Page 1

User's Guide

SLAU535B–February 2014–Revised July 2015

MSP430FR5969 LaunchPad™ Development Kit

(MSP‑‑EXP430FR5969)

The MSP-EXP430FR5969 (or the "FR5969 LaunchPad") is an easy-to-use evaluation module (EVM) for

the MSP430FR5969 microcontroller. It contains everything needed to start developing on the MSP430

FRAM platform, including on-board emulation for programming, debugging, and energy measurements.

The board features buttons and LEDs for quick integration of a simple user interface as well as a super

capacitor (super cap) that enables standalone applications without an external power supply.

Figure 1. MSP-EXP430FR5969

MSP430, LaunchPad, BoosterPack, Code Composer Studio, EnergyTrace++, EnergyTrace are trademarks of Texas Instruments.

IAR Embedded Workbench is a trademark of IAR Systems.

Sharp is a registered trademark of Sharp Corporation.

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

1

Page 2

www.ti.com

Contents

1 Getting Started............................................................................................................... 3

2 Hardware...................................................................................................................... 5

3 Software Examples ........................................................................................................ 22

4 Additional Resources ...................................................................................................... 34

5 FAQs......................................................................................................................... 36

6 Schematics.................................................................................................................. 37

List of Figures

1 MSP-EXP430FR5969....................................................................................................... 1

2 EVM Overview ............................................................................................................... 5

3 Block Diagram................................................................................................................ 6

4 MSP430FR5969 Pinout..................................................................................................... 7

5 eZ-FET Emulator............................................................................................................. 9

6 Application Backchannel UART in Device Manager................................................................... 10

7 EnergyTrace Technology Settings....................................................................................... 11

8 Debug Properties........................................................................................................... 12

9 Debug Session With EnergyTrace++ Windows........................................................................ 13

10 eZ-FET Isolation Jumper Block Diagram................................................................................ 14

11 MSP430FR5969 LaunchPad Power Domain Block Diagram ........................................................ 16

12 Debugger Power Configuration – USB eZ-FET and JTAG........................................................... 17

13 External Power Configuration – External and BoosterPack .......................................................... 18

14 Super Cap Power Configuration – Charging and Running Standalone............................................. 20

15 FR5969 LaunchPad to BoosterPack Connector Pinout............................................................... 21

16 Program <Example>.bat .................................................................................................. 23

17 Directing the Project→Import Function to the Demo Project......................................................... 24

18 When CCS Has Found the Project ...................................................................................... 25

19 Live Temperature Mode................................................................................................... 26

20 FRAM Log Mode ........................................................................................................... 27

21 FRAM Unified Memory With Dynamic Partitioning..................................................................... 33

22 MSP-EXP430FR5969 Software Examples in TI Resource Explorer ................................................ 35

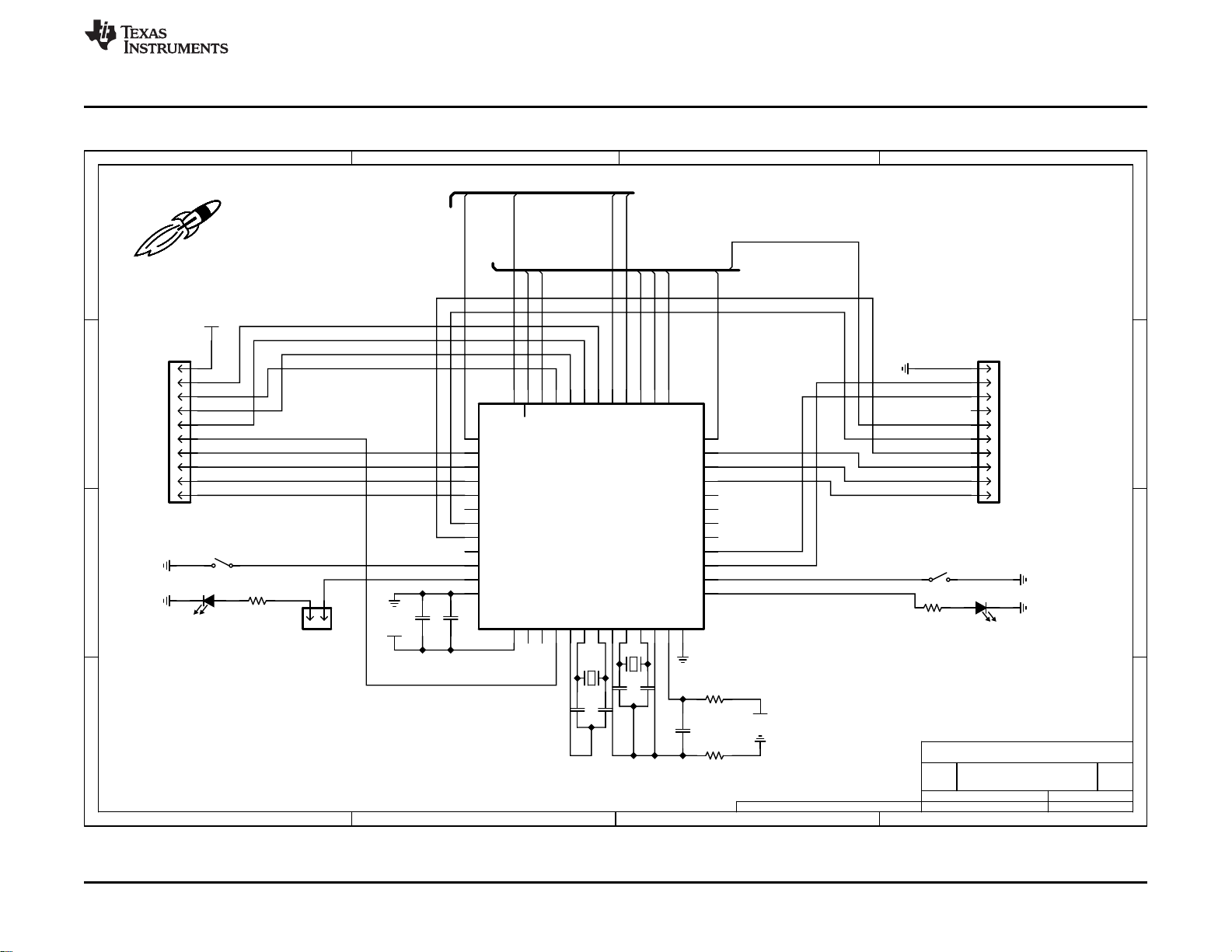

23 Schematic 1 of 5 ........................................................................................................... 37

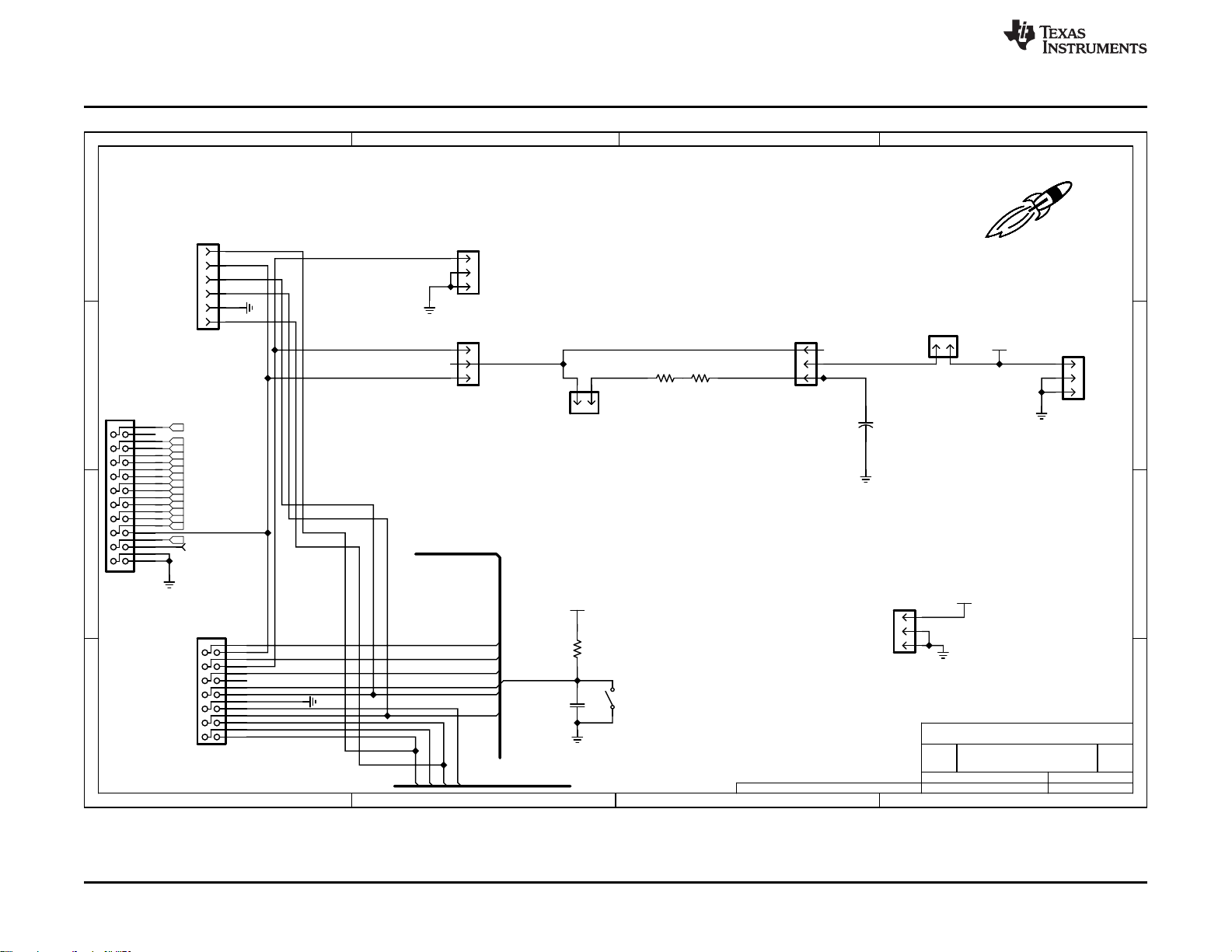

24 Schematic 2 of 5 ........................................................................................................... 38

