Page 1

DLP®LightCrafter™ Evaluation Module (EVM)

User's Guide

Literature Number: DLPU006C

January 2012–Revised December 2013

Page 2

Contents

Preface ....................................................................................................................................... 7

1 DLP

2 Operating the DLP LightCrafter ........................................................................................... 18

®

LightCrafter™ Module Overview ................................................................................... 8

1.1 Welcome ..................................................................................................................... 8

1.2 What is in the LightCrafter EVM? ......................................................................................... 8

1.2.1 Light Engine ........................................................................................................ 9

1.2.2 Driver Board ....................................................................................................... 10

1.2.3 System Board ..................................................................................................... 12

1.3 DLP LightCrafter Embedded Software Overview ..................................................................... 13

1.3.1 DM365 Software .................................................................................................. 13

1.3.1.1 Serial Communication ..................................................................................... 13

1.3.2 FPGA Overview ................................................................................................... 13

1.3.3 MSP430 Overview and Shutdown Protection Modes ........................................................ 14

1.4 Other Items Needed for Operation ...................................................................................... 15

1.5 DLP LightCrafter Connections ........................................................................................... 15

1.6 DLP LightCrafter's Dimensions .......................................................................................... 16

2.1 Installing the GUI .......................................................................................................... 18

2.2 Connecting to a PC ....................................................................................................... 18

2.2.1 Installing the RNDIS Driver on Windows XP .................................................................. 20

2.2.2 Installing the RNDIS Driver on Windows 7 .................................................................... 20

2.2.3 Enabling the RNDIS Driver on Linux ........................................................................... 23

2.2.4 Fixing the USB Start-Up Delay in Windows ................................................................... 25

2.2.5 Changing the DLP LightCrafter's IP Address ................................................................. 27

2.2.6 Connecting Multiple DLP LightCrafter's to One PC .......................................................... 28

2.3 Selecting the Display Mode .............................................................................................. 29

2.4 Setting the LED Current .................................................................................................. 30

2.5 Controlling Image Orientation ............................................................................................ 31

2.6 Triggering External Peripherals (Camera and So Forth) ............................................................. 32

2.7 Streaming 24-bit RGB Video from the HDMI Port ..................................................................... 34

2.8 Creating Pattern Sequences ............................................................................................. 35

2.8.1 Internal Stored Pattern Sequences ............................................................................ 35

2.8.1.1 Hardwired Pattern Sequences ............................................................................ 39

2.8.1.2 Multiple Bit-Depth and Multiple Color Pattern Sequences ............................................ 40

2.8.2 External Pattern Sequences Streaming from HDMI Port ................................................... 44

2.8.3 Extended Pattern Sequences ................................................................................... 44

2.9 Uploading Static Images or Colors ...................................................................................... 45

2.10 Using Test Patterns ....................................................................................................... 46

2.11 Saving and Loading Solutions ........................................................................................... 46

2.12 Capturing Images using the Camera Connector ...................................................................... 47

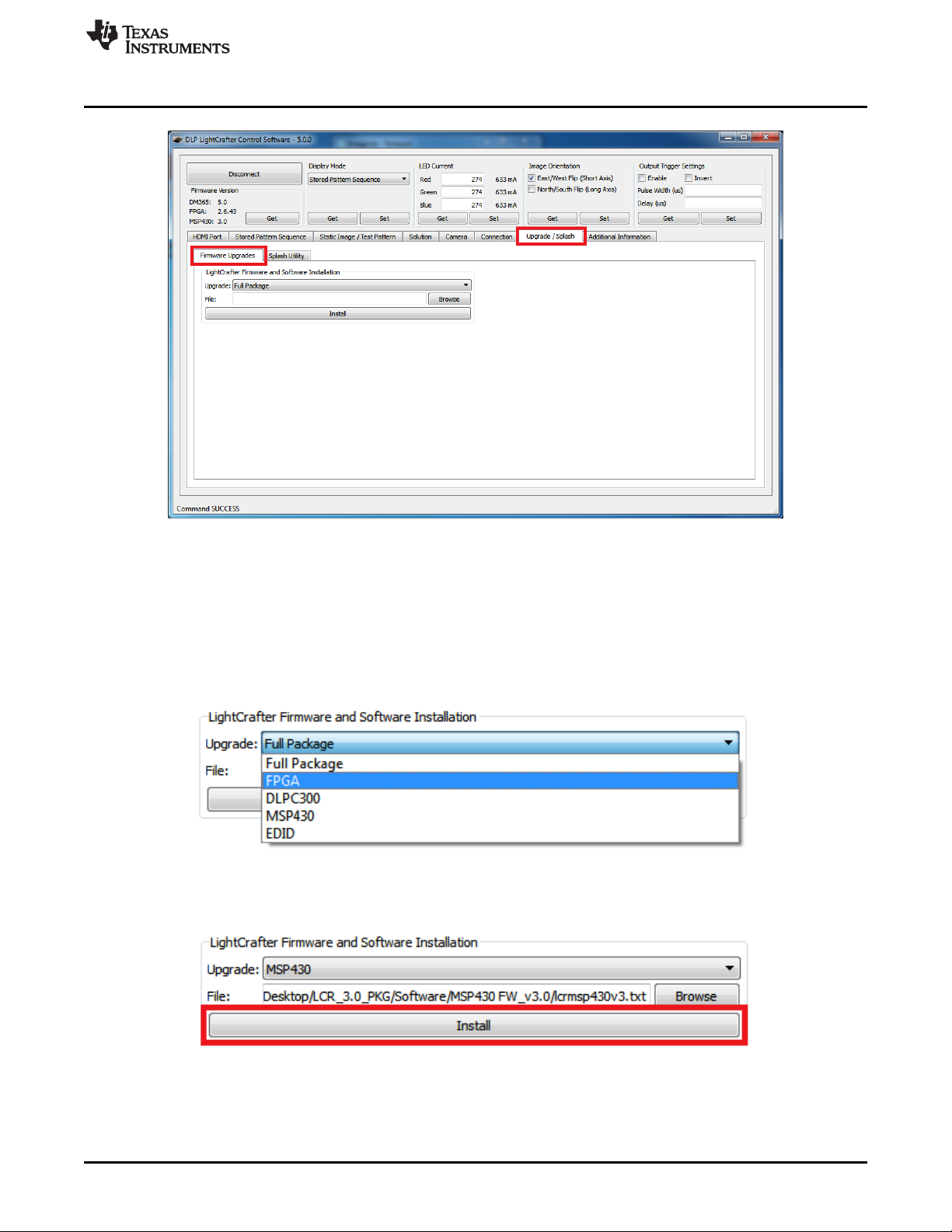

2.13 Upgrading Firmware ...................................................................................................... 48

2.13.1 Updating the MSP430, FPGA, DLPC300, or EDID using the GUI ........................................ 48

2.13.2 Updating the DM365 Firmware ................................................................................ 50

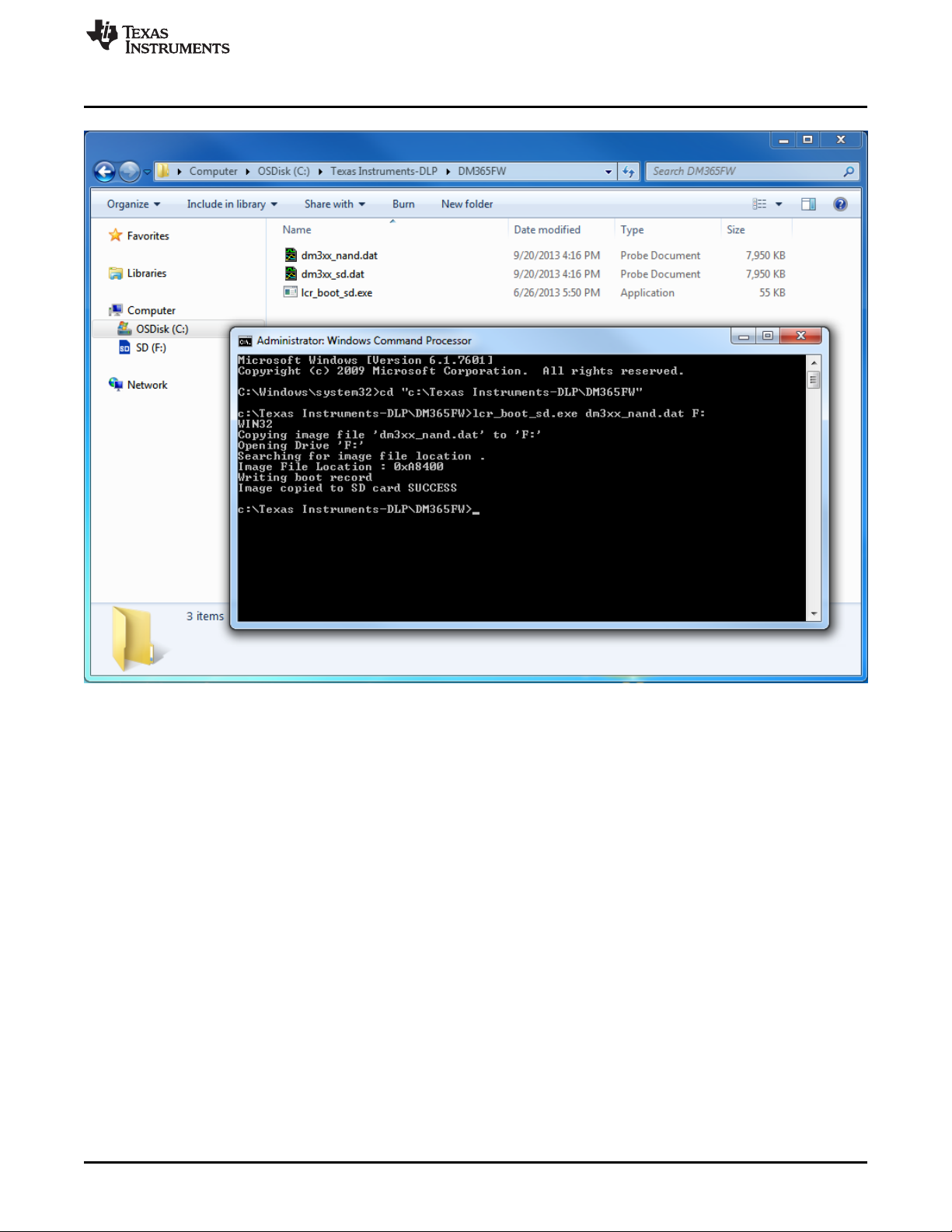

2.13.2.1 Setting up the SD Card on Windows .................................................................... 50

2.13.2.2 Setting up the SD Card on Linux ......................................................................... 53

2.13.2.3 Installing the DM365 Firmware into the NAND ......................................................... 53

2

Contents DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

2.13.2.4 Booting from the SD Card ................................................................................. 54

2.14 Changing the Splash Screens ........................................................................................... 54

2.15 Loading Images from the SD Card with Slide Show Mode .......................................................... 54

3 Developing with the DLP LightCrafter .................................................................................. 55

3.1 Compiling the GUI Using QT Creator ................................................................................... 55

3.2 Compiling the MSP430 Firmware Using Code Composer ........................................................... 55

3.3 Developing with the TI DVSDK .......................................................................................... 55

4 Pattern Sequences ............................................................................................................ 56

4.1 Pattern Sequence Background .......................................................................................... 56

4.2 External Patterns .......................................................................................................... 57

4.3 Internal Patterns ........................................................................................................... 58

5 Connectors ....................................................................................................................... 59

5.1 Trigger Connector ......................................................................................................... 59

5.2 Camera Connector ........................................................................................................ 59

5.3 UART ........................................................................................................................ 60

5.4 I

2

C ........................................................................................................................... 60

5.5 Fan .......................................................................................................................... 60

5.6 Power ....................................................................................................................... 61

Revision A History ...................................................................................................................... 62

Revision B History ...................................................................................................................... 62

Revision C History ...................................................................................................................... 62

DLPU006C–January 2012–Revised December 2013 Contents

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

3

Page 4

www.ti.com

List of Figures

1. DLP LightCrafter Evaluation Module .................................................................................... 7

1-1. DLP LightCrafter Block Diagram.......................................................................................... 9

1-2. 0.3-inch DMD Pixel Geometry............................................................................................. 9

1-3. DLP LightCrafter Driver Board Block Diagram ........................................................................ 11

1-4. DLP LightCrafter System Board Block Diagram....................................................................... 12

1-5. DM365 DVSDK Software Platform...................................................................................... 13

1-6. DLP LightCrafter FPGA Block Diagram ................................................................................ 14

1-7. DLP LightCrafter Connector Locations ................................................................................. 16

1-8. DLP LightCrafter Module Dimensions .................................................................................. 17

2-1. DLP LightCrafter GUI Connect Button.................................................................................. 19

2-2. DLP LightCrafter GUI Disconnect Button .............................................................................. 19

2-3. Windows XP Found New Hardware Popup............................................................................ 20

2-4. Windows XP Found New Hardware Wizard ........................................................................... 20

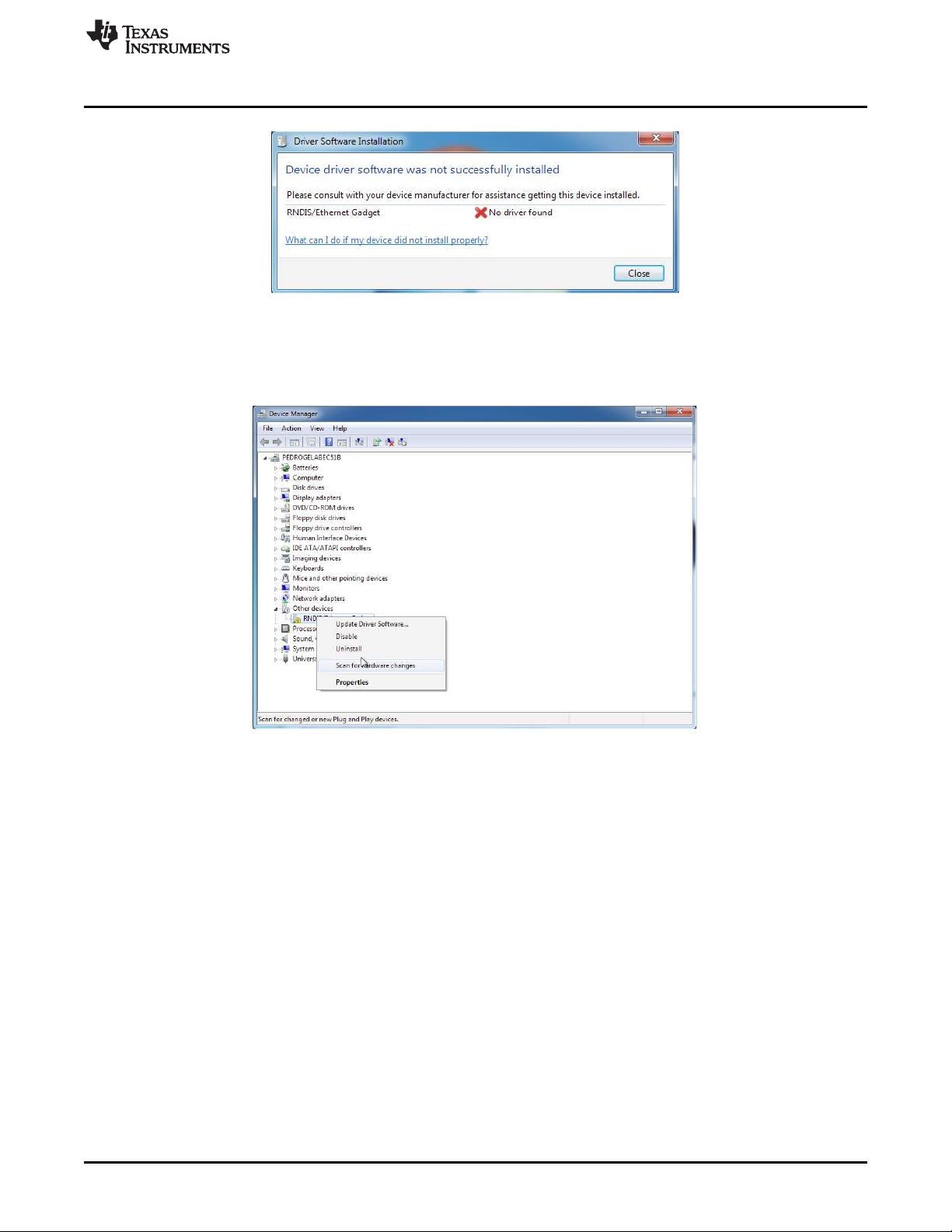

2-5. Windows 7 Driver Software Installation Window ...................................................................... 21

