查询PT6510供应商

PT6510 Series

8-A 5-V/3.3-V Input Adjustable ISR

with Short-Circuit protection

Description

The PT6510 series of power modules

is the recommended direct replacement

for the PT6500 series in existing designs.

The modules have the same output current rating as the PT6500 series (8 A)

and were designed to be functionally identical in as many aspects as possible. This

includes the input voltage range, on/off

standby control, and output voltage adjustment.

When used as a replacement, a PT6510

series part exhibits a number of performance enhancements over its PT6500

series equivalent. These include improved

power dissipation and efficiency, significantly reduced inrush current, and better

line and load regulation.

The modules are housed in the same

14-Pin SIP (Single In-line Package), and

include the same package options.

Features

• 8-A Rated Output Current

• Replaces PT6500 Series

• High Efficiency (91% for PT6511)

• Small Footprint (0.75 in², Suffix ‘N’)

• Output On/Off Standby Control

• Output Short-Circuit Protection

• Over-Temperature Protection

• Adjustable Output Voltage

• Soft Startup

• 16-pin Mount Option (Suffixes L & F)

Ordering Information

PT6511¨ = 3.3 Volts

† PT6512¨ = 1.5 Volts

PT6513¨ = 2.5 Volts

PT6514¨ = 3.6 Volts

† PT6515¨ = 1.2 Volts

† PT6516¨ = 1.8 Volts

† 3.3V Input Bus Capable

PT Series Suffix

Case/Pin Order Package

Configuration Suffix Code *

Vertical N (EED)

Horizontal A (EEA)

SMD C (EEC)

Horizontal, Top Tab H (EEH)

SMD, 2-Pin Tab L (EEL)

SMD, 2-Pin Ext Tab F (EEF)

Vertical, Side Tab R (EEE)

Horizontal, Side Tab G (EEG)

SMD, Side Tab B (EEK)

* Previously known as package styles 400/410.

(Package availability varies with output voltage option.

Reference the applicable package code drawing for the

dimensions and PC board layout)

(PT1234x)

SLTS220 FEBRUARY 2004

Pin-Out Information

Pin Function

1Vo Sense

2 Do Not Connect

3 STBY*

4V

in

5V

in

6V

in

7 GND

8 GND

9 GND

10 GND

11 V

out

12 V

out

13 V

out

14 V

* For further information, see

application notes.

out

Adjust

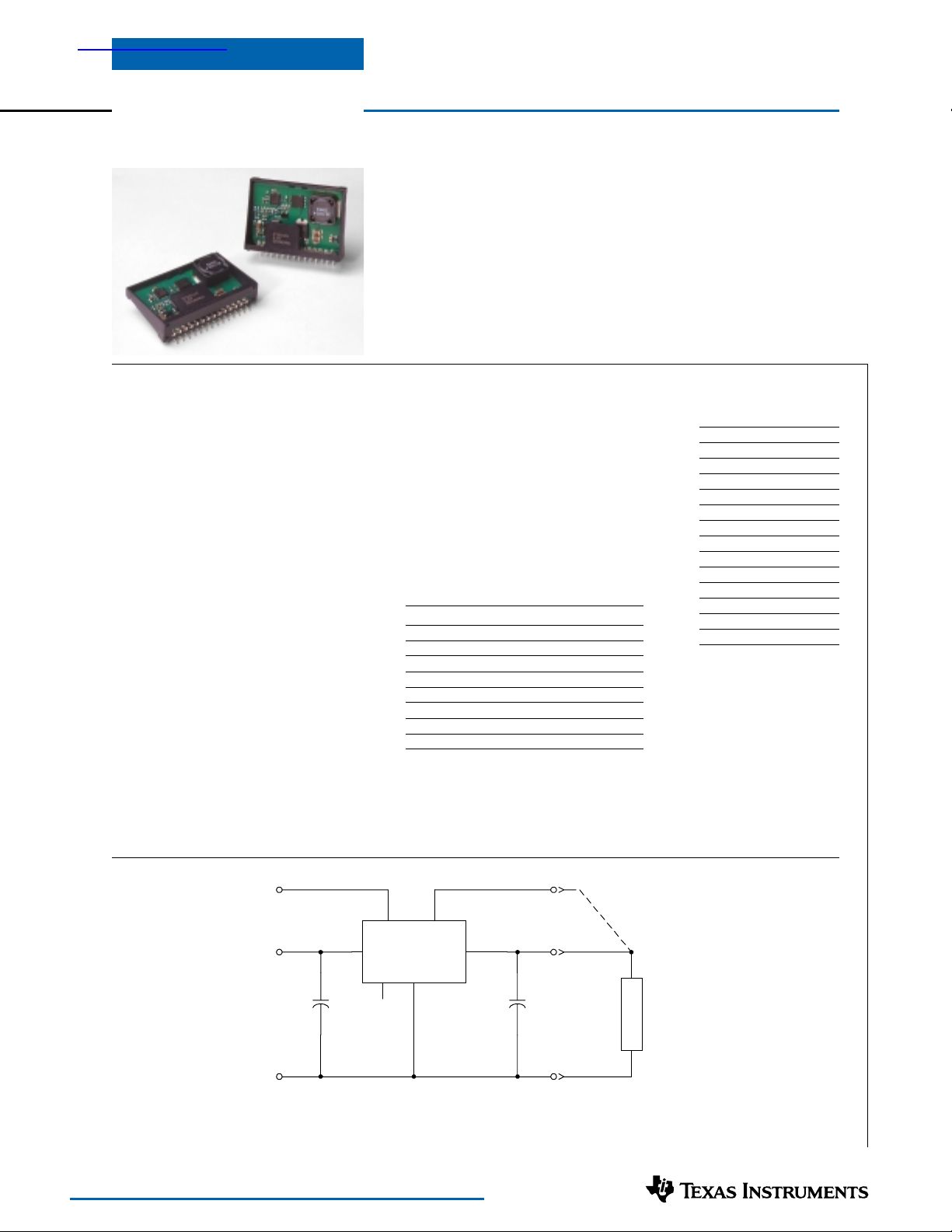

Standard Application

VoADJ

V

IN

C

COM

For technical support or further information, visit http://power.ti.com

4,5,6

+

IN

14

PT6510

7–10

3

SENSE

V

o

1

V

11,12,13

C

OUT

OUT

+

COM

L

O

A

D

Cin= Required 330 µF electrolytic capacitor.

C

= Required 330 µF electrolytic capacitor.

out

PT6510 Series

8-A 5-V/3.3-V Input Adjustable ISR

with Short-Circuit protection

Specifications (Unless otherwise stated, T

=25 °C, Vin =5 V, Cin =330 µF, C

a

=330 µF, and Io =Iomax)

out

SLTS220 FEBRUARY 2004

PT6510 SERIES

Characteristic Symbol Conditions Min Typ Max Units

Output Current I

Input Voltage Range V

o

in

Over Vin range 0.1

Over Io Range V

≥ 2.5 V 4.5

o

≤ 1.8 V 3.1

V

o

Vo = 3.6 V 4.8

(1)

—8 A

(2)

—6

(2)

— 6 VDC

(2)

—6

Output Voltage Tolerance Vo tol Ta = –40 to +85 °C Vo – 0.1 — Vo + 0. 1 V

Line Regulation Reg

Load Regulation Reg

line

load

Efficiency η I

Vo Ripple (pk-pk) V

r

Over Vin range ±2 — ±10 mV

Over Io range ±2 — ±10 mV

=3 A Vo =3.3 V — 92 —

o

=8 A Vo =3.3 V — 91 —

I

o

Vo =2.5 V — 89 —

=1.8 V — 83 — %

V

o

=1.5 V — 80 —

V

o

Vo =1.2 V — 75 —

=2.5 V — 87 —

V

o

Vo =1.8 V — 81 — %

=1.5 V — 77 —

V

o

Vo =1.2 V — 72 —

20 MHz bandwidth — 15 — mV

Over-Current Threshold Io trip Reset, followed by auto-recovery — 15 — A

Transient Response t

Switching Frequency ƒ

On/Off Standby (Pin 3) Referenced to –Vin (pin 7)

