Page 1

Evaluation Board for the

TLC320AD50C DSP Analog

Interface Circuit

User’s Guide

2000 Mixed Signal Products

SLAU039

Page 2

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Page 3

About This Manual

This user’s guide discusses the design, use, and performance of the

TLC320AD50 Evaluation Module.

How to Use This Manual

Notational Conventions

Preface

Read This First

This document contains the following chapters:

-

-

-

-

-

-

-

Notational Conventions

This document uses the following conventions.

-

Chapter 1 – Introduction

Chapter 2 – AD50-EVM Design and Construction

Chapter 3 – Setting Up the AD50-EVM

Chapter 4 – Results Obtained With AD50 EVM

Appendix A –Installing the AD50-EVM

Appendix B –Programmable Logic

Appendix C –Converting DSK+ Software for the AD50-EVM

Program listings, program examples, and interactive displays are shown

in a special typeface similar to a typewriter’s. Examples use a bold

version of the special typeface for emphasis; interactive displays use a

bold version of the special typeface to distinguish commands that you

enter from items that the system displays (such as prompts, command

output, error messages, etc.).

Here is a sample program listing:

0011 0005 0001 .field 1, 2

0012 0005 0003 .field 3, 4

0013 0005 0006 .field 6, 3

0014 0006 .even

Read This First

iii

Page 4

Running Title—Attribute Reference

Here is an example of a system prompt and a command that you might

enter:

C: csr –a /user/ti/simuboard/utilities

-

In syntax descriptions, the instruction, command, or directive is in a bold

typeface font and parameters are in an

that are in bold should be entered as shown; portions of a syntax that are

in

an example of a directive syntax:

italic typeface

italics

describe the type of information that should be entered. Here is

. Portions of a syntax

.asect ”

section name

”,

address

.asect is the directive. This directive has two parameters, indicated by

tion name

address

. When you use .asect, the first parameter must be

and

an actual section name, enclosed in double quotes; the second parameter

must be an address.

-

Square brackets ( [ and ] ) identify an optional parameter. If you use an

optional parameter, you specify the information within the brackets; you

don’t enter the brackets themselves. Here’s an example of an instruction

that has an optional parameter:

LALK

The LALK instruction has two parameters. The first parameter,

stant

16–bit constant [, shift]

, is required. The second parameter,

16-bit con-

shift

, is optional. As this syntax

shows, if you use the optional second parameter, you must precede it with

a comma.

Square brackets are also used as part of the pathname specification for

VMS pathnames; in this case, the brackets are actually part of the pathname (they are not optional).

-

Braces ( { and } ) indicate a list. The symbol | (read as or) separates items

within the list. Here’s an example of a list:

sec-

{ * | *+ | *– }

This provides three choices: *, *+, or *–.

Unless the list is enclosed in square brackets, you must choose one item

from the list.

-

Some directives can have a varying number of parameters. For example,

the .byte directive can have up to 100 parameters. The syntax for this directive is:

.byte

value1 [, ... , valuen]

This syntax shows that .byte must have at least one value parameter, but

you have the option of supplying additional value parameters, separated

by commas.

iv

Page 5

Related Documentation From Texas Instruments

Related Documentation From Texas Instruments

TLC320AD50C Data Manual, Literature number SLAS131

Data Acquisition Data Book, Literature number SLAD001

Data Converter Selection Guide, Literature number SLABE05

Operational Amplifiers Data Book Volume A, Literature number SLYD011

Operational Amplifiers Data Book Volume B, Literature number SLYD012

Rail-to-Rail Operational Amplifier Selection Guide,

Literature number SLOBE02

Single Supply Operational Amplifier Selection Guide,

Literature number SLOBE03

Mixed Signal Analog CD-ROM, Literature number SLYC005

TMS320C54x CPU and Peripherals, Literature number SPRU131

TMS320C54x Algebraic Instruction Set, Literature number SPRU179

TMS320C54x DSKplus User’s Guide, Literature number SPRU191

Much useful software is available from the TI Internet site. The main TI Web

site is at

http://www.ti.com/

Information on the DSK+ is at

http://www.ti.com/sc/docs/dsps/tools/c54x/c54xdskp.htm

DSK+ software can be downloaded from

http://www.ti.com/sc/docs/dsps/tools/c54x/softsupp.htm

Read This First

v

Page 6

vi

Page 7

Running Title—Attribute Reference

Contents

1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Scope of User’s Guide 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Block Diagram of AD50-EVM 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Special Considerations When Using Sigma-Delta Converters 1-4. . . . . . . . . . . . . . . . . . . . .

1.3.1 Advantages 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Disadvantages 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 AD50-EVM Design and Construction 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 PCB Construction 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Power Supply 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 System Clock 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Reset 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Serial Port Interfacing 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Analog Input 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Preamp Design 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Input Stage Design 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Op Amp Selection 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.4 Antialiasing Filter 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Analog Output 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Setting Up the AD50-EVM 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Setting Up the AD50-EVM With the DSK+ 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Setting Up the AD50-EVM in Stand-Alone Mode 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Configuring the Serial Interface 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Programming the AD50 Registers 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Sine-Wave Generator and Loopback Program 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Results Obtained With AD50 EVM 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 ADC Results 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 DAC Results 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Installing the AD50-EVM A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Board Outline Drawing With Jumper Locations on the AD50 EVM A-2. . . . . . . . . . . . . . . . .

A.2 Connecting the AD50-EVM to the DSK+ A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 Parts List A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4 Circuit Diagrams A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5 PCB Diagrams A-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Title—Attribute Reference

vii

Page 8

Running Title—Attribute Reference

B Programmable Logic B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 DSK+ Mode B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 Stand-Alone Mode B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 Logic Compiler Listing B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Converting DSK+ Software for the AD50-EVM C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 9

Running Title—Attribute Reference

Figures

1–1 AD50-EVM Block Diagram 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 AD50-EVM Input Stage 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–4 AD50-EVM Antialiasing Filter Options 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–5 AD50-EVM Differential to Single-Ended Output Converter 2-9. . . . . . . . . . . . . . . . . . . . . . . . . .

4–1 AD50-EVM ADC Distortion Measurement at 8 ksps 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–2 AD50-EVM ADC Distortion Measurement at 20 ksps 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3 AD50-EVM DAC Distortion Measurement at 8 ksps 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–4 AD50-EVM DAC Distortion Measurement at 20 ksps 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–1 Diagram of the AD50-EVM A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

ix

Page 10

Running Title—Attribute Reference

Tables

2–1 Sampling Frequencies for Various MCLK and Register 4 Values 2-4. . . . . . . . . . . . . . . . . . . . .

A–1 Jumper Positions A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–2 Control and Serial Connections A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–3 Analog Input/Output Connectors A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–1 AD50-EVM Registers B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

Page 11

Chapter 1

Introduction

This user’s guide discusses the design of the AD50-EVM evaluation board and

its use to demonstrate the performance of the TLC320AD50C (AD50) analog

interface circuit.

The TLC320AD50C provides high-resolution low-speed signal conversion

from digital-to-analog (D/A) and from analog-to-digital (A/D) using oversampling sigma-delta technology . This device consists of two serial synchronous

conversion paths (one for each data direction) and includes an interpolation

filter before the DAC and a decimation filter after the ADC. Other overhead

functions provide on-chip timing and control. The sigma-delta architecture produces high-resolution analog-to-digital and digital-to-analog conversion at low

system speeds and low cost.

The options and the circuit configurations of this device can be programmed

through the serial interface. The options include reset, power down, communications protocol, serial clock rate, signal sampling rate, gain control, and test

mode.

T opic Page

1.1 Scope of User’s Guide 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Block Diagram of AD50-EVM 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Special Considerations When Using Sigma-Delta Converters 1-4. . . . .

Introduction

1-1

Page 12

Scope of User’s Guide

The TLC320AD50 is an analog interface circuit (AIC) with many features that

make it suitable for DSP-based applications

-

Single 5-V supply or dual (5-V analog and 3.3-V digital) supplies

-

16-bit resolution sigma-delta ADC and DAC

-

85 dB (min) signal to noise

-

Inherent antialiasing filtering and sin(x)/x compensation

-

High input impedance

-

Supports up to 4 devices on one serial interface

-

Low operating power (175 mW max)

-

Power down mode ( 20 mW max )

-

Small package size

1.1 Scope of User’s Guide

This application note discusses the design of the AD50-EVM evaluation board

and its use to demonstrate the performance of the TLC320AD50C (AD50)

analog interface circuit. The results come from measurements on a small number of samples. For specifications refer to the datasheet.

The AD50-EVM has two AD50 devices for stereo operation. Two AD50-EVMs

can be configured as a four-channel system using a single serial interface. The

AD50-EVM can be interfaced directly to the DSK+ DSP starter kit or other systems which have a compatible synchronous serial interface.

The objective was to design a development board (the AD50-EVM) which

would allow prospective users of the AD50 to determine its capabilities with

a minimum effort. The board can be directly connected to the low cost

TMS320C54x DSP starter kit (DSK+), or to any other system with a compatible

synchronous serial interface. Directly compatible DSP devices include

TMS320C2x, C2xx, C3x, C5x, C54x and C6xxx.

An example program for the DSK+ development system allows the board to

be used as a sine-wave generator, or to output on the DAC samples read in

from the ADC. In this echo mode signal processing functions such as filtering

can easily be included. The AD50-EVM board was also interfaced to a

TMS320C25 development board, which was used to transfer analog data to

a personal computer running real-time FFT spectrum analysis software. This

system was used to prepare the ADC and DAC FFT spectrograms shown in

this user’s guide.