25 Schematic 3 of 5 ........................................................................................................... 39

26 Schematic 4 of 5 ........................................................................................................... 40

27 Schematic 5 of 5 ........................................................................................................... 41

List of Tables

1 EnergyTrace++ Debug Windows......................................................................................... 12

2 EnergyTrace™ Technology Control Bar Icons ......................................................................... 13

3 Isolation Block Connections............................................................................................... 14

4 Hardware Change Log..................................................................................................... 22

5 Software Examples ........................................................................................................ 22

6 IDE Minimum Requirements for MSP430FR5969 ..................................................................... 23

7 Source Files and Folders.................................................................................................. 26

8 Source Files and Folders.................................................................................................. 28

9 FRAM Endurance Calculation for 1KB Block of FRAM ............................................................... 30

10 How MSP430 Device Documentation is Organized ................................................................... 34

2

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

1 Getting Started

1.1 Introduction

MSP430™ ultra-low-power (ULP) MCUs with embedded Ferroelectric Random Access Memory (FRAM)

technology now join the MCU LaunchPad™ Development Kit ecosystem. The MSP-EXP430FR5969 (or

the "FR5969 LaunchPad") is an easy-to-use evaluation module (EVM) for the MSP430FR5969

microcontroller. It contains everything needed to start developing on the MSP430 FRAM platform,

including on-board emulation for programming, debugging, and energy measurements. The board features

buttons and LEDs for quick integration of a simple user interface as well as a super capacitor (super cap)

that enables standalone applications without an external power supply.

Rapid prototyping is simplified by the 20-pin BoosterPack™ plug-in module headers, which support a wide

range of available BoosterPacks. You can quickly add features like wireless connectivity, graphical

displays, environmental sensing, and much more. You can either design your own BoosterPack or choose

among many already available from TI and third-party developers.

The MSP430FR5969 device features 64KB of embedded FRAM, a nonvolatile memory known for its ultralow power, high endurance, and high-speed write access. The device supports CPU speeds up to 16 MHz

and has integrated peripherals for communication, ADC, timers, AES encryption, and more – plenty to get

you started in your development.

Free software development tools are also available - TI's Eclipse-based Code Composer Studio™ IDE

(CCS) and IAR Embedded Workbench™ IDE (IAR), and the community-driven Energia open-source code

editor. More information about the LaunchPad including documentation and design files can be found on

the tool page at www.ti.com/tool/msp-exp430fr5969.

Getting Started

1.2 Key Features

• MSP430 ultra-low-power FRAM technology based MSP430FR5969 16-bit MCU

• 20-pin LaunchPad standard that leverages the BoosterPack ecosystem

• 0.1-F super capacitor for standalone power

• Onboard eZ-FET emulation with EnergyTrace++™ Technology

• Two buttons and two LEDs for user interaction

• Backchannel UART through USB to PC

1.3 Kit Contents

• 1 x MSP-EXP430FR5969

• 1 x Micro USB cable

• 1 x Quick Start Guide

1.4 First Steps – Out-of-Box Experience

An easy way to get familiar with the EVM is by using its pre-programmed out-of-box demo code, which

demonstrates some key features of the MSP-EXP430FR5969 LaunchPad.

The out-of-box demo showcases MSP430FR5969's ultra-low power FRAM by utilizing the device's internal

temperature sensor while running only off of the on-board Super Capacitor.

First step is to connect the LaunchPad to the computer using the included Micro-USB cable.

The RED and GREEN LEDs near the bottom of the LaunchPad toggle a few times to indicate the pre-

programmed out-of-box demo is running.

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

3

Page 4

Getting Started

Using the out-of-box demo GUI, included in the MSP-EXP430FR5969 Software Examples, the user can

place the LaunchPad into two different modes:

• Live Temperature Mode

This mode provides live temperature data streaming to the PC GUI. The user is able to influence the

temperature of the device and see the changes on the GUI.

• FRAM Logging Mode

This mode shows the FRAM data logging capabilities of the MSP430FR5969. After starting this mode,

the LaunchPad will wake up every five seconds from sleep mode (indicated by LED blink) to log both

temperature and input voltage values. After reconnecting to the GUI, these values can be uploaded

and graphed in the GUI.

A more detailed explanation of each mode can be found in Section 3.

1.5 Next Steps – Looking Into the Provided Code

After the out-of-box demo, more features can be explored. The hardware features on the LaunchPad are

shown in Section 2, and the provided code examples and how to use them are in Section 3. More details

and documentation can be found at http://www.ti.com/tool/msp-exp430fr5969. Code is licensed under BSD

and TI encourages reuse and modifications to fit your needs.

www.ti.com

4

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

2 Hardware

Figure 2 shows an overview of the LaunchPad hardware.

Hardware

Figure 2. EVM Overview

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

5

Page 6

Target Device

MSP430FR5969

Crystals

HF (MHz)

and

32.768 kHz

Micro-B

USB

3.3-V LDO

ESD

Protection

Debug

MCU

LED

Red, Green

Crystal

4 MHz

UART, SBW to Target

User Interface

2 buttons and 2 LEDs

20-pin LaunchPad

standard headers

Power Selection

100-mF

SuperCap

Power to Target

14-pin JTAG

header

Reset

button

Hardware

2.1 Block Diagram

Figure 3 shows the block diagram.

www.ti.com

2.2 MSP430FR5969

The MSP430FR5969 is the first device in TI's new ULP FRAM technology platform. FRAM is a cutting

edge memory technology, combining the best features of flash and RAM into one nonvolatile memory.

More information on FRAM can be found at www.ti.com/fram.

Device features include:

• 1.8-V to 3.6-V operation

• Up to 16-MHz system clock and 8-MHz FRAM access

• 64KB FRAM and 2KB SRAM

• Ultra-low-power operation

• Five timer blocks and up to three serial interfaces (SPI, UART, or I2C)

• Analog: 16-channel 12-bit differential ADC and 16-channel comparator

• Digital: AES256, CRC, DMA, and hardware MPY32

6

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Figure 3. Block Diagram

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

P1.4/TB0.1/UCA0STE/A4/C4

1P1.0/TA0.1/DMAE0/RTCCLK/A0/C0/VREF-/VeREF-

2P1.1/TA0.2/TA1CLK/COUT/A1/C1/VREF+/VeREF+

3P1.2/TA1.1/TA0CLK/COUT/A2/C2

4P3.0/A12/C12

5P3.1/A13/C13

6P3.2/A14/C14

7P3.3/A15/C15

8

P1.3/TA1.2/UCB0STE/A3/C3 9

10

P1.5/TB0.2/UCA0CLK/A5/C5 11

P4.7

12PJ.0/TDO/TB0OUTH/SMCLK/SRSCG1/C6

13

PJ.1/TDI/TCLK/MCLK/SRSCG0/C7

14

PJ.2/TMS/ACLK/SROSCOFF/C8

15

PJ.3/TCK/SRCPUOFF/C9

16

P4.0/A817P4.1/A9

18

P4.2/A10

19

P4.3/A11

20

P2.5/TB0.0/UCA1TXD/UCA1SIMO

21

P2.6/TB0.1/UCA1RXD/UCA1SOMI

22

TEST/SBWTCK

23

RST/NMI/SBWTDIO

24

25 P2.1/TB0.0/UCA0RXD/UCA0SOMI/TB0.0

26 P2.2/TB0.2/UCB0CLK

27 P3.4/TB0.3/SMCLK

28 P3.5/TB0.4/COUT

29 P3.6/TB0.5

30 P3.7/TB0.6

31 P1.6/TB0.3/UCB0SIMO/UCB0SDA/TA0.0

32 P1.7/TB0.4/UCB0SOMI/UCB0SCL/TA1.0

33 P4.4/TB0.5

34 P4.5

35 P4.6

36 DVSS

37

DVCC

38

P2.7

39

P2.3/TA0.0/UCA1STE/A6/C10

4041

AVSS

42

PJ.6/HFXIN

43

PJ.7/HFXOUT

44

AVSS

45

PJ.4/LFXIN

46

PJ.5/LFXOUT

47

AVSS

48

AVCC

P2.4/TA1.0/UCA1CLK/A7/C11

www.ti.com

Hardware

Figure 4. MSP430FR5969 Pinout

To compare the various MSP430 derivatives, download the MSP430 Product Brochure (SLAB034), which

is also available from http://www.ti.com/msp430. The brochure has a table that lets you see, at a glance,

how the families compare, and their pricing. This document is frequently updated, as new MSP430

derivatives become available.

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

7

Page 8

Hardware

2.2.1 Measure MSP430 Current Draw

A specific jumper J9 is placed on the LaunchPad to allow for measuring current draw of the

MSP430FR5969 device. The current measured includes the FR5969, and any current drawn through the

BoosterPack headers and jumper J1.

To measure ultra-low power, follow these steps:

1. Remove the J9 jumper; attach an ammeter across this jumper.

2. Consider the effect that the backchannel UART and any circuitry attached to the FR5969 may have on

current draw. Maybe these should be disconnected at the isolation jumper block, or their current

sinking and sourcing capability at least considered in the final measurement.

3. Make sure there are no floating input I/Os. These cause unnecessary extra current draw. Every I/O

should either be driven out or, if an input, should be pulled or driven to a high or low level.

4. Begin target FR5969 execution.

5. Measure the current. (Keep in mind that if the current levels are fluctuating, it may be difficult to get a

stable measurement. It is easier to measure quiescent states.)

