Page 1

RS-232 Sound Le vel Meter

72-860A

INSTRUCTION MANUAL

www.tenma.com

1. SAFETY INFORMATION

Read the following safety information carefully before attempting to operate or service

the meter.

Use the meter only as specified in this manual; otherwise, the protection provided by the

meter may be impaired.

Environment conditions

c

Altitude up to 2000 meters

d

Relatively humidity 90% max.

e

Operation Ambient 0 ~40

Maintenance & Clearing

c

Repairs or servicing not covered i n this manual sh ould only be performed by qualifie d

personnel.

d

Periodically wipe the case with a dry cloth. Do no t use abrasives or solven ts on this

instruments.

Do not use abrasives or solvents on this instruments.

Safety symbols

Meter is protected throughout by double insulation or

reinforced insulation.

When servicing, use only specified replacement parts.

Comply with EMC

℃

1

2. GENERAL DESCRIPT IO N AN D FEATURES

Thanks you for selecting our Sound Level Meter. To ensure that you can get the most from

it, we recommend that you read and follow the manual carefully before use.

This unit was designed according to the IEC651 , ANSI S1.4 for Sound Level Meters.

The Sound Level Meter has been designed to meet the measurement requirements for

Industrial safety offices and sound quality control in various environments.

Ranges from 35dB to 130dB at frequencies between 31.5Hz and 8KHz.

Display with 0.1dB steps on a 4-digits LCD.

With two weighting , A and C.

3. SPECIFICATIONS

Standard applied : According to IEC651, ANSI S1. 4

Frequency range : 31.5Hz ~ 8KHz

Measuring level range

Frequency weighting : A/C

: 35~130dB

2

Microphone : 1/2 inch Electret condenser microphone

Display : LCD

Digital display : 4 digits

Resolution

Display periodÖ 0.5 sec.

Time weighting : FAST (125mS ), SLOW (1 sec.)

Level ranges : Lo: 35~100dB and Hi: 65~130dB

Accuracy :

Dynamic range : 65dB

Alarm function : “ OVER “ is show when input is out of range.

Maximum hold : Hold readings, with decay < 1dB∕3minutes.

Calibration : Electrical calibration with the internal oscillator

RS232 output : Baud rate 19200, Parity none, Data bits 8, Stop bits 1.

Power supply : One 9V battery 006P or IEC 6F22 or NEDA 1604

Power life : About 50hrs ( alkaline cell )

Operating temperature

Operating humidity : 10 to 90%RH

Storage temperature : -10 to 60℃ ( 14 to 140℉)

Storage humidity : 10 to 75%RH

Dimensions : 240 (L)×68 (W)×25 (H)mm

±

2.0dB (under reference conditions)

(1KHz sine wave)

: 0 to 40℃ ( 32 to 104℉)

Ö

0.1dB

3

Weight : 210g ( including battery )

Accessories : 9V battery, carrying case. Screwdriver, Instruction manual,

3.5φplug, windscreen, Software for Windows

,

RS-232 cable.