2-6. Windows 7 Device Manager Window................................................................................... 21

2-7. Windows 7 Update Driver Software Search or Browse Window ................................................... 22

2-8. Windows 7 Update Driver Software Select Device Window ........................................................ 22

2-9. Windows 7 Update Driver Software Select Network Driver Window ............................................... 23

2-10. Windows 7 Update Driver Software Successfully Updated Window ............................................... 23

2-11. Ubuntu Command Terminal and "interfaces" File..................................................................... 24

2-12. Ubuntu Command Terminal "ifconfig" Result Before USB Setup ................................................... 24

2-13. Ubuntu Command Terminal "ifconfig" Result After USB Setup .................................................... 25

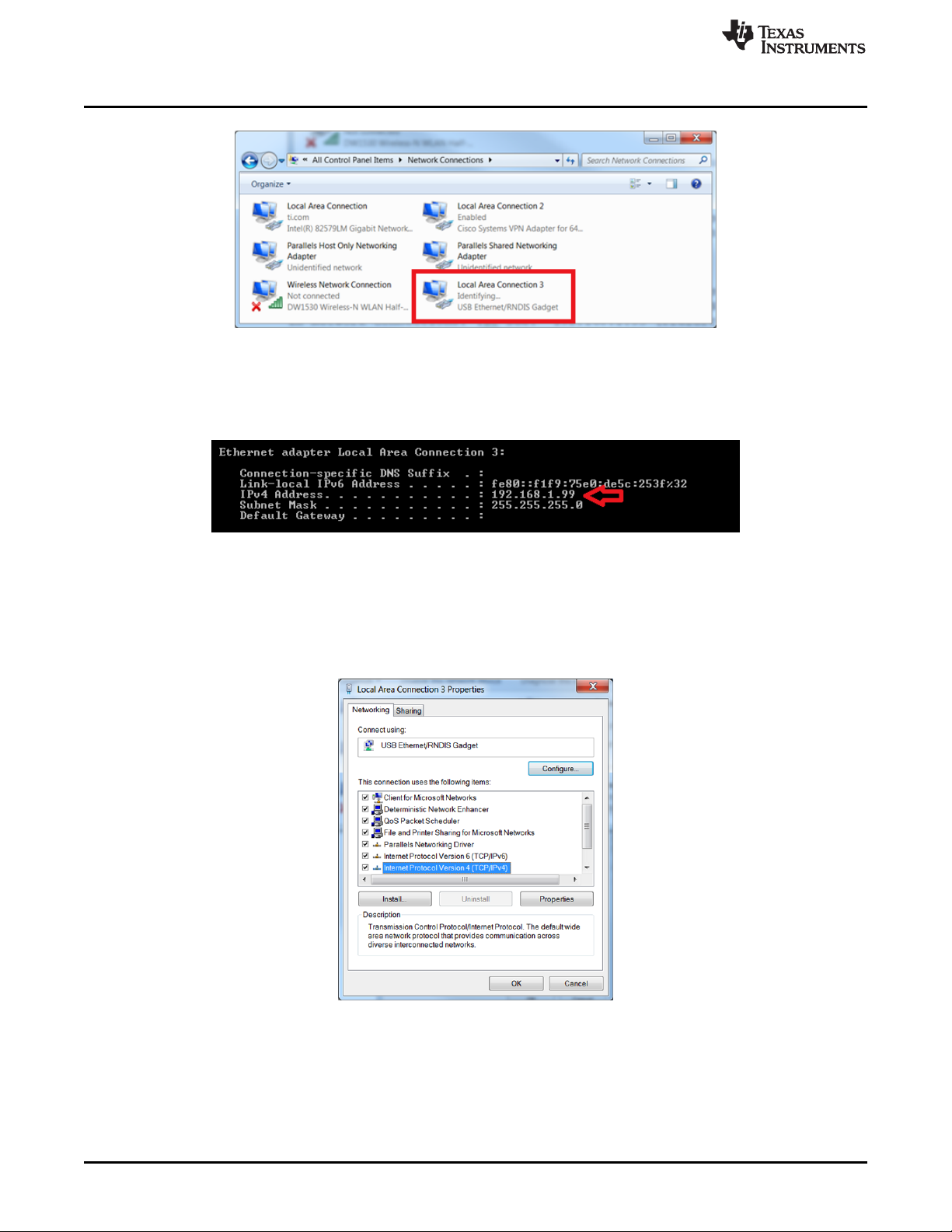

2-14. Windows 7 Network Connections Window ............................................................................ 25

2-15. Windows 7 Network Connections Identifying Local Area Connection ............................................. 26

2-16. Windows 7 Command Window Local Area Connection IPv4 Address ............................................. 26

2-17. Windows 7 Local Area Connection Properties ........................................................................ 26

2-18. Windows 7 Local Area Connection TCP/IPv4 Properties............................................................ 27

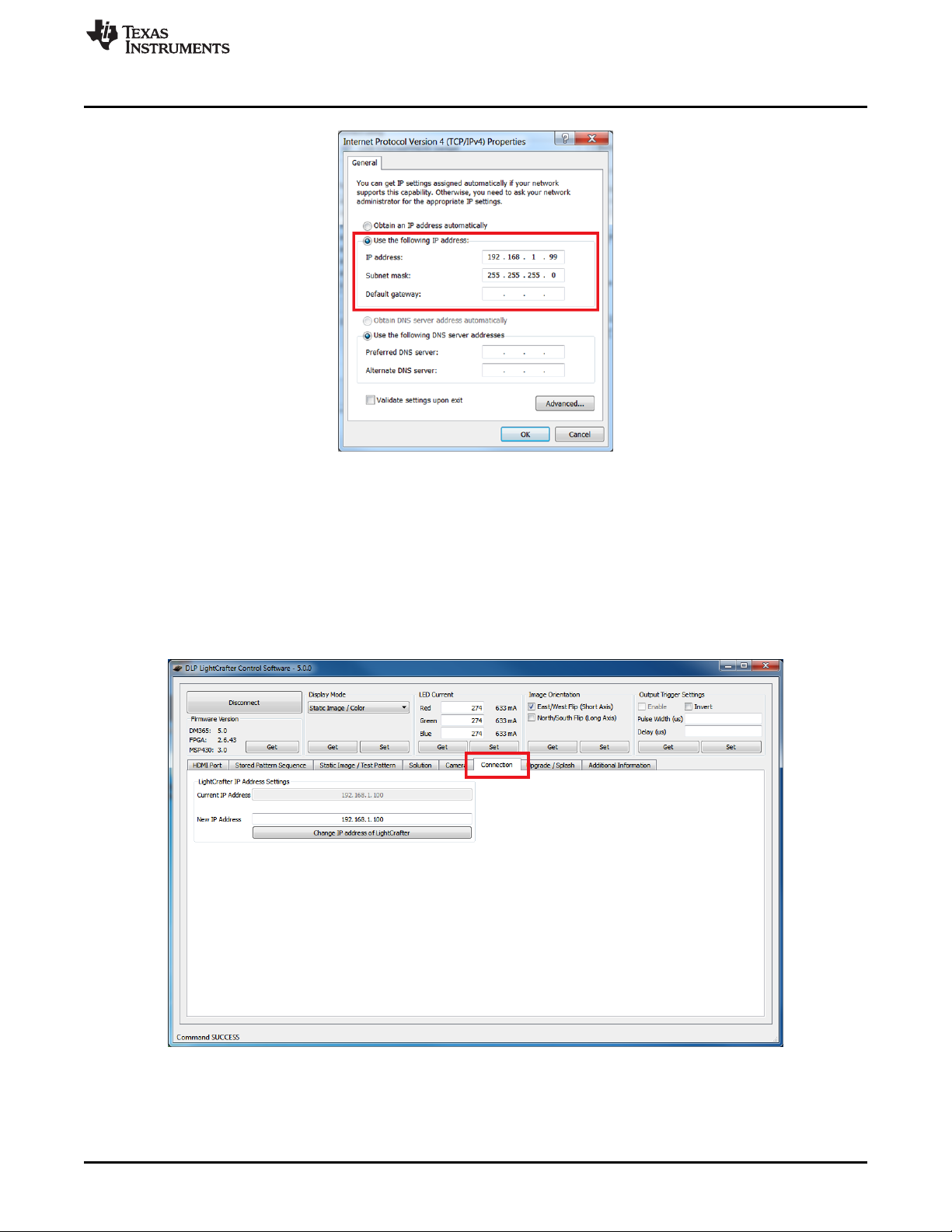

2-19. DLP LightCrafter GUI Connection Tab ................................................................................. 27

2-20. DLP LightCrafter GUI Connection New IP Address Textbox ........................................................ 28

2-21. DLP LightCrafter GUI Changing IP Popup............................................................................. 28

2-22. DLP LightCrafter GUI Connection Current IP Address Textbox .................................................... 28

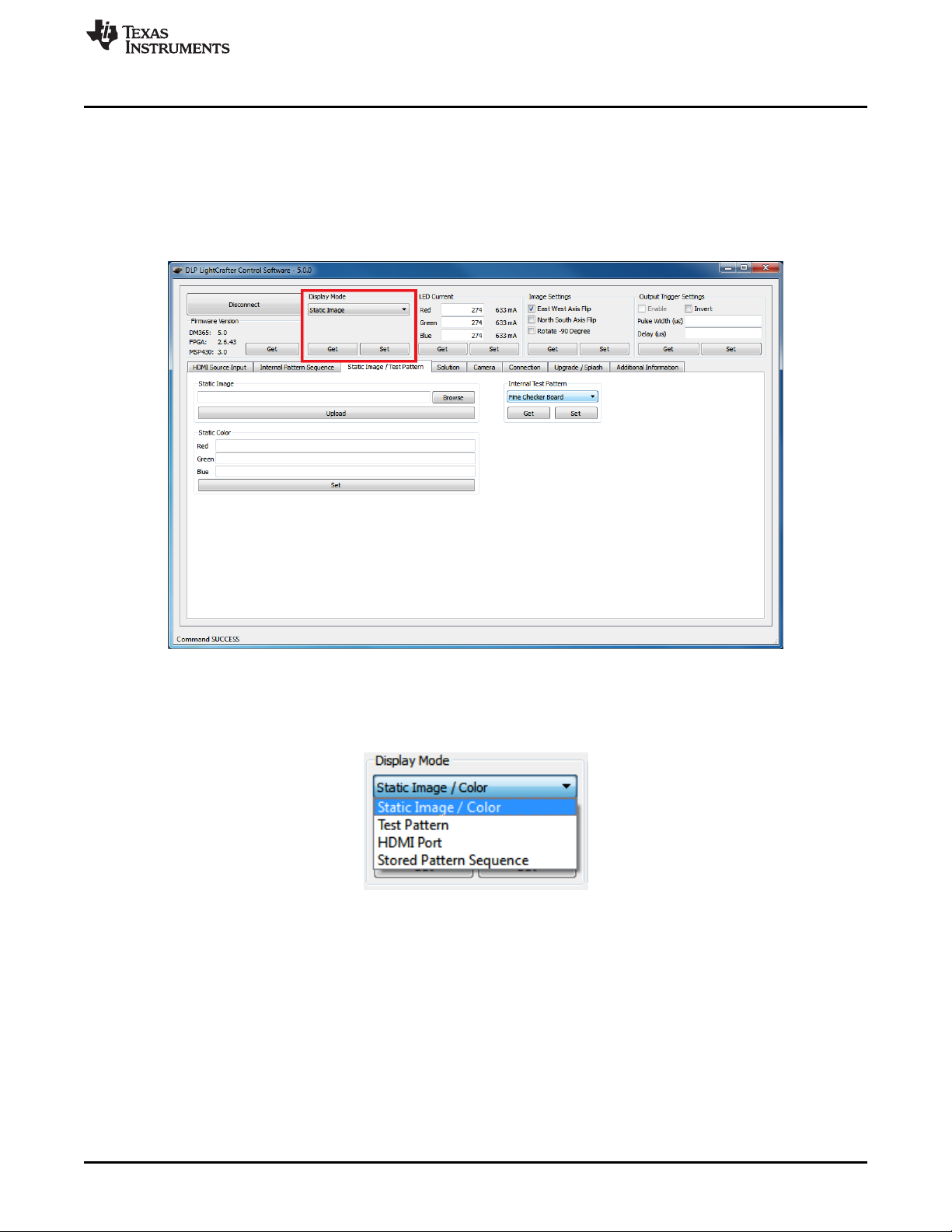

2-23. DLP LightCrafter GUI Display Mode Setting........................................................................... 29

2-24. DLP LightCrafter GUI Display Mode Options.......................................................................... 29

2-25. DLP LightCrafter GUI Display Mode Set Button....................................................................... 30

2-26. DLP LightCrafter GUI LED Current Settings........................................................................... 30

2-27. DLP LightCrafter GUI LED Current Setting Active Cooling Needed................................................ 31

2-28. DLP LightCrafter GUI LED Current Setting Not Recommended .................................................... 31

2-29. DLP LightCrafter GUI LED Current Setting Set Button............................................................... 31

2-30. DLP LightCrafter GUI Image Orientation Settings .................................................................... 32

2-31. DLP LightCrafter GUI Output Trigger Settings ........................................................................ 33

2-32. DLP LightCrafter GUI Output Trigger Enable Checkbox............................................................. 33

2-33. DLP LightCrafter GUI Output Trigger Set Button ..................................................................... 33

2-34. DLP LightCrafter GUI RGB Video Streaming Selected on HDMI Port Tab........................................ 34

2-35. DLP LightCrafter GUI RGB Video Streaming Set Button ............................................................ 35

2-36. DLP LightCrafter GUI Sequence Settings Tab in Stored Pattern Sequence Tab................................. 36

2-37. Relationship between Trigger Period, Trigger Delay, and Exposure Time ........................................ 37

2-38. DLP LightCrafter GUI Pattern Sequence Settings Set Button....................................................... 37

4

List of Figures DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

2-39. DLP LightCrafter GUI Load Pattern Images ........................................................................... 38

2-40. DLP LightCrafter GUI Select Images Window......................................................................... 38

2-41. DLP LightCrafter GUI Upload All Pattern Images Button ............................................................ 39

2-42. DLP LightCrafter GUI Pattern Sequence Control Start Button ...................................................... 39

2-43. DLP LightCrafter GUI Hardwired Pattern Sequence Settings and Pattern Selection ............................ 40

2-44. MBMC Pattern Sequence Output Example............................................................................ 41

2-45. DLP LightCrafter GUI Multiple Bit and Multiple Color Sequence Settings Tab in Stored Pattern Sequence

2-46. DLP LightCrafter GUI Multiple Bit and Multiple Color Sequence Settings Tab in Stored Pattern Sequence

2-47. DLP LightCrafter GUI Example Sequence Settings for MBMC Sequence ........................................ 43

2-48. DLP LightCrafter GUI External Streaming Pattern Sequence Settings in HDMI Port Tab....................... 44

2-49. DLP LightCrafter GUI Static Image and Test Pattern Tab ........................................................... 45

2-50. DLP LightCrafter GUI Static Image Upload Button ................................................................... 45

2-51. DLP LightCrafter GUI Static Color Set Button......................................................................... 46

2-52. DLP LightCrafter GUI Internal Test Pattern Settings ................................................................. 46

2-53. DLP LightCrafter GUI Solution Tab..................................................................................... 47

2-54. DLP LightCrafter GUI Camera Tab ..................................................................................... 48

2-55. DLP LightCrafter GUI Firmware Upgrade Tab......................................................................... 49

2-56. DLP LightCrafter GUI Firmware Select Drop-Down Options ........................................................ 49

2-57. DLP LightCrafter GUI Firmware Install Button......................................................................... 49

