Page 1

bq35100

Technical Reference Manual

Literature Number: SLUUBH1C

August 2016–Revised March 2018

Page 2

Contents

Preface ........................................................................................................................................ 5

1 Introduction......................................................................................................................... 7

2 Basic Measurement Systems................................................................................................. 8

2.1 Voltage ........................................................................................................................ 8

2.2 Temperature.................................................................................................................. 8

2.3 Coulombs ..................................................................................................................... 8

2.4 Current ........................................................................................................................ 8

3 Factory Calibration ............................................................................................................. 10

3.1 General I

3.2 Calibration Overview....................................................................................................... 10

3.2.1 Method.............................................................................................................. 10

3.2.2 Sequence........................................................................................................... 10

3.3 Enter CALIBRATION Mode ............................................................................................... 11

3.4 Voltage Calibration......................................................................................................... 12

3.5 CC Offset.................................................................................................................... 13

3.6 Board Offset................................................................................................................. 14

3.7 Obtain Raw Calibration Data ............................................................................................. 15

3.8 Current Calibration ......................................................................................................... 16

3.9 Temperature Calibration................................................................................................... 17

3.10 Floating Point Conversion................................................................................................. 18

3.11 Exit CALIBRATION Mode................................................................................................. 19

4 Basic Configuration............................................................................................................ 20

4.1 Operation Config A......................................................................................................... 20

5 Battery Gauging ................................................................................................................. 21

5.1 ACCUMULATOR Mode ................................................................................................... 21

5.1.1 Total Capacity Update ............................................................................................ 21

5.2 STATE-OF-HEALTH (SOH) Mode....................................................................................... 21

5.2.1 Low State-Of-Health Alert........................................................................................ 21

5.3 End-Of-Service (EOS) Mode ............................................................................................. 22

5.3.1 Initial EOS Learning............................................................................................... 22

5.3.2 End-Of-Service Detection ........................................................................................ 23

5.3.3 End-Of-Service Smoothing....................................................................................... 23

6 Power Control.................................................................................................................... 25

6.1 Device Functional Modes ................................................................................................. 25

6.2 Flash Updates .............................................................................................................. 27

7 Battery Condition Warnings................................................................................................. 28

7.1 Battery Low Warning....................................................................................................... 28

7.2 Temperature Low Warning................................................................................................ 28

7.3 Temperature High Warning ............................................................................................... 28

7.4 Battery Low SOC Warning................................................................................................ 29

7.5 Battery EOS OCV BAD Warning......................................................................................... 29

8 ALERT Signal..................................................................................................................... 30

9 Lifetime Data Collection ...................................................................................................... 31

2

C Command Information ...................................................................................... 10

2

Contents

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

www.ti.com

10 SHA-1 Authentication.......................................................................................................... 32

10.1 Overview..................................................................................................................... 32

10.2 HMAC Description.......................................................................................................... 32

10.3 Authentication............................................................................................................... 32

10.4 AuthenticateData(): 0x40…0x53 ......................................................................................... 33

10.5 AuthenticateChecksum(): 0x54........................................................................................... 33

11 Data Commands................................................................................................................. 34

11.1 Command Summary....................................................................................................... 34

11.2 Control(): 0x00/0x01 ....................................................................................................... 34

11.3 CONTROL_STATUS: 0x0000 ............................................................................................ 35

11.3.1 DEVICE_TYPE: 0x0001......................................................................................... 37

11.3.2 FW_VERSION: 0x0002 ......................................................................................... 37

11.3.3 HW_VERSION: 0x0003 ......................................................................................... 37

11.3.4 STATIC_CHEM_DF_CHKSUM: 0x0005...................................................................... 37

11.3.5 CHEM_ID: 0x0006 ............................................................................................... 37

11.3.6 PREV_MACWRITE: 0x0007.................................................................................... 37

11.3.7 BOARD_OFFSET: 0x0009...................................................................................... 37

11.3.8 CC_OFFSET: 0x000A........................................................................................... 37

11.3.9 CC_OFFSET_SAVE: 0x000B .................................................................................. 37

11.3.10 GAUGE_START: 0x0011...................................................................................... 37

11.3.11 GAUGE_STOP: 0x0012 ....................................................................................... 38

11.3.12 SEALED: 0x0020 ............................................................................................... 38

11.3.13 CAL_ENABLE: 0x002D........................................................................................ 38

11.3.14 LT_ENABLE: 0x002E .......................................................................................... 38

11.3.15 RESET: 0x0041................................................................................................. 38

11.3.16 NEW_BATTERY: 0xA613 ..................................................................................... 38

11.4 AccumulatedCapacity(): 0x02/0x05...................................................................................... 38

11.5 Temperature(): 0x06/0x07................................................................................................. 38

11.6 Voltage(): 0x08/0x09....................................................................................................... 38

11.7 BatteryStatus() 0x0A....................................................................................................... 38

11.8 BatteryAlert() 0x0B......................................................................................................... 39

11.9 Current(): 0x0C/0x0D ...................................................................................................... 39

11.10 ScaledR(): 0x16/0x17 ..................................................................................................... 39

11.11 MeasuredZ(): 0x22/0x23.................................................................................................. 39

11.12 InternalTemperature(): 0x28/0x29 ....................................................................................... 39

11.13 StateOfHealth(): 0x2E/0x2F .............................................................................................. 40

11.14 DesignCapacity(): 0x3C/3D............................................................................................... 40

11.15 ManufacturerAccessControl(): 0x3E/0x3F ............................................................................. 40

11.16 MACData(): 0x40 through 0x5F.......................................................................................... 40

11.17 MACDataSum(): 0x60..................................................................................................... 40

11.18 MACDataLen(): 0x61 ..................................................................................................... 40

12 Data Flash ......................................................................................................................... 41

12.1 Accessing Data Flash...................................................................................................... 41

12.1.1 Write to DF Example............................................................................................. 41

12.1.2 Read from DF Example ......................................................................................... 41

12.1.3 Auto-Increment Reading ........................................................................................ 41

12.2 Access Modes .............................................................................................................. 41

12.2.1 Sealing/Unsealing Data Flash Access......................................................................... 42

12.3 BlockDataChecksum(): 0x60.............................................................................................. 42

12.4 BlockDataLength(): 0x61 .................................................................................................. 42

12.5 BlockDataControl(): 0x62.................................................................................................. 42

13 Data Flash Summary........................................................................................................... 43

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Contents

3

Page 4

www.ti.com

14 Communications ................................................................................................................ 48

14.1 I

2

C Interface................................................................................................................. 48

Revision History.......................................................................................................................... 49

4

Contents

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

About This Manual

This technical reference manual (TRM) discusses the modules and peripherals of the bq35100 device,

and how each is used to build a complete battery fuel gauge and end-of-service monitor. Content in this

TRM complements, not supersedes, information in the bq35100 Lithium Primary Battery Fuel Gauge and

End-Of-Service Monitor Data Sheet (SLUSCM6).

Notational Conventions

This document uses the following conventions:

• Hexadecimal numbers may be shown with the suffix h or the prefix 0x. For example, the following

number is 40 hexadecimal (decimal 64): 40h or 0x40.

• Registers in this document are shown in figures and described in tables.

– Each register figure shows a rectangle divided into fields that represent the fields of the register.

Each field is labeled with its bit name, its beginning and ending bit numbers above, and its

read/write properties with default reset value below. A legend explains the notation used for the

properties.

– Reserved bits in a register figure can have one of multiple meanings:

• Not implemented on the device,

• Reserved for future device expansion,

• Reserved for TI testing,

• Reserved configurations of the device that are not supported.

– Writing non-default values to the Reserved bits could cause unexpected behavior and should be

avoided.

Preface

SLUUBH1C–August 2016–Revised March 2018

Read This First

Formatting in This Document

The following formatting convention is used in this document:

• SBS Commands: italic with parenthesis and no breaking spaces; for example, RemainingCapacity()

• Data Flash: italic, bold, and breaking spaces; for example, Design Capacity

• Data Flash Bits: italic and bold; for example, [LED1]

• Register Bits and Flags: italic and brackets; for example, [TDA]

• Modes and States: ALL CAPITALS; for example, UNSEALED

Trademarks

E2E is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

Related Documentation From Texas Instruments

See the bq35100 Lithium Primary Battery Fuel Gauge and End-Of-Service Monitor Data Sheet

(SLUSCM6).

For product information, visit the Texas Instruments website at http://www.ti.com/product/bq35100.

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Read This First

5

Page 6

Community Resources

Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the

respective contributors. They do not constitute TI specifications and do not necessarily reflect TI's views;

see TI's Terms of Use.

TI E2E™ Online Community— TI's Engineer-to-Engineer (E2E) Community. Created to foster

collaboration among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore

ideas and help solve problems with fellow engineers.

Design Support— TI's Design Support Quickly find helpful E2E forums along with design support tools

and contact information for technical support.

Definitions

A Battery Glossary is available at the Battery University on ti.com.

Glossary

TI Glossary —This glossary lists and explains terms, acronyms, and definitions.

www.ti.com

6

Read This First

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

Chapter 1

SLUUBH1C–August 2016–Revised March 2018

Introduction

The bq35100 Battery Fuel Gauge and End-Of-Service Monitor provides highly configurable fuel gauging

for non-rechargeable lithium primary batteries—without requiring forced discharge of the battery. Built so

that optimization is not necessary, the patented TI gauging algorithms support replaceable batteries and

enable accurate results with ultra-low average power consumption through host control via the GAUGE

ENABLE (GE) pin.

The fuel gauging functions use voltage, current, and temperature information to provide State-Of-Health

(SOH) and End-Of-Service (EOS) data. The bq35100 device is only required to be powered long enough

to gather data and to make calculations to support the selected algorithm and the frequency of updates

required by the system.

