Page 1

D

Low Supply Voltage Range 1.8 V – 3.6 V

D

Ultralow-Power Consumption

Low Operation Current,

1.3 µA at 4 kHz, 2.2 V

160 µA at 1 MHz, 2.2 V

D

Five Power Saving Modes:

(Standby Mode: 0.8 µA,

RAM Retention Off Mode: 0.1 µA)

D

Wake-Up From Standby Mode in 6 µs

D

16-Bit RISC Architecture, 125 ns

Instruction Cycle Time

D

Basic Clock Module Configurations:

– Various Internal Resistors

– Single External Resistor

– 32 kHz Crystal

– High Frequency Crystal

– Resonator

– External Clock Source

D

16-Bit Timer With Three Capture/Compare

Registers

D

Slope A/D Converter With External

Components

D

On-Chip Comparator for Analog Signal

Compare Function or Slope A/D

Conversion

description

D

Serial Onboard Programming

D

Programmable Code Protection by Security

Fuse (C11x1 Only)

D

Family Members Include:

MSP430C1 111: 2KB ROM,128B RAM

MSP430C1 121: 4KB ROM, 256B RAM

MSP430F1101: 1KB + 128B Flash Memory

MSP430F1121: 4KB + 256B Flash Memory

D

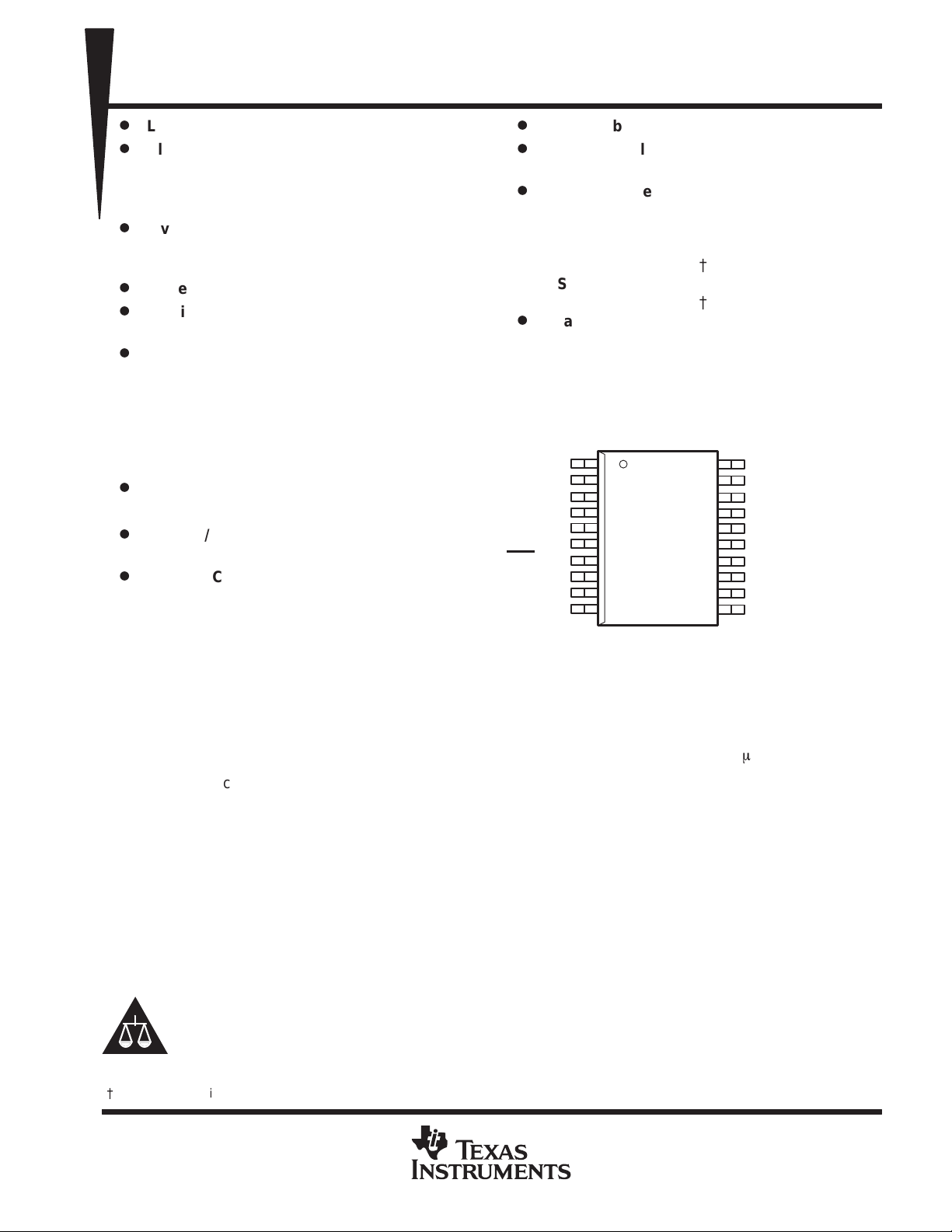

Available in a 20-Pin Plastic Small-Outline

Wide Body (SOWB) Package and 20-Pin

Plastic Thin Shrink Small-Outline Package

(TSSOP)

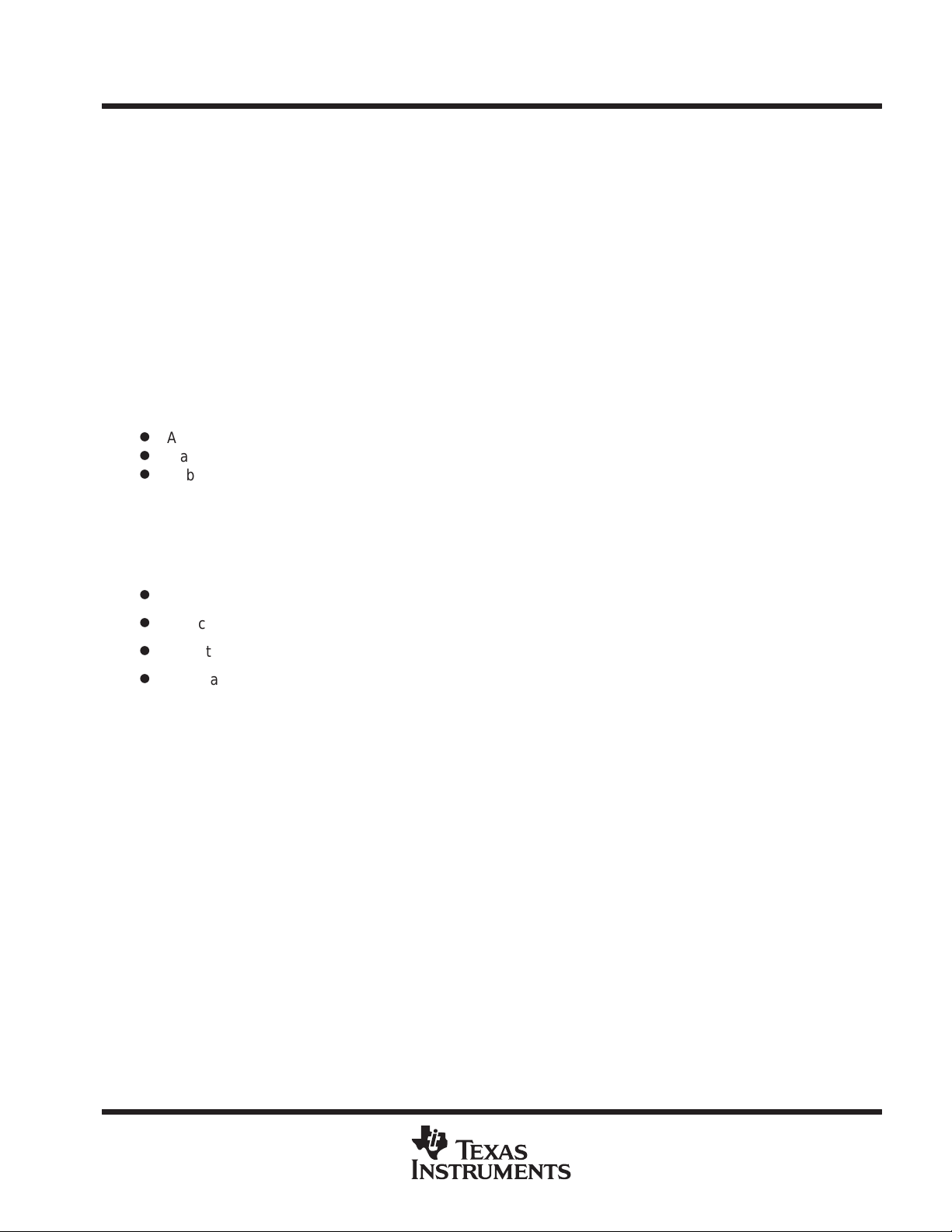

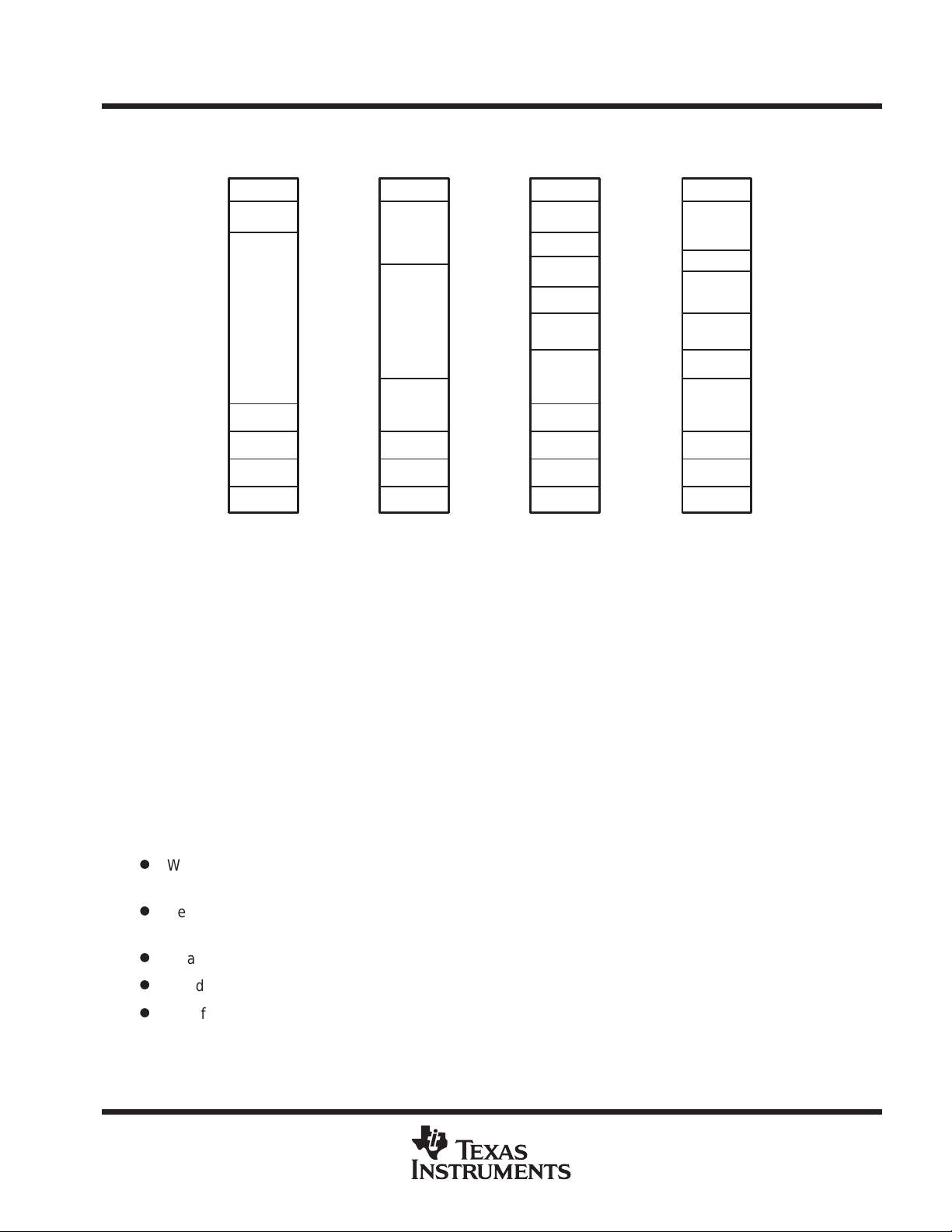

TEST

VCC

P2.5/R

osc

V

SS

XOUT

XIN

/NMI

RST

P2.0/ACLK

P2.1/INCLK

P2.2/CAOUT/TA0

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

(MTP{), 128B RAM

(MTP{), 256B RAM

DW OR PW PACKAGE

(TOP VIEW)

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

P1.7/TA2/TDO/TDI

P1.6/TA1/TDI

P1.5/TA0/TMS

P1.4/SMCLK/TCK

P1.3/TA2

P1.2/TA1

P1.1/TA0

P1.0/TACLK

P2.4/CA1/TA2

P2.3/CA0/TA1

The T exas Instruments MSP430 series is an ultralow-power microcontroller family consisting of several devices

featuring different sets of modules targeted to various applications. The microcontroller is designed to be battery

operated for an extended-application lifetime. With 16-bit RISC architecture, 16 bit integrated registers on the

CPU, and a constant generator, the MSP430 achieves maximum code efficiency. The digitally-controlled

oscillator provides fast wake-up from all low-power modes to active mode in less than 6 ms.

Typical applications include sensor systems that capture analog signals, convert them to digital values, and then

process the data and display them or transmit them to a host system. Stand alone RF sensor front end is another

area of application. The I/O port inputs provide single slope A/D conversion capability on resistive sensors. The

MSP430x11x series is an ultralow-power mixed signal microcontroller with a built in 16-bit timer and fourteen

I/O pins. The MSP430x11x1 family adds a versatile analog comparator.