2-58. Windows 7 SD Card Right-Click Menu................................................................................. 50

2-59. Winodws 7 Format SD Card Window................................................................................... 51

2-60. Windows 7 Run cmd.exe Right-click Menu ............................................................................ 52

2-61. Windows 7 Create Bootable SD Card Program....................................................................... 53

4-1. Relationship Between Bit Planes and 24-Bit RGB Images .......................................................... 56

4-2. Relationship Between Bit Partition and Time .......................................................................... 56

4-3. Bit Planes and Triggers................................................................................................... 57

Tab .......................................................................................................................... 42

Tab .......................................................................................................................... 43

DLPU006C–January 2012–Revised December 2013 List of Figures

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

5

Page 6

www.ti.com

List of Tables

1-1. DLP LightCrafter Light Engine Specifications ......................................................................... 10

1-2. DLP LightCrafter Protection Shutdown Modes........................................................................ 14

2-1. LED Current Settings ..................................................................................................... 30

2-2. Supported Resolutions for Video Input................................................................................. 34

2-3. MBMC Pattern Sequence Information Input........................................................................... 41

4-1. Allowable External Pattern Combinations ............................................................................. 57

4-2. Maximum Internal Pattern Rate ......................................................................................... 58

4-3. Internal Pattern Exposure Time ......................................................................................... 58

5-1. Trigger Connector Pins................................................................................................... 59

5-2. Camera Connector Pins.................................................................................................. 59

5-3. UART Connector Pins .................................................................................................... 60

5-4. I

5-5. Fan Connector Pins....................................................................................................... 61

5-6. Power Connector Pins.................................................................................................... 61

2

C Connector Pins ........................................................................................................ 60

6

List of Tables DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

About This Guide

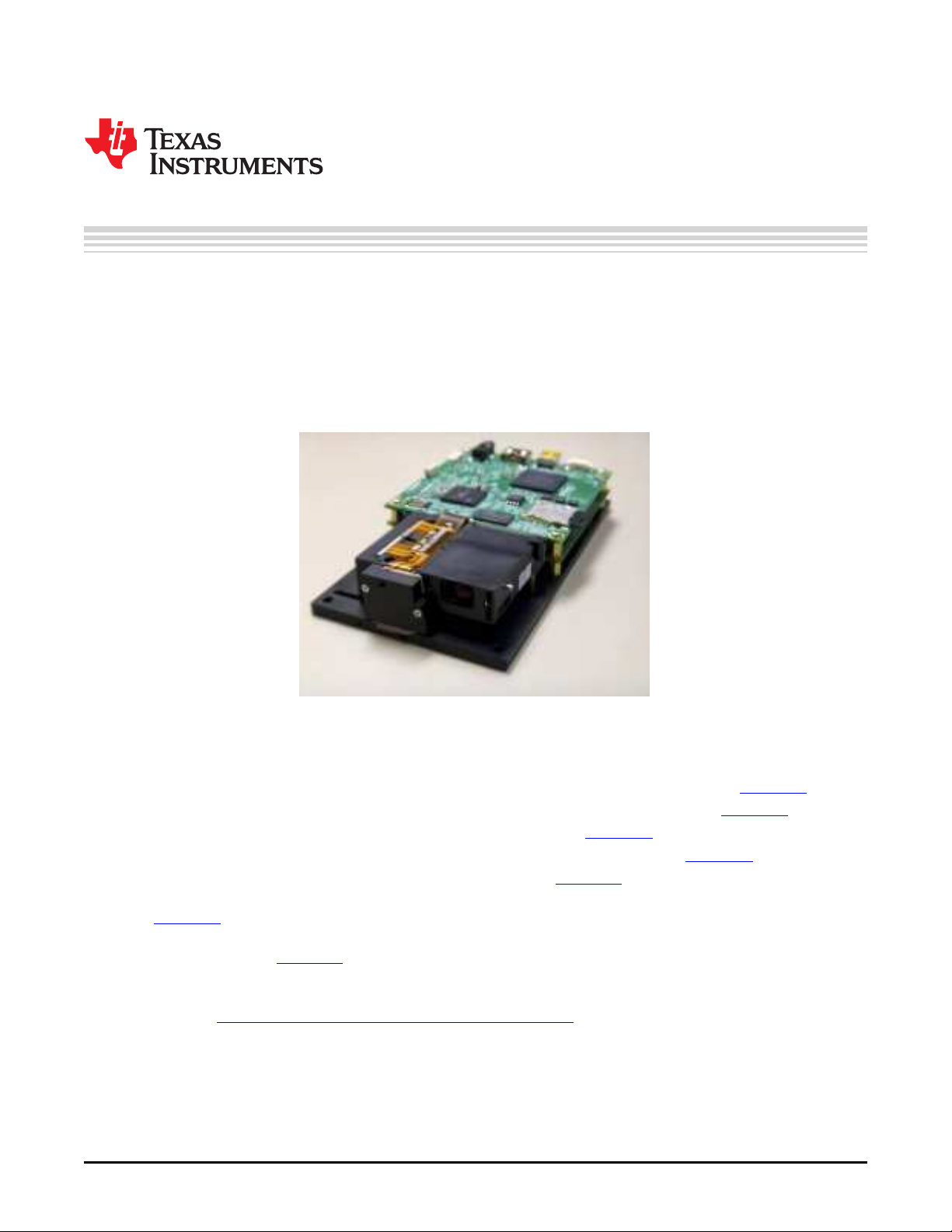

The DLP®LightCrafter™ is a third party implementation of a next generation DLP 0.3-inch WVGA chipset

reference design to enable faster development cycles for applications requiring small form factor and

intelligent pattern display.

This guide is an introductory document for the DLP LightCrafter that provides an overview of the system

and its software. Other documents provide more in-depth information of the hardware and software

features of the components of the DLP LightCrafter.

Preface

DLPU006C–January 2012–Revised December 2013

Read This First

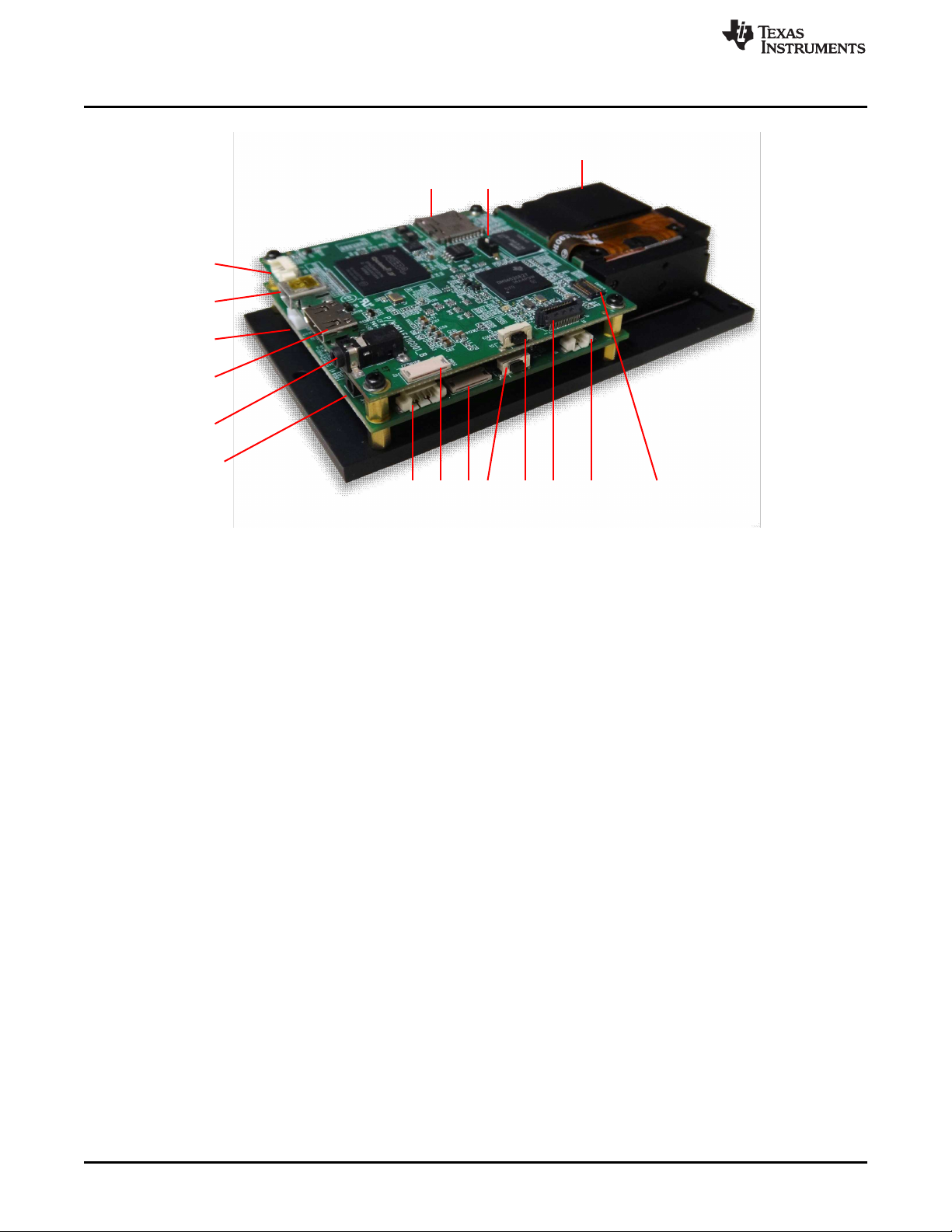

Figure 1. DLP LightCrafter Evaluation Module

Related Documentation from Texas Instruments

• DLPC300 data sheet: DLP Digital Controller for DLP3000 DMD, TI literature number DLPS023

• DLP3000 data sheet: DLP 0.3 WVGA DDR Series 220 DMD, TI literature number DLPS022

• DLPC300 Software Programmer’s Guide, TI literature number DLPU004

• DLP®LightCrafter™ DM365 Command Interface Guide, TI literature number DLPU007

• DLP®LightCrafter™ FPGA Overview TI literature number DLPA042

• Using the DLP®LightCrafter™ to Trigger CCD Cameras from The Image Source® TI literature number

DLPA032

• Creating Multiple Bit Depth and Multiple Color Pattern Sequences for DLP®LightCrafter™ Kit TI

literature number DLPA035

If You Need Assistance

Refer to the DLP and MEMS TI E2E Community support forums.

LightCrafter is a trademark of Texas Instruments.

DLP is a registered trademark of Texas Instruments.

DLPU006C–January 2012–Revised December 2013 Read This First

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

7

Page 8

DLP®LightCrafter™ Module Overview

This chapter introduces the DLP LightCrafter module.

1.1 Welcome

Your new DLP LightCrafter module allows you to evaluate TI’s DLP 0.3-inch WVGA chipset platform along

with TI’s DaVinci Technology and the DM365 architecture.

This technology brings together a set of components providing an efficient and compelling system solution

for:

• Small display projector: embedded display, interactive display, information overlay

• Structured light applications: 3D modeling/design, biometric: fingerprint identification and face

recognition, machine vision and inspection

• Medical and life sciences: vascular imaging, dental impression scanner, intraoral dental scanners,

orthopaedics, prosthesis, CT/MRI/X-ray marking, retail cosmetics

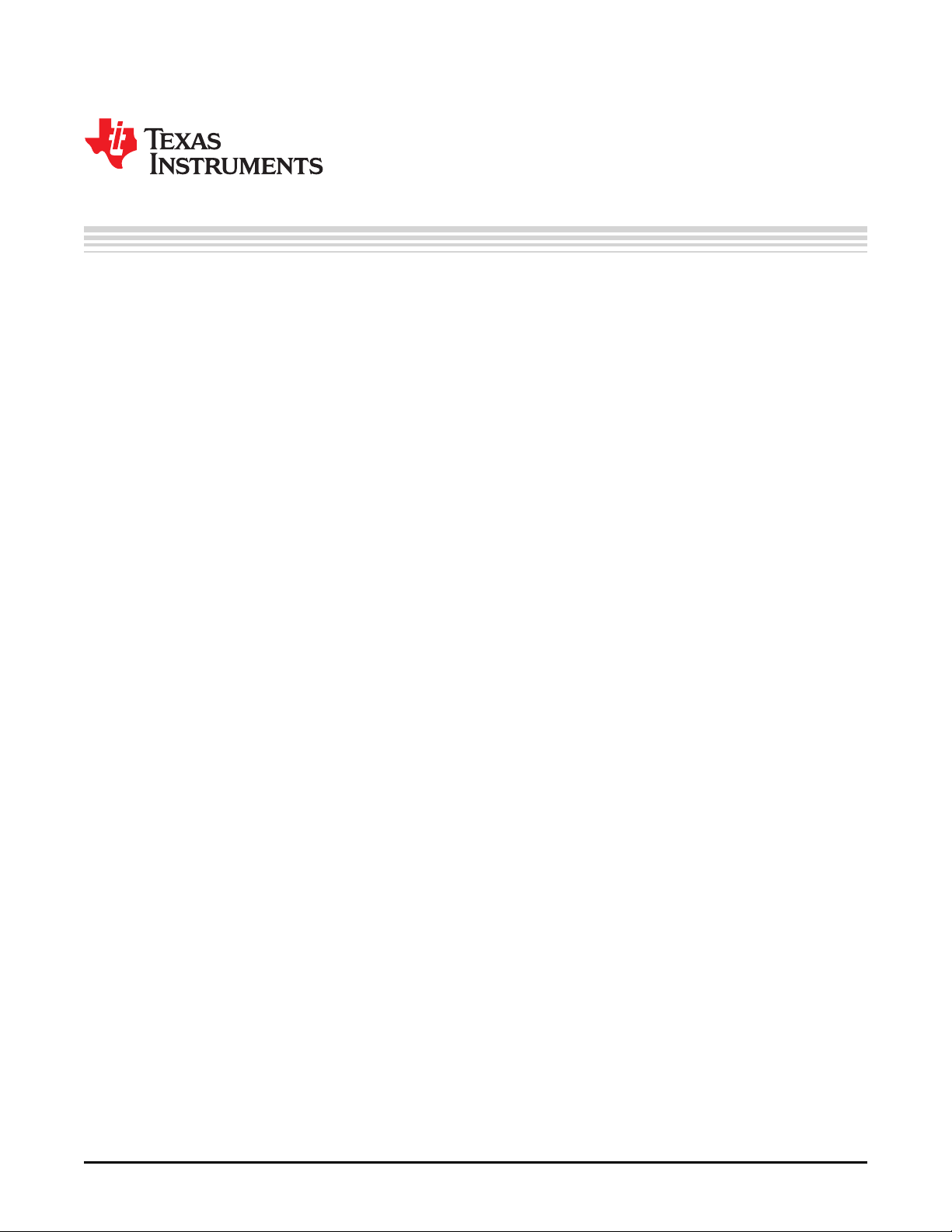

1.2 What is in the LightCrafter EVM?

The DLP LightCrafter module consists of three subsystems:

• Light engine – includes the optics, red, green, and blue LEDs, and the 608 x 684 diamond pixel 0.3inch WVGA DMD. Capable of 20 lumens out-of-the-box with support to 50 lumens with user’s addition

of active cooling.

• Driver board – includes the LED driver circuits, DLPC300 DMD Controller, power management circuits,

and MSP430.

• System board – includes TMS320DM365, FPGA, and several connectors for external inputs.

Figure 1-1 shows the major hardware components.

Chapter 1

DLPU006C–January 2012–Revised December 2013

8

DLP®LightCrafter™ Module Overview DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

7 .6

3 7um

7

.

6

3

7

u

m

10.8 um

10 .8um

www.ti.com

What is in the LightCrafter EVM?

