Page 1

DLP®NIRscan™ Nano EVM User's Guide

User's Guide

Literature Number: DLPU030B

June 2015–Revised July 2015

Page 2

Contents

Preface ........................................................................................................................................ 6

1 DLP NIRscan Nano Overview ................................................................................................ 8

1.1 Introduction ................................................................................................................... 8

1.2 What is the DLP NIRscan Nano EVM? ................................................................................... 8

1.2.1 Optical Engine....................................................................................................... 9

1.2.2 DLP NIRscan Nano Electronics................................................................................. 12

1.2.3 Connections........................................................................................................ 14

2 Getting Started................................................................................................................... 18

2.1 Operating Modes ........................................................................................................... 18

2.1.1 USB Connection................................................................................................... 18

2.1.2 Bluetooth Connection............................................................................................. 19

3 Operating the DLP NIRscan Nano EVM ................................................................................. 20

3.1 NIRscan Nano GUI......................................................................................................... 20

3.1.1 Scanning a Sample ............................................................................................... 22

3.1.2 Displaying Previous Scans ...................................................................................... 27

3.1.3 Transferring Scans Stored in microSD Card .................................................................. 28

3.1.4 Utilities.............................................................................................................. 29

4 DLP NIRscan Nano Hardware............................................................................................... 31

4.1 External Power Supply Requirements .................................................................................. 31

5 DLP NIRscan Nano Software................................................................................................ 35

5.1 Overview..................................................................................................................... 35

5.1.1 TI RTOS ............................................................................................................ 35

5.1.2 TivaWare ........................................................................................................... 36

5.1.3 USB Driver ......................................................................................................... 36

5.1.4 SDSPI Driver ...................................................................................................... 36

5.1.5 Bluetopia Stack.................................................................................................... 36

5.1.6 DLP Spectrum Library ............................................................................................ 37

5.1.7 DLP Spectrum Library Workflow ................................................................................ 37

5.2 Software System Overview ............................................................................................... 39

5.3 Bluetooth Client App Workflow........................................................................................... 40

5.3.1 Bluetooth Client Establishing a Connection.................................................................... 40

5.3.2 Bluetooth Client GATT Profiles.................................................................................. 41

6 iOS App............................................................................................................................. 45

6.1 NanoScan iOS App ........................................................................................................ 45

A Installing the DLP NIRscan Nano Software ............................................................................ 48

A.1 DLP NIRscan Nano Software Installation............................................................................... 48

B Required Tools to Compile Tiva Software.............................................................................. 49

B.1 Tiva Tools Installation...................................................................................................... 49

B.1.1 Code Composer Studio Installation............................................................................. 49

B.1.2 Updating TI-RTOS ................................................................................................ 49

C How to Compile Tiva Source Code ....................................................................................... 51

C.1 Tiva Libraries Compilation ................................................................................................ 51

C.1.1 Tiva driverlib Compilation ........................................................................................ 51

2

Contents DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

C.1.2 Tiva usblib Library................................................................................................. 51

C.1.3 DLP Spectrum Library ............................................................................................ 51

C.2 Tiva Main Source........................................................................................................... 51

C.3 Project Settings............................................................................................................. 52

D Required Tools to Compile NIRscan Nano GUI....................................................................... 53

D.1 NIRscan Nano GUI......................................................................................................... 53

D.1.1 Compiling the DLP Spectrum Library........................................................................... 53

D.1.2 Compiling NIRscan Nano GUI................................................................................... 53

E Tiva EEPROM Contents....................................................................................................... 54

E.1 Tiva EEPROM .............................................................................................................. 54

F DLP NIRscan Nano Connectors............................................................................................ 55

F.1 Battery Connector.......................................................................................................... 55

F.2 Battery Thermistor Connector ............................................................................................ 55

F.3 Expansion Connector...................................................................................................... 55

F.4 JTAG Connector............................................................................................................ 56

F.5 Trigger Connector.......................................................................................................... 56

G DLP NIRscan Nano Command Description............................................................................ 58

G.1 Command Handler Supported Commands ............................................................................. 58

H DLP NIRscan Nano USB Communications............................................................................. 62

I DLP NIRscan Nano Bluetooth Communications..................................................................... 65

I.1 Bluetooth Communications ............................................................................................... 65

I.1.1 GATT Supported Services ....................................................................................... 65

I.2 Bluetooth Packets.......................................................................................................... 71

Revision B History....................................................................................................................... 72

Revision A History....................................................................................................................... 72

DLPU030B–June 2015–Revised July 2015 Contents

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

3

Page 4

www.ti.com

List of Figures

1. DLP NIRscan Nano Evaluation Module .................................................................................. 6

1-1. DLP NIRscan Nano Block Diagram ....................................................................................... 9

1-2. DLP NIRscan Nano Optical Engine...................................................................................... 10

1-3. DLP NIRscan Nano Dimensions ......................................................................................... 11

1-4. DLP NIRscan Connectors (Rear View).................................................................................. 14

1-5. DLP NIRscan Connectors (Front View) ................................................................................. 15

1-6. DLP NIRscan Nano Button Locations ................................................................................... 16

1-7. DLP NIRscan Nano LED Locations...................................................................................... 17

3-1. DLP NIRscanNano GUI Information Screen............................................................................ 21

3-2. DLP NIRscanNano GUI Scan Screen................................................................................... 22

3-3. DLP NIRscanNano GUI Scan Configuration Dialog ................................................................... 24

3-4. DLP NIRscan Nano GUI Scan Select Menu............................................................................ 25

3-5. Absorbance Spectrum of Aspirin......................................................................................... 26

3-6. Displaying Previous Scans................................................................................................ 27

3-7. Number of Scans Detected on microSD Card.......................................................................... 28

3-8. 3 Scans Transferred from microSD Card ............................................................................... 29

3-9. DLP NIRscan Nano GUI Uitlities Screen................................................................................ 30

4-1. DLP NIRscan Nano Power Block Diagram ............................................................................. 32

4-2. DLP NIRscan Nano Tiva Connections .................................................................................. 33

4-3. DLP NIRscan Nano Tiva Connections to DLPC150 Controller Board .............................................. 34

5-1. DLP NIRscan Nano Software Architecture ............................................................................. 35

5-2. DLP Spectrum Library View Configuration Information Workflow ................................................... 37

5-3. DLP Spectrum Library Decode Scan Results Workflow .............................................................. 38

5-4. DLP Spectrum Library Compute Reference Workflow ................................................................ 38

5-5. DLP Spectrum Library Compute and Display Reflectance Workflow ............................................... 38

5-6. DLP Spectrum Library Compute and Display Absorbance ........................................................... 39

5-7. DLP NIRscan Nano Software Block Diagram .......................................................................... 40

5-8. Bluetooth Low Energy Connection Workflow........................................................................... 40

5-9. GATT Calibration Service Workflow..................................................................................... 41

5-10. GATT Scan Configuration Service Workflow........................................................................... 42

5-11. GATT Scan Data Service Workflow ..................................................................................... 43

5-12. GATT Scan Data Service Workflow to Display an Existing Scan or Performing a New Scan................... 44

6-1. NanoScan Main Screen ................................................................................................... 45

6-2. NanoScan Scan Screen................................................................................................... 46

6-3. NanoScan Scan Plot Screen ............................................................................................. 47

H-1. USB HID Protocol .......................................................................................................... 62

4

List of Figures DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

1-1. DLP NIRscan Nano EVM Specifications................................................................................ 11

1-2. DLP NIRscan Nano Electronics.......................................................................................... 13

1-3. DLP NIRscan Nano Connectors.......................................................................................... 14

1-4. DLP NIRscan Nano LED Indicators...................................................................................... 17

3-1. Typical Scan Configuration Parameters................................................................................. 23

E-1. Tiva EEPROM .............................................................................................................. 54

F-1. Battery Power Connector (Tiva J6) ...................................................................................... 55

F-2. Battery Thermistor Connector (Tiva J7)................................................................................. 55

F-3. Expansion Connector (Tiva J3)........................................................................................... 56

F-4. ARM Cortex 10-pin JTAG Connector (Tiva J4) ........................................................................ 56

F-5. Trigger Connector (DLPC150 J500)..................................................................................... 57

G-1. DLP NIRscan Nano Supported Commands ............................................................................ 58

I-1. Device Information Service (DIS) ........................................................................................ 66

I-2. Battery Service (BAS) ..................................................................................................... 66

I-3. GATT General Information Service...................................................................................... 67

I-4. GATT Date and Time Service ............................................................................................ 68

I-5. GATT Calibration Information Service................................................................................... 68

I-6. GATT Scan Configuration Information Service......................................................................... 69

I-7. GATT Scan Data Information Service................................................................................... 69

List of Tables

DLPU030B–June 2015–Revised July 2015 List of Tables

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

5

Page 6

About This Guide

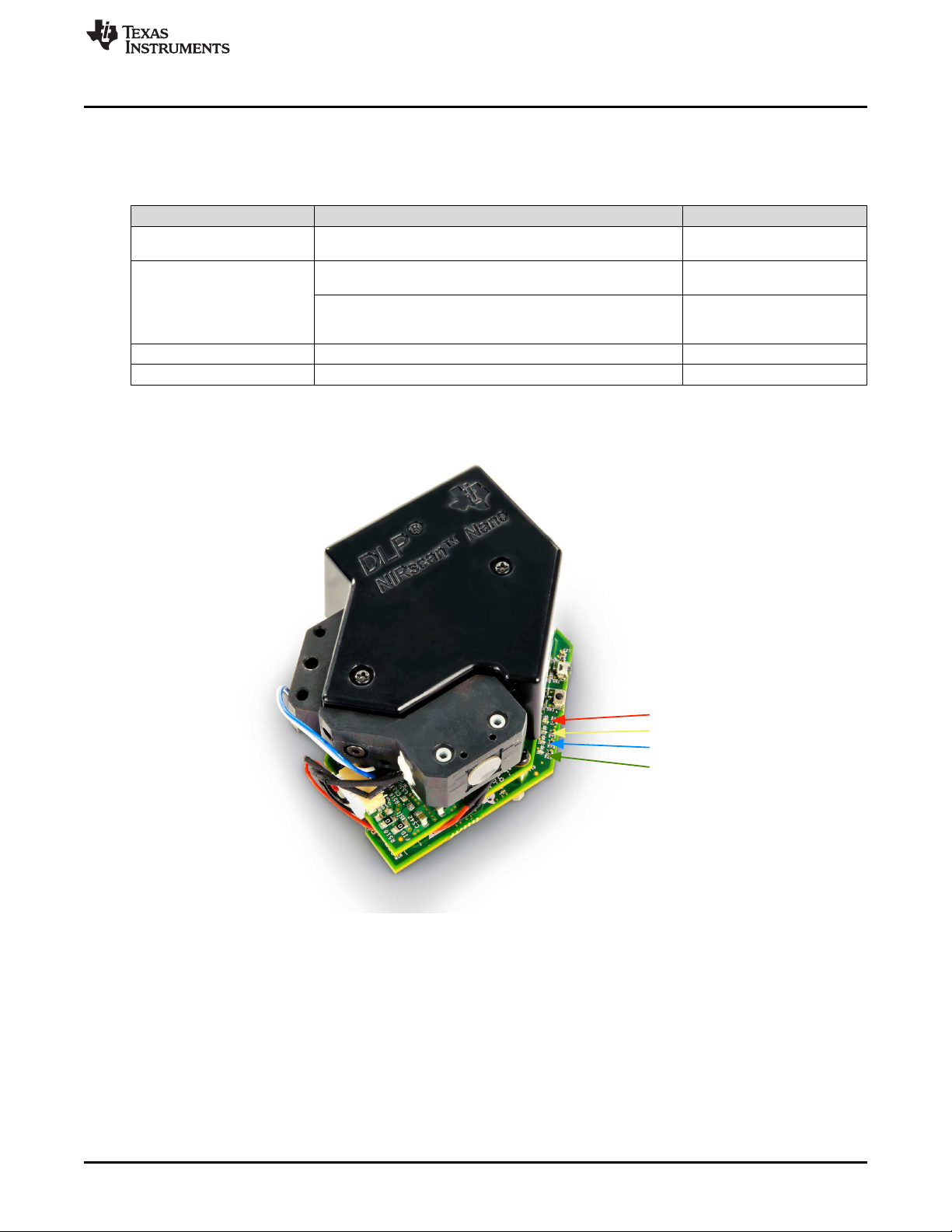

The DLP®NIRscan™ Nano EVM is a third-party implementation of the next generation DLP reference

design to enable faster development cycles for mobile spectrometer applications.