The flash memory provides added flexibility of in-system programming and data storage without significantly

increasing the current consumption of the device. The programming voltage is generated on-chip, thereby

alleviating the need for an additional supply , and even allowing for reprogramming of battery-operated systems.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

{

MTP = Multiple Time Programmable

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Copyright 2000, Texas Instruments Incorporated

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1

Page 2

MSP430x11x1

40°C to 85°C

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

T

A

°

–

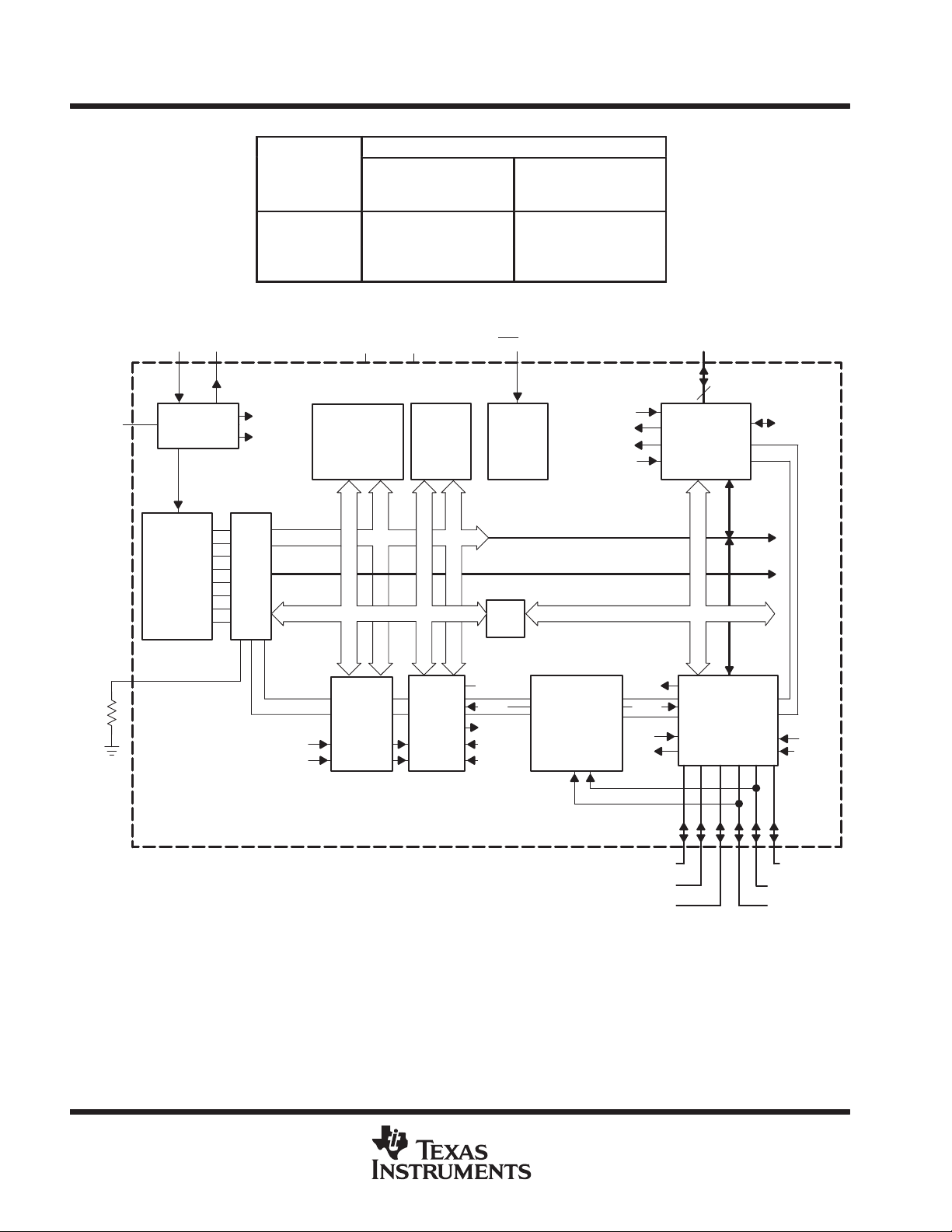

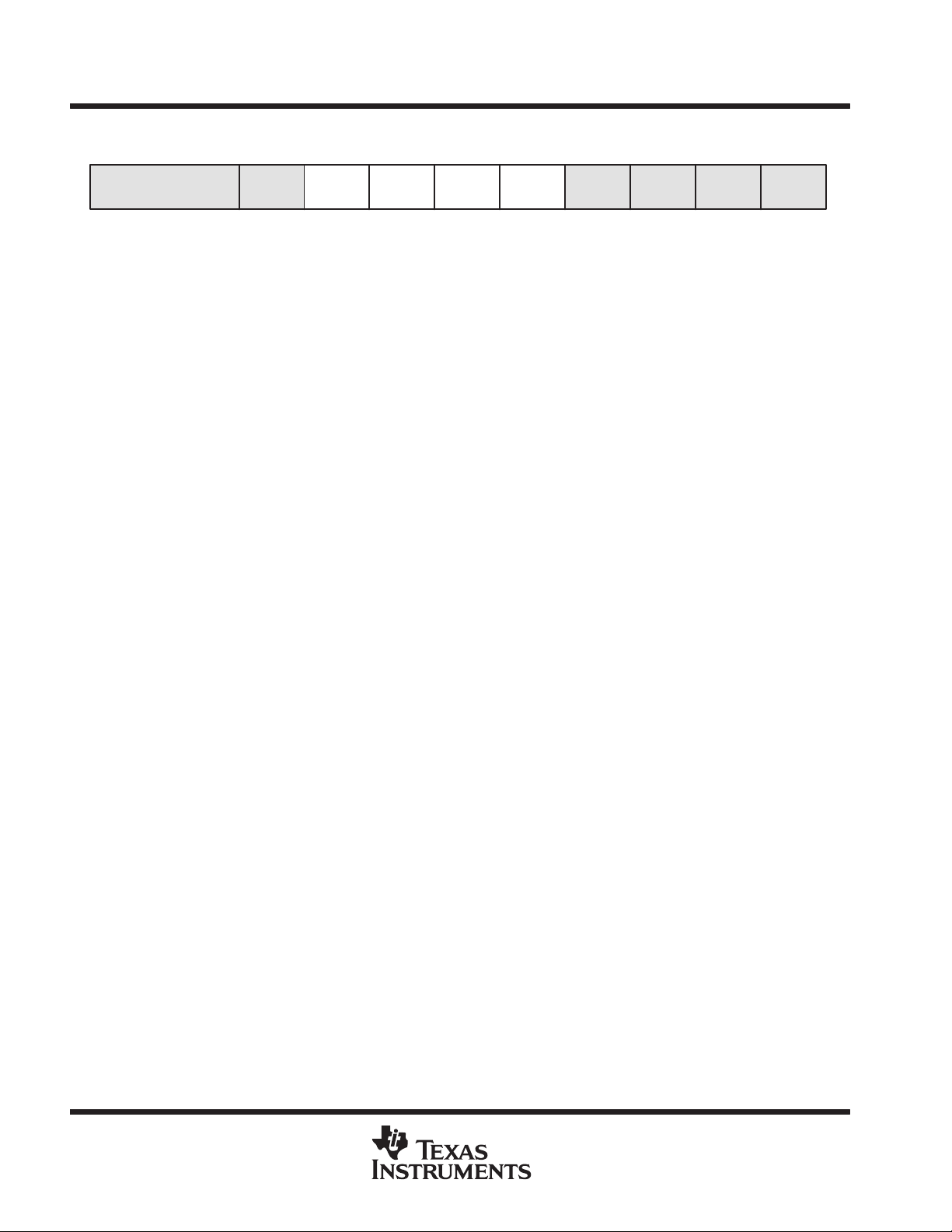

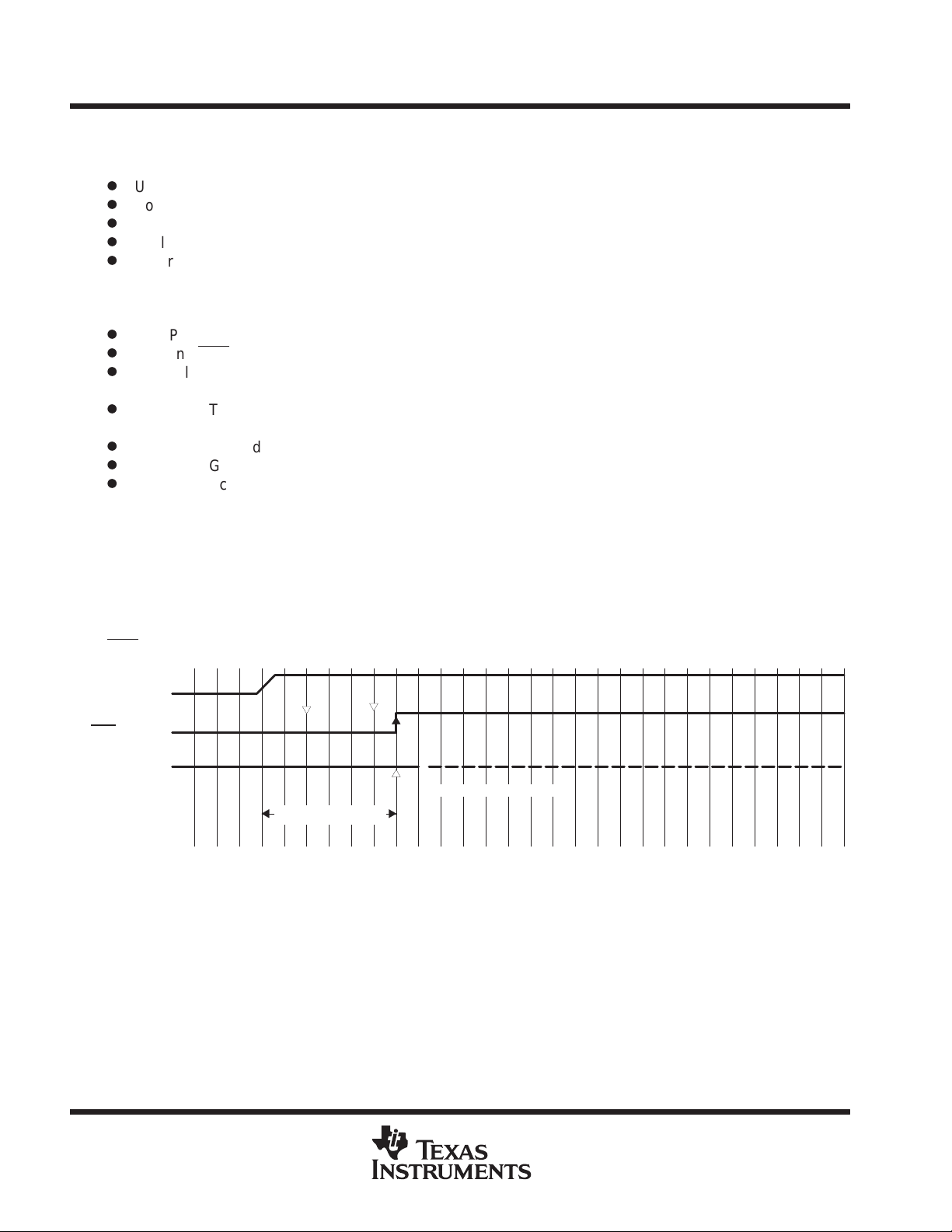

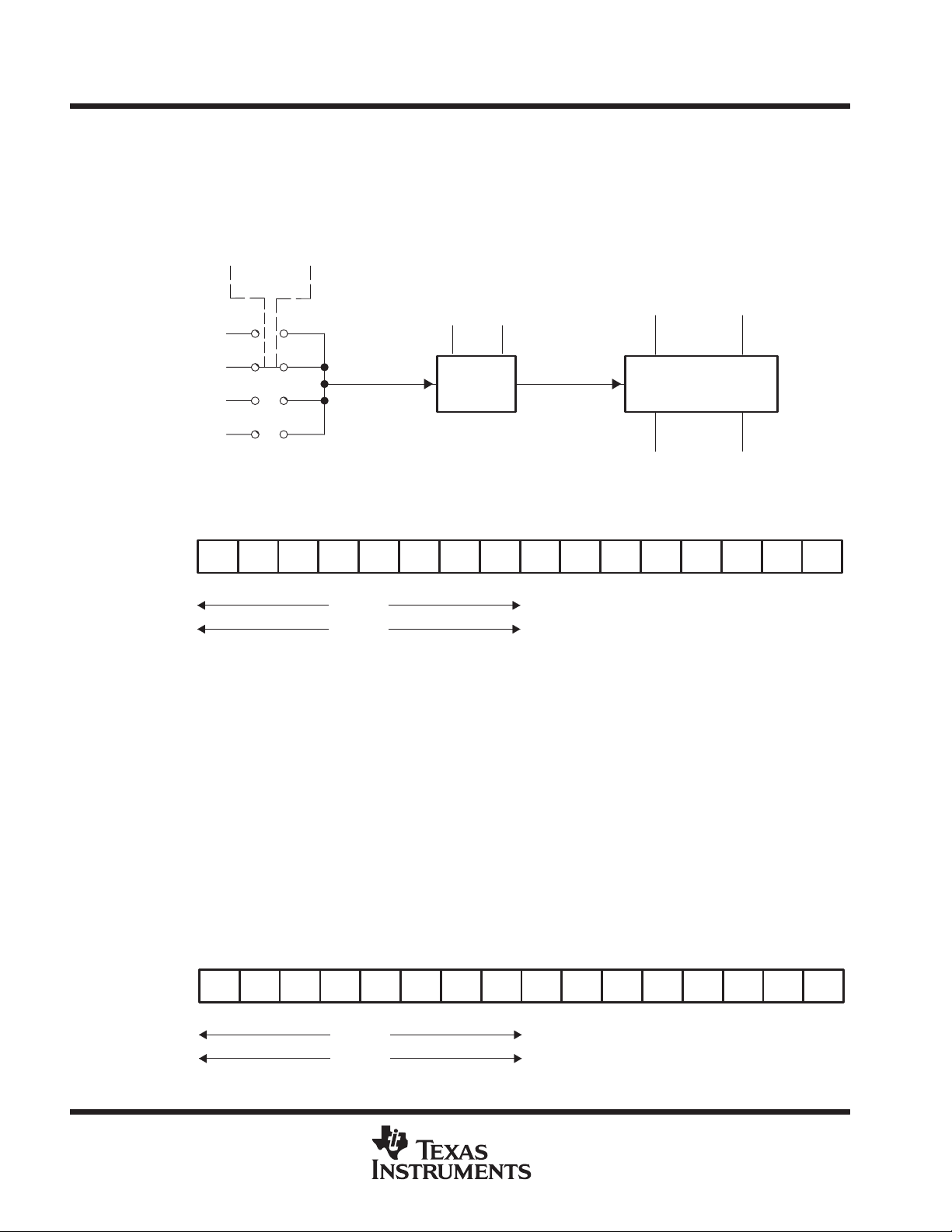

functional block diagram

°

AVAILABLE OPTIONS

PACKAGED DEVICES

PLASTIC

20-PIN SOWB

(DW)

MSP430C1111IDW

MSP430C1121IDW

MSP430F1101IDW

MSP430F1121IDW

PLASTIC

20-PIN TSSOP

(PW)

MSP430F1101IPW

MSP430F1121IPW

TEST

Rosc

†

XIN XOUT

Oscillator

System Clock

MCLK

CPU

Incl. 16 Reg.

Test

JTAG

ACLK

SMCLK

MAB, 16 Bit

MDB, 16 Bit

ACLK

SMCLK

V

CC

1/2/4 KB ROM/

Flash+126/256B

Flash INFO

’C’: ROM

’F’: Flash

Watchdog

Timer

15/16 Bit

V

SS

128/256B

RAM

Timer_A

3 CC

Register

CCR0/1/2

x = 0, 1, 2

RST/NMI P1.0–7

Power-on-

Reset

Bus

Conv.

TACLK or

INCLK

CCI1

Outx

CCIx

CCIx

Comparator-A

Input Multiplexer

RC Filtered O/P

Internal Vref

Analog Switch

Outx

CCIxA

TACLK

SMCLK

MAB, 4 Bit

MCB

MDB, 8 Bit

INCLK

Out0

CCI0

8 I/O’s, All With

CCI1

8

I/O Port P1

Interrupt

Capabililty

I/O Port P2

6 I/O’s All With

Interrupt

Capabililty

JTAG

ACLK

DCOR

†

2

A pulldown resistor of 30 kΩ is needed on F11x1.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

P2.0 / ACLK

P2.1 / INCLK

P2.2 / CAOUT/TA0

P2.5 / Rosc

P2.4 / CA1/TA2

P2.3 / CA0/TA1

Page 3

MSP430x11x1

TERMINAL

I/O

DESCRIPTION

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

Terminal Functions

NAME NO.