The host can read the gathered data through a 400-kHz I2C bus. An ALERT output is also available to

interrupt the host, based on a variety of configurable options.

The device has extended capabilities, including:

• Fuel Gauge for Single- and Multi-Cell Primary (Non-Rechargeable) Batteries

• Supports Lithium Thionyl Chloride (LiSOCl2) and Lithium Manganese Dioxide (LiMnO2)

• Provides Four Configurable Algorithm Options:

– Coulomb Accumulation (ACC)

– State-Of-Health (SOH)

– End-Of-Service (EOS)

• Ultra-Low Average Power Consumption Supported Through Gauge-Enable Control

• Accurate Coulomb Counter, Voltage, and Temperature Measurement Options

• I2C Host Communication, Providing Battery Parameter and Status Access

• Configurable Host Interrupt

• Data Logging Options

• SHA-1 Authentication

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Introduction

7

Page 8

2.1 Voltage

The bq35100 device measures the BAT input using the integrated delta-sigma ADC, which is scaled by

the internal translation network, through the ADC. The measured voltage is available through Voltage(),

and is updated for the host to read once per second. The translation gain function is determined by a

calibration process. See Factory Calibration for further details.

In systems where the battery voltage is greater than V

external voltage scaling circuit is required. If [EXTVCELL] is set, then the voltage is measured via the VIN

pin. The input to VIN must be scaled to a maximum of 1 V.

The VEN pin can be used to enable and disable the external divider to conserve power. The firmware will

then scale this < 1-V value to reflect an average cell value, and then again by the number of series cells to

reflect the full battery voltage value.

Chapter 2

SLUUBH1C–August 2016–Revised March 2018

Basic Measurement Systems

MAX (for example, 2-series cell or more), an

IN(BAT)

CLASS SUBCLASS NAME TYPE SIZE MIN VALUE

Gas gauging Design

The configured battery voltage measurement is made available through the Voltage() command.

2.2 Temperature

The device can measure temperature through an integrated temperature sensor or an external NTC

thermistor using the integrated delta-sigma ADC. Only one source can be used for gauging and the

selection is made by setting Operation A [TEMPS] appropriately. The resulting measured temperature is

available through the Temperature() command, and is updated for the host to read once per second. The

internal temperature sensor is always measured in support of voltage measurement accuracy, and the

result is also available through the InternalTemperature() command.

When an external thermistor is used, REG25 (pin 7) is used to bias the thermistor, and TS (pin 11) is used

to measure the thermistor voltage (a pull-down circuit is implemented inside the device). The device then

correlates the voltage to temperature, assuming the thermistor is a Semitec 103AT or similar device.

There is a configurable option for the host to write the temperature to the Temperature() command when

[WRTEMP] = 1. This option is disabled by default.

2.3 Coulombs

The integrating delta-sigma ADC (coulomb counter) in the device measures the discharge flow of the

battery by measuring the voltage drop across a small-value sense resistor between the SRP and SRN

pins in a range from –0.125 V to 0.125 V. The device continuously monitors the measured current and

integrates this value over time using an internal counter. This measurement is updated for the host to read

once per second.

Series cell

count

MAX

VALUE

Integer 1 1 8 1 Count

DEFAULT

VALUE

UNIT

2.4 Current

For the primary battery current, the integrating delta-sigma ADC in the device measures the discharge

current of the battery by measuring the voltage drop across a small-value sense resistor between the SRP

and SRN pins, and is available through the Current() command, and is updated for the host to read once

per second.

8

Basic Measurement Systems

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

The measured current also includes the current consumed by the device. To subtract this value from the

reported current, a value programmed in EOS Gauge Load Current is subtracted for improved accuracy.

Current() = Actual Measured (SRP–SRN) Current – EOS Gauge Load Current

Current

CLASS SUBCLASS NAME TYPE SIZE MIN VALUE

EOS data Values

EOS gauge

load current

Integer 1 1 255 35 0.01 mA

MAX

VALUE

DEFAULT

VALUE

UNIT

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Basic Measurement Systems

9

Page 10

The bq35100 fuel gauge requires factory calibration. The gauge performs only a limited number of

calibration functions. The rest must be performed by a host system using commands provided by the

gauge for this purpose. The following sections give a detailed description of the various calibration

sequences with the help of flowcharts.

3.1 General I2C Command Information

In the following flowcharts, all I2C functions take three arguments.

Write command arguments:

• Address

• Data

• Wait time in ms

Read command arguments:

• Address

• Number of bytes read

• Wait time in ms

Chapter 3

SLUUBH1C–August 2016–Revised March 2018

Factory Calibration

3.2 Calibration Overview

3.2.1 Method

The calibration method is broken up into the following sections. The first four sequences are subroutines

to be used in the main calibration sequences. Once in CALIBRATION mode, it is important to perform

voltage calibration first.

• Section 3.3, Enter CALIBRATION Mode

• Section 3.4, Voltage Calibration

• Section 3.5, CC Offset

• Section 3.6, Board Offset

• Section 3.7, Obtain Raw Calibration Data

• Section 3.8, Current Calibration

• Section 3.9, Temperature Calibration

• Section 3.10, Floating Point Conversion

• Section 3.11, Exit CALIBRATION Mode

3.2.2 Sequence

Perform the following calibration sequence during battery pack manufacturing process:

1. Perform Voltage Calibration.

2. Perform CC Offset.

3. Perform Board Offset.

4. Perform Current Calibration.

5. Perform Temperature Calibration.

10

Factory Calibration

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

I2CWriteWord(0x0000, 0x0081,100)

ENTER_CAL MAC Command:

0x0081 to 0x0000

I2CWriteWord(0x0000, 0x0000,100)

I2CReadBlock(0x00, 2,100)

calMod == 1

Device did not

enter calibration

mode; retry

True

False

End

www.ti.com

6. Write calibration results to data flash.

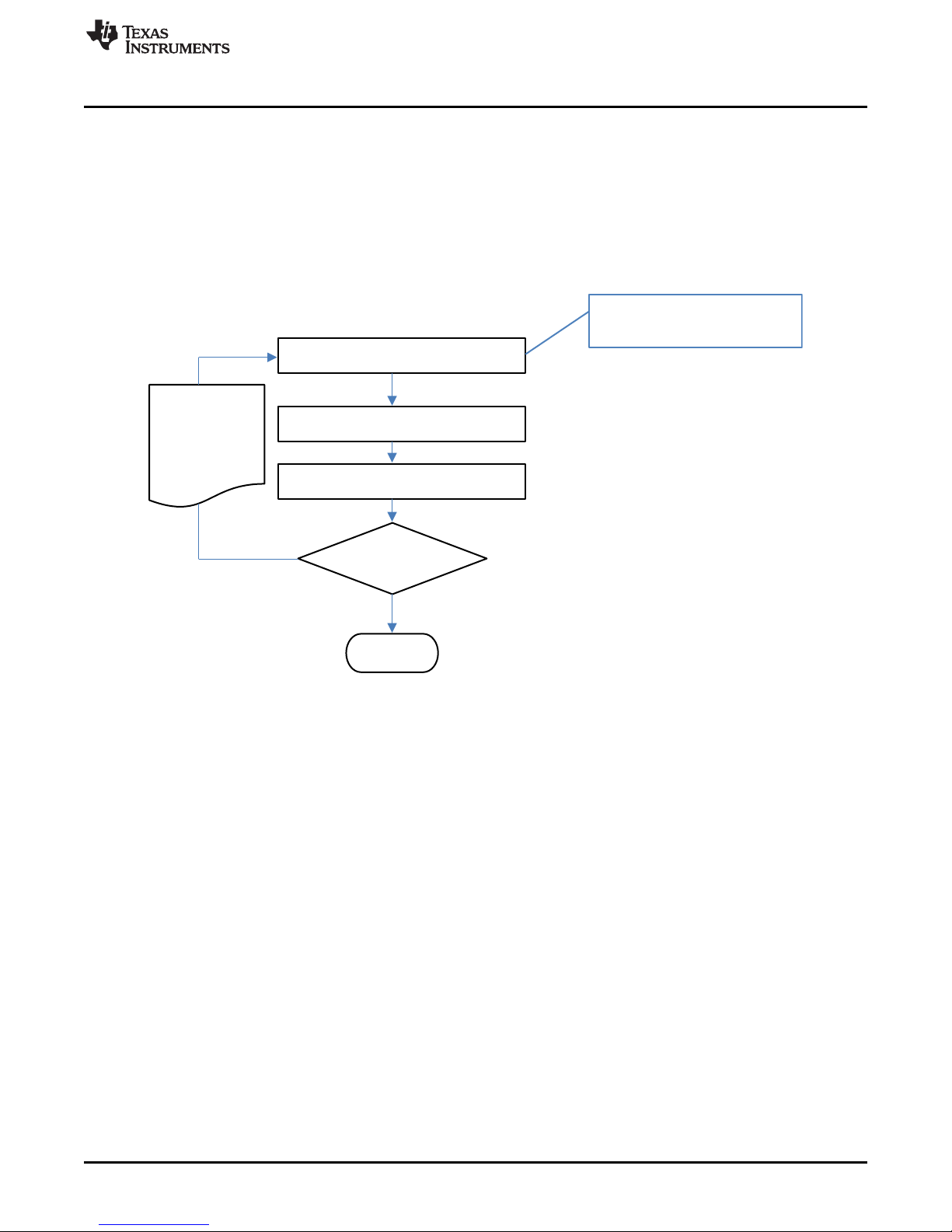

3.3 Enter CALIBRATION Mode

The bq35100 device must be enabled (GE High) and in ACC mode (Operation Config A [GMSEL1:0] =

00) AND the GAUGE_START() command should have been sent. When using bqStudio, these steps are

automatic.