This guide is an introductory document for the DLP NIRscan Nano EVM that provides an overview of the

system and the system software.

Preface

DLPU030B–June 2015–Revised July 2015

Read This First

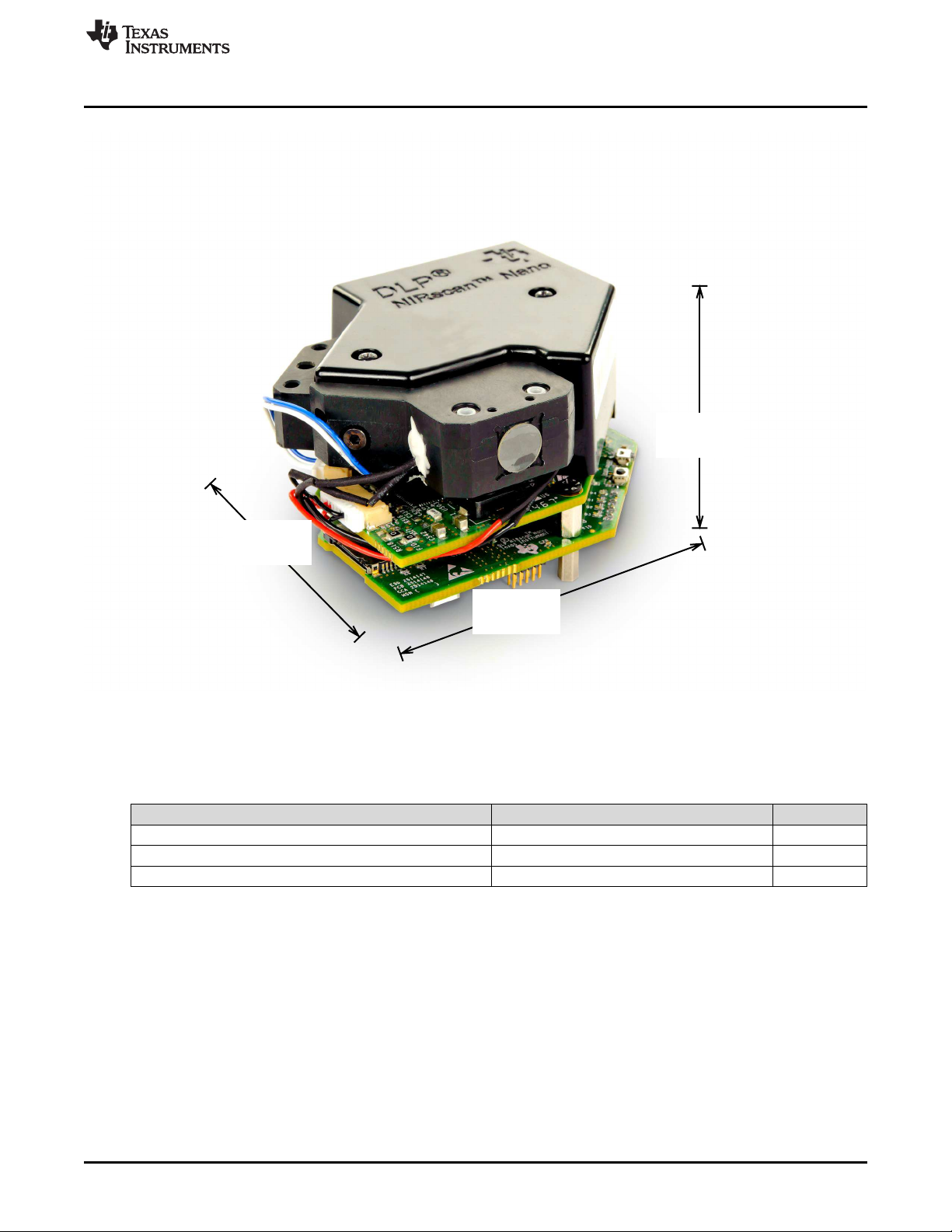

Figure 1. DLP NIRscan Nano Evaluation Module

NIRscan, Tiva, TivaWare, SimpleLink, Code Composer Studio are trademarks of Texas Instruments.

DLP is a registered trademark of Texas Instruments.

ARM is a registered trademark of ARM Limited.

Apple, iPhone, iPad are registered trademarks of Apple Inc.

Bluetooth is a registered trademark of Bluetooth SIG.

Windows is a registered trademark of Microsoft Corporation.

All other trademarks are the property of their respective owners.

6

Read This First DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

Related Documentation from TI

• DLP2010NIR data sheet: DLP 0.2 WVGA Near-Infrared DMD, DLPS059

• DLPC150 data sheet: DLPC150 DLP Digital Controller for Advanced Light Control, DLPS048

• DLPC150 programmer's guide: DLPC150 Programmer’s Guide User's Guide, DLPU031

• DLP design guide: DLP Spectrometer Design Considerations, DLPA049

• Tiva™ TM4C1297 data sheet: Tiva TM4C1297NCZAD Microcontroller Data Sheet SPMS435

• TivaWare™ USB library: TivaWare USB Library User's Guide, SPMU297

• TivaWare™ peripheral driver library: TivaWare Peripheral Driver Library User's Guide, SPMU298

• TI-RTOS 2.10: TI-RTOS 2.10 User's Guide, SPRUHD4

• CC2564MODN data sheet:CC2564MODN Bluetooth®Host Controller Interface Module, SWRS160

• ADS1255 data sheet:Very Low Noise, 24-Bit Analog-to-Digital Converter Data Sheet, SBAS288

If You Need Assistance

Search the DLP and MEMS TI E2E Community Support forums.

Search the TM4C Microcontrollers TI E2E Community Support forums.

Search the Bluetooth®CC256x TI E2E Community Support forums.

Search the SimpleLink™ Bluetooth®CC256x Wiki.

Related Documentation from TI

DLPU030B–June 2015–Revised July 2015 Read This First

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

7

Page 8

1.1 Introduction

The DLP® NIRscan Nano™ EVM is a complete evaluation module to design a high performance,

affordable near-infrared portable spectrometer. This flexible tool contains everything a designer needs to

start developing a DLP-based spectrometer right out of the box. DLP technology enables handheld

spectral analyzers for use in the food, pharmaceutical, oil and gas, medical, security, and other emerging

industries to deliver lab performance levels in the field. The EVM contains the DLP2010NIR digital

micromirror device, DLPC150 digital controller, and DLPA2005 integrated power management

components. This technology brings together a set of components providing an efficient and compelling

spectroscopy system solution for:

• Portable process analyzers

• Ultra-mobile spectrometer

The new DLP2010NIR DMD is optimized for operation at wavelengths between 700 and 2500 nm. The

DLP NIRscan Nano EVM is one possible implementation of this new DLP technology, operating from 900

to 1700 nm.

Chapter 1

DLPU030B–June 2015–Revised July 2015

DLP NIRscan Nano Overview

1.2 What is the DLP NIRscan Nano EVM?

The DLP NIRscan Nano EVM is a complete NIR spectrometer EVM using DLP technology. The EVM

package includes:

• Near-infrared optomechanical spectrometer engine optimized for 900 to 1700 nm wavelength range:

– Reflective illumination module with two integrated infrared lamps

– 1.69-mm × 0.25-mm input slit

– Collimating lenses

– 885-nm long wavepass filter

– Reflective diffraction grating

– Focusing lenses

– DLP2010NIR DMD (0.2-inch WVGA, 854 × 480 orthogonal pixel, NIR optimized)

– Collection optics

– 1-mm single-pixel InGaAs non-cooled detector

• Electronics subsystem with the electronics consisting of four boards:

– Microcontroller board

• Tiva TM4C1297 microprocessor for system control operating at 120 MHz

• 32MB SDRAM for pattern storage

• Power management with Lithium-polymer or Lithium-ion battery charging circuits using bq24250

• CC2564MODN Bluetooth Low Energy module for Bluetooth 4.0 connectivity

• USB micro connector for USB connectivity

• microSD card slot for external data storage

• HDC1000 humidity and temperature sensor

– DLP controller board

• DLPC150 DLP controller

• DLPA2005 integrated power management circuit for DMD and DLP controller supplies

8

DLP NIRscan Nano Overview DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

Microcontroller Board

DMD Board

DLP Controller Board

Detector Board

DLP Controller

DLPC150

Flash

DMD

DLP2010NIR

DMD Flex

24-bit ADC

ADS1255

SPI

Microprocessor

TM4C129

USB Slave

I2C2

Amplifier

OPA2376

InGaAs

Detector

24bit RGB

Power

Management

TPS63036

TPS81256

TPS82671

TPS386596

TPS22904

SSI2

I2C 24bit RGB

SSSI3

UART3

Bluetooth

CC2564MODN

SSI1

PMIC

DLPA2005

LVDS

SPI

SPI

Ctrl

Ctrl

Grating

Processor

Interface

RF/IF

Amplifier

Logic

Power

ADC/DAC

Clocks

Others

LEGEND

Battery

Charger

BQ24250

Sample

Reflective

Module

Li-Polymer

Battery*

*Battery Not Included

Amp

OPA350

2.5V Ref

REF5025

I2C6

Hum & Temp Sensor

HDC1000

SENS

IR Temp

TMP006

I2C7

EPI0

SDRAM

AS4C16M16S (32MB)