Input High Voltage V

Input Low Voltage V

Input Low Current I

∆V

tr

tr

s

IH

IL

IL

1 A/µs load step, 50 % to 100 % Iomax — 100 — µs

Vo over/undershoot — ±150 — mV

Over Vin and Io range 475 550 725 kHz

— — Open

–0.1 — +0.4

(3)

— –0.5 – mA

Standby Input Current Iin stby Pins 3 & 7 connected — 1 5 mA

External Output Capacitance C

External Input Capacitance C

Operating Temperature Range T

Storage Temperature T

out

in

a

s

Reliability MTBF Per Bellcore TR-332

Mechanical Shock — Per Mil-Std-883D, method 2002.3,

Mechanical Vibration — Per Mil-Std-883D, method 2007.2,

Weight — Suffixes N, A, & C — 12.5 —

See application schematic 330 — 5,000

See application schematic 330

(5)

——µF

Over Vin range –40 — +85

— –40 — +125 °C

50 % stress, Ta =40 °C, ground benign

1 ms, half-sine, mounted to a fixture

20-2000 Hz

Suffixes R, G & B — 16.5 —

Suffix H — 18.5 — grams

Suffix L — 15.5 —

Suffix F — 22 —

6.4 — — 10

— 500 — G’s

—10—G’s

(4)

(6)

Flammability — Materials meet UL 94V-0

Notes: (1) The ISR will operate at no load with reduced specifications.

(2) The minimum input voltage required by the part is V

(3) The STBY* control (pin 3) has an internal pull-up and if it is left open circuit the module will operate when input power is applied. The open-circuit

voltage is the input voltage, Vin. Refer to the application notes for other interface considerations.

(4) The module requires a 330 µF output capacitor for proper operation in all applications. For transient or dynamic load applications, additional output

capacitance (Cout) may be necessary. The maximum allowable output capacitance is 5,000 µF.

(5) In addition, the input capacitance (C

application note on capacitor recommendations.

(6) See Safe Operating Area curves or contact the factory for the appropriate derating.

) must be rated for a minimum of 1.2 Arms ripple current rating. For more information consult the related

in

+ 1.2 V, or 3.1 V, whichever is greater.

out

(7) The tab pins on the 16-pin mount package types (suffix L) must be soldered. For more information see the applicable package outline drawing.

pp

V

µF

°C

6

Hrs

For technical support and further information, visit http://power.ti.com

PT6510 Series

)

)

)

)

)

)

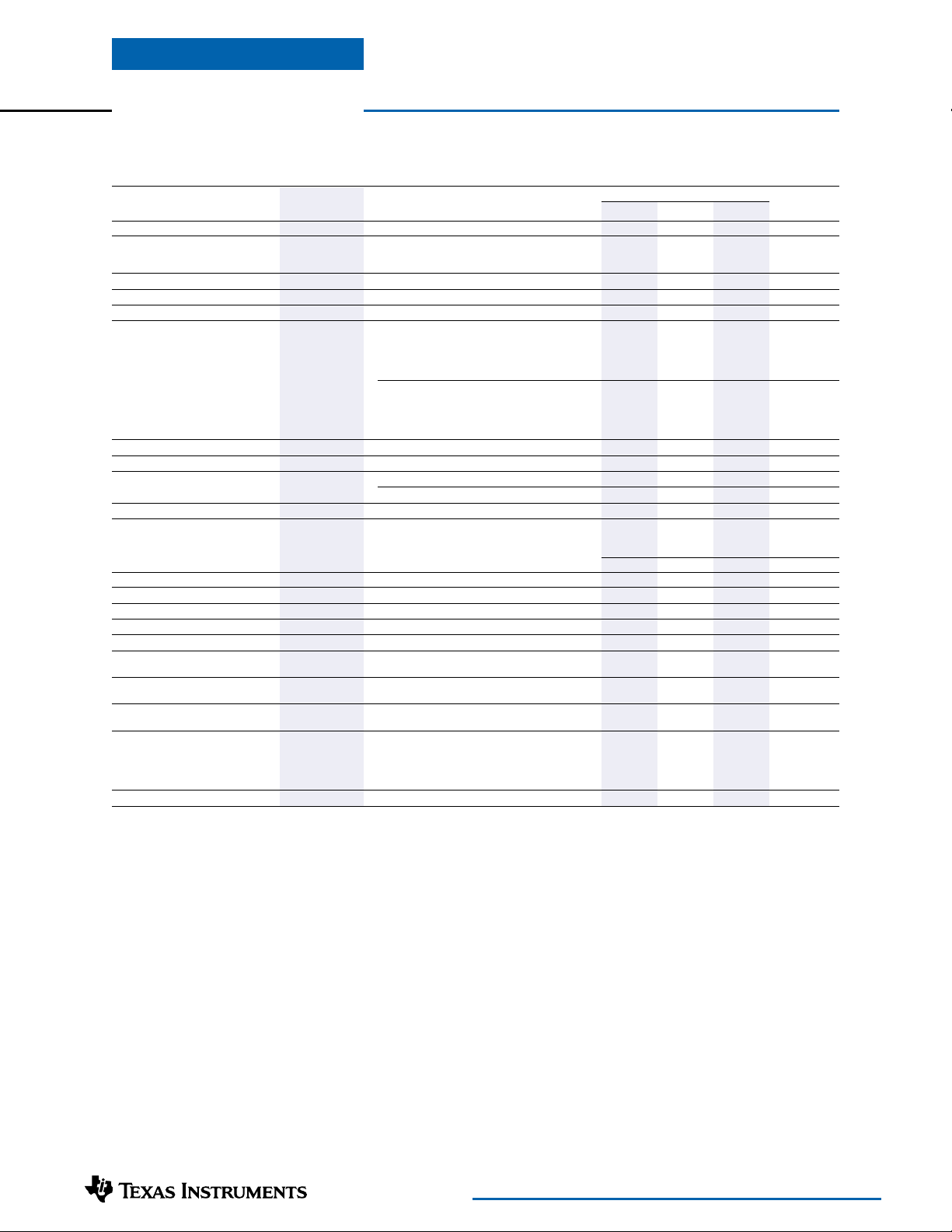

Typical Characteristics

8-A 5-V/3.3-V Input Adjustable ISR

with Short-Circuit protection

Characteristic Data; Vin =5 V (See Note A) Characteristic Data; Vin =3.3 V (See Note A)

Efficiency vs Output Current Efficiency vs Output Current

100

90

80

70

Efficiency - (%)

60

50

02468

Output Ripple vs Output Current

40

30

20

Ripple Voltage - (mV)

10

I

- (A

OUT

V

OUT

3.6 V

3.3 V

2.5 V

1.8 V

1.5 V

1.2 V

V

OUT

1.8 V

2.5 V

3.3 V

1.5 V

3.6 V

1.2 V

100

90

80

70

Efficiency - (%)

60

50

02468

Output Ripple vs Output Current

40

30

20

Ripple Voltage - (mV)

10

I

- (A

OUT

SLTS220 FEBRUARY 2004

V

OUT

2.5 V

1.8 V

1.5 V

1.2 V

V

OUT

1.8 V

1.5 V

1.2 V

2.5 V

0

02468

Power Dissipation vs Output Current Power Dissipation Output Current

4

3

2

1

Power Dissipation - (W)

0

02468

I

- (A

OUT

V

OUT

1.2 V

1.5 V

1.8 V

2.5 V

3.3 V

3.6 V

I

- (A

OUT

0

02468

4

3

2

1

Power Dissipation - (W)

0

02468

I

- (A

OUT

I

- (A

OUT

V

OUT

1.2 V

1.5 V

1.8 V

2.5 V

Note A: Characteristic data has been developed from actual products tested at 25°C. This data is considered typical data for the Converter.