2.2.2 Clocking

The FR5969 LaunchPad provides external clocks in addition to the internal clocks in the device.

• Y4: a 32-kHz crystal

• Y1: an unpopulated region that supports HF crystal or resonator (4 to 24 MHz)

The 32-kHz crystal allows for lower LPM3 sleep currents than do the other low-frequency clock sources.

Therefore, the presence of the crystal allows the full range of low-power modes to be used.

For more information about internal clocks and how to use the 32-kHz or HF crystal, see the

MSP430FR59xx family user's guide.

www.ti.com

8

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

2.3 eZ-FET Onboard Emulator With EnergyTrace™ Technology

To keep development easy and cost effective, TI's LaunchPad development tools integrate an onboard

emulator, eliminating the need for expensive programmers.

The FR5969 LaunchPad has the new eZ-FET emulator (see Figure 5), a simple and low-cost debugger

that supports almost all MSP430 device derivatives.

Hardware

The eZ-FET provides many features that make debugging an easy experience. Included is a

"backchannel" UART-over-USB connection with the host, EnergyTrace Technology, and a distinct isolation

from the target side microcontroller.

The eZ-FET hardware can be found in the schematics in Section 6 and in the accompanying hardware

design files. The eZ-FET software and more information about the debugger can be found at the eZ-FET

lite wiki.

2.3.1 Emulator/Debugger

The eZ-FET is an on-board emulation solution for MSP430 microcontrollers. It allows direct interfacing to a

PC for easy programming, debugging, and evaluation. The eZ-FET uses Spy-Bi-Wire (SBW) two-wire

protocol to interface with the MSP430 devices. These pins are the SBW RST and SBW TST pins located

on the emulator isolation block. More details on the isolation block can be found in Section 2.3.4.

The eZ-FET on-board emulation is supported by the MSP430 DLL and can be used with IAR Embedded

Workbench for MSP430 Integrated Development Environment (IDE) or Code Composer Studio (CCS) IDE

to write, download, and debug applications.

The debugger is unobtrusive and allows the user to run an application at full speed with hardware

breakpoints and single stepping available while consuming no extra hardware resources. The firmware for

the eZ-FET is field undatable, so any updates can be received as needed.

More information on SBW can be found in the MSP430 Hardware Tools User's Guide (SLAU278), and

information on the MSP430 DLL can be found at www.ti.com/mspds.

Figure 5. eZ-FET Emulator

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

9

Page 10

Hardware

2.3.2 Application (or "Backchannel") UART

The backchannel UART allows communication with the USB host that isn't part of the target application's

main functionality. This is very useful during development, and also provides a communication channel to

the PC host side. This can be used to create GUIs and other programs on the PC that communicate with

the FR5969 LaunchPad.

The pathway of the backchannel UART is shown in Figure 10. The backchannel UART (USCI_A0) is

independent of the UART on the 20-pin BoosterPack connector (USCI_A1).

On the host side, a virtual COM port for the application backchannel UART is generated when the

LaunchPad enumerates on the host. You can use any PC application that interfaces with COM ports,

including terminal applications like Hyperterminal or Docklight, to open this port and communicate with the

target application. You need to identify the COM port for the backchannel. On Windows PCs, Device

Manager can assist (see Figure 6).

Figure 6. Application Backchannel UART in Device Manager

The backchannel UART is the "MSP Application UART1" port. In this case, Figure 6 shows COM13, but

this varies from one host PC to the next. After you identify the correct COM port, configure it in your host

application, according to its documentation. You can then open the port and begin talking to it from the

host.

On the target FR5969 side, the backchannel is connected to the USCI_A0 module.

The eZ-FET has a configurable baud rate, therefore, it is important that the PC application configures the

baud rate to be the same as the rate configured on the USCI_A0.

The eZ-FET also supports hardware flow control, if desired. Hardware flow control (CTS/RTS

handshaking) allows the target FR5969 and the emulator to tell each other to wait before sending more

data. At low baud rates and with simple target applications, flow control may not be necessary.

Applications with faster baud rates and more interrupts to service have a higher likelihood that they cannot

read the USCI_A0's RXBUF register in time, before the next byte arrives. If this happens, the USCI_A0's

UCA0STATW register will report an overrun error.

www.ti.com

10

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

2.3.3 EnergyTrace™ Technology

EnergyTrace™ Technology is an energy-based code analysis tool set that is useful for measuring and

viewing the application’s energy profile and optimizing it for ultra-low power consumption. The

MSP430FR5969 device supports EnergyTrace++ (EnergyTrace + [CPU State] + [Peripheral States]) for

full access to the application energy profile as well as CPU and peripheral states.

By default, EnergyTrace technology is disabled in CCS. To enable EnergyTrace, click Window →

Preferences → Code Composer Studio → Advanced Tools → EnergyTrace™ Technology. Select the

"Enable" checkbox and the EnergyTrace++ setting for full functionality (see Figure 7).

Hardware

Figure 7. EnergyTrace Technology Settings

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

11

Page 12

Hardware

To fully enable the EnergyTrace++ setting, the ultra-low-power debug mode must be enabled. Right click

on the active project in the project explorer and click Properties. In the Debug section, enable "Ultra Low

Power debug/ Debug LPMx.5" option in the Low Power Mode Settings (see Figure 8). If this option is not

enabled, the EnergyTrace++ mode cannot capture data from the device.

www.ti.com

Figure 8. Debug Properties

After the correct settings are chosen, the EnergyTrace window automatically opens when debug is started.

The EnergyTrace++ window has four separate tabs: Profile, States, Power, and Energy.

Table 1. EnergyTrace++ Debug Windows

EnergyTrace++ Description

Debug Window

Profile Displays a compressed view of captured data and allows comparison with previous data

States Real-time trace of the target microcontroller's internal states captured. Includes power modes and peripheral

Power Dynamic power consumption of the target over time. A previous trace profile for comparison is yellow in color.

Energy Accumulated energy of the target over time. A previous trace profile for comparison is yellow in color.

on/off states.

12

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

These tabs allow you to see exactly what is happening in your application, and find power black holes. An

example application with the EnergyTrace++ windows is shown in Figure 9.

Hardware

Figure 9. Debug Session With EnergyTrace++ Windows

After the EnergyTrace window is active, it can be controlled with the buttons in Table 2.

Table 2. EnergyTrace™ Technology Control Bar Icons

Enable or disable EnergyTrace Technology. When disabled, icon turns gray.

Set capture period: 5 sec, 10 sec, 30 sec, 1 min, or 5 min. Data collection stops after time has elapsed. However,

the program continues to execute until the Pause button in the debug control window is clicked.

Save profile to project directory. When saving an EnergyTrace++ profile, the default filename will start with

"MSP430_D" followed by a timestamp. When saving an EnergyTrace profile, the default filename will start with

"MSP430" followed by a timestamp.

Load previously saved profile for comparison.

Restore graphs or open Preferences window.

Switch between EnergyTrace++ mode and EnergyTrace mode

An example application using the MSP-EXP430FR5969 with EnergyTrace++ Technology is provided in

the application note: MSP430 Advanced Power Optimizations: ULP Advisor SW and EnergyTrace

Technology (SLAA603). For more details on EnergyTrace, refer to the Code Composer Studio v6.0 for

MSP430 User's Guide (SLAU157).

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

13

Page 14

eZ-FET

Emulator

MCU

Isolation

Jumper Block

Spy-Bi-Wire (SBW)

Emulation

Application UART

3.3V Power

5V Power

Target

MSP430FR5969

MCU

eZ-FETMSP430FR5969 Target

USB Connector

in out

LDO

BoosterPack Header

BoosterPack Header

USCI A0

USB

Hardware

2.3.4 Emulator Connection – Isolation Jumper Block

The isolation jumper block at Jumper J13 allows the user to connect/disconnect signals that cross from

the eZ-FET domain into the FR5969 target domain. This includes eZ-FET Spy-Bi-Wire signals, application

UART signals, and 3V3 and 5V power (see Table 3).

Reasons to open these connections:

• To remove any and all influence from the eZ-FET emulator for high accuracy target power

measurements

• To control 3-V and 5-V power flow between eZ-FET and target domains

• To expose the target MCU pins for other use than onboard debugging and application UART

communication

• To expose programming and UART interface of the eZ-FET so it can be used for devices other than

the onboard MCU.

Table 3. Isolation Block Connections

Jumper Description

GND Ground

V+ 3.3-V rail, derived from VBUS by an LDO in the eZ-FET domain

RTS >>

CTS <<

RXD <<

TXD >>

RST Spy-Bi-Wire emulation: SBWTDIO data signal. This pin also functions as the RST signal (active low)

TST Spy-Bi-Wire emulation: SBWTCK clock signal. This pin also functions as the TST signal

Backchannel UART: Ready-To-Send, for hardware flow control. The target can use this to indicate whether 'it is

ready to receive data from the host PC. The arrows indicate the direction of the signal.

Backchannel UART: Clear-To-Send, for hardware flow control. The host PC (through the emulator) uses this to

indicate whether or not it is ready to receive data. The arrows indicate the direction of the signal.

Backchannel UART: the target FR5969 receives data through this signal. The arrows indicate the direction of the

signal.

Backchannel UART: the target FR5969 sends data through this signal. The arrows indicate the direction of the

signal.

www.ti.com

14

Figure 10. eZ-FET Isolation Jumper Block Diagram

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

2.3.5 14-Pin JTAG Connector

This EVM contains a footprint for TI's standard 14-pin MSP430 JTAG header. This connector can be used

as needed. For debug purposes, this connector offers 4-wire JTAG compared to the 2-wire Spy-Bi-Wire

from the eZ-FET. In certain use cases this can be advantageous. The MSP-FET or another MSP430

external debug tool such as MSP-FET430UIF or third-party tool can be used. This JTAG connector can be

used to power the system directly or can be used with external power. The MSP-FET tool supports

EnergyTrace™ technology and can perform the same measurements as the eZ-FET onboard emulator.

