRING,

’T’, 0, ’e’, 0, ’x’, 0, ’a’, 0, ’s’, 0, ’ ’, 0, ’I’, 0, ’n’, 0,

’s’, 0, ’t’, 0, ’r’, 0, ’u’, 0, ’m’, 0, ’e’, 0, ’n’, 0, ’t’, 0,

’s’, 0,

(23*2) + 2, // Size of Product String.

USB_DTYPE_STRING,

// "Device Firmware Upgrade"

’D’, 0, ’e’, 0, ’v’, 0, ’i’, 0, ’c’, 0, ’e’, 0, ’ ’, 0, ’F’, 0,

’i’, 0, ’r’, 0, ’m’, 0, ’w’, 0, ’a’, 0, ’r’, 0, ’e’, 0, ’ ’, 0,

’U’, 0, ’p’, 0, ’g’, 0, ’r’, 0, ’a’, 0, ’d’, 0, ’e’, 0,

(3*2) + 2, // Size of Serial Number.

USB_DTYPE_STRING,

// "1.0"

’1’, 0, ’.’, 0, ’0’, 0

};

uint8_t pui8USBBootROMInfo[] =

{

0xbe, 0x1c, // TI VID

0xff, 0x00, // Tiva DFU PID

0x00, 0x02, // USB version 2.0

0x00, // 0mA of Bus power

0xC0, // Self powered using no bus power

pui8Strings // Address of the string table

}

//

// Call to ROM USB boot loader.

//

ROM_UpdateUSB(pui8USBBootROMInfo);

Example: Two Languages with English(United States) and Spanish(Mexico) strings.

uint8_t pui8Strings[] =

{

(2*2) + 2, // Two languages

USB_DTYPE_STRING,

0x09, 0x04, // Language code for English(United States).

0x0a, 0x08, // Language code for Spanish(Mexico)

(10*2) + 2, // Size of Manufacturer String.

24 April 8, 2013

Page 25

Boot Loader

// "My Company"

USB_DTYPE_STRING,

’M’, 0, ’y’, 0, ’ ’, 0, ’C’, 0, ’o’, 0, ’m’, 0, ’p’, 0, ’a’, 0,

’n’, 0, ’y’, 0

(23*2) + 2, // Size of Product String.

USB_DTYPE_STRING,

// "Device Firmware Upgrade"

’D’, 0, ’e’, 0, ’v’, 0, ’i’, 0, ’c’, 0, ’e’, 0, ’ ’, 0, ’F’, 0,

’i’, 0, ’r’, 0, ’m’, 0, ’w’, 0, ’a’, 0, ’r’, 0, ’e’, 0, ’ ’, 0,

’U’, 0, ’p’, 0, ’g’, 0, ’r’, 0, ’a’, 0, ’d’, 0, ’e’, 0,

(4*2) + 2, // Size of Serial Number.

USB_DTYPE_STRING,

// "1.01"

’1’, 0, ’.’, 0, ’0’, 0, ’1’, 0

(10*2) + 2, // Size of Manufacturer String.

USB_DTYPE_STRING,

// "My Company"

’M’, 0, ’y’, 0, ’ ’, 0, ’C’, 0, ’o’, 0, ’m’, 0, ’p’, 0, ’a’, 0,

’n’, 0, ’y’, 0

’s’, 0,

(25*2) + 2, // Size of Product String.

USB_DTYPE_STRING,

// "Actualizacion de Firmware"

’A’, 0, ’c’, 0, ’t’, 0, ’u’, 0, ’a’, 0, ’l’, 0, ’i’, 0, ’z’, 0,

’a’, 0, ’c’, 0, ’i’, 0, ’o’, 0, ’n’, 0, ’ ’, 0, ’d’, 0, ’e’, 0,

’ ’, 0, ’F’, 0, ’i’, 0, ’r’, 0, ’m’, 0, ’w’, 0, ’a’, 0, ’r’, 0,

’e’, 0,

2, // Size of Serial Number, this will use the last

// serial number found since this represents a null

// string.

USB_DTYPE_STRING,

};

uint8_t pui8USBBootROMInfo[] =

{

0xbe, 0x1c, // TI VID

0xff, 0x00, // Tiva DFU PID

250, // 500mA of Bus power

0x80, // Bus Powered

0x00, 0x02, // USB version 2.0

pui8Strings // Address of the string table

};

//

// Call to ROM USB boot loader.