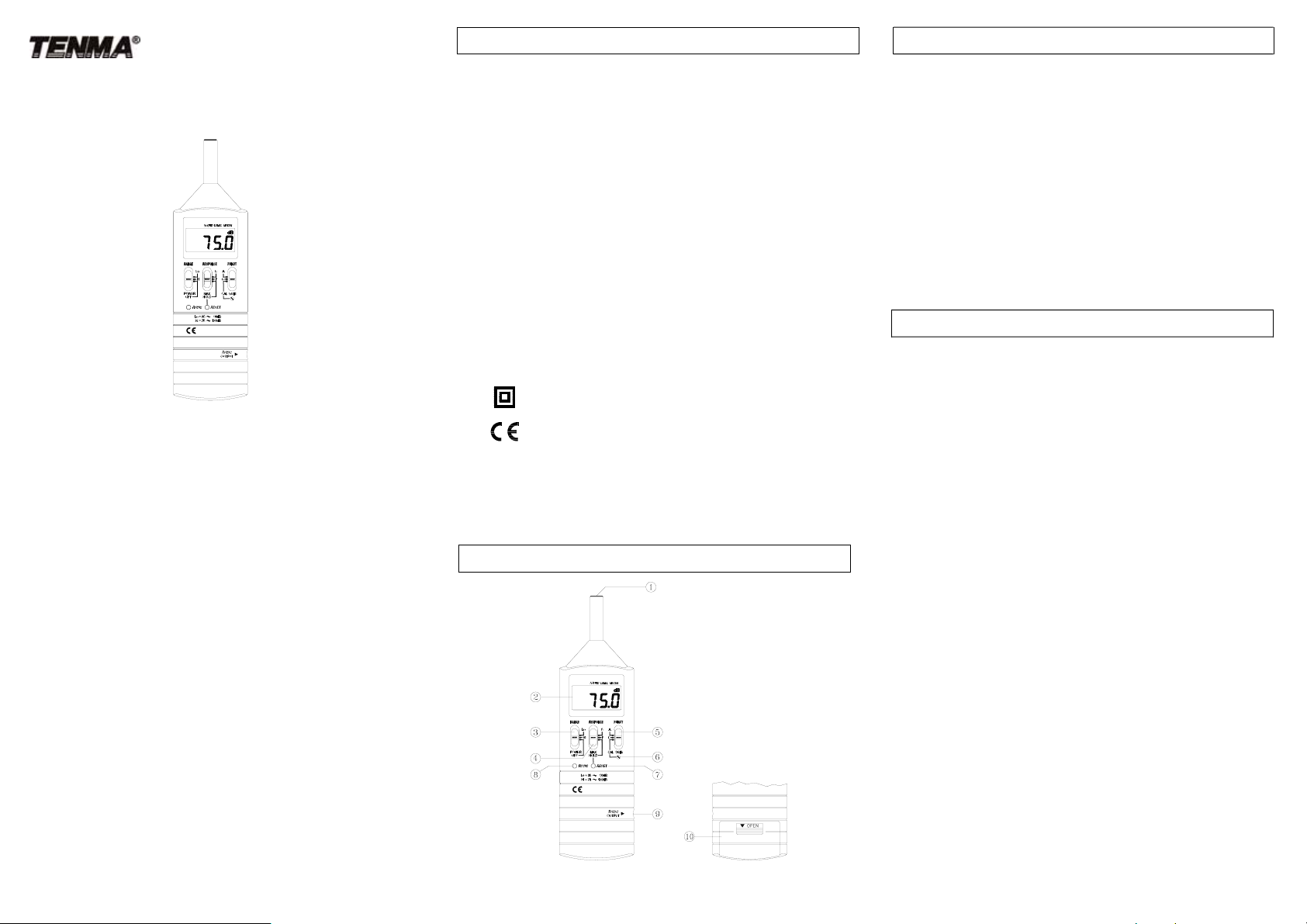

4. DESCRIPTION OF CONTROLS

4

c

Microphone

1/2 inch Electric Condenser microphone

d

Display

Serves to display the sound pressure level (dB), over or under range “OVER” ,

maximum hold data “MAX HOLD” and Low battery indicator “BT”.

dB

: Sound pressure level with 0.1dB resolution.

OVER

: Shown when the range setting is too high (or Low) .

e

Power and Range switch

z

Turn power ON and select measurement range.

(Hi range = 65~130dB, Lo range = 35~100dB)

z

When “OVER” is indicated, Slide range switch to another range for measurement.

f

Response and Max hold switch

Setting the meter dynamic characteristics (Fast/slow) and maximum value hold.

S

(slow response) : for comparatively stable noise measurement.

F

(fast response) : for fast varying noise.

MAX HOLD

T o re-fresh please set switch to “F” or “S” position to cancel existing v alue,

then, set switch to “MAX HOLD” position.

