Features

ä

Power monitoring and switching

for nonvolatile control of SRAMs

ä

Write-protect control

ä

Battery-low and battery-fail indicators

ä

Reset output for system power-on

reset

ä

Input decoder for control of up to

2 banks of SRAM

ä

3-volt primary cell input

ä

3-volt rechargeable battery input/output

General Description

The CMOS bq2203A SRAM Nonvolatile

Controller With Battery Monitor provides all the necessary functions for converting one or two banks of standard

CMOS SRAM into nonvolatile

read/write memory. The bq2203A is

compatible with the Personal Computer

Memory Card International Association

(PCMCIA) recommendations for

battery-backed static RAM memory

cards.

A precision comparator monitors the 5V

V

CC

input for an out-of-tolerance condition. When out of tolerance is detected,

the two conditioned chip-enable outputs

are forced inactive to write-protect

banks of SRAM.

Power for the external SRAMs is

switched from the VCCsupply to the

battery-backup supply as VCCdecays. On a subsequent power-up, the

V

OUT

supply is automatically

switched from the backup supply to

the VCCsupply. The external SRAMs

are write-protected until a powervalid condition exists. The reset output provides power-fail and power-on

resets for the system. The battery

monitor indicates battery-low and

battery-fail conditions.

During power-valid operation, the

input decoder selects one of two

banks of SRAM.

