Page 1

DLP®NIRscan™ Evaluation Module

User's Guide

Literature Number: DLPU016C

April 2014–Revised April 2019

Page 2

Contents

Preface ........................................................................................................................................ 5

1 DLP NIRscan Evaluation Module Overview.............................................................................. 8

1.1 Introduction ................................................................................................................... 8

1.2 What is in the DLP NIRscan EVM? ....................................................................................... 8

1.2.1 Optical Engine ..................................................................................................... 10

1.2.2 DLP NIRscan EVM Electronics.................................................................................. 12

1.3 Other Items Needed for Operation....................................................................................... 14

1.4 DLP NIRscan Connections................................................................................................ 14

1.5 DLP NIRscan EVM Jumpers.............................................................................................. 16

2 Quick Start ........................................................................................................................ 18

2.1 Power-Up the DLP NIRscan EVM ....................................................................................... 18

3 Operating the DLP NIRscan EVM.......................................................................................... 20

3.1 Quick Scan Mode .......................................................................................................... 21

3.2 Custom Scan Mode ........................................................................................................ 23

3.3 Slew Scan Mode ........................................................................................................... 28

3.4 File Download Icon ........................................................................................................ 32

3.5 System Information ........................................................................................................ 32

A Safety ............................................................................................................................... 34

A.1 Warnings and Cautions.................................................................................................... 34

B Power Supply Requirements................................................................................................ 35

B.1 External Power Supply Requirements................................................................................... 35

C NIRscan EVM Reprogramming Procedure ............................................................................. 36

C.1 Creating a bootable microSD Card ...................................................................................... 36

C.2 Reprogramming the DLP NIRscan EVM Application Software....................................................... 36

C.3 Upgrading the DLPC350 Firmware ...................................................................................... 39

Revision History.......................................................................................................................... 40

2

Contents

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 3

www.ti.com

1. DLP NIRscan Evaluation Module ......................................................................................... 6

1-1. DLP NIRscan EVM Block Diagram........................................................................................ 9

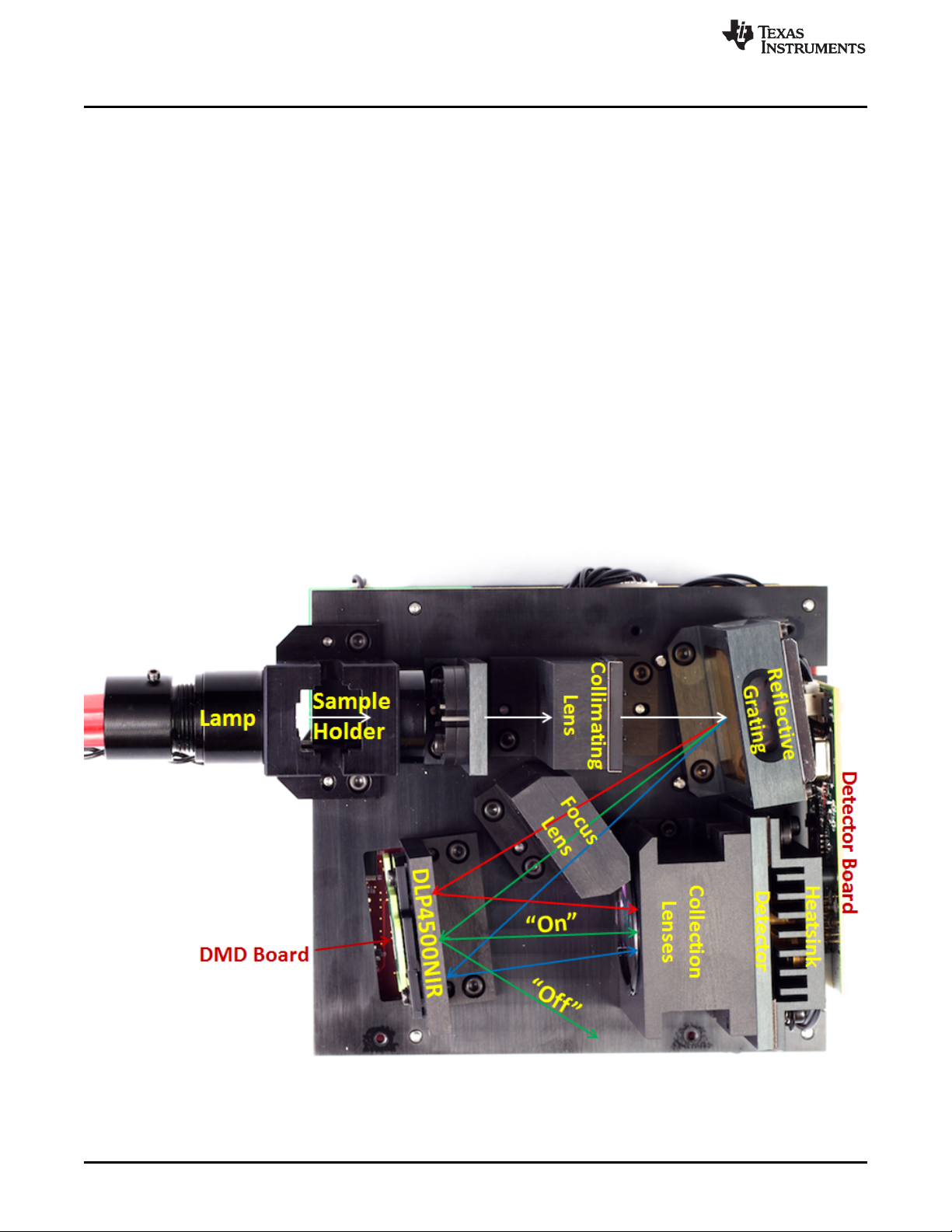

1-2. DLP NIRscan EVM Optical Engine ...................................................................................... 10

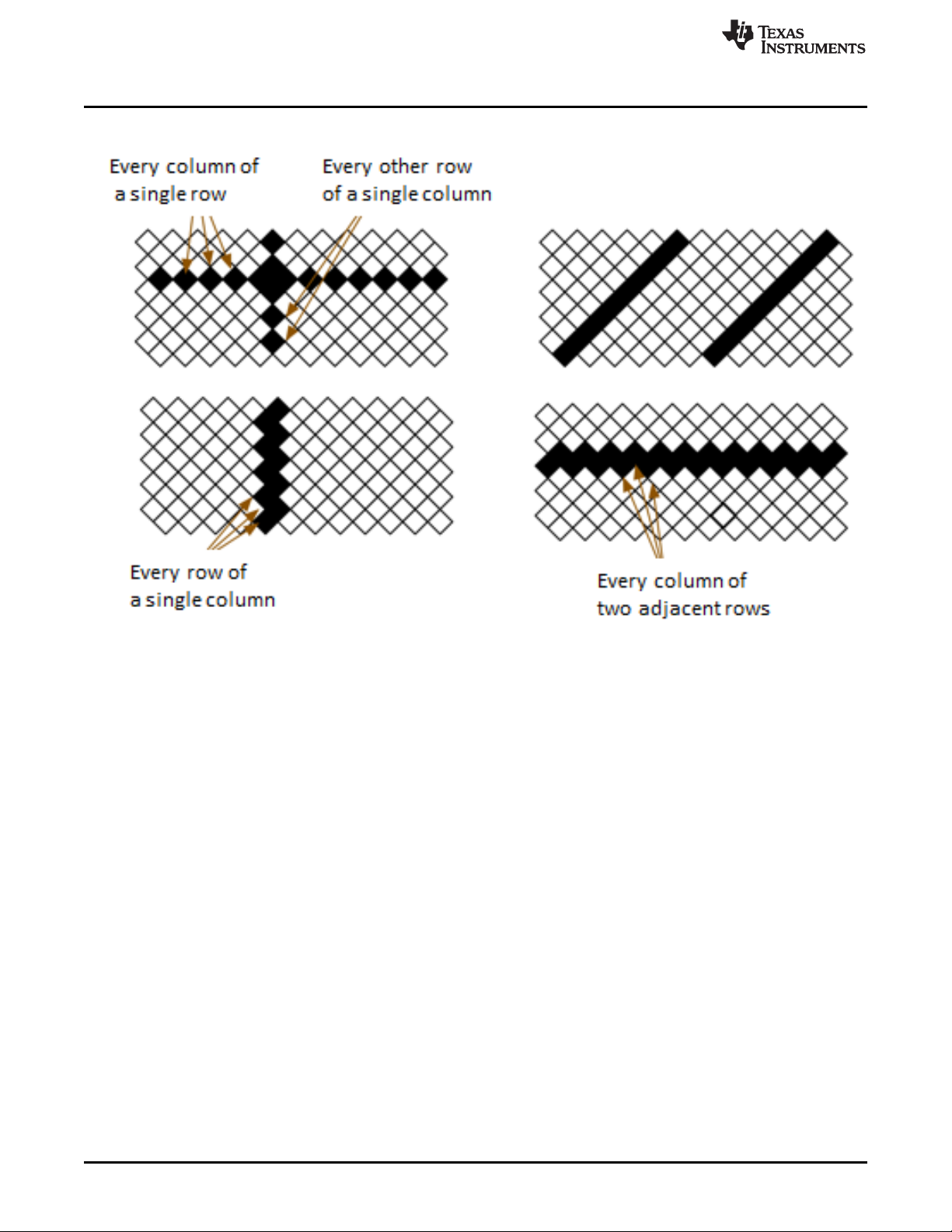

1-3. 0.45-Inch DMD Diamond Pixel Geometry............................................................................... 11

1-4. 0.45-Inch DMD Diamond Pixel Array Configuration ................................................................... 11

1-5. Diamond Pixel for Vertical, Horizontal, and Diagonal Lines.......................................................... 12

1-6. DLP NIRscan EVM......................................................................................................... 13

1-7. DLP NIRscan EVM Connectors (Backside View)...................................................................... 15

1-8. DLP NIRscan Connectors (Upside-Down Side View) ................................................................. 15

1-9. DLP NIRscan Jumper Locations ......................................................................................... 16