: The max hold position is used to measure the maximum level of

sounds. The maximum measured level is up dated continuously.

5

Page 2

g

Function switch (A/C weighting & calibration selector)

A

C

CAL 94dB

h

Calibration control can be adjusted cloc kwise or co untercloc kwise to stand ard 94 .0dB .

i

Reset button :

Serves to reset the maximum level indication.

j

RS-232 button.

k

RS-232 output jack

l

Battery cover (on bottom)

: A-weighting

: C-weighting

: Calibration

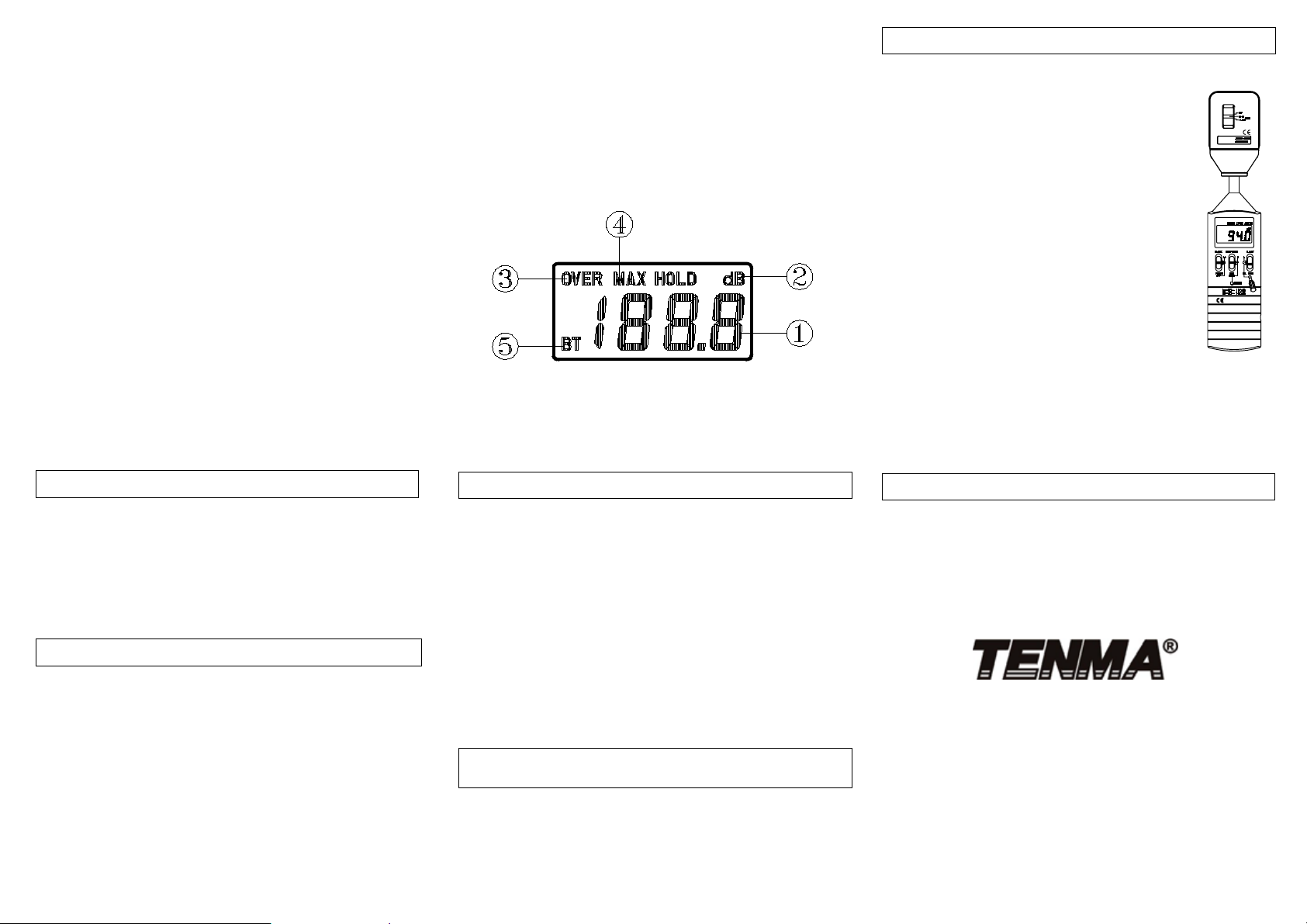

LCD Descr iption

c

Sound Pressure Level measuring value, resolution 0.1dB.