For technical support or further information, visit http://power.ti.com

)

)

)

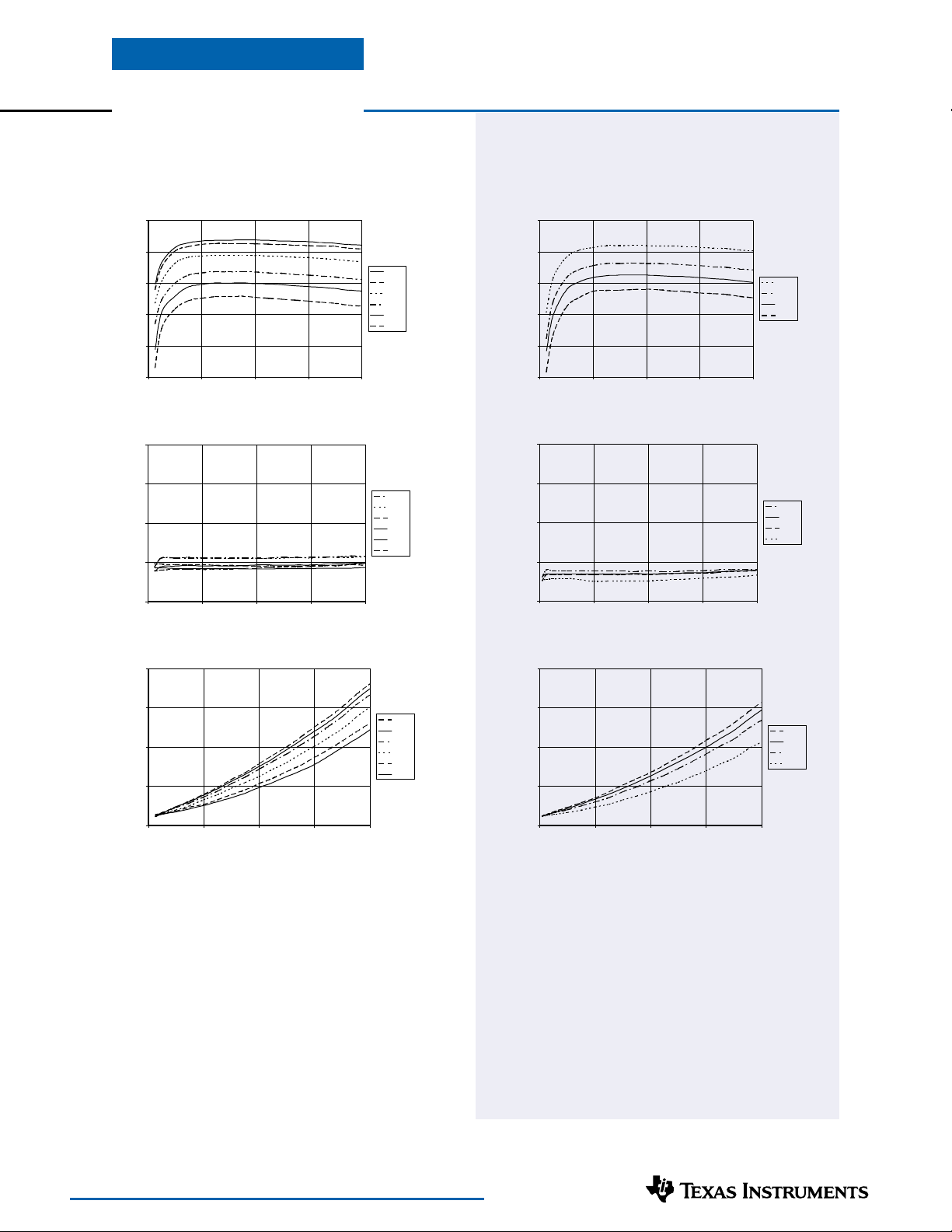

PT6510 Series

Typical Characteristics

8-A 5-V/3.3-V Input Adjustable ISR

with Short-Circuit protection

in

PT6511; V

90

80

70

60

50

40

Ambient Temperature (°C)

30

20

012345678

PT6515; V

90

80

70

60

50

40

Ambient Temperature (°C)

30

20

012345678

= 3.3 V PT6515; V

OUT

I

(A

OUT

= 1.2 V

OUT

I

(A

OUT

=5 V (See Note B)

Airflow

200LFM

120LFM

60LFM

Nat Conv

Airflow

200LFM

120LFM

60LFM

Nat Conv

Safe Operating Area; 3.3 V (See Note B) Safe Operating Area; V

=1.2 V

90

80

70

60

50

40

Ambient Temperature (°C)

30

20

012345678

OUT

I

(A

OUT

SLTS220 FEBRUARY 2004

Airflow

200LFM

120LFM

60LFM

Nat Conv

Note B: SOA curves represent the conditions at which internal components are at or below the manufacturer’s maximum operating temperatures

For technical support and further information, visit http://power.ti.com

Application Notes

PT6510 Series

Using the PT6510 Series as a Replacement for the

PT6500 Series in Existing Designs

Scope

The PT6510 series of power modules is the recommended

plug-in replacement for PT6500 series parts. The PT6510

series uses the same single-in-line package (SIP) outlines

and footprint as the PT6500 series, and was designed to be

functionally identical to the PT6500. This application

note highlights the differences in electrical performance

between a PT6510 series replacement compared to an

original PT6500 series part.

Overview

The features that the PT6510 series share with the

PT6500 series includes the output current rating, thermal

shutdown, and on/off standby. The input voltage range,

output voltage adjustment, and output voltage options

are also the same. In addition, applications that use the

PT6510 series as a replacement will experience a number

of performance enhancements. These include improved

efficiency and power dissipation, lower in-rush current

and output ripple voltage. The ‘off’ standby current is

also significantly reduced. Table 1-1 provides a cross

reference between the current PT6500 series part numbers and their equivalent PT6510 series part.

Table 1-1; PT6500 / PT6510 Series Equivalent Parts

PT6500 Series V

OUT

PT6510 Series

PT6501 3.3 V PT6511

PT6502 1.5 V PT6512

PT6503 2.5 V PT6513

PT6504 3.6 V PT6514

PT6505 1.2 V PT6515

PT6506 1.8 V PT6516

Electrical and Functional Differences

Although the PT6510 series was designed as a drop-in

replacement for PT6500 series, there are minor differences

in the electrical characteristics. These are described in the

following text and should be used to assess the replacement part’s compatibility with the system or end product.

A replacement part’s compatibility with the system can

be further verified with appropriate board-level tests.

On/Off Standby: The Standby input of the PT6510 series

is compatible with both the logic polarity and thresholds

of PT6500 series. One exception is the internal pull-up

voltage, which is slightly higher on the PT6510 parts.

The open-circuit voltage for the PT6510 series is the

input voltage, Vin, versus about 1 V for the PT6500 series.

This should not be a problem if the standby input is

controlled with an open-drain transistor with a sufficient

max-Vds rating.

Over-Current & Over-Temperature Protection:

To protect against short circuits and load impedance

faults, the PT6500 employs a constant output current

limit combined with over-temperature shutdown. The

PT6500 will feed a limited steady-state current into a

load fault. When limiting output current, the PT6500

exhibits higher power dissipation, which increases the

module's operating temperature. When its internal temperature rises above the over-temperature threshold, the

module will shut itself down for a few seconds. The

module will then continue to periodically shut down until

the load fault is removed.

The over-current protection mechanism of the PT6510

series is different. If the output current increases above

the modules over-current threshold, its output voltage

is momentarily turned off. It then attempts to recover

by executing a soft-start power up. The module will

continue in a rapid succession of shutdowns and restarts

until the load fault is removed. During this period the

output current is not steady state, but a series of short

high-amplitude pulses (frequency <100 Hz). However,

when operating into a short-circuit load fault, the average

output current and power dissipation are significantly

lower than under normal operation.