P1.0/TACLK 13 I/O General-purpose digital I/O pin/Timer_A, clock signal TACLK input

P1.1/TA0 14 I/O General-purpose digital I/O pin/Timer_A, capture: CCI0A input, compare: Out0 output

P1.2/TA1 15 I/O General-purpose digital I/O pin/Timer_A, capture: CCI1A input, compare: Out1 output

P1.3/TA2 16 I/O General-purpose digital I/O pin/Timer_A, capture: CCI2A input, compare: Out2 output

P1.4/SMCLK/TCK 17 I/O General-purpose digital I/O pin/SMCLK signal output/test clock, input terminal for device programming

P1.5/TA0/TMS 18 I/O General-purpose digital I/O pin/Timer_A, compare: Out0 output/test mode select, input terminal for

P1.6/TA1/TDI 19 I/O General-purpose digital I/O pin/Timer_A, compare: Out1 output/test data input terminal

P1.7/TA2/TDO/TDI

P2.0/ACLK 8 I/O General-purpose digital I/O pin/ACLK output

P2.1/INCLK 9 I/O General-purpose digital I/O pin/Timer_A, clock signal at INCLK

P2.2/CAOUT/T A0 10 I/O General-purpose digital I/O pin/Timer_A, capture: CCI0B input/comparator_A, output

P2.3/CA0/T A1 11 I/O General-purpose digital I/O pin/Timer_A, compare: Out1 output/comparator_A, input

P2.4/CA1/T A2 12 I/O General-purpose digital I/O pin/Timer_A, compare: Out2 output/comparator_A, input

P2.5/R

osc

RST/NMI 7 I Reset or nonmaskable interrupt input

TEST 1 I Select of test mode for JTAG pins on Port1. Must be tied low with less than 30 kΩ (F11x1).

VCC 2 Supply voltage

V

SS

XIN 6 I Input terminal of crystal oscillator

XOUT 5 I/O Output terminal of crystal oscillator

†

TDO or TDI is selected via JTAG instruction.

†

20 I/O General-purpose digital I/O pin/Timer_A, compare: Out2 output/test data output terminal or data input

3 I/O General-purpose digital I/O pin/Input for external resistor that defines the DCO nominal frequency

4 Ground reference

and test

device programming and test

during programming

short-form description

processing unit

The processing unit is based on a consistent, and orthogonally-designed CPU and instruction set. This design

structure results in a RISC-like architecture, highly transparent to the application development, and noted for

its programming simplicity . All operations other than program-flow instructions are consequently performed as

register operations in conjunction with seven addressing modes for source, and four modes for destination

operands.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

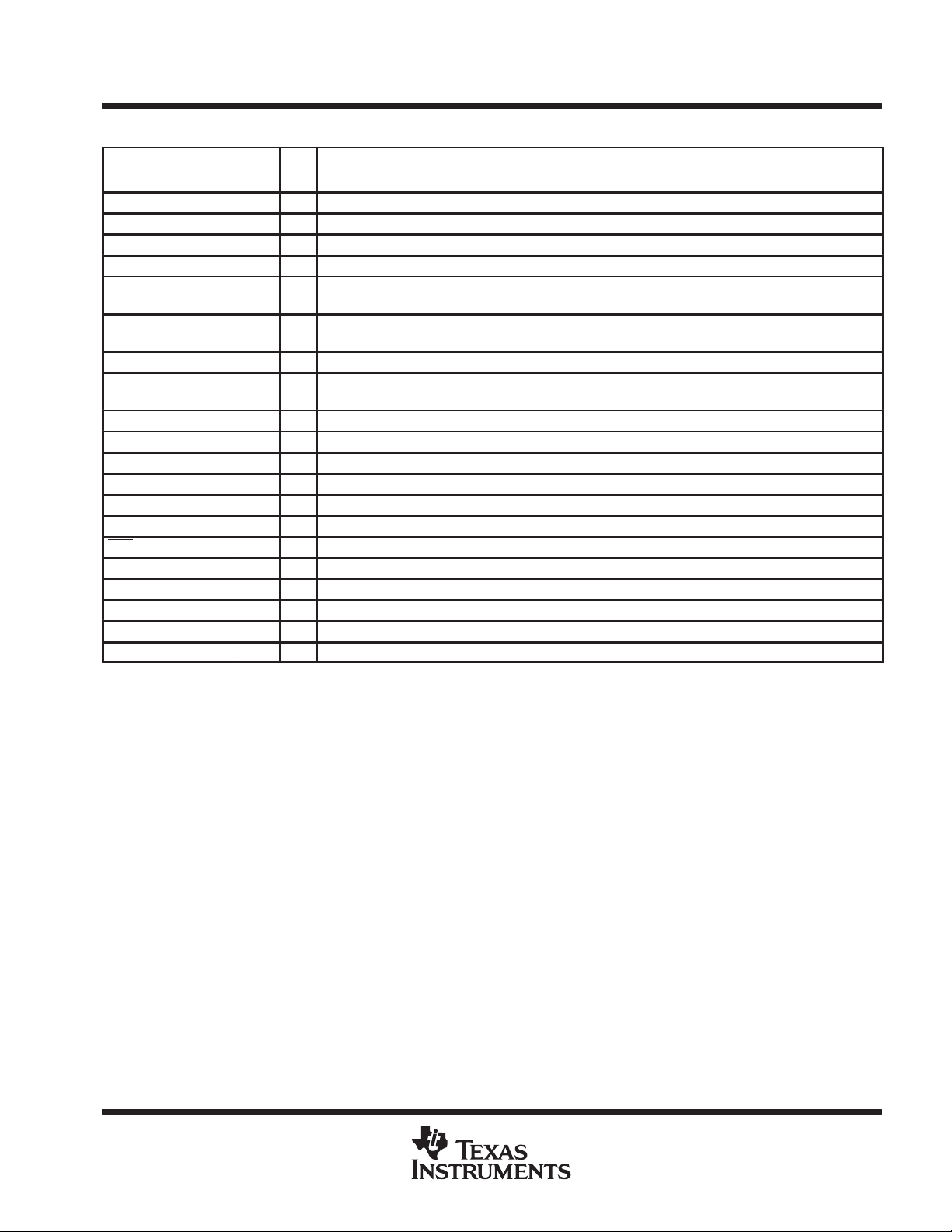

Page 4

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

short-form description (continued)

CPU

Program Counter

PC/R0

All sixteen registers are located inside the CPU,

Stack Pointer

SP/R1

providing reduced instruction execution time. This

reduces a register-register operation execution

Status Register

SR/CG1/R2

time to one cycle of the processor.

Constant Generator

CG2/R3

Four registers are reserved for special use as a

program counter, a stack pointer , a status register,

General-Purpose Register

R4

and a constant generator. The remaining twelve

registers are available as general-purpose

General-Purpose Register

R5

registers.

Peripherals are connected to the CPU using a

data address and control buses and can be

General-Purpose Register R14

handled easily with all instructions for memory

manipulation.

General-Purpose Register

R15

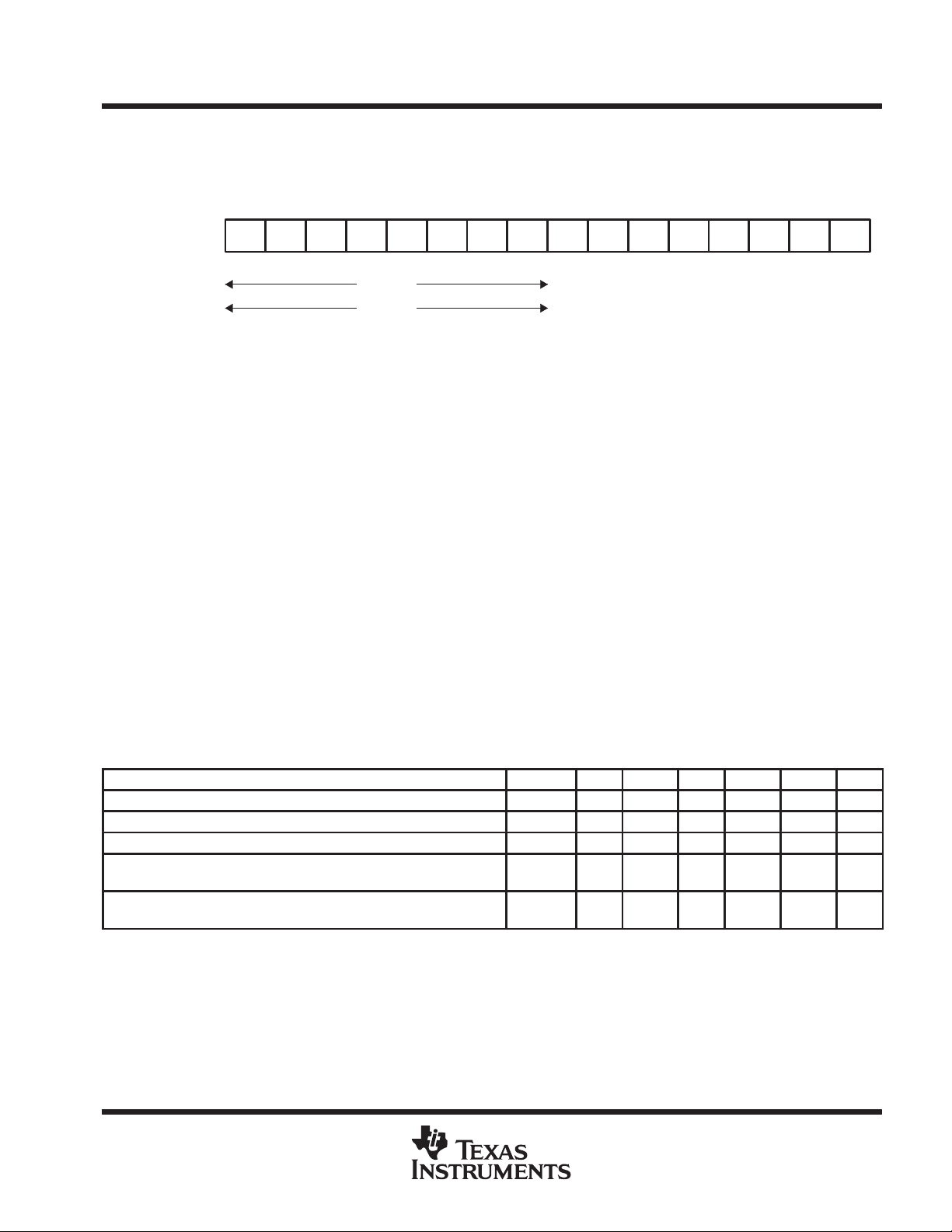

instruction set

The instructions set for this register-register architecture provides a powerful and easy-to-use assembly

language. The instruction set consists of 51 instructions with three formats and seven addressing modes.

T able 1 provides a summation and example of the three types of instruction formats; the addressing modes are

listed in Table 2.

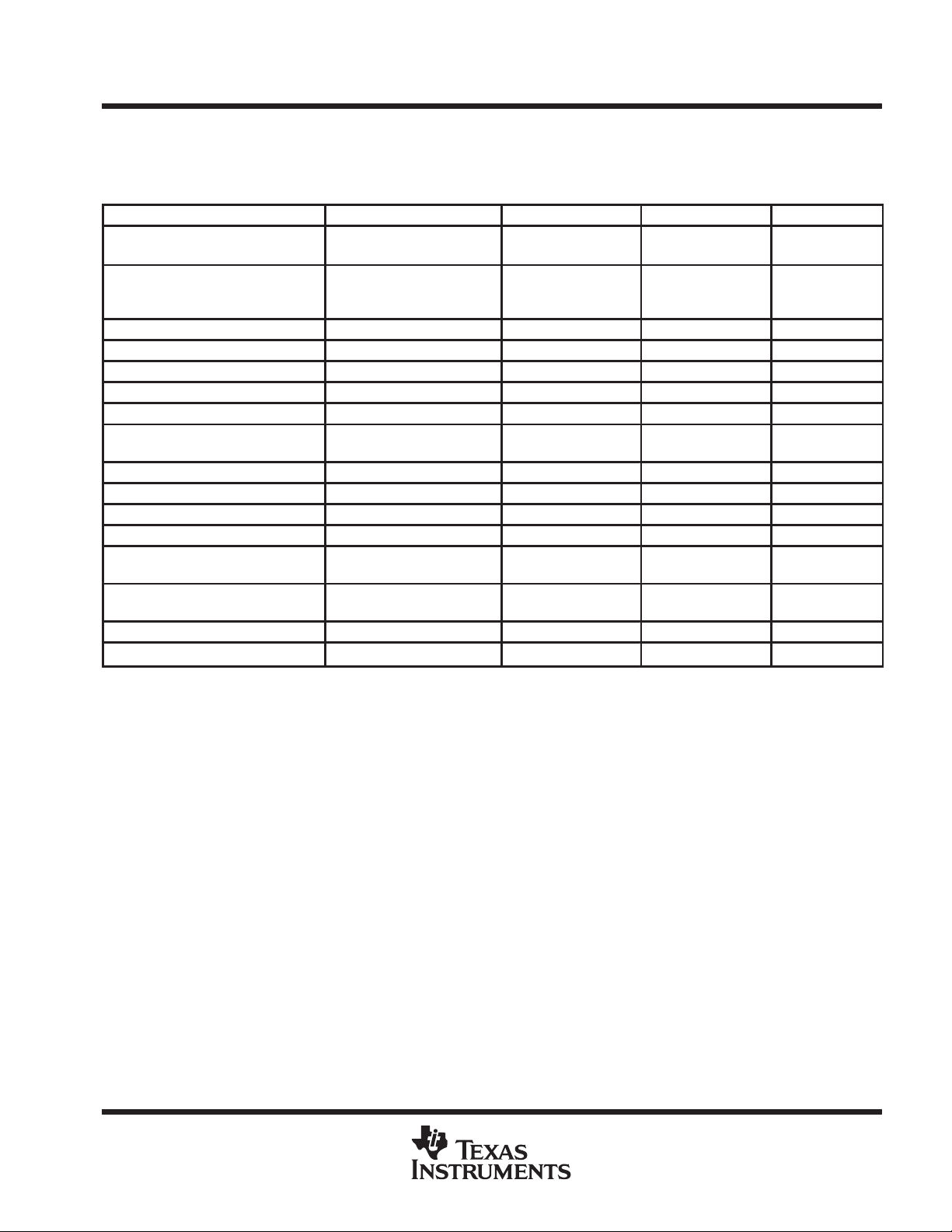

Table 1. Instruction Word Formats

Dual operands, source-destination e.g. ADD R4, R5 R4 + R5 → R5

Single operands, destination only e.g. CALL R8 PC → (TOS), R8 → PC

Relative jump, un-/conditional e.g. JNE Jump-on equal bit = 0

Most instructions can operate on both word and byte data. Byte operations are identified by the suffix B.

Examples: Instructions for word operation Instructions for byte operation

MOV EDE,TONI MOV.B EDE,TONI

ADD #235h,&MEM ADD.B #35h,&MEM

PUSH R5 PUSH.B R5

SWPB R5 —

Table 2. Address Mode Descriptions

ADDRESS MODE s d SYNTAX EXAMPLE OPERATION

Register √ √ MOV Rs, Rd MOV R10, R11 R10 → R11

Indexed √ √ MOV X(Rn), Y(Rm) MOV 2(R5), 6(R6) M(2 + R5) → M(6 + R6)

Symbolic (PC relative) √ √ MOV EDE, TONI M(EDE) → M(TONI)

Absolute √ √ MOV &MEM, &TCDAT M(MEM) → M(TCDAT)

Indirect √ MOV @Rn, Y(Rm) MOV @R10, Tab(R6) M(R10) → M(Tab + R6)

Indirect autoincrement √ MOV @Rn+, RM MOV @R10+, R11 M(R10) → R11, R10 + 2 → R10

Immediate √ MOV #X, TONI MOV #45, TONI #45 → M(TONI)

NOTE: s = source d = destination Rs/Rd = source register/destination register Rn = register number

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 5

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

instruction set (continued)

Computed branches (BR) and subroutine calls (CALL) instructions use the same addressing modes as the other

instructions. These addressing modes provide

calls. The full use of this programming capability permits a program structure different from conventional 8- and

16-bit controllers. For example, numerous routines can easily be designed to deal with pointers and stacks

instead of using flag type programs for flow control.

indirect

operation modes and interrupts

The MSP430 operating modes support various advanced requirements for ultralow-power and ultralow energy

consumption. This is achieved by the intelligent management of the operations during the different module

operation modes and CPU states. The advanced requirements are fully supported during interrupt event

handling. An interrupt event awakens the system from each of the various operating modes and returns with

the

RETI

instruction to the mode that was selected before the interrupt event. The different requirements of the

CPU and modules, which are driven by system cost and current consumption objectives, necessitate the use

of different clock signals:

D

Auxiliary clock ACLK (from LFXT1CLK/crystal’s frequency), used by the peripheral modules

D

Main system clock MCLK, used by the CPU and system

D

Subsystem clock SMCLK, used by the peripheral modules

addressing, ideally suited for computed branches and

low-power consumption capabilities

The various operating modes are controlled by the software through controlling the operation of the internal

clock system. This clock system provides many combinations of hardware and software capabilities to run the

application with the lowest power consumption and with optimized system costs:

D

Use the internal clock (DCO) generator without any external components.