This sequence puts the gauge into CALIBRATION mode. These steps must be performed when the

gauge is in UNSEALED mode.

Enter CALIBRATION Mode

Figure 3-1. Enter CALIBRATION Mode Flow

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Factory Calibration

11

Page 12

Apply known voltage

Voltage() = known voltage

End

int vOffset = Voltage()

– avgRawVoltage

Write vOffset to DF

Obtain avgRawVoltage

Voltage Calibration

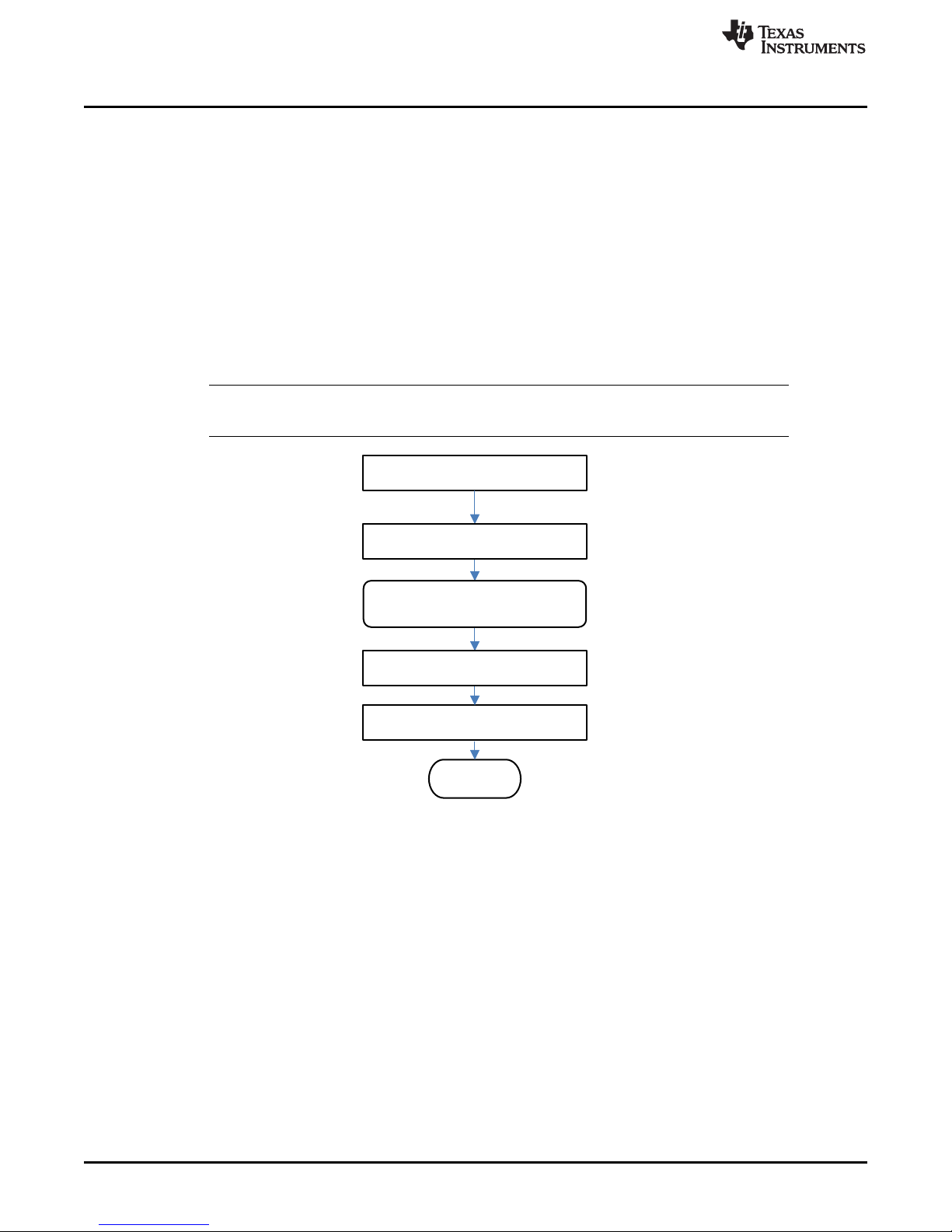

3.4 Voltage Calibration

A known voltage must be applied to the device for voltage calibration, but the voltage can be measured in

two different ways. See Voltage for more details.

The bq35100 device is default-configured to use the BAT input for voltage measurement, and the data

used for calibration is made available through the calibration commands in units of millivolts (mV). In this

setup, the calculated voltage offset must be written to the corresponding location in DF. The voltage offset

is represented by an integer that is a single byte in size and can be written to the appropriate location in

DF without any intermediate steps. The host system must ensure that the fuel gauge is UNSEALED.

The device has the option to use an external voltage divider circuit where the voltage is measured through

the VIN pin, and the data used for calibration is made available through the calibration commands. In this

setup, there is no user offset required and the reported RawVoltage is actually RawADCounts. The gain

of the voltage translation circuit needs to be calculated and stored, where: V

65536. This resulting integer is written to VIN

NOTE: The step labeled Obtain avgRawVoltage refers to Section 3.7, Obtain Raw Calibration

Data.

Gain

www.ti.com

= (V

cellGain

/RawADCounts) ×

cal

.

12

Factory Calibration

Figure 3-2. Voltage Calibration Flow

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

I2CWriteWord (0x0000, 0x000A, 100)

CCA == 1

I2CReadBlock (0x00, 2, 100)

CCA == 0

Wait for CCA bit

to clear

End

Device is not calibrating

CC offset; retry.

The device is in the

process of calibrating

CC offset while the

CCA bit is set. Host

should check

the CCA bit more

than once every 0.5 s.

NOT

True

True

False

False

CC_OFFSET MAC Command:

0x000A to 0x0000

I2CWriteWord (0x0000, 0x0000, 100)

Enter Calibration Mode

Exit Calibration Mode

I2CWrite Word (0x0000, 0x000B, 100)

www.ti.com

3.5 CC Offset

Use MAC commands for CC Offset calibration. The host system does not need to write information to the

data flash (DF). See CONTROL_STATUS: 0x0000 for the description of the CONTROL_STATUS[CCA]

bit. The host system must ensure that the fuel gauge is UNSEALED.

NOTE: While the device is calibrating the CC Offset, the host system must not read the

CC Offset

CONTROL_STATUS register at a rate greater than once every 0.5 seconds and no current

should be flowing.

The step labeled Enter CALIBRATION Mode refers to Section 3.3, Enter CALIBRATION

Mode.

The step labeled Exit CALIBRATION Mode refers to Section 3.11, Exit CALIBRATION

Mode.

Figure 3-3. CC Offset Flow

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Factory Calibration

13

Page 14

I2CWriteWord(0x0000, 0x0009, 100)

CCA == 1 && BCA == 1

I2CReadBlock(0x00, 2, 100)

Wait for CCA bit

to clear

End

Device is not calibrating

CC offset; retry

The device is in the

process of calibrating

CC offset while the

CCA bit is set. The

CCA bit will clear and

then the device will

calibrate the board

offset. Host should

check the CCA/

BCA bits more than

once every 0.5 s.

NOT

True

True

False

False

BCA == 0

I2CWriteWord(0x0000, 0x0000, 100)

BOARD_OFFSET MAC Command:

0x0009 to 0x0000

Enter Calibration Mode

Exit Calibration Mode

Board Offset

3.6 Board Offset

Use MAC commands for Board Offset calibration. The host system does not need to write information to

the DF. The host system must ensure that the fuel gauge is UNSEALED. See CONTROL_STATUS:

0x0000 for the description of the CONTROL_STATUS[CCA] and [BCA] bits.

NOTE: While the device is calibrating the Board Offset, the host system should not read the

CONTROL_STATUS() register at a rate greater than once every 0.5 seconds and no current

should be flowing.

The step labeled Enter CALIBRATION Mode refers to Section 3.3, Enter CALIBRATION

Mode.

The step labeled Exit CALIBRATION Mode refers to Section 3.11, Exit CALIBRATION

Mode.

www.ti.com

14

Factory Calibration

Figure 3-4. Board Offset Flow

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

Analog Conversion Counter:

0x79

Read MSB and LSB of the raw data we

are interested in.

counterNow = Analog Conversion Counter

counterNow ==

counterPrev

True

False

End

Enter Calibration Mode

Wait 200 ms

loopCount = 0, rawDataSum = 0

counterNow = Analog Conversion Counter

counterPrev = counterNow

Analog Current:

0x7A, 0x7B (LSB, MSB)

*Analog Cell Voltage:

0x7C, 0x7D (LSB, MSB)

Analog Temperature:

0x7E, 0x7F (LSB, MSB)

rawDataSum + = (MSB << 8) + LSB

loopCount++

counterPrev = counterNow

loopCount <

samplesToAvg

True

avgRawData = rawDataSum/samplesToAvg

Exit Calibration Mode

* When measurement input is

- BAT, then units are millivolts.