1-2

Page 13

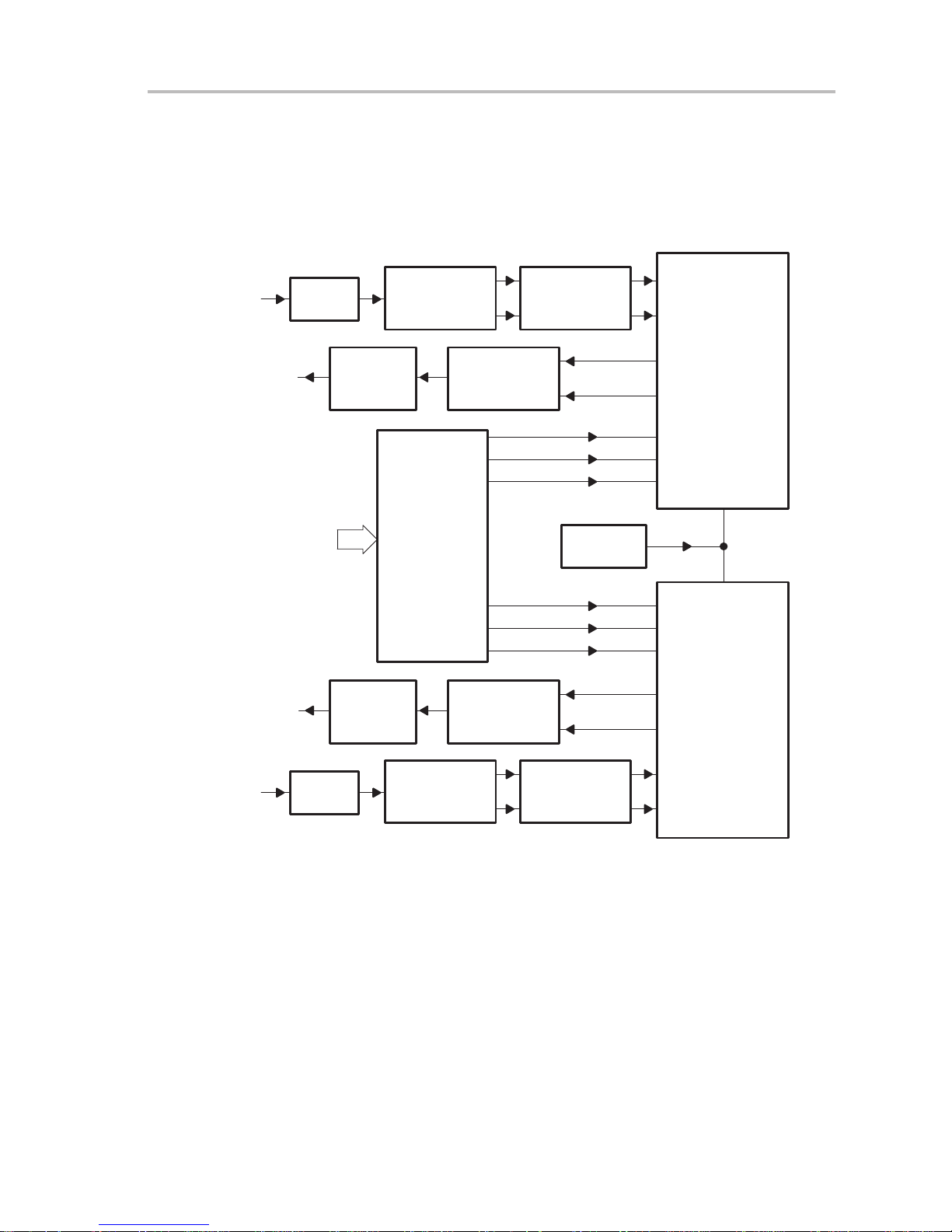

1.2 Block Diagram of AD50-EVM

Figure 1–1 shows the block diagram of the AD50-EVM evaluation

board.

Figure 1–1.AD50-EVM Block Diagram

Block Diagram of AD50-EVM

Audio In

Audio Out

Audio Out

Preamp

DSP Bus

Low Pass

Filter

Programmable

Low Pass

Filter

Level Shift and

Differential

Conversion

Single Ended

Conversion

Logic

Single Ended

Conversion

Antialiasing

Filter

TLC320AD50C

AIC

Serial Interface

Powerdown

FC

Oscillator

FC

Powerdown

Serial Interface

AIC

TLC320AD50C

Audio In

Preamp

The input signal is first buffered and optionally amplified by the preamp stage

before being level-shifted and converted to a differential pair of signals. The

external antialiasing filter is a simple continuous time filter to remove RF noise.

The output from the codec is converted to a single ended signal and is filtered

to remove high frequency noise.

A negative power supply is generated on the AD50-EVM to allow for dc

coupled input and output signals. The clock signal for the codec can be generated by an oscillator on the board or from an external clock. The sampling frequency is set using the programmable clock divider within the AD50. The

AD50 FC, RESET, and POWERDOWN signals can be controlled via a software programmable register.

Level Shift and

Differential

Conversion

Antialiasing

Filter

Introduction

1-3

Page 14

Special Considerations When Using Sigma-Delta Converters

1.3 Special Considerations When Using Sigma-Delta Converters

Sigma-delta analog-to-digital converters typically consist of an analog modulator (fourth order in the case of the AD50) followed by a digital filter section.

The modulator contains a 1-bit ADC (a comparator) which produces a 1-bit

wide data stream, which is applied to the input of the digital filter. It is also applied to the input of a 1-bit DAC, the output of which is fed back to the input of

the modulator. The 1-bit ADC is clocked much faster than the desired output

sampling frequency (F

tization noise generated is uniformly spread over a wide range of frequencies.

A noise-shaping filter within the analog modulator reduces the noise in the

pass-band, increasing it elsewhere. A low-pass digital filter then removes the

unwanted high frequency quantization noise and the signal is resampled at the

desired output frequency.

The sigma-delta DAC in the AD50 consists of a digital interpolating filter operating at 256 × F

S

digital filter removes most of the image frequencies, that would otherwise be

present at the output of a conventional DAC. This avoids the need for a high-order analog low-pass reconstruction filter. Separate sin(x)/x compensation is

not needed, as this is inherent in the DAC architecture.

), (64 × FS for the AD50) and the large amount of quan-

S

followed by a 1-bit DAC and a second-order modulator. The

1.3.1 Advantages

Sigma-delta converters have several advantages and a few disadvantages

relative to other types of ADC which are summarized below.

-

Sigma-delta conversion is inherently linear because there is no reference

resistor chain as in flash or successive approximation converters. This results in extremely low distortion.

-

Inherent monotonicity

-

No missing codes

-

Antialias filtering is inherent within sigma-delta converters. This greatly

simplifies their application, because only a simple external RC filter is required at the input of the ADC to achieve the necessary alias rejection.

-

The digital filters which form an integral part of the ADC and DAC are usually of the finite impulse response type, which gives a linear phase characteristic with high stability.

-

The cutoff frequency of the digital filters automatically tracks the sampling

rate.

-

DAC anti-image filtering is greatly simplified because an internal digital filter attenuates image frequencies. A simple analog filter is sufficient to remove HF noise.

-

No need for sin(x)/x compensation.

-

The sigma-delta architecture is compatible with dense, low-cost, digital IC

processes.

1-4

Page 15

1.3.2 Disadvantages

Special Considerations When Using Sigma-Delta Converters

-

The digital filters in sigma-delta converters introduce into the conversion

process a time delay that makes them unsuitable for some control applications. The AD50 ADC has a delay of 17 samples and the DAC has an 18

sample delay.

-

It is not practical to multiplex several inputs to a single sigma-delta ADC

except at very low rates, because each channel would be corrupted by the

earlier samples from other channels still propagating through the digital

filter. Although the AD50 has an input multiplexer , this is only for selecting

one or another input, not for interleaving two input channels onto one data

stream.

-

Audio band converters are optimized for ac signals and a small dc offset

may be present.

-

Spurious low level tones can sometimes occur at very low input signal

levels, especially if clock signals at Fs/2 are allowed to couple into the

reference voltage pins. Such tones can be identified because their

frequency is affected by small changes in dc offset.

Introduction

1-5

Page 16

1-6

Page 17

Chapter 2

AD50-EVM Design and Construction

This chapter discusses the printed-circuit board design considerations for the

AD50-EVM.

T opic Page

2.1 PCB Construction 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Power Supply 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 System Clock 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Reset 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Serial Port Interfacing 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Analog Input 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Analog Output 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AD50-EVM Design and Construction

2-1

Page 18

PCB Construction

2.1 PCB Construction

The AD50-EVM printed-circuit board is constructed of 4 layers, with ground

and power planes sandwiched between the top and bottom signal-carrying

layers. This minimizes the coupling of RF noise into the system by providing

very low impedance to power and ground, and by shielding signal tracks. The

AD50 is available in two surface-mount packages, the DW and PT . The PT has

a smaller footprint size and is much thinner (only 1.6 mm high). It has 48 pins

at a pitch of 0.5 mm, making it very suitable for PCMCIA and other miniature

applications. However it is difficult to hand solder , and for prototype evaluation

the use of the DW package is recommended. This package has 28 pins at a

pitch of 1.27 mm (0.05 inch) and so is much easier to handle. Surface-mounted

components were used except for the connectors, which through-hole connectors offering robustness.

The printed-circuit board is the same size as the DSK+ board. The AD50-EVM

and the DSK+ can be stacked one above the other using inter-board links. Either board can be on top, but placing the AD50-EVM on top gives better access

to the EVM test points.

A separate connector has been provided for interfacing to systems other than

the DSK+. This brings out the SCLK, FS

Each signal is interleaved with a ground conductor in the ribbon cable, allowing

a longer cable length without crosstalk. Nevertheless, this cable should be as

short as reasonably possible, since ringing in the unterminated cable may become excessive for lengths greater than 3 feet. T o minimize RF emissions, the

cable should be shielded, with the shield connected to the ground plane at the

ground point provided adjacent to pins 1 and 2 of the connector. This connector

must not be used simultaneously with the connections around the edge of the

AD50-EVM board that are specifically intended for the DSK+.

, DIN, DOUT, and RESET signals.

2-2

For the best signal-to-noise ratio, it is often recommended that the

ground plane be split into separate analog and digital sections, joined

together in only one place with the split passing under the AD50 package between its analog and digital ground pins. The split prevents digital noise currents from inducing noise voltages in the analog ground of