d

Measuring unit

e

When readout is out of range.

f

MAX HOLD: Maximum hold.

g

BT: Low battery indicator.

5. CALIBRATION PROCEDURES

(1). Using a acoustic calibrator

a).

Make the following switch settings.

RANGE : Hi

RESPONSE : F

FUNCT : A

b). Insert the microphone carefully into the in sertion hole of

the calibrator.

c). T urn on the s witch of calibrato r and adjust the CA L screw of

the instrument, until the level display indicates the desired

level.

Note: Our products are well calibrated before shipment.

Recommended calibrator cycle is one year.

(2). Calibration using the internal oscillator

a).

Make the following switch settings.

RANGE : Hi

RESPONSE : F

FUNCT : CAL 94dB

b). Display will show 94.0 ± 1.5dB

6

6. MEASUREMENT PREPARATION

(1). Battery Loading:

Remove the battery cover on the back of the unit replace 9V battery and refit

battery cover.

Note : make sure the battery polarity is correct.

(2). Battery Replacement:

When the battery voltage drops below the operating voltage, “ BT “ mark will

appear in the display and, battery should be replaced with new one.

7. OPERATING PRECAUTIONS

(1). Wind blowing acros s th e mi cr op ho n e wo u l d cause additional extr aneous noises.

When using the instrument in the presence of wind, you must use the

windscreen to avoid any undesirable signals.

(2). Calibrate the instrument before operation if the unit has been left used for any

length of time is being operated in poor conditions.

(3). Do not store or operate this instrument at high temperature and in a high

humidity environment for any length of time.

(4). Keep microphone dry and avoid severe vibration.

(5). Please take out the battery and keep the instrument in low humidity environment

when not in use.

9

7

8. MEASUREMENT

(1). Open battery cover and install a 9-volt battery in the battery compartment.

(2). Turn on power and select the desired response a nd weighting. If the sound source

consists of short bursts or only catching sound peak, set RESPONSE to FAST. To

measure average sound level, use the slow setting.

Select A- weighting for general noise sound level and C-weighting for measuring sound

level of acoustic material.

(3). Hold the instrument comfortably in hand or fix on tripod and point the microphone at

the suspected noise source, the sound pressure level will be displayed.

(4). When MAX HOLD mode is chosen. The instrument captures and holds the maximum

noise level for a long period.

Press “ RESET” button to reset the maximum level indica ti on.

(5). Turn OFF the instrument when not in use.

(6). For RS-232 measurements please refer to the instruction manual enelosed on the CD-ROM.

9. RS-232 INTERFACE, SOFTWARE INSTALLATION and

OPERATION

For the detailed instruction, please refer to the content of attached

CD-ROM, which has the complete instruction of RS-232 interface,

software operation and rel evant information.

RS-232 protocol : are enclosed within the content of CD-ROM, please

open the CD-ROM for details.