//

ROM_UpdateUSB(pui8USBBootROMInfo);

April 8, 2013 25

Page 26

Boot Loader

26 April 8, 2013

Page 27

3 AES Data Tables

Introduction . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . . . . 27

Functions . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .27

3.1 Introduction

The Advanced Encryption Standard (AES) is a publicly defined encryption standard used by the

U.S. Government. It is a strong encryption method with reasonable performance and size. AES

is fast in both hardware and software, is fairly easy to implement, and requires little memory. AES

is ideal for applications that can use pre-arranged keys, such as setup during manufacturing or

configuration.

Four data tables used by the XySSL AES implementation are provided in the ROM. The first is

the forward S-box substitution table, the second is the reverse S-box substitution table, the third is

the forward polynomial table, and the final is the reverse polynomial table. The meanings of these

tables and their use can be found in the AES code provided in TivaWare.

AES Data Tables

3.2 Data Structures

Data Structures

ROM_pvAESTable

3.2.1 Data Structure Documentation

3.2.1.1 ROM_pvAESTable

This structure describes the AES tables that are available in the ROM.

ROM Location:

ROM_APITABLE is an array of pointers located at 0x0100.0010.

ROM_SOFTWARETABLE is an array of pointers located at ROM_APITABLE[21].

ROM_pvAESTable is an array located at &ROM_SOFTWARETABLE[7].

Definition:

typedef struct

{

unsigned char ucForwardSBox[256];

unsigned long ulForwardTable[256];

unsigned char ucReverseSBox[256];

unsigned long ulReverseTable[256];

}

ROM_pvAESTable

Members:

ucForwardSBox This table contains the forward S-Box, as defined by the AES standard.

April 8, 2013 27

Page 28

AES Data Tables

ulForwardTable This table contains the forward polynomial table, as used by the XySSL AES

implementation.

ucReverseSBox This table contains the reverse S-Box, as defined by the AES standard. This

is simply the reverse of ucForwardSBox.

ulReverseTable This table contains the reverse polynomial table, as used by the XySSL AES

implementation.

28 April 8, 2013

Page 29

4 Analog Comparator

Introduction . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . . . . 29

Functions . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .29

4.1 Introduction

The comparator API provides a set of functions for dealing with the analog comparators. A comparator can compare a test voltage against individual external reference voltage, a shared single

external reference voltage, or a shared internal reference voltage. It can provide its output to a

device pin, acting as a replacement for an analog comparator on the board, or it can be used to

signal the application via interrupts or triggers to the ADC to cause it to start capturing a sample

sequence. The interrupt generation and ADC triggering logic is separate, so that an interrupt can

be generated on a rising edge and the ADC triggered on a falling edge (for example).

4.2 Functions

Analog Comparator

Functions

void ROM_ComparatorConfigure (uint32_t ui32Base, uint32_t ui32Comp, uint32_t ui32Config)

void ROM_ComparatorIntClear (uint32_t ui32Base, uint32_t ui32Comp)

void ROM_ComparatorIntDisable (uint32_t ui32Base, uint32_t ui32Comp)

void ROM_ComparatorIntEnable (uint32_t ui32Base, uint32_t ui32Comp)

bool ROM_ComparatorIntStatus (uint32_t ui32Base, uint32_t ui32Comp, bool bMasked)

void ROM_ComparatorRefSet (uint32_t ui32Base, uint32_t ui32Ref)

bool ROM_ComparatorValueGet (uint32_t ui32Base, uint32_t ui32Comp)

4.2.1 Function Documentation

4.2.1.1 ROM_ComparatorConfigure

Configures a comparator.

Prototype:

void

ROM_ComparatorConfigure(uint32_t ui32Base,

uint32_t ui32Comp,

uint32_t ui32Config)

ROM Location:

ROM_APITABLE is an array of pointers located at 0x0100.0010.

ROM_COMPARATORTABLE is an array of pointers located at ROM_APITABLE[6].

ROM_ComparatorConfigure is a function pointer located at ROM_COMPARATORTABLE[1].

April 8, 2013 29

Page 30

Analog Comparator

Parameters:

Description:

ui32Base is the base address of the comparator module.

ui32Comp is the index of the comparator to configure.

ui32Config is the configuration of the comparator.