the device. The DSK+ has ground and power pins along both edges of

the board, making the use of split ground planes ineffective. Instead

short breaks were inserted on the ground plane to separate the analog

and digital grounds and reduce the common impedance

Page 19

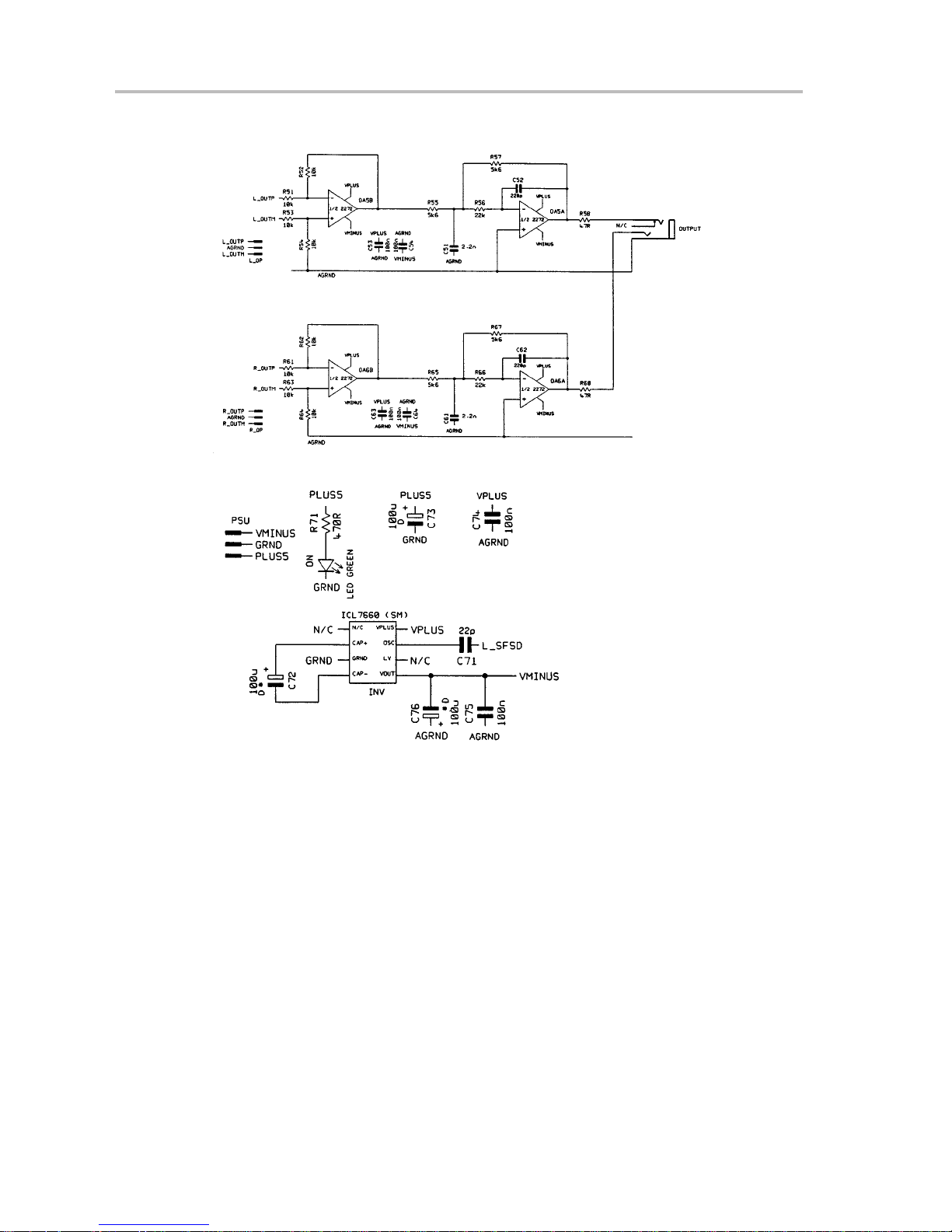

2.2 Power Supply

2.3 System Clock

Power Supply

The AD50-EVM board requires only +5 Vdc; a –5-Vdc supply for some of the

op-amps is generated on the board using a CMOS 7660 charge pump phaselocked to the frame sync output of the AD50. Phase-locking minimizes the risk

of audible beats between the sampling clock and the 7660 clock. The OSC pin

of the 7660 is coupled to the master FSD

with a 22 pF capacitor. This method

allows the 7660 oscillator to free-run when there is no frame sync, ensuring

that the negative power is always maintained, even when the AD50 is held in

reset. The 7660 divides the signal on the OSC pin by 2 internally , ensuring that

the charge pump operates at a 50% duty cycle, even with a grossly asymmetric

input such as that provided by frame sync. Not all negative supply generators

contain a divider. Check before using any other type.

The digital part of the AD50 can be operated at 3.3 V . Users wishing to investigate this should remove R16 and R36 and connect 3.3 V power to L_VD and

R_VD.

When the AD50-EVM is used in standalone mode, in conjunction with a

separate DSP system, a crystal oscillator must be fitted to the socket provided.

A frequency of 10.24 MHz is suggested, as this will allow standard sampling

frequencies such as 10, 16, and 20 kHz to be achieved by programming the

AD50 clock divider and phase-locked loop. Table 2–1 shows the sampling

frequencies that can be selected for a number of master clock frequencies.

Frequencies shown in brackets are above the maximum sampling frequency

specified for the AD50.

In standalone mode the AD50-EVM can be clocked at frequencies up to

22.579 MHz. However, when used in conjunction with the DSK+ the upper

frequency is limited by the maximum clock rate of the TMS320C542 DSP

device. The 10.24 MHz oscillator supplied with the AD50-EVM will drive the

TMS320C542 on the DSK+ at 40.96 MHz, which is only slightly higher than its

maximum operating frequency of 40.00 MHz. However, at room temperature

this should not cause any problems, because the TMS320C542 is tested by

TI at 40.00 MHz over the temperature range 0-70_C. The authors have

successfully operated a DSK+ in conjunction with an AD50-EVM at MCLK

frequencies from 4 MHz to 13 MHz at room temperature, but this may not work

with all DSK+ units. Alternatively, the DSK+ and AD50-EVM clocks can be

separated by removing resistor R80 from the AD50-EVM board and a suitable

oscillator installed on each board. (If this modification is made, 3 and 4 channel

modes will not work correctly because all the AD50s must have an identical

MCLK. Removing R80 prevents the clock from being transmitted between the

boards.)

It is important to ensure that only one oscillator is used in the system (except

as described above), otherwise results will be unpredictable. No damage will

be caused, however, as current limiting resistors are provided on the output

of each oscillator. Electrically it makes no difference whether the oscillator is

fitted to the DSK+, or to the first or second AD50-EVM board.

AD50-EVM Design and Construction

2-3

Page 20

Reset

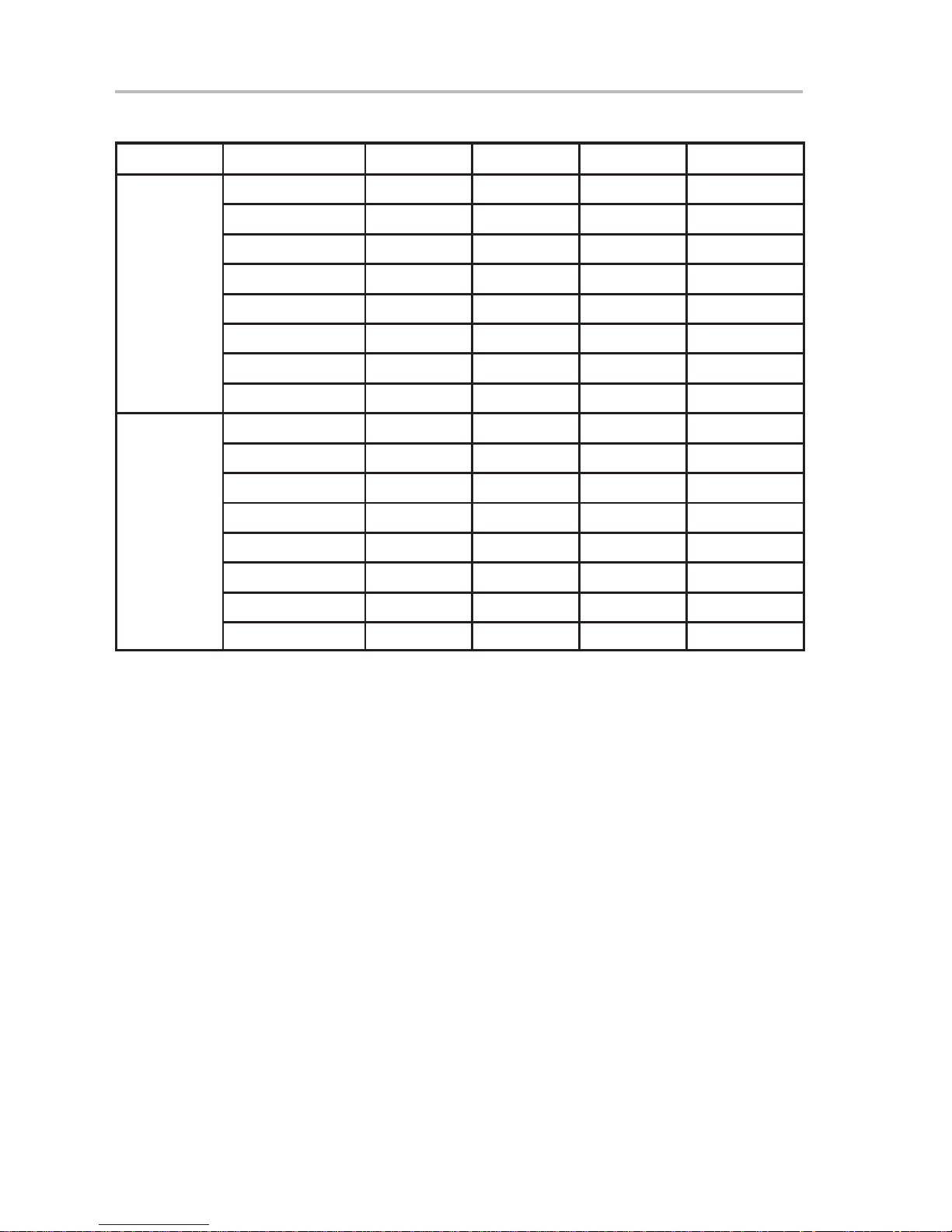

Table 2–1.Sampling Frequencies for Various MCLK and Register 4 Values

Reg 4, Bit 7 Reg 4, Bits 6–4 8.192 MHz 10.000 MHz 10.240 MHz 11.2896 MHz

0 (default) 8 kHz 9.765 kHz 10 kHz 11.025 kHz

1 (64 kHz) (78.125 kHz) (80 kHz) (88.2 kHz)

2 (32 kHz) (39.063kHz) (40 kHz) (44.1 kHz)

bit 7 = 0

PLL on

bit 7 = 1

PLL off

3 21.333 kHz (26.042 kHz) (26.666 kHz) (29.4 kHz)

4 16 kHz 19.531 kHz 20 kHz 22.05 kHz

5 12.8 kHz 15.625 kHz 16 kHz 17.64 kHz

6 10.666 kHz 13.021 kHz 13.333 kHz 14.7 kHz

7 9.1432 kHz 11.161 kHz 11.429 kHz 12.601 kHz

0 2 kHz 2.441 kHz 2.500 kHz 2.756 kHz

1 16 kHz 19.531 kHz 20 kHz 22.05 kHz

2 8 kHz 9.766 kHz 10 kHz 11.025 kHz

3 5.333 kHz 6.510 kHz 6.666 kHz 7.35 kHz

4 4 kHz 4.883 kHz 5 kHz 5.513 kHz

5 3.2 kHz 3.906 kHz 4 kHz 4.41 kHz

6 2.666 kHz 3.255 kHz 3.333 kHz 3.675 kHz

7 0.798 kHz 2.79 kHz 2.857 kHz 3.15 kHz

2.4 Reset

2-4

In all operating modes the AD50-EVM is reset when the power is switched on.

In DSK+ mode it is also reset when the DSK+ itself is reset. The programmable

logic on the AD50-EVM is configured so that in the reset state all the AD50s

are powered down and in slave mode and that the AC01 on the DSK+ is powered up as normal. This means that even with one or two AD50-EVMs attached

to a DSK+ system, all the DSK+ demonstration software works normally with

the AC01 AIC.

To use one or more AD50s it is necessary to program bits 0-3 of I/O address

0. Bit 0 controls the reset state of the AD50s. Bit 0 = 0 resets all AD50s and

bit 0 = 1 allows them to run. Bits 1, 2, and 3 are encoded to control the number

of AD50s that are powered up (see Table B–1 for details). Note that no provision has been made to operate the AD50s and the AC01 together. This is because their control registers are incompatible and it would be difficult to prevent bus conflicts on the serial interface.

The reset pins are connected to both the SERIAL and CONTROL cable headers for use in standalone mode (see Table A–2 for pinouts).

Page 21

Serial Port Interfacing

2.5 Serial Port Interfacing

The AD50-EVM has been designed to interface to the same synchronous serial port that is used by the AC01 on the DSK+ system. This is achieved by sharing the serial clock, frame sync and data signals, and by powering down the

AC01 when AD50s are in use.