1

1

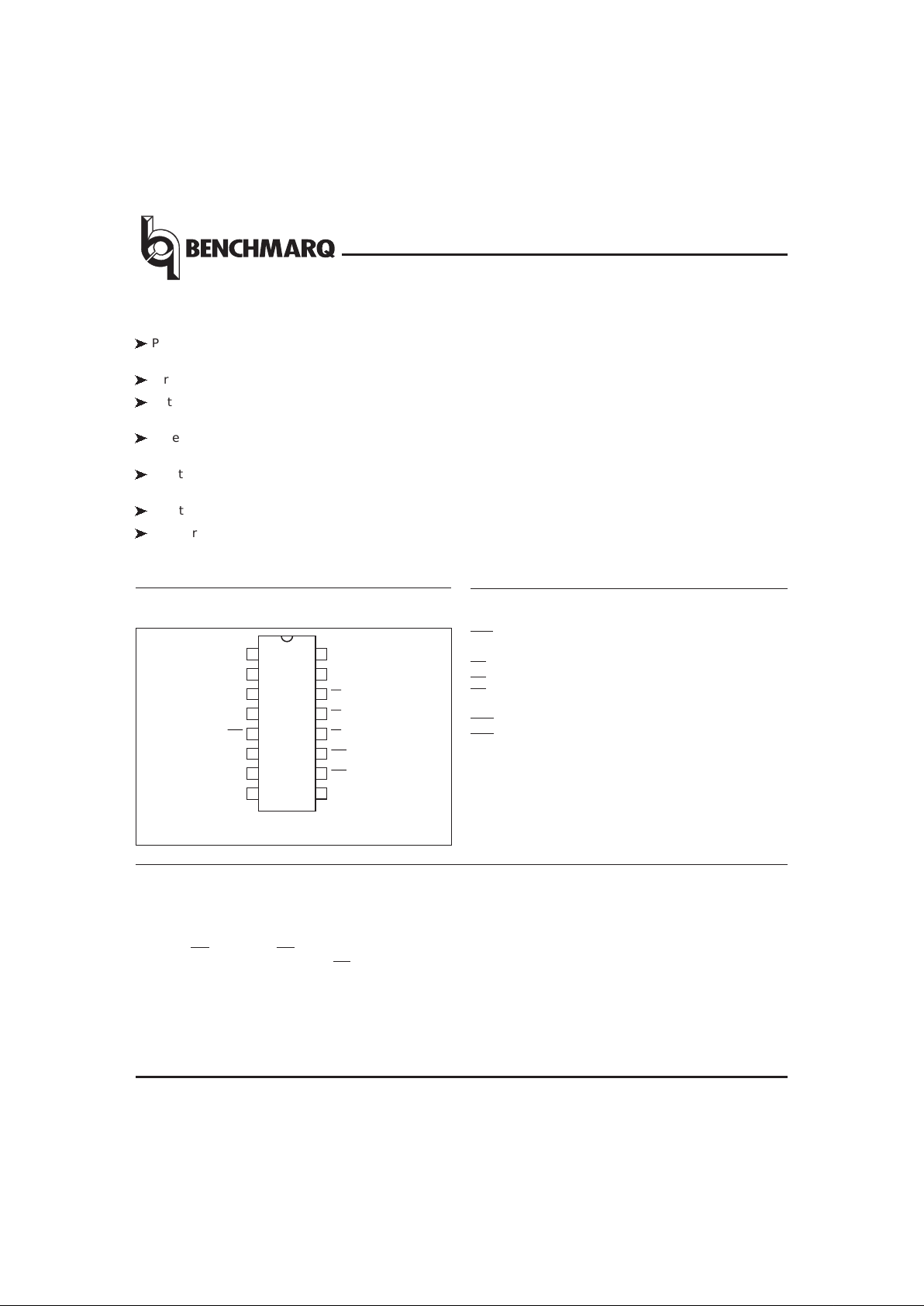

PN220301.eps

16-Pin Narrow DIP or SOIC

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

CC

BC

S

CE

CE

CON1

CE

CON2

BCL

RST

NC

V

OUT

BC

P

NC

A

BCF

NC

THS

V

SS

bq2203A

Nov.1994 B

Pin Connections

Two banks of CMOS static RAM can be battery-backed using the V

OUT

and the conditioned chip-enable output pins

from the bq2203A. As the voltage input VCCslews down

during a power failure, the two conditioned chip-enable

outputs, CE

CON1

and CE

CON2

, are forced inactive

independent of the chip-enable input CE.

This activity unconditionally write-protects external SRAM

as V

CC

falls to an out-of-tolerance threshold V

PFD.VPFD

is

selected by the threshold select input pin, THS. If THS is

tied to VSS, the power-fail detection occurs at 4.62V typical

for 5% supply operation.

If THS is tied to VCC, power-fail detection occurs at

4.37V typical for 10% supply operation. The THS pin

must be tied to VSSor VCCfor proper operation.

If a memory access is in process to any of the two external banks of SRAM during power-fail detection, that

memory cycle continues to completion before the memory

is write-protected. If the memory cycle is not terminated

within time t

WPT

(150µs maximum), the two chip-enable

outputs are unconditionally driven high, write-protecting

the controlled SRAMs.

Functional Description

NV Controller With Battery Monitor

Pin Names

V

OUT

Supply output

RST Reset output

THS Threshold select input

CE chip-enable active low input

CE

CON1

, Conditioned chip-enable outputs

CE

CON2

A Bank select input

BCF Battery fail push-pull output

BCL Battery low push-pull output

BC

P

3V backup supply input

BC

S

3V rechargeable backup supply input/output

NC No connect

V

CC

5-volt supply input

V

SS

Ground

As the supply continues to fall past V

PFD

, an internal

switching device forces V

OUT

to the external backup en-

ergy source. CE

CON1

and CE

CON2

are held high by the

V

OUT

energy source.

During power-up, V

OUT

is switched back to the 5V supply as VCCrises above the backup cell input voltage

sourcing V

OUT

. Outputs CE

CON1

and CE

CON2

are held

inactive for time t

CER

(120ms maximum) after the

power supply has reached V

PFD

, independent of the CE

input,toallowforprocessorstabilization.

During power-valid operation, the CE

input is passed

through to one of the two CE

CON

outputs with a propagation delay of less than 10ns. The CE input is output on

one of the two CE

CON

output pins depending on the level

of bank select input A,asshownintheTruthT able .