This function configures a comparator. The ui32Config parameter is the result of a logical

OR operation between the COMP_TRIG_xxx, COMP_INT_xxx, COMP_ASRCP_xxx, and

COMP_OUTPUT_xxx values.

The COMP_TRIG_xxx term can take on the following values:

COMP_TRIG_NONE to have no trigger to the ADC.

COMP_TRIG_HIGH to trigger the ADC when the comparator output is high.

COMP_TRIG_LOW to trigger the ADC when the comparator output is low.

COMP_TRIG_FALL to trigger the ADC when the comparator output goes low.

COMP_TRIG_RISE to trigger the ADC when the comparator output goes high.

COMP_TRIG_BOTH to trigger the ADC when the comparator output goes low or high.

The COMP_INT_xxx term can take on the following values:

COMP_INT_HIGH to generate an interrupt when the comparator output is high.

COMP_INT_LOW to generate an interrupt when the comparator output is low.

COMP_INT_FALL to generate an interrupt when the comparator output goes low.

COMP_INT_RISE to generate an interrupt when the comparator output goes high.

COMP_INT_BOTH to generate an interrupt when the comparator output goes low or high.

The COMP_ASRCP_xxx term can take on the following values:

COMP_ASRCP_PIN to use the dedicated Comp+ pin as the reference voltage.

COMP_ASRCP_PIN0 to use the Comp0+ pin as the reference voltage (this the same as

COMP_ASRCP_PIN for the comparator 0).

COMP_ASRCP_REF to use the internally generated voltage as the reference voltage.

The COMP_OUTPUT_xxx term can take on the following values:

COMP_OUTPUT_NORMAL to enable a non-inverted output from the comparator to a

device pin.

COMP_OUTPUT_INVERT to enable an inverted output from the comparator to a device

pin.

Returns:

None.

4.2.1.2 ROM_ComparatorIntClear

Clears a comparator interrupt.

Prototype:

void

ROM_ComparatorIntClear(uint32_t ui32Base,

uint32_t ui32Comp)

30 April 8, 2013

Page 31

Analog Comparator

ROM Location:

ROM_APITABLE is an array of pointers located at 0x0100.0010.

ROM_COMPARATORTABLE is an array of pointers located at ROM_APITABLE[6].

ROM_ComparatorIntClear is a function pointer located at ROM_COMPARATORTABLE[0].

Parameters:

ui32Base is the base address of the comparator module.

ui32Comp is the index of the comparator.

Description:

The comparator interrupt is cleared, so that it no longer asserts. This function must be called in

the interrupt handler to keep the handler from being called again immediately upon exit. Note

that for a level-triggered interrupt, the interrupt cannot be cleared until it stops asserting.

Note:

Because there is a write buffer in the Cortex-M4 processor, it may take several clock cycles

before the interrupt source is actually cleared. Therefore, it is recommended that the interrupt

source be cleared early in the interrupt handler (as opposed to the very last action) to avoid

returning from the interrupt handler before the interrupt source is actually cleared. Failure to

do so may result in the interrupt handler being immediately reentered (because the interrupt

controller still sees the interrupt source asserted).

Returns:

None.

4.2.1.3 ROM_ComparatorIntDisable

Disables the comparator interrupt.

Prototype:

void

ROM_ComparatorIntDisable(uint32_t ui32Base,

ROM Location:

ROM_APITABLE is an array of pointers located at 0x0100.0010.

ROM_COMPARATORTABLE is an array of pointers located at ROM_APITABLE[6].

ROM_ComparatorIntDisable is a function pointer located at ROM_COMPARATORTABLE[5].

Parameters:

ui32Base is the base address of the comparator module.

ui32Comp is the index of the comparator.

Description:

This function disables generation of an interrupt from the specified comparator. Only comparators whose interrupts are enabled can be reflected to the processor.

Returns:

None.

uint32_t ui32Comp)

April 8, 2013 31

Page 32

Analog Comparator

4.2.1.4 ROM_ComparatorIntEnable

Enables the comparator interrupt.

Prototype:

void

ROM_ComparatorIntEnable(uint32_t ui32Base,

ROM Location:

ROM_APITABLE is an array of pointers located at 0x0100.0010.

ROM_COMPARATORTABLE is an array of pointers located at ROM_APITABLE[6].

ROM_ComparatorIntEnable is a function pointer located at ROM_COMPARATORTABLE[4].