I2C9

SSI0

Exp

Conn

UART4

Triggers

GPIOs

LEDs Buttons

On/Off

Bluetooth

Scan

On/Off Scan/BT Pair

JTAG

ARM

10pin header

Lamp Driver

OPA567INA213TPS81256

T

*Thermistor Not Included

Thermistor

charging

USB Power

www.ti.com

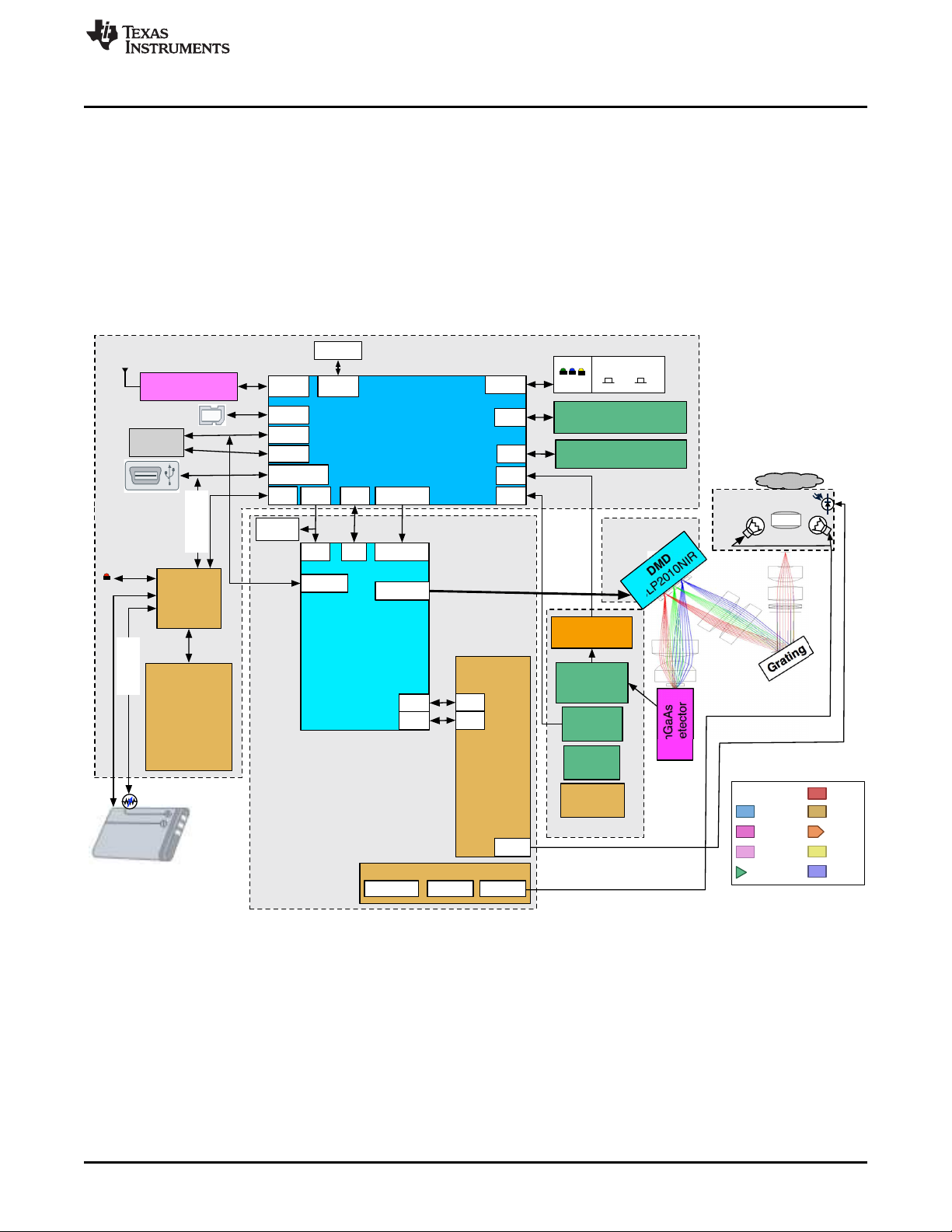

Figure 1-1 shows the NIRscan Nano hardware block diagram.

What is the DLP NIRscan Nano EVM?

• Constant current lamp driver based on OPA567 and monitored by INA213

– Detector board

• Low-noise differential amplifier circuit

• ADS1255 30 kSPS analog-to-digital converter (ADC) with SPI

• TMP006 thermopile sensor for detector and ambient temperature measurement

• 1-mm non-cooled Hamamatsu G12180-010A InGaAs photodiode

– DMD board

• DLP2010NIR near-infrared digital micromirror device

1.2.1 Optical Engine

DLPU030B–June 2015–Revised July 2015 DLP NIRscan Nano Overview

Submit Documentation Feedback

Figure 1-1. DLP NIRscan Nano Block Diagram

The DLP NIRscan Nano EVM spectrometer optical engine is mounted on top of the electronics

subsystem. The configuration is a post-dispersive architecture with a removable reflectance sample

module. The reflectance module includes two lens-end broadband tungsten filament lamps. In this specific

implementation, depicted in Figure 1-2, a sample is placed against the sapphire front window of the

reflectance head. During a scan, the sample absorbs a specific amount of NIR light and diffusely reflects

the non-absorbed light into the system. The amount of light absorbed at each wavelength is dependent on

the molecular makeup of the material, and is specific to that material, a chemical fingerprint. The light

diffusely reflected from the sample is gathered by the collection lens and focused into the optical engine

Copyright © 2015, Texas Instruments Incorporated

9

Page 10

Collimating

Lenses

Grating

Wavepass

Filter

Slit

Lamp

Lamp

DMD Board

Microcontroller Board

DLP Controller Board

Detector Board

Detector

Sample

Window

Focusing

Lenses

Collection

Lenses

Illumination

Module

What is the DLP NIRscan Nano EVM?

through the input slit. The slit size is chosen to balance wavelength resolution with SNR of the

spectrometer. This spectrometer uses a 25-μm wide by 1.69-mm tall slit. The light that passes through the

slit is collimated by the first set of lenses, passes through an 885-nm long wavepass filter, and then strikes

a reflective grating. This grating, in combination with the focusing lens, disperses the light into its

constituent wavelengths. The focusing lenses form an image of the slit at the DLP2010NIR DMD. Different

wavelengths of this slit image are spread horizontally across the DLP2010NIR DMD. The optical system

images 900-nm wavelengths to one end of the DMD and 1700-nm to the other end, with all other

wavelengths dispersed in between. When specific DMD columns are selected as on, or tilted to the +17°

position, the energy reflected by the selected columns is directed through the collection optics to the single

pixel InGaAs detector. All other DMD columns selected as off, or tilted to the –17° position, diverts the

unselected wavelengths away from the detector optical path so as not to interfere with the selected

wavelength measurement.

The DLP NIRscan Nano reflectance module operates by illuminating the sample under test at an angle so

that specular reflections are not collected, while gathering and focusing diffuse reflections to the slit. The

illuminating lamps are designated as lens-end lamps because the front end of the glass bulb is formed into

a lens that directs more light from the filament to the sample test region. The collection lens gathers

collimated light from a 2.5-mm diameter region at the sample window. The size of the collection region

was matched to the nominal illumination spot size created by the lens-end lamps. This requires that the

sample be placed directly against the sapphire window, where the two angled light source paths intersect

the collection vision cone of the lens. If the sample is shifted farther away from the window, the sample

may not receive enough illumination for the system to perform an accurate scan.

www.ti.com

The optical engine footprint drives the size of the DLP NIRscan Nano EVM. The NIRscan Nano EVM

measures approximately 62-mm long, 58-mm wide, and 36-mm tall as shown in Figure 1-3.

Figure 1-2. DLP NIRscan Nano Optical Engine

10

DLP NIRscan Nano Overview DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

58 mm

62 mm

36 mm

www.ti.com

What is the DLP NIRscan Nano EVM?

Figure 1-3. DLP NIRscan Nano Dimensions

Table 1-1 lists the specifications of the DLP NIRscan Nano EVM.

Table 1-1. DLP NIRscan Nano EVM Specifications

PARAMETER MIN TYP MAX UNIT

Supported wavelengths 900 1700 nm

Optical resolution 10 12 nm

Lamp power 1.4 W

DLPU030B–June 2015–Revised July 2015 DLP NIRscan Nano Overview

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

11

Page 12

What is the DLP NIRscan Nano EVM?

1.2.2 DLP NIRscan Nano Electronics

The DLP NIRscan Nano EVM contains the following four boards:

• Microcontroller board: The Microcontroller board is the largest board in the DLP NIRscan Nano EVM.

This board includes the following:

– Tiva TM4C1297 microcontroller: The Tiva processor controls the whole system. The Tiva runs the

TI realtime operating system (RTOS), the Bluetopia stack, and the spectroscopy software. When it

receives a scan command through USB, Bluetooth, or through pressing the scan button, the Tiva

streams through its LCD interface a set of unique wavelength specific patterns to the DLPC150 for

display on the DMD while synchronizing the sampling of the spectrometer's ADC. An external

32MB SDRAM allows for additional code storage and stores the pattern buffer streamed to the

DLPC150.

– External interfaces: The Microcontroller board provides two main interfaces to the outside world:

USB and Bluetooth Low Energy. To leverage the DLP NIRscan EVM platform for new product

development using the Tiva processor, the microcontroller board also contains a Tiva debug JTAG

port, which can be used with Code Composer Studio™ emulation software and XDS100, XDS200,

or XDS560 emulators. The Microcontroller board also includes and expansion connector with SPI,

UART, and GPIO capability for connection to external systems.

– Battery charging circuits: An optional 3.7-V Lithium-Ion or Lithium-Polymer can be added to power

the system. The on-board power management circuits of the bq24250 device take power from USB

and simultaneously charge the battery if its voltage is below 4.2 V at up to 1-A charge current. The

bq24250 also monitors an optional thermistor for battery temperature monitoring during charge.

– microSD card connector: The microSD card connector allows additional storage for scan data when

the system is not connected to a PC nor iOS device.

– HDC1000 humidity and temperature sensor: Measures the humidity and temperature of the system.

These values are captured with each scan.

• DLP controller board: The DLPC150 controller board is the second largest board in the DLP NIRscan

Nano EVM. This board includes the following:

– DLPC150 controller: The DLPC150 receives the pattern data from the Tiva TM4C1297 processor

over a 24-bit RGB bus. The DLPC150 decodes the pattern information and converts the information

into the correct format for the DLP2010NIR DMD. The DLPC150 controls and synchronizes all the

DMD signals, thereby directing each individual mirror to its desired state.

– DLPA2005 PMIC: The DLPA2005 is a power management IC that controls all the supplies to the

DLP2010NIR DMD and the DMD interface portion of the DLPC150 supplies.

– Lamp driver circuit: To provide constant current to the near-infrared lamps, a OPA567 based power

amplifier circuit regulates the current to the lamps to 280 mA at 5 V based on the voltage across a

sense resistor monitored by the INA213 current shunt monitor.

• Detector board: The detector board includes the following:

– Transimpedance low-noise amplifier: Amplifies the signal form the InGaAs detector to the ADC.

– ADS1255 ADC: Converts the amplified signal of the InGaAs detector into a 24-bit value for Tiva

processing.

– TMP006 thermopile sensor: Measures the InGaAs detector temperature and ambient temperature

of the system. These values are captured with each scan.

– 1-mm non-cooled Hamamatsu G12180-010A InGaAs photodiode

• DMD board: The DMD board includes the DLP near-infrared digital micromirror.

The DLP NIRscan Nano electronics contain many devices manufactured by Texas Instruments. Table 1-2

lists the main parts and their functions.

www.ti.com

12

DLP NIRscan Nano Overview DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

What is the DLP NIRscan Nano EVM?