10

8

10. SERVICE, REPAIR AND CALIBRATION

For service, repair and calibration pl ease contact your local Tenma distributor

or go to http://www.tenma.com

TEST EQUIPMENT

405 Pioneer Blvd.

Springboro, Ohio, 45066

http://www.tenma.com

Mar-2007-1

Page 3

Dat alogger and RS232 Interface

RS232 Wiring Hardware ……………………………………………………………2

RS232 Protocol ………………………………..…………………………………..3

Hardware Requirements and Setup ………………………………………………4

Software Requirements and Setup …………………..……………………………5

Communicating Operation …………………….……………………………………8

Run the Software …………………………………...…….………………….….8

Record………..……………………………………………………………………10

Download…...………………………..……………………………………………11

Data Convert....……….……………..……………………………………………12

Apply for Excel ……………………………………………………………………12

Apply for Graph……………………………………………………………………15

Sampling Time…………………………..…………………………..…………….16

1

Page 4

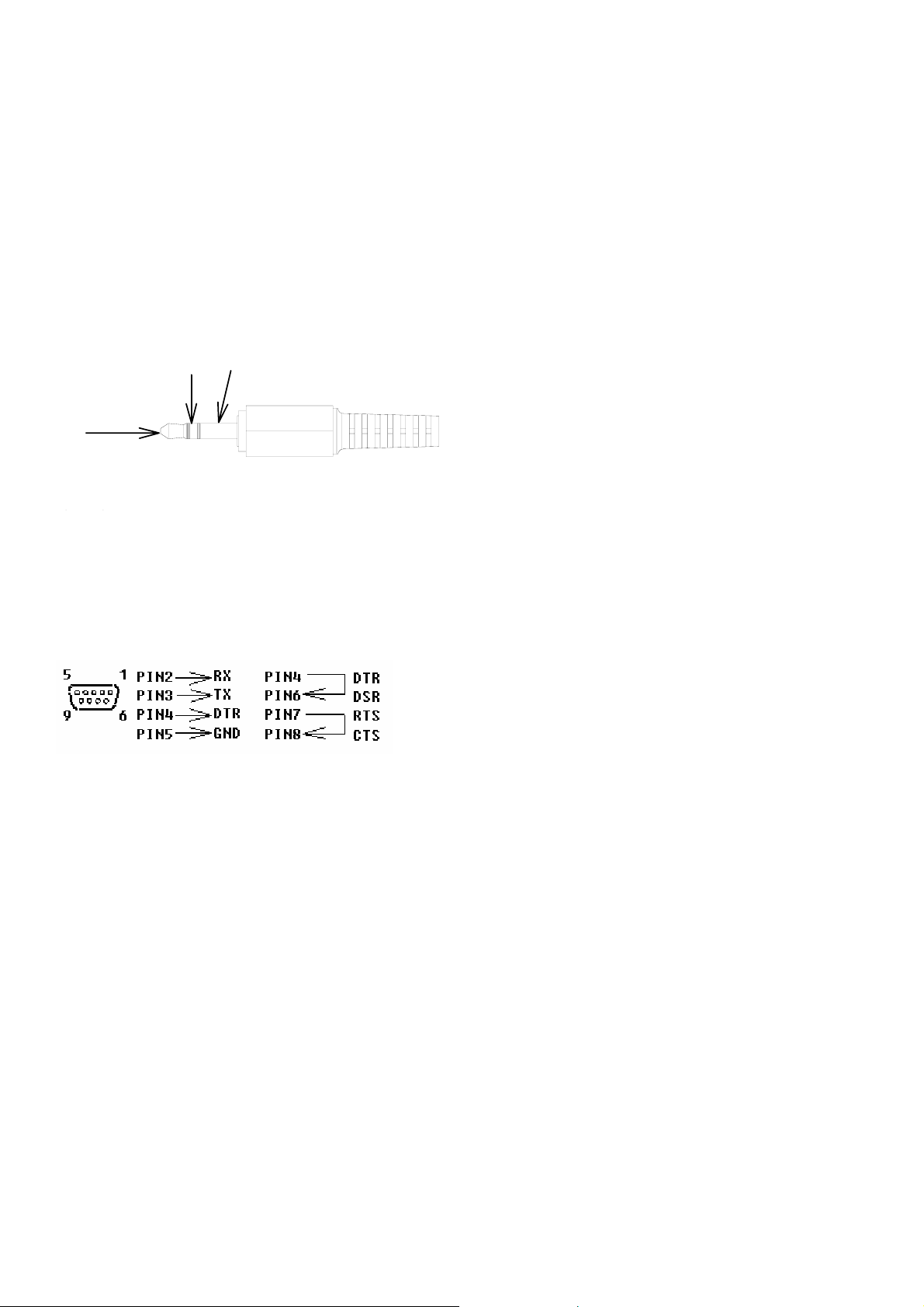

RS232 Wiring Hardware

PC Interface Cable

Meter side of PC Interface Cable

The RS-232 “phono” plug side of the PC Interface Cable connects to the meter’s RS-232 phono

jack. Refer to the diagram below for wiring information.

RX

TX

GND

Computer’s Serial Port side of Interface Cable

The RS-232 “DB-9” side of the PC Interface Cable connects to the PC’s COM port. Refer to the

diagram below for wiring information. Note that a SERIAL to USB Adapter may be used.