Power-Up Characteristic: Following the application of a

valid input source, the PT6510 series modules exhibit a

slightly longer time delay than the equivalent PT6500

series part. The PT6510 series has a soft-start power-up

feature, which lowers the in-rush current at its input.

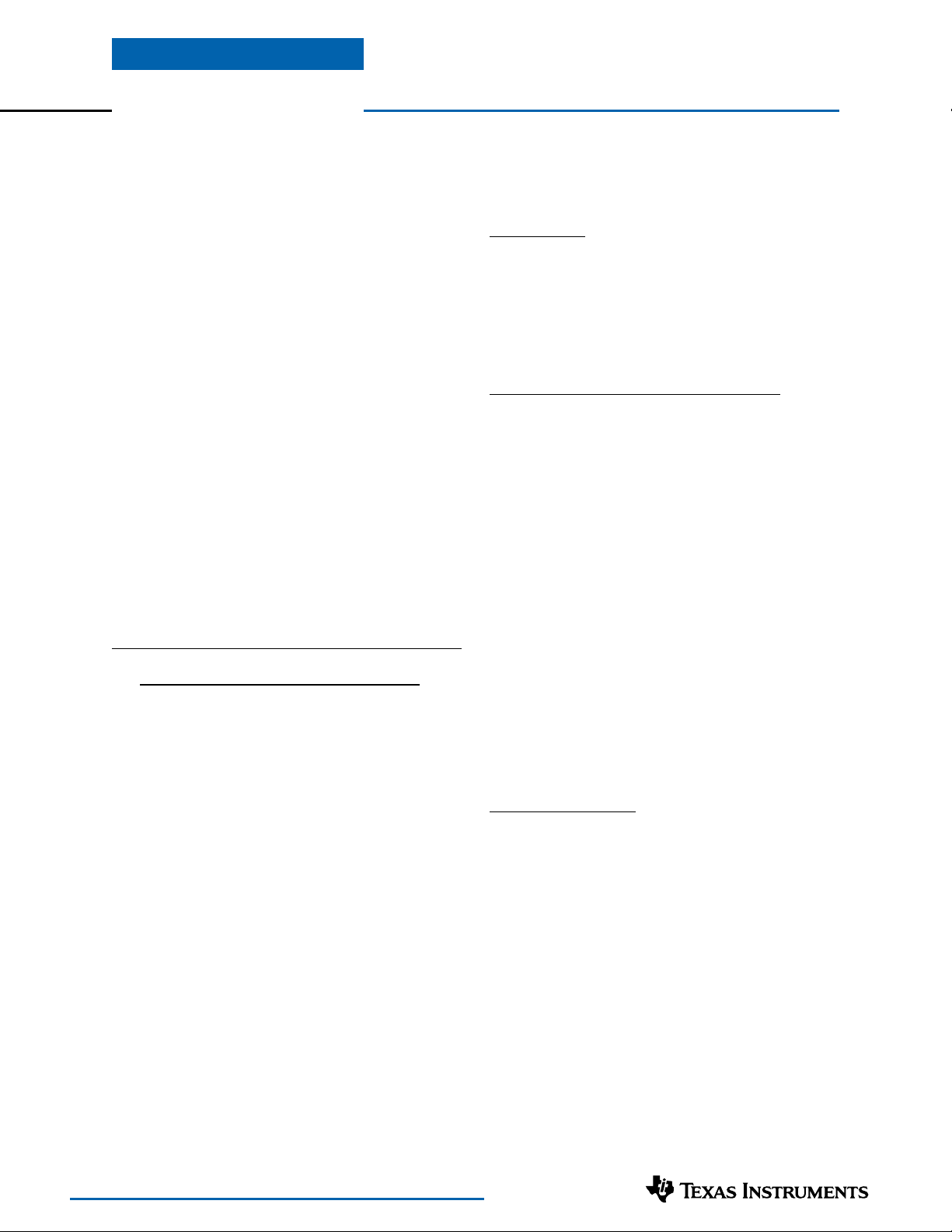

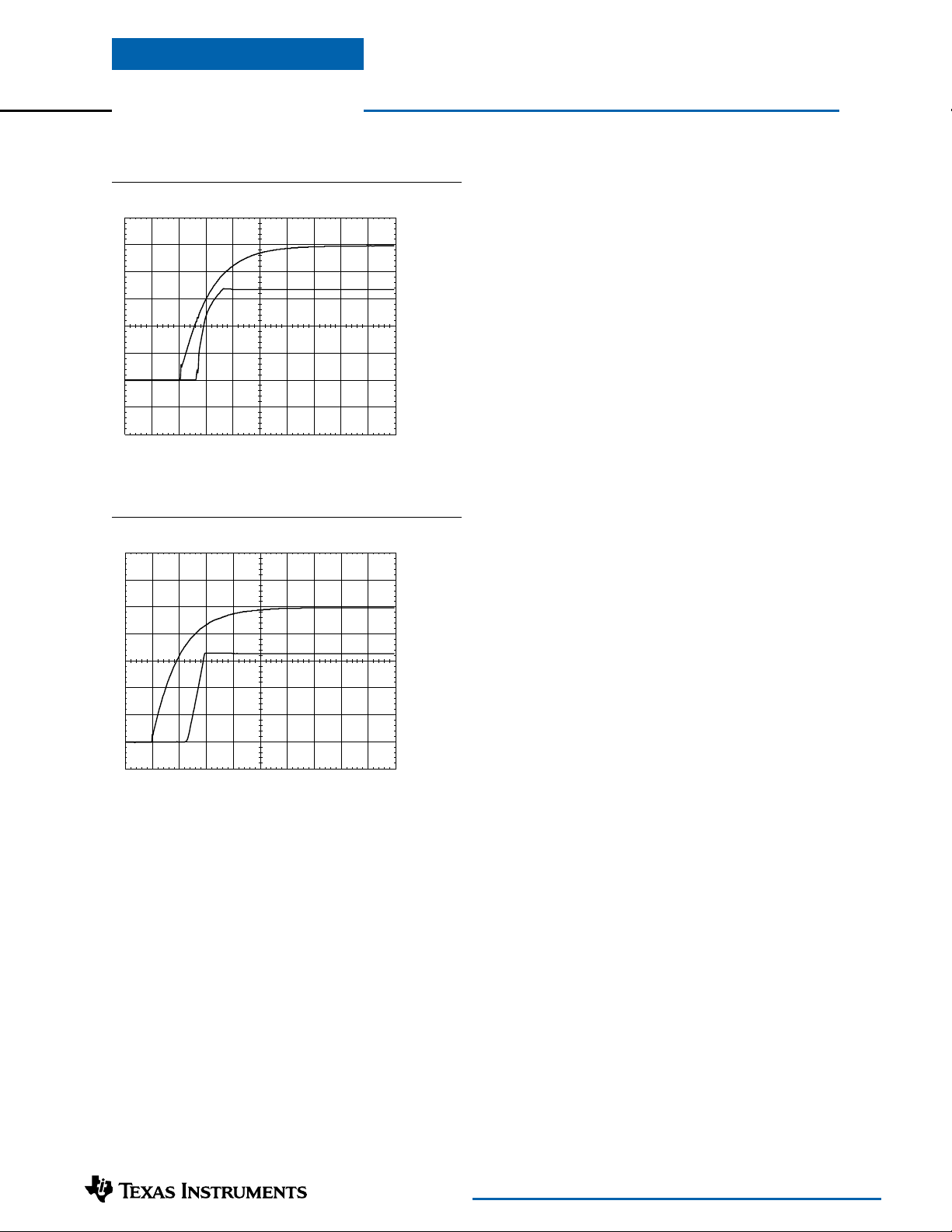

Figure 1-1 and Figure 1-2 show the power-up characteristics of the PT6501 and PT6511 respectively. Both

modules have a 3.3-V regulated output, and rise to their

regulated output voltage in a similar period. Note that

the output voltage of the PT6501 begins to rise when

the input voltage reaches 2.2 V, whereas the output voltage

of the PT6511 doesn’t begin to rise until the input voltage

has reached 3.5 V.