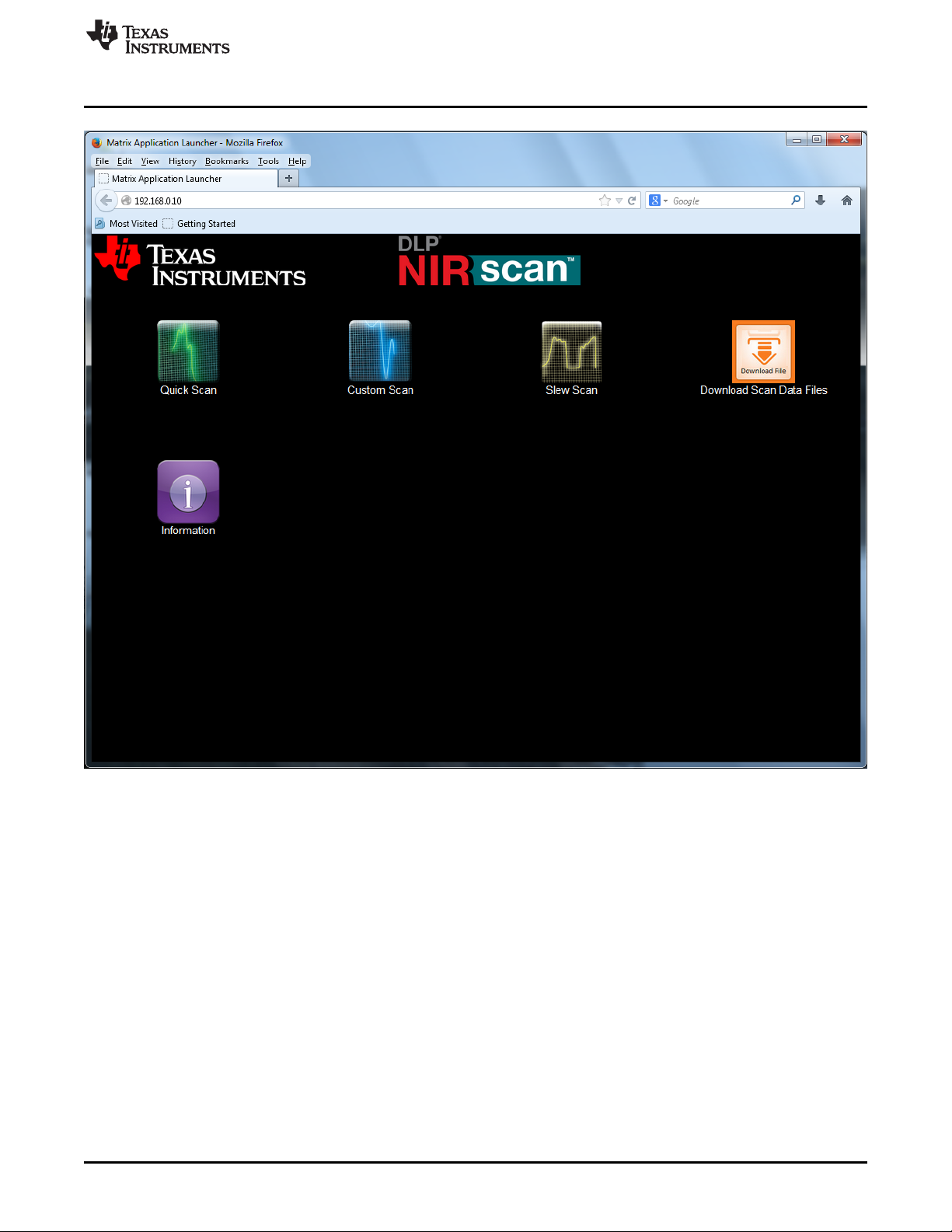

2-1. DLP NIRscan Homepage ................................................................................................. 19

3-1. Quick Scan Screen......................................................................................................... 21

3-2. Example Quick Scan....................................................................................................... 22

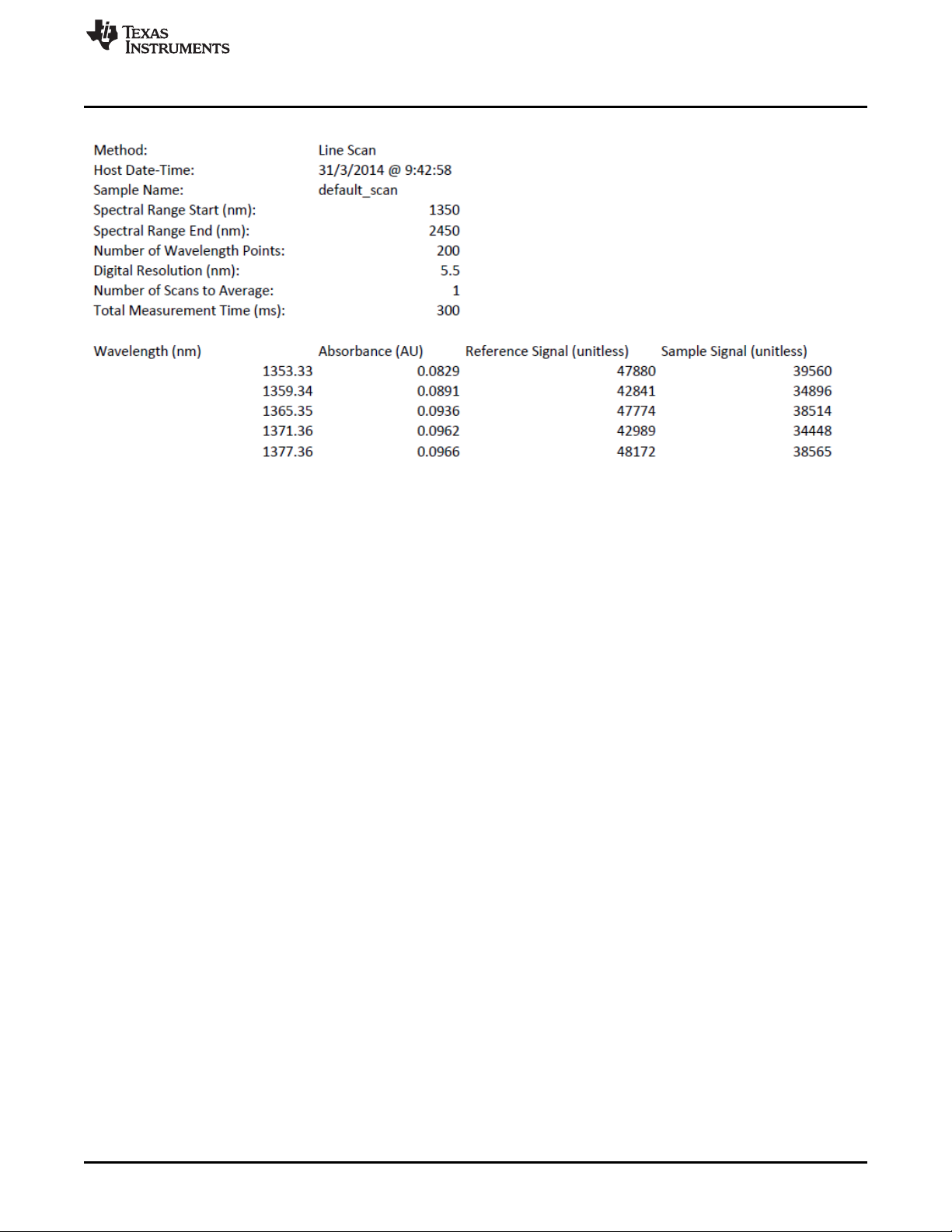

3-3. Example Quick Scan Spectrum Data.................................................................................... 23

3-4. Custom Scan Screen ...................................................................................................... 24

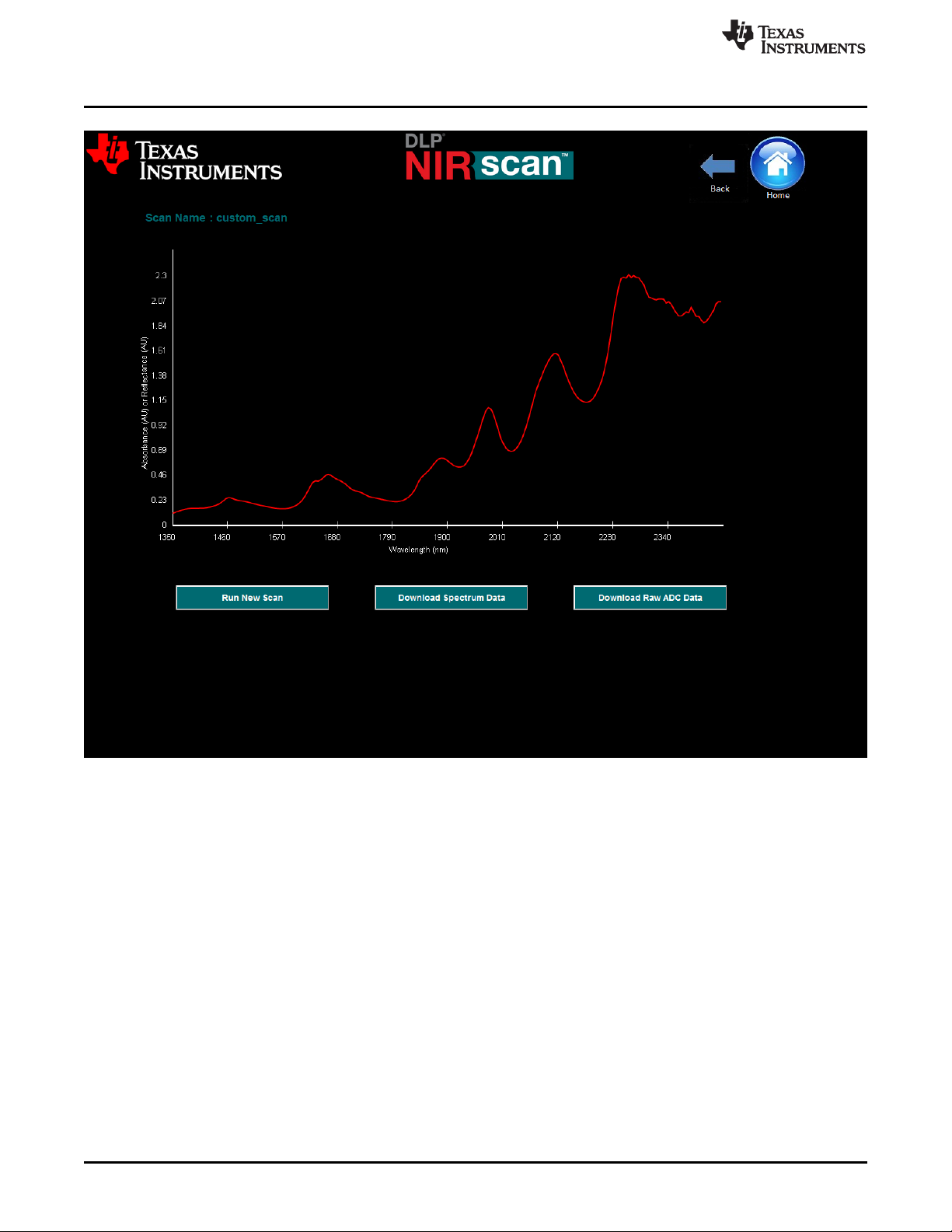

3-5. Example Custom Scan .................................................................................................... 26