Figure 1-1. DLP LightCrafter Block Diagram

1.2.1 Light Engine

Young Optics, Inc. developed the DLP LightCrafter’s light engine. The light engine consists of the

following components:

• 0.3-inch WVGA DMD (DLP3000)

• OSRAM Red LED (LE A Q9WN)

• OSRAM Green LED (L CG H9RN)

• OSRAM Blue LED (LE B Q9WN)

• Murata NTC Thermistor (NCP15WF104F03RC)

• Optics with 1.66 Throw Ratio

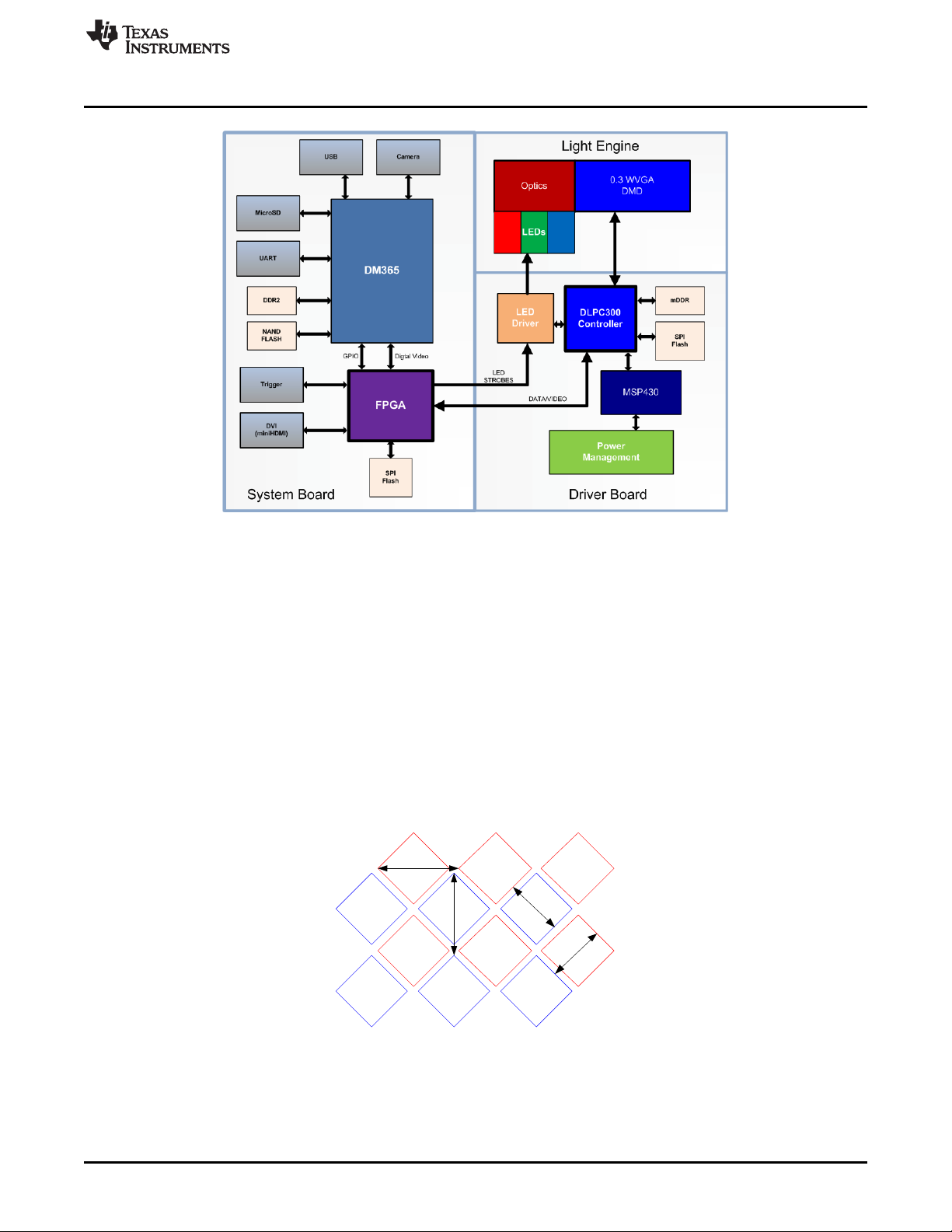

The DLP3000 0.3-inch DMD contains 415872 mirrors arranged in a 608 by 684 with the diamond pattern

geometry shown in Figure 1-2

The DMD is vertically mounted at the end of the light engine. The light engine, including the LEDs and not

including the heat sinks, has a length of 39.3 mm, width of 41.6 mm, and height of 11 mm. Table 1-1 lists

the specifications of the light engine:

Figure 1-2. 0.3-inch DMD Pixel Geometry

DLPU006C–January 2012–Revised December 2013 DLP®LightCrafter™ Module Overview

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

9

Page 10

What is in the LightCrafter EVM?

Table 1-1. DLP LightCrafter Light Engine Specifications

Brightness 25 at 1.85 W LED lm

Brightness uniformity (JBMA) 70 %

ANSI contrast 43:1

Full-on full-off contrast 685:1

Color uniformity (CIE x) 0.03

Color Uniformity (CIE y) 0.04

Throw ratio 1.66

Offset 100 %

Focus range 364 2169 mm

Image diagonal size 10 60 inch

Focus stroke 1 mm

The MSP430 monitors the light engine's thermistor to shutdown the EVM if excessive heat is measured on

the green LED. Passively cooled systems (no extra heat sinks or fans) have a thermal limit resulting in

LED currents under 633 mA. Actively cooled systems (extra heat sink and fan) have a thermal limit

resulting in LED currents under 1.5 A. Please see Table 2-1 for the corresponding LED current software

settings.

www.ti.com

MIN TYP MAX UNIT

10 at 0.6 W LED

30 at 2.25 W LED

1.2.2 Driver Board

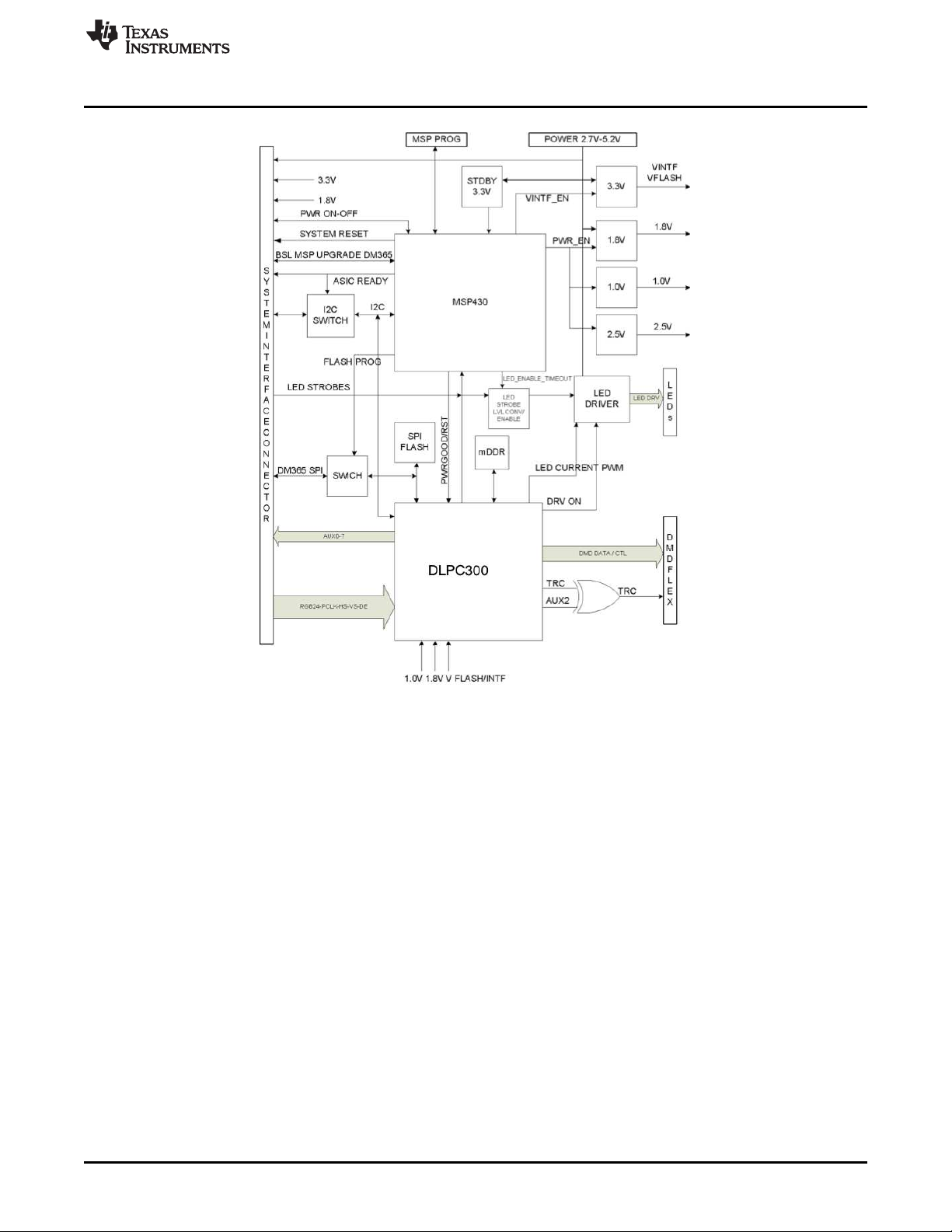

Figure 1-3 shows the DLP LightCrafter’s driver board block diagram.

10

DLP®LightCrafter™ Module Overview DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

What is in the LightCrafter EVM?

Figure 1-3. DLP LightCrafter Driver Board Block Diagram

The major components of the DLP LightCrafter’s driver board are:

• DLP3000: 0.3-inch WVGA chipset DMD

• DLPC300: 0.3-inch WVGA chipset controller for DLP3000 with:

– 2MB SPI FLASH that contains DLPC300 firmware

– 32MB mDDR that buffers images for the DLP3000

• MSP430:

– Controls power supply sequencing and system initialization

– Shuts down system upon detection of low or high input voltage

– Shuts down system if LED anode voltages exceed maximum limit

– Measures thermistor and shuts down system when maximum temperature ratings are exceeded

• LED driver circuitry

• Power management:

– TPS63020: Buck-Boost Regulator for LED supplies

– TPS63020: Buck-Boost Regulator for 3.3 V supply

– TPS62260: Step Down Converter for DLPC300 2.5 V supply

– TPS62400: Step Down Converter for DLPC300 1.0 V and 1.8 V supply

– TPS65120: 4-CH Bias for DMD VRST and VBIAS supplies

– TPS71501: LDO for DMD VOFS supply

DLPU006C–January 2012–Revised December 2013 DLP®LightCrafter™ Module Overview

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

11

Page 12

What is in the LightCrafter EVM?

1.2.3 System Board

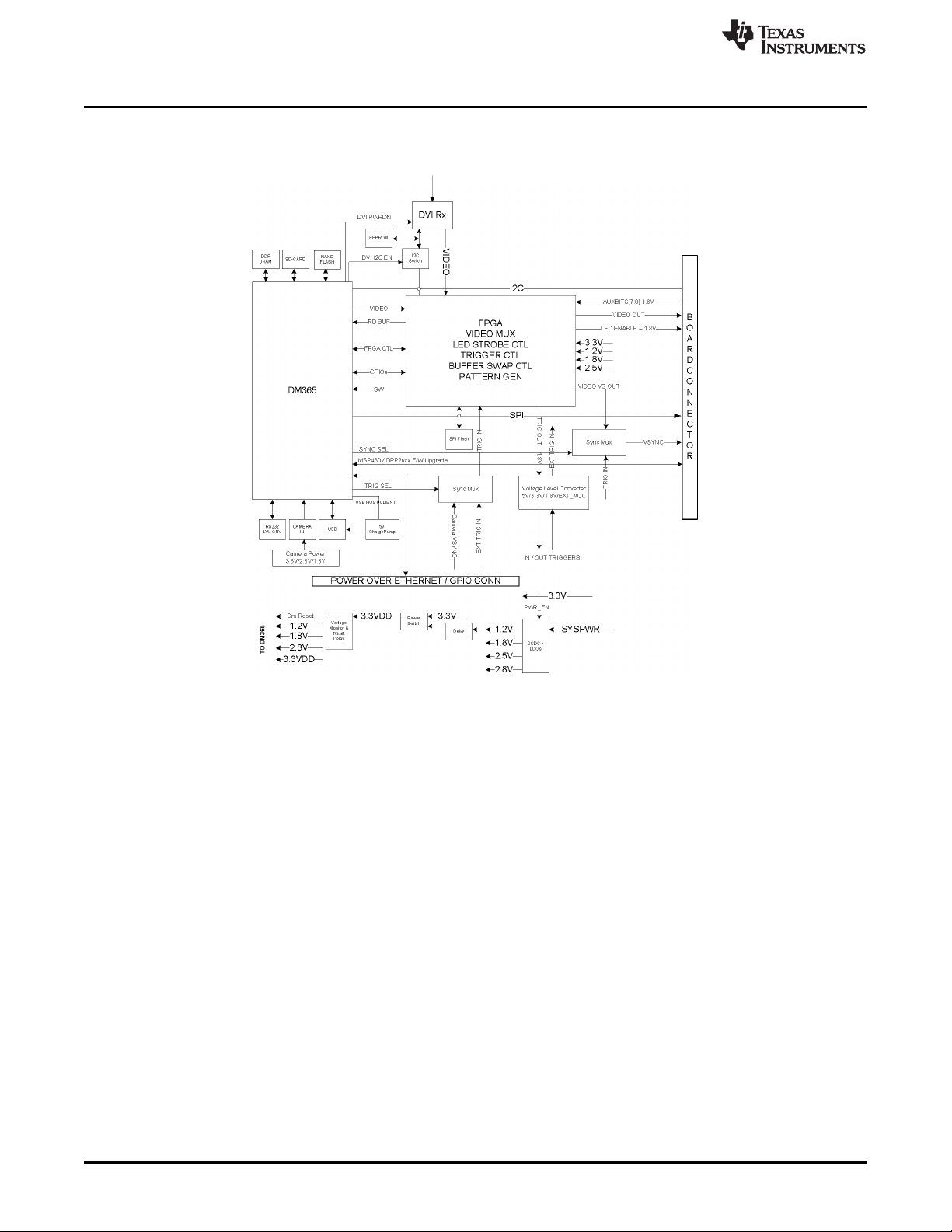

Figure 1-4 shows the DLP LightCrafter’s system board.

www.ti.com

Figure 1-4. DLP LightCrafter System Board Block Diagram

The major components of the system board are:

• Altera Cyclone IV FPGA:

– Controls video muxing (external miniHDMI or DM365)

– Controls LEDs enables

– Generates programmable camera triggers

– Manages four internal buffers for fast pattern display

• DM365: Embedded Linux main processor that controls camera interface, connectivity with PC, nonvolatile storage (Micro-SD and NAND Flash), FPGA control, video output, and video buffer in DDR2.

– 128MB DDR2 memory

– Micro-SD connector

– Mini-USB connector

– UART mini-plug

• MiniHDMI connector (DVI-D compliant)

• Power management:

– TPS650531: 2-Step Down Converter for FPGA’s and DM365’s 1.2 V and 1.8 V supplies with three

LDOs for FPGA’s 2.5-V supply and camera interface optional 2.8-V supply

12

DLP®LightCrafter™ Module Overview DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

1.3 DLP LightCrafter Embedded Software Overview

1.3.1 DM365 Software

The DLP LightCrafter module software is based on TI’s DVSDK platform running on the Digital Media

System-on-Chip DM365. The DVSDK platform is a collection of royalty-free software components built

upon Linux operating system and pre-tested by TI. The software components include Linux kernel, Linux

filesystem, Linux product support package (PSP), application framework (APIs), codec libraries (MPEG4,

H.264, MPEG2, G.711, JPEG), example programs, DSP Codegen, and CodeSourcery tool chain with IDE

for cross-compiling and debugging target systems.

DLP LightCrafter Embedded Software Overview

Out of the box, the DLP LightCrafter boots from the on-board NAND FLASH. The DM365 acts as the main

processor of the system and boots as an embedded Linux device. The Linux file system resides on the

NAND or micro-SD card. Thus, the DLP LightCrafter does not require an NFS mount nor a TFTP server to

run. The embedded Linux system utilizes Remote Network Drivers Interface Specification (RNDIS) to send

packets through USB. DLP LightCrafter has a default IP address of 192.168.1.100.

1.3.1.1 Serial Communication

DLP LightCrafter’s UART port serves as a console output of the embedded Linux device. The DM365

sends error messages through the UART and accepts root level commands. A 2.5-mm stereo plug to

female DB9 connector is needed to connect the DLP LightCrafter’s UART port to a PC. For PCs with only

USB ports, use a USB-to-serial RS232 adapter.