See Section 2.4 for more details on the JTAG system power requirements.

2.3.6 Using the eZ-FET Emulator With a Different Target

The eZ-FET emulator on the FR5969 LaunchPad can interface to most MSP430 derivative devices, not

just the on-board FR5969 target device.

To do this, disconnect every jumper in the isolation jumper block. This is necessary because the emulator

cannot connect to more than one target at a time over the Spy-Bi-Wire (SBW) connection.

Next, make sure the target board has proper connections for Spy-Bi-Wire. Note that to be compatible with

SBW, the capacitor on RST/SBWTDIO cannot be greater than 2.2 nF. The documentation for designing

MSP430 JTAG interface circuitry is the MSP430 Hardware Tools User's Guide (SLAU278).

Finally, wire together these signals from the emulator's side of the isolation jumper block to the target

hardware:

• 3.3 V (V+)

• GND

• SBWTDIO

• SBWTCK

• TXD (if the UART backchannel is to be used)

• RXD (if the UART backchannel is to be used)

• CTS (if hardware flow control is to be used)

• RTS (if hardware flow control is to be used)

This wiring can be done either with jumper wires or by designing the board with a connector that plugs into

the isolation jumper block.

Hardware

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

15

Page 16

J3

V+

J13

Debugger

JTAG

eZ-FET

J10

J12

External

VCC

GND

GND

J9

J2

Bypass

Use

Charge

J11

Super

Cap

External

J4

J5

VCC

GND

GND

J1

Current

MSP430FR5969

target and

BoosterPack

Target

MSP430FR5969

Device

Measure

Debug

Power

Domain

External

Power

Domain

Super Cap

Power

Domain

Target and

BoosterPack

Power

Domain

Legend

Hardware

2.4 Power

The board is designed to support five different power scenarios. The board can be powered by the eZFET or JTAG debugger, external power, BoosterPack power, or standalone super cap power.

www.ti.com

16

Figure 11. MSP430FR5969 LaunchPad Power Domain Block Diagram

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

J3

V+

J13

Debugger

eZ-FET

J10

J12

External

VCC

GND

GND

J9

J2

Bypass

Use

Charge

J11

J4

J5

VCC

GND

GND

J1

Current

MSP430FR5969

target and

BoosterPack

Target

MSP430FR5969

Device

Measure

USB (eZ-FET) Power

Configuration

J3

J13

Debugger

JTAG

J10

J12

External

VCC

GND

GND

J9

J2

Bypass

Use

Charge

J11

J4

J5

VCC

GND

GND

J1

Current

MSP430FR5969

target and

BoosterPack

Target

MSP430FR5969

Device

Measure

JTAG Power

Configuration

V+

www.ti.com

2.4.1 eZ-FET USB Power

The most common scenario is power from USB through the eZ-FET debugger. This provides 5-V power

from USB and also regulates this power rail to 3.3 V for eZ-FET operation and 3.3 V to the target side of

the LaunchPad. Power from the eZ-FET is controlled by jumper J13. For 3.3 V, ensure that a jumper is

connected across the J13 "V+" terminal. The eZ-FET is a debugger, so J10 must be set to debugger for

power to reach the target MSP430FR5969 device.

For the power configuration diagram, see Figure 12.

2.4.2 14-Pin JTAG

When powering directly from the JTAG connector through the MSP-FET430UIF or other MSP430

debugger tool, ensure that jumper J10 is set to "Debugger." JTAG debugging can also be used with an

external power source, when J10 is set to "External," and some external power source is connected

through J12. In this case the JTAG debugger will sense the external power and debug the system without

providing its own power.

For power configuration diagram, see Figure 12.

Hardware

Figure 12. Debugger Power Configuration – USB eZ-FET and JTAG

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

17

Page 18

J3

V+

J13

Debugger

J10

J12

External

VCC

GND

GND

J9

J2

Bypass

Use

Charge

J11

External

J4

J5

VCC

GND

GND

J1

Current

MSP430FR5969

target and

BoosterPack

Target

MSP430FR5969

Device

Measure

External Power

Source Configuration

J3

V+

J13

Debugger

J10

J12

External

VCC

GND

GND

J9

J2

Bypass

Use

Charge

J11

J4

J5

VCC

GND

GND

J1

Current

MSP430FR5969

target and

BoosterPack

Target

MSP430FR5969

Device

Measure

VCC

GND

BoosterPack Power

Configuration

Hardware

2.4.3 External Power Supply

An extra header J12 is present on the board to supply external power. When supplying external power,

jumper J10 must be set to "External." It is important to understand the device voltage operation

specifications when supplying external power. The MSP430FR5969 has an operating range of 1.8 V to 3.6

V. More information can be found in the device data sheet.

For power configuration diagram, see Figure 13.

2.4.4 BoosterPack

In some use cases it might be required to power the board from a BoosterPack. When powered from a

BoosterPack, the BoosterPack voltage should be across J4 Pin 1 (Vcc) and J5 Pin 20 (GND). This

complies with the BoosterPack pinout shown in Section 2.5. These pins are connected directly to the

FR5969 target device, and do not require any specific jumper configuration. Header J1 also provides

power directly to the target device.

Because J1 and the BoosterPack headers are connected directly to the target device Vcc, there are two

primary consequences:

• The super cap cannot charge through J11. Use of the super cap with this power scenario is not

recommended.

• Current of the target device through J9 cannot be measured. It is best to remove J9 in this scenario to

prevent back-powering of any additional circuitry such as the eZ-FET.

For power configuration diagram, see Figure 13.

www.ti.com

Figure 13. External Power Configuration – External and BoosterPack

18

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

2.4.5 Super Cap

A 100-mF (0.1-F) super cap is mounted onboard and allows powering the system without any external

power. This highlights the ultra-low power of the MSP430FR5969 target device. See how long you can run

your application on the super cap alone!

2.4.5.1 Charging the Super Cap

To charge the super cap, jumper J11 is used. By default there is no jumper across J11. Place a jumper

across J11 to charge the super cap. If another jumper is not handy, the GND jumper on the isolation

jumper block can be used- as this jumper doesn't actually disconnect the GND connection.

To charge the super cap, power must be coming from a debugger (eZ-FET or JTAG) or external power

through J10. External power through J1 or a BoosterPack will not charge the super cap through J11.

Placing a jumper across J11 will charge the super cap when there is 3.3-V Vccpresent, regardless of the

state of the Bypass/Use J2 jumper, however if J2 is in the "Bypass" state, changing it over to the "Use"

state will remove power from the target MSP430FR5969 and it will be reset.

2.4.5.2 Using the Super Cap

To use the super cap to power the LaunchPad, first change the J2 jumper to select "Use" and then set a

jumper on J11 to charge the super cap. After waiting for it to charge, any external power can be removed

from the system, and it will be powered completely by the super cap.

To remove any additional power drain from the super cap, remove any jumper to disconnect power to any

external source. This can be J11, J10, or J13 depending on the power configuration. This prevents the

super cap from back-powering the debug circuitry or any external power circuitry connected.

The most effective method for charging the capacitor is outlined in the following steps. These steps

assume the LaunchPad is powered by USB cable through the eZ-FET debugger.

1. Set "Power Selector" jumper (J10) to "Debugger" position.

2. Set jumper J2 to "Use" super cap position.

3. Set jumper J11 to "Charge" super cap position.

4. Set "V+" jumper J13.

5. Connect board to PC with USB cable.

6. Allow two to three minutes for the super cap to charge (time may vary depending on initial charge of

the super cap) to full VCC.

7. Remove the "V+" jumper J13.

For power configuration diagram, see Figure 14.

Hardware

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

19

Page 20

*Power from

Debugger

or External

J3

V+

J13

Debugger

JTAG

eZ-FET

J10

J12

External

VCC

GND

GND

J9

J2

Bypass

Use

Charge

J11

Super

Cap

External

J4

J5

VCC

GND

GND

J1

Current

MSP430FR5969

target and

BoosterPack

Target

MSP430FR5969

Device

Measure

Super Cap Charging

Configuration

J3

V+

J13

Debugger

J10

J12

External

VCC

GND

GND

J9

J2

Bypass

Use

Charge

J11

Super

Cap

J4

J5

VCC

GND

GND

J1

Current

MSP430FR5969

target and

BoosterPack

Target

MSP430FR5969

Device

Measure

Super Cap Running

Standalone Configuration

Hardware

www.ti.com

2.4.5.3 Disabling the Super Cap

To disable the super cap, change J2 to "Bypass," and remove jumper J11 to prevent additional current for

charging the super cap. With these two jumper selections, the super cap is completely disconnected from

the system.

2.5 BoosterPack Plug-in Module Headers

The BoosterPack headers allow for a variety of applications to be created by plugging BoosterPacks onto

the LaunchPad. BoosterPacks cover a wide range of possible applications including wireless connectivity,

environmental sensing, and LCD displays. Leverage the growing BoosterPack ecosystem to rapidly

prototype nearly any application with the LaunchPad rapid prototyping platform. Available BoosterPacks

can be found at www.ti.com/boosterpacks.

The FR5969 LaunchPad adheres to the 20-pin LaunchPad pinout standard. A standard was created to aid

compatibility between LaunchPad and BoosterPack tools across the TI ecosystem.

The 20-pin standard is compatible with the 40-pin standard used by other LaunchPads like the MSP-

EXP430F5529LP. This allows some subset of functionality of 40-pin BoosterPacks to be used with 20-pin

LaunchPads.

Figure 14. Super Cap Power Configuration – Charging and Running Standalone

20

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

+3.3V

P4.2

P4.3

P2.6

P2.4

P2.2

P3.4

P3.5

P3.6

P2.5

UART

RX

TX

Analog In

Analog In

SPI CLK

I2C*

SCL

SDA

A1h

TB0.1

UCA1RXD

UCA1SOMI

TB0.0

UCA1TXD

UCA1SIMO

A11

TA1.0

UCA1CLK

A7

C11

TB0.2

UCB0CLK

TB0.3

SMCLK

TB0.4

COUT

TB0.5

MSP-EXP430FR5969 Pin Map

+3.3V

GPIO (!)