- VIN, then units are RawADCounts.

www.ti.com

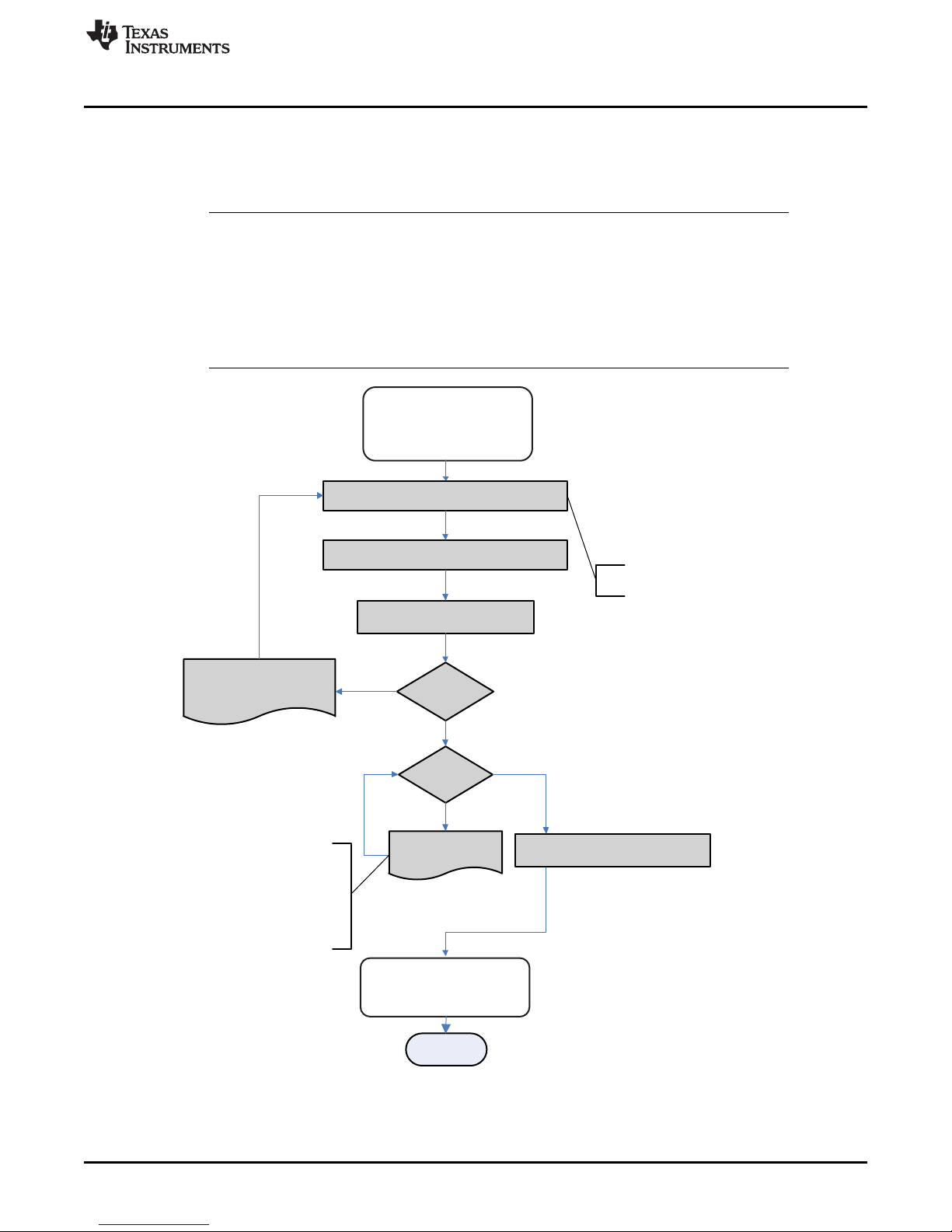

3.7 Obtain Raw Calibration Data

The following flowchart demonstrates how the host system obtains the raw data to calibrate current,

voltage, and temperature. The host system uses this flow in conjunction with the current, voltage, and

temperature flows described in this chapter. It is recommended that the host system samples the raw data

multiple times at a rate of once per second to obtain an average of the raw current, voltage, and

temperature. The host system must ensure that the fuel gauge is UNSEALED.

NOTE: The step labeled Enter CALIBRATION Mode refers to Section 3.3, Enter CALIBRATION

Mode.

The step labeled Exit CALIBRATION Mode refers to Section 3.11, Exit CALIBRATION

Mode.

Obtain Raw Calibration Data

Figure 3-5. Obtain Raw Calibration Data Flow

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Factory Calibration

15

Page 16

Force known load current

End

ccDelta = ccGain * 1,193,046

Typically 1000 mA

The signs of the variables are very

important. and

should be positive. ccOffset should be

treated as a 16-bit signed integer and

boardOffset should be an 8-bit signed

integer.

current avgRawCurrent

current = forced load current

Obtain CC Offset and Board offset

from DF

Obtain avgRawCurrent

The sign of current should be positive. Raw

current samples are positive in discharge

mode. This ensures that ccGain is positive.

Convert ccGain and ccDelta to

Gauge’s floating point

representation and write to DF

ccGain = current /(avgRawCurrent-(ccOffset + boardOffset) / 16)

Current Calibration

3.8 Current Calibration

CC Gain and CC Delta are two calibration parameters of concern for current calibration. A known load,

typically 1000 mA, is applied to the device during this process. Details on converting the CC Gain and CC

Delta to floating point format are in Floating Point Conversion. The host system must ensure that the fuel

gauge is UNSEALED.

NOTE: The step labeled Obtain avgRawCurrent refers to Section 3.7, Obtain Raw Calibration

Data.

The step labeled Convert ccGain and ccDelta to Gauge’s floating point representation

and write to DF refers to Section 3.10, Floating Point Conversion.

www.ti.com

Figure 3-6. Current Calibration Flow

16

Factory Calibration

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

Apply known temperature

temp = known temperature

End

int tOffset = temp - avgRawVoltage

Write tOffset to DF

Obtain avgRawTemp

www.ti.com

3.9 Temperature Calibration

This feature calibrates the internal temperature and the external temperature sensor if the source is set by

Operation Config A [TEMPS]. A known temperature must be applied to the device for temperature

calibration. The calculated temperature offset is written to the corresponding location in DF. The

temperature offset is represented by an integer that is a single byte in size and can be written to the

appropriate location in DF without any intermediate steps. The host system must ensure that the fuel

gauge is UNSEALED.

NOTE: a) The step labeled Obtain avgRawTemp refers to Section 3.7, Obtain Raw Calibration

Data.

b) When using bqStudio, ensure that the selected calibration of Internal or External

temperature matches the setting on the [TEMPS] selection.

Temperature Calibration

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Figure 3-7. Temperature Calibration Flow

Copyright © 2016–2018, Texas Instruments Incorporated

Factory Calibration

17

Page 18

val < 0

mod _val = val

False

True

mod_val = val x (-1)

tmpVal = mod _val

False

True

byte2 = tmpVal LHS* of decimal

tmpVal = 2

8

× (tmpVal ± byte2)

False

byte1 = tmpVal LHS* of decimal

True

tmpVal = 28 × (tmpVal ± byte1)

decrement exp by 1

byte0 = tmpVal LHS* of decimal

False

True

True

Byte 2 OR with 0x80

False

True

False

rawData[byte0] = exp + 128

rawData[byte1] = byte2

rawData[byte2] = byte1

rawData[byte3] = byte0

exp < í128

End

val = read in value

Create integer, set to 0

exp = 0

tmpVal = tmpVal × (1+2

±25

)

tmpVal < 0.5

tmpVal < 0.5

multiply tmpVal by 2

tmpVal > = 1.0

tmpVal > = 1.0

divide tmpVal by 2

increment exp by 1

exp > 127

exp = 127

Write rawData [0-3] to

corresponding DF location

val < 0

tmpVal = 2

(8 ± exp)

× mod_val ± 128

exp í128

Floating Point Conversion

3.10 Floating Point Conversion

This section details how to convert the floating point CC Gain and CC Delta values to the format

recognized by the gauge.

18

Factory Calibration

* LHS is an abbreviation for Left-Hand Side. This refers to truncating the floating point value by removing anything to

the right of the decimal point.

Figure 3-8. Floating Point Conversion Flow

Copyright © 2016–2018, Texas Instruments Incorporated

www.ti.com

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Page 19

I2CWriteWord(0x0000, 0x0080, 100)

EXIT_CAL MAC Command:

0x0080 to 0x0000

I2CWriteWord(0x0000, 0x0000, 100)

I2CReadBlock(0x00, 2, 100)

calMod == 0

Device did not

exit calibration

mode; retry

True

False

End

www.ti.com

3.11 Exit CALIBRATION Mode

This sequence takes the gauge out of CALIBRATION mode. These steps must be performed when the

gauge is in UNSEALED mode.

NOTE: It is recommended to reset the gauge after calibration is completed to ensure all

measurements are taken using the new calibration.

Exit CALIBRATION Mode

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Factory Calibration

19

Page 20

4.1 Operation Config A

Chapter 4

SLUUBH1C–August 2016–Revised March 2018

Basic Configuration

CLASS SUBCLASS NAME TYPE SIZE

Configuration Registers Operation Config A Hex 1 0x00 0xff 0x80 —

7 6 5 4 3 2 1 0

TEMPS EXTVCELL WRTEMP LF_EN RSVD GNDSEL GMSEL1 GMSEL0

LEGEND: R/W = Read/Write; R = Read only; -n = value after reset

MIN

VALUE

MAX

VALUE

DEFAULT

VALUE

TEMPS (Bit 7): Enables the external temperature sensor (TS)

1 = External Temperature Sensor is enabled.

0 = Internal temperature sensor is enabled.

EXTVCELL (Bit 6): Enables the external cell voltage translation measurement (VEN, VIN)

1 = External cell voltage translation measurement is used.

0 = Internal cell voltage translation measurement is used.

WRTEMP (Bit 5): Enables host to write the temperature to the gauge

1 = Enabled

0 = Disabled

LF_EN (Bit 4): Enables the Lifetime Data gathering feature

1 = Enabled

0 = Disabled

RSVD (Bit 3): Reserved. Do not use.

GNDSEL (Bit 2): Enables the use of SRN as GND for the ADC conversions

1 = ADC Ground is SRN.