To view UART console messages, configure a terminal emulator with the following parameters:

• Baud: 115200

• Data Bits: 8

• Stop Bits: 1

• Parity: None

• Flow Control: None

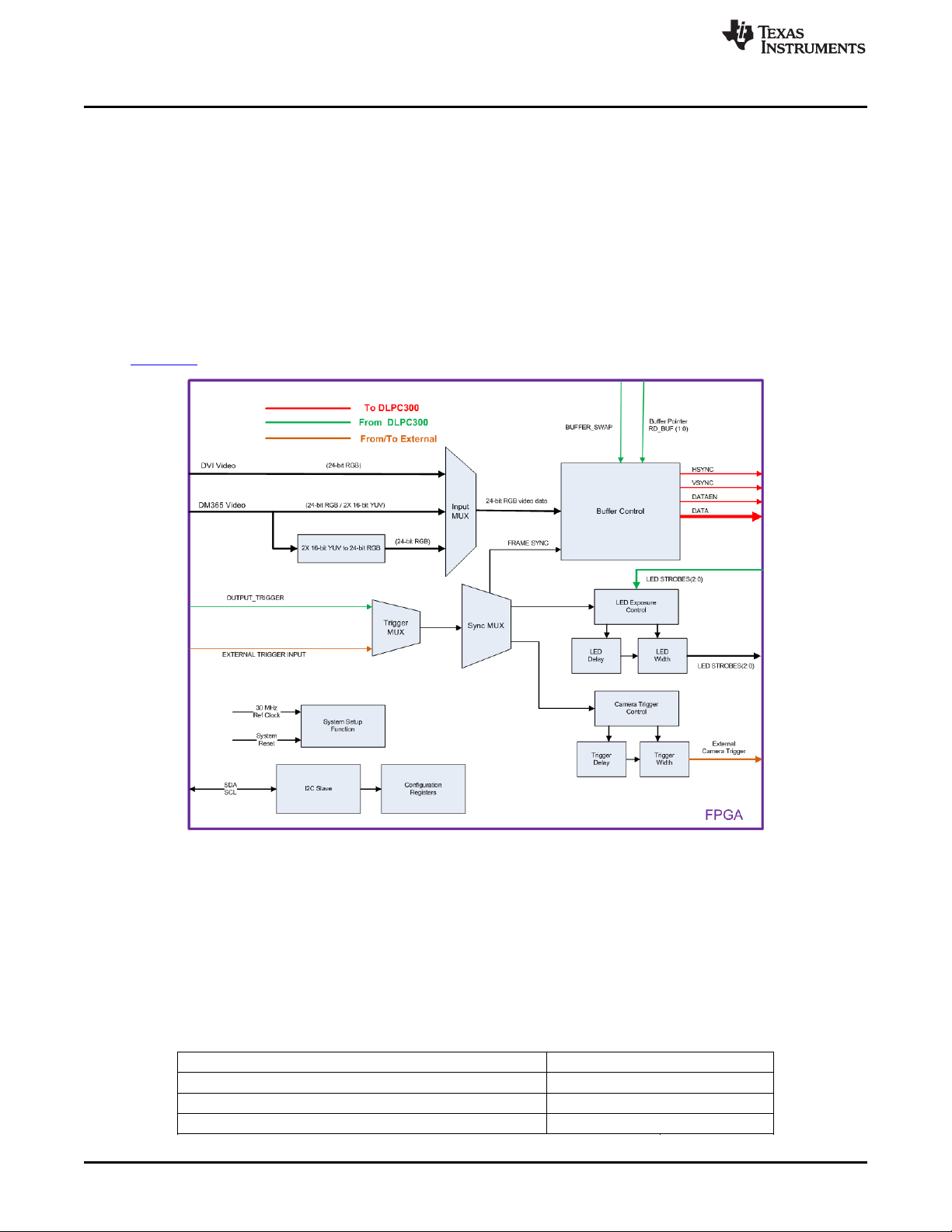

1.3.2 FPGA Overview

The FPGA expands the functionality of the DLP 0.3-inch WVGA chipset to enable the features of DLP

LightCrafter. An important feature of DLP LightCrafter is the ability to display stored patterns at high frame

rates. The FPGA provides the timing and signal management to implement a four buffer rotation scheme,

which enables a stored pattern capability of 4x24=96 binary patterns. Additional capabilities include:

• An external trigger input, which allows an external device to trigger stored patterns; configurable for

polarity (positive or negative), delay, and duration (pulse width).

• An external trigger output, which provides the ability to synchronize an external camera with the

display of patterns; configurable for polarity (positive or negative), delay, and duration (pulse width).

Figure 1-5. DM365 DVSDK Software Platform

DLPU006C–January 2012–Revised December 2013 DLP®LightCrafter™ Module Overview

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

13

Page 14

DLP LightCrafter Embedded Software Overview

• A timing generator, which implements the internal auto trigger for continuously repeated pattern

display.

• Control for the illumination LEDs; generates LED strobe signals with configurable delay and duration to

set exposure; synchronized with the trigger.

• A video data source input selector (MUX); sends the video data to the DLPC300 parallel input. Inputs

are:

– Video from the TFP401A DVI receiver

– DM365 24-bit RGB (not bit identical with stored patterns)

– DM365 YUV4:2:2 video converted to RGB888 (bit identical with stored patterns).

• Timing and signal management for a "circular" frame buffer.

Please read the DLP LightCrafter FPGA Overview application note for more details. TI literature number

DLPA042 . Figure 1-6 shows the block diagram of the FPGA hardware.

www.ti.com

Figure 1-6. DLP LightCrafter FPGA Block Diagram

1.3.3 MSP430 Overview and Shutdown Protection Modes

The MSP430 controls the power sequencing, initializes the DLPC300, and provides safety shutdown

protection modes for DLP LightCrafter. The MSP430 has three shutdown protection modes. The shutdown

modes require that both the system power and USB cable be disconnected before a reboot is allowed.

Each mode is displayed by blinking the Red LED (D3) on the driver board at different rates. Table 1-2

describes the protection modes.

Table 1-2. DLP LightCrafter Protection Shutdown Modes

Shutdown Mode Description D3 On Time (s) D3 Off Time (s)

System voltage less than 3.9 V or greater than 5.5 V 5.0 0.5

LED anode voltage above 5.8 V 5.0 5.0

Light engine thermistor above 70°C 1.5 1.0

14

DLP®LightCrafter™ Module Overview DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

Other Items Needed for Operation

1.4 Other Items Needed for Operation

The DLP LightCrafter module is a flexible, ready to use EVM. However, DLP

LightCrafter EVM does not ship with any cables, power supply, or additional

hardware components. To use the EVM, you need:

• Power supply: center positive 5-V output with 2- to 3-A current rating and a

plug of 0.7 mm inner diameter x 2.35 mm outer diameter and 9.5-mm

female shaft.

• USB cable: A to mini-B

• RS232 cable with 2.5-mm stereo plug

1.5 DLP LightCrafter Connections

DLP LightCrafter offers the following connectivity options:

• Power Connector: supplies 5-V to DLP LightCrafter module

– Output: 5-V with 2- to 3-A current rating

– Inner plug diameter: 0.7 mm

– Outer diameter: 2.35 mm

– Female shaft length: 9.5 mm

– Positive center

• Mini-HDMI: supports external video input with 608 × 684 resolution at 60 Hz

• Micro-SD: tested to support up to 4GB, class 10, high capacity cards for

DM365 software and local data storage

• Mini USB: interfaces to PC as a slave device. A program running on the PC

issues commands to the DLP LightCrafter module

• Camera Connector: 28-pin connector using ITU-R BT.656 compatible

camera interface. The camera interface supports up to 12-bit data.

• Trigger connector: supports external or internally generated triggers for

camera capture

• Serial FLASH programming connectors:

– Driver board: programs the MSP430 FLASH and the DLPC300 serial

FLASH

– System board: programs the FPGA serial FLASH

• UART mini-plug: allows serial messages with the following RS-232

compatible serial configuration:

– 2.5-mm stereo plug: tip-RX, ring-TX, ground-GND

– Bits per second: 115200

– Data Bits: 8

– Parity: None

– Stops Bits: 1

– Flow Control: None

Figure 1-7 depicts the connectors and their respective locations.

DLPU006C–January 2012–Revised December 2013 DLP®LightCrafter™ Module Overview

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

15

Page 16

1

2

3

4

5

7 8 9 10

15

17

6

12

13 14

16

11

DLP LightCrafter's Dimensions

www.ti.com

1. Trigger Input and Output

2. Mini USB

3. Power Connector

4. Mini HDMI

5. UART

6. Power Socket

7. I2C

8. FPGA SPI Flash Programming Interface

9. MSP430 or DLPC300 Flash Programming Interface

10. On or Off Button – Do not turn off while the Linux system is

booting

11. Input Selection Button (DM365, Internal Test Pattern, or HDMI

input)

12. Ethernet PHY

13. Fan

14. Camera

15. Focus Control

16. Boot Mode Selection Switch

17. Micro-SD card

Figure 1-7. DLP LightCrafter Connector Locations

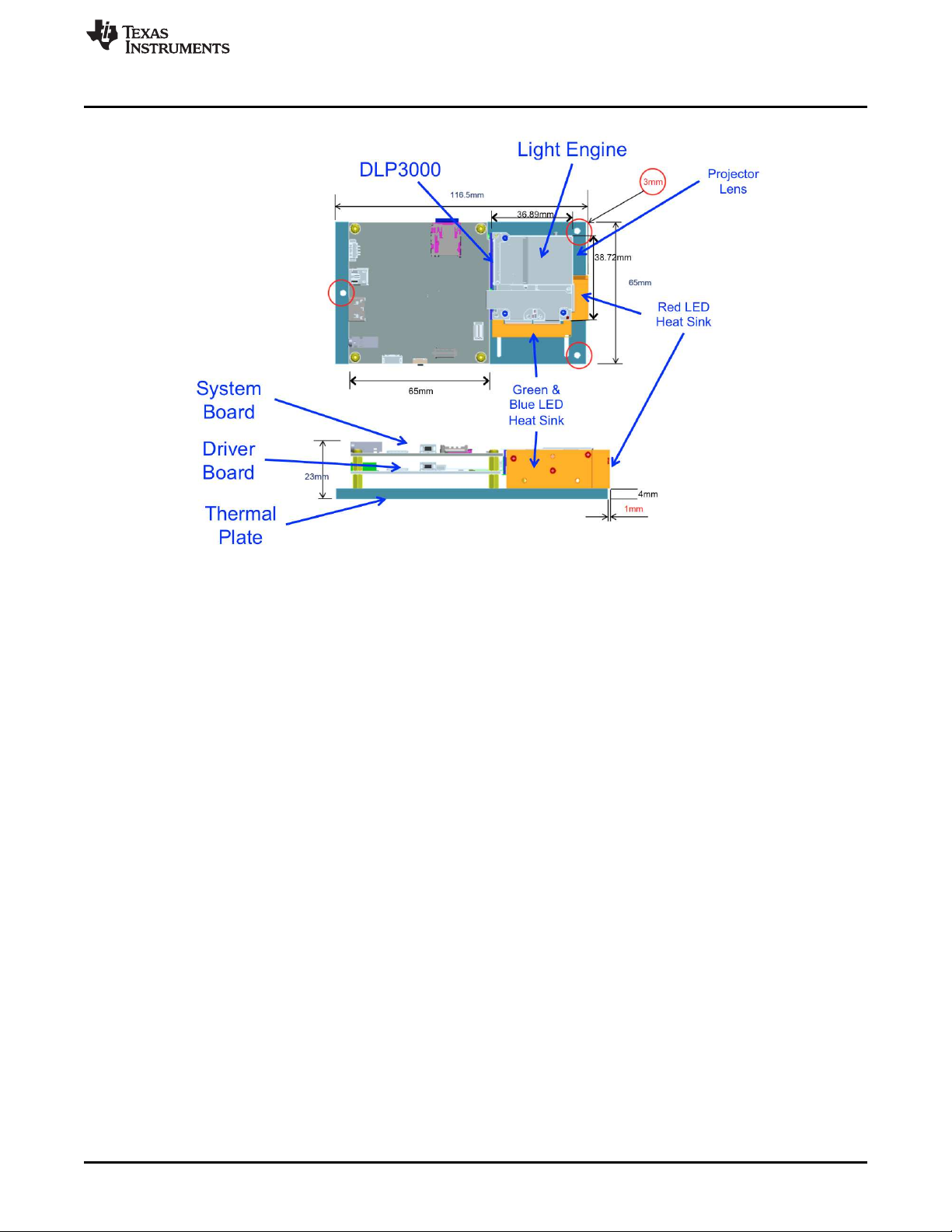

1.6 DLP LightCrafter's Dimensions

The DLP LightCrafter optical engine is mounted on top of a thermal plate to

provide passive cooling to the module. The DLP3000, 0.3-inch DMD, is

vertically mounted at the end of the optical engine and attached with a

connector to the driver board. The system board is mounted on top of the

driver board. This module has dimensions of 116.5-mm long, 65-mm wide, and

16

DLP®LightCrafter™ Module Overview DLPU006C–January 2012–Revised December 2013

23-mm tall. Figure 1-8 illustrates the DLP LightCrafter dimensions.

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

www.ti.com

DLP LightCrafter's Dimensions

Figure 1-8. DLP LightCrafter Module Dimensions

DLPU006C–January 2012–Revised December 2013 DLP®LightCrafter™ Module Overview

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

17

Page 18

This chapter describes installing the Graphical User Interface (GUI), controlling the DLP LightCrafter

Module using the GUI, and upgrading the firmware on the EVM. All instructions relating to the GUI in this

document refer to the latest DLP LightCrafter GUI v5.0.

2.1 Installing the GUI

DLP LightCrafter includes a QT-based GUI to control the module through USB. QT is a Nokia crossplatform application and user interface framework with open source and commercial licenses. To install

the DLP LightCrafter GUI, follow these steps.

1. Download the most recent version of the DLP LightCrafter Software Bundle from

http://www.ti.com/tool/dlplightcrafter.

• Linux users will also need to install the latest QT version 5 library. Available from http://qt-

project.org/downloads. After the QT library has been installed, the user must create a file in the

"etc/ld.so.conf.d" directory so that the GUI coorrectly accesses the QT library. Create a file called

"Qt5.conf" in the "etc/ld.so.conf.d" directory and enter the location of the QT5 library directory. For

example, "<QtInstall_dir>/5.1.1/gcc/lib". Verify the actual directory path of the "lib" directory in the

installed QT5 library. After the file has been saved, run "ldconfig" in the terminal.

2. Extract the files from the downloaded zip file.

3. Run the DLP LightCrafter Software Bundle installer.

• Linux users may need to right click on the installer file and set a property to "Allow executing file as

program" so the installer executes correctly.

• Linux and Mac installers may attempt to install the software bundle to the root directoy, which for

some users may not be accessible. Choosing a different installation directory, such as the user's

home or documents folder should allow the installation to run properly.

4. From the GUI directory of the installed software, double click on the LightCrafterGUI application to run

the GUI. By default the GUI is installed in one of the following directories:

• Windows XP & 7: "C:\Texas Instruments-DLP\DLPLCRSoftwareBundle-3.0\LightCrafterGUI-v5.0-

Windows"

• Linux: ".../Texas Instruments-DLP/DLPLCRSoftwareBundle-3.0/LightCrafterGUI-v5.0-Linux"

– Linux users may need to right click on the GUI executable file and set a property to "Allow

executing file as program" so the GUI operates correctly.