When two AD50-EVMs are connected together the serial interface frame sync

signals need to be configured differently on the primary and secondary boards.

This is achieved using the 22V10 programmable logic device as shown in

Figure 2–1. The logic equations are listed in Appendix B. The serial clock,

serial data in, and serial data out signals are connected to all devices. Only one

device at a time drives these lines.

When two AD50-EVMs are used in standalone mode together with a separate

DSP system, the ribbon cable must be attached to the primary board so that

the master device frame sync signal is transmitted to the external system. The

two AD50-EVM boards have all the necessary signals linked via the four connectors around the periphery.

Figure 2–1.Configuration of Serial Interface on Primary and Secondary AD50-EVMs

FS

22V10

EXT FS

DSK+ Primary

AD50-EVM

FS

AD50

FSD

FS

AD50

FSD

EXT FS

Secondary

AD50-EVM

22V10

FS

AD50

FSD

FS

AD50

FSD

AD50-EVM Design and Construction

2-5

Page 22

Analog Input

2.6 Analog Input

The AD50 can be operated from a single 5 V supply or from a 5 V analog supply

and a 3.3 V digital supply . The AD50-EVM uses 5 V for both analog and digital

supplies to be compatible with the DSK+, and generates an additional –5 V

supply on the board. This negative supply allows the input and output circuitry

to be dc coupled. In an ac coupled system alternative configurations may be

used that do not require a negative supply.

The input circuitry consists of a switchable gain preamp, a single-ended to differential converter with level shifting, and an antialiasing filter.

2.6.1 Preamp Design

This amplifier stage, illustrated in Figure 2–2 allows the use of either a line level

input (approximately 1 Vrms full scale) or a low level input (approximately

100mVrms full scale). With the link labeled

ty gain from dc to 20 kHz. With this link inserted the preamp gain is increased

by 20 dB.

The signal can be ac coupled, by removing the link labeled DC. The use of two

tantalum capacitors back-to-back allows ±10 V dc voltage bias at the input

without damaging the capacitors.

GAIN

removed the preamp has uni-

Figure 2–2.AD50-EVM Input Preamp

DC

2.2 kΩ

IN

4.7 µF

Tant

4.7 µF

Tant

This preamp uses the op amp in the inverting configuration to ensure that the

input common mode range of the op amp cannot be exceeded, since both inputs are always at a voltage close to ground. In the non-inverting configuration

the op amp inputs can approach the supply rails, causing distortion.

2.6.2 Input Stage Design

Gain

22 kΩ

5 V

_

+

–5 V

1 nF

22 kΩ

100 nF

1/2 TLC2272

100 nF

The AD50 analog to digital section uses differential inputs biased at 2.5 V . Maximum code is generated with 3 V

put stage provides the necessary level shifting and single-ended to differential

conversion, prior to the inputs of the AD50.

2-6

PEAK-PEAK

on both differential inputs. The in-

Page 23

Figure 2–3.AD50-EVM Input Stage

Analog Input

10 kΩ

5 V

Input

10 kΩ

5 V

_

+

–5 V

100 nF

10 kΩ

100 nF

1/2 TLC2272

100 nF

10 kΩ

FILT

12 kΩ

10 kΩ

10 kΩ

_

+

10 kΩ

5 V

_

+

100 nF

NEG

1/2 TLC2272

100 nF

POS

1/2 TLC2272

The first op amp inverts the incoming signal, to provide the differential pair

while the second two op amps do the necessary level shifting. The design of

this stage ensures that any noise on FILT appears equally, and in phase, on

both differential inputs. The first op amp needs ±5-V supplies, while the second

two are powered from just 5-V and ground to ensure that the inputs to the AD50

never go below ground.

It is recognized that this device is likely to be used in predominantly digital designs, powered from a single 5 V supply , where the need for a negative supply

could be perceived as a problem. However, since the current drawn from this

negative supply will be small, it is possible to use an inverter chip to provide

a local negative rail for the op amps. The 7660 device requires no external inductors and just 2 external capacitors. Its internal clock can be synchronized

to the codec’s sampling clock, ensuring that any interference generated by the

7660 appears on the codec’s output as a dc offset or at the Nyquist frequency

rather than as noise in the pass-band.

2.6.3 Op Amp Selection

The design of the input stage uses op amps in the inverting configuration. This

has the advantage of keeping both inputs at the reference voltage, preventing

problems with input common mode range.

AD50-EVM Design and Construction

2-7

Page 24

Analog Input

For a full-scale signal the outputs of the op amps that drive the codec inputs

will reach 4 V . Many op amps will not behave well at this output level with a 5-V

supply (in fact the system was tested at 4.75 V to allow for the minimum rated

power supply voltage of the AD50).

Miniature systems often require that analog and digital circuits be in close

proximity to each other. This can lead to problems where radio frequency interference from clock signals or DSP bus lines is demodulated by op amps, leading to an increased DC offset. If the RF is modulated, then that modulation may

appear at the op amp output. CMOS and BiFET op amps can be more resistant

to demodulating RF than bipolar devices. Take particular care to keep digital

signals away from analog ones, and be generous with power supply decoupling and filtering. Power planes help a great deal in reducing system noise.

The authors chose the TI device TLC2272 which is a low noise CMOS dual

op amp designed for single supply operation. It has full rail to rail output swing

and low distortion. However the distortion increases when driving loads of

about 2 kΩ or less.

2.6.4 Antialiasing Filter

Sigma-delta converters have the advantage of providing anti-aliasing filtering

as an integral part of their operation. However this filtering has

multiples of the oversampling frequency . The AD50 is a 64 times oversampling

converter so for a sampling rate of 20 kHz the first

1.28 MHz and will be 20 kHz wide. It is important to ensure that no energy at

this frequency is present across the inputs to the codec. A simple single pole

RC filter is sufficient. If ceramic capacitors are used for this filter they should

be of the COG or NPO dielectric type. Significant distortion can be introduced

by the voltage dependent capacitance of other types of dielectric. Two filter

configurations are possible, as shown in Figure 2–4.

holes

hole

will be centered at

in it, at

Figure 2–4.AD50-EVM Antialiasing Filter Options

TLC320AD50C

+

_

+

_

2-8

4.7 kΩ

INP

1/2 TLC2272

220 pF

4.7 kΩ

INM

1/2 TLC2272

(a)

Figure 2–4a gives good rejection of differential noise signals but common

mode noise is not removed.

Figure 2–4b gives good rejection of common mode noise signals and, if the

capacitors and resistors are well matched, good rejection of differential noise.

+

_

1/2 TLC2272

+

_

1/2 TLC2272

TLC320AD50C

4.7 kΩ

INP

470 pF

4.7 kΩ

INM

470 pF

(b)

Page 25

2.7 Analog Output

Analog Output

Since most noise sources are likely to be coupled equally into both inputs the

filter in Figure 2–4b is usually the best choice (the evaluation board has

footprints to allow for either or both configurations, with the capacitor in

Figure 2–4a not connected).

The AD50 allows higher source impedances at its inputs than many

sigma-delta converters, easing the drive requirements.

The aux inputs also have antialiasing filters connected, allowing the use of

these inputs from external sources without any special filtering requirements.

The antialiasing filter components are placed as close as possible to the inputs

to the AD50 to reduce the possibility of noise pickup between the filter and the

ADC. The use of 0603 footprint surface-mount components makes this

possible.

The AD50 uses a pair of differential voltage outputs. The output stage needs

to convert the differential signals to a single ended output, and to attenuate

noise outside the pass-band. This filter is not a conventional reconstruction filter, since the AD50 has an integral low-pass reconstruction filter. The filter is

a 12-kHz second order low-pass filter designed for use at 20 ksps and will be

less effective at lower sampling rates. Since this filter only removes out of band

noise it will be unnecessary in many applications.

Figure 2–5.AD50-EVM Differential to Single-Ended Output Converter

5.6 k

TLC320AD50C

OUT_P

OUT_M

10 kΩ

10 kΩ

10 kΩ

10 kΩ

5 V

_

+

–5 V

100 nF

1/2 TLC2272

100 nF

2.2 nF

5.6 k

22 kΩ

220 pF

5 V

_

+

–5 V

1/2 TLC2272

100 nF

100 nF

50

Out

AD50-EVM Design and Construction

2-9

Page 26

2-10

Page 27

Chapter 3

Setting Up the AD50-EVM

Setting up the AD50-EVM normally involves coupling it to the synchronous

serial port of a digital signal processing system. Two configurations are

supported. The first is to couple the AD50-EVM to a DSK+ development

system by means of four connectors directly linking the circuit boards together.

The DSK+ consists of a TMS320C542 16-bit fixed point digital signal

processor combined with a 14-bit analog interface circuit and PC printer port

compatible data interface. This allows the downloading and debugging of C

or assembler programs from a DOS or Windows environment. Many example

programs are supplied with the DSK+, which can readily be adapted to

interface to the AD50-EVM. (See Appendix C for detailed information on

adapting example programs.) The second configuration is standalone mode

where a ribbon cable up to 1 m long connects the AD50-EVM to a separate

DSP system. In standalone mode some options such as the number of active

AD50s must be set using jumpers or by control signals from the remote

processor. In DSK+ mode, almost everything is set from software.

Topic Page

3.1 Setting Up for the DSK+ 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Setting Up for Stand-Alone Mode 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Configuring the Serial Interface 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Programming the AD50 Registers 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Sine-Wave Generator and Loopback Program 3-4. . . . . . . . . . . . . . . . . . .

Setting Up the AD50-EVM

3-1

Page 28

Setting Up the AD50-EVM With the DSK+

3.1 Setting Up the AD50-EVM With the DSK+

The first step is to couple the two circuit boards together using four inter-board

connectors. See Appendix A for full details. The AD50-EVM takes its power

directly from the DSK+. Inputs and outputs are provided on stereo 3.5 mm

jacks. Note that in single channel mode, the active device connects to the ring

contact on the jack. This is conventionally the left channel on stereo headphones. Attaching the AD50-EVM to the DSK+ does not affect the operation

of the AC01 on the DSK+ because the reset default is for both AD50 devices

to be powered down and in slave mode. The master clock source can be the

10.00 MHz oscillator supplied with the DSK+, the 10.24 MHz oscillator provided with the AD50-EVM or any other oscillator module within the capabilities

of the DSK+ (see section 2.3 for details). It does not matter which socket is

used, so long as only one oscillator module is present in the system. Check

that the operation of the SELFTEST and example programs has not been affected by adding the AD50-EVM or the oscillator selection.

Either type in and assemble a program such as the sine-wave generator listed

below, or modify an appropriate example program such as OSCOPE supplied

with the DSK+. Appendix C shows how OSCOPE was modified to work with

the AD50-EVM.

3.2 Setting Up the AD50-EVM in Stand-Alone Mode

In stand-alone mode the AD50-EVM needs to be connected to a system with

a suitable DSP serial interface. This should include a means of controlling the

RESET signal. The connector marked SERIAL has all the necessary signals,

with interleaved grounds. The POWERDOWN and other control signals are

available on the CONTROL connector. In stand-alone mode all the devices are

powered up by default.