Parameters:

ui32Base is the base address of the comparator module.

ui32Comp is the index of the comparator.

Description:

This function enables generation of an interrupt from the specified comparator. Only comparators whose interrupts are enabled can be reflected to the processor.

Returns:

None.

uint32_t ui32Comp)

4.2.1.5 ROM_ComparatorIntStatus

Gets the current interrupt status.

Prototype:

bool

ROM_ComparatorIntStatus(uint32_t ui32Base,

ROM Location:

ROM_APITABLE is an array of pointers located at 0x0100.0010.

ROM_COMPARATORTABLE is an array of pointers located at ROM_APITABLE[6].

ROM_ComparatorIntStatus is a function pointer located at ROM_COMPARATORTABLE[6].

Parameters:

ui32Base is the base address of the comparator module.

ui32Comp is the index of the comparator.

bMasked is false if the raw interrupt status is required and true if the masked interrupt status

is required.

Description:

This returns the interrupt status for the comparator. Either the raw or the masked interrupt

status can be returned.

uint32_t ui32Comp,

bool bMasked)

Returns:

true if the interrupt is asserted and false if it is not asserted.

32 April 8, 2013

Page 33

4.2.1.6 ROM_ComparatorRefSet

Sets the internal reference voltage.

Prototype:

void

ROM_ComparatorRefSet(uint32_t ui32Base,

ROM Location:

ROM_APITABLE is an array of pointers located at 0x0100.0010.

ROM_COMPARATORTABLE is an array of pointers located at ROM_APITABLE[6].

ROM_ComparatorRefSet is a function pointer located at ROM_COMPARATORTABLE[2].

Parameters:

ui32Base is the base address of the comparator module.

ui32Ref is the desired reference voltage.

Description:

This function sets the internal reference voltage value. The voltage is specified as one of the

following values:

COMP_REF_OFF to turn off the reference voltage

COMP_REF_0V to set the reference voltage to 0 V

COMP_REF_0_1375V to set the reference voltage to 0.1375 V

COMP_REF_0_275V to set the reference voltage to 0.275 V

COMP_REF_0_4125V to set the reference voltage to 0.4125 V

COMP_REF_0_55V to set the reference voltage to 0.55 V

COMP_REF_0_6875V to set the reference voltage to 0.6875 V

COMP_REF_0_825V to set the reference voltage to 0.825 V

COMP_REF_0_928125V to set the reference voltage to 0.928125 V

COMP_REF_0_9625V to set the reference voltage to 0.9625 V

COMP_REF_1_03125V to set the reference voltage to 1.03125 V

COMP_REF_1_134375V to set the reference voltage to 1.134375 V

COMP_REF_1_1V to set the reference voltage to 1.1 V

COMP_REF_1_2375V to set the reference voltage to 1.2375 V

COMP_REF_1_340625V to set the reference voltage to 1.340625 V

COMP_REF_1_375V to set the reference voltage to 1.375 V

COMP_REF_1_44375V to set the reference voltage to 1.44375 V

COMP_REF_1_5125V to set the reference voltage to 1.5125 V

COMP_REF_1_546875V to set the reference voltage to 1.546875 V

COMP_REF_1_65V to set the reference voltage to 1.65 V

COMP_REF_1_753125V to set the reference voltage to 1.753125 V

COMP_REF_1_7875V to set the reference voltage to 1.7875 V

COMP_REF_1_85625V to set the reference voltage to 1.85625 V

COMP_REF_1_925V to set the reference voltage to 1.925 V

COMP_REF_1_959375V to set the reference voltage to 1.959375 V

COMP_REF_2_0625V to set the reference voltage to 2.0625 V

COMP_REF_2_165625V to set the reference voltage to 2.165625 V

Analog Comparator

uint32_t ui32Ref)

April 8, 2013 33

Page 34

Analog Comparator

COMP_REF_2_26875V to set the reference voltage to 2.26875 V

COMP_REF_2_371875V to set the reference voltage to 2.371875 V

Returns:

None.

4.2.1.7 ROM_ComparatorValueGet

Gets the current comparator output value.

Prototype:

bool

ROM_ComparatorValueGet(uint32_t ui32Base,

ROM Location:

ROM_APITABLE is an array of pointers located at 0x0100.0010.

ROM_COMPARATORTABLE is an array of pointers located at ROM_APITABLE[6].