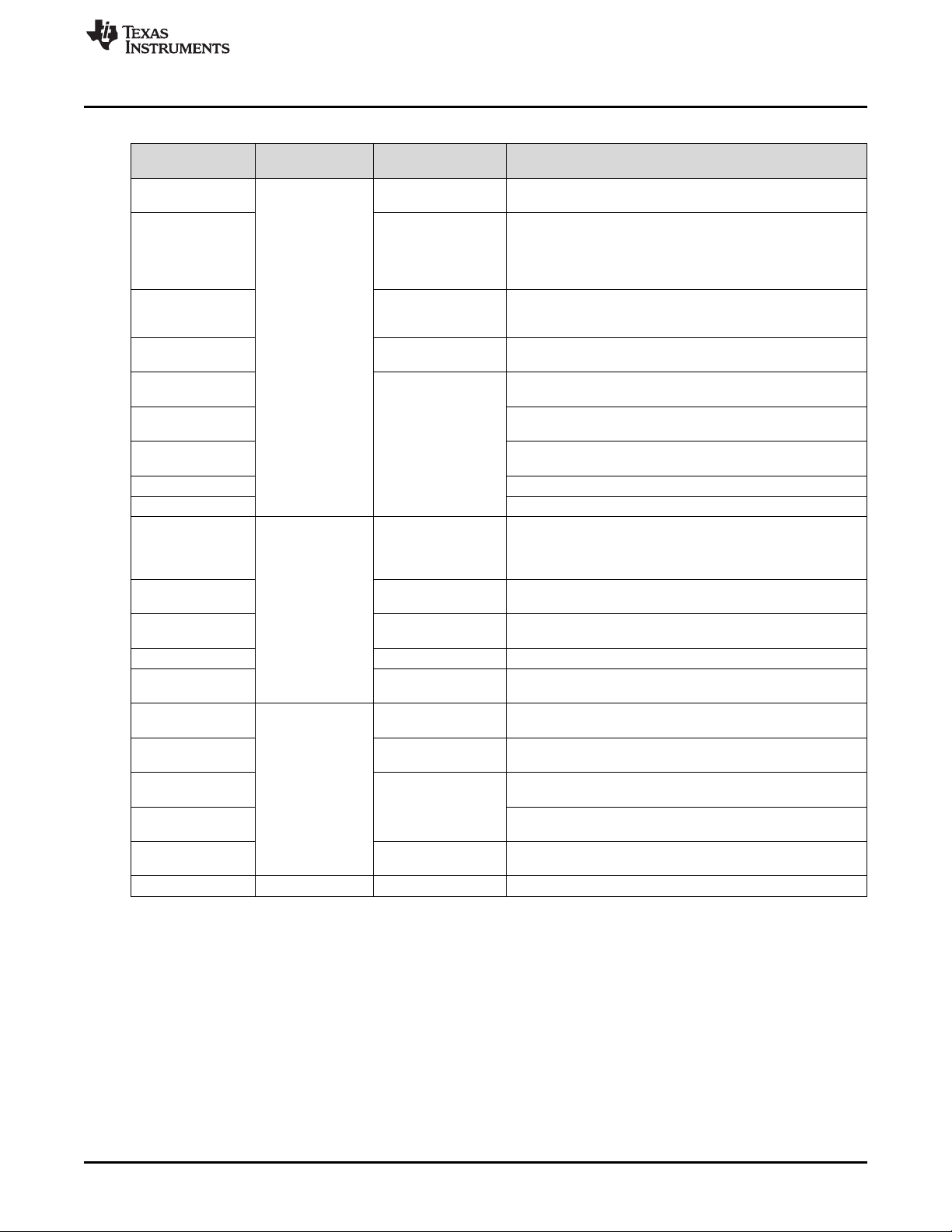

Table 1-2. DLP NIRscan Nano Electronics

Device Electronics Type Description

TM4C1297 Microprocessor

bq24250 Battery charger phases: trickle charge, precharge, constant current, and

CC2465MODN host controller

HDC1000 Sensor

TPS63036

TPS81256

TPS82671

TPS386596 Quad reset supervisor

TPS22904 Load switch supplies 1.8 V for Bluetooth circuits.

DLPC150 DLP

DLPA2005

TPS81256 Power management

OPA567 Power amplifier 2-A power amplifier that supplies 280-mA lamp current.

INA213 Analog monitor

ADS1255 Analog

REF5025 Power management

OPA2376 Detector board

OPA350

TMP006 Sensor

DLP2010NIR DMD board DLP DLP near-infrared digital micromirror

Electronic

Subsystem

Microcontroller

board

DLP controller

board

Cortex-M4 microprocessor operating at 120 MHz with

integrated 1MB flash, 256K SRAM, and USB 2.0 interface.

Single cell Lithium-Ion or Lithium-Polymer battery charger with

up to 1-A charge current from USB. Battery is charged in four

constant voltage. In all charge phases, an optional battery pack

thermistor monitors the battery temperature for safe charging.

Bluetooth Low Energy

interface module

Power management

DLP power DLP power management integrated circuit that powers the DLP

management 1.8-V, 10-V, 18-V, and –14-V supplies.

Precision amplifier

Single chip Bluetooth 4.1 Low Energy subsystem module with

on-board antenna.

Low power, high accuracy temperature and humidity sensor

with 14-bit resolution.

High-efficiency buck-boost converter in wafer chip scale

package supplies 3.3 V.

High-efficiency step-up converter in microSIP package supplies

5.0 V for analog circuits.

High-efficiency step-down converter in microSIP package

supplies 1.8 V.

DLP digital controller for advanced light control. The Tiva

microprocessor in conjunction with the DLPC150 controls

individual DLP2010NIR micromirrors to reflect specific

wavelengths of light to a single point InGaAs detector.

High efficiency step-up converter in microSIP package that

supplies the 5 V for the lamp driver

Voltage output, current-shunt monitor that monitors lamp

current.

Very-low-noise 24-bit analog-to-digital converter. Converts the

analog output of the InGaAs detector into a 24-bit digital value.

Low-noise, very-low-drift, precision voltage reference that

provides the 2.5-V reference for the transimpedance amplifier.

Low-noise precision operational amplifier. Used as a

transimpedance amplifier for the InGaAs detector.

High-speed operation amplifier that buffers the 2.5-V reference

voltage of the transimpedance amplifier.

Infrared thermopile sensor that measures ambient and detector

temperature

DLPU030B–June 2015–Revised July 2015 DLP NIRscan Nano Overview

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

13

Page 14

microSD

Battery

USB

Lamp

Battery

Thermistor

Lamp

Photodetector

Detector

What is the DLP NIRscan Nano EVM?

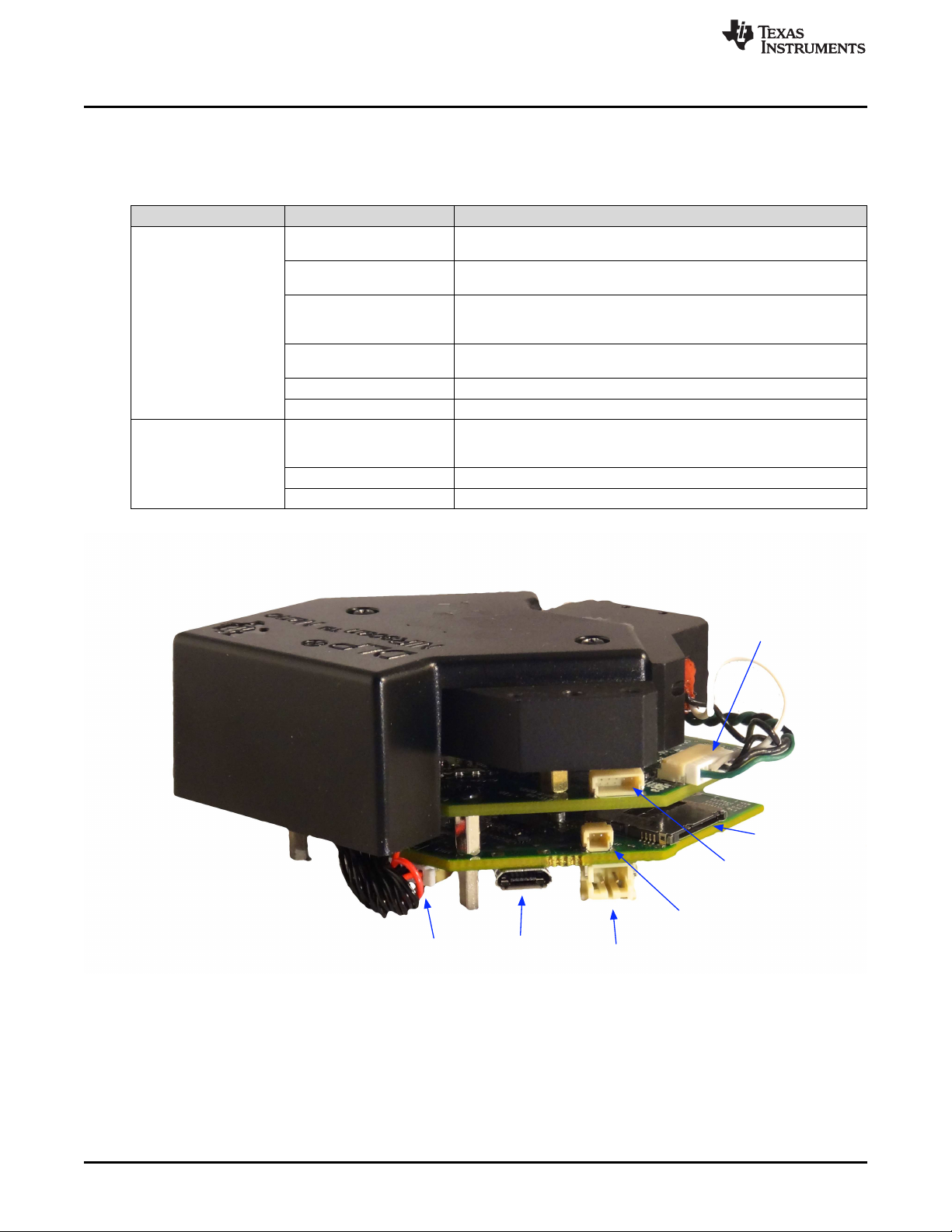

1.2.3 Connections

Table 1-3 lists the DLP NIRscan Nano connectors with its locations shown in Figure 1-4 and Figure 1-5.

BOARD SCHEMATIC LABEL DESCRIPTION

Microcontroller board

DLP controller board

www.ti.com

Table 1-3. DLP NIRscan Nano Connectors

J1

J2

J3 external device. UART4 is used as Tiva's console output for debugging

J4

J6 Lithium-Ion or Lithium-Polymer battery connection

J7 Battery thermistor connection

J500 this connector requires to removal of the Microcontroller and DLP

J501 Lamp photodetector connector

J503 Lamp power connector

Micro-USB connector: Provides power and PC connectivity with HID

commands

Detector board interface: Provides Tiva's SSI1 connection to ADS1255

and Tiva's I2C7 to TMP006

Expansion connector: Provides TIva's UART4 or SSI0 interface to

information

JTAG connector: ARM Cortex 10-pin emulation (XDS100, XDS200, or

XDS560) connection

Trigger connector. This connector is covered by the top cover. Access to

controller boards from the optical engine

14

Figure 1-4. DLP NIRscan Connectors (Rear View)