For technical support or further information, visit http://power.ti.com

Application Notes

continued

PT6510 Series

Figure 1-1 PT6501 Power-Up Characteristics

HORIZ SCALE: 5 ms/Div

Vin (1 V/Div)

Vout (1 V/Div)

Figure 1-2; PT6511 Power-Up Characterstic

Vin (1 V/Div)

Vo (1 V/Div)

HORIZ SCALE: 5 ms/Div

Conclusion

The differences in electrical performance between the

PT6500 series and the PT6510 series are small. This

should result in only a few, if any, compatibility issues

when a PT6510 series part is used to replace a PT6500

series part in an existing application. In most cases, the

use of a PT6510 part will improve the performance of

the end product over the original PT6500. The performance differences are described to help customers work

through any compatibility issues, and thereby minimize

the impact to their end products. For additional information and questions call Texas Instrument's product

information center (PIC) and request application assistance for plug-in power products.

For technical support and further information, visit http://power.ti.com

Application Notes

PT6510 Series

Capacitor Recommendations for the PT6510 Series of

Integrated Switching Regulators

Input Capacitors:

The recommended input capacitance is determined by

330 µF minimum value (300 µF for Oscon or low-ESR

tantalum types), and 1 A minimum ripple current rating.

Ripple current and less than 100 mΩ equivalent series

resistance (ESR) are the major parameters, along with

temperature, when selecting an input capacitor. Tantalum capacitors have a recommended minimum voltage

rating of twice 2× (max. DC voltage + AC ripple). This

is standard practice to insure reliability.

Output Capacitors:

The ESR of the required output capacitor must not be

greater than 150 mΩ. Electrolytic capacitors have poor

ripple performance at frequencies greater than 400 kHz

but excellent low-frequency transient response. Above

the ripple frequency, ceramic capacitors are necessary to

improve the transient response and reduce any high

frequency noise components apparent during higher

current excursions. Preferred low-ESR type capacitor

part numbers are identified in Table 2-1.

Tantalum Capacitors

Tantalum type capacitors may be used for the output but

only the AVX TPS, Sprague 593D/594/595, or Kemet

T495/T510 series. These capacitors are recommended

over many other tantalum types due to their higher rated

surge, power dissipation, and ripple current capability.

As a caution the TAJ series by AVX is not recommended.

This series has considerably higher ESR, reduced power

dissipation, and lower ripple current capability. The TAJ

series is less reliable than the AVX TPS series when

determining power dissipation capability. Tantalum or

Oscon types are recommended for applications where

ambient temperatures fall below 0 °C.

Capacitor Table

Table 2-1 identifies the characteristics of capacitors from

a number of vendors with acceptable ESR and ripple

current (rms) ratings. The number of capacitors required

at both the input and output buses is identified for each

capacitor type.

This is not an extensive capacitor list. Capacitors from other

vendors are available with comparable specifications. Those listed

are for guidance. The RMS ripple current rating and ESR

(at 100 kHz) are critical parameters necessary to insure both

optimum regulator performance and long capacitor life.

Table 2-1: Suggested Input/Output Capacitors

roticapaC

/rodneV

tnenopmoC

seireS

cinosanaP

CF

detinU

noC-imehC

/SF/VXL

ZXL

nocihciN

MP/LP

cinosanaP

CF

)gtMecafruS(

SS-nocsO

VS

XVA

mulatnaT

SPT

temeK

/015T

594T

eugarpS

D495

gnikroW

egatloV)Fµ(eulaV

V52

V53

V53

V61

V53

V01

V02

V53

V53

V05

V01

V53

V61

V01

V01

V02

V01

V01

V01

V01

V01

V01

V01

RSE.xaM

zHk001ta

Fµ065

Fµ093

Fµ033

Fµ033

Fµ074

Fµ033

Fµ051

065Fµ

033Fµ

074Fµ

0001Fµ

033Fµ

033Fµ

033Fµ

Fµ033

051Fµ

Fµ033

Fµ033

Fµ022

Fµ033

Fµ022

Fµ033

Fµ022

5600.0 Ω

560.0 Ω

711.0 Ω

021.0 Ω

250.0 Ω

520.0 Ω

030.0 ÷2 Ω

840.0 Ω

560.0 ÷2 Ω

640.0 Ω

340.0 Ω

560.0 Ω

051.0 Ω

520.0 Ω

520.0 Ω

420.0 ÷2 Ω

001.0 ÷2 Ω

001.0 ÷2 Ω

590.0 Ω

330.0 Ω

70.0 ÷Ω 530.0=2 Ω

540.0 Ω

560.0 Ω

N/R –Not recommended. The ripple current rating and ESR does not meet the requirements.

scitsiretcarahCroticapaCytitnauQ

)smrI(

Am5021

Am5021

Am555

Am555

Am0221

Am0053

Am0023

Am0631

Am0201

Am0741

Am5021

Am5021

Am076

Am0063

Am0041

Am0532

elppiR.xaM

C°58tatnerruC

Am0053>

Am0083>

Am0052>

Am0003>

Am0002>

Am0002>

Am0002>

eziSlacisyhP

tupnI

)mm(

51x5.21

1

51x5.21

2

5.11x8

21x8

02x01

1

5.01x01

1

5.01x01

2

51x61

1

51x5.21

1

51x81

1

5.61x21

1

61x5.21

1

2.01x01

5.01x0.01

1

3.01x3.01

1

3.01x3.01

2

xL3.7

2

xW3.4

H1.4

H1.4

2

2

W7.5xL3.7

2

H0.4x

2

xL3.7

2

xW0.6

2

tuptuO

suB

suB

1

1

R/N

1

R/N

1

1

1

2

1

1

1

1

1

R/N

1

1

1

2

1

1

2

1

2

1

2

M033SF01

M051SF02

M033SS01

M033VS01

M051VS02

rebmuNrodneV

S165E1CFUEE

S193V1CFUEE

133C1CFUEE

LL21X8M133BV61ZXL

LL02X01M174BV53ZXL

6HHM165V1LPU

6HHM133V1LPU

6HHM1174H1MPU

QL201A1CFVEE

QL133V1CFVEE

P133C1CFVEE

tnuoMecafruS=VS

0010R010M733VSPT

0600R010M733VSPT

0010R5010M722VSPT

SA010M733X015T

SA010M722X594T

T2R0100X733D4

T2D0100X722D495

For technical support or further information, visit http://power.ti.com

Application Notes

PT6510 Series

Using the Standby Function of the PT6510

Series of Integrated Switching Regulators

The PT6510 series of power modules incorporate a

Standby function. This may be used in applications that

require power-up/shutdown sequencing, and wherever

there is a requirement for the output status of the module to be controlled by external circuitry.

The standby function is provided by the STBY* control,

pin 3. If pin 3 is left open-circuit

normally, and provides a regulated output whenever a

valid supply voltage is present at applied to Vin (pins 4-6)

with respect to GND (pins 7–10). Applying a ground

signal to pin 3 disables the regulator’s output and reduces

the input current to about 1 mA 4. The standby control

may also be used to hold off the regulator output during

the period that input power is applied.

Pin 3 is ideally controlled with an open-drain discrete

1

transistor

(See Figure 3-1). It may also be driven directly

from a dedicated TTL 3 compatible gate. Table 3-1 gives

the circuit parameters for the control of this input.

Table 3-1 Standby Control Requirements

Parameter Min Typ Max

Input Low (VIL) –0.1 V 0.4 V

Input High (VIH) 2 V V

Input Low Current (IIL) –0.4 mA

Notes:

1 The standby control input is ideally controlled using an

open-drain discrete transistor. An external pull-up resistor

is not necessary. The open-circuit voltage of the STBY*

pin is the input voltage, V

2. To ensure the regulator output is disabled, the control pin

must be pulled to less than 0.4 Vdc with a low-level

0.5-mA sink to ground.