3-6. Example Custom Scan Spectral Data................................................................................... 27

3-7. Example Custom Scan Raw Data ....................................................................................... 28

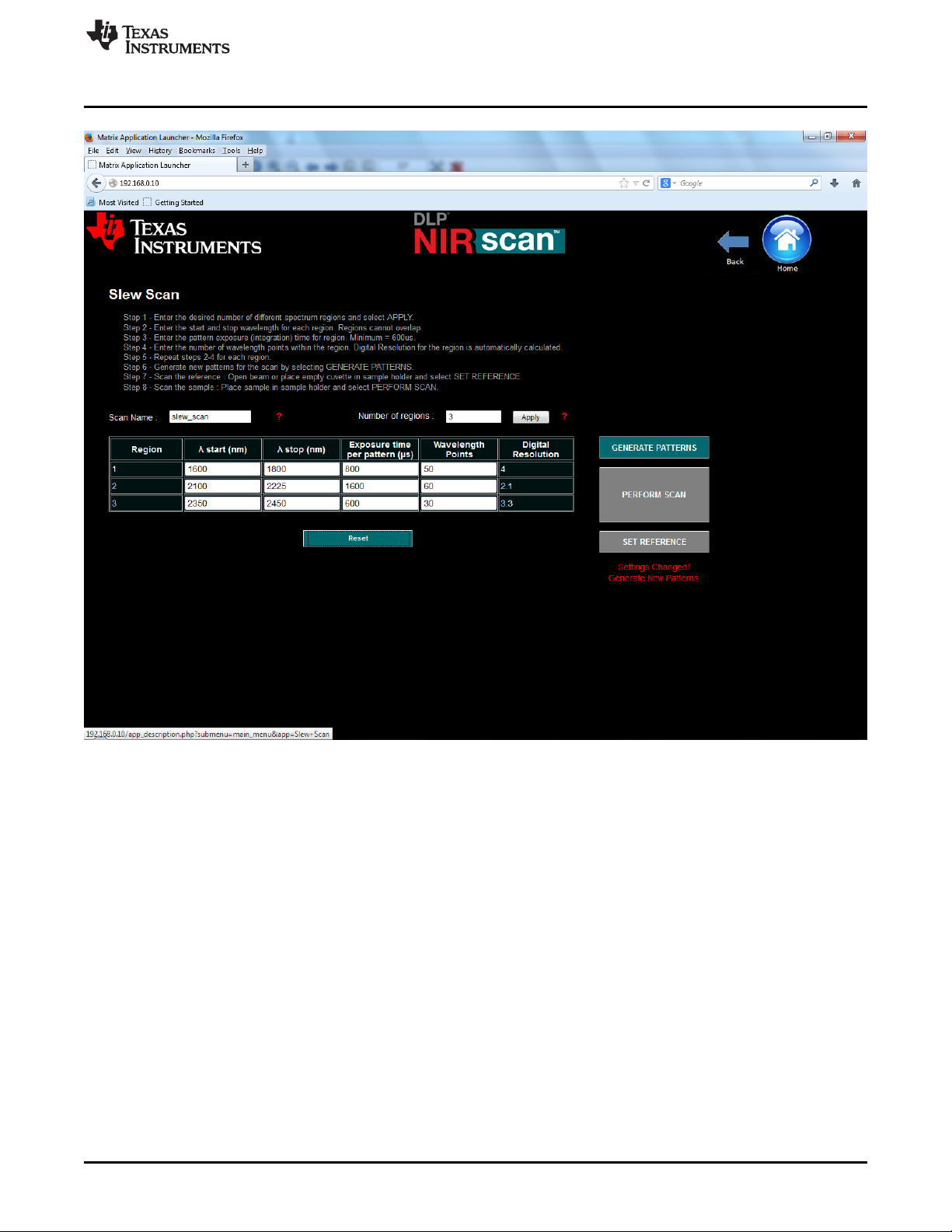

3-8. Slew Scan Screen.......................................................................................................... 29

3-9. Eample Slew Scan ......................................................................................................... 31

3-10. File Download Screen ..................................................................................................... 32

3-11. Information Screen......................................................................................................... 33

C-1. MicroSD Card Slot ......................................................................................................... 37

C-2. Boot Switch Location ...................................................................................................... 38

C-3. LED Location................................................................................................................ 39

List of Figures

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Copyright © 2014–2019, Texas Instruments Incorporated

List of Figures

3

Page 4

www.ti.com

List of Tables

1-1. DLP NIRscan EVM Specifications ....................................................................................... 11

1-2. DLP NIRscan EVM Components......................................................................................... 14

1-3. DLP NIRscan Connections................................................................................................ 15

4

List of Tables

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 5

The DLP®NIRscan™ EVM is a third-party implementation of the next generation DLP reference design to

enable faster development cycles for spectrometer applications requiring small form factors.

Trademarks

NIRscan, Sitara are trademarks of Texas Instruments.

DLP is a registered trademark of Texas Instruments.

Safari is a registered trademark of Apple Inc.

Digi-Key is a registered trademark of Digi-Key Corporation.

Google is a trademark of Google Inc.

Internet Explorer is a registered trademark of Microsoft Corporation.

Mozilla Firefox is a registered trademark of Mozilla Corporation.

Sullins Connector Solutions is a registered trademark of Sullins Connector Solutions, Inc.

About This Guide

This guide is an introductory document for the DLP NIRscan EVM that provides an overview of the system

and the systems software. Other documents provide more in-depth information of the hardware and

software features of the components of the DLP NIRscan EVM.

This document covers DLP NIRscan Software version 2.0 - version 2.0 is an update to version 1.0 which

adds the Slew Scan mode and Custom Scan - Hadamard mode of operation. For instructions on how to

update the NIRscan software from version 1.0 to version 2.0, please see Appendix C of this document.

Preface

DLPU016C–April 2014–Revised April 2019

Read This First

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Copyright © 2014–2019, Texas Instruments Incorporated

Read This First

5

Page 6

www.ti.com

Figure 1. DLP NIRscan Evaluation Module

Use the most recent versions of either Firefox, Safari, Google Chrome, or Internet Explorer. There are

some compatibility issues noted with IE8 and IE9 so these versions are not recommended.

6

Read This First

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 7

www.ti.com

Related Documentation

DLPC350 data sheet: DLPC350 DLP Digital Controller for Portable Advanced Light Control, DLPS029

DLP4500NIR data sheet: DLP 0.45 WXGA NIR DMD, DLPS032

Programmer's guide: DLPC350 Programmer’s Guide, DLPU010

Design guide: DLP Spectrometer Design Considerations, DLPA049

Technical Support

Refer to the DLP and MEMS TI E2E community support forums.

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Copyright © 2014–2019, Texas Instruments Incorporated

Read This First

7

Page 8

1.1 Introduction

The DLP®NIRscan™ EVM is a complete evaluation module (EVM) to design a high performance,

affordable near-infrared spectrometer. This flexible tool contains everything a designer needs to start

developing a DLP-based spectrometer right out of the box. The EVM features the DLP 0.45 WXGA NIR

chipset. It is the first DLP chipset optimized for use with near-infrared (NIR) light. With DLP technology,

spectrometers for use in the food, pharmaceutical, oil and gas and other emerging industries are able to

deliver lab performance levels in the factory and the field. This technology brings together a set of

components providing an efficient and compelling spectroscopy system solution for:

• Process analyzers

• Laboratory equipment

• Dedicated analyzers

The new DLP4500NIR DMD is optimized for operation at wavelengths between 700 nm and 2500 nm. The

DLP NIRscan EVM is one possible implementation of this new DLP technology, operating from 1350 nm

to 2450 nm.