ROM_ComparatorValueGet is a function pointer located at ROM_COMPARATORTABLE[3].

Parameters:

ui32Base is the base address of the comparator module.

ui32Comp is the index of the comparator.

uint32_t ui32Comp)

Description:

This function retrieves the current value of the comparator output.

Returns:

Returns true if the comparator output is high and false if the comparator output is low.

34 April 8, 2013

Page 35

Analog to Digital Converter (ADC)

5 Analog to Digital Converter (ADC)

Introduction . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . . . . 35

Functions . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .. . . . . . .. . . . . . .. . . . .. . . .. . .. . . . .35

5.1 Introduction

The analog to digital converter (ADC) API provides a set of functions for dealing with the ADC.

Functions are provided to configure the sample sequencers, read the captured data, register a

sample sequence interrupt handler, and handle interrupt masking/clearing.

The ADC supports twelve input channels plus an internal temperature sensor. Four sampling sequences, each with configurable trigger events, can be captured. The first sequence will capture up

to eight samples, the second and third sequences will capture up to four samples, and the fourth

sequence will capture a single sample. Each sample can be the same channel, different channels,

or any combination in any order.

The sample sequences have configurable priorities that determine the order in which they are captured when multiple triggers occur simultaneously. The highest priority sequence that is currently

triggered will be sampled. Care must be taken with triggers that occur frequently (such as the

“always” trigger); if their priority is too high it is possible to starve the lower priority sequences.

Hardware oversampling of the ADC data is available for improved accuracy. An oversampling factor of 2x, 4x, 8x, 16x, 32x, and 64x is supported, but reduces the throughput of the ADC by a

corresponding factor. Hardware oversampling is applied uniformly across all sample sequences.

5.2 Functions

Functions

void ROM_ADCComparatorConfigure (uint32_t ui32Base, uint32_t ui32Comp, uint32_t

ui32Config)

void ROM_ADCComparatorIntClear (uint32_t ui32Base, uint32_t ui32Status)

void ROM_ADCComparatorIntDisable (uint32_t ui32Base, uint32_t ui32SequenceNum)

void ROM_ADCComparatorIntEnable (uint32_t ui32Base, uint32_t ui32SequenceNum)

uint32_t ROM_ADCComparatorIntStatus (uint32_t ui32Base)

void ROM_ADCComparatorRegionSet (uint32_t ui32Base, uint32_t ui32Comp, uint32_t

ui32LowRef, uint32_t ui32HighRef)

void ROM_ADCComparatorReset (uint32_t ui32Base, uint32_t ui32Comp, bool bTrigger, bool

bInterrupt)

void ROM_ADCHardwareOversampleConfigure (uint32_t ui32Base, uint32_t ui32Factor)

void ROM_ADCIntClear (uint32_t ui32Base, uint32_t ui32SequenceNum)

void ROM_ADCIntDisable (uint32_t ui32Base, uint32_t ui32SequenceNum)

void ROM_ADCIntEnable (uint32_t ui32Base, uint32_t ui32SequenceNum)

uint32_t ROM_ADCIntStatus (uint32_t ui32Base, uint32_t ui32SequenceNum, bool bMasked)

uint32_t ROM_ADCPhaseDelayGet (uint32_t ui32Base)

April 8, 2013 35

Page 36

Analog to Digital Converter (ADC)

void ROM_ADCPhaseDelaySet (uint32_t ui32Base, uint32_t ui32Phase)

void ROM_ADCProcessorTrigger (uint32_t ui32Base, uint32_t ui32SequenceNum)

uint32_t ROM_ADCReferenceGet (uint32_t ui32Base)

void ROM_ADCReferenceSet (uint32_t ui32Base, uint32_t ui32Ref)

void ROM_ADCSequenceConfigure (uint32_t ui32Base, uint32_t ui32SequenceNum, uint32_t

ui32Trigger, uint32_t ui32Priority)

int32_t ROM_ADCSequenceDataGet (uint32_t ui32Base, uint32_t ui32SequenceNum,

uint32_t ∗pui32Buffer)

void ROM_ADCSequenceDisable (uint32_t ui32Base, uint32_t ui32SequenceNum)

void ROM_ADCSequenceEnable (uint32_t ui32Base, uint32_t ui32SequenceNum)

int32_t ROM_ADCSequenceOverflow (uint32_t ui32Base, uint32_t ui32SequenceNum)

void ROM_ADCSequenceOverflowClear (uint32_t ui32Base, uint32_t ui32SequenceNum)

void ROM_ADCSequenceStepConfigure (uint32_t ui32Base, uint32_t ui32SequenceNum,

uint32_t ui32Step, uint32_t ui32Config)

int32_t ROM_ADCSequenceUnderflow (uint32_t ui32Base, uint32_t ui32SequenceNum)

void ROM_ADCSequenceUnderflowClear (uint32_t ui32Base, uint32_t ui32SequenceNum)