RS232 Settings

19200, N, 8, 1

2

Page 5

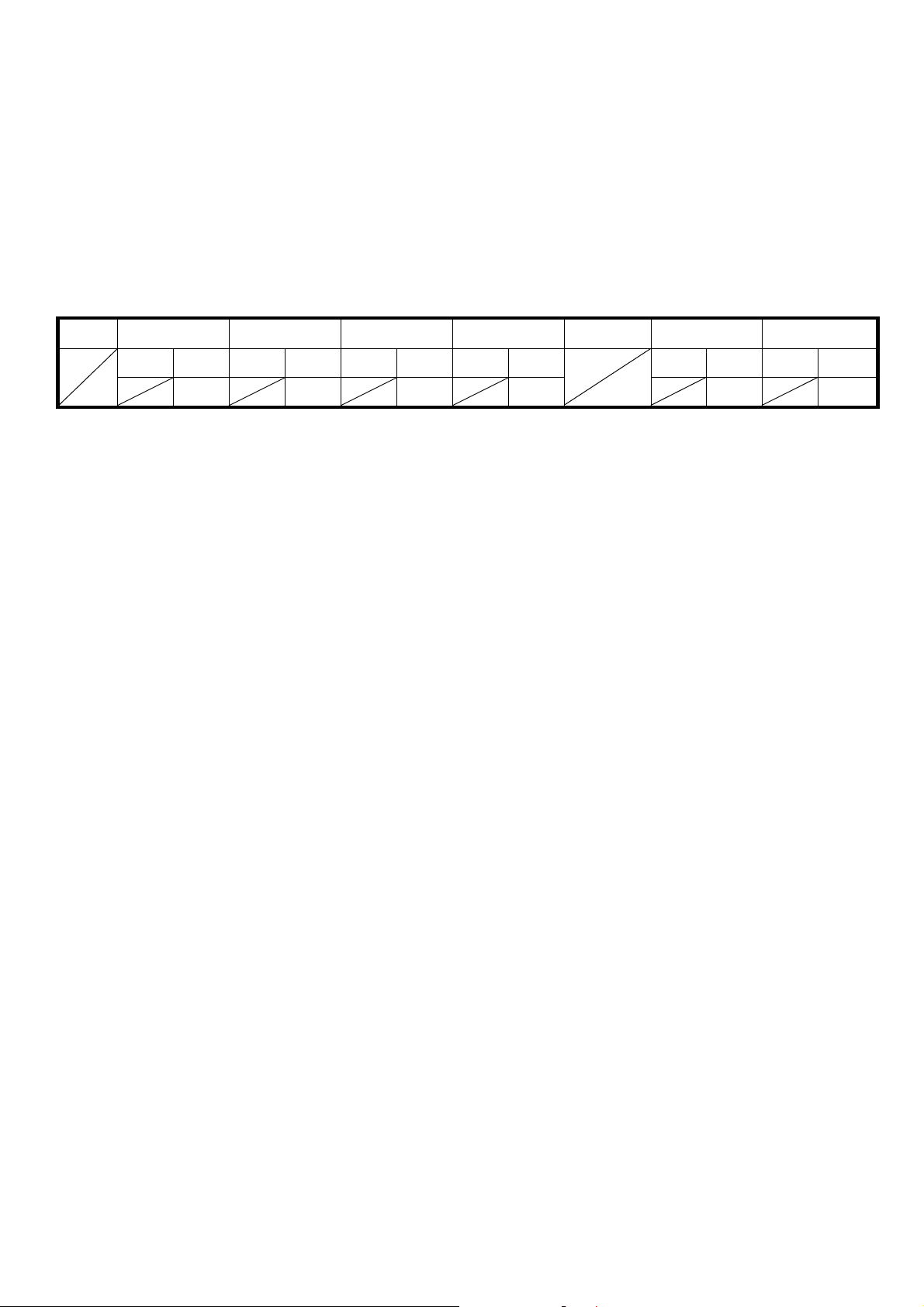

RS232 Protocol

1. RS232 Settings :

c

Baud rate : 19200bps d Parity check : None e Data bits : 8 f Stop bit : 1

2. Transfer Format :

Command : “SPACE” Key

Protocol :

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6789 Byte 10 Byte 11

bit4~6 bit0~3 bit4~6 bit0~3 bit4~6 bit0~3 bit4~6 bit0~3 bit4~6 bit0~3 bit4~6 bit0~3

100 10 1 0.1

1101 1010

Byte 1 : Don’t Care

Byte 2,3,4,5 : LCD Bytes

Byte 6,7,8,9 : Don’t Care

Byte 10,11 : Checking Code

3

Page 6

Hardware Requirements and Setup

PC HardWare Requirements :

HDD, CD Rom, 486 PC or above, with available COM port

EGA or higher monitor

4M bytes or more memory size

PC HardWare Setup :

1) Switch off all power related to the PC

2) Connect the DB9 (female) end of the supplied RS-232 cable to available COM port

3) Switch on all related power

4) Connect the phono plug end of the RS232 cable to the meter

4

Page 7

Software Requirements and Setup

1) Start up windows 98 / XP operating system

2) Close all other applications

3) Insert disk in CD drive

Wait for “Autorun” to start and follow on-screen instructions

(If “autorun” does not start, click on “Start” then “Run”. Type the drive letter and

“: \Disk1\Setup.exe” and click “OK” .)

1).

Setup program will run automatically.

2).

Click Next> button

5

Page 8

3).

a. Click Next> to use the default folder

or

