Page 1

DLP®LightCrafter 4500™ Evaluation Module

User's Guide

Literature Number: DLPU011E

July 2013–Revised September 2015

Page 2

Contents

Preface ........................................................................................................................................ 6

1 DLP LightCrafter 4500 Module Overview................................................................................. 9

1.1 Welcome...................................................................................................................... 9

1.2 What is in the LightCrafter 4500 EVM?................................................................................... 9

1.2.1 Light Engine........................................................................................................ 10

1.2.2 Driver Board ....................................................................................................... 13

1.2.3 Embedded Processor Interface ................................................................................. 14

1.3 Other Items Needed for Operation....................................................................................... 14

1.4 DLP LightCrafter 4500 Connections..................................................................................... 15

1.5 DLP LightCrafter 4500 Jumpers.......................................................................................... 17

1.6 Dimensions.................................................................................................................. 19

2 Quick Start ........................................................................................................................ 22

2.1 Power-up the DLP LightCrafter 4500.................................................................................... 22

3 Operating the DLP LightCrafter 4500 .................................................................................... 24

3.1 DLP LightCrafter 4500 Software ......................................................................................... 24

3.2 PC Software................................................................................................................. 24

3.2.1 System Status ..................................................................................................... 25

3.2.2 Operating Mode ................................................................................................... 26

3.2.3 Image Orientation ................................................................................................. 27

3.2.4 LED Current Settings ............................................................................................. 28

3.2.5 Video Mode ........................................................................................................ 29

3.3 Pattern Sequence Mode .................................................................................................. 30

3.3.1 Sequence Settings ................................................................................................ 30

3.3.2 Sequence Settings [Variable Exposure]........................................................................ 35

3.3.3 Image Load Timing................................................................................................ 36

3.3.4 Trigger Controls ................................................................................................... 37

3.3.5 LED Delay Control ................................................................................................ 39

3.4 Firmware Upgrade ......................................................................................................... 40

3.5 Storing Images in Flash Memory......................................................................................... 41

3.6 Peripheral Control.......................................................................................................... 44

4 Pattern Sequences ............................................................................................................. 46

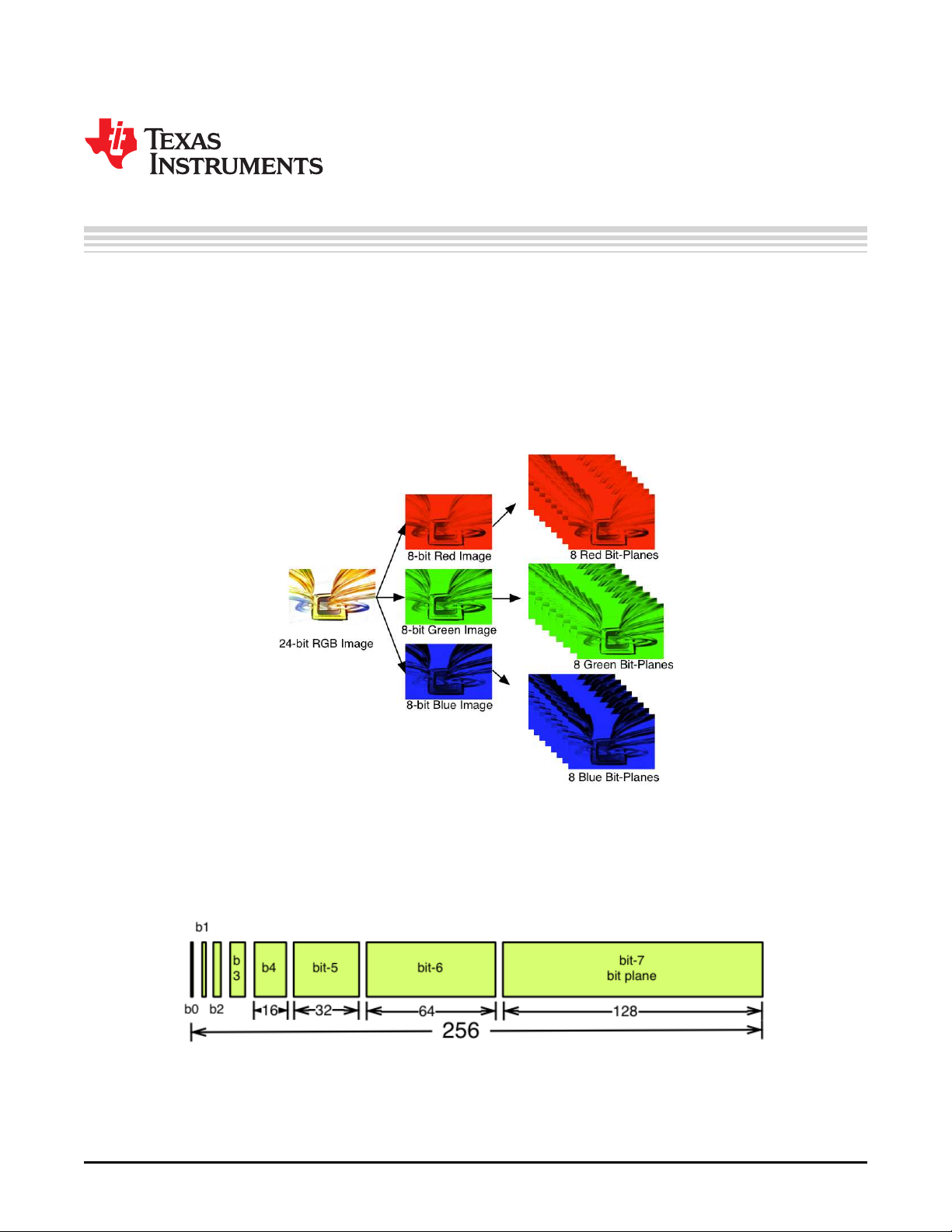

4.1 Pattern Sequence Background........................................................................................... 46

5 Saving Solutions ................................................................................................................ 51

5.1 Applying Solutions.......................................................................................................... 51

5.2 Changing Default Solutions ............................................................................................... 51

5.3 Modifying .ini Files ......................................................................................................... 51

5.3.1 Available Parameters ............................................................................................. 51

5.3.2 Save Solution Button ............................................................................................. 53

5.3.3 Manual Editing..................................................................................................... 54

5.3.4 LUT Entry Helper Tool............................................................................................ 54

6 PandaBoard Interface ......................................................................................................... 56

6.1 PandaBoard 4500.......................................................................................................... 56

6.1.1 DLP LightCrafter 4500 to PandaBoard Interface.............................................................. 57

6.1.2 PandaBoard Software ............................................................................................ 61

2

Contents DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

7 Connectors........................................................................................................................ 64

7.1 Input Trigger Connectors.................................................................................................. 64

7.2 Output Trigger Connectors................................................................................................ 64

7.3 DLPC350 UART............................................................................................................ 65

7.4 DLPC350 I2C0.............................................................................................................. 65

7.5 DLPC350 I2C1.............................................................................................................. 65

7.6 Fan ........................................................................................................................... 66

7.7 Red LED..................................................................................................................... 66

7.8 Green LED .................................................................................................................. 66

7.9 Blue LED .................................................................................................................... 67

7.10 FPD-Link..................................................................................................................... 67

7.11 JTAG Boundary Scan...................................................................................................... 68

7.12 Power ........................................................................................................................ 68

A Safety ............................................................................................................................... 70

B Power Supply Requirements................................................................................................ 72

B.1 External Power Supply Requirements................................................................................... 72

Revision E History....................................................................................................................... 74

DLPU011E–July 2013–Revised September 2015 Contents

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

3

Page 4

www.ti.com

List of Figures

1. DLP LightCrafter 4500 Evaluation Module (EVM) ...................................................................... 6

1-1. DLP LightCrafter 4500 Block Diagram .................................................................................. 10

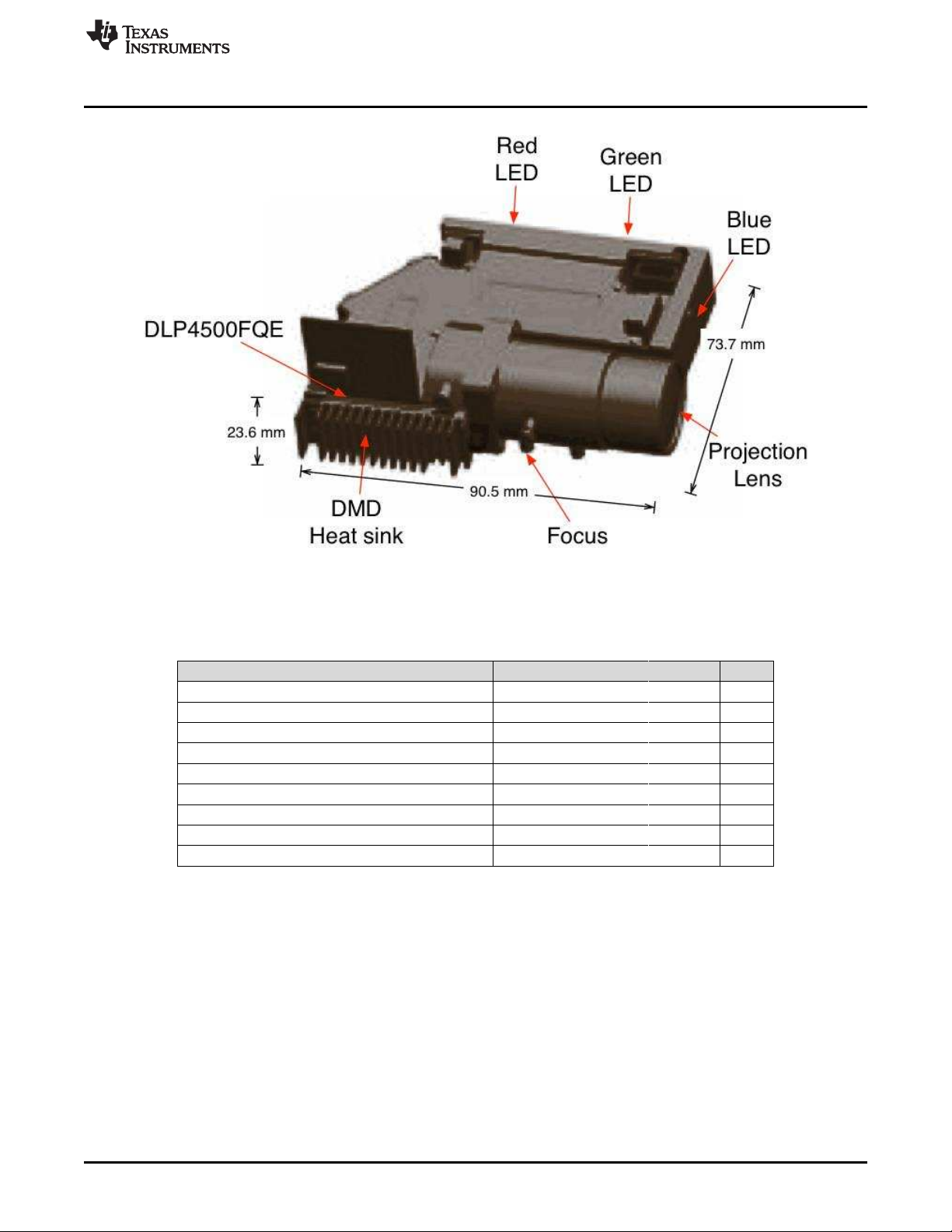

1-2. iView Light Engine ......................................................................................................... 11

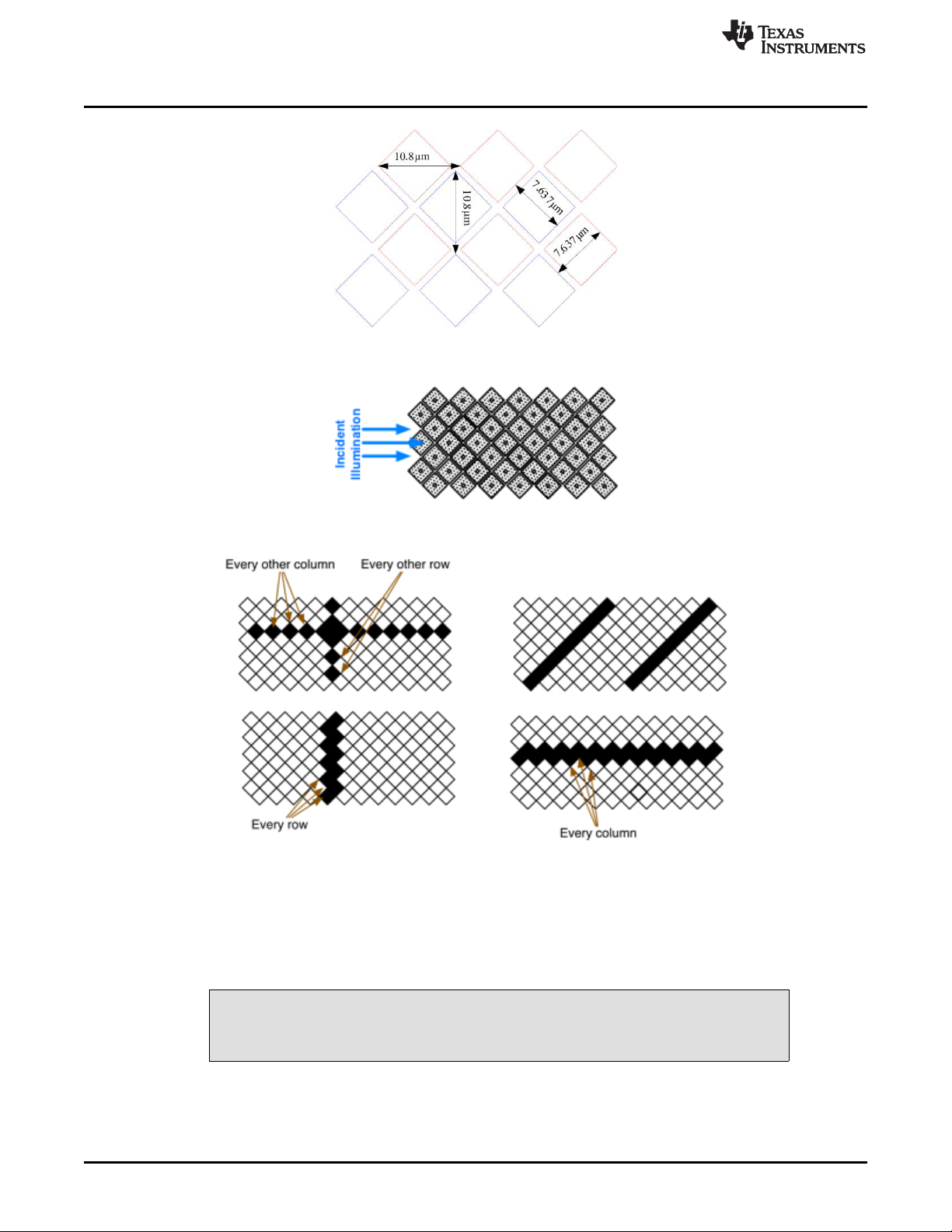

1-3. 0.45-Inch DMD Diamond Pixel Geometry............................................................................... 12

1-4. 0.45-Inch DMD Diamond Pixel Array Configuration ................................................................... 12

1-5. Diamond Pixel for Vertical, Horizontal, and Diagonal Lines.......................................................... 12