5.2.1 Function Documentation

5.2.1.1 ROM_ADCComparatorConfigure

Configures an ADC digital comparator.

Prototype:

void

ROM_ADCComparatorConfigure(uint32_t ui32Base,

ROM Location:

ROM_APITABLE is an array of pointers located at 0x0100.0010.

ROM_ADCTABLE is an array of pointers located at ROM_APITABLE[5].

ROM_ADCComparatorConfigure is a function pointer located at ROM_ADCTABLE[15].

Parameters:

ui32Base is the base address of the ADC module.

ui32Comp is the index of the comparator to configure.

ui32Config is the configuration of the comparator.

Description:

This function will configure a comparator. The ui32Config parameter is the result of a logical

OR operation between the ADC_COMP_TRIG_xxx, and ADC_COMP_INT_xxx values.

The ADC_COMP_TRIG_xxx term can take on the following values:

uint32_t ui32Comp,

uint32_t ui32Config)

ADC_COMP_TRIG_NONE to never trigger PWM fault condition.

ADC_COMP_TRIG_LOW_ALWAYS to always trigger PWM fault condition when ADC out-

put is in the low-band.

ADC_COMP_TRIG_LOW_ONCE to trigger PWM fault condition once when ADC output

transitions into the low-band.

36 April 8, 2013

Page 37

Analog to Digital Converter (ADC)

ADC_COMP_TRIG_LOW_HALWAYS to always trigger PWM fault condition when ADC

output is in the low-band only if ADC output has been in the high-band since the last

trigger output.

ADC_COMP_TRIG_LOW_HONCE to trigger PWM fault condition once when ADC output

transitions into low-band only if ADC output has been in the high-band since the last trigger

output.

ADC_COMP_TRIG_MID_ALWAYS to always trigger PWM fault condition when ADC output is in the mid-band.

ADC_COMP_TRIG_MID_ONCE to trigger PWM fault condition once when ADC output

transitions into the mid-band.

ADC_COMP_TRIG_HIGH_ALWAYS to always trigger PWM fault condition when ADC output is in the high-band.

ADC_COMP_TRIG_HIGH_ONCE to trigger PWM fault condition once when ADC output

transitions into the high-band.

ADC_COMP_TRIG_HIGH_HALWAYS to always trigger PWM fault condition when ADC

output is in the high-band only if ADC output has been in the low-band since the last

trigger output.

ADC_COMP_TRIG_HIGH_HONCE to trigger PWM fault condition once when ADC output

transitions into high-band only if ADC output has been in the low-band since the last trigger

output.

The ADC_COMP_INT_xxx term can take on the following values:

ADC_COMP_INT_NONE to never generate ADC interrupt.

ADC_COMP_INT_LOW_ALWAYS to always generate ADC interrupt when ADC output is

in the low-band.

ADC_COMP_INT_LOW_ONCE to generate ADC interrupt once when ADC output transi-

tions into the low-band.

ADC_COMP__INT_LOW_HALWAYS to always generate ADC interrupt when ADC output

is in the low-band only if ADC output has been in the high-band since the last trigger output.

ADC_COMP_INT_LOW_HONCE to generate ADC interrupt once when ADC output tran-

sitions into low-band only if ADC output has been in the high-band since the last trigger

output.

ADC_COMP_INT_MID_ALWAYS to always generate ADC interrupt when ADC output is

in the mid-band.

ADC_COMP_INT_MID_ONCE to generate ADC interrupt once when ADC output transitions into the mid-band.

ADC_COMP_INT_HIGH_ALWAYS to always generate ADC interrupt when ADC output is

in the high-band.

ADC_COMP_INT_HIGH_ONCE to generate ADC interrupt once when ADC output transitions into the high-band.