Bank select input A is usually tied to a high-order ad-

dress pin so that a large nonvolatile memory can be designed using lower-density memory devices. Nonvolatility and decoding are achieved by hardware hookup as

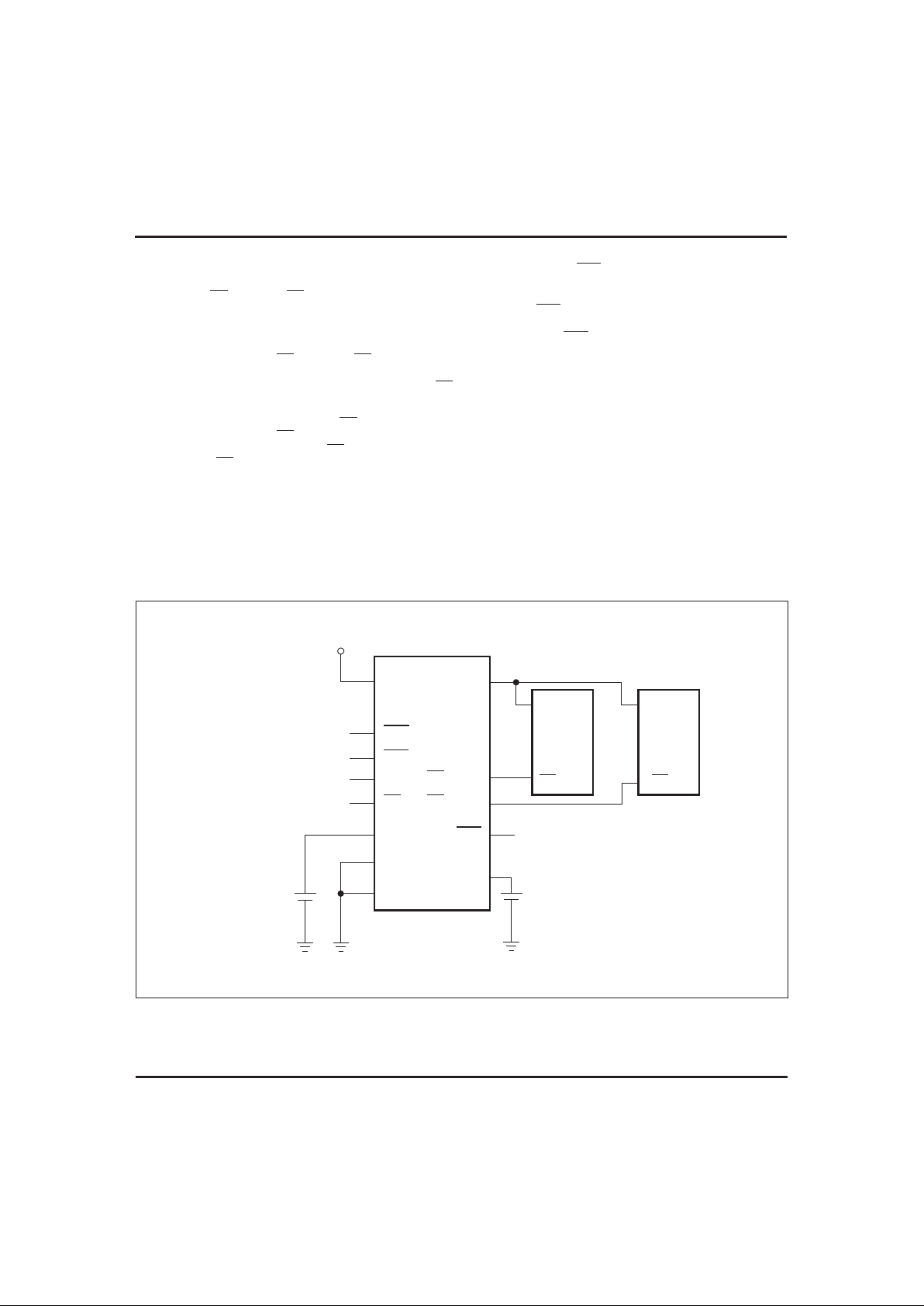

shown in Figure 1.