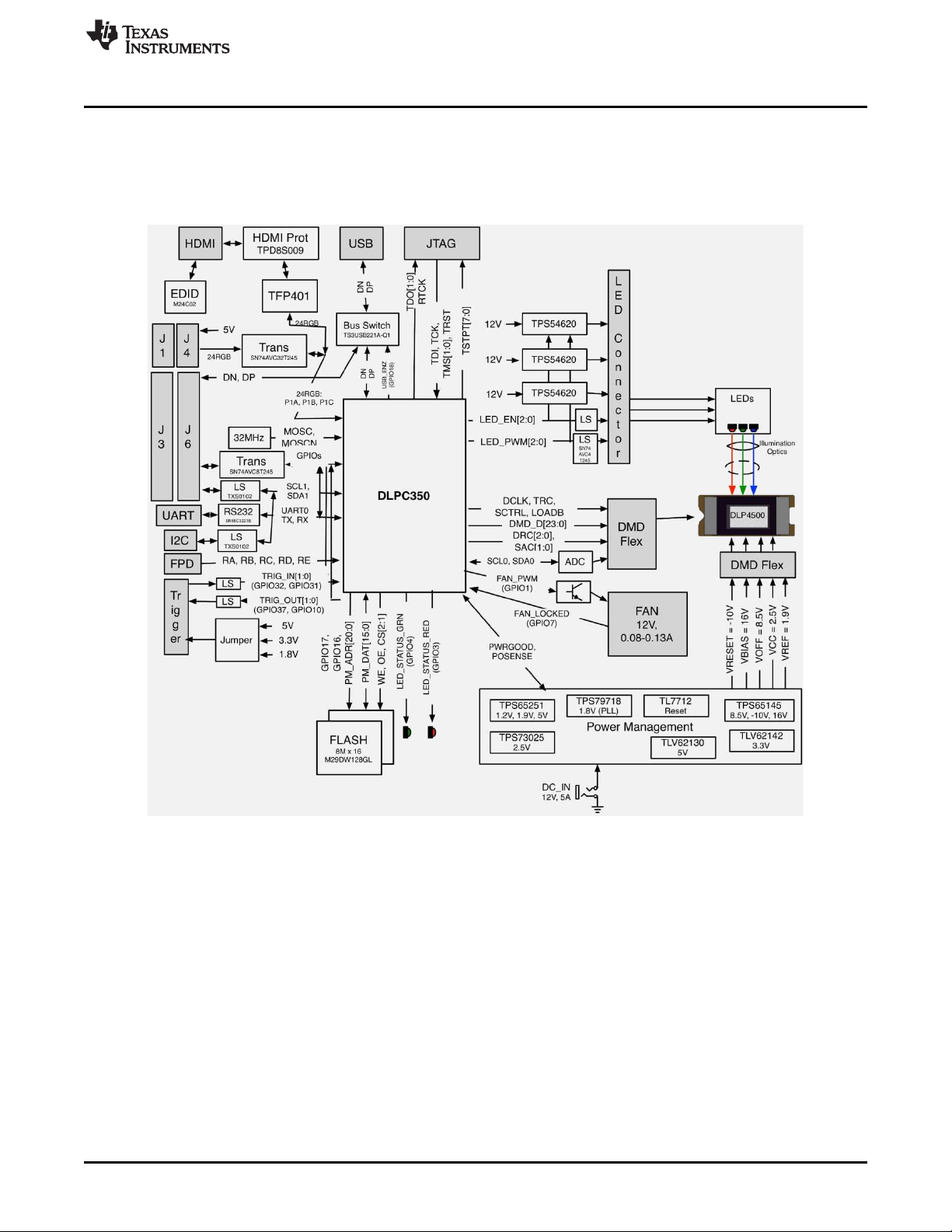

1-6. DLP LightCrafter 4500 Driver Board Block Diagram .................................................................. 13

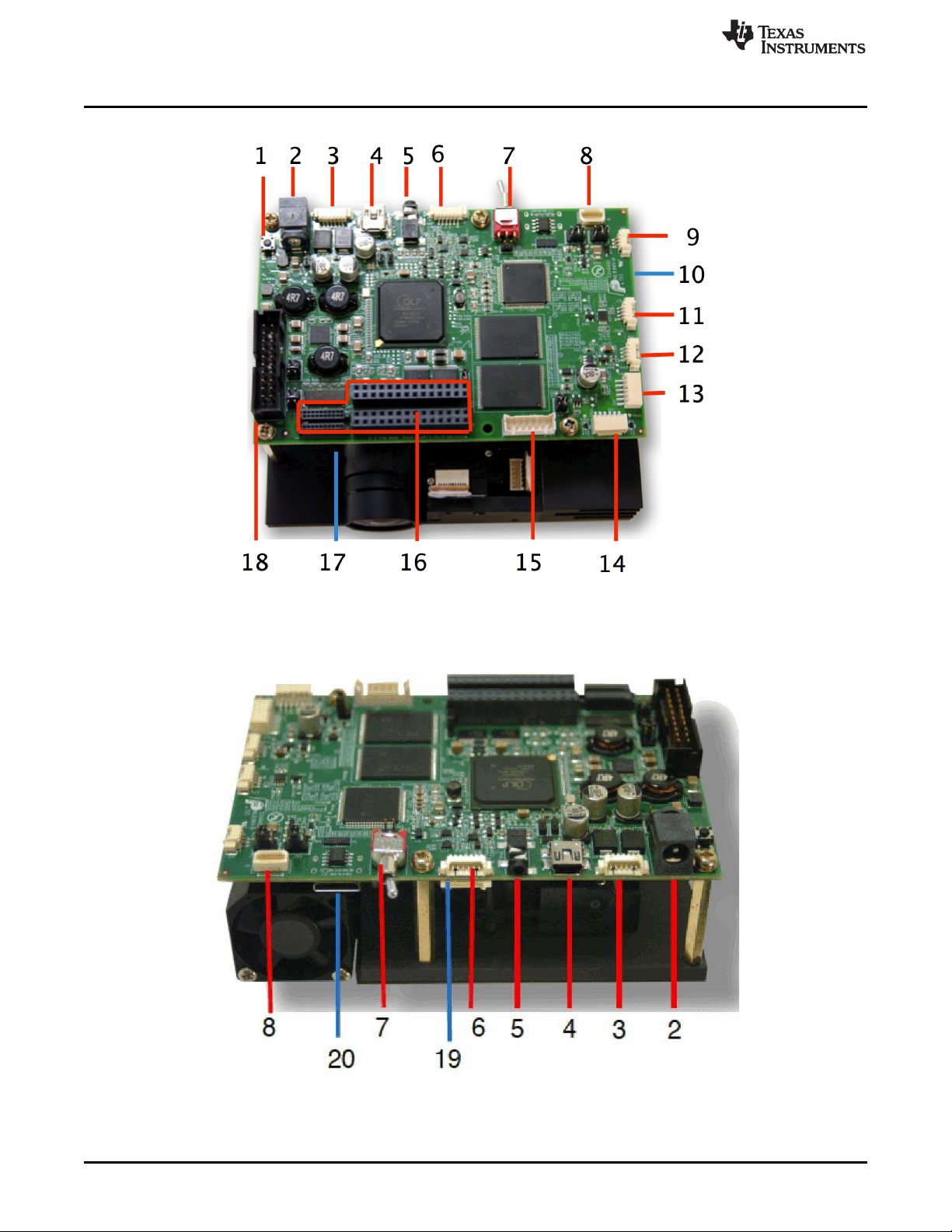

1-7. DLP LightCrafter 4500 Connectors (Top View) ........................................................................ 16

1-8. DLP LightCrafter 4500 Connectors (Back-Side View)................................................................. 16

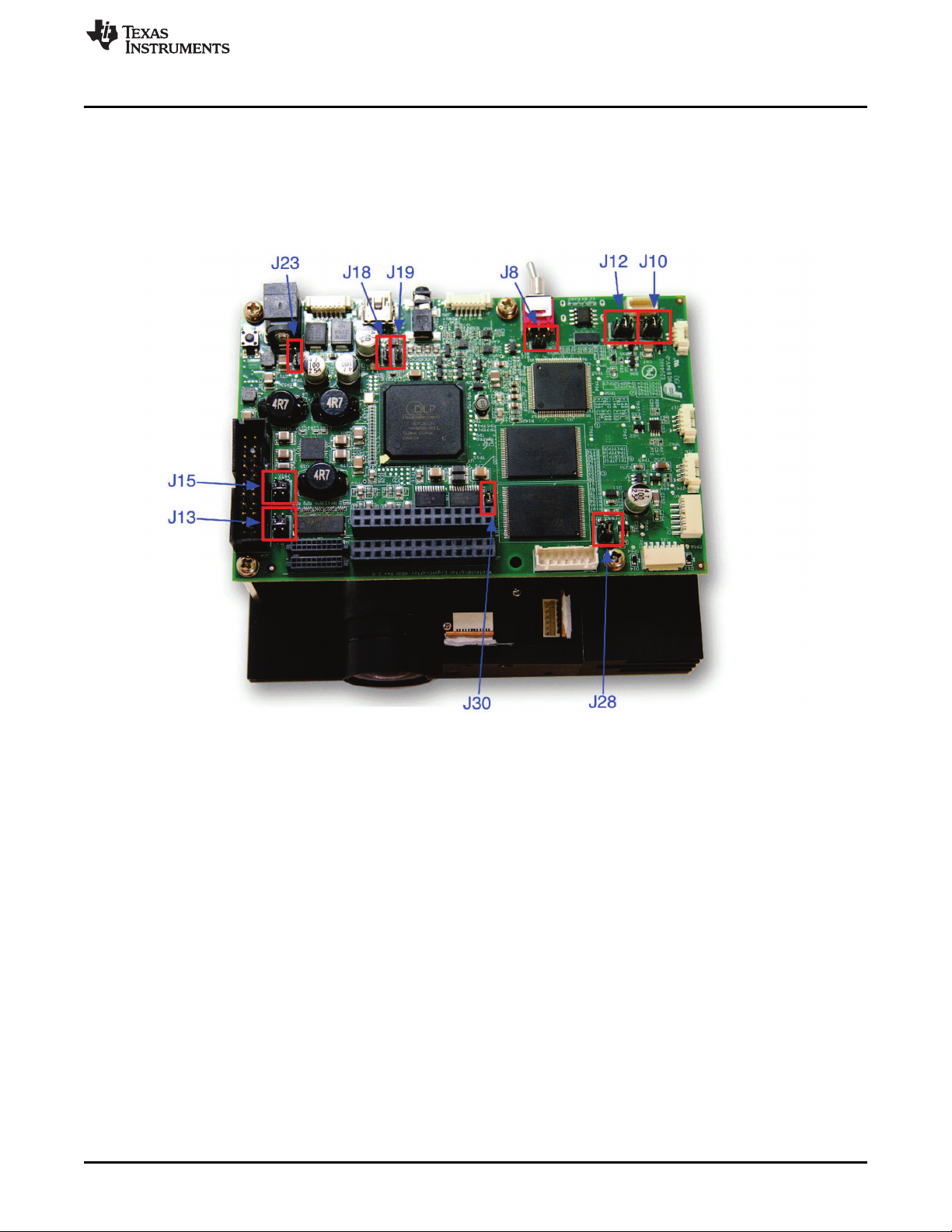

1-9. DLP LightCrafter 4500 Jumper Locations............................................................................... 17

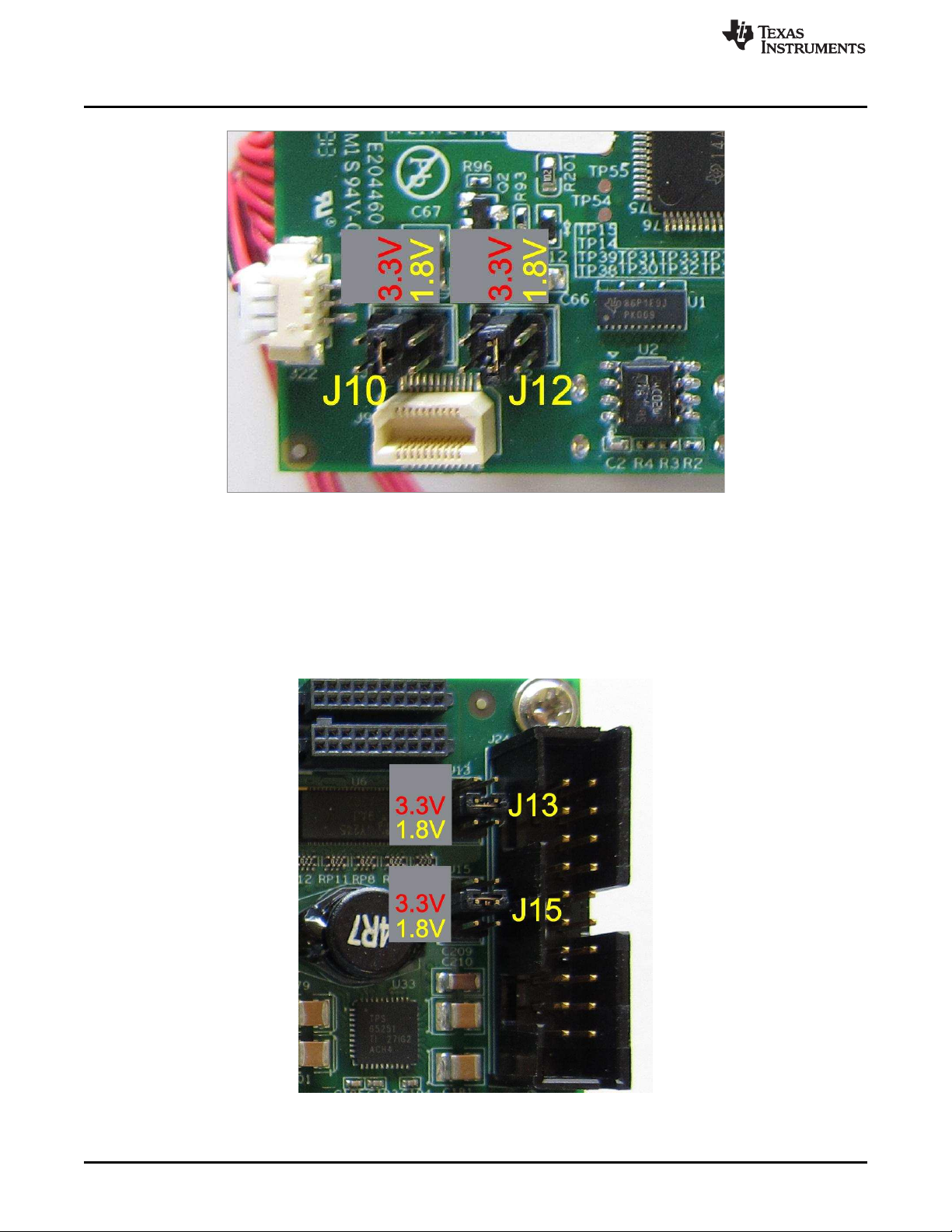

1-10. DLP LightCrafter 4500 J10 and J12 Voltage Jumpers ................................................................ 18

1-11. DLP LightCrafter 4500 J13 and J15 Voltage Jumpers ................................................................ 18

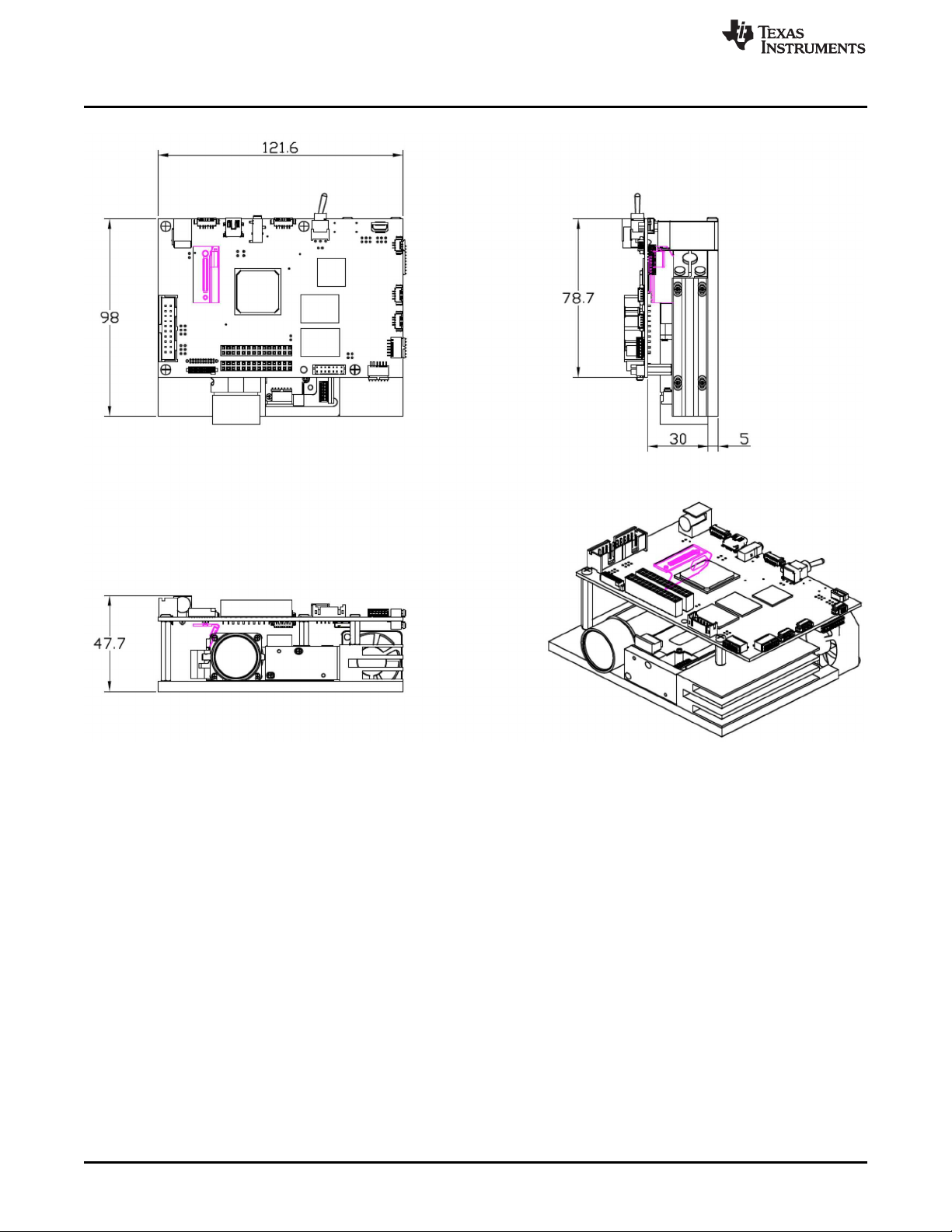

1-12. DLP LightCrafter 4500 Dimensions ...................................................................................... 20