D

Select an external crystal or ceramic resonator for lowest frequency or cost.

D

Select and activate the proper clock signals (LFXT1CLK and/or DCOCLK) and clock pre-divider function.

D

Apply an external clock source.

Four of the control bits that influence the operation of the clock system and support fast turnon from low power

operating modes are located in the status register SR. The four bits that control the CPU and the system clock

generator are SCG1, SCG0, OscOff, and CPUOff:

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

Page 6

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

status register R2

15 9 8 7 0

Reserved For Future

Enhancements

rw-0 rw-0 rw-0 rw-0 rw-0 rw-0 rw-0 rw-0 rw-0 rw-0

V SCG1 SCG0 OscOff

6543 21

CPUOff GIE N Z C

The bits CPUOff, SCG1, SCG0, and OscOff are the most important low-power control bits when the basic

function of the system clock generator is established. They are pushed onto the stack whenever an interrupt

is accepted and thereby saved so that the previous mode of operation can be retrieved after the interrupt

request. During execution of an interrupt handler routine, the bits can be manipulated via indirect access of the

data on the stack. That allows the program to resume execution in another power operating mode after the

return from interrupt (RETI).

SCG1: The clock signal SMCLK, used for peripherals, is enabled when bit SCG1 is reset or disabled if

the bit is set.

SCG0: The dc-generator is active when SCG0 is reset. The dc-generator can be deactivated only if the

SCG0 bit is set and the DCOCLK signal is not used for MCLK or SMCLK. The current consumed

by the dc-generator defines the basic frequency of the DCOCLK. It is a dc current.

The clock signal DCOCLK is deactivated if it is not used for MCLK or SMCLK or if the SCG0 bit

is set. There are two situations when the SCG0 bit cannot switch off the DCOCLK signal:

1. DCOCLK frequency is used for MCLK (CPUOff=0 and SELM.1=0).

2. DCOCLK frequency is used for SMCLK (SCG1=0 and SELS=0).

NOTE:

When the current is switched off (SCG0=1) the start of the DCOCLK is delayed slightly . The delay

is in the µs-range (see device parameters for details).

OscOff: The LFXT1 crystal oscillator is active when the OscOff bit is reset. The LFXT1 oscillator can only

be deactivated if the OscOff bit is set and it is not used for MCLK or SMCLK. The setup time to

start a crystal oscillation needs consideration when oscillator off option is used. Mask

programmable (ROM) devices can disable this feature so that the oscillator can never be switched

off by software.

CPUOff: The clock signal MCLK, used for the CPU, is active when the CPUOf f bit is reset or stopped if it

is set.

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 7

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

interrupt vector addresses

The interrupt vectors and the power-up starting address are located in the memory with an address range of

0FFFFh-0FFE0h. The vector contains the 16-bit address of the appropriate interrupt handler instruction

sequence.

INTERRUPT SOURCE INTERRUPT FLAG SYSTEM INTERRUPT WORD ADDRESS PRIORITY

Power-up, external reset, watchdog

NMI, oscillator fault, flash memory

access violation

Comparator_A CAIFG maskable 0FFF6h 11

Watchdog timer WDTIFG maskable 0FFF4h 10

Timer_A CCIFG0 (Note 2) maskable 0FFF2h 9

Timer_A

I/O Port P2 (eight flags – see Note 3)

I/O Port P1 (eight flags)

NOTES: 1. Multiple source flags

2. Interrupt flags are located in the module

3. There are eight Port P2 interrupt flags, but only six Port P2 I/O pins (P2.0–5) are implemented on the 11x1 devices.

4. (non)-maskable: the individual interrupt enable bit can disable an interrupt event, but the general interrupt enable cannot.

Nonmaskable: neither the individual nor the general interrupt enable bit will disable an interrupt event.

WDTIFG (Note1)

KEYV (Note 1)

NMIIFG (Notes 1 and 4)

OFIFG (Notes 1 and 4)

ACCVIFG (Notes 1 and 4)

CCIFG1, CCIFG2, TAIFG

(Notes 1 and 2)

P2IFG.0 to P2IFG.7

(Notes 1 and 2)

P1IFG.0 to P1IFG.7

(Notes 1 and 2)

Reset 0FFFEh 15, highest

(non)-maskable,

(non)-maskable,

(non)-maskable

maskable 0FFF0h 8

maskable 0FFE6h 3

maskable 0FFE4h 2

0FFFCh 14

0FFFAh 13

0FFF8h 12

0FFEEh 7

0FFECh 6

0FFEAh 5

0FFE8h 4

0FFE2h 1

0FFE0h 0, lowest

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

Page 8

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

special function registers

Most interrupt and module enable bits are collected into the lowest address space. Special function register bits

that are not allocated to a functional purpose are not physically present in the device. Simple software access

is provided with this arrangement.

interrupt enable 1 and 2

Address

0h

7654 0

rw-0 rw-0 rw-0

WDTIE: Watchdog timer enable signal

OFIE: Oscillator fault enable signal

NMIIE: Nonmaskable interrupt enable signal

ACCVIE: Access violation at flash memory

Address

01h

7654 0321

interrupt flag register 1 and 2

Address

02h NMIIFG

7654 0

WDTIFG: Set on overflow or security key violation or

Reset on V

power-on or reset condition at RST/NMI-pin

CC

OFIFG: Flag set on oscillator fault

NMIIFG: Set via RST/NMI-pin

Address

03h

7654 0321

321

NMIIEACCVIE

321

rw-0 rw-1 rw-0

OFIE WDTIE

rw-0

OFIFG WDTIFG

8

Legend rw:

rw-0:

Bit can be read and written.

Bit can be read and written. It is reset by PUC

SFR bit is not present in device.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 9

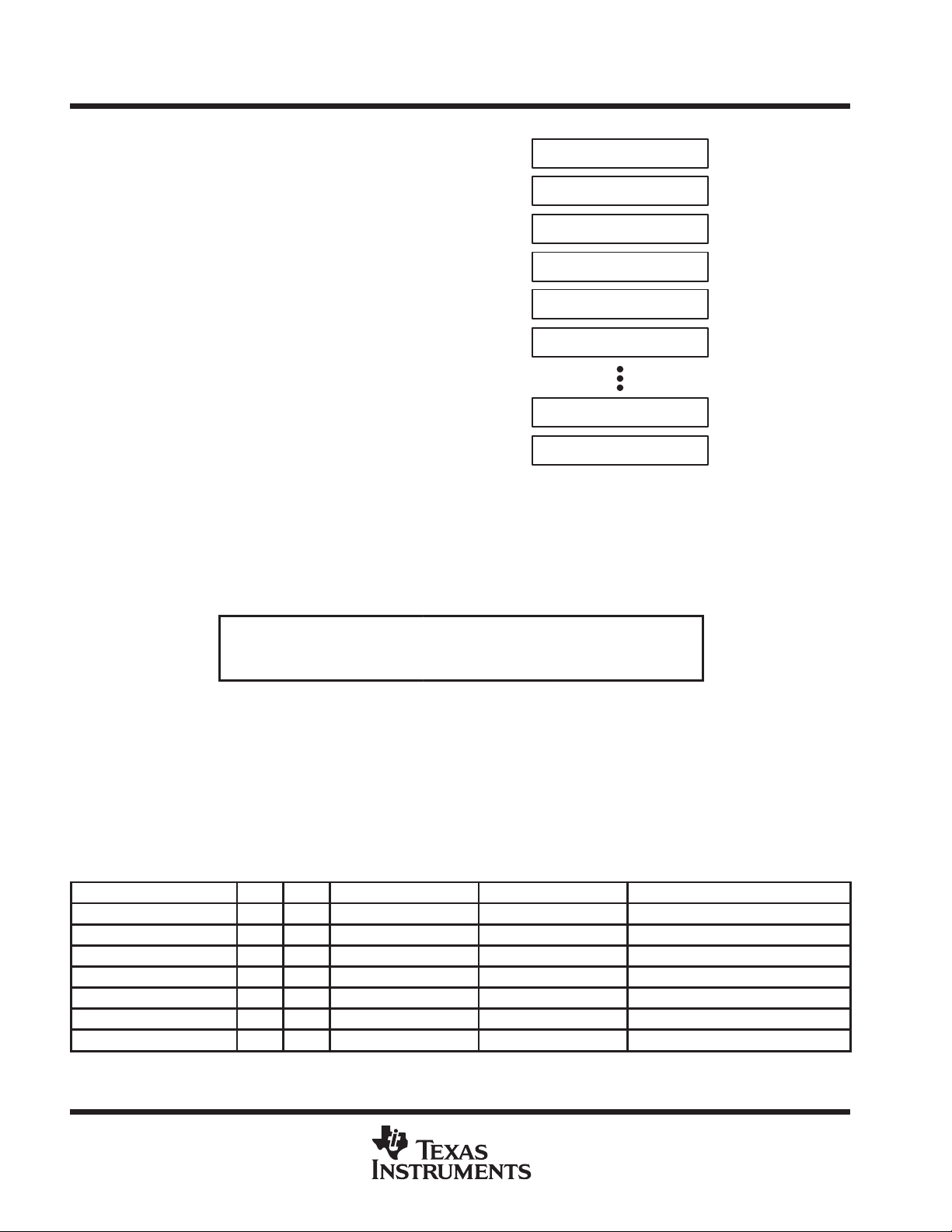

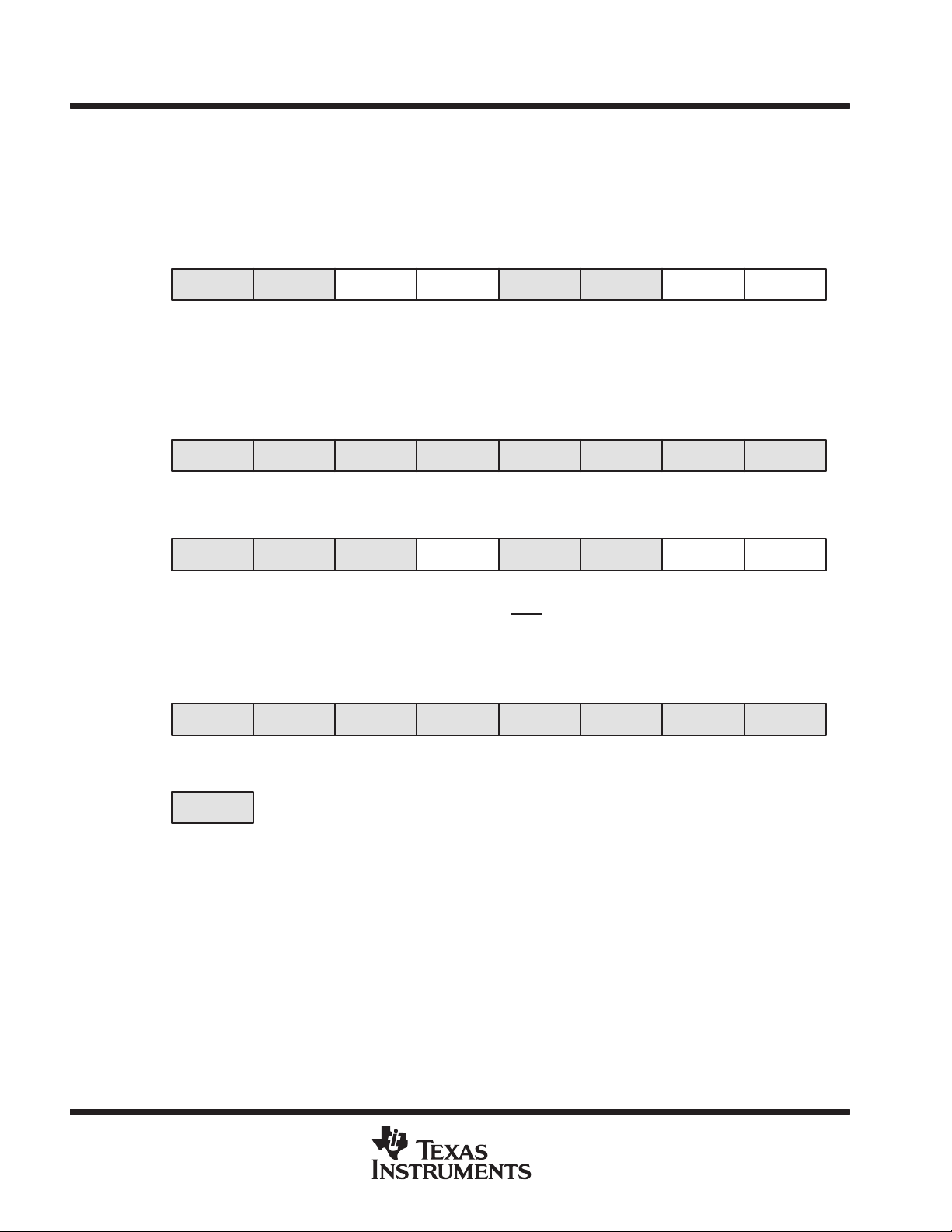

memory organization

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

FFFFh

FFE0h

FFDFh

F800h

027Fh

0200h

01FFh

0100h

00FFh

0010h

000Fh

0000h

MSP430C111 1

Int. Vector

2 KB ROM

128B RAM

16b Per.

8b Per.

SFR

FFFFh

FFE0h

FFDFh

F000h

02FFh

0200h

01FFh

0100h

00FFh

0010h

000Fh

0000h

MSP430C1121

Int. Vector

4 KB

ROM

256B RAM

16b Per.

8b Per.

SFR

FFFFh

FFE0h

FFDFh

FC00h

10FFh

1080h

0FFFh

0C00h

027Fh

0200h

01FFh

0100h

00FFh

0010h

000Fh

0000h

MSP430F1101

Int. Vector

1 KB Flash

Segment0,1

128B Flash

SegmentA

1 KB

Boot ROM

128B RAM

16b Per.

8b Per.

SFR

FFFFh

FFE0h

FFDFh

F000h

10FFh

1000h

0FFFh

0C00h

02FFh

0200h

01FFh

0100h

00FFh

0010h

000Fh

0000h

MSP430F1121

Int. Vector

4 KB

Flash

Segment0–7

2 × 128B

Flash

SegmentA,B

1 KB

Boot ROM

256B RAM

16b Per.

8b Per.