A power supply of 5 V at approximately 150 mA needs to be supplied to the

positive (+) and 0 pins of the PSU connector. The negative (–) pin is an output

from the negative voltage converter.

In stand-alone mode an oscillator of up to 22.579 MHz needs to be inserted

in the socket on the AD50-EVM. A 10.24 MHz oscillator is supplied.

Configuration of the registers in the AD50s is software controlled via the serial

interface, as described for the DSK+ mode. However the RESET, POWERDOWN and FC signals need to be set via the CONTROL connector.

3.3 Configuring the Serial Interface

First, the four least significant bits of I/O address 0 must be configured with the

value 2. This selects one AD50 and disables the AC01, holding the AD50 in

reset. Note that the AC01 on the DSK+ is reset by manipulating the XF output

of the C542, whereas the AD50-EVM implements the software reset control

as bit 0 of I/O address 0. This frees the XF bit for other uses, such as driving

3-2

Page 29

an oscilloscope for debugging purposes. Then the ’C542 serial port is initialized to 16-bit mode with external frame sync pulses. The AD50 is then taken

out of reset by writing 3 to I/O address 0. The AD50 starts sending frame sync

pulses and a serial clock signal to the ’C542, which responds by transmitting

data from the serial port. This data consists of a list of alternating primary and

secondary transmissions. The primary transmissions are dummy words with

bit 0 set to 1 to request the interleaved secondary transmissions. Each secondary transmission is a 16-bit word containing commands to initialize the four

control registers of the AD50.

For each secondary transmission, bits 12-8 encode the binary address of the

register to be accessed, bit 13 specifies a read or write access and bits 7–0

contain the data to be written for write operations.

3.4 Programming the AD50 Registers

Register 0 is a dummy register, equivalent in principle to a NOP instruction.

Writing to it does nothing. It is needed so that when several AD50s are cascaded it is possible to modify the control registers of one device without disturbing the others.

Programming the AD50 Registers

Register 1 controls reset and power-down status, input selection, monitor amplifier signal source and gain, digital loop back test mode and 15 or 16 bit DAC

mode. Once 16 bit mode has been selected, it is not possible to request further

secondary communications by setting bit 0 of a serial port data word. However,

the AD50-EVM provides a means for driving the FC pin of the AD50 chip by

writing to bit 0 of I/O address 1. The value written is applied to the FC pin, and

a 1 initiates a hardware secondary communication request. FC is sampled by

the AD50 on the rising edge of frame sync.

Register 2 allows control of the flag bit, reading of the decimator overflow flag,

selection of 15 or 16 bit ADC mode and control of the analog loop back test

mode.

Register 3 is used to select the number of cascaded AD50 devices (up to a

maximum of 1 master and 3 slaves) and to control the time between communications from each device. It is important that register 3 is only programmed

after the sampling frequency has been set. It is convenient to program everything common to all the devices prior to setting register 3. Thereafter, when

secondary communications are requested, each device takes part in turn and

must either be programmed individually or a NOP instruction sent to register

0.

Register 4 controls the analog input and output gains and the sampling

frequency.

It is only necessary to reprogram those registers that have unsuitable default

values. If none of the AD50 registers are programmed, the system will default

to a sampling frequency of 10 kHz for a MCLK frequency of 10.24 MHz. If I/O

address 0 is not programmed as described above, the system will default to

using the AC01 ADC and DAC as normal.

Setting Up the AD50-EVM

3-3

Page 30

Sine-Wave Generator and Loopback Program

3.5 Sine-Wave Generator and Loopback Program

The following code is for a very simple sine-wave generator and loop back program that demonstrates how the DSK+ can be programmed to drive the

AD50-EVM. The sine-wave is generated by means of a lookup table which is

cyclically indexed. This program was used to generate the test waveforms for

the DAC distortion measurements in section 4 below. The sine table delivers

an output waveform at -3dB relative to clipping, to allow direct comparison with

the levels used in the AD50 data book.

This program (AD50SIN.ASM) generates a sine-wave when the assembler

variable

it to the DAC. Filtering code can be inserted if desired. The variable

specifies whether the least significant bit of data written to the DAC is masked

out.

The program should be edited using a text editor (such as MSDOS EDIT) and

assembled as follows:

This generates a binary object file called AD50SIN.OBJ which is loaded into

the DSK+ as follows:

makesine

is set to 1. Otherwise it reads data from the ADC and copies

DSKPLASM AD50SIN

mode16bit

LOADAPP -A AD50SIN.OBJ

.title ”Sine-wave generator for AD50-EVM and C54x DSK+”

.width 80

.length 55

; Adapted from DSK+ example programs by John Walliker and Julian Daley

; June 1997

.mmregs

.setsect ”.text”,0x1800,0 ; these assembler directives specify

.setsect ”.data”,0x0200,1 ; the absolute addresses of different

.setsect ”vectors”,0x0180,0 ; sections of the assembly code

makesine .set 1

mode16bit .set 0

sinestepsize .set 1

sinetablesize .set 20 ; for 1kHz at 20 ksps

; The vectors in this table can be configured for processing external and

; internal software interrupts. The DSKplus debugger uses four interrupt

; vectors. These are RESET, TRAP2, INT2, and HPIINT.

; * DO NOT MODIFY THESE FOUR VECTORS IF YOU PLAN TO USE THE DEBUGGER *

;

; All other vector locations are free to use. When programming always be sure

; the HPIINT bit is unmasked (IMR=200h) to allow the communications kernel and

; host PC interact. INT2 should normally be masked (IMR(bit 2) = 0) so that the

; DSP will not interrupt itself during a HINT. HINT is tied to INT2 externally.

.sect ”vectors”

reset goto #80h ;00; RESET * DO NOT MODIFY IF USING DEBUGGER *

nop

nop

3-4

Page 31

Sine-Wave Generator and Loopback Program

nmi return_enable ;04; non-maskable external interrupt

nop

nop

nop

trap2 goto #88h ;08; trap2 * DO NOT MODIFY IF USING DEBUGGER *

nop

nop

.space 52*16 ;0C-3F: vectors for software interrupts 18-30

int0 return_enable ;40; external interrupt int0

nop

nop

nop

int1 return_enable ;44; external interrupt int1

nop

nop

nop

int2 return_enable ;48; external interrupt int2

nop

nop

nop

tint return_enable ;4C; internal timer interrupt

nop

nop

nop

brint return_enable ;50; BSP receive interrupt

nop

nop

nop

bxint return_enable ;54; BSP transmit interrupt

nop

nop

nop

trint dgoto receive ;58; TDM receive interrupt

nop

nop

txint return_enable ;5C; TDM transmit interrupt

nop

nop

nop

int3 return_enable ;60; external interrupt int3

nop

nop

nop

hpiint goto #0e4h ;64; HPIint * DO NOT MODIFY IF USING DEBUGGER *

nop

nop

.space 24*16 ;68-7F; reserved area

.data

sineindex .word 0 ; index to sine-wave table

sinevalue .word 0 ; workspace for sine-wave generation

Setting Up the AD50-EVM

3-5

Page 32

Sine-Wave Generator and Loopback Program

initwork .word 0 ; workspace for initialization

.text

start: intm = 1 ; disable all interrupts

pmst = #01a0h ; Interrupt pointer maps vectors to address 180h

sp = #0ffah ; stack pointer located in Communications Kernel

imr = #240h ; unmask TDM RINT and HPIINT(host port interface)

OVM = 0 ; OVM = 0 (do not clip overflow)

ASM = #0 ; ASM = 0 (shift=0)

DP = #0

AC01INIT:

; initialize serial port and ad50-evm on-board logic

ar1 = #initwork ; workspace for storing value to be output to ad50-evm

*ar1 = #0010b ; switch on one AD50 and hold it in reset

port(0) = *ar1 ; write the data to i/o port 0

repeat(#23) ; hold reset low for at least 6 mclk cycles

nop ; (4 dsp clock cycles == 1 mclk cycle)

tcr = #10h ; stop timer

imr = #240h ; unmask RXINT and HPIINT

tspc = #0008h ; stop TDM serial port

tdxr = #0h ; send 0 as first xmit word

tspc = #00c8h ; reset and start TDM serial port

*ar1 = #0011b ; bring ad50 out of reset with one channel powered up

port(0) = *ar1

; initialize ad50 registers

a = #0000010010010000b ; register 4

call ad50init ; change fsamp to 20kHz

a = #0000001011000000b ; register 4

call ad50init ; light led

; a = #0000000100000001b ; select 16 bit dac mode

; call ad50init ; this must be the last command

intm = 0 ; enable all interrupts

WAIT idle(1) ; idle waiting for interrupts

nop

goto WAIT

;------------------------------------------------------------------------------; ad50 init routines here

ad50init

ifr = #080h ; clear flag from IFR

tdxr = #01h ; request secondary when AD50 starts

call waitfortdx ; wait for primary to xmit

tdxr = a ; send register value to serial port

ifr = #080h ; clear flag from IFR

call waitfortdx ; wait for secondary to xmit

tdxr = #0h ; send neutral state in case last init

ifr = #080h ; clear flag from IFR

call waitfortdx ; wait for neutral state to xmit

3-6

Page 33

Sine-Wave Generator and Loopback Program

return ; return from subroutine

waitfortdx ; a robust way of waiting for a tdm port

b = mmr(ifr) ; transmission to complete

b &= #10000000b

nop

nop

if(BEQ) goto waitfortdx

return

;-------------------------------------------------------------------------------receive

; save context if necessary

B = mmr(TRCV) ; always read serial port to avoid buffer overflow

; which would stop interrupts from being generated

.if makesine = 0 ; don’t make a sinewave - just echo data from adc to dac

; put code for filtering etc here

.else ; make a sinewave on LEFT channel

AR1 = #sineindex

AR2 = #sinevalue

A = *AR1

A += #sinestepsize

B = A

A -= #sinetablesize

nop ; two nops to allow for pipeline delay

nop

if (ALT) execute(1) ; check whether index points outside table

A = B

*AR1 = A

A += #sinetable20_3dB

*AR2 = prog(A) ; get sinewave value from table in program memory

B = *AR2 ; (could use sine table in rom for this)

.endif

.if mode16bit = 0

B &= #1111111111111110b; mask least significant bit if in 15 bit mode to

.endif ; prevent inadvertent secondary communication requests

mmr(TDXR) = B

; restore context if necessary

return_enable ; return to waiting loop

;-------------------------------------------------------------------------------transmit: ; Transmit and receive interrupts are inherently

; synchronized so there is no point in using both

return_enable

;-------------------------------------------------------------------------------sinetable20_3dB ; -3dB re clipping, 1kHz @ 20 ksps, 20 samples/cycle

.word 0, 7160, 13619, 18745, 22036, 23170, 22036, 18745, 13619, 7160

.word 0, -7160, -13619, -18745, -22036, -23170, -22036, -18745, -13619, -7160

sinetable8_3dB ; -3dB re clipping, 1kHz @ 8 ksps , 8 samples/cycle

.word 0, 16384, 23170, 16384, 0, -16384, -23170, -16384

.end

Setting Up the AD50-EVM

3-7

Page 34

3-8

Page 35

Chapter 4

Results Obtained With AD50 EVM

This chapter describes the results possible with the AD50 EVM. Actual measurements are presented.