3-1. DLP LightCrafter 4500 GUI – Video Mode.............................................................................. 25

2 Typical Red LED Current and Illuminance Based on PWM Values ................................................. 28

3 Typical Green LED Current and Illuminance Based on PWM Values............................................... 28

4 Typical Blue LED Current and Illuminance Based on PWM Values................................................. 28

3-5. DLP LightCrafter 4500 GUI – Pattern Sequence Mode .............................................................. 31

3-6. Pattern Sequence Mode: Start, Pause, Stop........................................................................... 34

3-7. Pattern Sequence Mode — Variable Exposure ........................................................................ 36

3-8. Image Load Timing......................................................................................................... 37

3-9. Trigger Control Subtab .................................................................................................... 38

3-10. VSYNC Pattern Trigger Mode ............................................................................................ 39

3-11. External Pattern Trigger Mode ........................................................................................... 39

3-12. LED Delay Control Subtab ................................................................................................ 40

3-13. Firmware Upgrade Tab.................................................................................................... 41

3-14. Create Images Tab......................................................................................................... 42

3-15. Firmware Builder ........................................................................................................... 43

3-16. Peripheral Control Tab..................................................................................................... 44

4-1. Relationship Between Bit-Planes and 24-bit RGB Images ........................................................... 46

4-2. Bit Partition.................................................................................................................. 46

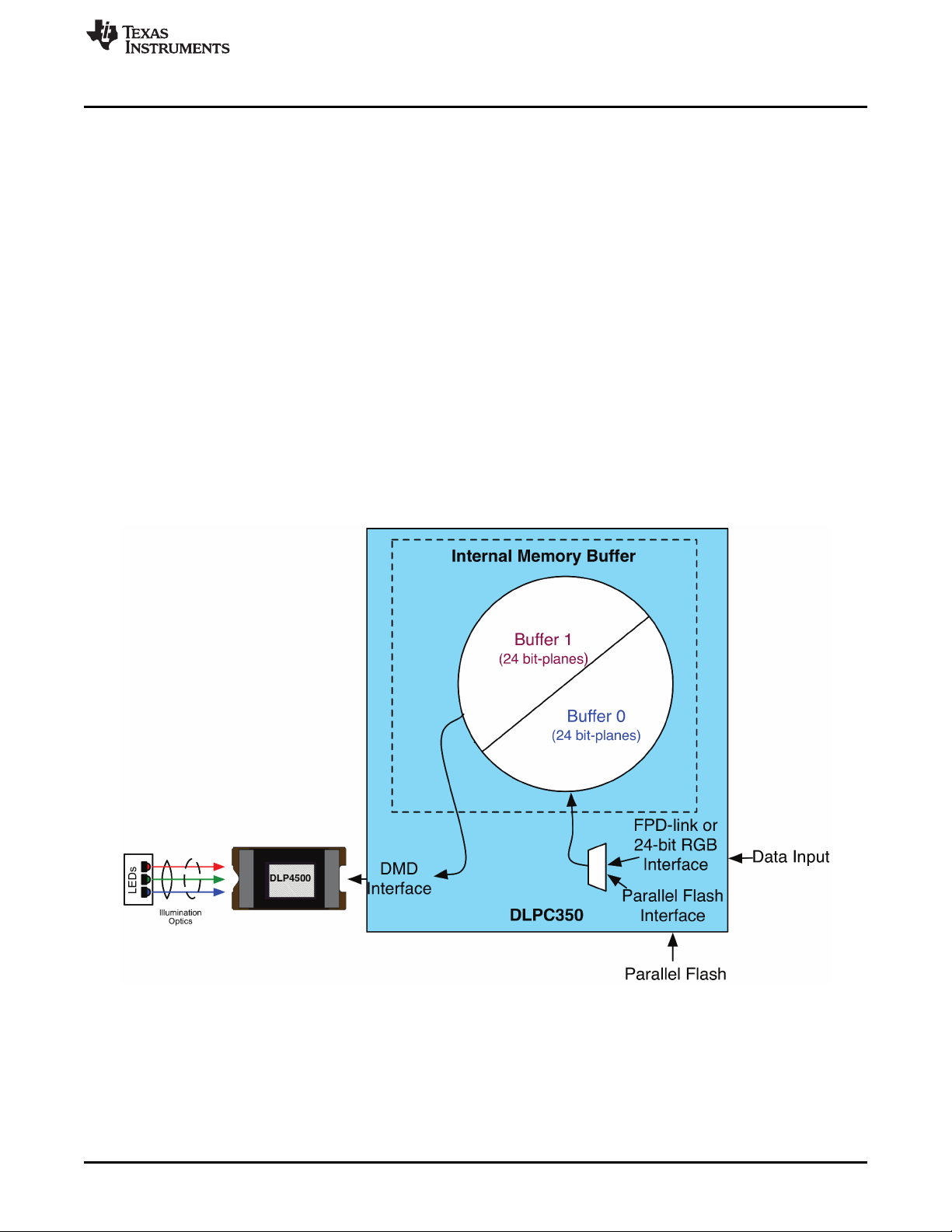

4-3. DLPC350 Internal Memory Buffer........................................................................................ 47

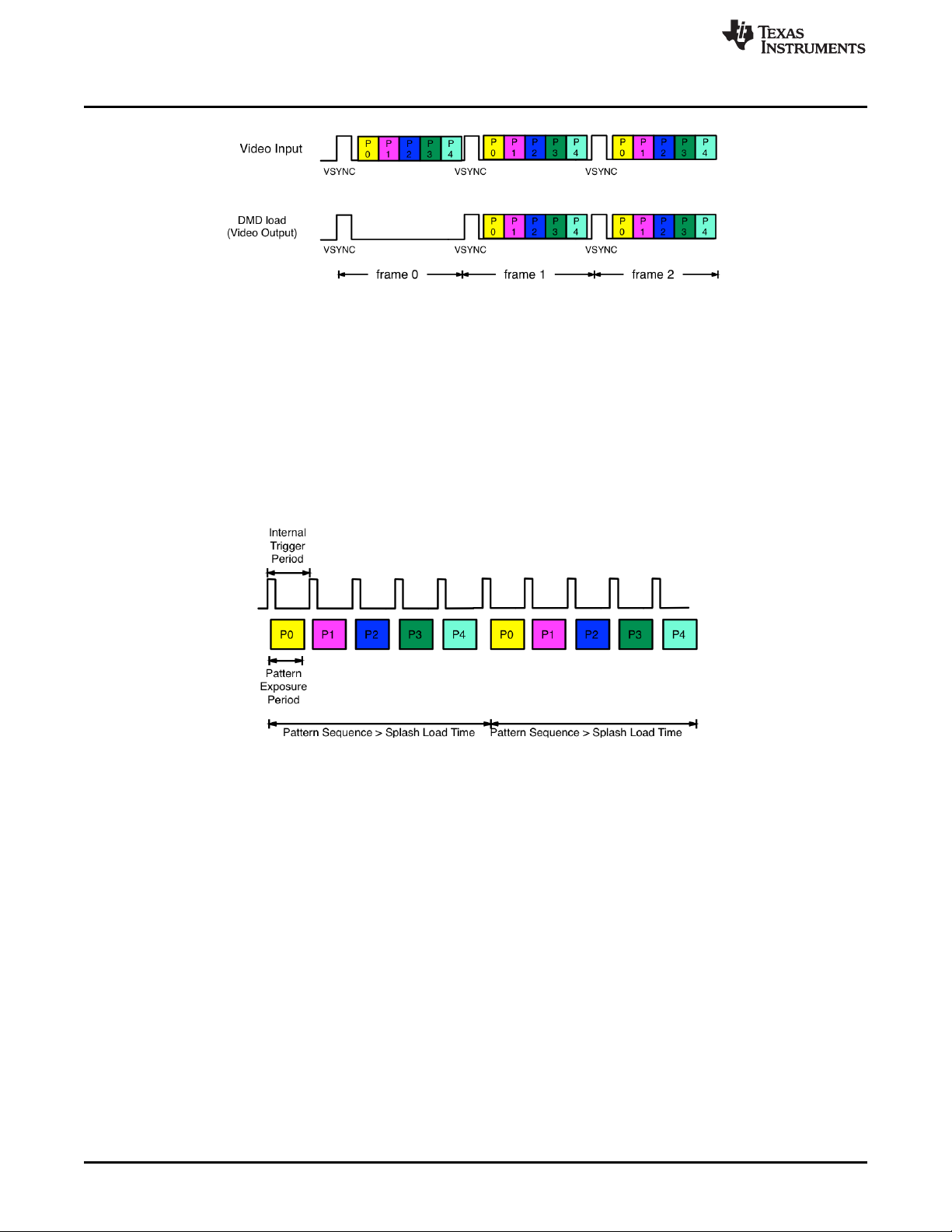

4-4. Frame Delay Between Parallel Interface Input and Projection Output.............................................. 48

4-5. Image Load Time and Pattern Sequence Timing ...................................................................... 48

6-1. DLP LightCrafter 4500 With PandaBoard 4500........................................................................ 57

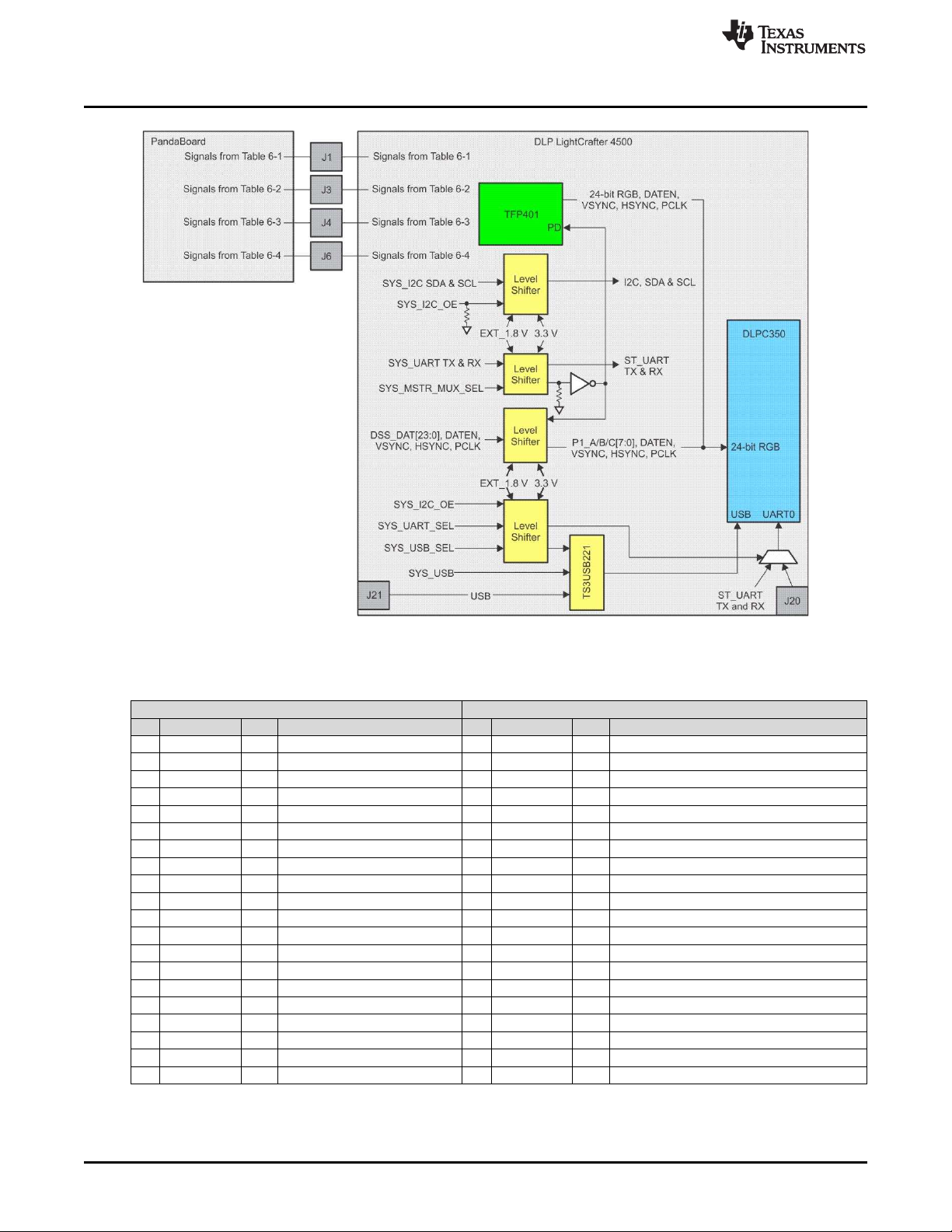

6-2. Block Diagram of the PandaBoard Interface ........................................................................... 58

4

List of Figures DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

1-1. DLP LightCrafter Light Engine Specifications .......................................................................... 11

4-1. Allowable Pattern Combinations ......................................................................................... 49

5-1. List of Available Parameters when Saving Solutions.................................................................. 52

5-2. Image LUT Entries Example.............................................................................................. 54