SFR

Main

Memory

Information

Memory

boot ROM containing bootstrap loader

The intention of the bootstrap loader is to download data into the flash memory module. V arious write, read, and

erase operations are needed for a proper download environment. The bootstrap loader is only available on F

devices.

functions of the bootstrap loader:

Definition of read: apply and transmit data of peripheral registers or memory to pin P1.1 (BSLTX)

write: read data from pin P2.2 (BSLRX) and write them into flash memory

unprotected functions

Mass erase, erase of the main memory (Segment0 to Segment7)

Access to the MSP430 via the bootstrap loader is protected. It must be enabled before any protected function

can be performed. The 256 bits in 0FFE0h to 0FFFFh provide the access key.

protected functions

All protected functions can be executed only if the access is enabled.

D

Write/program byte into flash memory; Parameters passed are start address and number of bytes (the

segment-write feature of the flash memory is not supported and not useful with the UART protocol).

D

Segment erase of Segment0 to Segment7 in the main memory and segment erase of SegmentA and

SegmentB in the information memory.

D

Read all data in main memory and information memory.

D

Read and write to all byte peripheral modules and RAM.

D

Modify PC and start program execution immediately.

NOTE:

Unauthorized readout of code and data is prevented by the user’s definition of the data in the

interrupt memory locations.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

Page 10

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

boot ROM containing bootstrap loader (continued)

features of the bootstrap loader are:

D

UART communication protocol, fixed to 9600 baud

D

Port pin P1.1 for transmit, P2.2 for receive

D

TI standard serial protocol definition

D

Implemented in flash memory version only

D

Program execution starts with the user vector at 0FFFEh or with the bootstrap loader (start vector is at

address 0C00h)

hardware resources used for serial input/output:

D

Pins P1.1 and P2.2 for serial data transmission

D

Test and RST/NMI to start program execution at the reset or bootstrap loader vector

D

Basic clock module: Rsel=5, DCO=4, MOD=0, DCOCLK for MCLK and SMCLK, clock divider for MCLK

and SMCLK at default: dividing by 1

D

Timer_A: Timer_A operates in continuous mode with MCLK source selected, input divider set to 1,

using CCR0, and polling of CCIFG0.

D

WDT: Watchdog timer is halted

D

Interrupt: GIE=0, NMIIE=0, OFIFG=0, ACCVIFG=0

D

Memory allocation and stack pointer:

If the stack pointer points to RAM addresses above 0220h, 6 bytes of the stack are allocated

plus RAM addresses 0200h to 0219h. Otherwise the stack pointer is set to 0220h and allocates

RAM from 0200h to 021Fh.

NOTE:

When writing RAM data via bootstrap loader, take care that the stack is outside the range

of the data being written.

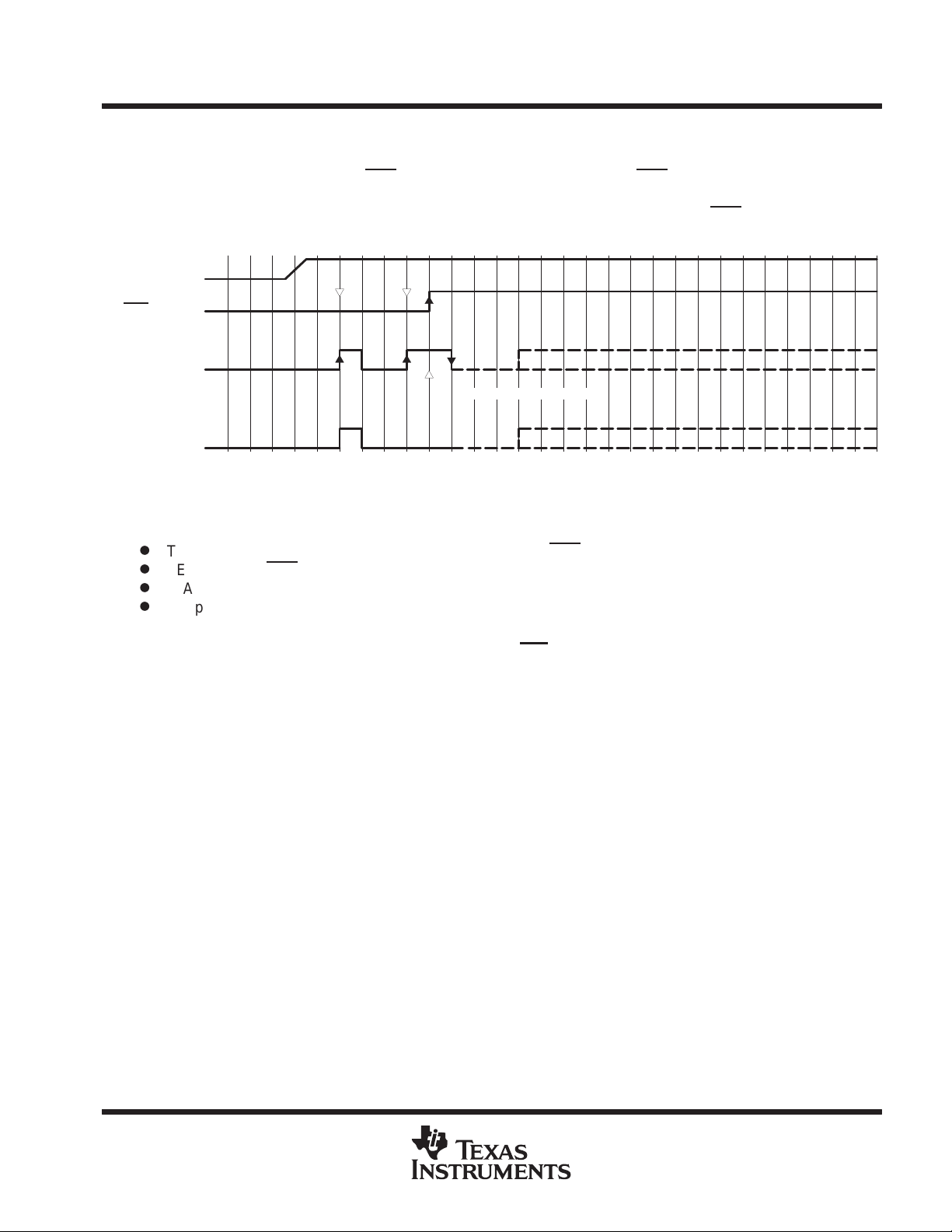

Program execution begins with the user’s reset vector at FFFEh (standard method) if TEST is held low while

RST

/NMI goes from low to high:

V

CC

RST/NMI PIN

TEST PIN

User Program Starts

Reset Condition

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 11

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

boot ROM containing bootstrap loader (continued)

Program execution begins with the bootstrap vector at 0C00h (boot ROM) if a minimum of two positive edges

have been applied to TEST while RST/NMI is low, and TEST is high when RST/NMI goes from low to high. The

TEST signal is normally used internally to switch pins P1.4, P1.5, P1.6, and P1.7 between their application

function and the JTAG function. If the second rising edge at TEST is applied while RST

internal TEST signal is held low and the pins remain in the application mode:

V

CC

RST/NMI PIN

TEST PIN

Bootstrap loader Starts

TEST

(Internal)

/NMI is held low, the

Test mode can be entered again after TEST is taken low and then back high.

The bootstrap loader will not be started (via the vector in address 0C00h), if:

D

There were less than two positive edges at TEST while RST/NMI is low

D

TEST is low if RST/NMI goes from low to high

D

JTAG has control over the MSP430 resources

D

Supply voltage VCC drops and a POR is executed

WARNING:

The bootstrap loader starts correctly only if the RST

to the NMI function, unpredictable program execution may result. However, a

bootstrap-load may be started using software and the bootstrap vector, for example the

instruction BR &0C00h.

/NMI pin is in reset mode. If it is switched

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

Page 12

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

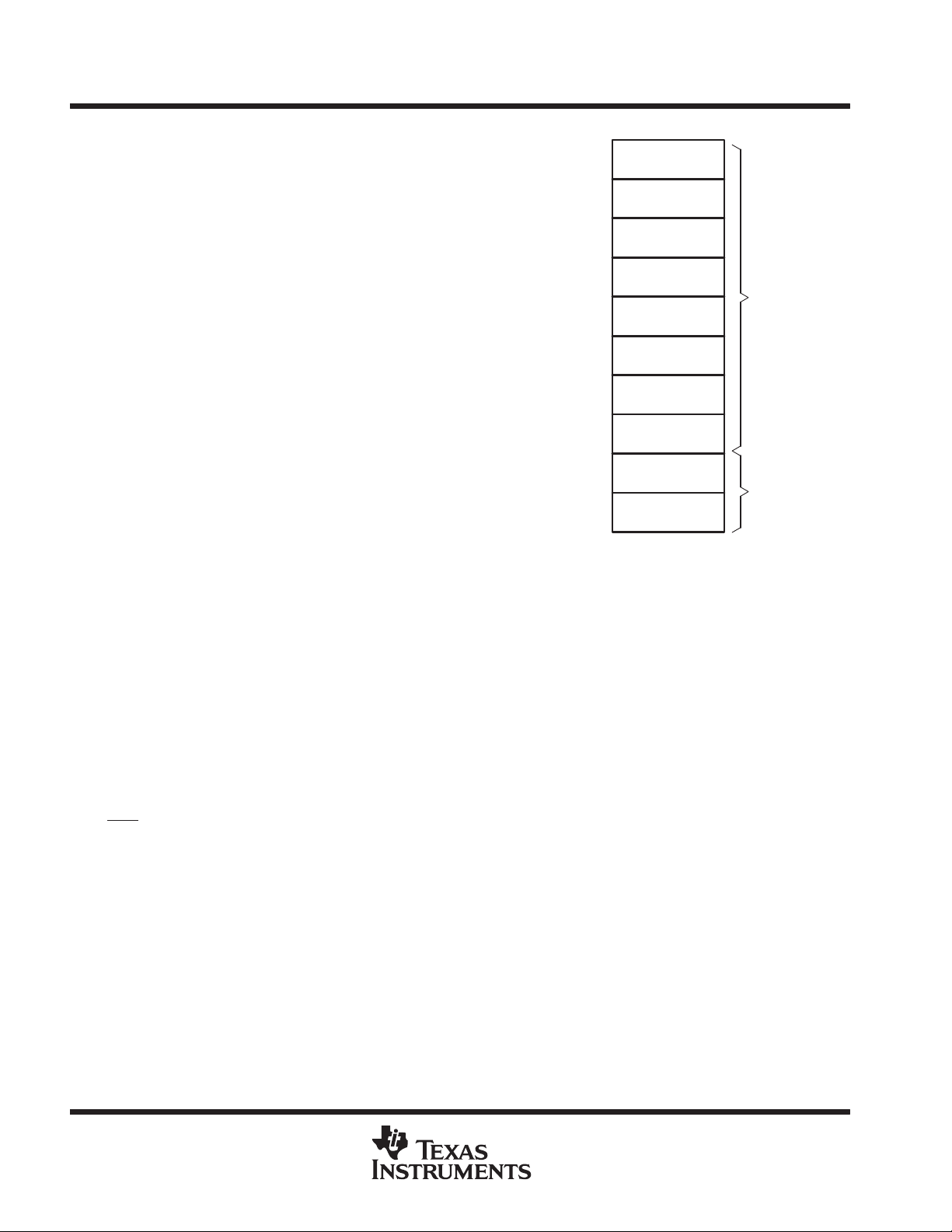

flash memory

The flash memory consists of 512-byte segments

in the main memory and 128-byte segments in the

information memory. See device memory maps

for specific device information.

Segment0 to Segment7 can be erased

individually, or altogether as a group.

SegmentA and SegmentB can be erased

individually, or as a group with segments 0–7.

The memory in SegmentA and SegmentB is also

called

Information Memory.

VPP is generated internally. VCC current

increases during programming.

During program/erase cycles, VCC must not drop

below the minimum specified for program/erase

operation.

Program and erase timings are controlled by the

flash timing generator—no software intervention

is needed. The input frequency of the flash timing

generator should be in the proper range and must

be applied until the write/program or erase

operation is completed.

0FFFFh

0FE00h

0FDFFh

0FC00h

0FBFFh

0FA00h

0F9FFh

0F800h

0F7FFh

0F600h

0F5FFh

0F400h

0F3FFh

0F200h

0F1FFh

0F000h

010FFh

01080h

0107Fh

01000h

NOTE: All segments not implemented on all devices.

Segment0 w/

Interrupt Vectors

Segment1

Segment2

Segment3

Segment4

Segment5

Segment6

Segment7

SegmentA

SegmentB

Flash Main Memory

Memory

Information

During program or erase, no code can be executed from flash memory and all interrupts must be disabled by

setting the GIE, NMIE, ACCVIE, and OFIE bits to zero. If a user program requires execution concurrent with

a flash program or erase operation, the program must be executed from memory other than the flash memory

(e.g., boot ROM, RAM). In the event a flash program or erase operation is initiated while the program counter

is pointing to the flash memory, the CPU will execute JMP $ instructions until the flash program or erase

operation is completed. Normal execution of the previously running software then resumes.

Unprogrammed, new devices may have some bytes programmed in the information memory (needed for test

during manufacturing). The user should perform an erase of the information memory prior to first use.

flash memory control register FCTL1

All control bits are reset during PUC. PUC is active after V

is applied, a reset condition is applied to the

CC

RST/NMI pin, the watchdog timer expires, a watchdog access violation occurs, or an improper flash operation

has been performed. A more detailed description of the control-bit functions is found in the flash memory module

description (refer to

MSP430x1xx User’s Guide

, literature number SLAU049). Any write to control register

FCTL1 during erase, mass erase, or write (programming) will end in an access violation with ACCVIFG=1.

Special conditions apply for segment-write mode. Refer to

MSP430x1xx User’s Guide

, literature number

SLAU049 for details.

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 13

flash memory control register FCTL1 (continued)

Read access is possible at any time without restrictions.

The control bits of control register FCTL1 are:

FCTL1

0128h

FCTL1 read:

FCTL1 write:

096h

0A5h

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

7

815

SEG

WRT

rw–0

WRT

rw–0

res.r0res.r0res.

MEras Erase res.

r0

0

r0rw-0rw–0

Erase 0128h, bit1,

Erase a segment

0:1:No segment erase will be started.

Erase of one segment is enabled. The segment to be erased is defined by a

dummy

write into any address within the segment. The erase bit is

automatically reset when the erase operation is completed.

MEras 0128h, bit2,

Mass Erase, main memory segments are erased together.

0:1:No segment erase will be started.

Erase of main memory segments is enabled. Erase starts when a dummy

write to any address in main memory is executed. The MEras bit is

automatically reset when the erase operation is completed.

WRT 0128h, bit6, Bit WRT must be set for a successful write execution.

If bit WRT is reset and write access to the flash memory is attempted, an

access violation occurs and ACVIFG is set.

SEGWRT 0128h, bit7,

Bit SEGWRT may be used to reduce total programming time.

Refer to

MSP430x1xx User’s Guide

, literature number SLAU049 for details.

0:1:No segment-write acceleration is selected.

Segment-write is used. This bit needs to be reset and set between segment

borders.

Table 3. Allowed Combinations of Control Bits Allowed for Flash Memory Access

FUNCTION PERFORMED SEGWRT WRT MEras Erase BUSY WAIT Lock

Write word or byte 0 1 0 0 0 0 0

Write word or byte in same segment, segment write mode 1 1 0 0 0 → 1 0 → 1 0

Erase one segment by writing to any address in the target segment 0 0 0 1 0 0 0

Erase all segments (0 to 7) but not the information memory

(segments A and B)

Erase all segments (0 to 7 and A and B) by writing to any address in

the flash memory module

NOTE: The table shows all valid combinations. Any other combination will result in an access violation.