3. The STBY* input is also compatible with a differential

output from standard TTL logic, providing the IC

shares the same supply voltage as the module.

4. When the regulator output is disabled the current drawn

from the input source is typically reduced to about 1 mA.

1

the regulator operates

(2)

.

in

in

Figure 3-1

1

Vo (Sns)

V

in

COM

Inhibit

4,5,6

Vin Vo

PT6511

Vo Adj

GND

STBY

C

IN

Q1

BSS138

3

V

in

11–13

147–10

C

OUT

V

o

COM

Turn-On Time: In the circuit of Figure 3-1, turning Q1 on

applies a low voltage to the STBY control (pin 3) and

disables the regulator ouput. Correspondingly, turning

off removes the low-voltage signal and enables the

Q

1

output. Once enabled, the output will typically experience

a 10–15 ms delay followed by a predictable ramp-up of

voltage. The regulator should provide a fully regulated

output voltage within 40 ms. The waveform of Figure 3-2

shows the output voltage and input current waveforms of

a PT6511 (3.3 V) following the turn-off of Q

off of Q

corresponds to the rise in Vstby. The waveforms

1

. The turn

1

were measured with a 5 Vdc input voltage, and 4.5 A

resistive load.

Figure 3-2

Vstby (2 V/Div)

HORIZ SCALE: 2 ms/Div

For technical support and further information, visit http://power.ti.com

Vo (1 V/Div)

Application Notes

PT6510 Series

Adjusting the Output Voltage of the

PT6510 5V/3.3V Bus Converters

The output voltage of the PT6510 series switching regulators may be adjusted higher or lower than the factory

trimmed pre-set voltage with the addition of a single

external resistor. Table 4-1 gives the allowable adjustment range for each model in the series as Va (min) and

Va (max).

Adjust Up: An increase in the output voltage is obtained

by adding a resistor R

, between Vo Adjust (pin 14) and

2

GND (pins 7-10).

Adjust Down: Add a resistor (R

(pin 14) and V

(pins 11-13).

out

), between Vo Adjust

1

Refer to Figure 4-1 and Table 4-2 for both the placement and

value of the required resistor, either (R

) or R2 as appropriate.

1

Notes:

1. Use only a single 1 % resistor in either the (R1) or R

location. Place the resistor as close to the ISR as

possible.

2. Never connect capacitors from Vo Adjust to either

GND, V

added to the V

, or the Vo Sense pin. Any capacitance

out

Adjust pin will affect the stability of

o

the ISR.

3. If the remote sense feature is used, connecting the

resistor (R

) between Vo Adjust (pin 14) and Vo Sense

1

(pin 1) can benefit load regulation.

4. The minimum input voltage required by the part is

V

+ 1.2 or Vin(min) from Table 4-1, whichever is

out

higher.

Figure 4-1

1

Vin

4–6

V

in

STBY

+

C

in

COM

The values of (R1) [adjust down], and R2 [adjust up], can

2

also be calculated using the following formulae.

(R1) =

R

2

=

Vo(Sense)

PT6510

GND

3

Ro (Va – 1.0)

– Va)

(V

o

R

- V

V

a

11–13

V

out

(adj)

V

o

147–10

(R1)

Adj Down

R2

Adjust Up

– R

kΩ

s

o

– R

o

kΩ

s

Where: Vo= Original output voltage

Va= Adjusted output voltage

= The resistance value in Table 4-1

R

o

= The series resistance from Table 4-1

R

s

V

out

L

+

COM

O

A

D

C

out

Table 4-1

PT6510 ADJUSTMENT AND FORMULA PARAMETERS

Series Pt # PT6515 PT6512 PT6516 PT6513 PT6511 PT6514

Vo (nom) 1.2 1.5 1.8 2.5 3.3 3.6

Va (min) 1.14 1.27 1.4 1.8 2.25 2.5

Va (max) 2.35 2.65 2.95 3.5 4.2 4.3

ΩΩ

Ro (k

Ω) 2.49 2.49 2.49 4.99 12.1 10

ΩΩ

ΩΩ

Rs (k

Ω) 2 2 2 4.22 12.1 12.1

ΩΩ

Vin(min) 3.1 3.1 3.1 4.5 4.5 4.5

For technical support or further information, visit http://power.ti.com

Application Notes

continued

PT6510 Series

Table 4-2

PT6500 ADJUSTMENT RESISTOR VALUES

Series Pt # PT6515 PT6512 PT6516 PT6513 PT6511 PT6514

Vo (nom) 1.2 V 1.5 V 1.8 V 2.5 V 3.3 V 3.6 V

Va (req’d)

1.15 (5.5) kΩ

1.2

1.25 47.8 kΩ

1.3 22.9 kΩ (1.7) kΩ

1.35 14.6 kΩ (3.8) kΩ

1.4 10.5 kΩ (8.0) kΩ (0.5) kΩ

1.45 8.0 kΩ (20.4) kΩ (1.2) kΩ

1.5 6.3 kΩ (2.2) kΩ

1.55 5.1 kΩ 47.8 kΩ (3.5) kΩ

1.6 4.2 kΩ 22.9 kΩ (5.5) kΩ

1.65 3.5 kΩ 14.6 kΩ (8.8) kΩ

1.7 3.0 kΩ 10.5 kΩ (15.4) kΩ

1.75 2.5 kΩ 8.0 kΩ (35.4) kΩ

1.8 2.2 kΩ 6.3 kΩ (1.5) kΩ

1.85 1.8 kΩ 5.1 kΩ 47.8 kΩ (2.3) kΩ

1.9 1.6 kΩ 4.2 kΩ 22.9 kΩ (3.3) kΩ

1.95 1.3 kΩ 3.5 kΩ 14.6 kΩ (4.4) kΩ

2.0 1.1 kΩ 3.0 kΩ 10.5 kΩ (5.8) kΩ

2.05 0.9 kΩ 2.5 kΩ 8.0 kΩ (7.4) kΩ

2.1 0.8 kΩ 2.2 kΩ 6.3 kΩ (9.5) kΩ

2.15 0.6 kΩ 1.8 kΩ 5.1 kΩ (12.2) kΩ

2.2 0.5 kΩ 1.6 kΩ 4.2 kΩ (15.7) kΩ

2.25 0.4 kΩ 1.3 kΩ 3.5 kΩ (20.7) kΩ (2.3) kΩ

2.3 0.3 kΩ 1.1 kΩ 3.0 kΩ (28.2) kΩ (3.6) kΩ

2.35 0.2 kΩ 0.9 kΩ 2.5 kΩ (40.7) kΩ (5.1) kΩ

2.4 0.8 kΩ 2.2 kΩ (65.6) kΩ (6.7) kΩ

2.45 0.6 kΩ 1.8 kΩ (140.0) kΩ (8.5) kΩ

2.5 0.5 kΩ 1.6 kΩ (10.6) kΩ (1.5) kΩ

2.55 0.4 kΩ 1.3 kΩ 95.6 kΩ (12.9) kΩ (2.7) kΩ

2.6 0.3 kΩ 1.1 kΩ 45.7 kΩ (15.6) kΩ (3.9) kΩ

2.65 0.2 kΩ 6.9 kΩ 29.0 kΩ (18.6) kΩ (5.3) kΩ

2.7 0.8 kΩ 20.7 kΩ (22.2) kΩ (6.8) kΩ

2.75 0.6 kΩ 15.7 kΩ (26.4) kΩ (8.5) kΩ

2.8 0.5 kΩ 12.4 kΩ (31.5) kΩ (10.4) kΩ

2.85 0.4 kΩ 10.0 kΩ (37.6) kΩ (12.6) kΩ

2.9 0.3 kΩ 8.3 kΩ (45.4) kΩ (15.0) kΩ

2.95 0.2 kΩ 0.9 kΩ (55.3) kΩ (17.9) kΩ

3.0 5.8 kΩ (68.6) kΩ (21.2) kΩ

3.1 4.1 kΩ (115.0) kΩ (29.9) kΩ

3.2 2.9 kΩ (254.0) kΩ (42.9) kΩ

3.3 2.0 kΩ (64.6) kΩ

3.4 1.3 kΩ 109.0 kΩ (108.0) kΩ

3.5 0.8 kΩ 48.4 kΩ (238.0) kΩ

3.6 28.2 kΩ

3.7 18.2 kΩ 87.9 kΩ

3.8 12.1 kΩ 37.9 kΩ

3.9

4.0 5.2 kΩ 12.9 kΩ

4.1 3.0 kΩ 7.9 kΩ

4.2 1.3 kΩ 4.6 kΩ

4.3 2.2 kΩ

R1 = (Blue) R2 = Black

4/.