• Mac: ".../Texas Instruments-DLP/DLPLCRSoftwareBundle-3.0/LightCrafterGUI-v5.0-Mac"

Chapter 2

DLPU006C–January 2012–Revised December 2013

Operating the DLP LightCrafter

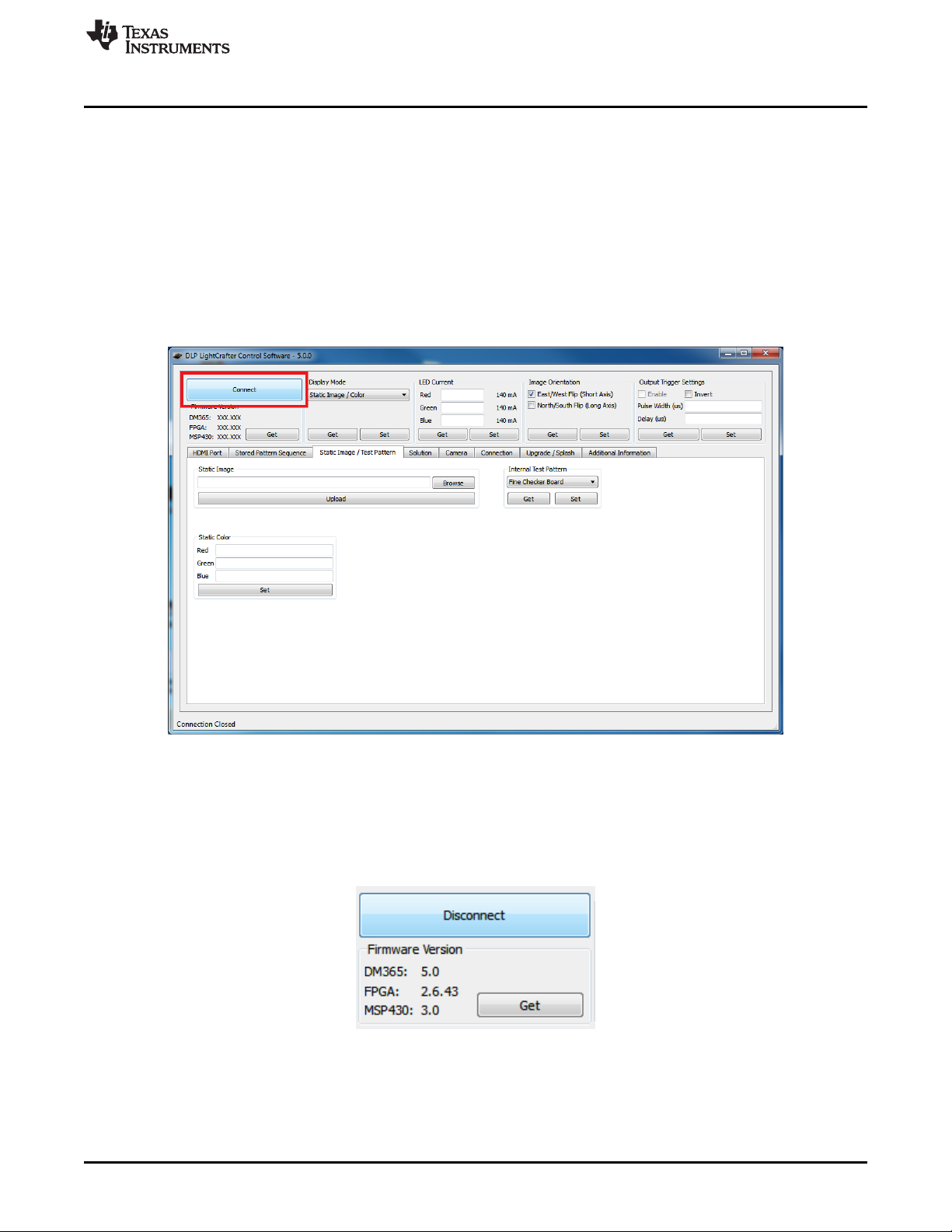

2.2 Connecting to a PC

The DLP LightCrafter utilizes Remote Network Drivers Interface Specification (RNDIS) to send packets

through USB. Please read Section 2.2.1 or Section 2.2.2 to install the RNDIS drivers on Windows

systems. The drivers are already installed for Linux and Mac computers. Some Linux systems need to

have USB networking enabled.

After the RNDIS driver has been installed on the PC, please follow these steps to connect the DLP

LightCrafter. By default DLP LightCrafter's default IP address is "192.168.1.100," but this can be changed

to allow for multiple DLP LightCrafter's to connect to one computer. Please read Section 2.2.6 for more

details. To connect DLP LightCrafter to a PC, follow these steps:

1. Connect the DLP LightCrafter to the PC using a mini-USB cable.

18

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

2. Turn on DLP LightCrafter using the On-Off switch. A new network using the RNDIS driver should

3. Open the DLP LightCrafter GUI.

4. Click the "Connect" button. See Figure 2-1.

Connecting to a PC

initialize.

• The network interface on Windows systems may take a couple minutes to initialize. Please read

Section 2.2.4 to speed up the initialization.

to speed up the initialization.

• The GUI connects to the IP address in the "Current IP Address" textbox from the "Connections"

tab. Please read Section 2.2.5 steps 7 and 8 for more details.

• After connecting, the GUI displays DLP LightCrafter's firmware versions. Select the correct tab,

according to the Display Mode, to update the GUI's tab settings to match the EVM's settings.

Figure 2-1. DLP LightCrafter GUI Connect Button

5. Click the "Disconnect" button before disconnecting the USB cable between DLP LightCrafter and the

computer. See Figure 2-2.

• The "Connect" button changes to the "Disconnect" button after a DLP LightCrafter connects.

• Unplugging the USB cable before disconnecting can cause problems when trying to reconnect to

the DLP LightCrafter if the device has not been shutdown.

Figure 2-2. DLP LightCrafter GUI Disconnect Button

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

19

Page 20

Connecting to a PC

2.2.1 Installing the RNDIS Driver on Windows XP

The first time DLP LightCrafter connects to Windows XP, a system pop-up window shows the new

"RNDIS/Ethernet Gadget" hardware device. Windows XP Service Pack 2 or greater includes the RNDIS

drivers, so these drivers should be found by the OS. Follow these steps to install the "RNDIS/Ethernet

Gadget" driver to enable USB communication with the EVM:

1. When the "Found New Hardware" dialog appears, as shown in Figure 2-3 and Figure 2-4, allow

Windows Update to search for the software.

2. Select “Install the software automatically (Recommended)” and click "Next." See Figure 2-4.

• The computer must have an active internet connection to download the driver.

Figure 2-3. Windows XP Found New Hardware Popup

www.ti.com

Figure 2-4. Windows XP Found New Hardware Wizard

2.2.2 Installing the RNDIS Driver on Windows 7

The first time DLP LightCrafter is connected on Windows 7 systems a pop-up window appears stating that

a new hardware device called a "RNDIS/Ethernet Gadget" was found. Follow these steps to install the

"RNDIS/Ethernet Gadget" driver to enable USB communication with the EVM:

1. The "Driver Software Installation" dialog should appear. Windows 7 will try to automatically download

the driver and fail. A message indicating that the “device driver software was not successfully installed"

is displayed. See Figure 2-5

20

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

2. Right click on “My Computer” and open the Device Manager.

3. Expand Other Devices. Right click on “RNDIS/Ethernet Gadget” and select “Update Driver Software.”

Connecting to a PC

Figure 2-5. Windows 7 Driver Software Installation Window

See Figure 2-6.

Figure 2-6. Windows 7 Device Manager Window

4. Select “Browse my computer for driver software” from the “Update Driver Software” window. See

Figure 2-7.

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

21

Page 22

Connecting to a PC

5. On the next dialog, select “Let me pick from a list of device drivers on my computer.”

6. Select "Network Adapter." See Figure 2-8.

www.ti.com

Figure 2-7. Windows 7 Update Driver Software Search or Browse Window

22

Figure 2-8. Windows 7 Update Driver Software Select Device Window

7. Select "Microsoft Corporation" as the manufacturer and “Remote NDIS Compatible Device” as the

network adapter. Click "Next." See Figure 2-9.

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

8. Click "Close" after the software updates. See Figure 2-10.

Connecting to a PC

Figure 2-9. Windows 7 Update Driver Software Select Network Driver Window

Figure 2-10. Windows 7 Update Driver Software Successfully Updated Window

2.2.3 Enabling the RNDIS Driver on Linux

DLP LightCrafter connects to Linux systems as a Linux-USB Ethernet/RNDIS device. Some systems

require USB networking support to be manually enabled. To enable USB networking follow these steps:

1. Open a command terminal.

2. Open the "/etc/network/interfaces" file in superuser mode. See Figure 2-11.

• For example, "sudo gedit /etc/network/interfaces"

3. Add "iface usb0 inet dhcp" to the file. See Figure 2-11.

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

23

Page 24

Connecting to a PC

4. Save the file.

5. Reboot the Linux system and run "ifconfig." See Figure 2-12.

• If "usb0" is not present, continue to step 6.

www.ti.com

Figure 2-11. Ubuntu Command Terminal and "interfaces" File

24

Figure 2-12. Ubuntu Command Terminal "ifconfig" Result Before USB Setup

6. Setup usb0 with IP address. See Figure 2-13.

• For example, "sudo ifconfig usb0 192.168.1.99 up"

• Choose an IP address different than the address of the LightCrafter.

7. Check that usb0 was properly assigned an IP address using "ifconfig." See Figure 2-13.

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

www.ti.com

Figure 2-13. Ubuntu Command Terminal "ifconfig" Result After USB Setup

2.2.4 Fixing the USB Start-Up Delay in Windows

When DLP LightCrafter is first connected to a Windows system, the Local Area Connection created

automatically obtains an IP address. This "Identifying..." process for the Local Area Connection can take

over a minute on some systems. To decrease the time required for DLP LightCrafter to connect, the Local

Area Network assigned an IP address allowing the computer to connect to the EVM within seconds after

fully booting. Follow these steps to assign an IP address for the Local Area Connection:

1. Open the Control Panel and type "Network Connections" into the search bar.

2. Select "View Network Connections." See Figure 2-14.

Connecting to a PC

Figure 2-14. Windows 7 Network Connections Window

3. Connect DLP LightCrafter to the computer via a mini-USB cable.

4. Power on DLP LightCrafter. While it boots, a new Local Area Connection in your Network Connections

will appear.

5. Wait until the LAN connection stops "Identifying" or "Acquiring" a network address. See Figure 2-15.

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

25

Page 26

Connecting to a PC

Figure 2-15. Windows 7 Network Connections Identifying Local Area Connection

6. Open a cmd terminal and run "ipconfig /all"

7. A list of all connections will be displayed. Find the IPv4 address and Subnet Mask of DLP

LightCrafter's Local Area Connection. See Figure 2-16.

www.ti.com

Figure 2-16. Windows 7 Command Window Local Area Connection IPv4 Address

8. From the Network Connections window, right click on DLP LightCrafter's Local Area Connection and

click "Properties"

9. In the box "This connection uses the following items" under the Networking tab, look for “Internet

Protocol Version 4”. Highlight the item by clicking on it and then click “Properties” underneath the box.

See Figure 2-17.

26

Figure 2-17. Windows 7 Local Area Connection Properties

10. Choose "Use the following IP address"

11. Enter the IPv4 address and Subnet Mask found from step 7. See Figure 2-18.

• Please note that each connected device and USB port requires a unique IP address for its Local

Area Connection.

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 27

www.ti.com

12. Click "OK" to exit the IPv4 Properties

13. Click "OK" to exit the LAN connection properties.

Connecting to a PC

Figure 2-18. Windows 7 Local Area Connection TCP/IPv4 Properties

2.2.5 Changing the DLP LightCrafter's IP Address

To change DLP LightCrafter's IP address, follow these steps:

1. Connect DLP LightCrafter GUI to EVM.

2. Select the "Connections" tab. See Figure 2-19.

Figure 2-19. DLP LightCrafter GUI Connection Tab

3. Change the last three digits of the IP address in the "New IP Address" textbox. See Figure 2-20.

• For example: Change "192.168.1.100" to "192.168.1.106"

• Even IP addresses are recommended to prevent IP Address conflicts between the computer's

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

27

Page 28

Connecting to a PC

Local Area Connection and DLP LightCrafter.

4. Click the "Change IP address of LightCrafter" button.

5. A popup window, as shown in Figure 2-21, will ask "Do you want to change the IP of the LightCrafter?"

Click "Yes."

6. Restart the EVM using the On/Off button on the Driver board, by powering the device off and back on.

• The GUI will disconnect from DLP LightCrafter automatically.

• The "Current IP Address" textbox will not be updated until the EVM has been reconnected.

7. After DLP LightCrafter has restarted and the network has initialized, select the "Connection" tab.

8. Type DLP LightCrafter's new IP address into the "Current IP Address" textbox. See Figure 2-22.

• This setting cannot be modified while the GUI is connected to an EVM.

www.ti.com

Figure 2-20. DLP LightCrafter GUI Connection New IP Address Textbox

Figure 2-21. DLP LightCrafter GUI Changing IP Popup

Figure 2-22. DLP LightCrafter GUI Connection Current IP Address Textbox

9. Click the "Connect" button.

2.2.6 Connecting Multiple DLP LightCrafter's to One PC

By changing DLP LightCrafter's IP address, it is possible to control multiple EVMs from a single computer.

Follow these steps to control multiple DLP LightCrafter's from a single computer:

1. Connect one DLP LightCrafter to the computer with a USB cable.

2. Follow the steps in Section 2.2.5 to set a unique IP addresses for the connected EVM.

3. Disconnect and turn off the EVM.

4. Repeat steps 1-3 for each DLP LightCrafter.

5. After all DLP LightCrafter's have unique IP addresses, start an instance of the DLP LightCrafter GUI for

each EVM

• For example: If three DLP LightCrafters will be connected, there should be three GUI windows

running.

6. For each open GUI window, follow steps 7 to 9 in Section 2.2.5 to connect each DLP LightCrafter,

using their unique IP address, to the open GUI windows.

28

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 29

www.ti.com

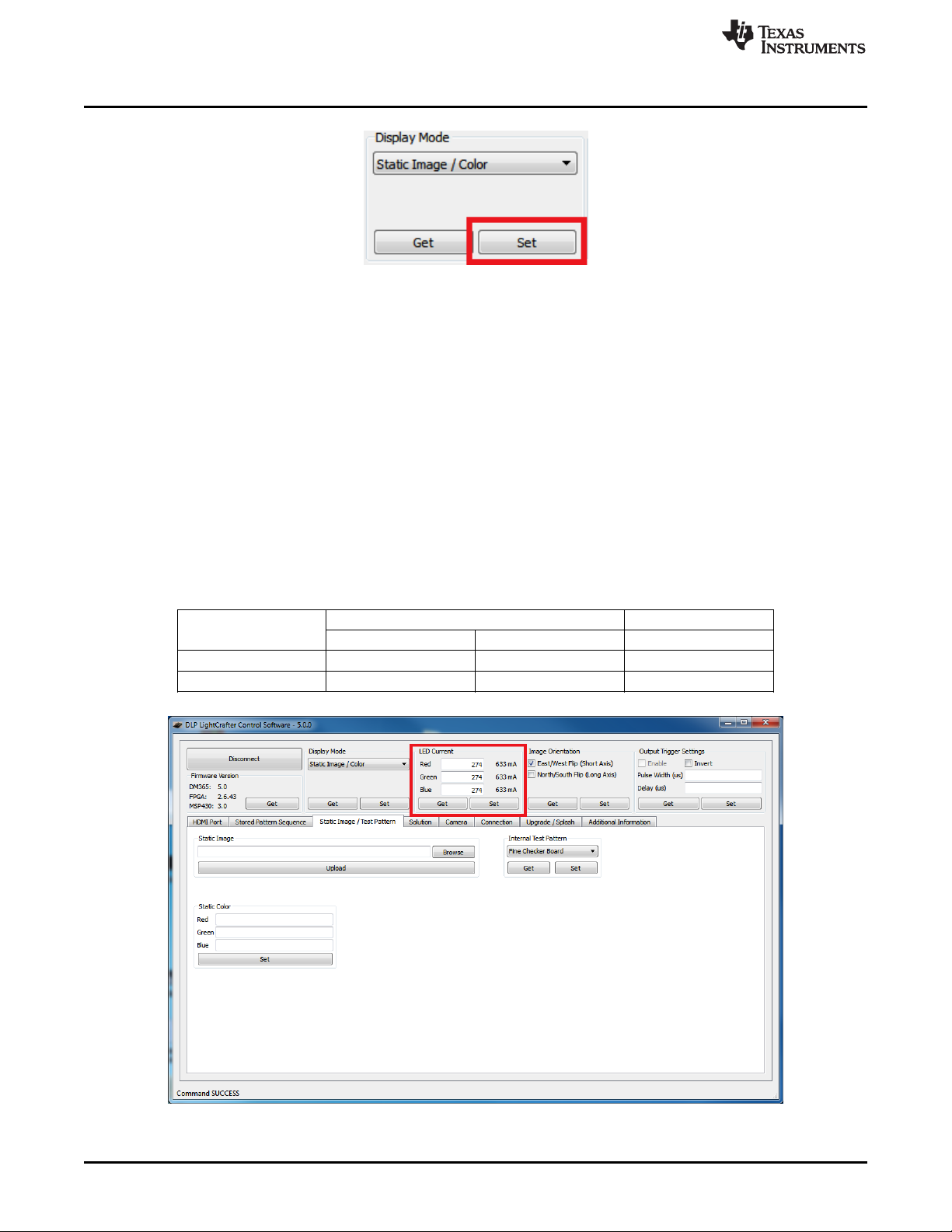

2.3 Selecting the Display Mode

The DLP LightCrafter has four display modes: Static Image/Color, Test Patterns, HDMI Port, and Stored

Pattern Sequence. To upload static 24-bit RGB images or project a single color read section Section 2.9.