Chapter 1

DLPU016C–April 2014–Revised April 2019

DLP NIRscan Evaluation Module Overview

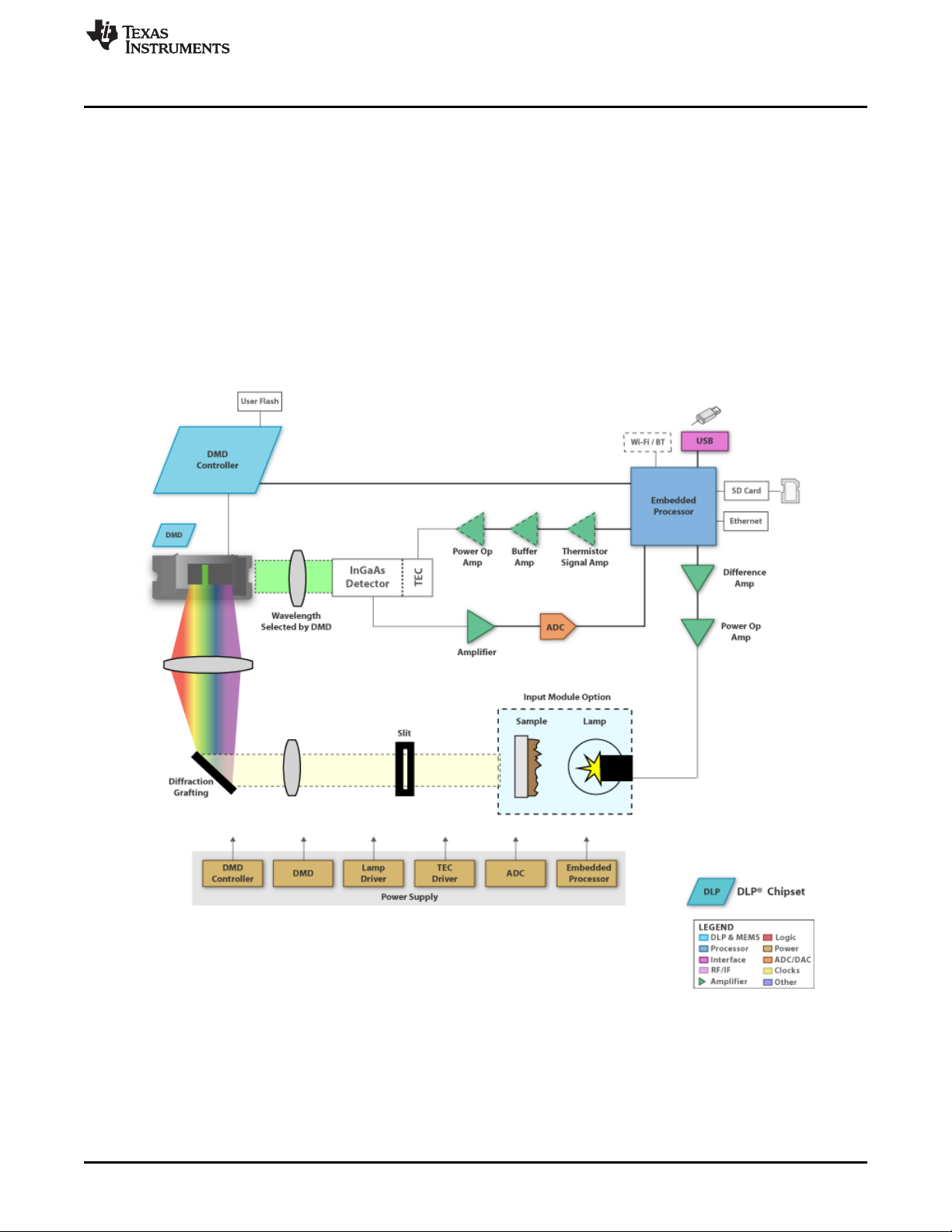

1.2 What is in the DLP NIRscan EVM?

The DLP NIRscan EVM is a complete NIR spectrometer EVM using DLP technology. The EVM package

includes:

• Near infrared optomechanical spectrometer engine:

– Transmissive sample holder with broadband visible-to-infrared tungsten-halogen lamp

– 25-µm input slit

– Collimating lenses

– 1300 to 2500 nm bandpass filter

– Reflective diffraction grating

– Focusing lens

– DLP4500NIR DMD (.45-inch WXGA, 912 × 1140 diamond pixels, NIR optimized)

– Collection optics

– 2-mm single-pixel, cooled InGaAs detector

• Electronics subsystem with the electronics consisting of five boards:

– Spectro board

• DLPC350 controller ASIC

• Sitara™ processor (AM3358) for system control and analysis

• Power management circuits

• Connectivity through Ethernet and USB

• Non-volatile eMMC flash memory

• Micro SD card slot for external programming

• Open source Linux web-server application software

– Detector board

• 2-mm, single-pixel cooled InGaAs detector with TEC and thermistor

• Low-noise differential amplifier circuit

8

DLP NIRscan Evaluation Module Overview

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 9

www.ti.com

• Three disposable cuvettes, each 12.5 × 12.5 mm with 10-mm path length, for use during the

Figure 1-1 shows the major hardware components.

What is in the DLP NIRscan EVM?

• ADS1255 30 kSPS analog-to-digital converter (ADC) with SPI interface

– Lamp driver board

• Low noise, constant current supply for the broadband lamp

– TEC driver board

• Thermistor feedback signal amplifier for temperature measurement

• Closed loop TEC current control with high current driver

– DMD interconnect board

– Associated cable harnesses

spectrometer evaluation.

Figure 1-1. DLP NIRscan EVM Block Diagram

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

DLP NIRscan Evaluation Module Overview

Copyright © 2014–2019, Texas Instruments Incorporated

9

Page 10

What is in the DLP NIRscan EVM?

1.2.1 Optical Engine

The DLP NIRscan EVM spectrometer optical engine is mounted on top of a thermal plate which acts as a

stable platform for mounting the optics. The configuration is a post-dispersive architecture where the

broadband light from the tungsten lamp is directed through a transmissive sample. In this specific

implementation, the lamp or sample holder module allows insertion of standard cuvettes. These cuvettes

are designed to hold liquid samples. There is also a slit in the sample holder, which allows insertion of

various thickness NIR transmissive samples such as plastic sheets and coated glass.

Each sample passes (and absorb) a specific amount of NIR light through the sample. The amount passed

(and absorbed) depends on the molecular makeup of the material, and is specific to that material, similar

to a fingerprint. The light which passes through the sample enters the engine through the input slit. Slit

size is relative to the desired wavelength resolution of the spectrometer. This spectrometer uses a 25-µm

wide slit, which is approximately 4.2-mm tall. After light passes through the slit, the light then passes

through a collimating lens, through a 1350- to 2450-nm bandpass filter where the light then strikes a

reflective grating. This grating, in combination with the focusing lens, disperses the NIR wavelengths

across the DLP4500NIR DMD in a horizontal fashion, with 1350 nm projected to one side of the DMD,

2450 nm to the other end, and all wavelengths dispersed between. When specific DMD columns are

selected as 'on', or tilted to the +12º position, the energy reflected by the selected columns diverts through

the collection optics to the single pixel detector. All other DMD columns which are not selected as 'on' are

by default 'off' (tilted to the –12º position). 'Off' DMD pixels divert the unselected wavelengths away from

the detector optical path so as not to interfere with the selected wavelength measurement.

The DLP NIRscan EVM size is mostly driven by the size of the optical engine and measures

approximately 197-mm long, 112-mm wide, and 96-mm tall.

www.ti.com

10

Figure 1-2. DLP NIRscan EVM Optical Engine

DLP NIRscan Evaluation Module Overview

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 11

www.ti.com

Table 1-1 lists the specifications of the light engine.

The optical engine includes the DLP4500NIR 0.45-inch DMD with 1039680 mirrors, arranged in 912

columns × 1140 rows with the diamond pixel array geometry and configuration shown in Figure 1-3 and

Figure 1-4. Due to the diamond pixel configuration, the array produces smooth diagonal lines, with jagged

vertical and horizontal lines, as shown in Figure 1-5. Conceptually, the spectroscopy application running

on the DLP NIRscan GUI uses vertical columns to select wavelengths. These vertical lines are

programmable in width as selected in the DLP NIRscan GUI software. Wider columns tend to provide

more light to the detector, but less digital resolution. Narrow columns provide higher digital resolution, but

less light to the detector.

What is in the DLP NIRscan EVM?

CAUTION

Do not disassemble the optical engine. The optical engine contains lenses,

gratings, and detectors that have been calibrated at the factory. Loosening or

tightening screws and optical components may move pieces out of alignment

and cause decreased system performance. Removal of the cover may allow

dust intrusion, which can also decrease system performance.

Table 1-1. DLP NIRscan EVM Specifications

PARAMETER MIN TYP MAX UNIT

Supported wavelengths 1350 2450 nm

Spectrometer typical power 12 W

Tungsten lamp typical power 4 W

Figure 1-3. 0.45-Inch DMD Diamond Pixel Geometry Figure 1-4. 0.45-Inch DMD Diamond Pixel Array

Configuration

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Copyright © 2014–2019, Texas Instruments Incorporated

DLP NIRscan Evaluation Module Overview

11

Page 12

What is in the DLP NIRscan EVM?

www.ti.com

Figure 1-5. Diamond Pixel for Vertical, Horizontal, and Diagonal Lines

1.2.2 DLP NIRscan EVM Electronics

The DLP NIRscan EVM contains five boards which support all the electrical and software capabilities of

the spectrometer. The five boards are:

• Spectro board: The spectro board is the largest board in the DLP NIRscan EVM. The board provides

the following:

– Sitara processor: The Sitara processor (AM3358) runs a webserver which provides an HTML-based

method of controlling the spectrometer and displaying the results of sample scans. The Sitara

formulates and streams unique wavelength specific patterns to the DLPC350 for display on the

DMD while synchronizing the sampling of the spectrometer's ADC. The Sitara runs a Linux-based

spectrometer application on an open source Linux kernel. The user controls the web pages through

an RNDIS connection over USB, or by IP address over Ethernet connected to the local area

network.

– DLPC350 ASIC: The controller of the DLP4500NIR-based DLP system, the DLPC350 device

receives the pattern data from the Sitara over a 24-bit RGB bus. The DLPC350 decodes the pattern

information and converts the information into the correct format for the DMD. The device controls all

the DMD signals and synchronization, thereby directing each individual mirror to its desired state.

– External interfaces: The spectro boards provide multiple interfaces to the outside world. Standard

interfaces for communicating with the DLP NIRscan EVM are Ethernet-over-USB and a standard

RJ45 ethernet connection. To leverage the DLP NIRscan EVM platform for new product

development using the Sitara processor, the spectro board also contains a Sitara debug port, which

can be used with console software to control and debug the EVM software.

– Internal interfaces: The spectro board is at the center of the spectrometer electronics and software.

All boards plug into the spectro board though either a hard board connector or wiring harness.

12

DLP NIRscan Evaluation Module Overview

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 13

www.ti.com

• DMD board: The DLP4500NIR DMD is located in the optical engine portion of the system. The DMD

• Detector board: The detector board is located within the optical engine and connects the InGaAs

• TEC driver board: The TEC driver board uses the feedback from a thermistor located in the detector

• Lamp driver board: The lamp driver board provides an extremely-low noise, high-power source for the

Figure 1-6 shows the spectro, TEC driver, and lamp driver boards. The detector board is located within the

optical engine. The DMD board plugs into the backside of the spectro board and connects it to the DMD

located inside the optical engine.

What is in the DLP NIRscan EVM?

board plugs into the spectro board and connects the DLPC350 to the DMD.

detector to the TEC driver board. The detector board also houses the differential amplifier circuits

which source the detector signal to the TI ADS1255 ADC. The ADS1255 ADC is used to over-sample

the resultant signals being routed from the detector for each wavelength-specific pattern being

displayed on the DMD.

to provide electrical current to the detector TEC in a closed-loop control circuit, thereby cooling the

detector to approximately –40°F and reducing detector noise.

tungsten-halogen lamp, which illuminates the sample. A low-noise source is important for a

spectrometer which has a high signal-to-noise ratio (SNR).

The DLP NIRscan EVM electronics contain many devices by TI, which are critical to the design and

performance of the DLP NIRscan EVM (see Table 1-2).