Topic Page

4.1 ADC Results 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 DAC Results 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Results Obtained With AD50 EVM

4-1

Page 36

ADC Results

4.1 ADC Results

T o evaluate the performance of the ADC channel of the AD50-EVM, FFT measurements were performed.

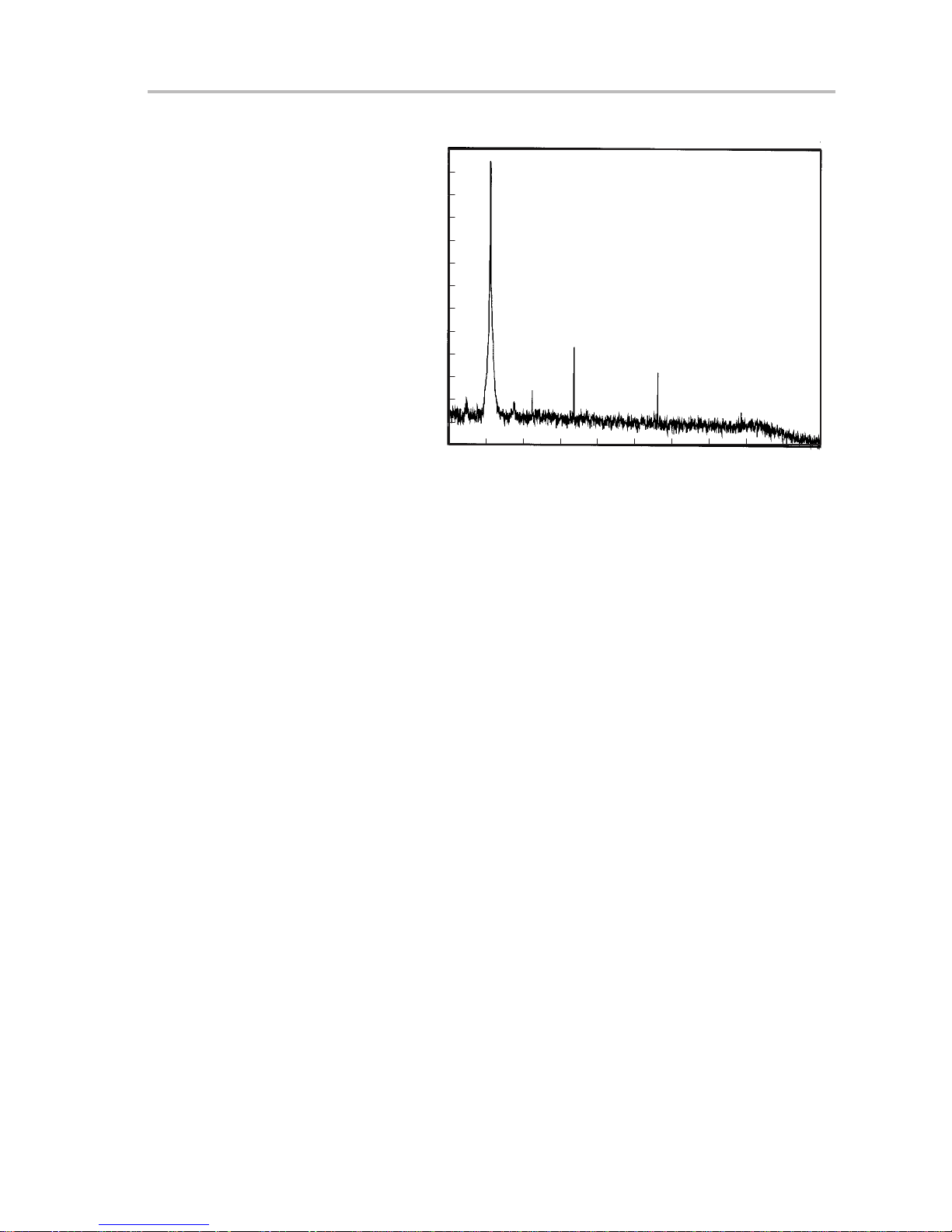

Figure 4–1.AD50-EVM ADC Distortion Measurement at 8 ksps

0

–10

–20

–30

–40

–50

–60

–70

–80

Full Scale – dB

–90

–100

–110

–120

–130

0 0.5 1 1.5 2 2.5 3

Input Signal: 1.1 kHz, –3 dB

FFT: 8ksa/s, 2048 Frequency Bins,

16 Averages

f – Frequency – kHz

3.5 4

Figure 4–1 shows an FFT plot obtained from the ADC of the AD50-EVM. The

input signal was a 1.2-kHz sine wave at -3 dB relative to maximum input. A digital oscillator using a 20 bit DAC was used to produce the test signal. By adding

up the energy in each frequency bin within (a) the signal, (b) the harmonics and

(c) the rest of the noise floor, figures for SNR, SNR and SINAD can be calculated. The figures were 82.9 dB SNR, 79.4 dB SDR and 77.8 dB SINAD. These

figures have not been compensated for noise and distortion components in the

oscillator output.

4-2

Page 37

Figure 4–2.AD50-EVM ADC Distortion Measurement at 20 ksps

0

–10

–20

–30

–40

–50

–60

–70

–80

Full Scale – dB

–90

–100

–110

–120

–130

0123 45 6

Figure 4–2 shows an FFT plot obtained from the ADC while sampling at

20 ksps. The performance figures were 82.7 dB SNR, 81.0 dB SDR and

78.7 dB SINAD.

Input Signal: 1.1 kHz, –3 dB

FFT: 20 ksa/s, 2048 Frequency Bins,

16 Averages

f – Frequency – kHz

ADC Results

78910

Results Obtained With AD50 EVM

4-3

Page 38

DAC Results

4.2 DAC Results

The DAC was characterized using a sine-wave table lookup program running

on a TMS320C5x DSK+ coupled to an AD50-EVM.

Figure 4–3.AD50-EVM DAC Distortion Measurement at 8 ksps

0

–10

–20

–30

–40

–50

–60

–70

Full Scale – dB

–80

–90

–100

–110

–120

0123456

AD50 DAC: 8ksa/s Generating a 1 kHz Sine Wave

at–3 dB ref Full Scale

FFT: 40ksa/s, 2048 Frequency Bins, 16 Averages

7111213

8 9 10 14 15 19 2016 17 18

f – Frequency – kHz

Figure 4–3 shows an FFT plot of the output from the AD50-EVM. This was

measured using a T exas Instruments AD55-EVM acquisition system running

at 40 ksps coupled to a DSP development system in a PC.

The signal to noise plus distortion ratio (SINAD) measured in the pass-band

(excluding dc) was 80.5 dB. The SNR was 83.6 dB and the SDR was 83.4 dB.

These measurements have not been adjusted for the noise and distortion of

the acquisition system.

The rise in the noise floor above 4 kHz is due to the digital noise-shaping filter

in the AD50 DAC, which decreases pass-band noise at the expense of increased high frequency noise. This is partially attenuated by the output filter

on the AD50-EVM but continues to rise to a plateau at approximately –100 dB.

This filter is optimized for use at 20 ksps and therefore the out of band noise

is worse than at higher sampling frequencies.

4-4

Page 39

Figure 4–4.AD50-EVM DAC Distortion Measurement at 20 ksps

0

–10

–20

–30

–40

–50

–60

–70

Full Scale – dB

–80

–90

–100

–110

–120

0123456

Similar measurements were made at 20 ksps. The results were 78.6 dB SNR,

84.8 dB SDR and 77.6 dB SINAD. Again this has not been compensated for

the characteristics of the acquisition system.

AD50 DAC: 20 ksa/s Generating a 1 kHz Sine

Wave at –3 dB ref Full Scale

FFT: 40 ksa/s, 2048 Frequency Bins, 16 Averages

78910

f – Frequency – kHz

DAC Results

11 12 13 14 15 16 17 18 19 20

The spike at 10 kHz is caused by breakthrough from the negative supply generator. The larger peaks above 16 kHz are images that have not been completely removed by the reconstruction filters. These are well outside the passband of the DAC.

All the above measurements were made using a well-regulated low noise 5 V

power supply because the power supply shipped with the DSK+ was found to

introduce extra noise.

Results Obtained With AD50 EVM

4-5

Page 40

4-6

Page 41

Appendix A

Installing the AD50-EVM

This chapter discusses the configuration jumper settings for the AD50 EVM,

along with guidelines for connecting it to the DSK+. The parts list, schematics,

gerber plots, and board outline drawings are included.

Topic Page

A.1 Board Outline Drawing With Jumper Locations on the AD50 EVM A-2.

A.2 Connecting the AD50-EVM to the DSK+ A-4. . . . . . . . . . . . . . . . . . . . . . . . .

A.3 Parts List A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.4 Circuit Diagrams A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.5 PCB Diagrams A-??. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the AD50-EVM