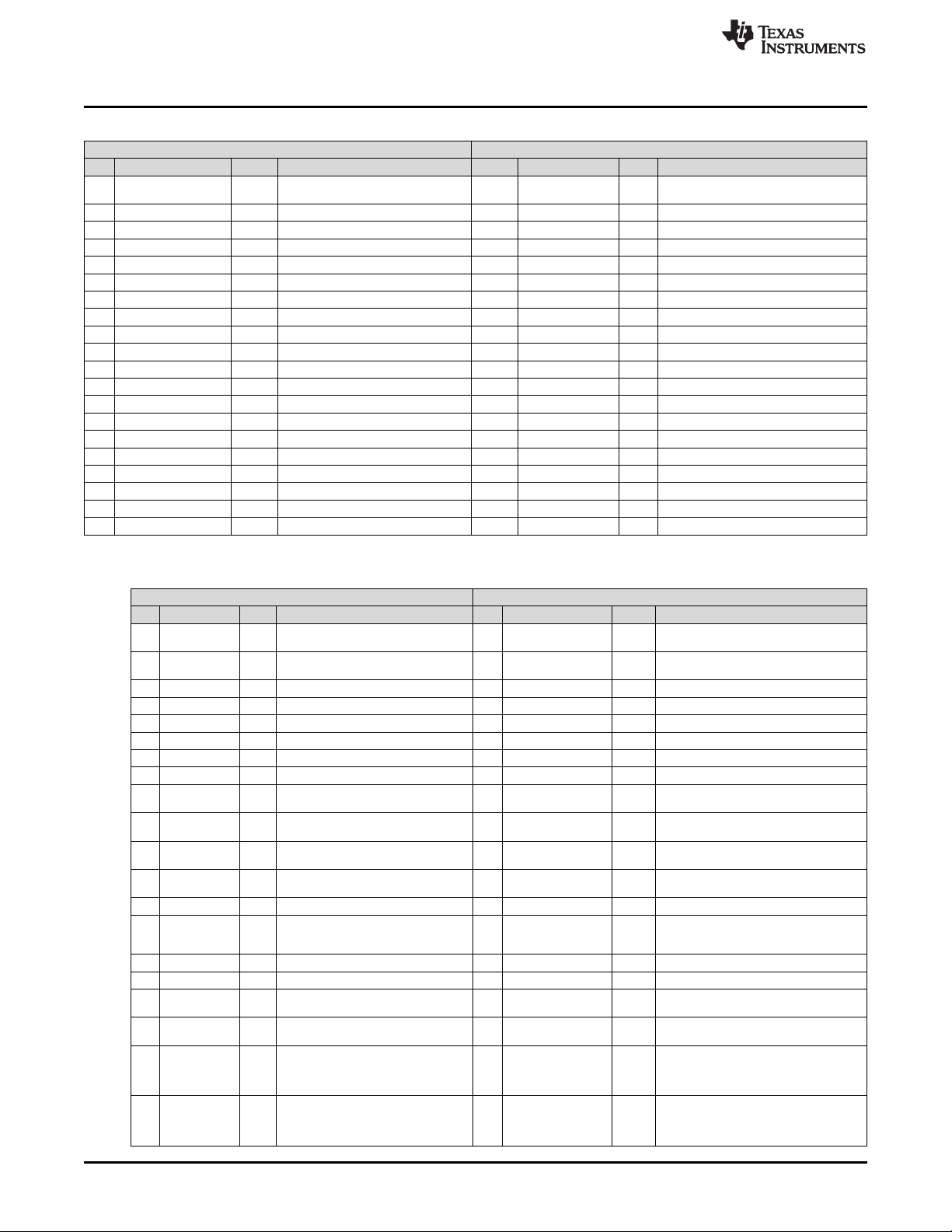

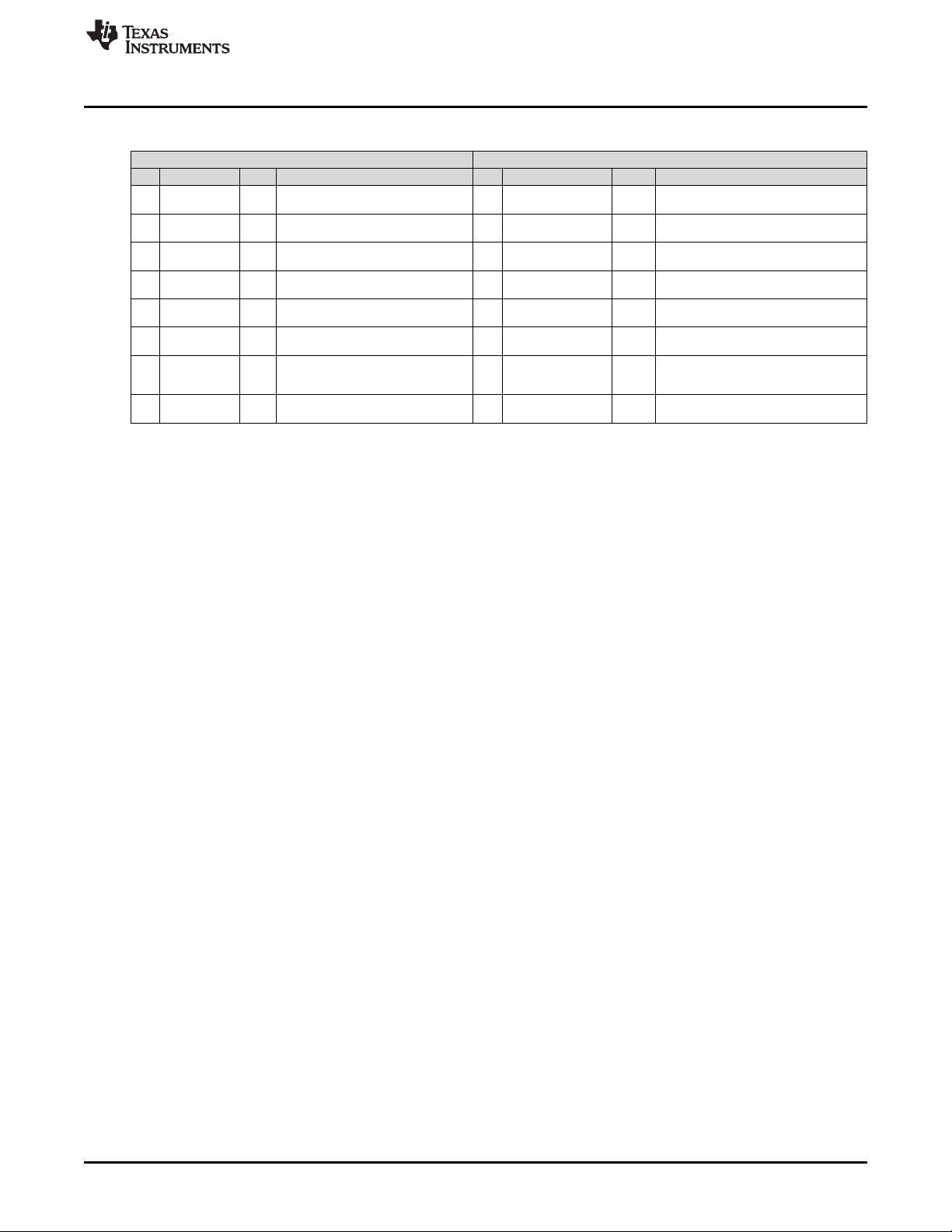

6-1. J1 PandaBoard 4500 to DLP LightCrafter 4500 Interface............................................................ 58

6-2. J3 PandaBoard 4500 to DLP LightCrafter 4500 Interface............................................................ 59

6-3. J4 PandaBoard 4500 to DLP LightCrafter 4500 Interface............................................................ 60

6-4. J6 PandaBoard 4500 to DLP LightCrafter 4500 Interface............................................................ 60

7-1. Input Trigger Connector Pins............................................................................................. 64

7-2. Output Trigger Connector Pins........................................................................................... 64

7-3. UART Connector Pins ..................................................................................................... 65

7-4. I

7-5. I

7-6. Fan Connector Pins........................................................................................................ 66

7-7. Red LED Connector Pins ................................................................................................. 66

7-8. Green LED Connector Pins............................................................................................... 67

7-9. Blue LED Connector Pins................................................................................................. 67

7-10. FPD-Link Connector Pins................................................................................................. 67

7-11. JTAG Boundary Scan Connector Pins .................................................................................. 68

7-12. Power Connector Pins..................................................................................................... 68

List of Tables

2

C0 Connector Pins ....................................................................................................... 65

2

C1 Connector Pins ....................................................................................................... 65

DLPU011E–July 2013–Revised September 2015 List of Tables

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

5

Page 6

About This Guide

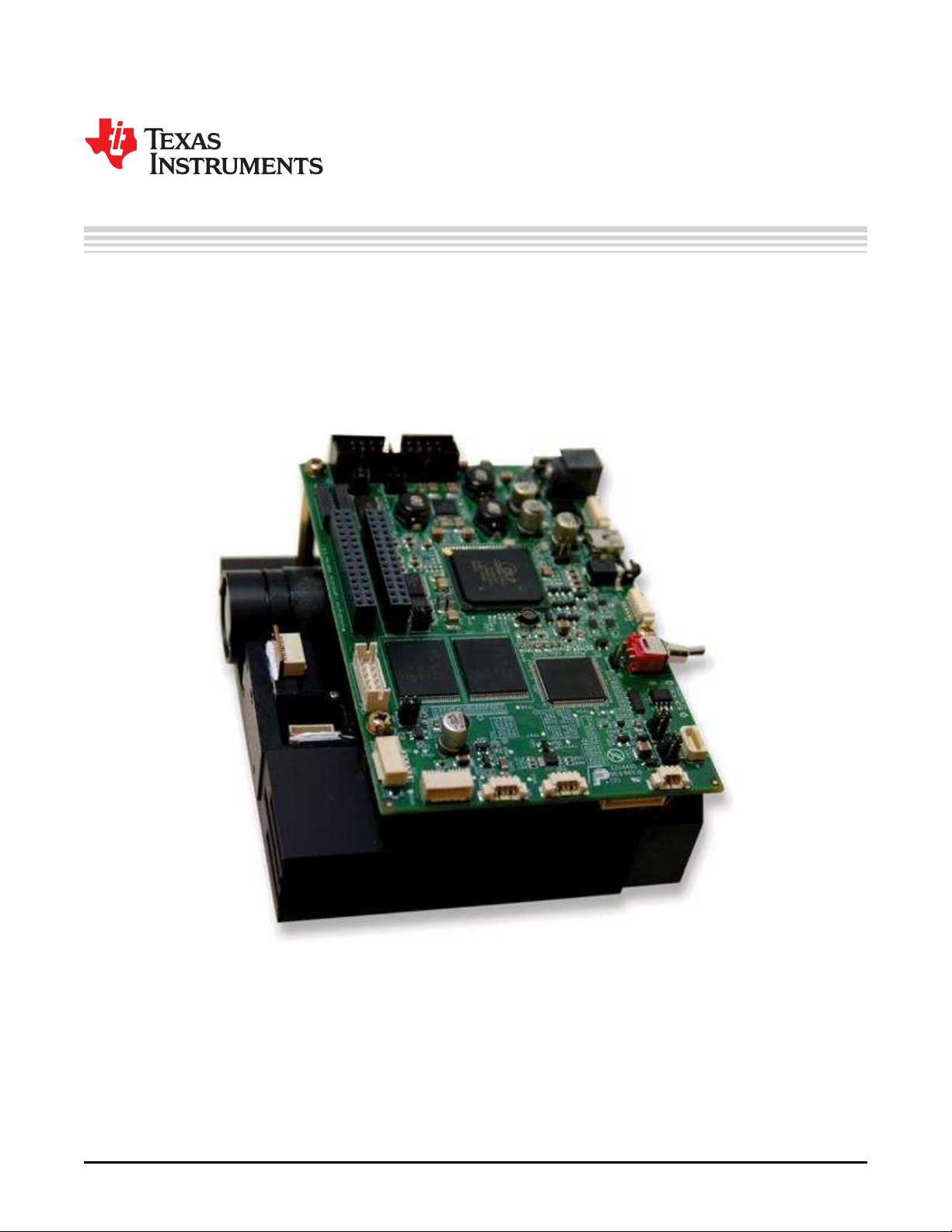

The DLP®LightCrafter 4500™ is a third-party implementation of the next generation DLP reference design

to enable faster development cycles for applications requiring small form factor and intelligent pattern

display.

This guide is an introductory document that provides an overview of the DLP LightCrafter 4500 system

and its software. Other documents provide more in-depth information of the hardware and software

features of the components of the DLP LightCrafter 4500.

Preface

DLPU011E–July 2013–Revised September 2015

Read This First

Figure 1. DLP LightCrafter 4500 Evaluation Module (EVM)

6

Read This First DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

Related Documentation From Texas Instruments

DLPC350 data sheet: DLP Digital Controller for the DLP4500 DMD, DLPS029

DLP4500 data sheet: DLP 0.45 WXGA DMD, DLPS028

DLPC350 and DLP4500 chipset manual: DLP 0.45 WXGA Chipset Data Manual, DLPU009

User's guide: DLPC350 Programmer’s Guide, DLPU010

Application note: Using DLP®LightCrafter 4500™ Triggers to Synchronize Camera, DLPA036

If You Need Assistance

Refer to the DLP and MEMS TI E2E Community support forums: DLP LightCrafter 4500 Development

Platform Forum

Related Documentation From Texas Instruments

LightCrafter 4500 is a trademark of Texas Instruments.

DLP, Linux are registered trademarks of Texas Instruments.

Bluetooth is a registered trademark of Bluetooth SIG, Inc..

Ubuntu is a registered trademark of Canonical Ltd..

SVTronics is a registered trademark of SVTRONICS, INC..

Sullins Connector Solutions is a registered trademark of Sullins Connector Solutions, Inc..

DLPU011E–July 2013–Revised September 2015 Read This First

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

7

Page 8

If You Need Assistance

www.ti.com

8

Read This First DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

1.1 Welcome

The DLP LightCrafter 4500 evaluation module (EVM) allows evaluation of the DLP 4500 platform from TI.

This technology brings together a set of components providing an efficient and compelling system solution

for:

• 3D scanning structured light applications:

– 3D modeling and design

– Fingerprint identification and face recognition

– Machine vision and robotic factory automation

– Industrial inspection

• Medical and life sciences:

– Vascular imaging

– Hyperspectral imaging

– Dental impression scanners

– Intraoral dental scanners

– Orthopedics, prosthesis, CT, MRI, and X-ray marking

– Retail cosmetics

• Small display projectors:

– Embedded display

– Interactive display

– Information overlay

• Spectroscopy and chemical sensing

– Material identification

– Oil & Gas analysis

– Water & air quality

– Food & drug inspection

– TI NIRscan EVM uses the DLP4500NIR DMD (similar to the DLP4500 in the LightCrafter4500 EVM

and optimized for near-infrared light) in structured light mode to provide a high performance and

cost-competitive spectroscopy solution

Chapter 1

DLPU011E–July 2013–Revised September 2015

DLP LightCrafter 4500 Module Overview

1.2 What is in the LightCrafter 4500 EVM?

The DLP LightCrafter 4500 module consists of two subsystems:

• Light engine – includes the optics; red, green, and blue LEDs; and the 912 × 1140 diamond pixel 0.45inch WXGA DMD, heat sinks, and fan. The light engine produces approximately 150 lumens at 15-W

LED power consumption.

• Driver board – includes the LED driver circuits, DLPC350 DMD controller, power-management circuits,

DVI-to-RGB conversion with the TFP401, and a 32-MB flash storage

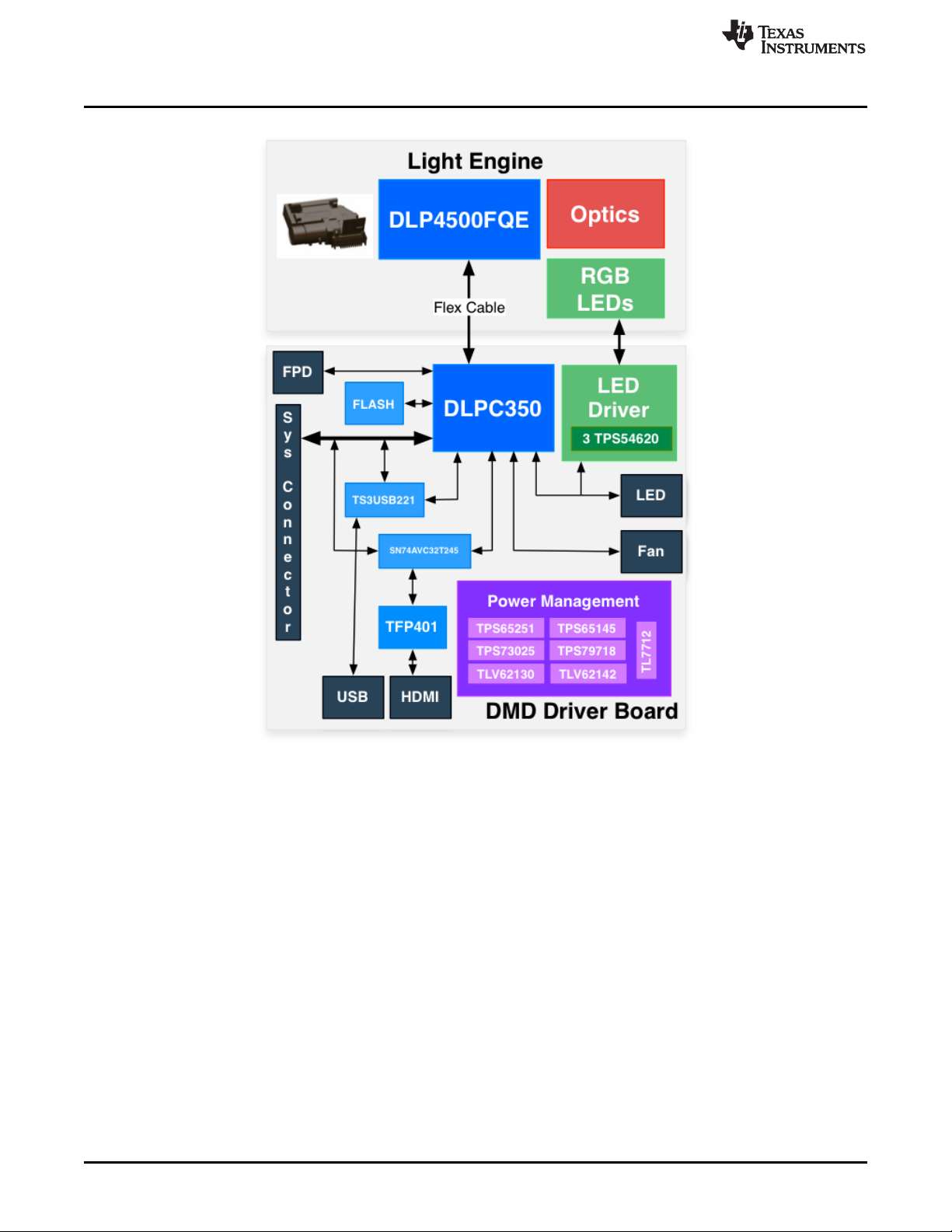

Figure 1-1 shows the major hardware components.