The reset output (RST) goes active within t

PFD

(150µs

maximum) after V

PFD,

and remains active for a minimum of 40ms (120ms maximum) after power returns

valid. The RST output can be used as the power-on reset for a microprocessor. Access to the external RAM

may begin when RST returns inactive.

Energy Cell Inputs—BCP,BC

S

Two backup energy source inputs are provided on the

bq2203A—a primary cell BC

P

and a secondary cell BCS.

The primary cell input is designed to accept any 3V primary battery (non-rechargeable), typically some type of

lithium chemistry.If a primary cell is not to be used, the

BCPpin should be tied to VSS. The secondary cell input

BCSis designed to accept constant-voltage currentlimited rechargeable cells.

During normal 5V power valid operation, 3.3V typical is output on the BC

S

pin and is current-limited internally . Although this charging method can be used with various 3V

secondary cells, it is specifically designed for a Panasonic VL

(vanadium-lithium) series of rechargeable cells.

2

FG220301.eps

CE

BC

P

THS

V

SS

V

OUT

bq2203A

V

CC

CE

CMOS

SRAM

V

CC

5V

From Address

Decoder

CE

CON2

BC

S

CE

CON1

A

RST

V

CC

CE

CMOS

SRAM

To Microprocessor

3V Secondary

Cell

3V Primary

Cell

BCL

BCF

Figure 1. Hardware Hookup (5% Supply Operation)

Nov.1994 B

bq2203A

If a secondary cell is not to be used, the BCSpin must be

tied directly to VSS.

V

CC

falling below V

PFD

starts the comparison of BC

S

and BCP. The BC input comparison continues until V

CC

rises above VSO. Power to V

OUT

begins with BCSand

switches to BCPonly when BCSis less than BCPminus

V

BSO

. The controller alternates to the higher BC voltage

when the difference between the BC input voltages is

greater than V

BSO

. Alternating the backup batteries allows one-at-a-time battery replacement and efficient use

of both backup batteries.

To prevent battery drain when there is no valid data to

retain, V

OUT

,CE

CON1

, and CE

CON2

are internally iso-

lated from BCPand BCSby either of two methods:

■

Initial connection of a battery to BCPor BCS(V

CC

grounded) or

■

Presentation of an isolation signal on CE.