DLP NIRscan Nano Overview DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

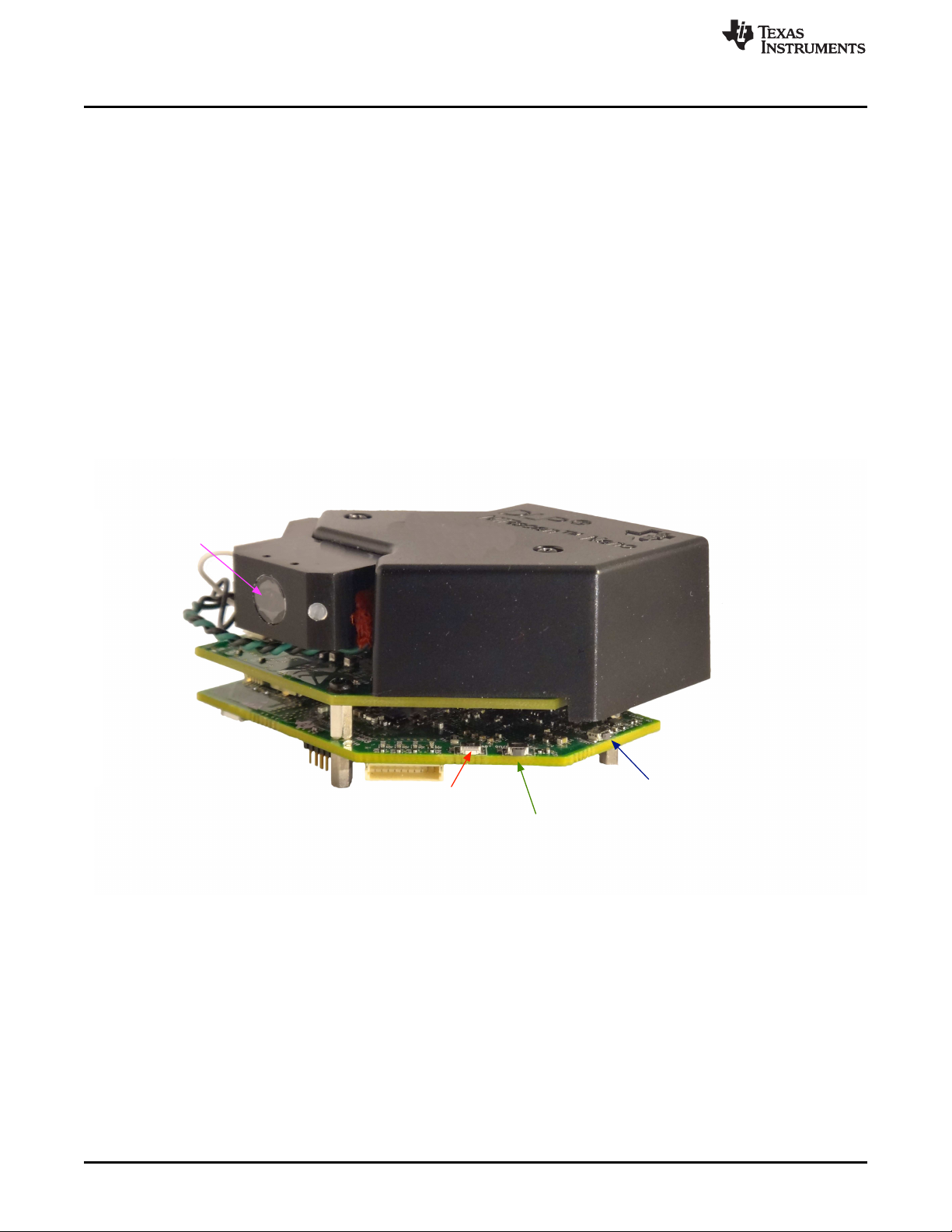

Expansion

JTAG

www.ti.com

What is the DLP NIRscan Nano EVM?

Figure 1-5. DLP NIRscan Connectors (Front View)

DLPU030B–June 2015–Revised July 2015 DLP NIRscan Nano Overview

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

15

Page 16

Reset Button

Wake Button

Scan / Bluetooth

Button

Sample

Window

What is the DLP NIRscan Nano EVM?

1.2.3.1 Buttons

The DLP NIRscan Nano EVM includes three buttons:

• Wake button:

– When the system is in standby, pressing the Wake button will wake the system from hibernation

mode.

– Upon wake up, the green LED will pulse on and off.

• Scan/Bluetooth button:

– When pressed and released, the system performs a scan. During a scan, the yellow LED is

illuminated and the lamps will turn on for the duration of the scan.

– When pressed, held for more than 3 seconds, and then released, the Bluetooth subsystem powers

up and advertises a connection. While a Bluetooth Low Energy connection is advertised, the blue

LED will turn on. When a Bluetooth Low Energy connection is active, the blue LED will pulse off

and on. The pulsing may coincide with the green LED or may pulse opposite to the green LED

pulses.

• Reset button:

– Pressing the Reset button will initiate a hardware reset of the NIRscan Nano system.

www.ti.com

16

Figure 1-6. DLP NIRscan Nano Button Locations

DLP NIRscan Nano Overview DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

Power On LED

Scan LED

Bluetooth LED

Battery Charging LED

www.ti.com

1.2.3.1.1 LEDs

The DLP NIRscan Nano EVM includes four LEDs to indicate activity as shown in Table 1-4.

What is the DLP NIRscan Nano EVM?

Table 1-4. DLP NIRscan Nano LED Indicators

LED CONDITION DESCRIPTION

Green Pulse on and off, once a second

ON

Blue

Pulse on and off, once a second connection has been

Yellow ON Scan is being performed

Red ON System is charging a battery

Indicates system is powered

and active

Bluetooth circuits are active

and advertizing

Bluetooth Low Energy

established

Figure 1-7. DLP NIRscan Nano LED Locations

DLPU030B–June 2015–Revised July 2015 DLP NIRscan Nano Overview

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

17

Page 18

2.1 Operating Modes

The DLP NIRscan Nano supports the following modes of operation:

• USB connection: A Windows®application with a graphical user interface (GUI), running on a PC with

the Windows 7 or 8 operating system, controls the system. Control includes scan initiation, parameter

settings, and data download. The PC GUI displays the intensity or absorbance of the scan. The PC

powers the NIRscan Nano through the USB cable.

• Bluetooth connection: An iOS app (available from KS Technologies through the Apple®App StoreSM)

running on an iPhone®or iPad®with iOS 7.1 or later operating system controls the system. Control

includes scan initiation, parameter settings, and downloading data. The iOS app displays the intensity

or absorbance of the scan. A USB cable or optional battery powers the NIRscan Nano.

• Standalone: The NIRscan Nano can be preconfigured through the PC GUI or Bluetooth iOS app.

Scans are invoked through the Scan button and data is stored on the on-board SDRAM or microSD

card. The stored scan data can be later downloaded to a host PC through USB or Bluetooth

connection.

Chapter 2

DLPU030B–June 2015–Revised July 2015

Getting Started

2.1.1 USB Connection

When a USB cable is inserted into the DLP NIRscan NanoJ1 micro-USB connector (see Figure 1-4), the

system powers up from the PC's USB VBUS 5-V supply, and the power-on LED pulses to indicate the

system is operational and ready for a command. The PC GUI will show as connected after the DLP

NIRscan Nano enumerates through USB.

2.1.1.1 NIRscan Nano GUI

The DLP NIRscan Nano software includes a QT-based PC GUI called NIRscanNanoGUI.exe. This GUI

requires the following dynamic link libraries (DLLs) to reside in the same directory as the executable file:

• hidapi.dll — USB human interface device (HID) class communication driver

• icudt53.dll — Qt Creator v5.3 Unicode library

• icuin53.dll — Qt Creator v5.3 Unicode library

• icuuc53.dll — Qt Creator v5.3 Unicode library

• libgcc_sdw2-1.dll — GCC library

• libstdc++6.dll — Standard C++ library

• libwinpthread-1.dll — Pthreads for Windows library

• Qt5Core.dll — Qt Core class library

• Qt5Gui.dll — Qt Graphical User Interface class library

• Qt5Svg.dll — Qt Scalable vector graphics class library

• Qt5Widgets.dll — Qt Widgets class library

• platforms/qwindows.dll — Platform plugin for Windows applications

• lmdfu.dll — Tiva USB device firmware upgrade

• lmusb.dll — Tiva USB driver

The Qt windeployqt executable will list all the DLLs necessary by a Qt application.

18

Getting Started DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

2.1.2 Bluetooth Connection

To connect to the DLP NIRscan Nano, the Bluetooth circuits must first be powered. The following steps

activate the Bluetooth circuits:

1. Press the Scan/Bluetooth button and hold it for more than 3 seconds to power the Bluetooth circuits.

2. After the Bluetooth circuits are powered and active, the blue LED turns on and the DLP NIRscan Nano

advertises its presence through Bluetooth.

3. Run the iOS App and click the Scan button at the top-right of the screen. This will establish a

connection with the DLP NIRscan Nano. The Bluetooth icon on the top-right of the screen will flash.

4. After the DLP NIRscan Nano establishes connection, the blue LED will pulse to indicate that the

connection was successful.