A-1

Page 42

Board Outline Drawing With Jumper Locations on the AD50 EVM

A.1 Board Outline Drawing With Jumper Locations on the AD50 EVM

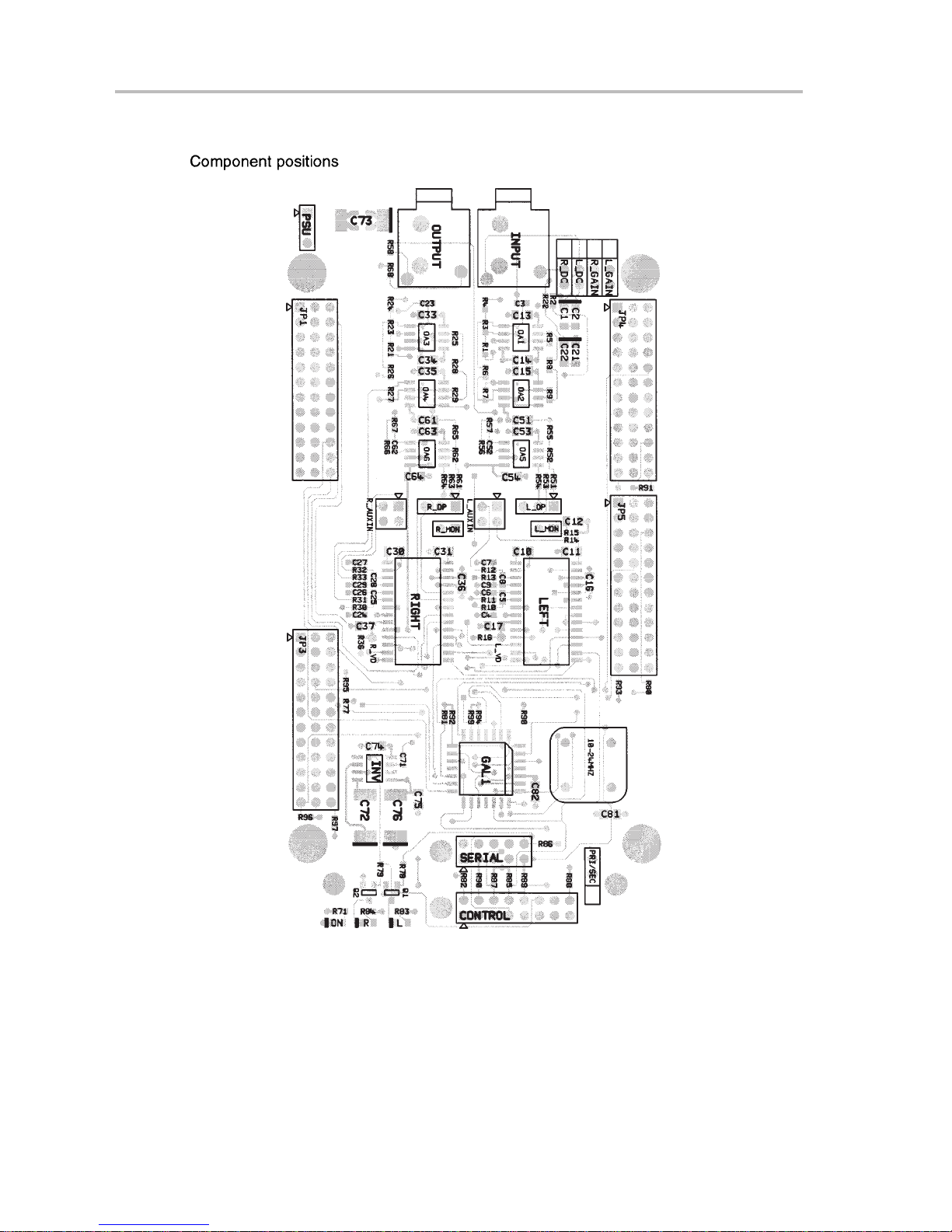

Figure A–1 shows a diagram of the AD50-EVM board showing locations of connectors and jumpers etc.

Figure A–1.Diagram of the AD50-EVM

JP5

L_MON

L_AUXIN

R_MON

R_AUXIN

JP3

L_GAIN

R_GAIN

L_DC

R_DC

INPUT

OUTPUT

PSU

JP4

L_OP

R_OP

JP1

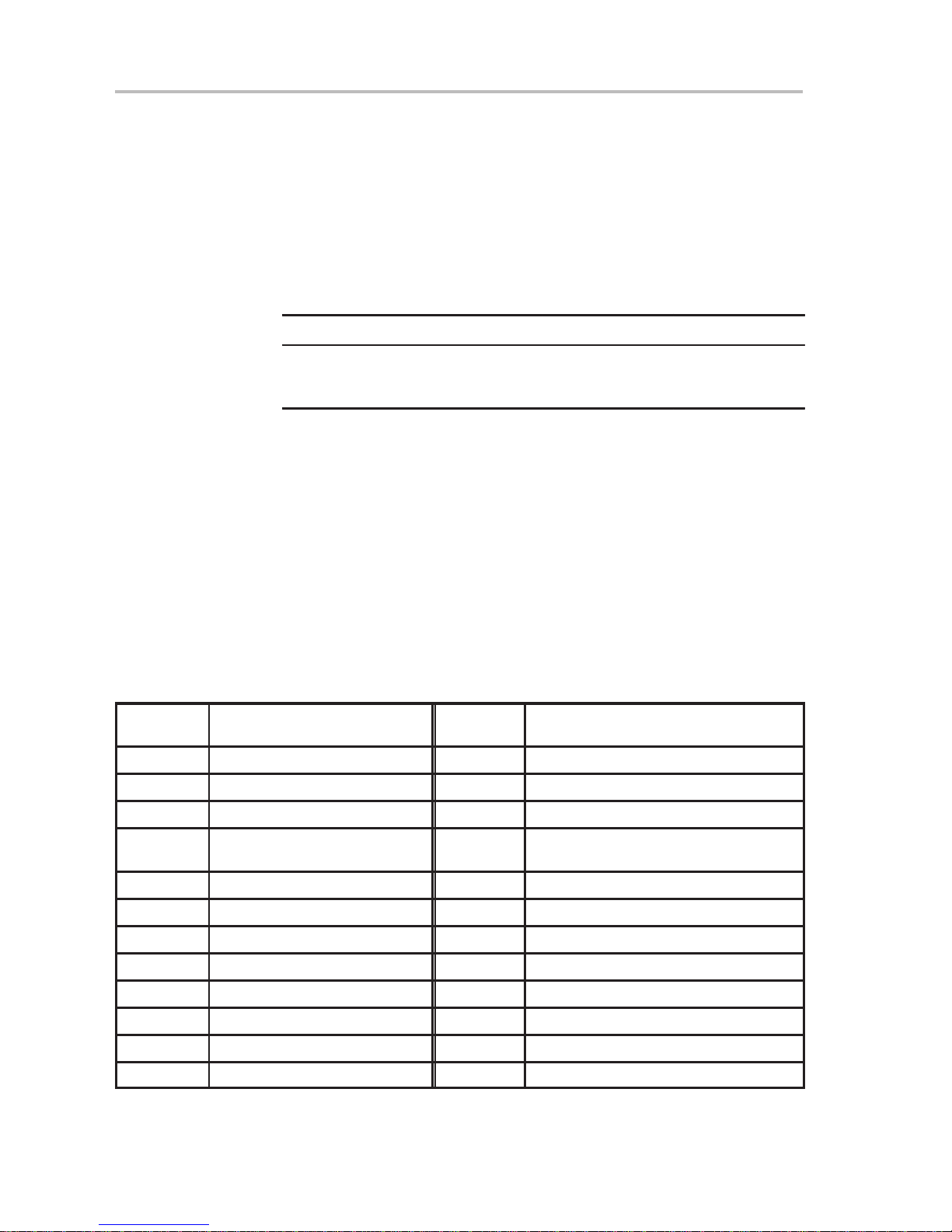

T able A–1.Jumper Positions

OPEN CLOSED DEFAULT

L_DC Left channel ac input coupling Left channel dc input coupling OPEN

R_DC Right channel ac input coupling Right channel dc input coupling OPEN

L_GAIN Left channel 0 dB input gain Left channel 20 dB input gain OPEN

R_GAIN Right channel 0 dB input gain Right channel 20 dB input gain OPEN

PRI/SEC

SERIAL

CONTROL

PRI/SEC Primary board Secondary board OPEN

The connectors marked SERIAL and CONTROL are for use in interfacing the

AD50-EVM to systems other than the DSK+. The pinouts are shown in

Table A–2.

If two AD50-EVMs are used the serial connection should be made to the

primary board.

A-2

Page 43

Board Outline Drawing With Jumper Locations on the AD50 EVM

Table A–2.Control and Serial Connections

Pin Control Serial

1 GROUND GROUND

2 PRI/SEC SERIAL DATA IN

3 GROUND GROUND

4 RIGHT ALTDATA SERIAL DATA OUT

5 GROUND GROUND

6 RIGHT PWRDN LEFT FRAME SYNC

7 RESET GROUND

8 LEFT PWRDN SERIAL CLOCK

9 GROUND GROUND

10 FC RESET

11 GROUND

12 RIGHT FLAG

13 GROUND

14 LEFT FLAG

14 GROUND

16 LEFT ALTDATA

There are 4 sets of connectors that provide direct access to the analog I/O pins

of the AD50. The pinouts for these are shown in Table A–3.

Table A–3.Analog Input/Output Connectors

Label Aux ip Diff-op Mon out

Left L_AUXIN L_OP L_MON

Right R_AUXIN R_OP R_MON

Pin Aux ip Diff-op Mon out

1 AUXP OUTP MONOUT

2 1.25 V GROUND GROUND

3 AUXM OUTM

4 GROUND

There is a set of pins labeled PSU provided for connecting power supplies. The

locally generated –5 V supply can be accessed via this connector.

Installing the AD50-EVM

A-3

Page 44

Connecting the AD50-EVM to the DSK+

A.2 Connecting the AD50-EVM to the DSK+

The two boards are stacked together using plug and socket connectors. Four

pairs of connectors are needed, in JP2, JP3, JP4, and JP5.

The boards can be stacked either way round, although a slightly wider spacing

is needed if the AD50-EVM is on top of the DSK+, due to the height of the audio

jack connectors used on the DSK+. Suitable connectors that will allow the

boards to be stacked either way with a spacing of approximately 13 mm, can

be obtained from the following supplier.

Manufacturer Plug Socket

Samtec

Tel: 1-800-SAMTEC-9 (USA)

+44 1236 739292 (UK)

In order to ensure that the connectors are properly aligned it is suggested that

the plugs and sockets be mated before being soldered to the boards. T o allow

development work with the AD50-EVM it is suggested that the sockets be soldered to the bottom of the AD50-EVM and the pins to the top of the DSK+. This

puts the AD50-EVM on top of the DSK+ and provides good access to the signals on the AD50-EVM

TSW-112-14-T-T SSW-112-21-G-T

If two AD50-EVM boards are being used in conjunction with a DSK+, then a

different socket, with pass through pins, should be used on the middle board.

The Samtec part number is SSQ-112-24-G-T.