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Figure 1-6. DLP NIRscan EVM

Copyright © 2014–2019, Texas Instruments Incorporated

DLP NIRscan Evaluation Module Overview

13

Page 14

Other Items Needed for Operation

Table 1-2. DLP NIRscan EVM Components

Electronics Device Number Description

DLP chipset

Embedded processor AM3358 Sitara processor

Analog chain for detector

Analog chain for TEC driver

and lamp driver

Power management

ESD protection TPD4S012 4-channel USB ESD solution with power clamp

DLPC350 Controller for the DLP4500 family of DMDs

DLPC4500NIR DMD

ADS1255 24-bit, 30 kSPS very-low noise delta-sigma ADC

OPA2376 Precision, low noise, low quiescent current operation amplifier

OPA569 Power operational amplifier, output signal swings within 200 mV of rails at 2-A output

INA330 Thermistor signal amplifier for temperature control

OPA340 Micro operational amplifier for PID control of TEC driver

TPS65217C Single-chip PMIC for battery-powered systems for AM3358, DDR3

TPS65145

TPS73025 Single output LDO, 200 mA, fixed (2.5 V), high PSRR, low noise for DLP4500NIR power

TPS65251 PMU with three DC-to-DC converters, up to 18-Vin for DLPC350 power

TPS79718

TLV61230 5-V supply for USB and input to TPS65217

TLV61230 3.3-V supply

REF5025 Low noise, very-low drift, precision voltage reference for TEC and ADC references

TPS71750 5-V analog supply for ADC and TEC

TPS71733 3.3-V analog supply for ADC

4-channel LCD bias with fully-integrated positive charge pump, 3.3-V LDO controller for

DLP4500NIR power

Single output LDO, 50 mA, fixed (1.8 V), low quiescent current, Powergood out for

DLPC350 power

www.ti.com

1.3 Other Items Needed for Operation

The DLP NIRscan EVM spectrometer is a flexible, ready-to-use EVM. However, the DLP NIRscan EVM

does not ship with cables, power supply, or additional hardware components. To use the EVM, the user

needs:

• Power supply:

– Nominal voltage: 12-V DC

– Typical current: 3 A

– Maximum current: 5 A

– DC connector size:

• Inner diameter: 2.5 mm

• Outer diameter: 5.5 mm

• Shaft: 9.5-mm female, center positive

– Efficiency level: V

– A recommended power supply is Digi-Key®part number 271-2718-ND, or equivalent

• USB cable: A-to-mini-B USB cable

• External laptop, desktop, or personal computer

1.4 DLP NIRscan Connections

Figure 1-7 and Figure 1-8 depict the connectors with their respective locations. No cables, nor power

supply are included with the unit. Only connection 8 and connection 14 or 7 are required for typical

operation. All of the connections are listed for completeness in Table 1-3.

14

DLP NIRscan Evaluation Module Overview

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 15

www.ti.com

Table 1-3. DLP NIRscan Connections

Connection Type Description

1 DLPC350 I2C bus Do not use while the Sitara processor is controlling the DLPC350.

2 Fan power Power output from the spectro board to power the fan.

3 TEC control cable

4 Micro-SD card slot Used for future DLP NIRscan software upgrades.

5 USB connectors

6

7 Ethernet RJ45

8 Power connector

9 Lamp power Connector from the lamp driver board to the tungsten-halogen lamp.

10

11

12

13 ADC converter SPI bus Data interface to the ADS1255 ADC

14 Mini-USB to Sitara

15 S1 Resets the DLP NIRscan to its power-up condition.

Mini-USB interface to

the DLPC350

JTAG interface for the

DLPC350

External trigger input

connector

External trigger output

connector

Connects the TEC driver board to the detector board to drive the detector TEC and read

the thermistor value from the detector.

There are two USB expansion connections in connector 5. These connections can be

used for most USB-compatible applications, such as USB memory storage, USB WLAN,

or Bluetooth applications. The software to support these expansion features is not

included in the DLP NIRscan EVM.

USB connection allows the DLP LightCrafter4500 GUI to access the DLPC350 or to

control the DLPC350 through an external USB-capable microcontroller.

Alternative to the Ethernet-over-USB connection 14. As of software release v1.0, to use

the ethernet connection requires knowledge of the IP address assigned to the DLP

NIRscan EVM at power-up. If a static IP address cannot be assigned, TI recommends

using connection 14.

Use a power supply with a 12-V DC output with 3- to 5-A current rating and a plug of

2.5-mm inner diameter × 5.5-mm outer diameter and 9.5-mm female center positive shaft.

Supports two trigger input signals for DMD pattern synchronization.

Supports two trigger output signals. These are jumper configurable:

• With jumper J13 installed, the output triggers are referenced to internal 3.3 V with up

to 100 mA available at the external connector.

• Without J13 installed, the triggers are reference to an externally supplied

1.8- to 5-V input.

Main method of connecting a laptop, desktop, or PC to the DLP NIRscan EVM. The

supported protocol is ethernet-over-USB and requires the RNDIS driver on the host PC.

DLP NIRscan Connections

Figure 1-7. DLP NIRscan EVM Connectors

(Backside View)

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Figure 1-8. DLP NIRscan Connectors

(Upside-Down Side View)

DLP NIRscan Evaluation Module Overview

Copyright © 2014–2019, Texas Instruments Incorporated

15

Page 16

DLP NIRscan EVM Jumpers

1.5 DLP NIRscan EVM Jumpers

The DLP NIRscan EVM has jumpers and a variable resistor to provide flexible board control options. This

section lists the jumpers on the DLP NIRscan spectro board. Figure 1-9 depicts the locations of these

jumpers. These jumpers require a 2-mm jumper, such as Sullins Connector Solutions®SPN02SYBN-RC,

Digi-Key part number S3404-ND.

www.ti.com

16

Figure 1-9. DLP NIRscan Jumper Locations

TEC Driver Board

• VR1 – This variable resistor sets the maximum current provided to the TEC of the detector. This

current level determines the ambient temperatures at which the detector remains cooled to

approximately –40ºC. The factory establishes this amount of resistance. Do not change the

resitance unless the application requires a different detector or ambient temperature.

Lamp Driver Board

• H1 – sets the current to the lamp.

– Terminals 1 and 2 = 1 A

– Terminals 2 and 3 = 0.75 A (default)

Spectro Board

• J1 – Sitara UART0 port. Connect to this port for debug messages and Sitara debug control.

– Terminal 1 = GND

DLP NIRscan Evaluation Module Overview

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 17

www.ti.com

DLP NIRscan EVM Jumpers

– Terminal 2 = NC

– Terminal 3 = NC

– Terminal 4 = UART_RX

– Terminal 5 = UART_TX

– Terminal 6 = NC

• J10 – Trigger In 1

– Terminals 1 and 2 = External connector triggers the DLPC350

– Terminals 2 and 3 = Sitara triggers the DLPC350 (default)

• J12 – Trigger In 2

– Terminals 1 and 2 = External connector triggers the DLPC350

– Terminals 2 and 3 = Sitara triggers the DLPC350 (default)

• J14 – Trigger out 1

– Terminals 1 and 2 = DLPC350 generated trigger out 1 (default)

– Terminals 2 and 3 = Sitara generated trigger out 1

• J16 – Trigger out 2

– Terminals 1 and 2 = DLPC350 generated trigger out 2 (default)

– Terminals 2 and 3 = Sitara generated trigger out 2

• J13 – Power selector for trigger out voltage levels

– Jumper installed = Trigger outputs on J15 use internal 3.3-VDC levels (default)

– Jumper open = Trigger outputs on J15 use voltage levels supplied J15 terminal-1

– Note: Externally supplied voltage levels need to be 1.8, 3.3, or 5 V

• J18 – DLPC350 hold bootloader

– Jumper open = Normal operation (default)

– Jump across this header to hold the DLPC350 in bootloader mode. This hold is required only if

the DLPC350 firmware becomes corrupted and requires reprogramming through the JTAG

boundary scan or USB (atypical).

• J19 – DLPC350 I2C address select

– Jumper installed sets I2C address to 0×3A and USB device serial number to LCR3

– Jumper not installed sets I2C address to 0×34 and USB device serial number to LCR2 (default)

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

DLP NIRscan Evaluation Module Overview

Copyright © 2014–2019, Texas Instruments Incorporated

17

Page 18

This chapter details the steps to power-up and use the DLP NIRscan EVM spectrometer.

2.1 Power-Up the DLP NIRscan EVM

The DLP NIRscan is ready to use, out of the box. Follow these steps to power up, connect the EVM to a

computer, and access the home screen.

1. Connect a 12-V DC power supply to the input power supply connector.

2. An LED next to the power connector on the spectro board lights up green. The fan starts and the

DLPC350 and Sitara processor start booting. After 5 to 10 s, the DLPC350 is confirmed to be running

its firmware if green LED D3 (in the middle of the spectro board) starts flashing a heartbeat

(approximately one flash per second). A blue LED next to the Sitara Micro-USB connector also

illuminates to indicate that the Sitara power supplies are up.

3. The EVM Sitara processor runs a webserver, which provides display information to the user through an

HTML browser such as Mozilla Firefox®, Google™ browser, Safari®, or Internet Explorer®. Connect the

USB port of the computer with the browser to the EVM through the micro-USB connection at location

14.

4. Many computers ship with RNDIS drivers installed, which are required to use Ethernet-over-USB. After

plugging-in the micro-USB cable in step 3, if there is no RNDIS driver installed on the computer, the

software typically prompts the user before searching for the driver. After the RNDIS driver is installed,

start a browser session. The following steps install the RNDIS drivers on Windows 7 or Windows 10 in

case they are not installed.

• Download RNDIS drivers from this link:

http://www.catalog.update.microsoft.com/Search.aspx?q=USB%20RNDIS%20Gadget (5

entry from top/bottom).

• Extract the contents of .cab file to a folder.

• Connect the NIRScan EVM to PC, power it on and open Device Manager. The device displays as

COM device.

• Right Click the device and select Update Drivers.

• Select Browse My Computer For Device Software.

• Point to the folder that holds the extracted the contents of the .cab file in step 2.

• Click Next to install the new drivers.

After the drivers have been installed, the NIRScan EVM displays as USB Ethernet/RNDIS Device and

operates as expcted. Network Connections in the Control Panell displays a new ethernet connection

with description USB Ethernet/RNDIS Device. Wait until the network status changes from Identifying...

to Unidentified Network.

5. Enter http://192.168.0.10 in the URL window at the top of the browser screen: . The first time the cable

is connected on a PC, the DLP NIRscan enumerates. If the browser does not connect within 30

seconds, or the browser times out, the user may need to refresh the browser once or twice to provide

more time for the system to enumerate, load the RNDIS driver, and register its IP address with the

host PC.