Operating Modes

DLPU030B–June 2015–Revised July 2015 Getting Started

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

19

Page 20

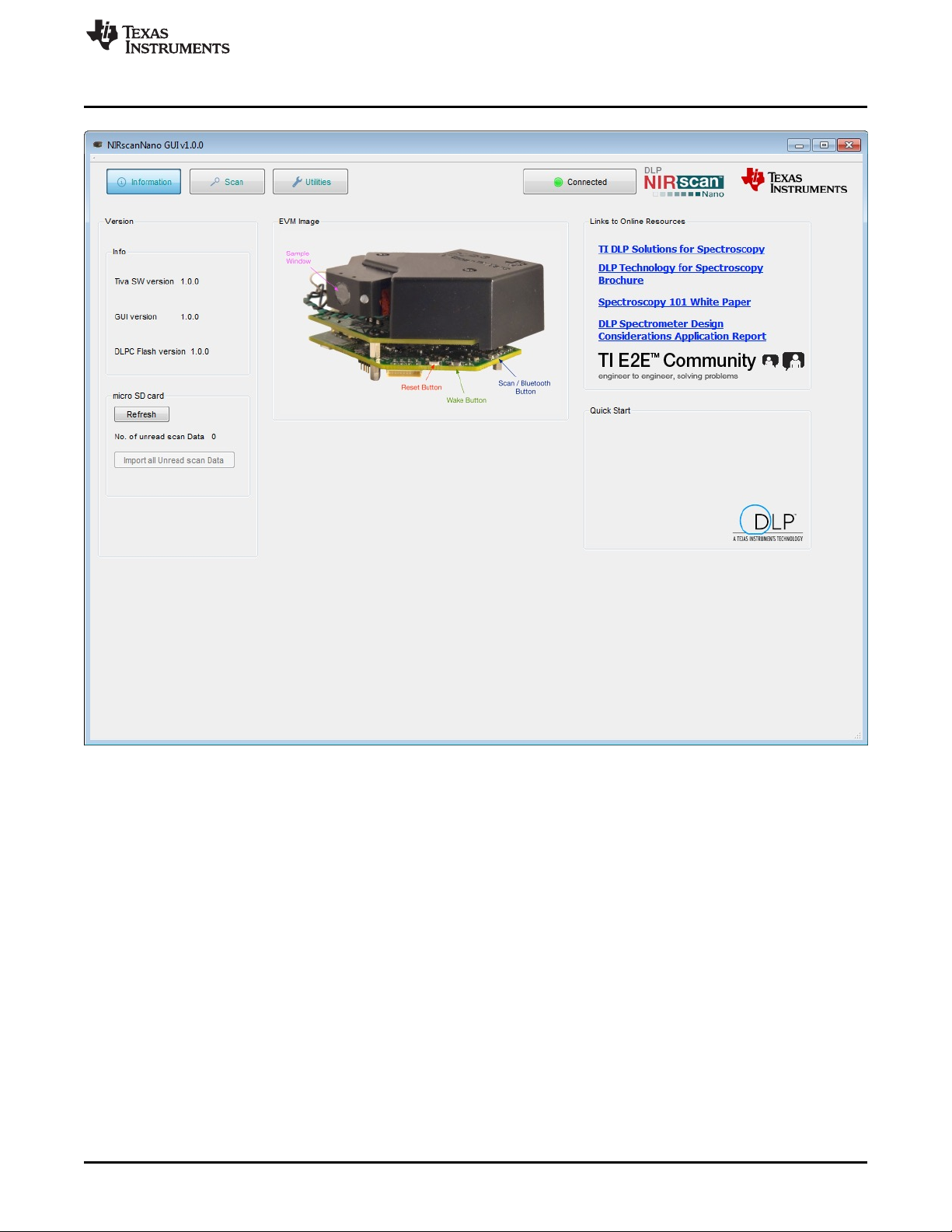

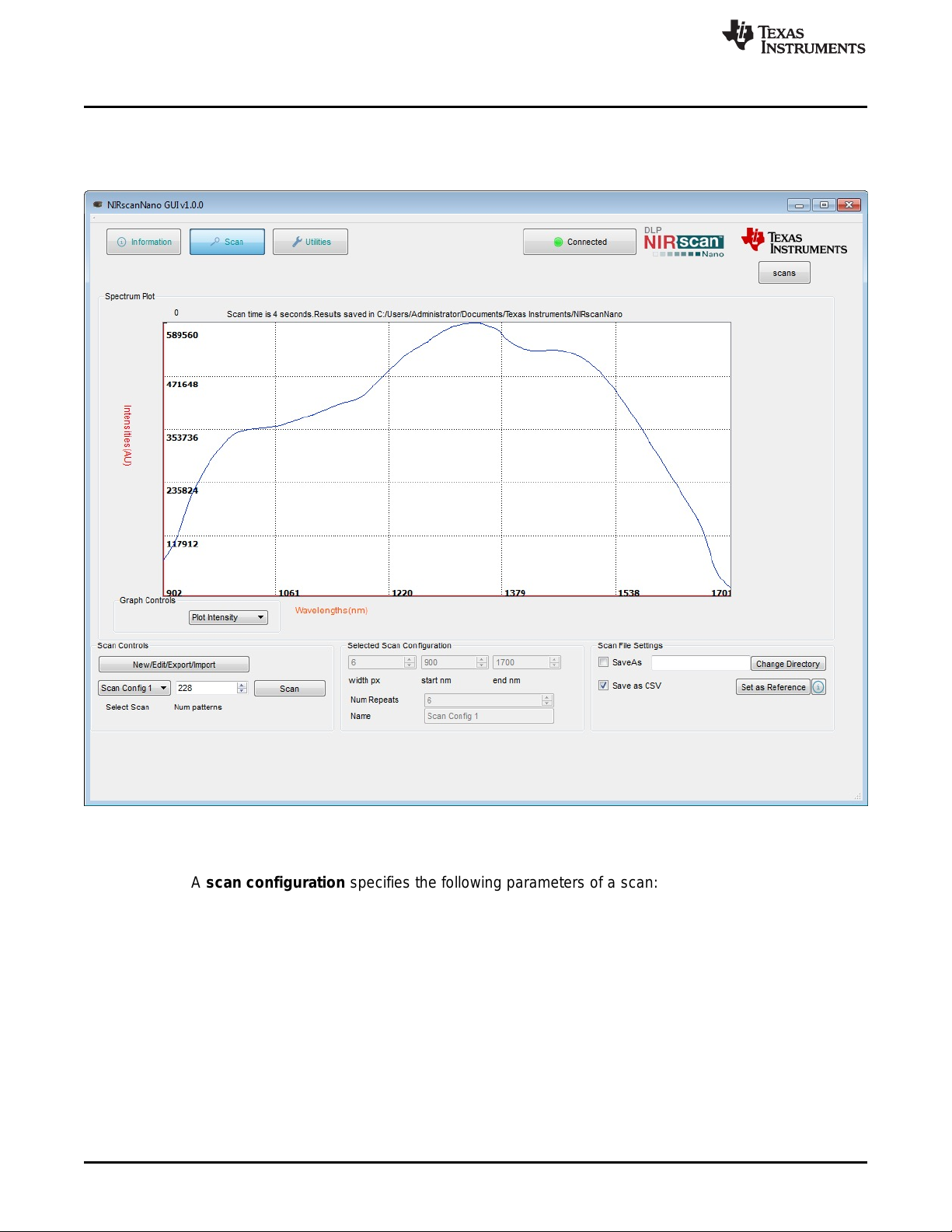

3.1 NIRscan Nano GUI

Upon execution of the NIRscanNanoGUI.exe, the software checks for the DLP NIRscan Nano EVM

enumerating through USB and displays the information screen shown in Figure 3-1. The GUI is divided

into two sections:

• The top section displays the connected state of the DLP NIRscan Nano EVM on the top-right side. It

also has four buttons:

– Information: Changes the bottom portion of the GUI to display version information, and links to

online resources.

– Scan: Changes the bottom portion of the GUI to display spectrum plots and controls for scan

configurations and parameters.

– Utilities: Changes the bottom portion of the GUI to display sensor information and to synchronize

data and time with PC, ADC PGA settings, and firmware upgrades.

– Connected Status Button: Once a DLP NIRscan Nano enumerates, the icon in the connected status

button will change from a gray indicator light with a "Not Connected" message to a green indicator

light with a "Connected" message. Pressing this button has no effect. Disconnecting the DLP

NIRscan Nano, powering down the device, or resetting the DLP NIRscan Nano will toggle the state

of this button.

• The lower section displays information related to the three main operational modes: information, scan,

and utilities.

Chapter 3

DLPU030B–June 2015–Revised July 2015

Operating the DLP NIRscan Nano EVM

20

Operating the DLP NIRscan Nano EVM DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

NIRscan Nano GUI

Figure 3-1. DLP NIRscanNano GUI Information Screen

The information screen displays:

• Version information, including the version number of the Tiva and DLPC150 firmware, as well as the

GUI software version number.

• EVM image, which displays the locations of the buttons and their functionality.

• Links to online resources, including Texas Instruments DLP brochures, white papers, and application

notes on spectroscopy with DLP technology. For support, users can search TI's E2E Community. The

TI E2E icon includes a link to direct users to the Texas Instruments DLP E2E forums.

• Presence of microSD card by clicking the Refresh button. Under this button, the "Import all Unread

scan Data" buttons transfer any scan data residing on the microSD card to the PC.

DLPU030B–June 2015–Revised July 2015 Operating the DLP NIRscan Nano EVM

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

21

Page 22

NIRscan Nano GUI

3.1.1 Scanning a Sample

The Scan button at the top of the NIRscan Nano GUI displays spectrum plots and controls scan

configurations and parameters, as shown in Figure 3-2.

www.ti.com

22

Figure 3-2. DLP NIRscanNano GUI Scan Screen

A scan configuration must be created to scan a sample. (See Figure 3-3 for the Scan Configuration dialog

screen.) A scan configuration specifies the following parameters of a scan:

• Wavelength range: Start and End wavelengths (in nm) or spectral range of interest for the scan. The

minimum wavelength is 900 nm and the maximum wavelength is 1700 nm.

• Width in nm: This number must be greater than 8 nm and corresponds to the desired smallest

wavelength content that you want to resolve in a scan. The DLP NIRscan Nano optical resolution is 10

nm, so values less than 10 nm result in lower signal intensity.

• Number of patterns: This number defines how many wavelength points are captured across the

defined spectral range. Depending on the previous setting, the GUI computes the maximum number of

patterns and indicates them as the "Max Limit."

• Number of scans to average: This is the repeated back-to-back scans that are averaged together.

Typical scan configuration parameters for four type of scans that resolve wavelength content in 20-, 15-,

10-, and 8-nm, are shown in Table 3-1.

Operating the DLP NIRscan Nano EVM DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

NIRscan Nano GUI

Table 3-1. Typical Scan Configuration Parameters

SCAN CONFIGURATION 20-nm 15-nm

PARAMETERS CONTENT CONTENT

Wavelength range 900 to 1700 nm 900 to 1700 nm 900 to 1700 nm 900 to 1700 nm 900 to 1700 nm

Width in nm 20 15 10 8 8

Number of patterns 80 108 160 225 248

Oversampling 2 2 2 2.25 2.48

Number of scans to average 18 12 8 to 9 6 5

10-nm CONTENT 8-nm CONTENT

The following steps create a scan configuration:

1. Click the "New/Edit/Export/Import" button in the Scan control box to invoke the Scan Configuration

dialog box.

2. The Scan Configuration dialog box shown in Figure 3-3 has three sections:

• The top-left section displays previous scan configurations saved to the PC.

• The top-right section displays the scan configurations saved on the DLP NIRscan Nano EVM.

• The bottom section displays the scan configuration parameters of the selected PC or DLP NIRscan

Nano EVM stored scan configuration.

3. Click the New button in the top-left section of the Scan Configuration dialog. Then, type the desired

spectral range between 900 and 1700 nm.

4. Select the width in nm that corresponds to the smallest wavelength content that you want to resolve.

5. Enter the desired number of wavelength points captured across the spectral range.

6. Enter the number of scans to average for corresponding back-to-back scans to average.

7. Enter a configuration name and click Save.

8. Close the Scan Configuration dialog by clicking OK.

DLPU030B–June 2015–Revised July 2015 Operating the DLP NIRscan Nano EVM

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

23

Page 24

NIRscan Nano GUI

www.ti.com

24

Figure 3-3. DLP NIRscanNano GUI Scan Configuration Dialog

Operating the DLP NIRscan Nano EVM DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

www.ti.com

After a scan configuration is defined, it appears under the Select Scan drop-down menu, as shown in

Figure 3-4.

NIRscan Nano GUI

Figure 3-4. DLP NIRscan Nano GUI Scan Select Menu

DLPU030B–June 2015–Revised July 2015 Operating the DLP NIRscan Nano EVM

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

25

Page 26

NIRscan Nano GUI

After a scan configuration is selected with the drop-down, define a reference by scanning a reflective

reference standard. Then, click the Set as Reference button. After these steps, scanning any sample will

allow the plot of absorbance as shown in Figure 3-5.

www.ti.com

26

Figure 3-5. Absorbance Spectrum of Aspirin

Operating the DLP NIRscan Nano EVM DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 27

www.ti.com

3.1.2 Displaying Previous Scans

To display previous scans, click the Scans button under the Texas Instruments logo. A sub-window will

pop up displaying the previous scans stored in the PC. The files are stored with the name of the scan

configuration appended with the date and time of the scan. To plot a file as shown in Figure 3-6, select

one of the files and click the Display Spectrum button. Click the Hide button to hide this subwindow.

NIRscan Nano GUI

Figure 3-6. Displaying Previous Scans

DLPU030B–June 2015–Revised July 2015 Operating the DLP NIRscan Nano EVM

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

27

Page 28

NIRscan Nano GUI

3.1.3 Transferring Scans Stored in microSD Card

Whenever scans are taken by pressing the Scan button on the microprocessor board, the scans are

stored on microSD card, if one is present. To transfer the stored scan on microSD:

• On the Information Tab, under microSD card, click the Refresh button.

• This will read all the scans stored on the microSD card, and will report the number of scans detected

after "No. of unread scan Data", as shown in Figure 3-7.

• On the Scan tab, click the Scans button in the upper-right corner to display the previous scans. Scans

transferred from the microSD card will be listed with filenames starting with "scan" followed by a four

digit number, as shown in Figure 3-8.

www.ti.com

28

Figure 3-7. Number of Scans Detected on microSD Card

Operating the DLP NIRscan Nano EVM DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 29

www.ti.com

NIRscan Nano GUI

Figure 3-8. 3 Scans Transferred from microSD Card

3.1.4 Utilities

The DLP NIRscanNano GUI includes a Utilities screen, as shown in Figure 3-9, that displays:

• Sensor data:

– Battery voltage, if a Lithium-Ion or Lithium polymer single cell battery is connected to J6 connector.

– Ambient temperature read by the TMP006 in the Detector Board.

– Detector temperature read by the TMP006 in the Detector Board.

– Ambient humidity read by the HDC1000 in the Microcontroller Board.

– HDC temperature read by the HDC1000 in the Microcontroller Board.

– Tiva internal temperature read by the Tiva internal sensor in the microcontroller board.

• Tiva's hibernation module date and time. Pressing the "Sync Data/Time" button will read the PC's date

and time and store it in the Tiva hibernation module's date and time registers.

• DLPC150 Firmware update tool.

– To update the DLPC150 firmware, click the Browse button to search for the DLPC150 firmware file

(for example, C:\ti\DLPR150PROM_1.0.0.img).

– Then, click the Update DLPC150 Firmware button. The firmware will be flashed to the board while

DLPU030B–June 2015–Revised July 2015 Operating the DLP NIRscan Nano EVM

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

29

Page 30

NIRscan Nano GUI

the progress bar indicates the update process.

• Tiva Firmware update tool.

– To update the Tiva firmware, click the Browse button to search for the Tiva firmware file (for

example, C:\ti\DLPNIRscanNanoSoftware_1.0.0\Binaries\NIRscanNano.bin).