DLPU011E–July 2013–Revised September 2015 DLP LightCrafter 4500 Module Overview

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

9

Page 10

What is in the LightCrafter 4500 EVM?

www.ti.com

1.2.1 Light Engine

iView Limited developed the IPD 1231 light engine for the DLP LightCrafter 4500. As shown in Figure 1-2,

the light engine includes:

• DLP4500FQE DMD

• DMD heat sink

• Red, green, and blue LEDs

• Focus control

• Projection lens

The iView Light Engine is mounted on top of a large thermal plate to cool the module. The DLP4500 DMD

is mounted vertically between the DMD heat sink and the light engine. On the opposite side to the DMD,

the red and green LEDs are mounted between a thermal plate and the light engine. The blue LED is

mounted between a thermal plate and the light engine, next to the projection lens. An LED heat sink is

mounted behind the red and green LED thermal plate and thermally connected to the blue LED thermal

plate. A fan forces air across the LED heat sink to cool the LEDs.

The light engine, not including the LED heat sinks, has a length of 90.5 mm, width of 73.7 mm, and height

of 23.6 mm.

10

DLP LightCrafter 4500 Module Overview DLPU011E–July 2013–Revised September 2015

Figure 1-1. DLP LightCrafter 4500 Block Diagram

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

What is in the LightCrafter 4500 EVM?

Figure 1-2. iView Light Engine

Table 1-1 lists the specifications of the light engine:

Table 1-1. DLP LightCrafter Light Engine Specifications

Parameter MIN TYP MAX UNIT

Brightness 150 lm

LED power consumption 15 W

Full-on full-off contrast 1000:1

Uniformity 80 90 %

F-number 2.1

Throw ratio 1.4

Offset 100 %

Focus range 0.5 1 2 m

Image diagonal size 16.7 32.8 65 inch

The light engine includes the DLP4500 0.45-inch DMD with 1039680 mirrors, each 7.6 µm, arranged in

912 columns by 1140 rows with the diamond pixel array geometry and configuration (see Figure 1-3 and

Figure 1-4). Due to the diamond pixel configuration, the array produces smooth diagonal lines, with jagged

vertical and horizontal lines, as shown in Figure 1-5. Two options exist to produce the vertical and

horizontal lines: use every row or column, or use every other row or column. When every row or column is

used, a more thick line is projected. When every other row or column is used, a more faint line is

projected.

DLPU011E–July 2013–Revised September 2015 DLP LightCrafter 4500 Module Overview

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

11

Page 12

What is in the LightCrafter 4500 EVM?

Figure 1-3. 0.45-Inch DMD Diamond Pixel Geometry

Figure 1-4. 0.45-Inch DMD Diamond Pixel Array Configuration

www.ti.com

Figure 1-5. Diamond Pixel for Vertical, Horizontal, and Diagonal Lines

1.2.1.1 Light Engine Thermal Limits

The DLP LightCrafter 4500 is an actively cooled system with a thermal limit requiring that of all three

simultaneous LED currents is less than 4.3 A.

Do not overheat the system by driving all LEDs at maximum power.

12

DLP LightCrafter 4500 Module Overview DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

CAUTION

Submit Documentation Feedback

Page 13

www.ti.com

1.2.2 Driver Board

The DLP LightCrafter 4500 driver board contains the electronics to drive the DLP4500 DMD, LEDs of the

light engine, and the LED cooling fan. The driver board offers several interface options for USB, I2C,

trigger inputs and outputs, video input through mini-HDMI and FPD-link connector, and a system board

interface. Figure 1-6 shows the driver board block diagram of the DLP LightCrafter 4500.

What is in the LightCrafter 4500 EVM?

Figure 1-6. DLP LightCrafter 4500 Driver Board Block Diagram

The DLP LightCrafter 4500 driver board major components are:

• DLP4500: 0.45 inch-WXGA DMD

• DLPC350: DLP4500 controller

• 32-MB parallel flash contains DLPC350 firmware and 24-bit compressed images

• TPS54620: Synchronous step-down converter serving as an LED driver capable of driving up to 5 A

per LED

• Power management:

– TPS65251: Triple output buck switcher for DLPC350 1.2-V, 1.9-V supplies and 5-V board supply.

– TPS65145: Triple output boost converter for DLP4500 8.5-, –10-, and 16-V supplies

– TPS73025: Step-down converter for DLP4500 2.5-V supply

– TLV62130: Step-down converter for 3.3-V supply

– TLV62130: Step-down converter for 5-V system board supply

– TPS79718: LDO for DLPC350 1.8-V analog supply

DLPU011E–July 2013–Revised September 2015 DLP LightCrafter 4500 Module Overview

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

13

Page 14

What is in the LightCrafter 4500 EVM?

– TL7712: Programmable time delay for power-supply sequencing

• TFP401: Digital Receiver for DVI to 24-bit parallel RGB interface

• TS3USB2221A: ESD-protected high-speed USB multiplexer

• SN74AVC32T245: 32-bit dual supply bus transceiver for system board interface

1.2.3 Embedded Processor Interface

The DLP LightCrafter 4500 driver board allows the connection of a PandaBoard ES. See, Chapter 6.

1.3 Other Items Needed for Operation

The DLP LightCrafter 4500 module is a flexible, ready-to-use EVM. However, the DLP LightCrafter 4500

EVM does not ship with cables, power supply, or additional hardware components. To use the EVM, the

user needs the following:

• Power supply:

– Nominal voltage: 12-V DC

– Typical current: 6 A

– Maximum current: 7 A

– DC connector size:

• Inner diameter: 2.5 mm

• Outer diameter: 5.5 mm

• Shaft: 9.5-mm female, center positive

– Efficiency level: V

– A recommended power supply is Digi-Key part number 62-1186-ND , or equivalent.

• USB cable: A to mini-B USB cable

• Optional: PandaBoard 4500

www.ti.com

14

DLP LightCrafter 4500 Module Overview DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

1.4 DLP LightCrafter 4500 Connections

Figure 1-7 and Figure 1-8 depict the switches and connectors with their respective locations. The following

list corresponds to the callouts on these figures. The figure does not include cables, or a power supply.

1. Reset button

2. Power connector: Use a power supply with a 12-V DC output with current of 6 to 7-A rating and a plug

of 2.5-mm inner diameter × 5.5-mm outer diameter and 9.5-mm female center positive shaft. The

current output of the power supply determines how much current the LED driver can supply

3. External trigger output connector: Supports two trigger output signals, each with configurable voltage of

3.3 V and 1.8 V through jumpers, J13 and J15, respectively.

4. Mini-USB connector: use an A to mini-B USB cable to connect to a PC.

5. UART/RS232 mini-plug connector output: DLPC350 3.3-V UART output for error messages. Mini-plug

tip is DLPC350 transmit (TX) and ring is DLPC350 receive (RX) signals. UART has the following serial

configuration:

• Bits per second: 115200

• Data bits: 8

• Parity: None

• Stop bits: 1

• Flow control: None

6. External trigger Input connector: Supports two trigger input signals, each with configurable voltage of

5 V, 3.3 V and 1.8 V through jumpers, J10 and J12

7. Stand-by switch: Places the DLP LightCrafter 4500 in standby mode, powering down the LED driver

and the DLPC350

8. Flat panel display-link connector

9. Fan connector

10. Red LED supply connector (bottom of the board)

11. DLPC350 I2C1 bus

12. DLPC350 I2C0 bus

13. Green LED supply connector

14. Blue LED supply connector

15. External LED driver connector: Install a jumper in J30 to disable the DLP LightCrafter 4500 LED

drivers and set jumper J28 for 3.3-V or 1.8-V supply. Then use this connector to control an external

LED driver board to power the LEDs of the DLP LightCrafter 4500 light engine or external light engine.

16. System board connector: This interface routes USB, I2C, GPIO, and triggers from DLPC350 to a

system board to control the DLP LightCrafter 4500.

17. Focus control (bottom of the board): Adjust focus from 0.5 m to infinity

18. JTAG connector for DLPC350

19. JTAG Boundary Scan for DLPC350 (bottom of the board)

20. DVI input through mini-HDMI connector (bottom of the board). This input supports resolutions of 1280

× 800, 1024 × 768, 1024 × 640, 912 × 1140, 800 × 600, 800 × 500, and 640 × 480 at up to 120 Hz. In

Video Mode, the DLPC350 scales the input resolution to the native resolution of the DLP4500 DMD. In

Pattern Sequence mode, this input supports 912 × 1140 resolution.

DLP LightCrafter 4500 Connections

DLPU011E–July 2013–Revised September 2015 DLP LightCrafter 4500 Module Overview

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

15

Page 16

DLP LightCrafter 4500 Connections

www.ti.com

Figure 1-7. DLP LightCrafter 4500 Connectors (Top View)

16

Figure 1-8. DLP LightCrafter 4500 Connectors (Back-Side View)

DLP LightCrafter 4500 Module Overview DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

www.ti.com

1.5 DLP LightCrafter 4500 Jumpers

The DLP LightCrafter 4500 has jumper options to disable the onboard LED driver, control voltages of the

LED signals to an external board, and control the trigger input and output voltages. This section lists all

the jumpers on the DLP LightCrafter 4500 driver board. Figure 1-9 depicts the locations of these jumpers.

These jumpers require a 2-mm jumper, like Sullins Connector Solutions®SPN02SYBN-RC, Digi-Key part

number S3404-ND.

DLP LightCrafter 4500 Jumpers

Figure 1-9. DLP LightCrafter 4500 Jumper Locations

• J8: EDID write protect disable jumper. Place this jumper to reprogram the EDID EEPROM (U2) using

I2C commands through the mini-HDMI connector. Remove the jumper when programming of the EDID

is complete. The EDID is programmed at the factory with resolutions of 1280 x 800 and 912 x 1140.

• J10: DLPC350 TRIG1_IN voltage selection. See to Figure 1-10.

– Jump across pins 3 to 4 for 3.3 V

– Jump across pins 5 to 6 for 1.8 V

• J12: DLPC350 TRIG2_IN voltage selection. See to Figure 1-10.

– Jump across pins 3 to 4 for 3.3 V

– Jump across pins 5 to 6 for 1.8 V

DLPU011E–July 2013–Revised September 2015 DLP LightCrafter 4500 Module Overview

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

17

Page 18

DLP LightCrafter 4500 Jumpers

Figure 1-10. DLP LightCrafter 4500 J10 and J12 Voltage Jumpers

• J13: DLPC350 TRIG1_OUT voltage selection. See to Figure 1-11.

– Jump across pins 3 to 4 for 3.3 V

– Jump across pins 5 to 6 for 1.8 V

• J15: DLPC350 TRIG2_OUT voltage selection. See to Figure 1-11.

– Jump across pins 3 to 4 for 3.3 V

– Jump across pins 5 to 6 for 1.8 V

www.ti.com

18

Figure 1-11. DLP LightCrafter 4500 J13 and J15 Voltage Jumpers

• J18: DLPC350 HOLD_IN_BOOT. Jump across this header to hold the DLPC350 in bootloader mode.

DLP LightCrafter 4500 Module Overview DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

This action is needed only if the DLP LightCrafter 4500 firmware becomes corrupted and must be

reprogrammed through the JTAG boundary scan or USB. The graphical user interface (GUI) firmware

upgrade process places the DLPC350 in bootloader mode through software commands and does not

need the jumper.

• J19: Device address select

– Jump across header to set I2C address to 0x3A and USB device serial number to LCR2.

– Do not populate jumper to set I2C address to 0x34 and USB device serial number to LCR2.

• J23: Hold in reset. Jump across header to drive and hold reset line low. Jumping across this header is

equivalent to pressing and holding the reset switch.

• J28: DLPC350 LED signals voltage selection. This jumper must be populated when bypassing the

onboard LED driver and using an external LED driver.

– Jump across pins 1 to 2 to set the DLPC350 LED enables and PWM signals to 3.3 V.

– Jump across pins 3 to 4 to set the DLPC350 LED enables and PWM signals to 1.8 V.

• J30: DLPC350 LED driver disable. This jumper must be populated when bypassing the onboard LED

driver and using an external LED driver.

– Jump across header to disable the onboard LED driver and turn off all LEDs, regardless of the DLP

LightCrafter 4500 video mode.

– Do not populate this header for normal operation using the onboard LED driver.

1.6 Dimensions

The DLP LightCrafter 4500 optical engine is mounted on top of a thermal plate to provide passive cooling

to the module. A heat sink and fan provide active cooling to the LEDs. The DLP4500, 0.45-in. DMD, is

vertically mounted at the end of the optical engine and attached with a flex cable to the driver board that

lies on top of the light engine. The dimensions of the DLP LightCrafter 4500 are of 98 mm long, 121.6 mm

wide, and 47.7 mm tall. Figure 1-12 shows DLP LightCrafter 4500 dimensions.

Dimensions

DLPU011E–July 2013–Revised September 2015 DLP LightCrafter 4500 Module Overview

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

19

Page 20

Dimensions

www.ti.com

20

Figure 1-12. DLP LightCrafter 4500 Dimensions

DLP LightCrafter 4500 Module Overview DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

Dimensions

DLPU011E–July 2013–Revised September 2015 DLP LightCrafter 4500 Module Overview

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

21

Page 22

This chapter details the steps to power up the DLP LightCrafter 4500 and connect to a PC.

2.1 Power-up the DLP LightCrafter 4500

The DLP LightCrafter 4500 is ready to use, out of the box. Steps 1 through 5 show how to power, display

an image, and connect the device to a PC.

1. Connect a 12-V DC power supply to the power supply connector (connector 2 in Figure 1-8).

2. An LED on the bottom of the LightCrafter 4500 board, next to the flex cable lights up green. The fan

starts, stops, and then restarts while the DLPC350 is booting. After 5 to 10 seconds, the DLPC350

bootloads and displays a screen with the DLP and LightCrafter 4500 logo. The D4 LED on top of the

LightCrafter 4500 board flashes on and off green. If the board shuts down after briefly turning on the

display, the power supply current rating might be too low.

3. To display video, connect a DVI source to the mini-HDMI connector (connector 20 in Figure 1-8).

4. Control the DLP LightCrafter 4500 with the free GUI software (available to download from

http://www.ti.com/dlplightcrafter4500).

5. After installing the software on the computer, connect the PC to the DLP LightCrafter 4500 using a

USB to mini-USB cable (connector 4 in Figure 1-8). The first time the cable is connected on a PC, the

DLP LightCrafter 4500 emulates a USB composite device with human-interface device (HID) class. No

drivers are required because these drivers are natively handled by all operating systems.

Chapter 2

DLPU011E–July 2013–Revised September 2015

Quick Start

22

Quick Start DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

Power-up the DLP LightCrafter 4500

DLPU011E–July 2013–Revised September 2015 Quick Start

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

23

Page 24

This chapter introduces the PC software provided with the DLP LightCrafter 4500.

3.1 DLP LightCrafter 4500 Software

The DLP LightCrafter 4500 includes a QT-based GUI application to control the module through the USB

interface. QT is a Nokia cross-platform application and user-interface framework with open source and

commercial licenses. To install the QT GUI, just expand the LightCrafter4500_GUI.zip file into a directory

and double-click on the executable file.