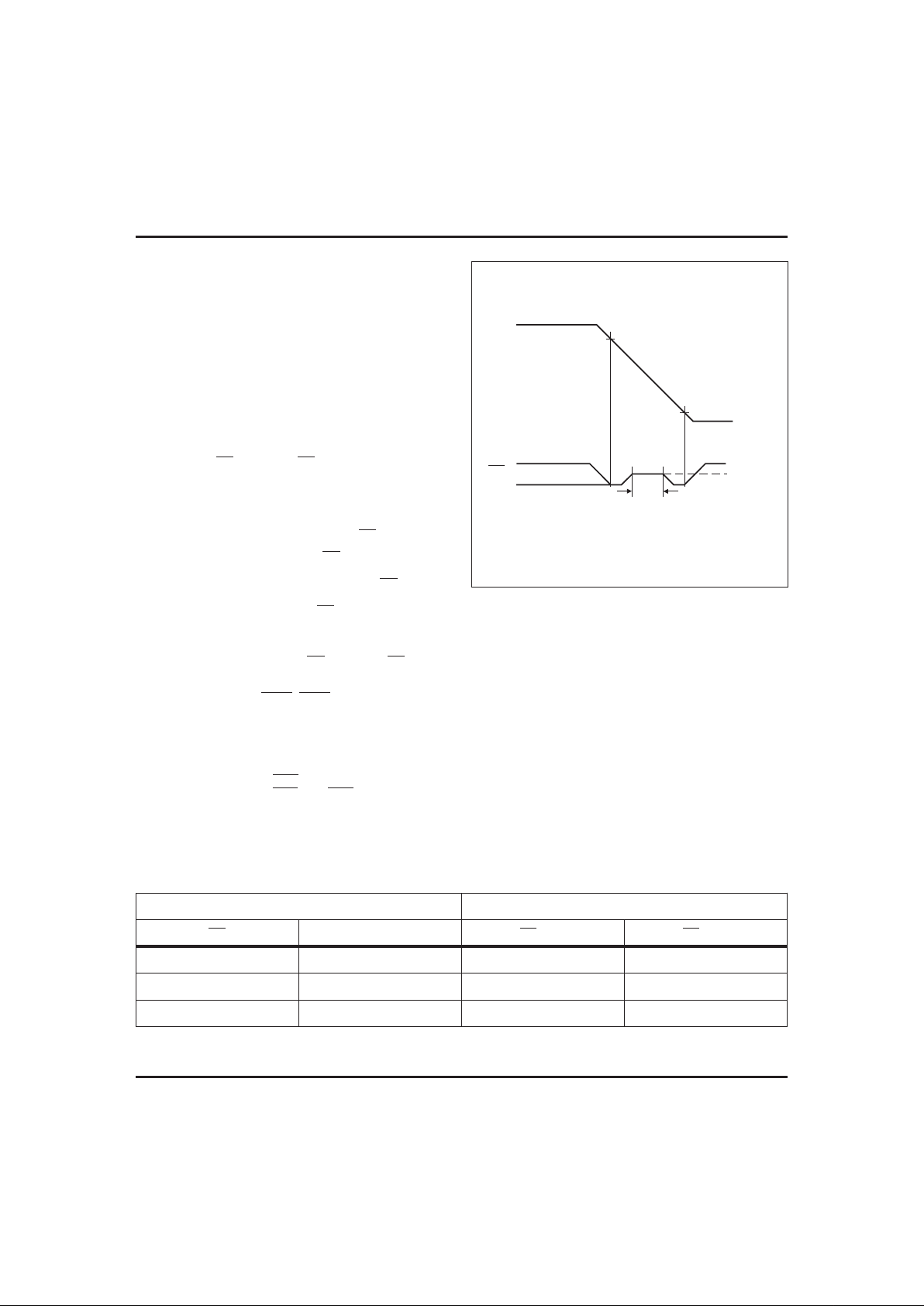

A valid isolation signal requires CE

low as VCCcrosses

both V

PFD

and VSOduring a power-down. See Figure

2. Between these two points in time, CE must be

brought to V

CC

*

(0.48 to 0.52) and held for at least 700ns.

The isolation signal is invalid if CE exceeds V

CC

*

0.54 at

any point between VCCcrossing V

PFD

and VSO.

The isolation function is terminated and the appropriate

battery is connected to V

OUT

,CE

CON1

, and CE

CON2

by

powering VCCup through V

PFD

.

Battery Monitor—BCL, BCF

As VCCrises past V

PFD

, the battery voltage on BCPis

compared with a dual-voltage reference. The result of

this comparison is latched internally, and output after

tBCwhen VCCrises past V

PFD

. If the battery voltage on

BCPis below VBL, then BCL is asserted low. If the battery is below VBF, then BCL and BCF are asserted low.

The results of this comparison remain latched until V

CC

falls below V

PFD

.