To use the internally generated test patterns, read Section 2.10. To stream 24-bit RGB video through the

HDMI port read Section 2.7. To create a pattern sequence using external patterns from the HDMI port,

read Section 2.8.2. To create a pattern sequence using stored patterns, read Section 2.8.1. See Figure 2-

23.

Selecting the Display Mode

Figure 2-23. DLP LightCrafter GUI Display Mode Setting

To change the display mode, follow these steps:

1. Click and select the desired display mode from the drop down options as shown in Figure 2-24.

Figure 2-24. DLP LightCrafter GUI Display Mode Options

2. Click the "Set" button as shown in Figure 2-25.

• The GUI automatically changes to the correct tab and updates the GUI settings in that tab to

match the EVM's settings if the display mode is properly set.

• The resolution, active pixels, and active lines are reset to their default value if the display mode

changes from "HDMI Port" to "Stored Pattern Sequence".

• When the display mode changes, the "Start Vector" and "Num of Vectors" reset to 0.

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

29

Page 30

Setting the LED Current

Figure 2-25. DLP LightCrafter GUI Display Mode Set Button

3. To retrieve the EVM's display mode, click the "Get" button.

• The GUI will automatically change to the correct tab and update the GUI settings in that tab to

match the EVM's settings.

2.4 Setting the LED Current

The DLP LightCrafter uses current drivers to individually control the current through each LED using an

integer current value. The LED current is computed as follows:

LED Current (mA) = 1.8 × (LED Current Value) + 140 (1)

When at room temperature, the maximum value allowed is dependent on the cooling system of the DLP

LightCrafter. The passively cooled systems of the DLP LightCrafter (no extra heat sinks or fans) have a

thermal limit resulting in LED currents under 633 mA. DLP LightCrafter actively cooled systems (extra heat

sink and fan) have a thermal limit resulting in LED currents under 1.5 A. Table 2-1 summarizes these

constraints. Figure 2-26 shows the "LED Current" settings in the GUI.

www.ti.com

Table 2-1. LED Current Settings

DLP LightCrafter LED CURRENT VALUE LED CURRENT

COOLING SYSTEM

Passively cooled 1 274 633 mA

Actively cooled 1 758 1.5 A

MIN MAX MAX

30

Figure 2-26. DLP LightCrafter GUI LED Current Settings

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 31

www.ti.com

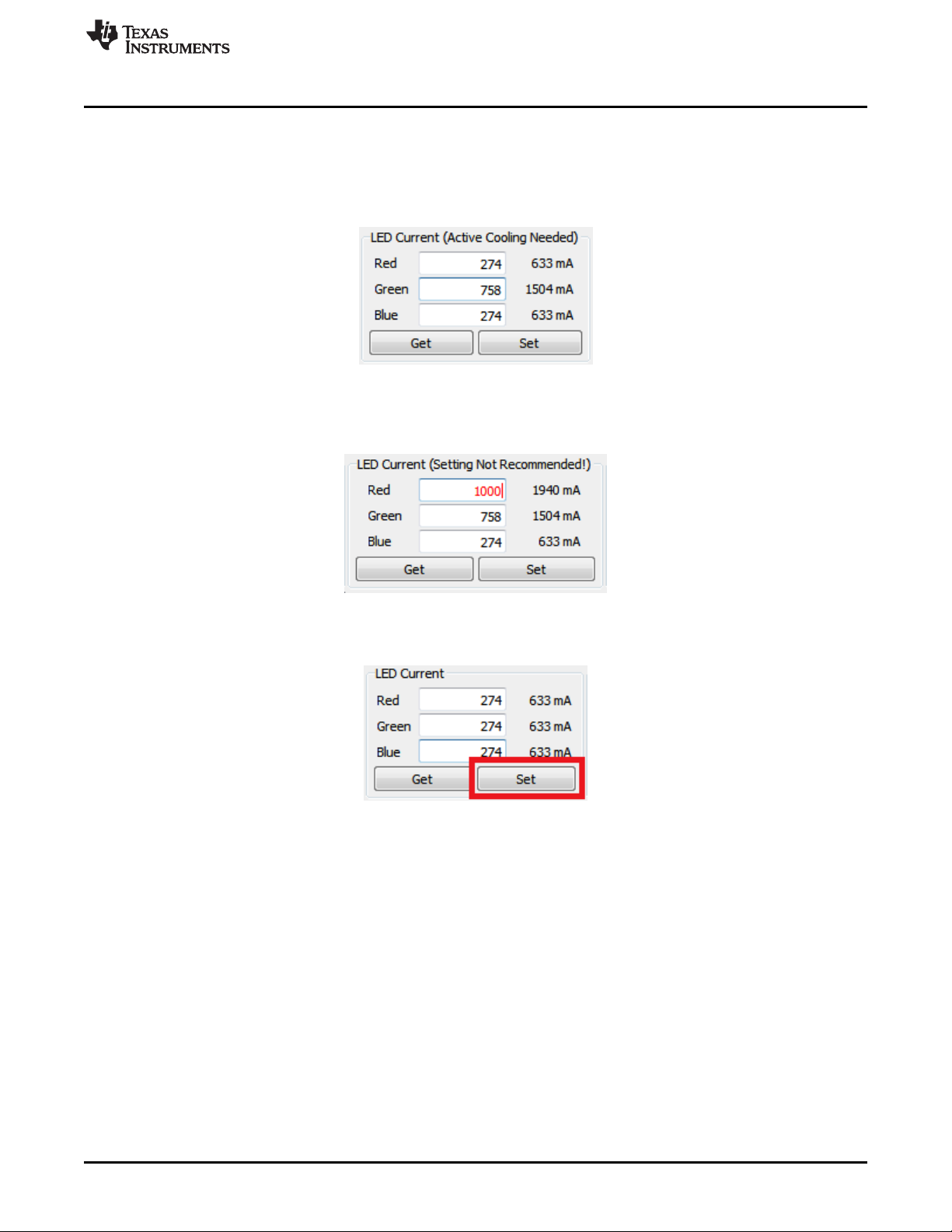

To change the DLP LightCrafter LED current follow these steps:

1. Type the LED Current Value into the corresponding LED's textbox. The GUI automatically calculates

Controlling Image Orientation

and displays the LED current in mA.

• If the value is above 274, a note is added to the LED Current title to inform the user that active

cooling is needed. See Figure 2-27.

Figure 2-27. DLP LightCrafter GUI LED Current Setting Active Cooling Needed

• If the value is above 758, the value turns red and a note is added to the LED Current title to inform

the user that this is not a recommended setting. See Figure 2-28.

Figure 2-28. DLP LightCrafter GUI LED Current Setting Not Recommended

2. Click the "Set" button as shown in Figure 2-29.

Figure 2-29. DLP LightCrafter GUI LED Current Setting Set Button

3. To retreive the EVM's current LED Current Value, click the "Get" button.

2.5 Controlling Image Orientation

The Image Orientation controls the long- and short-axis flips to support front, rear, table, and ceiling

mounted projection. The Image Orientation takes place after the "Set" button has been clicked. Figure 2-

30 shows the "Image Orientation" settings in the GUI.

• East/West Flip (Short-Axis): If checked, the image is flipped along the east/west axis of the projected

image. Normal table front projection has this setting checked (otherwise, the image is flipped

horizontally).

• North/South Flip (Long-Axis): If checked, the image is flipped along the north/south axis of the

projected image. Normal table front projection has this setting unchecked (otherwise, the image is

flipped vertically).

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

31

Page 32

Triggering External Peripherals (Camera and So Forth)

Figure 2-30. DLP LightCrafter GUI Image Orientation Settings

www.ti.com

2.6 Triggering External Peripherals (Camera and So Forth)

The DLP LightCrafter features a trigger output on connecter J7 to allow cameras and other peripherals to

be in sync with the EVM. The trigger output is an open drain type with a 10 kΩ internal pull-up resistor.

This works well with cameras accepting a standard TTL level trigger input. Some cameras with global

trigger capability require a minor hardware change on the DLP LightCrafter system board in order to

function correctly. For more information, read Using the DLP® LightCrafter™ to Trigger CCD Cameras

from The Image Source®, TI literature number DLPA032. Figure 2-31 shows the "Output Trigger Settings"

in the GUI.

32

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 33

www.ti.com

Triggering External Peripherals (Camera and So Forth)

Figure 2-31. DLP LightCrafter GUI Output Trigger Settings

To setup the output Trigger, follow these steps:

1. Check the "Enable" checkbox in the Output Trigger Settings as shown in Figure 2-32.

• The output trigger can only be enabled if the EVM is in either "Stored Pattern Sequence" mode or

"External Streaming Pattern Sequence" while in "HDMI Port" mode.

Figure 2-32. DLP LightCrafter GUI Output Trigger Enable Checkbox

2. If an active low trigger output is desired, check the "Invert" checkbox. If an active high trigger output is

desired do not check "Invert"

3. Enter the pulse width and delay in microseconds

• Pulse Width: width of trigger output pulse in microseconds

• Delay: number of microseconds pulse is delayed after pattern exposure begins

4. Click "Set" as shown in Figure 2-33.

Figure 2-33. DLP LightCrafter GUI Output Trigger Set Button

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

33

Page 34

Streaming 24-bit RGB Video from the HDMI Port

5. To retrieve DLP LightCrafter's current output trigger settings, click the "Get" button

2.7 Streaming 24-bit RGB Video from the HDMI Port

DLP LightCrafter can operate as a DVI-D compliant projector with its mini-HDMI connector. By default, the

EVM has the 608 x 684 EDID software installed, and supports resolutions listed in Table 2-2.

Table 2-2. Supported Resolutions for Video Input

240x320 640x480 480x852 864x480

320x240 480x720 852x480 720x240

240x427 720x480 480x853 720x288

427x240 480x752 853x480 360x640

430x640 752x480 480x853 640x360

640x430 480x800 854x480 854x480

480x640 800x480 480x854 608x684

To stream 24-bit RGB video, follow these steps:

1. Connect an active HDMI source to the mini HDMI connector.

2. Set Display Mode to “HDMI Port.”

3. Select "RGB Video Streaming (24 bits per pixel)" as shown in Figure 2-34.

www.ti.com

(1)

Figure 2-34. DLP LightCrafter GUI RGB Video Streaming Selected on HDMI Port Tab

4. Select the frame rate.

5. Enter one of the resolutions listed in Table 2-2.

6. If the full frame is desired:

• Set Active Pixels Start to 0

• Set Active Pixels Width to the resolution width entered in step 5

• Set Active Lines Start to 0

• Set Active Lines Height to the resolution height entered in step 5

7. Click the “Set” button as shown in Figure 2-35.

(1)

The video input port is DVI-D compliant, but not HDMI compliant.

34

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 35

www.ti.com

8. To retrieve the EVM's current video mode settings, click the "Get" button.

Creating Pattern Sequences

Figure 2-35. DLP LightCrafter GUI RGB Video Streaming Set Button

2.8 Creating Pattern Sequences

The DLP LightCrafter can perform external and internal pattern sequences. External sequences use

streaming patterns from the mini-HDMI port. Internal sequences use preloaded patterns and can be stored

on the LightCrafter with solutions for reuse. The following sections describe how to setup pattern

sequences on DLP LightCrafter.

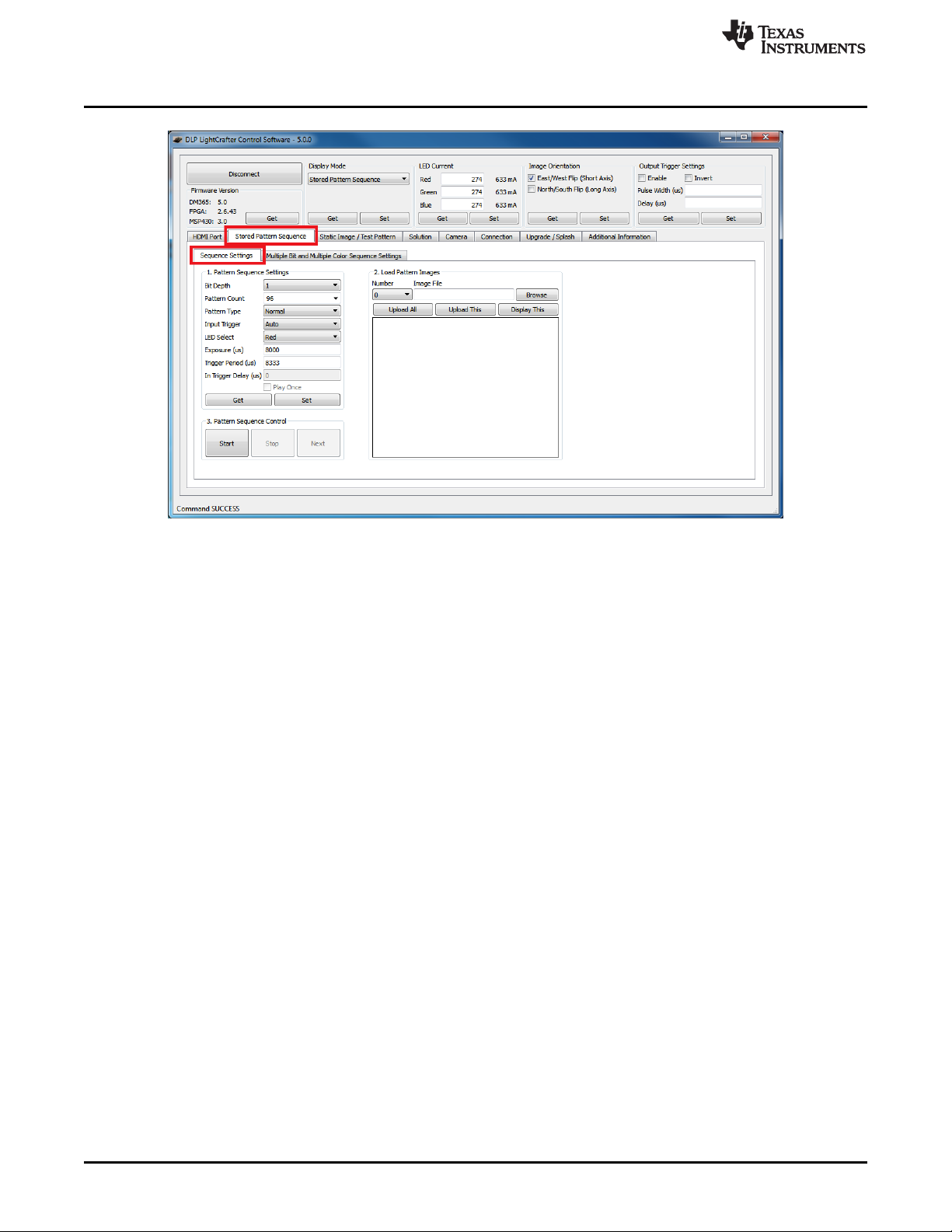

2.8.1 Internal Stored Pattern Sequences

To create an internal pattern sequence follow these steps:

1. Set the display mode as "Stored Pattern Sequence".

2. Select the "Stored Pattern Sequence", then the "Sequence Settings" tab as shown in Figure 2-36.

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

35

Page 36

Creating Pattern Sequences

Figure 2-36. DLP LightCrafter GUI Sequence Settings Tab in Stored Pattern Sequence Tab

www.ti.com

3. Set Pattern settings by updating the following parameters inside the Pattern Setting box:

• Bit Depth: bit depth of the image. Allowed values are from 1 to 8.