The DLP LightCrafter 4500 supports three main modes of operation:

• Video mode displays images from:

– DVI input through the mini-HDMI connector

– 24-bit RGB bitmaps stored in flash memory

– 24, 20, 16, 10, and 8-bit RGB input through the system board connectors (J1, J3, J4, and J6)

– Internal test patterns

– 30-bit RGB through flat panel display (FPD) link

• Pattern Sequence mode displays images from:

– 1-, 2-, 3-, 4-, 5-, 6-,7-, and 8-bit bitmap images stored in flash memory

– 1-, 2-, 3-, 4-, 5-, 6-, 7-, and 8-bit bitmap images streamed through the DLPC350 24-bit RGB

interface (mini-HDMI, FPD-link, or system board connectors)

– The chosen pattern exposure and pattern period times apply to all patterns in the pattern sequence

• Pattern Sequence [Variable Exposure] mode displays images from the same sources as Pattern

Sequence mode:

– 1-, 2-, 3-, 4-, 5-, 6-,7-, and 8-bit bitmap images stored in flash memory

– 1-, 2-, 3-, 4-, 5-, 6-, 7-, and 8-bit bitmap images streamed through the DLPC350 24-bit RGB

interface (mini-HDMI, FPD-link, or system board connectors)

– This mode allows for the pattern exposure time and pattern period to be set per pattern in the

pattern sequence

Chapter 3

DLPU011E–July 2013–Revised September 2015

Operating the DLP LightCrafter 4500

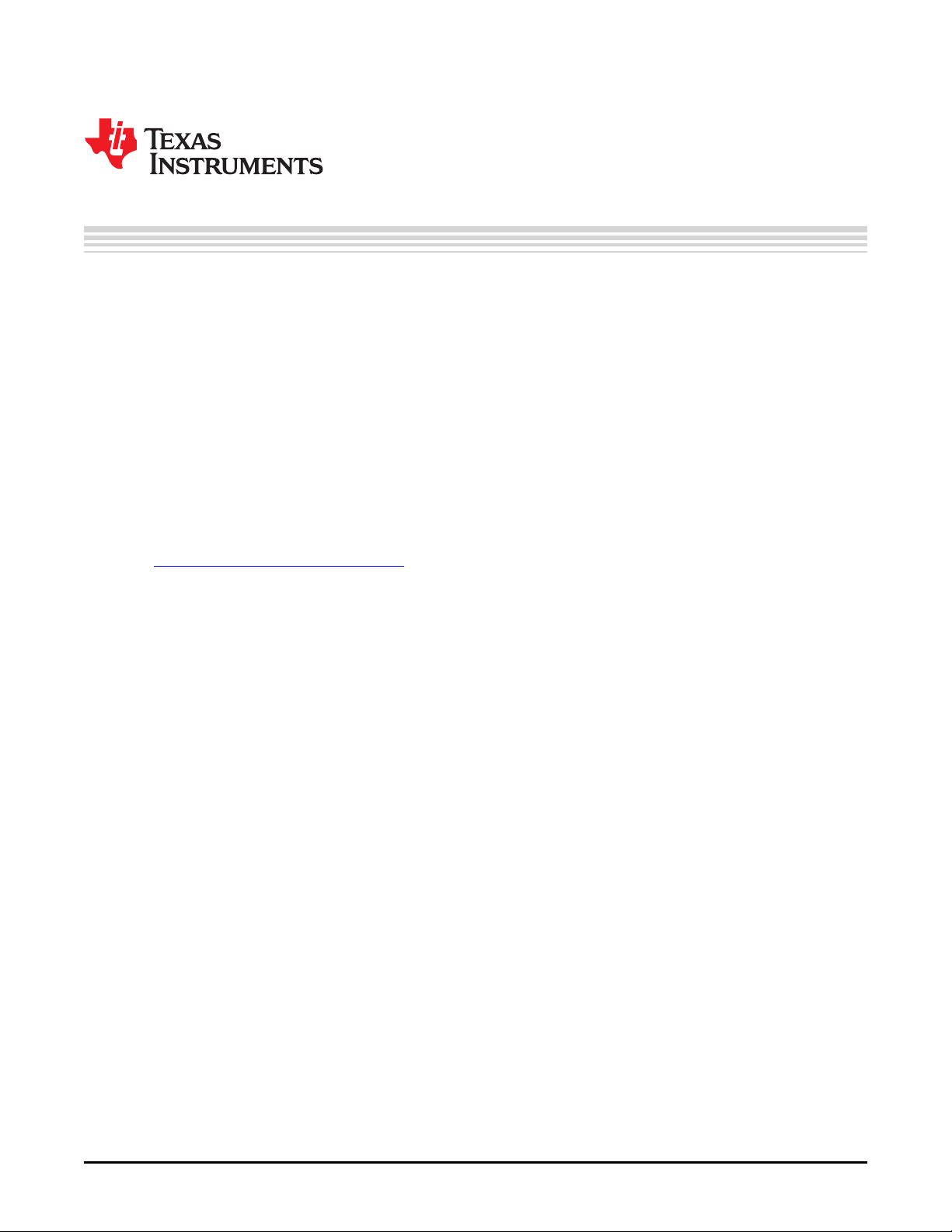

3.2 PC Software

Upon execution of the LightCrafter4500.exe file, the window shown in Figure 3-1 displays. The GUI

window contains the following two sections:

• The top portion of the GUI window displays the System Control and controls the Operating Mode,

Image Orientation, LED Driver Control settings, and LED Selection. There are also controls for saving

and applying solutions.

• The bottom portion of the GUI window offers a set of tabs to further control the selected Operating

Mode.

In any of the GUI sections, clicking a Get button reads the current settings of that particular subsection.

Clicking the Set button programs the settings in the respective subsection. Some commands may require

additional steps before the GUI display is updated.

24

Operating the DLP LightCrafter 4500 DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

www.ti.com

PC Software

Figure 3-1. DLP LightCrafter 4500 GUI – Video Mode

The DLP LightCrafter 4500 GUI communicates with the DLPC350 using USB 1.1. The DLPC350 emulates

as a USB device with HID support. The PC polls all the HID peripherals and once the PC detects the

DLPC350, the Connected button changes to green. If the USB cable is disconnected, the color of the

Connected button changes to red and the Connected text is grayed-out. Once the System Status shows

Connected, the firmware version, firmware tag, hardware, and System Status indicators are displayed.

There is no need to press the Connected button, because the HID peripheral is detected by the operating

system after USB enumeration.

3.2.1 System Status

At the top-left portion of the GUI window, the hardware and System Status indicators report the following:

• Init Done: When highlighted green, it indicates the successful completion of the DLPC350 initialization.

When highlighted grey, it indicates the DLPC350 had an error during initialization.

• Sequencer Running: When highlighted green, the DLPC350 sequencer is running as usual. When

highlighted gray, the DLPC350 sequencer is stopped.

• DRC Error: DMD Reset Controller Error indicator. When highlighted grey, the DMD Reset Controller

has not detected an error. When highlighted red, the DMD Reset Controller has found multiple

overlapping bias or reset operations accessing the same DMD block of micromirrors.

DLPU011E–July 2013–Revised September 2015 Operating the DLP LightCrafter 4500

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

25

Page 26

PC Software

• Forced Swap: When highlighted red, the DLPC350 sequencer detected a forced buffer swap error

indicating that image data has been displayed from the wrong internal display buffer. When highlighted

gray, no buffer swap error has occurred. This error can occur if the DLP LightCrafter 4500 is set to

Video Mode and the vertical backporch timing is too small. The error can also occur if the DLP

LightCrafter 4500 is set to Pattern Sequence mode with patterns input from the video port and pattern

sequence timings do not match the video port VSYNC.

• Sequencer Error: When highlighted red, the DLPC350 sequencer has detected an error. When

highlighted gray, the DLPC350 sequencer detected that no error occurred.

• DMD Parked: When highlighted yellow, the DMD micromirrors are parked in the position normal to the

DMD plane. When highlighted gray, the DMD micromirrors are not parked.

• Buffer Freeze: When highlighted yellow, the frame buffer is frozen. When highlighted gray, the frame

buffer is not frozen. This is cleared on the next buffer swap.

• Sequencer Abort: When highlighted red, the DLPC350 sequencer has detected an error condition that

caused an abort. When highlighted gray, the DLPC350 sequencer detected that no error occurred.

These indicators are updated every 2 seconds, or when a command is issued to the DLPC350.

• Auto Update Status. When checked, all indicators will continue to update every two seconds. When

unchecked, the indicators will stop updating and turn gray. While running in Pattern Sequence Mode,

keeping the option unchecked prevents the GUI from interrupting the DLPC350 controller which will be

processing critical functions related to pattern display.

3.2.2 Operating Mode

To the right of the System Status, the Operating Mode sets how the DLP LightCrafter 4500 operates:

• Pattern Sequence mode: The DLPC350 takes 1-, 2-, 3-, 4-, 5-, 6-, 7-, and 8-bit data from one of the

following interfaces:

– 24-bit RGB interface

– FPD-link interface

– Flash memory

www.ti.com

The DLPC350 does not apply any video processing functions and provides a pixel accurate mode

where every pixel maps to the native DMD resolution of 912 × 1140.

• Pattern Sequence [Variable Exposure] mode: The DLPC350 takes 1-, 2-, 3-, 4-, 5-, 6-, 7-, and 8-bit

data from one of the following interfaces:

– 24-bit RGB interface

– FPD-link interface

– Flash memory

This mode differs from Pattern Sequence mode in that the pattern exposure time and pattern period

can be varied per pattern in the pattern sequence.

The DLPC350 does not apply any video processing functions and provides a pixel accurate mode

where every pixel maps to the native DMD resolution of 912 × 1140.

• Video Mode: The DLPC350 takes 24, 20, 16, 10, and 8-bit data from one of the following interfaces:

– 24-bit RGB interface

– FPD-link interface

– Internal test pattern generator

– Flash memory

The DLPC350 then applies video processing functions, such as scaling, gamma correction, and color

coordinate adjustments, and sends the processed image to the DMD.

• Power Standby: Places the DLPC350 in low-power state and powers down the DMD interface.

26

Operating the DLP LightCrafter 4500 DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 27

www.ti.com

3.2.3 Image Orientation

Beneath Operating Mode, the Image Orientation controls the long and short axis flips to support front,

rear, table, and ceiling mounted projection. The Image Orientation occurs on the next image or frame load

in Video mode, and on the next download to the DLP LightCrafter 4500 in Pattern Sequence mode.

• East/West Flip: If checked, the image is flipped along the east and west axis of the projected image.

Usual table front projection has this setting unchecked. Otherwise, the image is flipped horizontally.

• North/South Flip: If checked, the image is flipped along the north and south axis of the projected

image. Usual table front projection has this setting unchecked. Otherwise, the image is flipped

vertically.

PC Software

DLPU011E–July 2013–Revised September 2015 Operating the DLP LightCrafter 4500

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

27

Page 28

PC Software

3.2.4 LED Current Settings

On the top-right of the GUI window, the LED Current settings control the individual currents of the red,

green, and blue LEDs. A setting of 255 corresponds to the maximum LED current. A setting of 0

corresponds to minimum LED current. The LED current is computed as follows:

Red LED Current (A) = 0.0175 × (LED Current Value) + 0.4495 (1)

Green LED Current (A) = 0.0181 × (LED Current Value) + 0.3587 (2)

Blue LED Current (A) = 0.0160 × (LED Current Value) + 0.1529 (3)

Typical performance of the red, green, and blue LEDs are shown in Figure 2, Figure 3, and Figure 4,

respectively. Manufacturing processes can lead to variations in LED brightness and current consumption.

Actual LED performance might vary from those shown in the following figures.

www.ti.com

Figure 2. Typical Red LED Current and Illuminance Based Figure 3. Typical Green LED Current and Illuminance

on PWM Values Based on PWM Values

Figure 4. Typical Blue LED Current and Illuminance Based on PWM Values

CAUTION

The DLP LightCrafter 4500 is an actively cooled system that has a thermal limit

resulting in total simultaneous red, green, and blue LED currents less than

4.3 A for continuous LED operation. Do not overheat the system by turning all

LEDs at maximum power during prolonged and simultaneous LED use.

Exceeding more than 4.3 A for continuous or simultaneous LED operation can

damage the LightCrafter 4500 LEDs.

28

Operating the DLP LightCrafter 4500 DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 29

www.ti.com

Typical variations in LED manufacturing can lead to changes in the brightness and current consumption.

Thus for typical white balance point, TI recommends the following percentages of colors:

• Red or green is approximately 87.5%

• Blue or green is approximately 97.6%

At the default LED current values of:

• Red = 104

• Green = 135

• Blue = 130

The LED Selection box determines the control of the LED enables signals. Two options are allowed:

• Automatic: LED enables are controlled by the DLPC350 sequencer. In Video Mode, the LED enables

are set in color sequential order. In Pattern Sequence mode, the LED enables are controlled by the

downloaded Pattern Sequence settings.

• Manual: LED enables are controlled by the check boxes. Checking a color, continuously enables the

LED of that color at the given LED current setting.

3.2.5 Video Mode

When the DLP LightCrafter 4500 is configured in Video Mode, the Input Source Select section in Figure 3-

1 in the top-left part of the Video Mode tab selects the input source to be displayed by the DLPC350. The

DLPC350 treats these as video inputs and applies image processing functions, like scaling, gamma

correction, color coordinate adjustments, and so forth. The following lists the allowable input sources:

• Parallel RGB interface: Supports 24-, 20-, 16-, 10-, and 8-bit data inputs. This interface is connected to

the TFP401 for DVI input from the mini-HDMI connector or to the system board connectors. The Pixel

Data Format section is below the Source Select interface selects the allowable pixel data formats for

the Parallel RGB interface:

– RGB 4:4:4

– YCrCb 4:4:4

– YCrCb 4:2:2

• Internal Test Pattern: 24-bit internal pattern generator with RGB 4:4:4 pixel data format. The internal

test patterns offer color control of the foreground and background color of the pattern through the

Internal Test Pattern Color section. The available internal test patterns and their respective foreground

and background color control are:

– Solid field: Foreground color control only

– Horizontal ramp: Foreground color control only

– Vertical ramp: Foreground color control only

– Horizontal lines: Foreground and Background color control

– Diagonal lines: Foreground and Background color control

– Vertical lines: Foreground and Background color control

– Grid: Foreground and Background color control

– Checkerboard: Foreground and Background color control

– Red, green, and blue ramps: Foreground color control only

– Color bar: Foreground color control only

– Step bar: Foreground color control only

• Flash images: single-frame, 24-bit Still images stored in external flash memory. The flash memory

supports up to 32MB of storage with up to 64 images. The images stored in flash memory support

RGB 4:4:4 and YCrCb 4:2:2 pixel data formats.

• FPD-link: Flat Panel Display Link connector. The FPD-link interface supports 30-, 24-, 20-, 16-, 10-,

and 8-bit data inputs with RGB 4:4:4 pixel data format. The FPD Mode and Field Select configures the

mapping of the pixel mode, polarity, and CONT1 and CONT2 field signals.

PC Software

DLPU011E–July 2013–Revised September 2015 Operating the DLP LightCrafter 4500

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

29

Page 30

Pattern Sequence Mode

For the Parallel RGB and FPD-link video input modes, the DLPC350 interprets channel A as green,

channel B as red, and channel C as blue. However, the Parallel RGB or FPD-link source can have

different mapping of channels to colors. The Input Source Port Data Swap section sets the mapping of

channels to colors. Port1 refers to Parallel RGB interface while Port2 refers to the FPD-link interface. The

mapping options are:

• ABC → ABC, no swapping of data subchannels

• ABC → CAB, data subchannels are right-shifted and circularly rotated

• ABC → BCA, data subchannels are left-shifted and circularly rotated

• ABC → ACB, data subchannels B and C are swapped

• ABC → BAC, data subchannels A and B are swapped

• ABC → CBA, data subchannels A and C are swapped

For all video input modes, the Display Dimensions section defines the active displayed resolution. The

maximum supported input and output resolutions for the DLP4500 0.45 WXGA DMD are 1280 pixels

(columns) by 800 lines (rows). The display area settings set the first pixel column (Start Pixel) and the first

line (Start Line) as well as, the numbers of pixels per line (total columns) and the number of lines per

frame (total rows). This setting also provides the option to define a subset of active input frame data using

pixel (column) and line (row) counts. In other words, this feature allows cropping of the source image as

the first step in the processing chain.

For the Parallel RGB and FPD-link video input modes, the Video Signal Information section provides

details about the video source connected to the LightCrafter4500. These signal parameters can only be

read from the device, they cannot be set in the section.

The Signal Status parameter has the following states:

• Processing: The video source VSYNC signal has not yet locked when the Get Video Info button was

pressed

• Detected: The video source VSYNC signal has been locked

• Stopped: The LightCrafter4500 is no longer locking to the video source. This occurs in the Pattern

Sequence modes when video port input pattern streaming is selected. This prevents a delay in pattern

display if synchronization is temporarily lost with the video source.

• Lock Failed: The LightCrafter4500 was not able to lock to the incoming video source. Please see

sections 6.7 and 6.8 in the DLPC350 datasheet on Input Pixel Interface Timing Requirements to verify

the video input is meeting specifications.

www.ti.com

3.3 Pattern Sequence Mode

When the DLP LightCrafter 4500 is configured in Pattern Sequence mode, the DLPC350 supports 1-, 2-,

3-, 4-, 5-, 6-, 7-, and 8-bit images with a 912 columns × 1140 rows resolution. These images are pixel

accurate, meaning that each pixel corresponds to a micromirror on the DMD and is not processed by any

of the video processing functions. Three subtabs control the Pattern Sequence settings: Sequence

Settings, Pattern Sequence Start/Stop/Pause, Trigger Controls, and LED Delay Control.

3.3.1 Sequence Settings

A pattern sequence is composed of several patterns loaded from flash memory or streamed through the

24-bit RGB video port. Each individual pattern can have a specific set of LEDs illuminating it, a particular

bit-depth, and an internal or external trigger. The Sequence Settings subtab lets the user define and set all

the Individual Pattern Settings. The Trigger Controls subtab and the LED Delay Control subtab set the

trigger and LED enable edge timings, respectively. The Pattern Sequence Start/Stop/Pause tab shows the

pattern sequence validation status indicators and allows the user to play, pause and stop the

sequence.Figure 3-5 shows the DLP LightCrafter 4500 GUI with the Pattern Sequence tab selected.

30

Operating the DLP LightCrafter 4500 DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 31

www.ti.com

Pattern Sequence Mode

Figure 3-5. DLP LightCrafter 4500 GUI – Pattern Sequence Mode

The Pattern Sequence displays images from one of the following two input sources:

• Flash: Images stored in flash memory. The flash memory can store up to sixty-four 24-bit compressed

images.