3

TD220101.eps

V

CC

CE

V

PFD

V

SO

0.5 V

CC

700ns

Figure 2. Battery Isolation Signal

Truth Table

Input Output

CE

ACE

CON1

CE

CON2

HXHH

LLLH

LHHL

Nov.1994 B

bq2203A

4

Recommended DC Operating Conditions (T

A=TOPR

)

Symbol Parameter Minimum Typical Maximum Unit Notes

V

CC

Supply voltage

4.75 5.0 5.5 V THS = V

SS

4.50 5.0 5.5 V THS = V

CC

V

BCP

Backup cell input voltage

2.0 - 4.0 V VCC<V

BC

V

BCS

2.0 - 4.0 V VCC<V

BC

V

SS

Supply voltage 0 0 0 V

V

IL

Input low voltage -0.3 - 0.8 V

V

IH

Input high voltage 2.2 - VCC+ 0.3 V

THS Threshold select -0.3 - VCC+ 0.3 V

Note: Typical values indicate operation at TA= 25°C, VCC=5V.

Absolute Maximum Ratings

Symbol Parameter Value Unit Conditions

V

CC

DC voltage applied on VCCrelative to V

SS

-0.3 to +7.0 V

V

T

DC voltage applied on any pin excluding V

CC

relative to V

SS

-0.3 to +7.0 V V

T

≤

V

CC

+ 0.3

T

OPR

Operating temperature

0 to 70 °C Commercial

-40 to +85 °C “N” Industrial

T

STG

Storage temperature -55 to +125 °C

T

BIAS

Temperature under bias -40 to +85 °C

T

SOLDER

Soldering temperature 260 °C For 10 seconds

I

OUT

V

OUT

current 200 mA

Note: Permanent device damage may occur if Absolute Maximum Ratings are exceeded. Functional opera-

tion should be limited to the Recommended DC Operating Conditions detailed in this data sheet. Exposure to conditions beyond the operational limits for extended periods of time may affect device reliability.

Nov.1994 B

bq2203A

5

DC Electrical Characteristics (T

A=TOPR,VCC

=5V±10%)

Symbol Parameter Minimum Typical Maximum Unit Conditions/Notes

I

LI

Input leakage current - -

±

1

µ

AVIN=VSSto V

CC

V

OH

Output high voltage 2.4 - - V IOH= -2.0mA

V

OHB

VOH, backup supply VBC- 0.3 - - V

VBC>VCC,IOH= -10µA

V

OL

Output low voltage - - 0.4 V IOL= 4.0mA

I

CC

Operating supply current - 3 6 mA No load on outputs

V

PFD

Power-faildetect voltage

4.55 4.62 4.75 V THS = V

SS

4.30 4.37 4.50 V THS = V

CC

V

SO

Supply switch-over voltage - V

BC

-V

I

CCDR

Data-retention mode

current

- - 100 nA No load on outputs

V

BC

Active backup cell voltage

-V

BCS

-VV

BCS>VBCP+VBSO

-V

BCP

-VV

BCP>VBCS+VBSO

V

BSO

Battery switch-over voltage 0.25 0.4 0.6 V

R

BCS

BC

S

charge output internal

resistance

500 1000 1750

Ω

V

BCSO

≥

3.0V

V

BCSO

BCScharge output voltage 3.15 3.3 3.5 V

V

CC>VPFD

, RST inactive,

full charge or no load

I

OUT1

V

OUT

current - - 160 mA V

OUT

≥

V

CC

- 0.3V

I

OUT2

V

OUT

current - 100 -

µ

AV

OUT

≥

V

BC

- 0.2V

V

BL

Voltagebattery low 2.3 - 2.5 V BCPinput only

V

BF

Voltagebattery fail 2.0 - 2.2 V BCPinput only

Note: Typical values indicate operation at TA= 25°C, VCC=5VorVBC.

Capacitance (T

A

= 25°C, F = 1MHz, VCC= 5.0V)

Symbol Parameter Minimum Typical Maximum Unit Conditions

C

IN

Input capacitance - - 8 pF Input voltage = 0V

C

OUT

Output capacitance - - 10 pF Output voltage = 0V

Note: This parameter is sampled and not 100% tested.