0 = ADC Ground is SRP.

GMSEL1:0 (Bit 1, Bit 0): Enables specific gauging mode

0 0 = Enables ACCUMULATOR mode

0 1 = Enables STATE-OF-HEALTH VOLTAGE CORRELATION mode for LiMnO

1 0 = Enables END-OF-SERVICE RESISTANCE CORRELATION mode for LiSOCl

2

2

1 1 = Invalid setting, do not use.

UNIT

20

Basic Configuration

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

The bq35100 device can operate in three distinct modes: ACCUMULATOR (ACC) mode, STATE-OFHEALTH (SOH) mode, and END-OF-SERVICE (EOS) mode. The device can be configured and used for

only one of these modes in the field, as it is not intended to be able to actively switch between modes

when in normal use.

5.1 ACCUMULATOR Mode

In this mode, the bq35100 device measures and updates cell voltage, cell temperature, and load current

every 1 s and begins accumulating after GAUGE_START is received. This data is provided through the

I2C interface while ControlStatus() [GA] is set.

This mode is enabled when [GMSEL1:0] in Operation Config A = 00.

5.1.1 Total Capacity Update

When in ACCUMULATOR mode, the bq35100 device tracks and then stores the total accumulated

capacity to its internal data flash.

Chapter 5

SLUUBH1C–August 2016–Revised March 2018

Battery Gauging

Care should be taken when enabling and using this feature to ensure that the

maximum number of writes, which is 200,000, is not exceeded. For example,

this translates to no more than 25 writes per day over 20 years.

When the GE pin is asserted, the device will update AccumulatedCapacity() from the value stored in data

flash. When ControlStatus() [GA] is set, the device adds each coulomb counter measurement to the value

of AccumulatedCapacity().

Sending the GAUGE_STOP() command prior to the GE pin being pulled low initiates the latest value of

AccumulatedCapacity() to be written to data flash memory. As this operation takes a finite amount of time,

the gauge will assert [G_DONE] in ControlStatus() and can optionally trigger the ALERT pin to inform the

host when the operation is complete.

5.2 STATE-OF-HEALTH (SOH) Mode

This mode is enabled when [GMSEL1:0] in Operation Config A = 01. This mode is suitable for

determining SOH for Lithium Manganese Dioxide (LiMnO2) chemistry. In this mode, cell voltage and

temperature are precisely measured immediately after the GE pin is asserted. The gauge uses this data to

compute SOH.

SOH = DOD(TermV) – DOD(OCV, temperature)

Where:

TermV is a DF constant determined by the manufacturer to be discharge voltage below which the cell

cannot provide the power required by the device.

CAUTION

5.2.1 Low State-Of-Health Alert

BatteryStatus() [SOH_LOW] is set when StateOfHealth() is less than or equal to the value programmed in

SOHLOW for a period of SOH Set Time.

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Battery Gauging

21

Page 22

End-Of-Service (EOS) Mode

www.ti.com

CLASS SUBCLASS NAME TYPE SIZE

Configuration Discharge SOHLOW Integer 1 0 100 10 %

Configuration Discharge SOH Set Time Integer 1 0 60 0 s

Configuration Discharge

When BatteryStatus() [SOH_LOW] is set, the device can optionally trigger the ALERT pin. SOH_LOW is

cleared if StateOfHealth() is greater than SOH Clear Threshold. See Alert Signal for more information.

The GAUGE_START() and GAUGE_STOP() commands can be used in this mode to detect a Battery Low

Alert condition during a continuous discharge.

5.3 End-Of-Service (EOS) Mode

This mode is enabled when [GMSEL1:0] in Operation Config A = 10. This mode is suitable for gauging

Lithium Thionyl Chloride (LiSOCl2) cells. The End-Of-Service gauging algorithm uses voltage, current, and

temperature data to determine the resistance (R) and rate of change of resistance of the battery. The

resistance data is then used to find Depth of Discharge (DOD) = DOD(R). As above, SOH is determined

and in turn used to determine the EOS condition.

When in this mode, a GAUGE_START() command should be issued prior to any major discharge activity.

This will ensure that any major discharge pulses are used in the determination of the battery's condition.

Upon completion of any major discharge, the GAUGE_STOP() command should be sent to the device.

The gauge will continue to collect data in a low power state for the number of seconds determined by R

Data Seconds. The device then completes any calculations and flash writes. Once these tasks are

completed, then [G_DONE] is set and the device can be powered down.

SOH Clear

Threshold

MIN

VALUE

Integer 1 0 100 10 %

MAX

VALUE

DEFAULT

VALUE

UNIT

CLASS SUBCLASS NAME TYPE SIZE

EOS Data Values R Data Seconds U1 1 0 255 15 s

5.3.1 Initial EOS Learning

For optimal accuracy, the first event where the device updates its impedance value is required to be when

the battery is full (a fresh battery). If the battery was partially discharged, then the accuracy of the EOS

detection is compromised.

When a new battery is inserted, then the NEW_BATTERY() command should be sent to the device to

ensure the initial learned resistance RNEW is refreshed correctly.

In some cases, it may be necessary to compensate for anode passivation effects if there is a delay

between when the battery was conditioned for use and when the device is put into service. Several initial

impedance readings can be discarded (to remove passivation effects) by setting an appropriate value for

New Batt R Scale Delay.

CLASS SUBCLASS NAME TYPE SIZE

EOS Data Values

EOS Data Values R Table Scale Integer 2 –1 –1 –1 —

EOS Data Values

New batt R scale

delay

R Table Scale

Update Flag

MIN

VALUE

MIN

VALUE

Unsigned

Integer

Hex 1 0x00 0xff 0xff —

1 0 255 2 Readings

MAX

VALUE

MAX

VALUE

DEFAULT

VALUE

DEFAULT

VALUE

UNIT

UNIT

NOTE: Do not update R Table Scale and R TableScaleUpdateFlag.

22

Battery Gauging

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

5.3.2 End-Of-Service Detection

The bq35100 device can detect when a sharp increase in the trend of tracked impedance occurs,

indicating that the battery is reaching its end-of-service condition.

When in this mode, each time the GAUGE_START() command is received, then the internal counter "EOS

Detection Pulse Count" is incremented. This internal value is stored to EOS Detection Pulse Count once

GAUGE_STOP() is received.

NOTE: EOS Detection Pulse Count must be programmed to 0 prior to final system installation.

When the device has enough information to update Impedance, the present value of Impedance is

copied to Previous Impedance in preparation for the new Impedance value to be updated.

Using this data, the device monitors the trend through a moving average algorithm. For improved

accuracy, it is recommended to gather new data on a fixed periodic base: for example, every 24 hours. As

the device is powered down when not needed for EOS monitoring, it has no "time" information.

There are two moving average trends that are calculated after an Impedance update:

Short Trend Average = Impedance × 1/DF1 + Previous Impedance × (1–1/DF1) (1)

Long Trend Average = Impedance × 1/DF2 + Previous Impedance × (1–1/DF2) (2)

Where:

DF1 (50) and DF2 (100) are the time constants of the moving average.

The trend detection equation is:

Short Trend Average > Long Trend Average × (1 + EOS Trent Detection / 100) (3)

When this occurs the Battery Status [EOS] flag is set and cannot be cleared.

Where:

EOS Trent Detection is the % increase of Short Trend Average over Long Trend Average.

For example: If EOS Trent Detection = 20, then the [EOS] flag is set when Short Trend Average is

120% × Long Trend Average.

End-Of-Service (EOS) Mode

CLASS SUBCLASS NAME TYPE SIZE

EOS Data Values R short trend filter Unsigned Int 1 1 255 251 —

EOS Data Values R long trend filter Unsigned Int 1 1 255 253 —

EOS Data Values EOS trend detection Unsigned Int 1 1 100 20 —

EOS Data Values EOS detection pulse count Unsigned Int 2 1 20000 120 —

EOS Data Values

EOS Data Values Short trend average Unsigned Int 4 1 8355712 0 —

EOS Data Values Long trend average Unsigned Int 4 1 8355712 0 —

EOS detection pulse count

Thrhd

5.3.3 End-Of-Service Smoothing

In EOS mode, the State-Of-Health() output is smoothed to provide a more stable output value that will

converge, and not jump, at the terminate voltage. Smoothing occurs when Voltage() < EOS SOH Smooth

Start Voltage. The value of EOS SOH Smooth Start Voltage must be higher than Cell Terminate

Voltage.

NOTE: When EOS Smoothing is enabled, Lifetime Data gathering must also be enabled. This can

be done by sending (Control() 0x002E [LT_EN]) and confirming that it is enabled when

OperationStatus()[LTEN] = 1.

In EOS mode, the accuracy of the SOH reported value can vary significantly with a load

profile. Perform in-system evaluation to determine the reported value at the desired EOS

level. In some instances, the value of SOH should be ignored.

MIN

VALUE

Unsigned Int 2 1 20000 120 —

MAX

VALUE

DEFAULT

VALUE

UNIT

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Battery Gauging

23

Page 24

End-Of-Service (EOS) Mode

The Smoothing Margin can be set to control the rate of smoothing, but it is recommended to not change

it.

www.ti.com

CLASS SUBCLASS NAME TYPE SIZE

Gas Gauging Design

EOS Values

EOS Data Values

Cell Terminate

Voltage

EOS SOH Smooth

Start Voltage

EOS SOH

Smoothing Margin

Integer 2 0 5000 2900 mV

Integer 2 0 5000 2800 mV

Integer 1 0 255 128

MIN

VALUE

MAX

VALUE

DEFAULT

VALUE

UNIT

24

Battery Gauging

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

System Current

0

GE LOW

GE HIGH

The bq35100 device has only one active power mode that is enabled through the GAUGE ENABLE (GE)

pin. The power consumption of the bq35100 device can change significantly based on host commands

that it receives and its default configuration, specifically with respect to data flash updates.