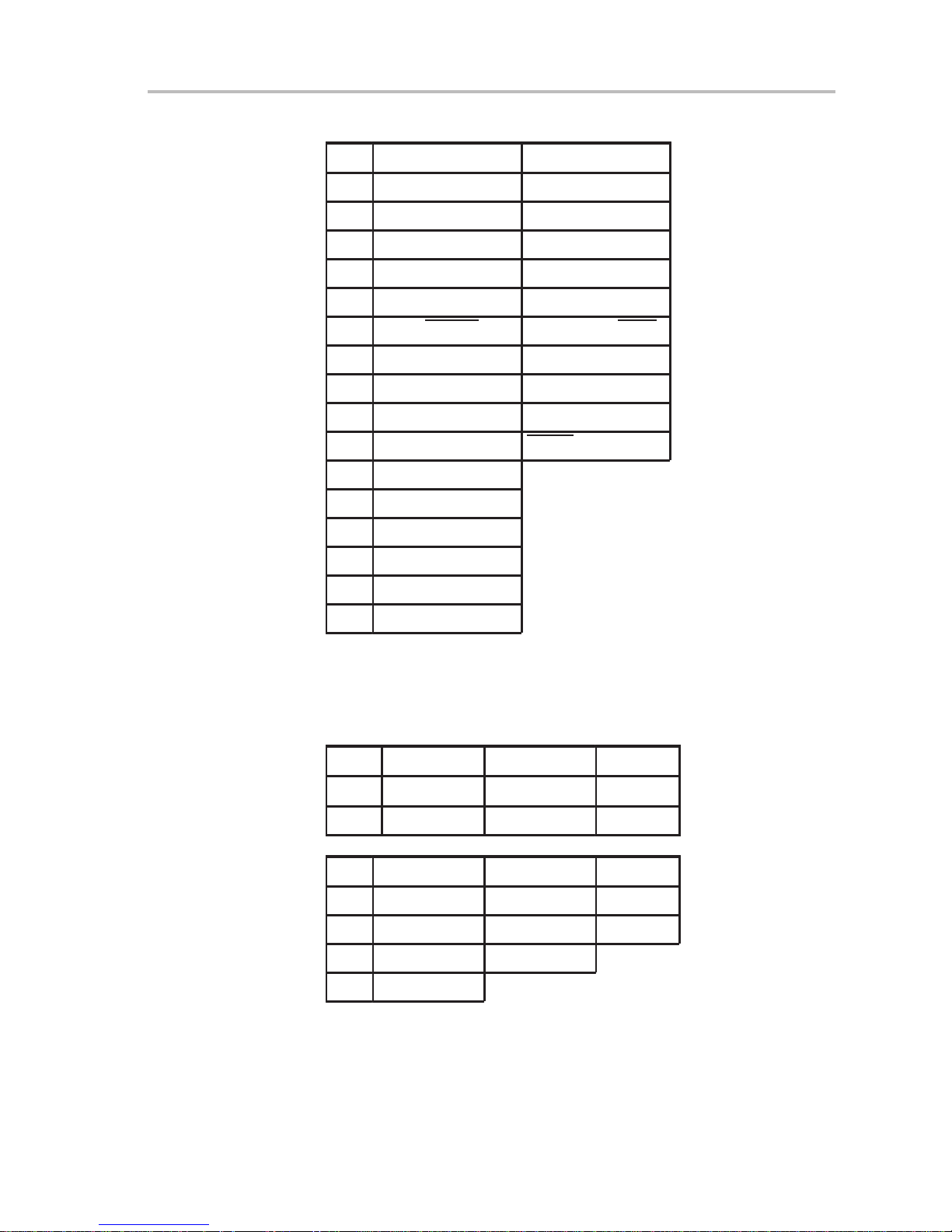

A.3 Parts List

Silk Screen

Name

LEFT TLC320AD50CDW OA6 TLC2272ACD

RIGHT TLC320AD50CDW Q1 BC848 SOT23

GAL1 CMOS 22V10 25 ns, PLCC Q2 BC848 SOT23

INV ICL7660 8 pin SO 10–24 MHZ 10.24 MHz 8-pin format TTL or CMOS

ON SM LED 2 mm × 1.25 mm green R1 22K (all resistors 1% 0603)

L SM LED 2 mm × 1.25 mm red R2 (2.2 k) 2K2

R SM LED 2 mm × 1.25 mm red R3 22K

OA1 TLC2272ACD R4 10K

OA2 TLC2272ACD R5 10K

OA3 TLC2272ACD R6 10K

Component

Silk Screen

Name

Component

oscillator module

†

OA4 TLC2272ACD R7 10K

OA5 TLC2272ACD R8 10K

†

British notation used in schematics A–4.

A-4

Page 45

Parts List

Silk Screen

Name

Component

R9 10K R58 (47) 47R

R10 (4.7 k) 4K7

R11 (4.7 k) 4K7

R12 (4.7 k) 4K7

R13 (4.7 k) 4K7

†

†

†

†

Silk Screen

Name

Component

R61 10K

R62 10K

R63 10K

R64 10K

†

R14 56K R65 12K

R15 39K R66 18K

R16 0 Ω link R67 12K

R21 22K R68 47R

R22 (2.2 k)2K2

†

R71 (1.8 k) 1K8

R23 22K R77 10k

R24 10K R78 (4.7 k) 4K7

R25 10K R79 (4.7 k) 4K7

R26 10K R80 (4.7 k) 4K7

R27 10K R81 10k

†

†

†

†

R28 10K R82 10k

R29 10K R83 (470) 470R

R30 (4.7 k) 4K7

R31 (4.7 k) 4K7

R32 (4.7 k) 4K7

R33 (4.7 k) 4K7

†

†

†

†

R84 (470) 470R

R85 10k

R86 10k

R87 10k

†

†

R36 0 Ω link R88 10k

R51 10K R89 10k

R52 10K R90 10k

R53 10K R91 10k

R54 10K R92 10k

R55 12K R93 10k

R56 18K R94 10k

R57 12K R95 10k

R96 10k C30 100 nF X7R 0805

R97 10k C31 100 nF X7R 0805

R98 10k C33 100 nF X7R 0805

R99 10k C34 100 nF X7R 0805

†

British notation used in schematics A–4.

Installing the AD50-EVM

A-5

Page 46

Parts List

Silk Screen

Name

Component

Silk Screen

Name

Component

C1 4.7 µF 10 V size A tantalum C35 100 nF X7R 0805

C2 4.7 µF 10 V size A tantalum C36 100 nF X7R 0805

C3 470 pF COG/NPO 0603 C37 100 nF X7R 0805

C4 470 pF COG/NPO 0603 C51 2.2 nF COG/NPO 0805

C5 470 pF COG/NPO 0603 C52 220 pF COG/NPO 0603

C6 470 pF COG/NPO 0603 C53 100 nF X7R 0805

C7 470 pF COG/NPO 0603 C54 100 nF X7R 0805

C8 470 pF COG/NPO 0603 C61 2.2 nF COG/NPO 0805

C9 470 pF COG/NPO 0603 C62 220 pF COG/NPO 0603

C10 100 nF X7R 0805 C63 100 nF X7R 0805

C1 1 100 nF X7R 0805 C64 100 nF X7R 0805

C12 100 nF X7R 0805 C71 22 pF COG/NPO 0603

C13 100 nF X7R 0805 C72 100 µF 10 V size D tantalum

C14 100 nF X7R 0805 C73 100 µF 10 V size D tantalum

C15 100 nF X7R 0805 C74 100 nF X7R 0805

C16 100 nF X7R 0805 C75 100 nF X7R 0805

C17 100 nF X7R 0805 C76 100 µF 10V size D tantalum

C21 4.7 µF 10 V size A tantalum C81 100 nF X7R 0805

C22 4.7 µF 10 V size A tantalum C82 100 nF X7R 0805

C23 470 pF COG/NPO 0603 INPUT Marushin MJ156L 3.5 mm stereo pcb jack

socket

C24 470 pF COG/NPO 0603 OUTPUT Marushin MJ156L 3.5 mm stereo pcb jack

socket

C25 470 pF COG/NPO 0603 PRI/SEC Right angle header

C26 470 pF COG/NPO 0603 L_DC Right angle header

C27 470 pF COG/NPO 0603 L_GAIN Right angle header

C28 470 pF COG/NPO 0603 R_DC Right angle header

C29 470 pF COG/NPO 0603 R_GAIN Right angle header

A-6

Page 47

A.4 Circuit Diagrams

Circuit Diagrams

Installing the AD50-EVM

A-7

Page 48

A-8

Page 49

Installing the AD50-EVM

A-9

Page 50

A-10

Page 51

A.5 PCB Diagrams

Top Side Silkscreen

PCB Diagrams

Installing the AD50-EVM

A-11

Page 52

Top Side Tracks

1 – Top Side Tracks

A-12

Page 53

Bottom Side Tracks

Installing the AD50-EVM

A-13

Page 54

Ground plane

A-14

Page 55

Power plane

Installing the AD50-EVM

A-15

Page 56

A-16

Page 57

Appendix B

Programmable Logic

The 22V10 programmable logic device incorporates all the logic needed by the

AD50-EVM when used in stand-alone mode or in conjunction with the DSK+.

Note that in many applications little or no logic is required for interfacing the

AD50 to a DSP system.

When used in stand-alone mode, most of the 22V10 outputs are high impedance to allow an external device complete freedom of control. This is controlled by the state of the DSK_PRESENT signal, which is pulled low when the

AD50-EVM is connected to a DSK+. Otherwise a pull-up resistor makes it default to stand-alone mode.

One or two AD50-EVM boards can provide 1, 2, 3, or 4 simultaneously

sampled channels. When two boards are coupled together the primary/secondary jumper controls the daisy-chaining of serial frame sync pulses and controls the way that data from the DSK+ is interpreted.

Designers familiar with the AC01 should note that the power-down behavior

of the AD50 serial interface is different. The AC01 clock and frame sync outputs are always high impedance in power-down mode. The AD50 clock and

frame sync outputs are driven high in power-down master mode, but are high

impedance in power-down slave mode.

Topic Page

B.1 DSK+ Mode B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 Stand-Alone Mode B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 Logic Compiler Listing B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programmable Logic

B-1

Page 58

DSK+ Mode

B.1 DSK+ Mode

Address bits 0, 14, and 15 are decoded in conjunction with the I/O space select

and the write enable from the C542 on the DSK+. Signals on the data bus are

latched on the rising edge of the

iostrobe

signal if a valid write address has

been decoded. Bits 14 and 15 are decoded so as to leave 48 k words of contiguous I/O address space free for other hardware that the user might wish to interface to the system. Bit 0 selects one of two control registers implemented

with D latches within the 22V10 device. The first register is used to control the

device reset and

powerdown

inputs for both codecs on each board and to control the powerdown signal to the TLC320AC01 codec on the DSK+ board. The

second register just controls the FC signal. This is to simplify programming of

interleaved secondary communications when the DAC is in 16 bit mode. When

two AD50-EVM boards are used a jumper must be fitted to the primary/secondary header of one of the boards. The board with the jumper becomes the

secondary one and has channels 3 and 4.

The 22V10 must have a propagation delay of 25 ns or less, assuming that one

or more I/O wait states are programmed in the TMS320C542. Zero wait state

operation would have negligible benefit and would need a much faster and

more costly device.

The AD50s are reset either when the DSK+ is reset or when a 0 is programmed

into bit 0 of address 0. Reset must be held low for at least 6 master clock cycles.

The default configuration at reset is for all the AD50s to be powered down and

for the AC01 on the DSK+ to be operating normally . This means that DSK+ will

continue to operate normally until the 22V10 is programmed for AD50 operation.

B.2 Stand-Alone Mode

In stand-alone mode all the logic except that used to link the serial interface

is 3-stated. This allows maximum flexibility to control the AD50s via the

CONTROL and SERIAL cable headers.

Table B–1. AD50-EVM Registers

I/O

Address

0

Bits 15–4 Bit 3 Bit 2 Bit 1 Bit 0 Function

X X X X 0 Hold AD50 in reset

X X X X 1 Release AD50 from reset

X 0 0 0 X AC01 on DSK+ active

X 0 0 1 X 1 AD50 active

1

B-2

X 0 1 0 X 2 AD50s active

X 0 1 1 X 3 AD50s active

X 1 0 0 0 4 AD50s active

X X X X 0 FC pin low

X X X X 1 FC pin high

Page 59

Logic Compiler Listing

B.3 Logic Compiler Listing

TITLE AD50 programmable address decoder & control port

AUTHOR John Walliker and Julian Daley

COMPANY For Texas Instruments

DATE 14 March 1997, 6 April 1997

OPTIONS

EXPAND = ON

INVERSION = OFF ; to ensure correct power–up reset state

MINIMIZATION = ON

CHIP AD50LOGIC EP22V10FN

;PIN 1 NC0

PIN 2 iostrb ; rising edge of DSK+ iostrobe clocks the D latches

PIN 3 DSK_reset ; global reset from DSK+

PIN 4 d0

PIN 5 d1 ; data bus

PIN 6 d2

PIN 7 d3

;PIN 8 NC1

PIN 9 a15

PIN 10 a14 ; address bus