GPIO (!)

(!)

(!)

(!)

(!)

(!)

(!)

(!)

(!)

(!)

GND

P1.2

P3.h

RST

P1.6

P1.5

P1.4

P1.3

P1.7

A2

TA1.1

TA0CLK

COUT

C2

A12

C12

TB0.3

UCB0SDA

TA0.1

TB0.4

UCB0SCL

TA1.0

UCB0SOMI

A5

TB0.2

UCA0CLK

C5

A4

TB0.1

UCA0STE

C4

A3

TA1.2

UCB0STE

C3

UCB0SIMO

SPI

MOSI

MISO

SPI CS Wireless

SPI CS Display

SPI CS Other

BoosterPack Standard

GND

NC

RST

PWM Out

GPIO (!)

GPIO (!)

GPIO (!)

GPIO (!)

GPIO (!)

(!)

(!)

(!)

(!)

(!)

(!)

(!)

MSP-EXP430FR5969 Pin Map

BoosterPack

Standard

Below are the pins exposed at the BoosterPack connector

Also shown are functions that map with the BoosterPack standard.

* Note that to comply with the I2C channels of the BoosterPack standard, a software-emulated I2C must be used.

** Some LaunchPads do not 100% comply with the standard. Please check your LaunchPad to ensure compatability.

(!) Denotes I/O pins that are interrupt-capable.

GPIO**

www.ti.com

While most BoosterPacks are compliant with the standard, some are not. The FR5969 LaunchPad is

compatible with all 20-pin BoosterPacks that are compliant with the standard. If the reseller or owner of

the BoosterPack does not explicitly indicate compatibility with the FR5969 LaunchPad, you should

compare the schematic of the candidate BoosterPack with the LaunchPad to ensure compatibility. Keep in

mind that sometimes conflicts can be resolved by changing the FR5969 device pin function configuration

in software. More information about compatibility can be found at http://www.ti.com/launchpad.

Figure 15 shows the 20-pin pinout of the FR5969 LaunchPad.

Note that software's configuration of the pin functions plays a role in compatibility. The FR5969

LaunchPad side of the dashed line shows all of the functions for which the FR5969 device's pins can be

configured. This can also be seen in the MSP430FR5969 data sheet. The BoosterPack side of the dashed

line shows the standard. The FR5969 function whose color matches the BoosterPack function shows the

specific software-configurable function by which the FR5969 LaunchPad adheres to the standard.

Hardware

2.6 Design Files

Figure 15. FR5969 LaunchPad to BoosterPack Connector Pinout

A complete schematic is available in Section 6. All hardware design files including schematics, layout, bill

of materials (BOM), and Gerber files are available in the MSP-EXP430FR5969 Hardware Design Files.

The software examples are made available in the MSP-EXP430FR5969 Software Examples. For more

information on the software examples, see Section 3.

The MSP-EXP430FR5969 LaunchPad was designed in Mentor Graphics PADS schematic and layout. A

free viewer is available to see both the schematic and layout files on the Mentor Graphics website at

http://www.mentor.com/pcb/downloads/pads-pcb-viewer. A full time-limited version of PADS is available

online for free. This version has complete functionality until the 30 day license expires. This version can be

downloaded directly from http://www.mentor.com/pcb/product-eval/pads-download-evaluation.

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

21

Page 22

Hardware

2.7 Hardware Change log

Table 4 shows the hardware revision history.

PCB Revision Description

Rev 1.6 Initial Release

Rev 2.0

Added EnergyTrace functionality, extended PCB dimensions, added mounting holes, updated isolation block

order, added 5V BP pin, updated silkscreen

3 Software Examples

There are three software examples included with the FR5969 LaunchPad, which can be found in the

MSP-EXP430FR5969 Software Examples. Table 5 describes these examples.

Demo Name BoosterPack Required Description More Details

OutOfBox_FR5969 the factory. Its function was described in Section 1.4. Section 3.3

430BOOST- Demonstrates features of MSP430FR5969 ULP FRAM device

SHARP96_ULP_FRAM with various application modes.

430BOOST- A very simple example showing how to use MSP430 Graphics

SHARP96_GrlibDisplay Library (grlib) to display graphics primitives and images.

430BOOST-SHARP96 Section 3.4

430BOOST-SHARP96 Section 3.5

www.ti.com

Table 4. Hardware Change Log

Table 5. Software Examples

The out-of-box demo pre-programmed on the LaunchPad from

Demonstrates features of MSP430FR5969 ULP FRAM device.

3.1 MSP430 Software: Driver Library, Graphics Library, and Capacitive Touch Library

The examples are built upon three MSP430 libraries available from TI shown below. All three libraries are

available as part of MSP430Ware. Downloading CCS will include MSP430Ware along with TI Resource

Explorer.

• Driver library (driverlib): a foundational MSP430 software library, useful for interfacing with all MSP430

core functions and peripherals, especially clocks and power.

• Graphics library (grlib): a library for interfacing MSP430 devices to dot-matrix LCD displays. Contains

primitives for simple drawing as well as images and more.

• Capacitive Touch Library: a library for capacitive touch sensing applications. This library supports the

use of buttons, sliders, wheels and more. Highly configurable for each application.

When you begin your own development, you will need more information about these libraries than can be

included in this User's Guide. All the information you need is in MSP430Ware or specific library

documentation linked above.

22

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

3.2 Development Environment Requirements

To use any of the below software examples with the MSP430FR5969 LaunchPad, you must have an

integrated development environment (IDE) that supports the MSP430FR5969 device.

Table 6. IDE Minimum Requirements for MSP430FR5969

Code Composer Studio™ IDE IAR Embedded Workbench™ IDE

CCS v5.5 or later IAR EW430 v5.60 or later

For more details on where to download the latest IDE, see Section 4.3.

3.2.1 Pre-Compiled Binary

The /Binary/ folder inside the MSP-EXP430FR5969 Software Examples includes pre-compiled TI-TXT

binary files for each of the above projects that are ready to be flashed onto the LaunchPad. A copy of the

MSP430Flasher tool is also shipped to interface with the eZ-FET Emulator.

To quickly program a demo onto the LaunchPad, simply navigate into the corresponding demo project's

directory and double click the "Program <Example>.bat" file.

Software Examples

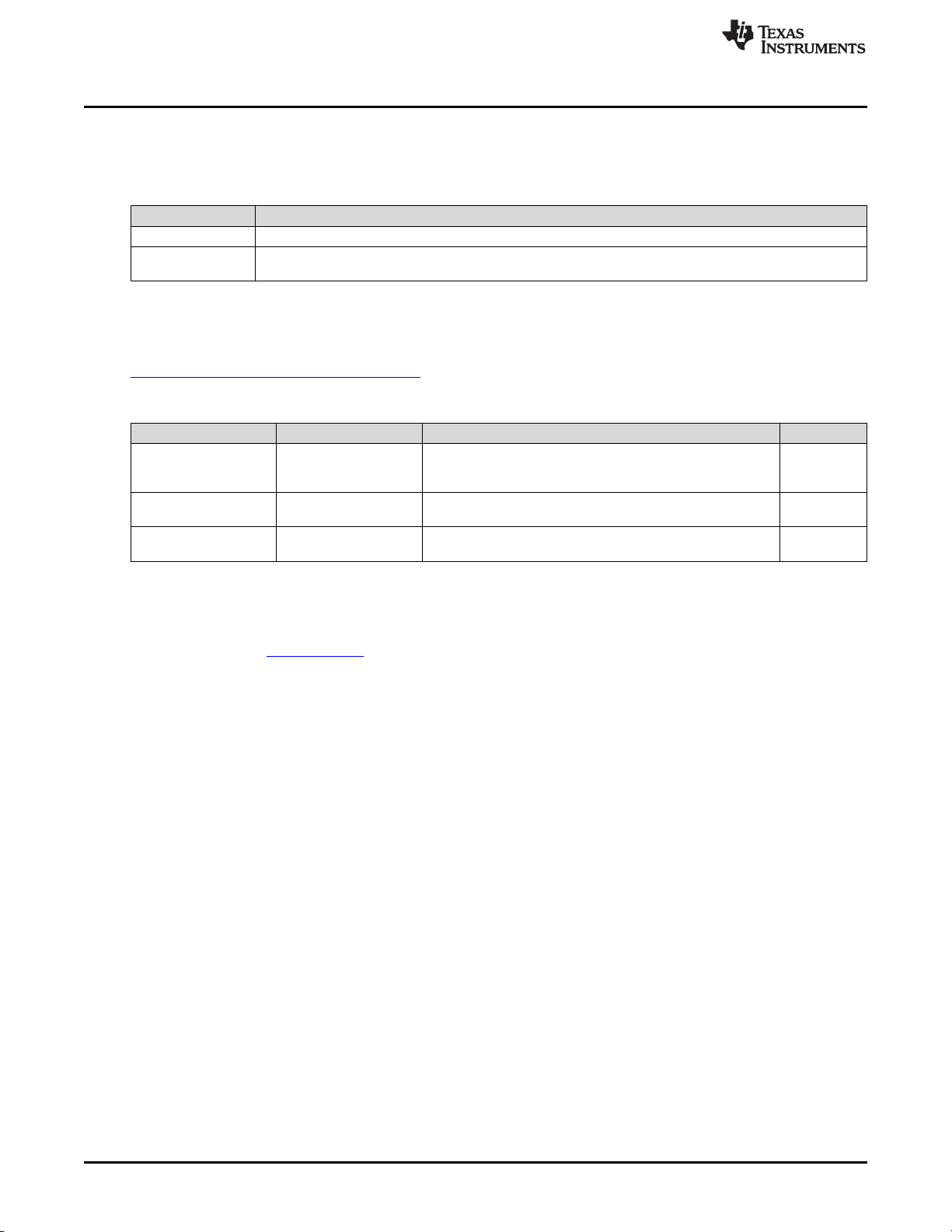

Figure 16. Program <Example>.bat

If desired, the "Program <Example>.bat" file can be modified to point to your own project's binary file.