• Pattern Count: amount of patterns to display in sequence. Allowed values 1 to 96 divided by the bit

depth. For example, if the bit depth is 8, the maximum amount of patterns is 96 / 8 = 12. If the bit

depth is 1, the maximum amount of patterns is 96/1 = 96.

• Pattern Type

– Normal: display the pattern sequence. Available for all bit depths.

– Inverted: display the pattern sequence with each pattern followed by its inverted pattern.

Available for pattern sequences with Bit Depth equal to 1.

– HW Pattern: display a pattern sequence created from hardwired (HW) patterns. See

Section 2.8.1.1 for more details.

• Trigger Type: selects how the patterns are triggered.

– Auto: patterns displayed after end of Trigger Period.

– Command: patterns displayed when the Next button is pressed.

– External (Positive): patterns displayed after an external active high trigger signal.

– External (Negative):patterns display after an external active low trigger signal.

• LED Select: selects which color LED is active (Red, Green, or Blue). See Section 2.8.1.2 for

details about using the "Multiple" setting.

• Trigger Delay: number of microseconds delay after trigger is received and pattern is displayed.

See Figure 2-37.

• Exposure Time: number of microseconds the pattern is displayed. Input 0 to display the pattern

through the whole trigger period. See Figure 2-37.

• Trigger Period: number of microseconds delay between two consecutive patterns. See Figure 2-

37.

36

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 37

www.ti.com

4. Click the "Set" button as shown in Figure 2-38.

Creating Pattern Sequences

Figure 2-37. Relationship between Trigger Period, Trigger Delay, and Exposure Time

• If the exposure or trigger period values are less than the minimum allowed, DLP LightCrafter

automatically sets the minimum values.

Figure 2-38. DLP LightCrafter GUI Pattern Sequence Settings Set Button

NOTE: Changing the bit-depth, exposure, or pattern count requires that all the images need to be

uploaded again. Uploading all images is necessary since the pattern arrangement in the

frame memory buffer depends on these settings.

5. Click the "Browse" button to select the number of bitmap patterns matching the bit depth and number

previously set. See Figure 2-39 and Figure 2-40.

• The pattern number should be set to 0.

• The patterns must be a BMP file with a resolution of 608 by 684.

• The pattern file names should have their corresponding pattern numbers within the name (that is

00_PAT, 01_PAT, 02_PAT, and so forth)

– Each file should have the same number of digits for the pattern number

• Correct: 00_PAT, 01_PAT, 02_PAT, ... , 10_PAT, and so forth

• Wrong: 0_PAT, 1_PAT, 2_PAT, ... , 10_PAT, and so forth

• Click the pattern number drop down list to view the pattern in the GUI. This selected pattern can

then be displayed on the EVM by clicking "Display This" button.

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

37

Page 38

Creating Pattern Sequences

www.ti.com

Figure 2-39. DLP LightCrafter GUI Load Pattern Images

Figure 2-40. DLP LightCrafter GUI Select Images Window

6. Upload the patterns to DLP LightCrafter by clicking the "Upload All" button as shown in Figure 2-41.

38

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 39

www.ti.com

Creating Pattern Sequences

Figure 2-41. DLP LightCrafter GUI Upload All Pattern Images Button

7. Start the pattern sequence by clicking "Start" as shown in Figure 2-42.

Figure 2-42. DLP LightCrafter GUI Pattern Sequence Control Start Button

2.8.1.1 Hardwired Pattern Sequences

The DLPC300 can generate a set of 15 vertical 1-bit monochrome patterns with its internal pattern

generator. These patterns are called hardwired patterns in the DLP LightCrafter GUI. Up to 32 of these

vertical patterns can be arranged in any order with or without inversion. The inversion of a pattern

converts the black regions to white and the white regions to black. For a description of the available

patterns, see Table 2-64 from the DLPC300 Programmer’s Guide, TI literature number DLPU004. Pattern

numbers 0 through 10 form a set of gray coded patterns. Pattern numbers 11 through 14 can be used for

auto-focus.

The extended pattern sequence mode follows the same steps as those listed in Section 2.8.1 for regular

internal stored pattern sequences except for selecting the images. Rather than clicking the "Browse"

button, select the desired HW Pattern from the drop-down list. See Figure 2-43.

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

39

Page 40

Creating Pattern Sequences

Figure 2-43. DLP LightCrafter GUI Hardwired Pattern Sequence Settings and Pattern Selection

www.ti.com

NOTE: While the DLP LightCrafter internally generates hardwired patterns, the "Upload All" button

still needs to be clicked after all hardwired patterns have been selected for each pattern.

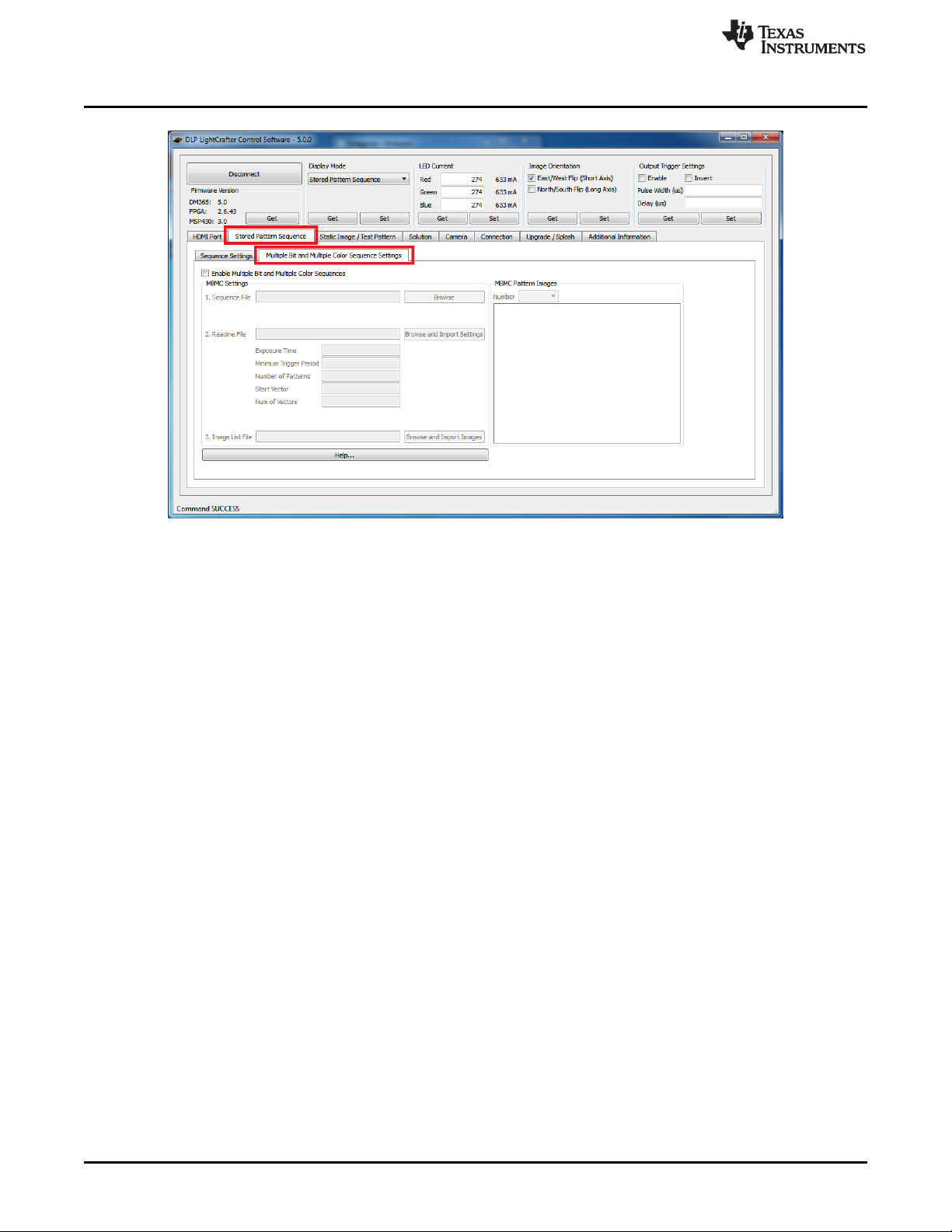

2.8.1.2 Multiple Bit-Depth and Multiple Color Pattern Sequences

With the latest FPGA Firmware (version 2.6.43) and DM365 software (version 4 or above), the DLP

LightCrafter can run internal pattern sequences that use multiple bit depths and multiple colors (MBMC).

To create an MBMC pattern sequence, follow these steps:

1. Submit MBMC pattern sequence requests on TI's E2E forum in the DLP LightCrafter Development

Platform subsection (http://e2e.ti.com/) by creating a post titled "MBMC Request" and provide the

following information:

• Pattern Exposure time (250 µs < PExT ≤ 20000 µs).

– This parameter influences the maximum bit-depth possible in the sequence for each pattern.

For example, if the exposure time is 1000 µs then it is only possible to have 1-bit or 2-bit depth

patterns. On the other hand, an exposure time ≥ 8333 µs supports patterns of all bit-depths

from 1 to 8. See Table 4-3 to find the minimum exposure time for each pattern’s bit-depth.

• Patterns Sequence Information as shown in Table 2-3.

– Patterns must be listed in the order to be displayed.

– Depending on the order of patterns with different bit-depths it is possible that there will be

unused bit-planes that still count towards the maximum 96 bit-planes. The system will not allow

split multiple bit-depth patterns across the 24-bit frame buffer boundaries. For example, in the

1st row of Table 2-3, there are five, 5bpp patterns. This would translate to 5 x 5 = 25 individual

bit planes, but each frame buffer can only accommodate 24 individual binary frames. Therefore,

in a pattern sequence of five, 5-bit patterns, 20 reside in the first frame buffer, while the last 5bit plans reside in the next frame buffer. The 5bpp x 5 pattern set actually consumes 29

individual bit planes of the frame buffer:

• 5bpp × 4 patterns + 4 unused patterns = 24 patterns (from the first frame buffer)

• 5bpp × 1 pattern = 5 patterns (from the second frame buffer)

• Results in 24 + 5 = 29 individual binary patterns.

40

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 41

Trigger Input

Auto/External/Camera

Pattern Display

8333 Secμ

MBMC Pattern Sequence:

1bppX1R_2bppX1G_3bppX1B_4bppX1R_5bppX1G_6bppX1B_7bppX1R_8bppX1G_83333 Secμ

1-Bit 2-Bit 3-Bit 4-Bit 5-Bit 6-Bit 7-Bit 8-Bit 1-Bit 2-Bit

MBMC Pattern Sequence

www.ti.com

Creating Pattern Sequences

Table 2-3. MBMC Pattern Sequence Information Input

Pattern Pattern Color

Bit-Depth (Red/Green/Blue)

5 5 Blue

1 6 Red

.. .. …

.. .. …

7 2 Green

1 3 Blue

Number of Patterns

• Pattern Sequence Equation in the following form:

– <pattern_bit-depth>X<num_of_patterns><color (R)ed or (G)reen or (B)lue>_<pattern_bit-

depth>X<num_of_patterns><color (R)ed or (G)reen or (B)lue>_.....<pattern_bit-

depth>X<num_of_patterns><color (R)ed or (G)reen or (B)lue>_<exposure_time>µs

– For example,

1bppX1G_2bppX1G_3bppX1G_4bppX1G_5bppX1G_6bppX1G_7bppX1G_8bppX1G_8333µs

• The development time frame of the project (optional)

• A description of the application and the need for this capability (optional)

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Figure 2-44. MBMC Pattern Sequence Output Example

2. Prepare image list file.

• Create a TXT file.

• Add one BMP image filename per line.

3. Set Display mode to "Stored Pattern Sequence."

4. Select "Stored Pattern Sequence" tab and "Multiple Bit and Multiple Color Sequence Settings" tabs.

See Figure 2-45.

Copyright © 2012–2013, Texas Instruments Incorporated

41

Page 42

Creating Pattern Sequences

Figure 2-45. DLP LightCrafter GUI Multiple Bit and Multiple Color Sequence Settings Tab in Stored

Pattern Sequence Tab

www.ti.com

5. Check the "Enable Multiple Bit and Multiple Color Sequences" checkbox. See Figure 2-46.

• This disables several settings in the "Sequence Settings" tab and requires that a readme file be

imported

6. Browse and select the "Sequence File" (.BIN).

7. Browse and Import the settings from the "Readme File" (.TXT)

• The GUI automatically imports all the necessary values from the readme file into the GUI

8. Browse for the "Image List File" and import the images.

• The GUI automatically parses the images listed in the file into 1bpp patterns and loads them into

the GUI. This means that the "Browse" button in the "Sequence Settings" tab does not need to be

used.

• The GUI displays the MBMC patterns as the DLP LightCrafter will project in the "MBMC Pattern

Images" in the "Multiple Bit and Multiple Color Sequence Settings" tab.

42

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

Page 43

www.ti.com

Creating Pattern Sequences

Figure 2-46. DLP LightCrafter GUI Multiple Bit and Multiple Color Sequence Settings Tab in Stored

Pattern Sequence Tab

9. Select "Sequence Settings" tab. See Figure 2-47.

10. Click the sequence settings "Set" button.

11. Click "Upload All" button.

12. Click "Start".

Figure 2-47. DLP LightCrafter GUI Example Sequence Settings for MBMC Sequence

DLPU006C–January 2012–Revised December 2013 Operating the DLP LightCrafter

Submit Documentation Feedback

Copyright © 2012–2013, Texas Instruments Incorporated

43

Page 44

Creating Pattern Sequences

2.8.2 External Pattern Sequences Streaming from HDMI Port

To create an external pattern sequence follow these steps:

1. Set the display mode as "HDMI Port".

2. Select "External Streaming Pattern Sequence" in the "HDMI Port" tab. See Figure 2-48.

3. Set the LED Select.

4. Set the Color Bit Depth.

5. Set the Frame Rate.

6. Click "Set."

• The GUI calculates the patterns per frame and pattern rate from the bit depth and frame rate.

• The resolution in "External Streaming Pattern Sequence" mode cannot be changed. The video

stream must supply frames with a 608 × 684 pixel resolution.

www.ti.com

Figure 2-48. DLP LightCrafter GUI External Streaming Pattern Sequence Settings in HDMI Port Tab

2.8.3 Extended Pattern Sequences

In addition to the high-speed internal stored pattern sequences, DLP LightCrafter can run extended

pattern sequences that allows more than 96 patterns and exposure times up to 5 seconds.

some constraints to the extended pattern sequence mode:

• Sequences with more than 96 patterns:

– Maximum of 1050 patterns for 1-bit per pixel patterns

– Maximum of 131 patterns for 8-bit per pixel patterns

• Longer exposures than 20 ms:

– Maximum exposure of 5 second for 8-bit per pixel patterns

– Maximum exposure of 2 second for 1-bit per pixel patterns

• Minimum trigger period of 18 ms

• Minimum exposure of 5 ms

• "Play Once" not supported

• A 330 µs dark frame occurs every 20 ms

• "Multiple Bit and Multiple Color" mode not supported

(1)

Multiple bit and multiple color pattern sequences are not enabled in extended pattern sequence mode.

44

Operating the DLP LightCrafter DLPU006C–January 2012–Revised December 2013

Copyright © 2012–2013, Texas Instruments Incorporated

Submit Documentation Feedback

(1)

There are

Page 45

www.ti.com

• Resistor R205 must be installed on system boards from DLP LightCrafter hardware prior to revision

2.0.

• FPGA Firmware must be version 2.4.39 or newer

The extended pattern sequence mode follows the same steps as those listed in Section 2.8.1 for regular

internal stored pattern sequences except for selecting the pattern count. Type in the pattern count instead