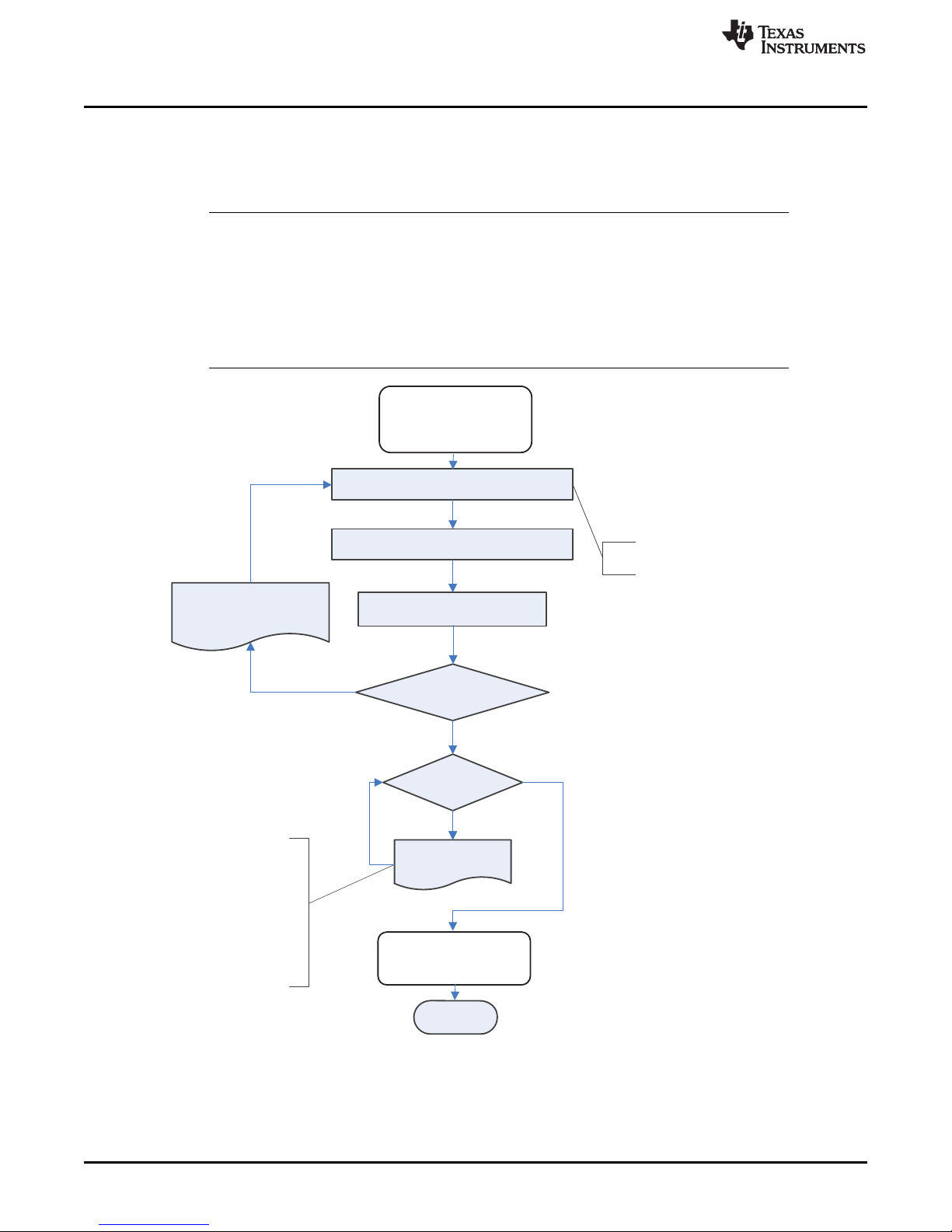

6.1 Device Functional Modes

The bq35100 device is intended for systems where the battery electronics are required to consume a very

low average current. To achieve this, the device is intended to be fully powered off when not required

through control of the GAUGE ENABLE pin.

When this pin is low, then the device is fully powered down where no measurements are made and no

data, unless in flash, is retained. In this state, the power consumption of the device is a few 10s of nA.

This value is primarily leakage of the device and other components on the board, but also includes

measurement errors. Due to the level of possible variations, use a conservative value of 50 nA for

example calculations.

An example system current profile is shown along with the state of GE to reduce the average power

consumption of the battery electronics.

Chapter 6

SLUUBH1C–August 2016–Revised March 2018

Power Control

Figure 6-1. System Current Profile Example

The average power consumption of the bq35100 device is an average of the periods where GAUGE

ENABLE is high AND low over a given period.

For example, if the system enters a high power state (315 µA) for 30 s every 4 hours, the average current

will be:

315 µA × 30 s / 4 hrs = 0.66 µA (4)

When GAUGE ENABLE is low (GE = Low), then the device is powered off and the current is nominally

I

CC_GELOW

and is the leakage current into the REGIN pin. Other components connected to this node should

also be evaluated to determine the "System Off" current total.

When the device is used for gas gauging, it transitions through several power states based on the

selection of Operation Cfg A[GMSEL].

Figure 6-2 highlights the operational flow and conditional decisions.

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Power Control

25

Page 26

Systems wants to

begin monitoring

KEY:

GE = GAUGE ENABLE Pin

Host sets GE High

YES

YES

Take initial

measurements and

check for warnings

Set INITCOMP= 1

RX ‘START’ CMD

from Host

Startup Phase

NO

Is GMSEL= 10

NO

Update Discharge

Accumulation from

Coulomb Counter

Update Voltage and

Temperature

RX ‘STOP’ CMD

from Host

Update Voltage and

Current with128 ×

8-ms conversions

Check for Warnings

and update status

YES

Execute End of

Service detection

algorithm and

update status

NO

Execute Lifetime

Checks

Is GMSEL= 10

Write Accumulated

data and status to

DF

YES

NO

Are DF updates

Enabled?

Are Lifetime

updates

Enabled?

YES

NO

Update Lifetime DF

YES

Set G_DONE = 1

Device OK to

power Down

Active

Phase

Data Update

Phase

Waiting Phase

Device powers up

NO

Update Voltage

Device Functional Modes

www.ti.com

26

Power Control

Figure 6-2. Operational Flow

Copyright © 2016–2018, Texas Instruments Incorporated

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Page 27

www.ti.com

6.2 Flash Updates

If enabled, data flash can only be updated if either of the two following conditions is true:

1. ControlStatus() [GA] = 1 AND Voltage() ≥ Flash Update OK Voltage.

2. ControlStatus() [GA] = 0.

If enabled, data flash can only be updated if Voltage() ≥ Flash Update OK Voltage. Flash programming

current can cause an increase in LDO dropout. The value of Flash Update OK Voltage should be

selected such that the device VCCvoltage does not fall below its minimum of 2.4 V during Flash write

operations.

Flash Updates

CLASS SUBCLASS NAME TYPE SIZE

Configuration Power

Flash Update OK

Voltage

Integer 2 0 4200 2800 mV

MIN

VALUE

MAX

VALUE

DEFAULT

VALUE

UNIT

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Power Control

27

Page 28

7.1 Battery Low Warning

The bq35100 device can indicate and optionally trigger the ALERT pin when the primary battery voltage

falls below a programmable threshold.

STATUS CONDITION ACTION

Normal Voltage() > BatLow Voltage Set Threshold BatteryAlert()[BATLOW] = 0

Trip

Voltage() ≤ BatLow Voltage Set Threshold for

BATLOW:Delay duration BatLow Voltage Set Time

Chapter 7

SLUUBH1C–August 2016–Revised March 2018

Battery Condition Warnings

BatteryAlert()[BATLOW] = 1

CLASS SUBCLASS NAME TYPE SIZE

Configuration Discharge

Configuration Discharge

7.2 Temperature Low Warning

The bq35100 device can indicate and optionally trigger the ALERT pin when the primary battery

temperature falls below a programmable threshold.

Status Condition Action

Normal Temperature() > Under Temperature Set Threshold BatteryAlert()[TEMPLOW] = 0

Trip

Recovery

CLASS SUBCLASS NAME TYPE SIZE

Configuration Discharge

Configuration Discharge

Configuration Discharge

Temperature() ≤ Under Temperature Threshold for

TEMPLOW:Delay duration for Under Temperature

Set Time duration

Temperature() > Under Temperature Clear

Threshold

BatLow Voltage Set

Threshold

BatLow Voltage Set

Time

Under Temperature

Set Threshold

Under Temperature

Set Time

Under Temperature

Clear Threshold

MIN

VALUE

Integer 2 0 5000 2800 mV

Integer 1 0 255 10 s

BatteryAlert()[TEMPLOW] = 1

BatteryAlert()[TEMPLOW] = 0

MIN

VALUE

Signed

Integer

Integer 1 0 255 4 s

Integer 2 0 255 100 0.1°K

2 –400 850 –200 0.1°K

MAX

VALUE

MAX

VALUE

DEFAULT

VALUE

DEFAULT

VALUE

UNIT

UNIT

7.3 Temperature High Warning

The bq35100 device can indicate and optionally trigger the ALERT pin when the primary battery

temperature rises above a programmable threshold.