0 0 1 0 0 0 0

0 0 1 1 0 0 0

flash memory, timing generator, control register FCTL2

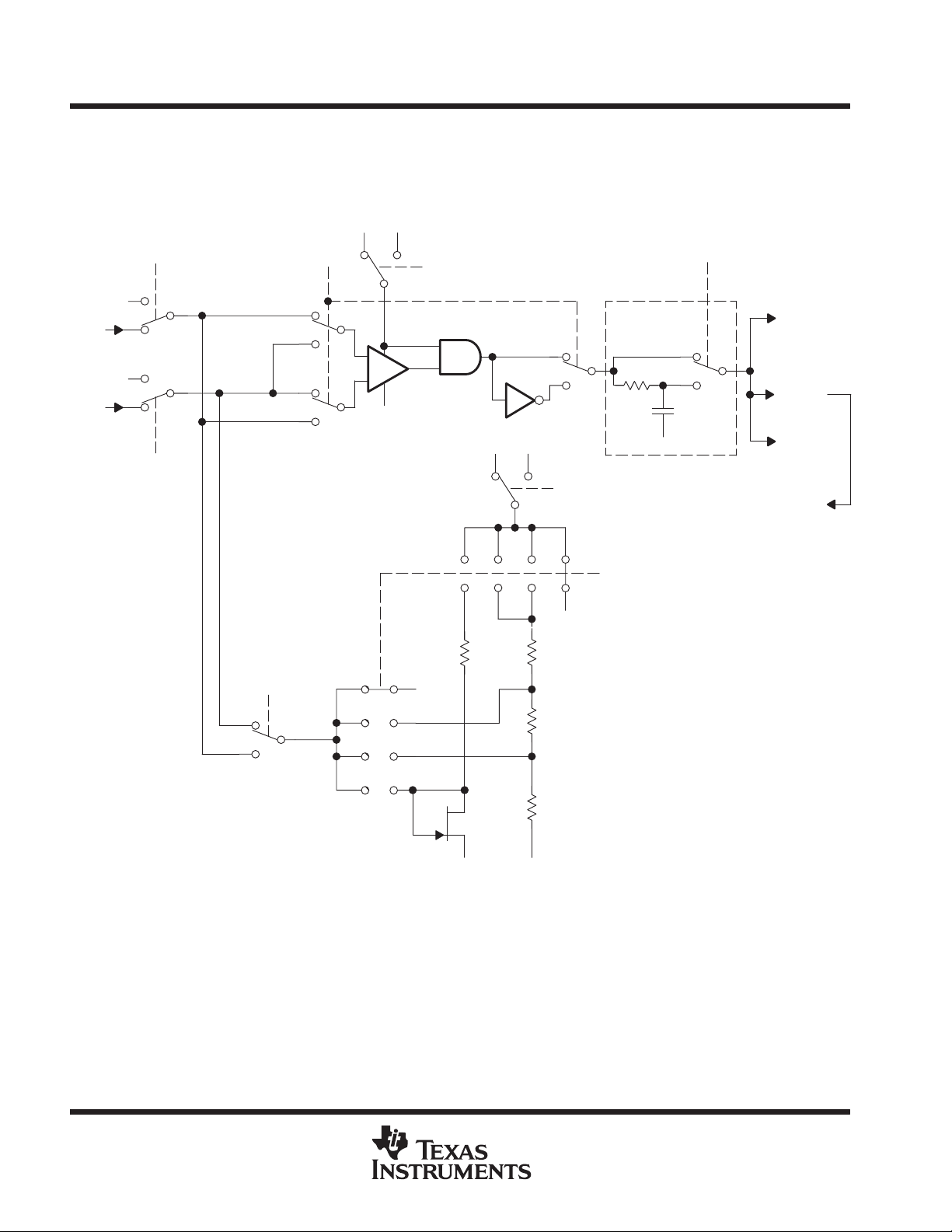

The timing generator (Figure 1) generates all the timing signals necessary for write, erase, and mass erase from

the selected clock source. One of three different clock sources may be selected by control bits SSEL0 and

SSEL1 in control register FCTL2. The selected clock source should be divided to meet the frequency

requirements specified in the recommended operating conditions.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

13

Page 14

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

flash memory, timing generator, control register FCTL2 (continued)

The flash timing generator is reset with PUC. It is also reset if the emergency exit bit EMEX is set.

Control register FCTL2 may not be written to if the BUSY bit is set; otherwise, an access violation will occur

(ACCVIFG=1).

Read access is possible at any time without restrictions.

SSEL1

SSEL0

Write ’1’ to

Reset

Flash Timing

Generator

ACLK

MCLK

SMCLK

SMCLK

0

1

2

3

FN5.......... FN0

Divider,

1 .. 64

f

X

PUC EMEX

BUSY WAIT

Figure 1. Flash Memory Timing Generator Diagram

8

FCTL2

012Ah

FCTL2 read:

FCTL2 write:

15

096h

0A5h

SSEL1

rw–0

7

SSEL0

rw–1

FN5 FN4 FN3

rw-0rw-0rw-0

FN2 FN1 FN0

The control bits are:

FN0–FN5 012Ah, bit0–5 These six bits define the division rate of the clock signal. The division

rate is 1 to 64, according to the digital value of FN5 to FN0 plus one.

0

rw-0rw-1rw–0

SSEL0, SSEL1 012Ah, bit6,7 Clock source select

0: ACLK

1: MCLK

2: SMCLK

3: SMCLK

The flash timing generator is reset with PUC. It is also reset if the EMEX bit is set.

flash memory control register FCTL3

There are no restrictions to modify this control register.

7

8

res.

res.r0EMEX Lock WAIT

r0

14

FCTL3

012Ch

FCTL3 read:

FCTL3 write:

15

096h

0A5h

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0

ACCV

KEYV BUSY

IFG

rw-1rw-1rw-0

r(w)-0rw-(0)rw–0

Page 15

flash memory control register FCTL3 (continued)

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

BUSY 012Ch, bit0,

KEYV, 012Ch, bit1

ACCVIFG, 012Ch, bit2 Access violation interrupt flag

WAIT, 012CH, bit3

The BUSY bit shows if an access to the flash memory is allowed (BUSY=0), or

if an access violation occurs. The BUSY bit is read-only , but a write operation is

allowed. The BUSY bit should be tested before each write and erase cycle. The

flash timing-generator hardware immediately sets the BUSY bit after start of a

write, segment-write, erase, or

completed the operation, the BUSY bit is reset by the hardware.

No program code can be executed from the

program or erase cycle.

0: Flash memory is not busy.

1: Flash memory is busy, and remains in busy state if segment write function

is in

wait

mode.

Key violation

0: Key 0A5h (high byte) was not violated.

1: Key 0A5h (high byte) was violated. Violation occurs when a write access to

registers FCTL1, FCTL2, or FCTL3 is executed and the

equal to 0A5h. If the security key is violated, bit KEYV is set and a PUC is

performed.

The access-violation flag is set when any combination of control bits other than

those shown in Table 3 is attempted, or an instruction is fetched while a

segment-write operation is active.

Reading the control registers will not set the ACCVIFG bit.

NOTE: The respective interrupt-enable bit ACCVIE is located in the interrupt

enable register IE1 in the special function register. The software can set

the ACCVIFG bit. If set by software, an NMI is also executed.

In the segment-write mode, the WAIT bit indicates that data has been written and

the flash memory is prepared to receive the next data for programming. The

WAIT bit is read only, but a write to the WAIT bit is allowed.

0: The segment-write operation has began and programming is in progress.

1: The segment-write operation is active and data programming is complete.

mass

erase operation. If the timing generator has

busy

flash memory during the entire

high byte

is not

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

15

Page 16

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

flash memory control register FCTL3 (continued)

LOCK 012Ch, bit4,

EMEX, 012Ch, bit5,

The lock bit may be set during any write, segment-erase, or

Any active sequence in progress is completed normally . In segment-write mode,

the SEGWRT bit is reset and the W AIT bit is set after the mode ends. The lock

bit is controlled by software or hardware. If an access violation occurs and the

ACCVIFG is set, the LOCK bit is set automatically.

0: Flash memory may be read, programmed, erased, or

1: Flash memory may be read but not programmed, erased, or

A current program, erase, or

The access-violation interrupt flag ACCVIFG is set when data are written to

the flash memory module while the lock bit is set.

Emergency exit. The emergency exit should only be used if the flash memory

write or erase operation is out of control.

0: No function.

1: Stops the active operation immediately, and shuts down all internal parts in

the flash memory controller. Current consumption immediately drops back

to the active mode. All bits in control register FCTL1 are reset. Since the

EMEX bit is automatically reset by hardware, the software always reads

EMEX as 0.

mass

-erase operation will complete normally .

mass

-erase request.

mass

erased.

mass

flash memory, interrupt and security key violation

One NMI vector is used for three NMI events: RST/NMI (NMIIFG), oscillator fault (OFIFG), and flash-memory

access violation (ACCVIFG). The software can determine the source of the interrupt request since all flags

remain set until they are reset by software. The enable flag(s) should be set simultaneously with one instruction

before the return-from-interrupt RETI instruction. This ensures that the stack remains under control. A pending

NMI interrupt request will not increase stack demand unnecessarily.

erased.

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 17

ACCV

FCTL1.1

S

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

ACCVIFG

IE1.5

PUC

RST/NMI

IFG1.4

PUC

IE1.4

PUC

OSCFault

IFG1.1

IE1.1

PUC

Clear

S

Clear

Clear

S

Clear

ACCVIE

NMIFG

NMIIE

OFIFG

OFIF

NMI_IRQA

Counter

NMITMSELNMIES

WDT

IFG1.0

POR

IRQA

TIMSEL

IE1.0

Flash Module

Flash Module

Flash Module

POR PUC

KEYV

System Reset

Generator

WDTQn EQU

S

Clear

Clear

WDTIFG

WDTIE

VCC

PUC

POR

NMIRS

PUC POR

IRQ

IRQA: Interrupt Request Accepted

Figure 2. Block Diagram of NMI Interrupt Sources

Watchdog Timer Module

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PUC

17

Page 18

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

peripherals

Peripherals are connected to the CPU through data, address, and control buses and can be handled easily with

memory manipulation instructions.

oscillator and system clock

Three clocks are used in the system—the system (master) clock MCLK, the subsystem (master) clock SMCLK,

and the auxiliary clock ACLK:

Main system clock MCLK, used by the CPU and the system

Subsystem clock SMCLK, used by the peripheral modules

Auxiliary clock ACLK, originated by LFXT1CLK (crystal frequency) and used by the peripheral modules

After a POR, the DCOCLK is used by default, the DCOR bit is reset, and the DCO is set to the nominal initial

frequency. Additionally, if LFXT1CLK fails as the source for MCLK, the DCOCLK is automatically selected to

ensure fail-safe operation.

SMCLK can be generated from LFXT1CLK or DCOCLK. ACLK is always generated from LFXT1CLK.

The crystal oscillator can be defined to operate with watch crystals (32768 Hz) or with higher-frequency ceramic

resonators or crystals. The crystal or ceramic resonator is connected across two terminals. No external

components are required for watch-crystal operation. If the high frequency XT1 mode is selected, external

capacitors from XIN to VSS and XOUT to VSS are required as specified by the crystal manufacturer.

The LFXT1 oscillator starts after applying VCC. If the OscOff bit is set to 1, the oscillator stops when it is not

used for MCLK. The clock signals ACLK and SMCLK may be used externally via port pins.

Different application requirements and system conditions dictate different system clock requirements, including:

High frequency for quick reaction to system hardware requests or events

Low frequency to minimize current consumption, EMI, etc.

Stable peripheral clock for timer applications, such as real-time clock (RTC)

Start-stop operation to be enabled with minimum delay

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 19

oscillator and system clock (continued)

OSCOff XTS

XIN

LFXT1CLK

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

DIVA

2

/1, /2, /4, /8

ACLKGEN

ACLK

Auxiliary Clock

XOUT

V

CC

P2.5/Rosc

P2.5

LFXT1 OSCILLATOR

0,1

V

CC

1

0

SCG0

sel

DC

Generator

DCGEN

DCOR

DCO MODR

Digital Controlled Oscillator (DCO)

+

Modulator (MOD)

The DCO-Generator is connected to pin P2.5/Rosc if DCOR control bit is set.

The port pin P2.5/Rosc is selected if DCOR control bit is reset (initial state).

DCOCLK

53

DCOMOD

SELM CPUOff

3

2

SELS SCG1

0

1

DIVM

22

/1, /2, /4, /8, Off

MCLKGEN

DIVS

2

/1, /2, /4, /8, Off

SMCLKGEN

MCLK

Main System Clock

SMCLK

Subsystem Clock

Figure 3. Clock Signals

Two clock sources, LFXT1CLK and DCOCLK, can be used to drive the MSP430 system. The LFXT1CLK is

generated from the LFXT1 crystal oscillator. The LFXT1 crystal oscillator can operate in three modes—low

frequency (LF), moderate frequency (XT1), and external input mode. The LFXT1 crystal oscillator may be

switched off when it is not in use.

DCOCLK is generated from the DCO. The nominal DCO frequency is defined by the dc generator and can be

set by one external resistor, or can be set to one of eight values with integrated resistors. Additional adjustments

and modulations of DCOCLK are possible by software manipulation of registers in the DCO module. DCOCLK

is stopped automatically when it is not used by the CPU or peripheral modules. The dc generator can be shut

down with the SCG0 bit to realize additional power savings when DCOCLK is not in use.

NOTE:

The system clock generator always starts with the DCOCLK selected for MCLK (CPU clock) to

ensure proper start of program execution. The software defines the final system clock generation

through control bit manipulation.

digital I/O

There are two eight-bit I/O ports, port P1 and port P2 – implemented (1 1x1 parts only have six port P2 I/O signals

available on external pins). Both ports, P1 and P2, have seven control registers to give maximum flexibility of

digital input/output to the application:

• All individual I/O bits are programmable independently.

• Any combination of input, output, and interrupt conditions is possible.

• Interrupt processing of external events is fully implemented for all eight bits of port P1 and for six bits of

port P2.

• Read/write access to all registers with all instructions

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

19

Page 20

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

digital I/O (continued)

The seven registers are:

• Input register 8 bits at port P1/P2 contains information at the pins

• Output register 8 bits at port P1/P2 contains output information

• Direction register 8 bits at port P1/P2 controls direction

• Interrupt edge select 8 bits at port P1/P2 input signal change necessary for interrupt

• Interrupt flags 8 bits at port P1/P2 indicates if interrupt(s) are pending

• Interrupt enable 8 bits at port P1/P2 contains interrupt enable bits

• Selection (Port or Mod.) 8 bits at port P1/P2 determines if pin(s) have port or module function

All these registers contain eight bits. Two interrupt vectors are implemented: one commonly used for any

interrupt event on ports P1.0 to P1.7, and one commonly used for any interrupt event on ports P2.0 to P2.7.

NOTE:

Six bits of port P2, P2.0 to P2.5, are available on external pins – but all control and data bits for port

P2 are implemented.

watchdog timer

The primary function of the watchdog timer (WDT) module is to perform a controlled system restart after a

software problem has occurred. If the selected time interval expires, a system reset is generated. If this

watchdog function is not needed in an application, the module can work as an interval timer, which generates

an interrupt after the selected time interval.

The watchdog timer counter (WDTCNT) is a 16-bit up-counter which is not directly accessible by software. The

WDTCNT is controlled through the watchdog timer control register (WDTCTL), which is a 16-bit read/write

register. W riting to WDTCTL is, in both operating modes (watchdog or timer), only possible by using the correct

password in the high-byte. The low-byte stores data written to the WDTCTL. The high-byte must be the

password 05Ah. If any value other than 05Ah is written to the high-byte of the WDTCTL, a system reset PUC

is generated. When the password is read, its value is 069h. This minimizes accidental write operations to the

WDTCTL register. In addition to the watchdog timer control bits, there are two bits included in the WDTCTL

register that configure the NMI pin.