6. When connected to the DLP NIRscan, the NIRscan Home Screen displays in the browser window (see

Figure 2-1).

Chapter 2

DLPU016C–April 2014–Revised April 2019

Quick Start

th

18

Quick Start

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 19

www.ti.com

Power-Up the DLP NIRscan EVM

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Figure 2-1. DLP NIRscan Homepage

Copyright © 2014–2019, Texas Instruments Incorporated

Quick Start

19

Page 20

Chapter 3

DLPU016C–April 2014–Revised April 2019

Operating the DLP NIRscan EVM

This chapter introduces the software executing within the DLP NIRscan EVM. The DLP NIRscan

Homepage has five icons:

• Quick Scan – Scans can be made quickly and effortlessly with fixed configuration parameters.

• Custom Scan – Users can interact with certain settings to customize scans and access raw scan data.

• Slew Scan – Users can customize the scan for distinct regions for select wavelengths, resolutions,

and integration times.

• Download Files – Users can download the spectral and/or raw data files for scans to their local

machine.

• Information – This icon provides the DLP NIRscan EVM software version information and links to DLP

NIRscan information located on www.ti.com

20

Operating the DLP NIRscan EVM

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 21

www.ti.com

3.1 Quick Scan Mode

From the NIRscan Home screen, clicking the Quick Scan icon takes the user to the Quick Scan screen

(see Figure 3-1).

Quick Scan Mode

The steps to take a Quick Scan are:

1. Set the reference by clicking either Run Reference Scan or Use Previous Reference.

• Run Reference Scan causes the spectrometer to scan the reference sample.

• Use Previous Reference does not re-scan the reference, but uses reference data from the last

Quick Scan reference.

• If measuring a liquid sample in a cuvette, then the reference scan is typically taken using an empty

cuvette in the sample holder. This reference scan allows the absorbance of the cuvette material to

be negated when the absorbance of the liquid sample material is calculated.

• For measurement of solid transmissive materials such as sheet plastic, the sample holder must

remain empty during the reference scan.

2. Users can change the scan name or use the default name. The scan name becomes part of the

resulting scans filenames. These filenames can be downloaded from the DLP NIRscan EVM once

scans are complete.

3. Load the cuvette with the liquid sample or insert the sheet plastic into the sample holder.

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Figure 3-1. Quick Scan Screen

Copyright © 2014–2019, Texas Instruments Incorporated

Operating the DLP NIRscan EVM

21

Page 22

Quick Scan Mode

4. Click Perform Scan. The DLP NIRscan scans the sample, calculates the sample material absorbance,

and displays the absorbance in graphical format on the next screen. Figure 3-2 shows an example of

this screen.

www.ti.com

22

Figure 3-2. Example Quick Scan

The graphical representation shows the absorbance spectrum of the material, with absorbance units (AU)

on the y-axis and sampled wavelength on the x-axis.

1. To run another Quick Scan, insert a new sample in the sample holder and select the Run New Scan

button. The new scan is taken, the new absorbance spectrum is calculated (using the previous

reference), and the new spectrum re-plots to the screen all with a single click. This action can be

performed repeatedly. The filename provided on the previous Quick Scan screen is incremented with

each sample run so that sample data files can be distinguished from each other.

2. To save the spectrum data to a local machine, click the Download Spectrum Data button. This action

prompts the user to open the .csv file in excel (if available on the users machine) or to save the file

locally. The file format imports into excel as shown in Figure 3-3.

Operating the DLP NIRscan EVM

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 23

www.ti.com

Custom Scan Mode

Figure 3-3. Example Quick Scan Spectrum Data

Note that the header in the download file contains many important aspects of the scan, including:

1. Method: This defaults to linescan mode at this time, referencing how the sample is taken by scanning

vertical lines across the DMD, each line representing a specific wavelength.

2. Host Date-Time: This is the date (browser date) and time the scan was taken.

3. Sample name: this is the scan name entered on the first Quick Scan screen. If the scan name has not

been changed, the sample name defaults to default_scan.

4. Spectral Range Start: always 1350 nm for Quick Scan mode

5. Spectral Range Stop: always 2450 nm for Quick Scan mode

6. Number of wavelength points: 200 for Quick Scan mode

7. Digital resolution: 5.5 nm for Quick Scan mode

8. Number of scans to average: 1 scan for Quick Scan mode

9. Total measurement time: The time taken to scan all wavelengths

10. The rest of the file is the actual data and includes:

• Wavelength

• Calculated spectrum value for each wavelength

• Average reference ADC value for each wavelength

• Average sample ADC value for each wavelength

After the data is saved locally on the machine running the browser, the user can return to the Quick Scan

screen.

3.2 Custom Scan Mode

From the NIRscan Home screen, clicking the Custom Scan icon takes the user to the Custom Scan

screen (see Figure 3-4).

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Copyright © 2014–2019, Texas Instruments Incorporated

Operating the DLP NIRscan EVM

23

Page 24

Custom Scan Mode

www.ti.com

24

Figure 3-4. Custom Scan Screen

The Custom Scan mode allows more flexibility than the Quick Scan mode by allowing the user to

change the configuration parameters for the scan. The parameters for the Custom Scan mode are:

• Spectral range: for faster scan times, sub-ranges of the total 1350- to 2450-nm range can be used.

The smaller the spectral range entered, the faster the scan. For a custom wavelength range, the

smaller wavelength must be located on the left and the larger on the right. All values must be

between 1350 nm and 2450 nm.

• Number of wavelength points: This number defines into how many wavelengths the spectral

range is divided. The minimum is 3 and the maximum is 1100. The included optical system has an

optical resolution of ≤12 nm. Increasing the number of wavelength points such that the computed

digital resolution is much less than 12 nm reduces system throughput without much of an optical

resolution advantage.

• Digital resolution: This is an informational output field for the user. The calculated resolution is the

wavelength range divided by the number of wavelength points.

• Number of scans to average: This is the number of times the entire wavelength range is

repeatedly sampled. If the number in this field is 1, then the wavelength range entered is scanned

only one time. If the number 2 is entered, the wavelength range is scanned twice, one complete

scan after another. The average spectrum data for each wavelength is averaged with the data for

the same wavelength on subsequent scans.

Operating the DLP NIRscan EVM

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 25

www.ti.com

In the Custom Scan mode, the user must select actions which have green buttons. Clicking on graycolored buttons is ignored. To run the Custom Scan, perform the following tasks:

1. Accept the values in the custom parameter fields or enter custom parameters based on the previous

2. If the user accepts the default parameters, then the Generate Patterns button remains gray. If the

3. If the Generate Patterns button is green, click this button. When selected, the DLP NIRscan

4. Select the Set Reference button.

5. Insert the sample in the sample holder (with or without cuvette).

6. Click Perform Scan. The DLP NIRscan EVM scans the sample, calculates the sample material

Custom Scan Mode

• Total measurement time: The length of time needed to run the entire scan across all wavelengths

as entered.

• Scan name: This field allows changing the scan name to reflect something more specific to the

user, that is, like the material being scanned.

descriptions.

user changes the parameters, the Generate Patterns button turns green.

calculates the new DMD patterns for the user-selected inputs, generates the patterns, applies the

hardware-specific calibration, and saves the patterns in memory for the scan to commence. This step

is complete when the Set Reference button turns green and the message Patterns Generated - Set

New Reference! message appears.

• To measure a liquid sample in a cuvette, first run the reference scan with an empty cuvette in the

sample holder. This allows the absorbance of the cuvette material to be negated when the

absorbance of the material is calculated.

• When measuring a solid transmissive material such as a plastic by inserting the plastic into the

sample holder, ensure the sample holder is empty during the reference scan.

absorbance, and displays the absorbance in graphical format on the next screen. Figure 3-5 shows an

example of this screen.

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Copyright © 2014–2019, Texas Instruments Incorporated

Operating the DLP NIRscan EVM

25

Page 26

Custom Scan Mode

www.ti.com

26

Figure 3-5. Example Custom Scan

The graphical representation shows the absorbance spectrum of the material, with absorbance units (AU)

on the y-axis and sampled wavelength on the x-axis.

1. To run another scan, insert a new sample (or use the same sample, to re-sample the same material),

and select the Run New Scan button. The new scan runs, the new absorbance spectrum calculates

(using the previous reference), and the new spectrum plots all with one button click. This action can be

performed repeatedly. Note that the scan name provided on the previous Custom Scan screen

increments with each sample run.

2. To save the spectrum data to a local machine, click the Download Spectrum Data button. This action

prompts the user to open the .csv file in excel (if available on the users machine) or to save the file

locally. The file format imports into excel as shown in Figure 3-6.

Operating the DLP NIRscan EVM

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 27

www.ti.com

Custom Scan Mode

Figure 3-6. Example Custom Scan Spectral Data

Note that the header in the download file contains many important aspects of the scan, including:

1. Method: This defaults to linescan mode at this time, referencing how the sample is taken by scanning

vertical lines across the DMD, each line representing a specific wavelength.

2. Host Date-Time: This is the date (browser date) and time the scan was taken.

3. Sample Name: This is the scan name entered on the first Custom Scan screen. If the scan name has

not been changed, the sample name defaults to default_scan.

4. Spectral Range Start: This reflects the lower scan limit entered on the Custom Scan screen.

5. Spectral Range End: This reflects the upper scan limit entered on the Custom Scan screen.

6. Number of Wavelength Points: This reflects the number entered on the Custom Scan screen.

7. Digital Resolution: This reflects the number calculated on the Custom Scan screen.

8. Number of Scans to Average: This reflects the number entered on the Custom Scan screen.

9. Total Measurement Time: This reflects the number calculated on the previous screen.

10. The rest of the file is the actual data and includes:

• Wavelength

• Calculated absorbance value for each wavelength

• Average reference ADC value for each wavelength

• Average sample ADC value for each wavelength

After the data is saved locally on the machine running the browser, the user can return to the Custom

Scan screen.

Download Raw ADC Data: In the Custom Scan mode, there is another button located beneath the plotted

absorbance spectrum labeled Download Raw ADC Data. Whereas the Download Spectrum button

provides averaged reference and sample data values, there are potentially cases where a user may want

to download all the data points sampled during the scan. To save the raw data to a local machine, click

the Download Raw ADC Data button. This action prompts the user to open the .csv file in excel (if

available on the users machine) or to save the file locally. The file format imports into excel as shown in

Figure 3-7.