28

Battery Condition Warnings

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 29

www.ti.com

Battery Low SOC Warning

STATUS CONDITION ACTION

Normal Temperature() < OT Dsg Threshold BatteryAlert()[TEMPHIGH] = 0

Trip

Recovery Temperature() < OT Dsg Recovery BatteryAlert()[TEMPHIGH] = 0

Temperature() ≥ OT Dsg Threshold for OT Dsg Time

duration

BatteryAlert()[TEMPHIGH] = 1

CLASS SUBCLASS NAME TYPE SIZE

Configuration Discharge OT Dsg

Configuration Discharge OT Dsg Time Integer 2 0 255 4 s

Configuration Discharge OT Dsg Recovery Integer 2 0 255 100 0.1°K

Signed

Integer

2 –400 850 450 0.1°K

MIN

VALUE

MAX

VALUE

DEFAULT

VALUE

7.4 Battery Low SOC Warning

The bq35100 device can indicate and optionally trigger the ALERT pin when the primary battery state-ofhealth (SOH) falls below a programmable threshold.

STATUS CONDITION ACTION

Normal StateOfHealth() > SOH Low BatteryStatus()[SOHLOW] = 0

Trip StateOfHealth() ≤ SOH Low BatteryStatus()[SOHLOW] = 1

CLASS SUBCLASS NAME TYPE SIZE

Configuration Discharge SOH Low

Configuration Discharge SOH Set Time

Configuration Discharge

SOH Clear

Threshold

Signed

Integer

Signed

Integer

Signed

Integer

MIN

VALUE

1 0 100 10 %

1 0 100 10 %

1 0 100 10 %

MAX

VALUE

DEFAULT

VALUE

UNIT

UNIT

7.5 Battery EOS OCV BAD Warning

The device assumes that when GE is asserted, the cell is at rest and uses the initialization voltage reading

to determine the Open Circuit Voltage (OCV). If the cell was not fully relaxed at that point, then the voltage

after the pulse could rise above the OCV. This causes an incorrect impedance to be calculated.

If the device measures a voltage value above the initial OCV, then it increments an internal counter. When

this counter increments up to EOS Relax V Hi Max Counts, then [EOS_OCV_BAD] is set in

CONTROL_STATUS().

If [EOS_OCV_BAD] becomes set, then the battery requires a longer time to rest and the device should be

powered down (GE driven low). As a guideline, from the last major discharge, a rest of 5 hours should

allow full relaxation.

CLASS SUBCLASS NAME TYPE SIZE

EOS Data Values

EOS Relax V

Hi Max Counts

Integer 1 1 255 3 counts

MIN

VALUE

MAX

VALUE

DEFAULT

VALUE

UNIT

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Battery Condition Warnings

29

Page 30

Chapter 8

SLUUBH1C–August 2016–Revised March 2018

ALERT Signal

The ALERT signal can be configured to be triggered by a variety of status conditions. When the ALERT

Configuration bit is set AND the corresponding bit in BatteryStatus() or ControlStatus() is set, then the

corresponding BatteryAlert() bit is set, triggering the ALERT signal.

For example: If BatteryStatus() [BATLOW] AND ALERT Configuration [BATLOW] = 1, then

BatteryAlert() [BATLOW] is set and the ALERT pin is triggered.

The ALERT signal is cleared upon a read of BatteryStatus().

Table 8-1. Data Flash ALERT Configuration

CLASS SUBCLASS NAME TYPE SIZE

Configuration Registers ALERT Configuration Hex 1 0x00 0xff 0x00 —

7 6 5 4 3 2 1 0

BATLOW TEMPLOW TEMPHIGH SOH_LOW EOS RSVD G_DONE INITCOMP

LEGEND: R/W = Read/Write; R = Read only; -n = value after reset

MIN

VALUE

MAX

VALUE

DEFAULT

VALUE

BATLOW (Bit 7): Battery voltage low condition

0 = ALERT is not triggered when BATLOW becomes set (default).

1 = ALERT is triggered when BATLOW becomes set.

TEMPLOW (Bit 6): Battery temperature low condition

0 = ALERT is not triggered when TEMPLOW becomes set (default).

1 = ALERT is triggered when TEMPLOW becomes set.

TEMPHIGH (Bit 5): Battery temperature high condition

0 = ALERT is not triggered when TEMPHIGH becomes set (default).

1 = ALERT is triggered when TEMPHIGH becomes set.

SOH_LOW (Bit 4): Low SOH State detected

0 = ALERT is not triggered when SOH_LOW becomes set (default).

1 = ALERT is triggered when SOH_LOW becomes set.

EOS (Bit 3): End-Of-Service state detected

0 = ALERT is not triggered when EOS becomes set (default).

1 = ALERT is triggered when EOS becomes set.

RSVD (Bit 2): Reserved. Do not use.

G_DONE (Bit 1): Gauge Done State reached

0 = ALERT is not triggered when G_DONE becomes set (default).

1 = ALERT is triggered when G_DONE becomes set.

INITCOMP (Bit 0): Initialization Complete

0 = ALERT is not triggered when INITCOMP becomes set (default).

1 = ALERT is triggered when INITCOMP becomes set.

UNIT

30

ALERT Signal

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 31

Chapter 9

SLUUBH1C–August 2016–Revised March 2018

Lifetime Data Collection

The bq35100 device can be enabled by writing to Control() 0x002E [LT_EN] to gather data regarding the

primary battery and to store it to data flash.

The following data is collected in RAM and only written to DF when the host sends the End command to

the device.

• Min and Max Cell Voltage

• Min and Max Discharge Current

• Min and Max Temperature

CLASS SUBCLASS NAME TYPE MIN MAX DEFAULT UNIT

LTFlash Voltage Max I2 0 32767 0 mV

LTFlash Voltage Min I2 0 32767 0 mV

LTFlash Current Max Discharge I2 0 32767 0 mA

LTFlash Current Min Discharge I2 0 32767 0 mA

LTFlash Temperature Max Cell I2 –128 127 0 °C

LTFlash Temperature Min Cell I2 –128 127 0 °C

LTFlash Temperature Max Gauge I2 –128 127 0 °C

LTFlash Temperature Min Gauge I2 –128 127 0 °C

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Lifetime Data Collection

31

Page 32

10.1 Overview

As of March 2012, the latest revision is FIPS 180-4. SHA-1, or secure hash algorithm, is used to compute

a condensed representation of a message or data also known as hash. For messages < 264, the SHA-1

algorithm produces a 160-bit output called a digest.

In a SHA-1 one-way hash function, there is no known mathematical method of computing the input given,

only the output. The specification of SHA-1, as defined by FIPS 180-4, states that the input consists of

512-bit blocks with a total input length less than 264 bits. Inputs that do not conform to integer multiples of

512-bit blocks are padded before any block is input to the hash function. The SHA-1 algorithm outputs the

160-bit digest.

The device generates a SHA-1 input block of 288 bits (total input = 160-bit message + 128-bit key). To

complete the 512-bit block size requirement of the SHA-1 function, the device pads the key and message

with a 1, followed by 159 0s, followed by the 64-bit value for 288 (000...00100100000), which conforms to

the pad requirements specified by FIPS 180-4.

• http://www.nist.gov/itl/

• http://csrc.nist.gov/publications/fips

• www.faqs.org/rfcs/rfc3174.html

Chapter 10

SLUUBH1C–August 2016–Revised March 2018

SHA-1 Authentication

10.2 HMAC Description

The SHA-1 engine calculates a modified HMAC value. Using a public message and a secret key, the

HMAC output is considered to be a secure fingerprint that authenticates the device used to generate the

HMAC.

To compute the HMAC: Let H designate the SHA-1 hash function, M designate the message transmitted

to the device, and KD designate the unique 128-bit Unseal/Full Access/Authentication key of the device.

HMAC(M) is defined as: H[KD || H(KD || M)], where || symbolizes an append operation.

10.3 Authentication

The authentication feature is used in the following sequence:

1. MAC command 0x0000: Command = 0x0000, write the 20 bytes to 0x40, then write the checksum+len

at 0x60. The response will be available as a MAC response, so 0x3E/0x3F will be 0x0000, 0x40 will

have the SHA1 result, and 0x60/0x61 will have the checksum and length.

2. Generate 160-bit message M using a random number generator that meets approved random number

generators described in FIPS PUB 140–2.

3. Generate SHA-1 input block B1 of 512 bytes (total input = 128-bit authentication key KD + 160-bit

message M + 1 + 159 0s + 100100000).

4. Generate SHA-1 hash HMAC1 using B1.

5. Generate SHA-1 input block B2 of 512 bytes (total input = 128-bit authentication key KD + 160-bit hash

HMAC1 + 1 + 159 0s + 100100000).

6. Generate SHA-1 hash HMAC2 using B2.

7. With no active MACData() data waiting, write 160-bit message M to MACData() in the format

0xAABBCCDDEEFFGGHHIIJJKKLLMMNNOOPPQQRRSSTT, where AA is LSB.

8. Wait 250 ms, then read MACData() for HMAC3.

32

SHA-1 Authentication

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 33

www.ti.com

9. Compare host HMAC2 with device HMAC3, and if it matches, both host and device have the same key

KD and the device is authenticated.

10.4 AuthenticateData(): 0x40…0x53

UNSEALED Access—This data block has a dual function: It is used for the authentication challenge and

response and is part of the 32-byte data block when accessing data flash.

SEALED Access—This data block has a dual function: It is used for authentication challenge and

response, and is part of the 32-byte data block when accessing Manufacturer Data.

10.5 AuthenticateChecksum(): 0x54

UNSEALED Access—This byte holds the authentication checksum when writing the authentication

challenge to the device, and is part of the 32-byte data block when accessing data flash.

SEALED Access—This byte holds the authentication checksum when writing the authentication challenge

to the device, and is part of the 32-byte data block when accessing Manufacturer Data.