NOTE: After importing and compiling the software source code in an IDE such as CCS or IAR, the

TI-TXT binary files located in the /Binary/ folder will not be updated automatically. You must

copy your newly compiled binary from your IDE's /Workspace/Project/ directory and replace

the "<Example>.txt" in /Binary/ for the batch file to program your own binary file.

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

23

Page 24

Software Examples

3.2.2 CCS

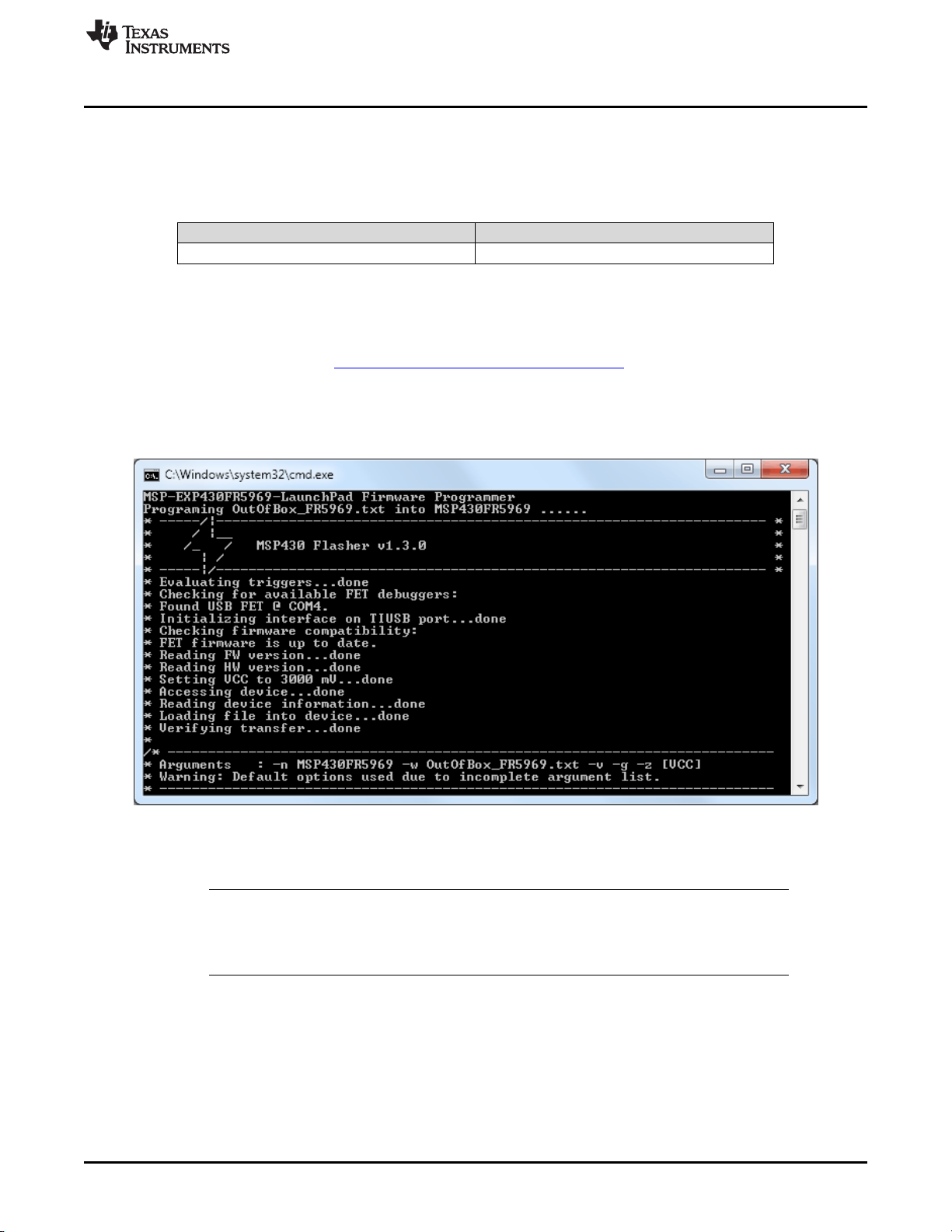

CCS v5.5 or higher is required. When CCS has been launched, and a workspace directory chosen, use

Project→Import Existing CCS Eclipse Project. Direct it to the desired demo's project directory containing

main.c. This is one of the OutOfBox_FR5969, 430BOOST-SHARP96_ULP_FRAM, or 430BOOSTSHARP96_GrlibDisplay projects (see Figure 17).

www.ti.com

Figure 17. Directing the Project→Import Function to the Demo Project

Selecting the \CCS or \CCS_Code_Size_Limited folder also works. The CCS-specific files are located

there.

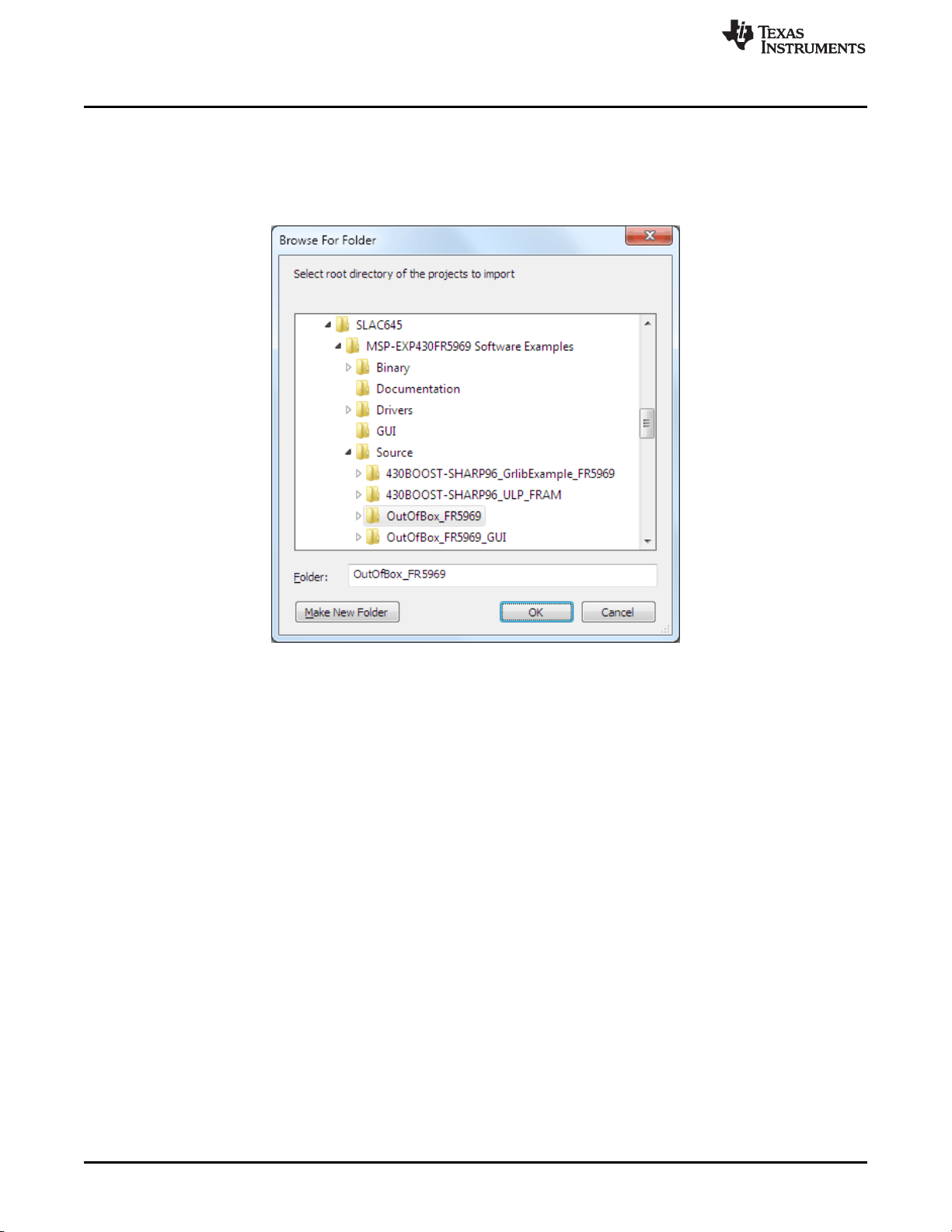

When you click "OK", CCS should recognize the project and allow you to import it. The indication that

CCS has found it is that the project appears in the box shown in Figure 18, and it has a checkmark to the

left of it.

24

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

www.ti.com

Software Examples

Figure 18. When CCS Has Found the Project

Sometimes CCS finds it but does not have a checkmark; this might mean that a project by that name is

already in the workspace. Rename or delete that project to resolve this conflict. (Even if you don't see it in

the CCS workspace, be sure to check the workspace's directory on the file system.)

3.2.3 IAR

IAR Embedded Workbench™ IDE v5.60 or higher is required. To open the demo in IAR, simply choose

File→Open→Workspace…, and direct it to the *.eww workspace file inside the \IAR subdirectory of the

desired demo. All workspace information is contained within this file.

The subdirectory also has an *.ewp project file; this file can be opened into an existing workspace, using

Project→Add-Existing-Project….

Although the software examples have all the code required to run them, IAR users may wish to download

and install MSP430Ware, which contains driverlib, grlib, capacitive touch library, and the TI Resource

Explorer. These are already included in a CCS installation (unless the user selected otherwise).