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Copyright © 2014–2019, Texas Instruments Incorporated

Operating the DLP NIRscan EVM

27

Page 28

Slew Scan Mode

www.ti.com

Note that the header in the download file contains many important aspects of the scan, including:

1. Method: This defaults to linescan mode at this time, referencing how the sample is taken by scanning

vertical lines across the DMD, each line representing a specific wavelength.

2. Host Date-Time: This is the date (browser date) and time the scan was taken.

3. Sample Name: This is the scan name entered on the first Custom Scan screen. If the scan name has

not been changed, the sample name defaults to default_scan.

4. Spectral Range Start: This reflects the lower scan limit entered on the previous screen

5. Spectral Range Stop: This reflects the upper scan limit entered on the previous screen

6. Number of Wavelength Points: This reflects the number entered on the previous screen

7. Digital Resolution: This reflects the number calculated on the previous screen

8. Number of Scans to Average: This reflects the number entered on the previous screen.

9. Total Measurement Time: This reflects the number calculated on the previous screen

10. The rest of the file is the actual raw data and includes:

• DMD pattern number

• Individual reference ADC data values for each pattern (wavelength)

• Individual sample ADC data values for each pattern (wavelength)

After the data is saved locally on the machine running the browser, the user can return to the Custom

Scan screen.

3.3 Slew Scan Mode

From the NIRscan Home screen, clicking the Slew Scan icon takes the user to the Slew Scan screen

(see Figure 3-1).

Figure 3-7. Example Custom Scan Raw Data

28

Operating the DLP NIRscan EVM

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 29

www.ti.com

Slew Scan Mode

The Slew Scan screen provides users the ability to divide the 1350-2450nm spectral range into user

defined regions, each region with its own spectral range, exposure (integration) times, and spectral

resolutions. Non-overlapping regions from 1 to 10 can be defined. This provides unique scan methods

which enable the following use cases:

• Wavelength Skipping: Sometimes, the entire spectral range need not be scanned for users to identify

specific molecules within a sample. Scanning a subset of defined spectral regions of the spectral range

is all that is needed. In this case, uninteresting regions of the spectrum can be omitted in the scan by

specifying only the spectral regions of interest. Gaps between segments are allowed. Figure 3-8 shows

a Slew Scan configuration example showing how spectral regions of interest are entered in the table all other areas of the spectrum not entered are ignored, thereby making the scan much shorter yet still

capable of detecting the presence (or absence) of important molecules.

• Variable Resolution: Based on the spectrum expected for a given substance, there may be regions of

the spectrum where high digital resolution is needed, with less interesting areas requiring less

resolution. Each region in the configuration table can be configured to have different resolutions. Lower

resolutions for areas of little (expected) detail help speed up scan times.

• Variable Integration: Exposure (Integration) Times for each defined region can be increased or

decreased to meet user specific Signal-to-Noise Ratio (SNR) requirements. In regions which have high

absorbance, longer exposure times (averaging) may be needed to improve SNR, and in regions of low

absorbance and possibly little importance, shorter exposure times are more than adequate for

deterministic results. By decreasing exposure times for these uninteresting regions, it helps to speed

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Figure 3-8. Slew Scan Screen

Copyright © 2014–2019, Texas Instruments Incorporated

Operating the DLP NIRscan EVM

29

Page 30

Slew Scan Mode

up overall scan times.

Below are the steps to setup and execute a Slew Scan. This example uses 3 regions which are not

contiguous, have different exposure times per pattern in each region, and different digital resolutions for

each region. The configuration is located above in Figure 3-8. Graphical output results are shown below in

Figure 3-9

1. Determine the number of distinct spectral segments required and enter that number in the Number of

Regions box. Now click the Apply button and the entry table expands or contracts to provide one row

for each Region. Now the user can enter the desired configuration settings for each of the desired

regions:

• Lambda Start (nm): is the starting wavelength for the region N. The starting wavelength must be

• Lambda Stop (nm): is the stopping wavelength for the region N. The stopping wavelength must

• Exposure time per pattern (µs): The minimum exposure time is 600 µs. Ensure that [maximum

• Wavelength Points: The number of wavelength points defines the number of the patterns being

• Digital Resolutions is only one of the contributors to the true spectral resolution of a DLP based

2. As in the other scan modes, the user can change the scan name, or leave the default name in place.

The sfotware embeds in the resulting filenames for imminent scans, which can be downloaded from

the DLP NIRscan after the scans are complete.

3. As in the Custom Scan mode, whenever new configuration data are entered, or existing settings are

modified, the NIRscan generates new patterns defined by the new configuration data. The Generate

Patterns button turns green when the configuration data changes to indicate new patterns are needed.

• Click Generate Patterns. This step is complete when the Set Reference button turns green and

4. Click Set Reference .

• If planning to measure a liquid sample in a cuvette, first run the reference scan with an empty

• When measuring a solid transmissive material such as sheet plastic by inserting the plastic into the

5. Insert the sample in the sample holder (with or without cuvette).

6. Click Perform Scan. The DLP NIRscan EVM scans the sample, calculates the sample material

absorbance, and displays the absorbance in graphical format on the next screen. Figure 3-5 shows an

example of this output.

www.ti.com

≥1350 and must be

> the Region (N-1)'s Lambda Stop value.

be > the region N Lambda start value, and must be ≤2450.

allowed exposure time (µs/pattern)] × [the number of wavelength points] is less than or equal to 1

second. The NIRscan EVM software design limits the exposure time constraints. Because the DLP

patterns applied to the DMD are inherently programmable, customer systems can implement much

longer integration times for applications which require them.

applied to the DMD within this region only. [Lambda stop – Lambda Start] / # wavelength points) =

the Digital Resolution for which the DMD is programmed

spectrometer. See DLP Spectrometer Design Considerations for more information regarding

spectrometer resolution as a function of DMD digital resolution, input slit width, and optical point

spread function.

the message Patterns Generated - Set New Reference! message displays.

cuvette in the sample holder. This scan allows the absorbance of the cuvette material to be

negated when the absorbance of the material is calculated.

sample holder, ensure the sample holder remains empty during the reference scan.

30

Operating the DLP NIRscan EVM

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 31

www.ti.com

Slew Scan Mode

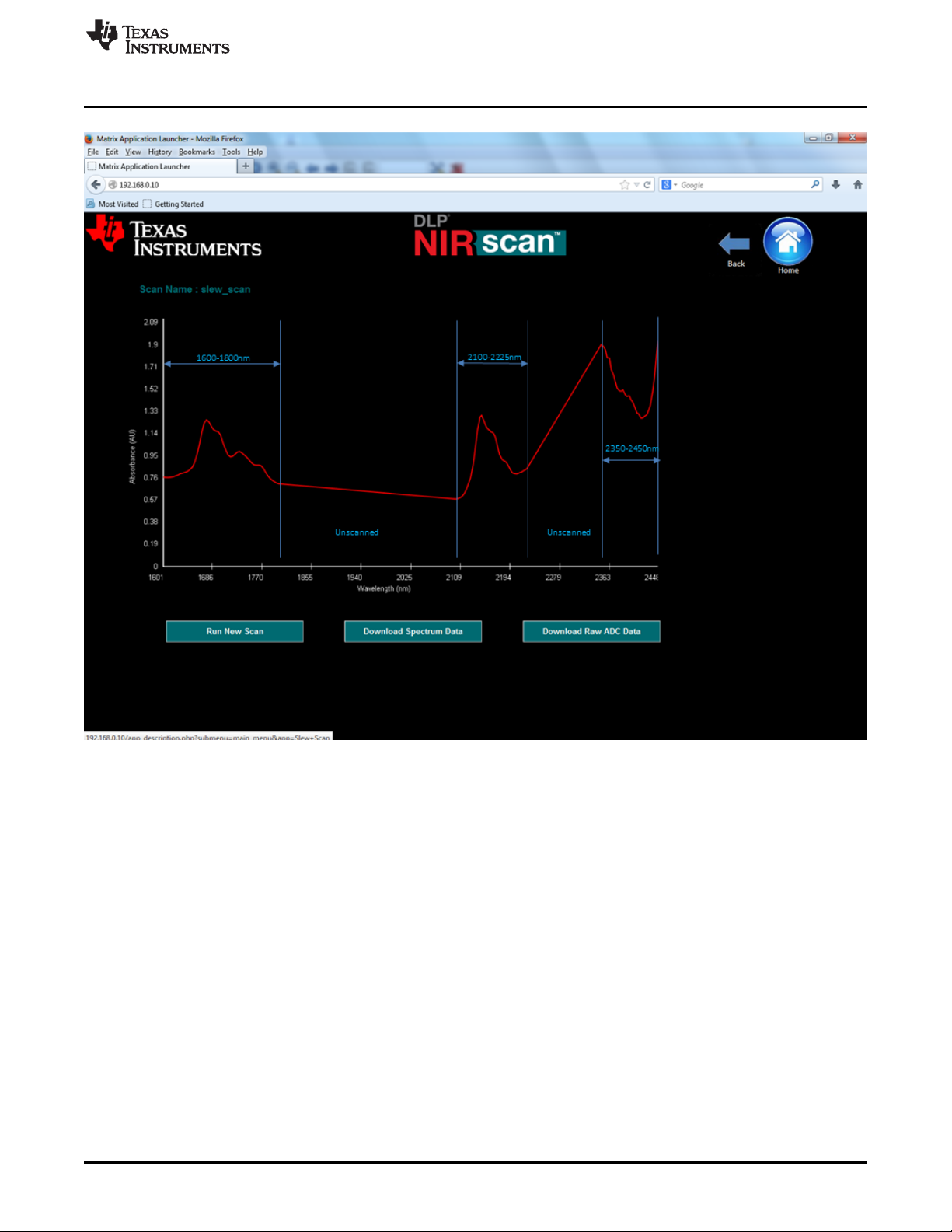

The graphical representation in Figure 3-9 shows the absorbance spectrum of the sampled material, with

absorbance units (AU) on the y-axis and wavelength on the x-axis. The 3 regions of interest are

highlighted in blue and the two regions not of interest are identified with the word "unscanned". Each

scanned region is measured based on the configuration information supplied for that region. For

unscanned spectral regions not configured in the configuration table, the graphical output shows a straight

line from the last wavelength in region N to the first wavelength in region N+1.

1. To run another scan, insert the new sample and select the Run New Scan button. The new scan runs,

the new absorbance spectrum calculates (using the previous reference), and the new spectrum plots

all with one button click. This action can be performed repeatedly. The scan filename provided on the

previous Slew Scan configuration screen increments with each sample run. Data files for these scans

can then be downloaded to a local machine.