Nov.1994 B

bq2203A

bq2203A

6

AC Test Conditions

Parameter Test Conditions

Input pulse levels 0V to 3.0V

Input rise and fall times 5ns

Input and output timing reference levels 1.5V (unless otherwise specified)

Output load (including scope and jig) See Figure 3

FG220102.eps

5V

960

100pF

CE

CON

510

Figure 3. Output Load

Nov.1994 B

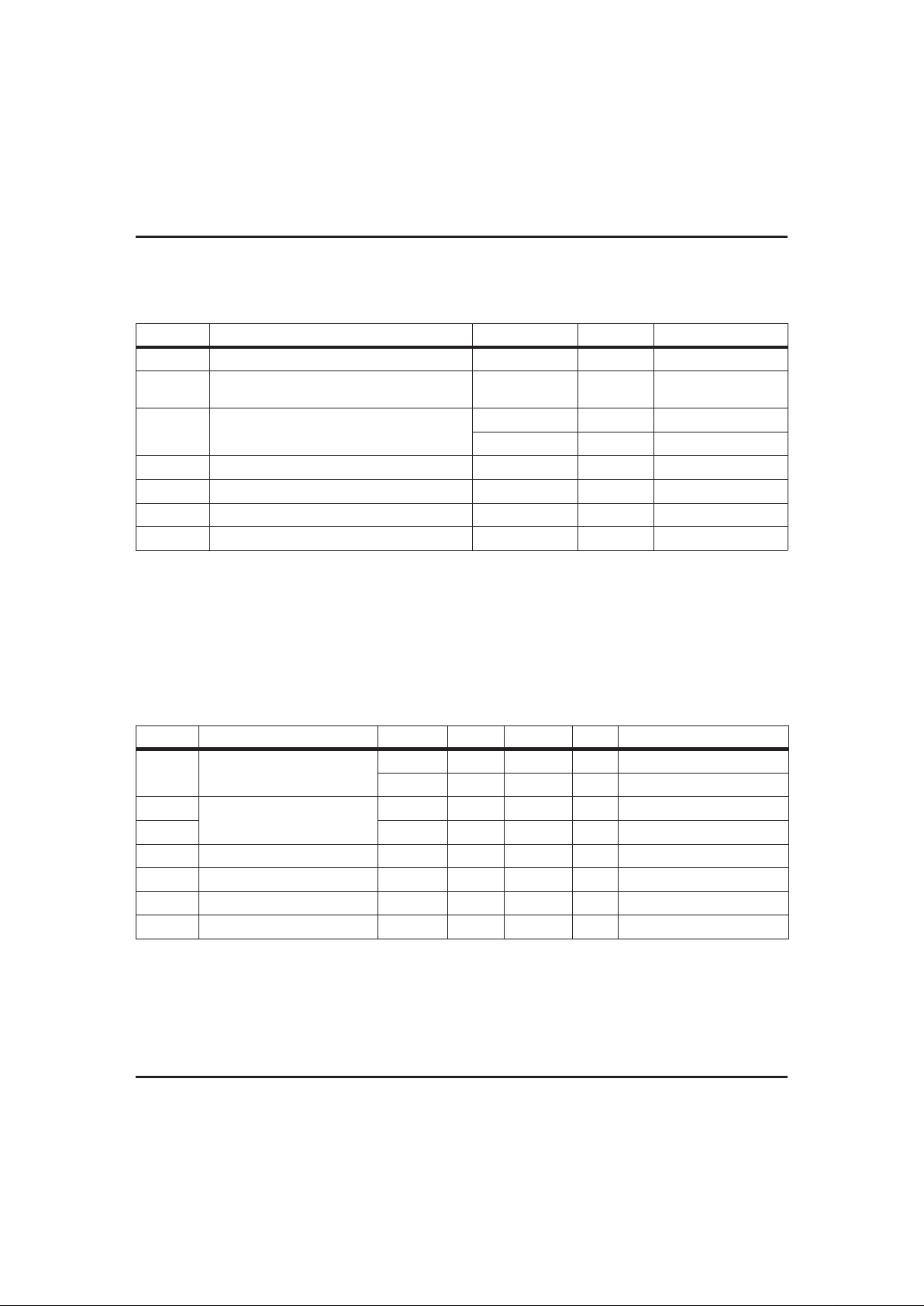

Power-Fail Control (TA=T

OPR

)