3.3 Out-of-Box Software Example

This section describes the functionality and structure of the out-of-box software that is preloaded on the

EVM.

The full out-of-box demo cannot be built with the free version of CCS or IAR (IAR Kickstart) due to the

code size limit. To bypass this limitation, a code-size-limited CCS version is provided, that has most

functionality integrated into a library. The code that is built into the library is able to be viewed by the user,

but it cannot be edited. For full functionality download the full version of either CCS or IAR.

There are two modes in the out-of-box software, which can only be interacted with using the provided GUI

in the MSP-EXP430FR5969 Software Examples.

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

25

Page 26

Software Examples

3.3.1 Source File Structure

The project is organized in multiple files. This makes it easier to navigate and reuse parts of it for other

projects. Table 7 describes each file in the project.

Name Description

main.c The out-of-box demo main function, initializations, shared ISR's, etc

LiveTempMode.c Main function file for live temperature streaming mode

FRAMLogMode.c Main function file for FRAM data logging mode

Library: Driverlib Device driver library (MSP430DRIVERLIB)

3.3.2 Power Up and Idle

When the out-of-box demo powers up, the red and green LEDs toggle several times. The MSP430FR5969

then enters low-power mode 3 to wait for UART commands from the PC GUI.

The GUI that is included in the MSP-EXP430FR5969 Software Examples download is required to connect

to the serial port that the LaunchPad's UART communication uses. Follow the "Setup" instructions in the

GUI to establish the connection. After connection has been established, the GUI pings the LaunchPad

every few seconds to make sure that it is still present. If no response is received from the LaunchPad, the

GUI automatically closes the serial port connection.

www.ti.com

Table 7. Source Files and Folders

3.3.3 Live Temperature Mode

To enter the live temperature mode, click the "Start" button below "Live Temp Mode" in the GUI's

Application Controls panel (see Figure 19).

26

Figure 19. Live Temperature Mode

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 27

www.ti.com

The MSP430FR5969 first sends two calibration constants for the temperature sensor to the PC GUI. It

then sets up its 12-bit ADC for sampling and converting the signals from its internal temperature sensor. A

hardware timer is also configured to trigger the ADC conversion every 0.125 seconds before the device

enters low-power mode 3 to conserve power. As soon as the ADC sample and conversion is complete,

the raw ADC data is sent the through the UART backchannel to the PC GUI.

As the raw ADC data is received by the PC GUI, Celsius and Fahrenheit units are calculated first. The PC

GUI keeps a buffer of the most recent 100 temperature measurements, which are graphed against the

PC's current time on the Incoming Data panel.

A red horizontal line is drawn across the data plot to indicate the moving average of the incoming data.

To exit this mode, click the "Stop" button under "Live Temp Mode". You must exit this mode before

starting the FRAM Log Mode.

3.3.4 FRAM Log Mode

To enter the FRAM Log Mode, click the "Start" button under "FRAM Log Mode" in the GUI's Application

Controls panel. The PC GUI immediately sends the current system timestamp to be stored in the

LaunchPad. This timestamp is later used to extrapolate the X-axis time values when the FRAM logged

data are transferred to the GUI (see Figure 20).

Software Examples

Figure 20. FRAM Log Mode

When the MSP430FR5969 receives the UART command from the GUI, it starts the entry sequence by

initializing the Real-Time Clock to trigger an interrupt every 5 seconds. The red LED blinks three times to

indicate successful entry into FRAM Log Mode.

Unlike in the Live Temperature Mode, the MSP430FR5969 enters low-power mode 3.5 to further decrease

power consumption and wakes up every 5 seconds to perform data logging. Because the UART

communication module does not retain power in LPM3.5, the GUI automatically disconnects from the

LaunchPad after entry into FRAM Log Mode.

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

27

Page 28

Software Examples

Each time the device wakes up, the green LED lights up to indicate its state to the user. The 12-bit ADC is

set up to sample and convert the signals from its internal temperature sensor and battery monitor (Super

Cap voltage).

A section of the device's FRAM is allocated to store the raw ADC output data (address 0x9000 to

0xEFFF). This allows the demo to store up to 6144 temperature and voltage data points (5

seconds/sample is approximately 8.5 hours of data).

The FRAM Log Mode also provides the option to log temperature data while powered either through the

USB cable or only by the on-board Super Cap. The PC GUI contains step-by-step instructions in its side

panel for configuring the jumpers on the LaunchPad to power the device with the Super Cap. See

Section 2.4.5 for more detail on the Super Cap.

To exit the FRAM Log Mode, press the S2 (right) push button on the LaunchPad. The red LED turns on

briefly to indicate successful exit. The LaunchPad returns to the Power up and Idle state, and you can

reconnect the LaunchPad with the GUI to transfer the logged data from FRAM to the PC. Click the

"Transfer FRAM Data" button in the GUI to begin transfer. A progress bar shows progress until the

transfer completes, and the temperature and voltage data are plotted in the Incoming Data panel.

3.4 430BOOST-SHARP96 ULP FRAM Demo

This section describes the functionality and structure of the 430BOOST-SHARP96 ULP FRAM demo that

is included in the MSP-EXP430FR5969 Software Examples.

NOTE: The 430BOOST-SHARP96 ULP FRAM demo relies on the 430BOOST-SHARP96

BoosterPack and has a very limited use without it.

www.ti.com

The full demo source code cannot be built with the free version of CCS or IAR (IAR KickStart) because of

the code size limit. To bypass this limitation, a code-size-limited CCS version is provided that has most

functionality integrated into a library. The code that is built into the library can be viewed by the user, but it

cannot be edited. For full functionality, download the full version of either CCS or IAR.

There are five applications in the demo software. All of them are in one project and the different

applications can be cycled through in the user interface.

3.4.1 Source File Structure

The project is split into multiple files. This makes it easier to navigate and reuse parts of it for other

projects.

Name Description

Main.c The user experience demo main function, shared ISRs, and other functions

ActivePowerMeasure.c Main function file for Active Mode Power app

ClockApp.c Main function file for Clock app

FR59xx_EXP.c File for handling system init, main menu, and button operations

FRAMSpeedApp.c Main function file for FRAM Speed app

Game.c Main function file for SliderBall video game app

SYS.c Functions to enter and exit LPM3.5

myTimer.c Contains all timer-based functions and interrupts

ULPMeter.c Main function file for Battery Free Stopwatch app

Library: CTS Capacitive Touch Software Library (CAPSENSELIBRARY)

Library: Driverlib Device driver library (MSP430DRIVERLIB)

Library: grlib Graphics library for the SHARP LCD (MSP430-GRLIB)

Folder: Preloaded images Images for the LCD screen

Table 8. Source Files and Folders

28

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 29

www.ti.com

3.4.2 Navigation and Main Menu

Upon powering up the demo, the title screens appear on the LCD, and are followed by the main selection

menu. The main menu displays all the applications available in the demo. The application options in the

menu are highlighted by using the left capacitive touch slider.

NOTE: Only the left capacitive touch slider is activated for navigation.

After an application is selected, the right button (S2) is used to enter the application. To change the

application or exit, use the left button (S1) and then navigate the main menu to switch to a different

application.

3.4.3 Clock Application

NOTE: This application relies on the operation of the 32.768-kHz clock crystal that is pre-populated

on the LaunchPad.

To enter this application, highlight the "Clock" option on the main menu and then push the right button

(S2).

Immediately upon entering the Clock app, the user is expected to set the date and time details before the

clock starts running. This needs to be done every time the application is entered, because the clock

values are not maintained when running any of the other applications. To set the time and data

parameters use the following steps:

1. When the app starts, the parameter being modified begins to blink.

2. The left capacitive touch slider can be used to increment or decrement the blinking parameter by

placing a finger on the top or bottom portion, respectively, of the slider.

3. The value of the blinking parameter can be locked by placing a finger in the middle of the left

capacitive touch slider.

4. The parameter that is being modified can be changed with the right button (S2).

5. Repeat steps 2 to 4 until all parameters have been set, after which the clock resets the seconds and

begins to track the time from the set time and date.

When the clock begins to run, note that an option to turn on or off the seconds display is provided using

the left button (S1). This is useful when attempting to measure power. The device spends most of the time

in standby (LPM3), waking up every one second to update the RTC values. However if the display is

updated every second, the average power is much higher than just the LPM3 power due to time and

energy required to modify the LCD through SPI. If the SecON option is turned off, the device continues to

provide a one second wakeup to update the RTC values but the display is updated only once a minute to

save power. In this configuration the device power will be similar to power in LPM3 (refer device data

sheet for exact values).

When attempting to measure power using the Current jumper J9, ensure that the meter is in place before

the board is powered up. Removing this jumper while the application is running results in a power cycle of

the device (because the connection to VCCis broken), and the clock parameters must be re-entered.

Software Examples

3.4.4 FRAM Speed Application

To enter the FRAM Speed app, the "FRAM Speed" option on the main menu must be highlighted and the

right button (S2) then pushed. In this application, the FRAM write speed (in kilobytes per second), the total

data written to FRAM (in kilobytes), and the FRAM endurance (in percentage) is tracked and displayed on

the LCD. No user interaction is required.

The application uses Direct Memory Access (DMA) to transfer data to a 1KB block of FRAM. The starting

address of this block is defined and can be modified within the FRAMSpeedApp.h file. Note that changing

this location can cause an overlap with other application code. This is not advised, because code may be

overwritten while running the application. Hence special care needs to be taken to evaluate the size of the

code to ensure that it is not over-written while measuring the FRAM write speed.

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

29

Page 30

Software Examples

It should be noted that this application is optimized for speed rather than power. The speed of this

application is approximately 7500KB (7.5MB) per second. On a flash device, the achievable speed would

be approximately 13KB per second.