V

>3.8 Vdc requires Vin >5 Vdc ! 8.1 kΩ 21.2 kΩ

out

For technical support and further information, visit http://power.ti.com

MECHANICAL DATA

MPSI013 – MARCH 2001

EEA (R–PSIP–T14) PLASTIC SINGLE-IN-LINE MODULE

1.71 (43,43) MAX.

0.38 0.59

(9,65)

(14,98)

0.018 (0,45)

0.012 (0,30)

0.52

(13,20)

0.175

(4,44)

1.31

(33,27)

1

1

0.100 (2,54) TYP.

0.017 (0,43) TYP.

0.205 (5,20)

1.77 (44,95)

1.42 (36,06)

Note F

ø0.035 (0,88) MIN. 14 Places

Plated through

0.100 (2,54) 13 Places

0.235 (5,96)

1.22 (30,98)

MAX.

Note E

0.20 (5,08)

0.040

0.040 (1,01)

(1,77)0.07

(1,01)

0.42

(10,66)

MAX.

Note G

0.017 (0,43)

TYP.

0.140 (3,55)

MIN.

PC Layout

NOTES: A. All linear dimensions are in inches (mm).

B. This drawing is subject to change without notice.

C. 2-place decimals are

D. 3-place decimals are

E. Recommended mechanical keep-out area.

F. No copper, power or signal traces in this area.

" 0.030 (" 0,76 mm).

" 0.010 (" 0,25 mm).

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

4202005/A 02/01

G. D-suffix parts include a metal heat spreader.

No signal traces are allowed under the heat spreader area.

A solid copper island is recommended, which may be

grounded.

A-suffix does not include a metal heat spreader.

1

MECHANICAL DATA

MPSI014A – MARCH 2001 – REVISED FEBRUARY 2002

EEK (R–PSIP–G14) PLASTIC SINGLE-IN-LINE MODULE

0.325

(8,25)

0.52

(13,20)

0.205 (5,20)

0.350 (8,89)

0.175

(4,44)

2.36 (62,48) MAX.

2.000 (50,80)

1.71 (43,43) MAX.

0.38

(9,65)

(14,98)

1

1.77

1.42

0.59

0.100 (2,54) TYP.

0.017 (0,43) TYP.

(61,46)

2.42

2.000

(50,80)

(44,95)

(30,06)

ø0.187 (4,74)

2 Places

0.41

(10,41)

1.22 (30,98)

0.83

(21,08)

0.61 (15,49)

0.325

Note E, F

Hole for #6–32 screws

MAX.

0.19 (4,82)

(8,25)

0.080

(2,02)

MIN

0.42

(10,66)

MAX.

Suffix B

Note F

Seating Plane

0.006 (0,15) MAX.

0.10

(2,54)

0.17

(4,32)

0.150

(3,81)

NOTES: A. All linear dimensions are in inches (mm).

B. This drawing is subject to change without notice.

C.

2–place decimals are " 0.030 (" 0,76 mm).

D.

3–place decimals are " 0.010 (" 0,25 mm).

E. Recommended mechanical keep-out area.

F. The metal tab is isolated but electrically conductive.

No signal traces are allowed under the metal tab area.

A solid copper island is recommended, which may be

grounded.

Note H

Note G

0.040 (1,01) 14 Places

0.100 (2,54) 13 Places

0.235 (5,97)

0.350 (8,89)

PC LAYOUT

0.86

(21,84)

1.35

(34,29)

0.64 (16,25)

0.040 (1,01)

0°–7°

Gage Plane

G. Power pin connections should utilize two or more

vias per input, ground and output pin.

H. No copper , power or signal traces in this area.

0.017

TYP.

(0,43)

4202006/B 02/02

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1

MECHANICAL DATA

MPSI015A – MARCH 2001 – REVISED JANUARY 2002

EEC (R–PSIP–G14) PLASTIC SINGLE-IN-LINE MODULE

0.52

(13,20)

0.175

(4,44)

1.71 (43,43) MAX.

0.38 0.59

(9,65)

1

(14,98)

0.017 (0,43) TYP.

0.205 (5,20)

1.77 (44,95)

0.100 (2,54) TYP.

1.42 (36,06)

1.22 (30,98)

MAX.

0.080 (2,02) MIN.

Note E, F

0.42

(10,66)

MAX.

Suffix E, C (Note F)

0.018 (0,45)

0.012 (0,30)

Note F

Seating Plane

0.006 (0,15) MAX.

Note H

1

0.150

(3,81)

0.235 (5,96)

NOTES: A. All linear dimensions are in inches (mm).

B. This drawing is subject to change without notice.

C.

2–place decimals are " 0.030 (" 0,76 mm).

D.

3–place decimals are " 0.010 (" 0,25 mm).

E. Recommended mechanical keep-out area.

F. E-suffix parts include a metal heat spreader.

No signal traces are allowed under the heat spreader area.

A solid copper island is recommended, which may be

grounded.

C-suffix does not include a metal heat spreader.

See Note G

0.040 (1,01) 14 Places

0.100 (2,54) 13 Places

PC LAYOUT

1.35

(34,29)

0°–7°

Gage Plane

0.10 (2,54)

0.17 (4,31)

G. Power pin connections should utilize two or more

vias per input, ground and output pin.

H. No copper , power or signal traces in this area.

0.040 (1,01)

TYP

(0,43)0.017

4202007/B 12/01

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1

MECHANICAL DATA

MPSI016A – MARCH 2001 – REVISED FEBRUARY 2002

EEG (R–PSIP–T14) PLASTIC SINGLE-IN-LINE MODULE

0.325

(8,25)

0.52

(13,20)

0.205 (5,20)

0.350 (8,89)

0.175

(4,44)

2.36 (62,48) MAX.

2.000 (50,80)

1.71 (43,43) MAX.

0.59

(14,98)

1

2.42

2.000

1.77

1.42

0.38 (9,65)

0.100 (2,54) TYP.

0.017 (0,43) TYP.

(61,46)

(50,80)

(44,95)

(30,06)

ø0.187 (4,74)

2 Places

0.41 (10,41)

1.22 (30,98)

0.83

(21,08)

0.61

(15,49)

(8,25)

0.325

Note E, F

Hole for #6–32 screws

MAX.

0.19

(4,82)

0.040

(1,01)

0.42

(10,66)

MAX.

Suffix G

Note F

0.017

(0,43)

TYP.

0.140

(3,55)

MIN.

0.20

(5,08)

0.07

(1,77)

NOTES: A. All linear dimensions are in inches (mm).

B. This drawing is subject to change without notice.

C. 2-place decimals are

D. 3-place decimals are

E. Recommended mechanical keep-out area.

F. The metal tab is isolated but electrically conductive.

No signal traces are allowed under the metal tab area.

A solid copper island is recommended, which may be grounded.

G. No copper , power or signal traces in this area.

Note G

ø0.035 (0,88) MIN. 14 Places

Plated through

0.100 (2,54) 13 Places

0.235 (5,97)

0.350 (8,89)

PC LAYOUT

" 0.030 (" 0,76 mm).