– Then, click the Update TIVA Firmware button. The firmware will be flashed on the Tiva internal

Flash while the progress bar indicates the update process.

• Detector board's ADS1255 PGA setting.

www.ti.com

30

Figure 3-9. DLP NIRscan Nano GUI Uitlities Screen

Operating the DLP NIRscan Nano EVM DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 31

4.1 External Power Supply Requirements

The DLP NIRscan Nano is powered from either a battery or a USB cable. The power requirements are:

• USB Cable:

– Voltage: 4.75 to 5.25 V

– Current Maximum: 560 mA when operating and 1 A when charging

– Cable: 3 ft, USB A male to micro-USB B male (cable not included)

– Digi-Key Part Number: Q853-ND

– Manufacturer: Qualtek

– Part Number: 3025010-03

• Battery: (Not Included)

– Single-Cell Lithium-Polymer UL certified battery

• Voltage: 3.7 V

• Capacity: 1700 mA

• Manufacturer: Tenergy

• Part Number: 103450

Chapter 4

DLPU030B–June 2015–Revised July 2015

DLP NIRscan Nano Hardware

NOTE: Only connect Tenergy 103450 Lithium Polymer UL certified battery or equivalent UL certified

battery that meets: maximum charge current of 1A or more, maximum charging voltage of

4.23V or higher, battery over voltage protection at 4.305V or higher, and battery under

voltage lockout at 2.5V or less.

If a battery is connected to the NIRscan Nano, a thermistor is required to safely charge the battery and

monitor its temperature. The battery thermistor requirements are:

• Battery Thermistor: (Not Included)

– 10-kΩ NTC thermistor

• Manufacturer: Murata

• Part number: NXRT15XH103FA1B040

• Digi-Key part number: 490-7167-ND

Figure 4-1 shows a block diagram of the power circuits. The main power input is the external battery and

USB connector. The bq24250 includes a single-cell battery charger and a highly efficient DC-DC converter

to regulate the system voltage at 3.52 V. With an optional thermistor, the bq24250 monitors the

temperature of the battery during charging. Note that a thermistor is required to charge the battery. The

battery charger is set to supply up to a 1-A current during charging.

The rest of the devices regulate power to the subsystem as follows:

• The DLPA2005 in the DLP controller board regulates the power to the DLP2010NIR and DLPC150.

• The TPS82671 in the microcontroller board regulates the 1.8-V supply used by the Bluetooth

subsystem CC2564MODN. To conserve power, a TPS22904 load switch turns off the 1.8-V supply to

the Bluetooth subsystem when not in used.

• The TPS630636 in the microcontroller board supplies the main 3.3 V for the microprocessor and

interface inputs and outputs to DLPC150, CC2564MODN, and Tiva microprocessor.

DLPU030B–June 2015–Revised July 2015 DLP NIRscan Nano Hardware

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

31

Page 32

EN logic

DLPA2005

VCORE

LS_OUT

VRST

VINC

VINL

VINR

DLPC150

VDD (252.9 mA)

VDDLP12

VCC_FLSH (1.0 mA)

VDD_PLL

VCC18 (12.62 mA)

VCC_INTF (1.5 mA)

RESETZ

P1P1V

TPS82671

(600 mA)

VOUT1

VIN

PROJ_ON

DLP2010NIR

VDDI (9.4mA)

VOFFSET (1.7 mA)

VDD (34.7mA)

VRESET (2 mA)

VBIAS (0.4 mA)

18V

-14V

P1P8V_SW

VINM

VINA

VBIAS

LS_IN

VOFS

VDD_PLLM (6 mA)

VDD_PLLD (6 mA)

PARKZ

RESETZ

INTZ

10V

P1P8V

TM4C129

VDD (117 mA)

VDDC

VDDA

VBAT

TPS63036

(500 mA)

VOUT1VIN

EN

P3P3V

TPS81256

(400 mA)

VOUT1

VIN

EN

ADS1255

OPA2376

DVDD (2 mA)

AVDD (50 mA)

VCC (1 mA)

P5P0V

V-

REF5025

OPA350

VCC (8.5 mA)

VOUT1

VIN (1.2 mA)

V+

CC2564MODN

VDD_IO (1 mA)

VDD_IN (41.2 mA)

EN

BQ24250

BAT

IN

SYS

3.53 - 4.2V

VLED

SW4

LDO

TS

BAT

Conn

BAT +

TEMP

BAT -

STAT

VDPM

(4.36V)

ILM (1A)

150

ISET (1A)

249

1.5K

TPS386596

(Reset Sup)

RESETZ

RESETZ

VIN

SENSE1

SENSE2

SENSE4

MRZ

28.7K

10K

95.3K

10K

SENSE3

RESETZ

100K

2.5uF

Tiva

PJ7

EN = SYSPWR (~PROJ _ON + ~RESETz + INTz)

EN

logic

EN

logic

RESETz

INTz

SYSPWR

EN

PROJ_ON

TPS22904

VOUT1VIN

EN

Tiva

PB2

P1P8V_BT

Emergency Shutdown Logic to allow

sufficient time for DLPA2005

to issue a Fast Park

PROJ_ONTiva PJ7

LS

charging

274k

107k

TPS81256

VOUT1VIN

EN

PROJ_ON

PROJ_ON

LS

OPA567

VCC (300 mA)

V+

Tiva PD2

LS

EN

OUT

0.1

INA213

OUT

IN-

IN+

V-

V+

Power Management

Legend

DLP chipset

DLP

Analog

External Power Supply Requirements

• The TPS81256 in the microcontroller board regulates the 5-V supply of the analog-to-digital converter

(ADS1255), transimpedance amplifiers circuits (OPA350 and OPA2276), and 2.5-V reference voltage

(REF5025) used in the detector board.

• A second TPS81256 in the DLP controller board regulates the 5-V supply for the lamp driver (OPA567

and INA213). The lamp driver drives two parallel lamps at 5 V and 280 mA. Each lamp is rated to a

maximum 140 mA at 5 V.

• The TPS386596 serves as reset supervisor to hold the system in reset whiles all the supplies reach

operational conditions. An external reset button issues a reset when the system has reached

operational conditions.

For detailed connections of these devices, refer to the DLP NIRscan Nano schematics.

www.ti.com

32

Figure 4-2 shows the Tiva connections to the components on the microprocessor board and detector

board. The Tiva uses a 16-MHz external crystal as input to its on-board PLL to run the Tiva system at 120

MHz. A 32-kHz crystal supplies the clock to the Tiva's hibernation module and Bluetooth circuits. An

external 32MB of SDRAM stores the patterns that are streamed to the DLPC150 through the Tiva's LCD

interface. Tiva communicates to the HDC1000 and TMP006 sensors through its I2C6 and I2C7

peripherals. Both sensors generate a DRDY signal when a new value is available. This DRDY signals

interrupt Tiva when a new value is available through PP7 for HDC1000 and PP6 for TMP006. Tiva's

UART3 communicates with the CC2564MODN for Bluetooth transfers. The UART3 defaults to a 115200

baud transfer rate. Tiva's PH5 enables the Bluetooth circuits. Tiva interfaces to the microSD card through

DLP NIRscan Nano Hardware DLPU030B–June 2015–Revised July 2015

Figure 4-1. DLP NIRscan Nano Power Block Diagram

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 33

TM4C1297

OSC0

OSC1

32.768KHz

16MHz

PB1/USB0VBUS

PB0/USB0ID

PL6/USBDP

PL7/USB0DM

USB

PF3/SSI3CLK

PF1/SSI3XDAT0

PF0/SSI3XDAT1

PF2/SSI3FSS

PQ4 (I)

microSD

CC2564MODN

BT_ANT

HCI_CTS

HCI_RX

HCI_TX

HCI_RTS

LS

PP4/U3RTS

PJ1/U3TX

PJ0/U3RX

PP5/U3CTS

SLOW_CLK_IN

PP3/RTCCLK

LS

LS

PH5 (O)

nSUTD

CLK

DIN

DOUT

CS

CARD_DET

PB5/SSI1CLK

PE4/SSI1XDAT0 (TX)

PE5/SSI1XDAT1 (RX)

PB4/SSI1FSS

PH6 (O)

PP2 (I)

ADS1255

SCLK

DIN

DOUT

CSZ

SYNC

DRDY

USB0_VBUS

USB_ID

USB_DP

USB_DM

BQ24250

EN1

EN2

CEZ

PQ1 (O)

PQ0 (O)

PQ2 (O)

PA0/I2C9SCL

PA1/I2C9SDA

SCL

SDA

PB6/I2C6SCL

PB7/I2C6SDA

PP7 (I)

HDC1000

SCL

SDA

DRDY

PD0/I2C7SCL

PD1/I2C7SDA

PP6 (I)

TMP006

PQ5 (I)INT

SCL

SDA

DRDRY

AS4C16M16

PK5/EPI0S31

PN3/EPI0S30

PN2/EPI0S29

PB3/EPI0S28

PL3/EPI0S19

PL2/EPI0S18

PL1/EPI0S17

PL0/EPI0S16

PM0/EPI0S15

PM1/EPI0S14

PM2/EPI0S13

PM3/EPI0S12

PG0/EPI0S11

PG1/EPI0S10

PA7/EPI0S9

PA6/EPI0S8

PC4/EPI0S7

PC5/EPI0S6

PC6/EPI0S5

PC7/EPI0S4

PH3/EPI0S3

PH2/EPI0S2

PH1/EPI0S1

PH0/EPI0S0

CLK

CKE

CSz

WEz

RASz

CASz

DQMH

DQML

D15

BA1/D14

BA0/D13

A12/D12

A11/D11

A10/D10

A9/D9

A8/D8

A7/D7

A6/D6

A5/D5

A4/D4

A3/D3

A2/D2

A1/D1

A0/D0

Power

JTAG Header

PC0/TCK

PC1/TMS

PC2/TDI

PC3/TDO

RESETZ

PF5 (O)

PH7 (O)

PL4 (O)

WAKEz (I)

PQ3 (I)

10K

PD4/AIN7

PD5 (O)

Battery Monitor

BAT_V_SW

SENSE_EN

Bluetooth

Scan

Scan/BT

Wake

Reset

Expansion Header

PA2/SSI0CLK/U4RX

PA3/SSI0FSS/U4TX

PA4/SSI0DAT0

PA5/SSI0DAT1

PK2/U4RTS

PK3/U4CTS

Charging

STAT

www.ti.com

SSI3 in SPI mode. Tiva's SSI1 interfaces to the ADS1255. The ADS1255 also generates a DRDY signal

when conversion is completed interrupting the Tiva processor through PP2. Tiva generates a

synchronization signal to the ADS1255 through PH6 to start an ADC conversion when a pattern is

displayed by the DLP2010NIR. To monitor the battery charger bq24250, PQ5 serves as a Tiva interrupt

and commands are sent through I2C9. PQ0, PQ1, and PQ2 allow Tiva to override default bq24250

parameters. The Wake and Scan buttons are connected to Tiva's WAKE and PQ3 pins. To measure

battery voltage, TIva enables an analog MOSFET switch with PD5 to connect the battery to Tiva's ADC7

and perform a voltage measurement. An expansion headers supports a combination of Tiva SSI0 and

UART4 pins. PF5, PH7, PL4 controls the green, blue, and yellow LED, respectively.