Symbol Parameter Min. Typ. Max. Unit Conditions

t

PF

VCCslew 4.75 to 4.25 V 300 - -

µ

s

t

FS

VCCslew 4.25 V to V

SO

10 - -

µ

s

t

PU

VCCslew 4.25 to 4.75 V 0 - -

µ

s

t

CED

Chip-enable propagation delay 7 10 ns

t

CER

Chip-enable recovery time 40 80 120 ms

Time during which SRAM is writeprotected after VCCpasses V

PFD

on

power-up

t

RR

V

PFD

to RST inactive t

CER

-t

CER

ms

Time, after V

CC

becomes valid, before

RST is cleared

t

AS

Input A set up to CE 0--ns

t

WPT

Write-protect time 40 100 150µs

Delay after V

CC

slews down past

V

PFD

before SRAM is write-protected

t

R

V

PFD

to RST active t

WPT

-t

WPT

µ

s

Delay after V

CC

slews down past

V

PFD

before RST is active

t

BC

V

PFD

to BCL/BCF active t

CER

-t

CER

ms

Delay after V

CC

slews up past V

PFD

before BCL or BCF is active

Note: Typical values indicate operation at TA= 25°C, VCC=5V.

Caution: Negative undershoots below the absolute maximum rating of -0.3V in battery-backup mode

may affect data integrity.

bq2203A

7

TD220202.eps

V

CC

CE

CON

t

PF

t

FS

4.75

V

PFD

4.25

V

SO

t

WPT

V

OHB

CE

t

R

RST

Power-Down Timing

TD220302.eps

V

CC

t

PU

CE

CE

CON

V

OHB

V

SO

4.25

V

PFD

4.75

t

CER

t

CED

t

CED

RST

BCL

BCF

t

RR

t

BC

Power-Up Timing

Nov.1994 B

bq2203A

TD220204.eps

CE

CON1

t

AS

CE

CE

CON2

A

t

CED

t

CED

Address-Decode Timing

8

bq2203A

Nov.1994 B

16-Pin SOIC Narrow

A

A1

.004

C

B

e

D

E

H

L

16-Pin SN(SOIC Narrow

)

Dimension Minimum Maximum

A 0.060 0.070

A1 0.004 0.010

B 0.013 0.020

C 0.007 0.010

D 0.385 0.400

E 0.150 0.160

e 0.045 0.055

H 0.225 0.245

L 0.015 0.035

All dimensions are in inches.

9

bq2203A

Nov.1994 B

16-Pin DIPNarrow

16-Pin PN(DIP Narrow

)

Dimension Minimum Maximum

A 0.160 0.180

A1 0.015 0.040

B 0.015 0.022

B1 0.055 0.065

C 0.008 0.013

D 0.740 0.770

E 0.300 0.325

E1 0.230 0.280

e 0.300 0.370

G 0.090 0.110

L 0.115 0.150

S 0.020 0.040

All dimensions are in inches.

10

bq2203A

Nov.1994 B

Data Sheet Revision History

Change No. Page No. Description Nature of Change

1 - Changed data sheet from “Preliminary”to “Final”

15

Changed maximum charge output internal resistance (R

BCS

)

Was:1500Ω

Is: 1750Ω

Note: Change 1 = Nov.1994 B changes from Dec. 1992 A.

11

bq2203A

Nov.1994 B

bq2203A

PackageOption:

PN = 16-pin plastic DIP Narrow

SN = 16-pin SOIC Narrow

Device:

bq2203A SRAM Nonvolatile Controller

WithBatteryMonitorandReset

*Contact factory for availability.

Ordering Information

TemperatureRange:

blank = Commercial (0 to +70°C)

N = Industrial (-40 to +85°C)*

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...