" 0.010 (" 0,25 mm).

0.65

(16,51)

0.86

(21,84)

0.040 (1,01)

1.31

(33,27)

4202008/B 02/02

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1

MECHANICAL DATA

MPSI017 – MARCH 2001

EED (R–PSIP–T14) PLASTIC SINGLE-IN-LINE MODULE

1.71 (43,43) MAX.

0.38 0.59

(9,65)

(14,98)

0.018 (0,45)

0.012 (0,30)

0.52

(13,20)

1

1

0.100 (2,54) TYP.

0.017 (0,43) TYP.

0.205 (5,20)

1.77 (44,95)

0.235 (5,96)

0.100 (2,54) 13 Places

ø0.035 (0,88) MIN. 14 Places

Plated through

1.22 (30,98)

MAX.

0.170 (4,31) MIN.

0.040 (1,01)

0.42

(10,66)

Note E

Note F

0.017 (0,43) TYP.

0.42

(10,66)

MAX.

PC LAYOUT

NOTES: A. All linear dimensions are in inches (mm).

B. This drawing is subject to change without notice.

C. 2-place decimals are

D. 3-place decimals are

E. Recommended mechanical keep-out area.

F. P-suffix parts include a metal heat spreader.

The heat spreader is isolated but electrically

conductive, it can be grounded.

N-suffix does not include a metal heat spreader.

" 0.030 (" 0,76 mm).

" 0.010 (" 0,25 mm).

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

4202009/A 02/01

1

MECHANICAL DATA

MPSI018A – MARCH 2001 – REVUSED FEBRUARY 2002

EEE (R–PSIP–T14) PLASTIC SINGLE-IN-LINE MODULE

Suffix R

2.36 (62,48) MAX.

2.000 (50,80)

1.71 (43,43) MAX.

ø0.187 (4,74)

2 Places

0.41 (10,41)

0.325

(8,25)

0.38 (9,65)

0.59

(14,98)

0.52

(13,20)

0.205 (5,20)

0.350 (8,89)

0.07

(1,77)

0.11

(2,79)

0.325

(8,25)

1

1

Note E

0.100 (2,54) TYP.

0.017 (0,43) TYP.

2.42 (61,46)

1.77 (44,95)

0.100 (2,54) 13 Places

0.235 (5,96)

ø0.035 (0,88) MIN. 14 Places

Plated through

PC LAYOUT

0.61

(15,49)

0.040 (1,01)

0.42

(10,66)

0.83

(21,08)

1.22 (30,98)

MAX.

0.19

(4,82)

0.170

(4,31)

MIN.

0.42

(10,66)

MAX.

Note F

0.017

(0,43)

TYP.

4202010/B 02/02

NOTES: A. All linear dimensions are in inches (mm).

B. This drawing is subject to change without notice.

C. 2-place decimals are

D. 3-place decimals are

E. Recommended mechanical keep-out area.

F. The metal tab is isolated but electrically

conductive, it can be grounded.

" 0.030 (" 0,76 mm).

" 0.010 (" 0,25 mm).

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1

MECHANICAL DATA

MPSI019A – MARCH 2001 – REVISED FEBRUARY 2002

EEF (R–PSIP–G14) PLASTIC SINGLE-IN-LINE MODULE

0.325

(8,25)

0.87

(22,11)

0.52

(13,20)

0.205 (5,20)

0.350 (8,89)

0.175

(4,44)

2.36 (62,48) MAX.

2.000 (50,80)

1.71 (43,43) MAX.

0.38

(9,65)

1

0.59

(14,98)

2.42

2.000

1.77

1.42

0.71

(18,07)

0.100 (2,54) TYP.

0.017 (0,43) TYP.

(61,46)

(50,80)

(44,95)

(30,06)

ø0.187 (4,74)

2 Places

0.41 (10,41)

1.22 (30,98)

0.83

(21,08)

0.61

(15,49)

0.325 (8,25)

0.19 (4,82)

Note E,F

Hole for #6–32 screws

MAX.

0.040 (1,01)

0.19 (4,82)

0.210 (5,33)

0.080

(2,02)

MIN.

Gage Plane

0°–7°

0.42

(10,66)

MAX.

Suffix F

Note J

Note F

Seating Plane

0.006 (0,15) MAX.

0.040 (1,01)

0.017 (0,43) TYP.

0.10

(2,54)

0.17

(4,32)

0.150

(3,81)

NOTES: A. All linear dimensions are in inches (mm).

B. This drawing is subject to change without notice.

C. 2-place decimals are

D. 3–place decimal are

E. Recommended mechanical keep-out area.

F. The metal tab is isolated but electrically conductive.

No signal traces are allowed under the metal tab area.

A solid copper island is recommended, which may be

grounded.

G. Power pin connections should utilize two or more

vias per input, ground and output pin.

0.545

(13,84)

CtoC

L

L

Note L

Note G

0.040 (1,01) 14 Places

0.100 (2,54) 13 Places

0.235 (5,97)

0.350 (8,89)

PC LAYOUT

" 0.030 (" 0,76 mm).

" 0.010 (" 0,25 mm).

(21,84)

0.64

(16,25)

0.86

1.35

(34,29)

1.120

(28,44)

to

C

C

LL

H. Minimum copper land area required for solder tab.

Vias are recommended to improve copper adhesion

or connect land to other ground area.I

J. Underside solder tabs detail.

K. Solder mask openings to copper island for solder

joints to mechanical pins.

L. No copper, power or signal traces in this area.

0.33

(8,38)

0.280

(7,11)

0.085

(2,16)

0.080 (2,03) 2 Places

Note H

0.210

(5,33)

0.38

(9,65)

4202011/B 02/02

Note K

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1

MECHANICAL DATA

MPSI020 – MARCH 2001

EEL (R–PSIP–G14) PLASTIC SINGLE-IN-LINE MODULE

0.87

(22,11)

0.52

(13,20)

0.205 (5,20)

0.175 (4,44)

1.71 (43,43) MAX.

0.38

(9,65)

(14,98)

1

1.42

0.59

1.77

(18,07)

0.100 (2,54) TYP.

0.017 (0,43) TYP.

(44,95)

(30,06)

0.71

1.22 (30,98)

MAX.

0.19 (4,82)

0.210 (5,33)

Note E

0.040 (1,01)

0.080 (2,02) MIN.

0°–7°

Gage Plane

Note J

0.42

(10,66)

MAX.

0.042

(1,06)

0.036(0,91)

Note F

Seating Plane

0.006 (0,15) MAX.

0.040

(1,01)

0.017

(0,43)

TYP.

0.10

(2,54)

0.17 (4,32)

0.150 (3,81)

NOTES: A. All linear dimensions are in inches (mm).

B. This drawing is subject to change without notice.

C.

2–place decimals are " 0.030 (" 0,76 mm).

D.

3–place decimals are " 0.010 (" 0,25 mm).

E. Recommended mechanical keep-out area.

F. The metal tab is isolated but electrically conductive.

No signal traces are allowed under the metal tab area.

A solid copper island is recommended, which may be

grounded.

G. Power pin connections should utilize two or more

vias per input, ground and output pin.

0.545

(13,84)

CtoC

L

L

Note L

Note G

0.035 (0,88) 14 Places

0.100 (2,54) 13 Places

0.235 (5,97)

PC LAYOUT

1.120

(28,44)

to

C

C

LL

1.35

(34,29)

0.080

0.280

0.33

(7,11)

(8,38)

0.085 (2,16)

H. Minimum copper land area required for solder tab.

Vias are recommended to improve copper adhesion

or connect land to other ground area.

J. Underside solder tabs detail

K. Solder mask openings to copper island for solder

joints to mechanical pins.

L. No copper, power or signal traces in this area.

0.210

(5,33)

0.38

(9,65)

2 Places

(2,03)

Note H

Note K

4202012/A 02/01

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...