b. Click Browse… to select a different folder

4).

Click Next> button

6

Page 9

Setup is complete.

7

Page 10

Communicating Operation

Run the software

1. Click "Start" form Start menu then move to "All Programs" (or “Programs”) then "SLM" and

then click the "SLM" icon.

8

Page 11

2.

Click an available COM port

3. Main software screen

9

Page 12

Record

Save to Hard Disk (PC)

Click button. The dialog box shown below will appear.

Input a file name and then click "Save" to begin saving data to the file just named.

Click button to stop recording.

10

Page 13

Download Data

1. Download Data from Hard Disk

Click button. The Open window, shown below, appears

Input the file that was selected earlier and then click the Open button.

11

Page 14

Data Convert

Apply for Excel

Open Microsoft Excel, find the file saved in Excel type, for example, test.xls.

or find any file already saved in HDD, for example, sample.dat.

12

Page 15

The "Text Import Wizard" then appears. Follow the steps 1 to 3 to complete.

Click Next> button

Click Next> button

13

Page 16

Click Finish button

14

Page 17

Apply for Graph

Open a saved data file in the software program and then click .

15

Page 18

Sampling Time

PC Sampling Rate:

(rate at which the PC collects readings while connected to the meter)

Click on the Menu Bar.

In the Input Sampling Time dialog box, input a sampling time and then click

"OK" button to confirm.

16

Loading...

Loading...