• Video port: Streamed through the Parallel RGB or FPD-link interface. Only one of these interfaces can

be connected to the DLP LightCrafter 4500 during Pattern Sequence mode.

To synchronize a camera or external system with the displayed patterns, the DLP LightCrafter 4500

supports a set of trigger inputs and outputs. These inputs and outputs are configured through the Trigger

Mode section and Trigger Controls subtab. The Trigger Mode selects the trigger input:

• Internal/External: Uses an internal trigger period to start the pattern sequence or uses the DLP

LightCrafter 4500 TRIG_IN2 signal to start and pause the pattern sequence. Each pattern in the

pattern sequence can be configured with either an internal or external trigger. With the Internal Trigger

setting, the Internal Trigger Period displays the next pattern. With External Trigger Period, the DLP

Light Crafter 4500 TRIG_IN_1 signal displays the next pattern.

• Vsync: Uses the VSYNC signal from the Parallel RGB or FPD-link interface to trigger the start of the

pattern sequence. After VSYNC, the patterns are displayed in the sequence shown on the Pattern

Sequence section. Each pattern length is determined by the Pattern Exposure time. Thus, the total

number of patterns multiplied by the pattern exposure must be less than or equal to the VSYNC period.

DLPU011E–July 2013–Revised September 2015 Operating the DLP LightCrafter 4500

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

31

Page 32

Pattern Sequence Mode

Pattern sequence timing is controlled by the Pattern Period and Pattern Exposure time.

• Pattern Exposure (us): Defines the amount of time a single pattern is displayed in microseconds.

• Pattern Period (us): Defines the amount of time between patterns (in microseconds) in a pattern

sequence.

A pattern sequence can be any combination of bit depth patterns with any combination of LED sources.

The pattern sequence can be played once or continuously repeated. The allowed LED sources are:

• White: Red, green, and blue LEDs on

• Cyan: Green and blue LEDs on

• Magenta: Red and blue LEDs on

• Yellow: Red and green LEDs on

• Red: Only red LED on

• Green: Only green LED on

• Blue: Only blue LED on

To create a pattern sequence, follow these steps:

1. Choose pattern input source (Flash or Video port) from the Pattern Source section.

2. Choose Internal/External, or VSYNC trigger mode from the Trigger Mode section.

3. Set the appropriate Trigger Controls, see Section 3.3.4

4. Set the Pattern Exposure period and Pattern Period.

5. Create the pattern sequence in the Individual Pattern Settings section:

(a) Choose the LED(s) to illuminate this pattern in the pattern sequence

(b) Select the trigger for the pattern: no trigger, external positive, external negative, or internal trigger.

Internal trigger has an internal hardware signal that is input to the pattern display state machine

(meaning the controller starts displaying after receiving the signal), whereas the no internal trigger

option will display a pattern without waiting for a trigger; each pattern will display in continuation

with the previous pattern. Creating an internally triggered pattern sequence with an external trigger

input may cause unexpected behavior.

(c) Choose the Flash Index (for Flash Pattern Source) or the Frame Index (for Video port Pattern

Source) and set the bit depth for the pattern.

(i) Flash Index: This is the image's index in flash as bundled with the firmware loaded on the

LightCrafter4500. You can view the images in Video mode by changing the Input Configuration

> Source Select to Images from Flash

(ii) Frame Index: This value can be left alone. The patterns will be pulled from the specified bit-

plane(s) from each transmitted video frame sequentially

www.ti.com

32

Note: In pattern sequence mode, you are not sending a standard 24 bit RGB image, you are

sending a group of images in parallel, anywhere from 3 8-bit images (grayscale) to 24 individual 1bit images. The color for each pattern in the sequence is determined by the LEDs selected when

that pattern was added to the sequence.

(d) Select the desired pattern bit-depth to be displayed. The bit-planes are labeled G0 - G7, R0 - R7,

and B0 - B7. Clicking on a rectangle will select this bit-plane. The grouping of bit-planes is

determined by the bit-depth selected. The groupings cannot be changed. When the source is the

video port, the trigger will always be VSYNC and the VSYNC period will be the total available time

for displaying patterns (i.e. the video frame will be updated on each VSYNC). The number of

patterns that can be displayed in this time is set by the pattern exposure and pattern period times

selected.

Note that if using the video port, the incoming image resolution must be 912x1140

(e) If a black image is desired between patterns, check the Clear DMD after exposure.

(f) Click the Add Pattern to Sequence button.

(g) Repeat Steps through for each pattern in the sequence.

Operating the DLP LightCrafter 4500 DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 33

www.ti.com

6. If the patterns sequence must be played once, set Play Once in Figure 3-5. This setting will play the

7. Clicking send will jump the GUI to the Pattern Sequence Start/Stop/Pause subtab as seen in Figure 3-

8. Pause or restart the pattern sequence through the Pause and Play buttons, respectively. If a pattern

The Pattern Sequence section in the Sequence Settings tab shows the pattern sequence as a set of

colored rectangles. The color corresponds to the LEDs used. The entries on the rectangles represent the

image source, the bit-plane, and the bit-depth as follows: S0::G0 (1) indicates flash location 0, bit-plane =

G0, bit-depth = 1. F2::G5 (3) indicates Frame 2, bit-plane = G5, bit-depth = 3. For example, in Figure 3-5,

a pattern sequence of three patterns is displayed. Each pattern is triggered every 500 ms and exposed for

500 ms. The first pattern is a 1-bit red pattern using bit-plane G0 from flash location 0. The second pattern

is a 1-bit green pattern using bit-plane G1 from flash location 0. The third pattern is a 1-bit yellow pattern

using bit-plane G2 from flash location 0.

A pulse icon in between the patterns indicates that a trigger is needed between the patterns. Right-clicking

on this icon allows the removal of the trigger, so two or more patterns can share the same trigger and are

exposed in sequence for the total exposure time. Right-clicking on a pattern allows the option of inverting

the pattern, removing the pattern, or inserting a black image by clearing the DMD after exposure time.

Pattern Sequence Mode

number of patterns set in Trigger Controls subtab under Trigger 2 Patterns per pulse. If set to 1, it

plays the first pattern in the sequence and stops. If set to 10, it plays the first 10 patterns in the

sequence. If the pattern sequence is to continuously repeat, set repeat. Make sure to click the Send

button after clicking on Play Once to download the new settings.

6. Clicking the Validate Sequence button executes a data validation and updates the Data Validation

status indicators in this tab. If the data validates successfully, the pattern sequence is downloaded to

the DLP LightCrafter 4500 and waits for the Play button to be pressed to start displaying the pattern

sequence.

If a data validation problem occurs, the appropriate status indicators are highlighted in the Data

Validation section:

• Exposure/Period OOR: When highlighted red, the Pattern Exposure period or Frame period is out

of range. The pattern exposure period must be greater than the fastest period supported, as listed

in Table 4-1.

• Pattern Number OOR: When highlighted red, the Pattern Number is out of range. The maximum

allowed patterns depend on the bit width and are listed in Table 4-1.

• Cont trig out overlaps black: When highlighted red, the continuous pattern exposure has a trigger

Out1 request or overlapping black sectors.

• Black vector missing: When highlighted red, the black vector is missing (this may also be referred

to as the post vector).

• Period, Exposure diff < 230: When highlighted red, the difference between the frame period or

internal trigger period and the exposure period of a pattern is less than 230 µs. The DMD needs

230 µs for load a pattern, so the trigger or frame period must be 230 µs greater than the pattern

exposure time.

sequence was previously loaded, the user can click the Read button to load the sequence into the GUI

window.

DLPU011E–July 2013–Revised September 2015 Operating the DLP LightCrafter 4500

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

33

Page 34

Pattern Sequence Mode

www.ti.com

Figure 3-6. Pattern Sequence Mode: Start, Pause, Stop

3.3.1.1 Pattern Sequence Example

To illustrate the Pattern Sequence mode, this section describes the steps to create a sequence with

Green LED. The DLPC350 firmware has several sets of images stored in the flash memory. Flash Image

1corresponds to 24 1-bit images (vertical columns) that have been packed into a single 24-bit RGB

bitmap. To load the pattern sequence, perform the following steps:

• Select Pattern Source: Flash

• Select Pattern Trigger Mode: Internal or External

• Set Pattern Exposure: 100000 µs

• Set Pattern Period: 100000 µs

• From the Individual Pattern Settings: Select Green and Internal Trigger

• Flash Image: Select 1

• For each 24 bit-plane of the packed 24-bit RGB image, select one bit-plane (a monochrome image)

and add it to the pattern sequence by:

34

Operating the DLP LightCrafter 4500 DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 35

www.ti.com

• This forms 24 1-bit images that are displayed back-to-back at 100-ms exposure. Click on the Send

Pattern Sequence Mode

– Clicking on G0, then clicking the Add Pattern to Sequence button

– Clicking on G1, then clicking the Add Pattern to Sequence button

– Clicking on G2, then clicking the Add Pattern to Sequence button

– Clicking on G3, then clicking the Add Pattern to Sequence button

– Clicking on G4, then clicking the Add Pattern to Sequence button

– Clicking on G5, then clicking the Add Pattern to Sequence button

– Clicking on G6, then clicking the Add Pattern to Sequence button

– Clicking on G7, then clicking the Add Pattern to Sequence button

– Clicking on R0, then clicking the Add Pattern to Sequence button

– Clicking on R1, then clicking the Add Pattern to Sequence button

– Clicking on R2, then clicking the Add Pattern to Sequence button

– Clicking on R3, then clicking the Add Pattern to Sequence button

– Clicking on R4, then clicking the Add Pattern to Sequence button

– Clicking on R5, then clicking the Add Pattern to Sequence button

– Clicking on R6, then clicking the Add Pattern to Sequence button

– Clicking on R6, then clicking the Add Pattern to Sequence button

– Clicking on R7, then clicking the Add Pattern to Sequence button

– Clicking on B0, then clicking the Add Pattern to Sequence button

– Clicking on B1, then clicking the Add Pattern to Sequence button

– Clicking on B2, then clicking the Add Pattern to Sequence button

– Clicking on B3, then clicking the Add Pattern to Sequence button

– Clicking on B4, then clicking the Add Pattern to Sequence button

– Clicking on B5, then clicking the Add Pattern to Sequence button

– Clicking on B6, then clicking the Add Pattern to Sequence button

– Clicking on B7, then clicking the Add Pattern to Sequence button

button to download the pattern sequence to the DLP LightCrafter 4500.

3.3.2 Sequence Settings [Variable Exposure]

When operating in Pattern Sequence [Variable Exposure] mode, use this subtab to set the sequence

settings. All of the sections are identical to the Sequence Settings subtab with the exception that the

Pattern Exposure time and Pattern Period are now set on a per pattern basis rather than set to the same

values for all patterns in the sequence.

DLPU011E–July 2013–Revised September 2015 Operating the DLP LightCrafter 4500

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

35

Page 36

Pattern Sequence Mode

www.ti.com

Figure 3-7. Pattern Sequence Mode — Variable Exposure

3.3.3 Image Load Timing

This subtab does an instant calculation on the time the DLPC350 takes to load a full 24-bit RGB bitmap

from flash. This measurement is instantaneous and is not the average nor worst-case timing. To get an

instantaneous measurement, perform the following steps:

1. Select the desired image number from Image Index.

2. Click the Get Load Image Timing button.

The DLPC350 decompresses the 24-bit RGB bitmap stored at the Image Index location and loads it to the

internal buffer. The time required for this process is displayed in milliseconds. This feature overwrites the

images currently in the display buffer.

36

Operating the DLP LightCrafter 4500 DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 37

www.ti.com

Pattern Sequence Mode

Figure 3-8. Image Load Timing

A typical time is 200 ms. Once an image is loaded from flash, 24 bit-fields reside in the frame buffer and

can be sequenced at higher speeds. Two 24-bit field display buffers are available in the DLPC350. If the

pattern sequence uses more than two images (48-bit fields), then approximately 200 ms is required to

load the new image into the DLPC350 internal display buffer.

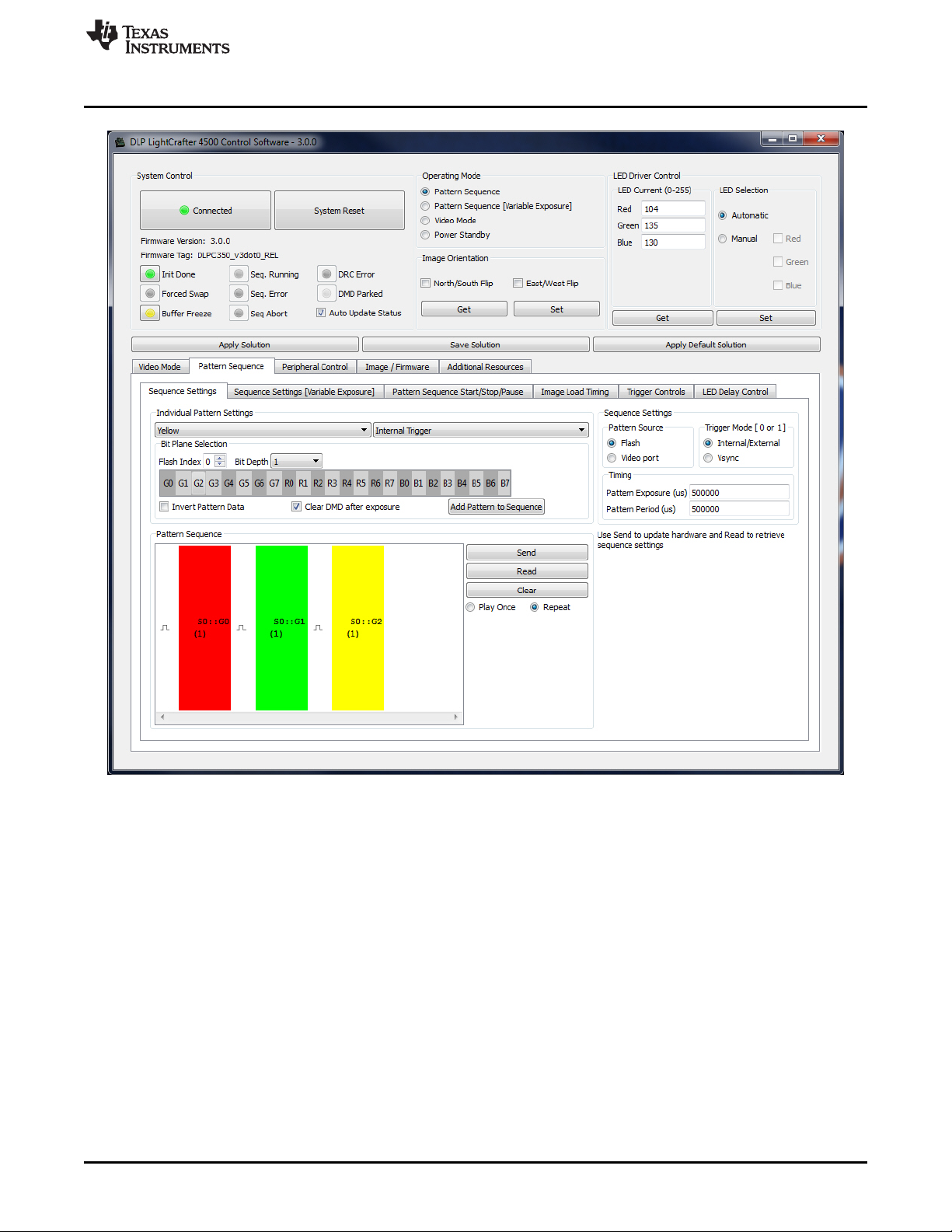

3.3.4 Trigger Controls

The Trigger Controls subtab sets the polarity and adjusts the rising and falling edge delay of the trigger

inputs and outputs, see Figure 3-9. The following trigger controls are available:

• TRIG_IN_1:

– Trigger 1 In Delay: Sets the rising edge delay of the DLPC350 TRIG_IN_1 signal in relation to the

display of the pattern on the DMD. Each number adds 107.136 ns. The GUI allows for delay ranges

between 0 µs and 28084.95 µs, but for more information on how to extend the delay range, see the

DLPC350 Programmer's Guide DLPU010

• TRIG_OUT_1:

DLPU011E–July 2013–Revised September 2015 Operating the DLP LightCrafter 4500

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

37

Page 38

Pattern Sequence Mode

– Trigger 1 Out Rising Edge Delay: Sets the rising edge delay of the DLPC350 TRIG_OUT_1 signal

in relation to the display of the pattern on the DMD. Each number adds 107.136 ns. Range is

–20.05 µs (before pattern exposure) to +2.79 µs (after pattern exposure) delay.