2. To save the spectrum data for the most recent scan to a local machine, click the Download Spectrum

Data button. This action prompts the user to open the .csv file in excel (if available on the users

machine) or to save the file locally. The file format provided for Slew Scan mode is very similar to the

previously defined Custom Scan file format, except that the system identifies the file format as a Slew

Scan and breaks in the wavelength data occur for undefined scan regions.

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Figure 3-9. Eample Slew Scan

Copyright © 2014–2019, Texas Instruments Incorporated

Operating the DLP NIRscan EVM

31

Page 32

File Download Icon

3.4 File Download Icon

From the NIRscan Home screen, clicking on the File Download Icon on the DLP NIRscan Home screen

diaplays a screen where the user can select for download either spectrum data files or raw data files from

previous scans. The system cleares all scan files from the DLP NIRscan EVM memory when the unit is

powered off or reset. (see Figure 3-10).

www.ti.com

The File Download Screen shows the files for all scans which have been captured on the NIRscan. The

user must select the scan type for the data they are seeking to download by selecting either the Quick

Scan button, the Custom Scan button, or the Slew Scan button.

After the scan type is selected, the user can select one file name per instance, and download the

Spectrum data by selecting Download Spectrum Data, or the raw data by selecting Download Raw

Data. The sytem displays a browser specific window that requires the user to either save or open the file.

To download another file, the user must select a different file from the list and follow the same procedure.

3.5 System Information

From the NIRscan Home screen, clicking on the Information Icon on the DLP NIRscan Home screen

displays the Information screen shown in Figure 3-10).

32

Operating the DLP NIRscan EVM

Figure 3-10. File Download Screen

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 33

www.ti.com

System Information

The version displayed on the screen is the software version for the Sitara processor. The screen also

included hyperlinks to documents relevant to the DLP NIRscan and its components.

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Figure 3-11. Information Screen

Copyright © 2014–2019, Texas Instruments Incorporated

Operating the DLP NIRscan EVM

33

Page 34

A.1 Warnings and Cautions

Possible hazardous optical radiation emitted from this product. Do

not stare at operating LEDs. May be harmful to eyes. Also, avoid

touching components during operation.

Appendix A

DLPU016C–April 2014–Revised April 2019

Safety

WARNING

CAUTION

To minimize the risk of fire or equipment damage, make sure that air is allowed

to circulate freely around the DLP NIRscan when operating.

CAUTION

The kit contains ESD-sensitive components. Handle with care to prevent

permanent damage.

34

Safety

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 35

B.1 External Power Supply Requirements

The DLP NIRscan EVM does not include a power supply. The external power supply requirements are:

• Nominal voltage: 12 V DC –5% / +10%

• Minimum current: 3 A

• Maximum current: 5 A

• DC connector size:

– Inner diameter: 2.5 mm

– Outer diameter: 5.5 mm

– Shaft: 9.5 mm female, center positive

• Efficiency level: V

• A recommended power supply is Digi-Key part number 271-2718-ND, or equivalent.

NOTE: External Power Supply Regulatory Compliance Certifications: Recommend selection and use

of an external power supply, which meets TI’s required minimum electrical ratings in addition

to complying with applicable regional product regulatory and safety certification requirements

such as (by example) UL, CSA, VDE, CCC, PSE, and so forth.

Appendix B

DLPU016C–April 2014–Revised April 2019

Power Supply Requirements

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Copyright © 2014–2019, Texas Instruments Incorporated

Power Supply Requirements

35

Page 36

NIRscan EVM Reprogramming Procedure

C.1 Creating a bootable microSD Card

When a new version for the DLP NIRscan EVM is available, the NIRscan can be reprogrammed only by

creating and using a micro-SD flash card. A minimum flash card size of 4GB is required. This card must

be created using the new version binary located on ti.com and the following procedure.

1. Download the DLP NIRscan MicroSD Image for Windows for programming the NIRscan. Access this

file from the DLP NIRscan EVM website. After signing into TI and starting the download, Select RUN

(rather than SAVE). The file size is approximately 1 GB. Save this file to a directory which is easy to

locate. The default path is C:\Texas Instruments-DLP\NIRscan_2.0.0

2. Unzip the downloaded file into the same directory using Winzip, 7-zip, or another Windows compatible

zip/unzip utility. The file isused to create the micro-SD card used to flash the eMMC of the NIRscan

electronics.

3. Download and unzip the Win32DiskImager software into a folder on the PC. This software creates and

installs the flash image on the micro-SD card.

4. Run the Win32DiskImager application. A small window displays a Help link. Use this to find answer to

questions regarding program usage.

5. Place a blank micro-SD card into the PC SD card slot. Within the Win32DiskImager application, select

the drive letter that corresponds to the PC's SD card reader. by clicking on the Device box with a letter

in it. Make sure to select the correct drive letter.

6. Select the file from the directory that holds the unzipped new image by clicking on the folder icon next

to the Device box.

7. Select the write option to start the writing process. Image file is approximately 3GB in size.

8. When finished, remove the microSD card from the reader. The card is now ready to reprogram the

DLP NIRscan EVM.

Appendix C

DLPU016C–April 2014–Revised April 2019

C.2 Reprogramming the DLP NIRscan EVM Application Software

For steps on programming the DLPC350, please see section C.3 below.

1. Prepare the NIRscan by UNPLUGGING ALL CABLES from the unit to be programmed, including the

power cable.

2. Insert newly created microSD card into the microSD card slot on the NIRscan Spectral board with

contacts facing away from the board as shown in Figure C-1.

36

NIRscan EVM Reprogramming Procedure

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 37

www.ti.com

Reprogramming the DLP NIRscan EVM Application Software

Figure C-1. MicroSD Card Slot

3. Press and hold down switch S2 (shown in Figure C-2) while plugging in the power cable. Do not use

any metal tools or objects as these could short potentially damage the electronics if misplaced.

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

NIRscan EVM Reprogramming Procedure

Copyright © 2014–2019, Texas Instruments Incorporated

37

Page 38

Reprogramming the DLP NIRscan EVM Application Software

www.ti.com

38

Figure C-2. Boot Switch Location

4. Continue to hold down S2 until any on-board LED lights up (about 1 second) - then release S2.

5. One or both of two blue LEDs (D1 and D2) as shown in Figure C-3, flash on and off erratically. This

behavior indicates the eMMC is being programmed.

NIRscan EVM Reprogramming Procedure

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 39

www.ti.com

Upgrading the DLPC350 Firmware

Figure C-3. LED Location

6. Reprogramming typically occurs in fewer than 10 minutes. When programming completes successfully,

D1 and D2 stop flashing and stay illuminated.

7. After confirming that D1 and D2 have illuminated steadily for at least 20 seconds, remove power from

the board by removing the power cable.

8. Remove the microSD card from the board.

9. Reapply power to the board by plugging in the cable.

10. The NIRscan boots from the new software. For the first operation after reprogramming, the NIRscan

boot takes slightly longer to complete. When LED D1 illuminates, it indicates that the NIRscan is ready

to communicate. Plug in the USB cable, enter http://192.168.0.10 into the browser URL window, hit

enter, and the NIRscan menu appears.

C.3 Upgrading the DLPC350 Firmware

This section describes how to reprogram the DLP NIRscan EVM with its application software. Because the

NIRscan firmware version and the DLPC350 version have dependencies, when upgrading the DLP

NIRscan EVM software, the DLPC350 may also require an upgrade.

These are the two compatible versions:

• NIRscan version 1.0.0 operates with DLPC350 firmware version 1.1 only.

• NIRscan version 2.0.0 operates with DLPC350 firmware version 2.0 only

The steps to reprogram the DLPC350 are:

1. Download the latest DLPC350 firmware version select save rather than open to a directory and

remember the file location. For example, if reprogramming the NIRscan with Application software

version 2.0.0, select DLPR350PROM version 2.0

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

NIRscan EVM Reprogramming Procedure

Copyright © 2014–2019, Texas Instruments Incorporated

39

Page 40

Revision History

2. Download the LightCrafter4500 PC-based GUI. To install the QT GUI, just expand the

LightCrafter4500_GUI.zip file into a directory and double-click on the executable file.

3. Turn on the NIRscan and then connect a USB cable from the PC to the DLPC350 USB connector J8.

4. After running the LightCrafter4500.exe file, the system displays the GUI main window. The green light

to the left of the word Connected in the upper left corner of the GUI iindicates a connection to the

DLPC350 device.

5. Select the Image / Firmware tab.

6. Select the Firmware Upload subtab.

7. Click Browse to select the file to install.

8. Click Upload .

9. Wait for the upload process to complete. The system erases the flash memory first, then rewriites it

with the new firmware image selected.

10. Remove power from the NIRscan EVM, close the LightCrafter 4500 GUI, and unplug the USB cable.

11. Plug the USB back into the NIRscan. If the NIRscan application code has already been updated, then

the NIRscan is ready to go. If not, then follow the instructions in C.1 and C.2 to reprogram the NIRscan

application code.

12. After both are updated, the NIRscan is ready to operate.

.

Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

www.ti.com

Changes from B Revision (November 2014) to C Revision ........................................................................................... Page

• Added steps to install RNDIS drivers fo Windows OS in Section 2.1............................................................. 18

Changes from A Revision (August 2014) to B Revision ................................................................................................ Page

• Added DLP Spectrometer Design Considerations to Related Documentation.................................................... 7

• Changed from Design Guide to Design Considerations and added URL link................................................... 30

• Changed to http://192.168.0.10 from http://192.168.1.10 .......................................................................... 39

Changes from Original (April 2014) to A Revision .......................................................................................................... Page

• Added Browser Recommendations..................................................................................................... 6

• Home Screen updated for v2.0 ........................................................................................................ 19

• Added Slew Scan and Download Files Icons........................................................................................ 20

• Update v2.0 Custom Scan image to include instructions........................................................................... 24

• Added the Slew Scan Mode Instructions ............................................................................................. 28

• Added the File Download Section ..................................................................................................... 32

• Updated the System Information/Revision screen .................................................................................. 32

• Added NIRscan Reprogramming Procedure......................................................................................... 36

40

Revision History

Copyright © 2014–2019, Texas Instruments Incorporated

DLPU016C–April 2014–Revised April 2019

Submit Documentation Feedback

Page 41

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2019, Texas Instruments Incorporated

Loading...

Loading...