External Power Supply Requirements

Figure 4-2. DLP NIRscan Nano Tiva Connections

DLPU030B–June 2015–Revised July 2015 DLP NIRscan Nano Hardware

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

33

Page 34

DLPC150

DATEN_CMD

PCLK

VSYNC_WE

HSYNC_CS

PDATA3

PDATA4

PDATA5

PDATA6

PDATA7

PDATA10

PDATA11

PDATA12

PDATA13

PDATA14

PDATA15

PDATA19

PDATA20

PDATA21

PDATA22

PDATA23

PDATA2

PDATA18

PDATA1

PDATA9

PDATA17

PDATA0

PDATA8

PDATA16

DLPA2005

SPI_CSZ

SPI_DIN

SPI_CLK

SPI_DOUT

RESETZ

SENS1

GPIO_3 (CS)

GPIO_2 (DOUT)

GPIO_1 (CLK)

GPIO_0 (DIN)

RESETZ

PARKZ

INTZ

0.2” TRP

VDDI

VOFFSET

VDD

VRESET

VBIAS

LS_OUT

VRST

VBIAS

VOFS

DMD Control

DMD Sub-LVDS

DMD Control

DMD Sub-LVDS

SPI0

SPI Flash

SPI_CLK

SPI_RX

SPI_TX

SPI_CS

TM4C1297

PJ6/LCDAC

PR0/LCDCP

PR1/LCDFP

PR2/LCDLP

PR4/LCDDATA00

PR5/LCDDATA01

PF7/LCDDATA02

PR3/LCDDATA03

PR6/LCDDATA04

PR7/LCDDATA05

PS4/LCDDATA06

PS5/LCDDATA07

PS6/LCDDATA08

PS7/LCDDATA09

PT0/LCDDATA10

PT1/LCDDATA11

PN7/LCDDATA12

PN6/LCDDATA13

PJ2/LCDDATA14

PJ3/LCDDATA15

PJ4/LCDDATA16

PJ5/LCDDATA17

PT2/LCDDATA18

PT3/LCDDATA19

PS0/LCDDATA20

PS1/LCDDATA21

PS2/LCDDATA22

PS3/LCDDATA23

PG7/SSI2CLK

PG5/SSI2XDAT0 (TX)

PG4/SSI2XDAT1 (RX)

PG6/SSI2FSS

SN74LVC2G125

SN74LVC1G125

PD2/I2C2SCL

PG3/I2C2SDA

IIC0_SCL

IIC0_SDA

LED_SEL

LED_SEL

PWM_IN

CMP_OUT

CMP_PWM

CMP_OUT

GPIO10/RC_CHARGE

PP0 (I)

PP1 (I)

PD3 (O)

TRIG_OUT_2

TRIG_OUT_!

TRIG_IN_1

Photodiode

LS

PJ7_O

PROJ_ON

LS

PLL_REFCLK

24MHz

SENS2

PROJ_ON

RESETZ

HOST_IRQ

PQ7 (I)

RESETZ

LS

PQ6 (I)

Logic

PE0 (O)

PE1 (O)

PD2/I2C8SCL

OPA567

EN

OUT

External Power Supply Requirements

Figure 4-3 shows the Tiva connections to the DLPC150 controller board. Tiva powers up the DLP

subsystem through PJ7. The TIva's LCD interface is connected to the DLPC150 Parallel Port interface.

Through this interface 24 patterns are transmitted per frame. DLPC150 sends two interrupts to the Tiva to

indicate when a pattern is exposed (TRIG_OUT_2) and when a new frame begins (TRIG_OUT_1). For

DLPC150 firmware updates, the Tiva con write to the DLPC150 serial flash through its SSI2 peripheral

when the DLP subsystem is powered down. Tiva's PD2 controls the lamp. A lamp photodiode is measured

by the DLPA2005 when a scan occurs. The value of the photodiode is transmitted to the DLPC150 and

then to the Tiva. This photodiode measures the lamp intensity.

www.ti.com

34

Submit Documentation Feedback

Figure 4-3. DLP NIRscan Nano Tiva Connections to DLPC150 Controller Board

DLP NIRscan Nano Hardware DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Page 35

Tiva TM4C1297

TI RTOS

TivaWare (Peripheral Library)

DLP Spectrum Library

Command Handler

USB

Driver

Scan Handler

GAP GATT

Attribute Protocol

L2CAP

HCI

HID

Protocol

FAT File

System

SDSPI

Driver

Main Application

Link Controller

RF

HCI

CC2564MODN

Bluetopia Stack

TMP006

Handler

HDC1000

Handler

5.1 Overview

The DLP NIRscan Nano's Tiva microprocessor is the system's main control processor. The Tiva handles

button presses, commands and data transfers over USB or Bluetooth, controls the DLP subsystem,

streams the patterns to select specific wavelengths, captures data from InGaAs detector, activates lamps,

and stores data in the microSD card. Due to the realtime nature of the system, the Tiva software includes

TI-RTOS that coordinates tasks while handling realtime interrupts and semaphores. Low-level drivers for

Tiva's USB, GPIO, EPI, I2C, LCD, SPI, and UART peripherals are handled by TivaWare libraries and

routines. The Bluetopia Stack handles Bluetooth communications. DLP Spectrum Library handles pattern

generation and data transformation from raw scan data to a wavelength spectrum. A command handler

interprets commands from USB or Bluetooth and starts the tasks needed to execute the commands. The

main application initializes the system and waits for commands from USB and Bluetooth. The overall

software architecture depicting these components is shown in Figure 5-1.

Chapter 5

DLPU030B–June 2015–Revised July 2015

DLP NIRscan Nano Software

Figure 5-1. DLP NIRscan Nano Software Architecture

5.1.1 TI RTOS

TI RTOS is a scalable, real-time operating system that handles scheduling and synchronization of tasks,

interrupts, includes a limited set of drivers, and provides hardware abstraction layer to ease application

software development. The TI RTOS also includes the FAT file system (FATFs) module to store data in

the microSD card. The TI RTOS drivers used by DLP NIRscan Nano are:

• I2C: driver used for Tiva communication with DLPC150, TMP006, and HDC100.

• SDSPI: SPI driver for Tiva communication with SDcard.

• USBMSCHFatFS: driver for USB mass storage class.

DLPU030B–June 2015–Revised July 2015 DLP NIRscan Nano Software

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

35

Page 36

Overview

5.1.2 TivaWare

TivaWare is a set of drivers for accessing the Tiva peripherals. DLP NIRscan Nano uses the following

TivaWare drivers:

• UART: Driver for Tiva interface with CC2564MODN

• USB: Driver for HID transfers between Tiva and PC. The USB drivers handles Tiva's USB interrupts

• SPI: Driver for Tiva interface with ADS1255

• ADC: Driver to control Tiva ADC peripheral

• GPIO: Driver to control Tiva GPIO pins

• LCD: Driver to interface Tiva with DLPC150 parallel port

5.1.3 USB Driver

USB Communication to the DLP NIRscan Nano uses the HID class. Tiva enumerates as a slave USB 2.0

high power device. Appendix G lists the commands supported through USB.

5.1.4 SDSPI Driver

To store data on the microSD card, Tiva's SSI3 peripheral communicates with the microSD card using SPI

mode (SDSPI). Tiva stores data on the microSD card using the file allocation table (FAT) file system.

5.1.5 Bluetopia Stack

The DLP NIRscan Nano wirelessly communicates using Bluetooth Low Energy (BLE) version 4.0. The

Bluetooth communication is handled by the TI Bluetopia stack and the Cc2564MODN. The TI Bluetopia

stack and CC2564MODN implement a fully certified Bluetooth 4.0 specification. The BLE wireless

communication uses two main profiles for discovery and communication with a remote host:

• GAP: Generic Access Profile for basic discovery and establishing connections.

• GATT: Generic Attribute Profile for commands and data transfer.

The DLP NIRscan Nano supports Bluetooth version 4.0 specification. When Bluetooth subsystem is

activated, the DLP NIRscan Nano broadcasts its availability while a smartphone, tablet or PC acts as an

observer. Once connected, the DLP NIRscan Nano acts as a server for the GATT profile while the

smartphone, tablet, or PC acts as a client.

The DLP NIRscan Nano Bluetooth GATT Profile supports the following services:

• Battery Service (BAS) to provide battery charge capacity.

• Device Information Service (DIS) to provide manufacturer name, model number, serial number,

hardware revision, spectrum library revision, and Tiva software revision.

• GATT General Information Service to provide temperature, humidity, status, hours of use, lamp hours,

and battery recharge cycles.

• GATT Date and Time Service to synchronize date and time information between smartphone, tablet, or

PC to the Tiva's realtime clock.

• GATT Calibration Service to provide calibration coefficients.

• GATT Scan Configuration Service to provide stored configurations and scan configuration data.

• GATT Scan Data Service to initiate scan, clear scan data, and return stored scan data.

The Tiva processor handles these profiles and uses the logical link control and adaptation protocol

(L2CAP) to pass packets through a host controller interface (HCI). The Tiva's UART3 peripheral

communicates with the CC2564MODN HCI module. The CC2564MODN transmits these packets to the

client device.

www.ti.com

36

DLP NIRscan Nano Software DLPU030B–June 2015–Revised July 2015

Copyright © 2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 37

Configuration

dlpspec_scan_read_configuration() Cast to scanConfig struct

Access properties

directly

Configuration

Buffer Size

www.ti.com

5.1.6 DLP Spectrum Library

The DLP spectrum library is a collection of C-language routines that provide the fundamental pieces to

use a DLP system in a spectroscopy application. The DLP spectrum library is resolution and host

processor independent, allowing the routines to be used with different DMD resolutions and processor

systems. The routine sources are shared by the Tiva code, the GUI code, and the iOS App. The DLP

Spectrum Library are classified into three main categories:

• Scan: Performing a column or Hadamard scan by:

– Generating the appropriate full-frame DMD patterns based on a specific scan configuration.

– Computing reflectance and absorbance data form the intensity data during a scan.

– Handling serialization and deserialization of scan configuration and scan data.

• Calibration: Calibrating a system at the factory by:

– Finding peaks from a scan of a calibrated lamp.

– Finding the full width half maximum of specific peaks data of a calibration scan.

– Computing the calibration coefficients for a system.

• Utilities: Utilities to handle:

– Conversion between DMD mirror column position to a calibrated wavelength or wave number, and

vice versa.

– Spectrum data calculations, such as: absorbance, reflectance, and spectrum comparisons.

– Matrix operations.

– Binary pattern packing.

The DLP NIRscan Nano utilizes a previously-created scan configuration (through the GUI or stored on the

NIRscan Nano) to perform a scan. This scan configuration is created on the NIRscanNanoGUI and

transferred to the system in serialized fashion. The system's Tiva processor deserializes this data and

generates a set of full-frame DMD patterns based on the scan configuration and the factory-stored

calibration data. Then, the Tiva turns on the lamps and streams the full-frame DMD patterns to perform a

scan. Tiva collects several data points for each pattern from the detector's ADC conversion. This data is

stored in a structure, and is then serialized and transferred to the PC through USB or Bluetooth. The

NIRscanNanoGUI or the iOS App deserializes this scan data, interprets it using the DLP Spectrum

Library, and plots the resulting spectrum.

Overview

5.1.7 DLP Spectrum Library Workflow

The following sections show the use of the DLP Spectrum Library workflow to read scan configuration

information, decode scan data, and compute reference, absorbance, and reflectance.

5.1.7.1 Scan Configuration Workflow

The DLP Spectrum Library routine to interpret scan configuration information is

dlpspec_scan_read_configuration(). This routine takes as input the serialized scan configuration

transferred through USB or Bluetooth and deserializes to extract all the scan configuration information.

Figure 5-2 shows the typical workflow to view configuration information. The white input box denotes USB

scan configuration data, while the blue input box denotes Bluetooth scan configuration data.

Figure 5-2. DLP Spectrum Library View Configuration Information Workflow

DLPU030B–June 2015–Revised July 2015 DLP NIRscan Nano Software

Submit Documentation Feedback

Copyright © 2015, Texas Instruments Incorporated

37