Larger blocks of data can be written, which results in faster write speeds but also higher power

consumption. For more information on how to optimize FRAM write speeds, refer to the application report

Maximizing FRAM Write Speed on the MSP430FR57xx (SLAA498).

In this application, the system main clock is configured to use the DCO at 8 MHz. The application

configures the DMA transfer of data and continuously executes it while remaining in LPM0. Each time the

DMA writes the 1KB block, a count variable is incremented and the next DMA transfer is triggered. A timer

is set up to interrupt the FRAM writing every 0.25 second to calculate the speed, total the kilobytes of data

written, update the endurance, and then output these parameters on the LCD.

Note that the FRAM endurance percentage is retained after a power cycle. To exit the application and

stop the FRAM writes, the left button (S1) can be pushed allowing the user to return to the main menu.

3.4.4.1 Understanding the Numbers Behind the FRAM Speed Application

The LCD is updated every 250 ms with an updated percentage change in the FRAM endurance. To

calculate the endurance, some approximations were made in order to provide a meaningful output on the

LCD.

Every 250 ms, 1.8MB of FRAM are programmed with a pattern. Hence the speed of FRAM writes is

calculated as 7.564 MB/s. The FRAM is written to in blocks of 1K bytes; it is this 1KB block that is subject

to the lifetime FRAM endurance specification.

FRAM endurance of block = E = 1015write cycles. This is a minimum specification for FRAM endurance

found in the device data sheet.

www.ti.com

Table 9. FRAM Endurance Calculation for 1KB Block of FRAM

Variable Derived From Value

E FRAM endurance Data sheet 1015writes

W Write speed Application 7.564 MB/second

B FRAM block size Application 1KB (1024 bytes)

N Number of writes to a unique byte/sec N = W / B 7386 writes/second

T

T

L Lifetime percentage reduction per LCD update L = (T

Time between LCD updates Application 250 ms

LCD

Time until endurance specification is met T

LIFE

The calculated value of L is rounded up to 2 × 10

endurance is decremented on the LCD every 250 ms.

Note that the FRAM endurance percentage is retained during on a power cycle. This parameter is

preserved by storing it in FRAM and preventing the variable from being overwritten on a power cycle.

Refer to the NO INIT and LOCATION pragmas in the CCS compiler documentation for more details. This

parameter will be reset when the device is reprogrammed, and the address overwritten.

3.4.5 Battery Free Application

To enter the Battery Free Stopwatch application, select the "Battery Free" option on the main menu and

then press the right button (S2).

This mode is intended to be used when running from the super cap only. See Section 2.4.5 for more

information on how to power the LaunchPad from the super cap.

When the application is entered, a submenu appears showing two possible actions to be taken. The first

action is to "Run App," which starts the Battery Free Stopwatch application and log . The other option is to

"Transmit Data", which transmits all logged data from previous runs through the MSP430 UART to a PC.

= E / N

LIFE

/ T

LCD

-10

%, or 0.0000000002%. This is the amount the FRAM

) × 100 1.85× 10

LIFE

1.35 × 1011seconds

(more than 4000 years)

-10

%

30

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 31

www.ti.com

The "Run App" selection has four modes:

1. Title Mode (Warning Page)

2. Deep Sleep -LPM3.5 Mode

3. Display Mode

4. Low Battery Indicator Mode

When in Title mode or Display mode, press the right button (S2) to put the device into LPM3.5 (Deep

Sleep Mode). Also in these two modes, press the left button (S1) at any time to exit the app and return to

the main menu.

When in Deep Sleep mode, the device remains in LPM3.5, and only the RTC is active. The left button

(S1) is deactivated while in this mode, and the right button (S2) can be used to wake the device from

LPM3.5 and send the device into Display mode. Also, in this mode the RTC wakes up the device

periodically to allow the ADC to sample the supply voltage before returning to LPM3.5. These ADC

samples of the supply voltage are logged into FRAM and can be transmitted back to a PC in the "Transmit

Data" mode.

The Display mode shows the stopwatch display and also the charge consumed while in LPM3.5. The

stopwatch is started when the device enters LPM3.5 and stopped on exit. Hence the total time spent in

LPM3.5 is displayed in HH:MM:SS format. The charge indicator is a reflection of the most recent ADC

sample of supply voltage. If the device is left inactive at the "Display Mode" screen for more than ten

seconds, the app times out, and control reverts to the main menu.

Low Battery mode is entered conditionally following an ADC measurement of the supply voltage. When

VCC< 2.2 V, the device displays a "Low Battery" warning screen. The screen recommends that the device

be plugged into the PC through USB for charging. In this mode, the left button (S1) is deactivated, and the

right button (S2) is used to check if USB has been plugged in or not. If the device has not been plugged

into USB and the right button (S2) is pushed, the device remains in Low Battery mode. If the device has

been plugged into USB and the right button (S2) is pushed, the device enters Deep Sleep mode again.

When running this application, the ADC measurements are logged in FRAM while the device is running

from the super cap indicating that the ADC sampling and FRAM write have a very low-power footprint.

These logged values can then be sent to the PC and the data processed to analyze the reduction of

charge over time. The transfer of data can be done in the UART transmit mode.

The basic operation of the UART transmit mode is outlined below.

1. The eUSCI-UART and DMA modules are set up to transfer the data from FRAM.

2. "Sending Data – Please Wait" screen is displayed while the operation is in progress.

3. On completion "Data Send Complete" screen is displayed.

4. The data can be viewed using any hyperterminal application on the PC.

Software Examples

3.4.6 Active Power Application

The active power of the MSP430FR5969 device is directly dependent on the code and data cache hit ratio

and the clock speed of the CPU. The Active Power application shows the impact of both these factors on

overall system power.

To measure the power consumption of the MSP430FR5969 for the different frequencies and cache hit

ratios, the following steps should be followed:

1. Remove the "Measure Current" jumper from the LaunchPad

2. Use an ammeter set to the "mA" range and connect the leads of the ammeter to the nodes of the

"Measure Current" jumper

3. Navigate the main menu to the "Active Mode" app

4. Choose a frequency and cache hit ratio from the subsequent menus

5. Press the right button (S2) to enter the cache hit code

6. Tune the ammeter range to obtain the most accurate current measurement values

7. Prior to exiting the cache hit code, ensure that ammeter is in "mA" range, then press right button (S2)

to exit cache hit code

SLAU535B–February 2014–Revised July 2015 MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969)

Submit Documentation Feedback

Copyright © 2014–2015, Texas Instruments Incorporated

31

Page 32

Software Examples

3.4.7 SliderBall Game

This application was designed to show the functioning ability of the two Capacitive Touch sliders in

conjunction with the LCD from the 430BOOST-SHARP96 BoosterPack.

To enter the application, the SliderBall game option on the main menu must be highlighted and the right

button (S2) then pushed. The SliderBall game requires the player to use a sliding paddle to keep the ball

in play. The goal of the game is to keep the ball alive and on the screen by having it hit off of the two

paddles at each end of the screen. Users start off with five lives to accumulate as many points as

possible. For each time that the ball is blocked by the paddle, points are awarded. The higher the

difficulty, the more points are awarded for each hit. Each time the ball reaches the end of the screen and

the paddle has not hit the ball, the user loses a life. After the life is lost, the ball automatically starts again

for another round. This repeats until all lives are exhausted, and the game is over. If the high score has

been achieved, a congratulations screen will be displayed to notify the user. At this point the final score,

as well as the board high score will be displayed and the user may then choose a new level of difficulty to

play once again.

To navigate the user levels menu and choose an option, the left capacitive touch slider and right button

are used similar to all previous menus. The user may choose between the following: easy, normal, hard,

and Insane. After selecting a difficulty, the game will begin to start, with the ball moving to the right-hand

side first. Both capacitive touch sliders are used to control their respective paddles along the side of the

screen. When the user misses the ball, it will be held in place for a few cycles before starting to move

again to give the user a chance to regroup following losing a life. To create "easier" versions of the game,

sleep cycles are added to slow down the game play.

The high score for each user level is stored in FRAM and is retained on subsequent power cycles. This

value is erased only when the device is re-programmed.

www.ti.com

3.4.8 Special Notes: Inverting the Display Color Scheme

A feature that has been built in to the demo code is the ability to invert the display colors. This can be a

useful feature for times when the original display color settings are difficult to read.

To invert the colors edit the file 'sharp96x96.h' within the 'grlib' directory. In the 'User Configuration for the

LCD Driver' section under 'Invert Display Option' use either one of the # defines 'NORMAL_DISPLAY' or

'INVERT_DISPLAY' as needed.

When INVERT_DISPLAY is defined it allows the demo to display with a black background and white

foreground once the demo code is re-downloaded onto the MSP-EXP430FR5969 board.

3.5 430BOOST-SHARP96 Graphics Library Demo

NOTE: This graphics library demo is dependent on the 430BOOST-SHARP96 BoosterPack that

comes with the MSP-BNDL-FR5969LCD bundle.

The grlib demo shows how to use the MSP430 Graphics Library http://www.ti.com/tool/msp430-grlib or

"grlib," in a project with the Sharp®display. This demo cycles screens without user interaction to show

simple graphics primitives.

• Pixels

• Lines

• Circles

• Rectangles

• Text

• Images

The demo introduces the functions to configure grlib such as initialization, color inversion, and using

foreground and background colors properly.

32

MSP430FR5969 LaunchPad™ Development Kit (MSP‑EXP430FR5969) SLAU535B–February 2014–Revised July 2015

Copyright © 2014–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 33

4#/ >UPAO NAMQENA@ =

96 LETAHO/NKS

0.5 LETAHO/>UPA

× 96 NKSO = 18432 >UPAO

4#/ >UPAO NAMQENA@ =

96 LETAHO/NKS

8 LETAHO/>UPA

× 96 NKSO = 1152 >UPAO

www.ti.com

FRAM memory devices like the MSP430FR5969 are touted for ultra-low power, but in some applications