Timer_A (Three capture/compare registers)

The Timer_A module on 1 1x1 devices of fers one sixteen bit counter and three capture/compare registers. The

timer clock source can be selected to come from two external sources T ACLK (SSEL=0) or INCLK (SSEL=3),

or from two internal sources, the ACLK (SSEL=1) or SMCLK (SSEL=2). The clock source can be divided by

one, two, four, or eight. The timer can be fully controlled (in word mode) since it can be halted, read, and written.

It can be stopped, run continuously , counted up or up/down, using one compare block to determine the period.

The three capture/compare blocks are configured by the application to run in capture or compare mode.

The capture mode is primarily used to measure external or internal events using any combination of positive,

negative, or both edges of the signal. Capture mode can be started and stopped by software. Three different

external events T A0, TA1, and TA2 can be selected. At capture/compare register CCR2 the ACLK is the capture

signal if CCI2B is selected. Software capture is chosen if CCISx=2 or CCISx=3 (see Figure 4).

The compare mode is primarily used to generate timings for the software or application hardware, or to generate

pulse-width modulated output signals for various purposes like D/A conversion functions or motor control. An

individual output module is assigned to each of the three capture/compare registers. The output modules can

run independently of the compare function, or can be triggered in several ways.

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 21

Timer_A (3 capture/compare registers) (continued)

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

P1.0

P2.1

P1.1

P2.2

P1.2

CAOUT

TACLK

ACLK

SMCLK

INCLK

CCI0A

CCI0B

GND

V

CC

CCI1A

CCI1B

GND

V

CC

SSEL0SSEL1

0

1

2

3

ID1

CCIS00CCIS01

0

1

2

3

CCI0 CCM00

CCIS10CCIS11

0

1

2

3

CCI1 CCM10

32 kHz to 8 MHz

Timer Clock

Input

Divider

ID0

Capture

Mode

CCM01

Capture

Mode

CCM11

15

CLK

POR/CLR

Capture

Capture

Data

16-Bit Timer

Carry/Zero

0

RC

15

Capture/Compare

Register CCR0

15

15

Capture/Compare

Register CCR1

15

Mode

Control

MC1 MC0

Comparator 0

Comparator 1

16-Bit Timer

Equ0

Set_TAIFG

Capture/Compare Register CCR0Timer Bus

0

0

0

0

OM02 OM00OM01

Output Unit 0

EQU0

Capture/Compare Register CCR1

OM12 OM10OM11

Output Unit 1

EQU1

Out 0

Out 1

P1.1

P1.5

P1.2

P1.6

P2.3

Capture/Compare Register CCR2

0

0

OM22 OM20OM21

EQU2

Out 2

Output Unit 2

P1.3

ACLK

CCI2A

CCI2B

GND

V

CC

CCIS20CCIS21

0

1

2

3

CCI2 CCM20

Capture

CCM21

Mode

Capture

15

Capture/Compare

Register CCR2

15

Comparator 2

Figure 4. Timer_A, MSP430x11x1 Configuration

Two interrupt vectors are used by the Timer_A module. One individual vector is assigned to capture/compare

block CCR0, and one common interrupt vector is implemented for the timer and the other two capture/compare

blocks. The three interrupt events using the same vector are identified by an individual interrupt vector word.

The interrupt vector word is used to add an offset to the program counter to continue the interrupt handler

software at the corresponding program location. This simplifies the interrupt handler and gives each interrupt

event the same overhead of 5 cycles in the interrupt handler.

UART

Serial communication is implemented by using software and one capture/compare block. The hardware

supports the output of the serial-data stream, bit by bit, with the timing determined by the comparator/timer. The

data input uses the capture feature. The capture flag finds the start of a character, while the compare feature

latches the input-data stream, bit by bit. The software/hardware interface connects the mixed-signal controller

to external devices, systems, or networks.

P1.3

P1.7

P2.4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

21

Page 22

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

Comparator_A

The primary function of the comparator module is to support precision A/D slope conversion applications,

battery voltage supervision, and observation of external analog signals. The comparator is connected to port

pins P2.3/CA0 and to P2.4/CA1. It is controlled via twelve control bits in registers CACTL1 and CACTL2.

V

0 V

CC

1

P2.3/

CA0/

TA1

P2.4/

CA1/

TA2

P2CA0

0

1

0

1

P2CA1

CA0

CA1

CAEX

0

1

0

1

0

+

_

0 V

CAON

0 V

Low Pass Filter

0

1

V

CC

1

0

CAON

CAF

0

1

0 V

τ ≈ 2.0 µs

CAOUT/TA0

CCI1B

CAOUT

Set CAIFG

Flag

P2.2/

CARSEL

1

0

V

CAREF

0123

0

2

1

3

0 V 0 V

0.5 x V

0.25 x V

CC

CC

Figure 5. Block Diagram of Comparator_A

CAREF

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 23

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

Comparator_A (continued)

The control bits are:

CAOUT, 05Ah, bit0, Comparator output

CAF, 05Ah, bit1, The comparator output is transparent or fed through a small filter

CA0, 05Ah, bit2, 0: Pin P2.3/CA0/TA1 is not connected to Comparator_A.

1: Pin P2.3/CA0/TA1 is connected to Comparator_A.

CA1, 05Ah, bit3, 0: Pin P2.4/CA1/TA2 is not connected to Comparator_A.

1: Pin P2.4/CA1/TA2 is connected to Comparator_A.

CACTL2.4

to

CATCTL2.7

CAIFG, 059h, bit0, Comparator_A interrupt flag

CAIE, 059h, bit1, Comparator_A interrupt enable

CAIES, 059h, bit2, Comparator_A interrupt edge select bit

CAON, 059h, bit3, The comparator is switched on.

CAREF, 059h, bit4,5, Comparator_A reference

CARSEL, 059h, bit6, An internal reference V

CAEX, 059h, bit7, The comparator inputs are exchanged, used to measure and compensate

05Ah, bit4,

05Ah, bit7,

Bits are implemented but do not control any hardware in this device.

0: The rising edge sets the Comparator_A interrupt flag CAIFG

1: The falling edge set the Comparator_A interrupt flag CAIFG

0: Internal reference is switched off, an external reference can be applied.

1: 0.25 × VCC reference selected.

2: 0.50 × VCC reference selected.

3: A diode reference selected.

, selected by CAREF bits, can be applied to

signal path CA0 or CA1. The signal V

CAREF

CAREF

is only driven by a voltage

source if the value of CAREF control bits is 1, 2, or 3.

the offset of the comparator.

MSP430x11x1

Eight additional bits are implemented into the Comparator_A module and enable the SW to switch off the input

buffer of port P2. A CMOS input buffer would dissipate supply current when the input is not near VSS or VCC.

Comparator_A port disable control bits CAPD0 to CAPD7 are initially reset, and the port input buffer is active.

The port input buffer is disabled if the appropriate control bit is set.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

23

Page 24

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

Comparator_A (continued)

0

CAIFG

rw-(0)

0

CAOUT

r-(0)

0

CAPD0

rw-(0)

CACTL1

059h

CACTL2

05Ah

CAPD

05Bh

7

CAEX

rw-(0)

7

CACTL

2.7

rw-(0)

7

rw-(0)

CA

RSEL

rw-(0)

CACTL

2.6

rw-(0)

rw-(0) rw-(0) rw-(0)

CA

REF1

rw-(0)

CACTL

2.5

rw-(0) rw-(0) rw-(0) rw-(0)

CA

REF0

rw-(0)

CACTL

2.4

CAPD4CAPD5CAPD6CAPD7

CAON

rw-(0)

CA1 CA0

CAPD3

rw-(0)

CAIES

rw-(0)

CAPD2

rw-(0)

CAIE

rw-(0)

CAF

rw-(0)

CAPD1

rw-(0)

NOTE:

Ensure that the comparator input terminals are connected to signal, power, or ground level.

Otherwise, floating levels may cause unexpected interrupts and current consumption may be

increased.

slope a/d conversion

The Comparator_A is well suited for use in single or multiple-slope conversions. The internal-reference levels

may be used to set a reference during timing measurement of charge or discharge operations. They can also

be used externally to bias analog circuitry.

Voltage, current, and resistive or capacitive sensor measurements are basic functions. The sensors sense

physical conditions like temperature, pressure, acceleration, etc.

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 25

peripheral file map

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

PERIPHERALS WITH WORD ACCESS

Timer_A Reserved

Flash Memory Flash control 3

Watchdog Watchdog/timer control WDTCTL 0120h

Reserved

Reserved

Reserved

Capture/compare register

Capture/compare register

Capture/compare register

Timer_A register

Reserved

Reserved

Reserved

Reserved

Capture/compare control

Capture/compare control

Capture/compare control

Timer_A control

Timer_A interrupt vector

Flash control 2

Flash control 1

CCR2

CCR1

CCR0

TAR

CCTL2

CCTL1

CCTL0

TACTL

TAIV

FCTL3

FCTL2

FCTL1

017Eh

017Ch

017Ah

0178h

0176h

0174h

0172h

0170h

016Eh

016Ch

016Ah

0168h

0166h

0164h

0162h

0160h

012Eh

012Ch

012Ah

0128h

MSP430x11x1

PERIPHERALS WITH BYTE ACCESS

Comparator_A Comparator_A port disable

Comparator_A control2

Comparator_A control1

System Clock Basic clock sys. control2

Basic clock sys. control1

DCO clock freq. control

Port P2 Port P2 selection

Port P2 interrupt enable

Port P2 interrupt edge select

Port P2 interrupt flag

Port P2 direction

Port P2 output

Port P2 input

Port P1 Port P1 selection

Port P1 interrupt enable

Port P1 interrupt edge select

Port P1 interrupt flag

Port P1 direction

Port P1 output

Port P1 input

Special Function SFR interrupt flag2

SFR interrupt flag1

SFR interrupt enable2

SFR interrupt enable1

CAPD

CACTL2

CACTL1

BCSCTL2

BCSCTL1

DCOCTL

P2SEL

P2IE

P2IES

P2IFG

P2DIR

P2OUT

P2IN

P1SEL

P1IE

P1IES

P1IFG

P1DIR

P1OUT

P1IN

IFG2

IFG1

IE2

IE1

05Bh

05Ah

059h

058h

057h

056h

02Eh

02Dh

02Ch

02Bh

02Ah

029h

028h

026h

025h

024h

023h

022h

021h

020h

003h

002h

001h

000h

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

25

Page 26

MSP430x11x1

MSP430C11x1

1.8

3.6

Su ly voltage during rogram execution, V

CC

(see Note 5)

V

f

(LFXT1)

(see Note 6)

XT1 mode selected, XTS=1

kH

Input levels at XIN, XOUT

V

2.2 V/3 V

V

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

absolute maximum ratings

†

Voltage applied at VCC to VSS (MSP430C11x1) –0.3 V to 4.6 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage applied at VCC to VSS (MSP430F11x1) –0.3 V to 4.1 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage applied to any pin (referenced to V

) –0.3 V to VCC+0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SS

Diode current at any device terminal ±2 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature, T

Storage temperature, T

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE: All voltages referenced to VSS.

(unprogrammed device) –55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

(programmed device) –40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

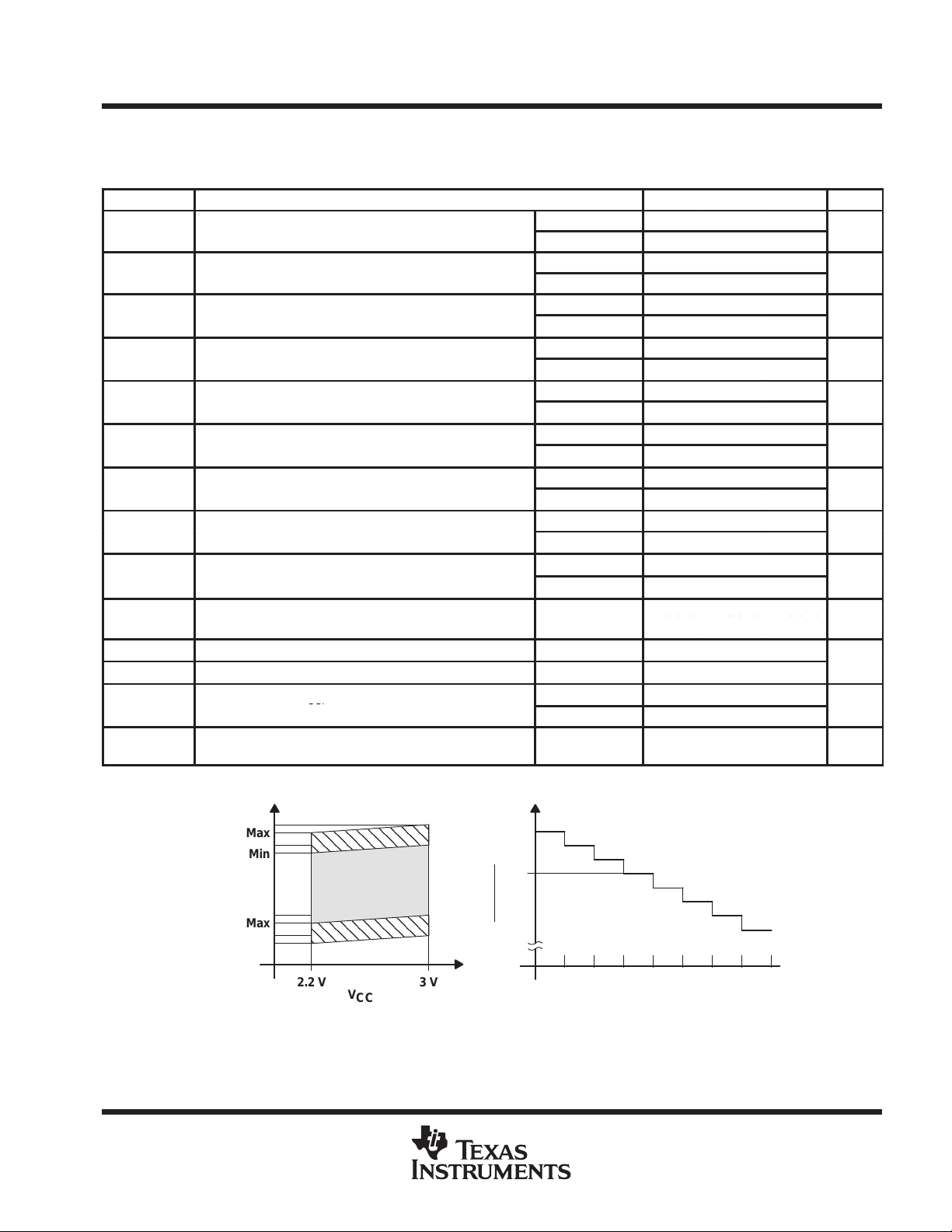

recommended operating conditions

MIN NOM MAX UNITS

pp

Supply voltage during program/erase flash memory, V

Supply voltage, V

Operating free-air temperature range, T

LFXT1 crystal frequency,

Processor frequency f

Flash timing generator frequency, f

Cumulative program time, segment write, t

Low-level input voltage (TCK, TMS, TDI, RST/NMI), V

(excluding XIN, XOUT)

High-level input voltage (TCK, TMS, TDI, RST/NMI), V

(excluding XIN, XOUT)

p

NOTES: 5. The LFXT1 oscillator in LF-mode requires a resistor of 5.1 MΩ from XOUT to VSS when VCC <2.5 V.

The LFXT1 oscillator in XT1-mode accepts a ceramic resonator or a crystal frequency of 4 MHz at VCC ≥ 2.2 V.

The LFXT1 oscillator in XT1-mode accepts a ceramic resonator or a crystal frequency of 8 MHz at VCC ≥ 2.8 V.