– Trigger 1 Out Falling Edge Delay: Sets the falling edge delay of the DLPC350 TRIG_IN_1 signal in

relation to the display of the pattern on the DMD. Each number adds 107.136 ns. Range is –20.05

µs (before the pattern exposure completes) to +2.79 µs (after the pattern exposure completes)

delay.

– Invert Trigger 1 Output: Sets the polarity of the TRIG_OUT_1 signal. When unchecked, the polarity

of TRIG_OUT_1 is active high. When checked, the polarity of TRIG_OUT_1 is active low.

• TRIG_OUT_2:

– Trigger 2 out Rising Edge Delay: Sets the rising edge delay of the DLPC350 TRIG_OUT_2 signal in

relation to the display of the pattern on the DMD. Each number adds 107.136 ns. Range is –20.05

µs (before pattern exposure) to +7.29 µs (after pattern exposure) delay.

– Invert Trigger 2 Output: Sets the polarity of the TRIG_OUT_2 signal. When unchecked, the polarity

of TRIG_OUT_2 is active high. When checked, the polarity of TRIG_OUT_2 is active low.

– Trigger 2 Patterns per Pulse: Indicates the number of patterns per TRIG_OUT_2 pulse.

www.ti.com

38

Figure 3-9. Trigger Control Subtab

The trigger output signals are:

Operating the DLP LightCrafter 4500 DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 39

www.ti.com

• TRIG_OUT_1 frames the exposure time of the pattern.

• TRIG_OUT_2 indicates the start of the pattern sequence or internal buffer boundary of a 24-bit-plane.

examples of signals Figure 3-10 and Figure 3-11 show.

Pattern Sequence Mode

Figure 3-10. VSYNC Pattern Trigger Mode

Figure 3-11. External Pattern Trigger Mode

3.3.5 LED Delay Control

In Pattern Sequence mode, the LED Delay Control subtab (see Figure 3-9) sets the rising and falling edge

offsets of the LED enable signals in relation to the display of the pattern on the DMD. The rising and

falling edge of the red, green, and blue LED enable signals can be independently changed between

–20.05 µs (before pattern exposure) to +7.29 µs (after pattern exposure) delay.

When the DLP LightCrafter 4500 is operating in Video Mode, set these delays to 0 (–20.05 µs).

DLPU011E–July 2013–Revised September 2015 Operating the DLP LightCrafter 4500

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

39

Page 40

Firmware Upgrade

www.ti.com

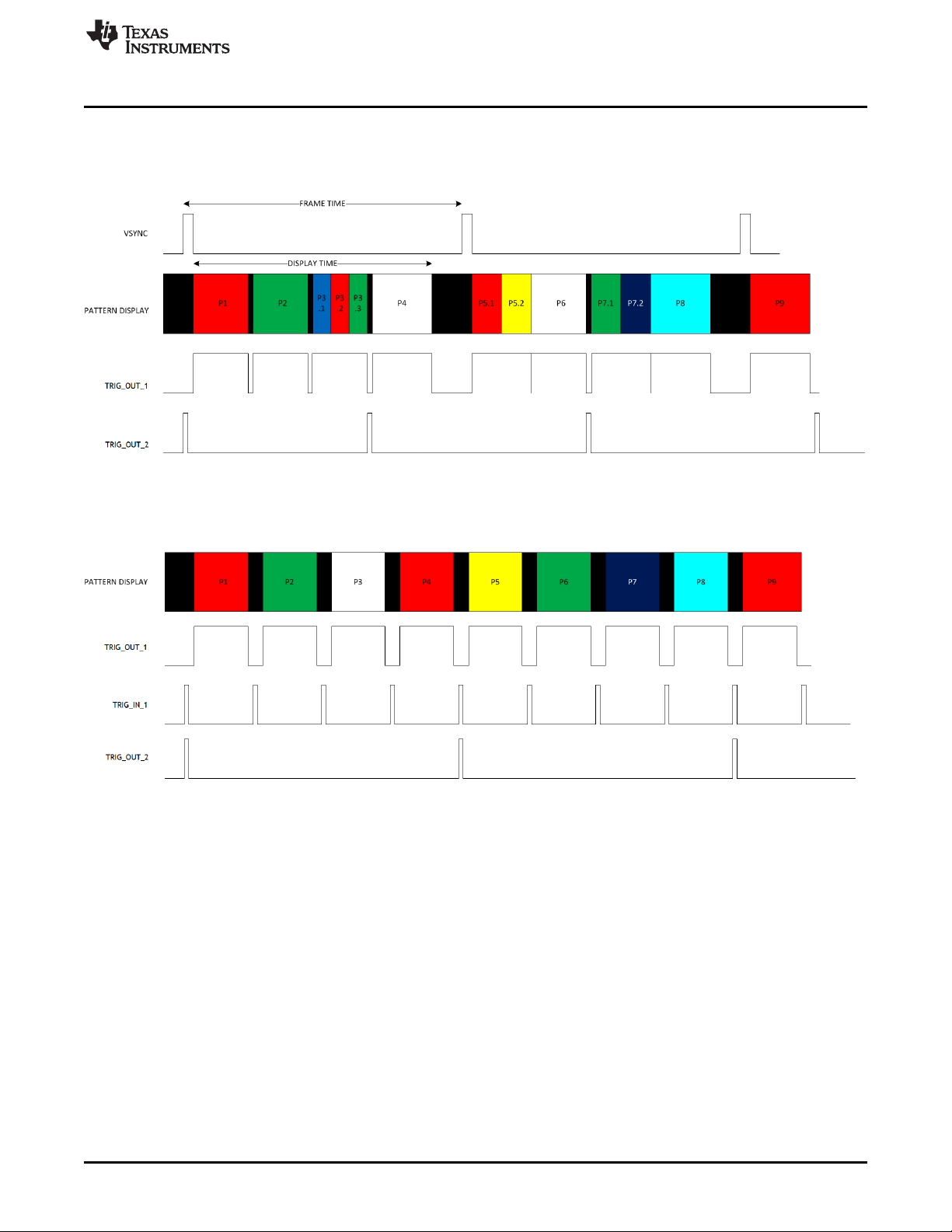

3.4 Firmware Upgrade

The DLP LightCrafter 4500 GUI allows field updates of the DLPC350 firmware. To update the DLPC350

firmware, perform the following steps Figure 3-13

1. Select the Image / Firmware tab and the Firmware Upload subtab.

2. Click the Browse button to select the file to install.

3. Click the Upload button.

4. Wait for the upload process to complete. The flash memory is erased first, then rewritten with the new

firmware image selected.

40

Operating the DLP LightCrafter 4500 DLPU011E–July 2013–Revised September 2015

Figure 3-12. LED Delay Control Subtab

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 41

www.ti.com

Storing Images in Flash Memory

Figure 3-13. Firmware Upgrade Tab

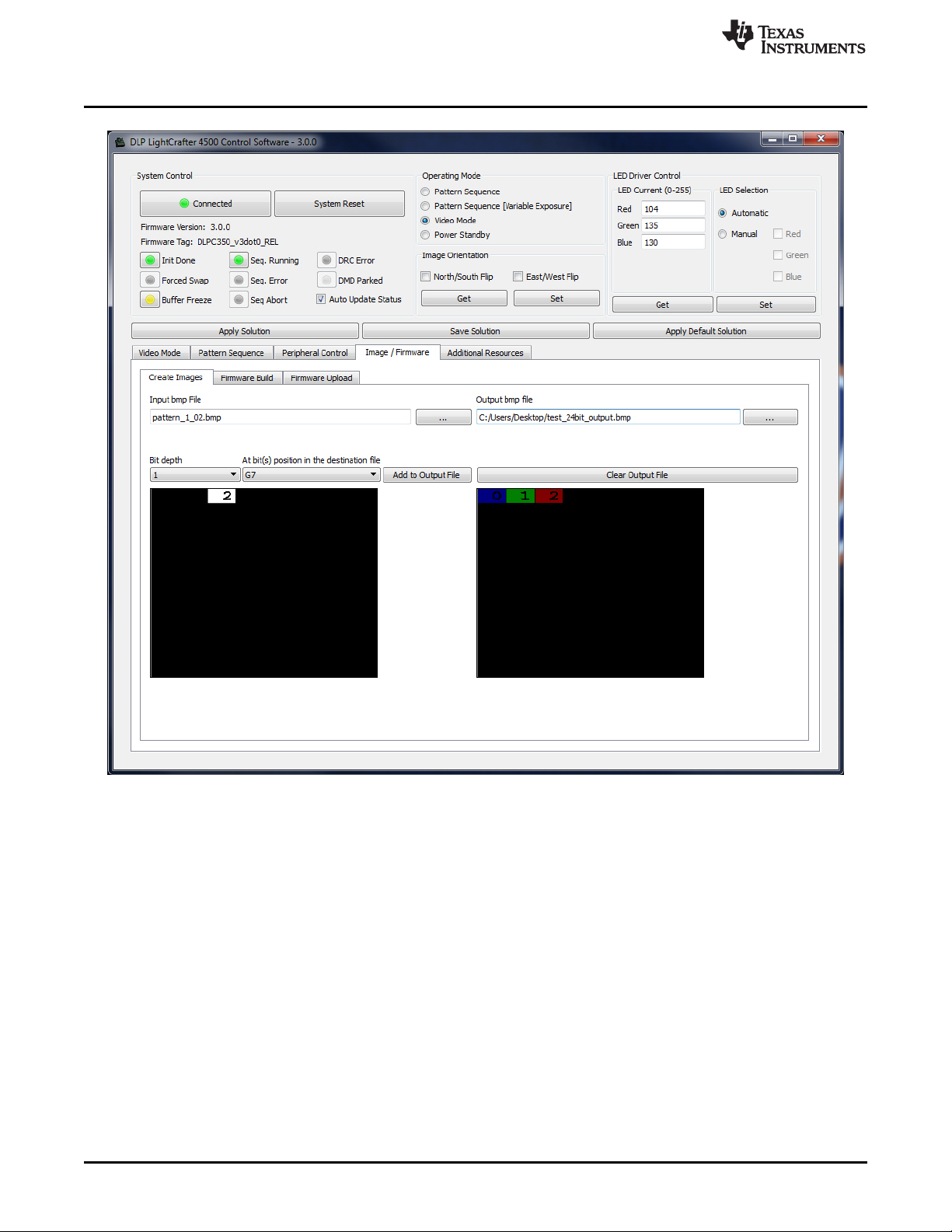

3.5 Storing Images in Flash Memory

LightCrafter 4500 allows images to be compressed and stored into the 32-MB flash memory. For most

efficient storage and compression of images, stored images are packed into groups of 24-bit RGB bitmap

images and decompressed on the fly while loaded from flash memory. To ease the packing of any bit

width images, the LightCrafter 4500 GUI offers the Create Images subtab, see Figure 3-14. To create a

24-bit image from different multiple bit depth images, perform the following steps:

1. Select the Image / Firmware tab and the Create Images subtab.

2. Select a bitmap file with 912 columns by 1140 rows by clicking the ... button next to Input bmp file

3. Select Output bitmap file by clicking the ... button next to Output bmp file

4. For an input file, add the individual bit-planes by repeating the following process:

(a) Set the bit depth and the bit field position with the Bit depth and the At bit position pulldown

selectors, respectively.

(b) Click the Add to Output File button. The current image is bit weighted and saved into the 24-bit

image of the output file.

DLPU011E–July 2013–Revised September 2015 Operating the DLP LightCrafter 4500

Submit Documentation Feedback

Copyright © 2013–2015, Texas Instruments Incorporated

41

Page 42

Storing Images in Flash Memory

www.ti.com

42

Figure 3-14. Create Images Tab

Underneath these selections, the left-hand window shows a preview of the Input file. The right-hand

window shows a preview of the 24-bit output file that has taken all the input files and bit weighted the

added images according to the bit-plane position requested. Images added at bit position B0 to B7 show

blue, bit position G0 to G7 show red, and bit position R0 to R7 show green. This is due to the DLPC350

display order being GRB (see table 2-69, Pattern Number Mapping, in the DLPC350 Programmer's

Guide), whereas BMP images are stored as RGB. For each color, bit position 0 is the least significant bit,

while bit position 7 is the most significant bit.

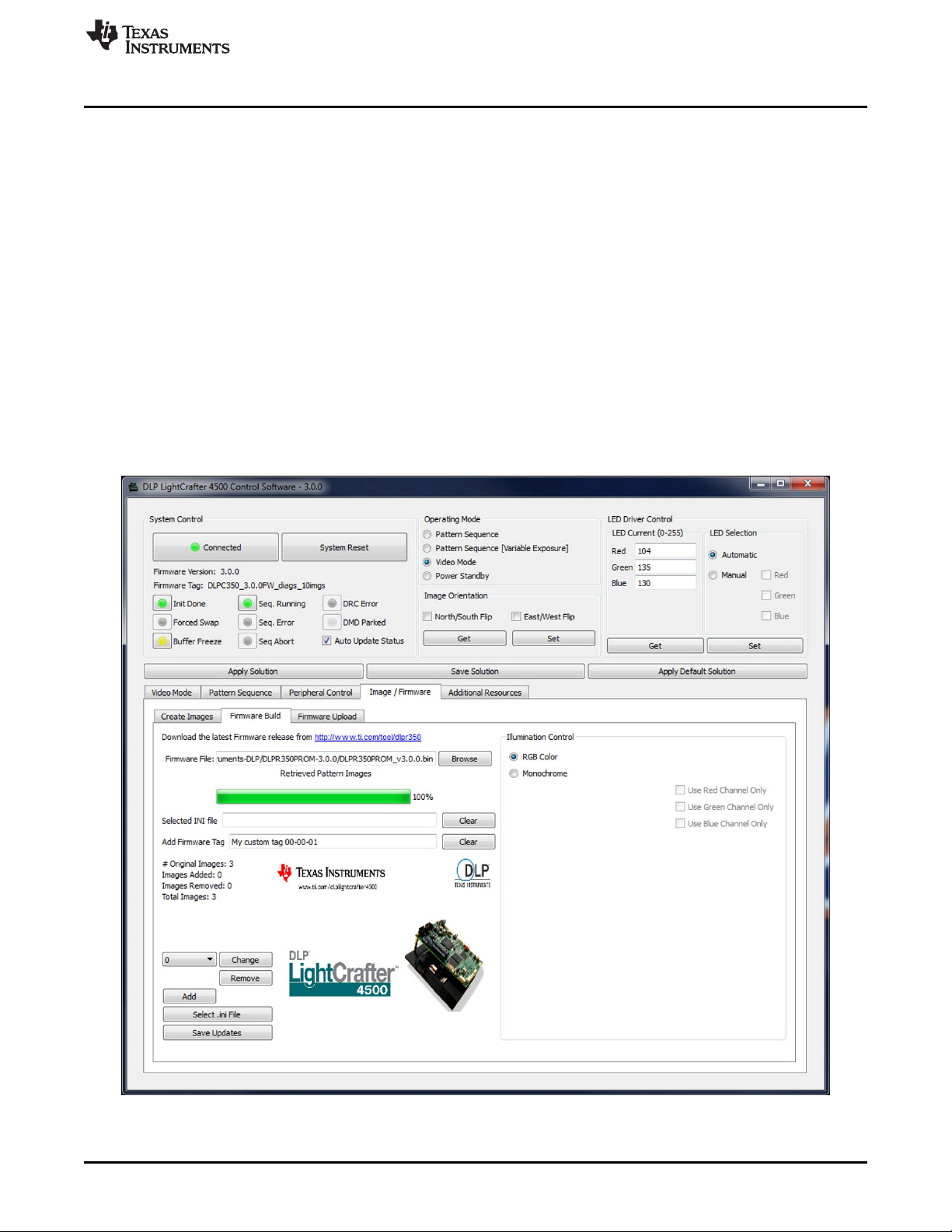

To download the images into flash, a series of 24-bit images must be added to the firmware file using the

Firmware Build subtab with the following steps:

1. Select the Image / Firmware tab and the Firmware Build subtab.

2. Select a firmware file by clicking the Browse button next to Firmware File.

3. If a new INI file is desired, refer to Section 5.2 for details on creating a custom file. Use the Select .ini

File button on the bottom left above the Save Updates button to select an existing INI file. Otherwise,

leaving this field blank will bundle the Default.ini file in the GUI top level directory with this firmware

build

Operating the DLP LightCrafter 4500 DLPU011E–July 2013–Revised September 2015

Copyright © 2013–2015, Texas Instruments Incorporated

Submit Documentation Feedback

Page 43

www.ti.com

4. Add a firmware tag. This is a 32 (or less) character string that will be associated with this firmware

5. Add 24-bit images by:

6. Choose the type of illumination control that will be used with this firmware. If you will only be using a