AuthenticateData(): 0x40…0x53

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

SHA-1 Authentication

33

Page 34

11.1 Command Summary

Chapter 11

SLUUBH1C–August 2016–Revised March 2018

Data Commands

Table 11-1. Data Command Summary

CMD MODE NAME FORMAT

0x00...0x01 R/W Control Hex 2 0x00 0xff — —

0x02…0x05 R AccumulatedCapacity Signed Int 4 0 4.29E9 — µAh

0x06…0x07 R Temperature

0x08...0x09 R Voltage Signed Int 2 0 65535 — mV

0x0A R BatteryStatus Hex 1 0x00 0xff — —

0x0B R BatteryAlert Hex 1 0x00 0xff — —

0x0C…0x0D R Current Signed Int 2 –32768 32767 — mA

0x16…0x17 R Scaled R

0x22…0x23 R Measured Z

0x28…0x29 R InternalTemperature

0x2E R StateOfHealth

0x3C…0x3D R DesignCapacity

0x79 R Cal_Count Hex 1 0x00 0xff — —

0x7A…0x7B R Cal_Current Signed Int 2 0 65535 — mA

0x7C…0x7D R Cal_Voltage Signed Int 2 0 32767 —

0x7E…0x7F R Cal_Temperature

(1)

mV when [EXTVCELL] = 0 and ADC counts when [EXTVCELL] = 1

Unsigned

Int

Unsigned

Int

Unsigned

Int

Unsigned

Int

Unsigned

Int

Unsigned

Int

Unsigned

Int

SIZE IN

BYTES

2 –32768 32767 — 0.1°K

2 0 65535 — mΩ

2 0 65535 — mΩ

2 –32768 32767 — 0.1°K

1 0 100 — %

2 0 65535 — mAh

2 0 65535 — °K

MIN

VALUE

MAX

VALUE

DEFAULT

VALUE

UNIT

mV or

Counts

(1)

11.2 Control(): 0x00/0x01

Issuing a Control() (or Manufacturer Access Control or MAC) command requires a 2-byte subcommand.

The subcommand specifies the particular MAC function desired. The Control() command enables the

system to control specific features of the gas gauge during normal operation and additional features when

the device is in different access modes, as described below. On this device, Control() commands may

also be sent to ManufacturerAccessControl().

Any subcommand that has a data response will be read back on MACData(). Reading the Control()

registers will always report the CONTROL_STATUS() data field, except after the DEVICE_TYPE() and

FW_VERSION() subcommands. After these subcommands, CONTROL_STATUS() will report the value

0xFFA5 one time before reverting to the normal data response. This is a flag to indicate that the data

response has been moved to MACData(). Writing a 0x0000 to Control() is not necessary to read the

CONTROL_STATUS(); however, doing so is okay.

34

Data Commands

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 35

www.ti.com

When executing commands that require data (such as data flash writes), the subcommand can be written

to either Control() or ManufacturerAccessControl() registers; however, it is recommended to write using

the ManufacturerAccessControl() registers as this enables performing the full command in a single I2C

transaction.

For example, the following return the same CHEM_ID data write:

0x0000 0x0800 ;

Read: 0x3e

Read: 0x3f

write: 0x3e 0x0800 ;

Read: 0x3e

Read: 0x3f

The Control() MAC command enables the host to control specific features of the device during normal

operation, and additional features when the bq35100 device is in different access modes, as described in

Table 11-2.

CONTROL_STATUS: 0x0000

Table 11-2. Control MAC Subcommands

CNTL FUNCTION CNTL DATA

CONTROL_STATUS 0x0000 Yes Reports the status of key features

DEVICE_TYPE 0x0001 Yes Reports the device type of 0x100 (indicating bq35100)

FW_VERSION 0x0002 Yes Reports the firmware (LSB) version on the device type

HW_VERSION 0x0003 Yes Reports the hardware (MSB) version of the device type

STATIC_CHEM_CHKSUM 0x0005 Yes Calculates chemistry checksum

CHEM_ID 0x0006 Yes

PREV_MACWRITE 0x0007 Yes Returns previous Control() command code

BOARD_OFFSET 0x0009 Yes

CC_OFFSET 0x000A Yes Forces the device to measure the internal CC offset

CC_OFFSET_SAVE 0x000B Yes Forces the device to store the internal CC offset

GAUGE_START 0x0011 Yes Triggers the device to enter ACTIVE mode

GAUGE_STOP 0x0012 Yes

SEALED 0x0020 No Places the device in SEALED access mode

CAL_ENABLE 0x002D No Toggle CALIBRATION mode enable

LT_ENABLE 0x002E No Enables Lifetime Data collection

RESET 0x0041 No Forces a full reset of the device

EXIT_CAL 0x0080 No Exit CALIBRATION mode

ENTER_CAL 0x0081 No Enter CALIBRATION mode

NEW_BATTERY 0xA613 Yes

SEALED

ACCESS

DESCRIPTION

Reports the chemical identifier used by the gas gauge

algorithms

Forces the device to measure and store the board

offset

Triggers the device to stop gauging and complete all

outstanding tasks

Used to refresh the gauge when a new battery is

installed and resets all recorded data.

11.3 CONTROL_STATUS: 0x0000

This command instructs the device to return status information to Control addresses 0x00/0x01. The

status word includes the following information.

SLUUBH1C–August 2016–Revised March 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Data Commands

35

Page 36

CONTROL_STATUS: 0x0000

15 14 13 12 11 10 9 8

FLASHF SEC1 SEC0 CalMode BCA CCA LTEN OCVFAIL

7 6 5 4 3 2 1 0

INITCOMP G_DONE SOH_ERR SOH_MERIT

LEGEND: R/W = Read/Write; R = Read only; -n = value after reset

EOS_BAD

_OCV

RSVD RSVD GA

FLASHF (Bit 15): Indicates the device has detected a failed write to data flash.

1 = Active

0 = Inactive

SEC1, SEC0 (Bit 14,13): Indicates which SECURITY mode the device is in 0.

0, 0 = Reserved

0, 1 = Full Access

1, 0 = Unsealed

1, 1 = Sealed

CalMode (Bit 12): Indicates the device is in CALIBRATION mode.

1 = Active

0 = Inactive

BCA (Bit 11): Indicates the device Board Calibration routine is active.

1 = Active

0 = Inactive

CCA (Bit 10): Indicates the device Coulomb Counter Calibration routine is active.

1 = Active

0 = Inactive

LTEN (Bit 9): Indicates that Lifetime Data collection has been enabled.

1 = Enabled

0 = Disabled

OCVFAIL (Bit 8): Indicates if too much current is detected when making the initial voltage measurement.

1 = Too much current detected

0 = Voltage measurement OK

INITCOMP (Bit7): Indicates the device initialization is complete.

1 = Initialization is complete.

0 = Initialization is not complete.

G_DONE (Bit 6): Indicates all tasks are complete and the device can be powered down.

1 = All tasks are complete.

0 = Some tasks have yet to complete.

SOH_ERR (Bit 5): Indicates the quality of the SOH calculation has overflowed.

1 = SOH Calculation has overflowed.

0 = SOH calculation has not overflowed.

SOH_MERIT (Bit 4): Indicates the quality of the SOH calculation was limited.

1 = SOH Calculation Limited

0 = SOH calculation was not limited.

EOS_BAD_OCV (Bit 3): Indicates the measured voltage exceeds the initial OCV voltage.

1 = Bad OCV measurements are made.

0 = Good OCV measurements are made.

GA (Bit 0): Indicates the device is in ACTIVE mode.

www.ti.com

36

Data Commands

SLUUBH1C–August 2016–Revised March 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 37

www.ti.com

1 = Active

0 = Inactive

11.3.1 DEVICE_TYPE: 0x0001

When reading DEVICE_TYPE(), a block read is used. This requires that a write to 0x00 of 0x0200 should

be followed by a read of 0x40 with 6 bytes to be read out. All In little-endian order, the first 2 bytes are

DEVICE_TYPE(), then 2 bytes of FW_VERSION() and 2 bytes of FW BUILD.

11.3.2 FW_VERSION: 0x0002

When reading FW_VERSION(), a block read is used. This requires that a write to 0x00 of 0x0200 should

be followed by a read of 0x40 with 6 bytes to be read out. All in little-endian order, the first 2 bytes are

DEVICE_TYPE(), then 2 bytes of FW_VERSION() and 2 bytes of FW BUILD.

11.3.3 HW_VERSION: 0x0003

This command instructs the device to return the hardware version to addresses 0x00/0x01.

11.3.4 STATIC_CHEM_DF_CHKSUM: 0x0005

This command instructs the fuel gauge to calculate chemistry checksum as a 16-bit unsigned integer sum

of all static chemistry data. The most significant bit (MSB) of the checksum is masked yielding a 15-bit

checksum. This checksum is compared with the value stored in the data flash Static Chem DF

Checksum. If the value matches, the MSB will be cleared to indicate a pass. If it does not match, the

MSB will be set to indicate a failure.

CONTROL_STATUS: 0x0000

11.3.5 CHEM_ID: 0x0006

This command instructs the fuel gauge to return the chemical identifier for the programmed chemistry

configuration to addresses 0x00/0x01. For evaluation purposes, the default CHEM_ID is a hybrid of a) Ra

table for LiSOCl2and b) OCV table for LiMnO2. The appropriate Chem ID for the cell to be used in the

target application should be used in production.

11.3.6 PREV_MACWRITE: 0x0007

This command instructs the fuel gauge to return the previous command written to addresses 0x00/0x01.

The value returned is limited to less than 0x0020.

11.3.7 BOARD_OFFSET: 0x0009

This command instructs the fuel gauge to calibrate board offset when is in ACTIVE mode. During board

offset calibration, the [BCA] bit is set. This command only returns updated data after GAUGE_START() is

received and prior to when GAUGE_STOP() is received.