6. The LFXT1 oscillator in LF-mode requires a watch crystal.

The LFXT1 oscillator in XT1-mode accepts a ceramic resonator or a crystal.

7. The cumulative program time must not be exceeded during a segment-write operation.

SS

p

(system)

CC

A

LF mode selected, XTS=0 Watch crystal 32768 Hz

(MCLK signal)

(FTG)

(see Note 7)

(CPT)

IL

IH

V

IL(XIN, XOUT)

V

IH(XIN, XOUT)

MSP430F11x1 1.8 3.6

MSP430F1 1x1 2.7 3.6 V

0 V

MSP430x11x1 –40 85 °C

Ceramic resonator 450 8000

Crystal 1000 8000

VCC = 1.8 V,

MSP430x1 1x1

VCC = 2.2 V,

MSP430x1 1x1

VCC = 3.6 V,

MSP430x1 1x1

MSP430F1 1x1 257 476 kHz

VCC = 2.7 V/3.6 V

MSP430F11x1

VCC = 2.2 V/3 V V

VCC = 2.2 V/3 V 0.8V

=

CC

dc 2

dc 5

dc 8

SS

CC

V

SS

0.8×V

CC

VSS+0.6 V

V

CC

0.2×V

CC

V

CC

MHz

3 ms

V

z

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 27

recommended operating conditions (continued)

MSP430x11x1 Devices

MSP430x11x1

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

9

8

7

6

5

3

2

– Maximum Processor Frequency – MHzf

1

(system)

0

01 2344

NOTE: Minimum processor frequency is defined by system clock. Flash

program or erase operations require a minimum VCC of 2.7 V.

5 MHz at

2.2 V

2 MHz at

1.8 V

VCC – Supply Voltage – V

8 MHz at

3.6 V

Figure 6. Frequency vs Supply Voltage

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

27

Page 28

MSP430x11x1

f

(MCLK)

f

(SMCLK)

MHz

A

C11x1

A

A

I

Active mode

f

MCLK

f

(SMCLK)

MHz

A

F11x1

A

A

C11x1

f

(MCLK)

f

(SMCLK)

MHz

I

A

F11x1

f

(MCLK)

f

(SMCLK)

MHz

I

Low-power mode, (LPM2)

f

(MCLK)

f

(SMCLK)

MHz

A

I

()

f

(MCLK)

f

(SMCLK)

MHz

A

I

()

,

L

(LPM4)

f

(MCLK)

MHz,

()

(C11x1)

()

L

(LPM4)

()

(F11x1)

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

electrical characteristics over recommended ranges of supply voltage and operating free-air

temperature (unless otherwise noted)

supply current (into VCC) excluding external current (f

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

TA = –40°C +85°C,

C11x1

(AM)

F11x1

(CPUOff)

(LPM2)

(LPM3)

(LPM3)

I

(LPM4)

I

(LPM4)

NOTE: All inputs are tied to 0 V or VCC. Outputs do not source or sink any current.

Low-power mode,

(LPM0)

p

Low-power mode, (LPM3)

(C11x1)

Low-power mode, (LPM3)

(F11x1)

ow-power mode,

ow-power mode,

f

TA = –40°C +85°C,

f

TA = –40°C +85°C,

f(ACLK)

TA = –40°C +85°C,

f

TA = –40°C +85°C,

f(ACLK)

TA = –40°C +85°C,

f(ACLK)

TA = –40°C +85°C,

f(ACLK)

TA = –40°C +85°C,

f(ACLK)

TA = –40°C 0.8 1.2

TA = 25°C

TA = 85°C

TA = –40°C

TA = 25°C

TA = 85°C 2.3 3.4

TA = –40°C

TA = 25°C

TA = 85°C

TA = –40°C 0.1 0.5

TA = 25°C

TA = 85°C 0.8 1.9

=

= 32,768 Hz

(ACLK)

= f

(MCLK)

(MCLK)

(SMCLK)

=

= 32,768 Hz

= f

(SMCLK)

= 0,

= 32,768 Hz

= 0,

= 32,768 Hz

=

= 32,768 Hz, SCG0 = 0

=

= 32,768 Hz, SCG0 = 1

= 1

f

f

(SMCLK)

f(ACLK)

(system)

= 1

= f

= f

= 0

= 0

,

= 4096 Hz

(ACLK)

,

= 4096 Hz

(ACLK)

= 1

= 1

= 0 MHz

0

= 0 Hz, SCG0 = 1

,

,

,

,

= 0 MHz,

= 1 MHz)

VCC = 2.2 V 160 200

VCC = 3 V 240 300

VCC = 2.2 V 1.3 2

VCC = 3 V 2.5 3.2

VCC = 2.2 V 200 250

VCC = 3 V 300 350

VCC = 2.2 V 1.6 3

VCC = 3 V 3 4.3

VCC = 2.2 V 30 40

VCC = 3 V 51 60

VCC = 2.2 V 32 45

VCC = 3 V 55 70

VCC = 2.2 V 11 14

VCC = 3 V 17 22

VCC = 2.2 V 1.2 1.7

VCC = 3 V 2 2.7

VCC = 2.2 V

VCC = 3 V

VCC = 2.2 V/3 V

VCC = 2.2 V/3 V

0.7 1

1.6 2.3

1.8 2.2

1.6 1.9

0.1 0.5

0.1 0.5

0.4 0.8

0.1 0.5

µ

µ

µ

µ

µ

µ

µ

µA

µA

µA

µA

current consumption of active mode versus system frequency, C version, F version

= I

I

AM

current consumption of active mode versus supply voltage, C version

IAM = I

current consumption of active mode versus supply voltage, F version

= I

I

AM

28

AM[1 MHz]

AM[3 V]

AM[3 V]

× f

system

[MHz]

+ 105 µA/V × (VCC–3 V)

+ 120 µA/V × (VCC–3 V)

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 29

MSP430x11x1

V

Positive-going input threshold voltage

V

V

Negative-going input threshold voltage

V

V

Input voltage hysteresis, (V

V

)

V

V

V

V

Port 1

(C11x1)

)

V

Port 1 (F11x1)

V

V

V

V

V

gg

V

V

V

V

V

V

Port 1

(C11x1

)

V

F11x1)

V

CC

V

I

High-impedance leakage current

nA

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

Schmitt-trigger inputs Port P1 to Port P2; P1.0 to P1.7, P2.0 to P2.5

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

IT+

IT–

hys

p

p

p

–

IT+

IT–

electrical characteristics over recommended ranges of supply voltage and operating free-air

temperature (unless otherwise noted) (continued)

outputs Port 1 to P2; P1.0 to P1.7, P2.0 to P2.5

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

High-level output voltage

OH

OH

OL

NOTES: 8. The maximum total current, I

and Port 2

Port 1 (F11x1

High-level output voltage

Port 2 (F11x1)

Low-level output voltage

and Port 2

F11x1

drop specified.

9. The maximum total current, I

drop specified.

10. One output loaded at a time.

,

I

(OHmax)

I

(OHmax)

I

(OHmax)

I

(OHmax)

I

(OHmax)

I

(OHmax)

I

(OHmax)

I

(OHmax)

I

(OLmax)

I

(OLmax)

I

(OLmax)

I

(OLmax)

OHmax

OHmax

= –1.5 mA

= –6 mA

= –1.5 mA

= –6 mA

= –1 mA

= –3.4 mA

= –1 mA

= –3.4 mA

= 1.5 mA

= 6 mA

= 1.5 mA

= 6 mA

and I

OLmax

and I

OLmax

= 2.2

CC

= 3

CC

= 2.2

CC

= 3

CC

= 2.2

CC

= 3

, for all outputs combined, should not exceed ±12 mA to hold the maximum voltage

, for all outputs combined, should not exceed ±48 mA to hold the maximum voltage

VCC = 2.2 V 1.1 1.3

VCC = 3 V 1.5 1.8

VCC = 2.2 V 0.4 0.9

VCC = 3 V .90 1.2

VCC = 2.2 V 0.3 1

VCC = 3 V 0.5 1.4

See Note 8 VCC–0.25 V

See Note 9 VCC–0.6 V

See Note 8 VCC–0.25 V

See Note 9 VCC–0.6 V

See Note 10 VCC–0.25 V

See Note 10 VCC–0.6 V

See Note 10 VCC–0.25 V

See Note 10 VCC–0.6 V

See Note 8 V

See Note 9 V

See Note 8 V

See Note 9 V

SS

SS

SS

SS

CC

CC

CC

CC

CC

CC

CC

CC

VSS+0.25

VSS+0.6

VSS+0.25

VSS+0.6

leakage current

lkg(Px.x)

NOTES: 1 1. The leakage current is measured with VSS or VCC applied to the corresponding pin(s), unless otherwise noted.

12. The leakage of the digital port pins is measured individually. The port pin must be selected for input and there must be no optional

pullup or pulldown resistor.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Port P1: P1.x, 0 ≤ ×≤ 7

p

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

(see Notes 11, 12)

Port P2: P2.x, 0 ≤ ×≤ 5

(see Notes 11, 12)

VCC = 2.2 V/3 V,

VCC = 2.2 V/3 V,

±50

±50

29

Page 30

MSP430x11x1

yg

V

CC

V/3 V

Port P1, P2: P1.x to P2.x

()

ns

()

ns

f

Input frequenc

Internal TA0, TA1, TA2, t

t

MH

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

electrical characteristics over recommended ranges of supply voltage and operating free-air

temperature (unless otherwise noted) (continued)

optional resistors, individually programmable with ROM code (see Note 13)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

R

(opt1)

R

(opt2)

R

(opt3)

R

(opt4)

R

(opt5)

R

(opt6)

R

(opt7)

R

(opt8)

R

(opt9)

R

(opt10)

NOTE 13: Optional resistors R

Resistors, individually programmable with ROM code, all port pins,

values applicable for pulldown and pullup

for pulldown or pullup are not available in standard flash memory device MSP430F11x1.

optx

inputs Px.x, TAx

PARAMETER TEST CONDITIONS VCC MIN TYP MAX UNIT

t

(int)

t

(cap)

NOTES: 14. The external signal sets the interrupt flag every time the minimum t

External interrupt timing

Timer_A, capture timing TA0, TA1, TA2. (see Note 15)

trigger signals shorter than t

cycles.

15. The external capture signal triggers the capture event every time when the minimum t

capture may be triggered with capture signals even shorter than t

a correct capture of the 16-bit timer value and to ensure the flag is set.

External trigger signal for the interrupt flag,

(see Note 14)

. Both the cycle and timing specifications must be met to ensure the flag is set. t

int

,

cap

= 2.2

2.2 V/3 V 1.5 cycle

2.2 V 62

3 V 50

2.2 V/3 V 1.5 cycle

2.2 V 62

3 V 50

cycle and time parameters are met. It may be set even with

int

. Both the cycle and timing specifications must be met to ensure

cap

2.5 5 10 kΩ

3.8 7.7 15 kΩ

7.6 15 31 kΩ

11.5 23 46 kΩ

23 45 90 kΩ

46 90 180 kΩ

70 140 280 kΩ

115 230 460 kΩ

160 320 640 kΩ

205 420 830 kΩ

is measured in MCLK

int

cycles and time parameters are met. A

internal signals TAx, SMCLK at Timer_A

PARAMETER TEST CONDITIONS VCC MIN TYP MAX UNIT

(IN)

f

(TAint)

p

Timer_A clock frequency Internally, SMCLK signal applied 2.2 V/3 V dc f

y

=

H

L

2.2 V 8

3 V 10

System

z

30

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 31

MSP430x11x1

P1.4/SMCLK

2.2 V/3 V

P2.0/ACLK

C

L

F

I

CAON=1

CARSEL=0

CAREF=0

A

(

(Refladder/

CAREF=1/2/3

load at

A

V

No load at P2.3/CA0/TA1 and

mV

A

ns

t

A

s

Overdrive 10 mV, without filter:

ns

(res onse HL)

A

s

MIXED SIGNAL MICROCONTROLLER

SLAS241C – SEPTEMBER 1999 – REVISED JUNE 2000

electrical characteristics over recommended ranges of supply voltage and operating free-air

temperature (unless otherwise noted) (continued)

outputs P1.x, P2.x, TAx

PARAMETER TEST CONDITIONS VCC MIN TYP MAX UNIT

f

(P20)

f

(TAx)

t

(Xdc)

t

(TAdc)

NOTE 16: The limits of the system clock MCLK has to be met. MCLK and SMCLK can have different frequencies.

Output frequency

Duty cycle of O/P

frequency

P2.0/ACLK, CL = 20 pF 2.2 V/3 V f

TA0, TA1, TA2, CL = 20 pF

Internal clock source, SMCLK signal applied (see Note 16)

f

CL = 20 pF

= 20

=

TA0, TA1, TA2, CL = 20 pF, Duty cycle = 50% 2.2 V/3 V 0 ±50 ns

,

,

p

f

f

f

f

f

f

SMCLK

SMCLK

SMCLK

SMCLK

= f

P20

= f

P20

= f

P20

= f

LFXT1

= f

LFXT1

= f

LFXT1/n

= f

DCOCLK

LFXT1

LFXT1

LFXT1/n

= f

= f

= f

= f

XT1

LF

XT1

LF

2.2 V/3 V dc f

40% 60%

35% 65%

50%–

15 ns

2.2 V/3 V

2.2 V/3 V

50%–

15 ns

40% 60%

30% 70%

50%

50%

50%

System

MHz

System

50%+

15 ns

50%+

15 ns

Comparator_A (see Note 17)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

(DD)

I

Refladder/

RefDiode)

V

(IC)

V

(Ref025)

See Figure 5

V

(Ref050)

See Figure 5

(RefVT)

V

(offset)

V

hys

(response LH)

Common-mode input

voltage

Voltage @ 0.25 VCCnode

V

CC

Voltage @ 0.5VCCnode

V

CC

Offset voltage See Note 18 VCC = 2.2 V/3 V –30 30 mV

Input hysteresis CAON=1 VCC = 2.2 V/3 V 0 0.7 1.4 mV

,

CAON=1, CARSEL=0,

P2.3/CA0/T A1 and P2.4/CA1/TA2

CAON =1 VCC = 2.2 V/3 V 0 VCC–1 V

PCA0=1, CARSEL=1, CAREF=1,

No load at P2.3/CA0/TA1 and

P2.4/CA1/T A2, See Figure 5

PCA0=1, CARSEL=1, CAREF=2,

No load at P2.3/CA0/TA1 and

P2.4/CA1/T A2, See Figure 5

PCA0=1, CARSEL=1, CAREF=3,

P2.4/CA1/TA2

TA = 25°C, Overdrive 10 mV, Without filter: CAF=0

TA = 25°C, Overdrive 10 mV, With

filter: CAF=1

TA = 25°C,

,

, No

VCC = 2.2 V 25 40

VCC = 3 V 45 60

VCC = 2.2 V 30 50

VCC = 3 V 45 71

VCC = 2.2 V/3 V 0.23 0.24 0.25

VCC = 2.2 V/3 V 0.47 0.48 0.5

VCC = 2.2 V 430 550 645

VCC = 3 V 450 565 660

VCC = 2.2 V 160 210 300

VCC = 3 V 90 150 200

VCC = 2.2 V 1.6 1.9 3.4

VCC = 3 V 1.1 1.5 2.6

VCC = 2.2 V 160 210 300

µ

µ

µ

t

p

NOTES: 17. The leakage current for the Comparator_A terminals is identical to I

18. The input offset voltage can be cancelled by using the CAEX bit to invert the Comparator_A inputs on successive measurements.

The two successive measurements are then summed together.

CAF=0

TA = 25°C,

Overdrive 10 mV , with filter: CAF=1